Page 1

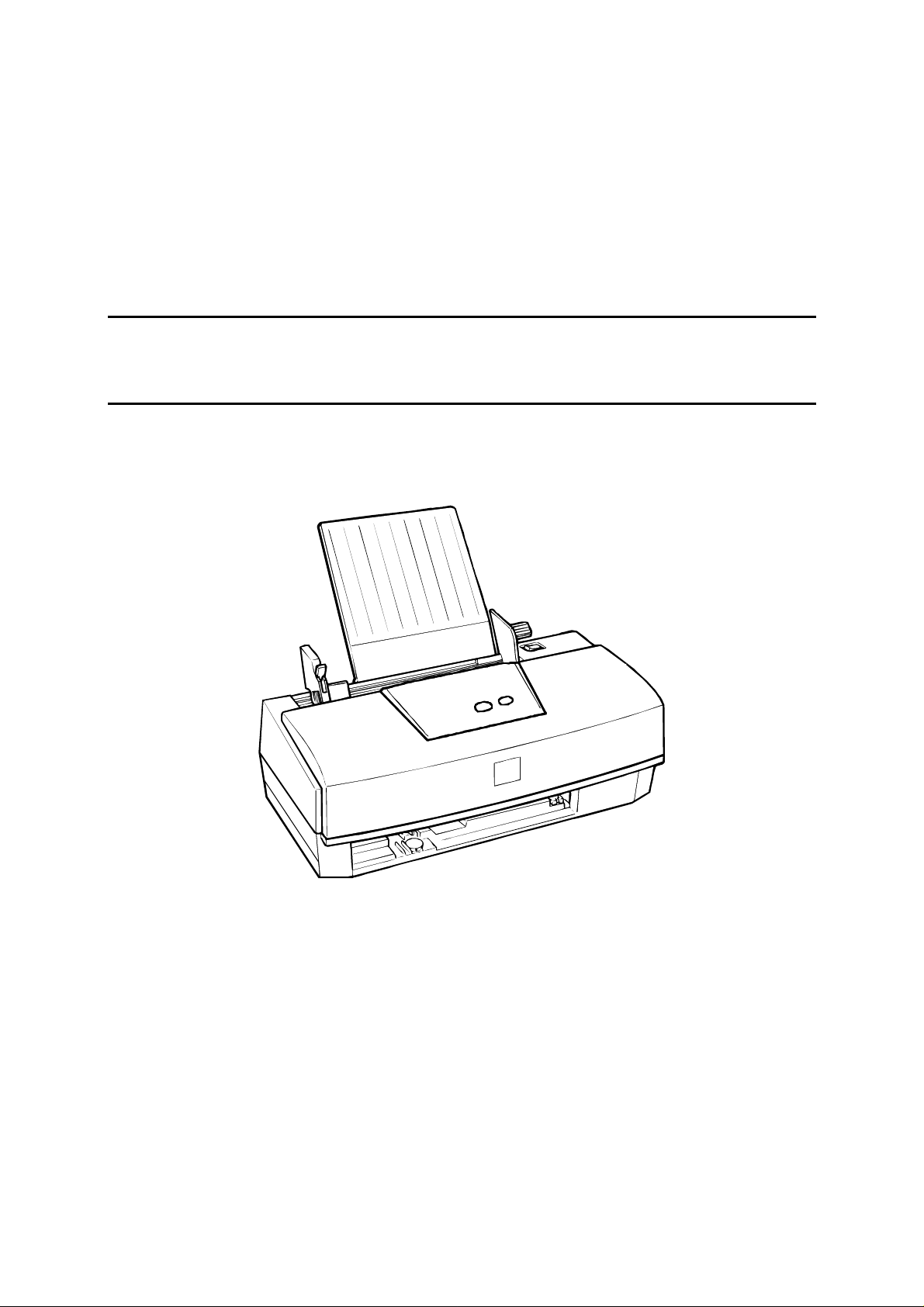

EPSON TERMINAL PRINTER

EPSON Stylus Color 300

SERVICE MANUAL

EPSON

4007996

Page 2

All rights reserved. No part of this manual may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO

EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual.

However, should any errors be deteced, SEIKO EPSON would greatly appreciate being

informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no

responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only

and may be trademarks or registered trademarks of their respective

owners. EPSON disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and

2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded

by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER

WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO.

WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME

CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQ UIPMENT, SUCH AS ANTI-STATIC W RIST STRAPS, W HEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations,

maintenance and repair procedures of EPSON Stylus Color 300. The instructions and

procedures included herein are intended for the experienced repair technicians, and

attention should be given to the precautions on the preceding page. The chapters are

organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved lubricants and

adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Page 5

REVISION SHEET

Revision Issued Contents

A July 2, 1997 First issue

Page 6

TABLE OF CONTENTS

CHAPTER 1.PRODUCT DESCRIPTIONS

CHAPTER 2.OPERATION PRINCIPLES

CHAPTER 3.DISASSEMBLY AND ASSEMBLY

CHAPTER 4.ADJUSTMENT

CHAPTER 5.TROUBLESHOOTING

CHAPTER 6.MAINTENANCE

APPENDIX

Page 7

CHAPTER 1

PRODUCT DESCRIPTIONS

1.1 FEATURES...................................................................................... 1-1

1.2 SPECIFICATIONS ...........................................................................1-2

1.2.1 Printing Specifications.......................................................... 1-2

1.2.2 Software Specifications........................................................ 1-3

1.2.3 Paper Handling ......................................................................1-4

1.2.4 Paper Specifications .............................................................1-4

1.2.5 Printable Area ........................................................................1-6

1.2.6 PG Adjust Lever Setting........................................................ 1-7

1.2.7 Paper Select Lever Setting ...................................................1-7

1.2.8 Ink Cartridge Specification................................................... 1-8

1.2.9 Electrical Specifications .......................................................1-9

1.2.10 Environmental Conditions..................................................1-9

1.2.11 Reliability............................................................................ 1-10

1.2.12 Acoustic Noise................................................................... 1-10

1.2.13 Safety Approvals................................................................ 1-10

1.2.14 CE Marking......................................................................... 1-10

1.2.15 Physical Specifications..................................................... 1-11

1.3 INTERFACE SPECIFICATION......................................................1-12

1.4 OPERATIONS................................................................................ 1-12

1.4.1 Control Panel .......................................................................1-12

1.4.1.1 Buttons.......................................................................1-12

1.4.1.2 LED Indicators ...........................................................1-14

1.5 MAIN COMPONENTS ................................................................... 1-15

1.5.1 Printer Mechanism .............................................................. 1-15

1.5.2 Main Control Board (C224 MAIN Board)............................ 1-15

1.5.3 Power Supply Unit (C160 PSB/PSE Board)....................... 1-15

1.5.4 Housing ................................................................................ 1-15

Page 8

Chapter 1 Product Descriptions

1.1 FEATURES

The EPSON Stylus Color 300 printer is a color ink jet printer that comes with standard four

colors (Black and CMY) printhead. The major features of this printer are:

Standard four-colors printing.

Both black and color (CMY) print nozzles are built in one-piece printhead.

High-quality color printing

360 dpi (Horizontal/Vertical) printing and semi-720 dpi (Vertical only) printing

High-speed printing

200 CPS at 10CPI (Pica) text printing in Black color.

Standard Bi-directional Parallel Interface (IEEE1284 Nibble mode)

Rev. A

1-1

Page 9

EPSON Stylus Color 300 Service Manual

1.2 SPECIFICATIONS

This section describes the product specifications for EPSON Stylus Color 300.

1.2.1 Printing Specifications

Print system: On-demand ink jet printer

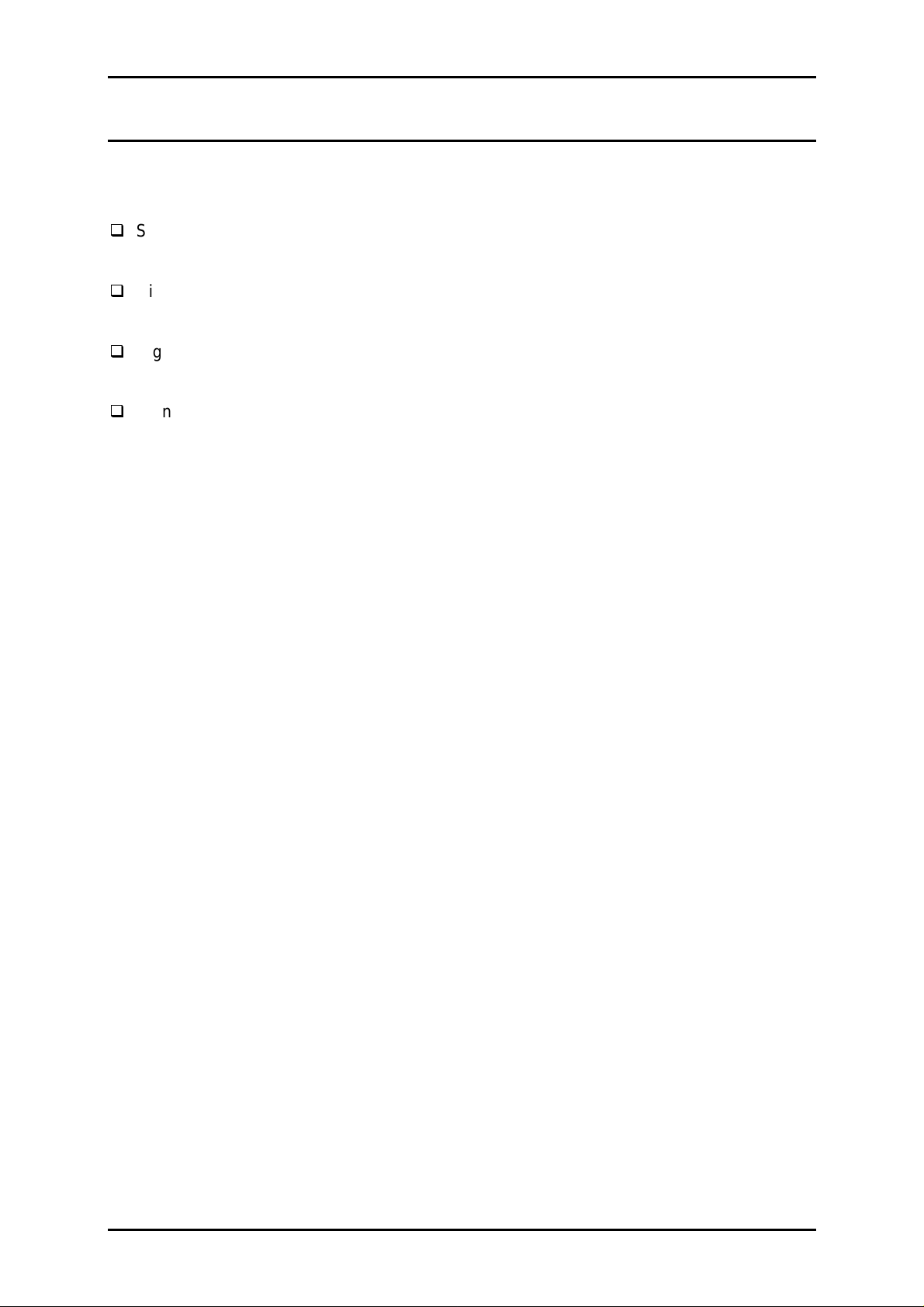

Nozzle configuration: Black: 31 nozzles

(11 nozzles x 2 columns and 10 nozzles x 1 column)

Color: 11 nozzles / color

16/360"

(1.1289mm)

#B30

Print direction (Paper feed)

1/60"

(0.4233mm)

#B3

#B2

1/180"

(0.1411mm)

#29

104/360"

(7.3378mm)

#31

1/180"

(0.1411mm)

#B1

1/180"

(0.1411mm)

1/180"

(0.1411mm)

Viewed from the back of the printhead

#C11

#C1

16/360"

(1.1289mm)

104/360"

(7.3378mm)

#M11

#M1

16/360"

(1.1289mm)

#Y11

1/60"

#Y1

(0.4233mm)

Figure 1-1. Printhead Nozzle Configuration

Print direction: Bi-directional printing with logical-seeking

Print speed: Text: 200 CPS (LQ/10CPI in Black color)

Graphics: 20 IPS (at 360DPI)

Printable column: Text: 80 columns (10CPI)

Graphics: 2880 dot (at 360DPI)

Character Table: No table and include only the following characters:

Alphabet [A to Z] (code 41H ~ 5AH)

Number [0 to 9] (code 30H ~ 39H)

SPACE (code 20H)

Symbol [#] (code 23H)

Typeface: Bitmap LQ / EPSON Courier (10CPI)

Input data buffer: 25Kbyte

1-2

Rev. A

Page 10

Chapter 1 Product Descriptions

3

1.2.2 Software Specifications

Printer Language: Exclusive control codes for EPSON Stylus Color 300

EPSON Remote Command

Control Code: <Character mode>

General operation: Initialize printer ESC @

Paper feeding: Form feed FF

Line feed LF

Carriage operation Carriage return CR

EEPROM Control ESC |

<Graphics mode>

General operation: Initialize printer ESC @

Uni-directional printing ESC U

CSF Mode control ESC EM

Paper feeding: Form feed FF

Line feed LF

Line spacing ESC +

Carriage operation: Carriage return CR

Page formatting: Page length ESC (C

Top/Bottom margin ESC (c

Print position control: Horizontal print position ESC $, ESC ¥

Vertical print position ESC (V, ESC (v

Spacing: Define unit ESC (U

Graphics: Graphics mode ESC (G

Raster graphics ESC . (∗1)

Color control: Printing color ESC r (∗2)

Note) EPSON Stylus Color 300 requires the specific printer driver for proper printing

operation and control, and use of other printer driver could result in improper

printing.

1: Works only with unique parameters.

∗

2: It works only as a print buffer select command.

∗

Rev. A

1-

Page 11

EPSON Stylus Color 300 Service Manual

1.2.3 Paper Handling

Feeding method: Friction feed with built-in ASF

Paper path: Rear-top entrance / Front eject

Line spacing: 1/6 inch or programmable in 1/360 inch minimum increments.

Paper feeding speed: 102 mS (at 1/6 inch paper feed pitch)

1.2.4 Paper Specifications

Cut sheet

Size:

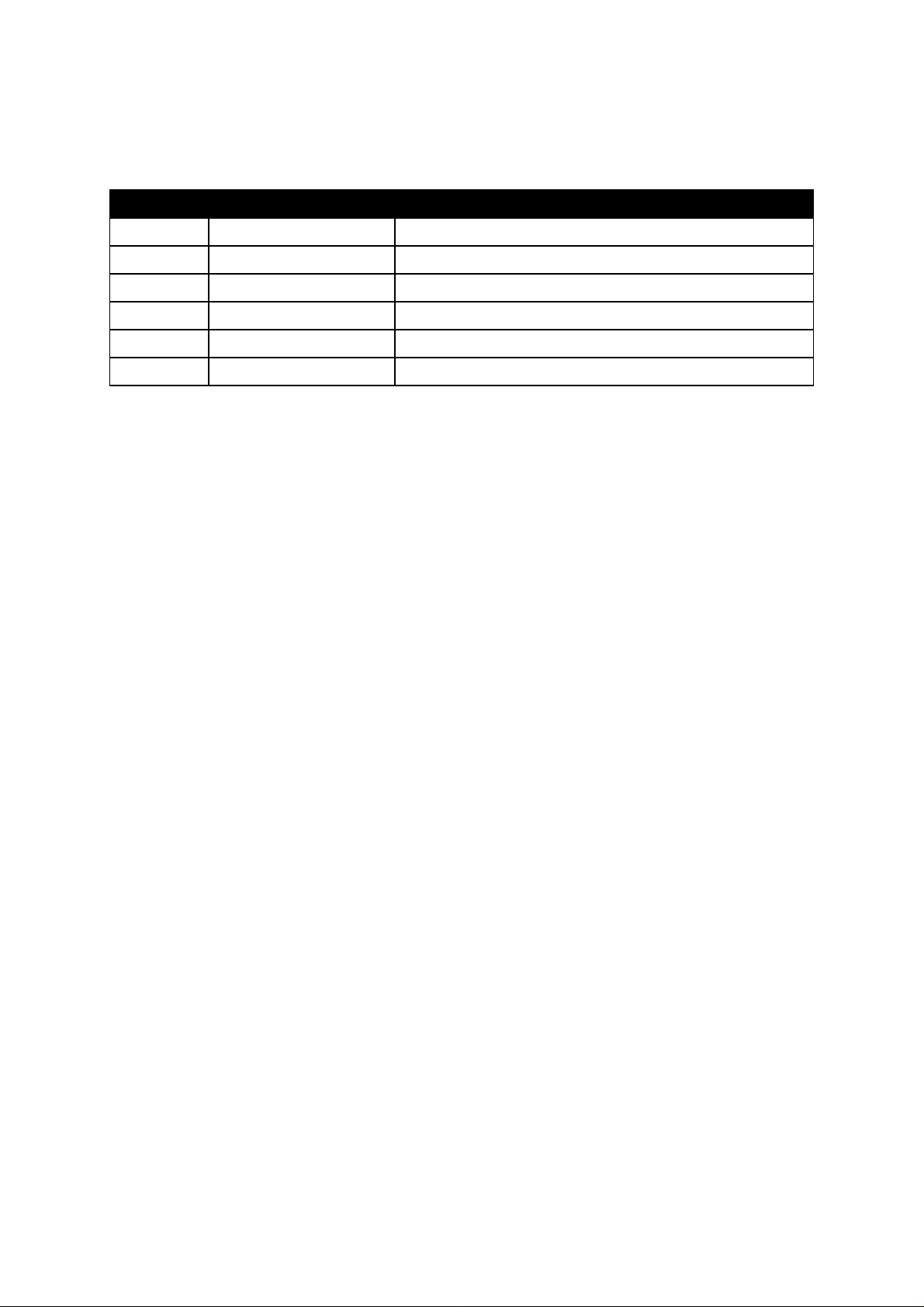

Table 1-1. Paper Size - Cut Sheet

Type Width Length

A4 210 mm

(8.3”)

LETTER 216 mm

(8.5”)

B5 182 mm

(7.2”)

LEGAL 216 mm

(8.5”)

Statement 139.7 mm

(5.5”)

Executive 184.2 mm

(7.25”)

297 mm

(11.7”)

279 mm

(11.0”)

257 mm

(10.1”)

356 mm

(14.0”)

215.9 mm

(8.5”)

266.7 mm

(10.5”)

Thickness: 0.08 ~ 0.11 mm (0.003 ~ 0.004”)

Weight: 64 ~ 90 g/m² (17 ~ 24 lb.)

Quality: Plain paper, Recycled paper, EPSON special medias

Envelope

Size:

Table 1-2. Paper Size - Envelope

Type Width Length

No.10 241 mm

DL 220 mm

Thickness: 0.16 ~ 0.52 mm (0.006 ~ 0.020”)

Weight: 45 ~ 90 g/m²

Quality: BOND paper, Plain paper, Airmail

1

(9

(8.7”)

/2”)

104.8 mm

(4 1/8”)

110 mm

(4.3”)

Note) ∗Envelope printing is allowed only under normal temperature/humidity

condition.

∗Set the longer side of envelope horizontally at setting.

1-4

Rev. A

Page 12

5

Others

Size:

Table 1-3. Paper Size - Special Media

Type Width Length

Transparency (A4) 210 mm

(8.3”)

Transparency (LETTER) 216 mm

(8.5”)

Glossy Paper (A4) 210 mm

(8.3”)

Glossy Paper (LETTER) 216 mm

(8.5”)

Index Card (A6 size) 105 mm

(4.1”)

Quality: Exclusive transparency/Glossy Paper

Thickness: 0.23 mm (0.0091”) for Index Card

Chapter 1 Product Descriptions

297 mm

(11.7”)

279 mm

(11.0”)

297 mm

(11.7”)

279 mm

(11.0”)

148 mm

(5.8”)

Note) Set the paper thickness lever to “THICK PAPER” position for index card

printing.

Rev. A

1-

Page 13

EPSON Stylus Color 300 Service Manual

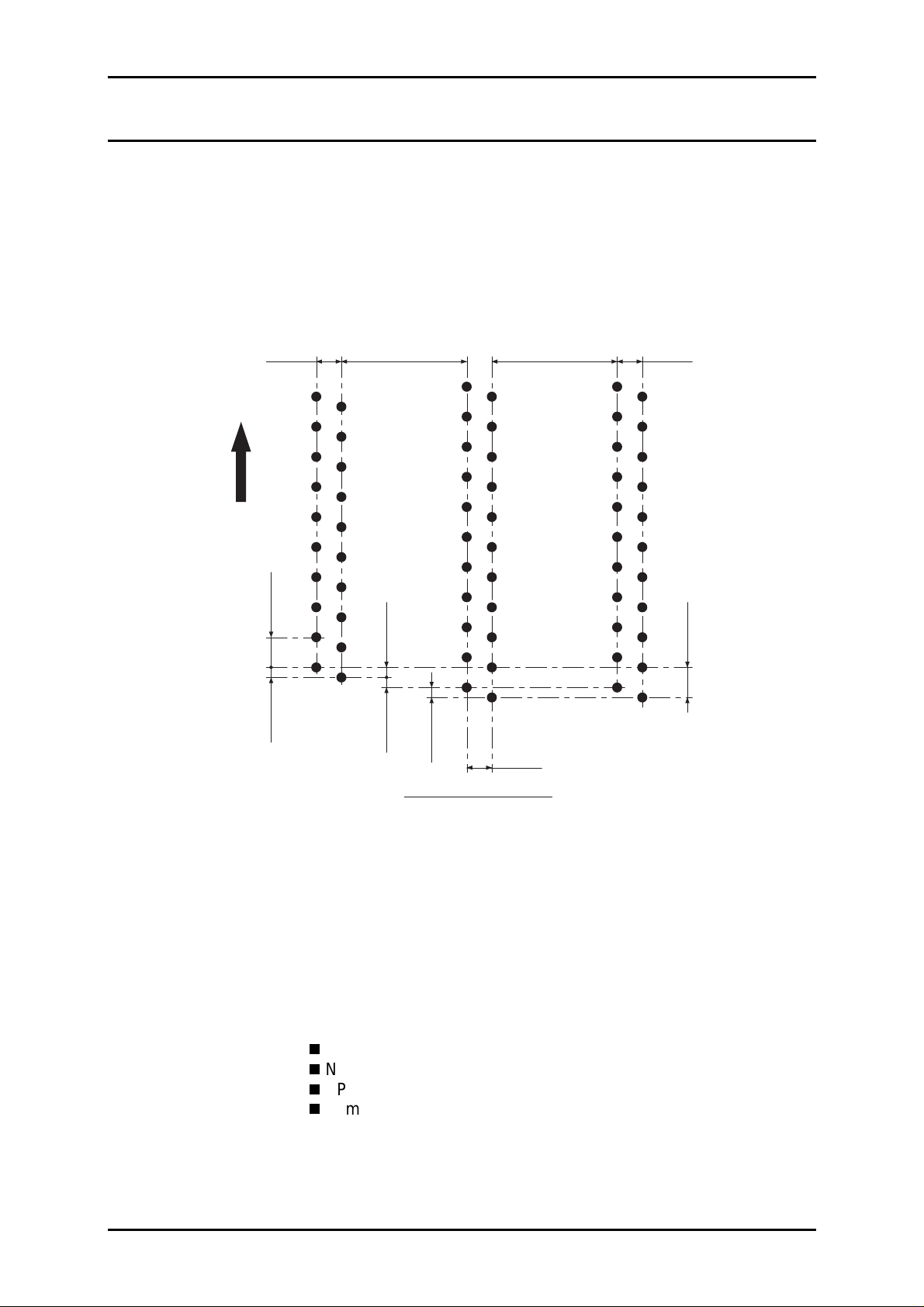

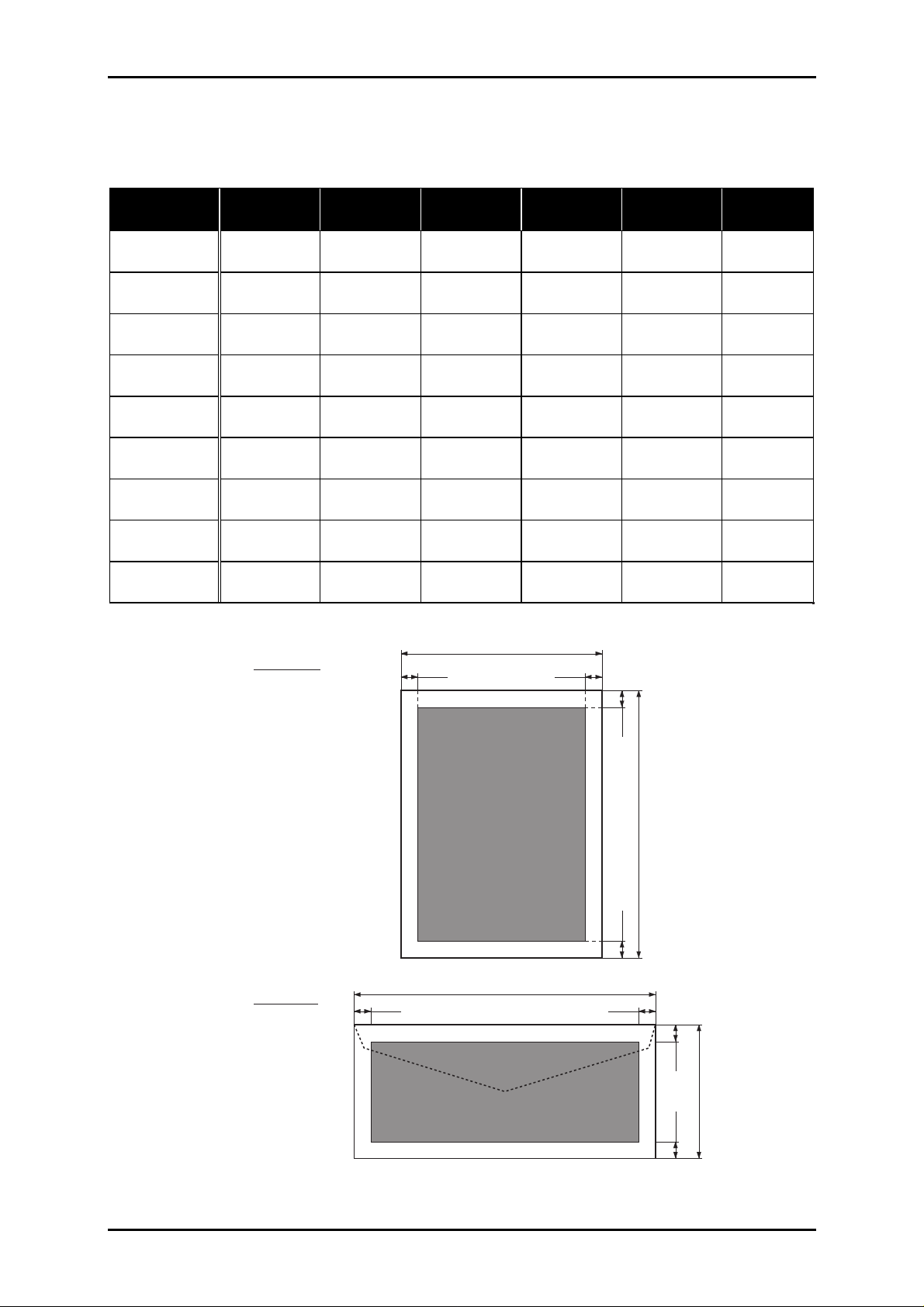

1.2.5 Printable Area

The maximum printable area with each type of paper is summarized in table below.

Table 1-4. Printable Area

Type PW

(typ.)

A4 210 mm

(8.3”)

LETTER 216 mm

(8.5”)

LEGAL 216 mm

(8.5”)

A6 105 mm

(4.1”)

B5 182 mm

(7.2”)

Statement 139.7 mm

(5.5”)

Executive 184.2 mm

(7.25”)

No.10 241 mm

(9.5”)

DL 220 mm

(8.7”)

CUT SHEET

PL

(typ.)

297 mm

(11.7”)

279 mm

(11.0”)

356 mm

(14”)

148 mm

(5.8”)

257 mm

(10.1”)

215.9 mm

(8.5”)

266.7 mm

(10.5”)

105 mm

(4.1”)

110 mm

(4.3”)

LM

(Min.)

3.0 mm

(0.12”)

RM

(Min.)

3.0 mm

(0.12”)

TM

(Min.)

3.0 mm

(0.12”)

BM

(Min.)

14.0 mm

(0.55”)

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑

33.8 mm

⇑⇑

(1.33”)

⇑

13.8 mm

⇑⇑

(0.54”)

PW

LM RM

ENVELOPE

TM

Printable Area

BM

PW

LM RM

Printable Area

PL

TM

PL

BM

1-6

Figure 1-2. Printable Area

Rev. A

Page 14

Chapter 1 Product Descriptions

7

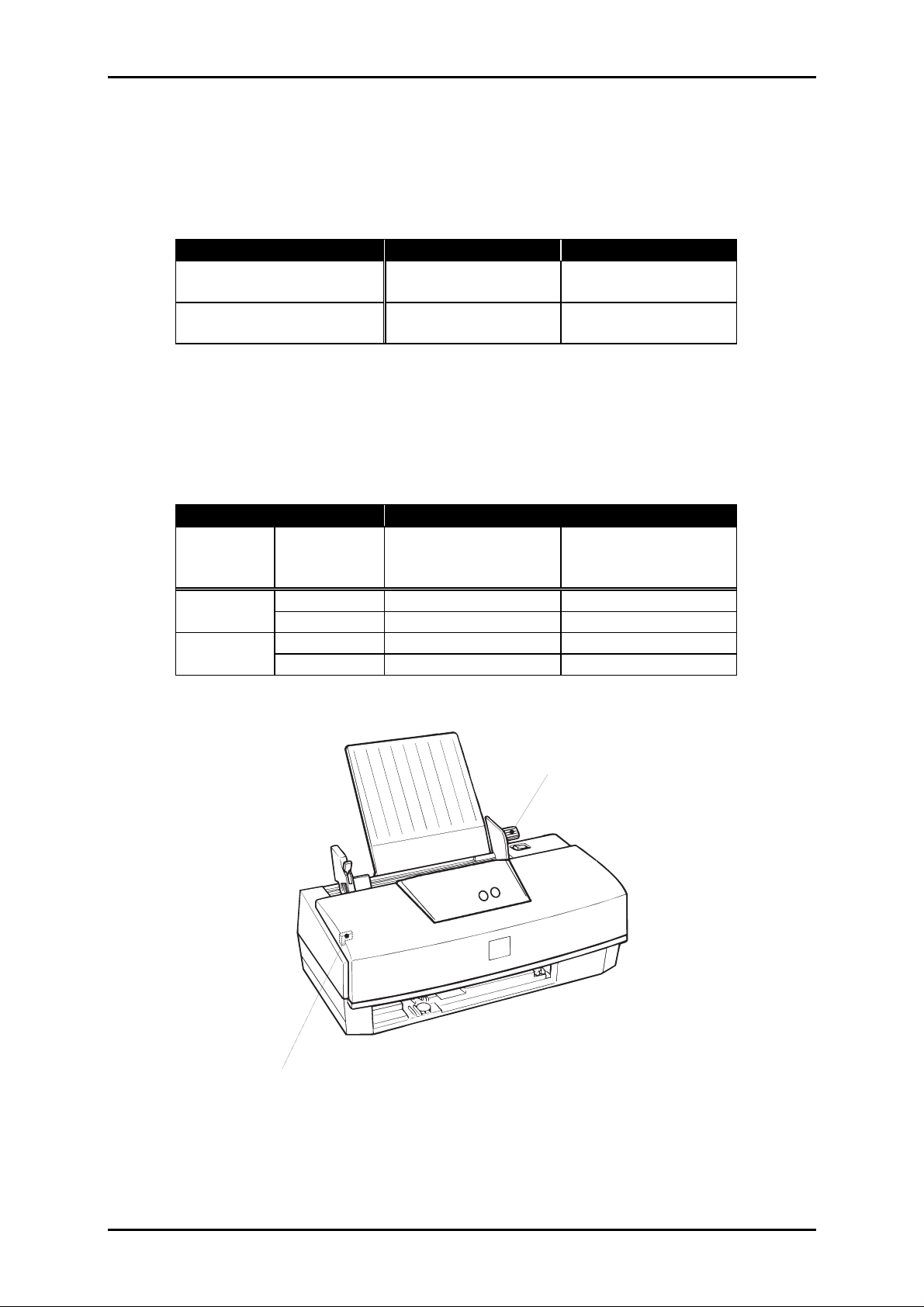

1.2.6 PG Adjust Lever Setting

The paper-gap (PG); a space between the printhead nozzle surface annd the paper

surface, can be adjusted to the appropriate level by the PG adjust lever which located

underneath the printer cover.

Table 1-5. PG Adjust Lever Setting

Paper Type Lever Position Gap Setting

Cut Sheet Front

0 mm

(“0” position)

Envelope Rear

+0.62 mm

(“+” position)

1.2.7 Paper Select Lever Setting

The built-in ASF is equipped with the adjust lever and the position of lever should be set to

appropriate position according to the type of paper used for the printing.

Table 1-6. Paper Select Lever Setting

Paper Feeding Paper Type

Source Select

Cut Sheet Envelope

Lever

Position

ASF Thick No OK

Normal OK No

Manual Thick OK OK

Insertion Normal No No

Paper Thickness Lever

(Forward position: Normal

Backward position: Thick paper)

Paper Thickness Lever

(Forward position: "0" Normal

Backward position: "+" Envelopes)

(Locate underneath the printer cover)

Figure 1-3. PG Adjust Lever and Paper Select Lever

Rev. A

1-

Page 15

EPSON Stylus Color 300 Service Manual

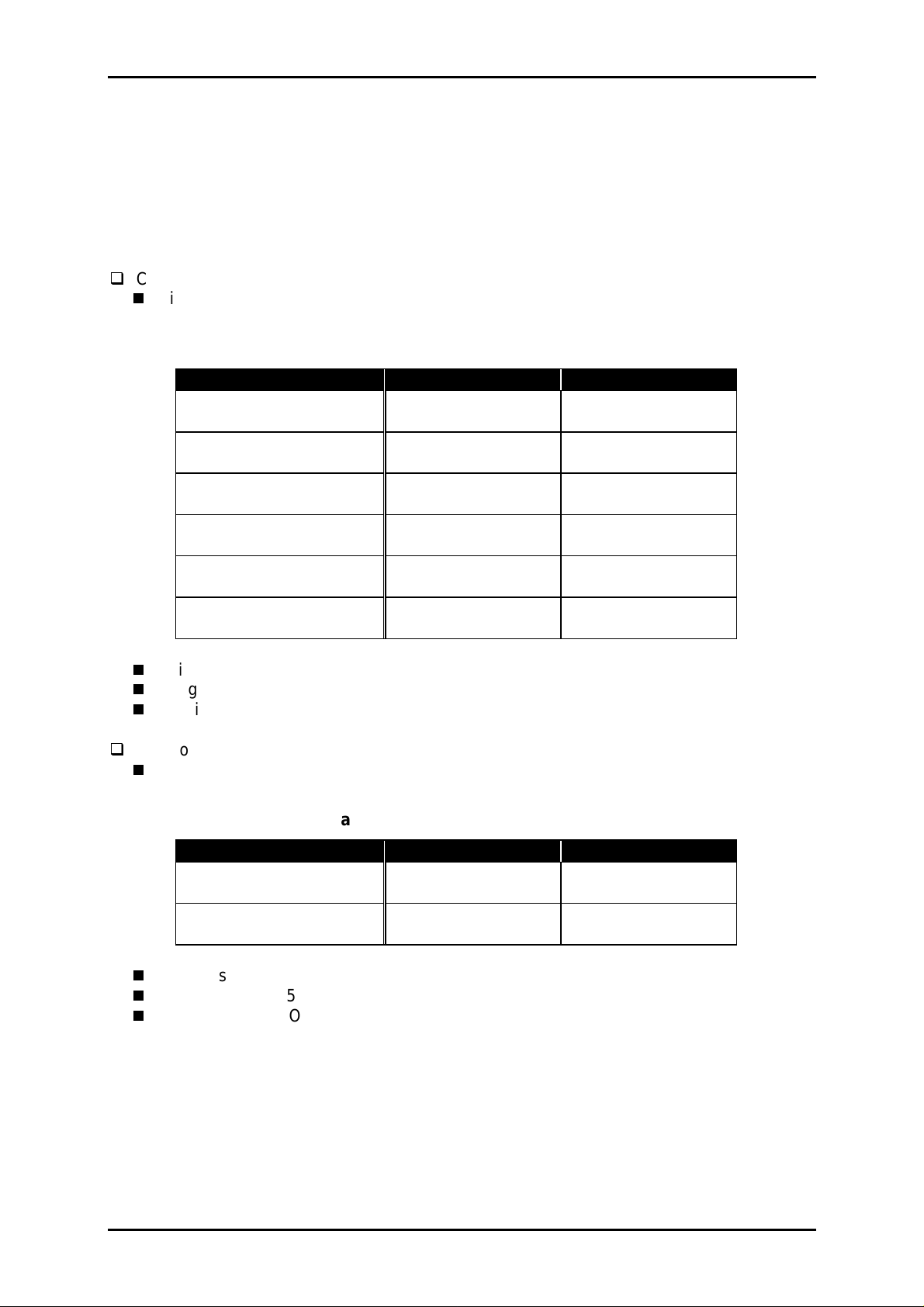

1.2.8 Ink Cartridge Specification

Type: Exclusive cartridge

Color: Black and CMY (Cyan, Magenta, Yellow)

Print capacity: 220 pages (360 DPI / 5% duty for each color on A4)

450 pages (ISO/IEC10561 LETTER pattern at 360 DPI

monochrome printing on A4)

Validity: 2 years (in sealed package)

6 months (out of package)

Storage conditions: Transit (Package): -30 ∼ 60 °C

(120 hours or less at 60 °C and

a month or less at 40 °C)

Storage (Package): -30 ∼ 40 °C

(A month or less at 40 °C)

After installation: -20 ∼ 40 °C

(A month or less at 40 °C)

Weight: 69.3 gram (internal ink amount = 41.1g)

Dimensions: 45.9 (W) × 56.5 (D) × 38.5 ±0.3 (H) mm

56.5 mm

38.5 mm

45.9 mm

Yellow

1-8

Magenta

Cyan

Black

Figure 1-4. Ink Cartridge

Rev. A

Page 16

9

1.2.9 Electrical Specifications

Table 1-7. Electrical Specification

Chapter 1 Product Descriptions

Item 120V Version

Rated Voltage 120 VAC

Input Voltage

103.5 ∼ 132 V 198 ∼ 264 V

Range

Rated Frequency

50 ∼ 60 Hz 50 ∼ 60 Hz

Range

Input Frequency

49.5 ∼ 60.5 Hz 49.5 ∼ 60.5 Hz

Range

Rated Current 0.5 A

(Max. 0.5 A)

Power

Consumption

Insulation

Resistance

(ISO/IEC10561 LETTER pattern)

(applying 500 VDC between AC

Approx. 15 W

10 MΩ, Min.

line and chassis)

Dielectric

Strength

AC 1000 Vrms for 1 min. or

AC 1200 Vrms for 1 sec.

(between AC line and chassis)

1.2.10 Environmental Conditions

220 ∼ 240V Version

220 ∼ 240 VAC

0.3 A

(Max. 0.3 A)

Approx. 15 W

(ISO/IEC10561 LETTER pattern)

Energy Star Compliant

10 MΩ, Min.

(applying 500 VDC between AC

line and chassis)

AC 1500 Vrms for 1 min.

(between AC line and chassis)

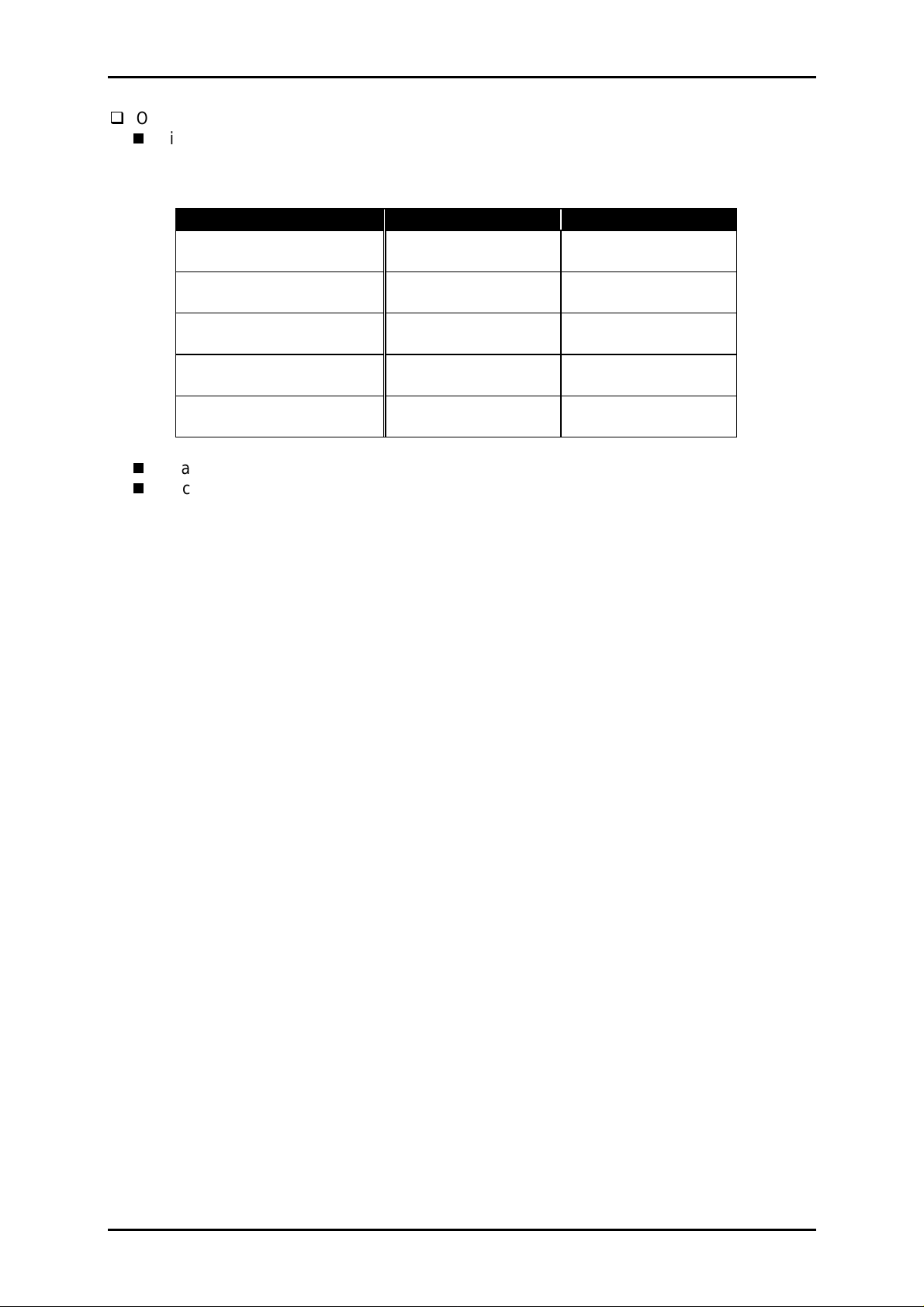

Table 1-8. Environmental Conditions

Condition Operating Non operating

Temperature

Humidity

Shock

Resistance

Vibration

10 ∼ 35 °C ∗3 -20 ∼ 60 °C ∗1

20 ∼ 80 % ∗2/3 5 ∼ 85 % ∗1/2

1G

(within 1 ms)

0.15G

(within 2 ms) ∗1

0.50G ∗1

Resistance

Note)∗1: Applicable when the unit is in a shipping container.

2: Without condensation.

∗

3: The unit should be operated within the range shown in figure below.

∗

Humidity

(%)

80

55

2G

20

10

27

Temperature

35

(°C)

Figure 1-5. Temperature and Humidity Range

Rev. A

1-

Page 17

EPSON Stylus Color 300 Service Manual

1.2.11 Reliability

Total Print Volume: 10,000 pages (A4 / LETTER)

Printhead Life: 1000 million dots / nozzle (Black and CMY)

1.2.12 Acoustic Noise

Level: Approx. 45 dB(A) (according to ISO7779)

1.2.13 Safety Approvals

Table 1-9. Safety Approvals

Item 120V Version

Safety Standard UL1950 with D3

CSA C22.2 No.950 with D3

EMI FCC part 15 subpart B class B

CSA C108.8 class B

1.2.14 CE Marking

[220 ~ 240V Version only]

Low Voltage Directive 73/26/EEC: EN60950

EMC Directive89/336/EEC: EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

220 ∼ 240V Version

EN 60950 (TÜV, NEMKO)

EN55022 (CISPR Pub.22) class B

AS/NSZ 3548 class B

1-10

Rev. A

Page 18

Chapter 1 Product Descriptions

1.2.15 Physical Specifications

Dimensions: 397 (W) × 319 (D) × 269 (H) mm

(operating condition)

Weight: 3.9 Kg (exclude the printhead and the ink cartridge)

319 mm

269 mm

397 mm

Figure 1-6. Dimensions

Rev. A

1-11

Page 19

EPSON Stylus Color 300 Service Manual

1.3 INTERFACE SPECIFICATION

Refer to the service manual of EPSON Stylus Color 200 / Stylus 200 for details.

1.4 OPERATIONS

This section describes the basic operation of the printer.

1.4.1 Control Panel

The control panel is equipped with two non-lock type push buttons and three LED

indicators, and operations of each button and LED indicator are described below.

Buttons

LOAD/EJECT

Figure 1-7. Control Panel

1.4.1.1 Buttons

Normal Operation

Table 1-10. Control Panel - Normal Operations

Button Operation Function

LOAD/EJECT Pressed less than

3 sec.

Pressed for 3 sec.

CLEANING Pressed less than

3 sec.

Pressed for 3 sec.

LED Indicators

PAPER OUT

INK OUT

POWER

(Red)

(Green)

• Loads or ejects the paper.

• When the carriage is at the ink-cartridge

replace position, return the carriage to the

home position.

• Starts the ink-cartridge replace operation and

the carriage moves to the ink-cartridge

replace position.

Starts the cleaning operation.

•

When the printer is in “Ink Low”, “Ink Out” or

•

“No ink cartridge” status, the printer moves the

carriage to the ink-cartridge replace position.

• When the carriage is at the ink-cartridge

replace position, return the carriage to the

home position.

CLEANING

(Red)

1-12

Rev. A

Page 20

3

Power-On Operation

Chapter 1 Product Descriptions

Table 1-11. Control Panel - Power-on Operations

Button Function

[1st button]

Hold down at

power on

nd

button]

[2

Pressed within

3 sec. after

The printer perform the following after

performing the control panel operation

in left column.

power on. ∗2

CLEANING ----- Self-printing test

LOAD/EJECT ----- Status printing

LOAD/EJECT

+

CLEANING

LOAD/EJECT

+

CLEANING ∗1

EEPROM Initialization

Note) ∗1: Holds down the specified buttons for 10 sec. or more until INK OUT and

PAPER OUT LED starts blinking.

∗2: After the power on, INK OUT and PAPER OUT LED starts blinking and

continue for about 3 sec. “Press within 3 sec. after power on” means to press

nd

buttons while these LED are blinking.

2

Self-test printing:The printer prints the self check test pattern. The printer prints

a page at a time and pauses between each page. When the

printer is in pause state, press LOAD/EJECT button to resume

printing and turn the power off to cancel the self-test printing.

Status printing: The printer prints; Firmware version, ink counter value and a

nozzle check pattern. The printer goes to a pause state after

print one page. To cancel the status printing, turn the power

off

while the printer is in pause state.

EEPROM Initialization: Initialize the following addresses of the EEPROM (refer to the

EEPROM address map table in Appendix.)

1AH: Interface selection (00H: Auto)

1BH: Interface Wait Time (02H: 2 sec.)

2CH/2DH: Counter A (Protect counter) (00H)

70H - 73H: 4-color head non-installation time (00H)

78H - 7BH: Power Off Timer (00H)

Rev. A

1-1

Page 21

EPSON Stylus Color 300 Service Manual

1.4.1.2 LED Indicators

The LED indicators of the control panel shows the various printer status as below.

Table 1-12. Control Panel - LED Status Indications

Status POWER INK OUT PAPER OUT Priority

Ink low (printable) ON Blink ----- Low

Ink out (not printable) ON ON ----Paper out ON ----- ON

Paper jam ON ----- Blink

No ink cartridge ON ON ----- Medium

No printhead ON Blink

(Fast)

• Replacing head/ink cartridge

Blink ----- ----- High

-----

• Printing

• During ink sequence

EEPROM initialization ON Blink Blink

Button(s) is pressed at power

on

• Carriage control error

Blink Blink

(Fast)

Blink ON ON Highest

Blink

(Fast)

• Fatal error

Maintenance request Blink

(Fast)

Blink

(Fast)

Blink

(Fast)

1-14

Rev. A

Page 22

Chapter 1 Product Descriptions

5

1.5 M AIN COMPONE NTS

The EPSON Stylus Color 300 is composed of the following main components:

Printer mechanism

Main control board (C224 MAIN Board)

Power Supply Unit (C160 PSB/PSE Board : Same as EPSON Stylus Color 200 / Stylus

200)

Control Panel

Housing

1.5.1 Printer Mechanism

The mechanical design of printer mechanism for EPSON Stylus Color 300 is basically the

same with EPSON Stylus Color 200/Stylus 200, and is equipped with the detachable 4colors one-piece printhead unit.

1.5.2 Main Control Board (C224 MAIN Board)

The main control board (C224 MAIN board) is controlled by the M37721S2BFP 16bit CPU

(IC2) which driven with 25MHz clock speed. The E05B49KA custom gate array (IC1)

controls the memories (ROM and RAM), a built-in parallel interface circuit and the printhead

drive voltage generation circuit.

1.5.3 Power Supply Unit (C160 PSB/PSE Board)

The power supply unit of EPSON Stylus Color 300 is exactly the same with EPSON Stylus

Color 200/Stylus 200.

1.5.4 Housing

In accordance with the control panel design change, the upper housing is also changed

from EPSON Stylus Color 200/Stylus 200.

Rev. A

1-1

Page 23

CHAPTER 2

OPERATING PRINCIPLES

2.1 OVERVIEW......................................................................................2-1

2.1.1 PRINTER MECHANISM ......................................................... 2-1

2.1.1.1 Printhead Unit..............................................................2-1

Page 24

Chapter 2 Operating Principles

2.1 OVERVIEW

Since most of the printer mechanism design and the electrical circuits of EPSON Stylus

Color 300 remains the same with EPSON Stylus Color 200/Stylus 200, this chapter only

describes the difference in the printer mechanism.

2.1.1 PRINTER MECHANISM

Based on the printer mechanism for EPSON Stylus Color 200/Stylus 200, a newly designed

one-piece 4-color printhead is incorporated on EPSON Stylus Color 300. This section only

describes the printhead.

2.1.1.1 Printhead Unit

The printhead unit for EPSON Stylus Color 300 is a new design printhead and has both

black and color (CMY) nozzles in one unit. The nozzle arrangement of the printhead is

shown below.

16/360"

(1.1289mm)

#B30

Print direction (Paper feed)

1/60"

(0.4233mm)

#B3

#B2

1/180"

(0.1411mm)

#29

104/360"

(7.3378mm)

1/180"

(0.1411mm)

1/180"

(0.1411mm)

#31

1/180"

(0.1411mm)

#B1

104/360"

(7.3378mm)

#C11

#C1

16/360"

(1.1289mm)

#M11

#M1

16/360"

(1.1289mm)

#Y11

1/60"

#Y1

(0.4233mm)

Viewed from the back of the printhead

Figure 2-1. Printhead (Nozzle Configuration)

To compensate the electrical characteristics variation of the piezo-electric element used on

each printhead unit, the electrical characteristics is measured at the factory and the

measured characteristic level is designated as an ID of the printhead. The ID of printhead is

recorded on each printedhead by changing a signal line pattern connection on the head

drive circuit of the printhead. The main control circuit detect the status of this signal line and

determines the printhead ID and adjust the head drive voltage level according to the

printhead ID. Therefore, no head ID registration to EEPROM is required on this printer.

Rev. A

2-1

Page 25

CHAPTER 3

DISASSEMBLY AND ASSEMBLY

3.1 OVERVIEW......................................................................................3-1

3.1.1 Upper Case Removal............................................................. 3-1

3.1.2 C224 MAIN Board Removal .................................................. 3-2

Page 26

Chapter 3 Disassembly and Assembly

3.1 OVERVIEW

This section describes procedures for disassembling and assembling the main components

of EPSON Stylus Color 300. Since the most of components are the same with EPSON

Stylus Color 200/Stylus 200, this manual only describes procedures unique to this printer.

3.1.1 Upper Case Removal

1. Remove the sheet guide from the printer.

2. Move the paper select lever to the backward position, then remove one screw

(CBP/M2x6) securing a knob to the paper select lever.

3. Open the printer cover, then remove five screws (one CBB/M4x6 and four CBP/M4x12)

securing the upper case to the bottom case.

4. Remove the upper case by lifting it upward.

Knob

(paper select lever)

CBP (M4x12)

CBP (M2x8)

Figure 3-1. Upper Case Removal

Printer Cover

CBB (M3x8)

Upper Case

Rev. A

3-1

Page 27

EPSON Stylus Color 300 Service Manual

3.1.2 C224 MAIN Board Removal

1. Remove the upper case. (See Section 3.1.1).

2. Remove five screws (CBB/M3x6); four screws fixing the shield plate directly to the C224

MAIN Board and one screw fixing the metal bracket to the shield plate.

3. Disconnect all cables connected to the C224 MAIN Board and remove the C224 MAIN

Board.

CBB (M3x6) CBB (M3x6)

Bracket

SHIELD PLATE

C224 MAIN BOARD

3-2

Figure 3-2. C224 MAIN Board Removal

Rev. A

Page 28

CHAPTER 4

ADJUSTMENT

4.1 OVERVIEW......................................................................................4-1

4.1.1 Adjustment Tools .................................................................. 4-1

4.1.2 Applicable Repair .................................................................. 4-1

4.1.3 Adjustment Program.............................................................4-2

4.1.3.1 Zig-Zag Adjustment ..................................................... 4-2

4.1.3.2 Bi-D Adjustment........................................................... 4-2

4.1.3.3 Head Angle Adjustment............................................... 4-2

4.1.3.4 RESET Fucntion.......................................................... 4-3

Page 29

Chapter 4 Adjustment

4.1 OVERVIEW

This section describes procedures for adjustments which required when the printer is

disassembled and assembled for repair.

CAUTION

Once the ink cartridge is removed from the printer before ink-end, never re-use it.

For adjustment and testing, always replace the ink cartridge to new one designed

exclusively for service:

Description:

Code:

4.1.1 Adjustment Tools

The table below lists the tools required to make adjustment on EPSON Stylus Color 300.

Table 4-1. Tools for Adjustment

Tool Code Applicable Adjustment

Thickness Gauge Set #F518*1B776702201

Adjustment Program

Name: CLR300.EXE

-----

• Platen Gap Adjustment

• Head Angle Adjustment

• Bi-D Adjustment

• Zig-Zag Alignment Adjustment

• RESET function for:

*Ink counter

*Initial charge flag

*Protect counter (Waste ink counter)

4.1.2 Applicable Repair

An appropriate adjustment have to be made according to the type of repair performed.

Table 4-2. Applicable Adjustment

Repair Applicable Adjustment

C224 MAIN board is replaced *1

Printhead is replaced *2

Printer mechanism is replaced *2

• CR Motor or timing belt is replaced

• Carriage assembly is disassembled

• Zig-Zag Alignment Adjustment

• Bi-D Adjustment

• Zig-Zag Alignment Adjustment

• Head Angle Adjustment

• Zig-Zag Alignment Adjustment

• Bi-D Adjustment

• Bi-D Alignment

Note) *1: Replace the ink cartridge and the waste ink pad to new one and reset

ink counter and protect counter.

*2: Replace the ink cartridge to new one and reset initial charge flag and

ink counter.

Rev. A

4-1

Page 30

EPSON Stylus Color 300 Service Manual

4.1.3 Adjustment Program

The adjustment program CLR300.EXE is specifically designed for use with the EPSON

Stylus Color 300 and the following adjustments can be made with this program.

Zig-Zag Adjustment

Bi-D Adjustment

Head Angle Adjustment

Reset operation

To start making adjustment with the program, execute the program on the PC that

connected to the target printer and follow the instruction shown on the PC monitor.

CAUTION

Since the mechanism design is the same with the EPSON Stylus Color 200, refer to

the service manual for EPSON Stylus Color 200, at Chapter 4 Adjustment, for the

detail procedures.

4.1.3.1 Zig-Zag Adjustment

This adjustment is required to specify the print timing control parameter that determines the

ink injection timing for each nozzle. If the adjustment is wrong, a vertical line printed within

single print pass become jagged.

Verify the check pattern printed by the program and specify the parameter until the check

pattern become aligned most properly.

4.1.3.2 Bi-D Adjustment

This adjustment is required to specify the control parameter that determines the print timing

in bi-directional printing. If the adjustment is wrong, the print position at each print direction

is not aligned each other.

Verify the check pattern printed by the program and specify the parameter until the check

pattern become aligned most properly.

4.1.3.3 Head Angle Adjustment

This adjustment is required when the printhead is replaced to new one. Every dot line

(raster) need to be parallel each other and the angle of the printhead, at which the

printhead is fixed on the carriage assembly, determines a parallel level.

The program prints the check pattern to judge the angle of printhead, and is the angle is not

correct, move the head angle adjust lever located at the right hand side of the carriage

assembly to a position with which the printed pattern become parallel.

4-2

Rev. A

Page 31

Chapter 4 Adjustment

3

4.1.3.4 RESET Fucntion

Since various ink system management information are stored in EEPROM on the main

board, the information integrity need to be kept even after the combination of the printer

mechanism and the main board is altered. Therefore, if any of the component (main board,

printer mechanism or the printhead) is replaced to new one, reset the appropriate

information (counter value or flag).

Table 4-3. RESET Operation

Type of Repair Required Operation

C224 MAIN board is replaced

Printer Mechanism is replaced

Printhead is replaced

• Ink Cartridge replacement

• Waste ink pad replacement

• [RESET] Ink counter

• [RESET] Protect counter

• [RESET] Initial charge flag

• [RESET] Ink counter

• Ink Cartridge replacement

• [RESET] Initial charge flag

• [RESET] Ink counter

• Ink Cartridge replacement

Rev. A

4-

Page 32

CHAPTER 5

TROUBLESHOOTING

5.1 OVERVIEW......................................................................................5-1

5.1.1 Unit Repair - C224 MAIN Board............................................ 5-1

Page 33

Chapter 5 Troubleshooting

5.1 OVERVIEW

Since the printer mechanism and the power supply unit are remains the same with EPSON

Stylus Color 200/Stylus 200, this chapter describes only the checkpoints on the main control

circuit; C224 MAIN Board.

5.1.1 Unit Repair - C224 MAIN Board

The table below provides various symptom, likely causes and checkpoint, relating to the

C224 MAIN Board.

Symptom Condition Cause Checkpoint Solution

Printer does

not operate

at all.

CPU does

not operate.

Reset IC (IC9)

is defective

Check the signal waveform at pin 6 of

IC9:

Replace IC9

ASIC does

not operate.

Oscillator

(CR2) or CPU

(IC2) is

defective

ASIC (IC1) is

defective

Is the signal waveform output from CR2

correct at pin 37/38?

Is the signal waveform at pins 52 of IC1

correct?

Correct:

Replace IC2

Incorrect:

Replace CR2

Replace IC1

Rev. A

5-1

Page 34

EPSON Stylus Color 300 Service Manual

Symptom Condition Cause Checkpoint Solution

Self-test

printing is

abnormal.

No printing. PWM signal is

not output.

Is PWM signal waveform correct at pin

140 of IC1?

Replace IC1

Carriage

does not

operate

normally.

Drive signals

are not

output

correctly.

Head drive

voltage

generation

circuit does

not operate.

CPU (IC2) is

defective

Check waveform of the signal VO: Replace any

defective

components:

Q1/2/4/7/8 or

QM1/3/4/5/6/7/8

Is the signal waveform correct at pin 5/6

of IC2?

Replace IC2

5-2

CR Motor

driver (IC8) is

defective

Is the signal waveform correct at pin

3/6/18/21 of IC8?

Correct:

Replace CR

Motor

Incorrect:

Replace IC9

Rev. A

Page 35

Chapter 5 Troubleshooting

3

Symptom Condition Cause Checkpoint Solution

Paper does

not advance

normally.

Drive signals

are not

output

correctly.

CPU (IC2) is

defective

Is the signal waveform correcr at pin 7/8

of IC2?

Replace IC2

PF Motor

driver (IC16)

is defective

Is the signal waveform correct at pin

14/17/20/23 of IC16?

Correct:

Replace PF

Motor

Incorrect:

Replace IC16

Rev. A

5-

Page 36

CHAPTER 6

MAINTENANCE

6.1 OVERVIEW......................................................................................6-1

6.1.1 Maintenance Request............................................................ 6-1

Page 37

Chapter 6 Maintenance

6.1 OVERVIEW

This section describes the maintenance points and the procedures specific for EPSON

Stylus Color 300.

WARNING

If ink gets in your eyes, flush them immediately with water and seek medical

attention.

Disconnect the printer from the power source when you clean inside the printer.

CAUTION

Once the ink cartridge is removed from the printer before ink-end, never re-use it.

For adjustment and testing, use the ink cartridge designed exclusively for service:

Description:

Code:

6.1.1 Maintenance Request

The printer counts total amount of ink drained to the waste ink pad and this information is

stored in the EEPROM on the main board, as the protect counter A value for ink system

operation management. When the counter value reaches the predetermined value, the

printer detects it as “Maintenance Request” error and displays the error status with the

control panel LED indicators (see Table 1-12 at Chapter 1, Section 1.4.1.2 LED Indicators).

When this error displayed, replace the waste ink pad to new one and reset the counter

value with the procedure shown below.

Turn the printer ON while

hold down the buttons:

continue for 3 seconds

Press the buttons within

3 seconds from power ON,

and kept them pressed until

"INK END", "PAPER OUT"

LEDs starts blinking:

"POWER" LED

"INK OUT" LED

"PAPER OUT" LED

LOAD/EJECT

CLEANING

LOAD/EJECT

CLEANING

Rev. A

"POWER" LED

"INK OUT" LED

"PAPER OUT" LED

Figure 6-1. “Maintenance Request” Error Clear Operation

6-1

Page 38

APPENDIX

A.1 OVERVIEW......................................................................................A-1

A.2 EEPROM Address Map..................................................................A-2

A.3 CIRCUIT DIAGRAM (C224 MAIN BOARD)....................................A-4

Page 39

Appendix

A.1 OVERVIEW

The main board of EPSON Stylus Color 300 is C224 MAIN BOARD and each connector

and its pin assignment are the same with the main board for EPSON Stylus Color 200.

Therefore, refer to the service manual for EPSON Stylus Color 200 for the details.

Rev. A

A-1

Page 40

EPSON Stylus Color 300 Service Manual

A.2 EEPROM Address Map

The table below shows the addresses of EEPROM and the contents stored at each

address.

Table A-1. EEPROM Address

Address Data Value Factory

Default

00 - 01H (Reserved) ----- 00H

02H Market (Model) 0: World

1: Japan

2 - 4: Custom

03 - 11H Customized model name

12 - 13H Bi-D Adjustment data

14 - 15H (Reserved) ----- 00H

16H Fire period adjustment

data

17H (Reserved) ----- 00H

18H EEPROM Status 00H: Used (once initialized)

19H

1AH Interface selection 00H: Auto

1BH Interface wait time 02H: 2sec.

1CH (Reserved) ----- -----

1DH Reply printer status

1EH Non-smear print mode Bit 0: <function>

1FH (Reserved) ----- -----

• THICK paper direction

• Auto LF

• Print direction

• Network I/F mode

control data

• Strings counter

• Strings of model field for device

ID

-36 ≤ n ≤ +36 (unit: 1/1440 inch)

-4 ≤ n ≤ +10 (unit: 0.08sec.)

other: Not used (to be initialized)

Bit 7: <Thick paper>

0: Index card (Portrait)

1: Envelope (Landscape)

Bit 3: <Auto LF>

0: OFF

1: ON

Bit 2: <Network I/F mode>

0: OFF

1: ON

Bit 1/0: <Print direction>

0/0: Bi-D

0/1: Uni-D

1/1: Auto

02H: Parallel I/F

03H: Serial I.F

03H: 3sec.

Bit 0: <function>

0: ON

1: OFF

0: Normal

1: Non-smear print mode

00H

00H

*1

*1

00H

82H

00H

*2

02H

*2

00H

00H

A-2

Rev. A

Page 41

Appendix

3

Table A-2. EEPROM Address (continued)

Address Data Value Factory

Default

20H CR Motor initial phase *1

21H (Reserved) ----- ----22 - 23H YMC Accumulated time 00H

24 - 25H Counter D 00H

26 - 27H Counter E

(Initial charge flag)

28 - 29H Counter R

(Cap flushing counter)

2A - 2BH Ink status 00H

2C 2DH

2E - 2FH Counter C

30 - 35H Fire dot counter K

36 - 3BH Fired dot counter Y

3C - 41H Fired dot counter M

42 - 47H Fired dot counter C

48 - 6BH (Reserved) ----- 00H

6C -6FH Head vacuuming time A 0 to FFFFFFFFH (unit: 10 min.)

70 - 73H 4-color head

74 - 77H (Reserved) ----- 00H

78 - 7BH Power off time 0 to FFFFFFFFH (unit: 10 min.)

7CH (Reserved) ----- -----

7DH VH adjust value (KR) (10000 x KR) ----7EH VH adjust value (Vad-L) (1000 x VerrAD(L)) ----7FH VH adjust value (Vad-H) (1000 x VerrAD(H)) -----

Counter A

(Protect counter)

(Number of power ON)

(Black )

(Yellow)

(Magenta)

(Cyan)

uninstallation time

00H: Initial charge required

01H: Initial charge done

1 count = 1ng 00H

1 count = 1ng 00H

1 count = 1ng 00H

1 count = 1ng 00H

Start from 1992/01/01 00:00

0 to FFFFFFFFH (unit: 10 min.)

Start from 1992/01/01 00:00

Start from 1992/01/01 00:00

00H

00H

00H

00H

01H

00H

00H

00H

00H

*2

00H

*2

Rev. A

A-

Page 42

EPSON Stylus Color 300 Service Manual

A.3 CIRCUIT DIAGRAM (C224 MAIN BOARD)

A-4

Rev. A

Page 43

EPSON OVERSEAS MARKETING LOCATIONS

EPSON AMERICA, INC.

20770 Madrona Ave.

P.O. Box 2842

Torrance, CA 90509-2842

Phone:(800) 922-8911

Fax: (310) 782-5220

EPSON DEUTSCHLAND GmbH

Zülpicher Straβe 6,

40549 Düsseldorf Germany

Phone:(0211) 56030

Telex: 8584786

EPSON AUSTRALIA PTY. LTD.

70 GIBBES STREET, CHATSWOOD 2067

NSW.

Phone:2-9903-9000

Fax: 2-9903-9177

EPSON HONG KONG LTD.

Rooms 4706-10, 47/F

China Resources Bldg.,

26 Harbour Road, Wanchai, Hong Kong

Phone:2585-4300

Fax: 2827-7083

EPSON ITALIA S.p.A.

EPSON UK LTD.

Campus 100, Mayland Avenue,

Hemel Hempstead, Herts,

HP2 7TJ, U.K.

Phone:(+44) 01442 61144

Fax: (+44) 01442 227227

EPSON FRANCE S.A.

68 bis, rue Marjolin

92300, Levallois-Perret, France

Phone:33.1.40.87.37.37

Telex: 610657

EPSON SINGAPORE PTE. LTD.

No.1 Temasek Avenue #36-00

Millenia Tower, Singapore 039192

Phone:(065) 33 77 911

Fax: (065) 33 41 185

EPSON TAIWAN TECHNOLOGY &

TRADING LTD.

10F, No.287 Nanking E. Road, Sec.3,

Taipei, Taiwan, R.O.C.

Phone:(02) 717-7360

Fax: (02) 712-9164

EPSON IBERICA S.A.

V. le F. lli Casiraghi 427

20099 Sesto S. Giovanni

MI, Italy

Phone:2-262331

Fax: 2-2440750

EPSON PORTUGAL, S.A.

R. do Progresso, 471, 1° Perafita

4460 Matosinhos, Portugal

Phone:(02) 996 14 02

Fax: (02) 996 14 11

Av. de Roma, 18-26

08290 Cerdanyola del Valles

Barcelona, Spain

Phone:582.15.00

Fax: 582.15.55

SEIKO EPSON CORPORATION

HIROOKA OFFICE / Imaging & Information Products Division

80 Harashinden, Hirooka

Shiojiri-Shi, Nagano-Ken

399-07 Japan

Page 44

EPSON

SEIKO EPSON CORPORATION

Loading...

Loading...