Page 1

EPSON COLOR INKJET PRINTER

Stylus 1500

SERVICE MANUAL

EPSON

4005452

Page 2

REVISION SHEET

Revision Issue Data Revision Page

Rev.A October 30,1995 1st issue

-v-

Page 3

PREFACE

This manualdescribes functions, theory of electrical and mechanical operations, maintenance, and repair of Stylus

1500.

The instructions and procedures included herein are intended for the experience repair technician, and attention

should be given to the precautions on the preceding page. The chapters are organized as follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

-iv-

Page 4

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENTS

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

-vi-

Page 5

Chapter 1 Product Description

Table of Contents

1.1 FEATURES 1-1

1.2 SPECIFICATIONS 1-3

1.2.1 Printing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.2 Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.3 Input Data Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.4 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.5 Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.6 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.7 Safety Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.8 CE Marking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.2.9 Acoustic Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3 INTERFACES 1-8

1.3.1 Hardware Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.1.1 Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.1.2 Optional Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.3.2 Printer Language and Control Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.4 OPERATIONS 1-13

1.4.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.4.1.1 Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.4.1.2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.4.2 Panel Functions at Power On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.3 Printer Conditions and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

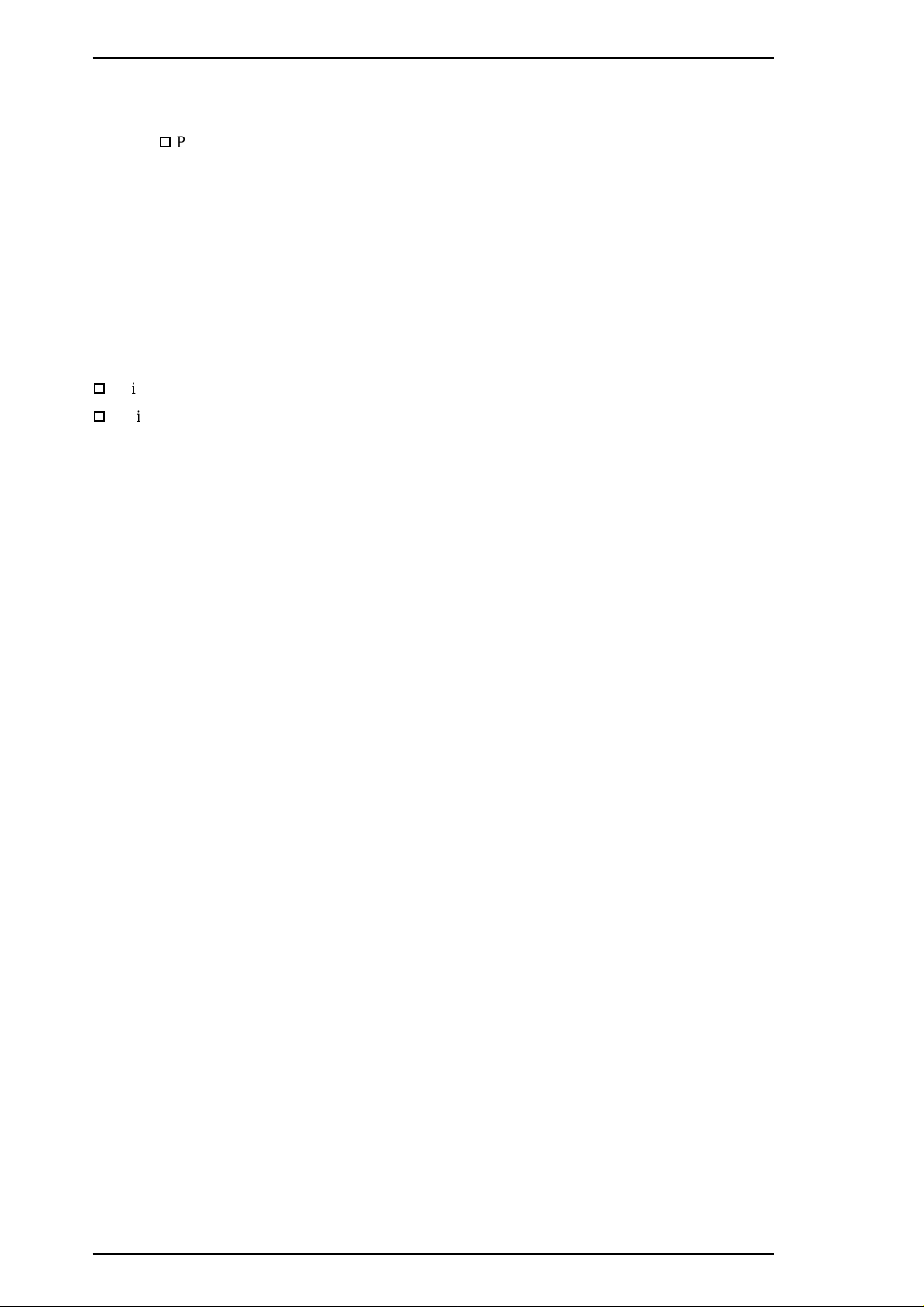

1.4.4 Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.4.1 Setting Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.4.2 Setting Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.4.5 Printer Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.4.6 Printer Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.4.7 Monochrome Printing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.5 PAPER SPECIFICATIONS 1-23

1.5.1 Paper Type Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.5.2 Printable Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

1.5.3 Adjust Lever Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.6 INK CARTRIDGE SPECIFICATIONS 1-30

1.7 PHYSICAL SPECIFICATIONS 1-31

1.8 MAIN COMPONENTS 1-32

1.8.1 Main Control Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

1.8.2 Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Page 6

List of Figures

Figure 1-1. Stylus 1500 Exterior View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

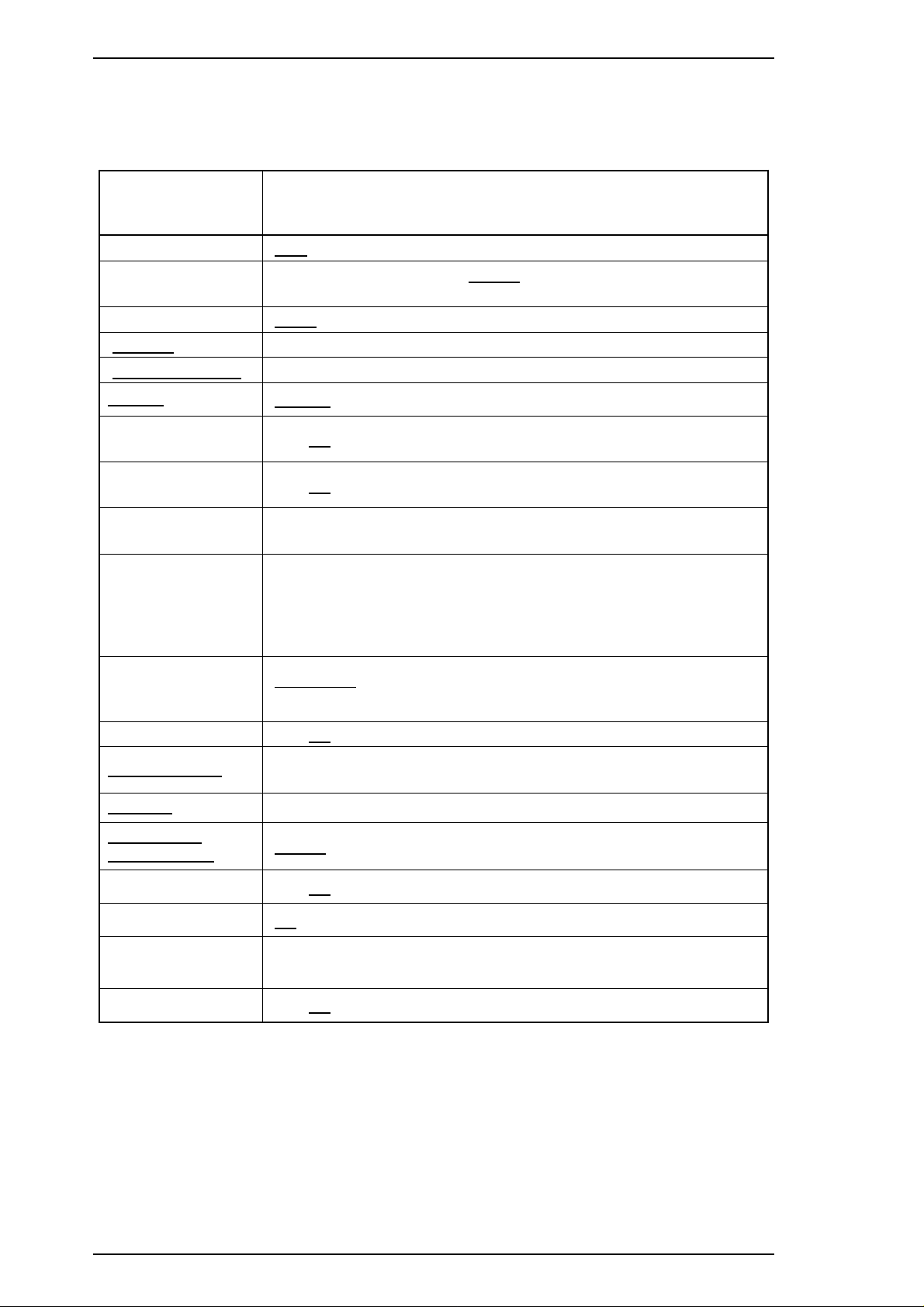

Figure 1-2. Nozzle Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-3. Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-4. Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-5. Control Panel Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

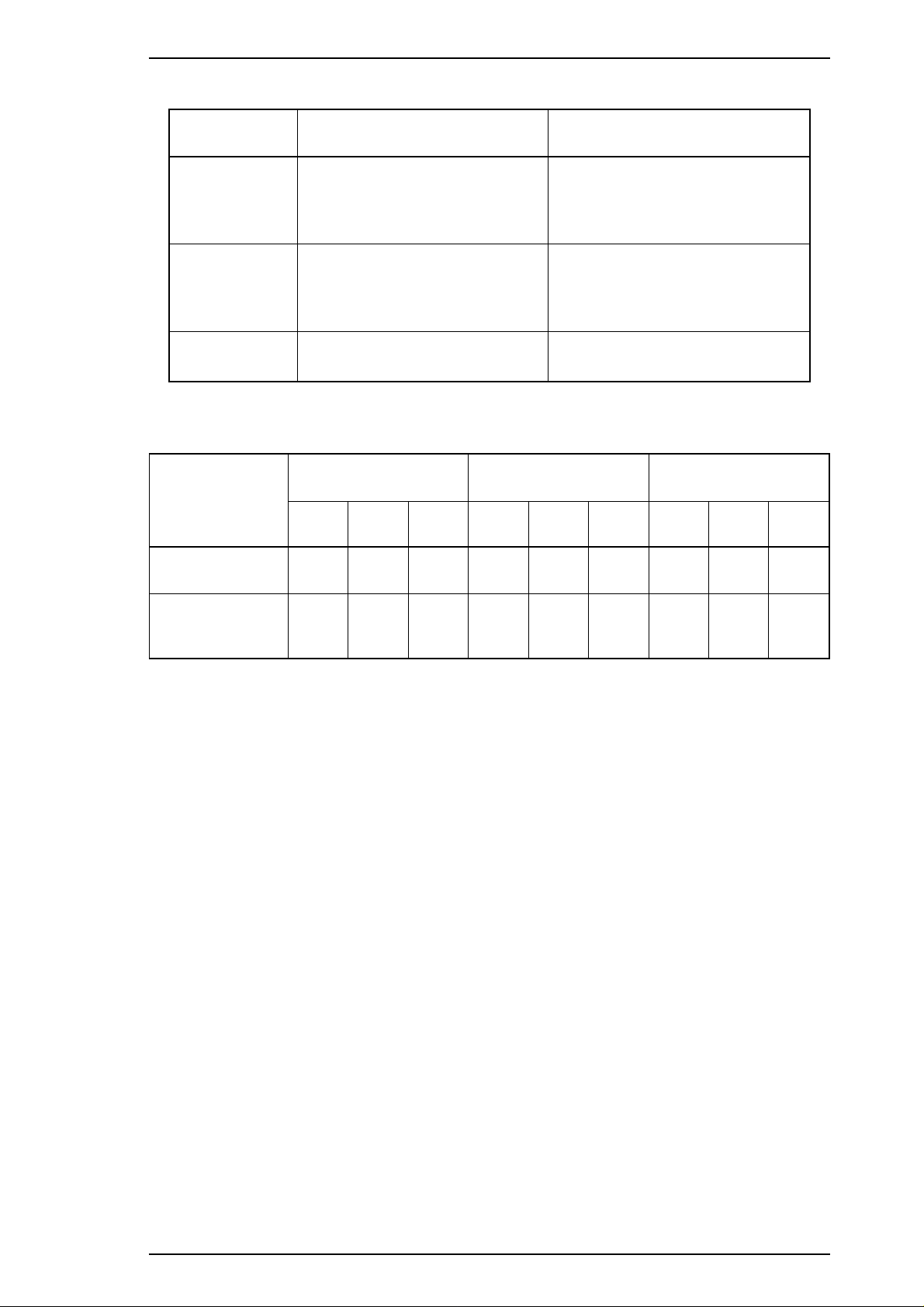

Figure 1-6. Default Setting Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Figure 1-7. Sample Adjustment Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Figure 1-8. Printable Area for Cut Sheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Figure 1-9. Printable Area for Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Figure 1-10. Printable Area for Continuous Paper . . . . . . . . . . . . . . . . . . . . . . 1-28

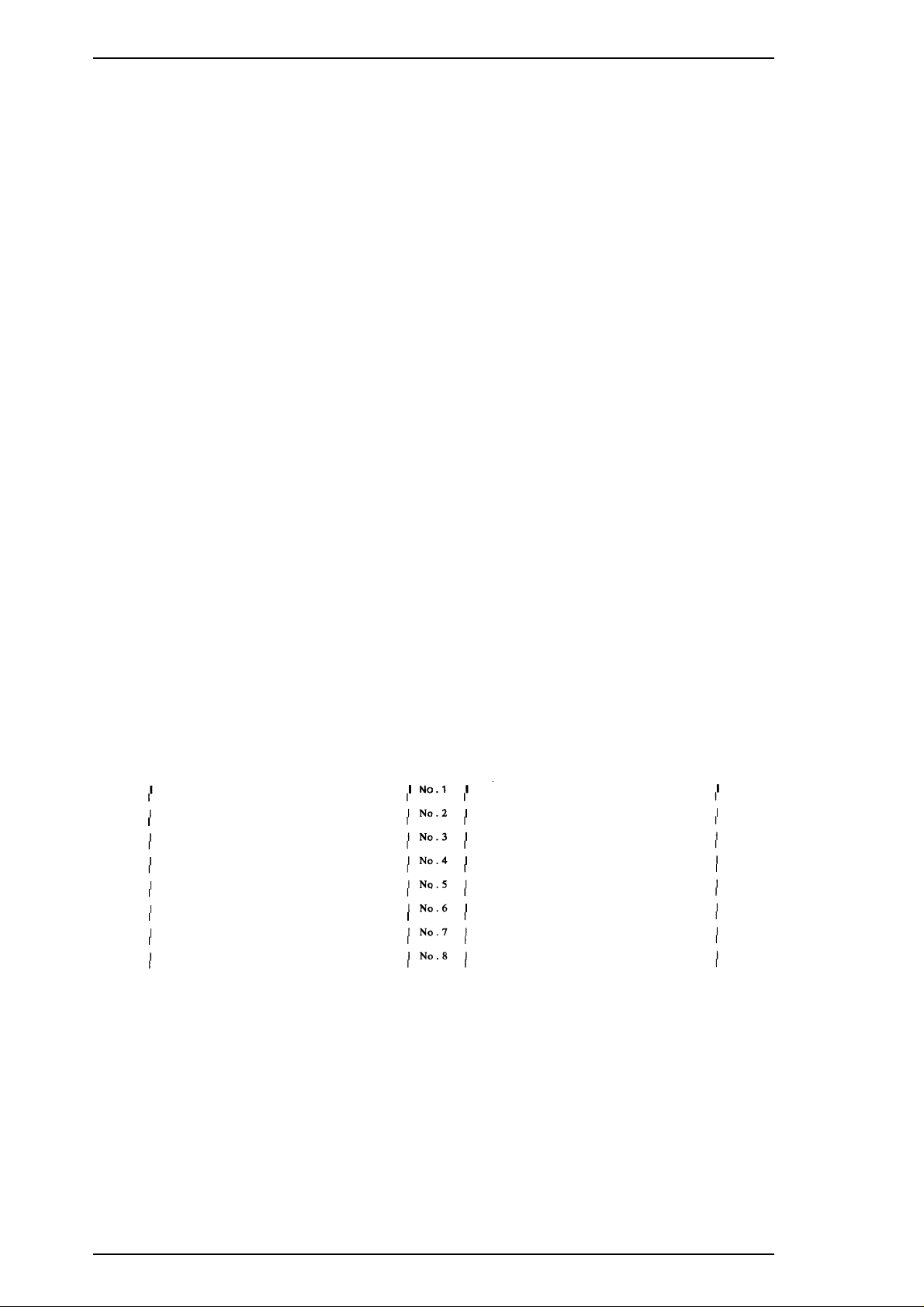

Figure 1-11. Adjust Lever Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Figure 1-12. C172 MAIN Board Component Layout . . . . . . . . . . . . . . . . . . . . . 1-32

Figure 1-13. C172 PSB/PSE Board Component Layout. . . . . . . . . . . . . . . . . . 1-32

List of Tables

Table 1-1. Options and Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Print Speeds and Printable Columns. . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-3. Character Tables and Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-4. Connector Pin Assignments and Signals (Forward Channel) . . . . . . 1-9

Table 1-5. Connector Pin Assignments and Signals (Reverse Channel) . . . . . 1-11

Table 1-6. Panel Functions at Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Table 1-7. Indicator Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

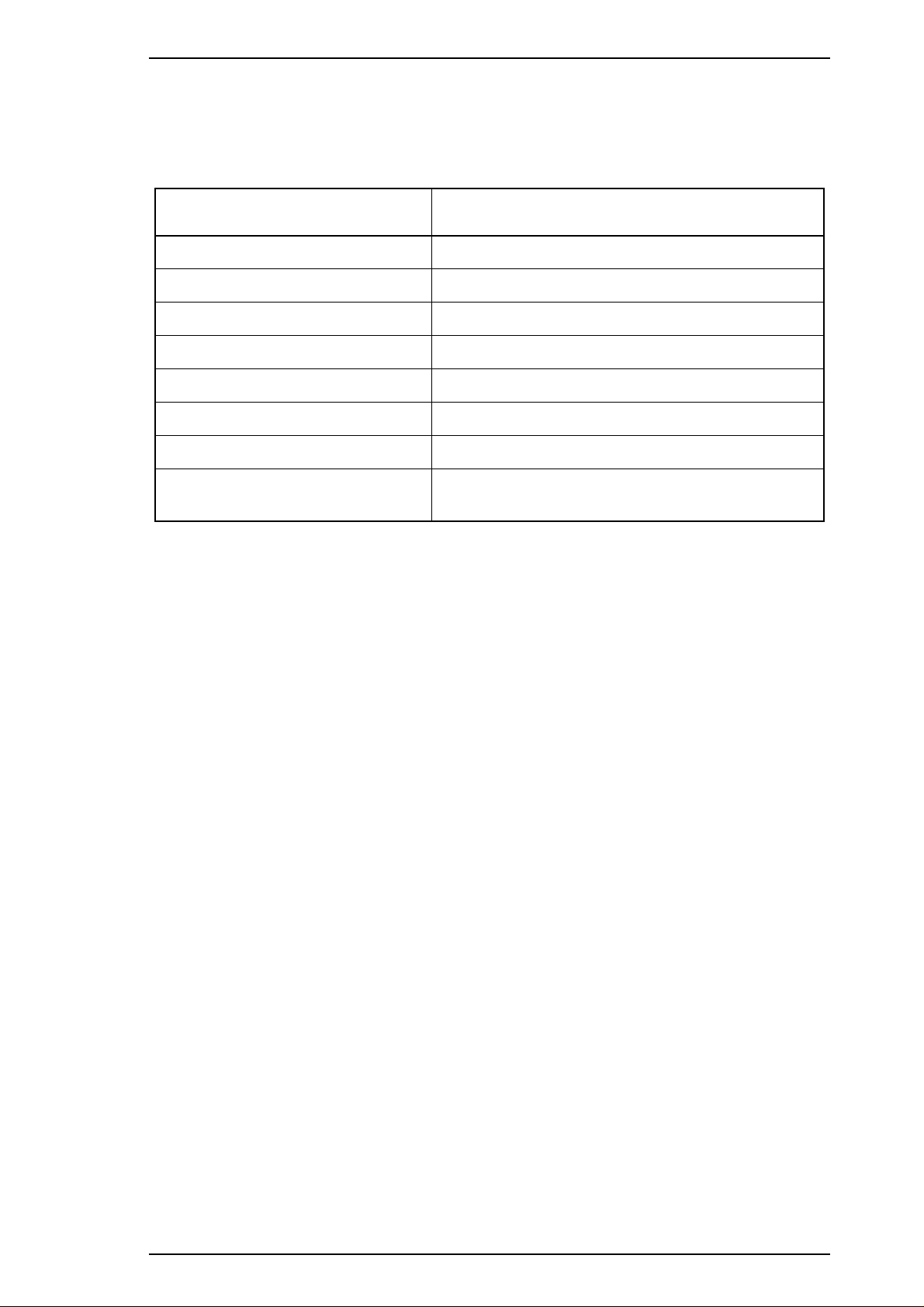

Table 1-8. Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

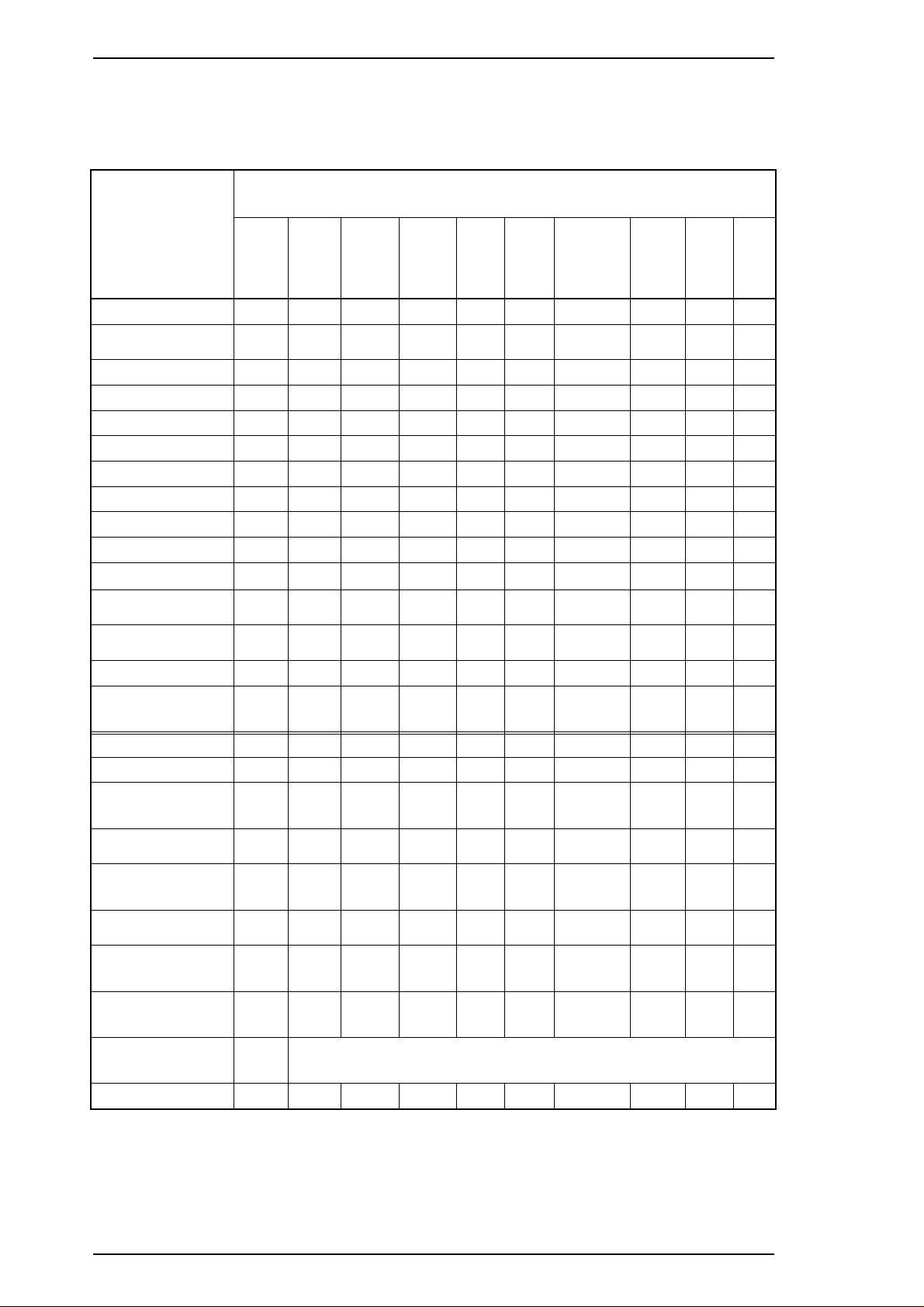

Table 1-9. Print Direction Mode Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table 1-10. Printing Direction and ESC U Command. . . . . . . . . . . . . . . . . . . . 1-19

Table 1-11. Cut Sheet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-12. Transparency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-13. Envelope Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-14. Index Card Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-15. Label (Cut Sheet) Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-16. Continuous Paper Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-17. Label (Continuous Paper) Specifications. . . . . . . . . . . . . . . . . . . . 1-24

Table 1-18. Banner Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Table 1-19. Minimum Margins for Different Cut Sheet Sizes . . . . . . . . . . . . . . 1-26

Table 1-20. Minimum Margins for Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Table 1-21. Adjust Lever Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Page 7

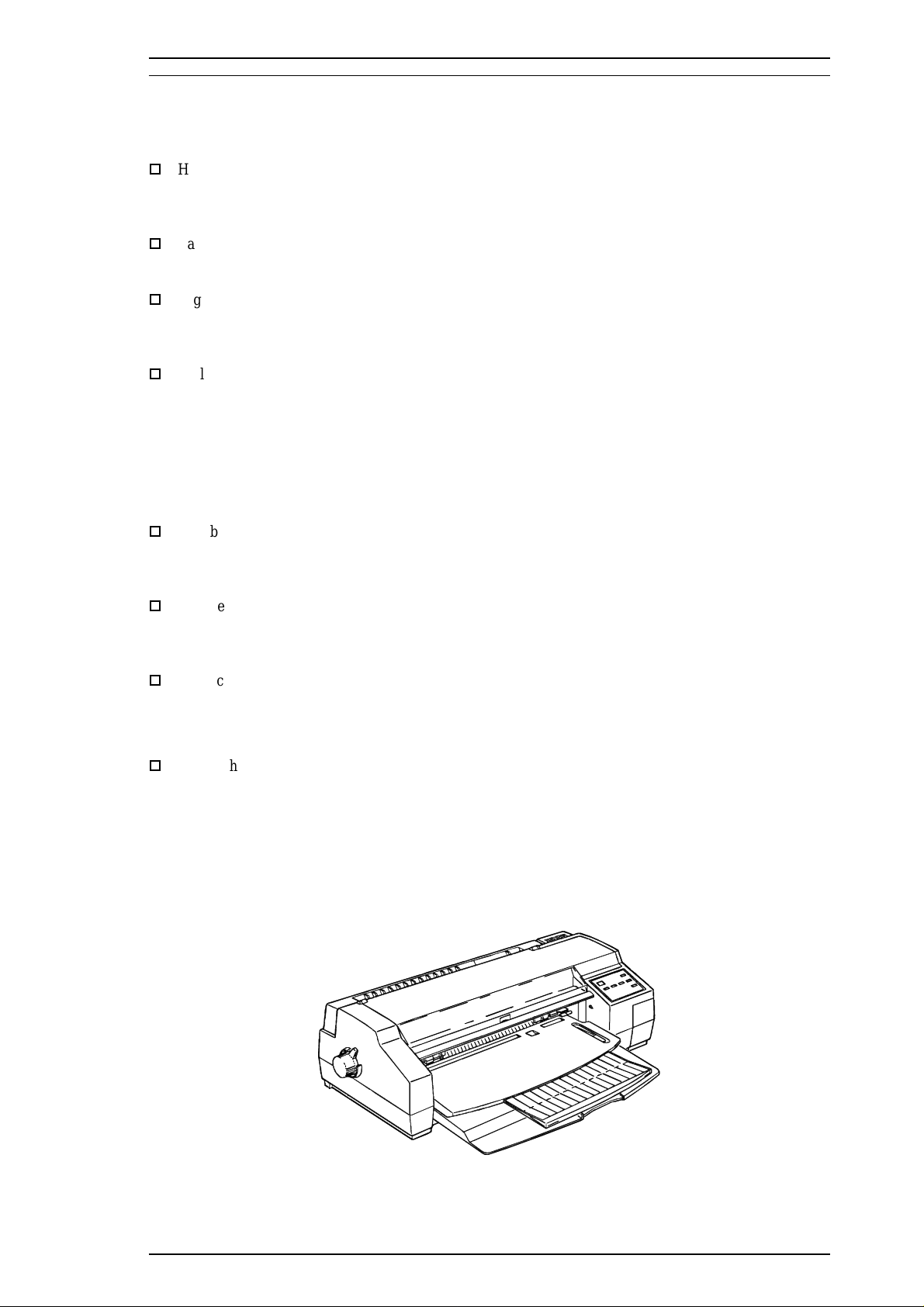

Stylus 1500 Service Manual General Description

1.1 FEATURES

The Stylus 1500 is a business-use, high-speed, and high-quality color ink jet printer. The main features of this

printer are:

o

High print quality for color graphics

720 dpi printing

High Speed semi 720 dpi printing

o

Large capacity black ink cartridge

3 million characters (LQ mode)

o

High-speed printing

LQ printing at 200 cps

Draft printing at 400 cps

o

Built-in auto sheet feeder and push tractor

This holds:

Envelope to A2 size portrait

100 cut sheets, using 14 lb (55 g/m

10 envelopes

50 transparency sheets

70 sheets of special paper

o

Two built-in interfaces

Bidirectional parallel I/F (IEEE-P1284 compatible)

Type-B I/F

o

Easy setup

Multilingual messages (five languages), selected using the control panel

No DIP switches

o

Four scalable fonts, five LQ fonts, and one draft font installed

Scalable fonts: Roman T, Sans Serif H, Roman, Sans Serif

LQ bitmap fonts: Roman, Sans Serif, Courier, Prestige, Script

o

Useful character tables

Standard: Italic, PC437, PC850, PC860, PC861, PC863, PC865, BRASCII,

NLSP: Italic, PC437, PC437 Greek, PC850, PC852, PC853, PC855, PC857,

2

) paper

Abicomp, Roman 8, ISO Latin 1

PC866, PC869, MAZOWIA, Code MJK, ISO 8859-7, ISO Latin 1T,

Bulgaria, Roman 8, PC774, Estonia, ISO Latin 1, ISO Latin 2,

PC866 LAT

Figure 1-1. Stylus 1500 Exterior View

Rev. A 1-1

Page 8

General Description Stylus 1500 Service Manual

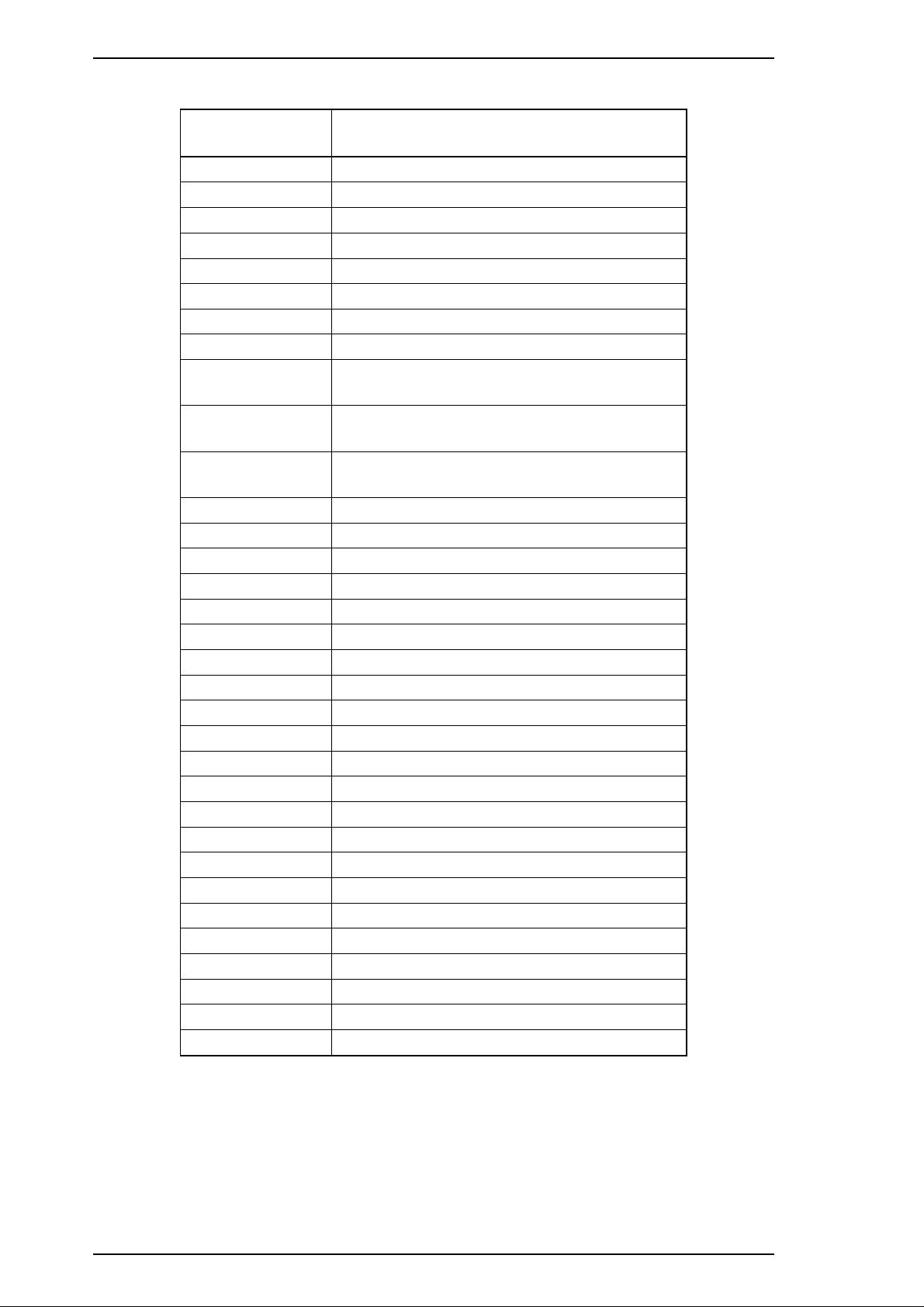

Table 1-1. Options and Consumables

Model Description

C83216* Color upgrade kit

C823071 / C823081 32 KB serial interface card

C82310* 32 KB parallel interface card

C82313* 32 KB IEEE-488 interface card

C82315* TWAIN interface card

C82312* Coax interface card

TM

C82312* LocalTalk

C82331* Ethernet interface card

C836021 / C836022

Parallel interface cable

(from D-SUB 25-pin to Amphenol 57)

interface card

C836031 / C836061

C836051 / C836061

S020062 Monochrome ink cartridge

S020049 Color ink cartridge

S041059 Exclusive paper (360 dpi) A4

S041060 Exclusive paper (360 dpi) Letter

S041065 Exclusive paper (360 dpi) A3

S041066 Exclusive paper (360 dpi) Super A3 / B

S041077 Exclusive paper (360 dpi) A2

S041066 Exclusive paper (720 dpi) A4

S041062 Exclusive paper (720 dpi) Letter

S041067 Exclusive paper (720 dpi) Legal

S041068 Exclusive paper (720 dpi) A3

S041069 Exclusive paper (720 dpi) Super A3 / B

S041070 Exclusive paper (720 dpi) B

S041076 Exclusive paper (720 dpi) A2

S041071 High quality glossy paper A4

S041072 High quality glossy paper Letter

S041073 High quality glossy paper A3

S041074 High quality glossy paper Super A3 / B

S041075 High quality glossy paper B

S041063 Transparency A4

S041064 Transparency Letter

S041054 Super coated index card for 720 dpi A6

Serial interface cable

(from D-SUB 25-pin to D-SUB 25-pin)

Serial interface cable

(from D-SUB 9-pin to D-SUB 25-pin)

* : The asterisk mean substitute for the last digit, which varies by each destinations.

1-2 Rev. A

Page 9

Stylus 1500 Service Manual General Description

1.2 SPECIFICATIONS

This section provides detailed information about the Stylus 1500.

1.2.1 Printing Specifications

Printing method: On-demand ink jet

Nozzle configuration: Monochrome: 64 nozzles (32 x 2 staggered)

Color: 60 nozzles (20 x 3, magenta, cyan, yellow)

#63

#61

#59

#57

#7

#5

#3

#1

0.847 mm

(12/360")

Monochrome

#64

#62

#60

#58

#6

#4

#2

Paper Feed Direction

#20

#2

1.129 mm

(16/360")

Magenta

#20

#19

#3

#2

#1

1.129 mm

(16/360")

#19

#3

#1

Cyan

Figure 1-2. Nozzle Configuration

Printing direction: Bidirectional with logic-seeking

#20

#2

1.129 mm

(16/360")

Yello w

#19

#3

#1

Table 1-2. Print Speeds and Printable Columns

Character Pitch Printable Columns LQ Speed Draft Speed

10 cpi (pica) 136 200 cps 400 cps

12 cpi (elite) 163 240 cps 480 cps

15 cpi 204 300 cps 600 cps

17 cpi (pica condensed) 233 343 cps 686 cps

20 cpi (elite condensed) 160 400 cps 800 cps

Control codes: ESC/P2 and extended raster graphics codes

EPSON remote commands

IBM XL24E emulation

Rev. A 1-3

Page 10

General Description Stylus 1500 Service Manual

Fonts:

Bitmap LQ fonts: EPSON Roman 10 cpi, 12 cpi, 15 cpi, Proportional

EPSON Sans Serif 10 cpi, 12 cpi, 15 cpi, Proportional

EPSON Courier 10 cpi, 12 cpi, 15 cpi

EPSON Prestige 10 cpi, 12 cpi, 15 cpi

EPSON Script 10 cpi, 12 cpi, 15 cpi

Scalable fonts: EPSON Roman 10.5 pt., 8 pt. - 32 pt. (in units of 2 pt.)

EPSON Sans Serif 10.5 pt., 8 pt. - 32 pt. (in units of 2 pt.)

EPSON Roman T 10.5 pt., 8 pt. - 32 pt. (in units of 2 pt.)

EPSON Sans Serif H 10.5 pt., 8 pt. - 32 pt. (in units of 2 pt.)

Note: Each typeface has four variations (normal, bold, italic, and bold italic).

Table 1-3. Character Tables and Fonts

Standard

Version

NLSP

Version

Character Tables

Italic

PC437 (U.S., Standard Europe)

PC850 (Multilingual)

PC860 (Portuguese)

PC861 (Icelandic)

PC863 (Canadian-French)

PC865 (Nordic)

BRASCII

Abicomp

Roman 8

ISO Latin 1

Italic

PC437 (U.S., Standard Europe)

PC437 (Greek)

PC850 (Multilingual)

PC852 (East Europe)

PC853 (Turkish)

PC855 (Cyrillic)

PC857 (Turkish)

PC866 (Russian)

PC869 (Greek)

MAZOWIA (Poland)

Code MJK (CSFR)

ISO 8859-7 (Latin/Greek)

ISO Latin 1T (Turkish)

Bulgaria

Roman 8

PC774

Estonia

ISO Latin 1

ISO Latin 2

PC866 LAT

Bitmap

Fonts

EPSON

Roman

EPSON

Sans Serif

EPSON

Courier

EPSON

Prestige

EPSON

Script

Supported Supported Supported

Supported Supported

Scalable Fonts

EPSON

Roman

EPSON

Sans Serif

EPSON

Roman T

EPSON

Sans Serif H

None

supported

1-4 Rev. A

Page 11

Stylus 1500 Service Manual General Description

1.2.2 Paper Feeding

Feeding method: Friction feed with built-in auto sheet feeder (ASF)

and push tractor feed

Note : Reverse feeding beyond 9.5 mm (0.38") is not allowed.

Line spacing: 1/6 inch, 1/8 inch, or programmable in units of 1/360 inch

Paper path: Cut sheet front entry / front exit by ASF

Single sheet rear entry / front exit and continuous paper rear

entry / front exit

Feeding speed: 71 ms (1/6 inch)

3 inches/second (continuous feeding)

1.2.3 Input Data Buffer

Capacity: 256 KB

1.2.4 Electrical Specifications

120 V Version

Rated voltage: 120 VAC

Input voltage range: 103.5 - 132 VAC

Rated frequency range: 50 - 60 Hz

Input frequency range: 49.5 - 60.5 Hz

Rated current: 0.7 A

Power consumption: Approximately 23 W (self-test with 10-cpi LQ characters)

Insulation resistance:

Dielectric strength: 1000 VAC RMS - 1 minute or 1200 VAC RMS - 1 second

10 MΩ minimum (500 VDC between AC line and chassis)

(between AC line and chassis)

220 V Version

Rated voltage: 220 - 240 VAC

Input voltage range: 198 - 264 VAC

Rated frequency range: 50 - 60 Hz

Input frequency range: 49.5 - 60.5 Hz

Rated current: 0.4 A

Power consumption: Approximately 20 W (self-test with 10-cpi LQ characters)

Insulation resistance:

Dielectric strength: 1000 VAC RMS - 1 minute or 1200 VAC RMS - 1 second

10 MΩ minimum (500 VDC between AC line and chassis)

(between AC line and chassis)

Rev. A 1-5

Page 12

Humidity

(% RH)

˚C

(˚F)

80%

55%

20%

10˚C

(50˚F)

27˚C

(80˚F)

35˚C

(95˚F)

Guaranteed Range

General Description Stylus 1500 Service Manual

1.2.5 Environmental Conditions

Temperature:

Operating: 10 to 35° C

Non-operating: –20 to 40° C

*1

Non-operating:

–20 to 60° C

1 month at 40° C

120 hours at 60° C

Humidity: Operating:

Non-operating:

*2

*1, *2

20 to 80% RH

5 to 80% RH

Resistance to shock: Operating: 1G, within 1 ms

Non-operating:

*1

2 G, within 2 ms

Resistance to vibration: Operating: 0.15 G

Non-operating:

*1

0.50 G

Notes: *1 In shipment container. *2 Without condensation.

Figure 1-3. Environmental Conditions

1.2.6 Reliability

Total print volume: 75,000 pages (letter or A4)

Printhead life: 1,000 million dots/nozzle

1.2.7 Safety Approvals

120 V Version

Safety standards: UL 1950 with D3

CSA 22.2 950 with D3

EMC: FCC part 15 subpart B class B

220 - 240 V Version

Safety standards: EN 60950 (TÜV, SEMKO, DEMKO, NEMKO, FIMKO)

EMC: EN 55022 (CISPR Pub. 22) class B

EN 50082-1

1-6 Rev. A

Page 13

Stylus 1500 Service Manual General Description

1.2.8 CE Marking

220 - 240 V Version

Lower Voltage Directive 73/23/EEC: EN60950

EMC Directive 89/336/EEC: EN55022 Class B

EN50082-1

IEC801-2

IEC801-3

IEC801-4

1.2.9 Acoustic Noise

Noise level: Approximately 45 dB(A) (according to ISO 7779)

Rev. A 1-7

Page 14

General Description Stylus 1500 Service Manual

1.3 INTERFACES

1.3.1 Hardware Interfaces

This section describes the Stylus 1500 interfaces. The printer is standard-equipped with a parallel interface.

1.3.1.1 Parallel Interface

Forward Channel

Transmission mode: 8 bit parallel, IEEE-P1284 compatibility mode

Synchronization:

Handshaking: BUSY and

Signal level: TTL-compatible level (IEEE-P1284 Level 1 device)

Adaptable connector: 57-30360 (Amphenol or equivalent)

STROBE pulse

ACKNLG signal

The BUSY signal is set HIGH before either

ERROR is set LOW or PE is set HIGH, and BUSY is held HIGH

until all these signals return to the inactive state. The BUSY signal goes HIGH in the following cases:

o During data entry (See Figure 1-4 below.)

o When the input data buffer is full.

o When the

o During a printer error condition (See the

INIT signal is LOW or during hardware initialization.

ERROR signal description below.)

o During self-test printing.

o In default setting mode.

o When the parallel interface is not selected.

ERROR signal is LOW when the printer is in one of the following conditions:

The

o Printer hardware error (fatal error).

o Paper-out error.

o Release lever operation error.

The PE signal is HIGH during a paper-out error.

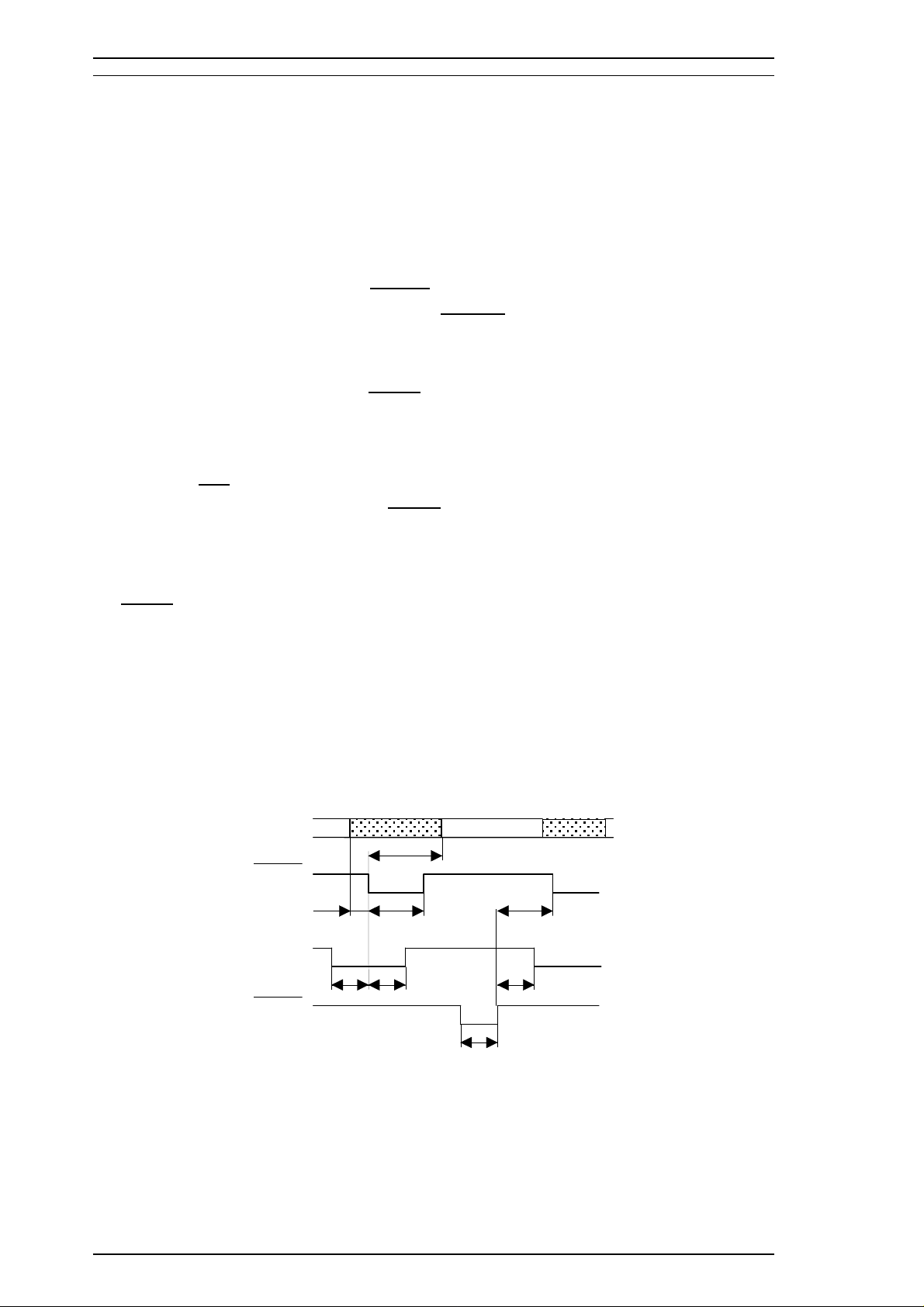

DATA

DATA (n)

DATA (n+1)

STROBE

500 ns (min.) 500 ns (min.)

BUSY

ACKNLG

* : The rise and fall time of every output signal must be less than 120 ns.

The rise and fall time of every input signal must be less than 200 ns.

500 ns (min.)

0 (min.) 500 ns (max.)

0 (min.)

0 (min.)

500 ns ~10 µs

Figure 1-4. Data Transmission Timing

1-8 Rev. A

Page 15

Stylus 1500 Service Manual General Description

Table 1-4 shows the connector pin assignments and signals for the forward channel of the parallel interface.

Table 1-5 shows this information for the reverse channel.

Table 1-4. Connector Pin Assignments and Signals (Forward Channel)

Pin No. Signal Name

1

2 - 9 DATA 0 - 7 20 - 27

10

11 BUSY 29

12 PE 28 O

13 SLCT 28 O

14

15 NC — — Not connected.

31

STROBE 19 I

ACKNLG 28

AFXT 30 I

INIT 30 I

Return

GND Pin

I/O Description

Reading of data is performed at the falling

edge of this pulse.

Signals DATA0 - DATA7 represent data bits 0

to 7, respectively. Each signal is HIGH when

I

the data is logical 1 and LOW when the data is

logical 0.

This signal is a negative pulse indicating that

O

the printer can accept more data.

When this signal is HIGH, the printer cannot

O

receive data.

When this signal is HIGH, the printer detects a

paper-out error.

This signal is always HIGH when the printer is

powered on.

The falling edge of a negative pulse or a LOW

signal on this line causes the printer to

initialize. A 50 µs (minimum) pulse is

necessary.

When this signal is LOW, the printer detects an

32

36

18 Logic H — O

35 +5 V —

17 Chassis GND —

16, 33

19 - 30

15, 34 NC —

ERROR 29

SLIN 30 I Not used.

GND —

O

error.

Pulled up to +5 V via a 3.9 KΩ resistor.

O

Pulled up to +5 V via a 3.3 KΩ resistor.

—

Chassis ground.

—

Signal ground.

—

Not used.

Note: The I/O column indicates the direction of the signal as viewed from the printer.

Rev. A 1-9

Page 16

General Description Stylus 1500 Service Manual

Reverse Channel

Transmission mode: IEEE-P1284 nibble mode

Adaptable connector: See the Forward Channel section earlier in this manual.

Synchronization: Refer to the IEEE-P1284 specification.

Handshaking: Refer to the IEEE-P1284 specification.

Data transmission timing: Refer to the IEEE-P1284 specification.

Signal level: Refer to the IEEE-P1284 specification.

Extensibility request: The printer responds affirmatively when the extensibility request

values are 00H or 04H, as follows:

00H: Request nibble mode reverse channel transfer

04H: Request device ID

Return data using nibble mode channel transfer

Device ID: The printer sends following device ID string when requested:

ESC/P2

00H 36H

MFG: EPSON;

CMD: ESCPL2-00;

MDL: Stylus 1500;

CLS: PRINTER;

XL24E

00H 37H

MFG: EPSON;

CMD: PRPXL24-00;

MDL: Stylus 1500;

CLS: PRINTER;

Note: 00H denotes a hexadecimal value of zero.

1-10 Rev. A

Page 17

Stylus 1500 Service Manual General Description

Table 1-5. Connector Pin Assignments and Signals (Reverse Channel)

Pin No. Signal Name

1 Host Clk 19 I Host clock signal.

2 - 9 DATA 0 - 7 20 - 27 I

10 PtrClk 28 O Printer clock signal.

11

12

13 Xflag / Data Bits 1, 5 28 O

14 Host Busy 30 I Host busy signal.

31

32

36 1284-Active 30 I Active signal for IEEE-P1284 mode.

18 Logic-H — O

35 +5 V — O

17 Chassis GND — — Chassis ground.

16, 33

19 - 30

15, 34 NC — — Not connected.

Ptr Busy /

Data Bits 3, 7

Ack Data Req /

Data Bits 2, 6

INIT 30 I Not used.

Data Avail /

Data Bits 0, 4

GND — — Signal ground.

Return

GND Pin

29 O

28 O

29 O

I/O Description

Signals DATA0 - DATA7 represent data

bits 0 to 7, respectively. Each signal is

HIGH when the data is logical 1 and LOW

when the data is logical 0. These signals

are used to transfer the extensibility request

values (described in IEEE-P1284) to the

printer.

Printer busy signal and reverse channel

transfer data bit 3 or 7.

Acknowledge data request signal and

reverse channel transfer data bit 2 or 6.

X-flag signal and reverse channel transfer

data bit 1 or 5.

Data available and reverse channel transfer

data bit 0 or 4.

Pulled up to +5 V via a 3.9 KΩ resistor.

Pulled up to +5 V via a 3.3 KΩ resistor.

Note: The I / O column indicates the direction of the signal as viewed from the printer.

1.3.1.2 Optional Interface

The Stylus 1500 supports an optional Type-B interface with the following characteristics:

Reply Message: ESC/P2 is selected:

Main type: MTP48p, PW136cl10cpi, PRG(L0xxxx)rev,AP800ma

Product name: Stylus 1500

Emulation type: ESCPL2-00

Entity type: EPSON LQ2

XL24E is selected:

Main type: MTP48p, PW136cl10cpi, PRG(L0xxxx)rev,AP800ma

Product name: Stylus 1500

Emulation type: PRPXL24-00

Entity type: EPSONPRPXL24

Rev. A 1-11

Page 18

General Description Stylus 1500 Service Manual

1.3.2 Printer Languages and Control Codes

Printer languages and control codes: ESC/P2

IBM 24XL

EPSON Remote

1-12 Rev. A

Page 19

Stylus 1500 Service Manual General Description

1.4 OPERATIONS

This section describes the controls, settings, and adjustments used to operate the Stylus 1500.

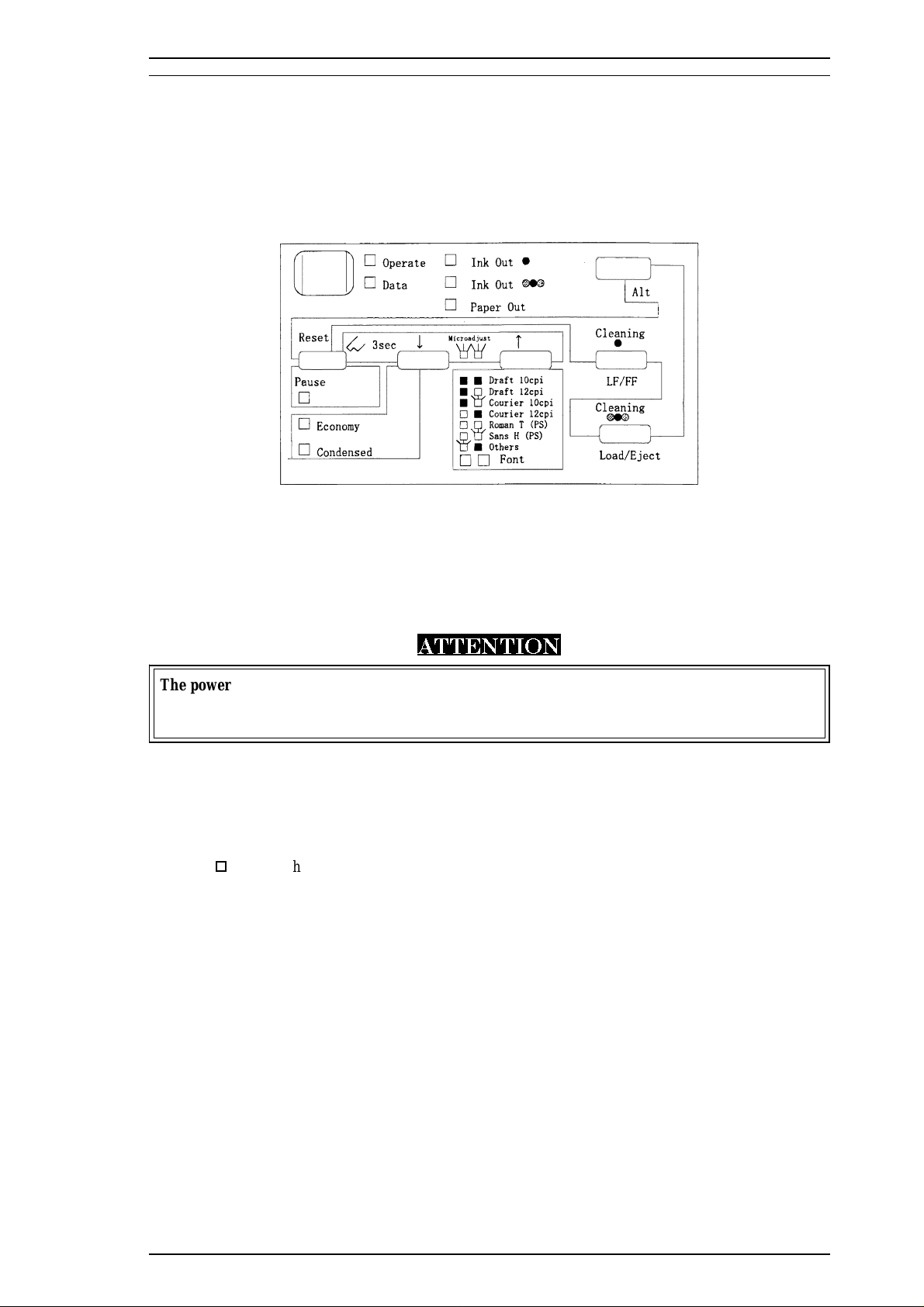

1.4.1 Control Panel

The control panel for this printer is in the center of the upper case. The panel has 1 lock-type and 6

non-lock-type pushbuttons, and 10 LED indicators for easy operation of the various print functions.

Figure 1-5. Control Panel Appearance

1.4.1.1 Buttons

Power

This button turns the printer on or off.

ATTENTION

The power button controls the secondary power supply circuit. Therefore, the primary circuit is

hot after power off. Do not connect the interface cable even if the printer power is off while the

AC inlet is connected. Otherwise, the circuit board or interface may be damaged.

Pause

This button alternates between printing and non-printing states when there is data in the print buffer. In the

pause state, printing stops but communication with the I/F does not stop. Therefore, even in the pause state,

the printer receives data from the host until the input data buffer is full.

o

Pressing the Pause button while holding down the Alt button resets the printer.

Alt

This button is usually used with another button.

o Holding down Alt for 3 seconds moves the printer carriage to the ink cartridge

installation position. Pressing Alt again returns the carriage to the home position.

LF/FF

This button feeds one line or a page.

o Pressing LF/FF while holding down Alt starts the black printhead cleaning cycle.

Economy/Condensed

This button selects economy or condensed printing mode.

Rev. A 1-13

Page 20

General Description Stylus 1500 Service Manual

Font

This button selects the desired font.

o

Pressing Font while holding down Alt starts the color printhead cleaning

cycle.

Load/Eject

This button loads and ejects the paper.

1.4.1.2 Indicators

Operate (green)

Lights when the printer power is on.

Data (orange)

o

Lights when there is data in the print buffer.

o

Blinks with the Pause LED when an error occurs.

Black Ink Out (red)

Lights when there is no ink in the black ink cartridge, and blinks when the cartridge is low.

Color Ink Out (red)

Lights when there is no ink in the color ink cartridge, and blinks when the cartridge is low.

Paper Out (red)

Lights when the printer is out of paper, and blinks when a paper jam occurs.

Pause (orange)

Lights when printing is paused.

Economy (green)

Lights when economy printing mode is selected.

Condensed (green)

Lights when condensed printing mode is selected.

Font (green)

Shows the selected font.

1-14 Rev. A

Page 21

Stylus 1500 Service Manual General Description

1.4.2 Panel Functions at Power On

The table below describes the functions performed when the indicated buttons are held down while turning on

the printer.

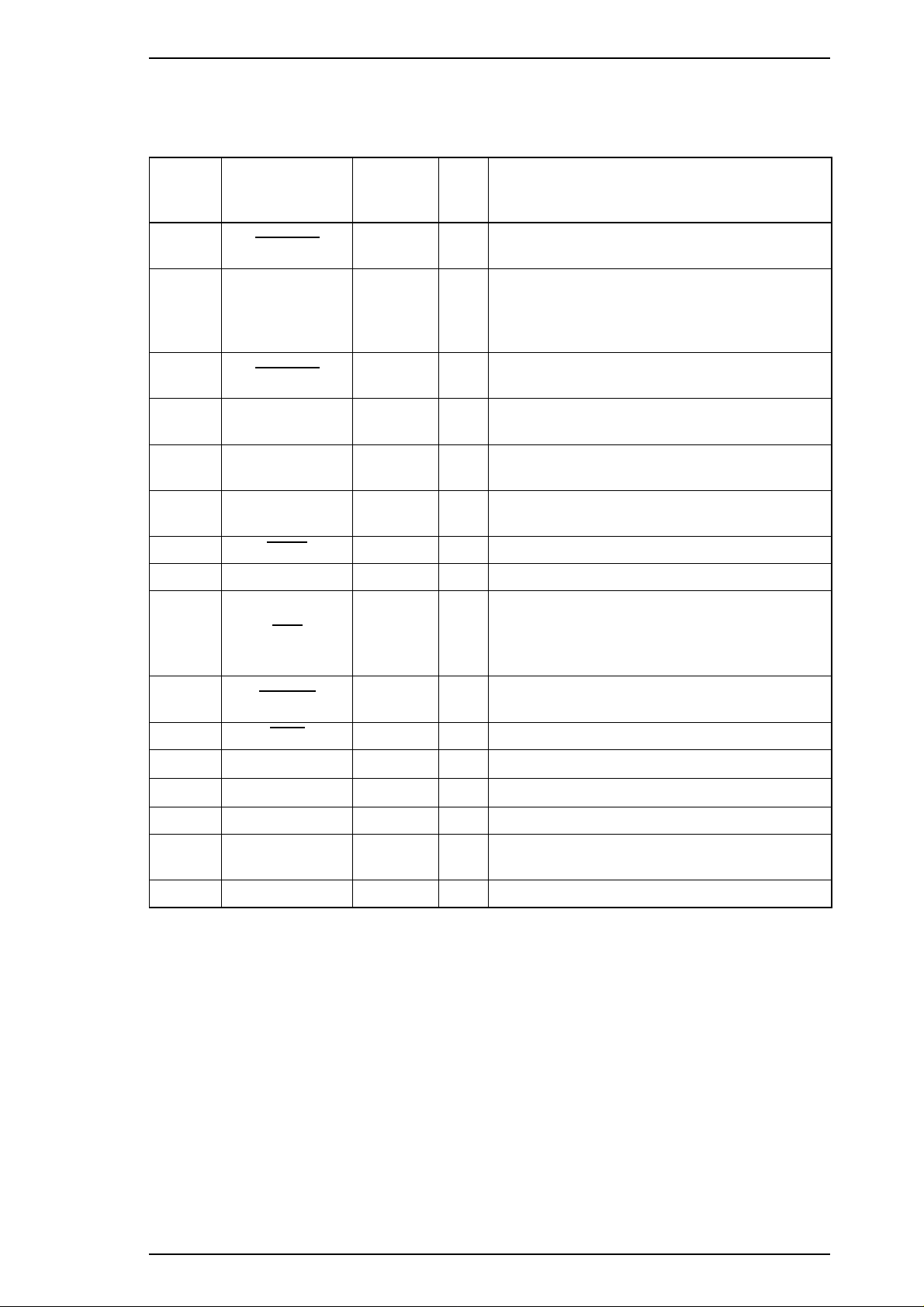

Table 1-6. Panel Functions at Power On

Button Function at Printer Power On

Alt Starts demonstration printing.

Economy/Condensed Enters default setting mode.

Pause Enters print adjustment mode.

Load/Eject Starts LQ mode self-test printing.

LF/FF Starts Draft mode self-test printing.

Alt + Pause Enters ink smudge prevention mode.

LF/FF + Load/Eject Enters hex dump mode.

Alt + Economy/Condensed + LF/FF +

Pause

Notes: 1. “+” means to press one button while holding down the other button(s).

2. The EEPROM and Timer IC must be reset only by qualified service personnel.

Enters reset mode for the EEPROM and Timer IC

(for factory and service use only).

Rev. A 1-15

Page 22

General Description Stylus 1500 Service Manual

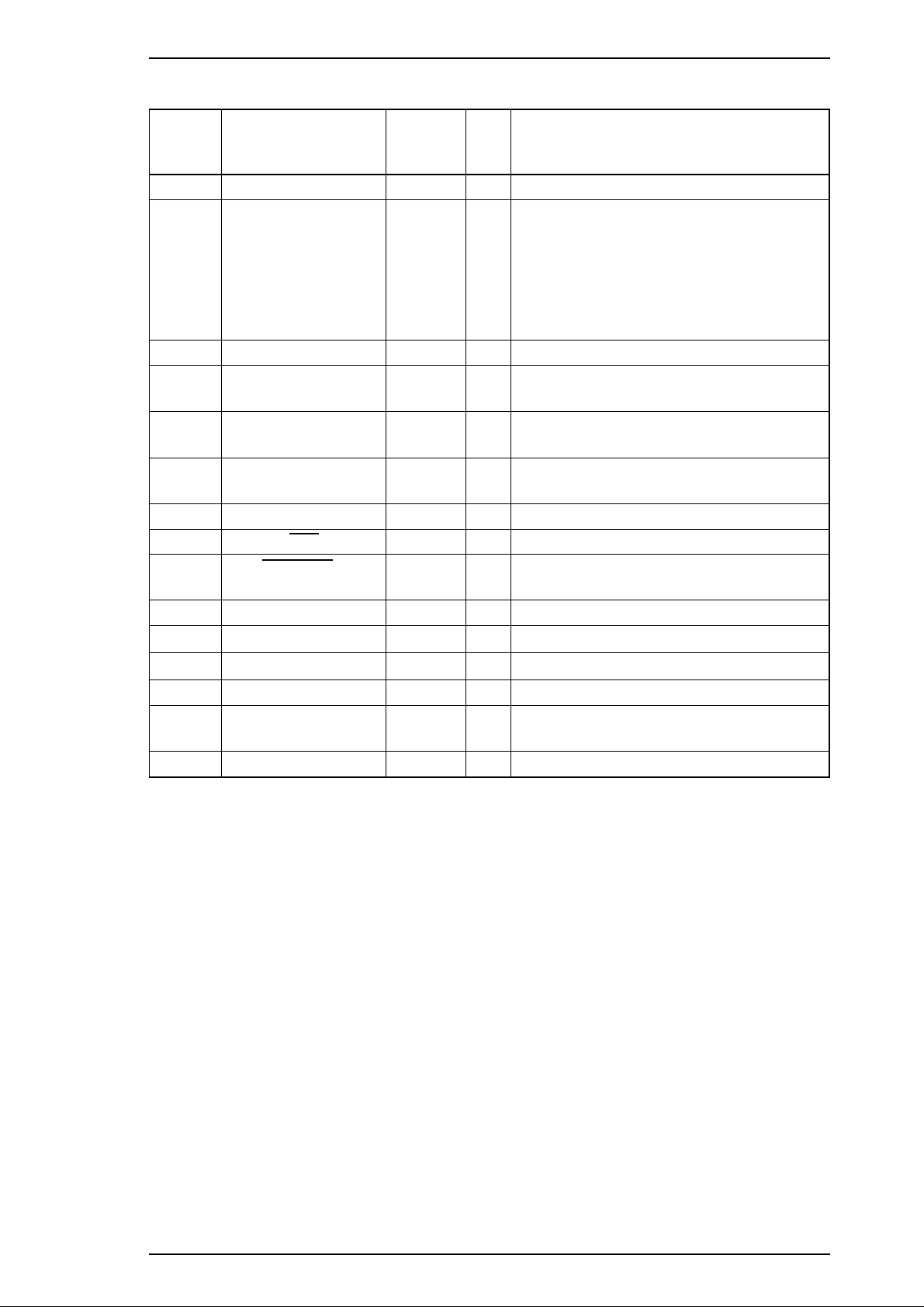

1.4.3 Printer Conditions and Status

The table below shows how the printer LEDs indicate status and operating conditions.

Table 1-7. Indicator Status

LEDs

Printer Status

Power Data

Power on On — — — — — — — — —

Capping after

power off

Data present — On — — — — — — — —

Economy mode — — — — — On — — — —

Condensed mode — — — — — — On — — —

Pause — — — — — — — On — —

Micro adjust mode — — — — — — — — Blink Blink

Draft 10 cpi — — — — — — — — Off Off

Draft 12 cpi — — — — — — — — Off On

Courier 10 cpi — — — — — — — — Off Blink

Courier 12 cpi — — — — — — — — On Off

Roman T

Proportional

Sans Serif H

Proportional

Ink sequence — — — — — — — Blink — —

Ink cartridge

change mode

Paper out — — — — On — — — — —

Paper jam — — — — Blink — — — — —

No ink cartridge

or ink end (black)

Ink level low

(black)

No ink cartridge

or ink end (color)

Ink level low

(color)

Release lever

error

Blink — — — — — — — — —

——— ——— — —OnOn

— — — — — — — — On Blink

— — — — — — — Blink — —

— — On — — — — — — —

— — Blink — — — — — — —

———On—— — ———

— — — Blink — — — — — —

— Blink — — Blink — — — — —

Ink

Out

(Black)

Ink

Out

(Color)

Paper

Out

Econ-

omy

Con-

densed

Pause

FontLFont

R

Maintenance

request

EEPROM and

timer reset

Fatal error — Blink — — — — — Blink — —

Blink Blink Blink Blink Blink Blink Blink Blink Blink Blink

— On (for 1 second only)

Note: “—” means that the indicated printer status does not affect the LED.

1.4.4 Default Settings

This printer has user-selectable default settings to which it refers at initialization. The default settings (and

factory settings ) are listed in Table 1-8.

1-16 Rev. A

Page 23

END

Change the settings?

YES

NO

Change setting menu:

Alt

button

Change setting value:

Pause

button

Turn printer power off to save settings to the EEPROM.on the main board

START

Hold down the Economy /Condensed

button, a nd tu rn on the print er.

The printer prints:

1. Firmware version,

Protec t co unte r va lue A/C.

2. How to set defaults.

3. Current settings.

Stylus 1500 Service Manual General Description

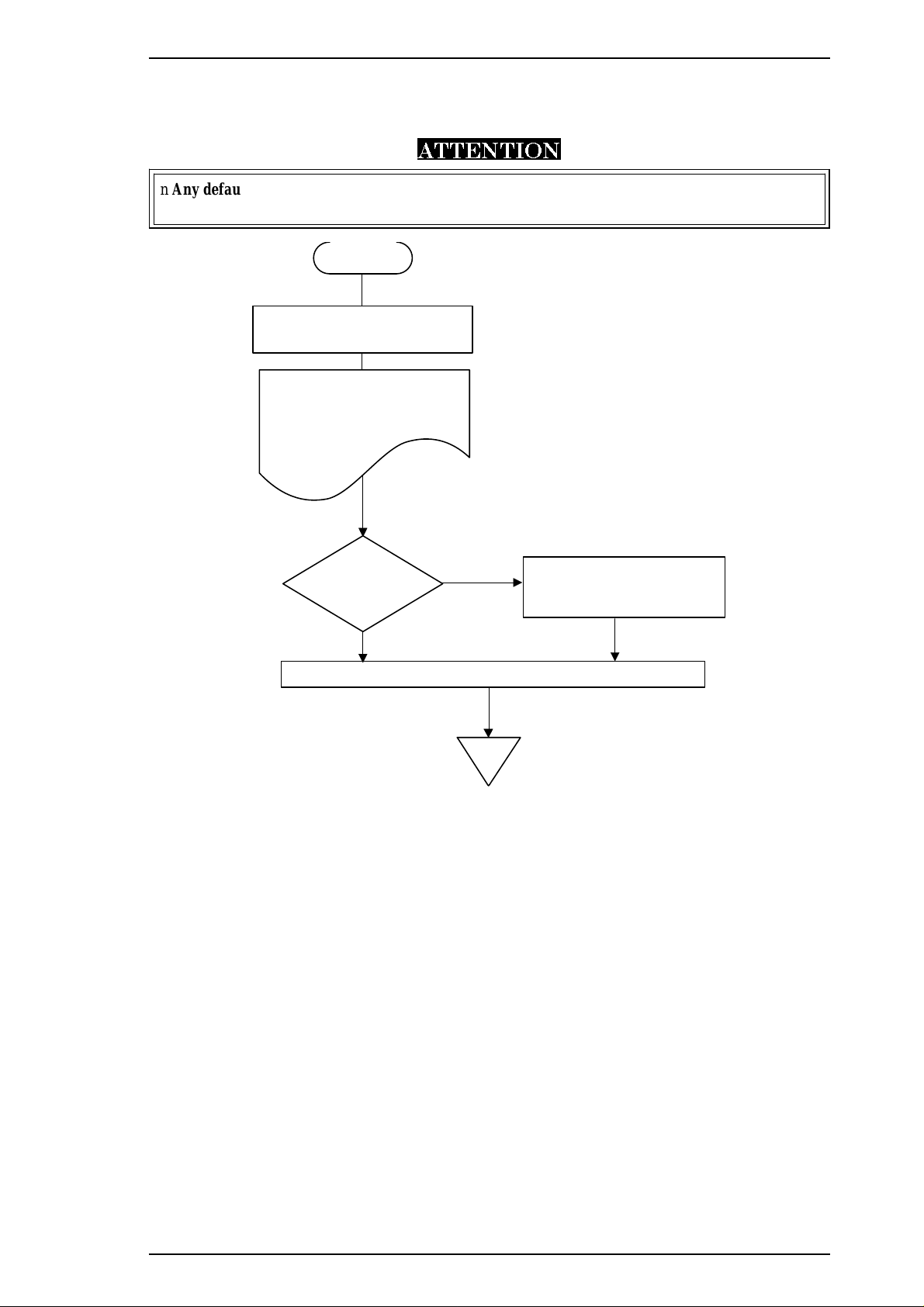

1.4.4.1 Setting Method

The method of setting defaults is shown in the flowchart below.

ATTENTION

n Any default value specified is not stored in the EEPROM until the printer is turned off.

n The last default value specified before power-off is stored in the EEPROM.

Figure 1-6. Default Setting Flowchart

Rev. A 1-17

Page 24

General Description Stylus 1500 Service Manual

1.4.4.2 Setting Menus

The default setting menus are described in the table below.

Table 1-8. Default Settings

Menus

Print direction

Font

Pitch

*1

Auto / Bi-D / Uni-D

Draft / Roman / Sans Serif /

Sans Serif H

10 cpi / 12 cpi / 15 cpi / 17.1 cpi / 20 cpi / Proportional

(underlines indicate factory default settings)

I/F mode Auto / Parallel / Serial

Auto I/F wait mode 10 seconds / 30 seconds

Software

Auto CR

(IBM mode only)

AGM

(IBM mode only)

Character tables

(standard version)

ESC/P2 / IBM X24E

Off

On /

Off

On /

Italic PC 437 PC 850 PC 860 PC 863 PC 865

PC 861 BRASCII Abicomp Roman 8 ISO Latin 1

Italic PC 437 PC 437 Greek PC 850 PC 853

Character tables

(NLSP version)

PC 855 PC 852 PC 857 PC 866 PC 869

MAZOWIA Code MJK ISO 8859-7 ISO Latin 1T Bulgaria

Roman 8 PC774 Estonia ISO Latin 1 ISO Latin 2

PC866 LAT

Settings

Courier / Prestige / Script / Roman T /

International

character set for

italic table

Auto line feed On /

Network I/F mode

Zero slash

Page length for

continuous paper

Skip over perforation

Auto tear off

Print mode

*3

Paper roll

Italic U.S.A. Italic France Italic Germany Italic U.K.

Italic Denmark Italic Sweden Italic Italy Italic Spain 1

Off

Off: Used in standalone environment

On: Used in network environment

0 / 0 with slash

11 inch 12 inch 8.5 inch 70/6 inch Other

Off

On /

On / Off

Plain paper (pure black) / Plain paper (composite black) /

Exclusive paper / Transparency

On /

Off

Notes: *1. Refer to Tables 1-9 and 1-10.

*2. This is selected when a value other than 11, 12, 8.5, or 70/6 inches has been placed

in EEPROM by the ESC | command.

*3. This mode is provided only for DOS users and is selected according to paper type.

Pure black and composite black are selected according to the printed result.

*2

1-18 Rev. A

Page 25

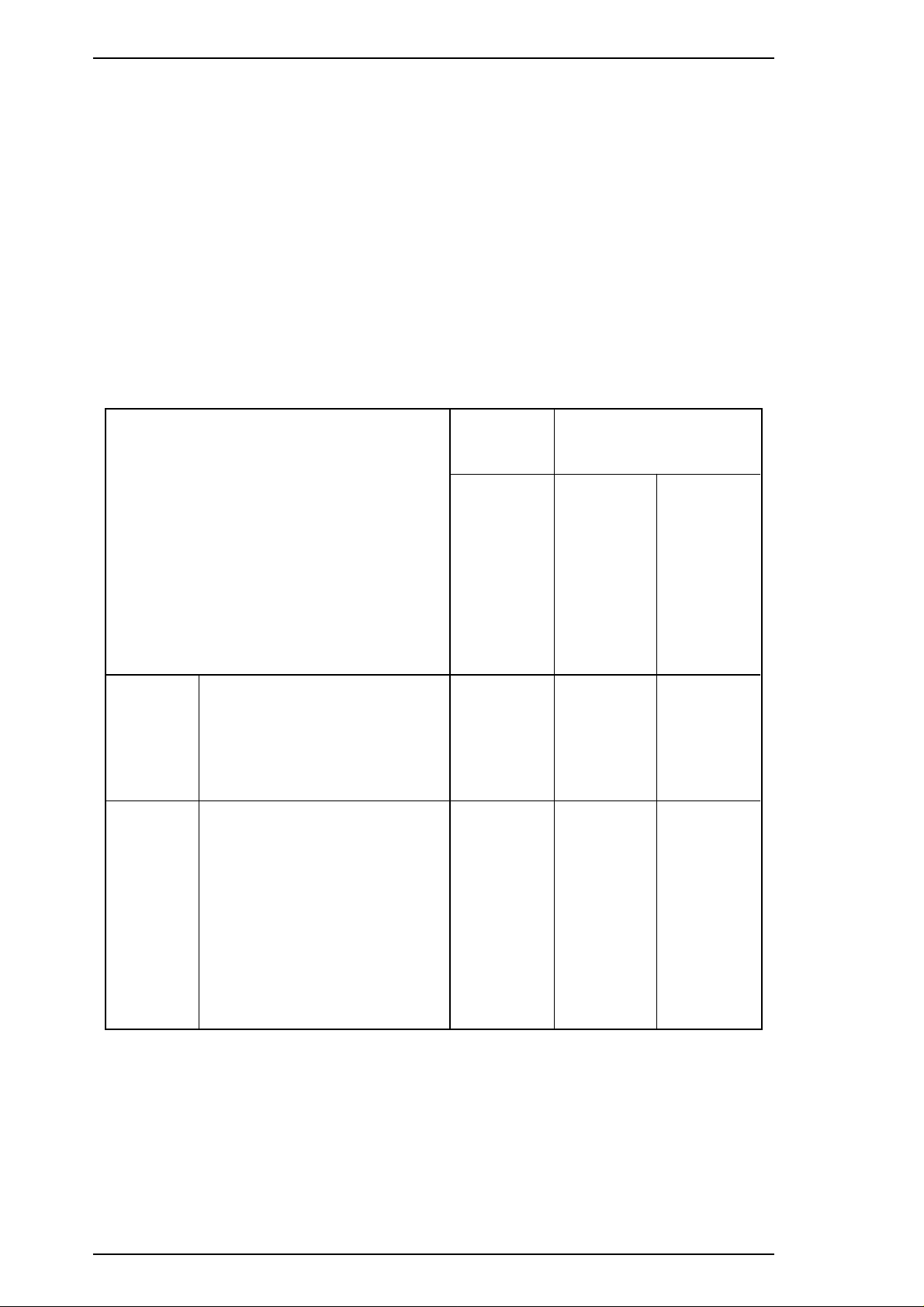

Stylus 1500 Service Manual General Description

Table 1-9. Print Direction Mode Characteristics

Item Monochrome Printing Color Printing

• Throughput is better.

Auto Throughput and quality is better.

Bi-D

• Throughput is best.

• Print quality may be down.

• Color quality with special paper is

worse. (Color correction depends

on the printing direction.)

• Throughput is better.

• Color quality with special paper is

worse. (Color correction depends

on the printing direction.)

Uni-D

• Throughput is worse.

• Print quality is better.

• Throughput is worse.

• Color quality is best.

Table 1-10. Printing Direction and ESC U Command

Default Setting

Mode

Character mode

(for DOS)

Raster graphics

mode

(for Windows)

ESC U0ESC U

Auto

Bi-D Uni-D Auto Bi-D Uni-D Bi-D Bi-D Uni-D Uni-D

Note: Printing direction is controlled by a driver in the Windows environment.

Auto Bi-D Uni-D

None

1

Auto Auto Bi-D Uni-D Bi-D Uni-D Uni-D Uni-D

ESC U0ESC U

1

None

ESC U0ESC U

None

1

Rev. A 1-19

Page 26

General Description Stylus 1500 Service Manual

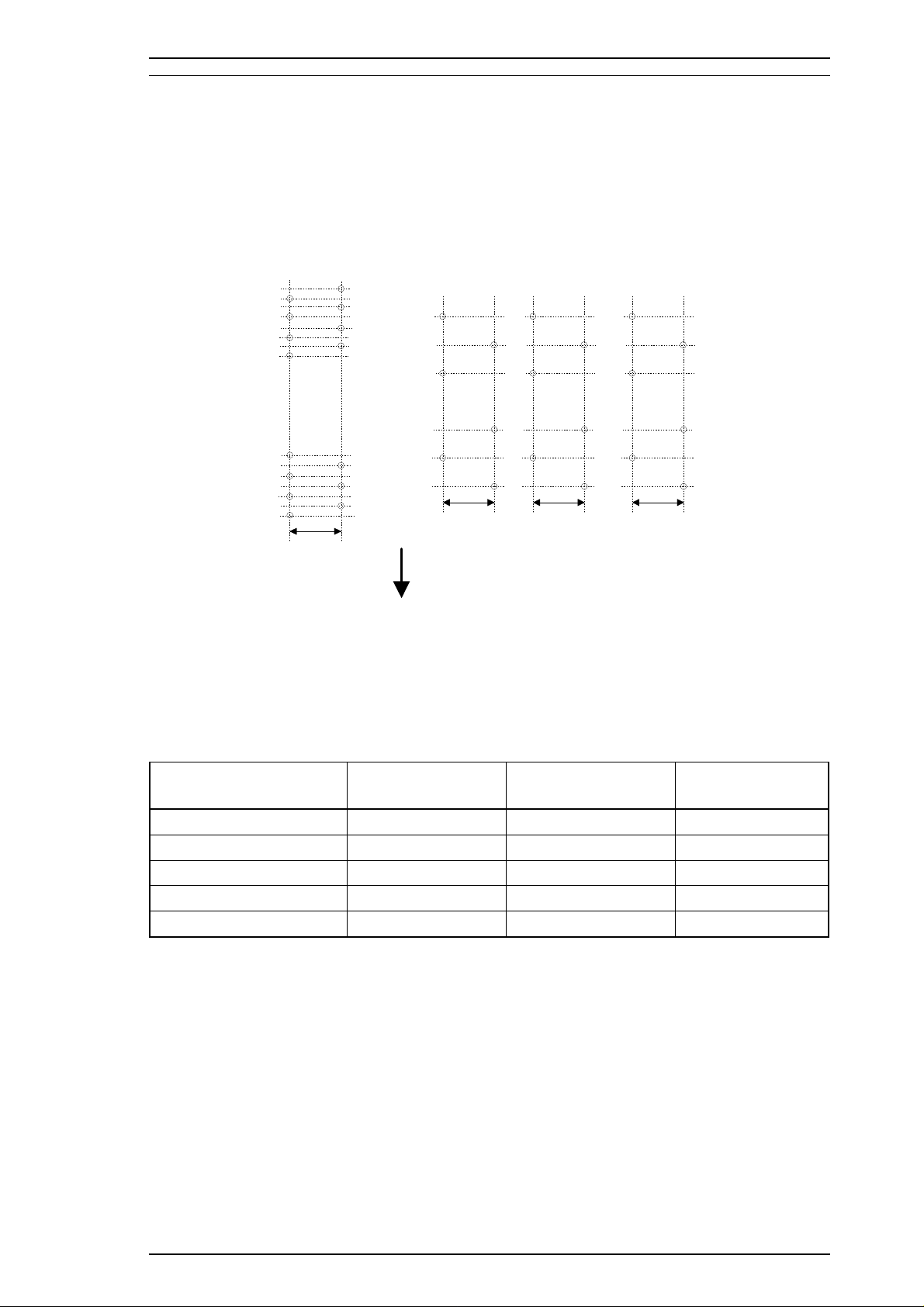

1.4.5 Printer Adjustment Mode

The Stylus 1500 allows the user to adjust the printing direction and head gap without a special program. The

following list shows the adjustments for this printer in order:

Pattern 1 Uni-D adjustment at 400 cps

Pattern 2 Bi-D adjustment at 100 cps

Pattern 3 Bi-D adjustment at 200 cps

Pattern 4 Bi-D adjustment at 400 cps

Pattern 5 Head gap adjustment (for the black and color printheads in the carriage movement direction

at 100 cps)

Pattern 6 Head gap adjustment (for the black and color printheads in the carriage movement direction

at 200 cps)

Pattern 7 Headgap adjustment (for the black and color printheads in the paper feed direction)*

* These adjustments are performed only when the color upgrade kit is installed in the printer.

Adjustment Method

Use the following steps to perform the adjustments:

1. Hold down the Pause button while turning on the power. The printer enters adjustment mode.

“Using this mode” and the pattern 1 are printed.

*

*

2. Select the number of the most closely aligned columns by pressing the Alt button.

The black Ink Out, color Ink Out, and Paper Out LEDs show the line number currently selected. This

selection advances once each time the Alt button is pressed, and the three LEDs change their

combination of On /Off / Blinking to indicate the selection.

3. Specify the selected number by pressing the Pause button.

The selected number is set, and the next pattern is printed.

Patterns 1

Figure 1-7. Sample Adjustment Pattern

1-20 Rev. A

Page 27

Stylus 1500 Service Manual General Description

4. Repeat steps 2 and 3 until the pattern No.4 or 7 is printed.

The adjustments are executed in the following order:

Pattern 1. Uni-D adjustment at 400 cps

Pattern 2. Bi-D adjustment at 100 cps

Pattern 3. Bi-D adjustment at 200 cps

Pattern 4. Bi-D adjustment at 400 cps

Pattern 5.

at 100 cps)

Pattern 6.

200 cps)

Pattern 7.

*

*

*

Head gap adjustment (for the black and color printheads in the carriage movement direction

Head gap adjustment (for the black and color printheads in the carriage movement direction at

Head gap adjustment (for the black and color printheads in the paper feed

direction at 360 dpi.)

* : When the optional color kit is not installed, the pattern 4 is the final pattern and the rest adjustments (pattern 5, 6 and 7)

are not executed.

ATTENTION

n Any adjustment value specified is not stored in the EEPROM untilthe printeris turned off.

n The last adjustment value specified before power-off is stored in the EEPROM..

n Before the whole adjustmentsare executed, the setting value is not stored in the printer.

5. Turn off the power to exit adjustment mode.

Rev. A 1-21

Page 28

General Description Stylus 1500 Service Manual

1.4.6 Printer Initialization

This printer has three initialization types: hardware, software, and panel.

1. Hardware Initialization

Hardware initialization is performed by turning on the printer or sending the INIT signal to the parallel interface. The following functions

are executed:

o The printer mechanism is initialized.

o The input data buffer is cleared.

o Downloaded character definitions are cleared.

o The print buffer is cleared.

o Default values are set.

2. Software Initialization

Software initialization is performed when the printer receives the ESC @ command. The following functions are executed:

o The print buffer is cleared.

o Default values are set.

Note: Thelast panel settings are kept after software initialization.

3. Panel Initialization

Panel initialization is performed by pressing the Load/Eject button while holding down the Alt button. The following functions are

executed:

o The input data buffer is cleared.

o The print buffer is cleared.

o Default values are set.

Note:

The last panel settings are kept after panel initialization.

1.4.7 Monochrome Printing Mode

This printer has a monochrome printing function that allows printing to continue with black ink when the color ink cartridge is out or the

color upgrade kit is not installed. This function is selected by the printer driver setting. To enter monochrome printing mode, turn the

Power button off and back on again.

Notes: 1. Once the printer has entered this function, print data must be resent.

2. The color select command (

ESC r

)isignored.

1-22 Rev. A

Page 29

Stylus 1500 Service Manual General Description

1.5 PAPER SPECIFICATIONS

1.5.1 Paper Type Specifications

1. Cut Sheets

Table 1-11. Cut Sheet Specifications

× 297 mm (11.7")

2

(14 lb) - 90 g/m2(24 lb)

Size

Thickness

Weight

Quality

A4: 210 mm (8.3")

Letter: 215.9 mm (8.5") × 279.4 mm (11.0" )

B5: 182 mm (7.2") × 257 mm (10.1")

Legal: 215.4 mm (8.5") × 355.6 mm (14.0")

B4: 257 mm (10.1") × 364 mm (14.3")

A3: 297 mm (11.7") × 420 mm (16.5")

Ledger: 279.4 mm (13.0") × 431.8 mm (17.0")

A3 wide: 329 mm (13.0") × 483 mm (19.0")

B3: 364 mm (14.3") × 514 mm (20.2")

A2: 420 mm (16.5") × 594 mm (23.4")

US C: 431.8 mm (17.0") × 558.8 mm (22")

B5 (ISO) 176 mm (6.9") × 250 mm (9.8")

B4 (ISO) 250 mm (9.8") × 353 mm (92.6")

0.065 mm (0.0025") - 0.11 mm (0.004")

ASF: 64 g/m2(17 lb) - 90 g/m2(24 lb)

Manual Insertion: 52g/m

Exclusive paper, bond paper, PPC, glossy paper

Note : The designated face must be used when printing on exclusive paper.

: A2 portrait, US-C portrait are used by manual insertion only.

2. Transparencies

Table 1-12. Transparency Specifications

Size

Thickness 0.075 mm (0.003") - 0.085 mm (0.0033")

Notes: 1. Printing on transparencies is supported only at normal temperatures.

2. The designated face must be used when printing on exclusive paper.

3. Envelopes

A4: 210 mm (8.3") × 297 mm (11.7")

Letter: 215.9 mm (8.5") × 279.4 mm (11.0")

Table 1-13. Envelope Specifications

No. 10: 241.3 mm (9.5") × 104.8 mm (4.125")

Size

Thickness 0.16 mm (0.006") - 0.52 mm (0.02")

Weight 45 g/m

Quality Exclusivepaper, bond paper, PPC, glossy paper

Notes: 1. Printing on envelopes is supported only at normal temperatures.

2. When inserting envelopes, keep the longer side horizontal.

3. When printing on envelopes, set the adjust lever to the proper position. (Refer to

Section 1.5.3, Adjust Lever Position.)

DL: 220 mm (8.7) × 110 mm (4.3")

C5: 229 mm (9") × 162 mm (6.4")

2

(12 lb) - 90 g/m2(24 lb)

Rev. A 1-23

Page 30

General Description Stylus 1500 Service Manual

4. Index Cards

Table 1-14. Index Card Specifications

Size

Thickness 0.23 mm (0.0091") and less

Note: When printing on index cards, set the adjust lever to the proper position. (Refer to

Section 1.5.3, Adjust Lever Position.)

A6: 105 mm (4.1") × 148 mm (5.8")

5. Labels (Cut Sheet)

Table 1-15. Label (Cut Sheet) Specifications

Size

Thickness 0.2 mm (0.0079") and less (base sheet and label)

Quality Page printer label

Note: Printing on cut-sheet labels is supported only at normal temperatures.

6. Continuous Paper

A4: 210 mm (8.3") × 297 mm (11.7")

Letter: 215.9 mm (8.5") × 279.4 mm (11.0")

Table 1-16. Continuous Paper Specifications

Size

Width: 101.6 mm (4") − 406.4 mm (16")

Folding length: 220 mm (8.7") − 110 mm (4.3")

Thickness 0.065 mm (0.0026") - 0.1 mm (0.0039")

2

Weight 52 g/m

(14 lb) - 82 g/m2(22 lb)

7. Labels (Continuous Paper)

Table 1-17. Label (Continuous Paper) Specifications

Size

(base paper)

Size

(label)

Thickness

(base paper +

label)

Thickness

(label)

Quality Plain paper

Note: Printing on continuous-paper labels is supported only at normal temperatures.

Width: 101.6 mm (4") - 406.4 mm (16")

Folding length: 101.6 mm (4")

Width: 63.5 mm (2.5")

Folding length: 23.9 mm (0.94")

0.2 mm (0.0079")

(The height from the base sheet to the label face is 0.12 mm or

less.)

0.12 mm (0.0047")

1-24 Rev. A

Page 31

Stylus 1500 Service Manual General Description

8. Banner

Table 1-18. Banner Specifications

Size

Thickness 0.08 mm (0.0031") - 0.1 mm (0.0039")

Weight 64 g/m

Quality Plain paper

Width: 210 mm (8.3") − 432 mm (17")

Length: 5 m (196.6") and less

2

(17 lb) - 82 g/m2(22 lb)

Rev. A 1-25

Page 32

General Description Stylus 1500 Service Manual

1.5.2 Printable Area

1. Cut Sheets

PW (Page Width)

LM

(Left Margin)

Printable Area

RM

(Right Margin)

TM

(Top

Margin)

BM

(Bottom

Margin)

PL

(Page Length)

Figure 1-8. Printable Area for Cut Sheets

PW

(Paper

Width)

A4

297 mm

(11.7")

Legal

landscape

356 mm

(14.0")

B4

landscape

364 mm

(14.3")

A3

landscape

420 mm

(16.5")

Table 1-19. Minimum Margins for Different Cut Sheet Sizes

(Left Margin)

(minimum)

Distance to

Left Edge

3 mm

(0.12")

5 mm

(0.20")

16 mm

(0.63")

25 mm

(0.98")

LM

Distance to

Right Edge

3 mm

(0.12")

3 mm

(0.12")

3 mm

(0.12")

13 mm

(0.51")

Distance to

Left Edge

3 mm

(0.12")

3 mm

(0.12")

3 mm

(0.12")

50 mm

(1.97")

RM

(Right Margin)

(minimum)

Distance to

Right Edge

3 mm

(0.12")

5 mm

(0.20")

16 mm

(0.63")

62 mm

(2.44")

TM

(Top

Margin)

(minimum)

3 mm

(0.12")

3 mm

(0.12")

3 mm

(0.12")

3 mm

(0.12")

BM

(Bottom

Margin)

(minimum)

14 mm

(0.54")

14 mm

(0.54")

14 mm

(0.54")

14 mm

(0.54")

Ledger

landscape

432 mm

25 mm

(0.98")

25 mm

(0.98")

62 mm

(2.44")

62 mm

(2.44")

3 mm

(0.12")

14 mm

(0.54")

(17.0")

Note: The printable area for a cut-sheet label is as same as that for the cut sheet itself.

1-26 Rev. A

Page 33

TM

RM

Printable area

LM

BM

Stylus 1500 Service Manual General Description

2. Envelopes

Figure 1-9. Printable Area for Envelopes

Table 1-20. Minimum Margins for Envelopes

LM

(Left Margin)

(minimum)

3 mm

(0.12")

RM

(Right Margin)

(minimum)

3 mm

(0.12")

TM

(Top Margin)

(minimum)

3 mm

(0.12")

BM

(Bottom Margin)

(minimum)

14 mm

(0.55")

Rev. A 1-27

Page 34

More than 13 mm (0.51") More than 13 mm (0.51")*

More than

3 mm (0.12" )

More than

9 mm (0.35" )

More than

9 mm (0.35")

More than

9 mm (0.35" )

More than

9 mm (0.35" )

More than

134 mm (5.28")

Perforation

Perforation

Perforation

More than

12.5 mm (0.49")

More than

14 mm (0.55")

Printable Area 2

Printable Area 1

Printable Area 1

Printable Area 1

Printable Area 1

Printable Area 1

Printable Area 1

Printable Area 1

Printable Area 2

Printable Area 2

Printable Area 2

General Description Stylus 1500 Service Manual

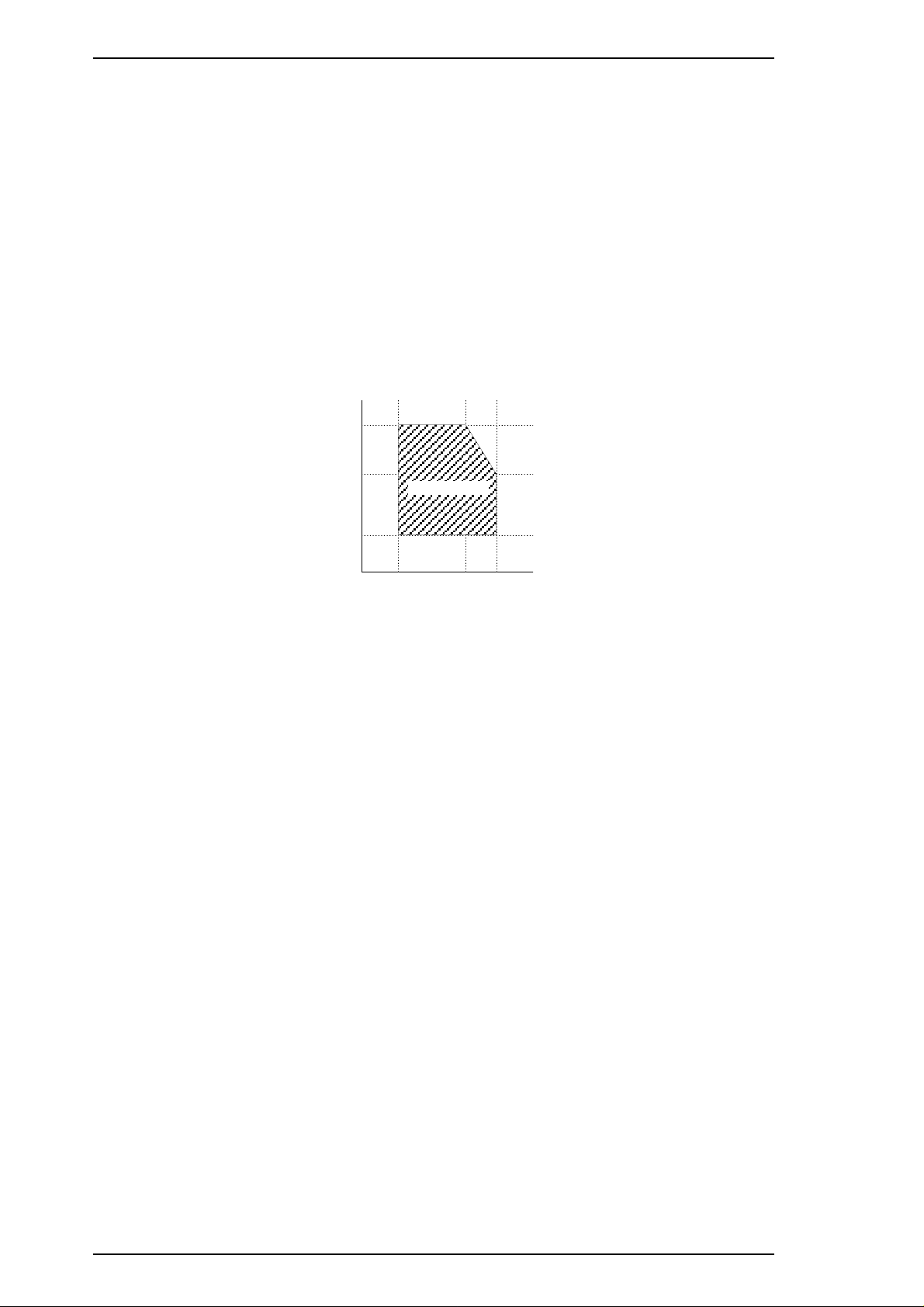

3. Continuous Paper

Printable Area 1 : Paper feed pitch is not guaranteed in this area.

Printable Area 2 : Paper feed pitch is guaranteed in this area.

*When the paper width is 406.4 mm (16"), this width is more than 38 mm (1.50").

Notes: 1. The printable area for a label is the same as that for continuous paper.

2. The base paper of a continuous-paper label is not within the printing area.

1-28 Rev. A

Figure 1-10. Printable Area for Continuous Paper

Page 35

0

+

Stylus 1500 Service Manual General Description

1.5.3 Adjust Lever Position

This printer has an adjust lever to prevent printing smudges caused by the paper thickness not fitting the head

gap. The adjust lever must be set to the proper position for the paper type. The adjust lever is located at the

left upper side of the printer cover.

Table 1-21. Adjust Lever Position

Paper Type Lever Position

Cut sheets,

transparencies,

continuous paper,

labels

Envelopes,

index cards

Far side 0

Near side + 0.7 mm

Platen Gap Adjustment

Value

Figure 1-11. Adjust Lever Settings

Rev. A 1-29

Page 36

General Description Stylus 1500 Service Manual

1.6 INK CARTRIDGE SPECIFICATIONS

Black

Type: Exclusive cartridge

Model: S020062

Color: Black

Print capacity 1900 pages /A4 ( LQ Roman ECMA text)

Life: 2 years from indicated production date

Storage temperature:

Dimensions:

Color

Type: Exclusive cartridge

Model: S020049

Color: Magenta, cyan, yellow

Print capacity: 320 pages / A4 (at 360 dpi, 5% duty and each color)

Life: 2 years from indicated production date

Storage temperature:

Dimensions:

–30° C - 40° C (86° F - 104° F)

Storage under a month at 40° C (104° F)

–30° C - 60° C (86° F - 140° F)

Transit under 120 hours at 60° C (140° F)

and under a month at 40° C (104° F)

25.1 mm (W) × 139.6 mm (D) × 105.3 mm (H)

–20° C - 40° C (–4° F - 104° F)

Storage under a month at 40° C (104° F)

–30° C - 40° C (86° F - 104° F)

Packing storage under a month at 40° C (104° F)

–30° C - 60° C (86° F - 140° F)

Transit under 120 hours at 60° C (140° F)

and under a month at 40° C (104° F)

42.9 mm (W) × 56.8 mm (D) × 38.5 mm (H)

Notes: 1. The ink cartridge cannot be refilled; it is the only consumable.

2. Do not use an ink cartridge that has exceeded the ink life.

°

3. The ink freezes below -3

C (37°F); however, it can be used after it returns to room

temperature.

1-30 Rev. A

Page 37

Stylus 1500 Service Manual General Description

1.7 PHYSICAL SPECIFICATIONS

Weight: 11 .5 kg

Dimensions:

664 mm (W) × 504 mm (D) × 202 mm (H)

Rev. A 1-31

Page 38

General Description Stylus 1500 Service Manual

1.8 MAIN COMPONENTS

The main components of the Stylus 1500 are designed for easy removal and repair. They are as follows:

o Main control board (C172 MAIN Board)

o Power supply board (C172 PSB/PSE Board)

o Control panel board (C172 PNL Board)

o Printer mechanism (M-4E60)

o Housing

1.8.1 Main Control Board (C172 MAIN Board)

This board consists of a CPU (TMP95C061AF), gate array (E05B16), ROM (CG), PROM, DRAM,

EEPROM, motor driver ICs, printhead driver circuits, etc.

Common Dr iver

EEPROM

RESET IC

DRAM

Gate Array (E05B16)

PF Motor Driver (UDN2917)

CR Motor Driver (SLA7043M)

MROM

Lithium Battery

CPU (TMP95C061AF)

Figure 1-12. C172 MAIN Board Component Layout

1.8.2 Power Supply Board (C172 PSB/PSE Board)

This board consists of a transformer, switching FET, regulator IC, diode bridge, etc. This board has two

ratings for input AC voltages (120 VAC/220-240 VAC). The power switch is equipped with a secondary

circuit that allows the CPU to remain active (min. 20 sec.) after the printer is turned off.

Fuse

Regulator IC

Diode Bridge

Transformer

Switching FET

Figure 1-13. C172 PSB/PSE Board Component Layout

1-32 Rev. A

Page 39

Chapter 2 Operating Principles

Table of Contents

2.1 OVERVIEW 2-1

2.2 PRINTER MECHANISM OPERATING PRINCIPLES 2-1

2.2.1 PrintingOperationPrinciples...................................2-1

2.2.2 PrinterMechanism...........................................2-3

2.2.3 CarriageDriveMechanism.....................................2-4

2.2.4 PaperFeedMechanism.......................................2-5

2.2.4.1AutoSheetFeederMechanism...........................2-6

2.2.4.2PushTractorMechanism................................2-7

2.2.4.3ManualFeedMechanism................................2-7

2.2.5 PlatenGapAdjustMechanism..................................2-8

2.2.6 Ink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.7 PumpMechanism...........................................2-10

2.2.8 CapMechanism............................................2-13

2.2.9 WipingMechanism..........................................2-13

2.3 ELECTRICAL CIRCUIT OPERATING PRINCIPLES 2-14

2.3.1 PowerSupplyCircuitOperatingPrinciples .......................2-14

2.3.2 MainControlCircuitOperatingPrinciples ........................2-16

2.3.2.1 ResetCircuits .......................................2-17

2.3.2.2 SensorCircuits ......................................2-17

2.3.2.3 Carriage Motor Driver Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.3.2.4 PaperFeedMotorDriverCircuit.........................2-20

2.3.2.5 Printhead Driver Circuit ................................2-21

2.4 INK SYSTEM MANAGEMENT 2-25

2.4.1 InkOperations .............................................2-25

2.4.2 Counters..................................................2-27

Page 40

List of Figures

Figure2-1.BlackPrintheadStructure................................. 2-1

Figure2-2.ColorPrintheadStructure................................. 2-1

Figure2-3.PrintingOperationStates................................. 2-2

Figure2-4.PrinterMechanismBlockDiagram.......................... 2-3

Figure 2-5. Carriage Movement Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure2-6.PaperFeedMechanism.................................. 2-6

Figure2-7.ASFMechanism........................................ 2-6

Figure2-8.TractorPaperAdvanceMechanism......................... 2-7

Figure2-9.PlatenGapAdjustMechanism............................. 2-8

Figure 2-10. Ink System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure2-11.ReleaseCamSet..................................... 2-10

Figure2-12.PumpMechanismFunction ............................. 2-10

Figure2-13.ReleaseCamReset................................... 2-11

Figure2-14.PaperFeedMechanismFunction......................... 2-11

Figure2-15.PumpOperation...................................... 2-12

Figure2-16.CapMechanism...................................... 2-13

Figure2-17.WipingMechanism.................................... 2-13

Figure2-18.ElectricalCircuitBlockDiagram.......................... 2-14

Figure2-19.PowerSupplyCircuitDiagram........................... 2-15

Figure2-20.MainControlCircuitBlockDiagram....................... 2-16

Figure2-21.ResetCircuitBlockDiagram............................. 2-17

Figure2-22.SensorCircuitBlockDiagram............................ 2-17

Figure 2-23. Carriage Motor Driver Circuit Block Diagram . . . . . . . . . . . . . . . . 2-19

Figure 2-24. Paper Feed Motor Driver Circuit Block Diagram . . . . . . . . . . . . . 2-20

Figure 2-25. Printhead Driver Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . 2-21

Figure2-26.NormalDotDataTransmissionTiming..................... 2-22

Figure 2-27. Color Upgrade Kit Connector Pin Alignment . . . . . . . . . . . . . . . . 2-23

Figure2-28.ColorDataTransmissionTiming ......................... 2-23

Figure 2-29. EPSON Micro Dot Printing Driver Waveform . . . . . . . . . . . . . . . . 2-24

List of Tables

Table 2-1. Carriage Motor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table 2-2. Drive Terms (Carriage Drive Mechanism) . . . . . . . . . . . . . . . . . . . . 2-4

Table2-3. PaperFeedMotorSpecifications........................... 2-5

Table 2-4. Drive Terms (Paper Feed Drive Mechanism) . . . . . . . . . . . . . . . . . . 2-5

Table2-5. PlatenGapAdjustLeverPositions.......................... 2-8

Table2-6. PumpMechanismOperation ............................. 2-12

Table2-7. DCVoltageDistribution.................................. 2-14

Table2-8. BlackInk-OutSensingMode ............................. 2-18

Page 41

Stylus 1500 Service Manual Operating Principles

2.1 OVERVIEW

This section describes the operating principles of the Stylus 1500 printer mechanism and electrical circuits.

2.2 PRINTER MECHANISM OPERATING PRINCIPLES

2.2.1 Printing Operation Principles

This printer mechanism uses a drop-on-demand ink jet system similar to the one used on all other

EPSON ink jet printers. However, the printhead in this system is completely redesigned to make it

more compact and to ensure a high level of reliability. The printer has two printheads: monochrome

(black ink) and color (yellow, cyan, and magenta ink).

1. Monochrome Printhead

The figure below shows the structure of the monochrome printhead, which consists of the nozzle,

nozzle plate, piezo elements, cavities, and printhead driver board.

For Ink Cartridge

Nozzle Plate

Printhead Driver Boar d

Piezo

Cavity

Nozzle

Figure 2-1. Black Printhead Structure

2. Color Printhead

The figure below shows the structure of the color printhead. Its structure is different from the

monochrome printhead. The color printhead consists of the nozzle plates, two rows of nozzles, piezo

elements, and cavities for each of the three colors.

Printhead Driver Board

For Cartridge

Nozzle Plate

Piezo

Cavity

Nozzle

Figure 2-2. Color Printhead Structure

Rev. A 2-1

Page 42

Operating Principles Stylus 1500 Service Manual

The printhead operates in one of two states to eject ink from each nozzle:

❏ Normal state

No electrical charge is applied to the piezoelectric element attached to the back of the cavity, and

pressure inside the cavity is kept at a constant level.

❏ Ejecting state

The head data signal is applied to a specific nozzle control line to select the active nozzle for

printing, and the piezoelectric element is gradually charged by the drive voltage. Charging the

piezoelectric element bends the vibration plate to compress the cavity. Ink is then ejected from the

nozzle.

Cavit y

Nozz le

Piezo

Vibration Plate

Normal

State

Cavit y

Piezo

Vibration Plate

Ejec ting

State

Figure 2-3. Printing Operation States

When the ink charge or printhead cleaning operation is performed, ink in the cavity is vacuumed out

with a pump mechanism. During printing, the ink is simultaneously supplied from the ink cartridge

and ejected from the nozzle, depending on changes in the volume of the cavity.

A thermistor is attached to the side of the black ink printhead driver board to monitor the

temperature, because the viscosity of the ink varies depending on the temperature. The detected

temperature level is fed back to the printhead driver voltage control circuit to change the time of the Tc

pulse.

3. EPSON Micro Dot Printing Mode

The Stylus 1500 has a special black ink printing mode called EPSON Micro Dot Printing Mode. This

mode can be selected when using a special paper type (such as glossy or transparency). Selecting this

printing mode via the printer driver can improve output quality because it eliminates banding that can

sometimes occur in normal mode. In normal dot printing mode, the print dot consists of two ink dots

combined into a single dot. In EPSON Micro Dot Printing Mode, the print dot consists of a single ink

dot only. Using this mode, the ink dot size is smaller than the normal dot and the graded

representation is larger than normal dot printing. This mode is effective for

720 dpi printing on normal paper.

2-2 Rev. A

Page 43

Stylus 1500 Service Manual Operating Principles

2.2.2 Printer Mechanism

The Stylus 1500 printer mechanism is composed of the printhead unit; paper feed, carriage drive,

pump, and push tractor feed mechanisms; and various sensors. The figure below shows a functional

block diagram of the printer mechanism. Depending on the position of the carriage unit, the paper

feed motor torque is transmitted to the paper feed, auto sheet feeding, push tractor feed, or pump

mechanisms via a disengage mechanism.

Release Lever

Pape r Fe e d M oto r

Carriage Motor

Figure 2-4. Printer Mechanism Block Diagram

Disengage Mecha nism

Black

Push Tractor Mechanism

Paper Feed Mechanism

Auto Sheet Feeder

Mechanism

Pump Unit Mechanism

Carriage Unit

Color

Rev. A 2-3

Page 44

Operating Principles Stylus 1500 Service Manual

2.2.3 Carriage Drive Mechanism

The timing belt attached to the base of the carriage unit is driven by the carriage motor, causing the

carriage unit to move along the carriage guide shaft from left to right or vice versa. The carriage drive

motor in this printer is a 4-phase, 96-pole, hybrid-type stepping motor, allowing the printer to stop the

carriage or change the carriage movement at any position. The carriage position is recognized by the

home position (HP) sensor, and position information is fed back to the CPU. This carriage motor is

driven by the SLA7043M motor driver IC.

Table 2-1. Carriage Motor Specifications

Item

Motor type

Drive voltage

Coil resistance

Drive frequency

Excitation mode

Minimum step

Print

Mode

^

Draft (black)

Draft (color)

Description

4-phase / 96-pole hybrid-type stepping motor

+42 VDC ± 5%

5 Ω±7%

480 - 9600 Hz

Constant current unipolar drive

❏ 0.026 mm (at 2W1-2 phase)

❏ 0.106 mm (at 1-2 phase)

Table 2-2. Drive Terms (Carriage Drive Mechanism)

Print

Speed

(cps)

400

Acceleration

1/2

0.8 / 0.8

0.9 / 0.9 ^

Current Value (A / Phase) +

Constant

Deceleration

1/2

0.7 0.96 / 0.96

Rush

(before/after)

0.5 / 0.5

LQ

SLQ

200 0.9 / 0.9 0.7 0.8 / 0.8 0.5 / 0.5

100 0.9 / 0.9 0.6 0.8 / 0.8 0.5 / 0.5

Drive Pulley

Timing Belt

Driven Pu lley

Eject Paper Frame

CR Motor

Carriage Unit

HP Sensor

CR Guide Shaft

Figure 2-5. Carriage Movement Mechanism

2-4 Rev. A

Page 45

Stylus 1500 Service Manual Operating Principles

2.2.4 Paper Feed Mechanism

This printer’s paper feed mechanism consists of the built-in ASF (auto sheet feeder), push tractor, PF

(paper feed) motor, front/rear PE (paper end) sensors, PF roller, eject roller unit, and disengage

mechanism. The PF motor is a 4-phase, 48-pole, PM-type stepping motor that directly drives the paper

feed mechanism (for paper advancing and paper pickup). This motor also drives the pump mechanism,

but only when the printer is in the cleaning state. The paper feed mechanism is driven using a 1-2

phase drive method, except in the paper feed drive sequence (W1-2 phase). The paper feed mechanism

is illustrated in Figure 2-6.

The disengage mechanism switches the PF motor torque between the PF drive and pump drive via the

carriage unit stop positions. The PF motor torque is transmitted to the PF roller via the PF motor

pinion, disengage mechanism, and gear train. The torque is then separated for each of the two

directions of the PF roller. One direction of torque transmission is used to drive the paper-ejecting

mechanism via the gear train of the upper paper guide assembly. The other direction is used to drive

the push tractor or ASF mechanism.

Table 2-3. Paper Feed Motor Specifications

Item

Motor type

Drive voltage

Coil resistance

Drive frequency

Excitation mode

Minimum step

Table 2-4. Drive Terms (Paper Feed Mechanism)

Mode

^

Paper loading (ASF)

Description

4-phase, 96-pole, HB-type

+42 VDC ± 5%

10 Ω ± 10%

300 - 2160 Hz

❑ Constant current bipolar drive

❑ Paper feed / pump drive: 2-2 phase, W1-2

phase

1/720" (2-2 phase)

Current Value (A / Phase) +

Frequency

(Hz)

2160 0.9 / 0.9 0.9 0.75 / 0.75 0.6 / 0.6

Acceleration

W1-2 / 2-2

Phase

Constant

Deceleration

W1-2 / 2-2

Phase

Rush

(before

/after)

Paper feed

Pump drive

Pump drive

(lower speed)

2160 0.9 / 0.9 0.9 0.75 / 0.75 0.6 / 0.6

700 — / 0.9 0.9 0.9 / — 0.75 / 0.75

300 — / — 0.9 — / — 0.75 / 0.75

Note: Hold current is 0.6 A.

Rev. A 2-5

Page 46

Pickup Roller

Paper Support

PE Sensor

PF Roller

ASF Transmission Gear

Disengage Gear

Pinion Gear

PF Motor

Paper

One Way Clutch

ASF Mechanism

Operating Principles Stylus 1500 Service Manual

Release Ge ar

To Tra ctor

To ASF

ASF Transmission Gear

Eject Roller Unit

PF Motor Pinion Gear

Disengage Gear

Paper Eject Roller

Figure 2-6. Paper Feed Mechanism

PF Motor

PF Roller

Pump Unit

Eject Paper Shaft

2.2.4.1 Auto Sheet Feeder Mechanism

The PF motor torque is transmitted to the ASF pickup rollers via a planetary gear in the disengage

mechanism. The pickup roller shaft has two arms on each side. The arms engage the paper support to

cause the paper surface to contact the pickup rollers. The one-way clutch makes the rollers rotate in

one direction for paper pickup. When not in paper pickup motion, the planetary gear does not

transmit torque to the pickup roller shaft.

After picking up paper, the planetary gear is released from the ASF mechanism. The torque of the PF

motor is then transmitted to the paper feed mechanism.

Figure 2-7. ASF Mechanism

2-6 Rev. A

Page 47

Release Lever

Releas e Gear

Rear PE Sensor

PF Roller

Disengage Gear

PF Motor

Pinion Gear

PF Mot or

Stylus 1500 Service Manual Operating Principles

2.2.4.2 Push Tractor Mechanism

The release gear of the push tractor is located on the left side of the printer mechanism. By operating

the release lever, the release gear is engaged between the PF roller gear and the push tractor gear. The

release gear transmits the PF motor torque from the PF roller to the push tractor. Continuous paper

can then be fed into the printer.

Figure 2-8. Tractor Paper Advance Mechanism

2.2.4.3 Manual Feed Mechanism

With the release lever moved to friction feed mode and a sheet inserted in the rear paper slot, the

printer switches to manual paper feed mode. In this mode, a single sheet can be fed from the rear

paper slot even if there is paper in ASF. This mode therefore allows the use of normal paper in the

ASF and special paper (such as glossy or transparency paper recommended for single-sheet feeding) in

the rear slot at the same time.

Rev. A 2-7

Page 48

Operating Principles Stylus 1500 Service Manual

2.2.5 Platen Gap Adjust Mechanism

The platen gap adjust lever, attached to the left upper side of the printer cover, should be set to the

appropriate position for the paper thickness. The platen gap adjust mechanism consists of the platen

gap adjust lever, carriage guide shaft, and two parallelism adjust bushings. Switching the lever

between positions 0 and + rotates the carriage guide shaft toward the front or rear. The bushings have

an eccentricity toward the center of the carriage guide shaft, and the platen gap is changed from wide

to narrow or vice versa.

Table 2-5. Platen Gap Adjust Lever Positions

Paper Type

Cut sheet

Transparency

Index card

Continuous paper

Envelope

Parallelism Adjust Bushing

Lever Position

0

Platen Gap

Adjustment Value

± 0mm

++0.7mm

Platen Gap Adjust Lever

Printhea d

Platen Surface

Eccentricity

CR Guide Shaft

Figure 2-9. Platen Gap Adjust Mechanism

2-8 Rev. A

Page 49

Stylus 1500 Service Manual Operating Principles

2.2.6 Ink System

This printer’s ink system is composed of the following mechanisms:

❑ Ink cartridge

❑ Pump mechanism

❑ Cap mechanism

❑ Waste ink drain tank

❑ Wiping mechanism

The figure below shows a diagram of the ink system.

Black Ink Cartridge

Color Ink Cartridg e (Option)

Air Valve

Pump 2

Head Cleaner

Clutch Unit

Pump 1

PF Motor

Disengage

Gear

Pump Unit

Gear Train

Waste Ink Drain Tank

Figure 2-10. Ink System Block Diagram

Rev. A 2-9

Page 50

Carriage Unit Switch Lever

Release Cam

Direction of Carriage Tr ansfer

Disengage Gear

Compression Spring

Direction of Release Cam Transfer

Carriage Unit Switch Lever

Disengage Mechanism

Release Lever

ASF Transmission Set Lever

Release Cam Set Lever

Release Cam Set Lever

Disengage Mechanism

Operating Principles Stylus 1500 Service Manual

2.2.7 Pump Mechanism

The paper feed motor drives the pump mechanism when the transmission gear moves to the position

where the motor engages the pump mechanism gear trains, when the carriage unit is at the ink system

home position. The release cam set is used to engage the pump mechanism (Figure 2-11) and disengage

it (Figure 2-13) to switch to paper feeding (Figure 2-14). Figure 2-12 shows a block diagram of the

pump mechanism. Pump system operation depends on the rotational direction of the paper feed motor,

as shown in Table 2-6.

1. Switching to the Pump Function

Figure 2-11. Release Cam Set

Carriage Unit

Switch Lever

Release Cam

PF Roller

PF Motor Pinion Gear

Figure 2-12. Pump Mechanism Function

PF Motor

Disengage Gear

Pump Unit

2-10 Rev. A

Page 51

Stylus 1500 Service Manual Operating Principles

2. Resetting from the Pump Function

Carriage Unit

Switching Lever

Disengage Mechanis m

Release Cam Lever

Switching Lever Path

Release Cam

Figure 2-13. Release Cam Reset

Carriage Unit

Switch Lever

Release Cam

PF Roller

PF Motor Pinion Gear

PF Motor

Disengage Ge ar

Pump Unit

Figure 2-14. Paper Feed Mechanism Function

Rev. A 2-11

Page 52

Operating Principles Stylus 1500 Service Manual

3. Pump Operation

The pump draws ink from the printhead nozzles and drains it into the waste ink drain tank to eliminate

dust or bubbles in the nozzles. The figure below illustrates pump operation. When the paper feed drive

motor rotates CCW (backward), the color pulleys in the wheel pump unit rotate in the direction of the

arrow while squeezing the ink tube to push the ink out to the waste ink drain tank. When the motor

rotates CW (forward), the black pulleys in the wheel pump unit rotate in the direction of the arrow

while squeezing the ink tube to push the ink out to the waste ink drain tank.

Table 2-6. Pump Mechanism Operation

PF Motor Rotational Direction

Clockwise (CW)

forward rotation

^

Counterclockwise (CCW)

backward rotation

^

Ink Tube

Ink Draining

Vacuuming

Pump Moto r ( CC W): Bla ck Pump i ng

Operation

❑ Black ink absorption

❑ Wiper reset

^

❑ Color ink absorption

❑ Wiper set

^

Ink Draining

Vacuuming

Pump Moto r (CW): C ol or Pu mp ing

No Ink Draining

No Vacuuming

Pump Motor (CW) : Bla ck N o P ump in g

Note:

CW = Clockwise; CCW = Cou nterclo ckwise

No Ink Draining

No Vacuuming

Pump Motor (CCW): Color No Pumping

Figure 2-15. Pump Operation

There are two pump rollers in the pump unit, and drive power is supplied from the paper feed motor

via the pump drive gear (D/E gear), which is moved by the carriage. In the pump unit, the

transmission gear supplies both the black and color pulleys, which are each rotated by the movement of

the other.

2-12 Rev. A

Page 53

Color Cartridge (Option)

Carriag e

Air Tube

Cap Holder

Cap 1

Cap 2

Air Valve

Valve Spring

Black Printhead

Right Side Frame

1

1'

Hinge

To Waste Ink Pad

To Waste Ink Pad

Stylus 1500 Service Manual Operating Principles

2.2.8 Cap Mechanism

The cap mechanism prevents the printhead nozzles from drying and keeps bubbles from forming inside

the nozzles while the printer is not in use. The printer performs the capping operation automatically

when it is not printing. If the printer power is turned off during printing or ink system operations,

capping is performed and then turn off. (The power switch uses a secondary circuit that allows this

operation to be performed.) This printer has two caps: one for the black printhead and one for the

color printhead.

Figure 2-16. Cap Mechanism

2.2.9 Wiping Mechanism

The wiping mechanism cleans the surface of the printhead when the printer is in the ink system

sequence. When the paper feed drive motor rotates CCW (backward), power from the motor (via the

clutch unit•and gears) is transmitted to the head cleaner (wiper) drive gear. The head cleaner moves

across the carriage unit’s path. When the motor rotates CW (forward), the head cleaner moves toward

the front to remove itself from the carriage unit’s path. Both the black and color printheads are

cleaned by this wiper.

Carriage Unit

Head Cleaner

Lever

Printhead

PF Motor

Carriage Unit

Head Cleaner

Head Cleaner Lever

Carriage Switch Lever

Disengage

Mechanism

Gear Train

Wiping Mechanism

Pump Gear / Clutch

Figure 2-17. Wiping Mechanism

Rev. A 2-13

Page 54

C172 PSB/PSE

+5 VDC

+42 VDC

C172 MAIN

C172 PNL

Mechanism Unit M-4E60

CR Motor

PF Motor

Carriage Unit

Color Head

Drive Circuit

(Option)

Black Head

Drive Circuit

Operating Principles Stylus 1500 Service Manual

2.3 ELECTRICAL CIRCUIT OPERATING PRINCIPLES

The Stylus 1500 contains the following circuit boards:

❏ C172 MAIN Board (main control circuit board)

❏ C172 PSB/PSE Board (power supply circuit board). This is the same board used in the Stylus

Color printer.

❏ C172 PNL (control panel board)

In addition to the circuit boards above, part of the printhead drive circuit is built on a separate circuit

board installed in the carriage unit; the printhead is attached directly to this board. The figure below

shows a block diagram of the electrical circuitry.

2.3.1 Power Supply Circuit Operating Principles

The power supply circuit for this printer is provided either by the C172 PSB board (120 VAC) or by

the C172 PSE board (220-240 VAC). Both boards are identical in design and function, except for the

components in the primary circuit that accommodate the specified input voltage. The input voltages

and applications of output voltages are summarized in the table below.

Voltage

+42 VDC

+5 VDC

Figure 2-18. Electrical Circuit Block Diagram

Table 2-7. DC Voltage Distribution

Application

❑ Motor drive (carriage and paper feed)

❑ Printhead (through the drive voltage generation circuit)

❑ C172 MAIN board logic circuit

❑ Sensors (home position, paper end, no ink cartridge, head thermistor)