Page 1

®

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Color ink jet printer

Stylus COLOR 860/1160

SEIJ99003

Page 2

EPSON Stylus COLOR 860/1160 Revision C

Notice:

n All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or tran smi tted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

n The contents of this manual are subject to change witho ut notice.

n All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

n The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the conse quences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

2

Page 3

EPSON Stylus COLOR 860/1160 Revision C

PRECAUTIONS

Precautionary notations through out the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures .

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-

STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

3

Page 4

EPSON Stylus COLOR 860/1160 Revision C

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of Stylus COLOR 860/

1160. The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the

precautions on the preceding page. The chapters are organi zed as fol lows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• EEPROM Address Map

• Connector Pin Assignments

• Component Layout

• Parts List and Exploded Diagrams

• C298MAIN Board Circuit Diagram

4

Page 5

EPSON Stylus COLOR 860/1160 Revision C

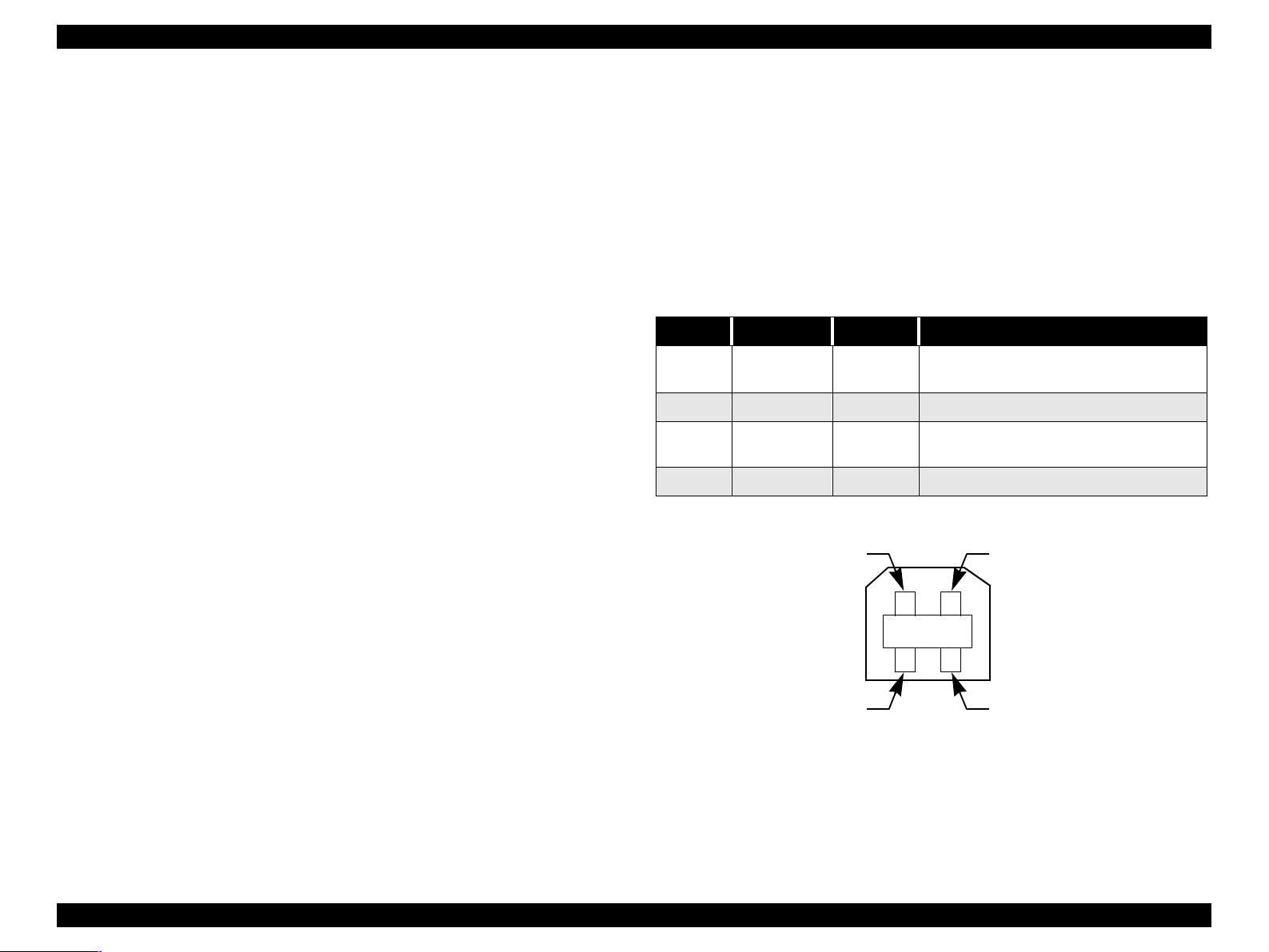

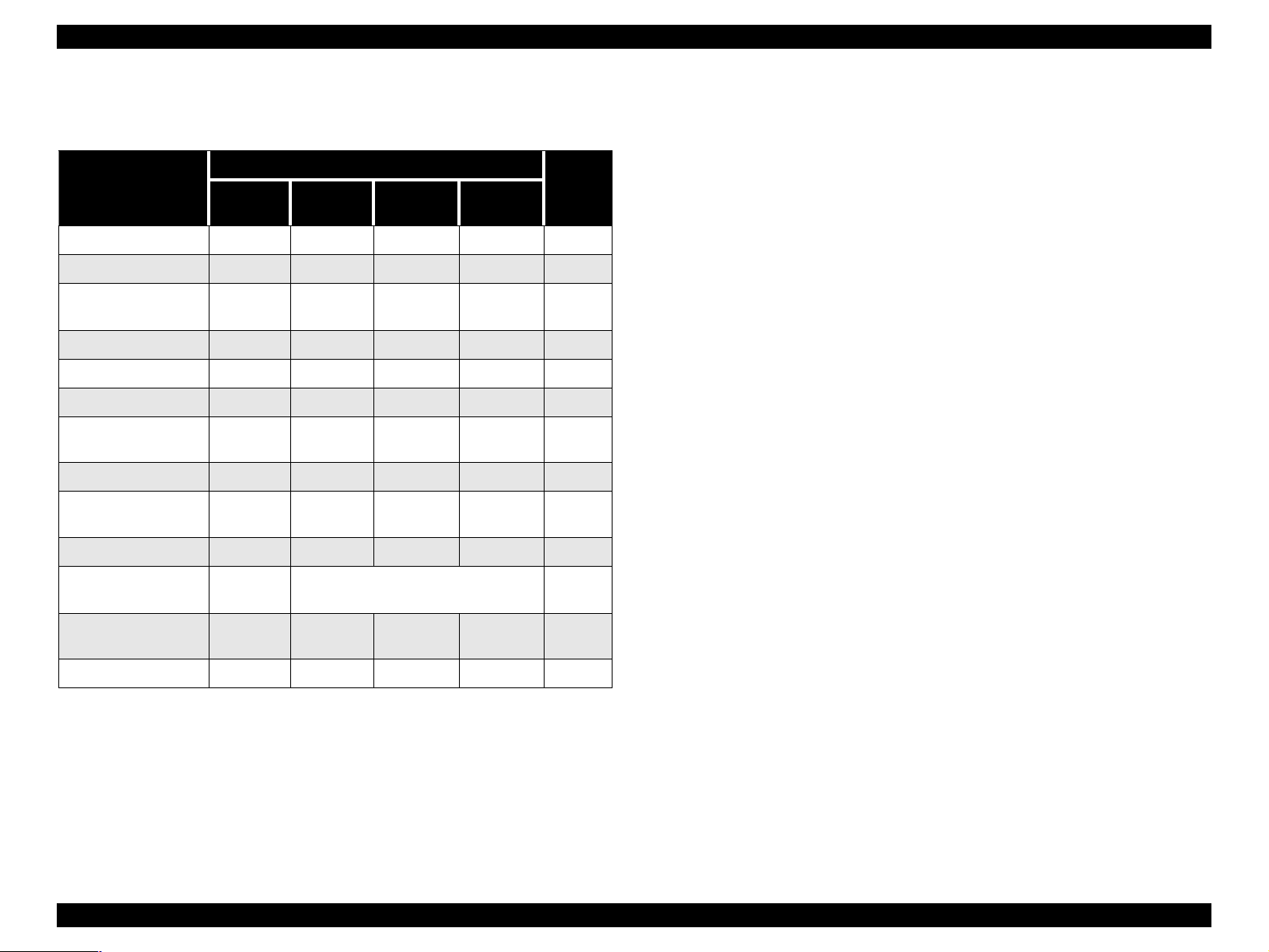

Revision Status

Revision Issued Date Description

A August 19, 1999 First Release

Second release

B October 5, 1999

C November 25,1999

• Correction has been made due to overall review of the manual.

• Appendix has additional information.

Third release

• Correction has been made due to overall review of the manual.

• Some T.B.D have been made clear.

• Appendix has additional information.

- Fig7-3, 7-4 has been mounted.

5

Page 6

EPSON Stylus COLOR 860/1160 Revision C

PRODUCT DESCRIPTION

FEATURES .................................... ...... ....... ...... ....... ...... ....... ...... ....... ........... 9

SPECIFICATIONS ...................................................................................... 10

Physical Specification ......................................................................................... 10

Printing Specification ......................................................................................... 10

Paper Feeding ..................................................................................................... 11

Input Data Buffer ................................................ ..... ........................................ ... 11

Electric Specification .......................................................................................... 11

Environmental Condition .................................................................................... 12

Reliability ........................................................................................................... 12

Safety Approvals .................................................................................. ..... ......... 12

Acoustic Noise .................................................................................................... 12

CE Marking ........................................................................................................ 12

INTERFACE ............................................................................................... 13

Parallel Interface (Forward Channel) ................................................................. 13

Parallel Interface (Reserve Channel) .................................................................. 16

USB Interface ..................................................................................................... 17

Prevention of Data Transfer Time-out ................................................................ 18

Interface Selection .............................................................................................. 18

IEEE1284.4 Protocol .......................................................................................... 18

OPERATOR CONTROLS ........................................................................... 19

Operating Switch ................................................................................................ 19

Control Panel ...................................................................................................... 19

Switches .......................................................................................................... 19

Indicators ........................................................................................................ 19

Panel Functions ................................................................................................... 20

Printer Condition and Panel Status ................................ ...... ............................... 21

Printer Initialization ............................................................................................ 21

Errors .................................................................................................................. 22

PAPER ......................................................................................................... 23

Paper Handling ................................................................................................... 23

Paper Specification ............................................................................................. 23

Cut Sheet ........................................................................................................ 23

Transparency, Glossy Paper ........................................................................... 23

Envelope ......................................................................................................... 23

Index Card ...................................................................................................... 24

Printing Area ....................................................................................................... 25

Cut Sheet ........................................................................................................ 25

Envelopes ....................................................................................................... 26

INK CARTRIDGE ....................................................................................... 27

Black Ink Cartridge ............................................................................................ 27

Color Ink Cartridge ............................................................................................. 27

Operating Principles

Overview ...................................................................................................... 29

Printer Mechanism ......................................................................................... ..... 29

Printing Mechanism ....................................................................................... 30

Printing Process .............................................................................................. 31

Carriage Mechanism .............................. ..... ...... ........................................ ..... 32

Platen Gap (PG) Adjust Mechanism .............................................................. 33

Paper Feeding Mechanism ............................................................................. 33

CR Lock Mechanism ...................................................................................... 35

Paper Loading Mechanism ............................................................................. 36

Pump Mechanism ........................................................................................... 38

Capping Mechanism ....................................................................................... 39

Electrical Circuit Operating Principles ......................................................... 40

C298PSB/PSE Board .......................................................................................... 41

C298MAIN Board .............................................................................................. 43

Printhead Driver Circuit ................................................................................. 45

Reset Circuit ................................................................................................... 46

CR Motor Driver Circuit ................................................................................ 47

PF Motor Driver Circuit ............................................... .................................. 49

ASF/Pump Motor Driver Circuit .................................................................... 50

EEPROM Control Circuit .............................................................................. 50

Sensor Circuit ........................................................................... ..... ................. 51

Troubleshooting

Overview ...................................................................................................... 54

Troubleshooting with LED Error Indications ..................................................... 55

Remedies for Paper Out Error ........................................................................ 57

Remedies for the Paper Jam Error .................................................................. 59

Remedies for No I/C and Ink Out Errors ....................................................... 60

Remedies for the Maintenance Error ............................................................. 62

Remedies for Fatal Error ................................................................................ 63

Isolating the Faulty Part on the Power Supply Board ........................................ 66

6

Page 7

EPSON Stylus COLOR 860/1160 Revision C

Isolating the Faulty Part according to the Phenomenon ..................................... 68

Disassembly and Assembly

Overview ...................................................................................................... 75

Precautions for Disassembling the Printer .......................................................... 75

Tools ................................................................................................................... 76

Specification for Screws ..................................................................................... 77

Service Checks After Repair ......................................... ...... ..... .......................... 78

Disassembly Procedures ............................................................................... 79

Removing the Upper Housing ............................................................................ 80

Removing the Circuit Board Assembly .............................................................. 81

Removing the Operation Panel ........................................................................... 83

Disassembling the Printer Mechanism ............................................................... 84

Removing the Printhead Unit ......................................................................... 85

Removing the Waste Ink Absorber Tray Assembly ....................................... 87

Removing the Ink System Assembly ............................................................. 89

Removing the CR Motor Assembly ............................................................... 92

Removing the DE Assembly (include the ASF/Pump motor) ....................... 93

Removing the ASF Assembly ........................................................................ 97

Removing the Paper Feed Roller Assembly............................................................. 99

Removing the Right and Left LD Roller Assembly............................................... 104

Removing the CR Assembly ........................................................................ 105

Disassembling the CR Assembly............................................................................ 108

Removing the PF Roller Assembly and Paper Eject Roller Assembly ........ 110

Remove the PF Motor Assembly ................................................................. 114

Removing the PE Detector Assembly .......................................................... 115

Adjustment

Overview .................................................................................................... 117

Required Adjustments ...................................................................................... 117

Adjustment Tools Required .............................................................................. 118

Adjustment ................................................................................................ 119

Parallelism Adjustment ............................................................. ...... .................. 119

Backlash value Adjustment for PF motor ......................................................... 122

Adjustment by Adjustment Program ................................................................ 125

About Adjustment Program .......................................................................... 125

How to set up the program ........................................................................... 125

Choose the Model ......................................................................................... 126

Market Destination Check ............................................................................ 127

Head Voltage ID Input ................................................................................. 128

Head Angular Adjustment ............................................................................ 131

Bi-D Adjustment .......................................................................................... 134

USB ID input ................................................................................................ 137

Initial Ink Charge Operation ........................................................................ 141

Head Cleaning Operation ............................................................................. 142

Protection Counter Check/Reset .................................................................. 143

Recovery for the clogged nozzle .................................................................. 145

Print A4 pattern ............................................................................................ 146

PF Loop scale unit assembling procedure ................................................... 147

Assembling the PF Loop scale unit .................................................................. 147

Sticking the PF Loop scale unit to Gear 76 ...................................................... 149

Maintenance

Overview .................................................................................................... 151

Cleaning ............................................................................................................ 151

Service Maintenance ......................................................................................... 151

Lubrication ........................................................................................................ 152

Appendix

Connector Summary .................................................................................. 161

Connector Pin Assignment ............................................................................... 161

EEPROM ADDRESS MAP ............................................................................. 164

Circuit Board Component Layout .............................................................. 169

Exploded Diagrams and Parts List for Stylus COLOR 860 ......................... 172

Exploded Diagrams and Parts List for Stylus COLOR 1160 ....................... 180

Circuit Diagram ......................................................................................... 189

7

Page 8

PRODUCT DESCRIPTION

CHAPTER

Page 9

EPSON Stylus COLOR 860/1160 Revision C

1.1 FEATURES

The major features of EPSON color inkjet printers EPSON Stylus COLOR 860/

1160 are:

o High Color Print Quality

n 1440 (H) X 720 (V) dpi printing

n Four Color Printing (YMCK)

n Traditional and New Microweave

o Built-in Auto Sheet Feeder

n Holds 100 cut-sheets (64g/m

n Holds 10 envelopes

n Holds 30 transparency films

o Two Built-in Interfaces

n Bi-directional parallel I/F (IEEE-1284 level 1 device)

n USB

o Windows/Macintosh exclusive

2

)

PRODUCT DESCRIPTION FEATURES 9

Page 10

EPSON Stylus COLOR 860/1160 Revision C

1.2 SPECIFICATIONS

This section covers specifications of the printers.

1.2.1 Physical Specification

o Weight: 6.0kg (without ink cartridges) for Stylus Color 860

8.0kg (without ink cartridges) for Stylus Color 1160

o Dimension:

[Stylus Color 860]

Storage: 450 mm (W) x 269 mm (D) x 175 mm (H)

Printing: 450 mm (W) x 628 mm (D) x 303 mm (H)

[Stylus Color 1160]

Printing: 609 mm (W) x 766 mm (D) x 414 mm (H)

1.2.2 Printing Specification

o Print Method

n On demand ink jet

o Nozzle Configuration

n Monochrome 144 nozzles (48 x 3 staggered)

n Color 48 nozzles x 3 (Cyan, Magenta, Yellow)

o Print Direction

n Bi-direction with logic seeking

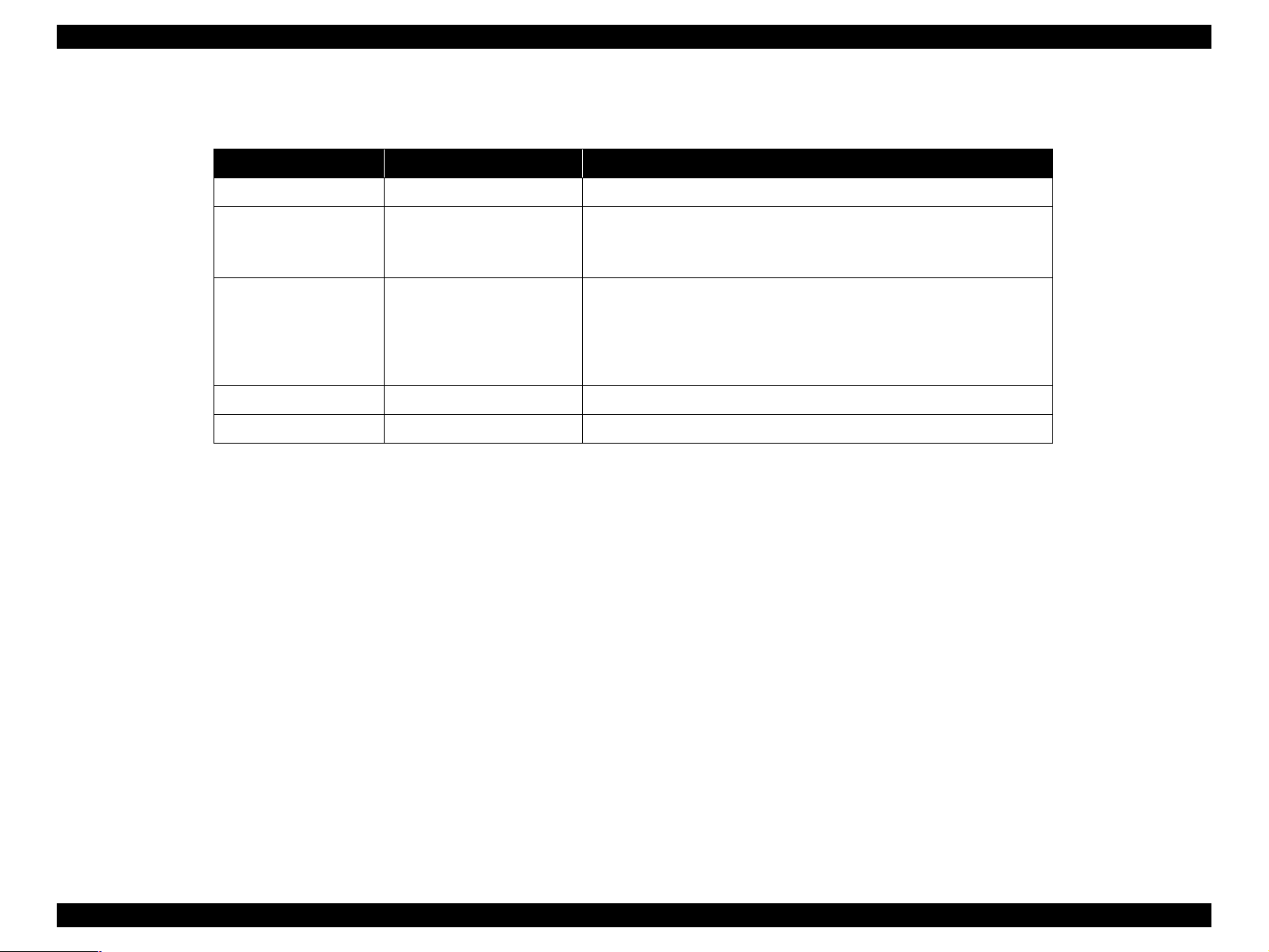

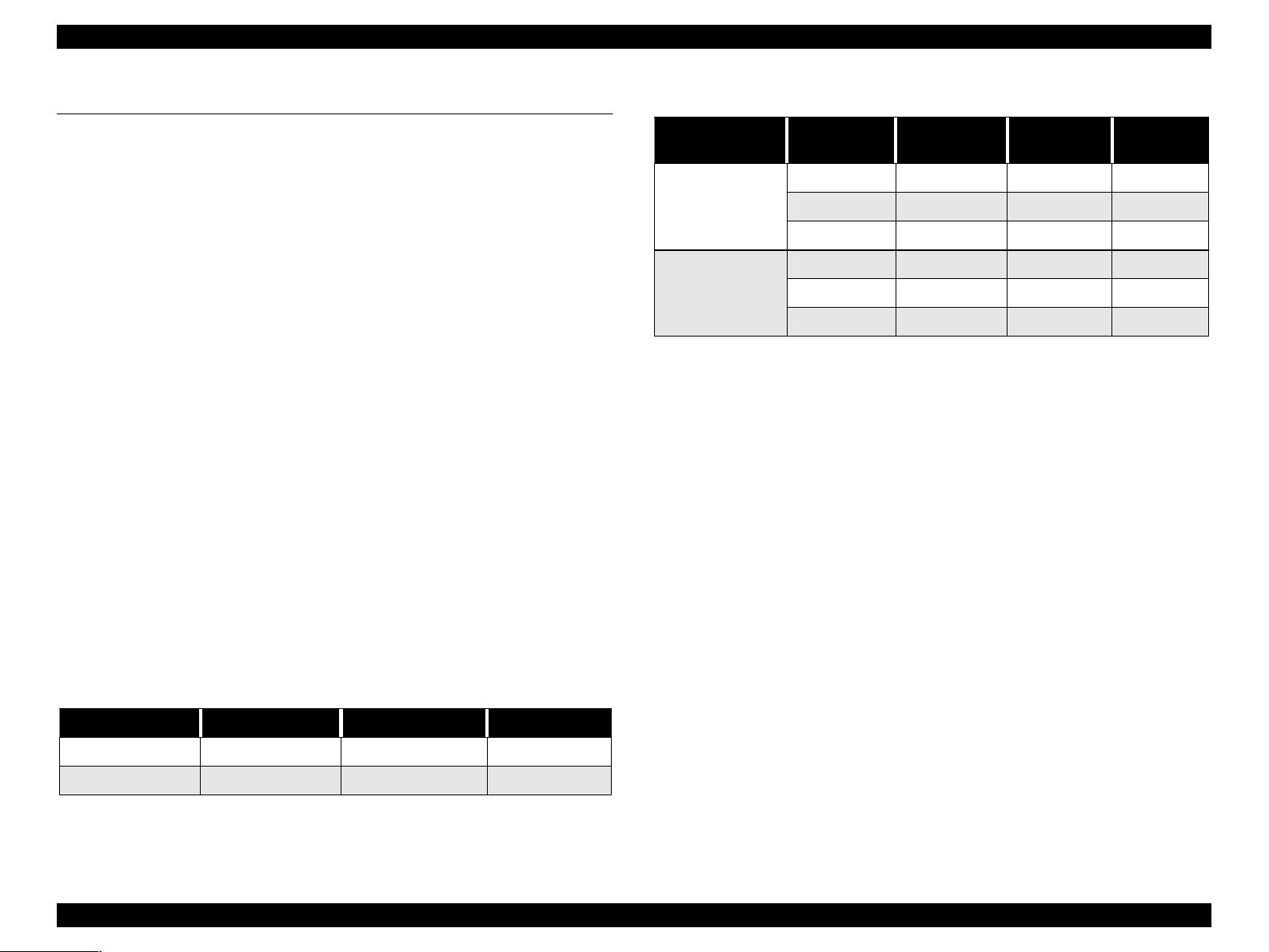

Table 1-2. Raster Graphics Mode

Model

Stylus Color 860

Stylus Color 1160

Horizontal

Resolution

180 dpi 8.26 inches 1488 23.8/19 IPS

360 dpi 8.26 inches 2976 23.8/19 IPS

720 dpi 8.26 inches 5952 19 IPS

180 dpi 12.716 inches 2289 23.8/19 IPS

360 dpi 12.716 inches 4578 23.8/19 IPS

720 dpi 12.716 inches 9156 19 IPS

o Control Code

n ESC/P Raster command

n EPSON Remote command

o Character Tables

n Two international character sets:

- PC 437 (US, Standard Europe)

- PC 850 (Multilingual)

o Typ eface

n Bit map LQ font:

EPSON Courier 10 CPI

Printable Area Available Dot CR Speed

o Print Speed & Printable Columns

Table 1-1. Character Mode

Model Character Pitch Printable Colum n LQ Speed

Stylus Color 860 10 CPI (Pica) 80 238 CPS*

Stylus Color 1160 10 CPI (Pica) 127 238 CPS*

*This value is the speed of normal-dot printing.

PRODUCT DESCRIPTION SPECIFICATIONS 10

Page 11

EPSON Stylus COLOR 860/1160 Revision C

1.2.3 Paper Feeding

o Feed Method

n Friction feed with ASF

o Paper Path

n Cut-sheet ASF (Top entry, Front out)

o Feed Speed

n 2.36 inch/sec (Normal, Continuous feed)

n 4.5 inch/sec (Fast, Continues feed)

1.2.4 Input Data Buffer

n 256KB

1.2.5 Electric Specification

[120V Version]

Rated Voltage: AC120V

Input Voltage Range: AC99∼132V

Rated Frequency Range: 50∼ 60Hz

Input Frequency Range: 49.5∼ 60.5Hz

Rated Current: 0.4A (for Stylus Color 860)

0.4A (for Stylus Color 1160)

Power Consumption: Approx. 18W (ISO10561 Letter Pattern)

Approx. 3.5W in standby mode

(for Stylus Color 860)

Approx. 18W (ISO10561 Letter Pattern)

Approx. 3.5W in standby mode

(for Stylus Color 1160)

Energy Star compliant

Insulation Resistance: 10M ohms min.

(between AC line and chassis, DC 500V)

Dielectric Strength: AC 1000V rms. 1 minutes or

AC 1200V rms. 1 second

(between AC line and chassis)

[220 ∼ 240V Version]

Rated Voltage: AC220V∼240V

Input Voltage Range: AC198∼264V

Rated Frequency Range: 50∼60Hz

Input Frequency Range: 49.5∼60.5Hz

Rated Current: 0.2 A (for Stylus Color 860)

0.2 A (for Stylus Color 1160)

Power Consumption: Approx. 18W (ISO10561 Letter Pattern)

Approx. 3.5W in standby mode

(for Stylus Color 860)

Approx. 18W(ISO10561 Letter Pattern)

Approx. 3.5W in standby mode

(for Stylus Color 1160)

Energy Star compliant

Insulation Resistance: 10M ohms min.

(between AC line and chassis, DC 500V)

Dielectric Strength: AC 1500V rms. 1 minute

(between AC line and chassis)

PRODUCT DESCRIPTION SPECIFICATIONS 11

Page 12

EPSON Stylus COLOR 860/1160 Revision C

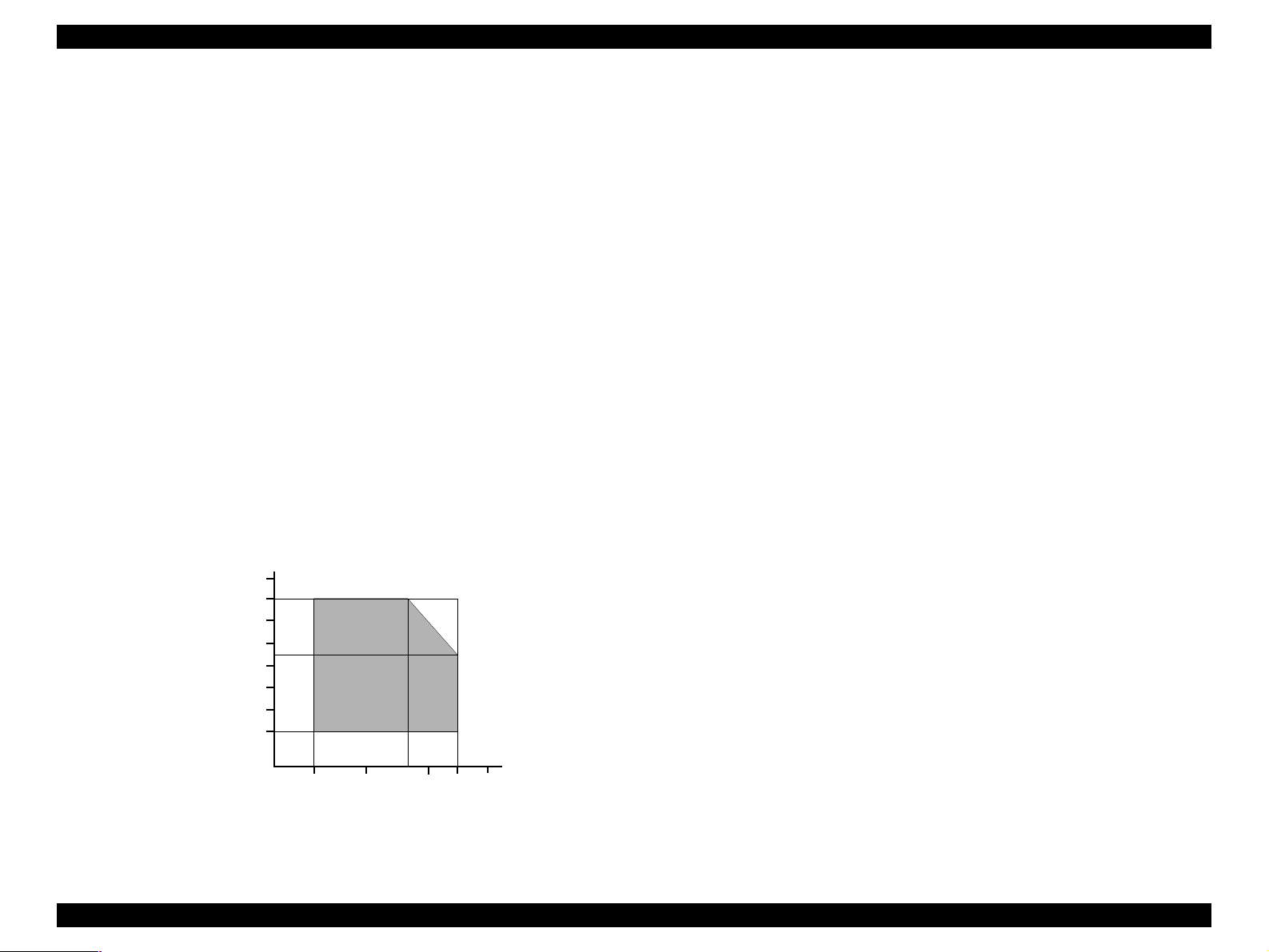

1.2.6 Environmental Condition

o Temperature

n Operating: 10 to 35°C (see the figure below for condition)

n Non-operating: -20 to 60°C (with shipment container)

1 month at 40°C and 120 hours at 60°C

o Humidity

n Operating: 20 to 80% RH

(without condensation / see the figure below for

condition)

n Non-operating: 5 to 85% RH

(without condensation / with shipment container)

o Resistance to Shock

n Operating: 1G, within 1 ms

n Non-operating: 2G, within 2 ms (with shipment container)

o Resistance to Vibration

n Operating: 0.15G

n Non-operating: 0.50G (with shipment container)

90

80

70

60

Humidity (%)

50

40

30

20

27

10

20

Temperature (°C)

30

35

40

1.2.7 Reliability

Total Print Volume: 75,000 pages (A4, Letter)

Print Head Life: 3 billion dots/nozzle

1.2.8 Safety Approvals

[120V Version]

Safety Standards: UL1950

CSA22.2 No.950

EMI: FCC part 15 subpart B Class B

CSA C108.8 Class B

[220∼240V Version]

Safety Standards: EN60950 (VDE)

EMI: EN55022 (CISPR Pub.22) Class B

AS/NZS 3548 Class B

1.2.9 Acoustic Noise

Level: Approx. 42dB(A) (According to ISO 7779)

-Used media : Plain Paper

- Print Quality: Fine

1.2.10 CE Marking

[220∼240V Version]

Low Voltage Directive 73/23/EEC: EN60950

EMC Directive 89/336/EEC: EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Figure 1-1. Temperature/Humidity Range

PRODUCT DESCRIPTION SPECIFICATIONS 12

Page 13

EPSON Stylus COLOR 860/1160 Revision C

1.3 INTERFACE

The EPSON Stylus COLOR 860/1160 provide USB and parallel interface as

standard.

1.3.1 Parallel Interface (Forward Channel)

Transmission Mode: 8 bit parallel, IEEE-1284 compatibility mode

Synchronization: By STROBE pulse

Handshaking: BY BUSY and ACKNLG signal

Signal Level: TTL compatible level

Adaptable Connector: 57-30360 (amphenol) or equivalent

BUSY signal is set high before setting either -ERROR low or PE high, and held

high until all these signals return to their inactive state.

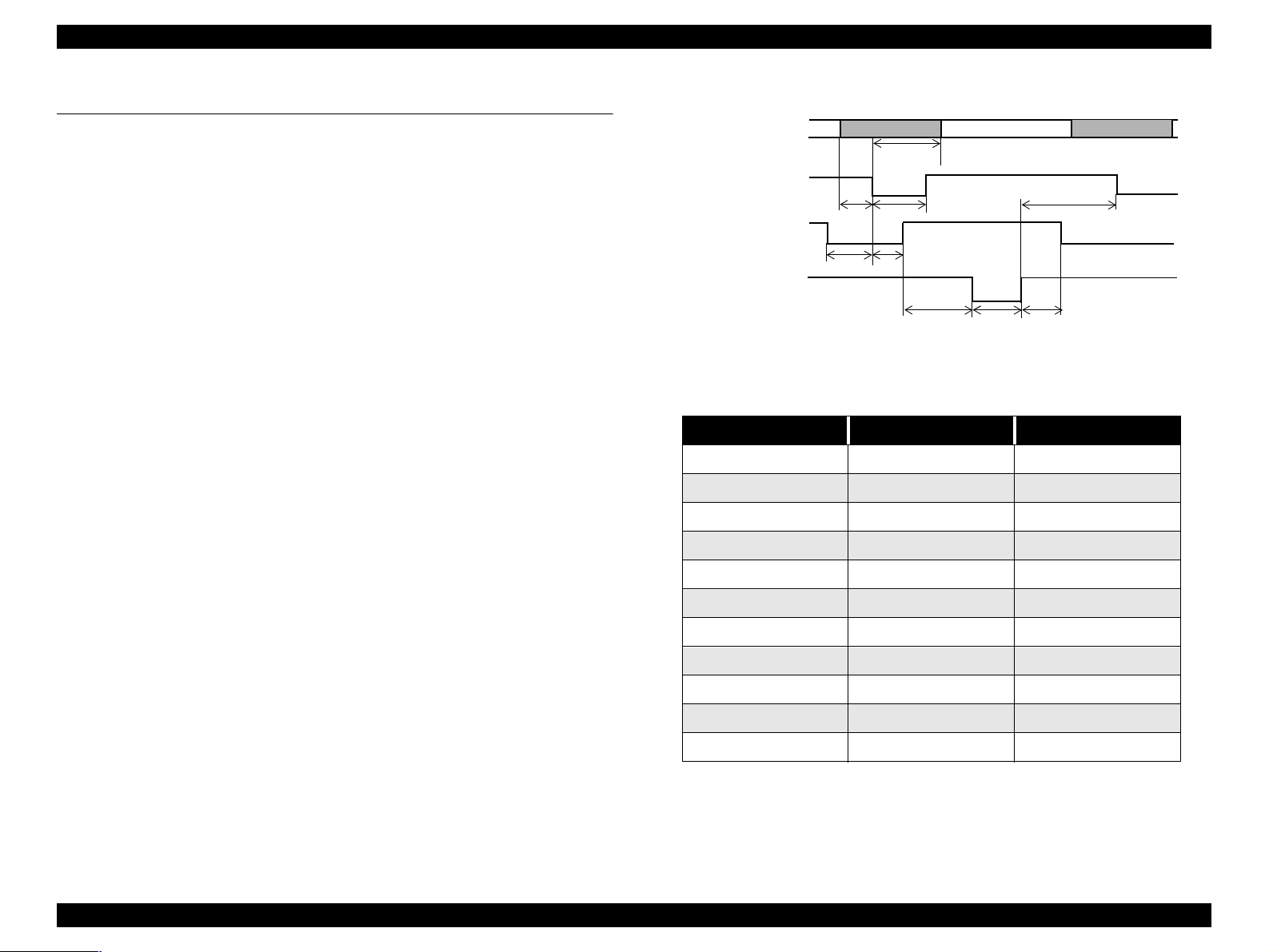

DATA

-STROBE

BUSY

-ACKNLG

data byte n

thold

tbusy

treply

tstb

tack

tnbusy

tsetup

tready

Figure 1-2. Data Transmission Timing

data byte n+1

tnext

BUSY signal is at high level in the following cases:

n During data entry (see data transmission timing).

n When input data buffer is full.

n During -INIT signal is at low level or during hardware initialization.

n During printer error (see -ERROR signal).

n When the parallel interface is not selected.

ERROR signal is at low level when the printer is in one of the following states:

n Printer hardware error (fatal error)

n Paper-out error

n Paper-jam error

n Ink-out error

PE signal is at high level during paper-out error.

Table 1-3.

Parameter Minimum Maximum

tsetup 500ns -

thold 500ns -

tstb 500ns -

tready 0 -

tbusy - 500ns

tt-out* - 120ns

tt-in** - 200ns

treply 0 -

tack 500ns 10us

tnbusy 0 -

tnext 0 -

* Rise and fall time of every output signal.

** Rise and fall time of every input signal.

*** Typical timing for tack is shown on the following page.

PRODUCT DESCRIPTION INTERFACE 13

Page 14

EPSON Stylus COLOR 860/1160 Revision C

Table 1-4. Typical Time of tack

Parallel I/F Mode Typical Time of tack

High Speed 1us

Normal Speed 3us

Table 1-5. Signal Level: TTL Compatibl e (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5V

VOL* -0.5V -

IOH* - 0.32mA VOH = 2.4V

IOL* - 12mA VOL = 0.4V

CO - 50pF

VIH - 2.0V

VIL 0.8V -

IIH - 0.32mA VIH = 2.0V

IIL - 12mA VIL = 0.8V

CI - 50pF

* A low logic level on the Logic H signal is 2.0V or less when the printer

is powered off, and this signal is equal to or exceeding 3.0V when the

printer is powered on. The receiver shall provide an impedance

equivalent to 7.5K ohm to ground.

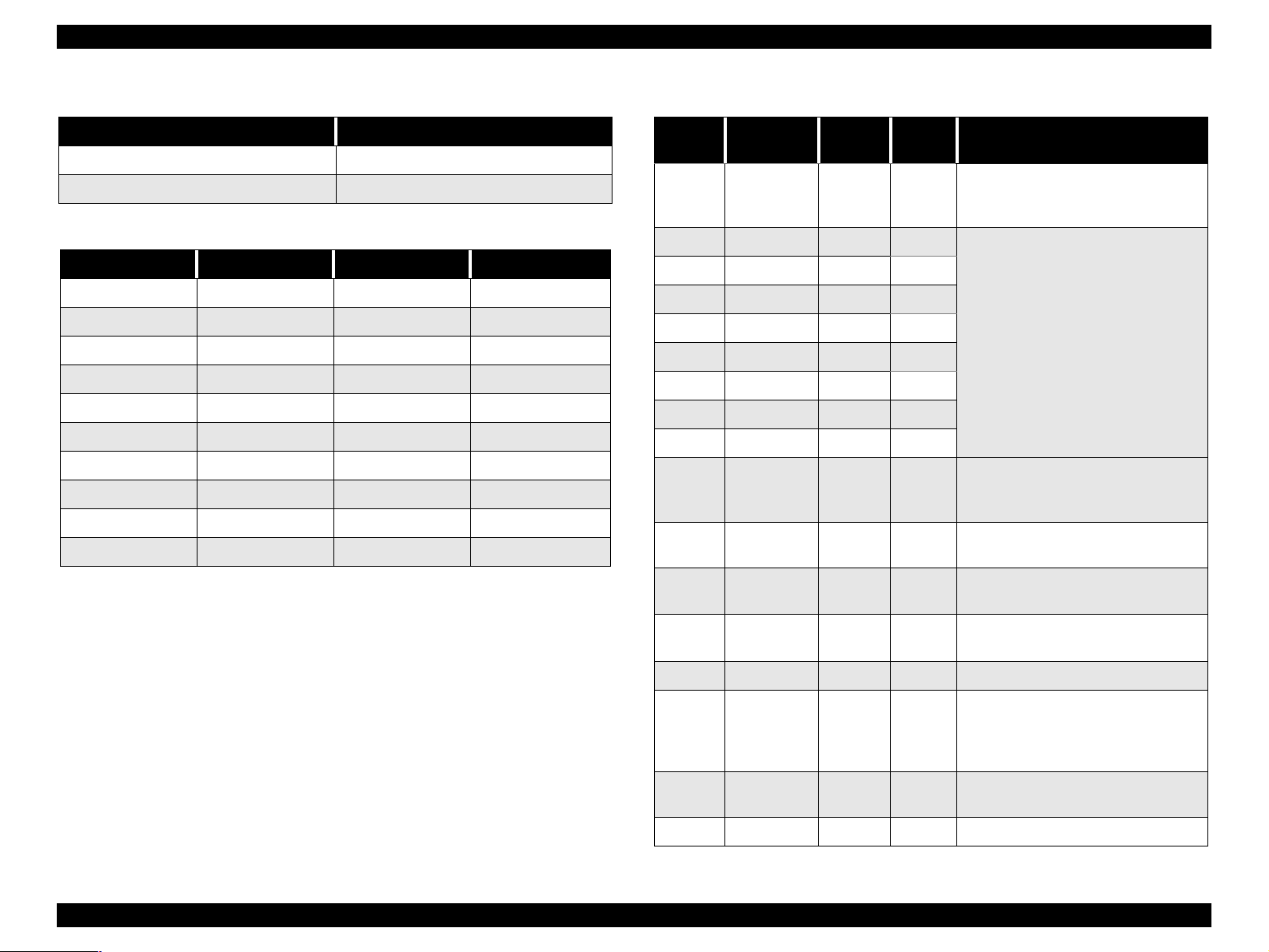

Table 1-6. Connector Pin Assignment and Signals

Pin No.

1 -STROBE 19 In

2 DATA0 20 In

3 DATA1 21 In

4 DATA2 22 In

5 DATA3 23 In

6 DATA4 24 In

7 DATA5 25 In

8 DATA6 26 In

9 DATA7 27 In

10 -ACKNLG 28 Out

11 BUSY 29 Out

12 PE 28 Out

13 SLCT 28 Out

Signal

Name

Return

GND Pin

In/Out Functional Descri ption

The strobe pulse. Read-in of data is

performed at the falling edge of this

pulse.

The DATA0 through DATA7 signals

represent data bits 0 to 7,

respectively.

Each signal is at high lev el when data

is logical 1 and low le vel whe n data is

logical 0.

This signal is a negative pulse

indicating that the printer can accept

data again.

A high signal indic ates that the printer

cannot receive data.

A high signal indicates paper-out

error.

Always at high level when the printer

is powered on.

14 -AFXT 30 In Not used.

The falling edge of a negative pulse

31 -INIT 30 In

32 -ERROR 29 Out

36 -SLIN 30 In Not used.

or a low signa l on this l ine c auses the

printer to initialize. Minimum 50us

pulse is necessary.

A low signal indicates printer error

condition.

PRODUCT DESCRIPTION INTERFACE 14

Page 15

EPSON Stylus COLOR 860/1160 Revision C

Table 1-6. Connector Pin Assignment and Signals (continued)

Pin No.

18 Logic H - Out

35 +5V - Out

17

16,33,

19-30

15,34 NC - - Not connected

Signal

Name

Chassis

GND

GND - - Signal GND

Return

GND Pin

- - Chassis GND

In/Out Functional Description

Pulled up to +5V via 3.9 K ohm

resistor.

Pulled up to +5V via 3.3K ohm

resistor.

NOTE: In/Out refers to the direction of signal flow seen from the printer

side.

PRODUCT DESCRIPTION INTERFACE 15

Page 16

EPSON Stylus COLOR 860/1160 Revision C

1.3.2 Parallel Interface (Reserve Channel)

Transmission Mode: IEEE-1284 nibble mode

Adaptable Connector See forward channel.

Synchronization: Refer to the IEEE-1284 specification

Handshaking: Refer to the IEEE-1284 specification

Data Trans. Timing: Refer to the IEEE-1284 specification

Signal Level: IEEE-1284 level 1 device

See forward channel.

Table 1-7. Connector Pin Assignment and Signals

Pin No.

1 HostClk 19 In Host clock signal.

2 DATA0 20 In

3 DATA1 21 In

4 DATA2 22 In

5 DATA3 23 In

6 DATA4 24 In

7 DATA5 25 In

8 DATA6 26 In

9 DATA7 27 In

10 PtrClk 28 Out Printer clock signal.

11

Signal

Name

PtrBusy /

DataBit-3,7

Return

GND Pin

29 Out

In/Out Functional Description

The DATA0 through DATA7 signals

represent data bits 0 to 7,

respectively.

Each signal is at high level when data

is logical 1 and low level when data is

logical 0.

These signals are used to transfer

the 1284 extensibility request values

to the printer.

Printer busy signal and reverse

channel transfer data bit 3 or 7.

Table 1-7. Connector Pin Assignment and Signals (continued)

Pin No.

32

36 1284-Active 30 In 1284 active signal.

18 Logic-H - Out

35 +5V - Out

17

16,33,

19-30

15,34 NC - - Not connected

Note) In/Out refers to the direction of signal flow from the printer’s point of view.

Signal

Name

-DataAvail /

DataBit-0,4

Chassis

GND

GND - - Signal GND

Extensibility Request:

The printer responds affirmatively when the extensibility request values are

00H or 04H, which means,

00H: Request Nibble Mode Reverse Channel Transfer.

04H: Request Device ID;

Return Data Using Nibble Mode Rev Channel Transfer.

Return

GND Pin

29 Out

- - Chassis GND

In/Out Functional Description

Data available signal and reverse

channel transfer data bit 0 or 4.

Pulled up to +5V via 3.9K ohm

resistor.

Pulled up to +5V via 3.3K ohm

resistor.

12

13

14 HostBusy 30 In Host busy signal.

31 -INIT 30 In Not used.

AckDataReq

/ DataBit-2,6

Xflag /

DataBit-1,5

28 Out

28 Out

Acknowledge data request signal

and reverse channel tran sfer data bit

2 or 6.

X-flag signal and reverse channel

transfer data bit 1 or 5.

PRODUCT DESCRIPTION INTERFACE 16

Page 17

EPSON Stylus COLOR 860/1160 Revision C

Device ID:

The printer sends the following device ID string when requested.

When IEEE1284.4 is enabled,

[00H] [5AH] (for Stylus Color 860)

[00H] [5CH] (for Stylus Color 1160)

MFG: EPSON;

CMD: ESCPL2, BDC, D4;

MDL: Stylus[SP]COLOR[SP]860/1160;

CLS: PRINTER;

DES: EPSON[SP]Stylus[SP]COLOR[SP]860/1160;

When IEEE1284.4 is disabled,

[00H] [57H] (for Stylus Color 860)

[00H] [59H] (for Stylus Color 1160)

MFG: EPSON;

CMD: ESCPL2, BDC;

MDL: Stylus[SP]COLOR[SP]860/1160;

CLS: PRINTER;

DES: EPSON[SP]Stylus[SP]COLOR[SP]860/1160;

NOTE 1:[00H] denotes a hexadecimal value of zero.

NOTE 2:MDL value depends on the EEPROM setting.

NOTE 3:CMD value depends on the IEEE1284.4 setting.

1.3.3 USB Interface

Standard: Based on:

“Universal Serial Bus Specifications Rev. 1.0”

“Universal Serial Bus Device Class Definition

for Printing Devices Version 1.0”

Bit Rate: 12Mbps (Full Speed Device)

Data Encoding: NRZI

Adaptable Connector: USB Series B

Recommended Cable Length: 2 meters

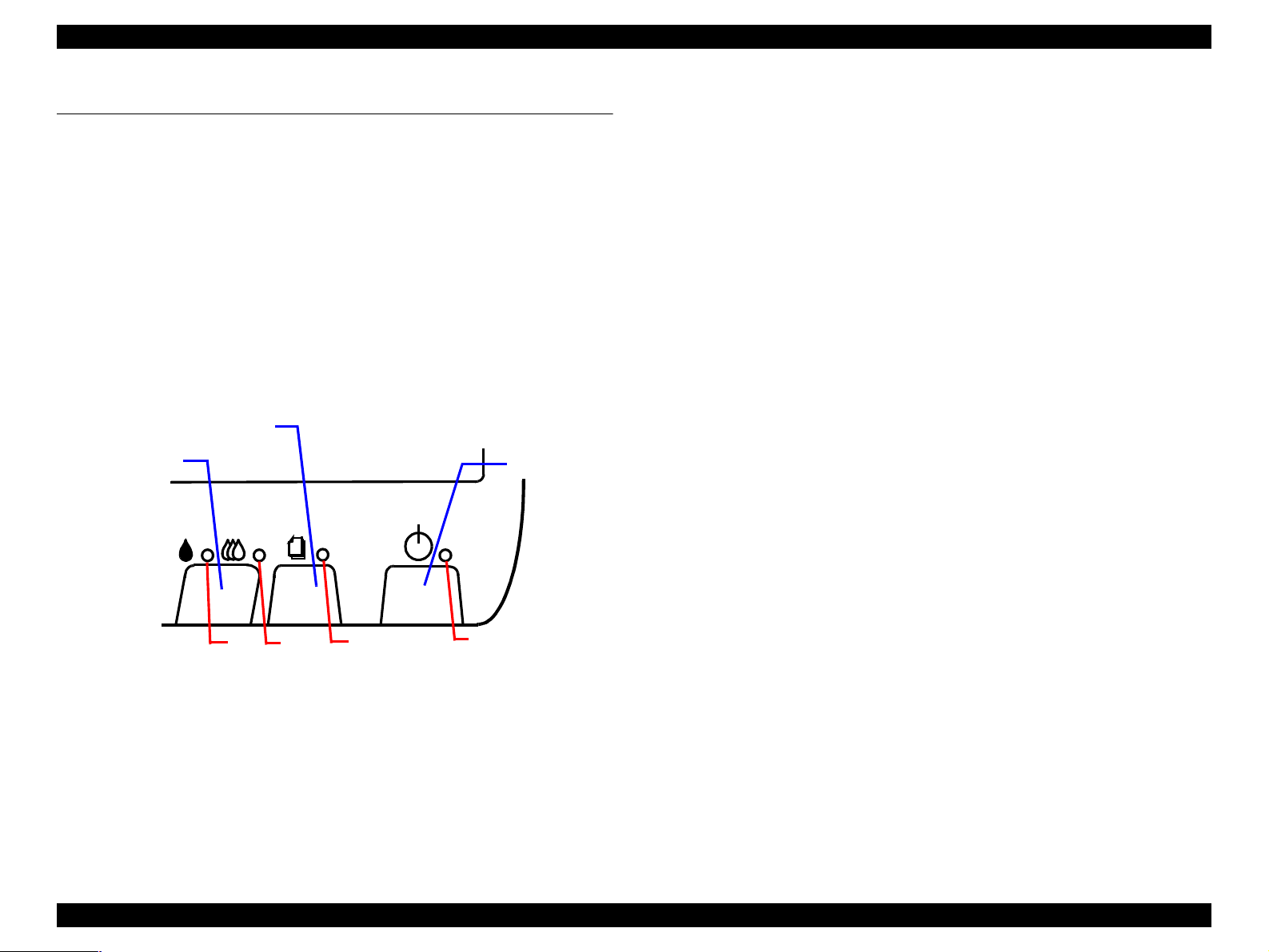

Table 1-8. Connector Pin Assignment and Signals

Pin No. Signal Name I/O Function Description

1VCC -

2 -Data Bi-D Data

3+DataBi-D

4 Ground - Cable ground

Pin #2

Cable power. Max. power consumption is

2mA.

Data, pull up to +3.3 V via 1.5K ohm

resistor.

Pin #1

Pin #3

Pin #4

Figure 1-3. USB Pin Assignment

PRODUCT DESCRIPTION INTERFACE 17

Page 18

EPSON Stylus COLOR 860/1160 Revision C

1.3.4 Prevention of Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when the peripheral is in

the busy state for dozens of seconds continuously. To prevent this kind of timeout, the printer receives data very slowly, several bytes per minute, even if the

printer is in the busy state. The slowdown starts when the remaining input

buffer becomes several hundreds of bytes, and the printer finally gets into the

busy state continuousl y when the input buffe r is full.

USB and IEEE1284.4 on the parallel interface do not require such function.

1.3.5 Interface Selection

The printer has two built-in interfaces: the USB and parallel interface.

These interfaces are selected automatically.

o Automatic Selection

In this automatic interface selection mode, the printer is initialized to the

idle state while scanning which interface receives data when it is powered

on. Then the interface which received data first is selected. When the host

stops data transfer and the printer is in the stand-by state for seconds, the

printer is returned to the idle state. As long as the host sends data or the

printer interface is in the busy state, the selected interface is let as it is.

o Interface State and Interface Selection

When the parallel interface is not selected, the interface gets into the busy

state. When the printer is initialized or returned to the idle state, the parallel

interface gets into the ready state. Note that the interrupt signal such as the

-INIT signal on the parallel interface is not effective while that interface is

not selected.

o Automatic Selection

An initial state is compatible interface and starts IEEE1284.4

communication when magic strings (1284.4 synchronous commands) are

received.

o On

An initial state is IEEE1284.4 communication and data that received it by

the time it is able to take synchronization by magic string (1284.4

synchronous commands) is discarded.

o Off

An initial state is compatible interface and never starts IEEE1284.4

communication even if magic strings (1284.4 synchronous commands) are

received.

1.3.6 IEEE1284.4 Protocol

The packet protocol described by IEEE1284.4 standard allows a device to

carry on multiple exchanges or conversations which contain data and/or control

information with another device at the same time across a single point-to-point

link. The protocol is not, however, a device control language. It does provide

basic transport-level flow control and multiplexing services. The multiplexed

logical channels are independent of each other and blocking of one has no

effect on the others. The protocol operates over IEEE1284.

PRODUCT DESCRIPTION INTERFACE 18

Page 19

EPSON Stylus COLOR 860/1160 Revision C

1.4 OPERATOR CONTROLS

1.4.1 Operating Switch

Operating switch is located on the control panel.

1.4.2 Control Panel

1.4.2.1 Switches

There are two non-lock type push switches, one lock-type push switch, and

four LED lights.

Load/Eject

Cleaning

Power

1.4.2.2 Indicators

(1) Power

Lights when the operating switch is “ON” and AC power is supplied.

(2) Paper Out

Lights during the paper-out condition, and blinks during the paper-jam

condition.

(3) Ink Out (Black)

Lights during no black ink condition, and blinks during the black

ink low condition.

(4) Ink Out (Color)

Lights during no color ink condition, and blinks during the color ink low

condition.

3

Figure 1-4. Control Panel

PRODUCT DESCRIPTION OPERATOR CONTROLS 19

4

2

1

Page 20

EPSON Stylus COLOR 860/1160 Revision C

1.4.3 Panel Functions

Table 1-9. Panel Functions

Switch Function

Load / Eject

(Push for less than

2 sec.*)

Load / Eject

(Push for 2 sec.*)

Cleaning

(Push for 2 sec.*)

Cleaning

(Push for less than

2 sec.*)

* It is described in the user’s manual that three seconds are

required.

**This function is not available in printing status.

• Loads or ejects a paper.

• When the carriage is on the ink cartridge replacement

position, return the carriage to the capping position.

• Starts the ink cartridge replacement sequence.**

• Moves the carriage to the cartridge replacement position.

• Starts cleaning of the printhead.

• In the condition of “In k Low”, “Ink Out” , or “No I nk Cartridge ”,

starts the ink cartridge replacement sequence.**

• When the carriage is on the ink cartridge replacement

position, return the carriage to the capping position.

Table 1-10. Panel Function with Power On

Switch Pressing with Power On Function

Load / Eject

Cleaning

Load/Eject

+

Cleaning

*1: One of the following actions is carried out according to the content of

1BH of EEPROM.

Content of 1BH of

EEPROM, [bit7] [bit6]

*2: Not described in the user’s manual.

*3: See the table below.

• 1) Starts status printing. *1

• Changes code pages / Selec t IEEE1284.4 mode fo r parallel

I/F. *2

• Enters the special settings mode. (Factory use only). *3

Action

00

11

01 Start hex-dump printing.

10 Start self test printing.

Print firmware version, ink counter, selected

code page and nozzle check pattern.

Table 1-11. Special Setting Mode

Switch Function

Load / Eject

Cleaning

(Push for 10 seconds)

• Initialize EEPROM and reset timer IC.

• Reset the ink overflow counter in EEPROM.

PRODUCT DESCRIPTION OPERATOR CONTROLS 20

Page 21

EPSON Stylus COLOR 860/1160 Revision C

1.4.4 Printer Condition and Panel Status 1.4.5 Printer Initialization

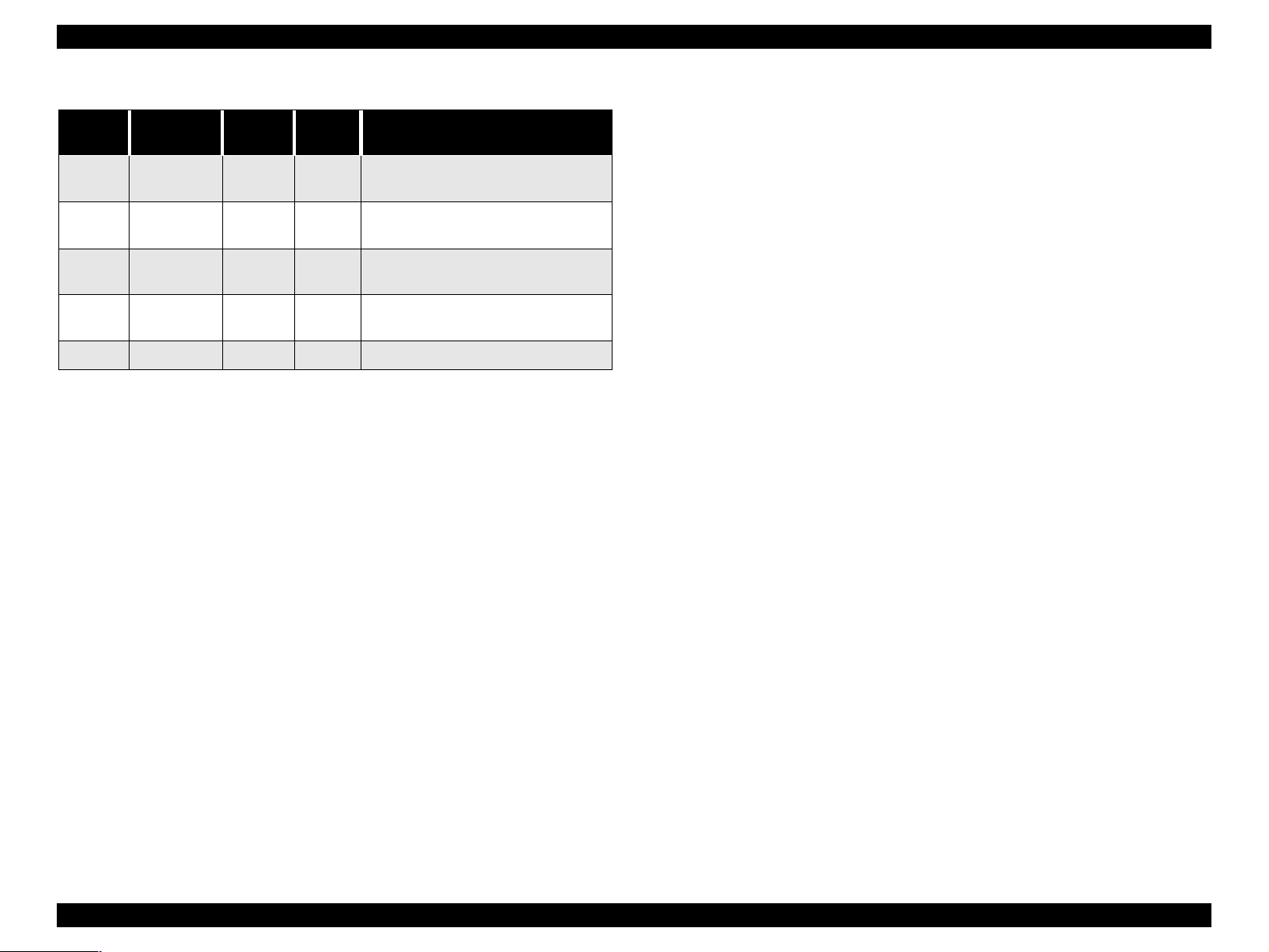

Table 1-12. Printer Condition and LED Status

Indicators

Printer Status

Power On Condition On - - - 9

Ink Sequence Blink - - - 6

Ink Cartridge

Replacement Mode

Data Processing Blink - - - 8

Paper Out - - - On 4

Paper Jam Condition - Off Off Blink 3

No Ink Cartridge /

Ink End (Black)

Ink Level Low (Black) - Blink - - 7

No Ink Cartridge or

Ink End (Color)

Ink Level Low (Color) - - Blink - 7

Enter EEPROM and

Timer IC Reset

Maintenance

Request

Fatal Error Blin k On On Blink 1

Power

Blink - - - 5

-On- -7

--On-7

- ON (for 1 second only) -

Blink Blink Blink Blink 2

Ink Out

(Black)

Ink Out

(Color)

Paper Out

Priority

There are three kinds of initialization methods, and the following explains each

initialization.

1. Power-on Initialization

This printer is initialized when turning the pri nte r power on, or prin ter

recognized the cold-reset command (remote RS command).

When printer is initialized, the following actions are performed:

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears print buffer.

(d) Sets default values.

2. Operator Initialization

This printer is initialized when turning the printer power on again within 10

seconds from last power off, or printer recognized the -INIT signal

(negative pulse) of parallel interfac e.

When printer is initialized, the following actions are performed:

(a) Cap the printer head.

(b) Eject a paper.

(c) Clears input data buffer.

(d) Clears print buffer.

(e) Sets default values.

3. Software Initialization

The ESC@ command also initializ e the printer.

When printer is initialized, the following actions are performed:

(a) Clears print buffer.

(b) Sets default values.

PRODUCT DESCRIPTION OPERATOR CONTROLS 21

Page 22

EPSON Stylus COLOR 860/1160 Revision C

1.4.6 Errors

o Ink Out

When the printer runs out most of the ink of any color, it indicates ink-low

and keeps printing. When the printer runs out the whole ink of any color, it

stops printing and indicates ink-out error. User is then requested to install a

new ink-cartridge in this state. An ink-cartridge that has been taken out

once should never be used again. Re-installation of the cartridge not filled

fully upsets the ink level detection and may eventually cause a serious

problem in the print head.

o Paper Out

When the printer fails to load a sheet, it goes into a paper out error.

o Paper Jam

When the printer fails to eject a sheet, it goes into a paper jam error.

o No Ink-Cartridge

When the printer detects that ink-cartridge comes off, it goes into this error

mode.

o Maintenance Request

When the total amount of ink wasted through cleanings and flushing

reaches to the limit, printer indicates this error and stops. In such a case,

the absorber in the printer enclosure needs to be replaced with new one by

service personnel.

o Fatal Errors

Carriage control error or CG access error.

PRODUCT DESCRIPTION OPERATOR CONTROLS 22

Page 23

EPSON Stylus COLOR 860/1160 Revision C

1.5 PAPER

1.5.1 Paper Handling

Do not perform reverse feed more than 9.5mm (0.38”).

1.5.2 Paper Specification

1.5.2.1 Cut Sheet

[Size]

For Stylus Color 860/1160:

A4: Width 210mm (8.3”) x Length 297mm (11.7”)

Letter: Width 216mm (8.5”) x Length 279mm (11.0”)

B5: Width 182mm (7.2”) x Length 257mm (10.1”)

Legal: Width 216mm (8.5”) x Length 356mm (14.0”)

Statement: Width 139.7mm (5.5”) x Length 215.9mm (8.5”)

Executive: Width 184.2mm (7.25”) x Length 266.7mm (10.5”)

Photo Paper: Width 101.6mm (4”) x Length 152.4mm (6”)

For Stylus Color 1160 only:

A3: Width 297mm (11.7”) x Length 420mm (16.5”)

A3+: Width 329mm (13.0”) x Length 483mm (19.0”)

1.5.2.2 Transparency, Glossy Paper

[Size]

For Stylus Color 860/1160:

A4: Width 210mm (8.3”) x Length 297mm (11.7”)

Letter: Width 216mm (8.5”) x Length 279mm (11.0”)

For Stylus Color 1160 only:

A3+: Width 329mm x Length 483mm (Glossy Paper)

[Thickness]

0.075mm (0.003”) - 0.085mm (0.0033”)

*Transparency printing is available only at normal temperature.

1.5.2.3 Envelope

[Size]

No.10: Width 241mm (9 1/2”) x Length 104.8mm (4 1/8”)

DL: Width 220mm (8.7”) x Length 110mm (4.3”)

C6: Width 162mm (6.4”) x Length 114mm (4.5”)

[Thickness]

0.16mm (0.006”) - 0.52mm (0.02”)

[Thickness]

0.08mm (0.003”) - 0.11mm (0.004”)

[Weight]

2

64g/m

[Quality]

Exclusive paper, Bond paper, PPC

(17Ib.) - 90g/m2 (24Ib.)

[Weight]

45g/m2 (12Ib.) - 75g/m2 (20Ib.)

[Quality]

Bond paper, Plain paper, Air mail

Note1: Envelope printing is available only at normal temperature.

Note 2: Keep the longer side of the envelope horizontally at setting.

PRODUCT DESCRIPTION PAPER 23

Page 24

EPSON Stylus COLOR 860/1160 Revision C

1.5.2.4 In dex Card

[Size]

A6 Index Card: Width 105mm (4.1”) x Length 148mm (5.8”)

A5 Index Card: Width 148mm (5.8”) x Length 210mm (8.3”)

5 x 8” Index Card: Width 127mm (5.0” x Length 203mm (8.0”)

10 x 8” Index Card: Width 127mm (5.0”) x Length 203mm (8.0”)

[Thickness]

Less than 0.23mm (0.0091”)

PRODUCT DESCRIPTION PAPER 24

Page 25

EPSON Stylus COLOR 860/1160 Revision C

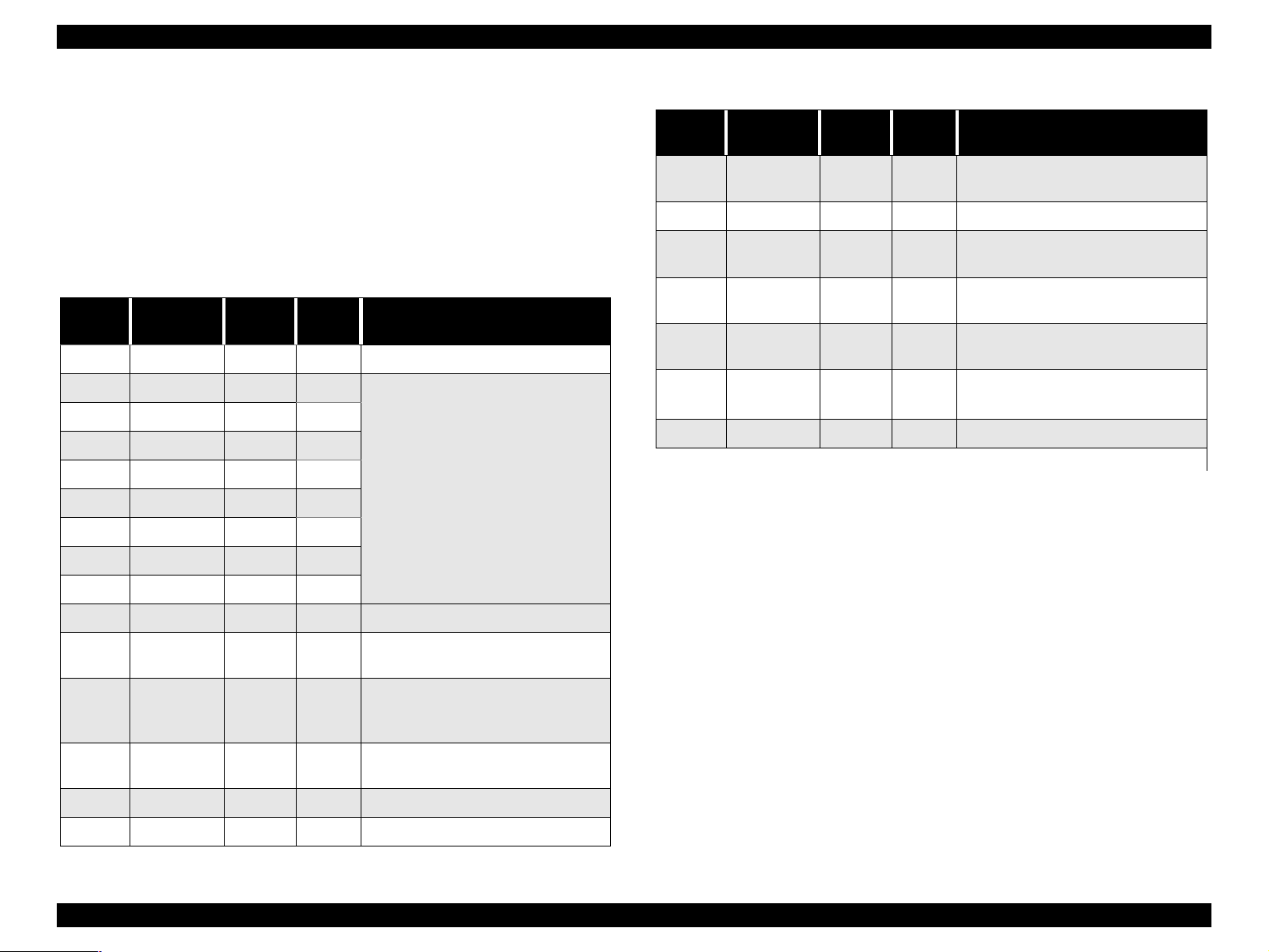

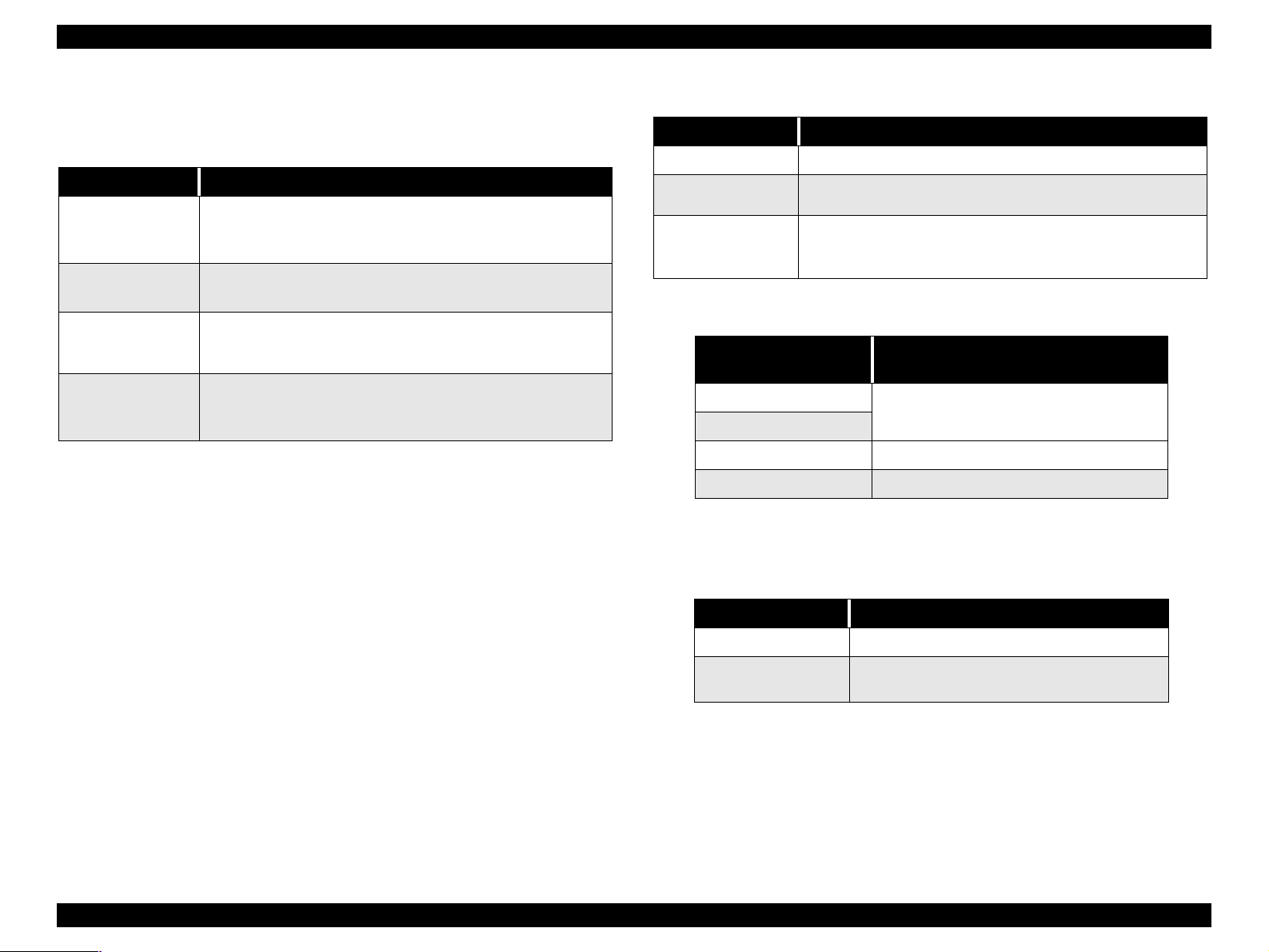

1.5.3 Printing Area

1.5.3.1 Cut Sheet

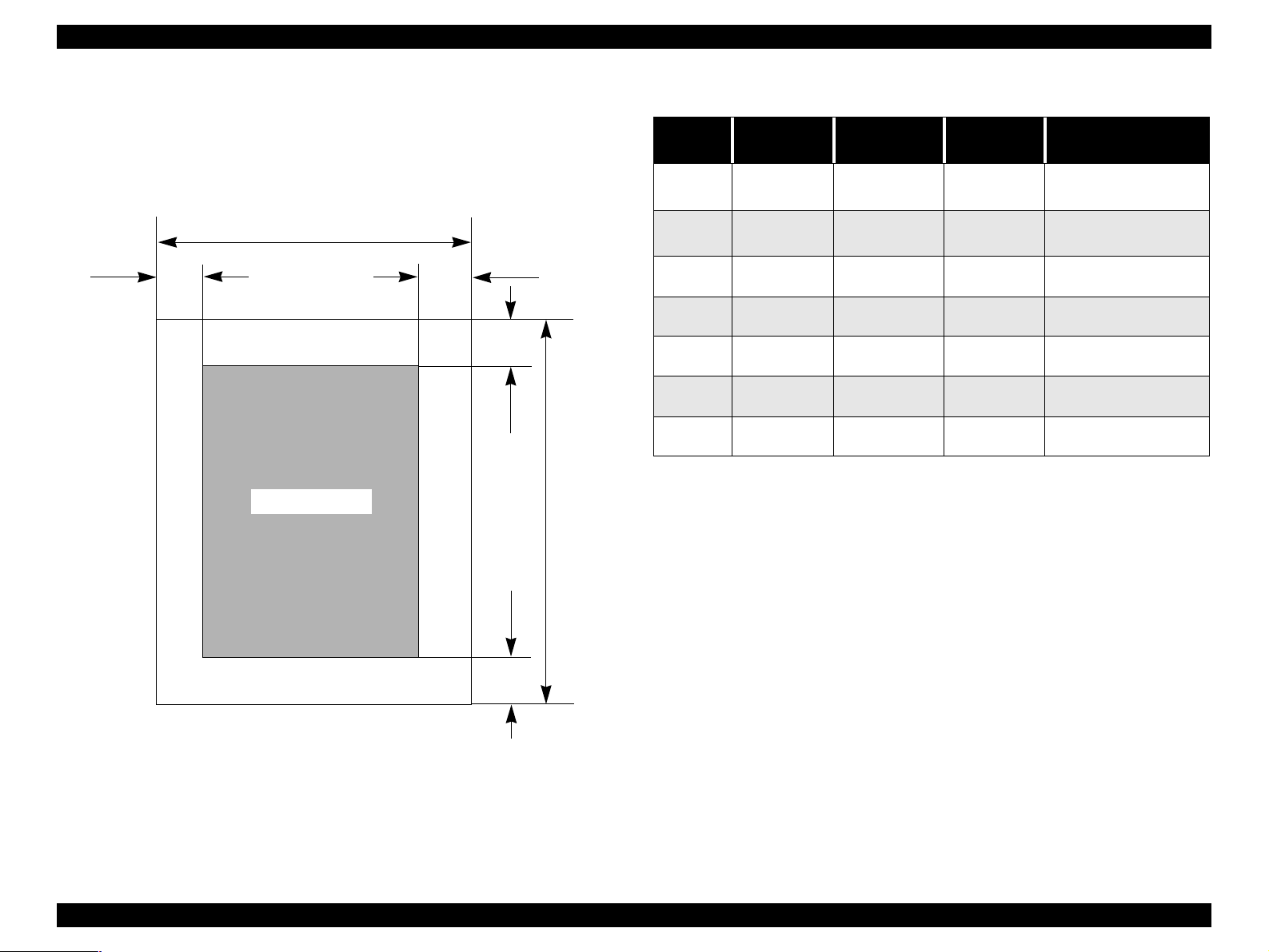

See the figure below and tables on the right for printable areas for Raster

Graphics mode and Character mode.

PW

LM

Printable Area

RM

TM

PL

Table 1-13. Character Mode

Paper

Size

A3 (*1) 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

A4 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Letter 3mm (0.12”) 9mm (0.35”) 3mm (0.12”)

B5 3mm (0.12”) 3 m (0.12”) 3mm (0.12”)

Legal 3mm (0.12”) 9mm (0.35”) 3mm (0.12”)

Statement 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Executive 3mm (0.12”) 3mm (0.12”) 3mm (0.12”)

Left Margin

(min.)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

(min.)

14mm (0.54”) /3mm

(0.12”) (*2)

14mm (0.54”) /3mm

(0.12”) (*2)

14 mm (0.54”) / 3mm

(0.12”) (*2)

14 mm (0.54”) / 3mm

(0.12”) (*2)

14 mm (0.54”) / 3mm

(0.12”) (*2)

14 mm (0.54”) / 3mm

(0.12”) (*2)

14 mm (0.54”) / 3mm

(0.12”) (*2)

BM

Figure 1-5. Printable Area for Cut Sheet

PRODUCT DESCRIPTION PAPER 25

Page 26

EPSON Stylus COLOR 860/1160 Revision C

Table 1-14. Raster Graphics Mode

Paper

Size

A3* 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

A3+* 3 mm (0.12 ”) 3 mm (0.12”) 3 mm (0.12”)

A4 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Letter 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

B5 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Legal 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Statement 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Exclusive 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

* For Stylus Color 1160 only.

** Bottom margin can be reduced to 3mm when paper dimension is

*** Refer to 1.5.2 Paper Specification for PW (paper width) and PL

Left Margin

(min.)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

(min.)

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

14 mm (0.54”) / 3mm

(0.12”) **

defined by using command, otherwise it is not reduced (14mm). As for

an area between 3mm and 14mm margin, printing quality may decline.

(paper length).

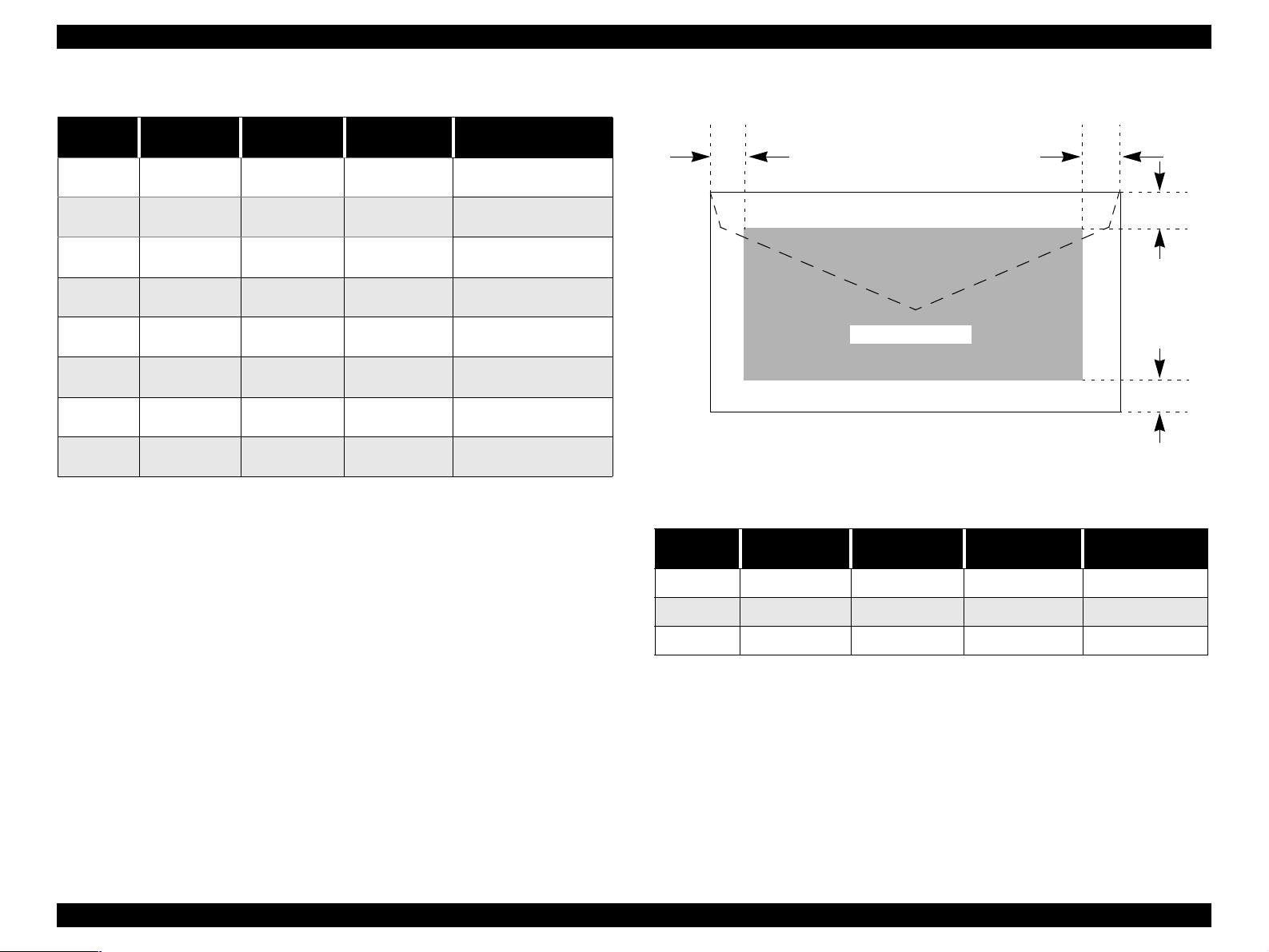

1.5.3.2 Envelopes

LM

Printable Area

Figure 1-6. Printable Area for Envelopes

Table 1-15. Envelope Margin

Size

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.55”)

DL 3 m m (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.55”)

Left Margin

(min.)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

RM

TM

BM

(min.)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.55”)

PRODUCT DESCRIPTION PAPER 26

Page 27

EPSON Stylus COLOR 860/1160 Revision C

1.6 INK CARTRIDGE

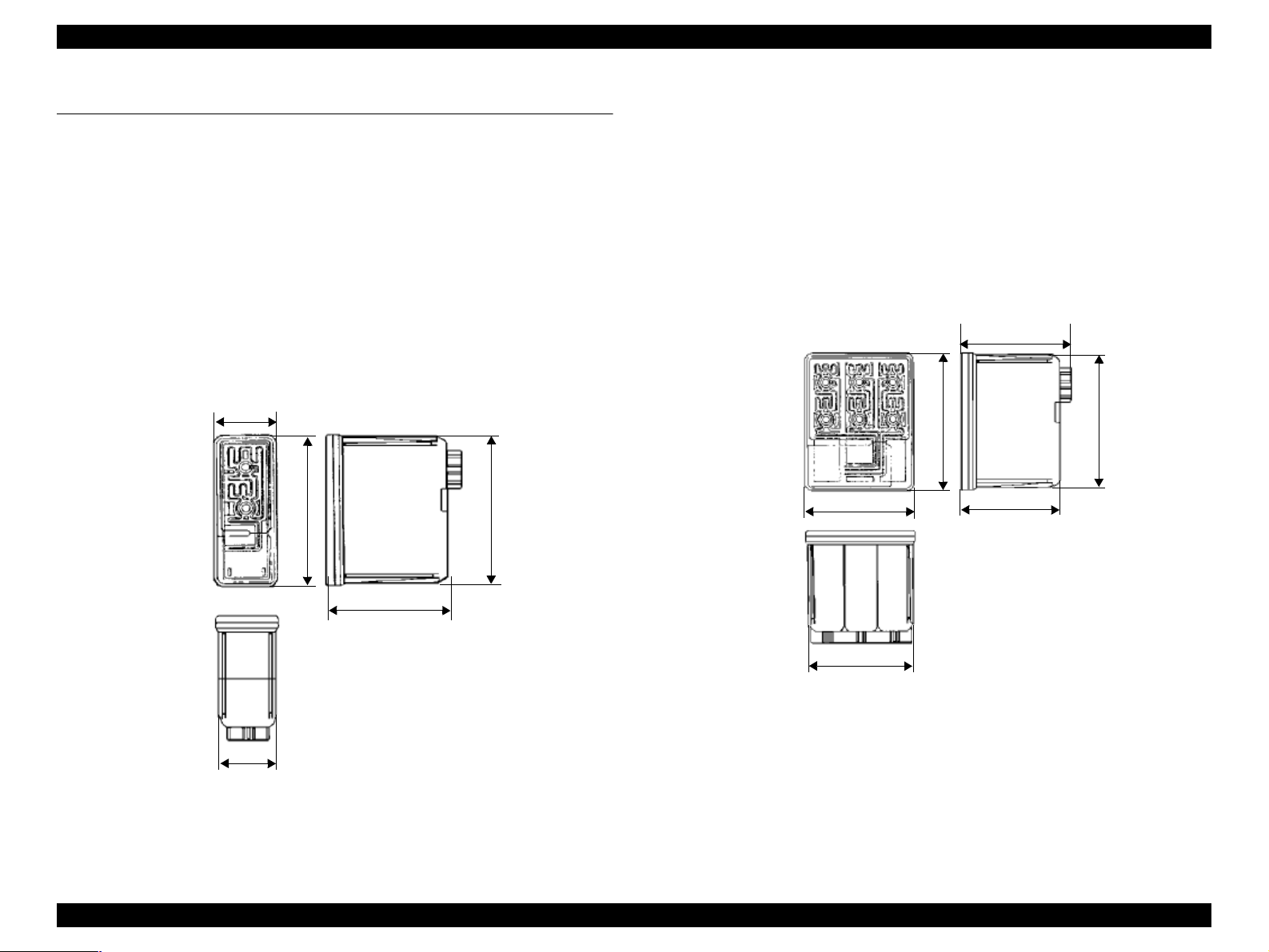

1.6.1 Black Ink Cartridge

Type: Exclusive Cartridge

Color: Black

Print Capacity: 900 pages/A4

(ISO/IEC 10561 Letter Pattern at 360 dpi)

Ink Life: 2 years from date of production

Storage Temperature:

Storage: -20

Packing: -30

Transit: -30

Dimension: 27.8 mm (W) x 52.7 mm (D) x 38.5 mm (H)

27.8

o

C to 40 oC (within a month at 40 oC)

o

C to 40 oC (within a month at 40 oC)

o

C to 60 oC (within 120 hours at 60 oC

and within a month at 40

52.7

o

C)

51.2

1.6.2 Color Ink Cartridge

Type: Exclusive Cartridge

Color: Magenta, Cyan, Yellow

Print Capacity: 300 pages / A4 (360 dpi, 5% duty each color)

Ink Life: 2 years from date of production

Storage Temperature:

Storage: -20

Packing: -30

Transit: -30

Dimension: 42.9 mm (W) x 52.7 mm (D) x 38.5 mm (H)

o

C to 40 oC (within a month at 40 oC)

o

C to 40 oC (within a month at 40 oC)

o

C to 60 oC (within 120 hours at 60 oC

and within a month at 40

52.7

42.9

43.2

38.5

o

C)

51.2

38.5

41.4

Figure 1-8. Color Ink Cartridge

26.3

Figure 1-7. Black Ink Cartridge

Note 1: Ink cartridge can not be refilled. The ink cartridge is prepared only

for article of consumption.

Note 2: Do not use the ink cartridge which contains life-expired ink.

Note 3: Ink will be frozen under -4

o

C environment; however, it will be

usable after being left at room temperature for more than three

hours.

PRODUCT DESCRIPTION INK CARTRIDGE 27

Page 28

OPERATING PRINCIPLES

CHAPTER

Page 29

EPSON Stylus COLOR 860/1160 Revision C

2.1 Overview

This section describes the operating principles of the printer mechanism and

electrical circuit boards. The EPSON Stylus COLOR 860/1160 has the

following boards:

o

Main board: C298MAIN Board (Stylus COLOR 860/1160)

o

Power supply board: C298PSB/PSE Board (Stylus COLOR 860/1160)

o

Panel board: C298PNL Board (Stylus COLOR 860)

C304PNL Board (Stylus COLOR 1160)

2.1.1 Printer Mechanism

Unlike other EPSON ink jet printers, the

motor for power source. Use of the DC motor enable the printer to lower noise

during printing to a great extent. Table 2-1 shows the various motor types used

in the printer and their applications.

Table 2-1. Motor Types and Corresponding Applications

Motor Name Type Application / Feature

CR Motor DC with brush

PF Motor DC with brush

Pump/ASF

4-Phase 48-pole

stepping motor

Stylus COLOR 860/1160

Used to drive the carriag e maki ng littl e noise . A

a linear scale is used to monitor the motor’s

operating condition.

• Drives paper feeding rollers used to send

paper at specified speeds and load/eject

paper.

• CR lock lever operation

• To monitor paper feeding pitch, a loop scale

is attached beside the high-precision gear.

Like the Stylus COLOR 800 and Stylus Pro

5000, this motor manages pump drive and

paper loading from ASF.

Since this is a stepping motor, it has no scales

or photo sensors that are used to monitor the

motor’s operating condit ion .

uses DC

The basic structure of the printer mechanism is mostly common to the Stylus

COLOR 400/600/440/640/740, except that the Stylus COLOR 860/1160 uses a

Pump/ASF motor. With this motor equipped, the paper loading mechanism and

the pumping mechanisms are independently driven, which allows the printer to

offer higher throughput as a result.

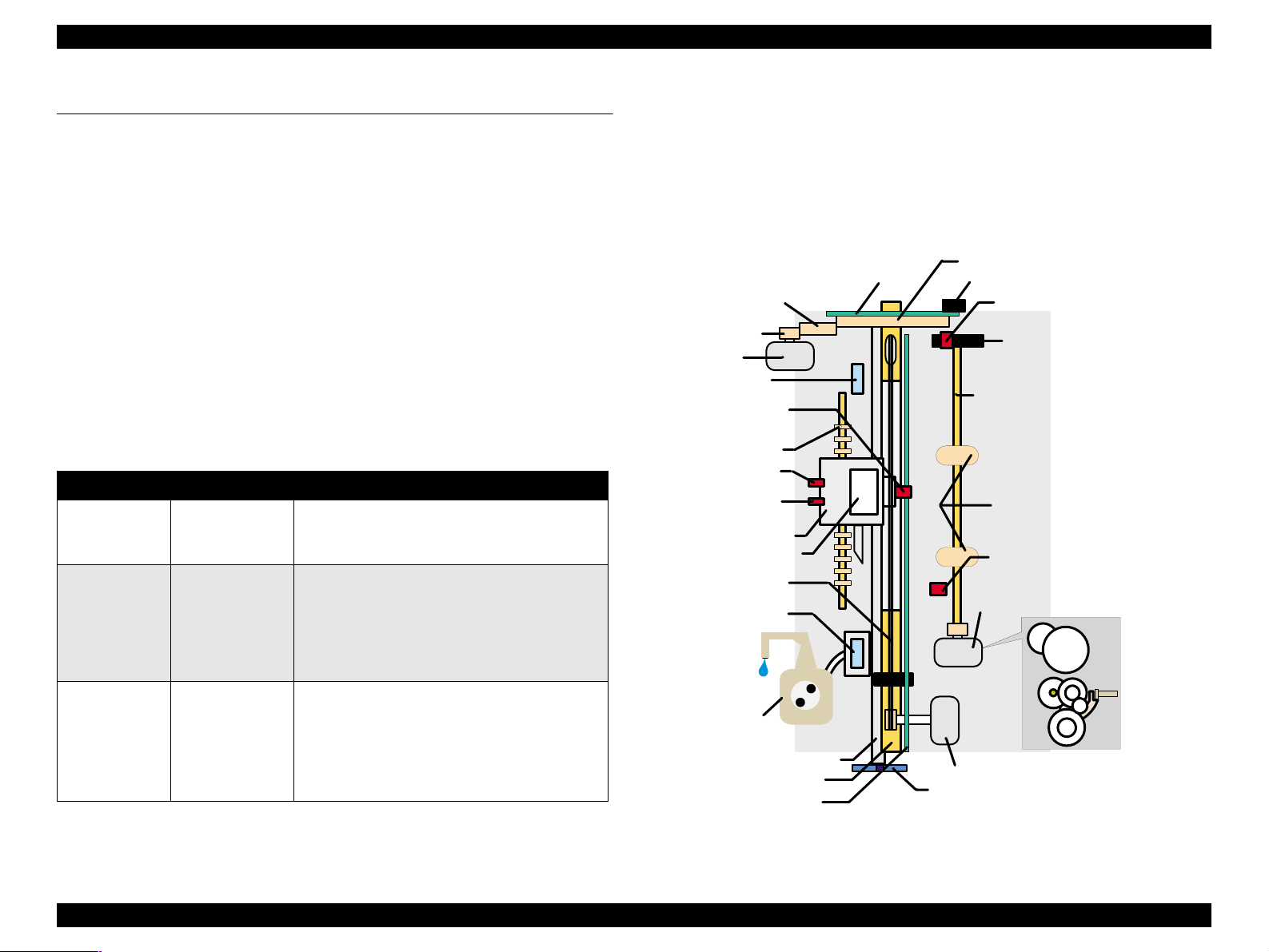

Figure 2-1 shows the printer mechanism block diagram for the Stylus COLOR

860/1160.

Loop Scale

Plain Gear

PF Motor Pinion

PF Motor

Flashing Window

(at 80th or 136th column)

Photo Interrupter

(Encoder for CR)

Star Wheel Roller

Bk I/C Sensor

CMY I/C Sensor

Carriage Unit

Printhead (one unit)

Timing Belt

Cap Unit

(without a valve)

Pump Unit

CR Guide Shaft

PF Roller

Liner Scale

PF Drive Gear

Encoder (PF)

ASF Sensor

Detector Wheel

Loading Shaft

Loading Rollers

PE Sensor

Pump/ASF Motor

(stepping motor)

CR Motor (DC motor)

PG Lever

Figure 2-1. Printer Mechanism Block Diagram

Operating Principles Overview 29

Page 30

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.1 P rinting Mechanism

The basic operating principles of the printhead, which plays a major role in

printing, are the same as previous models; ones that use a on-demand type UCHIP head method. (Refer to Figure1-1.)

Also, unlike the Stylus Color IIs, 820 and 200, the Stylus COLOR 860/1160 is

not an automatic correction type. So, in order to correct dispersion of multi

layer piezo electric element that drives each nozzle, you are required to input a

VH value written on the top surface of the printhead by using an exclusive

program when you replace the printhead, control board, or printer mechanism.

(Note there are no resistor arrays to determine the VH voltage on the main

control board.) Following explains printhead.

o PZT

PZT is an abbreviation of Piezo Electric Element. Print signals from the

Main board are sent through the driver board on the printhead unit to the

PZT. Then, the PZT pushes the top cavity whic h has ink sto red to

discharge the ink from each nozzle on the nozzle plate.

o Cavity Set

The ink absorbed from the ink cartridge goes through the filter and then is

stored temporarily in this tank called “cavity” until PZT is driven.

I/C Sensor Actuator

Nozzle Plate

PZT

Nozzle Selector Board

Ink Cartridge

Needle

Filter

Cavity

o Nozzle Plate

Figure 2-2. Printing Mechanism

The board with nozzle holes on the printhead surface is called Nozzle

Plate.

o Filter

When the ink cartridge is installed, if any dirt or dust around the cartridge

needle is absorbed into the head, there is a great possibility of causing

nozzle clog and disturbance of ink flow, and finally causing alignment

failure and dot missing. To prevent this problem, a filter is set below the

cartridge needle, where ink is filtered.

Operating Principles Overview 30

Page 31

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.2 P rinting Pro cess

Figure 2-3 and Figure 2-4 show the normal state and ejecting state of the

printhead, respectively.

1. Normal State:

When the print signal is not output, PTZ also does not move from a waiting

state (normal state). (Refer to Figure 2-3.)

2) Ejecting Stat e:

When the print signal is output from the C298MAIN board, IC (IR4C463S:

Nozzle Selector) located on the printhead unit latches data once by 1-byte

unit. An appropriate PZT latched by the nozzle selector is pushed into the

cavity by the common voltage applied from the main board. By this

operation, ink stored in the cavity spurts out from nozzles. (Refer to Figure

2-4.)

Ink Course Cavity

Figure 2-3. Print Head Normal State

PZT

Nozzle

Nozzle Plate

Figure 2-4. Print Head Ejecting State

Operating Principles Overview 31

Page 32

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.3 Carria ge Mechanism

The carriage mechanism for the Stylus COLOR 860/1160 is mostly the same

as for other ink jet printers except it is driven by a DC motor. See the table

below for the carriage motor specifications.

Table 2-2. Carriage Motor Specification

Items Specifications

Type DC Motor with brush

Drive Voltage +42 V +/- 5%(DRV IC voltage)

Internal Resistance 29.2 ohms +/- 25%

Inductance 30.8 mH +/- 25%

Drive Method Constant Current Chopping

Driver IC LB1947

Unlike a stepping motor, the DC motor that drives the carriage can not detect

the current carriage position by referring to the pulses given. Therefore, a linear

scale is attached along the carriage operation range to enable the printer to

mechanically detect the carriage position. The linear scale is also used to

produce the print timing signal (PTS signal), to which the printer refers to for a

correct ink ejection timing.

For detailed information on the CR motor control circuit, see Section 2.2.

Carriage Motor

PF Roller

Timing Belt

Carriage Unit

Front Side

Rear Side

Parallelism

Adjust Lever

The printhead, a core of the printing mechanism, is stored in the carriage unit.

When the adjustment lever is moved up and down, this printhead is maintained

tilt in a flexible and adjustable structure by the tilt adjustment mechanism.

Also, the parallelism adjustment levers, mounted on the left and right sides of

the carriage guide shaft, are used to set the carriage guide shaft parallel to the

platen when the shaft has been installed to the printer mechanism. After this

adjustment is completed, moving the PG adjustment lever sets the distance

between the platen surface and the printhead surface to one of two

possibilities: 1.14 mm or 1.84 mm. Moving the PG lever, you can rotate the

shafts of the carriage guide shaft which itself is decentralized to change the

distance. This is the mechanism that the user can use to adjust the appropriate

PG value according to the printing result or any other environmental conditions

such as thick paper.

Fixing

Bushing

Carriage

Guide Shaft

Eject Roller

Paper Guide (Front)

PF Motor

CR Lock Lever

Figure 2-5. Carriage Mechanism (Top view)

Operating Principles Overview 32

Page 33

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.4 Platen Gap (PG) Adjust Mechanism

The PG adjustment, at the left of the printer mechanism, consists of the PG

lever, PF support lever, right/left parallelism adjustment levers, and CR guide

shaft. The PG adjustment mechanism is designed to keep the platen gap

correct for the paper thickness to prevent ink from smearing. The PG lever

joins the CR guide shaft, which has an eccentricity via PG sub lever. Switching

the lever from “0” to “+” rotates the CR shaft and changes the platen gap from

narrow to wide.

Table 2-3. Platen Gap Adjust Lever Setting

Paper Lever Position PG adjustment value

All Media Front

If you find any print

problems or use thick

paper.

Rear

0 mm

(1.14 mm between head and platen)

0.7mm

(1.84 mm between head and platen)

2.1.1.5 Paper Feeding Mechanism

The paper feeding mechanism transports paper loaded from ASF using the PF

rollers and paper eject rollers. A new type of DC motor is used for the PF

motor. See the table below for the DC motor specifications.

Table 2-4. PF Motor Specifications

Item Description

Motor type DC Motor with Brush

Drive voltage +42V +/- 5% (DRV IC voltage)

Coil Resistance 31.1 ohm +/- 25%

Drive frequency [Hz] 26.6mH +/- 25%

Control method A3958

Unlike a stepping motor, the DC motor that drives the paper feeding

mechanism can not measure the paper feeding amount by referring to the

pulses given. For this reason, the loop scale and encoder sensor are directly

attached to the left end of the PF roller shaft to mechanically control paper feed

amount. See Section 2.2 for detailed information on the PF motor control

circuit.

Drive from the PF motor is sent to the PF rollers and paper eject rollers as

described below.

o To the PF rollers:

PF motor pinion gear

→ Spur gear (76) → PF rollers

o To the eject rollers:

PF motor pinion gear

Spur gear (28)

Figure 2-6 in the next page gives the paper feeding mechanism block diagram,

showing the parts along the PF motor drive transmission paths.

→ Spur gear (76) → Combination gear (13.5, 308) →

→ Paper eject rollers

Operating Principles Overview 33

Page 34

EPSON Stylus COLOR 860/1160 Revision C

Front Paper Guide

Eject Roller

PF Motor

Figure 2-6. Paper Feeding Mechanism

The printer loads paper at the ASF, which is detected by the PE sensor

attached to the right side of the top frame, and advances it to send the paper’s

leading edge to the halfway of the front paper guide. Then, to correct

deflection, the printer feeds the paper back specified steps toward ASF, and

advances the paper again toward the front paper guide and stops it at the

specified TOF (Top Of Form) position. Once the printer starts printing, it

transports paper using the PF rollers and sub rollers, and as the printer

transports or printing on the tailing 14 mm, it uses a star wheel gear and paper

eject rollers. Like the Stylus COLOR 440/640/740, this printer also provides

this extra printable range of 14 mm from the bottom edge, excluding the bottom

margin of 3mm, by changing the position of the star wheel gear; it has been

shifted by 5

this change, the tailing edge of paper is suppressed, and the printer can

advance paper steadily when printing around the bottom area. See Figure 2-7

next page that shows how paper is transported and parts involved.

° from the top of the eject roller toward the front paper guide. Due to

[Previous Models]

Star Wheel Assy.

Paper

Eject Roller

Printhead

Platen

[Stylus COLOR 860/1160]

Five Degrees

Figure 2-7. Paper Transportation

Support Roller

Bottom margin 3 mm touch es

the printhead surface.

Steady

PF Roller

Operating Principles Overview 34

Page 35

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.6 CR Lock Mechanism

The carriage lock mechanism prevents the carriage from being left at an

uncapped position for a long time, which is usually caused by vibration during

printer transportation, user’s mishandling of the printer, and so on.

The CR Lock mechanism is driven with the DC PF motor. For the motor

specifications, refer to the Table 2-4 . The PF motor drive is used for the Paper

Feed Mechanism also and the CR lock mechanism is controled depends on

the direction of the PF motor rotationa. The CR lock mechanism is assembed

on the right tip of the Paper Eject Roller as shown in the folloiwng figure.

Top view

Bushing 6

Paper Eject Roller

Figure 2-8. CR Lock mechanism

CR Lock Lev e r

Middle Frame

Right side view

CR unit

CR unit

The carriage lock mechanism prevents the carriage from being left at an

uncapped position for a long time, that is usually caused by vibration during

printer transportation, user’s mishandling of the printer, and so on. If the

carriage is left uncapped for a long time, ink on its surface will become

gradually thick and not spurt from the nozzles as a result.

To make matters worse, the holes (crater) of the nozzles may be completely

clogged by the thick ink, and they may not be able to return to a normal

condition just by a cleaning operation. To prevent this, the printer enters a

carriage lock condition in the foll owi ng condi tio ns .

o After Power-off operation:

If the printer power is turned off in the middle of printing or any other

performances, carriage lock takes place in the end after an initialization

operation.

o After Power-on operation:

After the printer power is turned on and an automatic power-on cleaning is

completed, carriage lock is performed. The power-on cleaning is an

automatic head cleaning that runs when the printer power is turned on. The

timer IC always calculates printer’s power off time using power from a

lithium battery mounted on the C298MAIN board. The power-on cleaning

function automatically selects a correct cleaning level according to the

length of time which the printer has been turned off.

o After ejecting paper:

After the Load/Eject button is pressed and the paper is ejected, if the

printer does not receive any data, it performs carriage lock and goes to a

standby state. However, if paper is loaded by pressing the Load/Eject

button, the printer does not perform the ca rria ge loc k opera tio n.

While the PF motor drive is used for paper feeding (PF motor rotation: CCW),

the CR Lock lever is set under the Paper Eject Frame, but the CR Lcok lever

rises up with clockwise rotation of the PF motor and locks the CR unit.

Drive from the PF motor is sent to the CR Lock lever via Papaer Eject Roller as

described below.

To the CR lock lever

PF motor pinion gear (CW rotation)

(13.5, 30.8)

→ Spur gear (28) → Paper eject rollers→ CR lock lever

→ Spur gear (76) → Combination gear

PF motor torque is always transmitted to the CR lock lever side, but the

operation of the CR lock mechanism varies depending on the rotational

direction of the PF motor, as shown in the table below.

Table 2-5. CR lock mechanism & PF rotational direction

Directions Corresponding Functions

Counterclockwise

ckwise

• Release the CR lock lever.

• Sets the CR lock lever.

Operating Principles Overview 35

Page 36

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.7 Paper Loading Mechanism

The paper loading mechanism loads paper at the ASF unit and feeds paper to

the PF rollers. The ASF unit, the same as in the Stylus COLOR 440/640/740,

uses a 4-phase 48-pole PM type stepping motor for the ASF/Pump motor.

Drive sent from this motor is switched between the ASF unit side and pump

unit by the disengage mechanism. See Figure 2-6 for the ASF/Pump motor

specifications.

Table 2-6. ASF/Pump Motor Specifications

Items Description

Motor type 4 Phase/ 48-pole /PM type pulse motor

Drive method Bipolar drive

Drive voltage +42V +/- 5% (DRV IC voltage)

Coil Resistance 10.4 ohm +/- 10%

Drive frequency [Hz] 15mH

Control method A3958

The rotational directions and their functions are shown in the table below:

Table 2-7. ASF/Pump Motor Rotation

Torque from the ASF/Pump motor is transmitted to the ASF as described

below:

o Torque transmission to the ASF unit

1) When the CR unit moves to the right end of the CR shaft, the DE lock lever

is pushed to the right end.

2) The ASF-Pump motor rotates clockwise specified steps (viewed from the

motor pinion gear side).

3) With the rotation of step 2), the planetary gear set in the disengage unit

shifts to the combination gear (12, 22.4) side.

4) The CR unit moves specified steps from the right end of the CR shaft to the

left. With this movement, the DE lock leve r fixes the planetary gear unit.

5) Torque from the ASF/Pump motor is transmitted as described below.

Motor pinion gear → Planetary gear (15.2) → Combination gear (12,

22.4)

→ Combination gear (14, 28) → Spur gear (32) in ASF

Figure 2-9 shows the disengage mechanism and the parts involved.

C om bination G ear 14,28

C om bination G ear 12,22.4

Planetary gear 15.2 unit

A

D E Lock Lever

Directions Corresponding Functions

Clockwise

Counterclockwise

• Sets the paper return lever.

• Switches torque to the ASF side.

• Loads paper at ASF.

P in io n fo r

AS F/Pum p M otor

: P aper loading rotation

C om bination G ear 17.19,25.6

: A S F s id e s w itc h ro ta tio n

Figure 2-9. Disengage Mechanism

Operating Principles Overview 36

Page 37

EPSON Stylus COLOR 860/1160 Revision C

Torque sent from the ASF/Pump motor to the ASF unit via the disengage

mechanism is used for the following operation.

o Paper loading operation

Like the Stylus COLOR 440/640/740, ASF of this printer has the multiple paper

loading prevention mechanism to provide steady paper loading. This

mechanism prevents a sheet of paper from falling from the paper set

position into the paper path. A paper return lever in the mechanism pushes

paper that may have fallen off back onto the hopper. After this motion is

completed, the LD roller starts loading paper. The paper loading

mechanism, including the multiple paper loading prevention mechanism, is

described in the following steps.

LD Roller

Hopper Hopper Spring

Cam

1. When the printer power is turned on, the ASF/Pump motor rotates

counterclockwise to detect ASF home position. Then the motor rotates

clockwise specified steps to set the LD roller and paper turn lever in place.

(See “Standby State” in Figure 2-10.)

2. When the paper loading signal is sent from the PC and the Load/Eject

button is pressed, ASF/Pump motor turns counterclockwise to let the LD

roller load paper. (See “Paper Pick Up State” in Figure 2-10.)

3. When the paper is transported to the PF roller, the LD roller stops where it

loses friction. (See “PF Roller Paper Feed State” in Figure 2-10.)

4. When the next print signal is sent and Load/Eject button is pressed, the

ASF/Pump motor rotates clockwise specified steps to set the LD roller and

the paper return lever in place. (See “Standby State” in Figure 2-10.)

NOTE: If no print signal is sent for several seconds in step 4, the LD roller and the

paper return lever automatically return to the standby state.

2

Pinch Roller

3

Paper Return

Lever

[Stand-by State]

Pad

Pad Spring

[Paper Pickup State]

[PF Roller Paper Load State]

Figure 2-10. Multiple Paper Loading Prevention Mechanism

Operating Principles Overview 37

Page 38

EPSON Stylus COLOR 860/1160 Revision C

2.1.1.8 Pump Mechanism

The pump mechanism absorbs ink from the printhead or the cap assembly.

The wiper for head cleaning is attached in the cap assembly. The pump

mechanism is driven by the ASF/Pump motor, a 4phase 48-pole PM type

stepping motor. See Table 2-6 for the ASF/Pump motor specifications. Torque

from the ASF/Pump motor is sent to the pump unit by the switching operation

of the planetary gear in the disengage mechanism. The ASF/Pump motor

torque is transmitted to the pump mechanism as described below.

o Torque transmission to the pump unit

1) When the CR unit moves to the right end of the CR s haft, the D E lock lever)

is pushed to the right end.

2) The ASF-Pump motor rotates specified steps counterclockwise (viewed

from the motor pinion gear side).

3) With the rotation of step 2), the planetary gear set in the disengage unit

moves to the combination gear (17.19, 25.6) side.

4) The CR unit moves specified steps from the right end of the CR shaft to the

left. With this motion, the DE lock lever fixes the planetary gear set.

5) Torque from the ASF/Pump motor is transmitted as described below.

Motor pinion gear

→

Tension belt → Spur gear → Pump unit

C om bination G ear 14,28

→

Planetary gear (15.2) → Combination gear (17.19, 25.6)

: P um p ink absorption rotation

: P u m p s id e s w itc h ro ta tio n

C om bination G ear 12,22.4

Planetary gear 15.2 unit

A

D E L o c k L e v e r

Tension Belt

When the ASF/Pump motor torque is switched to the pump unit side by the

disengage mechanism, the function of the pump mechanism varies depending

on the rotational direction of the motor, as shown in the table below.

Table 2-8. ASF/Pump Motor Functions

Directions Corresponding Functions

• Switches torque to the ASF side.

Counterclockwise

Clockwise

• Ink absorption by the pump

• Sets the wiper.

• Releases the pump.

• Resets the wiper.

Figure 2-12 shows the operating principles of the pump mechanism.

Counterclockwise

Tube pressured

Clockwis

Tube released

Figure 2-12. Pump Mechanism

P in io n fo r

A S F /P u m p M o to r

C o m b in a tio n G e a r 1 7 .1 9 ,2 5 .6

P u m p U n it G e a r

Figure 2-11. Torque to the Pump Mechanism

Operating Principles Overview 38

Page 39

EPSON Stylus COLOR 860/1160 Revision C

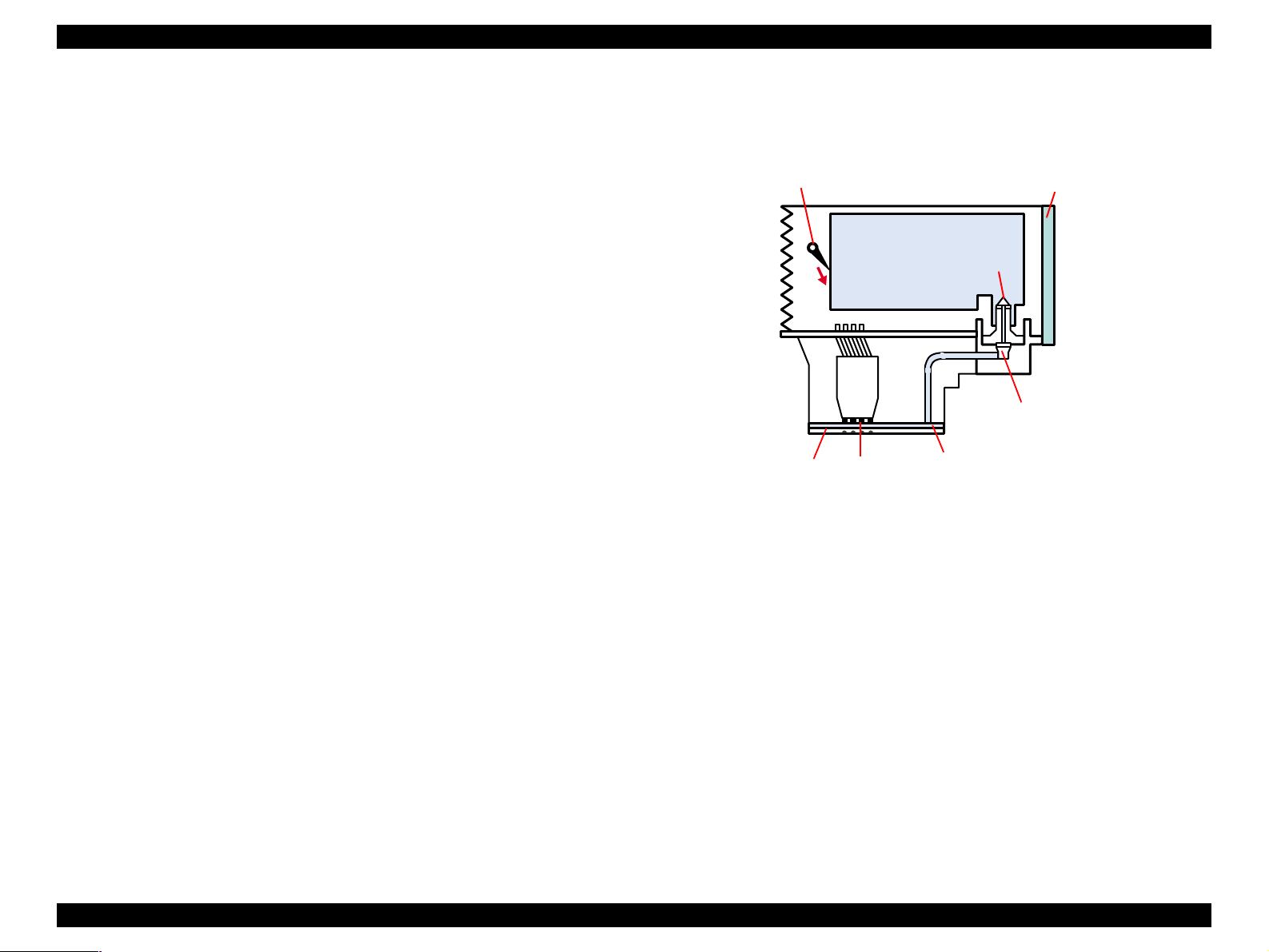

2.1.1.9 Capping Mechanism

The capping mechanism, which is driven by the pump unit, caps the printhead

closely to maintain air tightness of the cap. This operation is required to

vacuum ink from the ink cartridges, printhead, cavity, and cap. Also, to moisten

the inside of the cap while the printer power is off, this mechanism works to

keep the cap and the printhead surface in a tight contact. This function

prevents ink from clogging while the printer is not in use.

SC440/640/740 models

Flag for Carriage

Negative pressure

Ink Eject Valv e

Valve

For a specific feature of the Stylus COLOR 860/1160, it has a newly designed

valveless capping mechanism instead of other printers’ capping mechanism

that integrates an air valve. An air valve is usually equipped to remove bubbles

created inside the cap by releasing the negative pressure. However, due to

change in the ink sequence, the new valveless capping mechanism enables

this printer to maintain the initial ink charge and cleaning effects at the same

level as before. Figure 2-13 outlines the valveless capping mechanism.

SC860/1160 models

Flag for Carriage

Ink Eject Valve

Negative pressure

Closed state

Released state

Flags for

Frame

Air valve is not assembled

in this portion.

Figure 2-13. Valveless Capping Mechanism

Operating Principles Overview 39

Page 40

EPSON Stylus COLOR 860/1160 Revision C

2.2 Electrical Circuit Operating Principles

The electric circuit of the Stylus COLOR 860/1160 is composed of the following

boards.

o

Main board: C298MAIN (Stylus COLOR 860/1160)

o

Power supply board: C298PSB/PSE (Stylus COLOR 860/1160)

o

Panel board: C298PNL (Stylus COLOR 860)

C304PNL (Stylus COLOR 1160)

Refer to Figure 2-13 for the major connection of the three boards and their

roles.

C 298 P N L B oard (S C 860)

C 304 P N L B oard (S C 1160)

C 298 M A IN B oard

3.3V R egulator

Power off

+5VD C

C298 PSB/PSE

Board

+42VD C

Printer M echanism

C R M otor

PF M otor

AS F/P um p M otor

H ead D river B oard

Several S ensors

Figure 2-14. Electric Circuit of Stylus COLOR 860/1100

Operating Principles Electrical Circuit Operating Principles 40

Page 41

EPSON Stylus COLOR 860/1160 Revision C

2.2.1 C298PSB/PSE Board

The Stylus COLOR 860 and Stylus COLOR 1160 are equipped with the

C298PSB/PSE, the common power supply board for the both products. The

basic structure of the circuit is the same as for the C257PSB/PSE board used

in the Stylus COLOR 740. The power supply boards of these printers use a

RCC switching regulator, which generates +42VDC for drive line and +5VDC

for logic line to drive the printer. For one of the major characteristics of the