Page 1

EPSON

SQ-2000

Operating Manual

Printer

Page 2

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment generates and uses radio frequency energy and if not

installed and used properly, that is, in strict accordance with the

manufacturer’s instructions, may cause interference to radio and

television reception. It has been type tested and found to comply with

the limits for a Class B computing device in accordance with the

specifications in Subpart J of part 15 of FCC Rules, which are designed

to provide reasonable protection against such interference in a

residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

- Reorient the receiving antenna

- Relocate the computer with respect to the receiver

-

Plug the computer into a different outlet so that the computer and

receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced

radio/television technician for additional suggestions. The user may

find the following booklet prepared by the Federal Communications

Commission helpful:

“How to Identify and Resolve Radio-TV Interference Problems.”

This booklet is available from the U.S. Government Printing Office,

Washington, DC 20402. Stock No. 004-000-00345-4.

WARNING

The connection of a non-shielded printer interface cable to this printer

will invalidate the FCC certification of this device and may cause

interference which exceeds the limits established by the FCC for this

equipment. If this equipment has more than one interface connector,

do not leave cables connected to unused interfaces.

All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any

means, mechanical, photocopying, recording or otherwise, without the

prior written permission of Epson America, Inc. No patent liability is

assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book,

Epson America, Inc. assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of

the information contained herein.

Apple® is a registered trademark of Apple Computer, Inc.

Compaq

CP/M® is a registered trademark of Digital Research, Inc.

FX-80TM, FX-lOO™, and RX-80” are trademarks of Epson America, Inc.

IBM-PC@ is a registered trademark of International Business Machines

Corporation.

LQ-1500™

Microsof™ is a trademark of Microsoft Corporation.

QX-10™ is a trademark of Epson America, Inc.

Softalk® is a registered trademark of Softalk Publishing, Inc.

SQ-2000™

TRS-80® is a registered trademark of Radio Shack, a division of Tandy

Corporation.

80-Micro is published by Wayne Green Publishers.

Copyright © 1985 by Epson America, Inc.

Torrance, California 90505

TM

is a trademark of Compaq Computer Corporation.

is a trademark of Epson America, Inc.

is a trademark of Epson America, Inc.

Part No. 8492004

Page 3

Contents

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual . . . . . . . . . . . . . . . . . . . . . . . .

10 Steps to Printing

1

Selecting the Right Location

Unpacking the Printer

Putting on the Paper Feed Knob

Installing the Ink Cartridge

Setting Up the Single-Sheet Paper Guide

Installing the Interface Card

Connecting the Printer to Your Computer

Customizing the Printer

Loading Single-Sheet Paper

Self-Testing the Printer

A Word About Selecting Paper

Testing your paper

Printing Your First Document

Operation

2

Power Switch

Control Panel Buttons

ON LINE button

FF (Form Feed) button

LF (Line Feed) button

CLEANING button

SHEET FEED button

Indicators ..............................

Meaning of blinking indicators

Paper-end detector

Inklow ................................

Buzzer.. ................................

Initialization

................................

........................

................

......................

............

................

................

....................

................

....................

..............

......................

..............

............................

......................

........................

....................

....................

......................

....................

............

......................

..............................

....

....

1

1

2

3

6

7

8

9

10

11

13

14

15

17

18

19

20

23

23

24

24

25

25

25

25

26

26

27

27

27

28

...

111

Page 4

3

Using the SQ-2000

Using the SQ-2000 with Word Processors

Using the SQ-2000 with other application

programs

Programming with the SQ-2000

Computer-to-printer communications

ASCII codes

Control codes

ESCape sequences ......................

Translating the ASCII code ................

How to send control codes to printer

Using Master Select Command ..............

..............................

........................

............

............................

..........................

....

....

......

29

29

30

30

31

31

32

32

33

33

35

4

Printer Care and Maintenance

The Ink Jet Print Head

How Automatic Print Head Cleaning Works . .

For more extensive cleaning ..............

Special cleaning

Summary of Cleaning Cycles

Troubleshooting Guide ....................

5

User-Defined Characters

Dot-Matrix Printing

The print head

The print matrix

Defining Your Own Characters ..............

Sending information to the SQ-2000

Printing User-Defined Characters

Copying ROM to RAM

How Print Mode Affects User-Defined

Characters

Draft mode characters

Letter quality characters

Proportional mode characters ............

Mixing Print Styles

Other considerations

Defining Connecting Characters

Characters that connect vertically ..........

..............................

......................

........................

....................

........................

..........................

........................

....................

........................

....................

..............

................

............

..................

............

......

43

43

44

45

45

46

46

51

51

51

52

53

55

58

58

59

60

60

61

61

62

62

65

iv

Page 5

6

DotGraphics..

How the SQ-2000 Prints Dot Graphics

Syntax of the Graphics Command

Using Hand-Calculated Data to Print

Graphics..

Printing Multiple Lines of 8-Dot Graphics

Using the 24-Dot Graphics Options

Using the SQ-2000 as a Plotter

Individual Graphics Options Commands

Assigning Graphics Options

............................

..............................

........

............

....

..........

..............

....

................

67

67

70

71

72

75

78

85

85

7

Using the Hex Dump Feature

8

Programming Hints

High level language problems

Apple Computers

TRS-80 Computers

IBM Personal Computers

QX-10 Computers

.......................

.......................

..............

.....................

.........

.....................

...............

87

89

89

90

91

92

93

Page 6

Appendixes

SQ-2000 Command Summary

A

Vertical Spacing Commands

Horizontal Spacing Commands

Print Style Commands

Character Set Commands

Graphics Commands

Miscellaneous Commands

ASCII Code Conversion Chart . . . . . . . . . . . . . .

B

Widths of the Proportional Characters.

C

Setting the DIP Switches

D

Location of Switches

Before You Change the Switch Settings

Column DIP Switch Panel

Interface DIP Switch Panels

Interface DIP switch Panel 1 ....................

SW1-1

SWl-2

SW1-3

SW1-4

Interface DIP switch Panel 2

SW2-1, SW2-2, and SW2-3

SW2-4

SW2-5

SW2-6

SW2-7

SW2-8

..................................

..................................

..................................

..................................

..................................

..................................

..................................

..................................

..................................

..................

..................

......................

..........

............

..........

..............

..............

..................

..................

..............

................

. . .

. . .

. . .

. . .

. . .

. . .

.......

......

A-l

A-2

A-7

A-10

A-15

A-17

A-20

B-l

C-l

D-l

D-l

D-3

D-3

D-4

D-4

D-5

D-5

D-5

D-5

D-6

D-6

D-8

D-8

D-8

D-8

D-8

Using the Optional Tractor Unit

E

Printer Location

Installing the Tractor Unit

Installing the Paper Separator

Loading Continuous Paper

Specifications

F

Printing

Printer ....................................

Index

vi

..................................

..........................

..................

............................

............

..............

................

E-l

E-l

E-2

E-3

E-4

F-l

F-l

F-2

Page 7

Figures

1-1

Printer location

1-2

Printerparts

1-3

Interface card installed

Installing the paper feed knob’

1-4

The ink cartridge

1-5

Installing the single-sheet paper guide

1-6

Removing the protective plate

1-7

Sliding in the interface card

1-8

1-9

Snapping the interface card into place

1-10 Connecting the printer and computer

1-11 Locating the DIP switches

1-12 Loading single-sheet paper

1-13 Adjusting pressure bar rollers

1-14 Self-test

1-15 DIP switch setting for self-test

1-16 Paper is too absorbent

1-17 Paper is not absorbent enough

1-18 Good print quality

1-19 Sample document

2-l Power switch and control panel

2-2 Control panel buttons

2-3 Control panel indicators

4-1

Buttons for cleaning during printing.

.................................

............................

..............................

............

...

............

.

..........................

..............

................

.................

...............

.............

.............

.....................

.............

.......................

.........................

..............

......................

....................

......

........

.......

.........

6

7

7

8

9

10

11

11

12

13

14

15

16

17

17

18

18

19

21

24

24

26

45

The print head

5-1

5-2

Charactergrids . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User-defined character

5-3

5-4

Data bytes for the first column of a new

capitalA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character design grid for border characters

5-5

5-6

Three border designs

5-7

Design grid for integral sign made of two

vertically connecting characters . . . . . . . . . .

5-8

Integral sign made of two vertically connecting

characters

6-l

Graphics data byte and print head nozzles . . .

Values assigned to the print nozzles . . . . . . . . .

6-2

Value of the graphics data byte

6-3

6-4

Design sketch and sum of nozzle values

6-5

Data layout for multiple lines of g-dot

graphics . . . . . . . . .._.....................

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . _ . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. .

. . . . . .

52

53

54

55

64

64

66

66

68

69

70

72

73

vii

Page 8

6-6

Map of 24-dot graphics

6-7

Data layout for 24-dot graphics

6-8

Eight-dot (top) and 24-dot (bottom) versions of

the density

..............................

6-9 Figure produced by plotting program

6-10 Order of array elements

....................

..............

........

....................

6-11 Curve produced by minor change in plotting

program

................................

76

76

78

80

83

84

7-1

Hex dump feature

..........................

7-2 Hex dump printout of Chapter 6 graphics

program

C-l Character Q and its widths

D-l Location of column DIP switch panel

................................

..................

........

D-2 Location of interface DIP switch panels

E-l Continuous paper stacked below printer

E-2 Continuous paper stacked behind printer

E-3 Tractor installation

........................

E-4 Paper separator being assembled and

installed

E-5 Tractor release levers

E-6 Location of parts for tractor unit

E-7 Feeding the paper into the printer

E-8 Top-of-page position

................................

......................

............

..........

......................

......

....

....

87

88

c-2

D-2

D-2

E-l

E-2

E-2

E-3

E-4

E-5

E-6

E-7

Viii

Page 9

Tables

2-1 Messages of panel indicator lights

3-1

Proportional print styles

3-2 Draft pica print styles

3-3 Draft elite print styles

3-4 Letter quality pica print styles

3-5 Letter quality elite print styles

5-l User-defined character design grids

6-l Graphics options

6-2 Individual graphics options commands

D-l Column DIP switch setting for printing area

D-2 Interface DIP switch Panel 1 settings.

D-3 Interface DIP switch Panel 2 settings.

D-4 International character sets

D-5 DIP switch settings for international

characters ..............................

..........................

....................

......................

......................

..................

..........

..............

..............

..........

......

.........

.........

. .

26

37

38

39

40

41

60

70

85

D-4

D-4

D-6

D-7

D-7

ix

Page 10

Introduction

The Epson SQ-2000 Ink Jet Printer gives you the versatility,

speed, and graphics capability of a dot matrix printer, together

with print quality close to that of a daisy wheel printer. A major

advantage of the ink jet is its quiet operation, which sets it in a

class by itself.

Features

Like a conventional dot matrix printer, the SQ-2000 uses dots

to create each character. Instead of using a ribbon, it transfers the

characters onto the paper through 24 ink nozzles. The print head

cleans itself automatically, keeping the nozzles clear.

The SQ-2000 accepts a wide range of different types of paper;

you don’t need to buy specially manufactured stock. It’s designed

to work on smooth, ordinary bond paper.

The SQ-2000 offers dot graphic modes which let you create

custom characters, logos, and detailed graphic designs.

Page 11

About the Manual

This manual contains all the information you need to operate

the SQ-2000. In the first section, you’ll find the necessary details

to get your SQ-2000 up and running. The second part of the

manual contains information on how to take full advantage of

some of the printer’s special features.

Chapter 1 shows you how to print your first document in ten

easy steps. Chapters 2 and 3 include a description of the control

panel, information on using your printer with word processing,

and some programming tutorials. Chapter 4 describes how the

printer maintains itself and contains some troubleshooting suggestions.

If you already know how to program a printer, you will find

useful information on graphics capabilities in chapters 5 and 6.

Chapters 7 and 8 contain additional programming information.

The Appendixes provide reference information for programming, instructions for installing an optional tractor feed unit, and

specifications.

Page 12

Chapter 1

10

Setting up your SQ-2000 is simple and straightforward, even if

you’ve never used a printer before. In this chapter, you’ll learn

how to set up your printer and perform your first printing job in

10 easy steps, shown on the next two pages.

steps to Printing

3

Page 13

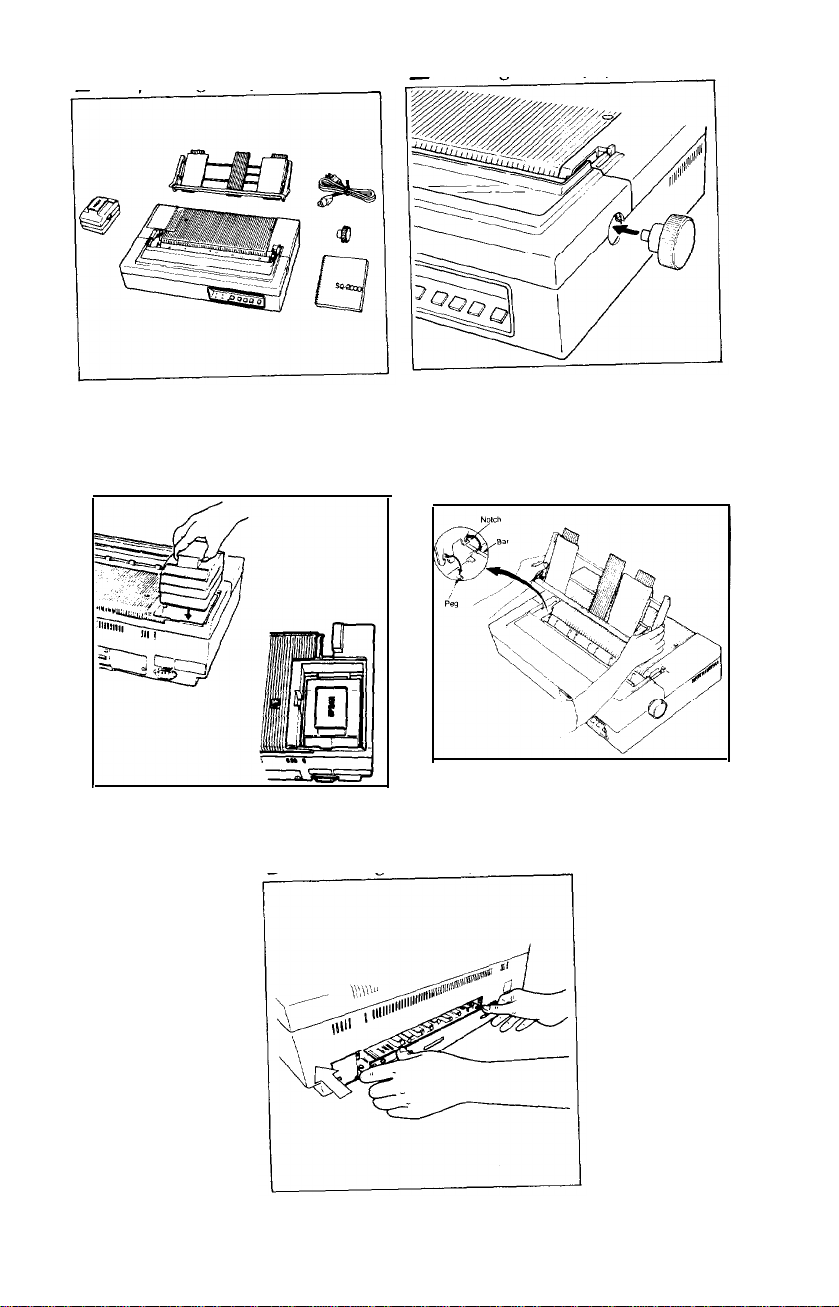

1

Unpacking the

printer

2

Putting

on the paper feed knob

3 Installing the ink cartridge

Installing the inferface card

5

4 Setting up the paper guide

4

Page 14

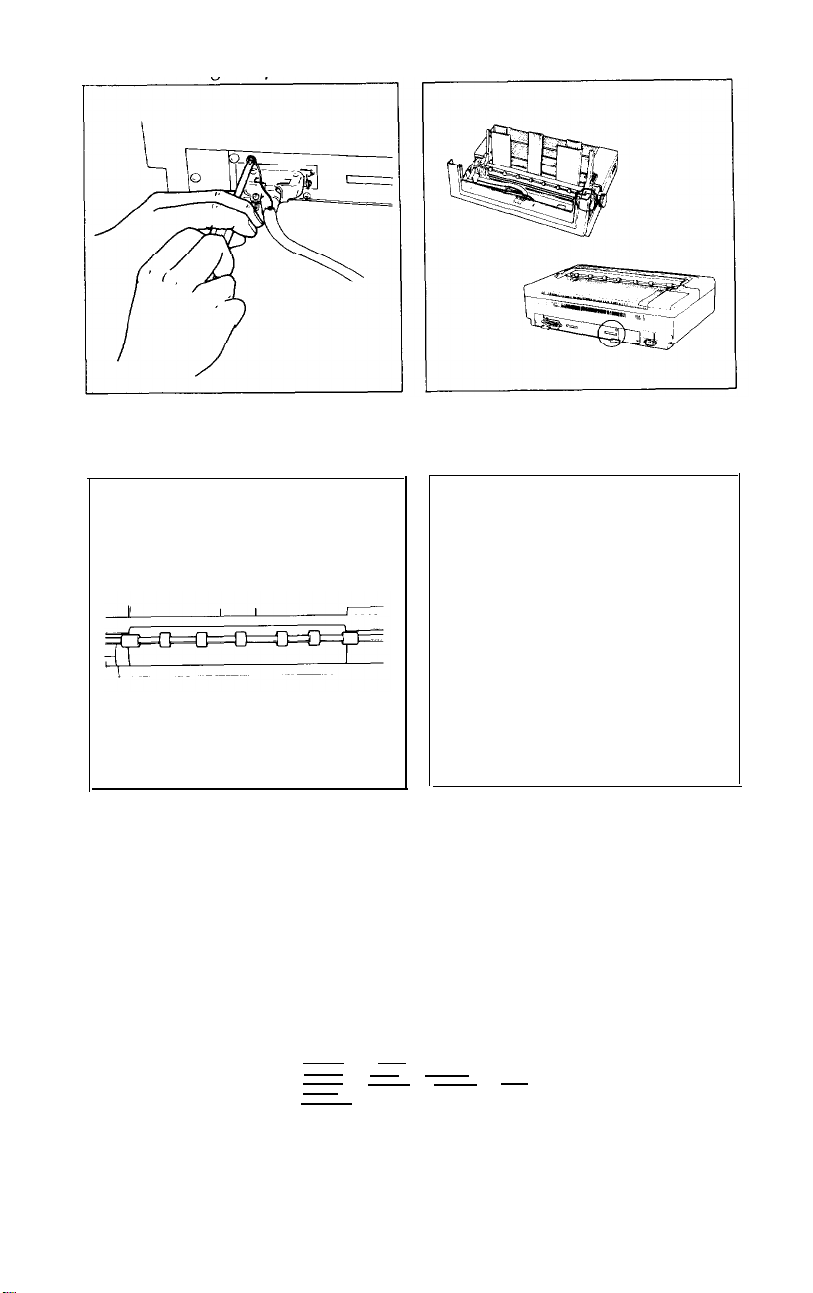

Connecting the printer

6

Customizing the printer

7

Loading the paper

8

Self-testing the printer

9

ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]

BCDEFGHIJKLMNOPQRSTUVWXYZ[\]^

CDEFGHIJKLMNOPQRSTUVWXYZ[\]^_

DEFGHIJKLMNOPQRSTUVWXYZ[\]^_'

EFGHIJKLMNOPQRSTUVWXYZ[\]^_'a

FGHIJKLMNOPQRSTUVWXYZ[\]^_'ab

GHIJKLMNOPQRSTUVWXYZ[\]^_'abc

HIJKLMNOPQRSTUVWXYZ[\]^_'abcd

IJKLMNOPQRSTUVWXYZ[\]^_'abcde

JKLMNOPQRSTUVWXYZ[\]^_'abcdef

KLMNOPQRSTUVWXYZ[\]^_'abcdefg

LMNOPQRSTUVWXYZ[\]^_'abcdefgh

MNOPQRSTUVWXYZ[\]^_'abcdefghi

NOPQRSTUVWXYZ[\]^_'abcdefghij

OPQRSTUVWXYZ[\]^_'abcdefghijk

PQRSTUVWXYZ[\]^_'abcdefghijkl

QRSTUVWXYZ[\]^_'abcdefghijklm

10 Printing your first document

MEMO

Text

Don Donnison, President

All employees

As you all know, we have just entered an e

field in sensing device industry,

rared sensors.

A smart infrared sensor incorporates microc

hnology in the form of a high-speed micropr

h standard infrared sensing equipment. The

ions for a sophisticated sensing device are

imited:

Industrial robots

Industrial quality assurance

Detecting electronic equipment failure

Security systems

Aviation

We believe the advances we are asking will br

pany to the sensing device industry.

5

Page 15

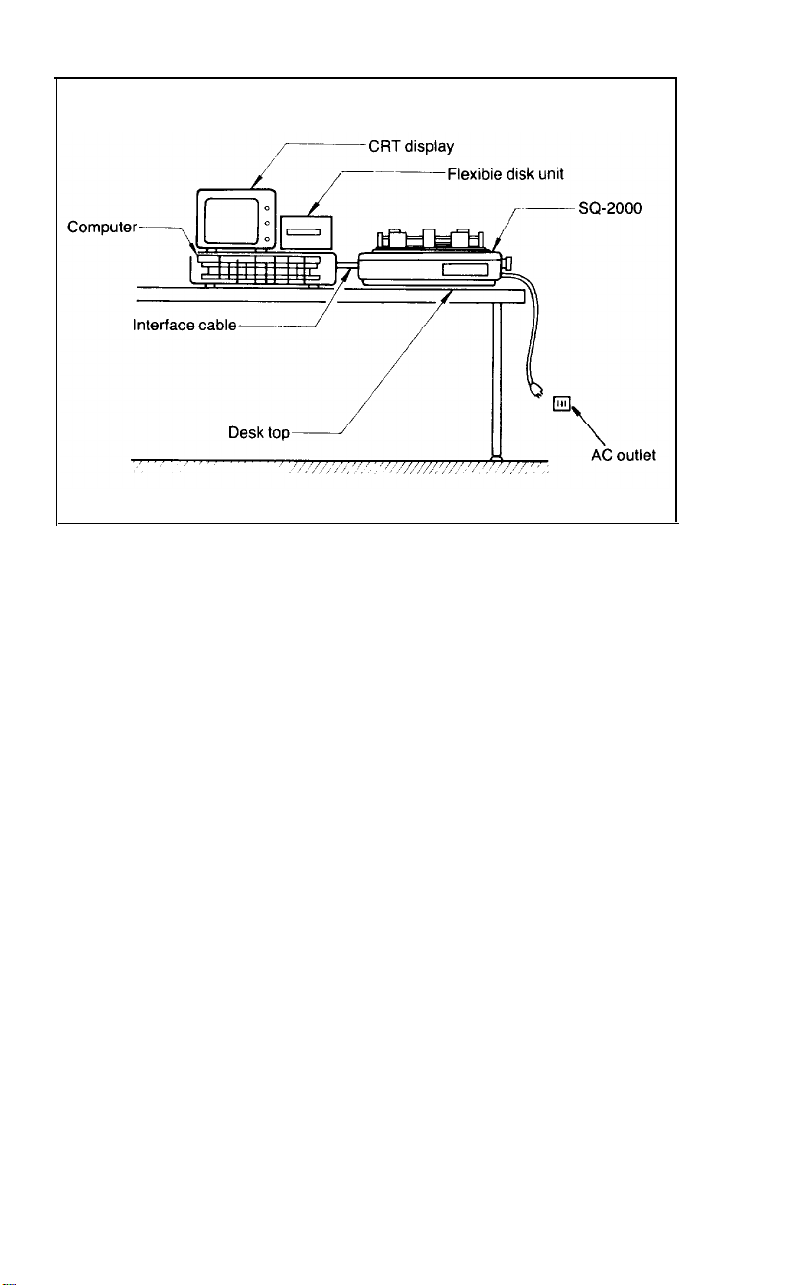

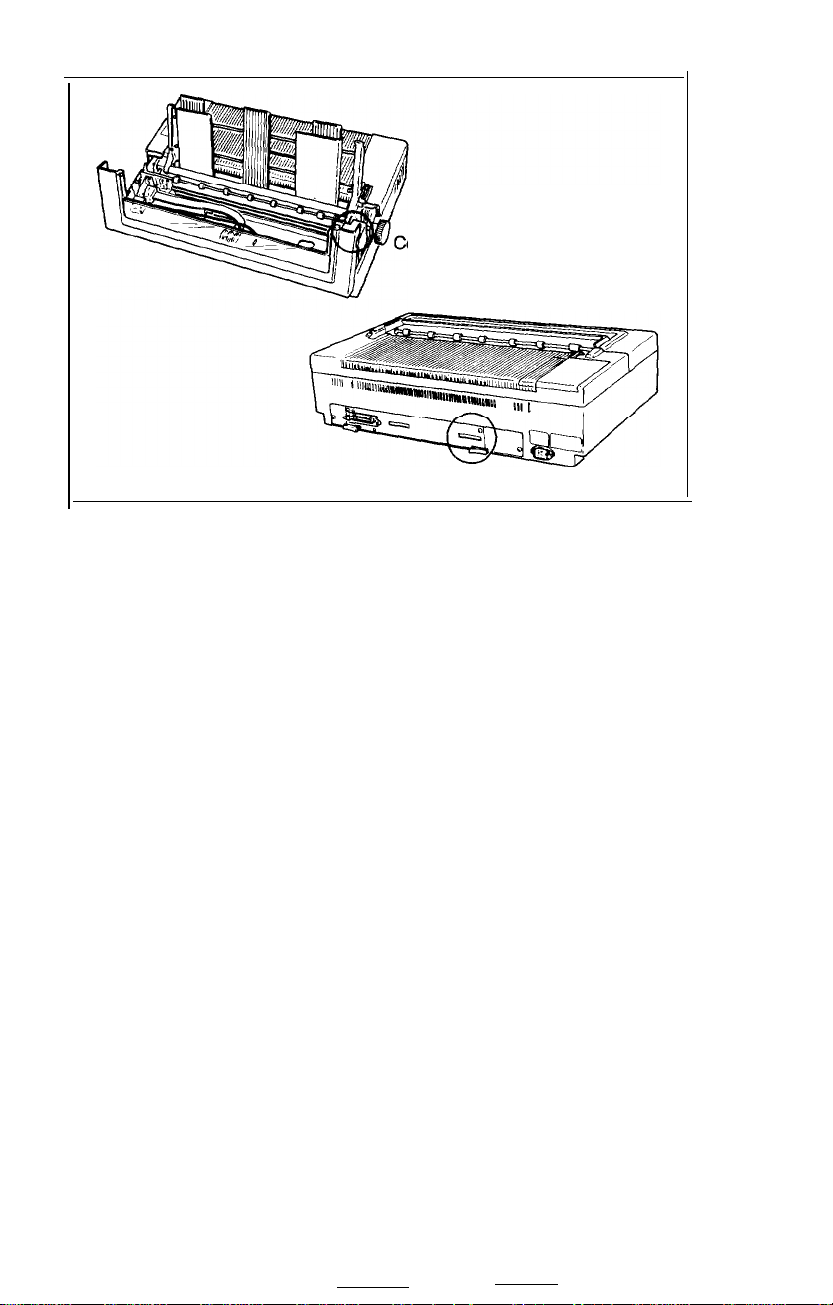

Figure 1-1. Continuous paper feeding

Selecting the Right Location

To make sure you’ve picked a satisfactory location for your

SQ-2000, keep the following points in mind.

The location should be:

l A flat, stable surface with enough room for continuous paper

feed as shown in the illustration.

l Served by an electrical outlet that cannot be turned off

accidentally by a wall switch or similar switch.

l Out of direct sunlight and not exposed to grease or dust.

l Away from electrical interference from motors and high vol-

tage power lines.

l Not subject to temperatures below 41°F (5°C) or above 95°F

(35°C) when the printer is operating.

l Not subject to either extremely high or extremely low

humidity.

If your location meets these conditions, you’re ready to begin

setting up your new printer.

6

Page 16

Single-sheet paper guide

Manual

Figure

1

tive shipping material and plastic wrapping. Save these packing

materials with the carton in case you need to ship or store your

printer later.

is missing or appears damaged, contact your dealer.

computer. If the back of your printer looks like the picture below,

the interface card is already in place.

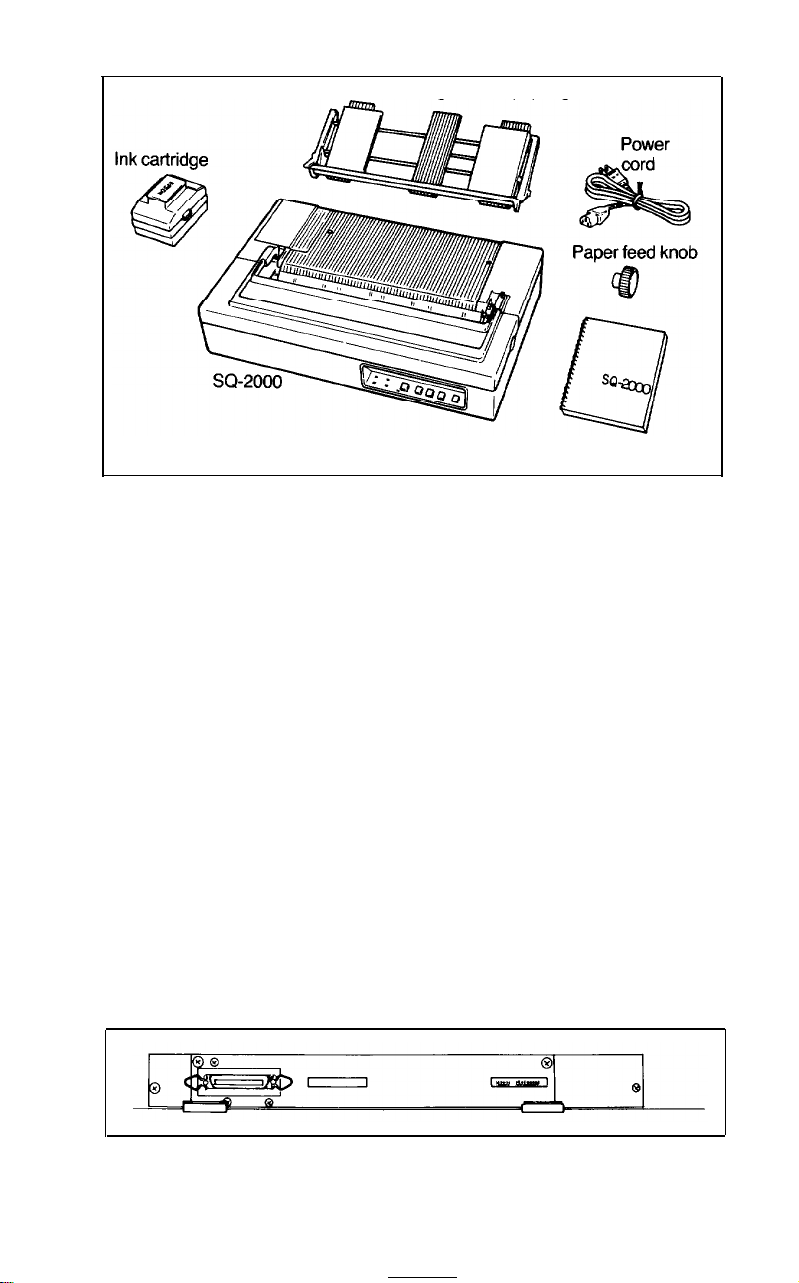

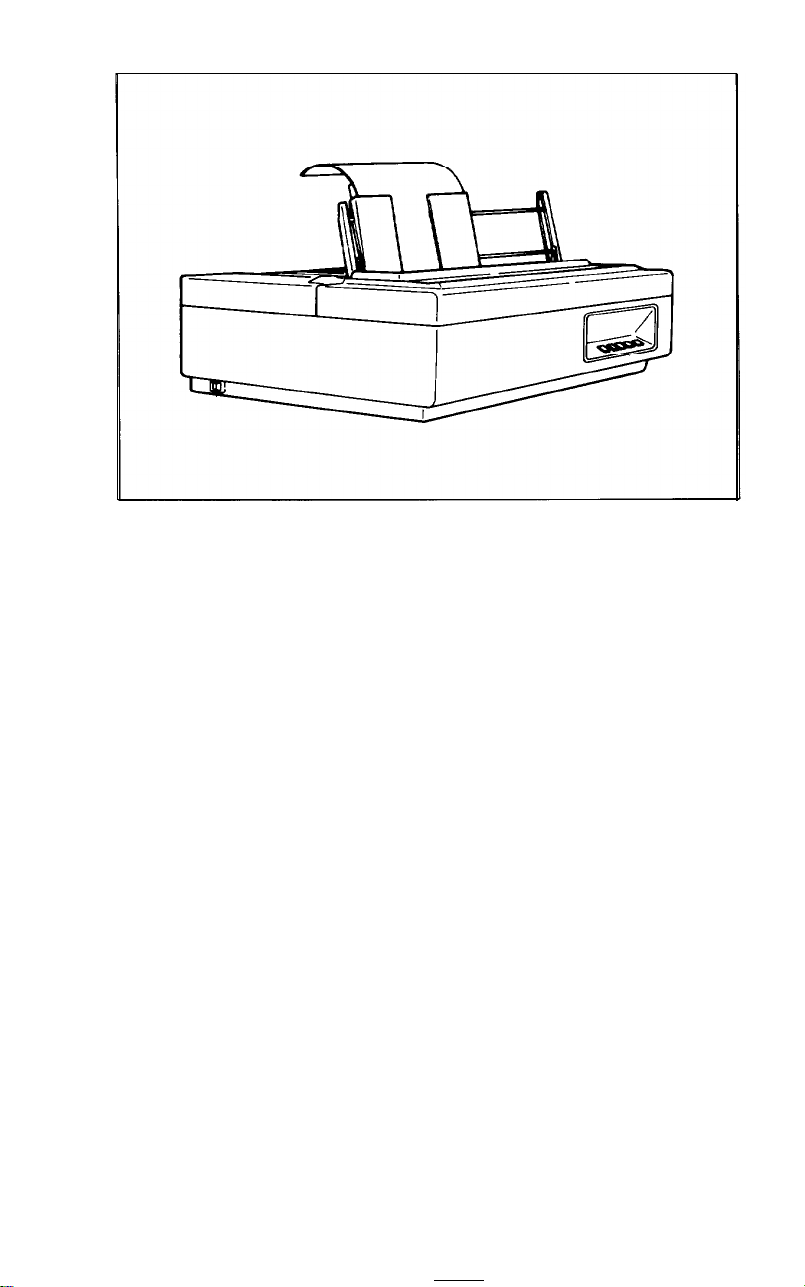

Unpacking the Printer

Carefully lift the SQ-2000 from the carton. Remove the protec-

Check to see that you have all the parts shown above. If a part

You should also have the printer interface card suitable for your

l-2.

Printer

parts

Caution:

Do not plug in the printer until Step 8.

Figure 1-3.

Interface

card

installed

7

Page 17

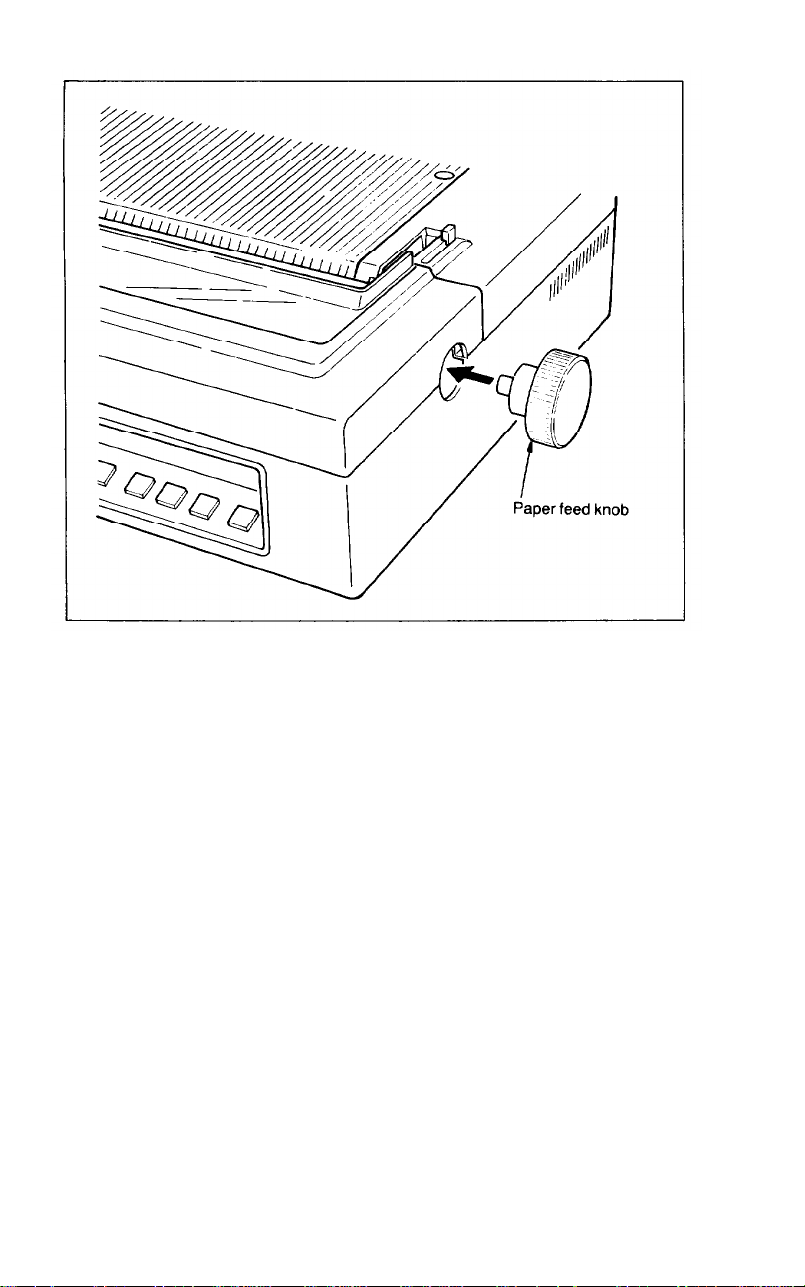

Figure 1-4. Installing the paper feed knob

2

knob so that it matches the flat side of the platen shaft.

Note:

If you’re going to ship the printer, be sure to remove the knob to

safeguard against damaging it.

8

Putting on the Paper Feed Knob

Slip the paper feed knob into place as shown above, aligning the

Page 18

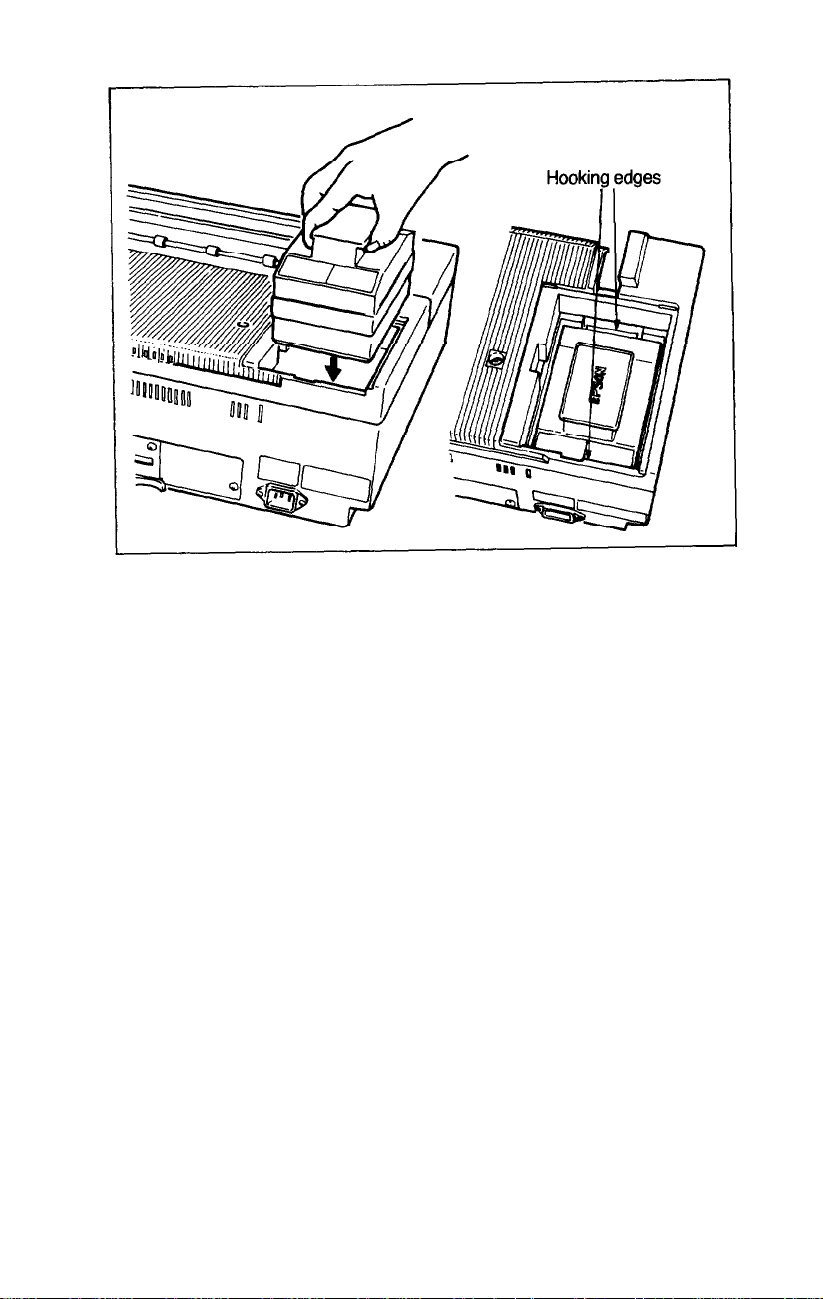

Figure 1-5. The ink cartridge

3

Installing the Ink Cartridge

Caution:

Under no circumstances should the power be switched ON

when the ink cartridge has been removed.

The ink compartment is located in the left rear corner of the

printer. To open the compartment, pull back and up on the lid

and set it aside.

Remove the ink cartridge tank from its vacuum-packed wrap-

ping.

Holding the tank with the white label toward the front of the

printer, insert the tank into the compartment. The tank has a

raised guide on the right side that fits snugly into a slot in the

printer.

Gently press down on the tank until it stops. Do not force it.

The cartridge is completely inserted when the top of the tank is

below the two flexible hooking edges shown above.

Now, snap the ink compartment lid back into place.

9

Page 19

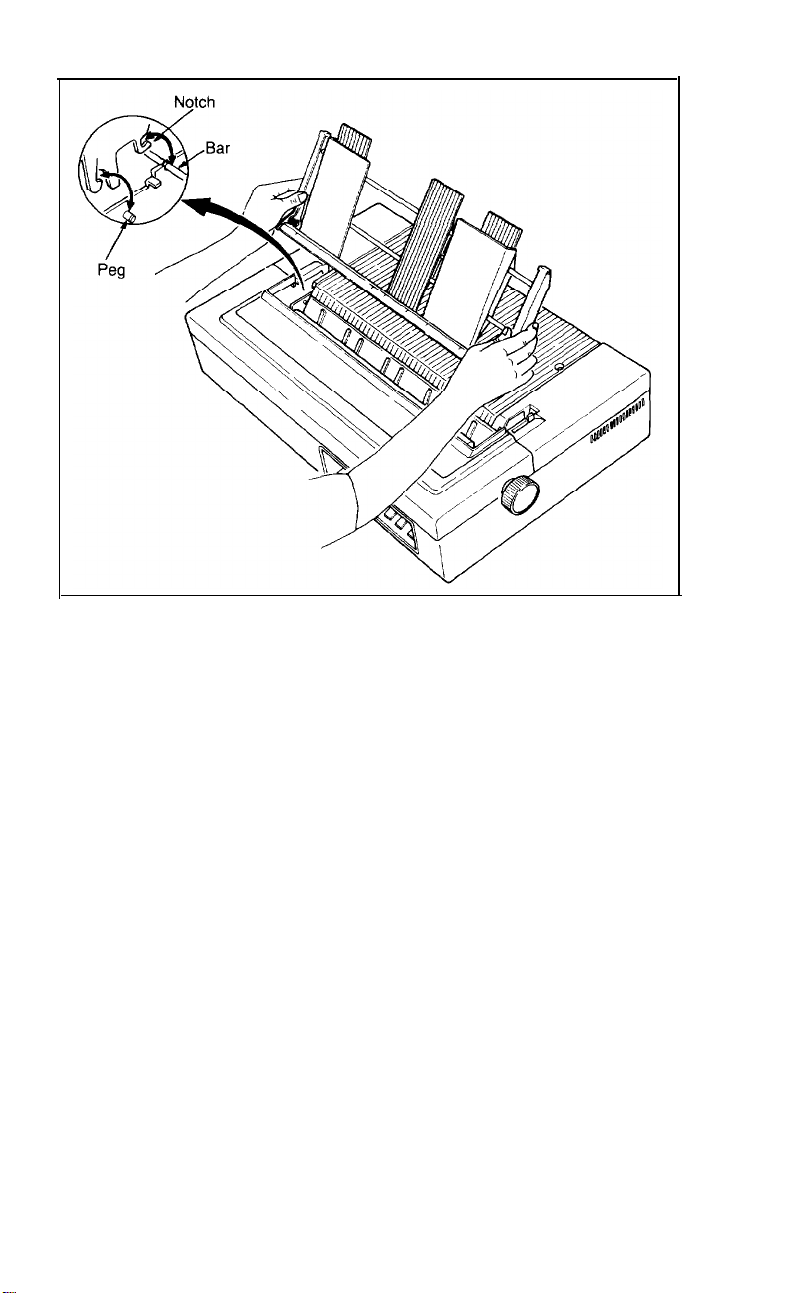

Figure 1-6. Installing the single-sheet paperguide

4

of paper into the SQ-2000.

To install this guide, hold the guide in both hands, facing the

front of the printer.

feet into the two slots shown above.

notches in the guide’s feet on these two bars.

into place with a click.

the guide away from you. Then lift it free of the printer.

10

Setting Up the Single-Sheet Paper Guide

You’ll use the single-sheet paper guide to feed individual sheets

With the guide tilted away from you, lower its two notched

At the back of each slot is a round horizontal bar. Place the

Then tilt the guide toward you and press gently until it locks

To remove the guide, press on the two locking levers and tilt

Page 20

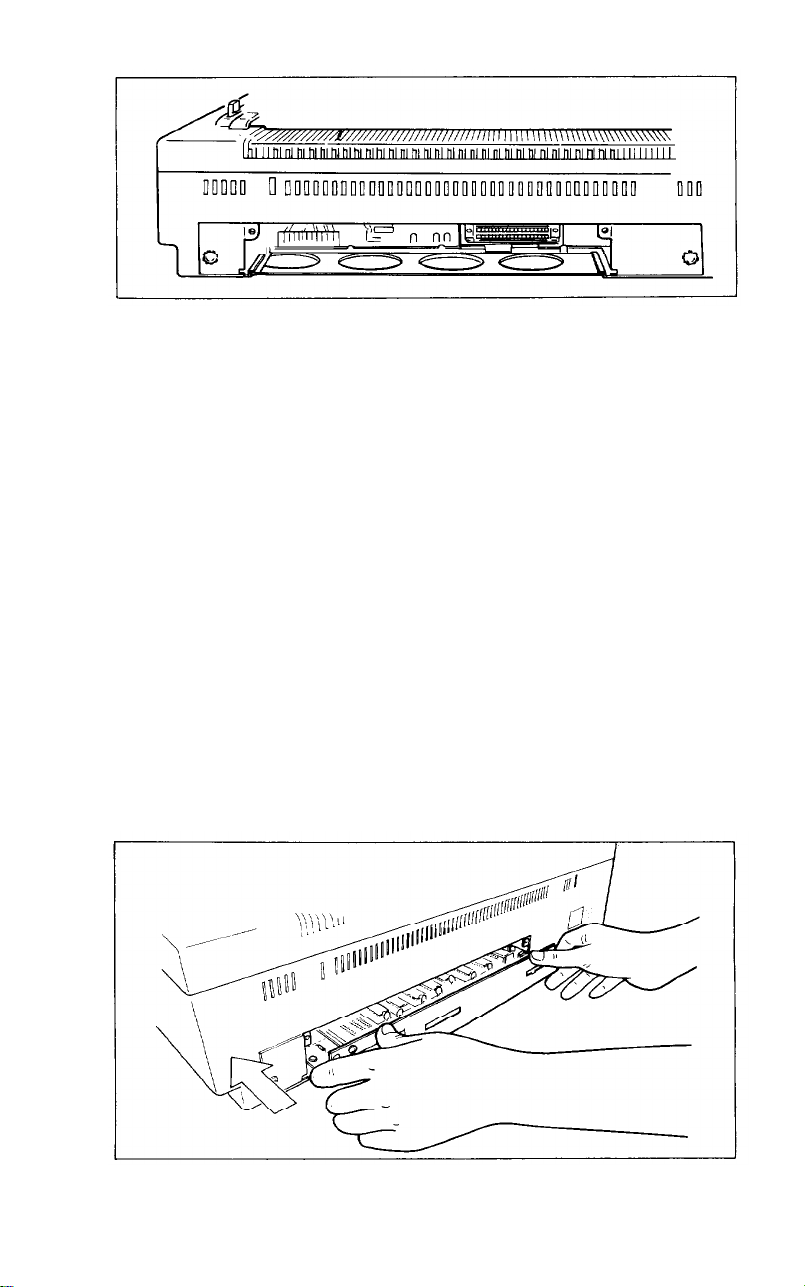

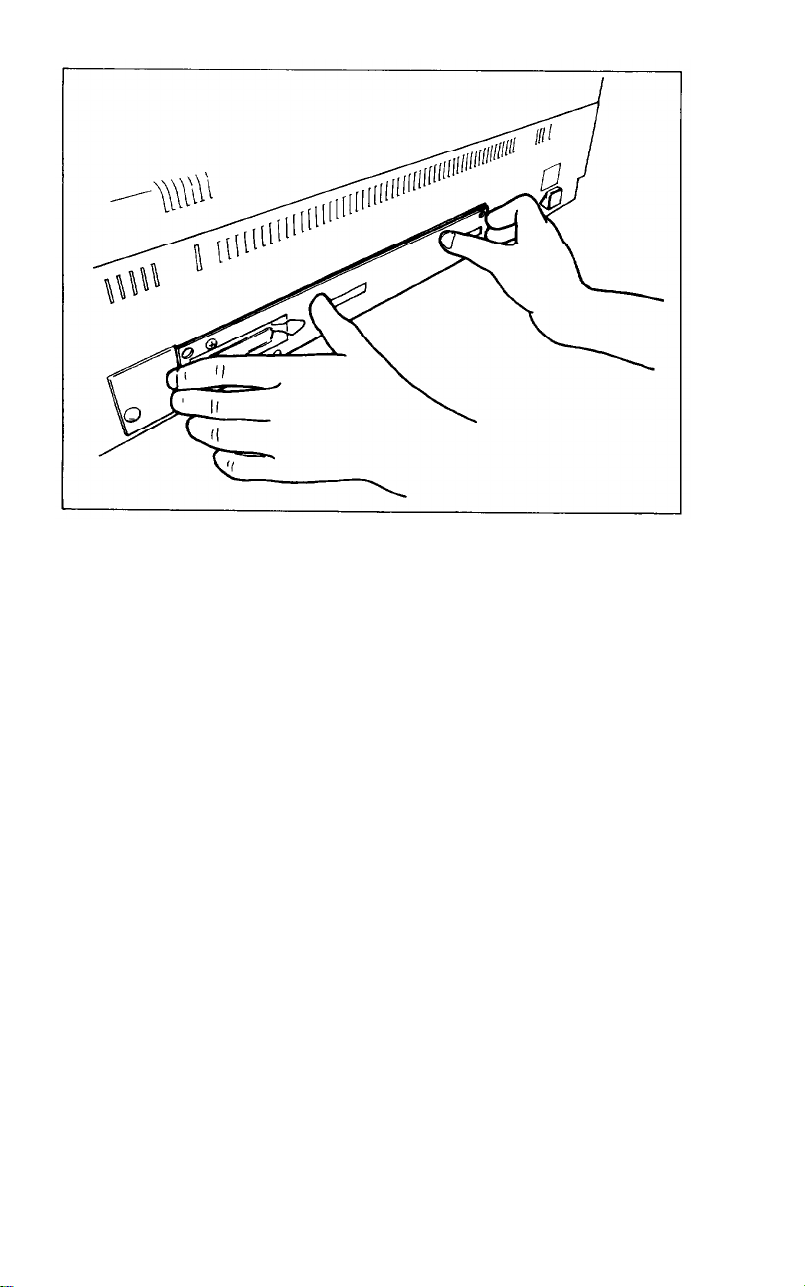

Figure 1-7. Removing the protective plate

5

to Step 6. (Look back to Step 1 to see how the card looks when it

is installed.)

Installing the Interface Card

If your printer already has the interface card installed, go ahead

Warning:

If you have been operating the printer, first turn it off, then

unplug it before attempting to install or remove the inter-

face card.

First, use a Phillips screwdriver to remove the two screws

shown above. Set them aside carefully so they won’t get lost.

Take off the U-shaped protective metal plate to gain access to the

printer. Remove the interface card from its package, taking care

not to touch the electrical parts.

Now, ease the card into the printer by sliding it into the

grooves as shown below. The metal back plate of the card should

be toward you and the electrical parts should be on too.

Figure Z-8. Sliding in the interface card

11

Page 21

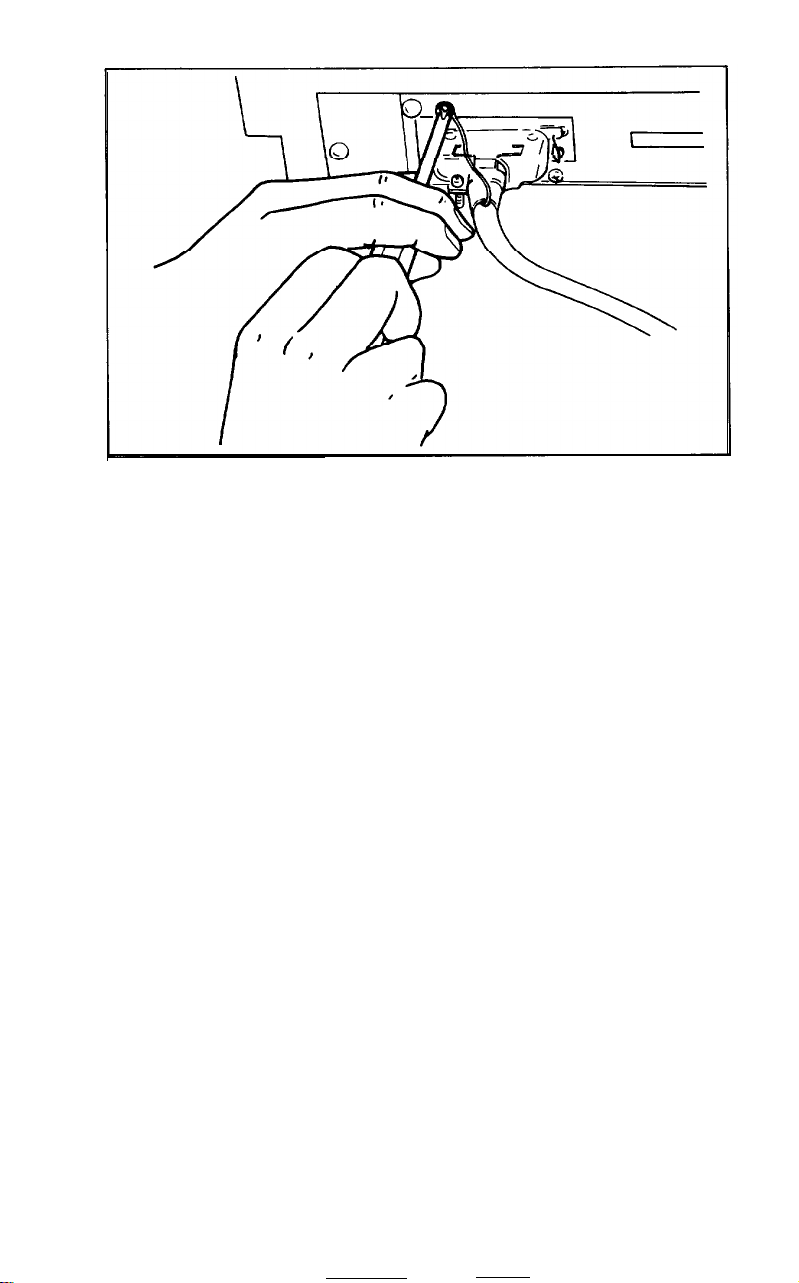

Figure l-9. Snapping the interface card into place

Use both thumbs as shown above to push the card into place.

You should feel a slight resistance when there’s about a quarter

of an inch to go. Press gently with gradually increasing pressure

until the card snaps into place.

If the card doesn’t seem to align correctly, remove it carefully

and try again. Be sure it is properly positioned in the grooves.

Now inspect the card. It should be firmly seated, the back plate

flush with the back of the printer.

Replace the two screws you removed earlier.

12

Page 22

Figure l-10. Connecting the printer and computer

6

To connect the SQ-2000 to your computer, you’ll need either a

parallel or serial interface cable, depending on your computer.

Refer to the manual for your computer or check with your dealer

for the proper cable.

OFF. Next, plug one end of the cable into the computer and the

other end into the connector on the interface card.

grounding screws next to the sockets of both machines as shown.

Connect the wire clips (or screws) to secure the plugs to their

sockets.

Connecting the Printer to Your Computer

First, make sure both the computer and printer are turned

If the cable comes with a grounding wire, attach it to the

13

Page 23

DIP switch panel

olumn

Interface DIP switch panel

Figure l-21. Locating the DIP switches

7

to customize the printer to your special needs. These are shown

in the picture.

to suit a variety of applications.

Customizing the Printer

There are two DIP switch panels on the SQ-2000 that allow you

The switches are preset at the factory, but they can be changed

For information on the DIP switches and how to change them,

see Appendix D.

14

Page 24

Figure l-12. Loading single-sheet paper

8

Loading Single-Sheet Paper

Before beginning the paper-loading procedure, plug in the

SQ-2000 and turn it on.

When you turn the printer on, a number of things happen:

l The print head moves all the way to the left, and goes through

a brief self-cleaning cycle. You’ll hear a whirring noise that

will last a few seconds then stop. (For more details on the

SQ-2000’s self-cleaning feature, see Chapter 4.)

l The indicator lights on the control panel light up. The

POWER, READY, and ON LINE lights glow green, and the

PAPER OUT light is red, indicating that there is no paper

loaded in the printer.

15

Page 25

Now you’re ready to load paper.

1. Press the ON LINE button. The ON LINE and READY lights

go out, indicating that the printer is off-line-the power is on

but the printer won’t print.

2. Insert a sheet of paper into the paper guide and press the

SHEET FEED button. The paper automatically feeds into the

printer, and the red PAPER OUT light goes out.

3. With the paper loaded, lift the dust cover and adjust the rollers

on the pressure bar as shown below.

I’

I

I

Figure 1-13. Adjusting pressure bar rollers

I

16

Page 26

ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefgh

BCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghi

CDEFGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghij

DEFGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijk

EFGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijkl

FGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijklm

GHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijklmn

HIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijklmno

IJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijklmnop

Figure l-14. Self-test

9

To

l

l

l

l Turn OFF the printer using its ON-OFF switch.

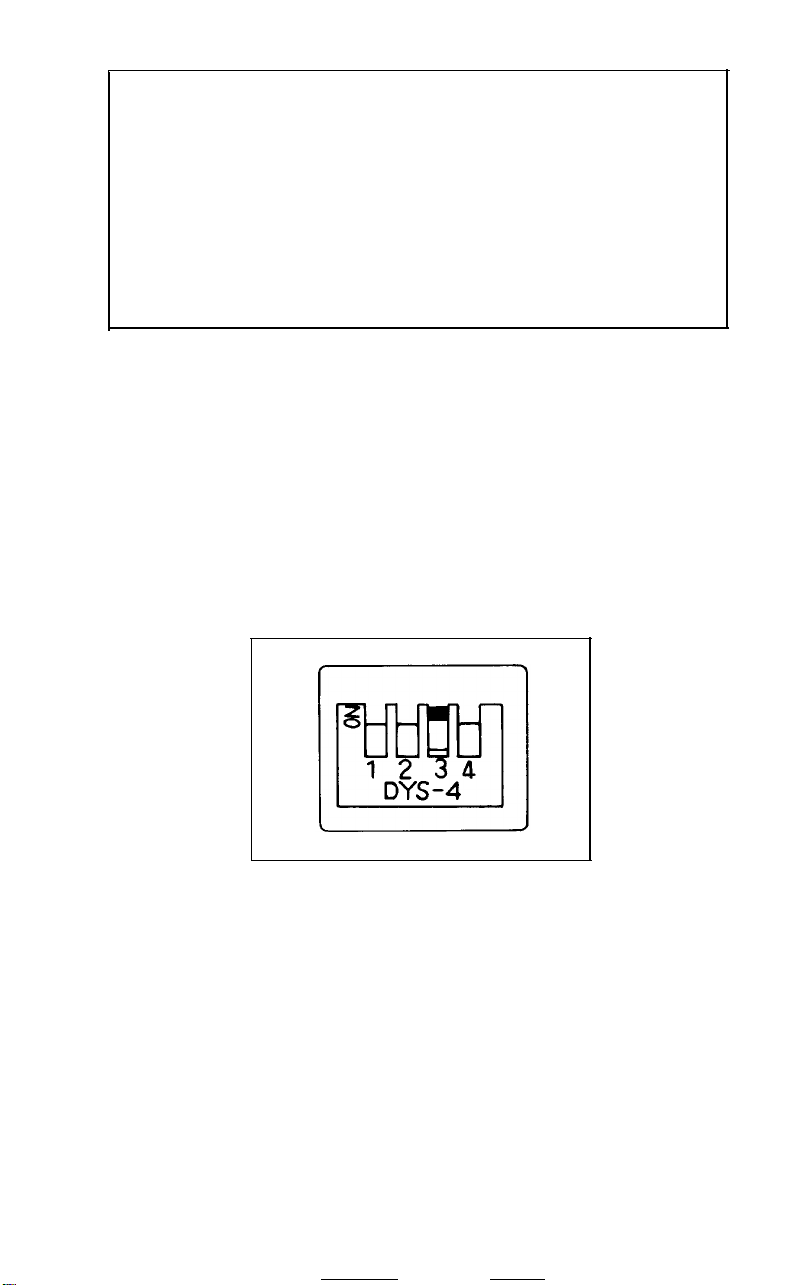

Self-Testing the Printer

self-test

the printer, follow these steps:

First,

wide loaded into the printer.

Be sure the DIP switches under

the setting below:

Adjust

be sure that you have a sheet of paper at least 8½ inches

the dust cover are set to match

Figure l-15. DIP switch setting for self-test

the paper pressure bar as shown in Step 8.

Now, turn ON the printer while holding down the LF button.

The printer will immediately begin printing out the self-test

characters shown above.

To stop the test, simply turn OFF the printer, or

stop when it reaches the bottom of the page.

wait for it to

17

Page 27

A Word About Selecting Paper

With an ink jet printer, paper absorbency is an important component for good print quality. Paper which is either too absorbent or not absorbent enough will give you less than optimum

print quality.

You can see in Figure 1-16 what happens when paper is used

which soaks up too much ink. The ink tends to bleed, causing

blurred or smeared characters.

Figure 1-17 shows what can happen when paper is not absor-

bent enough. The characters take too long to dry and are easily

smeared.

standard

for

infrared sensing

a sophisticated sens

ted:

Industrial robots

Industrial quality assuranc

Figure I-16. Paper is too absorbent

MEMO

Don Donnison, President

All employees

As

you all

field in

red sensors.

Figure l-77. Paper is not absorbent enough

know,

the

we have j

sensing

dev

Most dense-weave paper (of the quality used for business correspondence) can be used in the SQ-2000 without problems.

However, it’s a good practice to test the paper in your printer

before purchasing a large quantity. Of course, you should also

test labels and preprinted forms.

18

Page 28

Testing your paper

To test a supply of paper, take the top sheet from the package

and load it in the printer. Have your printer perform its self-test

as shown in Step 9.

Now carefully look at each character in every line. If no ink

bleeds, the paper should be suitable for your SQ-2000.

Then take a new sheet from the package. This time, turn the

sheet over and run the self test on the reverse side of the paper.

Some types of paper give you consistently better printing results

on one side of the paper than on the other side.

Your printing should have the crisp appearance of the sample

in Figure l-18.

MEMO

Don Donnison, President

All employees

As

you all know,

field in

the

we have ju

sensing

devi

red sensors.

A smart infrared sensor inco

ology in

standard

ns

for

the form of a

infrared sensing

a sophisticated sens

hig

ited:

Industrial robots

---------- -----Industrial quality assuranc

Figure l-18. Good print quality

Paper specially manufactured for use with ink jet printers can

also be ordered from your Epson dealer.

19

Page 29

10

Now you’re ready to print out your first document.

Simply follow the normal procedure for your word processor.

Additional information on printing documents can be found

in Chapter 3.

Printing Your First Document

20

Page 30

MEMO

-----

From:

To:

new

infrared sensors.

technology in

with

cations for

unlimited:

Don

Donnison.

President

All employees

AS

you all know,

field in

A smart infrared sensor incorporates

the sensing

the form of a

standard

Industrial robots

Industrial quality assurance

________

Detecting electronic equipment failurer

___

Security systems

Aviation

________

We believe the advances we are making will bring our

infrared sensing

a sophisticated sensing device

we have just entered an

device

industry,

microcomputer

high-speed

equipment.

microprocessor

The

are almost

company to the top of the sensing device industry.

Draft quality

MEMO

----

From:

To:

new field in the sensing device

infrared sensors.

Don Donnison, President

All employees

As you all know, we have just entered an

industry,

exciting

“Smart”

appli-

exciting

"smart"

A smart infrared sensor incorporates microcomputer

technology in the form of a high-speed microprocessor

with

cations

standard infrared sensing

for a sophisticated sensing device

equipment.

The

are

applialmost

unlimited:

We believe the advances we are making will bring our

company to the top of the sensing device industry.

Letter quality

Figure l-19. Sample document

21

Page 31

Chapter 2

Operation

This chapter covers the switches that control the operation of

the SQ-2000, the panel indicators, and initialization sequences.

Power Switch

The main power switch is a rocker switch on the left side of the

SQ-2000 towards the back. Press the front of the switch to turn

the power on and the back of the switch to turn it off.

Warning:

Never turn the power on or off by the switch at the main

outlet. Never turn the power on or off by inserting or removing the main cable at the outlet or the socket at the back

of the machine.

The SQ-2000 goes through a sequence of cleaning immediately

after being powered on and before powering off. You can damage the printer if this sequence is not carried out.

23

Page 32

Figure 2-l. Power switch and control panel

Control Panel Buttons

The control panel buttons are on the front of the printer. You

should familiarize yourself with their functions before operating

your printer.

Figure 2-2. Control panel buttons

ON LINE button

This button switches between the on-line and off-line states. If

the paper is properly loaded, the on-line state is automatically

selected when the power switch is turned on. The SQ-2000 then

stands by to receive data from the host computer.

24

Page 33

FF (Form Feed) button

This button is effective only when the SQ-2000 is in the off-

line state. When you press the FF button in the off-line state, the

paper is advanced to the next top of form.

LF (Line Feed) button

This button is effective only when the SQ-2000 is in the offline state. When you press this button in the off-line state, the

paper is advanced by a single line according to the current line

spacing value. If you hold down the switch, the paper continues

to advance.

Note:

To advance the paper a number of lines, use the FF and/or paper

feed knob. Pressing the LF switch continuously will shorten the

life of the motor.

CLEANING button

This button is effective only when the SQ-2000 is in the off-

line state. When you press the button at that time, the inside of

the print head is cleaned. Further details of cleaning are given in

Chapter 4.

SHEET FEED button

This button is effective only when the SQ-2000 is in the offline state. When you press the button in the off-line mode, the

paper bail opens and a single sheet of paper is loaded.

The first printed line is about one inch below the top edge of

the form.

25

Page 34

Indicators

The control panel has a number of lights that indicate the state

of the printer. The meanings of the indicators are as follows.

Figure 2-3. Control panel indicators

Table 2-l. Messages of panel indicator lights

Indicator

POWER

ON LINE

READY

INK LOW

PAPER OUT

Color

Green

Green

Green

Red

Red

ON

Power on Power off

On-line state

Ready to

receive data

Ink supply low

No more paper

OFF

Off-line state see below

Not ready to

receive data

Ink supply

adequate

Paper in platen

Blinking

see below

Meaning of blinking indicators

The ON LINE indicator will blink in the following cases:

Cause

Temperature of the print head

is below 59°F

At power-up during head cleaning

The READY light will blink during data transmission. This

flickering is normal.

Rate

5 times a second

2 times a second

26

Page 35

Paper-end detector

The printer is equipped with a paper-end detector that warns

you when the printer runs out of paper.

When

the printer detects

that the paper has run out, printing stops, the PAPER OUT indicator goes on and the buzzer sounds.

The PAPER OUT light goes out when paper is loaded. Howev-

er, printing does not restart until the ON LINE switch is pressed.

The SQ-2000 has an override which allows the paper to move

approximately one inch after the end of paper has been sensed.

For this reason, always remove paper using the LF or FF buttons.

If you manually remove the paper from the printer, you won’t

be sure the paper end has been detected. It is possible to later

place the printer in the on-line state and have data lost (and

printed onto the platen) if you don’t follow the correct procedure.

Ink low

When the ink cartridge is nearly empty, the INK LOW indicator lights and the buzzer sounds. Only 66 additional lines (approximately one page) can be printed in this state. If the ink is

low when the printer is switched on, the INK LOW indicator

lights up and the printer remains off-line until the ink cartridge is

replaced. To restart the printer, replace the cartridge, perform the

head cleaning operation (explained in Chapter 4), and then set

the printer on-line.

Buzzer

The buzzer is located on the control circuit board. It sounds for

about 0.25 second in the following cases:

l When the BEL code (ASCII code <BEL>) is sent to the printer.

l When the end of the paper is detected.

l When the printer carriage malfunctions.

l When the printer is out of ink.

Note:

The buzzer can be switched off when DIP switch SW2-6 is set to

ON (up). If a malfunction occurs the buzzer will sound even if

the switch is set to ON.

27

Page 36

Initialization

The SQ-2000

is

initialized

(i.e., set to a fixed set of conditions) in

the following cases:

l When you turn the power switch on.

l (When you use a parallel interface) If the INIT signal is re-

ceived from the host computer, causing pin 31 of the parallel

interface to become LOW.

l When you give the <ESC>@ software command.

The initialization sequence proceeds as follows (except when

using the software command):

1. All interface signals are reset.

2. The input buffer is cleared.

3. The ON LINE indicator goes on and the SQ-2000 waits to

receive data.

4. Printer parameters are initialized to the default settings.

5. The default values of the DIP switches are set.

The <ESC> @ sequence only performs the last two operations. The DIP switch values are set to the current values even if

the power has not been switched off.

28

Page 37

Chapter 3

Using the SQ-2000

This chapter tells you how to set up your word processor or

other applications software to work with the SQ-2000. If you are

interested in programming with the SQ-2000, the second part of

this chapter contains basic information on control codes and

ESCape sequences.

Using the SQ-2000 with Word Processors

Most word processing programs today support the SQ-2000

because it uses the same commands and control codes as many

Epson printers.

These programs usually have a setup or installation procedure

that prepares the program to work with a printer. This is often a

short question-and-answer session in which the program asks

two or three basic questions about your computer and printer. To

set up a program for use with the SQ-2000, you would give the

following answers:

Question

What type of computer

are you using?

What type of printer

are you using?

Answer

Your computer’s type

Choose LQ-1500 if listed. If not listed,

choose FX-80 or FX-100. If specific models are not listed, choose “Epson printer.” (When new printers are released, it

takes time to update the lists, so by

choosing another Epson printer, you

will still be sending the correct codes.)

29

Page 38

What type of interface Parallel or serial (this will depend on the

are you using?

Programs that don’t specifically list the SQ-2000 may ask other

questions about your printer. The following questions are asked

most often (the answers follow in bold).

interface board in the SQ-2000, your

computer, and the type of cable you

have).

1. Does your printer (SQ-2000) do standard backspacing?

2. How many passes of the print head are adequate for bold-

facing? Two

Some word processors let you redefine the printer instructions

(often called

processor certain information so that it can take advantage of

your printer’s features. This is covered later on in this chapter,

and in Appendix A.

printer drivers).

To do this, you must give your word

Yes

Using the SQ-2000 with other application programs

You can also use the SQ-2000 to print other documents, such as

spreadsheets, with various commercial software packages.

As with word processors,

straightforward. If your program has a printer selection routine,

then follow the advice given above.

most of your printing will be

Programming with the SQ-2000

This section provides an overview of the ASCII code system. It

also gives basic instruction on how to send control codes and

ESCape sequences to the printer in order to take advantage of the

SQ-2000’s special features, such as italics, enlarged, or proportional typestyles.

If you already know how to program your printer, you can

skip to Appendix A,

“ASCII Code Conversion Chart.”

“SQ-2000 Commands,” and Appendix B,

30

Page 39

Computer-to-printer communications

A computer and printer communicate by means of numbered

codes. If you press the letter A on the keyboard, it is translated

into a numeric code, transmitted to a peripheral device (such as a

video screeen or a printer) then displayed as the letter A.

To cope with the many different kinds of computers and print-

ers used today, a standard set of codes has been developed. This

set of codes is called the American Standard Code for Information

Interchange, or ASCII for short. Almost all computers use these

ASCII codes to communicate with printers.

There are ASCII codes for all of the letters in the alphabet, both

upper- and lowercase, and for the numbers from 0 to 9. The

ASCII code also includes most punctuation marks, and some

codes that control printer functions. If you refer to the ASCII chart

in Appendix B, you’ll find that all of these letters, numbers and

punctuation marks have been assigned code numbers from 33

through 255.

ASCII codes

Although these codes are standard from computer to compu-

ter, they can be expressed in a number of different ways. The

chart in Appendix B is a comparative table that lists each ASCII

code as a character (A, B, C, 1,2,3) and as a decimal or hexadecimal

number. For example, the letter A is represented as an A and as

the decimal number 65. If you wanted to print the letter A using

the BASIC language, you would use the decimal notation, written as CHR$(65).

The chart also shows the hexadecimal (or hex) value of each

character. The hexadecimal numbering system is based on units

of 16; our usual numbering system, decimal, is based on units of

10. In hex, the letter A is expressed as 41H (the H stands for

hexadecimal).

31

Page 40

Control codes

Most of the time you don’t give this code system a thought. If

you press A on the keyboard, the computer sends the code to the

printer and the letter A is printed. However, some printer codes,

like the one for a line feed, do not have a key on the keyboard.

These are the ASCII codes with values of less than 33. These

codes are called control codes because they control the operation

of the printer. These characters are not displayed on your screen

and aren’t printed as a character by your printer.

The ASCII codes 0 through 32 have commonly used abbreviations for their names, such as <LF> for a line feed. These controls are listed in Appendix A.

ESCape Sequences

There are not enough control codes for all of the advanced

features of modem printers, so multiple-code control sequences

have been developed. All of these control sequences begin with

the control code ASCII 27, which is called Escape. (In this manual

it is abbreviated as <ESC>.) These sequences can have more

than one code following Escape, depending on the command.

The ESCape code changes the interpretation of the codes that

follow it - they are interpreted as part of a printer command. For

example, if the SQ-2000 receives the number 52, it prints the

numeral 4 because 52 is the ASCII code for that letter. However, if

the printer receives a 27 just before the 52, it turns on the italic

mode, because ESCape “4” is the SQ-2000’s code for italic printing, as shown in Appendix A.

This same command could also be written with “4” (including

the quotation marks) in place of the 52. Many ESCape sequences

are written with letters or numbers enclosed in quotation marks.

These letters or numbers can be used in place of the decimal or

hexadecimal values as long as they’re placed in quotes. There’s

no functional difference between the two systems, but you might

find the letters and numbers easier to remember.

32

Page 41

Translating the ASCII code

You may also find that different manuals and programs use

different terms for the same characters or functions. For example,

your computer manual may say to send the decimal 10 for a line

feed, while your spreadsheet program recommends a <CR> or

CTRL-J for the same thing.

Appendix B contains a conversion chart for all the common

names of the ASCII codes, and shows the relationship between

the different forms of notation. In addition, Appendix A gives a

description of all the control codes and ESCape sequences used

on the SQ-2000.

How to send control codes to printer

The short program that follows illustrates the concepts of con-

trol codes and ESCape sequences. It is written in Microsoft

BASIC, but it can be adapted to other forms of BASIC or other

programming languages. If you have specific questions about

how BASIC works, consult the program’s documentation. How

to overcome problems specific to your computer is covered in

Chapter 8.

1. Make sure that you’re in BASIC; then type the following line

just as it appears here. (Don’t forget to include all semicolons,

even the ones at the end of the lines.)

10 LPRINT "NORMAL PRINTING" CHR$(lO) CHR$(13);

2. Now

press

RETURN,

The SQ-2000 prints:

type RUN, and press

RETURN

again.

NORMAL PRINTING

This line begins with a line number, 10, then the command

LPRINT. Anything that is enclosed in quotation marks after the

LPRINT command is sent to the printer.

If you check the ASCII chart in Appendix B, you’ll find that

CHR$(lO) is the control code for a line feed, so when the printer

receives this, it moves the paper up one line.

CHR$(13), according to the ASCII chart, is the code for carriage

return, so the print head returns to the left margin and awaits the

next command.

33

Page 42

3. Next type:

20 LPRINT CHR$(27) "4" "ITALIC PRINTING";

4. Now press RETURN, type RUN, and press RETURN again.

The SQ-2000 prints:

NORMAL PRINTING

ITALIC PRINTING

This time the printer receives a CHR$(27) which is the code for

ESCape or <ESC>. This tells the printer that whatever comes

next should be interpreted as a printer command.

Next comes “4” -- if you look under the SQ-2000 commands in

Appendix A, you’ll find that <ESC> “4” is the command for

italic print. So the SQ-2000 prints “ITALIC PRINTING” in italic

type.

5. Next type:

30 LPRINT CHR$(27)

6. Now press RETURN.

In this line the printer receives the ESCape code CHR$(27), so it

reads “5” as a printer code, in this case the code to turn off the

italic typestyle.

The next two codes, CHR$(1O) and CHR$(13), are for line feed

and carriage return respectively, as described in step 2.

7. Next type:

"5" CHR$(1O) CHR$(13);

40 LPRINT CHR$(27) "p" CHR$(1) "PROPORTIONAL

PRINTING";

50 LPRINT CHR$(27) "p" CHR$(0) CHR$(1O) CHR$(13);

8. Now press RETURN, type RUN, and press RETURN again.

The SQ-2000 prints:

NORMAL PRINTING

ITALIC PRINTING

PROPORTIONAL PRINTING

EMPHASIZED PRINTING

34

Page 43

The “p” 1 in line 40 turns on the proportional printing, and the

“p” 0 in line 50 turns it off.

9. Next type:

60 LPRINT CHR$(27) “E”

70 LPRINT CHR$(27) “F”;

10. Now press

The SQ-2000 prints:

NORMAL PRINTING

RETURN,

type RUN, and press

“EMPHASIZED PRINTING” ;

RETURN

again.

ITALIC PRINTING

PROPORTIONAL PRINTING

EMPHASIZED PRINTING

The “E” in line 60 turns on the emphasized printing and the “F”

in line 70 turns it off.

The program is now complete. To see it fully assembled on the

screen, type LIST and press

10 LPRINT “NORMAL PRINTING” CHR$(10) CHR$(13);

20 LPRINT CHR$(27) “4” “ITALIC PRINTING”;

30 LPRINT CHR$(27) “5” CHR$(1O) CHR$(13);

40 LPRINT CHR$(27) “p” CHR$(1) “PROPORTIONAL

PRINTING”;

50 LPRINT CHR$(27) “p” CHR$(0) CHR$(10) CHR$(13);

60 LPRINT CHR$(27) “E” “EMPHASIZED PRINTING”;

70 LPRINT CHR$(27) “F”;

RETURN. You

will see:

To send the entire program to the printer, type RUN, press

RETURN,

NORMAL PRINTING

and the SQ-2000 prints:

ITALIC PRINTING

PROPORTIONAL PRINTING

EMPHASIZED PRINTING

Using Master Select Command

The SQ-2000 can produce over 100 different combinations of

print styles. The Master Select command allows you to choose

any one of these styles. The Master Select command consists of

<ESC> “!" followed by a single ASCII code. The value of the

ASCII code determines the printing style that is selected. A typical master select command might look like this:

<ESC> “!” 66

35

Page 44

This command would select italic proportional print. In

BASIC, the same command would look like this:

LPRINT CHR$(27) “!” CHR$(66);

You can make up your own combinations quite easily. This is

possible because each print style has its own value you can use

with the Master Select command. To create a “custom” Master

Select Code, add the values of the print styles you wish to combine. The values of the print styles are as follows:

Elite

Proportional

Compressed

Emphasized

Expanded

Italic 64

Underlined

For example, if you want to find the code for elite emphasized

italic print you would add these values:

Elite

Emphasized

Italic

1

2

4

8

32

128

1

8

64

73

The Master Select Command you would use would look like

this:

<ESC> “!” 73 (in BASIC: CHR$(27) “!” CHR$(73);)

Note:

Proportional overrides pica/elite. Compressed works only in

draft print.

Some of the more popular styles the SQ-2000 can produce are

shown on the next four pages. The number following each example is the ASCII code (decimal) which will select that particular

print style.

Proportional print styles are shown first. These styles are avail-

able in both the letter quality and draft sets. The next page shows

the printing styles that are available in the letter quality set. The

final two pages show the printing styles that are available in the

draft set.

36

Page 45

The Select Print Quality command will select either the letter

quality or the draft set. The select print quality command looks

like this:

<ESC> “x” 0 - To select the draft set

<ESC> “x” 1 - To select the letter quality set

Table 3-1. Proportional print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Pica

Print

Sample

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

________

MISwiy

Master

Select

Number

10

66

74

130

138

194

202

Print

Sample

MISwiy

2

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Expanded

Master

Select

Number

34

42

98

106

162

170

226

234

37

Page 46

Table 3-2. Draft pica print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

italic underlined

Regular

Emphasized

Pica

Print

Sample

MISwiy 0

MISwiy 8

MISwiy 64

MISwiy 72

MISwiy 128

MISwiy 136

MISwiy 192

Master

Select

Number

MISwiy 200

Compressed

Print

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy 140

MISwiy

Master

Select

Sample

Number

MISwiy

4

12

68

76

132

196

204

Expanded

Print

Sample

MISwiy 32 MISwiy 36

Master

Number

Compressed

Expanded

Master

Sample

Number

MiSwiy 40 MISwiy 44

MlSwiy 96 MISwiy 100

MISwiy 104 MISwiy 108

MISwiy 160 MISwiy 164

MISwiy 168 MISwiy 172

MISwiy 224 MISwiy 228

MISwiy 232 MISwiy 236

Page 47

Table 3-3. Draft elite print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Elite

Print

Sample Number

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy 193

MISwiy 201

Master

Select

1

9

65

73

129

137

Compressed

Print

Sample Number

MISwiy

MIswiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Master

MISwiy

Select

5

13

69

71

133

141

197

205

Expanded

Print Print

Sample

MISwiy 33 MISwiy 37

MISwiy 41 MISwiy

MISwiy 97 MISwiy 101

Master Master

Select Select

Number

MISwiy 105 MISwiy

MISwiy 161 MISwiy

MISwiy 169 MISwiy

Compressed

Expanded

Sample

Number

45

109

165

173

MISwiy 225 MISwiy 229

MISwiy 233 MISwiy 237

Page 48

Table 3-4. Letter quality pica print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Pica Compressed

Print

Sample

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Master

Select

Number

0

8

64

72

128

136

192

200

Print

Sample Select

MISwiy

Master

Number

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

4

12

68

76

132

140

196

204

Expanded

Print

Sample

MISwiy 32

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Master

Select

Number

40 MISwiy

96 MISwiy

104 MISwiy

160 MISwiy

168 MISwiy

224 MISwiy

232 MISwiy

Compressed

Expanded

Print

Sample

Master

Select

Number

MISwiy 36

44

100

108

164

172

228

236

Page 49

Table 3-5. Letter quality elite print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Elite

Master

Sample

MISwiy

MISwiy

MISwiy 65

MISwiy

MISwiy

MISwiy

MISwiy 193

MISwiy

Select Select

Number

1

9

73

129

137

201

Compressed

Print

Sample Number

MISwiy 133

Miswiy

MISwiy 197

MISwiy 205

Master

MISwiy 5

MISwiy 13

MISwiy 69

MISwiy 77

141

Expanded

Print

Sample

Master

Select

Number

MISwiy 33

Compressed

Expanded

Print

Sample

Master

Select

Number

MISwiy 37

MISwiy 41 MISwiy 45

MISwiy 97

MISwiy

105

MISwiy 161

MISwiy

MISwiy

MISwiy

169

225

233

MISwiy 101

MISwiy 109

MISwiy 165

MISwiy 173

MISwiy 229

MISwiy 237

Page 50

Chapter3

Using the SQ-2000

This chapter tells you how to set up your word processor or

other applications software to work with the SQ-2000. If you are

interested in programming with the SQ-2000, the second part of

this chapter contains basic information on control codes and

ESCape sequences.

Using the SQ-2000 with Word Processors

Most word processing programs today support the SQ-2000

because it uses the same commands and control codes as many

Epson printers.

These programs usually have a setup or installation procedure

that prepares the program to work with a printer. This is often a

short question-and-answer session in which the program asks

two or three basic questions about your computer and printer. To

set up a program for use with the SQ-2000, you would give the

following answers:

Question

What type of computer

are you using?

What type of printer

are you using?

Answer

Your computer’s type

Choose LQ-1500 if listed. If not listed,

choose FX-80 or FX-100. If specific models are not listed, choose “Epson printer.” (When new printers are released, it

takes time to update the lists, so by

choosing another Epson printer, you

will still be sending the correct codes.)

29

Page 51

What type of interface Parallel or serial (this will depend on the

are you using?

Programs that don’t specifically list the SQ-2000 may ask other

questions about your printer. The following questions are asked

most often (the answers follow in bold).

interface board in the SQ-2000, your

computer, and the type of cable you

have).

1. Does your printer (SQ-2000) do standard backspacing?

2. How many passes of the print head are adequate for bold-

facing? Two

Some word processors let you redefine the printer instructions

(often called printer drivers). To do this, you must give your word

processor certain information so that it can take advantage of

your printer’s features. This is covered later on in this chapter,

and in Appendix A.

Yes

Using the SQ-2000 with other application programs

You can also use the SQ-2000 to print other documents, such as

spreadsheets, with various commercial software packages.

As with word processors,

straightforward. If your program has a printer selection routine,

then follow the advice given above.

most of your printing will be

Programming with the SQ-2000

This section provides an overview of the ASCII code system. It

also gives basic instruction on how to send control codes and

ESCape sequences to the printer in order to take advantage of the

SQ-2000’s special features, such as italics, enlarged, or proportional typestyles.

If you already know how to program your printer, you can

skip to Appendix A,

“ASCII Code Conversion Chart.”

“SQ-2000 Commands,” and Appendix B,

30

Page 52

Computer-to-printer communications

A computer and printer communicate by means of numbered

codes. If you press the letter A on the keyboard, it is translated

into a numeric code, transmitted to a peripheral device (such as a

video screeen or a printer) then displayed as the letter A.

To cope with the many different kinds of computers and print-

ers used today, a standard set of codes has been developed. This

set of codes is called the American Standard Code for Information

Interchange, or ASCII for short. Almost all computers use these

ASCII codes to communicate with printers.

There are ASCII codes for all of the letters in the alphabet, both

upper- and lowercase, and for the numbers from 0 to 9. The

ASCII code also includes most punctuation marks, and some

codes that control printer functions. If you refer to the ASCII chart

in Appendix B, you’ll find that all of these letters, numbers and

punctuation marks have been assigned code numbers from 33

through 255.

ASCII codes

Although these codes are standard from computer to compu-

ter, they can be expressed in a number of different ways. The

chart in Appendix B is a comparative table that lists each ASCII

code as a character (A, B, C, 1,2,3) and as a decimal or hexadecimal

number. For example, the letter A is represented as an A and as

the decimal number 65. If you wanted to print the letter A using

the BASIC language, you would use the decimal notation, written as CHR$(65).

The chart also shows the hexadecimal (or hex) value of each

character. The hexadecimal numbering system is based on units

of 16; our usual numbering system, decimal, is based on units of

10. In hex, the letter A is expressed as 41H (the H stands for

hexadecimal).

31

Page 53

Control codes

Most of the time you don’t give this code system a thought. If

you press A on the keyboard, the computer sends the code to the

printer and the letter A is printed. However, some printer codes,

like the one for a line feed, do not have a key on the keyboard.

These are the ASCII codes with values of less than 33. These

codes are called control codes because they control the operation

of the printer. These characters are not displayed on your screen

and aren’t printed as a character by your printer.

The ASCII codes 0 through 32 have commonly used abbreviations for their names, such as <LF> for a line feed. These controls are listed in Appendix A.

ESCape Sequences

There are not enough control codes for all of the advanced

features of modern printers, so multiple-code control sequences

have been developed. All of these control sequences begin with

the control code ASCII 27, which is called Escape. (In this manual

it is abbreviated as <ESC>.) These sequences can have more

than one code following Escape, depending on the command.

The ESCape code changes the interpretation of the codes that

follow it -- they are interpreted as part of a printer command. For

example, if the SQ-2000 receives the number 52, it prints the

numeral 4 because 52 is the ASCII code for that letter. However, if

the printer receives a 27 just before the 52, it turns on the italic

mode, because ESCape “4” is the SQ-2000’s code for italic printing, as shown in Appendix A.

This same command could also be written with “4” (including

the quotation marks) in place of the 52. Many ESCape sequences

are written with letters or numbers enclosed in quotation marks.

These letters or numbers can be used in place of the decimal or

hexadecimal values as long as they’re placed in quotes. There’s

no functional difference between the two systems, but you might

find the letters and numbers easier to remember.

32

Page 54

Translating the ASCII code

You may also find that different manuals and programs use

different terms for the same characters or functions. For example,

your computer manual may say to send the decimal 10 for a line

feed, while your spreadsheet program recommends a <CR> or

CTRL-J for the same thing.

Appendix B contains a conversion chart for all the common

names of the ASCII codes, and shows the relationship between

the different forms of notation. In addition, Appendix A gives a

description of all the control codes and ESCape sequences used

on the SQ-2000.

How to send control codes to printer

The short program that follows illustrates the concepts of con-

trol codes and ESCape sequences. It is written in Microsoft

BASIC, but it can be adapted to other forms of BASIC or other

programming languages. If you have specific questions about

how BASIC works, consult the program’s documentation. How

to overcome problems specific to your computer is covered in

Chapter 8.

1. Make sure that you’re in BASIC; then type the following line

just as it appears here. (Don’t forget to include all semicolons,

even the ones at the end of the lines.)

10 LPRINT "NORMAL PRINTING" CHR$(1O) CHR$(13);

2. Now

press

RETURN,

The SQ-2000 prints:

type RUN, and press

RETURN

again.

NORMAL PRINTING

This line begins with a line number, 10, then the command

LPRINT. Anything that is enclosed in quotation marks after the

LPRINT command is sent to the printer.

If you check the ASCII chart in Appendix B, you’ll find that

CHR$(lO) is the control code for a line feed, so when the printer

receives this, it moves the paper up one line.

CHR$(13), according to the ASCII chart, is the code for carriage

return, so the print head returns to the left margin and awaits the

next command.

33

Page 55

3. Next type:

20 LPRINT CHR$(27) "4" "ITALIC PRINTING";

4. Now press RETURN, type RUN, and press RETURN again.

The SQ-2000 prints:

NORMAL PRINTING

ITALIC PRINTING

This time the printer receives a CHR$(27) which is the code for

ESCape or <ESC>. This tells the printer that whatever comes

next should be interpreted as a printer command.

Next comes “4” -- if you look under the SQ-2000 commands in

Appendix A, you’ll find that <ESC> “4” is the command for

italic print. So the SQ-2000 prints “ITALIC PRINTING” in italic

type.

5. Next type:

30 LPRINT CHR$(27)

6. Now press RETURN.

In this line the printer receives the ESCape code CHR$(27), so it

reads “5” as a printer code, in this case the code to turn off the

italic typestyle.

The next two codes, CHR$(lO) and CHR$(13), are for line feed

and carriage return respectively, as described in step 2.

7. Next type:

"5" CHR$(1O) CHR$(13);

40 LPRINT CHR$(27) "p" CHR$(1) "PROPORTIONAL

PRINTING";

50 LPRINT CHR$(27) "p" CHR$(0) CHR$(10) CHR$(13);

8. Now press RETURN, type RUN, and press RETURN again.

The SQ-2000 prints:

NORMAL PRINTING

ITALIC PRINTING

PROPORTIONAL PRINTING

EMPHASIZED PRINTING

34

Page 56

The “p” 1 in line 40 turns on the proportional printing, and the

“p” 0 in line 50 turns it off.

9. Next type:

60 LPRINT CHR$(27) “E”

70 LPRINT CHR$(27) “F”;

10. Now press RETURN, type RUN, and press RETURN again.

The SQ-2000 prints:

NORMAL PRINTING

“EMPHASIZED PRINTING” ;

ITALIC PRINTING

PROPORTIONAL PRINTING

EMPHASIZED PRINTING

The “E” in line 60 turns on the emphasized printing and the “F”

in line 70 turns it off.

The program is now complete. To see it fully assembled on the

screen, type LIST and press RETURN. You will see:

10 LPRINT “NORMAL PRINTING” CHR$(10) CHR$(13);

20 LPRINT CHR$(27) “4” “ITALIC PRINTING”;

30 LPRINT CHR$(27) “5” CHR$(1O) CHR$(13);

40 LPRINT CHR$(27) “p” CHR$(1) “PROPORTIONAL

PRINTING”;

50 LPRINT CHR$(27) “p” CHR$(0) CHR$(10) CHR$(13);

60 LPRINT CHR$(27)

70 LPRINT CHR$(27) “F”;

“E” “EMPHASIZED PRINTING”;

To send the entire program to the printer, type RUN, press

RETURN, and the SQ-2000 prints:

NORMAL PRINTING

ITALIC PRINTING

PROPORTIONAL PRINTING

EMPHASIZED PRINTING

Using Master Select Command

The SQ-2000 can produce over 100 different combinations of

print styles. The Master Select command allows you to choose

any one of these styles. The Master Select command consists of

<ESC> “!" followed by a single ASCII code. The value of the

ASCII code determines the printing style that is selected. A typical master select command might look like this:

<ESC> “!” 66

35

Page 57

This command would select italic proportional print. In

BASIC, the same command would look like this:

LPRINT CHR$(27) “!” CHR$(66);

You can make up your own combinations quite easily. This is

possible because each print style has its own value you can use

with the Master Select command. To create a “custom” Master

Select Code, add the values of the print styles you wish to combine. The values of the print styles are as follows:

Elite

Proportional

Compressed

Emphasized

Expanded

Italic 64

Underlined

For example, if you want to find the code for elite emphasized

italic print you would add these values:

Elite

Emphasized

Italic

1

2

4

8

32

128

1

8

64

73

The Master Select Command you would use would look like

this:

<ESC> “!” 73 (in BASIC: CHR$(27) “!” CHR$(73);)

Note:

Proportional overrides pica/elite. Compressed works only in

draft print.

Some of the more popular styles the SQ-2000 can produce are

shown on the next four pages. The number following each example is the ASCII code (decimal) which will select that particular

print style.

Proportional print styles are shown first. These styles are avail-

able in both the letter quality and draft sets. The next page shows

the printing styles that are available in the letter quality set. The

final two pages show the printing styles that are available in the

draft set.

36

Page 58

The Select Print Quality command will select either the letter

quality or the draft set. The select print quality command looks

like this:

<ESC> “x” 0 -- To select the draft set

<ESC> “x” 1 -- To select the letter quality set

Table 3-1. Proportional print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Pica

Print

Sample

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Master

Select

Number

10

66

74

130

138

194

202

Print

Sample

MISwiy

2

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Expanded

Master

Select

Number

34

42

98

106

162

170

226

234

37

Page 59

Table 3-2. Draft pica print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

italic underlined

Regular

Emphasized

Pica

Print

Sample

MISwiy 0

MISwiy 8

MISwiy 64

MISwiy 72

MISwiy 128

MISwiy 136

MISwiy 192

MISwiy 200

Master

Select

Number

Compressed

Print Select

Sample Number

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy 140

MISwiy

MISwiy

Master

4

12

68

76

132

196

204

Expanded

Print

Sample

MISwiy 32 MISwiy 36

Select

Number

Compressed

Expanded

Master

Select

Number

MISwiy 40 MISwiy 44

MlSwiy 96 MISwiy 100

MISwiy 104 MISwiy 106

MISwiy 160 MISwiy 164

MISwiy 168 MISwiy 172

MISwiy 224 MISwiy 228

MISwiy 232 MISwiy 236

Page 60

Table 3-3. Draft elite print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Elite

Print

Sample Number

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy 193

MISwiy 201

Master

Select

1

9

65

73

129

137

Compressed

Print

Sample Number

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

Master

MISwiy

Select

5

13

69

77

133

141

197

205

Expanded

Print Print

Sample

MISwiy 33 MISwiy 37

MISwiy 41 MISwiy

MISwiy 97 MISwiy 101

Master Master

Select Select

Number

MISwiy 105 MISwiy

MISwiy 161 MISwiy

MISwiy 169 MISwiy

Compressed

Expanded

Sample

Number

45

109

165

173

MISwiy 225 MISwiy 229

MISwiy 233 MISwiy 237

Page 61

Table 3-4. Letter quality pica print styles

Regular

Emphasized

Italic

Regular

Emphasized

Underlined

Regular

Emphasized

Italic underlined

Regular

Emphasized

Print

Sample

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy

MISwiy