Page 1

EPSON TERMINAL PRINTER

SQ - 870/1170

4001225

REV.-A

Page 2

o

NOTICE

“ All

rights reserved. Reproduction of any part of this manual in any from

whatsoever without SEIKO EPSON’s express written permission is forbidden.

“ The contents of this manual are subject to change without notice.

“ All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

‘ The above notwithstanding SEIKO EPSON can assume no responsibility for any

errors in this manual or the consequences thereof.

@

Copyright 1992 by SEIKO EPSON CORPORATION

Nagano,

Japan

-i-

Page 3

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1 ) personal injury, and 2) damage

to equipment:

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which,

if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

KP CHIPS AND CIRCUITRY, USE STATIC

- ii –

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of the

The instructions and procedures included herein are intended for the

experienced repair technician,

precautions on the preceding page. The chapters are organized as follows:

and attention should be given to the

SQ-870/l

170.

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 - Describes preventive maintenance techniques.

‘

The contents of this manual are subject to change without notice.

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Includes a step-by-step guide for product disassembly and

assembly.

Includes a step-by-step guide for adjustment.

Provides Epson-approved techniques for troubleshooting.

–

iv -

Page 5

REVISION SHEET

REVISON DATE ISSUED CHANGE DOCUMENT

@

A

L

Feb. 21, 1992

1st issue

,:.;-.

,

..,,.

e

-v-

Page 6

TABLE OF CONTENTS

REV.-A

CHAPTER 1.

CHAPTER 2.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENTS

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

-

vi –

Page 7

REV

CHAPTER 1

GENERAL DESCRIPTION

1.1

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

.

1-3

1.2.1 Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Firmware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3

INTERFACE Overflew....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Parallel interface...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4

CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5

DIP SWITCHES AND JUMPER SETTING ......................................1-18

1.5.1 DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Jumper Setting

1.6

OPERATING

1.6.1

1.6.2

1.6.3

1.6.4

1.6.5

1.6.6

1.6.7

1.6.8

INSTRUCTIONS...

Self.Test...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hexadecimal Dump Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper-out Detection and Forms Override Function . . . . . . . . 1-20

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buzzer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sheet Loading and Sheet Ejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . 1-20

.

1-3

.

1-9

.

..1-14

.

........1 -14

.

....1 -16

.

1-18

1-19

.

1-20

.

1-20

.

..............1 -20

.

1-21

.

...........1 -21

.

.........1 -22

1.6.9

1.6.10 Adjust Lever Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.11 Printhead Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.12 Ink Charge

1.6.13 Ink End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.14 Cover Open Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.7

MAIN COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1

1.7.2 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.3

1.7.4 Printer Mechanism

1.7.5 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tear-off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C076

MAIN Board (Main Control Circuit Board)

C076

PSB/PSE Board (Power Supply Circuit Board)

(M.471

O/476 O).....................................l.28

............l-26

.

......................1 -28

.

1-23

.

1-23

.

.....1 -24

1-24

.

1-24

.

1-25

.

......1 -27

....l-27

I.i

Page 8

REV.-A

LIST OF FIGURES

Figure 1-1.

Figure 1-2.

Figure 1-3.

Figure

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

Figure 1-9.

Figure 1-10. Control Panel

Figure 1-11. Lever Positions

Figure 1-12.

Figure 1-13.

Figure 1-14. Control Panel

Figure 1-15.

Figure 1-16. Model-4710/4760 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Figure 1-17. Housing

Exterior View of the

Nozzle Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Release Lever Positions

14.

Label Size

Printable Area for Cut Sheets

Printable Area for Continuous Papers

Printer Operating Environment

Character Matrix

Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SQ-1 170 Component Layout

C076

C076

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAIN Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PSB/PSE Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SQ-1 170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...........................................................l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

.

.....1-3

1-4

1-5

1-6

1-6

1-8

1-13

. 1-14

1-16

1-23

1-25

1-26

1-27

-27

1-28

Table 1-1.

Table 1-2.

Table 1-3.

Table 14.

Table 1-5.

Table 1-6.

Table 1-7.

Table 1-8.

Table 1-9.

Table 1-10.

Table 1-1

Table 1-12.

Table 1-13.

Table 1-14.

Table 1-15.

Table 1-16.

LIST OF TABLES

Interface Options

Optional Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications for Cut Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications for Continuous Papers

Envelopes

Labels Specifications

Built in Bit-map Fonts

Printing (Text Mode)

Printing (Bit Image Mode)

Character Matrix and Character Size

Connector Pin Assignments and Signal Functions . . . . . 1-14

f.

Settings for DIP Switch

Settings for DIP Switch 2 (SW2).......... . . . . . . . . . . . . . . . . . . . . . . . . . . .

International Character Set Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page Length

Lever Positions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

(sw1)................................-.....1-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

.

1-2

.

1-4

1-4

1-5

1-5

1-9

1-1o

1-11

1-12

.

1-18

1-19

1-19

1-23

,..

...

kJ

Iii

Page 9

1.1 FEATURES

The

SQ-870/l

that is upper compatible with the

●

Use of

Ability to print multi-point fonts

Ability to receive and print raster graphic images

Compatibility with the

Printing speeds:

●

660

550

240

200

●

Optional interface card

Clear, easy-to-read printing with standard EPSON fonts

●

Multiple fonts resident in the printer

●

2 scalable fonts (Roman, Saris Serif)

8 LQ bit-map fonts (Roman, Saris Serif, Courier, Prestige, Script, Script C, Orator, Orator-S)

1 draft bit-map font

Control panel switch selection of fonts, pitch, and cut-sheet feeder

●

●

Optional tractor unit that can make up push-pull tractor

Easy handling of cut sheets with the optional cut-sheet feeder

●

●

Continuous Paper

Two ways to insert continuous paper (front/rear path)

Backout & loading

Continuous paper can be used without removing

Standard tractor unit can be attached in two positions (front/rear)

Cut Sheet

●

Two ways to insert cut sheets (front/top)

Auto loading

170 is a high speed 48-nozzle ink jet printer which provides advanced paper handling

ESC/P

2 control codes

cps (draft, 12 cpi)

cps (draft, 10 cpi)

cps (LQ, 12 cpi)

cps (LQ, 10 cpi)

LQ\SQ

TSQ-4800.

series available on the market

The printer’s main features are as follows:

(CSF) bin

CSF

REV.-A

The

SQ-870/l

options ensure compatibility with a wide variety of computers. Table 1-1 lists the interface options, Table

1-2 lists the optional units available for the

the

SQ-870/l 170

170 is equipped with the standard EPSON 8-bit parallel interface and various interface

SQ-870/l

170, and Figure 1-1 shows an exterior view of

Table 1-1. Interface Options

Descriptions

1-1

NOTE: Refer

Model

C82305

C82306

C82307

C82308

C82310

C82313

to the “Optional Interface Technical Manual” for details.

Serial interface card (inch screw)

Serial interface card (mini screw)

32KB serial interface card (inch screw)

32KB

serial interface card (mini screw)

32KB parallel interface card

32KB IEEE-488 interface card

Page 10

REV.-A

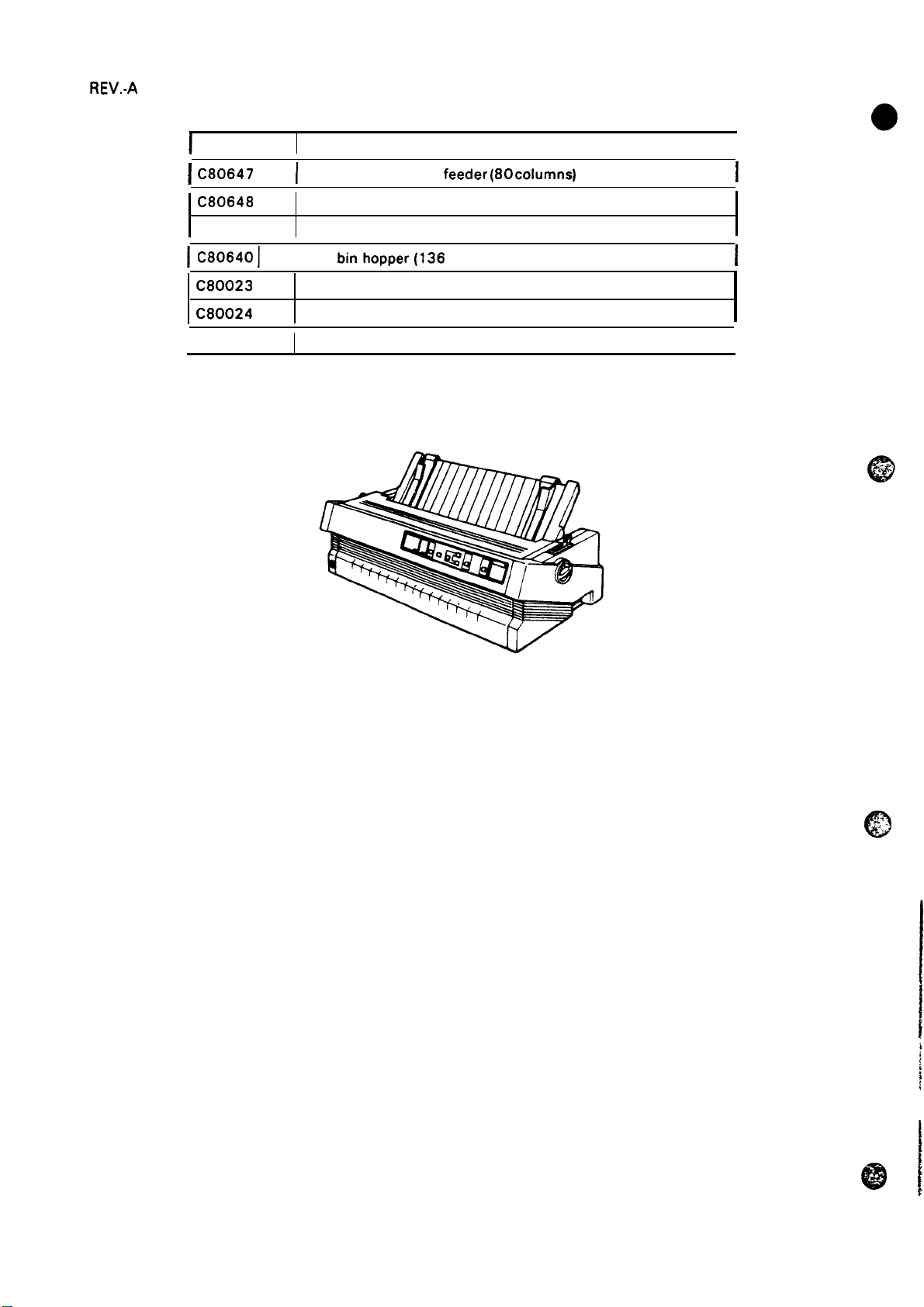

Table 1-2. Optional Units

Model

1

I C80647

C80648

C80637 Second bin hopper (80 columns)

/

Single-bin cut-sheet feeder (80

Single-bin cut-sheet feeder (136 columns)

Descriptions

columns]

I

I

IC80640 I

C80023

C80024

SO2OO1O

Second

Figure 1-1. Exterior View of the S(2-870/1 170

binhopper(136

Tractor unit (80 columns)

Tractor unit (136 columns)

Ink cartridge

columns)

I

J

1-2

?5

.,,

0

.

e

Page 11

1.2 SPECIFICATIONS

REV.-A

This section provides specifications for the

1.2.1

Hardware Specifications

SQ-870/l

170 printer.

Printing method On-demand type ink jet system

Nozzle configuration

48 nozzles (48 X

Al

h

1

‘o

a

m

~

3

\-

*

i

‘g

~

s

~1

*

●

A2

1/45”

1

diagonal)

2

‘

A3

(7.125°)

47/45”

Figure 1-2. Nozzle Configuration

Feeding methods

Friction feed (front/top)

Push tractor feed (front/rear)

Push-pull tractor feed (with optional tractor) (front/rear)

h

NOTE: Do not perform pull tractor feed.

Line spacing

Paper insertion

Paper-feed speed

1/6 inch, 1/8, or programmable in units of 1/180 or 1/360 inch

Friction feed —

Tractor feed — Front or rear

Friction without

Friction with

Tractor 45

Front or top side

side

CSF 45 msec (1/6-inch feed)

4.5 inches per second

CSF 49 msec (1/6-inch feed)

4.0

ips (continuous)

msec (1/6-inch feed)

4.5

ips (continuous)

(ips) (continuous)

NOTE: Following are the precautions for handling paper.

1

Friction feed (release lever in FRICTION POSITION).

The paper must be loaded from the front or top entrance.

●

Do not use continuous paper.

●

Do not perform any reverse paper feeds within the top 8.5 mm (.34 in.) or bottom 22 mm (.87 in.) area.

●

Do not perform reverse feeds greater than 1/6 inch after a paper end has been detected.

●

Push tractor feed (release lever in REAR PUSH POSITION or FRONT PUSH POSITION).

2

The paper must be loaded from the front or rear entrance.

●

Release the friction-feed mechanism.

●

Do not perform reverse feeds greater than 1/6 inch.

●

●

Since accuracy of paper feed cannot be assured after the paper end has been detected, do not perform

reverse feeding after the detection of a paper end.

1-3

Page 12

REV.-A

3. Push-pull tractor feed (release lever in REAR PUSH POSITION or FRONT PUSH POSITION).

● The paper must be loaded from the front or rear entrance.

● Release the friction-feed mechanism.

● Attach the pull tractor unit.

O Ensure that there is no slack in the paper between the platen and the pull tractor.

● Precisely adjust the horizontal position of the pull tractor and push tractor.

● Paper for multiple copies must be spot pasted on both side of the perforation

holes.

betvveen

the tractor

● Do not perform reverse feeds greater than 1/6 inch.

● Do not perform a reverse feed after the paper end has been detected.

Figure 1-3. Release Lever Positions

Paper specifications See tables 1-3, 1-4, 1-5, and 1-6

Table 1-3. Specifications for Cut Sheets

Width

Length

Thickness 0.065 mm to 0.10 mm (0.0025 in. to 0.0039 in.)

Weight

Quality

182 mrn to 257 mm

182 mm to 420 mm (7.2 in. to 16.5 in.) (136 columns)

182 mm to 364 mm (7.2 in. to 14.3 in.)

14 lb to 22

lb (52.3

Standard paper (photocopier paper, etc.)

(7.2 in. to 10.1 in.) (80 columns)

g/m2

Table 1-4. Specifications for Continuous Papers

Width

Quality

Thickness

Weight

I 101 mm to 254 mm (4.0 in. to 10.0 in.) (80 columns)

I

101 mm to 406 mm (4.0 in. to 16.0

Stan

jard

paper

0.065 mm to 0.10 mm (0.0025 in. to 0.0039 in.)

lb to 22 lb (52.3 g/m2 to 82

14

to 82 g/m2)

g/m2)

Rear Push Position

\

Release Position

in.)

(136 columns]

1-4

f-’

..:

i..)

Page 13

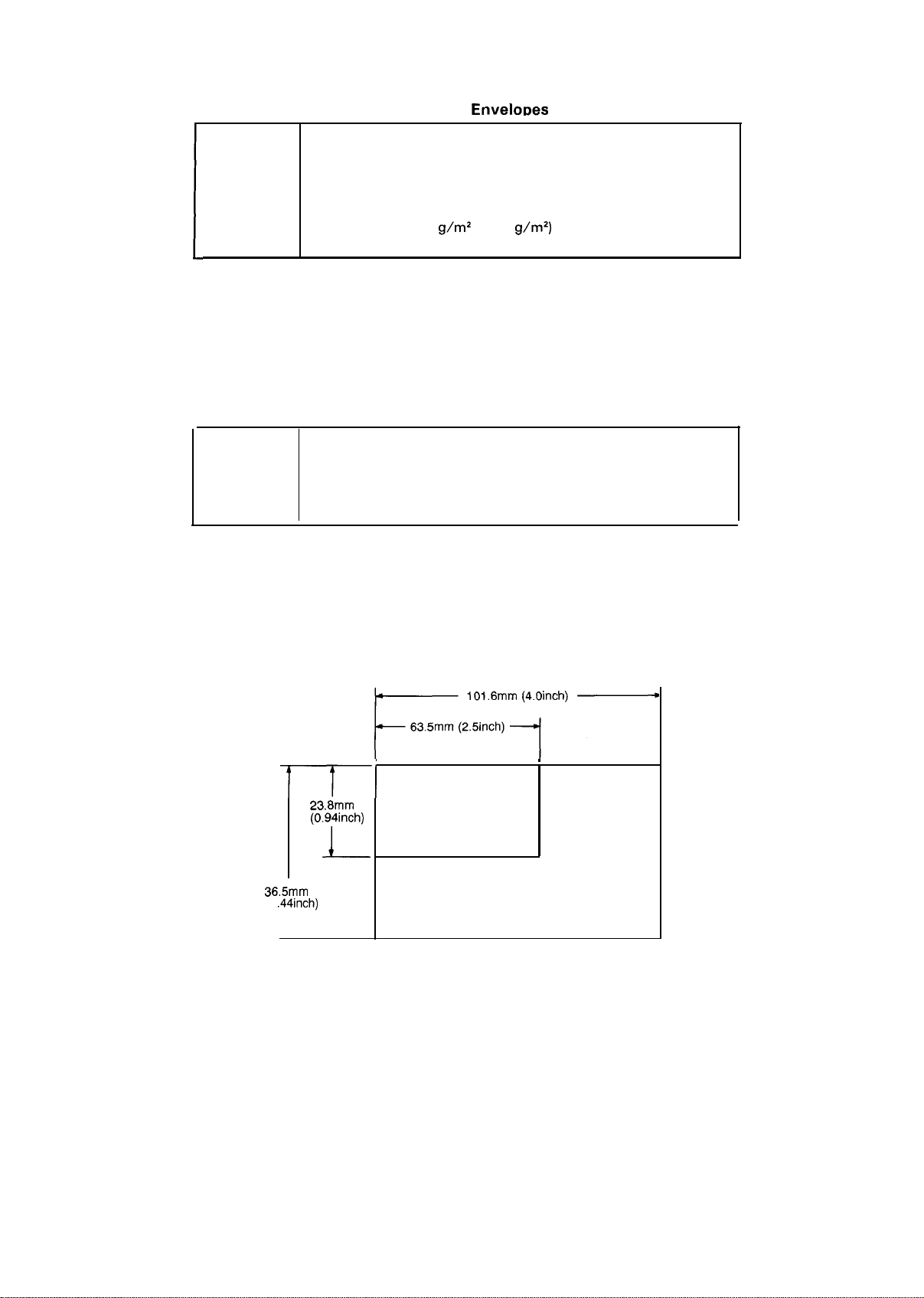

Table 1-5. EnveIo~es

REV.-A

Size

Thickness

Weight

Quality

[

NOTES: ● Printing on envelopes is available only at normal temperatures and only using top

insertion.

● Keep the longer side of the envelope horizontal during insertion.

● Place the left edge of a No. 6 envelope at the sheet guide setting mark.

Label size

Copies

Thickness 0.22 mm (0.0079 in.) maximum

NOTES: ● Printing on labels is available only at normal temperatures.

● Labels must be of the continuous type.

● Examples of labels AVERY CONTINUOUS FORM LABELS

No. 6 166 mm X 92 mm (6.5 in. X 3.625 in.)

No. 10240 mm X

0.16 mm to 0.52 mm (0.0063 in. to 0.0197 in.)

Differences in thickness within the printing area must be less

than 0.25 mm (0.0098 in.)

12 lb to 24 lb (45

Bond paper, standard paper, airmail

Table 1-6. Labels Specifications

2.5 in. X 0.94 in.

4.0 in. X 0.94 in.

4.0 in. X 1.44 in.

These three kinds of labels are recommended.

AVERY MINI-LINE LABELS

104 mm (9.5 in. X 4.125 in.)

g/m2

to 91

g/m2)

r’

36.5mm

.44inch)

(1

23.8mm

(0.94inch)

L

F;;::~?nch)-

Figure 1-4 Label Size

‘

1-5

Page 14

REV.-A

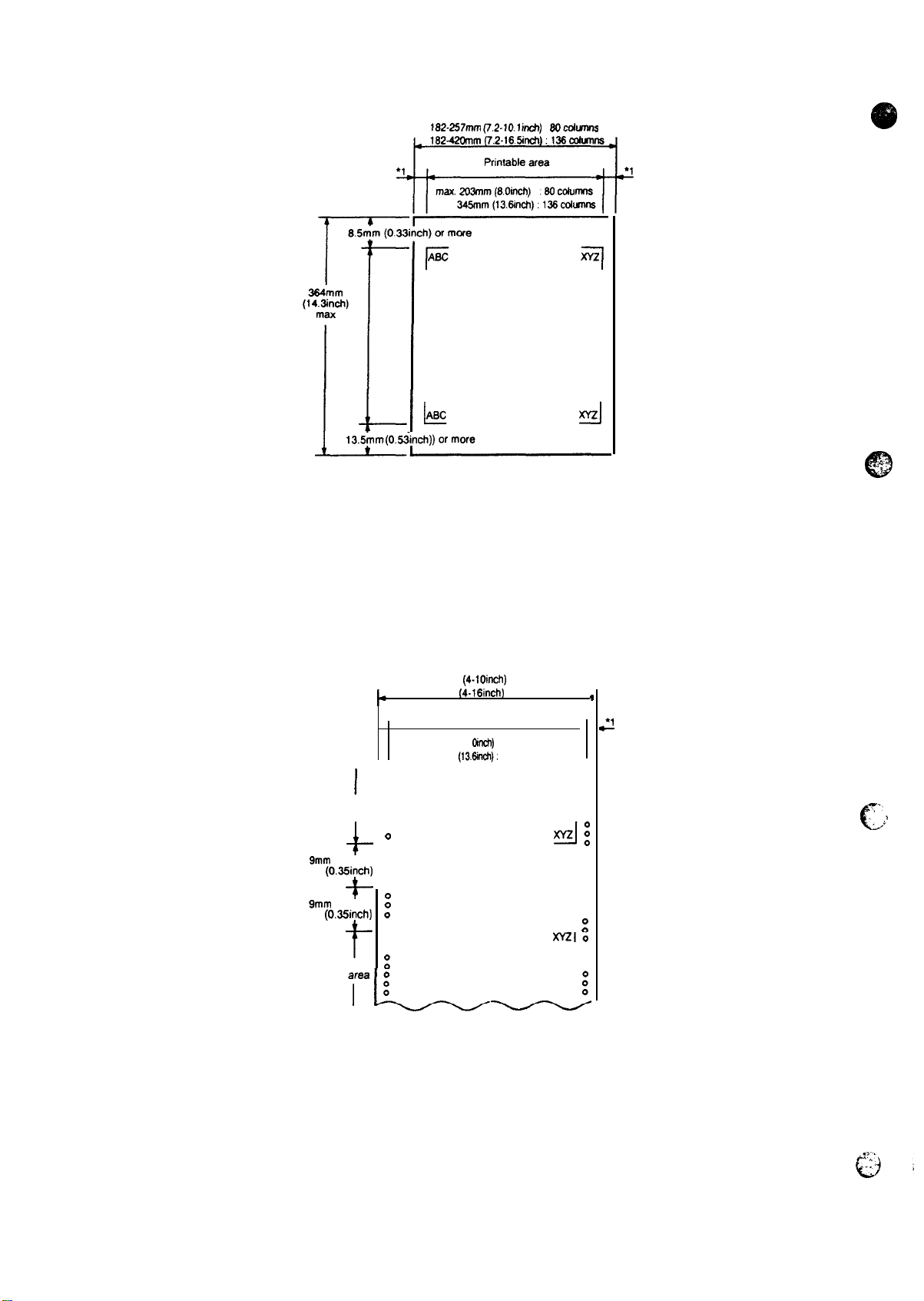

Printable area

See figures 1-5 and 1-6

=

13.5rnm (0.53-inti)

182-257mm ~.2-10.lind?)

or more

:

60cdm

k~

● 1: 80 columns: 3.0 mm (0.12 in.) or more when the width of paper is less than 229 mm (9 in.).

13 mm (0.51 in.) or more when the width of paper is 257 mm (10.1 in.).

136 columns: 3.0 mm (O. 12 in.) or more when the width of paper is less than 364 mm (1 4.3 in.)

25 mm (0.98 in.) or more when the width of paper is 420 mm (16.5 in.).

0

q.

~~•

NOTE: The paper feed accuracy can not be assured within the following area.

Front insertion: 47 mm (1 .85 in.) from the bottom edge of paper.

Rear insertion: 26 mm (1 .02 in.) from the bottom edge of paper.

Figure 1-5. Printable Area for Cut Sheets

Printable

9mm

or more

(0.35inch)

9mm

or more

(0.35inch)

Printable

101 -254mm

101 -406mm

b

●

1

max. 203mm (6.

0

0

I

0

0

area

0

0

0

ABC

L

o

4-

o

0

0

0

-----------------

r

?

:

o

0

0

o

ABC

o

-f-

r

:

[4-16inch)

Printable area

(13.6inch):

345mm

(4-10inch)

Oinch)

: 60 columns

136 columns

: 60 columns

: 136 columns

XYZ:

-1

-

XYzo

1

*

●

-

0

0

0

0

0

0

0

0

0

o

0

0

:

0

o

0

.

.,

>$’

c

.

1: 80 columns:

●

136 columns:

13 mm (0.51 in.) or more when the 101 mm (4.0 in.) to 241 mm (9.5 in.) width paper

is used.

26 mm (1 .02 in.) or more when the 254 mm (1 O in.) width paper is used.

13 mm (0.51 in.) or more when the “101 mm (4.0 in.) to 377.8 mm (1 4.87 in.) width

paper is used.

15 mm (0.59 in.) or more when the 381 mm (15 in.) to 406 mm (16 in.) width paper

is used.

Figure 1-6. Printable Area for Continuous Papers

1-6

@’

Page 15

REV.-A

Ink cartridge

Type:

Color: Black

Ink capacity:

Print capacity (depending on the cleaning operation):

Ink life: 2 years from production date

Storage temperature:

Dimension of cartridge:

Exclusive ink cartridge

105 to 115 cc

Draft:

Letter Quality: 3 million characters

–30 to 40 degrees C (–22 to 104 degrees F) -Storage

(within a month at 40 degrees C (104 degrees F))

–30 to 60 degrees C (–22 to 140 degrees F) -Transit

(within a month at 40 degrees C (104 degrees F))

(within 120 hours at 60 degrees C (140 degrees F))

24.8 mm (W) X 138 mm (D) X 99.3 mm (H)

(0.98 inch X 5.43 inch X 3.91 inch)

6 million characters

NOTES:

●

Ink will be frozen under –7 degrees C (19 degrees F) environment, however it will be usable after placing

it at room temperature. (It will take approx2.5 hours until melting at 25 degrees C (77 degrees F).)

● Do not use the ink cartridge which has been stored longer than the ink life.

Reliability

Life of

Safety approvals Safety

Electrical specifications 120 V version Rated voltage

printhead

Mean cycles between failures

Mean time between failures

4000 million dots/nozzle

standardsULl

Radio frequency interference

950 with D3 (U. Aversion)

CSA22.2#220

EN 60950 (TUV) (European version)

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

Insulation resistance

(MCBF) 5 million lines (excluding printhead)

(MTBF)

(RFI)

4000 power on hours

duty)(SQ-870)

6000 power on hours (POH)

duty)(SQ-1 170)

FCC class B (U. Aversion)

VDE0871 (self-certification) (European

version)

120

VAC

103.5 to 132

50 to 60 Hz

49.5 to 60.5 Hz

0.6 A

Approx. 30 W

Approx. 30 W (SQ-1 170)

(during a self-test in draft mode, 10 cpi)

10 Megohms minimum (at 500 VDC

between AC line and chassis).

VAC

(POH) (25%

(SQ-870)

(25’%.

1-7

Page 16

REV.-A

Environmental

conditions

Dielectric strength

220/240

version

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

(during a self-test in draft mode, 10 cpi)

Insulation resistance

between AC line and chassis).

Dielectric Strength

VAC rms 1 second (between AC line

and chassis)

Temperature

10 to 35 degrees C (50 to 95 degrees F) – operating

–30 to 60 degrees C (–22 to 140 degrees F) -in shipment

container

Humidity 20 to 80 % RH - operating

5 to 85 % RH - storage

1000

VAC rms 1 minute or 1200

VAC rms 1 second (between AC line

and chassis)

220 to 240

198 to 264

VAC

VAC

50 to 60 Hz

49.5 to 60.5 Hz

0.4 A

Approx. 30 W

(SQ-870)

Approx. 30 W (SQ-1 170)

10 Megohms minimum (at 500 VDC

1250

VAC rms 1 minute or 1500

o

.,.-:.

,

.,,

”’-

,,

,,

NOTE: Figure 1-5 shows the operating environment.

I

Figure 1-7. Printer Operating Environment

Resistance to

shock

Resistance to 0.25 G, 55 Hz,

vibration

Physical specifications Weight

Dimensions 462 mm (width) X 325 mm (depth) X 205 mm (height)

1 G, within 1 ms - operating

2 G, within 1 ms - storage

0.50 G, 55 Hz,

9.5 Kg,

approx. (2 1.0 pounds, approx.)

12.2 Kg, approx. (27.0 pounds, approx.) (SQ-1 170)

18.2

in(width) X 12.8 in(depth) X 8.1 in(height)

657 mm (width) X 325 mm (depth) X 205 mm (height)

25.9

in(width) X 12.8 in(depth) X 8.1 in(height) (SQ-1 170)

Temperature (“c)

max - operating

max - storage

(SQ-870)

(SQ-870)

1-8

Page 17

REV.-A

1.2.2 Firmware

Control code

Printing direction

Input data buffer

Character code

Character tables

Bit-map fonts

Scalable fonts

I

EPSON Roman

EPSON Saris-serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON Script-C

EPSON Orator

EPSON Orator-S

EPSON DRAFT

Specifications

ES

C/PTM

Bi-directional with logic seeking (text printing)

Uni-directional

16KB (Standard)

128KB (factory option)

8 bits

Italic character table, PC 437, PC 850, PC 860, PC 863, PC 865 (PC indicates

character table for

Fonts and pitches

See table 1-7

EPSON Roman

EPSON Saris-serif

I

Family No. I 10 CPI I 12 CPI I 15 CPI I Proportional

level 2 (EPSON standard code for printers)

(bit-image printing)

personal computer)

8 pt to 32 pt

8 pt to 32 pt

Table 1-7.

o

1

2

3

4

9

7

8

..-

Built in

Bit-ma~

Fonts

0 0 0 0

0 0

0 0 0

0 0

0 0

0 0

0

0

.

“

0 0 0

0 0

0

0

0

x

x

I

●

●

●

.

.

●

xx

0-- Resident

,

--

Desired pitch is made by software using selected font

x

--

print Roman 15

CPI

xx -- Print LQ proportional font selected by ESC k

Printing modes

Selection and mixture of the following modes are allowed, excluding 15

condensed mode:

O Print quality (draft/letter quality)

O Character pitch (1 O, 12, 15, or proportional)

O Condensed

O Double-width

O Double-height

O Emphasized

O Double-strike

O Italic

O Underlined

O Double-underlined

O Overscore

O Strike-through

O Outline

O Shadow

1-9

cpi

Page 18

REV.-A

Printing speed

Printing columns

Character matrix

Character size

Print

Pitch

10

Con-

densed

0 0 0 80 136

0 0

0

0

1

1

12

0 0 0

0

0

See Tables 1-8 and 1-9.

See Table 1-8.

See Table 1-10.

See Table 1-10.

Table 1-8. Printing (Text Mode)

Empha-

sized

1

1

x

x

0

1

Double

width

1

0

1

o

1

1

0 96

Printable

Columns

80

COi.

40 68

80

40

137

68 116

96

48

136

136

233

163

81

163

68

Col.

Charactar Printing Speed

Pitch

(cpi)

10

5

10

,

5

17.1

8.5

12

6

12

(Cps)

Draft

550

275 100

400

200 100

684

342

660

330 120

480

LQ

200

200

342

171

240

240

;,

?

e

CPI:

CPS:

LQ:

0

1

1

15

0 0 0

0

0

0

1

characters per inch

characters per second

letter quality

1

x

x

0

1

1

x

1

o

1

1

0

1

x

48 81 6 240 120

160 272 20

80 136

120

60

120

60

204

102 7.5 412

204

102

Cannot be condensed

7.5

10

15

15

800

400

825 300

600

300

400

200

150

300

150

1-1o

(’J

,<..

~

Page 19

Pins

8

m

REV.-A

Table 1-9. Printing (Bit Image Mode)

Dot

Density

(DPI)

0

60

Adjacent

Dot

Printing

Yes

256 X n2 + nl

80 Columns

480 816

136 Columns

Printing

Speed

(IPS)

55

DPI:

IPS:

2

3

4

6

24

48

32 60

33

38 90

39

40 360

71

72 360

73 360

dots per inch

inches per second

1

120

120

240

80

90

120

180

180

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

No

Yes

960

960

1920

640

720 1224 55

480

960

720

1440 2448 20

2880

1440 2448 20

2880

2880

1632 20

1632

3264

1088

816 55

1632 20

1224 55

4896 20

4896 20

4896 20

20

20

20

1-11

Page 20

REV.-A

Table 1-10. Character Matrix and Character Size

Printing Mode

;

Draft, 10 pitch

Draft, 12 pitch

Draft, 15 pitch 11 X 32

Draft, 17 pitch 15 x 44

Draft, 20 pitch 13 x 44

LQ,

10 pitch

LQ,

12 pitch 27 X 22

LQ,

15 pitch 22 X 16

LQ,

17 pitch 16 X 44

LQ,

20 pitch

LQ,

proportional Max. 37 X 44

LQ,

proportional,

super/subscript Min. 12 X 32

Face Matrix

15 x 44

13 x 44

31 x 22

14 x 44

Min. 18 X 44

Max. 28 X 32

HOD Character Size

180

180

180

360

360

360

360

360 1.6 X 2.3

360

360

360

360

360

360

2.1 x 3.1

1.s

X 3.1

1.6 X 2.3

1.1 x 3.1

0.9 x 3.1

2.2 x

3.1

1.9 x 3.1 180

1.1

x 3.1

1.0

x 3.1

2.6 X 3.1 180

1.()

x 3.1

1.8 X 2.3 180

0.7 X 2.3

Unit

ESC

120

120

120

120

120

180

180

180

180

sp

,

*

@

NOTES: ●

HDD

is horizontal dot density in dots per inch.

● Face matrix and character size indicate the maximum size of a character. This value is

dependent on paper, etc.

● Unit

ESC

sp (which also can be sent as unit, followed by the character string

indicates the minimum length to be added to the right of the character specified in the

SP control code.

CHR$(&h20)),

ESC

1-12

@

..; ,

Page 21

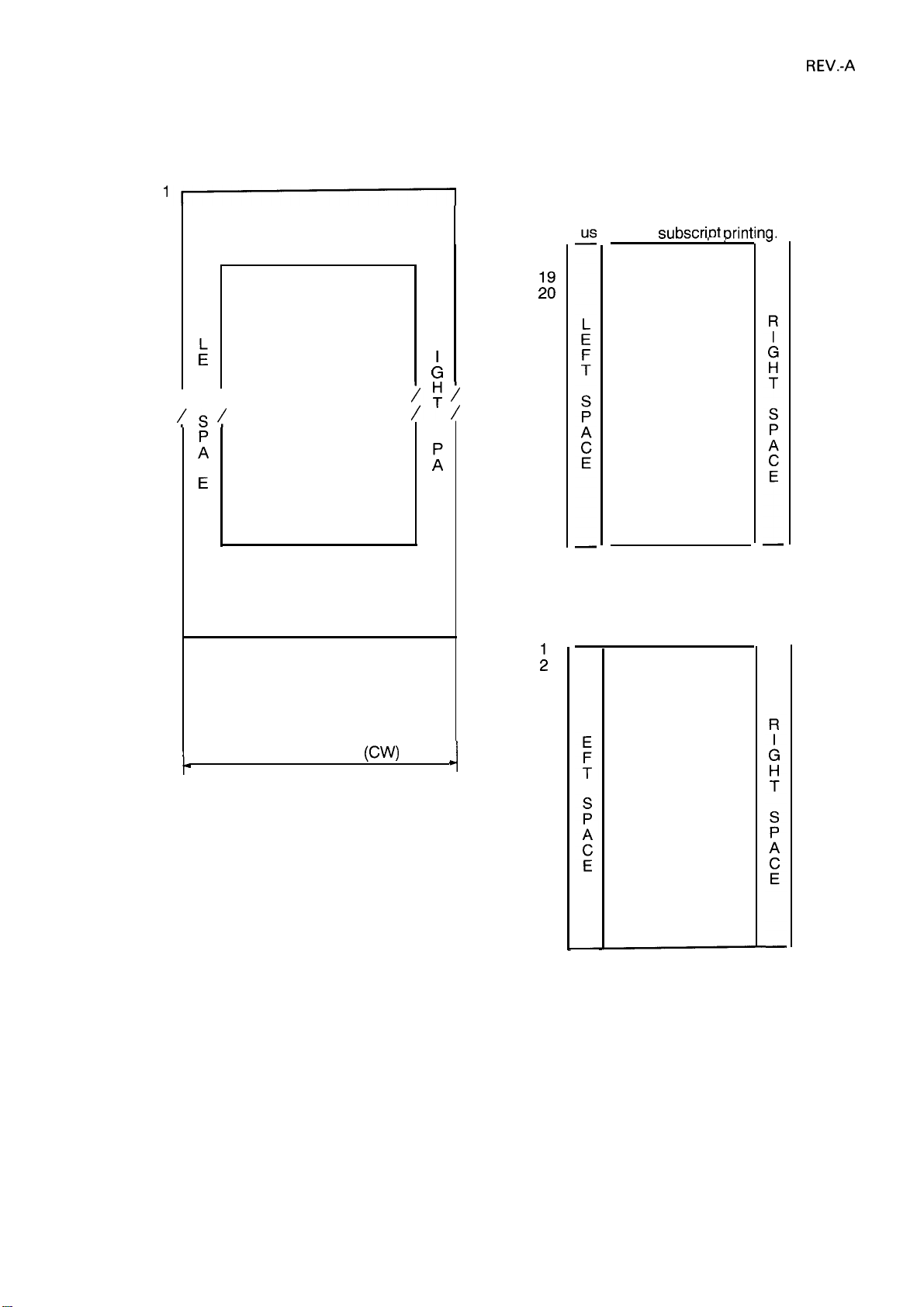

(Normal character)

REV.-A

39

40

41

46

47

48

1~

2

3

4

5

6

7

.

.

.

.

.

k

F

/T/

/s/

:

c

E

(aO)

L

Ascender area

Descender area

L

Character width (CW)

/y/

//

R

k

s

:

c

E

(a2)

(Sub-script character)

From dot No. 1 to 16 are not

17

18

1:

.

.

.

.

.

.

45

46

47

48

;

3

4

.

.

4

I while

(Super-script character)

From dot No. 33 to 48 are not

used while superscript printing.

L

subscri~t txinting.

,.

—

—

.

.

29

30

31

32

Figure 1-8. Character Matrix

1-13

Page 22

REV.-A

1.3 INTERFACE OVERVIEW

The printer has a parallel interface with the

1.3.1

Parallel Interface

Specifications for the 8-bit parallel interface are as follows:

Data format

Synchronization

Handshaking BUSY and

Signal level

Adaptable connector 57-30360 (Amphenol) or equivalent

Data transmission timing See Figure 1-9.

BUSY

ACKNLG

DATA

STROBE

o.5#s

min.

specifications described below.

8-bit parallel

STROBE signal

ACKNLG signal

ITL-compatible

It

,

4

[

o.5/.ls

min.

o.5/ls

min.

/

//

511s

WP

5ps

typ.

‘

Figure 1-9. Data Transmission Timing

Table 1-11 shows the connector pin assignments and signal functions of the 8-bit parallel interface.

Table 1-11. Connector Pin Assignments and Signal Functions

Pin

No.

1

2

3

4

5

6

7

8

9

10

Signal Name

Return Dir.

Pin No.

STROBE

DATA 1

DATA 2

DATA 3 22

DATA 4 23

DATA 5 24

DATA 6 25

DATA 7 26

DATA 8 27

ACKNLG

20

21

28 OUT

19

IN

IN

IN

IN

IN

IN

IN

IN

IN

STROBE pulse to read the input data. Pulse width must

be more than 0.5Ks. Input data is latched at falling

edge of this signal.

Parallel input data to the printer.

HIGH level means “ 1“.

LOW level means “O”.

This pulse indicates data has been received and the

printer is ready to accept more data. Pulse width is

approximately

Functional Description

1

Ips.

0

,-.’ ,

.

.

1

11

12

13

BUSY

PE

SLCT

29

30

OUT

OUT

OUT

HIGH indicates the printer cannot accept more data.

HIGH indicates paper out. This signal is effective only

when the ERROR signal is LOW,

Always HIGH output (Pulled up to

ohm resistor.)

1-14

+5V

through a 3.3K

Page 23

Table 1-11. Connector Pin Assignments and Signal Functions (Cont.)

Pin

No.

14

15

16

17

18

19 to 30

31

32

33

34

35

36

Signal Name

AUTOFEED-XT

GND

Chassis

GND

GND

I NIT

ERROR

GND

SLCT-IN

Return Dir.

Pin No.

--

IN

.-

. .

16

--

IN

OUT

--

--

. .

OUT

IN If LOW when the printer is initialized, DC

Functional Description

If LOW when the printer is initialized, the printer

automatically performs a

CR code (Auto LF).

Not used.

line feed upon input of the

Ground for twisted-pair grounding.

Chassis ground level of printer.

Not used.

Ground for twisted-pair grounding.

Pulse (width:

initialization.

50ws,

min., active LOW) input for printer

LOW indicates an error has occurred in the printer.

Ground for twisted-pair grounding.

Not used.

+5V

Always HIGH. (Pulled up to

resistor.)

through 3.3K ohm

l/DC3

control is disabled.

NOTES: 1. “Dir.” indicates the direction of the signal flow as viewed from the printer.

“Return Pin No.” denotes a twisted-pair return line.

2.

3. The cable used must be shielded to prevent noise.

4. All interface conditions are based on TTL levels. Both the rise and fall times of all signals

must be less than

5. The AUTOFEED-XT signal can be set to LOW by DIP switch 2-4.

6. The SELECT-IN signal can be set to LOW by jumper 1.

7. Printing tests, including those of the interface circuits, can be performed without using

external equipment by setting DATA 1 -DATA 8 pins to the STROBE signal.

0.2Ks.

1-15

Page 24

REV.-A

1.4

CONTROL PANEL

On the control

panel are: 10 non-lock type buttons, and 24 indicators.

k

——

I

Lom

I

-!.

I 0

111—

Figure 1-10. Control Panel

BUTTONS

(1) PAUSE Button

This button controls printer action. Pressing the button toggles the printer between PAUSE condition

(no printing, no paper feeding, or no data

(2) FORM FEED Button

Advances the paper to the next top of from position. This switch is also used for the micro feed function.

(3) LINE FEED Button

Advances the paper by one line ( 1/6

fed continuously until releasing this switch. This switch is also used for the micro feed function.

acception) and RUNNING.

inch)By pressing this switch more than 0.5 second, the paper is

(4) LOAD/EJECT Button

Pushing this switch loads the paper when paper-out condition is detectedAnd ejects the paper when

out of paper condition is not detected as in the Forms Override function.

(5) TEAR-OFF/BIN l/BIN 2 Button

In

tractor-feed mode, pressing this button advances continuous paper to the tear-off position, and the

TEAR-OFF indicator is

and the selected BIN indicator is lit.

(6) MICRO FEED Button

Selects or cancels the micro feed function. When this function is enabled, the MICRO FEED indicator

is lit. In the micro feed mode, the LINE FEED button is used to feed the paper forward, and the FORM

FEED button is used to feed the paper backward.

Paper feed performed by this micro feed function does not affect the page position control. And this

func!ion is also used to adjust the paper loading position and to adjust the continuous paper to meet

the tear off edge.

(7) FONT Button

Pressing this button selects a font, and pressing it continuously selects the following ones in sequence.

The

‘ONT

LED indicates the currently selected font.

Iitln friction-feed mode, pressing this button toggles between bin 1 and bin 2,

~.

.

.’)

c“

1-16

Page 25

REV.-A

(8) PITCH Button

Pushing this switch once selects the character pitch. And holding this button down selects the following

ones in sequence. PITCH indicators indicate the currently selected character pitch.

(9) RESET Button

Holding this button down more than 0.45 second, the input data buffer is cleared and the printer

initialized by software as ESC

(10) CLEANING Button

Holding this button down more than 0.5 second, the print head cleaning is performed. This button is

only effective in the PAUSE condition. The CLEANING button is located inside the DIP switch cover.

Cl?.

INDICATORS

(1) POWER (green)

when the printer’s power switch is on, and AC power is supplied.

Lit

(2) PAUSE (orange)

Lit when the printer is in PAUSE mode (no printing, no paper feed, or no data accepting).

(3) DATA (orange)

Lit when the printer has received data from the host machine.

(4) PAPER-OUT (red)

Lit when the paper-out detector detects no paper. Refer to Section 1.6.3, Paper-out Detection and Forms

Override Function.

(5) INK END (red)

Lit when the printer detects the ink empty condition.

(6) MICRO FEED (orange)

Lit when the micro feed function is enabled.

(7) TEAR-OFF (orange)

Lit when the sheet is advanced to the tear-off position.

(8) BIN 1 (green)

Lit when bin 1 is selected.

(9) BIN 2 (green)

Lit when bin 2 is selected.

(1 O) FONT (green) --Draft, Courier, Roman, Saris Serif, Prestige, Script, Script C, Orator, Orator-S

These indicators show the currently selected font.

(1 1) PITCH (green) --10

These indicators show the currently selected pitch.

CPI, 12 CPI, 15 CPI, 17 CPI, 20 CPI, PS

1-17

Page 26

REV.-A

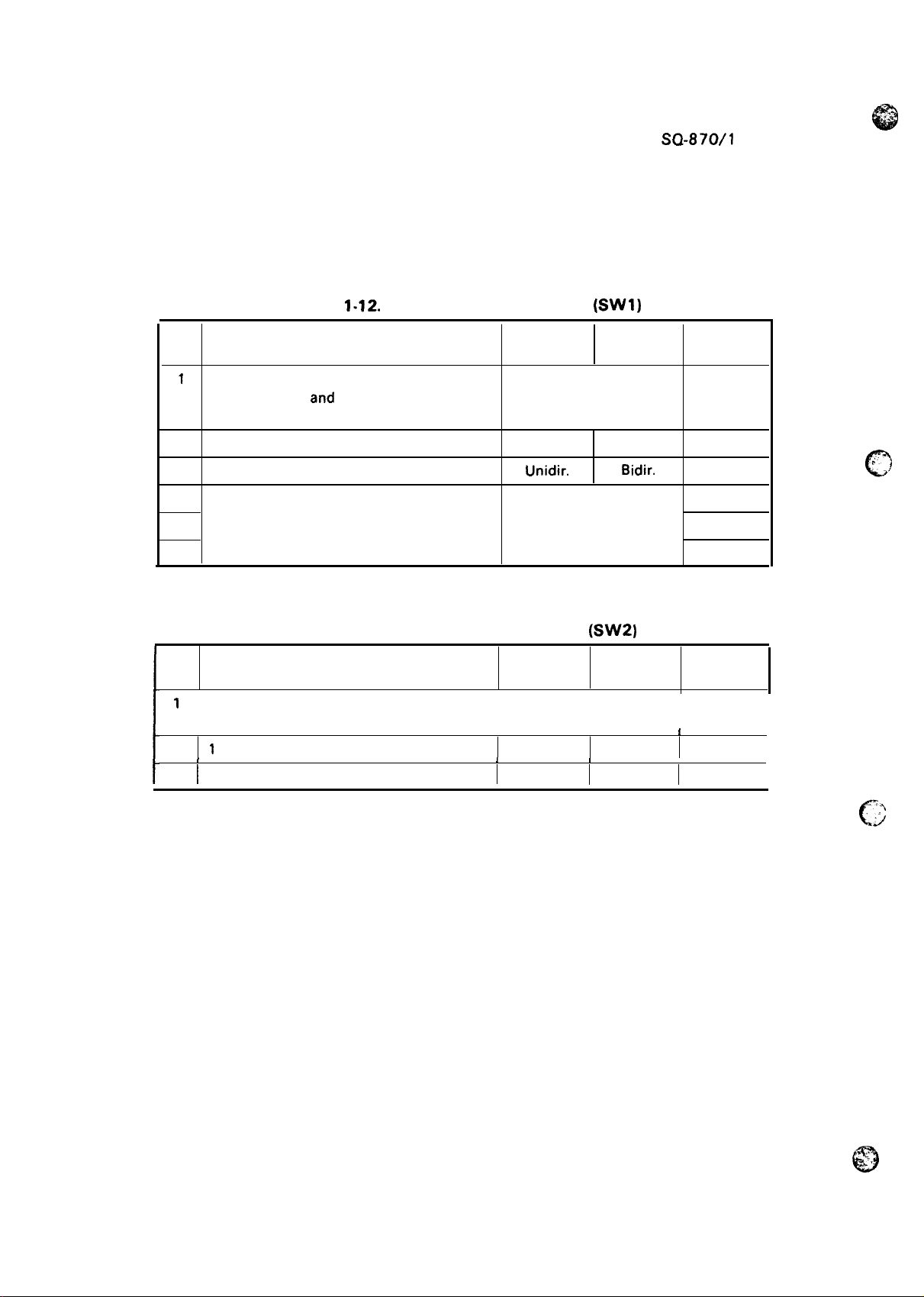

1.5 DIP SWITCHES AND JUMPER SETTING

This section describes the DIP switch selections and jumper setting for the

1.5.1 DIP Switch Settings

The two DIP switch banks for the printer, located on the control panel, are

conditions as shown in tables 1-12 through 1-15. (Note that the status of the

at power on or upon receipt of the INIT signal.)

Table 1.12. Settings for DIP Switch 1 (SW1)

No.

1

International

2

character set

3

4

5

6

7 OFF

8

selection

Character table selection

Graphic print direction

Not Used

Description ON

See

and

PC

Table 1-14

Graphic Italic

Unidir.

OFF

Bidir.

SQ-870/l

used to set various print

DIP switches is read only

170 printer.

Factory

Setting

ON

ON

ON

OFF

OFF

OFF

OFF

Table 1-13. Settings for DIP Switch 2 (SW2)

No.

1

Page length of continuous paper

2

I

I

3

1

inch skip for continuous paper

!

4

~

Auto LF

Description

ON

See Table 1-15

I

ON

1

ON OFF

OFF

OFF

I ,

Factory

Setting

I

[

OFF

OFF

OFF

OFF

I

I

I

1-18

@

=.

Page 27

1-1

1-2

Table 1-14. international Character Set Selection

1-3

Country

Pc

REV.-A

ON ON ON

ON

ON

ON OFF OFF U.K.

OFF ON ON

OFF ON OFF

OFF OFF

OFF

ON

OFF

OFF OFF

OFF

ON

ON

Us.

France

Germany

Denmark 1

Sweden

Italy

Spain 1

437

850

860

863

865

(437)

(437)

(437)

~

L

Table 1-15. Page Length

2-1

OFF OFF

ON

OFF

ON

2-2

OFF

ON

ON

Page Length

11 inches

12 inches

8.5 inches

70/6 inches

When SW 1-4 is ON,

If italic table was selected by

ESC

t O, country setting becomes U.S.

When SW 1-4 is OFF,

if graphic table was selected by

ESC

t 1, PC becomes 437.

1.5.2 Jumper Setting

If Jumper 1 is connected to GND, the SLCT-IN signal is fixed to LOW and DC

l/DC3

control is ignored.

1-19

Page 28

REV.-A

1.6 OPERATING INSTRUCTIONS

This section describes the self-test and hexadecimal dump functions as well as the error states, printer

initialization, and buzzer operation.

1.6.1 Self-Test

To run the self-test using draft mode, turn the printer on while pressing the LINE FEED button. To run

the self-test using the letter quality (LO) mode, turn the printer on while pressing the FORM FEED button.

You can stop or start self-test printing by pressing the PAUSE button. When you are satisfied with the

self-test, stop the printing by pressing the PAUSE button and turn the printer off.

The firmware revision number is printed on the first line of the self-test, followed by the current DIP

switch settings.

1.6.2 Hexadecimal Dump Function

To put the printer in hexdump mode, power it on while pressing both the LINE FEED and FORM FEED

buttons.

In

hexdump

the corresponding ASCII characters. This function is useful for checking the data the printer has received

from the host.

If input data is a control code rather than a character code, a period (.) is printed in the ASCII column.

mode, the printer prints out the hexadecimal representation of the input data, along with

*

“i” ,,

o

1.6.3 Paper-out Detection and Forms Override Function

When the paper-out detector detects a paper-out condition, the printer enters the PAUSE mode with

the following status.

PAPER OUT indicator lit

BUSY signal becomes HIGH

ERROR signal becomes LOW

PE signal becomes HIGH

In the PAUSE mode, you can perform the “Forms Override” function by pressing the PAUSE button,

or continue the printing operation by pressing the PAUSE button after loading new paper.

In the forms override function, the printer ignores the paper-out condition temporarily and prints

additional lines beyond the bottom line specified for the page. Once the “Forms Override” function is

performed, the paper-out detection will not be enabled until paper is loaded.

1.6.4 Error Conditions

If the following conditions are detected, the printer recognizes them as errors and enters the error mode.

● Paper-out

Paper-out is detected after performing paper loading operation.

. . .

.“..

c

I

‘) :

.,

. Ink end

Ink end condition is detected. Perform 200 lines of printing or remove the ink cartridge.

1-20

Page 29

REV.-A

● Cover open

The printer lid is opened.

● Fatal errors

In the following cases, the printer recognizes them as fatal errors and enters the fatal error mode. The

fatal error condition cannot be recovered until turning the power off.

● Carriage does not move correctly

● Control circuit cannot work correctly

When the error condition is detected, the printer automatically enters ‘PAUSE’ mode and outputs

appropriate interface signal.

When parallel interface is selected, the following interface signals are outputted to indicate the error

and to stop data transmission.

● BUSY signal becomes HIGH

● ERROR signal becomes LOW

● Output no ACKNLG pulse

● PE signal becomes HIGH (only paper out error)

1.6.5 Buzzer Operation

The buzzer sounds under the following conditions:

● A paper-out error is detected (beeps 3 times for 0.1 second respectively, with 0.1 second intervals).

● Ink end error is detected (beeps 5 times for 0.1 second respectively, with 0.1 second intervals).

● Cover open error is detected (beeps 5 times for 0.1 second respectively, with 0.1 second intervals).

● Fatal error is detected (beeps 5 times for 0.5 second respectively, with 0.5 second intervals).

● When panel setting is accepted (beeps 1 time for 0.1 second).

1.6.6 Printer Initialization

There are three initialization methods: hardware initialization, software initialization, and panel

initialization.

(1) Hardware initialization

This type of initialization takes place when the printer power button is turned on with the AC power

cord plugged in or when the INIT signal is received.

When the printer is initialized, it performs the following actions:

(a) Initialize printer mechanism.

(b) Clears input data buffer.

(c) Clears downloaded character set.

(d) Clears print buffer.

(e) Returns printer settings to their default values.

1-21

Page 30

REV.-A

(2) Software initialization

Input of the

perform functions (d) or(e) above. The settings changed by the last

ESC C2 command also initialize the printer. Printer initialization by

SelecType operation are maintained.

ESC C?

code does not

(3) Panel initialization

This printer can be initialized by pressing the RESET button on the front panel. When the printer is

initialized in this method, the functions (b), (d) and (e) above are not performed. The settings changed

by the last

SelecType

operation are maintained.

1.6.7 Default Values

When the printer is initialized, the following default values are set:

Page position

Left and right margins

Line spacing

Vertical tabs

Horizontal tabs

Family number of type style

Download characters

Character spacing

Printing effects

Printer condition

The current paper position becomes the top-of-form position

Released

1/6 inch

Cleared

Every 8 characters (relative)

Last font selected from the panel

Kept - software initialization

Cleared - hardware initialization

Last pitch selected from the panel

Cleared

Not PAUSE

,F

. ,.

Q

1.6.8 Sheet Loading and Sheet Ejection

The release lever has a disengage capability of tractor unit drive mechanism. Therefore, this printer

provides some improved paper handling in combination with the release

(a) Automatic cut sheet loading without cut sheet feeder

Change the release lever to friction feed position and

put’a

cut sheet with the paper guide (rear or front

insertion).

A few seconds laster, the cut sheet is automatically loaded to the top-of-form position.

(b) Automatic cut sheet loading & ejection with cut sheet feeder

Change the release lever to the friction feed position and the put

sheet feeder.

Pushing LOAD/EJECT button loads a sheet to the top-of-form

printing starts, a sheet is automatically loaded to the top-of-form position.

(c) Continuous paper loading & ejection (back-out)

Change the release lever to the rear push position

into the tractor unit. Pushing LOAD/EJECT button loads the paper automatically to the top-of-form

position. If paper out is detected before printing

top-of-form position.

if LOAD/EJECT button is pushed when continuous paper is loaded, the paper is ejected backward to

the push tractor unit.

or front push position, and set the continuous paper

statis, the paper is automatically loaded to the

1-22

cut sheets into the hopper of the cut

positionlf paper out is detected before

lever.

. .

,-~.

G

‘“’

F.<

o

““

Page 31

REV.-A

When the paper is at the top-of-form position, the loading position is adjustable by using the ‘MICRO

FEED’ function. In the ‘MICRO FEED’ function, pushing the LINE FEED button pushes the paper forward,

and pushing the FORM FEED button pulls the paper backward.

The adjusted loading position is stored into the memory and remains to be effective until the power

is turned off. But the adjusted loading position of the continuous paper is memorized into nonvolatile

RAM, so it remains effective even if the power is turned off.

1.6.9

Tear-off Function

By pressing the TEAR OFF button when the tractor feed is selected, the paper is advanced to the tear

off position and ‘TEAR OFF’ indicator is lit.

In this condition (tear off condition), the tear off position is adjustable by using the ‘MICRO FEED’

functionln

pushing the FORM FEED button pulls the paper backward.

The adjusted position is memorized into the nonvolatile RAM and remains effective even if the power

is turned off.

the ‘MICRO FEED’ function, pushing the LINE FEED button pushes the paper forward, and

If necessary to cancel this function, press the TEAR OFF button again or press the

send subsequent data to the printer. Then the paper is fed back to the top-of-form

1.6.10 Adjust Lever Operation

The adjust lever must be set to the proper position according to the type of paper

Table 1-16. Lever Positions

Lever Position

Front

side

I

Rear side

I

Paper Type

Envelope

I

Label

Cut sheet

I Continuous

I

paper I

PAUSE button or

position.

used.

Figure 1-11 Lever Positions

1-23

Page 32

REV.-A

1.6.11

To keep

(1) Power on cleaning

Performed at power on when ‘(4) Cleaning’ as defined below is not required. It takes about several

seconds.

(2) Capping

In the following cases the

Printhead Protection

the print quality, several kinds

printhead

is capped. It takes about a second.

printhead

of

cleaning functions are performed automatically.

● Printing is stopped about 3 seconds.

● Entering the PAUSE condition.

(3) Refresh nozzles

Performed about every 15 seconds during printing. It takes less than

(4) Cleaning

In the following cases the

● Turning the power on when the

printhead

cleaning is performed and it takes

printhead

has not been capped.

second.

a

about 20 seconds.

● Turning the power on more than 7 days after the last cleaning.

. Pressing the CLEANING button.

1.6.12 Ink Charge

Install the ink cartridge to the printer and turn the printer power on while pressing the CLEANING switch

down. The ‘Ink Charge’ function is started. It takes about 3 minutes to complete this

only at the first time the new printer is used.

functionlt

is needed

1.6.13 Ink End Detection

If ink end sensor detects ink end condition, ‘INK END’ indicator blinks performing 200 lines of printing,

and the printer enters the ink end condition. (’INK END’ indicator is lit.)

If ink cartridge is removed, ‘INK END’ indicator is lit and the printer enters the ink end condition

immediately.

1.6.14

Cover open detector is installed to stop the printing whenever the printer cover is opened. If cover open

is detected, the printer enters the cover open error condition.

CAUTION:

Don’t open the printer cover while printing.

Cover Open Detection

1-24

Page 33

1.7 MAIN COMPONENTS

REV.-A

The main components of the

SQ-870/l

170 printer are designed for easy removal and replacement

to facilitate maintenance and repair of the printer. The main components are:

1)

C076

MAIN board: the main control board; the CPU on this board controls all main functions.

2)

Control panel unit

3)

C076

PSB/PSE

4)

M-47 10/4760:

[

board: the

the printer

C076 PSB/PSE Board

n

power supply

mechanism.

\

)4

board.

C076 MAIN Board

- Printer Mechanism

,

1

M-4760

Figure 1-12. SQ-1 170

Component Layout

1-25

Page 34

REV.-A

1.7.1

The

mechanism driver circuit.

The

1 M byte memory space.

C076

C076

KPD70325

Memories

5 12K\l M bits program ROM

1 M bits

8M\4M\2M/l

Gate Arrays

Memory management unit

Motor control unit

Driver

CR motor (DC motor) driver (SLA4391)

PM motor (DC motor) driver

PF motor (Stepping motor) driver (STK67 12B)

Printhead driver

MAIN Board (Main Control Circuit

MAIN board is the main board in the printer,

(location: IC5) is used, and the

PS-RAM

M bits mask ROM (C.G)

(E05A65)

(E05A48)

(SDH03)

(MPD

16322)

Board)

and contains a logic circuit and printer

following memories and gate arrays are assigned in the

:Ic14

:IC

19/22/23

:lC3/4/24

:Ic12

:Iclo

:Ic17

:IC16

:Ic

11

:lC8/9

.,; . \

,..

c’

Others

PPD70325

I

❑ n

:IC2

:IC21

:IC7

:IC20

:BAT 1

P-ROM 5 12K

=

0

,~i

u

(IC14)

o’

1 M

PS-RAM

(IC19)

-

4

“p-RAM

(IC22))

EEPROM

Reset

Reset

Switching Regulator

Lithium

A lithium battery in the battery circuit backs up the head cleaning timer while the printer power is off.

IC

(MB3771)

IC (PST529C)

battew

~o

IJOQ

000

‘

I

(TL494)

GA E05A48 CPU

(Iclo)

\

~11

II

n

‘N

Mu

‘

L

1--1

(IC5)

00

II

b

I

BAT1/

Figure 1-13.

GA

L05A65

C076

MAIN Board

1-26

(1C12)

Page 35

1.7.2 Control Panel

REV.-A

The Control Panel is, which includes the indicator

Figure 1-14. Control Panal

1.7.3

The power supply unit consists of a switching regulator circuit, which converts the AC line voltage to

the DC voltages (for example, + 35V and

type, and the

C076

PSB/PSE Board (Power Supply Circuit Board)

+

5V) used by the printer. The

C076 PSE

board is

220/240V

input type.

LEDs,

switches, and DIP switches.

C076

PSB board is 120V input

Figure 1-15.

C076

PSB/PSE Board

❑

P

o

0

I

1-27

Page 36

REV.-A

1.7.4 Printer Mechanism (M-4710/4760)

The M-47 10/4760 printer mechanism was developed specifically for

the components are a carriage motor, carriage mechanism, paper-feed motor, paper-feed mechanism,

TE motor, top edge holding mechanism, pump motor, pump mechanism, printhead, and sensors. This

printer mechanism allows three ways of paper insertion.

SQ-870/l

170 printer. Included

. .

+:

-..

.,.

,’

o

Figure 1-16. Model-4710/4760 Printer Mechanism

1.7.5 Housing

The

LQ-870/l

control panel.

The lower case contains the printer mechanism, the main control circuit board, and power supply circuit

board.

170 housing consists of the upper, lower, and front cases. The front case houses the

Figure 1-17. Housing

1-28

Page 37

CHAPTER 2

OPERATION PRINCIPLES

OPERATING PRINCIPLES OF PRINTER MECHANISM..............2-1

2.1

REV.-A

2.1.1.

2.1.2. Carriage Mechanism

2.1.3.

2.1.4 Ink Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printhead Mechanism

Paper Feed Mechanism

2.1.3.1 Paper Feeding Mechanism.....................................2-6

2.1.3.2 Release Lever

2.1.3.3 Paper Insertion entrance

2.1.3.4 Top Edge Holder Mechanism Operation ...........2 -13

2.1.4.1

2.1.4.2

2.1.4.3

2.1.4.4

2.1.4.5

2.1.4.6

2.1.4.7

Pump Motor

Pump Mechanism

Cap Mechanism

Cleaning Mechanism and Carriage Lock

Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ink Cartridge and Ink End Sensor

Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wasted Ink Drain Tank...........................................2.2l

Operational Sequence of Ink Mechanism ........2 -22

.............................................................2.2

...............................................................2.4

..........................................................2.6

Operation.........................................2.8

........................................2.l

.

.............2 -14

................................................................2.l

.....................................................2.l 6

.........................................................2.l 7

. 2-18

. 2-20

O

5

2.1.5 Case Open Interlock

2.2

OPERATING PRINCIPLES OF POWER SUPPLY

2.2.1 Voltage Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Operating Principles of Power Supply Circuitry ............2 -27

OPERATING PRINCIPLES OF CONTROL CIRCUITRY ...............2 -29

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.3.7

2.3.8

2.3.9

2.3.10

Control Circuitry Overview

Reset Circuit

Detection Circuit

Paper Feed Motor Drive Circuit ...........................................2-32

Carriage Motor Drive

Printhead Drive Circuit ...........................................................2.34

Pump Motor Drive Circuit

TE Motor Drive Circuit

Timer Circuit and Backup Circuit ........................................2.37

EEPROM Control

...............................................................................2 -31

Switch..................................................2.26

CIRCUITRY..2-27

.

..2-27

...................................m.........mm.mmm.2.29

.......................................................................2.3 1

Circuit.................................................2.33

......................................................2.36

............................................................2.37

Circuit.........................................................2.38

z-i

Page 38

REV.-A

LIST OF FIGURES

Figure 2-1. Block Diagram of Printer Mechanism -Model

-47 10/4760

Figure 2-2.

Figure 2-3. Structure of a Nozzle

Figure 2-4. Printing Principle (1)

Figure 2-5.

Figure 2-6.

Figure 2-7. Carriage Mechanism

Figure 2-8.

Figure 2-9.

Figure 2-10. Push Tractor Operation

Figure 2-11. Push-Pull Tractor Method

Figure 2-12. Moving the Release Lever

Figure 2-13. Arrangement of Gears in Friction Feed

Figure 2-14. Arrangement of Gears in Front Push Tractor Feed.....2-9

Figure 2-15. Arrangement of Gears in Rear Push Tractor Feed ......2-9

Figure 2-16. Top Entrance - Friction Feed Method .............................2-10

Internal Structure of Printhead ..........................................2-2

Printing Principles (2)

Printing Principles (3)

Adjustment of Platen Gap

Friction Feed Method

(or Full Release)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.............................................................2.6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....................................................2.8

........................................................................2.9

2-1

2-2

2-3

2-3

2-3

24

2-5

2-7

2-8

Figure 2-17. Rear Entrance - Push Tractor

Figure 2-18. Rear Entrance - Push-Pull Tractor Method ...................2-l 1

Figure 2-19. Front Entrance - Friction Feed Method

Figure 2-20. Front Entrance - Push Tractor Method

Figure 2-21. Front Entrance - Push-Pull Tractor

Figure 2-22. Top Edge Holder Mechanism

Figure 2-23. Outline Ink Mechanism System

Figure 2-24. Pump Motor

Figure 2-25. Pump Movement

Figure 2-26. Cap Movement

Figure 2-27. Air Inlet Operation

Figure 2-28. Cleaner Blade Operation

Figure 2-29. Rubbing Block Operation

Figure 2-30. Set/Reset of Cleaner Lever

Figure 2-31. Carriage

Figure 2-32. internal Structure of Ink Cartridge

Figure 2-33. Structure of Ink Cartridge

Figure 2-34. Structure of Wasted Ink Drain Tank

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lock............................................................................2-

Method............................2-l O

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Method..................2-l 2

...............................................2-l

.........................................2-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Holder......................................2-2l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11

2-12

2-15

2-16

2-17

2-17

2-18

2-18

2-19

19

2-20

2-21

3

. . . . .

L

z-ii

Page 39

REV.-A

Figure 2-35.

Figure 2-36.

Figure 2-37.

Figure 2-38.

Figure 2-39.

Figure 3-40.

Figure 2-41.

Figure 2-42.

Figure 2-43.

Figure 2-44.

Figure 2-45.

Figure 2-46.

Figure 2-47.

Figure 2-48.

Figure 2-49.

Figure 2-50.

Operational Sequence of Ink Mechanism and

Carriage Position

Interlock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Circuit Block Diagram .................,.............2-28

Control Circuitry Block Diagram ........................................2.29

Reset Circuit Block Diagram

Detection Circuit Block Diagram

Paper Feed Motor Drive

Carriage Motor Drive Circuit

Printhead Drive

Charge/Discharge Circuit

Head Charge

Head Discharge Condition

Timing for Discharge/Charge

Block Diagram of Pump Motor Drive

Block Diagram of TE Motor Drive

Block Diagram of Timer Circuit/Backup Circuit ..........2-37

.....................................................................2.22

.

.2-26

...............................................2-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit..........................................2.32

...............................................2.33

Circuit..........................................................2.34

.....................................................2.35

Condition..........................................................2.35

....................................................2.35

Pulse..................................2-36

Circuit.................2-36

Circuit.......................2-37

2-31

1

Figure 2-51.

Table 2-1.

Table 2-2.

Table 2-3.

Table 2-4.

Table 2-5.

Table 2-6.

Table 2-7.

EEPROM Control Circuit

.......................................................2.38

LIST OF TABLES

Paper Feeding Method and Paper Entrance.......................2-6

Rotational Direction and Operation of Each Part ............2 -15

Ink End/Ink Cartridge Signal

Ratings of Power Supply Board..............................................2.27

Voltage Allocation

Major Elements on C076 MAIN Board and

Their Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage Motor Drive Modes ...................................................2.33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................................2.2O

.

2-27

.

...................2 -30

Z.iii

Page 40

REV.-A

2.1 OPERATING PRINCIPLES OF PRINTER MECHANISM

This section describes functions and operations of the printer mechanism - Model-47 10/4760.

Modei-47 10/4760 is a serial type printer mechanism with a 48-nozzle

This printer mechanism consists of the

Figure 2-1 shows the block diagram of the printer mechanism – Model-47 10/4760.

LOCK

Cover

Open

i

PF

PE/FPE/R

MSS S

s

Paper Feed

B

Figure 2-1. Block Diagram of Printer Mechanism - Model-471 0/4760

F/T

TE EDGE

MS

TE Holder

1

printhead

CM EN TH DG HEAD

G=-

1

unit, paper feed unit, ink mechanism, and sensors.

I .......1 I Ink

t-nnmeau

Cartridge

IE

IE2

printhead.

PM

I I Punp

UnitI . &:y:e:aln[

I

(Cap, Cleaner)

~

i

1

2-1

Page 41

REV.-A

2.1.1 Printhead Mechanism

The printhead of this printer employs the on-demand method, where part of the ink stored in the reservoir

within the

Figure 2-2 shows the internal structure of the

explained below.

● Head damper

When the carriage moves, the ink tube also moves, which results in the change of pressure within the

tube. The head damper is used to absorb this change of pressure and prevent the ink from rushing into

the reservoir.

● Reservoir

The ink supplied into the

O

Nozzle

The ink stored in the reservoir is injected through nozzles. The structure of a

2-3.

printhead

is supplied into the nozzle each time ink in the nozzle chamber is injected.

printhead

printhead.

is once stored in the reservoir.

The functions of the major components are

nozzle

is shown in Figure

,,

‘~~~

&

Reserver

—

\

\

Nozzle

Piezoelectric

Figure 2-2. Internal Structure of Printhead

Element

/<”-

,’/

/;

II

1

I

\

1

I

\-,/’

\\

Ink Inflow Gate

------’.\

,’

— —— —.-

\

‘

Filter

Diaphragm

/

Piezoelectric

Element

I

I

I

I

;

/

/

-Damper

2-2

\

T

\

Pressure

Chamber

!3

‘ozzem

Figure 2-3. Structure of a Nozzle

Page 42

< Printing >

This section describes how ink is injected through the nozzles.

REV.-A

(1) Normal condition

(2) Charging operation --When the electric charge of the

---Piezoelectric

the element is bent outward to let ink into the pressure chamber.

Element is electrically charged and bent inward.

Piezoelectric Element

/

)

Figure 2-4. Printing Principle (1)

1