Page 1

MF599-06

CMOS 4-BIT SINGLE CHIP MICROCOMPUTER

S1C62 Family

Development Tool Reference Manual

Page 2

NOTICE

No part of this material may be reproduced or duplicated in any form or by any means without the written permission of Seiko

Epson. Seiko Epson reserves the right to make changes to this material without notice. Seiko Epson does not assume any

liability of any kind arising out of any inaccuracies contained in this material or due to its application or use in any product or

circuit and, further, there is no representation that this material is applicable to products requiring high level reliability, such

as medical products. Moreover, no license to any intellectual property rights is granted by implication or otherwise, and there

is no representation or warranty that anything made in accordance with this material will be free from any patent or copyright

infringement of a third party. This material or portions thereof may contain technology or the subject relating to strategic

products under the control of the Foreign Exchange and Foreign Trade Law of Japan and may require an export license from

the Ministry of International Trade and Industry or other approval from another government agency.

MS-DOS, Windows, Windows 95, Windows 98 and Windows NT are registered trademarks of Microsoft Corporation, U.S.A.

PC-DOS, PC/AT, PS/2, VGA, EGA and IBM are registered trademarks of International Business Machines Corporation, U.S.A.

NEC PC-9800 Series and NEC are registered trademarks of NEC Corporation.

All other product names mentioned herein are trademarks and/or registered trademarks of their respective owners.

© SEIKO EPSON CORPORATION 2001 All rights reserved.

Page 3

S1C62 Family Development Tool Reference Manual

Preface

The explanation covering the outline and operation of the development support tools for the CMOS 4-bit

Single Chip Microcomputer S1C62 Family has been divided into the following parts.

I. INTRODUCTION

II. DEVELOPMENT TOOL MANAGEMENT SYSTEM DMS6200

III. CROSS ASSEMBLER ASM62XX

IV. MELODY ASSEMBLER MLA628X

V. FUNCTION OPTION GENERATOR FOG62XX

VI. SEGMENT OPTION GENERATOR SOG62XX

VII. EVALUATION BOARD S5U1C62XXXE

VIII. ICE CONTROL SOFTWARE ICS62XX

IX. MASK DATA CHECKER MDC62XX

Before Reading . . .

This manual indicates the model name as "S1C62XXX" and source file and output files as "C2XXYYY" for

purposes of explanation of the common content in each model of the S1C62 Family. You should substitute

the "XXX" parts for the various model names. Please allow Seiko Epson to specify the "YYY" section for

each customer.

Example: When the development model is S1C6S460, and the "YYY" section is to be specified as "0A0".

S1C6XXXX → S1C6S460

CXXXYYY → CS460A0

Reference Manual

The peculiar content of each model, device details and the like are explained in the below manual. You

should refer to it as required.

Development Tools ☞ S5U1C62xxxD Manual (Development Software Tool for S1C62xxx)

S5U1C62xxxE Manual (Evaluation Board for S1C62xxx)

S5U1C62000H Manual (S1C60/62 Family In-Circuit Emulator)

Device (S1C62xxx)

Instructions

∗ In this manual, "ICE" and "evaluation board" indicate S5U1C62000H and S5U1C62xxxE, respectively.

☞ S1C62xxx Technical Manual

☞ S1C6200/6200A Core CPU Manual

Page 4

Page 5

The information of the product number change

Starting April 1, 2001, the product number will be changed as listed below. To order from April 1,

2001 please use the new product number. For further information, please contact Epson sales

representative.

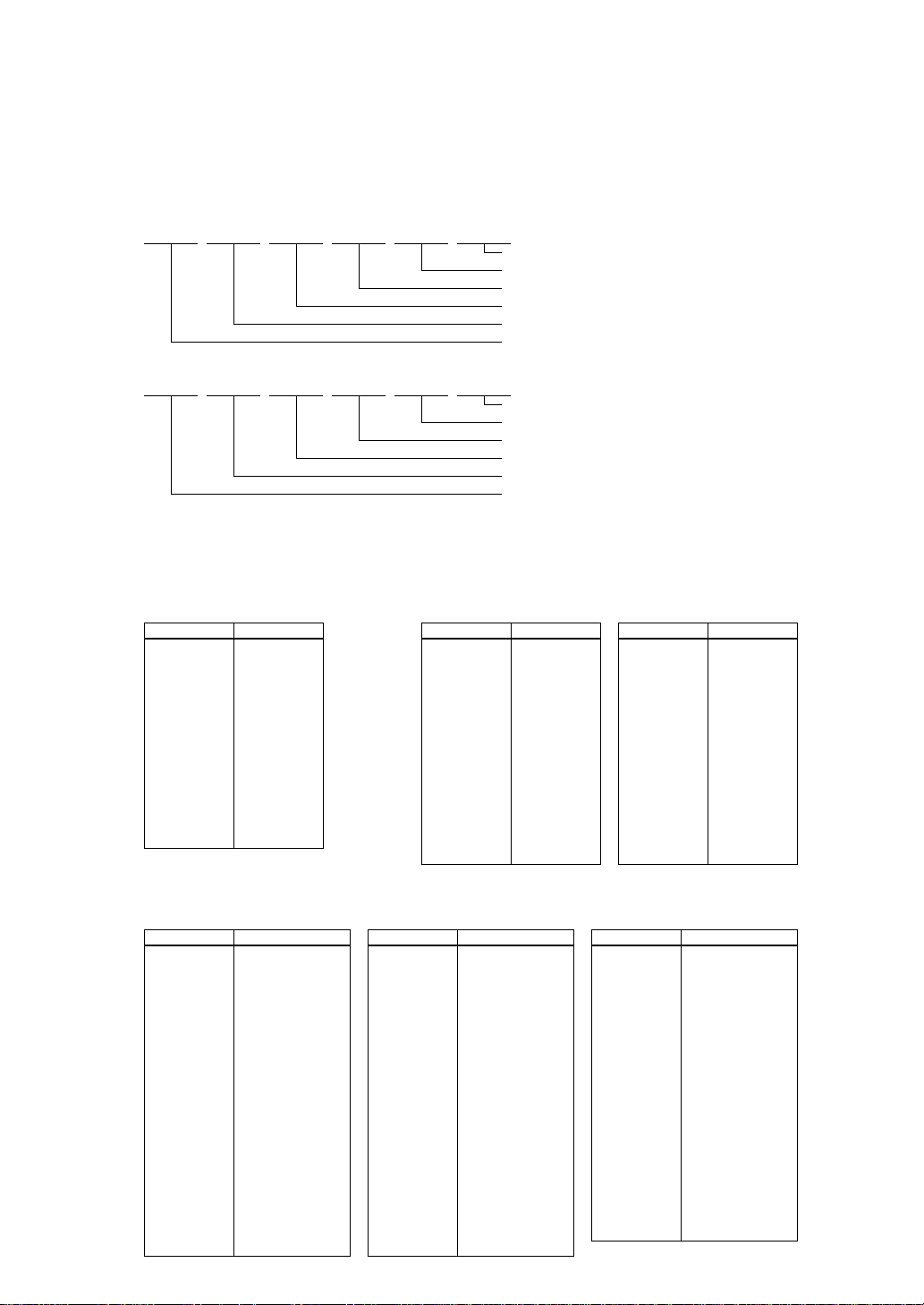

Configuration of product number

Devices

S1 C 60N01 F 0A01

Development tools

S5U1

∗1: For details about tool types, see the tables below. (In some manuals, tool types are represented by one digit.)

∗2: Actual versions are not written in the manuals.

C 60R08 D1 1

00

Packing specification

Specification

Package (D: die form; F: QFP)

Model number

Model name (C: microcomputer, digital products)

Product classification (S1: semiconductor)

00

Packing specification

Version (1: Version 1 ∗2)

Tool type (D1: Development Tool ∗1)

Corresponding model number (60R08: for S1C60R08)

Tool classification (C: microcomputer use)

Product classification

(S5U1: development tool for semiconductor products)

Comparison table between new and previous number

S1C60 Family processors

Previous No.

E0C6001

E0C6002

E0C6003

E0C6004

E0C6005

E0C6006

E0C6007

E0C6008

E0C6009

E0C6011

E0C6013

E0C6014

E0C60R08

New No.

S1C60N01

S1C60N02

S1C60N03

S1C60N04

S1C60N05

S1C60N06

S1C60N07

S1C60N08

S1C60N09

S1C60N11

S1C60N13

S1C60140

S1C60R08

S1C62 Family processors

Previous No.

E0C621A

E0C6215

E0C621C

E0C6S27

E0C6S37

E0C623A

E0C623E

E0C6S32

E0C6233

E0C6235

E0C623B

E0C6244

E0C624A

E0C6S46

New No.

S1C621A0

S1C62150

S1C621C0

S1C6S2N7

S1C6S3N7

S1C6N3A0

S1C6N3E0

S1C6S3N2

S1C62N33

S1C62N35

S1C6N3B0

S1C62440

S1C624A0

S1C6S460

Previous No.

E0C6247

E0C6248

E0C6S48

E0C624C

E0C6251

E0C6256

E0C6292

E0C6262

E0C6266

E0C6274

E0C6281

E0C6282

E0C62M2

E0C62T3

New No.

S1C62470

S1C62480

S1C6S480

S1C624C0

S1C62N51

S1C62560

S1C62920

S1C62N62

S1C62660

S1C62740

S1C62N81

S1C62N82

S1C62M20

S1C62T30

Comparison table between new and previous number of development tools

Development tools for the S1C60/62 Family

Previous No.

ASM62

DEV6001

DEV6002

DEV6003

DEV6004

DEV6005

DEV6006

DEV6007

DEV6008

DEV6009

DEV6011

DEV60R08

DEV621A

DEV621C

DEV623B

DEV6244

DEV624A

DEV624C

DEV6248

DEV6247

New No.

S5U1C62000A

S5U1C60N01D

S5U1C60N02D

S5U1C60N03D

S5U1C60N04D

S5U1C60N05D

S5U1C60N06D

S5U1C60N07D

S5U1C60N08D

S5U1C60N09D

S5U1C60N11D

S5U1C60R08D

S5U1C621A0D

S5U1C621C0D

S5U1C623B0D

S5U1C62440D

S5U1C624A0D

S5U1C624C0D

S5U1C62480D

S5U1C62470D

Previous No.

DEV6262

DEV6266

DEV6274

DEV6292

DEV62M2

DEV6233

DEV6235

DEV6251

DEV6256

DEV6281

DEV6282

DEV6S27

DEV6S32

DEV6S37

EVA6008

EVA6011

EVA621AR

EVA621C

EVA6237

EVA623A

New No.

S5U1C62620D

S5U1C62660D

S5U1C62740D

S5U1C62920D

S5U1C62M20D

S5U1C62N33D

S5U1C62N35D

S5U1C62N51D

S5U1C62560D

S5U1C62N81D

S5U1C62N82D

S5U1C6S2N7D

S5U1C6S3N2D

S5U1C6S3N7D

S5U1C60N08E

S5U1C60N11E

S5U1C621A0E2

S5U1C621C0E

S5U1C62N37E

S5U1C623A0E

Previous No.

EVA623B

EVA623E

EVA6247

EVA6248

EVA6251R

EVA6256

EVA6262

EVA6266

EVA6274

EVA6281

EVA6282

EVA62M1

EVA62T3

EVA6S27

EVA6S32R

ICE62R

KIT6003

KIT6004

KIT6007

New No.

S5U1C623B0E

S5U1C623E0E

S5U1C62470E

S5U1C62480E

S5U1C62N51E1

S5U1C62N56E

S5U1C62620E

S5U1C62660E

S5U1C62740E

S5U1C62N81E

S5U1C62N82E

S5U1C62M10E

S5U1C62T30E

S5U1C6S2N7E

S5U1C6S3N2E2

S5U1C62000H

S5U1C60N03K

S5U1C60N04K

S5U1C60N07K

Page 6

Page 7

I

S1C62 FAMILY DEVELOPMENT TOOL

INTRODUCTION

This part explains the composition of the development support tool for the 4-bit Single Chip Microcomputer S1C62 Family and the developmental

environment.

Page 8

Page 9

INTRODUCTION

INTRODUCTION

Contents

1 TYPES OF DEVELOPMENT SUPPORT TOOLS ____________________I-1

1.1 Composition of the Software Development Tools S5U1C62xxxD...........................I-1

1.2 Composition of the Hardware Tools .......................................................................I-1

2 DEVELOPMENTAL ENVIRONMENT_____________________________I-2

3 DEVELOPMENT FLOW ________________________________________I-2

4 INSTALLATION _______________________________________________I-4

5 DIFFERENCES FROM MODEL TO MODEL AND PRECAUTIONS ___I-5

6 TROUBLESHOOTING __________________________________________I-6

S1C62 FAMILY EPSON I-i

DEVELOPMENT TOOL REFERENCE MANUAL

Page 10

Page 11

INTRODUCTION

1 TYPES OF DEVELOPMENT

SUPPORT TOOLS

Here we will explain the composition of the software and hardware for the development support tools.

1.1 Composition of the Software Development Tools S5U1C62xxxD

The below software are included in the software development support tools used in each S1C62XXX

model.

1. Development Tool Management System DMS6200 ..Menu selections for each software / start-up software

2. Cross Assembler ASM62XX ...................................... Cross assembler for program preparation

3. Melody Assembler MLA628X (Note) .......................... Melody data preparation program

4. Function Option Generator FOG62XX .......................Function option data preparation program

5. Segment Option Generator SOG62XX (Note) ........... Segment option data preparation program

6. ICE Control Software ICS62XX.................................. ICE control program

7. Mask Data Checker MDC62XX.................................. Mask data preparation program

Note The 3 Melody Assembler MLA628X are only set in the models (S1C62N8X) that have melody

functions.

The 5 Segment Option Generator SOG62XX are only set in models that have LCD driver and

segment options.

1.2 Composition of the Hardware Tools

The following two types have been prepared for all types as hardware development support systems.

1. In-Circuit Emulator S5U1C62000H..... In-circuit emulator permitting high level debugging (common to each

model)

2. Evaluation Board S5U1C62xxxE........ Evaluation board that has the same functions as the actual IC (different

for each model)

S1C62 FAMILY EPSON I-1

DEVELOPMENT TOOL REFERENCE MANUAL

Page 12

INTRODUCTION

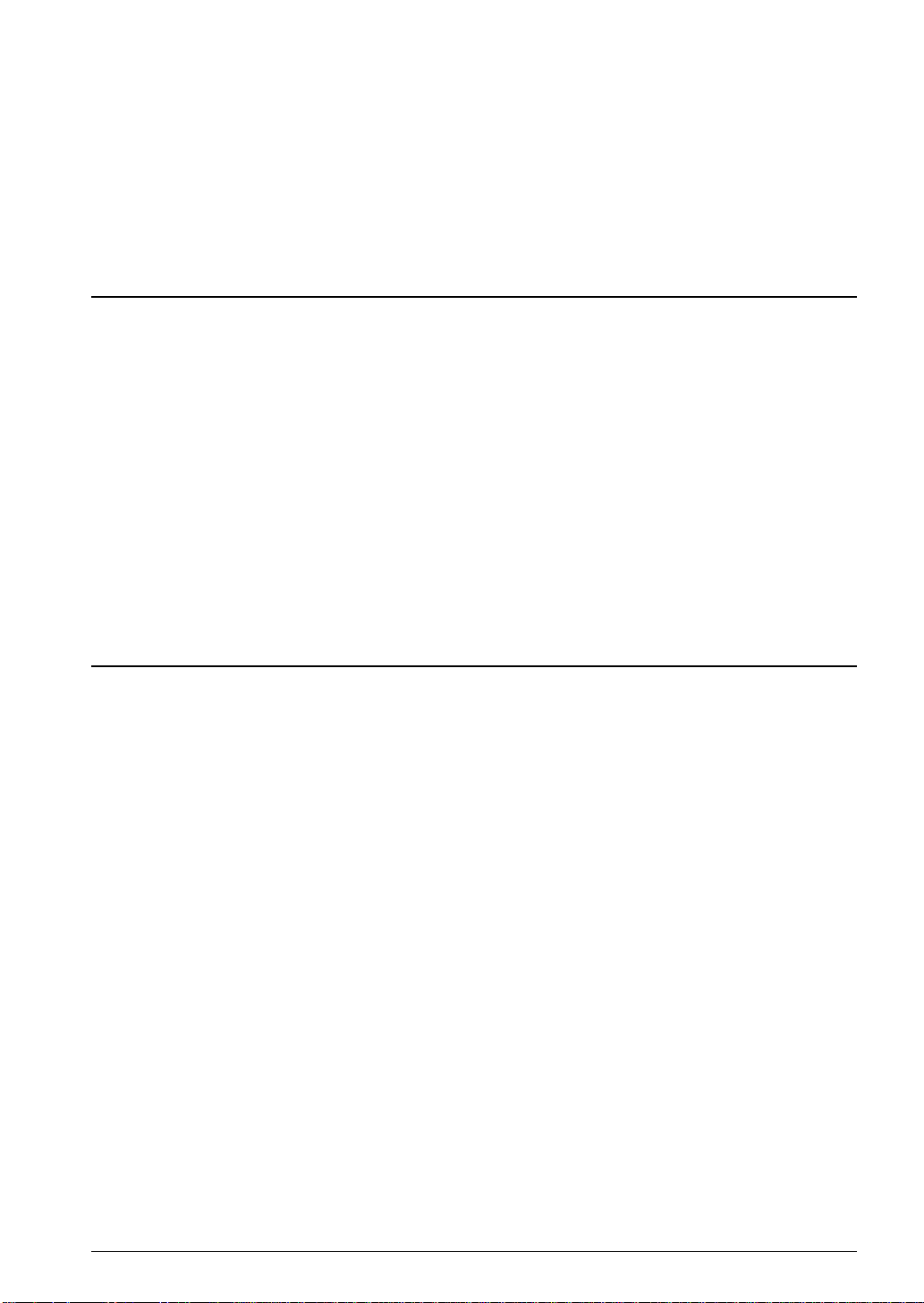

2 DEVELOPMENTAL ENVIRONMENT

The software product of the development support tool S5U1C62xxxD operates on the following host

systems:

• IBM PC/AT (at least PC-DOS Ver. 2.0)

When developing the S1C62XXX, the above-mentioned host computer, editor, P-ROM writer, printer, etc.

must be prepared by the user in addition to the development tool which is normally supported by Seiko

Epson.

Host computer

(IBM PC/AT)

PC-DOS

Editor

RS-232C

• P-ROM writer

• Printer

Note The S5U1C62xxxD system requires a host computer with a RAM capacity of about 140K bytes.

Since the ICE (S5U1C62000H) is connected to the host computer with a RS-232C serial interface,

adapter board for asynchronous communication will be required depending on the host computer

used.

S5U1C62000A

S1C62xxx Development Tool

Software tools

S5U1C62xxxD

DMS6200 SOG62xx

ASM62xx ICS62xx

MLA628x MDC62xx

FOG62xx

Hardware tools

ICE Evaluation Board

S5U1C62000H

To be prepared by the user

Fig. 2.1 System configuration

S5U1C62xxxE

Target board

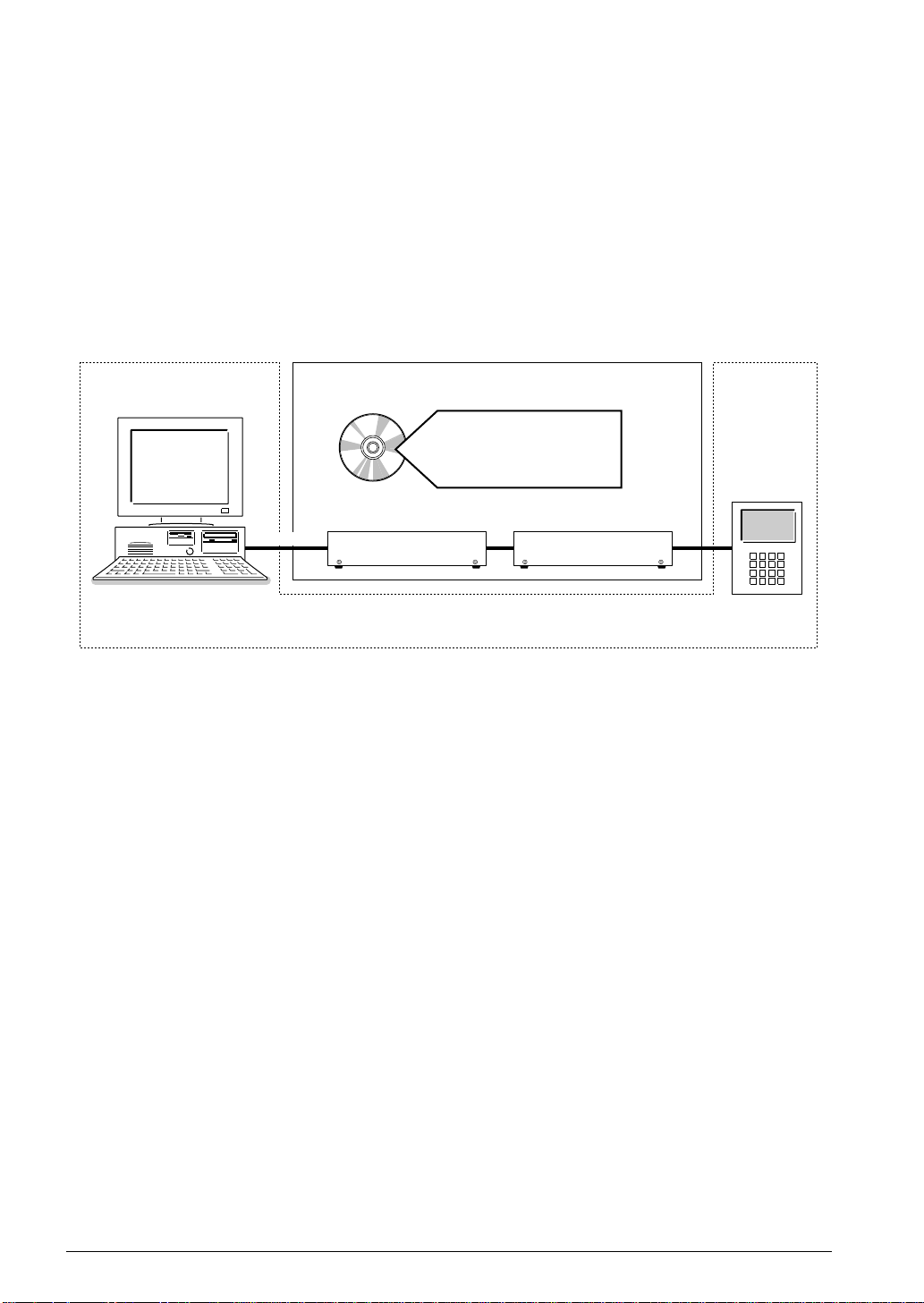

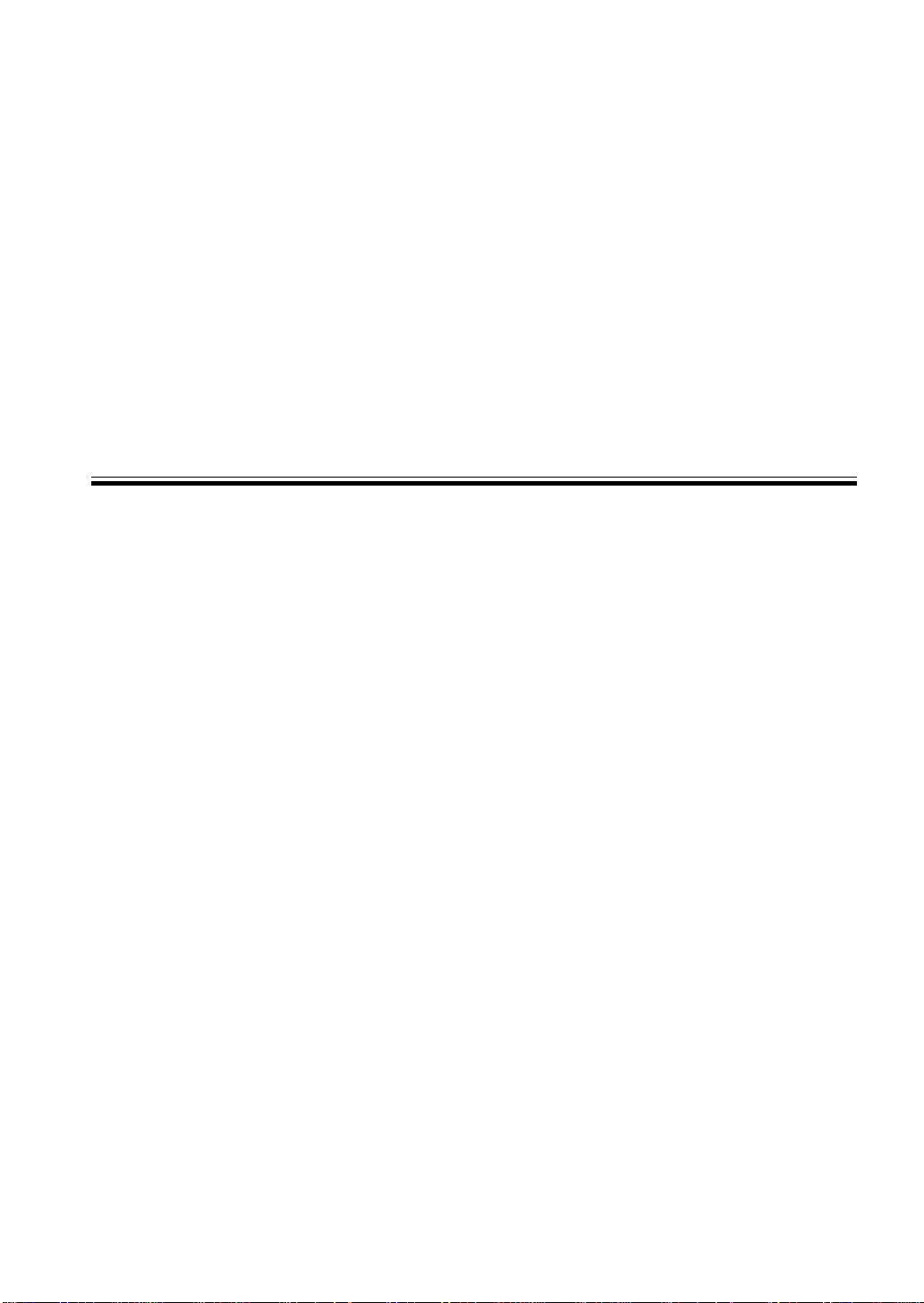

3 DEVELOPMENT FLOW

Figure 3.1 shows the development flow through the S5U1C62xxxD.

Concerning file names

All the input-output file name for the each development support tool commonly use "C2XXYYY". In

principle each file should be produced in this manner. Seiko Epson will designate the "YYY" for each

customer.

I-2 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 13

INTRODUCTION

*4, *5

Development support tool

selection on menu of

Development Tool

Management System DMS6200

C2XXYYY

.PRN

Assembly list Melody

Determination of

software specifications

*2, *3, *4 *4, *5*4, *5 *4, *5 *1, *6

Flow chart generation

and coding

Coding

sheet

Source file generation

by using editor

Program

C2XXYYY

.DAT

source file

Cross Assembler

ASM62XX execution

Object file

C2XXYYYL

.HEX

C2XXYYYH

.HEX

*1, *2 *1

Melody generation

and coding

Source file generation

by using editor

C28XYYY

.MDT

Melody Assembler

MLA628X execution

C28XYYY

.MPR

assembly list

C28XYYYA

.DOC

Melody

document file

Coding

sheet

Melody

source file

Determination of

hardware specifications

Function option list

generation

Function

option

list

*4, *5*4, *5 *4, *5*4, *5

Function Option Generator

FOG62XX execution

C2XXYYYF

.DOC

Function option

document file

Segment option list

generation

Segment

option

list

Source file generation

by using editor

Segment option

C2XXYYY

.SEG

source file

Segment Option Generator

SOG62XX execution

C2XXYYYS

.DOC

Segment option

document file

Creation of

target board

C2XXYYYF

.HEX

Function

option

HEX file

Function

option ROM

(one)

S5U1C62xxxE

C2XXYYYS

.HEX

ICS62XX

*4, *5

Debugging

completion

Debugging with

ICE Control Software

C28XYYYA

.HEX

Melody

HEX file

ICE Evaluation Board

S5U1C62000H

*4, *7 *6

*4, *5

Mask Data Checker

MDC62XX execution

Note The melody and segment option flow are

C62XXYYY

.PAn

SEIKO EPSON

File for

submission

only valid in models possessing those

functions.

Fig. 3.1 S5U1C62xxxD development flow

☞ Reference manual

*1 S1C62xxx Technical Manual (Hardware) *5 S5U1C62xxxD Manual

*2 S1C62xxx Technical Manual (Software) *6 S5U1C62xxxE Manual

*3 S1C6200/6200A Core CPU Manual *7 S5U1C62000H Manual

*4 S1C62 Family Development Tool Reference Manual (this manual)

Segment

option

HEX file

Segment

option ROM

(two)

Target board

S1C62 FAMILY EPSON I-3

DEVELOPMENT TOOL REFERENCE MANUAL

Page 14

INTRODUCTION

4 INSTALLATION

The S5U1C62xxxD tools are included on the CD-ROM of the S5U1C62000A (S1C60/62 Family Assembler

Package), and they can be installed in your hard disk using the installer (Setup.exe) on the CD-ROM.

Refer to the "S5U1C62000A Manual" for how to install the S5U1C62xxxD tools.

Note The DMS6200 configures a menu from files that are located in the current directory. Therefore, do

not move the development tools from the directory in which the DMS6200 exists.

To invoke an editor (DOS version) or other programs from the DMS6200, copy those executable

files to the directory in which the DMS6200 exists.

I-4 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 15

INTRODUCTION

5 DIFFERENCES FROM MODEL TO

MODEL AND PRECA UTIONS

There may be some models in which the following two types software tools contained in the

S5U1C62xxxD are not included.

(1) Segment Option Generator SOG62XX

This is not included in the software tools of models in which the segment option has not been set.

(2) Melody Assembler MLA628X

This is not included in the software tools for the models (Other than S1C62N8X) that do not have the

melody function.

Please be aware of the following points in setting the host system.

(1) The S5U1C62xxxD system requires a host computer with a RAM capacity of about 140K bytes.

(2) Since the ICE is connected to the host computer with a RS-232C serial interface, adapter board for

asynchronous communication will be required depending on the host computer used.

(3) In order for the MDC62XX to handle numerous files, set the number of files described in the

CONFIG.SYS to 10 or more (e.g., FILES = 20).

S1C62 FAMILY EPSON I-5

DEVELOPMENT TOOL REFERENCE MANUAL

Page 16

INTRODUCTION

6 TROUBLESHOOTING

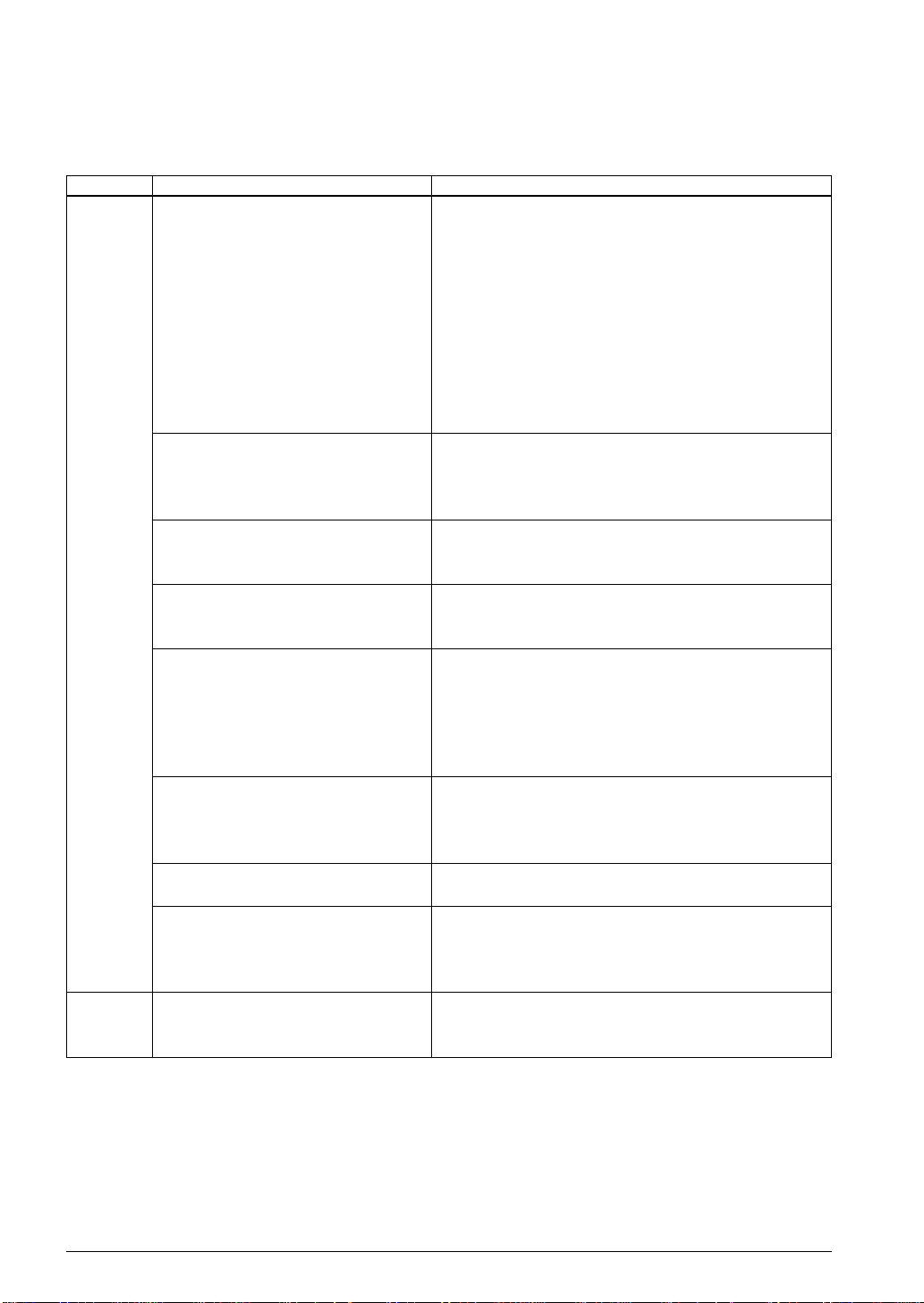

Tool

ICE

S5U1C62000H

SOG62XX

Problem

Nothing appears on the screen, or

nothing works, after activation.

The ICE fuse cut immediately after

activation.

<ILLEGAL VERSION ICE6200>

appears on the screen immediately after

activation.

<ILLEGAL VERSION PARAMETER

FILE> appears on the screen immediately after activation.

Immediate values A (10) and B (11)

cannot be entered correctly with the A

command.

<UNUSED AREA> is displayed by the

SD command.

You can not do a real-time run in

break-trace mode.

Output from the evaluation board is

impossible when data is written to the I/

O memory for Buzzer and Fout output

with the ICE command.

An R error occurs although the address

is correctly set in the segment source

file.

Remedy measures

Check the following and remedy if necessary:

• Is the RS-232C cable connected correctly?

• Is the RS-232C driver installed?

• Is MODE.COM on the disk?

• Is the execution file correct?

PC-DOS ICS62XXW.EXE

• Is the DOS version correct?

PC-DOS Ver. 2.1 or later

• Is the DIP switches that set the baud rate of the main ICE

unit set correctly?

• Is the fuse of the ICE cut off?

Check the following and remedy if necessary:

• Are connectors F1 and F5 connected to the evaluation

board correctly?

• Is the target board power short-circuiting?

The wrong version of ICE is being used. Use the latest

version.

The wrong version of ICS62XXP.PAR is being used. Use

the latest version.

The A and B registers are reserved for the entry of A and B.

Write 0A and 0B when entering A (10) and B (11).

Example: LD A, B Data in the B register is

loaded into the A register.

LD B, 0A Immediate value A is loaded

into the B register.

This massage is output when the address following one in

which data is written is unused. It does not indicates

problem. Data is correctly set in areas other than the readonly area.

Since the CPU stops temporarily when breaking conditions

are met, executing in a real-time is not performed.

Output is possible only in the real-time run mode.

Check the following and remedy if necessary:

• Does the address symbol use capital letters?

• Are the output ports set for every two terminals?

I-6 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 17

INTRODUCTION

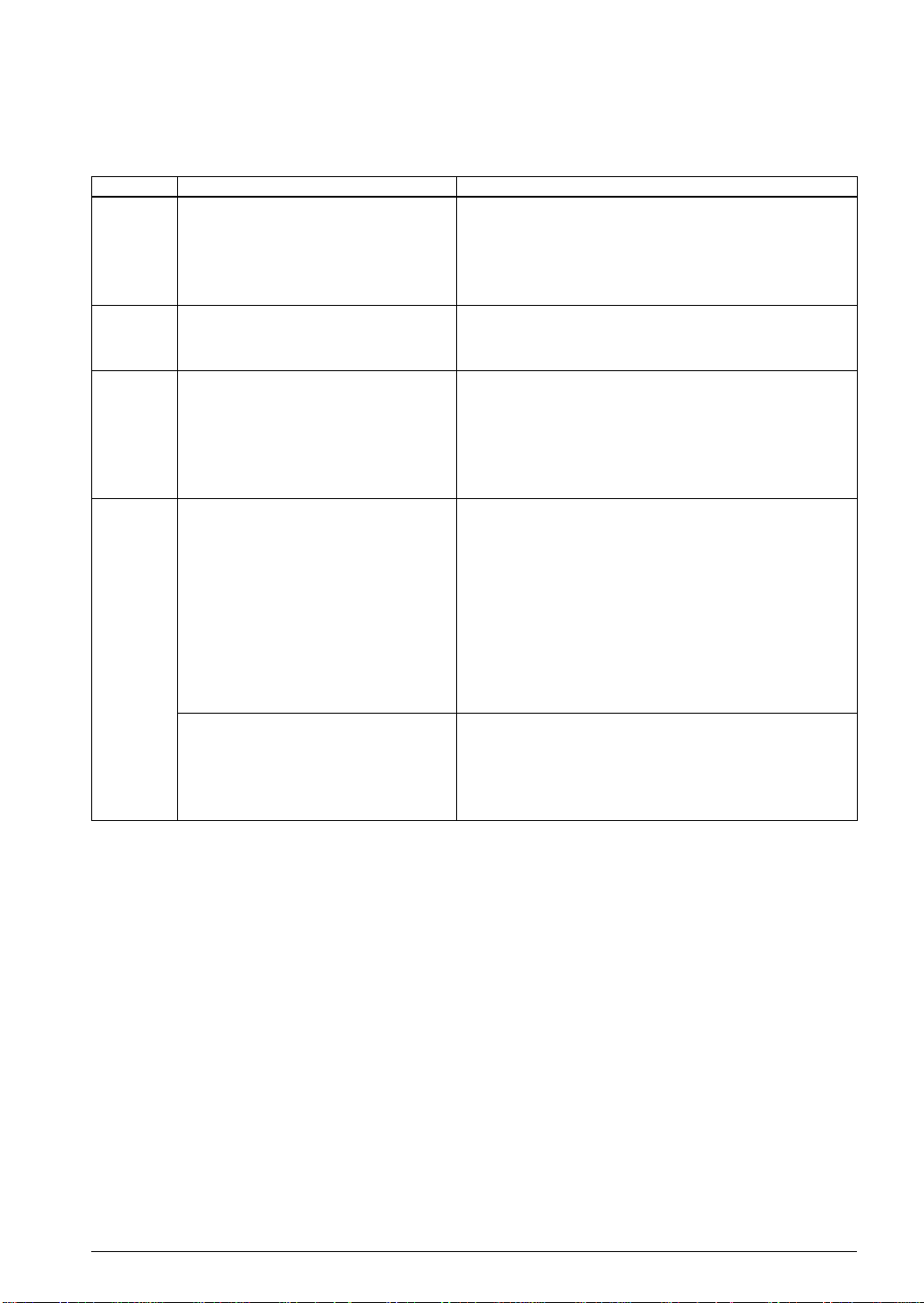

Tool

ASM62XX

MDC62XX

MLA628X

Evaluation

board

S5U1C62xxxE

Problem

An R error occurs although the final

page is passed.

Activation is impossible.

No melody is output.

The evaluation board does not work

when it is used independently.

Target segment does not light.

Remedy measures

The cross assembler is designed to output "R error" every

time the page is changed. Use a pseudo-instruction to set the

memory, such as ORG or PAGE, to change the page. See

"Memory setting pseudo-instructions" in the cross assembler manual.

Check the following and remedy if necessary:

• Is the number of files set at ten or more in OS environment file CONFIG.SYS?

Check the following and remedy if necessary:

•

Has the OPTLD command of the ICE been executed? (When

the ICE is connected to the

evaluation board

)

• Is the MELODY ROM installed? (When the evaluation

board is used independently)

• Is the attack bit of the melody data set to "1"?

Check the following and remedy if necessary:

• Has the EPROM for F.HEX and S.HEX been replaced by

the EPROM for the target?

• Is the EPROM for F.HEX and S.HEX installed correctly?

• Is the appropriate voltage being supplied? (5V DC, 3 A,

or more)

• Are the program ROMs (H and L) installed correctly?

• Is data written from address 4000H? (When the 27C256

is used as the program ROM)

• Is the EN/DIS switch on the evaluation board set to EN?

Check the following and remedy if necessary:

• Is an EPROM with an access time of 170 ns or less being

used for S.HEX.

• Has the VADJ VR inside the evaluation board top cover

been turned to a lower setting?

S1C62 FAMILY EPSON I-7

DEVELOPMENT TOOL REFERENCE MANUAL

Page 18

Page 19

II

DEVELOPMENT TOOL MANAGEMENT SYSTEM

DMS6200

This part mainly explains how to operate the Development Tool Management System DMS6200.

Page 20

Page 21

DEVELOPMENT TOOL MANAGEMENT SYSTEM DMS6200

DEVELOPMENT TOOL MANAGEMENT SYSTEM

Contents

1 DIFFERENCES DEPENDING ON THE MODEL __________________ II-1

2 DMS6200 OUTLINE ___________________________________________ II-1

3 DMS6200 OPERATION PROCEDURE ___________________________ II-2

S1C62 FAMILY EPSON II-i

DEVELOPMENT TOOL REFERENCE MANUAL

Page 22

Page 23

DEVELOPMENT TOOL MANAGEMENT SYSTEM DMS6200

1 DIFFERENCES DEPENDING

ON THE MODEL

The DMS6200 is a software tool that is common to the all models of the S1C62 Family and there is

no difference in operating procedure. However, the content of such things as the menu screen may vary

due to differences in the configuration of the software for each model and differences in the directory

content in the DMS6200.

The below two types that are included in the explanation and display screen examples may not be present

in certain models.

(1) The SOG62XX and C2XXYYYS.* are only available in models offering the segment option.

(2) The MLA628X, C28XYYY.M* and C28XYYYA.* are only available in models offering the melody

function.

When models that do not have the above functions are used, disregard the respective program names and

file names indicated in the manual.

Refer to the "S5U1C62xxxD Manual" for the software tools included in the S5U1C62xxxD.

2 DMS6200 OUTLINE

The DMS6200 (Development Tool Management System) is a software which selects the

S5U1C62xxxD software development support tool and the program such as an editor in menu form and

starts it.

In this way the various software frequently executed during debugging can be effectively activated.

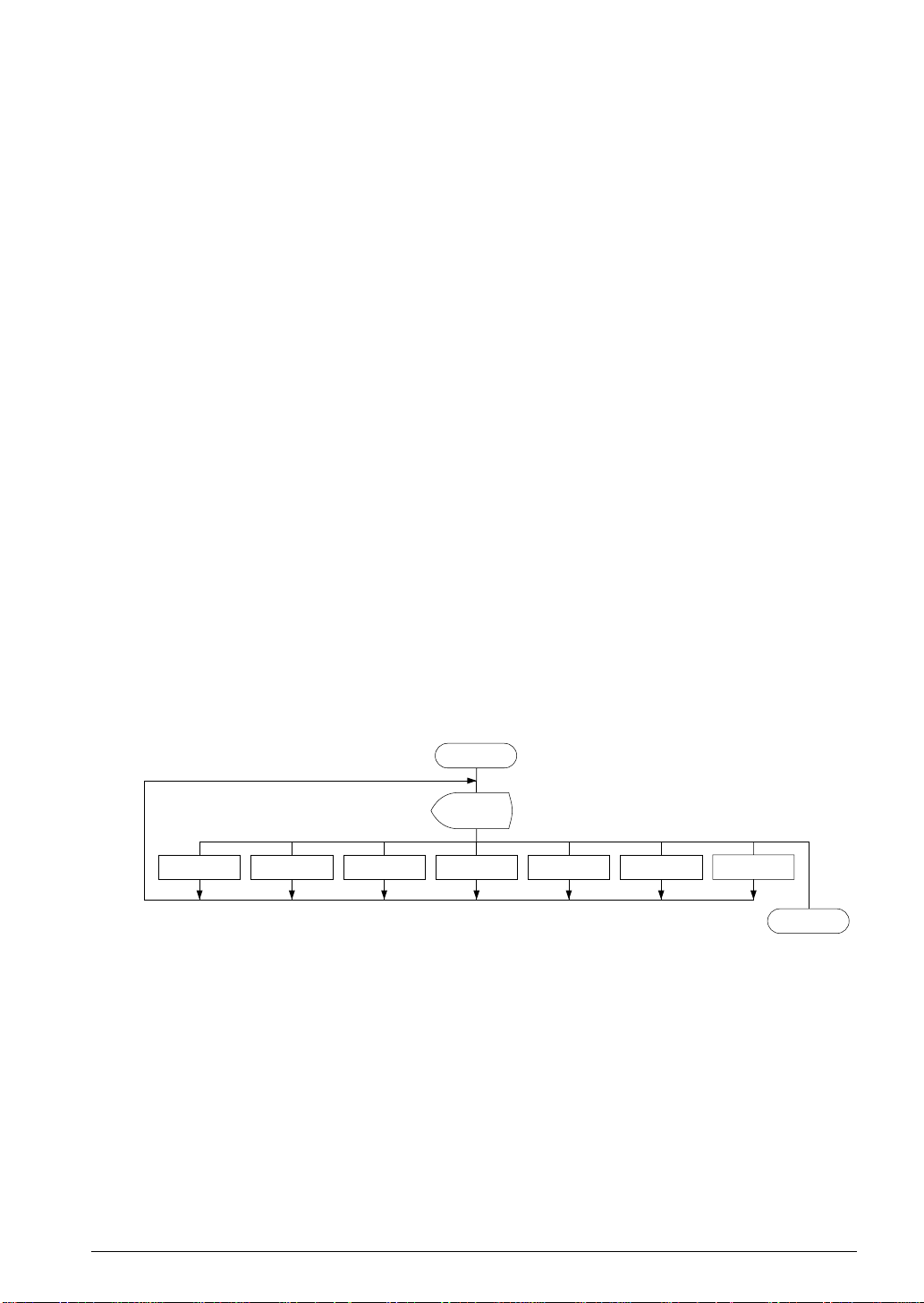

Figure 2.1 shows the DMS6200 execution flow.

DMS6200

Menu

selections

ASM62XX SOG62XX Editor etc.

Fig. 2.1 DMS6200 execution flow

ICS62XXFOG62XXMLA628X MDC62XX

To DOS

S1C62 FAMILY EPSON II-1

DEVELOPMENT TOOL REFERENCE MANUAL

Page 24

DEVELOPMENT TOOL MANAGEMENT SYSTEM DMS6200

3 DMS6200 OPERATION PROCEDURE

Set the directory containing the respective software development support tools into the current

directory prior to activating the DMS6200.

Since the development support tools each require input files (e.g., source file), first create the input files

according to the support tool manuals and then perform the following operations:

(1) The following is entered on the current drive:

DMS6200

indicates the return key.

The title is then displayed. To return to DOS at this point, press ^C (CTRL + C).

Initial screen

*** E0C6200 Development tool Management System. --- Ver 1.0 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) Copyright 1991 SEIKO EPSON CORP.

STRIKE ANY KEY.

(2) Press any key and the following menu screen will be displayed. A list of all executable files having

"EXE", "COM" and "BAT" extensions will appear on this menu screen; if any execution file other than

S5U1C62xxxD were copied to the current drive for execution, it will differ from the displays shown

below.

Menu screen

DMS6200 Version 1.0 Copyright(C) SEIKO EPSON CORP. 1991.

1) ASM62XX .EXE

2) FOG62XX .EXE

3) ICS62XXB.BAT

4) ICS62XXW.EXE

5) MDC62XX .EXE

6) MLA628X .EXE

7) SOG62XX .EXE

Input Number ? [ ]

To return to DOS at this point, press the "ESC" key.

II-2 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 25

DEVELOPMENT TOOL MANAGEMENT SYSTEM DMS6200

(3) Input the number of the development support tool you wish to start and then press the "RETURN" key.

Next, the screen for entering the source file will be displayed.

Input Number ? [1 ]

(4) The following sample screen is the screen which will be displayed when ASM62XX is selected.

Input the number of the source file.

Pressing the "ESC" key here will return the previous screen.

When the source file is selected by number, the edit line enclosed in [ ] will appear; enter the option

parameter if necessary. The "BS" key is valid on the edit line. Press the "RETURN" key when input is

completed.

Source file selection screen

DMS6200 Version 1.0 Copyright(C) SEIKO EPSON CORP. 1991.

1) C2XXYYY .DAT

2) C28XYYY .MDT

3) C28XYYY .MPR

4) C2XXYYY .PRN

5) C2XXYYY .SEG

6) C28XYYYA.DOC

7) C28XYYYA.HEX

8) C2XXYYYF.DOC

9) C2XXYYYF.HEX

10) C2XXYYYH.HEX

11) C2XXYYYL.HEX

12) C2XXYYYS.DOC

13) C2XXYYYS.HEX

14) C62XXYYY.PA0

Input Number ? [1 ]

Edit > [ASM62XX C2XXYYY ]

The above operation will activate the ASM62XX. (The MLA628X will also activate with the same

operation.)

When the source file is in another file or directory it will not be displayed in the menu. In such cases

you skip the number input using the return key and input the drive/directory and source file name in

the edit line.

When starting, press the "RETURN" key twice particularly for the support tools which do not require

source files (except the ASM62XX and the MLA628X).

Refer to the support manuals regarding operations after starting.

(5) When execution of the development support tool is completed, the following message will appear:

Input Any Key ...

Press any key and the first menu screen will be returned.

S1C62 FAMILY EPSON II-3

DEVELOPMENT TOOL REFERENCE MANUAL

Page 26

Page 27

III

CROSS ASSEMBLER

ASM62XX

This part mainly explains how to operate the

Cross Assembler ASM62XX for the S1C62

Family, and how to generate source files.

Page 28

Page 29

CROSS ASSEMBLER ASM62XX

CROSS ASSEMBLER ASM62XX

Contents

1 DIFFERENCES DEPENDING ON THE MODEL __________________ III-1

2 ASM62XX OUTLINE __________________________________________ III-2

2.1 Outline ................................................................................................................... III-2

2.2 ASM62XX Input/Output Files ................................................................................ III-2

3 ASM62XX OPERATION PROCEDURE __________________________ III-3

3.1 Starting ASM62XX ................................................................................................ III-3

3.2 Selecting Auto-Page-Set Function......................................................................... III-5

3.3 Generating a Cross-Reference Table .................................................................... III-5

4 SOURCE FILE FORMAT _____________________________________ III-6

4.1 Source File Name .................................................................................................. III-6

4.2 Statements .............................................................................................................. III-6

4.2.1 Label field .................................................................................................... III-6

4.2.2 Mnemonic field ............................................................................................ III-7

4.2.3 Operand field ............................................................................................... III-7

4.2.4 Comment field .............................................................................................. III-7

4.3 Index ...................................................................................................................... III-7

4.3.1 Label ............................................................................................................ III-7

4.3.2 Symbol ......................................................................................................... III-8

4.4 Constant and Operational Expression .................................................................. III-8

4.4.1 Numeric constant ......................................................................................... III-8

4.4.2 Character constant ...................................................................................... III-8

4.4.3 Operator ...................................................................................................... III-9

4.4.4 Location counter ......................................................................................... III-10

4.5 Pseudo-Instructions .............................................................................................. III-11

4.5.1 Data definition pseudo-instructions ........................................................... III-11

4.5.2 Memory setting pseudo-instructions........................................................... III-12

4.5.3 Assembler control pseudo-instructions ...................................................... III-15

4.6 Macro-Functions .................................................................................................. III-15

4.6.1 Macro-instructions ..................................................................................... III-15

4.6.2 Macro-definitions ....................................................................................... III-16

4.6.3 Macro-calls................................................................................................. III-17

5 ERROR MESSAGES__________________________________________ III-19

APPENDIX ASM62XX EXECUTION EXAMPLE __________________ III-20

1) Source file (C2XX0A0.DAT) ........................................................................... III-20

2) Running the assembler (display on the console) ............................................. III-21

3) Assembly listing file (C2XX0A0.PRN) ............................................................ III-22

4) Object files (C2XX0A0H.HEX, C2XX0A0L.HEX) .......................................... III-23

S1C62 FAMILY EPSON III-i

DEVELOPMENT TOOL REFERENCE MANUAL

Page 30

Page 31

CROSS ASSEMBLER ASM62XX

1 DIFFERENCES DEPENDING

ON THE MODEL

Since the memory capacity will vary with each model of the S1C62 Family you must pay attention

to the following points when preparing a program.

The limiting items for each model are indicated in the "S5U1C62xxxD Manual".

■ ROM area

The ROM capacity will vary depending on the model.

The number of banks (16 pages/bank) and the number of pages (256 steps/page) are determined by

this ROM capacity and the memory setting pseudo-instruction and the "PSET" instruction is limited to

within its range.

Valid specification range

ORG pseudo-instruction: 0000H–ROM final step

PAGE pseudo-instruction: 00H–number of page - 1

BANK pseudo-instruction: 1 bank configuration model → 0H only

2 bank configuration model → 0H and 1H

PSET instruction: 00H–number of page - 1

When a specification beyond this valid specification range is made to the ASM62XX an error is pro-

duced.

■ RAM area

The RAM capacity varies depending on the model.

The number of pages (256 words/page) is determined according to the RAM capacity. Also, the

undefined area includes from the 0 address to the final RAM address.

When an undefined address is set in the index register, memory access to it becomes invalid, but be

careful that no errors develop in the ASM62XX.

■ Undefined code

In the S1C62 Family, the instruction set is not different from model to model. However, you may not be

able to use instructions such as the SLP instruction and those that access the page section (XP and YP)

of the index register depending on the RAM content.

S1C62 FAMILY EPSON III-1

DEVELOPMENT TOOL REFERENCE MANUAL

Page 32

CROSS ASSEMBLER ASM62XX

2 ASM62XX OUTLINE

2.1 Outline

The ASM62XX cross assembler (the ASM62XX in this manual) is an assembler program for generating the

machine code used by the S1C62XXX 4-bit, single-chip microcomputers. It can be used under PC-DOS.

The Cross Assembler ASM62XX will assemble the

program source files which have been input by the

user's editor and will generate an object file in IntelHex format and assembly list file.

In this assembler, program modularization has been

made possible through macro definition functions and

programming independent of the ROM page structure

has been made possible through the auto page set

function. In addition, consideration has also been given

to precise error checks for program capacity (ROM

capacity) overflows, undefined codes and the like, and

for debugging of such things as label tables for assembly list files and cross reference table supplements.

The program name of the assembler is ASM62XX.EXE.

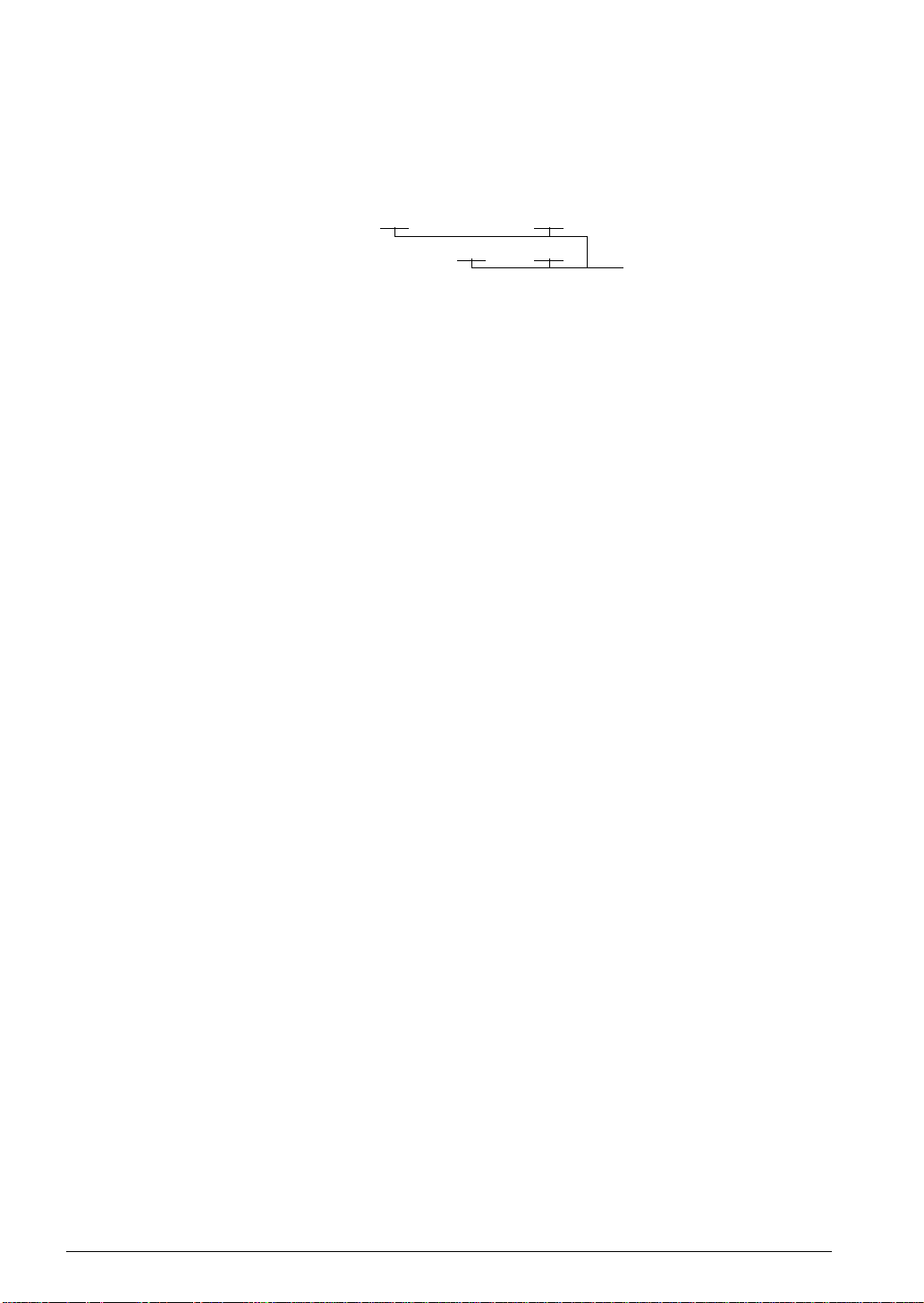

Figure 2.1.1 shows the ASM62XX execution flow.

Error

message

Error

message

A>EDLIN C2XXYYY.DAT

Create the source file

C2XXYYY

.DAT

A>ASM62XX C2XXYYY

Execute the cross assembler

C2XXYYY

.PRN

Assembly

listing file

C2XXYYYL

.HEX

Object file

C2XXYYYH

Fig. 2.1.1 ASM62XX execution flow

.HEX

2.2 ASM62XX Input/Output Files

ASM62XX reads a source file, assembles it, and outputs object files and an assembly listing file.

■ Source file (C2XXYYY.DAT)

This is a source program file produced using an editor such as EDLIN. The file name format is

C2XXYYY, and the file name must not exceed seven characters in length. Character string YYY should

be determined by referencing the device name specified by Seiko Epson. The file extension must be

added ".DAT".

■ Object file (C2XXYYYH.HEX, C2XXYYYL.HEX)

This is an assembled program file in Intel hex format. Because the machine code of the S1C62XXX is 12bit, the high-order bytes (bits 9 to 12 suffixed by high-order bits 0000B) are output to file

C2XXYYYH.HEX, and the low-order bytes (bits 8 to 1) are output to file C2XXYYYL.HEX.

■ Assembly listing file (C2XXYYY.PRN)

This is a program listing file generated by adding an operation codes and error messages (if any errors

have occurred) to respective source program statements. A cross-reference table is generated at the end

of the file, depending on the label table and options. The file name is C2XXYYY.PRN.

See the Appendix for the contents of each file.

III-2 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 33

CROSS ASSEMBLER ASM62XX

3 ASM62XX OPERATION PROCEDURE

This section explains how to operate ASM62XX.

3.1 Starting ASM62XX

When starting ASM62XX, enter the following at DOS command level (when a prompt such as A> is being

displayed):

ASM62XX _ [drive-name:] source-file-name [.shp] _ [-N]

When starting ASM62XX through the DMS6200, selects the "ASM62XX.EXE" and source file in the menu

screen, and input options necessary.

■ Drive name

If the source file is not on the same disk as ASM62XX.EXE, specify a disk drive mounted the floppy disk

storing the source file before input the source file name. If the source file is on the same disk as

ASM62XX.EXE, it does not need to specify the disk drive.

■ Source file name

This is the name of the source file to be entered for ASM62XX. The source file name must not exceed

seven characters in length. File extension .DAT must not be entered.

_ indicates a blank.

A parameter enclosed by [ ]

can be omitted.

indicates the return key.

■ .shp

Characters s, h, and p are options for specifying the file I/O drives, and can be omitted.

s: Specifies the drive from which the source file is to be input. A character from A to P can be

specified. If @ is specified, the source file in the current drive (directory) is input. Even if a drive

name is prefixed to the source file name, this option is effective.

h: Specifies the drive to which the object file (HEX) is to be output. A character from A to P can be

specified. If @ is specified, the object file is output to the current drive (directory). If Z is

specified, only assembly is executed; the object file is not generated.

p: Specifies the drive to which the assembly listing file is to be output. A character from A to P can

be specified. If @ is specified, the object file is output to the current drive (directory). If X is

specified, a listing containing error messages is output to the console. If Z is specified, the

assembly listing file is not generated.

Characters s, h, p must all be specified; only one or two of them is not sufficient.

■ -N option

The code (FFH) in the undefined area of program memory is not created.

Note The program data to be provided does not use the "-N" option. The FFH data should be inserted into

the undefined program area.

S1C62 FAMILY EPSON III-3

DEVELOPMENT TOOL REFERENCE MANUAL

Page 34

CROSS ASSEMBLER ASM62XX

Example 1: Basic assembly example

A>ASM62XX C2XXYYY

A>ASM62XX B:C2XXYYY

A>ASM62XX C2XXYYY.BBZ

Example 2: -N option use

A>ASM62XX C2XXYYY -N

The source file "C2XXYYY.DAT" is input from drive A, and the

object files "C2XXYYYH.HEX" and "C2XXYYYL.HEX" and

the assembly listing file "C2XXYYY.PRN" are output to drive A.

The source file "C2XXYYY.DAT" is input from drive B, and the

object files "C2XXYYYH.HEX" and "C2XXYYYL.HEX" and

the assembly listing file "C2XXYYY.PRN" are output to drive B.

The source file "C2XXYYY.DAT" is input from drive B, and the

object files "C2XXYYYH.HEX" and "C2XXYYYL.HEX" are

output to drive B. The assembly listing file is not generated.

No undefined program area is generated in the created object files

(C2XXYYYH.HEX, C2XXYYYL.HEX).

Refer to APPENDIX, "ASM62XX EXECUTION EXAMPLE".

A>ASM62XX C2XXYYY

When ASM62XX is started, the following start-up message is displayed.

Example: When assembling C2XX0A0.DAT

A>ASM62XX C2XX0A0

*** E0C62XX CROSS ASSEMBLER. --- Ver 2.00 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) COPYRIGHT 1991 SEIKO EPSON CORP.

SOURCE FILE NAME IS " C2XXYYY.DAT "

THIS SOFTWARE MAKES NEXT FILES.

C2XXYYYH.HEX ... HIGH BYTE OBJECT FILE.

C2XXYYYL.HEX ... LOW BYTE OBJECT FILE.

C2XXYYY .PRN ... ASSEMBLY LIST FILE.

In this case, FFH data is inserted into the undefined program area

of the object files.

III-4 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 35

CROSS ASSEMBLER ASM62XX

3.2 Selecting Auto-P age-Set Function

After the start-up message, the following message is displayed, prompting the user to select the auto-pageset function.

DO YOU NEED AUTO PAGE SET?(Y/N)

Press the "Y" key if selecting the auto-page-set function, or the "N" key if not selecting it. At this stage, the

user can also return to the DOS command level by entering "CTRL" + "C" key.

■ Auto-page-set function

When the program branches to another page through a branch instruction such as JP, the branchdestination page must be set using the PSET instruction before executing the branch instruction.

The auto-page-set function automatically inserts this PSET instruction. It checks whether the branch

instruction page is the same as the branch-destination one. If the page is different, the function inserts

the "PSET" instruction. If the page is the same, the function performs no operation.

Therefore, do not select the auto-page-set function if "PSET" instructions have been correctly included

in the source file.

Note When auto-page-set is selected, there are restricted items related to source programming. See

"4.3.1 Label".

3.3 Generating a Cross-Reference Table

After the auto-page-set function has been selected, the following message is output, prompting the user to

select cross-reference table generation.

DO YOU NEED CROSS REFERENCE TABLE?(Y/N)

Press the "Y" key if generating the cross-reference table, or the "N" key if not generating it. At this stage,

the user can also return to DOS command level by entering "CTRL" + "C" key.

Note If the assembly listing file output destination (p option) is specified as Z (listing not generated) at the

start of ASM62XX, the above message is not output and the cross-reference table is not generated.

■ Cross-reference table

The cross-reference table lists the symbols and their locations in the source file, and is output at the end

of the assembly listing file in the following format:

CROSS REFERENCE TABLE PAGE X- 1

LABEL1 4# 29 36 ....

LABEL2 15# 40

: : :

Symbol Number of the program statement

(# indicates the number of the statement at which the symbol was defined)

This table should be referenced during debugging. An error such as duplicate definition of a symbol can

be easily detected.

S1C62 FAMILY EPSON III-5

DEVELOPMENT TOOL REFERENCE MANUAL

Page 36

CROSS ASSEMBLER ASM62XX

4 SOURCE FILE FORMAT

The source file contains the source program consisting of S1C62XXX instructions (mnemonics) and

pseudo-instructions, and is produced using an editor such as EDLIN.

Refer to the "S1C6200/6200A Core CPU Manual" and the "S1C6xxx Technical Manual (Software)" for

instruction sets.

4.1 Source File Name

A desired file name not exceeding seven characters in length can be assigned to each source file. The

format must be as follows:

C2XXYYY.DAT

"YYY" of the "C2XXYYY.DAT" is an alphanumeric character string of up to three characters, and should be

determined by referencing the device name specified by Seiko Epson. The file extension must be ".DAT".

4.2 Statements

Each source program statement must be written using the following format.

Basic format: <Index>[:] <Instruction> <Expression> <; comment>

Example: ON EQU 1

START: JP INIT ;To init.

Label Mnemonic Operand Comment

field field field field

A statement consists of four fields: label, mnemonic, operand, and comment. Up to 132 characters can be

used for one statement. Fields must be delimited by one or more blanks or tabs.

The label and comment fields are optional. Blank lines consisting only of a carriage return (CR) code are

also allowed.

Although each statement and field (excluding the label field) can begin at any desired column. The

program becomes easier to understand if the heads of corresponding fields are aligned.

ORG 100H

Label field

4.2.1

The label field can contain a label for referencing the memory address, a symbol that defines a constant, or

a macro name. This field can be omitted if the statement name is not required. The label field must begin

at column 1 and satisfy the following conditions.

• The length must not exceed 14 characters.

• The same name as a mnemonic or register name must not be used.

• The following alphanumeric characters can be used, but the first character must not be a digit:

A to Z, a to z, 0 to 9, _ , ?

• The uppercase and lowercase forms of a letter are equivalent.

• ??nnnn (n is a digit) cannot be used as a name.

A colon ":" can be used as a delimiter between a label field and the mnemonic field. If a colon is used,

neither blanks nor tabs need to be written subsequently.

Statements consisting of only a label field are also allowed.

III-6 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 37

CROSS ASSEMBLER ASM62XX

4.2.2 Mnemonic field

The mnemonic field is used for an instruction mnemonic or a pseudo-instruction.

Operand field

4.2.3

The operand field is used for the operands of the instruction. The form of each operand and the number of

operands depend on the kind of instruction. The form of expressions specifying values must be one of the

following:

• A numeric constant, a character constant, or a symbol that defines a constant

• A label indicating a memory address

• An operational expression for obtaining the specified value

If the operand consists of two or more expressions, the expressions must be separated by commas ",".

Comment field

4.2.4

The comment field is used for comment data such as program headers and descriptions of processing. The

contents of this field do not affect assembly or the object files generated by assembly.

The part of the statement from a semicolon ";" to the CR code at the end of the statement is considered to be

the comment field. Statements consisting of only a comment field are also allowed. When a comment

spans multiple lines, a semicolon must be written at the beginning of each line.

4.3 Index

ASM62XX allows values to be referenced by their indexes.

Refer to Section 4.2.1, "Label field", for the restrictions on index descriptions.

Label

4.3.1

A label is an index for referencing a location in the program, and can be used as an operand that specifies a

memory address as immediate data in an instruction. For example, a label can be used as the operand of

an instruction such as JP by writing the label in the branch-destination statement.

The name written in the label field of an EQU or SET instruction is considered to be a symbol, not a label.

Example:

:

JP NZ,LABEL1

:

:

LABEL1: LD A,0

A label can be assigned to any statement, but the label assigned to the following pseudo-instructions is

ignored:

ORG, BANK, PAGE, SECTION, END, LABEL, ENDM

Note When selecting the auto-page-set function (see Section 3.2), a statement consisting of only a label

must be written immediately before the JP or CALL instructions.

Example:

PGSET:

JP LABEL

S1C62 FAMILY EPSON III-7

DEVELOPMENT TOOL REFERENCE MANUAL

Page 38

CROSS ASSEMBLER ASM62XX

4.3.2 Symbol

A symbol is an index that indicates a numeric or character constant, and must be defined before its value is

referenced (usually at the beginning of the program). The defined symbol can be used as the operand that

specifies immediate data in an instruction.

Example:

ON EQU 1 (See Section 4.5 for EQU.)

OFF EQU 0

:

LD A,ON ; = LD A,1

:

LD A,OFF ; = LD A,0

:

4.4 Constant and Operational Expression

This section explains the immediate data description formats.

Numeric constant

4.4.1

A numeric constant is processed as a 13-bit value by ASM62XX. If a numeric constant greater than 13 bits

is written, bit 13 and subsequent high-order bits are ignored.

Note that the number of actual significant bits depends on the operand of each instruction. If the value of a

constant is greater than the value that can be accommodated by the actual number of significant digits, an

error occurs.

Example:

ABC EQU 0FFFFH → ABC is defined as 1FFFH.

LD A,65535 → An error occurs because it exceeds the significant digit

count (4 bits).

The default radix is decimal. The radix description formats are as follows:

Binary numeral: A numeral suffixed with B, such as 1010B (=10) or 01100100B (=100).

Octal numeral: A numeral suffixed with O or Q, such as 012O (=10) or 144Q (=100).

Decimal numeral: A numeral alone or a numeral suffixed with D, such as 10 or 100D (=100).

Hexadecimal numeral: A numeral suffixed with H, such as 0AH (=10) or 64H (=100).

If the value begins with a letter from A to F, it must be prefixed with 0 to distinguish

it from a name.

Character constant

4.4.2

A character constant is one or two ASCII characters enclosed by apostrophes (' '). A single ASCII character

is processed as eight-bit data. If two or more ASCII characters are written, only the last two characters are

significant as 13-bit data.

Examples:

'A' (=41H), 'BC' (=0243H), 'PQ' (=1051H), 'DEFGH' → 'GH' (=0748H; DEF is ignored.)

The apostrophe itself cannot be processed as a character constant, so it must be written as a numeric

constant, such as 27H or 39.

III-8 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 39

CROSS ASSEMBLER ASM62XX

4.4.3 Operator

When specifying a value for an item such as an operand, an operational expression can be written instead

of a constant, and its result can be used as the value.

Labels and symbols as well as constants can be used as terms in expressions. These values are processed as

13-bit data (bit 14 and subsequent high-order bits are ignored); the operation result also consists of 13 bits.

If the result exceeds the number of significant digits of the instruction operand, an error occurs.

There are three types of operator—arithmetic, logical, and relational—as listed below (a and b represent

terms, and _ represents one or more blanks).

■ Arithmetic operators

There are 11 arithmetic operators including the ones for addition, subtraction, multiplication, division,

bit shifting, and bit separation.

+a Monadic positive (indicates the subsequent value is positive)

-a Monadic negative (indicates the subsequent value is negative)

a+b Addition (unsigned)

a-b Subtraction (unsigned)

a*b Multiplication (unsigned)

a/b Division (unsigned)

a_MOD_b Remainder of a/b

a_SHL_b Shifts a b bits to the left. ←[b7<<<<<<b1]←0

Example:

a_SHR_b Shifts a b bits to the right. 0→[b7>>>>>>b0]→

Example:

HIGH_a Separates the high-order eight bits from a (13 bits).

Example:

LOW_a Separates the low-order eight bits from a (13 bits).

Example: LOW 1234H → 34H

00000011B SHL 2 → 00001100B

11000011B SHR 2 → 00110000B

HIGH 1234H → 12H

■ Logical operators

There are four logical operators as listed below. The logical operator returns the result of logical

operation on the specified terms.

a_AND_b Logical product

Example:

a_OR_b Logical sum

Example: 00001111B OR 11110000B → 11111111B

a_XOR_b Exclusive logical sum

Example:

NOT_a Logical negation

Example:

S1C62 FAMILY EPSON III-9

DEVELOPMENT TOOL REFERENCE MANUAL

00001111B AND 00000011B → 00000011B

00001111B XOR 00000011B → 00001100B

NOT 00001111B → 11110000B

Page 40

CROSS ASSEMBLER ASM62XX

■ Relational operators

A logical operator compares two terms; if the relationship between the terms is as the operator

specifies, 1FFFH (true) is returned; if not, 0 (false) is returned.

a_EQ_b True when a is equal to b

a_NE_b True when a is not equal to b

a_LT_b True when a is less than b

a_LE_b True when a is less than or equal to b

a_GT_b True when a is greater than b

a_GE_b True when a is greater than or equal to b

Be sure to insert one or more blanks for symbol "_" between terms. All operators must be entered in

uppercase letters.

An expression can contain one or more operators and pairs of parenthesis. In this case, operators are

basically evaluated from left to right. However, an operation stipulated by an operator with higher priority

or by parentheses is executed earlier. Every left parenthesis must have a corresponding right parenthesis.

The following table shows the priority of operators.

Operator Priority

) Low

OR, XOR :

AND

EQ, NE, LT, LE, GT, GE

+ (addition), - (subtraction)

*, /, MOD, SHL, SHR

(

HIGH, LOW, NOT :

- (monadic negative), + (monadic positive) High

Examples: Operational expressions (ABC = 1, BCD = 3)

LD A,BCD*(ABC+1) ;A-register <- 6

LD A,ABC LT BCD ;A-register <- 0FH (1111B)

OR B,ABC SHL BCD ;Set bit 3 in B-register

;(=OR B,1000B)

AND B,ABC SHL BCD XOR 0FH

;Reset bit 3 in B-register

;(=AND B,0111B)

4.4.4 Location counter

The start address of each instruction code is set in the location counter when a statement is assembled. A

label or $ can be used when referencing the location counter value in a program.

■ Location counter

The location counter consists of 13 bits: one bit for the bank field, four bits for the page counter field,

and eight bits for the step counter field.

Bank Page counter Step counter

Bit 1211109876543210

Contents Bank Page address Step address

BNK PCP PCS

Example: Location counter

(BNK) (PCP) (PCS)

0 1 02 JP $+3

The location counter indicates the start address of the JP instruction, and the PCS value (02) is assigned to $.

Consequently, the statement is assembled as "JP 5", and the program sequence jumps to the location three

steps before (PCS=05) when it is executed.

III-10 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 41

CROSS ASSEMBLER ASM62XX

4.5 Pseudo-Instructions

There are four types of pseudo-instruction: data definition, memory setting, assembler control, and macro.

These pseudo-instructions as well as operational expressions can be used to govern assembly, and are not

executed in the developed program.

In the subsequent explanations, the items enclosed by < > in the pseudo-instruction format must be written

in the statement (do not write the < > characters themselves). Symbol _ represents one or more blanks or

tabs. One or more symbols and constants or an operational expression can be used in <expression>. See

Section 4.6 for macro functions.

Data definition pseudo-instructions

4.5.1

There are three data definition pseudo-instructions: EQU, SET, and DW. The EQU and SET pseudoinstructions each define a symbol, and the DW pseudo-instruction presets data in program memory.

■ EQU (Equate)

<Symbol>_EQU_<Expression> To define a symbol

The EQU pseudo-instruction defines <symbol> (written in the label field) as having the value of

<expression> (written in the operand field).

If a value greater than 13 bits is specified in <expression>, bit 14 and subsequent high-order bits are

ignored.

This definition must be made before the symbol is referenced in the program. A U-error occurs if an

attempt is made to reference a symbol that has not been defined.

The same symbol cannot be defined more than once. A P-error occurs if an attempt is made to define a

symbol that has already been defined.

Examples:

ZERO EQU 30H

ONE EQU ZERO+1

ONE EQU 31H ← P-error because ONE has been defined more than twice

FOUR EQU TWO*2 ← U-error because TWO has not been defined

■ SET

<Symbol>_SET_<Expression> To define a symbol

Like EQU, the SET pseudo-instruction defines the value of <symbol> as being <expression>. The SET

pseudo-instruction allows a symbol to be redefined.

Examples:

ZERO EQU 30H

BIT SET 1

:

BIT SET 2 ← Redefinition possible

:

BIT SET BIT SHL 1 ← Previously-defined items can be referenced

S1C62 FAMILY EPSON III-11

DEVELOPMENT TOOL REFERENCE MANUAL

Page 42

CROSS ASSEMBLER ASM62XX

■ DW (Define Word)

<Label>_DW_<Expression> To preset data

The DW pseudo-instruction assigns the value of <expression> (the low-order 12 bits when the value is

greater than 12 bits) to the current memory location, indicated by the location counter.

Examples:

Location counter

(BNK) (PCP) (PCS)

0 2 0A TABLE DW 141H ; = RETD 'A'

0 2 0B DW 142H ; = RETD 'B'

0 2 0C DW 143H ; = RETD 'C'

:

<label> can be omitted.

Memory setting pseudo-instructions

4.5.2

The program memory mounted at the S1C62XXX is divided into 256-step pages. Memory management

(including the setting of the program location and page boundaries) during program generation must be

controlled by the source program.

The memory setting pseudo-instructions are used to specify memory management. The assembler sets the

location counter according to these pseudo-instructions.

If a memory area that has already been used is specified or a statement that exceeds the page is used

without specifying that the statement is to exceed the page, the assembler displays an exclamation mark "!",

indicating a warning, and ignores all subsequent statements until the next correct statement. This should

be taken into account.

When using the auto-page-set function, the space for insertion of the "PSET" pseudo-instruction must be

allocated in each page.

■ ORG (Origin)

ORG_<Expression> To set the location counter

The ORG pseudo-instruction sets the location counter to the value of <expression>.

If the ORG pseudo-instruction is not written at the beginning of the program, the location counter is set

to 0 (BNK=0, PCP=0, PCS=0) and assembly is started.

The ORG pseudo-instruction can be used at multiple locations in the program. However, it cannot be

used to set the location to a value before the current location. If this is attempted, an exclamation mark

"!", indicating a warning, is displayed, and all subsequent statements until the next correct statement are

ignored.

A label can be written before the ORG statement, but it cannot be referenced because it is not cataloged

in the label table. In this case, write the label in the statement following the ORG pseudo-instruction.

Example:

ORG 0100H ; BNK=0, PCP=1, PCS=00H

START :

An R-error occurs if a value is specified exceeding the ROM capacity.

Note The upper limit of program memory depends on the model. (Refer to the "S5U1C62xxxD

Manual".)

III-12 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 43

CROSS ASSEMBLER ASM62XX

■ BANK

BANK_<Expression> To set the bank (BNK)

The BANK pseudo-instruction sets the value of <expression> in the bank (BNK) field, and sets the page

counter (PCP) and step counter (PCS) to 00H.

The BANK pseudo-instruction can be written at multiple locations in the program. However, it cannot

be used to specify the current bank (excluding the specification in page 00, step 00) or a previous bank.

If it is used to specify the current bank or a previous bank, an exclamation mark "!", indicating a

warning, is displayed, and all subsequent statements until the next correct statement are ignored.

A label can be written before the BANK statement, but it cannot be referenced because it is not

cataloged in the label table. In this case, write the label in the statement after the BANK pseudoinstruction.

■ PAGE

PAGE_<Expression> To set the page counter (PCP)

The PAGE pseudo-instruction sets the value of <expression> in the page counter (PCP) and sets the

step counter (PCS) to 00H.

The PAGE pseudo-instruction can be written at multiple locations in the program. However, it cannot

be used to specify the current page (excluding the specification in step 00) or a previous page. If it is

used to specify the current page or a previous page, an exclamation mark "!", indicating a warning, is

displayed, and all subsequent statements until the next correct statement are ignored.

A label can be written before the PAGE statement, but it cannot be referenced because it is not

cataloged in the label table. In this case, write the label in the statement after the PAGE pseudoinstruction.

Example:

Location counter

(BNK) (PCP) (PCS)

::: ::

0 0 1AH LD X,0

0 0 1BH LD Y,0

::: ::

0 0 F0H JP xxx

0 2 00H SUB1: LD A,MX

PAGE 2

0 2 01H LD B,MY

Ineffective because a previous page

was specified

::: ::

PAGE 1

! SUB2: LD A,MX

! LD B,MY

Effective

::

PAGE 3

0 3 00H SUB3: LD A,0

0 3 01H LD B,1

::: ::

An R-error occurs if a value is specified that exceeds the last page.

Note The last page depends on the model. (Refer to the "S5U1C62xxxD Manual".)

S1C62 FAMILY EPSON III-13

DEVELOPMENT TOOL REFERENCE MANUAL

Page 44

CROSS ASSEMBLER ASM62XX

■ SECTION

SECTION To change the section

The SECTION pseudo-instruction sets the first address of the subsequent section in the location counter. Sections are 16-step areas starting from the beginning of the program memory.

(BNK) (PCP) (PCS)

0 1 00H

Section 1 16 steps

0 1 10H

Section 2

0 1 20H

::: : :

0 1 F0H

Section 16

0 2 00H

Section 17

0 2 20H

::: : :

0 3 F0H

Section 48

A SECTION pseudo-instruction written in the last section of the page not only clears the step counter

but also updates the page counter, so a new page need not be specified.

A label can be written before the SECTION pseudo-instruction, but it cannot be referenced because it is

not cataloged in the label table. In this case, write the label in the statement following the SECTION

pseudo-instruction.

Example:

Location counter

(BNK) (PCP) (PCS)

::: : :

0 1 09H JPBA

0 1 0AH LD X,0

0 1 0BH LD Y,0

0 1 0CH LD MX,4

SECTION

0 1 10H TABLE LD A,1

0 1 11H ADD A,1

::: : :

0 1 FAH RET

0 2 00H LOOP SCF

SECTION

0 2 01H ADD A,MY

::: : :

III-14 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 45

CROSS ASSEMBLER ASM62XX

4.5.3 Assembler control pseudo-instructions

■ END

END To terminate assembly

The END statement terminates assembly. All statements following the END statement are ignored. Be

sure to write this statement at the end of the program. If it is missing, assembly may not terminate.

A label can be written before the END statement, but it cannot be referenced because it is not cataloged

in the label table.

4.6 Macro-Functions

When using the same statement block at multiple locations in a program, the statement block can be called

using a name defined beforehand. A statement block that has been so defined is called a macro.

Unlike a subroutine, the statement block is expanded at all locations where it is called, so the programmer

should consider the statement block size and frequency of use and determine whether a macro or a subroutine is more appropriate.

Macro-instructions

4.6.1

ASM62XX provides the macroinstructions listed below so that

branching between pages is possible

without specifying the destination

page using the PSET instruction.

Character string ps represents 13-bit

immediate data that indicates the

branch-destination address. A label

can be used for it.

Example:

Source file

:

JPM LABEL2

:

PAGE 2

LABEL2 LD A,0

:

Macro-

instruction

JPM ps

JPM C,ps

JPM NC,ps

JPM Z,ps

JPM NZ,ps

CALLM ps

Mnemonic

after expansion

PSET p

JP s

PSET p

JP C,s

PSWT p

JP NC,s

PSET p

JP Z,s

PSET p

JP NZ,s

PSET p

CALL s

1110987654321

1

1

1

0

0

0

1

1

1

1

0

0

1

1

1

1

0

0

1

1

1

1

0

1

1

1

1

1

0

1

1

1

1

0

0

1

Code

p1

p2

p3

p4

0

1

0

0

s3

s4

s5

s6

s7

0

p3

p4

0

1

0

0

s3

s4

s5

s6

s7

0

p3

p4

0

1

0

0

s3

s4

s5

s6

s7

1

p3

p4

0

1

0

0

s3

s4

s5

s6

s7

0

p3

p4

0

1

0

0

s3

s4

s5

s6

s7

1

p3

p4

0

1

0

0

s3

s4

s5

s6

s7

0

p0

s1

s2

s0

p1

p2

p0

s1

s2

s0

p1

p2

p0

s1

s2

s0

p1

p2

p0

s1

s2

s0

p1

p2

p0

s1

s2

s0

p1

p2

p0

s1

s2

s0

0

Assembly list file after expansion

:

JPM LABEL2

+ PSET LABEL2

+ JP LABEL2

:

PAGE 2

LABEL2 LD A,0

:

S1C62 FAMILY EPSON III-15

DEVELOPMENT TOOL REFERENCE MANUAL

Page 46

CROSS ASSEMBLER ASM62XX

4.6.2 Macro-definitions

The macro-definition should be done by using the MACRO and the ENDM instructions (pseudo-instruction).

■ MACRO ~ ENDM

<Macro-name>_MACRO_[<Dummy-argument>, ...]

Statement

:

ENDM

The statement block enclosed by a MACRO pseudo-instruction and an ENDM pseudo-instruction is

defined as a macro. Any name can be assigned to the macro as long as it conforms to the rules regarding the characters, length, and label field.

A macro can have an argument passed to it when it is called. In this case, any symbol can be used as a

dummy argument in the macro definition where the actual argument is to be substituted and the same

symbol must be written after the MACRO pseudo-instruction. Multiple dummy arguments must be

separated by commas (,).

Be sure to write the ENDM statement at the end of a macro-definition.

Example: This macro loads data from the memory location specified by ADDR into the A or B register specified

by REG. Sample call: LDM A,10H

LDM MACRO REG,ADDR

LD X,ADDR

LD REG,MX

ENDM

These dummy arguments are replaced by actual arguments when the macro is expanded.

■ LOCAL

If a macro having a label is expanded at multiple locations, the label duplicates, causing an error. The

LOCAL pseudo-instruction prevents this error occurring.

LOCAL_<Label-name>[,<Label-name>...]

The label specified by the LOCAL pseudo-instruction is replaced by "??nnnn" when the macro is

expanded. Field nnnn is a four-digit decimal field, to which values 0001 to 9999 are assigned

sequentially.

The LOCAL pseudo-instruction must be written at the beginning of the macro. The LOCAL pseudoinstruction is ignored if another instruction precedes it.

Example:

WAIT MACRO CNT

LOCAL LOOP

LD A,CNT

LOOP SBC A,1 ← Replaces LOOP with ??nnnn at expansion.

JP NZ,LOOP

ENDM

III-16 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 47

CROSS ASSEMBLER ASM62XX

4.6.3 Macro-calls

The defined macro-name can be called from any location in the program by using the following format:

[<Label>]_<Macro-name>_ [<Actual-argument>, ...]

The MACRO can be called by using the macro-name.

When arguments are required, write actual arguments corresponding to the dummy arguments used in the

macro-definition. Multiple actual arguments must be separated by commas (,).

Actual and dummy arguments correspond sequentially from left to right. If the number of actual arguments is greater than the number of dummy arguments, the excess actual arguments are ignored. If the

number of actual arguments is less than the number of dummy arguments, the excess dummy arguments

are replaced by nulls (00H).

Any label can be written before the macro-name.

Example:

Source file

ORG 0200H

CTAS EQU 00H

CTAE EQU 02H

CAFSET EQU 0101B

CAFRST EQU 0000B

CTBS EQU 10H

CTBE EQU 08H

CBFSET EQU 0001B

CBFRST EQU 0100B

COUNT MACRO FSET,FRST,CTS,CTE

LOCAL LOOP1

SET F,FSET

RST F,FRST

LD A,0

LD X,CTS

LOOP1 ACPX MX,A

CP XL,CTE

JP NZ,LOOP1

ENDM

COUNTA COUNT CAFSET,CAFRST,CTAS,CTAE

RET

COUNTB COUNT CBFSET,CBFRST,CTBS,CTBE

RET

END

The assembly listing file after assembly is shown on the next page.

S1C62 FAMILY EPSON III-17

DEVELOPMENT TOOL REFERENCE MANUAL

Page 48

CROSS ASSEMBLER ASM62XX

Assembly listing file

LISTING OF ASM62XX C2XX0A1.PRN ........ PAGE 1

LINE BANK PCP PCS OBJ SOURCE STATEMENT

1 ORG 0200H

2

3 0000= CTAS EQU 00H

4 0002= CTAE EQU 02H

5 0005= CAFSET EQU 0101B

6 0000= CAFRST EQU 0000B

7 0010= CTBS EQU 10H

8 0008= CTBE EQU 08H

9 0001= CBFSET EQU 0001B

10 0004= CBFRST EQU 0100B

11

12 COUNT MACRO FSET,FRST,CTS,CTE

13 LOCAL LOOP1

14 SET F,FSET

15 RST F,FRST

16 LD A,0

17 LD X,CTS

18 LOOP1 ACPX MX,A

19 CP XL,CTE

20 JP NZ,LOOP1

21 ENDM

22

23 COUNTA COUNT CAFSET,CAFRST,CTAS,CTAE

24 0 2 00 F45 + SET F,CAFSET

25 0 2 01 F50 + RST F,CAFRST

26 0 2 02 E00 + LD A,0

27 0 2 03 B00 + LD X,CTAS

28 0 2 04 F28 + ??0001 ACPX MX,A

29 0 2 05 A52 + CP XL,CTAE

30 0 2 06 704 + JP NZ,??0001

31 0 2 07 FDF RET

32

33 COUNTB COUNT CBFSET,CBFRST,CTBS,CTBE

34 0 2 08 F41 + SET F,CBFSET

35 0 2 09 F54 + RST F,CBFRST

36 0 2 0A E00 + LD A,0

37 0 2 0B B10 + LD X,CTBS

38 0 2 0C F28 + ??0002 ACPX MX,A

39 0 2 0D A58 + CP XL,CTBE

40 0 2 0E 70C + JP NZ,??0002

41 0 2 0F FDF RET

42

43 END

III-18 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 49

CROSS ASSEMBLER ASM62XX

5 ERROR MESSAGES

If an error occurs during assembly, ASM62XX outputs the appropriate error symbol or error

message listed below to the console and assembly listing file.

Only a single error symbol is output at the beginning (column 1) of the statement that caused the error. (If

two or more errors occurred, only the error with highest priority is output.)

The following error symbols are listed in order of priority, starting with the one with the highest priority.

S (Syntax Error) ............................................. An unrecoverable syntax error was encountered.

U (Undefined Error) ......................................The label or symbol of the operand has not been defined.

M (Missing Label) ..........................................The label field has been omitted.

O (Operand Error)......................................... A syntax error was encountered in the operand, or the operand

could not be evaluated.

P (Phase Error)............................................... The same label or symbol was defined more than once.

R (Range Error).............................................. • The location counter value exceeded the upper limit of the

program memory, or a location exceeding the upper limit was

specified.

• A value greater than that which the number of significant

digits of the operand will accommodate was specified.

! (Warning) .....................................................• Memory areas overlapped because of a "PAGE" or "ORG"

pseudo-instruction or both.

• A statement exceeded a page boundary although its location

was not specified.

FILE NAME ERROR.................................The source file name was longer than 8 characters.

FILE NOT PRESENT................................The specified source file was not found.

DIRECTORY FULL ...................................No space was left in the directory of the specified disk.

FATAL DISK WRITE ERROR...............The file could not be written to the disk.

LABEL TABLE OVERFLOW ................The number of defined labels and symbols exceeded the label

table capacity (4000).

CROSS REFERENCE TABLE OVERFLOW

...........The label/symbol reference count exceeded the cross- reference

table capacity (only when the cross-reference table is generated).

S1C62 FAMILY EPSON III-19

DEVELOPMENT TOOL REFERENCE MANUAL

Page 50

CROSS ASSEMBLER ASM62XX

APPENDIX ASM62XX EXECUTION EXAMPLE

1) Source file (C2XX0A0.DAT)

A>TYPE C2XX0A0.DAT

;

;*******<< SAMPLE PROGRAM :E0C62XX >>*******

;

ABC EQU 0F0H

TEN EQU 10

;

START LD A,0

LD X,8

LD Y,3

LDPX A,MX

;

ORG 0E0H

;

NEXT ADD B,TEN

LD MX,XH

AND A,101B

FAN MY,A

RCF

SCPX MX,B

JP C,NEXT

;

;-------<< ERROR >>------ EQU 0CH-2

ERROR EQU 4

ERROR LD A,3

SBD MX,A

INC Z

JP UNDEF

ORG 11100000B

NOP5

SECTION

ORG ABC+0FH

NOP7

NOP7

END

III-20 EPSON S1C62 FAMILY

DEVELOPMENT TOOL REFERENCE MANUAL

Page 51

CROSS ASSEMBLER ASM62XX

2) Running the assembler (display on the console)

A>ASM62XX C2XX0A0

*** E0C62XX CROSS ASSEMBLER. --- VERSION 2.00 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) COPYRIGHT 1991 SEIKO EPSON CORP.

SOURCE FILE NAME IS " C2XXYYY.DAT "

THIS SOFTWARE MAKES NEXT FILES.

C2XXYYYH.HEX ... HIGH BYTE OBJECT FILE.

C2XXYYYL.HEX ... LOW BYTE OBJECT FILE.

C2XXYYY .PRN ... ASSEMBLY LIST FILE.

DO YOU NEED AUTO PAGE SET?(Y/N) N

DO YOU NEED CROSS REFERENCE TABLE?(Y/N) Y

M 23 000A= EQU 0CH-2

P 24 0004= ERROR EQU 4

P 25 0 0 E7 E03 ERROR LD A,3

S 26 0 0 E8 FFF SBD MX,A

O 27 0 0 E9 FFF INC Z

U 28 0 0 EA 000 JP UNDEF

! 30 NOP5

R 34 0 1 00 NOP7

8 ERROR OR WARNING(S) DETECTED

USED : 6/2000 SYMBOLS

A>

S1C62 FAMILY EPSON III-21

DEVELOPMENT TOOL REFERENCE MANUAL

Page 52

CROSS ASSEMBLER ASM62XX

3) Assembly listing file (C2XX0A0.PRN)

A>TYPE C2XX0A0.PRN

LISTING OF ASM62XX C2XX0A0.PRN ........ PAGE 1

LINE BANK PCP PCS OBJ SOURCE STATEMENT

1 ;

2 ;*******<< SAMPLE PROGRAM :E0C62XX >>*******

3 ;

4 00F0= ABC EQU 0F0H

5 000A= TEN EQU 10

6 ;

7 0 0 00 E00 START LD A,0

8 0 0 01 B08 LD X,8