Page 1

®

Service Manual

Service Manual

Service ManualService Manual

B0 Wide-Format Professional Inkjet Printer

EPSON Stylus Pro 9500

SEIJ00005

Page 2

EPSON Stylus Pro 9500 Revision A

NOTE:

The contents of this book may change at anytime without notice.

No patent liability is assumed with respect to the use of information contained herein.

SEIKO EPSON CORPORATION assumes no liability for problems or damages resulting from the use of the information contained

herein.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Other product names used herein are for identification purposes only and may be trademarks of their respective owners. EPSON

disclaims any and all rights in those marks.

Copyright 2000 SEIKO EPSON CORPORATION.

2

Page 3

EPSON Stylus Pro 9500 Revision A

PRECAUTIONS

There are cautionary notes throughout the text to help you avoid personal injury or equipment damage.

W ARNING

Signals a precaution which, if ignored, could result

in serious or fatal personal injury. Great caution

should be exercised in performing procedures

preceded by a WARNING heading.

Always observe the measures listed below when performing repair o r maint enance procedures.

CAUTION

Signals a precaution which, if ignored, could result

in damage to equipment.

WARNING

1. Always disconnect the product from both the power source and host computer before performing any maintenance or repair procedure.

2. No work should be performed on the unit by persons unfamiliar wit h basic safety measures dictated for all electronics technicians in their line of

work.

3. In performing testing described in this manual, do not connect the unit to a power source until instructed to do so. When the power supply cable

must be connected, use extreme caution in working on the power supply and other electronic components.

CAUTION

1. Repairs on EPSON products should be performed only by an EPSON-certified repair technician.

2. Make certain that the sourc e voltage is t he same as the rated voltage li sted on the seri al number/rat ing plate. If the EPSON product has a primar y

AC rating different from the available power source, do not connect it to the power source.

3. Always verify that the EPSON product has been disconnected from the power source before removing or replacing printed circui t boards and/or

individual chips.

4. To protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps , when accessing internal

components.

5. Replace malfunctioning components only with those components recommended by the manufacturer; i ntroduction of second-source ICs or o ther

nonapproved components may damage the product and void any applicab le EPSON warranty.

3

Page 4

EPSON Stylus Pro 9500 Revision A

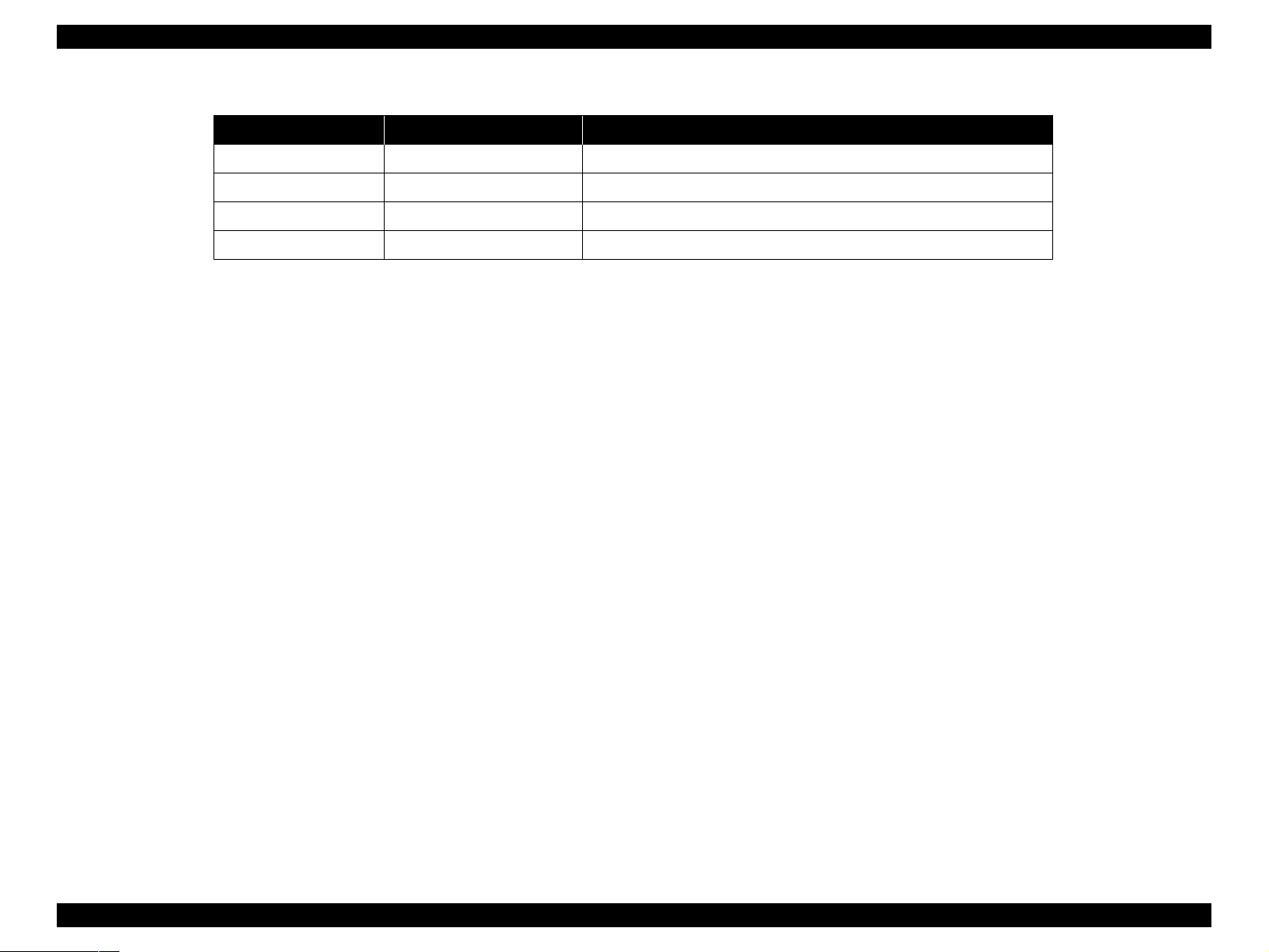

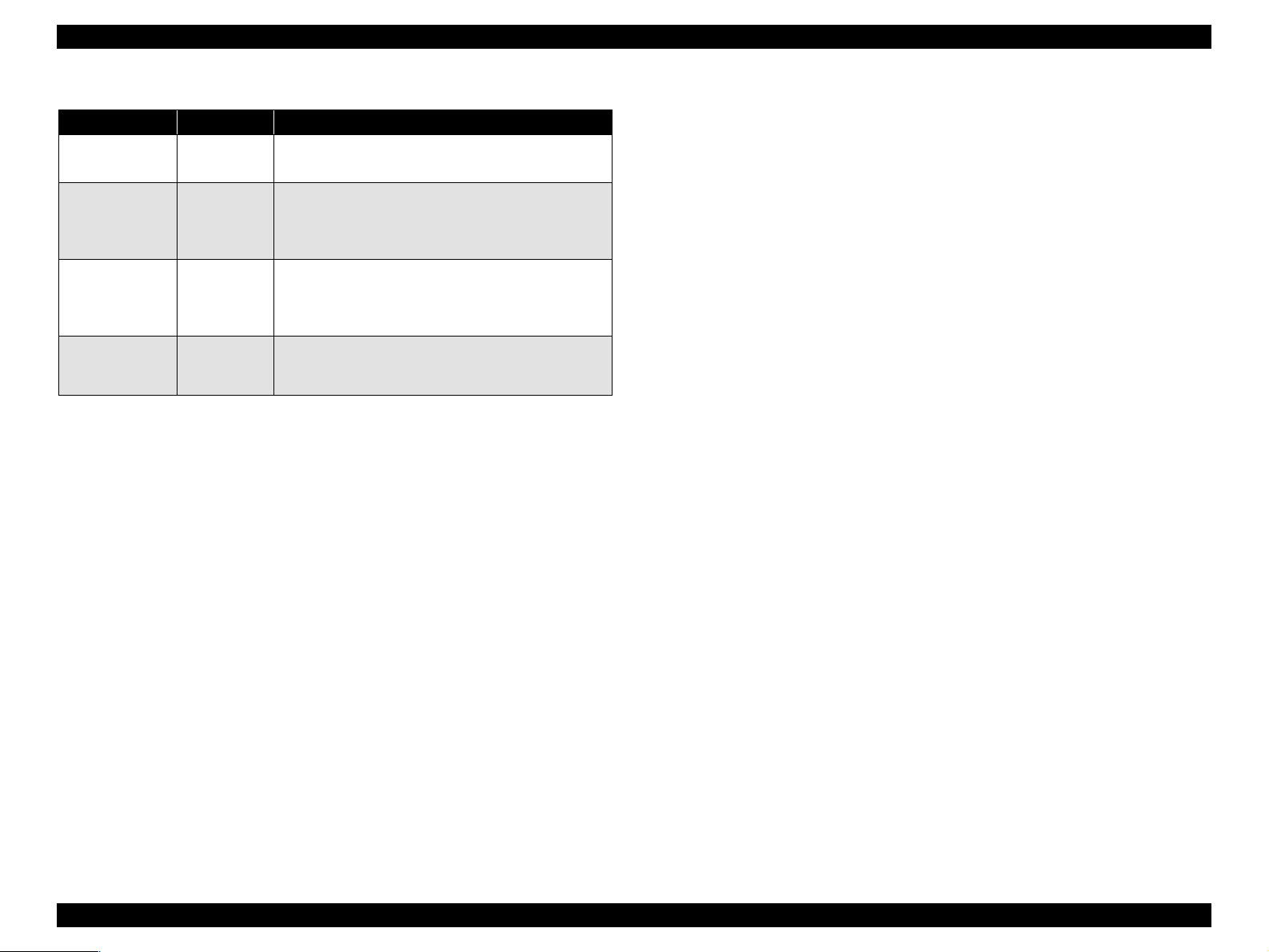

Revision Status

Revision Issued Date Description

A 31 August 2000 First Established Edition

4

Page 5

PRODUCT DESCRIPTION

ADJUSTMENT

Features ................................... ....... ...... ....... ...... ....... ...... ....... ...... .................. 7

Professional Color Printing Features......................................................... 7

Consumable Products & Options.............................................................. 8

SPECIFICATIONS. ....... ...... ...... ....... ...... ....... ............................................. ..... 9

Interfaces................................................................................................. 18

Initialization.............................................................................................. 23

Control Panel................................................................................................ 24

Normal Mode Panel Display.................................................................... 27

Control Panel Settings............................................................................. 28

Maintenance Call..................................................................................... 34

Service Errors....................................................... ...... ....... ...... ....... ......... 35

Service Related Printer Settings ............................................................. 37

Firmware Update..................................................................................... 41

Jumper Settings ......................... ...... ....... ...... ....... ...... ....... ...... ....... ...... ... 42

OPERATING PRINCIPLES

Component List & Illustrations...................................................................... 44

Print Mechanism Components................................................................ 44

Summary of Control Circuit Operations................................................... 64

TROUBLESHOOTING

Outline.......................................................................................................... 70

Test Points .............................................................................................. 70

General Errors......................................................................................... 75

DISASSEMBLY & ASSEMBLY

Summary ...................................................................................................... 83

Warnings ................................................................................................. 83

Tools........................................................................................................ 84

Screw List................................................................................................ 84

Disassembly Flow......................................................................................... 85

Removing the Housing............................................................................ 86

Circuit Board Removal ............................................................................ 93

Printer Mechanism Disassembly............................................................. 96

Conversion Kit...................................................................................... 122

Summary.................................................................................................... 156

Caution.................................................................................................. 156

Adjustment Tools .................................................................................. 156

Adjustment Items .................................................................................. 158

Adjustment Steps ....................................................................................... 161

Parameter Backup ................................................................................ 161

Firmware Update................................................................................... 164

Self-Diagnostics .................................................................................... 166

Adjustment Menu .................................................................................. 168

Test Menu ............................................................................................. 189

Cleaning menu...................................................................................... 198

Parameter menu ................................................................................... 198

Maintenance Mode................................................................................ 200

Mechanism Adjustment......................................................................... 203

Dip SW setting ...................................................................................... 218

MAINTENANCE & SETUP

General Maintenance Issues...................................................................... 220

Periodic Maintenance Items.................................................................. 221

Product Life Information ........................................................................ 222

Important Maintenance Items During Service Operations .................... 222

Lubrication............................................................................................. 223

Unpacking and Installing ...... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...... ...... 223

The Packaging ......... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ............ 223

Contents of the Packaging.................................................................... 224

Unpacking and Assembling...................... ....... ...................................... 225

APPENDIX

Wiring Diagrams......................................................................................... 233

Connector Pin Assignments ....................................................................... 235

C277MAIN Board.................................................................................. 235

Parts List .................................................................................................... 239

Exploded view Diagram.............................................................................. 248

Component Layout.................................. ...... ....... ...... ....... ...... ....... ...... ...... 262

Circuit Diagrams......................................................................................... 264

Page 6

PRODUCT DESCRIPTION

CHAPTER

Page 7

EPSON Stylus Pro 9500 Revision A

1.1 Features

The EPSON Stylus Pro 9500 is an ultra-wide, 6-color ink jet printer with

professional color output. It has the same printheads as the EPSON Stylus

Color 9000. The EPSON Stylus Pro 9500 provides the following major features

and more.

1.1.1 Professional Color Printing Features

o Large-size/poster printing

up to B0-wide paper (1118 cm/44 inches) including print-registration marks

o Excellent Photo-quality printing

1440 (H) x 720 (V) dpi combined with EPSON’s Microdot printing

o High-speed printing

n 64 nozzles per color (same printhead as the EPSON Stylus Pro 9000)

n The RISC-CPU and high-speed color raster ASIC quickly process

detailed print data

n A0/Medium Gloss Paper: Approx.17 min.(720x720dpi /Fast)

A0/Medium Gloss Paper: Approx.25 min.(720x720dpi /Beautiful)

A0/Medium Gloss Paper: Approx.50 min.(1440x720dpi /Highly detailed)

o Low running cost

Six separate ink cartridges so you only have to replace the empty ink

cartridge (each cartridge holds 220 ml)

o User-friendly features:

n Two roll holders for easy switching between paper types

n Standard roll-paper cutter

n Auto Loading (Cut sheet)

n Optional roll-paper take-up reel for automatically winding up your long

printouts

o Wide compatibility

The following interface alternatives are available:

n IEEE-1284 bidirectional parallel interface (supports ECP mode)

n Macintosh serial interface (approx. 1.8Mbps)

n One Type-B expansion slot for an optional interface (x1)

Product Description Features 7

Page 8

EPSON Stylus Pro 9500 Revision A

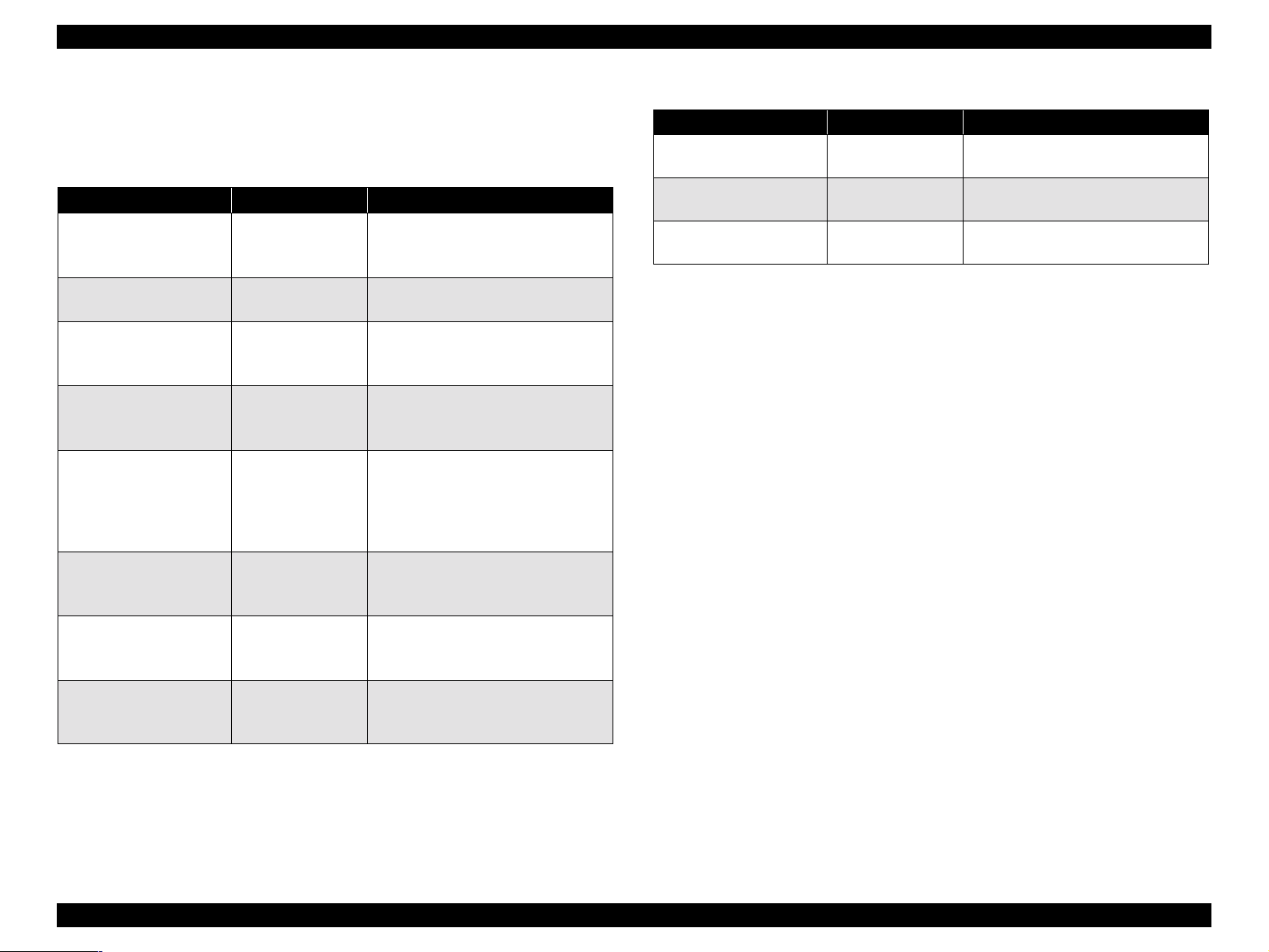

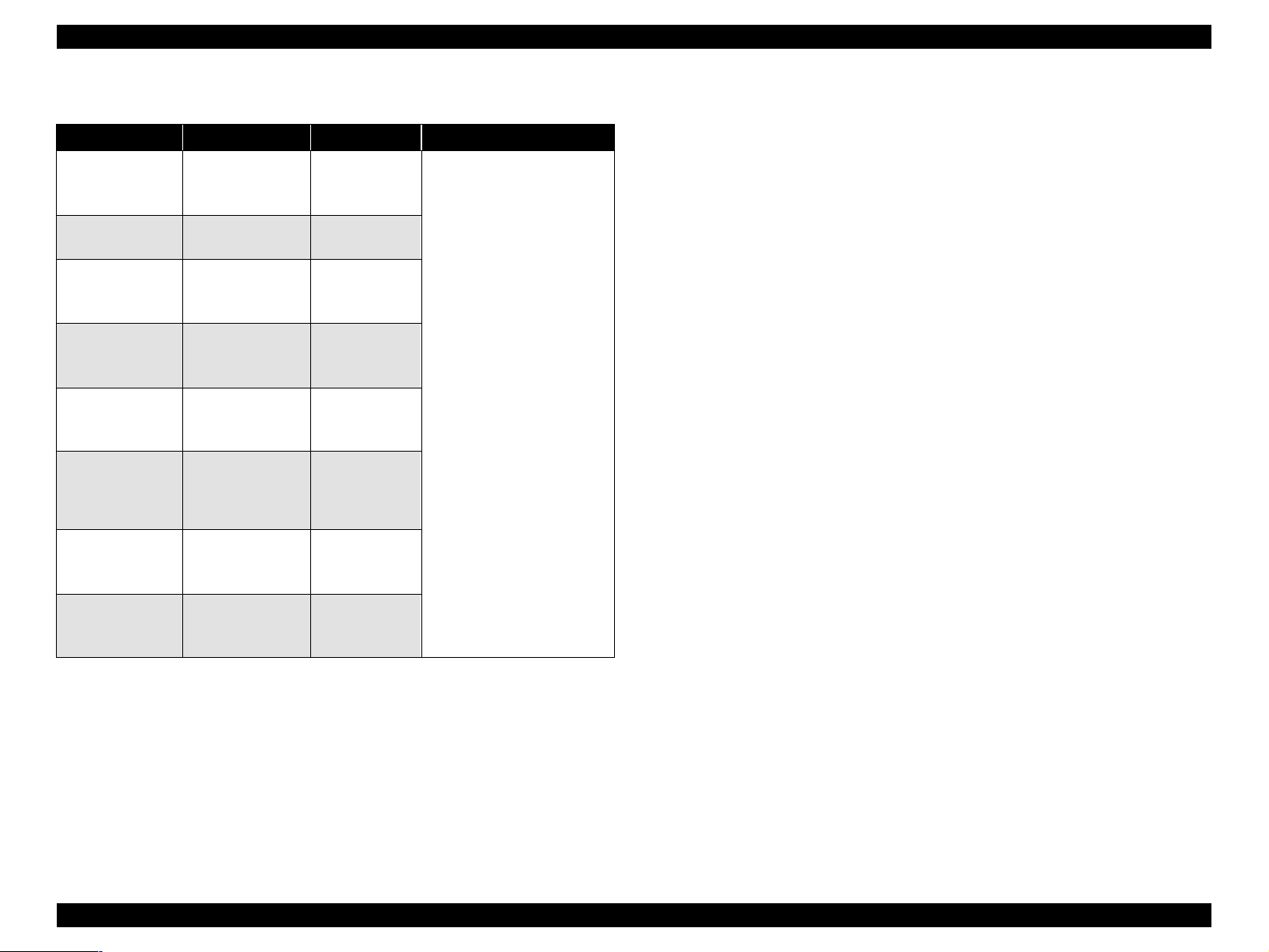

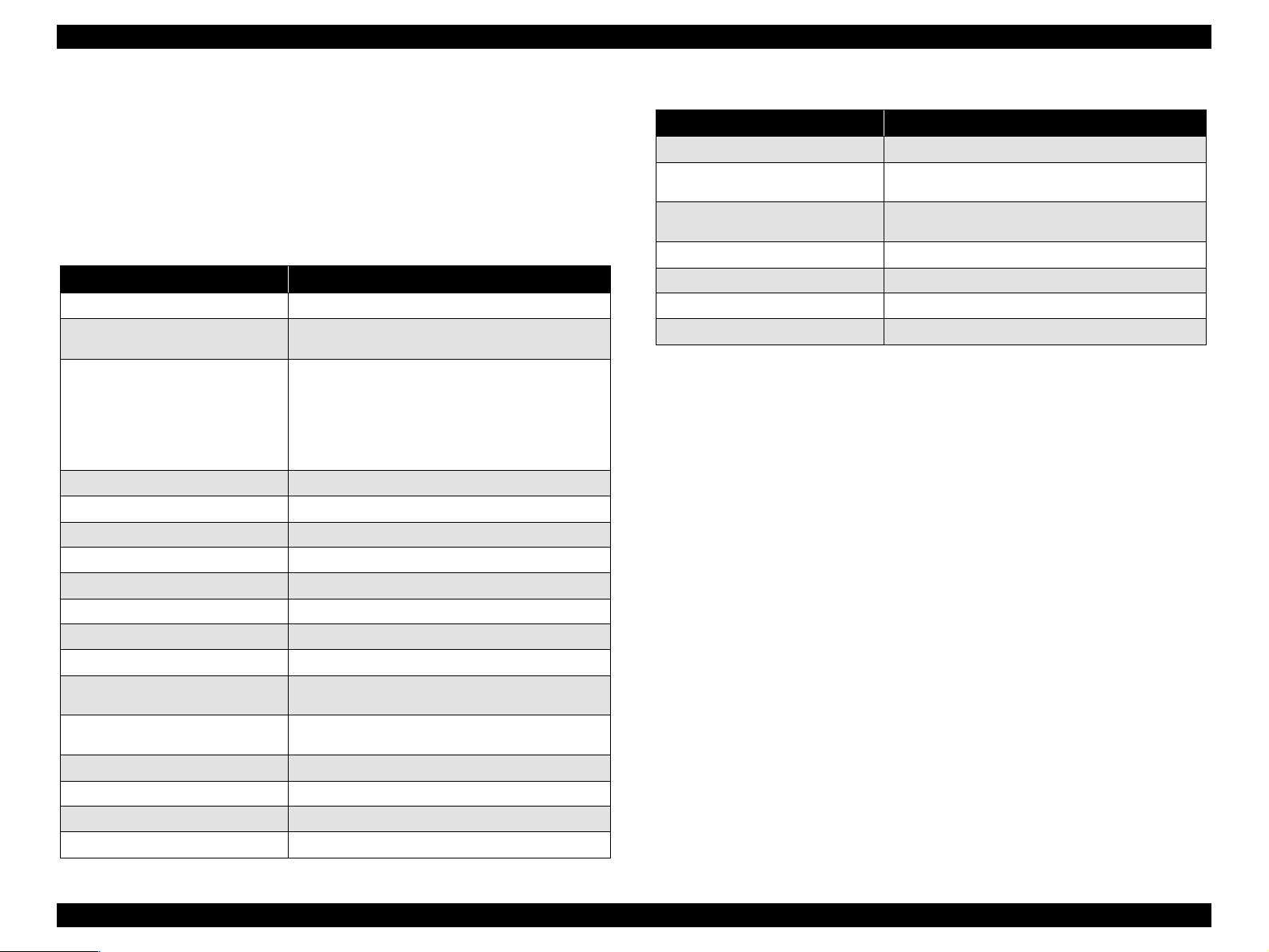

1.1.2 Consumable Products & Options

The following table lists the consumable items and options available for use

with the EPSON Stylus Pro 9500.

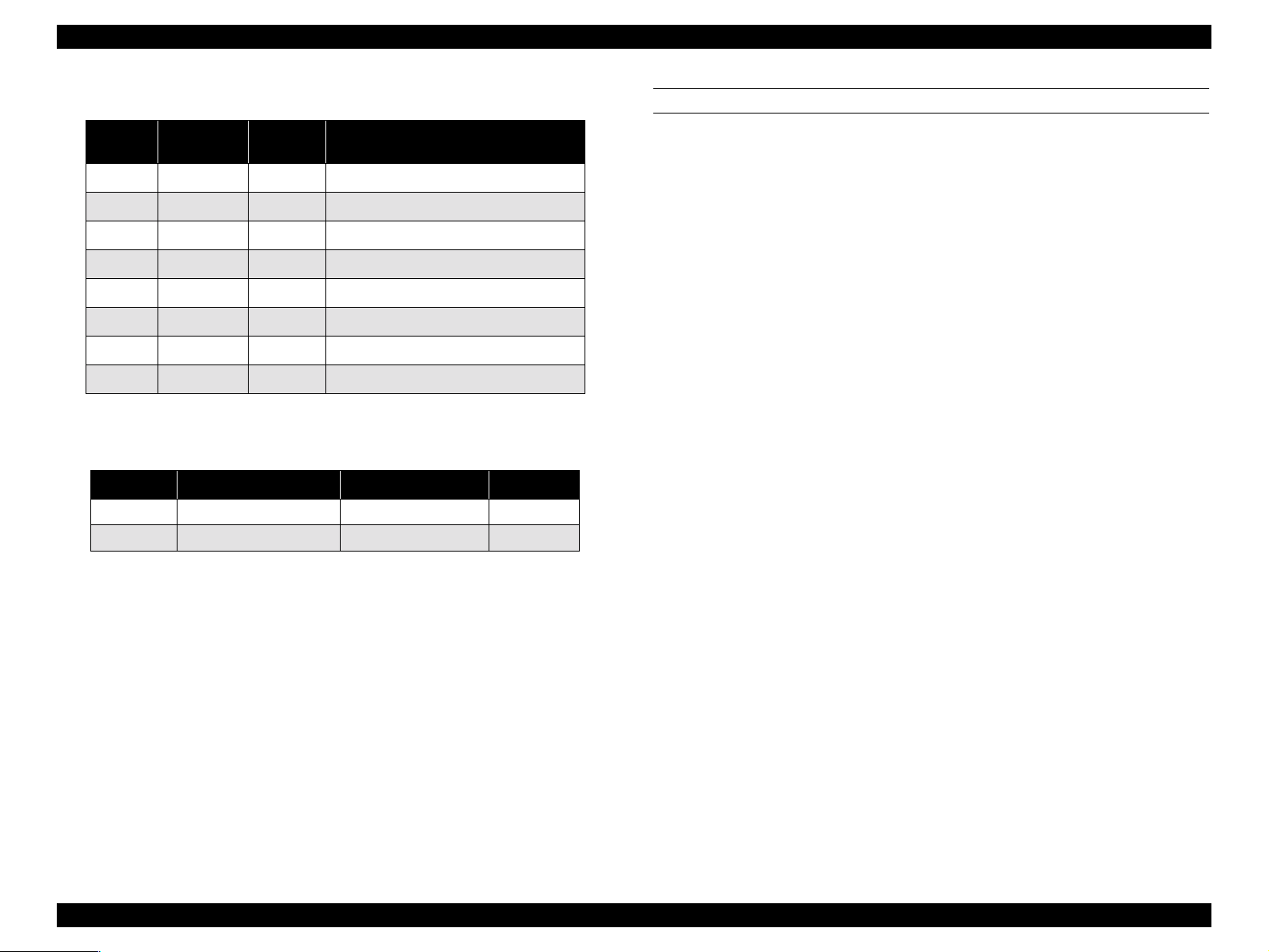

Table 1-1. Consumable Products & Available Options

Name Code Product

Doubleweight Matte

Paper

Glossy Paper - Photo

Weight

Premium Glossy Photo

Paper

Premium Semigloss

Photo Paper

Watercolor Paper Radiant White

Glossy Film

Synthetic Paper

Adhesive Syn thetic

Paper

S041385

S041386

S041387

S041388

S041389

S041390

S041391

S041392

S041393

S041394

S041395

S041396

S041397

S041398

S041352

S041351

S041314

S041313

S041312

S041399

S041400

S041401

S041402

S041403

S041404

24in. wide / 25m long

36in. wide / 25m long

44in. wide / 25m long

22in. wide / 20m long

44in. wide / 20m long

24in. wide / 30.5m long

36in. wide / 30.5m long

44in. wide / 30.5m long

24in. wide / 30.5m long

36in. wide / 30.5m long

44in. wide / 30.5m long

24in. wide / 18m long

36in. wide / 18m long

44in. wide / 18m long

A3 Wide / B

A3 Wide / B

610mm wide / 20m long

914mm wide / 20m long

1118mm wide / 20m long

24in. wide / 45m long

36in. wide / 45m long

44in. wide / 45m long

24in. wide / 30m long

36in. wide / 30m long

44in. wide / 30m long

Table 1-1. Consumable Products & Available Options (continued)

Name Code Product

Rip Station 5100 PS

Server Series

Multi-protocol Ethernet

interface card

100Mbps Multi-protocol

Ethernet interface card

Note *: Two rolls can be installed at the same time.

Note **: Can only be installed in the upper spindle holder.

Note 3: These papers can be used in the Stylus Pro 9000 also.

EAI - C850092

Other - C850093

C82362¬ Type-B 10Base-T

C82363¬ Type-B 100Base-T

Fiery Adobe® PostScript® 3™

Server

Product Description Features 8

Page 9

EPSON Stylus Pro 9500 Revision A

1.2 SPECIFICATIONS

PRINT SPECIFICATIONS

Print method: On-demand MACH (Multi-layer Actuator Head) ink

jet E-MACH type

Nozzle configuration: Black: 64 nozzles

Color: 320 nozzles/64 nozzles for each color (Yellow,

Magenta, Cyan, Light Magenta, and Light Cyan)

Print direction: Bi-directional with logic seeking

(high-speed return and skip only)

Print speed: See the following table:

n <Character mode>

Character Quality: High quality

Character Pitch: 10 cpi

Printable Area: 437 colu mns

Print Speed: 240 cps

n <Graphic mode>

See the table below.

n Character Code

PC 850 (Multilingual)

PC437 (US, Standard Europe)

n Type Faces

Bitmap LQ font: EPSON Courier IO CPI

PAPER-FEED SPECIFICATIONS

Feeding method: Friction feed

Line spacing: 1/6 or 1/720” programmable

Paper loading: Roll paper (two 2-inch rolls can be loaded at the

same time)

Single sheets loaded one at a time

Paper volume: 2” core roll paper = diameter of paper wound on roll

of less than 103mm (4.05”)

3” core roll paper = diameter of paper wound on roll

of less than 150mm (5.9”)

Single sheets = one sheet at a time

Feed speed: 200 ± 10 ms (when feeding at 1/6”)

2.5”/second (when continuously feeding)

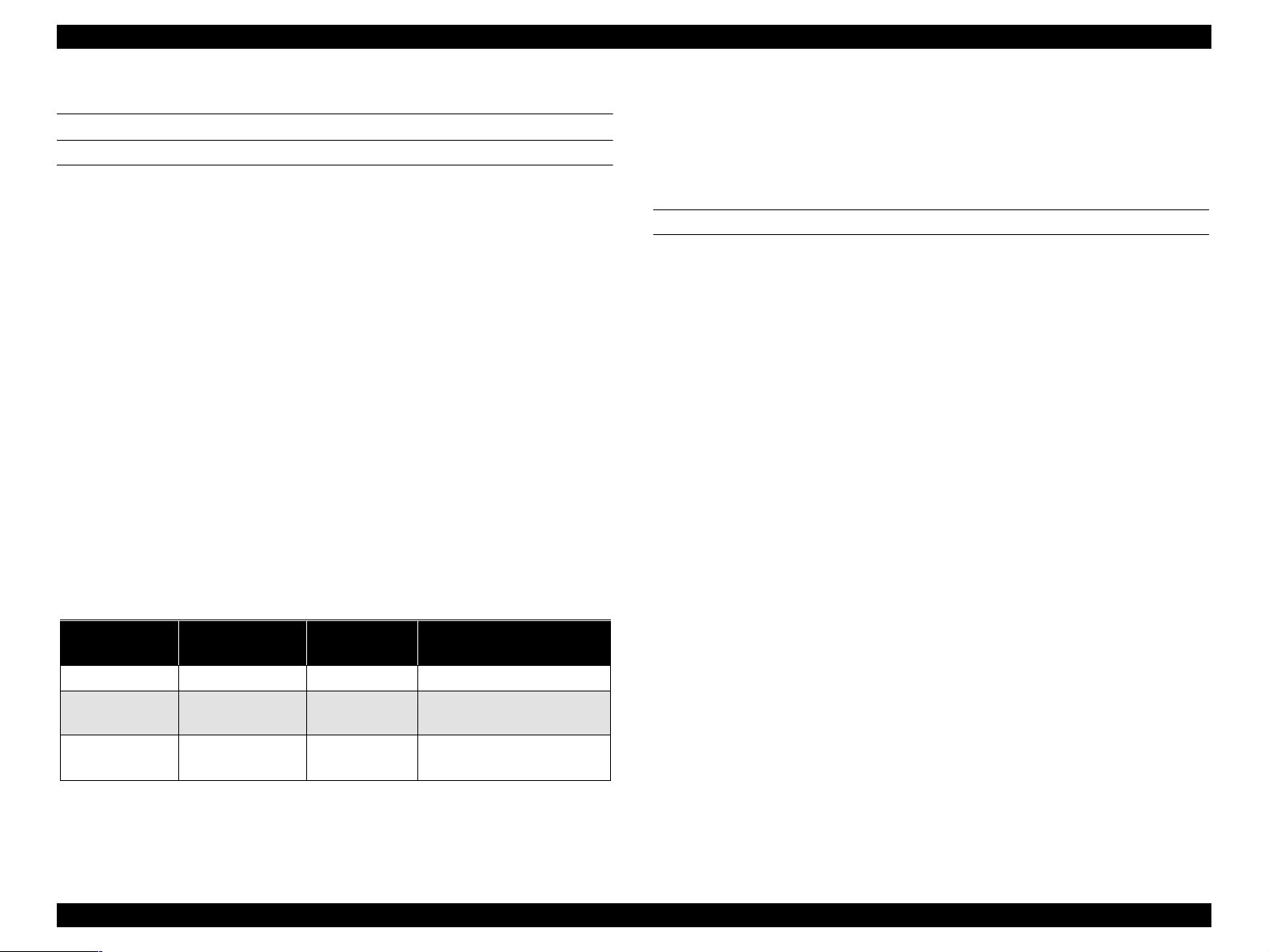

Table 1-2. Print Speed by Print Mode

Table 1-2.

Horizontal

Resolution

360 1112mm 15762 241 IPS/FOL

720 1112mm 31524 33. 31 IPS/FOL

1440 1112mm 63048 24IPS/FOL

Control code: ESC/P Raster (commands are not open to public)

Character Specifications:

Printable Area

Printable Dot

Count

Print Speed

33.31 IPS/4pass

33.31 IPS/4pass

Product Description SPECIFICATIONS 9

Page 10

EPSON Stylus Pro 9500 Revision A

PAPER SPECIFICATIONS

Size, roll paper {Minimum paper requireme nts}

Paper meeting the requirements described below

can be used with this printer, but neither the feeding

nor printout quality is guaranteed.

•Paper Size = Width 297~1118mm

(8.27~44.02”)

Length 720mm~45m

(28.35~1771.65”)

•Roll Size = 2” or 3” core

paper thickness = 103mm or less (4.05”)

150mm or less (5.9”)

•Paper Thickness = 0.08~0.5mm (0.003~0.019”)

*1): There should be no wrinkles, fuzz, tearing or

folding, of the paper, etc.

* 2): The exclusive option (3” roll paper spindle)

should be used when using 3” core roll paper.

{Normal paper}

For paper meeting the following requirements, the

feeding operation only is guaranteed.

•Paper Size = Width 297~1118mm

(8.27~44.02”)

Length 720mm~45m

(28.35~1771.65”)

•Roll Size = 2” or 3” spindle

paper thickness = 103mm or less (4.05”)

150mm or less (5.9”)

•Paper Thickness = 0.08~0.11mm (0.003~0.0043”)

•Paper Weight = 64~90gf/m

•Paper Quality = Normal paper, recycled paper

*1: Use at normal room temperature

(15~25°C (59~77°F)

2

(two 2” rolls)

(one 3” roll)

(two 2” rolls)

(one 3” roll)

(17~24 lb.s)

40~60% humidity)

*2: The printer exerts between 300~500gf to peel

off the rear edge of roll paper from the core

*3: The exclusive option (3” roll paper spindle) is

necessary when using 3” core roll paper.

*4: This product should be used in a place with a

normal room temperature environment

(Temperature: 15~25°C, Relative humidity:

40~60%)

*5: The guaranteed printable area for roll paper is

from the core to the point where it is cut off.

(Reference: The remaining paper length when the

paper comes off the roll is approximately 400 mm for

the upper holder and approximately 300 mm for the

lower holder.

{Special paper}

For special paper meeting the following

requirements, the feeding operation and print quality

are optimized.

Product Description SPECIFICATIONS 10

Page 11

EPSON Stylus Pro 9500 Revision A

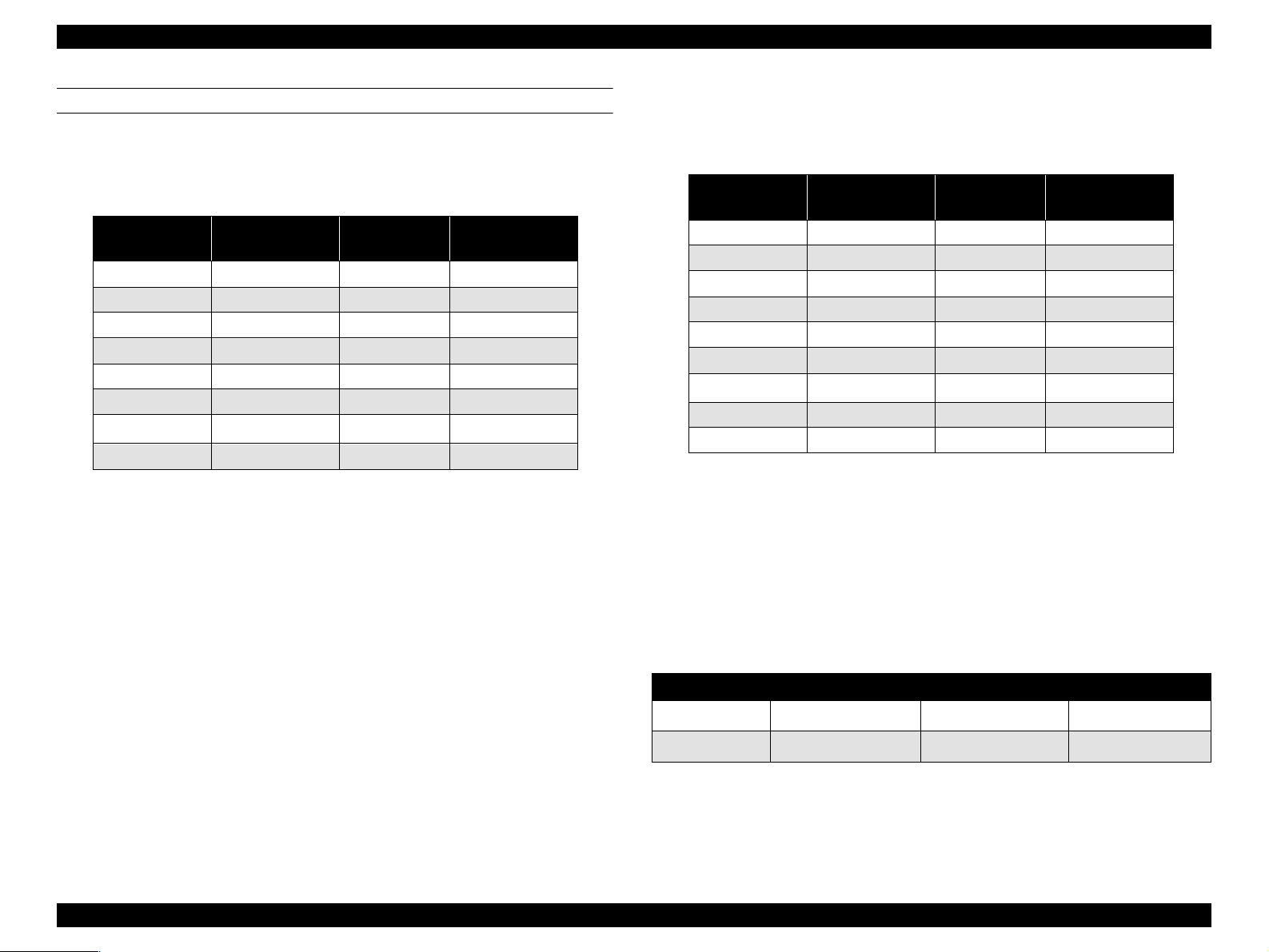

Table 1-3. Special Paper Specifications

Paper Code Paper Size Roll Size

Doubleweight

Matte Paper

Glossy Paper Photo Weight

Premium Glossy

Photo Paper

Premium

Semigloss Photo

Paper

Watercolor Paper

- Radiant White

Glossy Film

Synthetic Paper

Adhesive

Synthetic Paper

S041385

S041386

S041387

S041388

S041389

S041390

S041391

S041392

S041393

S041394

S041395

S041396

S041397

S041398

S041314

S041313

S041312

S041399

S041400

S041401

S041402

S041403

S041404

*1):There should be no wrinkles, fuzz, tearing or

folding, of the paper, etc.

24” x 25m

36” x 25m

44” x 25m

22” x 20m

44” x 20m

24” x 30.5m

36” x 30.5m

44” x 30.5m

24” x 30.5m

36” x 30.5m

44” x 30.5m

24” x 18m

36” x 18m

44” x 18m

610mm x 20m

914mm x 20m

1118mm x

20m

24” x 45m

36” x 45m

44” x 45m

24” x 30m

36” x 30m

44” x 30m

2” core/ paper thickness

(radius) of 103mm or less

(Reference: The remaining paper length when the

paper comes off the roll is

Approximately 400 mm for the upper holder and Approximately 300 mm for the

lower holder.

*2):This product should be used in a place with a

normal room temperature environment

(Temperature: 15~25°C, Relative humidity:

40~60%)

* 3):The guaranteed printable area for roll paper is

from the core to the point where it is cut off.

Product Description SPECIFICATIONS 11

Page 12

EPSON Stylus Pro 9500 Revision A

CUT SHEET PAPER SPECIFICATIONS

Loading of the following papers into this printer is possible, but for papers

other than the following plain paper and exclusive paper, feed through

characteristics and print quality are not guaranteed.

Table 1-4. Usable Single Sheet Paper Specifications

Size

Super B0 1118 x 1580mm A2 329 x 483mm

B0 1030 x 1456mm Super A3/B 297 x 483mm

B1 728 x 1030mm A3 297 x 420mm

B2 515 x 728mm ANSI E 34 x 44”

B3 364 x 515mm ANSI D 22 x 34”

Super A0 914 x 1292mm ANSI C 17 x 22”

A0 841 x 1189mm

A1 594 x 841mm

Dimensions

(W x H)

Size

ANSI B 11 x 17”

Paper Thickness: 420~728mm (16.54~28.66”) long

paper = 0.08~1.5mm

(0.003~0.059”)

728~1580mm (28.66~6 2.2” ) long

paper = 0.08~0.5mm

(0.003~0.019”)

Dimensions

(W x H)

Table 1-5. Usable Single Sheet Paper Specifications

Size

Super B0 1118 x 1580mm A2 329 x 483mm

B0 1030 x 1456mm Super A3 /B 297 x 420mm

B1 728 x 1030mm A3 22 x 36”

B2 515 x 728mm ANSI E 20 x 24”

B3 364 x 515mm ANSI D 18 x 22”

Super A0 914 x 1292mm ANSI C 34 x 44”

A0 841 x 1189mm

A1 594 x 841mm 17 x 22”

A2 420 x 594mm 11 x 17”

[Exclusive Papers]

{Normal paper}

For paper meeting the following requirements, only

the feeding operation is guaranteed.

Dimensions

(W x H)

Size

ANSI B 22 x 34”

Dimensions

(W x H)

• Paper Thickness = 0.08~0.11mm (0.003~0.0043”)

• Paper Weight = 64~90gf/m

2

(17~24 lb.s)

• Paper Quality: Nor m al, re cyc led paper

*1:Load short edge first (portrait)

The following genuine exclusive papers can be used.

Table 1-6. Specifications of Genuine Exclusive Papers

Paper Name Dimensions (H x W) MC Glossy Paper *1 MC Imaging Paper

A3

Super A3

*1: Guaranteed for Uni-D printing. The paper should be loaded longitudinally.

*2: There should be no wrinkles, fuzz, tearing or folding, of the paper, etc.

*3: This product should be used in a place with a normal room temperature environment

(Temperature: 15~25°C, Relative humidity: 40~60%).

297mm x 420mm

329mm x 483mm

¡

¡

-

-

Product Description SPECIFICATIONS 12

Page 13

EPSON Stylus Pro 9500 Revision A

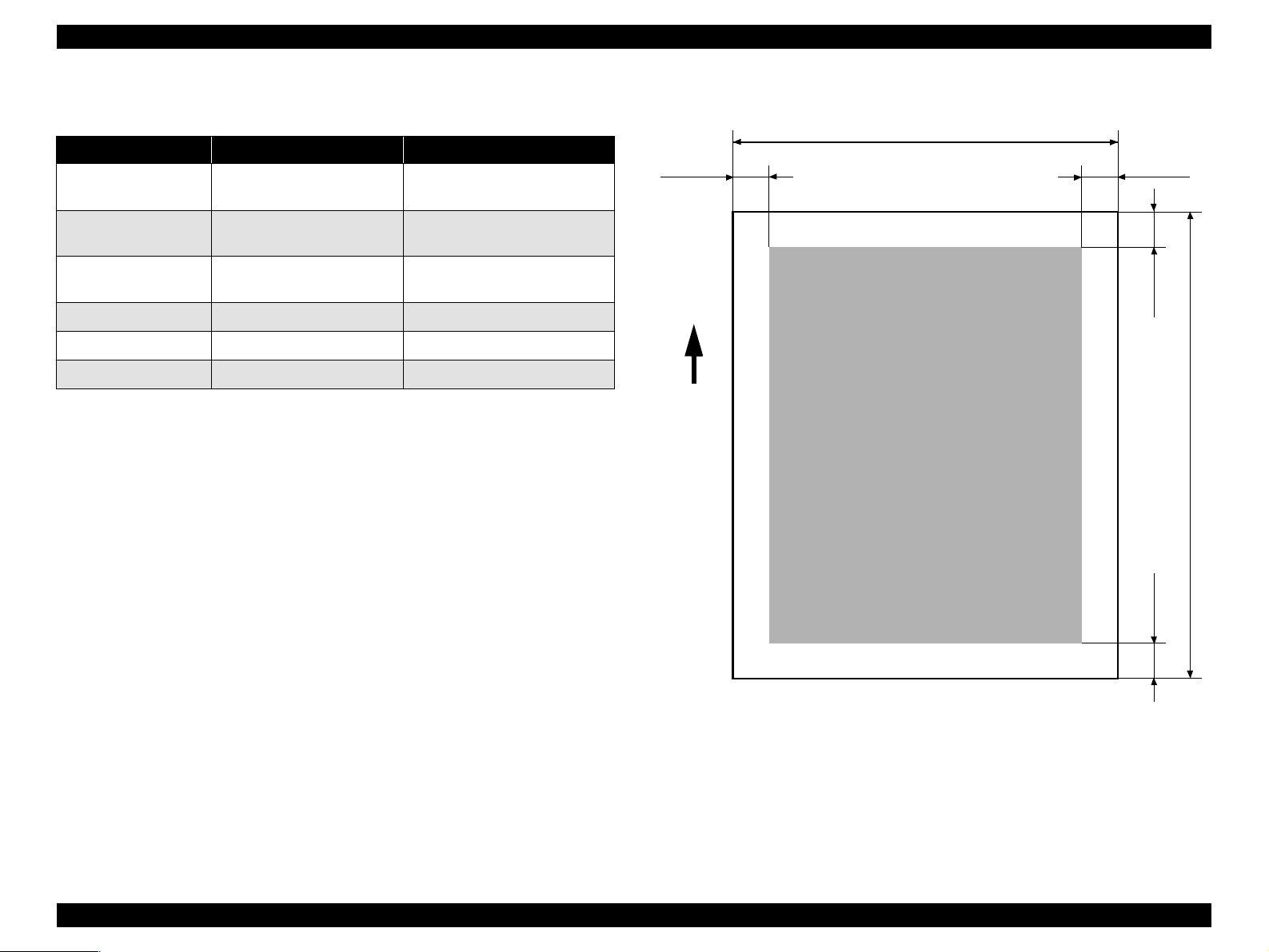

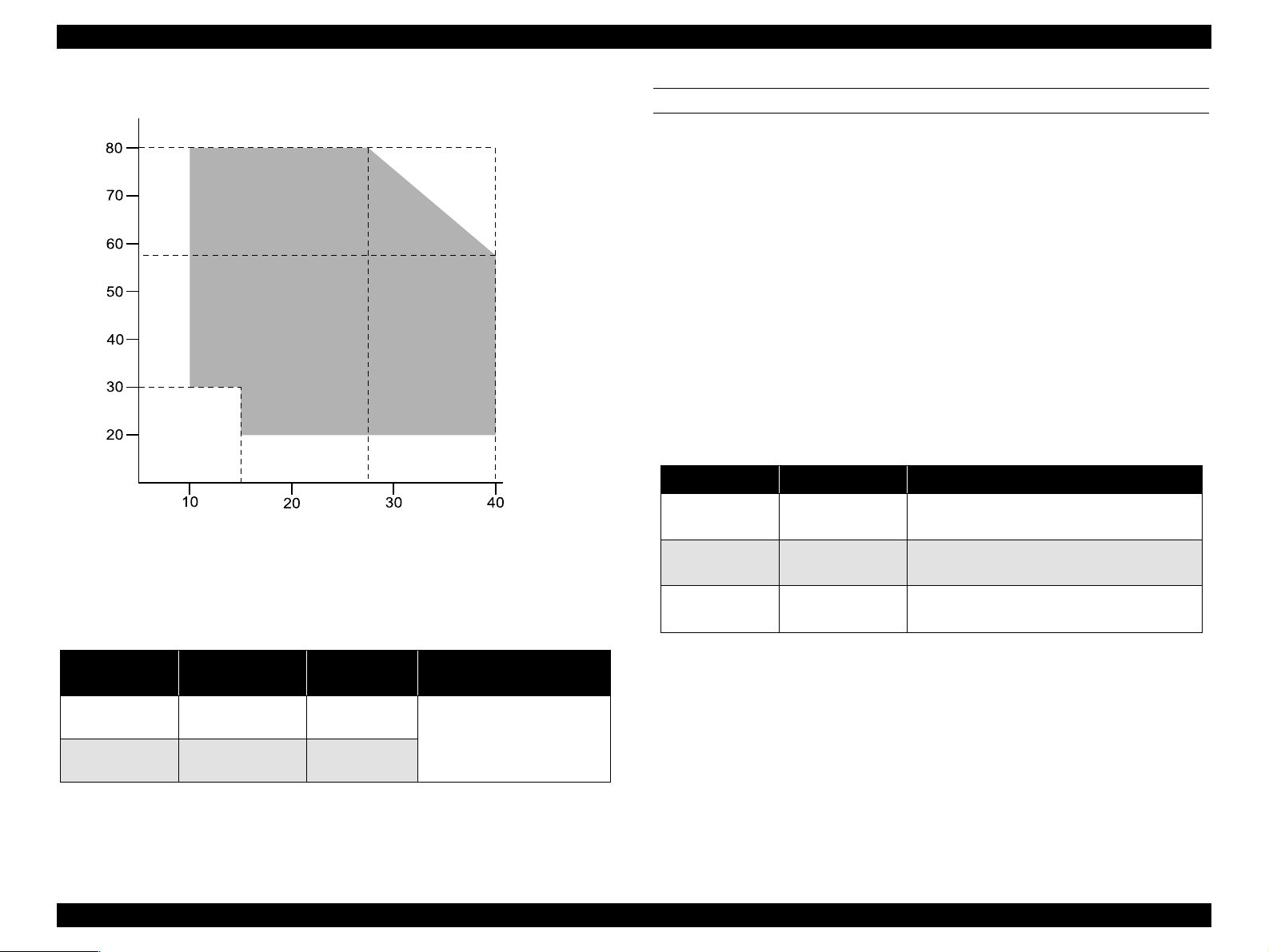

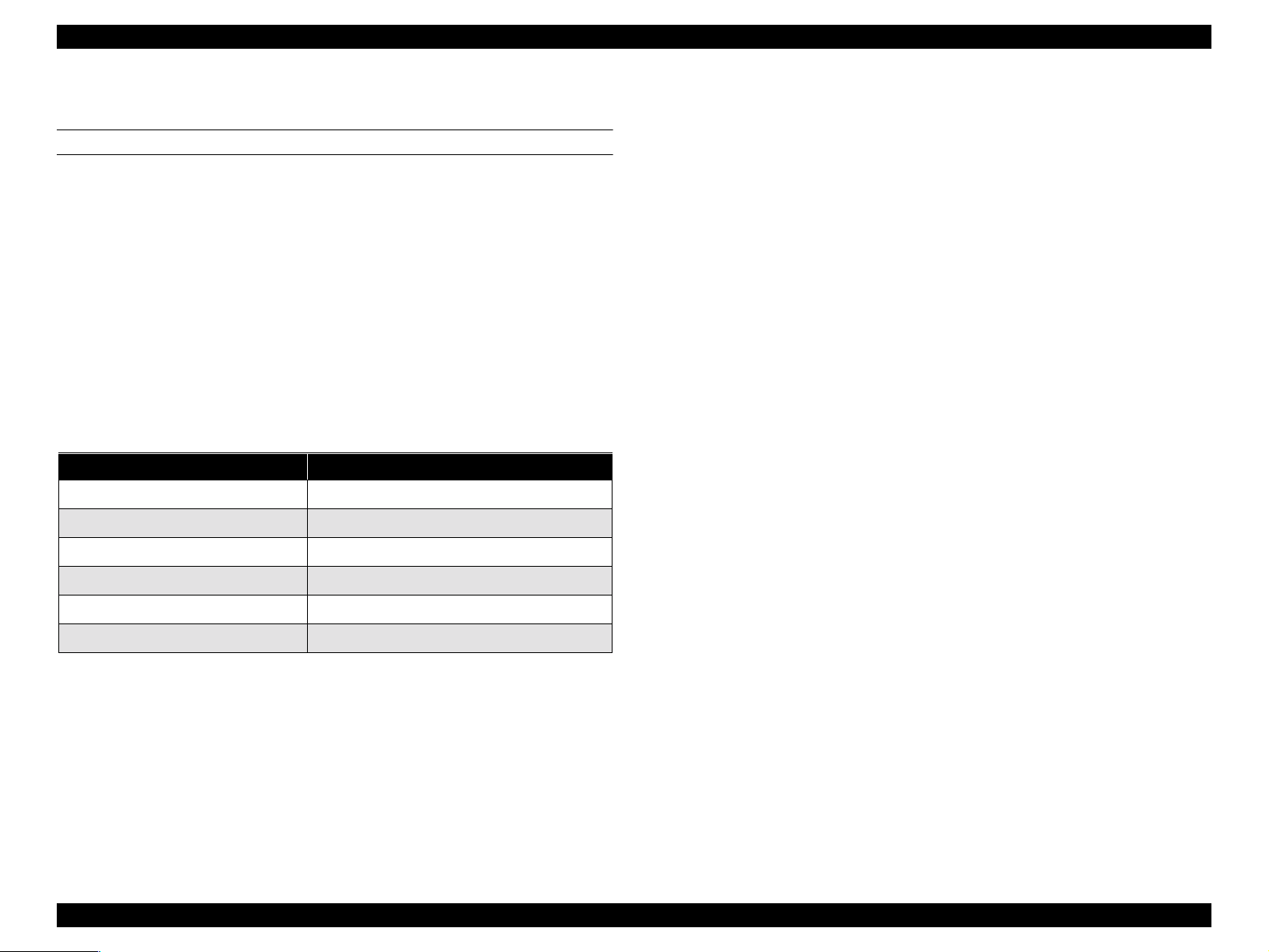

Printable area:See the following illustration and table for details.

Table 1-7. Printable Area

Heading Roll Paper Cut Sheets

PW (width)

PL (length)

LM (left margin)

TM (top) 3mm/15mm* 3mm

RM (right) 3mm/15mm* 3mm

BM (bottom) 3mm/15mm* 14mm

Note 1): The printer detects the paper width when the paper is set. (The paper width is not

detected when the paper width detection setting is Off.)

Note 2): Any image that exceeds the detected paper width, or the printable area specified by the

paper size setting, is not printed. (When paper detection setting is OFF, the printer may

print on the platen.)

Note 3): The size of the margin of roll paper can be changed from the panel as shown below.

Top and Bottom: 15 mm Left and Right: 3 mm, Top, Bottom, Left and Right: 3 mm,

Top, Bottom, Left and Right: 15 mm.

297 ~ 1118mm

(8.27 ~ 44.02”)

720mm ~ 45m

(8.27~1771.65”)

3mm/15mm*

(0.12~0.59”)

297 ~ 1118mm

(8.27 ~ 44.02”)

420~1580mm

(16.54~62.2”)

3mm

LM

Paper

Feed

PW

Printable Area

RM

TM

PL

BM

Figure 1-1. Printable Area

Product Description SPECIFICATIONS 13

Page 14

EPSON Stylus Pro 9500 Revision A

PAPER SET LEVER:

Lever Position = Up

o

The paper support is released and paper setting is possible.

o Lever Position = Down

The paper is in a fixed position and is ready to print on.

During printing, it is impossible to change the position of the paper set

lever.

During printing, an error occurs if the paper set lever is raised.

ELECTRICAL SPECIFICATIONS

Rated voltage range AC100~240V

Input voltage range AC90~264V

Rated frequency range 50 to 60Hz

Input frequency range 49 to 61Hz

Rated current

Power consumption

100 V System = 1.0 A

200 V System = 0.5 A

During operation = 100 W or less

During standby = 30 W or less

CONFORMITY/SAFETY APPROVALS

Safety Standards:

US Model UL 1950, CSA 22.2 No. 950

European Model EN60950 (VDE)

EMC:

US Model FCC part 15 subpart B class B

CSA C108.8 class B

European Model EN 55022 (CISPR Pub. 22) class B

EN 61000-3-2

EN 61000-3-3

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

Australian Model AS/NZS 3548 class B

International Energy Star Compliant

(EPA MOU2.1 Category Large Format Printer)

Insulation resistanc e

Dielectric strength

Current leakage 0.25 mA or less

10MW or higher

(CD 500 V / Between AC lin e and chassis)

AC 1.0 Kvrms / 1 min. or

AC 1.2 Kvrms / 1 sec. (between AC line and chassis)

Product Description SPECIFICATIONS 14

Page 15

EPSON Stylus Pro 9500 Revision A

RELIABILITY

Service Life: [Body] 20,000 Page (A0)

[Print Heads] 2 billion dots/nozzle

[Cutter] Approx. 2,000 times (Super B0)

Replacement Parts Service Life:

After printing of approx. 6200 sheets (A0), the

following parts are subject to simultaneous service

replacement.

• Waste ink pad

• Pump assembly

• Cap assembly (New part)

• Flushing box R

• Flushing box L (New part)

• Cleaner blade

CHECK

PO IN T

The above service replacement parts are available in

the following kit.

n Name: “Maintenance Kit Sylus Pro 9500

n Part Code: 1058462

n This maintenance kit is an exclusive kit for the

Sylus Pro 9500, and should not be used for the

Stylus Pro 9000.

ENVIRONMENTAL SPECIFICATIONS

Temperature/Humidity: See the following table.

Table 1-8. Temperature & Humidity

Condition Temperature Humidity Notes

Operating

Storage

Transportation

Notes:

1) When storing the printer, make sure the printheads are in the home, capped, position.

2) Before transporting the printer, remove the ink cartridges and turn the ink valves screws to

the closed position. Also make sure the printheads are in the home, capped, position. After

transporting the printer, install new ink cartridges.

3) When the temperature drops below -15°C (5

freezes. The ink thaws completely after three hours at 25°C (77

15~35°C

(59~95°F)

-20~40°C

(-4~104°F)

-20~60°C

(-4~140°F)

30~80%

20~85%

5-85%

°F), the ink in the cartridges and printheads

• Less than a month at

40°C (104°F)

Less than 120 hours at

60°C (140°F)

• Without condensation

°F).

Product Description SPECIFICATIONS 15

Page 16

EPSON Stylus Pro 9500 Revision A

Humidity (%)

Figure 1-2. Print Temperature and Humidity

Resistance to

Vibration & Shock: See the following table.

Table 1-9. Vibration & Shock Resistance

Temp.

(°C)

INK CARTRIDGE SPECIFICATIONS

Shape: Each ink cartridge is uniquely shaped so the

cartridges cannot be inserted in the wrong slots.

Ink colors: Black, Cyan, Magenta, Yellow, Light Cyan, Light

Magenta

Ink volume: 220 ± 5 ml

Ink avail. for printing: 190 ± 14ml

Print capacity: A0 = approx. 30 pages at 720dpi and 40% coverage

Dimensions: 25.1 x 260 x 105.3mm (WxDxH)

Weight: Approx. 370~385g (cartridge only)

Effective period: 2 years from production (in the sealed packaging)

plus time used (at room temp.)

Storage temperature: See the table below.

Table 1-10. Ink Cartridge (Environmental) Specifications

Situation Temperature Notes

Transporting

Storage

Installed

-30~60°C

(-22~140°F)

-30~40°C

(-22~104°F)

-20~40°C

(-4~104°F)

• Less than 120 hours at 60°C (140°F)

• Less than month at 40°C (104°F)

Less than a month at 40°C (104°F)

Less than a month at 40°C (104°F)

Condition

Operating 0.15G

Storage 0.50G

Vibration

Resistance

10~55Hz

10~55Hz

Shock

Resistance

1G

less than 1ms

2G

less than 2ms

Notes

X/Y/Z dir ection

Product Description SPECIFICATIONS 16

Page 17

EPSON Stylus Pro 9500 Revision A

CONTROLLER SPECIFICATIONS

CPU: 32 bit RISC-CPU (SH7043) 33Mhz

ROM: [Program]

CPU Internal = 128KB ROM

External = 1MB (Flash ROM/4Mbit x 2)

[Font] not-installed

RAM: 18MB (fixed)

(16MB: SIMM/2MB: IC18,19)

CHECK

PO IN T

Interface: [Standard]

The RAM installed in the form of a SIMM module is a

part of system memory and cannot be replaced (to

install a larger capacity SIMM) or removed.

IEEE1284 Bidirectional Parallel Interface

Macintosh Serial Interface

Type-B Card Slot (x1) for optional interface

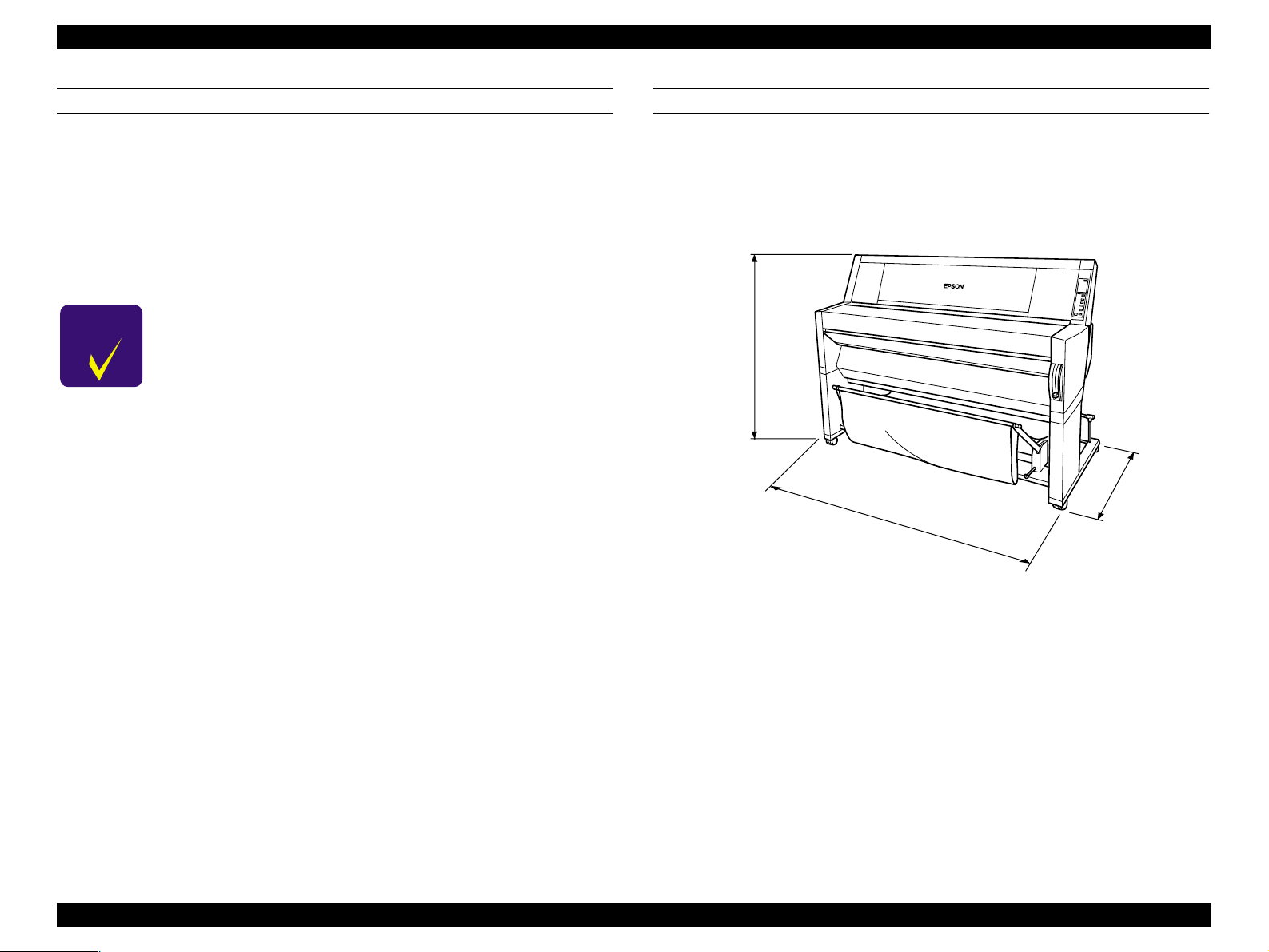

PRINTER DIMENSIONS & WEIGHT

Dimensions: 1688 x 699 x 1259mm (WxDxH)

(66.46 x 27.52 x 49.57 inches)

Weight: 96Kg (211.91 lb.s)

Printer alone = 74Kg (163.32 lb.s)

Stand = 22Kg (48.59 lb.s)

1259mm

(49.57”)

699mm

(27.52”)

1688mm

(66.46”)

Figure 1-3. Printer Dimensions

Product Description SPECIFICATIONS 17

Page 18

EPSON Stylus Pro 9500 Revision A

1.2.1 Interfaces

The EPSON Stylus Pro 9500 is equipped with parallel and Macintosh serial

interfaces and a card slot for an optional Type-B interface. This section

provides information on each interface.

PARALLEL INTERFACE

Parallel Interface [Compatibility Mode]

o

Transmission mode: 8-bit parallel, IEEE-1284 compatibility mode

Synchronization: By STROBE pulse

Handshaking: By BUSY and ACKNLG

Logic Level: TTL compatible level (IEEE-1284 Level 1 device)

Connector: 57-30360 (Amphenol) or equivalent 36-pin. The

interface cable length should be only long enough to

reach the shortest necessary distance.

signal

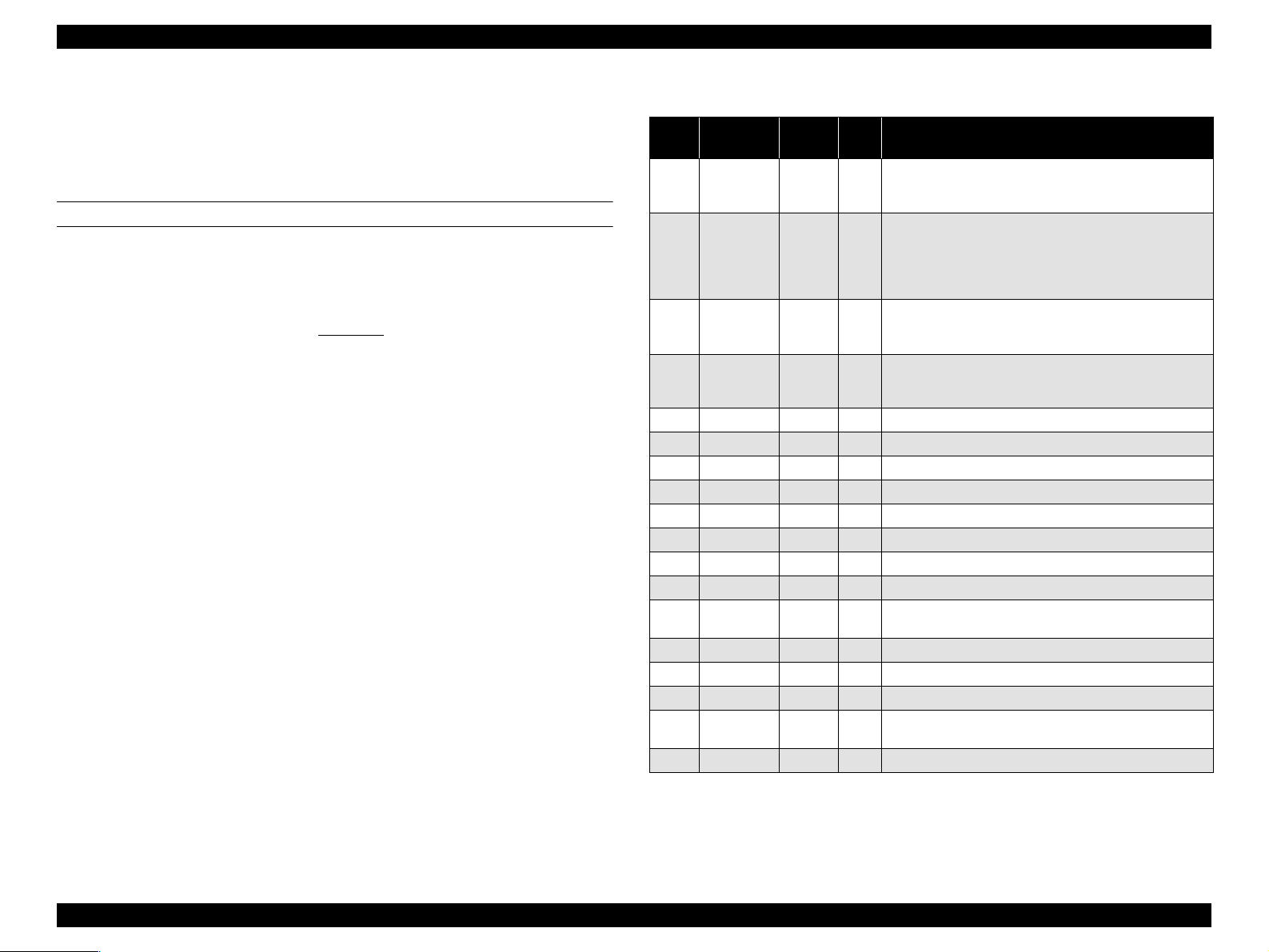

Table 1-11. Connector Pin Assignments - Forward Channel

Pin

No.

2-9

10

11

12

13

14

15

16

17

18

19-30

31

32

33

34

35

36

Note:See the next page.

Signal

Name

STROBE

1

DATA0~7

ACKNLG

BUSY

PE

SLCT

AFXT

NC Not connected

GND Ground for twisted pair return

Chassis Ground for frame/body

Logic H Pulled up to +5V via 3.9Kohm

GND Ground for twisted pair return

-INIT

ERROR

GND

NC

+5V

SLCTIN

Return

Pin

19 I

20-27 I

28 O

29 O

28 O

28 O

30 I

30 I

29 O

---- ----

---- ----

---- O

30 I

In/

Out

Data reception pulse, 0.5uS or greater pulse width

required. Usual state is HIGH, and reads data after

going to LOW state.

The DATA0 through DATA7 signals represent data bits

0 to7, respectively. Each signal is at high level when

data is logical 1 and low level when data is logical 0.

These signals are used to transfer the 1284 extensibility

request values to the printer.

When LOW the printer has finished preparing to receive

signals and can accept data. Pulse width is about 1uS or

3uS Printer clock signal.

HIGH means the printer cannot receive data. This

occurs when the printer is receiving data or when the

printer is in an error state.

HIGH means no paper is loaded. (LOW means an error.)

Always HIGH. Pulled up to +5V via 1.0Kohm

Not used

Pulse width of 50uS or more means LOW pulse, and the

falling edge of LOW signal causes the printer to initialize.

LOW means printer error

Ground for twisted pair return

Not connected

HIGH during normal operation. Pulled up to +5V via

1.0Kohm

Not used

Functional Description

Product Description SPECIFICATIONS 18

Page 19

EPSON Stylus Pro 9500 Revision A

Note 1: *1 The return side means the twisted pair return and is connected to the signal ground

level. Furthermore, when interfacing, a twisted pair cable should definitely be used for each

signal and the return side should definitely connected. Also, use of a shielded cable and

connection to the chassis ground of the center machine and the printer, respectively are

effective countermeasures against noise.

Note 2:All the interface conditions are TTL level standard conditions. The rise and fall time of each

signal is 0.2 _s or less.

Note 3:There must not be any data transfer with disregard of the /ACKNLG or BUSY signals. (Data

transfer to this printer must be performed after the ACKNLG level is confirmed or when

BUSY is in the “LOW” state.)

Note 4: A horizontal line above the signal name sows a LOW active signal.

Table 1-12. Parallel Interface Timing

Parameter Minimum Maximum

tsetup 500ns --

thold 500ns --

tstb 500ns --

tready 0 --

tbusy -- 500ns

treply --

tack Typical 2us

Tnbusy 0 --

tnext 0 --

o Nibble Mode

Transmission mode: 8-bit Parallel

Synchronization: External Supply STROBE Pulse Signal

Handshaking: ACKNLG and BUSY Signal

Signal level: TTL level (IEEE-1284 level 1 device)

Connector: 57-30360 (Amphenol) or equivalent

Data transfer timing: Refer to IEEE-1284 specification

Data requests

: When the printer receives the hexadecimal values 00H

or 04H, the printer responds in the following manner:

00H: The printer enters reverse channel mode, allowing

data to be sent to the host.

04H: The printer sends the device ID to the host; the

device ID consists of the following strings

device ID:

<00H><4EH>

MFG: EPSON

CMD: ESCPL2, BDC

MDL: Stylus[SP]Pro[SP]9000;

CLS: PRINTER

DES: EPSON[SP]Stylus[SP]Pro[SP]9500

Note: [SP] equals space code 20H

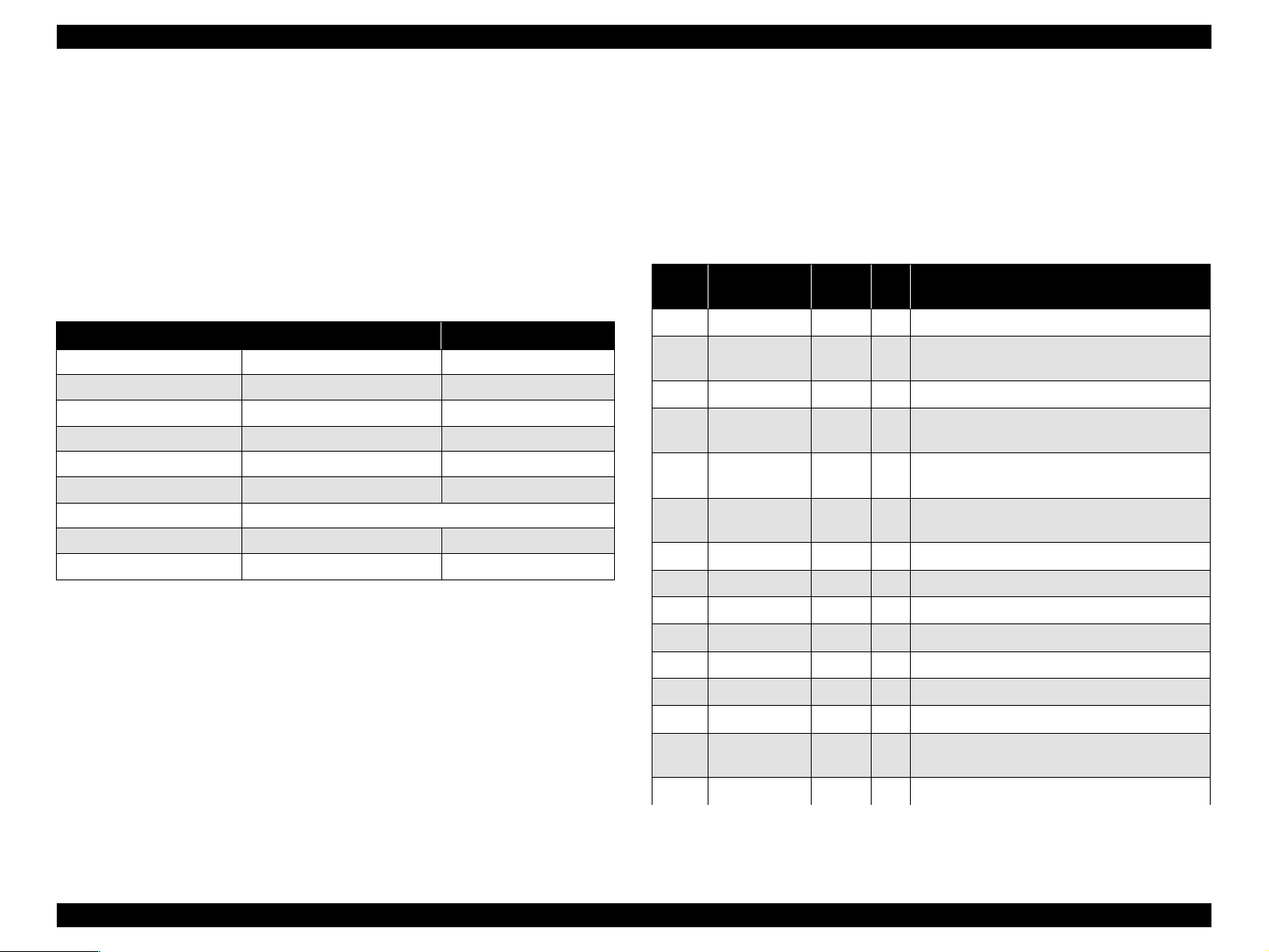

Table 1-13. Connector Pin Assignments - Reverse Channel

Pin

No.

19-30 GND Ground for twisted pair return

Signal Name

1 HostClk 19 I

2-9 Data0-7 20-27 I

10 PeriphClk 28 O Printer side clock signal.

PeriphAck/

11

PtrBusy

12 AckData Req 28 O

13 Xflag 28 O

14 HostBusy 30 I Hos t com pute r side BUS Y signal.

15 NC (Not used.)

16 GND Ground for twisted pair return.

17 Chassis GND Chassis Ground

18 Logic-H O +5 V pull-up at 3.9 K Ohm.

31 /INIT 30 I (Not used.)

32 /DataAvail 29 O

33 GND Ground for twisted pair return

Return

Pin

29 O

In/

Out

Functional Description

Host clock signal.

Each signal is at high level when data is

logical 1 and low l ev el w h en data is logical 0.

Printer side BUSY signal and data bit 3/7

in the reverse channel.

Acknowledge data request si gna l and

data bit 2/6 in the reverse channel.

X-flag signal and data bit 1/5 in the

reverse channel.

Data Available signal and data bit 0/4 in

the reverse channel.

Product Description SPECIFICATIONS 19

Page 20

EPSON Stylus Pro 9500 Revision A

Table 1-13. Connector Pin Assignments - Reverse Channel

Pin

Signal Name

No.

34 NC (Note used.)

35 +5V ---- O

36 1284-Active 30 I 1284 Active signal.

o

ECP Mode

Transmission mode: IEEE-1284 ECP mode

Synchronization: Refer to IEEE-1284 specification

Handshaking: Refer to IEEE-1284 specification

Signal level: TTL level IEEE-1284 level 1 device

Data transfer timing: Refer to IEEE-1284 specification

Data requests: When the printer receives the hexadecimal values 10H or

device ID: <00H><4EH>

Return

Pin

In/

Out

Functional Description

Normally HIGH state. +5 V pull-up at 1.0

K Ohm

14H, the printer responds in the following manner:

10H: The printer enters reverse channel mode, allowing

data to be sent to the host.

14H: The printer sends the device ID to the host; the

device ID consists of the following strings:

MFG: EPSON

CMD: ESCPL2, BDC

MDL: Stylus[SP]Pro[SP]9500

CLS: PRINTER

DES: EPSON[SP]Stylus[SP]Pro[SP]9500

Note: [SP] equals space code 20H

Table 1-14. Connector Pin Assignments - Reverse Channel

Pin

No.

Signal Name

1 HostClk 19 I

2-9 Data0-7 20-27 I

10 PeriphClk 28 O

PeriphAck/

11

PtrBusy

12 AckData Req 28 O

13 Xflag 28 O

14 HostBusy 30 I

15 NC - - (Not used.)

Return

Pin

29 O

In/

Out

Functional Description

Host clock signal.

Each signal is at high level when data is

logical 1 and low l ev el w h en data is logical 0.

Transmits data to the host computer

from the printer.

The printer uses this signal for forward

direction flow control. Also, this signal

offers data bit 9, which is used to judge

whether information output in the

reverse direction data signals is

command information or data

information.

The printer drives in Low and

acknowledges a nReverseRequest.

X-flag signal and data bit 1/5 in the

reverse channel.

The host uses this signal for reverse

direction flow control. Also, this signal

offers data bit 9, which is used to judge

whether information output in the

forward direction data signals is

command information or data

information.

16 GND - - Ground for twisted pair return.

17 Chassis GND Chassis Ground

18 Logic-H - O

19-30 GND - - Ground for twisted pair return.

31 /INIT 30 I (Not used.)

32 /DataAvail 29 O

Normally “HIGH” level. +5 V pull-up at

3.9 K Ohm

This signal is used to generate host

interrupts.

Product Description SPECIFICATIONS 20

Page 21

EPSON Stylus Pro 9500 Revision A

Table 1-14. Connector Pin Assignments - Reverse Channel

Pin

Signal Name

No.

33 GND Ground for twisted pair return.

34 NC (Not used.)

35 +5V ---- O

36 1284-Active 30 I

Return

Pin

In/

Out

Functional Description

Normally HIGH state. +5 V pull-up at 1.0

K Ohm.

1284 Active signal. “HIGH” when in the

ECP mode.

SERIAL INTERFACE

Transmission mode: Based on RS-423

Synchronization: Synchronous

Transfer speed: About 1.8 Mbps

Data format: Start bit: 1 bit

Data bit: 8 bits

Parity bit: None

Stop bit: 1 bit

Handshaking: X-ON/X-OFF, DTR protocol

Adaptable connector: 8-pin mini-DIN

Recommended I/F cable: Apple Genuine Cable

Product Description SPECIFICATIONS 21

Page 22

EPSON Stylus Pro 9500 Revision A

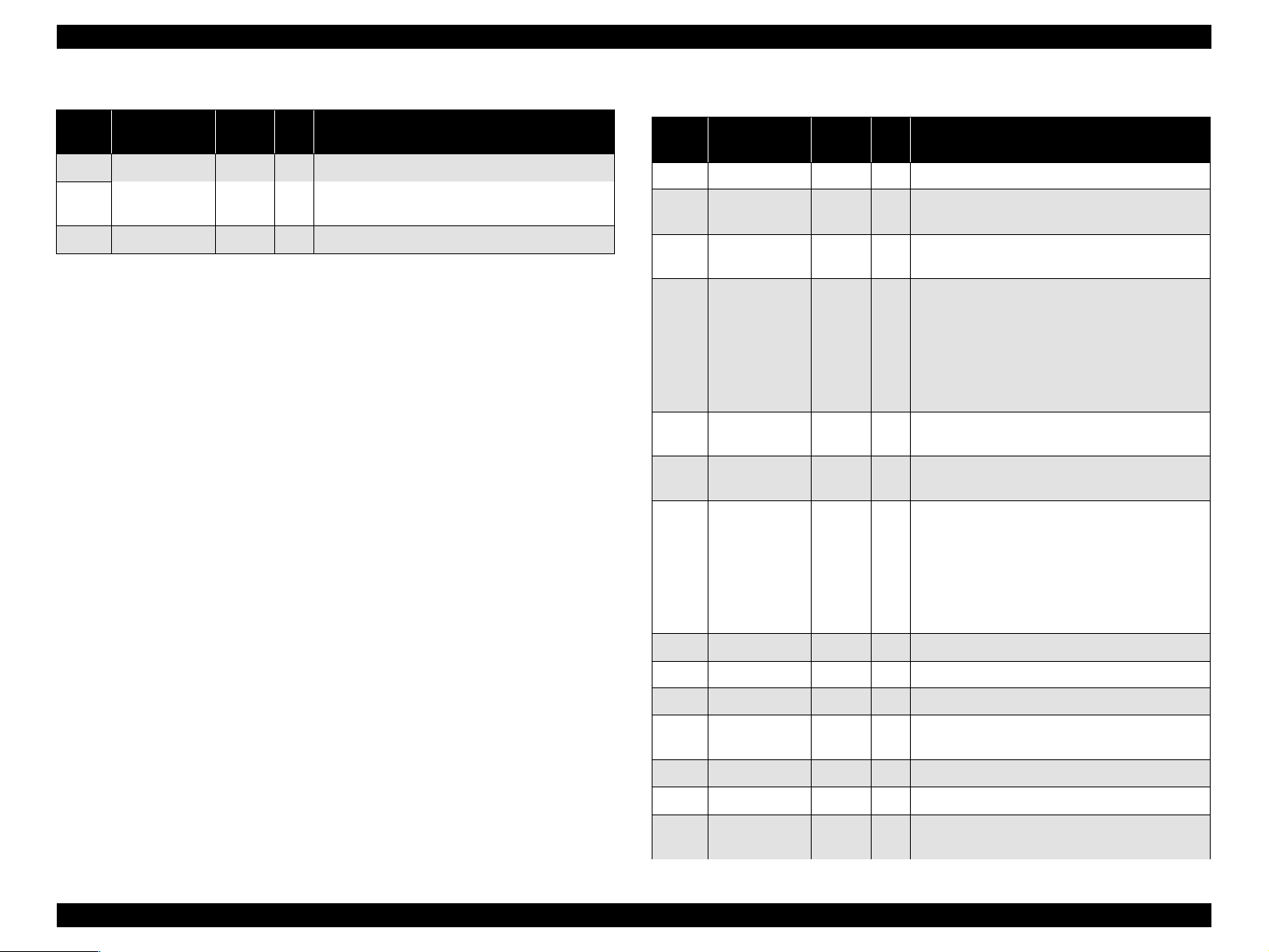

Table 1-15. Pin Assignment

Pin No.

1 SCLK O Synchronous clock signal

2 CTS I Clear To Send

3 TXD- O Transmit Data (-)

4 SG I (Signal Ground)

5 RXD- I Receive Data (-)

6 TXD+ O Balanced Transmit Data (+)

7 DTR O Data Terminal Ready

8 RXD+ I Balanced Receive Data (+)

o

DTR, Xon, Xoff Handshake Timing:

Signal

Name

I/O Description

Table 1-16. DTR, XON/XOFF Handshake Timingl

State Buffer Space X-ON/X-OFF DTR

Busy Less than 3072 bytes Send X-OFF code OFF

Ready More than 5120 bytes Send X-ON code ON

OPTIONAL INTERFACE

A Type B optional interface (Level 2 / 1200 mA type) can be used.

o Reply Message:

<When a Coax or Twinax Interface is installed> (Short Version)

n When using Co-ax/Twin-ax interface card:

Main type: MTP48p, PW12 7c l1 0c pi, PRG (KAx xx x)r ev,

AP1200ma

Product name: Stylus[SP]Pro[SP]9500

Emulation type: ESCPL2-00

Entity type: EPSONLQ2

<When an interface other than the above is installed>

Main type: M TP 48p , PW12 7c l1 0c pi, PRG (KAx xx )r ev,

AP1200ma, SPD0fast

Product name: Stylus[SP]Pro[SP]9500

Emulation type: ESCPL2-00

Entity type: ESPONLQ2

1.2.1.1 Receiving Buffer Full Operation

When receiving data via the parallel interface or the optional Type B interface

while in a state where no error has occurred (including the Pause state), if the

available capacity of the buffer drops to 4 KB or less, the printer receives at 1

byte/sec. and prevents the host from issuing a time out.

At the point when the available capacity of the buffer becomes 8 KB or higher,

1 byte/sec. reception is canceled and reception stops when the available

capacity is 32 bytes or less. At the point when the available capacity recovers

to 1K-byte or higher, reception at 1 byte/sec. is resumed.

Product Description SPECIFICATIONS 22

Page 23

EPSON Stylus Pro 9500 Revision A

1.2.1.2 Interface Selection

It is possible to switch between the manual fixed selection function or auto

selection function to select one of the interfaces which the printer is equipped

with (parallel, serial or optional interface).

o Manual Fixed Selection:

One of the interfaces which the printer is equipped with, can be selected

and fixed as the default setting.

o Auto Selection Function:

After the power is turned on, the interface from which data are first

received is selected. After that, if a predetermined period of time (fixed at

10 seconds) passes during which the reception of data is stopped, the

printer enters the idle state (a state where no interface is selected), then

selects the interface from which it first receives data next.

o Concerning interface selection and interface state:

n When an interface other than the parallel interface is selected, the

parallel interface is set in the BUSY state. At this time, the LH signal

goes “L.” The meaning of LH = L is that the power is cut off. That is, it

shows that the 1284 interface cannot respond. Therefore, a host

computer requesting reverse transmission must first check LH.

When the serial interface is not selected, DTR switches to the MARK

(High) state.

n When the optional interface is not selected, the OFF-LINE bit is set in

the Main Status Register (MNSTS).

n After the printer has been initialized, or when it is in the idle state (with

no interface selected), the status of each interface is a shown below.

• Parallel Interface : READY State

• Serial Interface : DTR = SPACE (Low) State

1.2.2 Initializat io n

This section describes the initialization procedures for the EPSON Stylus Pro

9500. There are three ways to initialize the EPSON Stylus Pro 9500:

o Hardware initialization:

When the power is turned on or a cold-reset command is sent to the printer

(remote RS command), the printer does the following:

n Initializes the printer mechanism

n Clears the input data buffer

n Clears the print buffer

n Restores the default values

o Software initialization:

When the printer receives an ESC@ command, it does the following:

n Clears the print buffer

n Restores the default values

o Control panel (operator) initialization:

When the Reset button is pressed or the printer receives an -INIT signal

(negative pulse) from the parallel inter face, the pr int er :

n Paper Eject (In the case of roll paper, the printed part is skipped and

when “Auto; Cut” is set in the paper select settings of the panel

settings, the paper is cut, and when “Cutter Off” is set, the paper is not

cut.)

n Caps the printheads

n Clears the input data buffer

n Clears the print buffer

n Resets the default values

• Optional Interface : OFF-LINE bit of the Main Status Register

(MNSTS) is reset.

n An interrupt signal, like the -INIT signal of the parallel interface, is

disregarded while that interface is not selected and while in the Nibble

mode or ECP m ode.

Product Description SPECIFICATIONS 23

Page 24

EPSON Stylus Pro 9500 Revision A

1.2.2.1 Initial Settings

The default values are shown below.

Page Position: Current paper position as page-start position

Line feed: 1/6”

Right margin: 440th character

Left margin: 1st character

Character pitch: 10 CPI

Print mode: Text mode (non-raster graphics mode)

Furthermore, as for the panel settings, default settings and remote command

storable items, their contents in memory are set at the default values.

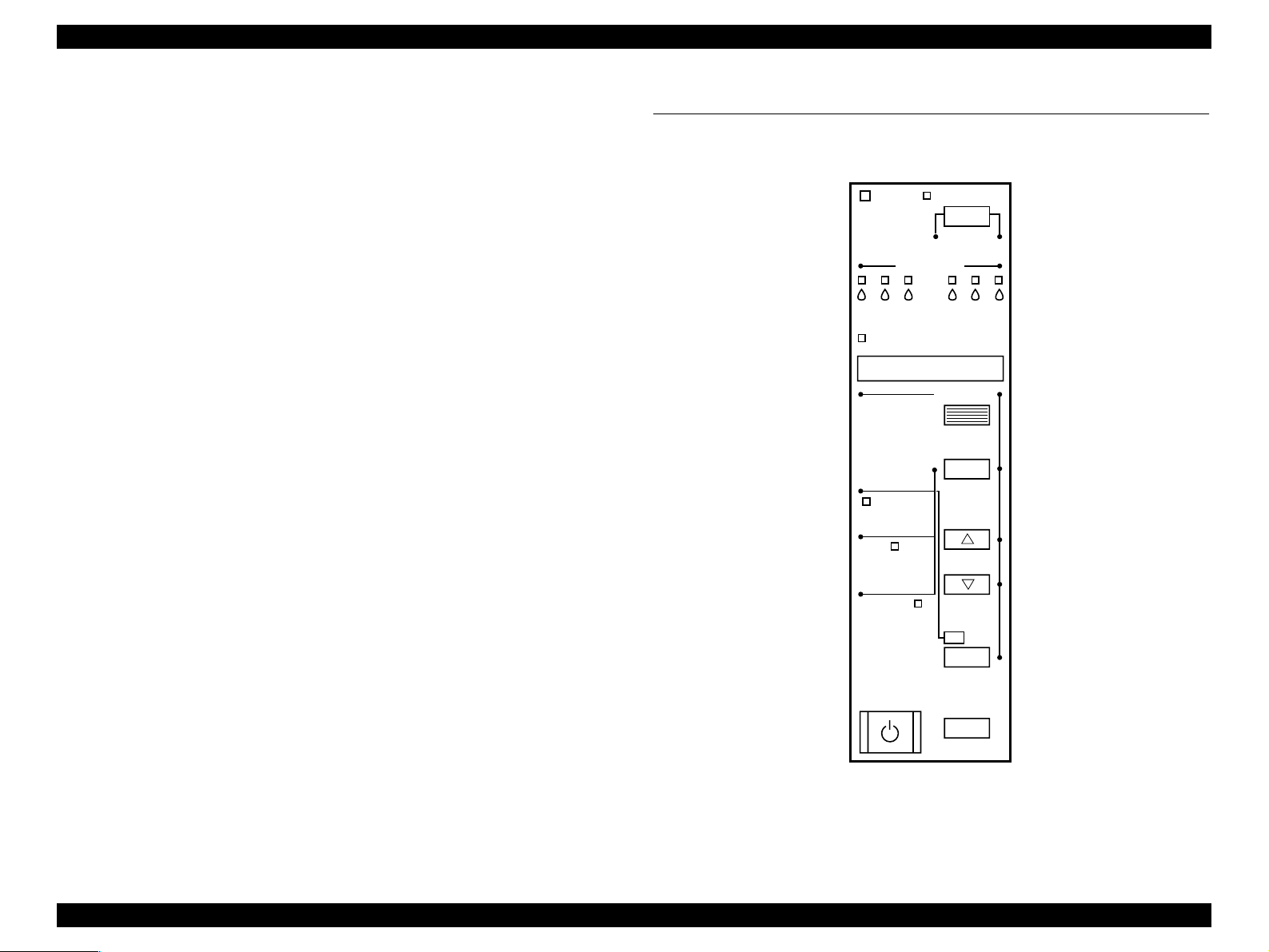

1.3 Control Panel

This section describes the control panel, the buttons, the lights, and the way

you make settings.]

Ink Out

Paper Source

Pause

Reset

3 sec.

SelecType

Item

+

Operate

KC LCMLMY

Paper Out

Roll

Auto Cut

Roll

Cutter Off

Paper Feed

Sheet

Power

_

Cut /Eject

Enter

Cleaning

3 sec.

Figure 1-4. Control Panel

Product Description Control Panel 24

Page 25

EPSON Stylus Pro 9500 Revision A

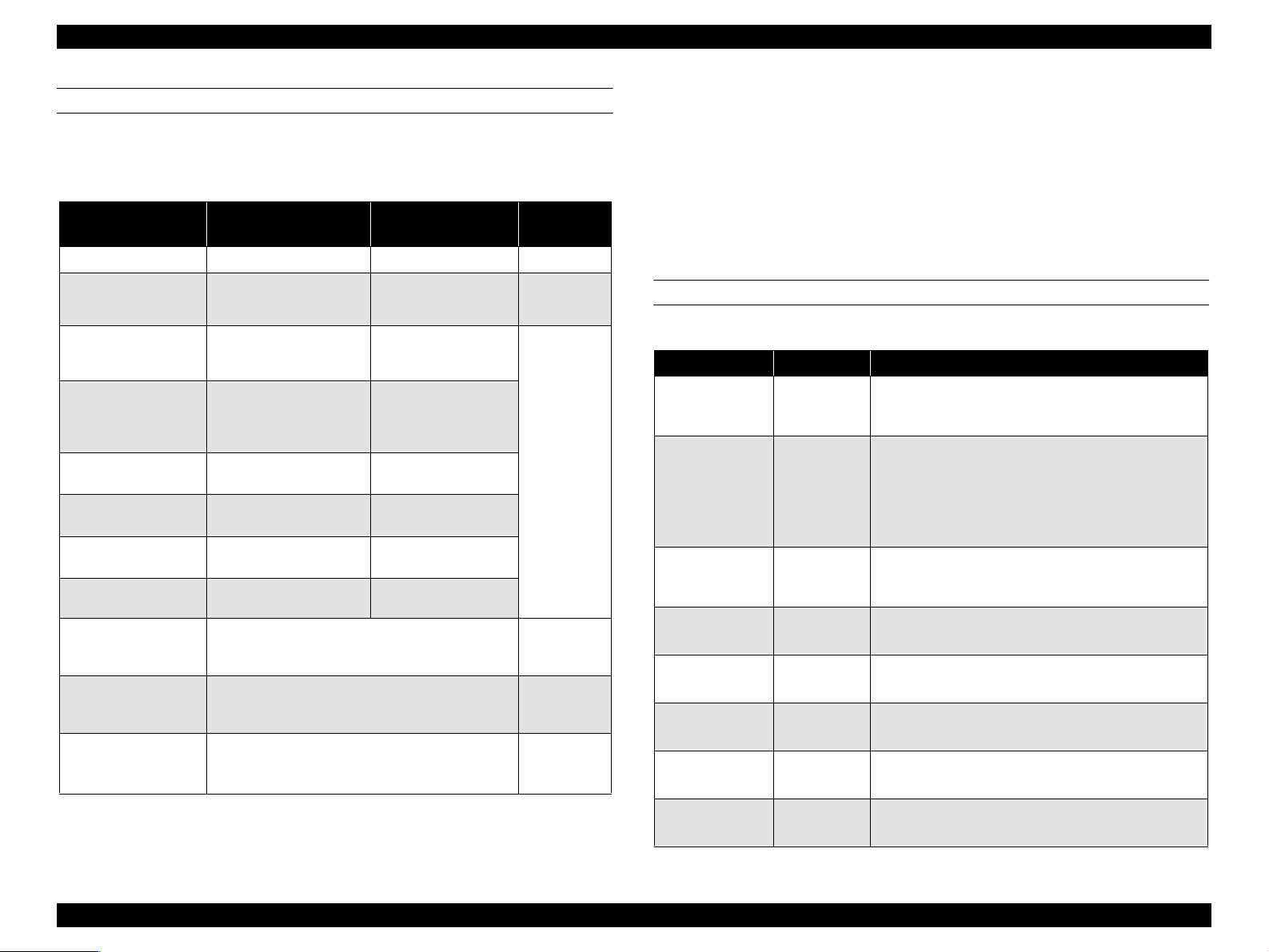

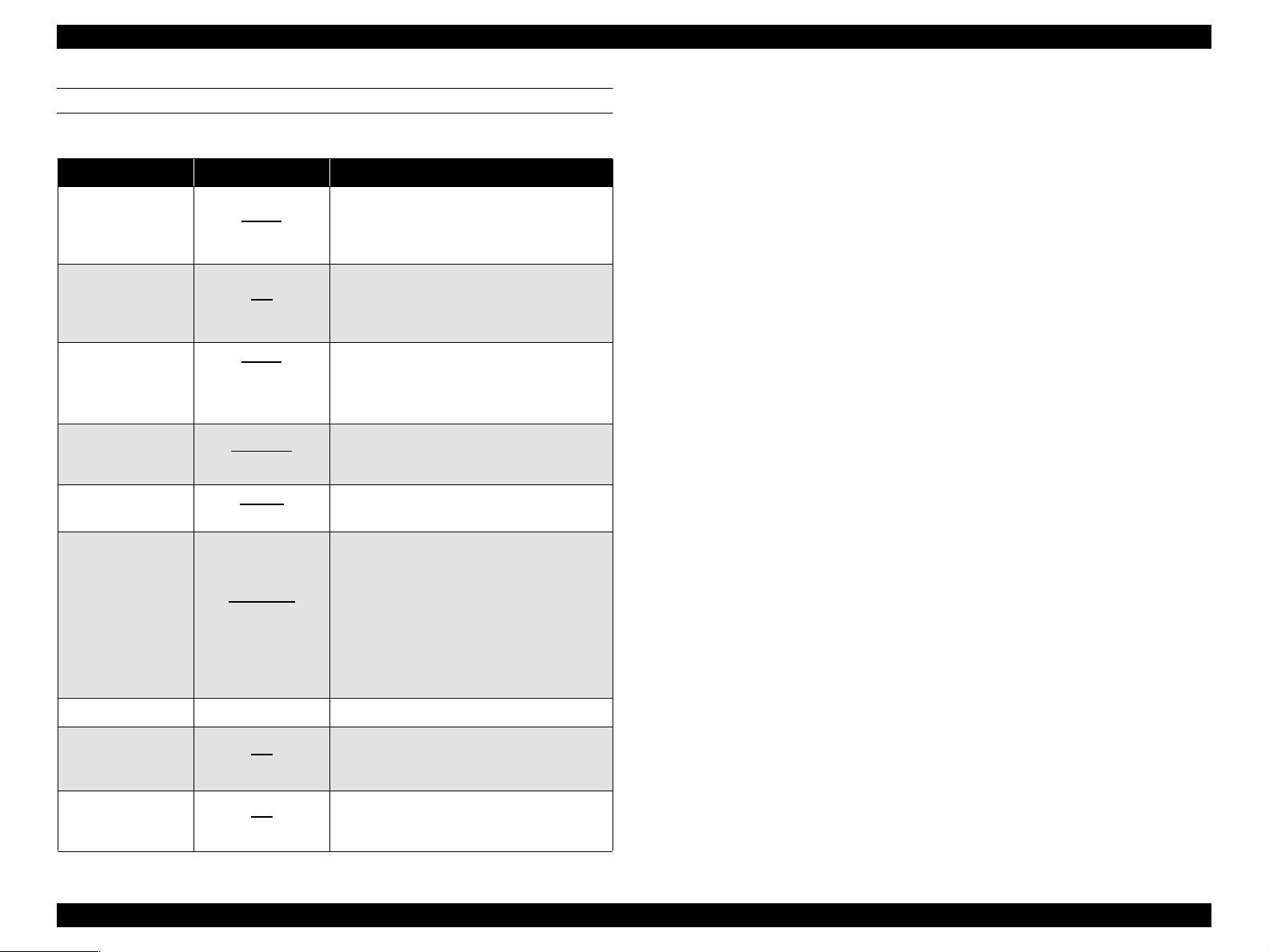

OPERATION BUTTONS

The functions of each of the buttons on the operation panel are as shown in the

following table.

Table 1-17. Control Panel Buttons & Functions

Button

(Second function)

Power Power on/off N/A N/A

Pause

(Reset)

SelecType

Cut/Eject

(Enter)

Paper Feed ↑ Feeds paper backward *2

Paper Feed ↓

(-)

Paper Source

(Item)

Cleaning

Paper Source

Cut/Eject

Paper Feed ↓

Paper Source

Cut/Eject

Cleaning

Paper Feed ↓

Cut / Eject

Cleaning

Function

(Normal)

• Switch - online/off-line

• Reset (press for three

seconds

Enters SelecType mode

(when printer is in Standby

mode)

Selects *1

•Auto Cut

•Cutter Off

•Sheet

Feeds paper forward *3

Selects paper source

Cleans both heads if

pressed for three seconds

SelecType

Function

N/A

Selects men u or major

category

Confirm and save value

Cycles backward/

increases value

Cycles forward/

decrease value

Selects item or minor

category

N/A

N/A

N/A

N/A

Power-On

Function

Maintenance

mode

N/A

Maintenance

Mode 2

Firmware

Update Mode

Self-

diagnostic

Mode

Notes:

1: During the ink drying time, ink drying is interrupted and the specified operation is

performed.

2: For 2 seconds after the button is pressed, the paper is fed at 12.7 mm/sec. (5.0 cps). If

the button is pressed for 2 seconds longer, the paper is fed at 76.2 mm/sec. (50.0 cps).

However, the paper can be reversed up to a maximum of 200 mm when the button is

pressed once.

3: For 2 seconds after the button is pressed, the paper is fed at 12.7 mm/sec. (5.0 cps). If

the button is pressed for 2 seconds longer, the paper is fed at 76.2 mm/sec. (50.0 cps).

LED INDICATORS

Table 1-18. LED Indicators

LED Status Condition

Operate

(Green)

Paper Out

(Red)

Pause

(Green)

Ink Out K

(Red)

Ink Out C

(Red)

Ink Out M

(Red)

Ink Out Y

(Red)

Ink Out LC

(Red)

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

• Power on

• Fatal error during data processing or during

power off p rocessing.

• Shows the no paper, roll paper end, roll paper/

cut sheet paper setting difference, paper support

lever released or cle aning impos sible error s tate.

• Shows a paper jam, paper cutting error, paper

skew error, paper recognition error, cut sheet

paper eject failure, or fatal error state.

• Print ready state.

• Blinks during head cleaning, during ink drying

time, and during initial filling processing.

• Ink end error state (K), I/C wrong insertion.

• Ink low state (K)

• Ink end error state (C), I/C wrong insertion.

• Ink low state (C)

• Ink end error state (M), I/C wrong insertion.

• Ink low state (M)

• Ink end error state (Y), I/C wrong insertion.

• Ink low state (Y)

• Ink end error state (LC), I/C wrong insertion.

• Ink low state (LC)

Product Description Control Panel 25

Page 26

EPSON Stylus Pro 9500 Revision A

Table 1-18. LED Indicators

LED Status Condition

Ink Out LM

(Red)

Paper Source

(Auto Cut)

Paper Type

(Cut Off)

Paper Type

(Single Sheet)

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

• Ink end error state (LM), I/C wr ong insertion.

• Ink low state (LM)

• Roll paper auto cutting is sele cte d (The paper is

cut automatically each page.)

• Difference from the roll paper auto cutting

setting. It shows that cut sheet paper is set.

• Roll paper with the cutter off is selected.

• Difference between the roll paper and cut sheet

paper setting. It shows that cut sheet paper is

set.

• Shows that cut sheet paper is selected.

• Difference between the roll paper and cut sheet

paper setting. It shows that roll paper is set.

Product Description Control Panel 26

Page 27

EPSON Stylus Pro 9500 Revision A

1.3.1 Normal Mode Panel Display

Messages are displayed in the LCD in the operation panel corresponding to the

printer status and error occurrence and other conditions. The messages

displayed are shown in the following table. Furthermore, the messages in the

following table are listed in the order of their display processing priority, from

high priority to low.

Table 1-19. LCD Messages

Display Message Meaning

SERVICE REQ nnnnnnnn *2

MAAINTENANCE REQ nnnn *3

WAIT *1

POWER OFF

INK OUT

COVER OPEN

OPTION I/F ERROR

LOWER PAPER SET LVR

LOAD xxx PAPER

PAPER JAM

PAPER NOT CUT

PAPER NOT STRAIGHT

PAPER OUT

RELOAD PAPER

INK COMPART.OPEN

INK OUT

PRESS PAUSE BUTTON

Fatal error

Printer requires maintenance from qualified service

person (such as replace waste ink tank)

Resetting Timer IC

Clearing NVRAM

Performing reset operation

Performing ink sequence operation

Initializing the printer

Dealing with initial paper operation

Preparing to shut down.

Replacing ink cartridge.

The cover is open.

A Type-B interface error has occurred.

Paper Release lever is in the release position.

Wrong paper loaded.

Paper is caught inside the printer.

Printer did not cut the paper (when Auto Cut selected)

Paper was fed at an angle, and the printer stopped to

prevent printing the page offcentered.

End of roll or sheet (or the paper detect sensor may

have dust or grime blocking its operation)

Paper check error

Replacing ink cartridge

An ink cartridge is empty

Waiting for paper initialize start trigger

Table 1-19. LCD Messages (continued)

Display Message Meaning

PAUSE

INK DRY xx MIN

INK LOW

PRINTING *1

READ *1

RESET

TURN PWR OFF AND ON

Notes:

1: If “Widen” is selected in the “Platen Gap” item in the panel settings, the letter “H” is

displayed in the 20th column.

2: See the separate table, Table 1-30, on page 38.

3: See the separate table, Table 1-29, on page 38.

Pause state.

Printer waits xx minutes before the next print job to

allow ink on previous print job time to dry.

Prepare a replacement cartridge for the color ink

indicated.

Processing print data.

Can receive and print data.

In the process of re-initializing.

Turn the printer off and turn it on again.

Product Description Control Panel 27

Page 28

EPSON Stylus Pro 9500 Revision A

1.3.2 Control Panel Settings

PANEL SETTING MENU SELECTION

By pressing the “SelecType” button while the printer is not printing, the printer

switches to the panel setting mode and the printing state is automatically

disabled. The following menu items are listed in the Panel Setting Mode, and

the setting menu is switched in order and displayed in the LCD each time the

“SelecType” button is pressed once. When selecting a menu, press the “Paper

Source” button once.

To return to the print ready state, press the “SelecType” button until the “Print

Ready” message is displayed in the LCD panel, or press the “Pause” button.

o Menu Selection: “SelecType” Button

o Selecting a Menu Item: “Paper Source” Button

o Mode End: “Pause” Button.

Table 1-20. Control Panel Settings

Menu Item Panel Display

SelecType Menu PRINTER SETTING MENU

Test Print Menu TEST PRINT MENU

Printer Status Menu PRINTER STATUS MENU

Paper Settings Menu PAPER CONFIG.MENU

Cutter Replacement Menu CUTTER REPLACE MENU

Head Alignment Menu HEAD ALIGNMENT MENU

Selecting a menu provides you with detailed options.

Product Description Control Panel 28

Page 29

EPSON Stylus Pro 9500 Revision A

PRINTER SETTING MENU

Table 1-21. SelecType Menu

Display Message Item Notes

Adjusts the P G width. (Normally used in

PLATEN GAP

PAGE LINE

AUTO

WIDE

ON

OFF

AUTO

INTERFACE

PARALLEL

MAC

OPTION

PARA I/F

CODE PAGE

COMFAT

ECP

PC437

PC850

T/B 15mm

ROLL MARG

15mm

3mm

INIT.PANEL EXEC. Initialize control panel setup values

Auto.)

For details concerning the PG setting

value, see the Operation Theory section.

When Auto Cut Off is selected on the

control panel, this setting determines

whether a line for manual cutting is

printed.

Determines which interface the printer

checks for data. Auto con tin uousl y chec ks

all interfaces and is good for normal use.

Determines the data transfer rate when

using this interface.(No rma lly, leave set to

Compatibility.)

Character code setting. (PC437:

expanded graphics/PC850: multi-lingual)

Sets the margin for roll paper. (disa bled for

cut sheet paper)

Vertical 15 mm: A margin of 15 mm is

provided on the left and ri ght o f the printed

portion, and a margin of 3 mm is provided

at the top and bottom / 3 mm: A margin of

3 mm is provided at the top, bottom, left

and right. / 15 mm: A margin of 15 mm is

provided at the top, bottom, left and right.

Notes:

1) The setting values in the above table with underlines are default setting values.

2) In the “Roll Paper Margins” setting, if “Vertical 15 mm” (15 mm is set at the top and bottom, and

3 mm is set at the left and right), or “15 mm” (15 mm is set at the top, bottom, left and right), the

printing position of vertical lines and horizontal lines in the portion where 15 mm is set at a

position 12 mm wider than the logical paper (the minimum margin is an area of 3 mm from the

paper edge). (Therefore, the margin becomes 3 mm + 12 mm = 15 mm.) Also, if the printable

area becomes X = 15 mm or greater from the right edge of the paper, that portion is not printed

on.

3) If the “Paper Skew Error Sensing” setting is turned OFF, even if the paper is skewed as it is

being fed, printing will continue, and even if the printed image spills over the edge of the paper

due to skewing, the printer will not give notice of the error, so the user should take full

responsibility for the possible consequences of this setting.

4) If the “Paper Width Sensor” setting is turned OFF, even if the paper is sensed to be in an

abnormal state, printing can be continued, but in that case, the paper width is decided and

printing continued based on the following standards.

• The paper’s left edge position is made the guide mark position on the paper guide.

• The printable area is the printable area specified in the command.

If the “Paper Width Sensor” setting is turned OFF, if printing is being done on a paper which has

a particularly low reflection rate and cannot be detected by the photosensor, this setting is used.

Through the “Paper Width Sensor” OFF setting, if an image which is larger than the set paper is

printed, printing may be done on the platen, so the user must take the responsibility for the

possible consequences. However, if detection of the top edge of the paper fails, it results in an

error.

PAPER ALIGN

CHK

( Note 3)

PAPER WIDTH

DETECTION

ON

OFF

ON

OFF

Turns the paper feed skew detection

setting ON / OFF. For details, see the

Operation Theory section.

Turns the paper feed paper width

detection ON / Off. For details, see the

Operation Theory section.

Product Description Control Panel 29

Page 30

EPSON Stylus Pro 9500 Revision A

TEST PRINT MENU

Test Print Menu

In the test print menu, the test printing shown in the following table can be

done. Each test is set by operating the following panel buttons. When each test

printing operation is completed, the printer returns automatically to the print

ready state.

o Test print menu selection: See the panel setting menu procedure.

o Test Print item selection: “Paper Source” Button

o Set print execution: “Enter” Button

In nozzle check pattern printing, the following data are printed. The printing

size is approximately 9 cm (W) x approximately 3 cm (H).

o Nozzle Check Pattern

o Firmware Version (V0xxxx)

o Waste Ink Counter (xx%) (Waste ink counter remaining capacity %)

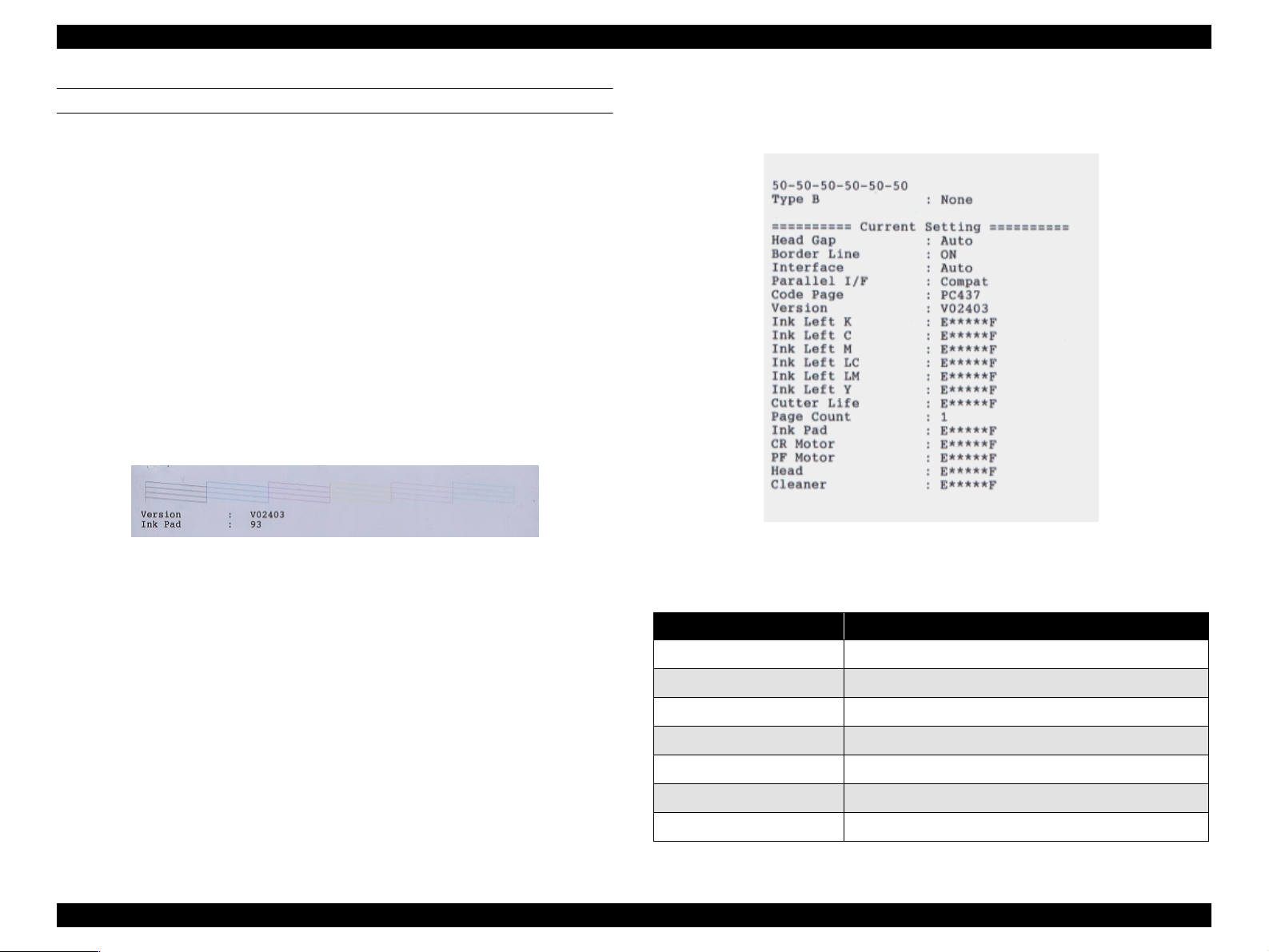

Figure 1-5. Nozzle Check Pattern Printing Results

version), Each Ink Life, Cutter Life, Page Count (total printed sheets

count), Ink Pad (Waste Ink Life), CR Motor (CR Motor Life), PF Motor (PF

Motor Life), Head (Head Life), Cleaner (Cleaning Unit Life).

Figure 1-6. Status printing result

In status sheet printing, the following data are printed. The printing size is

approximately 10 cm (W) x approximately 13 cm (H).

o Printer ID (= Head ID xx - xx - xx - xx - xx - xx)

In xx, the parameters stored in NVRAM are printed out in decimal

numbers.

o The order, from the left to right, is K - C - M - Y - Lc - Lm.

o Type B Interface Connection Condition

o The following printer settings

Head Gap, Border Line (perforation line), Interface (receiving settings),

Parallel Interface (Receiving Speed), Code Page, Version (Firmware

Display message Meaning

VERSION Shows the firmware version.

INK LEFT-C Shows the amount of remaining ink - Cyan

INK LEFT-M Shows the amount of remaining ink - Magenta

INK LEFT-LC Shows the amount of remaining ink - Light Cyan

INK LEFT-LM Shows the amount of remaining ink - Light Magenta

INK LEFT-Y Shows the amount of remaining ink - Yellow

INK LEFT-K Shows the amount of remaining ink - Black

Table 1-22. Printer Status Menu

Product Description Control Panel 30

Page 31

EPSON Stylus Pro 9500 Revision A

Table 1-22. Printer Status Menu (continued)

Display message Meaning

CUTTER LIFE Shows the remaining useful life of the cutter

TOTAL PRINTS Shows the total number of printed documents

WASTE INK Displays the CR motor life.

CR MOTOR Displays the PF motor life.

PF MOTOR Displays the head unit life.

HEAD UNIT Displays the head unit life.

CLEANING UNIT Displays the maintenance kit life.

See the following table concerning the display format for each item.

o Version

This is always displayed in 6 digits. Example: V00705

o Ink Life

Table 1-23. Remaining Ink Level Display

Remaining Ink Panel Display Ink Remaining

E*****F Off 100 ~ 81% remaining

E****F Off 80 ~ 61% remaining

Table 1-24. Cutter Life & Other Displays

Remaining Ink Life

E*****F 100 ~ 81% remaining

E****F 80 ~ 61% remaining

E***F 60 ~ 41% remaining

E**F 40 ~ 20% remaining

E*F 20% ~ 1% remaining

E Less than 1% remaining

Note 1) When the remainder on the cutter life counter becomes 0%, it does not result in a fatal

error since this is only a guideline. The cutter life counter is initialized by the “Cutter

Replacement Operation.”

Note 2) When the waste ink counter becomes less than 1%, a maintenance error occurs. If it

reaches 0%, a Service Call error occurs. The counter is reset in “Maintenance Mode 2”

when the waste ink pad replacement operation is performed.

Note 3) When remainder on the CR motor life counter becomes 0%, a fatal error is displayed.

Concerning the PF motor, head units and cleaning unit, there is no error display. The CR

motor life counter is reset in “Maintenance Mode 2.”

E***F Off 60 ~ 41% remaining

E**F Off 40 ~ 20% remaining

E*F Off 20% ~ Up to just before near end

nn% Blinking Near end up to just before ink end

0% Lights up Ink End

Note 1) When this counter becomes 0%, the LED lights up and the “Ink End” message is displayed

in the LCD.

Note 2)The ink consumption counter is reset when the ink cartridge is replaced.

o Printed Page Count

The total number of sheets printed is displayed by a decimal number with a

maximum of 6 digits.

o Cutter Life and Other (Motors, ink pad, heads, cleaning unit)

Product Description Control Panel 31

Page 32

EPSON Stylus Pro 9500 Revision A

CUTTER REPLACEMENT MENU

The following table includes the steps/messages that must be followed to

replace the cutter.

Each type of setting can be accomplished by operating the following panel

buttons.

o Cutter Replacement Menu Selection: See the panel setting menu

procedure.

o Cutter Replacement: “Paper Source” button

o Changing Setting Values: “+” or “–” button

o Setting the Set Values: “Enter” button

o Mode End: “Pause” button

Table 1-25. Cutter Replacement Messages

Display Mes sage Item Notes

CUT.REPLACE EXEC. Prepare a replacement cutter and

OPEN LOWER COVER - Open the front cover.

REPLACE CUTTER -

CLOSE LOWER COVER -

In this mode, if cutter replacement is carried out, the “Cutter Life” counter in the

print status menu is reset.

Remove the old cutter and install a

new one.

Close the front cover. The printer is

ready.

Product Description Control Panel 32

Page 33

EPSON Stylus Pro 9500 Revision A

GAP ADJUSTMENT MENU (BI-D ADJUSTMENT MENU)

Table 1-26. Gap Adjustment Menu

The paper thickness setting, Bi-D, gap (adjustment of the Bi-d deviation

between the left and right heads), and printing of the adjustment pattern as well

as adjustment are executed in the gap adjustment menu.

Each setting is made by operating the following panel buttons. If you select the

Gap Adjustment Menu, you cannot proceed to selection of the other items

without performing the “Paper Thickness” setting. After setting the paper

thickness (using the Set button), the menu automatically changes to the

adjustment mode.

o Gap Adjustment Menu Selection See the panel setting menu

procedure.

o Item Selection “Paper Source” button

o Changing or Selecting Setting Values “+” or “–” button.

Display Setting Value Contents

Specify the paper thickness used in the gap

PAPER

THICK

ADJUST.

PATT.

#1 1-7-15 Bi-D Adjustment (240 cps, Normal dot, Left)

#2 1-7-15 Bi-D Adjustment (240 cps, Normal dot, Right)

#3 1-7-15 Bi-D Adjustment (240 cps, Normal dot, Left)

Standard

or

0.0 ~ 1.6 mm

Print All

#1-#6

adjustment in 0.1 mm units. Ordinarily, the printer is

used with the “Standa rd” specificati on, and in th is case,

the paper thickness becomes as follows: Paper

Thickness Detect ion Sensor detection results = I f [ON /

Thin Paper] : 0.2 mmIf [OFF / Thick Paper] : 1.2 mm

Specifies the gap a dju stm en t pa ttern to be pri nte d. (All

patterns or the desired pattern.)

o Setting the Set Value “Enter” button

o Mode End “Pause” button

#4 1-7-15 Bi-D Adjustment (240 cps, Normal dot, Right)

#5 1-7-15 Gap Adjustment 1 (240 cps, Normal dot)

#6 1-7-15 Gap Adjustment 3 (333 cps, Normal dot)

Note 1) Values with underlines show default values.

Product Description Control Panel 33

Page 34

EPSON Stylus Pro 9500 Revision A

o

Setting Method

1.3.3 Maintenance Call

1) Set paper.

2) Enter the Gap Adjustment Menu by the panel.

3) If the paper thickness is set on 0.2 mm or 1.2 mm by the panel, it is

recognized as being the same as “Standard.” If you are setting other values,

input the paper thickness for the paper you are using in 0.1 mm units, in

accordance with the paper’s specifications. The purpose for inputting the

paper thickness at the first is to enable the printing of a pattern right from

the first that is thought to be close to the correction value that is already

being maintained by the printer, and thus to reduce the number of times the

operation has to be repeated.

4) Select an adjustment pattern to print (either all or individually) and print it.

After printing, the adjustment value input menu for that pattern will be

displayed in the LCD.

5) Input the pattern No. for the printed pattern that has the smallest deviation

in each adjustment item displayed in the LCD.

6) Repeat steps 4) ~ 5) until adjustment of all the items has been completed.

Note 1) If you are carrying out gap adjustment printing, printing paper with the

following lengths is necessary.

n When selecting and printing 1 pattern:Approx. 7 cm.

n When selecting and printing all printing patterns (6 patterns): Approx.

40 cm.

Some of the mechanical units used in this printer have counters which count

down the remaining service life based on the proper service life for each unit,

and when the predetermined value is reached, a “Maintenance Call nnnn”

message is displayed. If this message is displayed, it indicates that the end of

the service life of the affected unit is nearing, so it is necessary to replace the

affected unit as soon as possible.

If this message is displayed, the “Print?” or “Printing” display message is

replaced with the “Maintenance Call nnnn” message, and after replacing the

affected part, it is not cleared but continues to be displayed until the counter is

cleared in “Maintenance Mode 2.”

In the Stylus Pro 9500, when the remaining capacity of the waste ink pad is

less than 1% only, the following maintenance call is displayed in the LCD.

Even if the maintenance call is displayed, it is treated as a warning and it is

possible to continue printing.

Table 1-27. Maintenance Call / Code List

Error Code Error Content

0100

If use of the printer is continued while this maintenance call message is being

displayed, the remaining capacity of the waste ink pad will reach 0%, then a

Service Call error, 00000100, will be displayed.

• Waste ink pad service life (less than 1% of capacity remaining)

Note 2) Always, in printing of each pattern, 1 block of 15 patterns is printed 6

times. Pattern No. 8 of the 15 patterns in one block shows the current

setting value.

Product Description Control Panel 34

Page 35

EPSON Stylus Pro 9500 Revision A

1.3.4 Service Errors

When “Service Req nnnnnnnn” appears on the LCD display, a fatal error

requiring a service technician has occurred. The nnnnnnnn indicates what

needs to be fixed to return the printer to a working state.

Table 1-28. Maintenance Call / Error Code List

Error Code Error Content

Waste ink pad service life Note 1)

00000100

00000101

00010000

00010001

00010002

00010003

00010004

00010005

00010006

00010007

00010008

00010009

0001000A

0001000B

0001000C

0001000E

0001000F

(Replacement of the specified part and clearing of the counter are

necessary.)

Ink supply tube w ear Note 2)(This is equivalent to us in g the printer

beyond the product’s service life, so an error is displayed in

considerat ion of damage due to ink supply tube wear . Therefore,

when this error occurs, the status of the ink supply tubes should be

checked.)

PF Motor/ encoder check error.

PF Motor / Motor out of synch.

PF Motor / Overcurrent

PF Motor / In Position Time Out

CR Motor / Encoder check error

CR Motor / Motor out of synch.

CR Motor / Overcurrent

CR Motor / In Position Time Out

Servo interrupt WDT time out error

System interrupt WDT time out error

CR home position sensor failure

PF home position sensor failure

Head slide (SLID) home position sensor failure

Cover sensor failure (01)

CR Motor / PWM output abnormal

Table 1-28. Maintenance Call / Error Code List

Error Code Error Content

00020000

00020001

00020002

00020003

00020004

00020005

00020006

00020007

00020008

00020009

0002000A

0002000B

0002000C

10000004

10000006

10000009

1000000A

1000000B

Note 1) The following parts should be replaced and the relevant service life

counter cleared in “Maintenance Mode 2.”

[Replacement Parts]: “Maintenance Kit Stylus Pro 9500 (Part Code

Counter Clear: (Clear the counters in “Maintenance Mode 2”

“Waste Ink” Initialization

“Cleaning” Initialization

NVRAM error

NVRAM SUM Error

00020002

SRAM Check Error

DRAM Check Error

Vector Registration Error

CGRAM Error

Operation Code Error

DMA Error

Flash Memory SUM Error

CPU ROM Error

Insufficient Internal Memory Error

Review Error

CPU Vector 4 / General improper command issued.

CPU Vector 6 / Slot improper command

CPU Vector 9 / CPU address error

CPU Vector 10 / DMAC / DTC address error

CPU Vector 11 / WDT time out error

1058463)”

(Next page).)

000100010

PF Motor / PWM output abnormal

Product Description Control Panel 35

Page 36

EPSON Stylus Pro 9500 Revision A

Note 2) When this error occurs, check the condition of the ink supply tubes.

Even if there is no problem, it should be recommended to the user

that the parts comprising the CR System periodic replacement parts

kit, which is scheduled for introduction be replaced. If the printer is to

be used until CR system periodic replacement parts kit parts are

replaced, carry out “CR Motor Initialization” in “Maintenance Mode 2”

and cancel the error.

Product Description Control Panel 36

Page 37

EPSON Stylus Pro 9500 Revision A

1.3.5 Service Related Printer Settings

When the printer is not functioning properly, there are three modes that help

you detect what is wrong and can help you fix the problem. These modes are

“Maintenance Mode”, “Maintenance Mode 2”, and “Self-Diagnostic Mode”. To

enter a mode, press and hold down the appropriate button (described below)

while turning on the printer.

CAUTION

The following explanations regarding control panel service

functions and for service and support purposes only, none

of this information is to be shared with the end user.

MAINTENANCE MODE

Start Button: Turn the Power switch On while pressing the

o

“Pause” button.

o Setting Item Selection: “Paper Source” Button

o Changing Setting Values: “Setting Value +” or “Setting Value –” Button

o Setting the Set Values: “Enter” Button

o Setting End: Power ON/OFF

o Power-on button: Pause

Message Item Explanation

This prints out print data transferred

to the printer in hexadecimal form. 16

data items per line are displayed and

in addition, an ASCII character

corresponding to those data is

printed on the right side. If there are

HEX DUMP PRINT

no characters, such as print or control

codes, which correspond to the data,

a “.” (period) is printed. The panel

settings cannot be set while the

printer is in this mode. To end this

function, first stop printing by

operating the Pause button, then turn

the power switch off.

ENGLISH

The language displayed in the LCD

screen can be select English, French,

Italian, German, Spanish,

Portuguese.

LANGUAGE

FRENCH

ITALIAN

GERMAN

SPANISH

PORTUGUE

This selects M/W operation in the 720

x 720 dpi mode. A is the operating

MW7

A

B

mode that reduces banding in Bi-D

printing. B is the Stylus Pro 9000 /

7000 720 dpi x 720 dpi

interchangeable operating mode.

Note 1): Settings with underlines in the table show default values.

Product Description Control Panel 37

Page 38

EPSON Stylus Pro 9500 Revision A

Note 2): During HEX dump execution, the message “HEX MODE” is

displayed.

Note 3): If you are using the Stylus Pro 7000 to print in the single color mode

at 720 x 720 dpi, if banding is prominent, selecting this mode may

possibly reduce banding.

MAINTENANCE MODE 2

Start Button:Turn the Power switch On while pressing the following panel

o

buttons to start.

n “Paper Source Button” + “Cut / Eject Button” + “Paper Feed –

Button”

o Setting Item Selection:“Paper Source” Button

o Changing Setting Values:“Setting Value +” or “Setting Value –” Button

o Setting the Set Values:“Enter” Button

o Setting End:Power ON/OFF

This mode can be roughly divided into the following 3 items.

Table 1-29. Maintenance Mode 2 Setting Items

Item Panel Display

Counter Display Menu VIEW COUNTERS MENU

Counter Initialization Menu CLEAR COUNTERS MENU

Adjustment, Setting Menu SERVICE CONFIG MENU

For each major item, see the following page.

o Counter Display Menu

The items displayed in the Maintenance Mode 2 “Counter Display Menu” are

shown below.

Table 1-30. Counter Display Menu

Item Panel Display Setting Value

Remaining Ink (K) counter

Value Display

Remaining Ink (C) counter

Value Display

Remaining Ink (M) counter

Value Display

Remaining Ink (LC) c ounter

Value Display

INK K 0~4294967295 (Decimal number)

INK C 0~4294967295 (Decimal number)

INK M 0~4294967295 (Decimal number)

INK LC 0~4294967295 (Decimal number)

Product Description Control Panel 38

Page 39

EPSON Stylus Pro 9500 Revision A

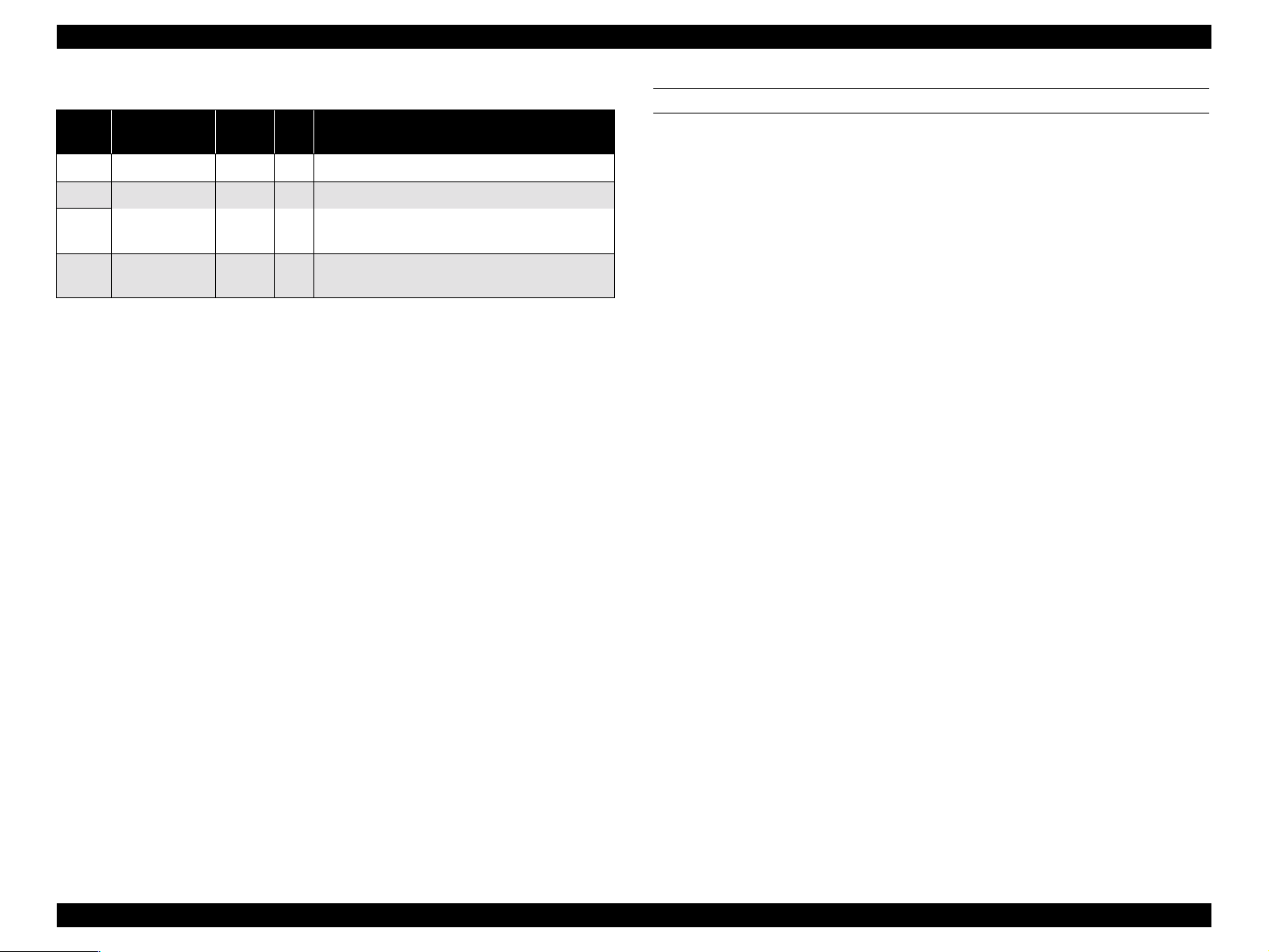

o

Table 1-30. Counter Display Menu

Counter Initialization Menu

Item Panel Display Setting Value

Remaining Ink (LM) cou nter

Value Display

Remaining Ink (Y) counter

Value Display

Cutter Life Counter Value

Display

Total Printed Sheet Counter

Value Display

Waste Ink Counter A Val ue

Display

Waste Ink Counter B Val ue

Display

CR Motor Service Life

Counter Value Display

PF Motor Service Life

Counter Value Display

Head Unit (K) Service Life

Counter Value Display

Head Unit (C) Service Life

Counter Value Display

Head Unit (M) Service Life

Counter Value Display

INK LM 0~4294967295 (Decimal number)

INK Y 0~4294 967295 (Dec imal number)

CUTTER 0~4294967295 (Decimal number)

TTL PAGES 0~4294967295 (Decim al number)

WAST INKA 0~4294967295 (D ecimal number)

WAST INK B 0~4294967295 (Decimal number)

CR MOTOR 0~4294967295 (Decimal number)

PF MOTOR 0~4294967295 (Decimal number)

HEAD K 0 ~4294967295 (Decimal number)

HEAD C 0~4294967295 (Decimal number)

HEAD M 0~4294967295 (Decimal num ber)

The items that can be initialized in the “Counter Initialization Menu” in

Maintenance Mode 2 are shown below.

Table 1-31. Counter Initialization Menu

Item Panel Display Setting Value

Initializes NVRAM / Ink System /

Mechanism Counters.

Initializes NVRAM contents (Panel

setting information, Bi-D and Cap

Adjustment parameters).