Page 1

Accelerometer for RS-422-Interface

M-A550AR2x

Data Sheet

(P/N: E91E60814x)

Rev.20160704

Page 2

NOTICE

No part of this material may be reproduced or duplicated in any form or by any means without the

written permission of Seiko Epson. Seiko Epson reserves the right to make changes to this material

without notice. Seiko Epson does not assume any liability of any kind arising out of any inaccuracies

contained in this material or due to its application or use in any product or circuit and, further, there is no

representation that this material is applicable to products requiring high level reliability, such as, medical

products. Moreover, no license to any intellectual property rights is granted by implication or otherwise,

and there is no representation or warranty that anything made in accordance with this material will be

free from any patent or copyright infringement of a third party. When exporting the products or

technology described in this material, you should comply with the applicable export control laws and

regulations and follow the procedures required by such laws and regulations. You are requested not to

use, to resell, to export and/or to otherwise dispose of the products (and any technical information

furnished, if any) for the development and/or manufacture of weapon of mass destruction or for other

military purposes.

All brands or product names mentioned herein are trademarks and/or registered trademarks of their

respective companies.

©SEIKO EPSON CORPORATION 2016, All rights reserved.

Page 3

Table of Contents

1. GENERAL DESCRIPTION .......................................................................................... 3

1.1. FEATURES ................................................................................................................................ 3

1.2. BLOCK DIAGRAM .................................................................................................................... 4

2. SPECIFICATIONS ....................................................................................................... 5

2.1. ABSOLUTE MAXIMUM RATINGS ............................................................................................ 5

2.2. RECOMMENDED OPERATING CONDITION ........................................................................... 5

2.3. PERFORMANCE & ELECTRICAL SPECIFICATIONS ............................................................. 6

3. MECHANICAL DIMENSIONS ..................................................................................... 9

3.1. OUTLINE DIMENSIONS ........................................................................................................... 9

3.2. CONNECTOR SPECIFICATIONS ........................................................................................... 10

4. TYPICAL PERFORMANCE CHARACTERISTICS..................................................... 11

5. CONNECTION EXAMPLE ......................................................................................... 12

5.1. CONNECTION TO HOST ........................................................................................................ 12

5.2. PRECAUTION FOR WIRING AND CABLING ........................................................................ 12

5.3. PRECAUTION FOR SUPPLYING POWER ............................................................................. 12

6. BASIC OPERATION .................................................................................................. 14

6.1. OPERATION MODE ................................................................................................................ 14

6.1.1. ST ATE TRANSITION .............................................................................................................. 14

6.1.2. INITIALIZATION INDICATION FUNCTION ........................................................................ 15

6.1.3. BIAS CORRECTION FUNCTION .......................................................................................... 15

6.1.4. OUTPUT UNIT SELECT FUNCTION .................................................................................... 15

6.1.5. OPERATION MODE DESCRIPTION ..................................................................................... 15

6.2. INTERNAL FILTER ................................................................................................................. 16

7. HOST INTERFACE .................................................................................................... 20

7.1. SERIAL INTERFACE SPECIFICATION ............................................................................... 20

7.1.1. COMUNICATION CONDITION ............................................................................................. 20

7.1.2. COMMAND SEQUENCE ........................................................................................................ 20

7.1.3. COMMAND DESCRIPTION ................................................................................................... 21

7.1.4. COMMAND FORMAT ............................................................................................................. 32

8. SAMPLE PROGRAM FLOW ..................................................................................... 36

8.1. RS422 FLOW .......................................................................................................................... 36

9. HANDLING NOTES ................................................................................................... 38

9.1. CAUTIONS FOR ATTACHING ................................................................................................ 38

9.2. OTHER CAUTIONS ................................................................................................................ 38

9.3. LIMITED WARRANTY ............................................................................................................. 39

10. PART NUMBER / ORDERING INFO. ........................................................................ 40

11. PACKING DIMENSIONS ........................................................................................... 41

11.1. PACKING MATERIAL SIZE .................................................................................................... 41

11.2. INNER BOX DESCRIPTION ................................................................................................... 41

11.3. OUTER BOX DESCRIPTION .................................................................................................. 42

M-A550AR2 Seiko Epson Corporation i

Rev.20160704

Page 4

11.4. PACKING LABEL .................................................................................................................... 42

11.5. STORAGE ENVIRONMENT .................................................................................................... 43

12. ST ANDARDS AND APPROVALS ............................................................................. 44

12.1. NOTICE ................................................................................................................................... 44

12.2. CE MARKING .......................................................................................................................... 44

12.3. RoHS & WEEE ........................................................................................................................ 44

12.4. FCC COMPLIANCE STATEMENT FOR AMERICAN USERS ................................................ 44

12.5. INDUSTRY ICES COMPLIANCE STATEMENT FOR CANADIAN USERS ............................ 45

13. REVISION HISTORY ................................................................................................. 46

ii Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 5

1. GENERAL DESCRIPTION

The M-A550AR2x is high accuracy and high stability 3 axis accelerometer. This sensor unit is based on

Quartz technology (QMEMS) for high accuracy, high stability, small size, and low power consumption.

This sensor unit enables wide dynamic range acceleration and vibration sensing. Acceleration, tilt angle

and tilt angular velocity is available as user selectable output measurement options. This sensor unit

uses the latest technology to improve performance and offer wider sensing bandwidth. With RS422

interface supported for host communication, the M-A550AR2x reduces technical barriers for users to

incorporate seismic and vibration sensing, and minimizes design resources to implement control and

monitoring applications. This unit is packaged in a water-proof and dust-proof metallic case making it

suitable for use in industrial and heavy duty applications.

The features of the sensor unit such as high stability, high precision, and small size make it easy to

create and differentiate applications in various fields of industrial systems.

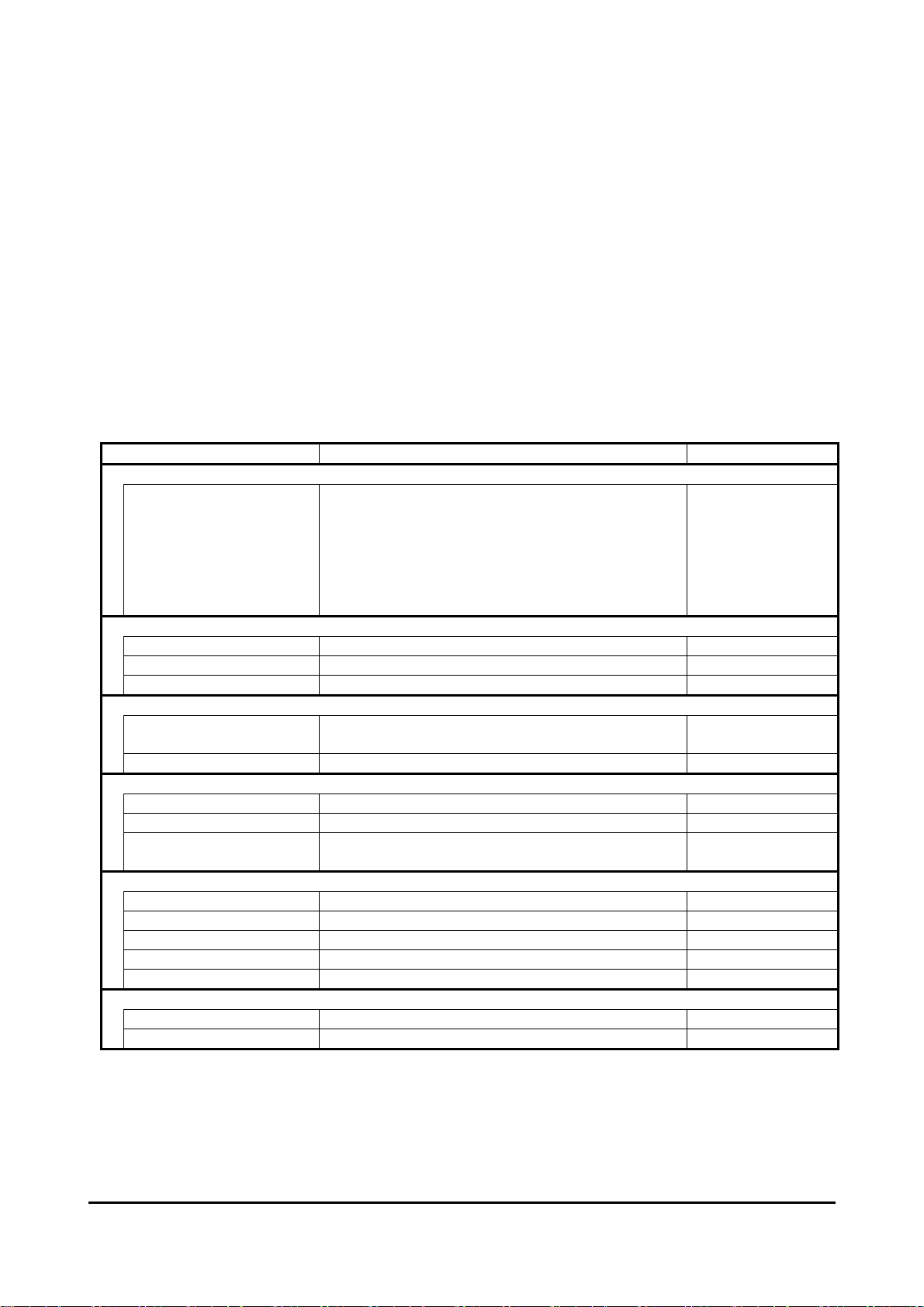

1.1. FEATURES

Item Specification Note

Sensor

Integrated sensor Model : M-A550AR2x

Resolution 0.06uG

Bandwidth 0-50Hz

Detection range ±5G

(Accuracy range ±1G)

Interface

Protocol (DL layer) RS-422 (TX/RX Pair, Full-Duplex transmission)

Bit rate Maximum 460.8kbps (programmable) 460.8kbps(default)

Cable Length 250m (max)

Others

Trigger function Internal timer event trigger function External trigger

Terminator Included (100Ωtyp)

General specification

Voltage supply 9 ~ 30V

Power consumption 15mA typ. (Vin=12V)

Operating temperature

-20 ~ +70°C

range

External dimension

Outer packaging Overall metallic shield case

Size 52×52×26 mm (Not including projection)

Weight 81g

Interface connecter M12, 8pin-male, water-proof

Water-proof, Dust-proof IP67

Regulation

EU CE marking (EN61326、RoHS Directive) ClassA

FCC FCCpart15B ClassA

not available

M-A550AR2 Seiko Epson Corporation 3

Rev.20160704

Page 6

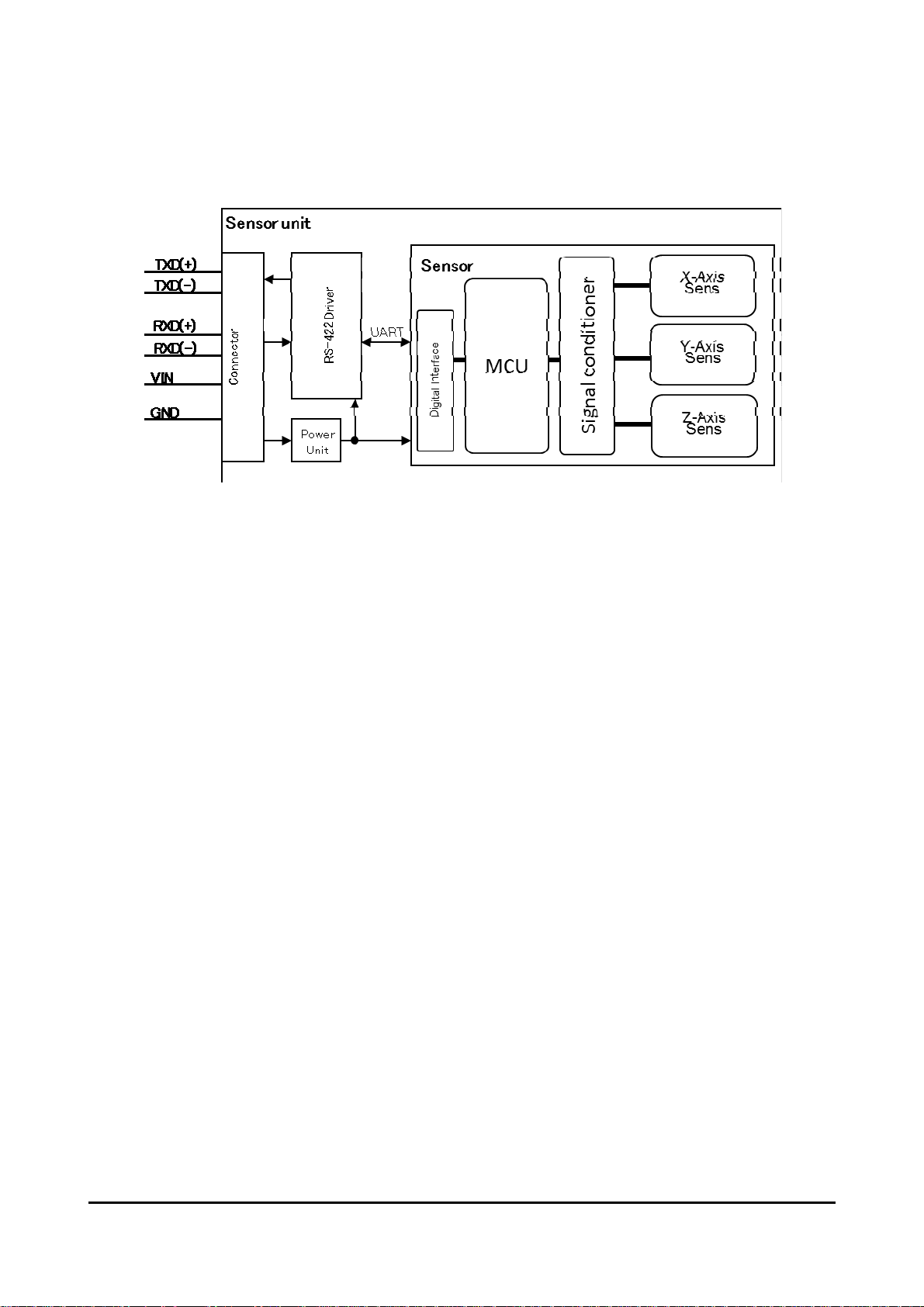

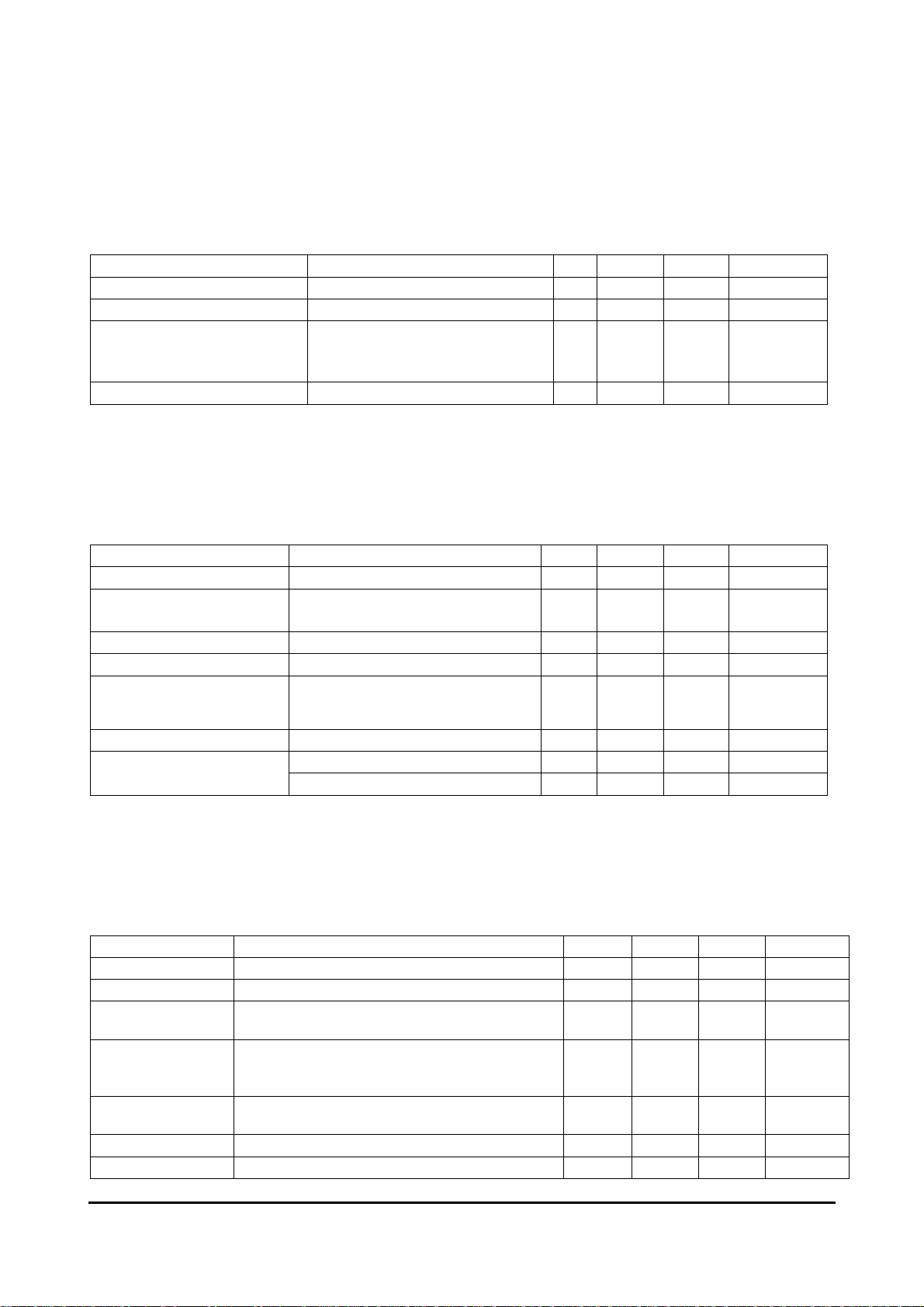

1.2. BLOCK DIAGRAM

Figure 1-1 Block Diagram

4 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 7

r

*

1

2. SPECIFICATIONS

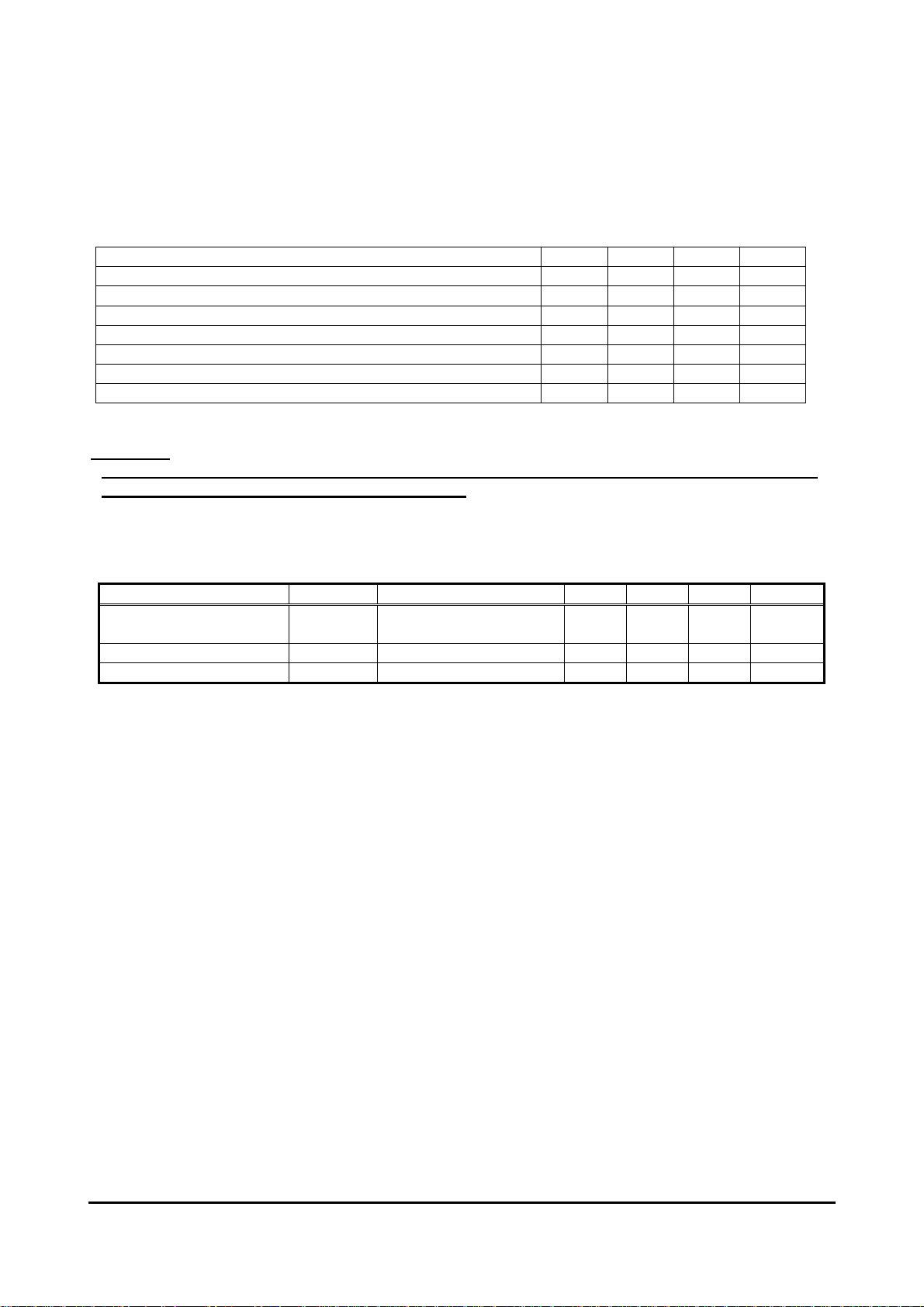

2.1. ABSOLUTE MAXIMUM RATINGS

Table 2-1 Absolute Maximum Ratings

Parameter Min Typ Max Unit

VIN to GND −0.3 +32 V

Voltage on any pin to GND −7 +12 V

Storage temperature range −20 85 °C

Operating temperature range -20 70 °C

Operating humidity (no condensation) 90 %R.H.

Storage humidity (no condensation) 90 %R.H.

Acceleration / Shock (Half-sine 0.5msec) *1 300 G

If the unit is operated beyond the absolute maximum rating, malfunction may occur or the unit may fail

completely. Although the unit may appear to operate normally, reliability may decrease.

CAUTION:

*1

Excessive vibration or shock independent of the above listed conditions may increase the

possibility of malfunction or causing a failure!

2.2. RECOMMENDED OPERATING CONDITION

Table 2-2 Recommended Operating Conditions

Paramete

Power supply voltage VIN VIN to GND *2 9

Port input voltage V

Operating temperature T

*1

When power supply voltage is 9V or less, the master may not be able to communicate with a node

normally even if the LED turns on.

*2

The power supply voltage must reach the recommended operating condition within 2 seconds after

power is applied to a node.

Term Condition Min. Typ Max. Unit

12 24 V

RD+/RD- to GND 3.3 V

PORT

-20 - 70 °C

OPE

M-A550AR2 Seiko Epson Corporation 5

Rev.20160704

Page 8

2.3. PERFORMANCE & ELECTRICAL SPECIFICATIONS

Table 2-3 Sensor Specifications (Common Items)

VIN=12V, ±1G unless otherwise noted

Parameter Test Conditions / Comments Min Typ Max Unit

Data output rate *1 500 sps

Frequency range TA=25°C, -3dB down 50 Hz

Misalignment from

mechanical reference

Temperature resolution *2

*1

The data output rate can be changed by user command.

*2

The temperature output is a reference value used for the internal temperature correction, an

-0.5 +0.5 deg

0.001 °C/LSB

d is not guaranteed to accurately output the interior temperature.

Table 2-4 Sensor Specifications (Acceleration)

VIN=12V, ±1G unless otherwise noted

Parameter Test Conditions / Comments Min Typ Max Unit

Detection range *1

Input range *2

Reduced accuracy operating

Accuracy guaranteed by

specification

-5 +5 G

-1 +1 G

Resolution +/-0.06 uG/LSB

Data temperature

Misalignment between

axes

-20~70°C

-4 4 mG

TA=25°C -0.1 +0.1 deg.

Nonlinearity TA=25°C, ±1G -0.03 +0.03 %

Noise density

*1

The range from above ±1G to ±5G is outside the guaranteed accuracy specification.

*2

The calibrated standard 1G gravitational acceleration value is 9.80665 m/s

TA=25°C, average 0.5Hz to 6Hz 0.5 2 uGrms/√Hz

TA=25°C, peak 0.5Hz to 100Hz 60 uGrms/√Hz

2

.

Table 2-5 Sensor Specification (Tilt Angle)

VIN=12V, ±45deg unless otherwise noted

Parameter Condition / Comment Min Typ Max Unit

Input Range *1 Reduced accuracy operating range -1.047 +1.047 rad

Input Range *2 Accuracy guaranteed by specification -0.785 +0.785 rad

Null Offset

Repeatability

Null Offset

TA=25°C and VCC=3.3V for one year after

±3.491 mrad

shipment

-20°C to +85°C -4.014 +4.014 mrad

Temperature

Variation

Axis Alignment

TA=25°C -1.745 +1.745 mrad

Error

Non-Linearity TA=25°C,±45deg. -0.03 +0.03 %

Noise Density TA=25°C, average 0.5Hz to 6Hz, horizontal 0.5 2 µrad/√Hz

6 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 9

p

p

Parameter Condition / Comment Min Typ Max Unit

Resolution 0.002 µrad/LSB

NOTE: The Max/Min value is the maximum/minimum value of the design or factory shipment

examination, unless otherwise specified.

*1

The range between ± 45deg to ± 60deg is outside the guaranteed accuracy specifications.

*2

The calibrated standard 1G gravitational acceleration value is 9.80665 m/s2.

The tilt angle is internally calculated from gravitational acceleration by the following expression.

Tilt Angle Calculation Formula

][ asin(G) rad

Table 2-6 Sensor Specification (Tilt Angle Speed)

Condition: T

=-20°C ~ +85°C, VCC=3.15V to 3.45V, and ±45deg, unless otherwise specified.

A

Parameter Condition/Comment Min Typ Max Unit

Calculation

Range

Unitpermillisecondofmeasurementtrigger ‐2.094 +2.094 rad/ms

Unitpersecondofmeasurementtrigger ‐2.094 +2.094 rad/s

Resolution Unitpermilli‐secondofmeasurementtrigger 2 (µrad/s)/LSB

Unitpersecondofmeasurementtrigger 0.002 (µrad/s)/LSB

NOTE: The Max/Min value is the maximum/minimum value of the design or factory shipment

examination, unless otherwise specified.

The tilt angle speed is a change of the tilt angle per unit time between the measurement intervals.

The tilt angle is internally calculated by the following expression.

Tilt Angle Speed Formula

)(

01

: Present tilt angle

1

: Tilt angle measured in previous sample

0

OutputRate_ms: Value of measurement interval by internal timer when command was set. Unit [ms] of measurement trigger.

OutputRate_s: Value of measurement interval by internal timer when command was set. Unit [s] of measurement trigger.

)(

01

1

_

msOutputRate

1

_

sOutputRate

]/[

msrad

]/[

srad

SENSOR

Accelerometer

SENSOR

Temperature

Sampling

Internal Clock

4k Sps/ch

Sampling

Internal Clock

1k Sps

FIR Filter

Moving

Average Filter

128ta

External trg.

Down

Sampling

Out

ut rate

Convert into

Temperature

Temperature

Correction

Alignment

Correction

Format

Conversion

RS422(UART)

Figure 2-1 Functional Block Diagram

Table 2-7 Interface Specification

M-A550AR2 Seiko Epson Corporation 7

Rev.20160704

Page 10

*2

TA=25°C, VIN=12V, unless otherwise noted

Parameter Test Conditions Min Typ Max Unit

Driver

Differential Output

Voltage

Common Mode Output

Voltage

Driver Short-Circuit

Current

Rise or Fall Time RL=100Ω 400 ns

Receiver

Input Resistance 100 Ω

Receiver Differential Input

Threshold Voltage

Receiver Input Hysteresis RD- =0V 25 mV

FUNCTIONAL TIMES Time until data is available

Power-On Start-Up Time

*1

Re-Initialization Time Reboot by a command*1 0.7 s

Measurement Wait Time

Command Response Time

*1

The device must not be accessed during initializing.

*2

The device should not be triggered to measure until the elapsed time immediately after the start of measurement.

*3

The measurement interval by the request command must be 500Sps or less.

*4

The timeout period from the last character reception to the “LF" reception. Following a timeout condition, the device issues an

error code response of “#".

RL=100Ω,TD- to TD+ 2 3.3 V

RL=OPEN, TD- to TD+ 3.3 V

RL=100Ω 3 V

-7V=<TD*=<12V -250 300 mA

-7V < RD- < 12V -0.2 0.2 V

*1

Include Initialization

1) REQDAT command Response

2) TSTSLF command Response

3) Command reception timeout

Response except for 1),2),3)

2.0 s

220

*3

1.3 ms

600 ms

*4

520 ms

4 ms

Table 2-8 Current Consumption

Ta=25°C,RL=100

Ω,unless otherwise specified; all voltages are defined with respect to ground; positive

currents flow into the sensor unit.;

Parameter Term Condition Min. Typ Max. Unit

Idle state I

Vin=12V - 10 - mA

IN(ready)

Vin=24V - 5 - mA

Continuous

measurement

mode

Maximum input

Vin=12V - 16 - mA

I

IN(op)

Vin=24V - 10 - mA

I

- - 60 mA

IN(max)

current

8 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 11

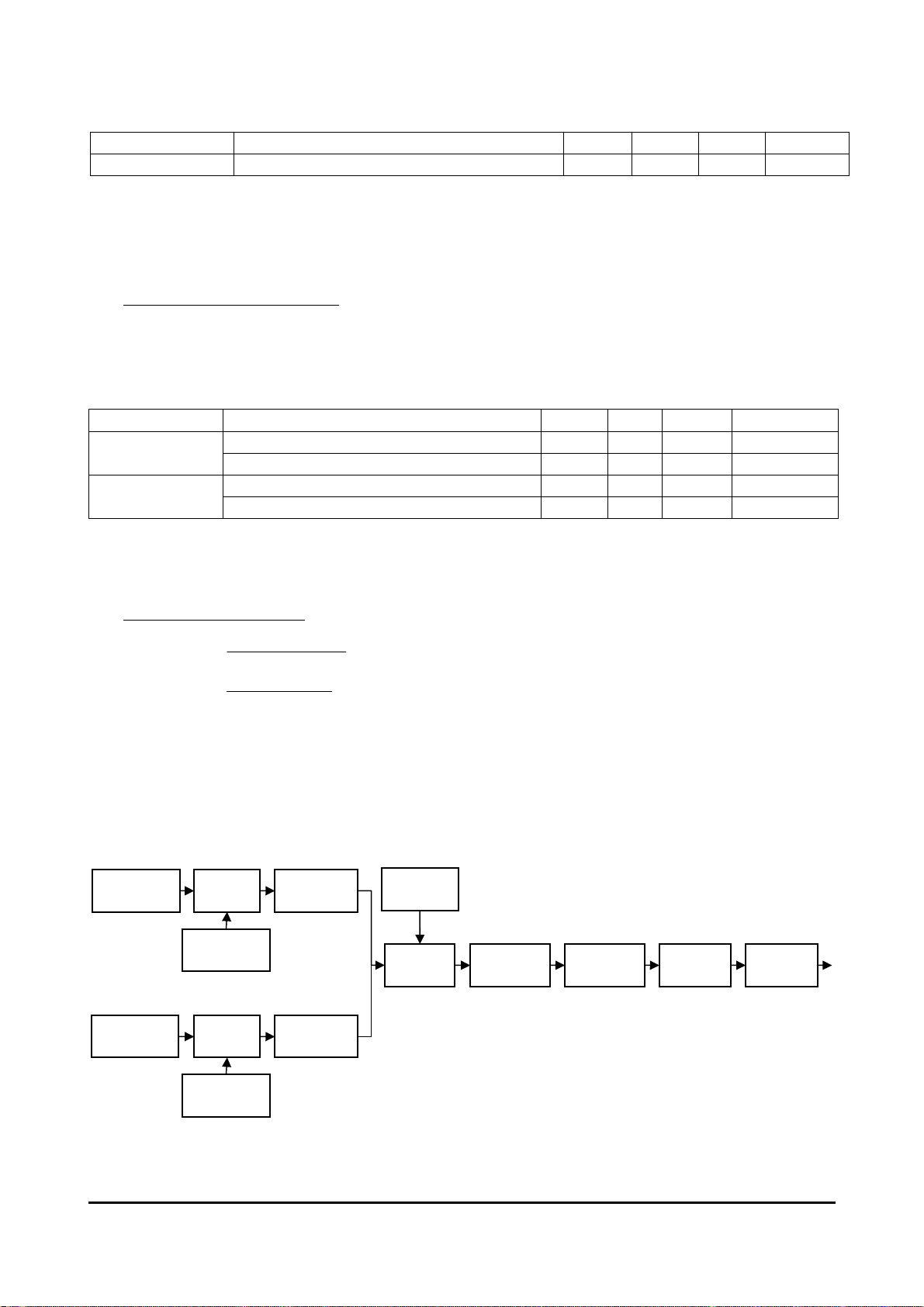

3. MECHANICAL DIMENSIONS

3.1. OUTLINE DIMENSIONS

9(max)

Referen ce Pla n e

4.2

Seria l No .

Figure 3-1 Outline Dimensions (millimeters)

4-M4

Figure 3-2 Recommended Mounting Dimension

M-A550AR2 Seiko Epson Corporation 9

Rev.20160704

Page 12

3.2. CONNECTOR SPECIFICATIONS

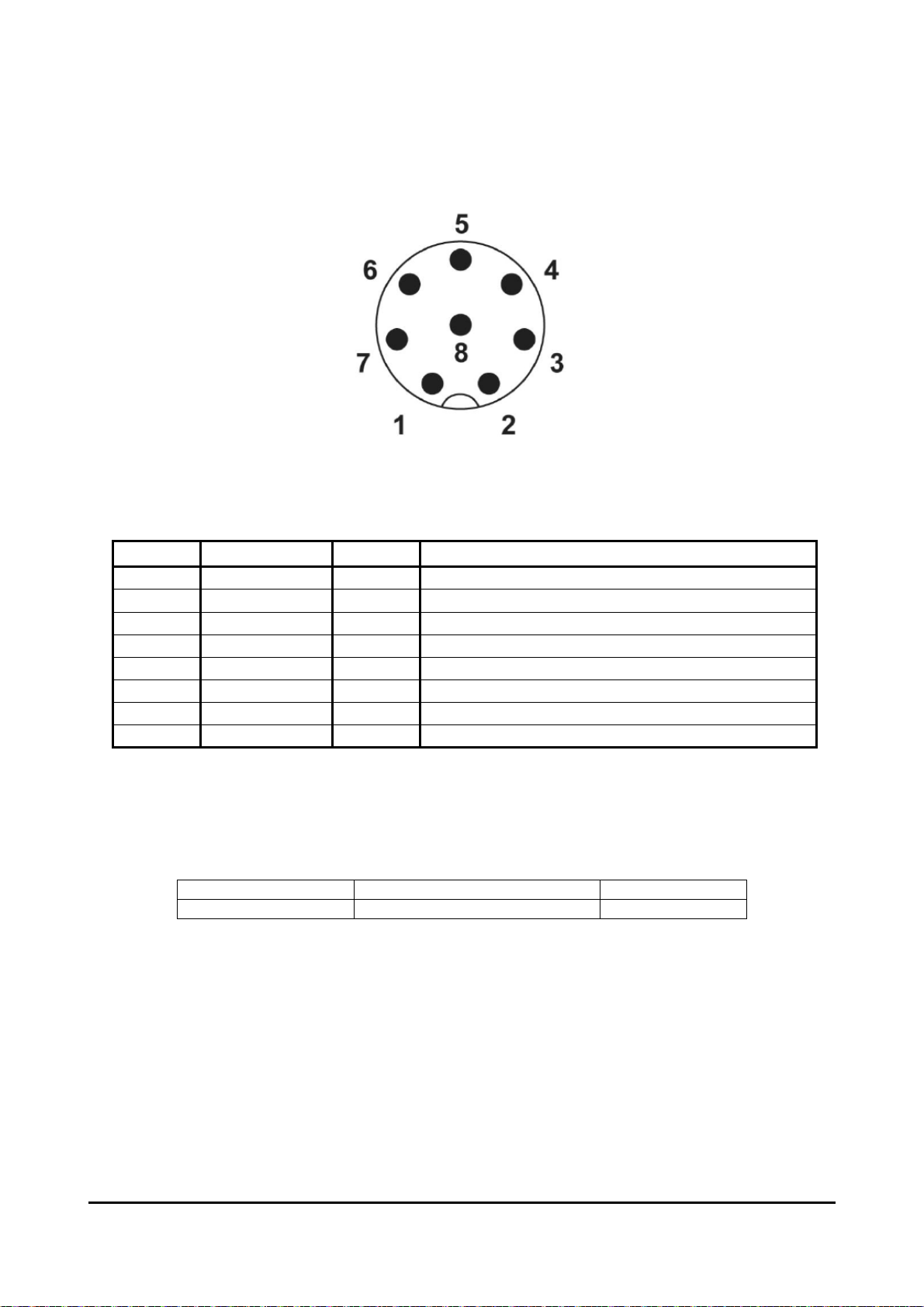

Figure 3-3 Connector Pin Terminal

Table 3-1 Pin Function Description

Pin No. Mnemonic Type*1 Description

1 NC N/A Do Not Connect

2 VIN S Power Supply (9-30V)

3 GND S 0V

4 TD- O Transmit Data (-)

5 RD+ I Received Data (+)

6 TD+ O Transmit Data (+)

7 NC N/A Do Not Connect

8 RD- I Received Data (-)

*1) Pin Type I :Input, O :Output, I/O :Input/Output, S :Supply, N/A :Not Applicable

Note: Please use an M12-8 pin mating female connector that corresponds to IP67 specifications.

Table 3-2 describes the connector manufacturer and the model number which is used in this

product.

Table 3-2 Conector Part Number

Manufacturer Part Number RoHS Compliant

PHOENIX CONTACT SACC-DSI-MS-8CON-M12-SCO SH

Yes

10 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 13

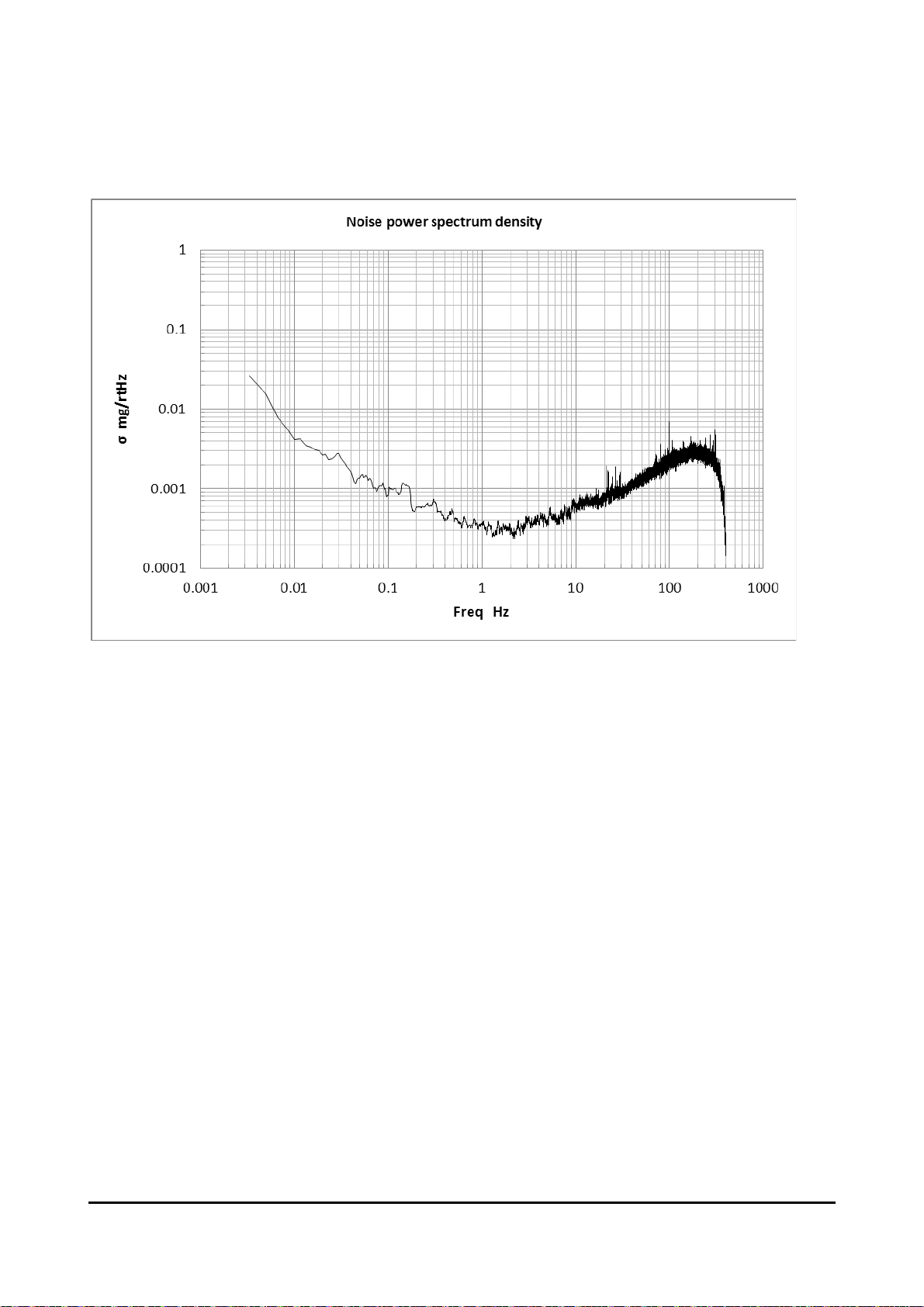

4. TYPICAL PERFORMANCE CHARACTERISTICS

Figure 4-1 Noise Density Characteristics

The above graph is a typical example of the product characteristics, and is not guaranteed by the

specification.

M-A550AR2 Seiko Epson Corporation 11

Rev.20160704

Page 14

5. CONNECTION EXAMPLE

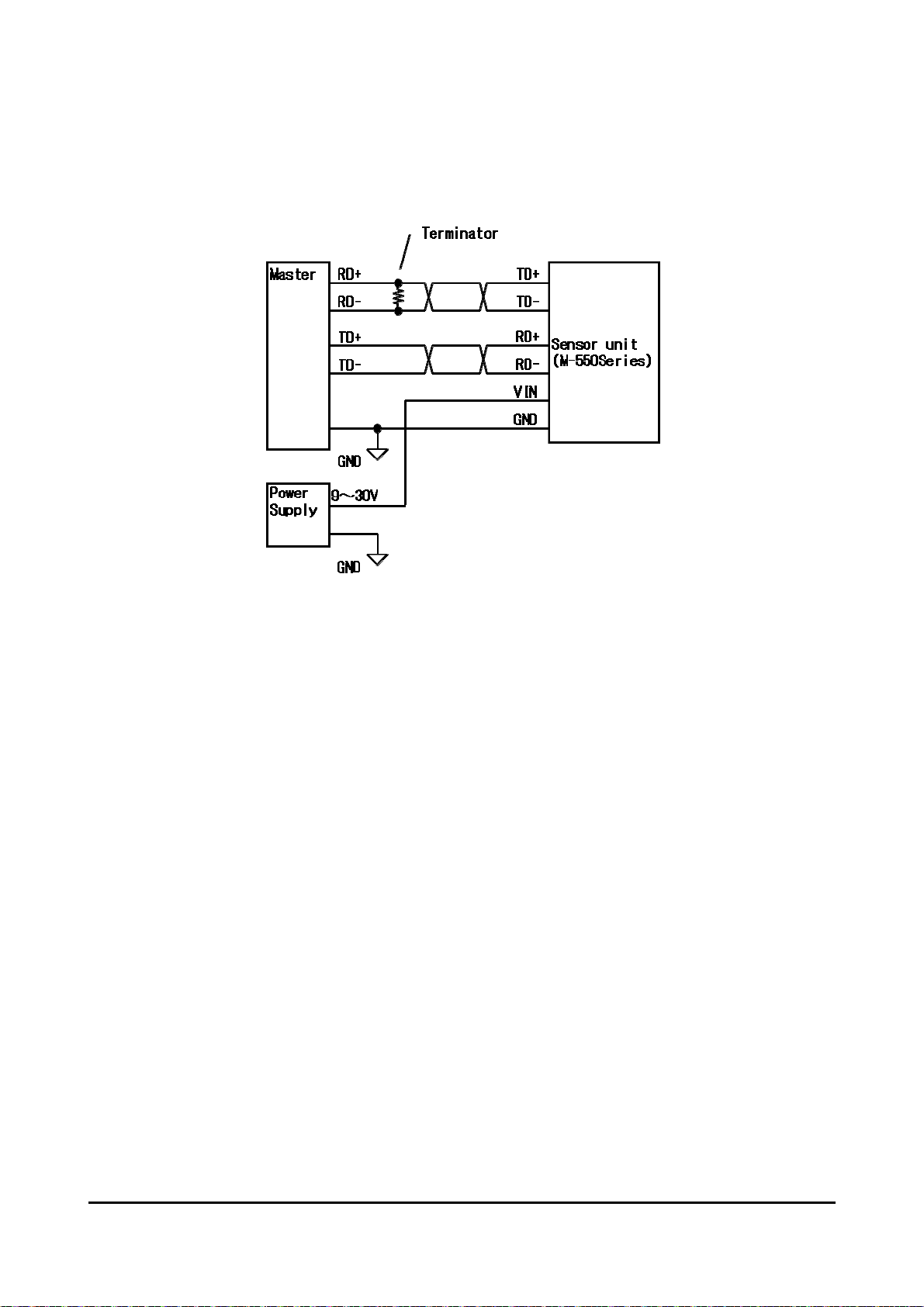

5.1. CONNECTION TO HOST

Figure 5-1 Connection Example

5.2. PRECAUTION FOR WIRING AND CABLING

・ This product has internal terminator on the receiver port (RD).

・ It is recommended that twisted pair cable with shielding should be used. Each signal pair should

be connected to each cable pair. (ex: RD+ and RD-)

・ It is recommended that shield connects to ground (at the host) when a cable with shield is used.

・ Maximum recommended cable length is 250 meters as a guideline. However, even if the cable

length is within the guidelines, the communication may be unstable or unusable depending on

system environment. The cabling should be evaluated in the target system environment to

confirm proper operation. (Ref: TIA-EIA-422-B ANNEX A)

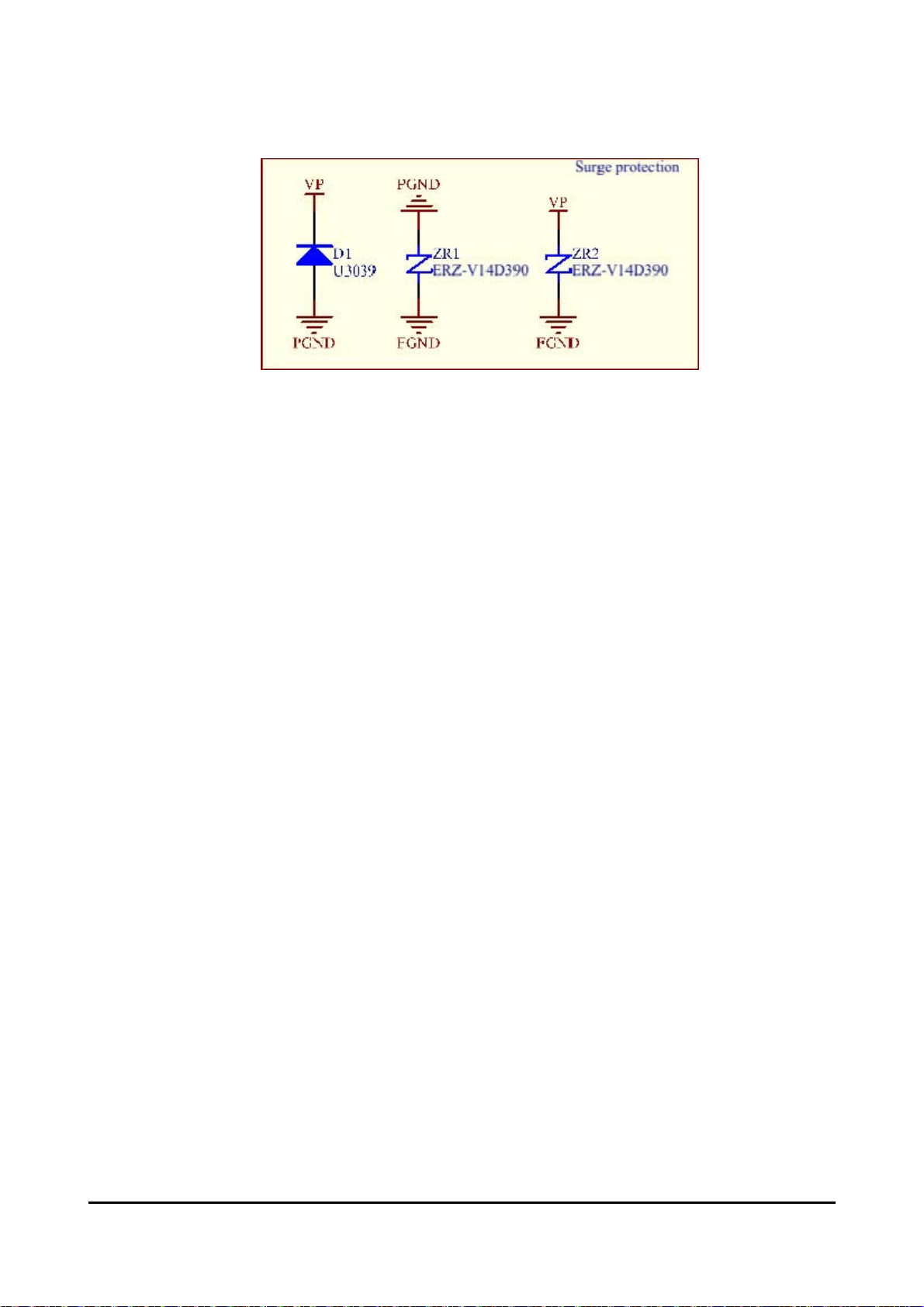

5.3. PRECAUTION FOR SUPPLYING POWER

・ The user should be aware of serious risks on the power supply exposure to the following:

High voltage noise by increased resistance and inductance on power supply line.

Surge voltage from lightning and environmental equipment.

・ Figure 5-2 describes reference protection circuit against the lightning surge with a surge level

based on IEC61000-4-5, +/-1kV(power supply line to the power supply ground) and

+/-2kV(power supply line to the earth).

VP: CAN_V+ (Power supply)

PGND: CAN_GND (Power supply ground)

FGND: EARTH (System ground earth)

U3039: Surge absorber to line (Okaya Electric Industries)

ERZ-V14D390: Surge absorber to ground (Panasonic)

12 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 15

Figure 5-2 Surge Protection Circuit

M-A550AR2 Seiko Epson Corporation 13

Rev.20160704

Page 16

(

(

(

N

(

6. BASIC OPERATION

6.1. OPERATION MODE

The following operational modes are available in the device.

IDLE mode

CONFIG mode

MEASUREMENT mode

The transitioning between these modes are controlled by AT commands in the RS422(UART)

interface. Please refer to Chapter 6 for details of the interface.

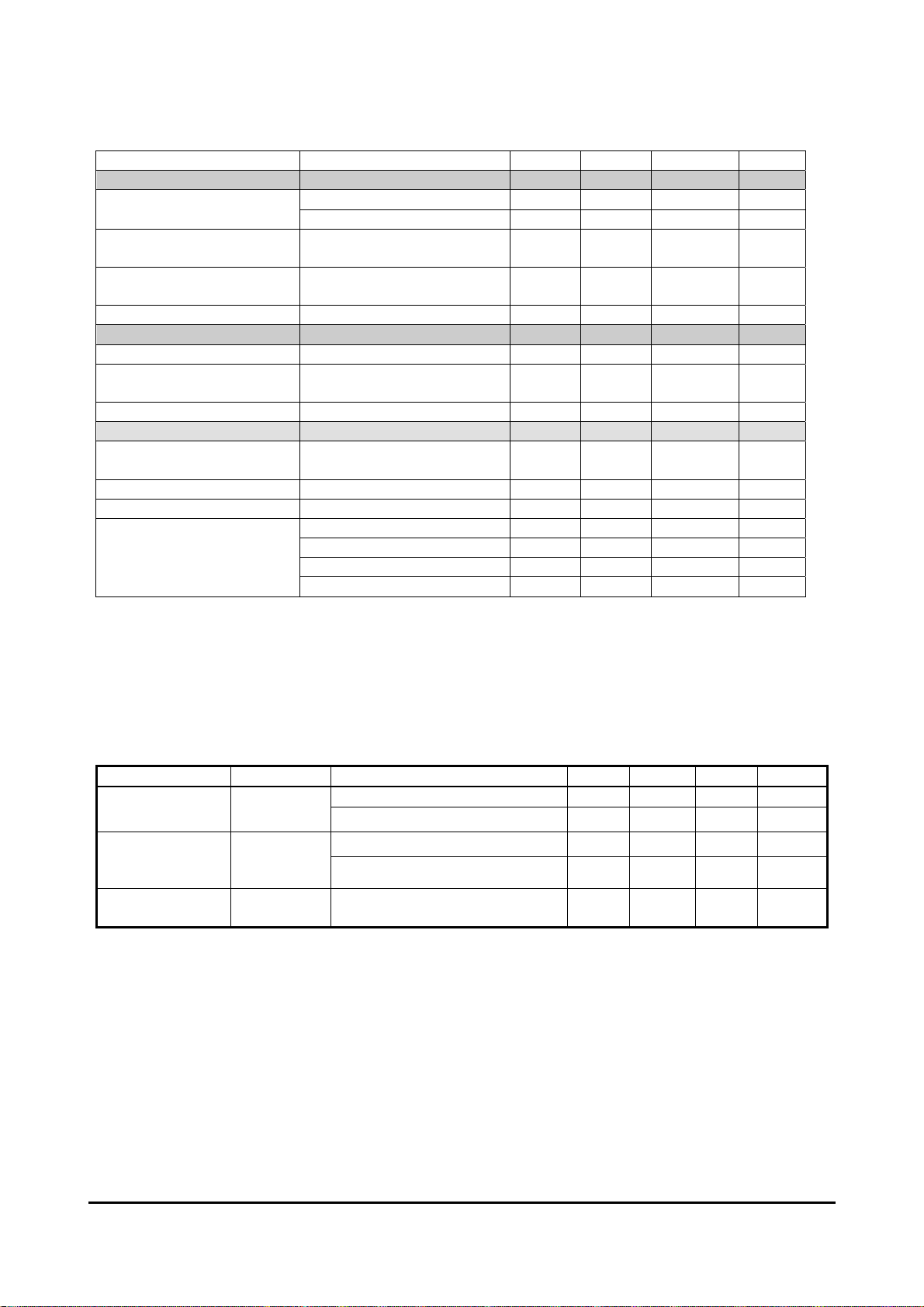

6.1.1. STATE TRANSITION

The sensor device starts an internal initialization immediately after power is supplied. After

initialization completes, the device enters IDLE Mode. The device transitions to various

operational modes by executing commands sent by the host. The state transition chart is

described as below.

Write to NVRAM

Received write command

in CONFIG mode.

Initialization

ot receive write command

in CONFIG mode.

ATENDCFG

(0xA5,0x00)

Configuration

ATWRDTRG (0xA0-0xA1)

ATWRUART (UART only)

ATWRDFRM (0xA3)

ATWDPYCL (0xA4)

ATWRFILT (0xA8)

ATWRAUTO (0xA3)

ATWRBIAS (0xD7-0xD2)

Write to RAM

Power ON

/ RESET

Internal

IDLE

MODE

ATCONFIG

0xA5,0x02)

MODE

Soft Reset

0xE0,0x01 : SPI only)

ATRDTRG (0x20-0x21)

AT R D U ART (U A RT onl y )

ATRDMODL (0x4C-0x30)

ATRDFVER (0x50-0x4D)

ATTSTSLF (0x51)

ATRDFRM (0x23)

ATRDPYCL(0x24)

ATRDFILT (0x28)

ATRDAUTO (0x23)

ATRDBIAS (0x57-0x52)

Read RAM

Data Output

UART : AT COMMAND

Host to M-A550

Measurement

STOP

ATENDMES

(0xA5,0x00)

ATREQDAT

Measurement

0xA5,0x13)

Measurement

START

Continuous

MODE1

Internal Timer

/ External Trigger

Data Output

AT MES MD 1

0xA5,0x11)

Auto Measure = Enable

Only at Power ON

CONFIG MODE

MEASUREMENT MODE

Figure 6-1 State Transition Diagram

14 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 17

6.1.2. INITIALIZATION INDICATION FUNCTION

The device enters initialization immediately after power-on/reset, receives a software reset

command, or after exiting CONFIG mode (ATENDCFG/MODE_CTRL) while receiving a write

command when in CONFIG mode. Refer to Figure 6-1 State Transition Diagram for the

processing sequence.

The device will send a response with "Init.M-A351<CR><LF>" to the host after initialization

ends.

VIN

Initialization

RXD(RS-422)

Typ.2.6s

Data Ready

TXD(RS-422)

“Init.M-A351”

Reboot by the command

MODE_CTRL / ATENDCFG

Typ.1s

“Init.M-A351”

Figure 6-2 Initialization Indication Diagram

6.1.3. BIAS CORRECTION FUNCTION

The device includes a bias correction function which allows the user to apply a fixed bias (offset)

correction to the acceleration value by user command. The correction value has a range of

-32767 to +32767 uG that is added to the measured acceleration value before output to the host.

The host should set the correction value to “0" (initial value) when not using the bias correction

function.

6.1.4. OUTPUT UNIT SELECT FUNCTION

The device includes an output unit select function which allows the user to individually select for

each axis between 3 output unit types by user command: acceleration (initial value), tilt angle, or

tilt angle speed. This individual select function for each axis is available in compound

measurement mode. The tilt angle and tilt angle speed are internally calculated from the

measured gravitational acceleration value. Please refer to Section 2.3 for a description of the

formula for computation.

6.1.5. OPERATION MODE DESCRIPTION

1) Measurement Mode 1

In Measurement Mode 1, the internal measurement circuits are enabled. To enter Measurement

Mode 1, the device must be in IDLE mode and the host sends the command UART:

“ATMESMD1<CR><LF>”.

If the measurement trigger is set to internal timer, the device will send measured acceleration

results at the programmed time interval. The measurement begins immediately after the internal

timer trigger event and a short measurement latency delay.

M-A550AR2 Seiko Epson Corporation 15

Rev.20160704

Page 18

While in Measurement Mode 1, the host can manually request measured acceleration results by

sending commands UART: ATREQDAT<CR><LF>.

To exit Measurement Mode 1 and move to IDLE mode, the host can send the command UART:

ATENDMES <CR><LF>.

Automatic Measurement Mode

After power on, the device will automatically shift to Measurement Mode 1, if automatic

measurement setting is enabled (without the host sending a command to enter Measurement Mode

1). After entering Measurement Mode 1 automatically, the device can accept commands as normal.

2) Configuration Mode

Configuration Mode allows the host to program or read device information / measurement

conditions such as internal timers, filter settings, or device manufacturing information. To enter

Configuration Mode, the device must be in IDLE mode and the host sends the command UART:

“ATCONFIG<CR><LF>”.

As an example when in Configuration Mode, if the host sends UART: “ATRDDTRG<CR><LF>” to

the device to read the current trigger setting, and the following result is returned

“DTRG=2,00005,0<CR><LF>” and “<CR><LF>OK<CR><LF>”. The device is currently set for

measurement trigger from internal timer with a measurement interval value of 5 ms.

6.2. INTERNAL FILTER

The device has programmable internal FIR filter. The FIR filter setting can be set using the WRFILT

command to program the FILTER_CTRL register. This filter uses a Kaiser Window with selectable

filter TAP (128, 256, or 512), and cutoff frequencies (fc=5, 10, 20, 50Hz). Refer to Figure 6-4 ~ Figure

6-7 to see the typical filter characteristics and output rate considerations.

Table 6-1 Internal Filter Cutoff Bandwidth

Parameter Condition Min Typ Max Unit

Filter bandwidth -3dB, 512Tap 121 Hz

Figure 6-3 FIR Kaiser Filter Characteristic (Tap512)

16 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 19

Figure 6-4 FIR Kaiser Filter Characteristic (Fc=5Hz)

Figure 6-5 FIR Kaiser Filter Characteristic (Fc=10Hz)

Figure 6-6 FIR Kaiser Filter Characteristic (Fc=20Hz)

M-A550AR2 Seiko Epson Corporation 17

Rev.20160704

Page 20

Figure 6-7 FIR Kaiser Filter Characteristic (Fc=50Hz)

18 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 21

r

The host must set the cutoff frequency of the FIR filter and the output rate in proper combination to

avoid aliasing. The RS422 interface supports an output rate of 500Sps.

Filte

F

Loss

Fs: Sampling frequency

Fn = fs/2: Nyquist frequency

Fc: Filter cutoff frequency

Magnitude

f

fn

0 fs

c

Frequency

Figure 6-8 Anti-Aliasing Relationship Diagram

Table 6-2 Supported Settings Output Rate and Filter Cutoff Frequency

Filter

512Tap

Filter

256Tap

Filter

128Tap

Group

delay

100Hz

50Hz × ○ × × ×

20Hz × ○ ○ × ×

10Hz × ○ ○ ○ ×

5Hz × ᇞ ᇞ ᇞ ᇞ

100Hz

50Hz × ○ × × ×

20Hz × ᇞ × × ×

10Hz × ○ ○ × ×

5Hz × ᇞ ᇞ ᇞ ×

100Hz

50Hz × ○ × × ×

20Hz × ᇞ × × ×

10Hz × ᇞ × × ×

5Hz × ᇞ ᇞ × ×

63.9ms

31.9ms

15.9ms

1000Sps 500Sps 200Sps 100Sps 50Sps

× × × × ×

× × × × ×

× × × × ×

Output Rate

○: F

ᇞ: F

< -120dB Recommended setting

Loss

< -60dB Although a possible setting, some decrease in measurement quality due to aliasing

Loss

×: Fn < Fc Invalid setting. The measurement data responds with error “0x64000000".

M-A550AR2 Seiko Epson Corporation 19

Rev.20160704

Page 22

7. HOST INTERFACE

This product can be controlled by AT commands by serial communication interface. Details of the AT

commands and parameters are described in this section.

7.1. SERIAL INTERFACE SPECIFICATION

7.1.1. COMUNICATION CONDITION

Table 7-1 UART Communication Settings

Parameter Supported Values

Transfer Rate 57.6 kbsp / 115.2kbps / 230.4kbps / 460.8kbps (Selectable by command)

Start 1bit

Data 8bit (LSB First)

Stop 1bit/ 2bit (Selectable by command)

Parity None/ Even/ Odd (Selectable by command)

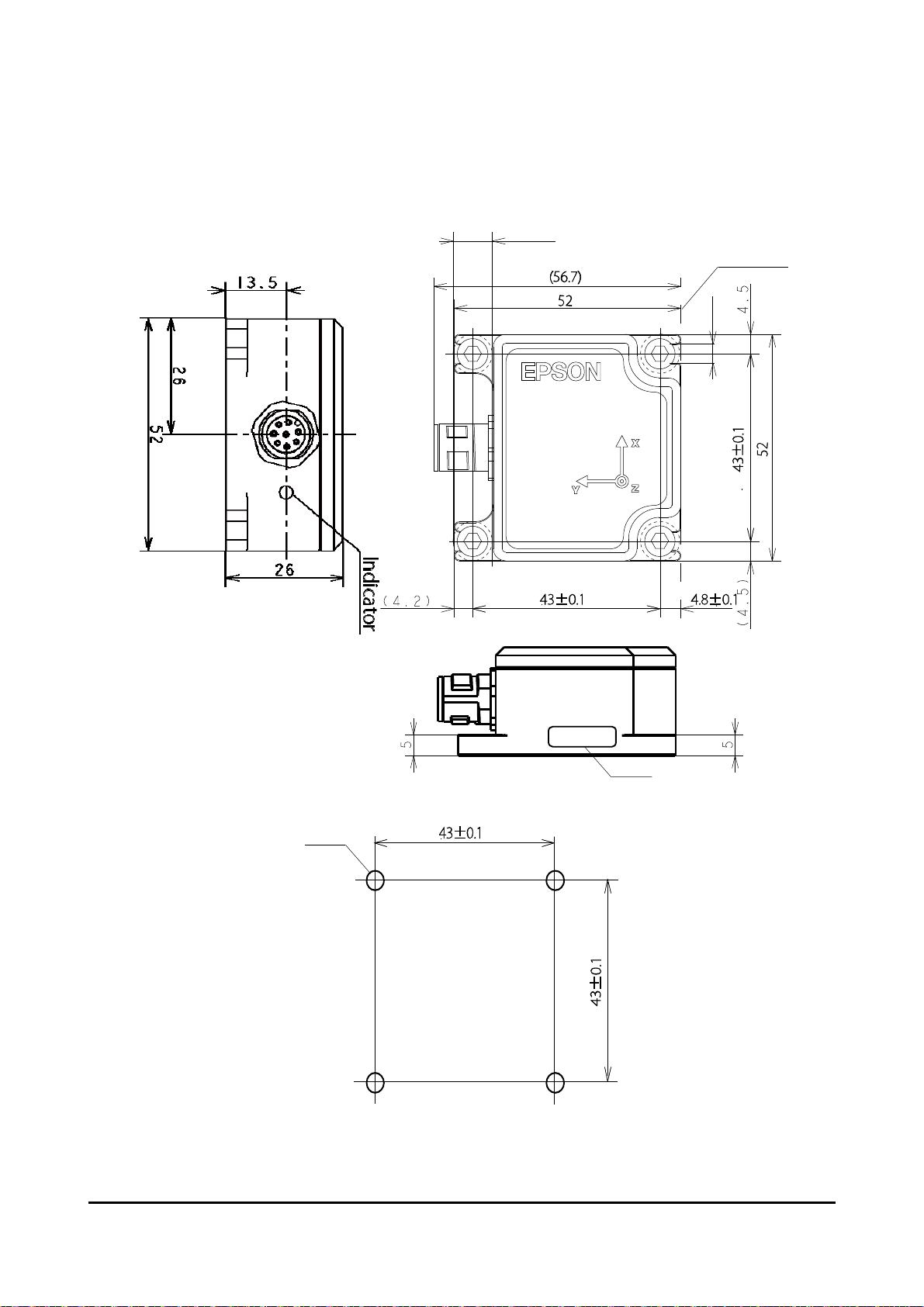

7.1.2. COMMAND SEQUENCE

This device responds to all commands received from the host with a result code. The host must

wait to receive the result code from the previous command before issuing the next command.

When the sensor unit is in measurement mode with internal timer triggering, this device keeps

sending the sensor data at the user programmed timer interval until the measurement end

command is received to go to IDLE mode.

Application

(HOST)

Command

Result Code

(1) Basic Sequence

Accelerometer

(M-A351)

Application

(HOST)

Command

Result Code

Sensor Data

Sensor Data

Sensor Data

(2) Measurement Sequence

(Internal Timer)

Accelerometer

(M-A351)

Figure 7-1 Command Sequence

20 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 23

7.1.3. COMMAND DESCRIPTION

The following describes the list of available commands and functions. All commands must be

pre-fixed or start with ”AT” and terminated or end with “<CR><LF>". All result codes returned

from the sensor unit to the host is either:

“<CR><LF>OK<CR><LF>” to indicate success.

“<CR><LF>#<CR><LF>" to indicate failure.

1) Available command during IDLE mode

Command

Function

Explanation

MESMD1

Go to Measurement Mode1.

Set device to Measurement Mode 1. When a request for sensor data is triggered,

data is transmitted to the host.

Return

<Result> OK (success)

# (failure)

Command CONFIG

Function Go to Configuration Mode.

Explanation Set device to CONFIG Mode to allow reading or writing device settings.

Response

<Result> OK (success)

# (failure)

2) Available commands in Measurement Mode1

Command

REQDAT

Function Request sensor data transmission.

Explanation The latest measurement data is sent to the host.

- The maximum request rate is 500Sps.

- Refer to Section 6.2 INTERNAL FILTER, to ensure the FIR filter is valid

according to Table 6-2 Supported Settings Output Rate and Filter Cutoff

Frequency to avoid aliasing.

Response

Refer to section 7.1.4 for the output format of the sensor data

Command

Function

ENDMES

End Measurement Mode 1.

Explanation

The device stops measurement operation, and goes to IDLE mode.

Response

<Result> OK (success)

# (failure)

M-A550AR2 Seiko Epson Corporation 21

Rev.20160704

Page 24

3) Available commands in Configuration mode :

Format RDMODL

Function Read the device model and other device manufacturing information.

Explanation The device sends model name, date of manufacture, and serial number.

MODL=<Model>,<yymmdd>,<SerNo>

<Result>

<Model> Model name

<yymmdd> Date of manufacture

<SerNo> Serial number

<Result> OK (success)

# (failure)

Response

Format RDFVER

Function Read the firmware version.

Example:

Model name = M-A351AU

Date of Manufacture = October 8, 2014

Serial number = 12345678

Device Output:

MODL = MA351AU, 141008, 12345678-*******

OK

Explanation The device sends the firmware version number.

FVER=<FVer>

<Result>

<FVer> Firmware version number

<Result> OK (success)

# (failure)

Response

(Example Case)

Firmware version number = 1.00

(Device Output)

FVER=1.00

OK

Format RDDTRG

Function Read the setting for sensor data transmission trigger.

Explanation

The device sends the current trigger source setting including the timer interval

value.

22 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 25

DTRG=<Trg>,<Intval>,<Unit>

<Result>

<Trg> Trigger source 0: None

1: Invalid (External trigger)

2: Timer

3: Timer (External trigger is disabled)

<Intval> Measurement Interval Unit of [s] seconds

00001~00060

Unit of [ms] millisecond

Response

00002 : 500Sps

00005 : 200Sps

00010 : 100Sps

00020 : 50Sps

<Unit> Time unit 0: [ms] milliseconds

1: [s] seconds

<Result> OK (success)

# (failure)

Format WRDTRG=<Trg>,<Time>,<Unit>

Function Write the setting for sensor data transmission trigger.

The host writes the specified parameters <Trg>, <Intval>, and <Unit> to the

device.

<Trg> Trigger source 0: None

1: Invalid (External trigger)

2: Timer

3: Timer (External trigger is disabled)

<Intval> Measurement Interval Unit of [s] seconds

00001~00060

Unit of [ms] millisecond

00002 : 500Sps

Explanation

00005 : 200Sps

00010 : 100Sps

00020 : 50Sps

<Unit> Time unit 0: [ms] milliseconds

1: [s] seconds

- Refer to Section 5.3, to ensure the FIR filter setting is valid according to

Table 5.3 Supported Settings Output Rate and Filter Cutoff Frequency to

avoid aliasing.

- When the Time unit is [s] seconds, the device internally downsamples to

50Sps (512Tap), and performs the following averaging process depending on

the measurement interval setting, except in the case when timer

measurement will output the latest value without averaging as in Note 1.

M-A550AR2 Seiko Epson Corporation 23

Rev.20160704

Page 26

Format WRDTRG=<Trg>,<Time>,<Unit>

1 ~ 10s: The averaging process uses the sensor data from the entire timer

interval.

11 ~ 60s: The averaging process uses the most recent 500 samples of sensor

data before the timer interval.

NOTE: The measurement interval is limited by the relationship with the UART

communication speed. Refer to the restrictions in Note 2 located after the

WRUART command description.

NOTE: The measurement interval is used to calculate the tilt angular speed

regardless of the measurement trigger conditions.

Response

<Result> OK (success)

# (failure)

NOTE 1: Averaging Process Output When Timer is Measured in Unit [s] Seconds

Intval (1~10s)

Down Sampling

50Sps

Average

RXD(UART)

Measurement data

Figure 7-2 Averaging Process Output When Timer Interval is 1-10s

Intval (10~60s)

Down Sampling

50Sps

Average

RXD(UART)

Measurement data

10s

Measurement data

Figure 7-3 Average Process Output When Timer Interval is 10-60s

24 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 27

Format RDUART

Function Read the device UART setting.

Explanation The device sends the UART setting (baud rate, parity bit, and stop bit).

UART=<BaudRate>,<ParityBit>,<Stop>

<Result>

Response

<BaudRate> Transmission rate

<ParityBit> Parity bit

<Stop> Stop bit

<Result>

57600 (57.6kbsp)

115200 (115.2kbps)

230400 (230.4kbps)

460800 (460.8kbps)

N (None)

E (Even)

O (Odd)

1 (one bit)

2 (two bits)

Format WRUART=<BaudRate>,<ParityBit>,<Stop>

Function Write the setting for UART transmission.

The host writes the specified parameters <BaudRate>, <ParityBit>, and <Stop> .

57600 (57.6kbsp)

115200 (115.2kbps)

230400 (230.4kbps)

460800 (460.8kbps)

N (None)

E (Even)

O (Odd)

1 (one bit)

2 (two bits)

Explanation

<BaudRate> Transmission rate

<ParityBit> Parity bit

<Stop> Stop bit

NOTE: These UART settings take effect after receiving the "ENDCFG" command

to exit Configuration Mode.

Response

<Result> OK (success)

# (failure)

NOTE 2: Sensor Data Transmission Cycle and UART Transmission Rate

The time required to transmit is different according to the number of output axes and the UART

transmission rate. Please refer to Table 6.2 when configuring the transmission rate.

M-A550AR2 Seiko Epson Corporation 25

Rev.20160704

Page 28

Table 7-2 UART Baud Rate and Sensor Data Transmission Cycle

Transmission

Rate (bps)

57600 10

115200 5

230400 2

460800 2

Minimum Measurement

Interval (msec)

Based on UART transmission setting:

Stop bit =1, Parity =None

Based on output condition:

Outputs three axes, and temperature

Format ENDCFG

Function End Configuration mode.

The device exits Configuration mode.

While in CONFIG mode, if any “WR****”commands were received before the

Explanation

ENDCFG command, the device will write the settings to non-volatile memory,

perform an internal initialization, and go to IDLE mode.

If no "WR****" command was received, the device goes immediately to IDLE

mode.

Response

<Result> OK (success)

# (failure)

Format TSTSLF

Function Initiate a self-diagnosis test, and send the result.

The device performs a self-diagnosis test and the results are sent.

The following diagnostic outcomes are sent for each test.

Refer to Note 3 for description of the self-diagnostic tests.

Test Number Test Description

Explanation

1 Power-supply voltage

2 Non-volatile RAM

3 Reference clock

4 Acceleration sensor

5 Temperature sensor

6 Built-in RAM

< Result > Judgment + Test Number

Judgment O: OK

Response

N: NG

Example:

"O3" means no failure was detected on the Reference Clock test

"N4" means a failure was detected in the Acceleration sensor test

NOTE 3: Self-diagnosis Test Description

The following describes the details of the self-diagnosis tests.

1. Power-supply voltage

The result of the self-test on the power-supply voltage is shown. The internal power-supply

voltage for sensor device is confirmed to be approximately within the range of 3.0~3.6V.

26 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 29

2. Non-volatile RAM

The result of a self-test on the non-volatile RAM(EEPROM) is shown. The checksum result of

data in non-volatile RAM is correct.

3. Reference clock

The result of the self-test on the 32.768kHz & 32MHz quartz oscillator for the control IC is

shown. The frequency of 32MHz is compared relative to the 32.768kHz quartz oscillator for

frequency tolerance within ±400ppm.

4. Acceleration sensor

The result of the self-test of the acceleration sensor is shown. The synthesized value of the

acceleration sensor vector for the X, Y, and Z axis under the static conditions is confirmed to be

approximately in the range of 0.8~1.2G.

5. Temperature sensor

The result of the self-test on the temperature sensor is shown.

6. Built-in RAM

The result of the self test on the built-in RAM is shown. A write and read verification of RAM is

confirmed. This test is only performed at device startup.

Format RDDFRM

Function Read the sensor data output format.

Explanation

Response

The device sends the current sensor data output format (model, temperature

output, and output axis).

DFRM=<Model>,<Temp>,<Axis>

<Result>

<Model> Model Type

<Temp> Temperature Output

<Axis> Axis Output Configuration

0: Accelerometer

1: Inclinometer

2: Tilt angle speed

3: Compound measurement

0: Temperature data not included

1: Temperature data included

X: X axis

Y: Y axis

Z: Z axis

XY: X axis + Y axis

XZ: X axis + Z axis

YZ: Y axis + Z axis

XYZ: X axis + Y axis + Z axis

M-A550AR2 Seiko Epson Corporation 27

Rev.20160704

Page 30

Format WRDFRM=<Model>,<Temp>,<Axis>

Function Write the setting for the sensor data output format

The host writes the specified value for each parameter <Model>, <Temp>, and

<Axis>.

Explanation

<Model> Model Type

<Temp> Temperature Output

<Axis> Axis Output Configuration

0: Accelerometer

1: Inclinometer

2: Tilt angle speed

3: Compound measurement

0: Temperature data not included

1: T emperature data included

X: X axis

Y: Y axis

Z: Z axis

XY: X axis + Y axis

XZ: X axis + Z axis

YZ: Y axis + Z axis

XYZ: X axis + Y axis + Z axis

Response

<Result> OK (success)

# (failure)

Format RDPYCL

Function Read sensor data physical output setting when compound output is selected.

Explanation

The device sends the physical output format for each axis when compound output

(acceleration, tilt angle, and tilt angle speed) is set.

PYCL=<X-PhyQ>,<Y- PhyQ>,<Z- PhyQ>

<Result>

Response

< X- PhyQ> X axis physical output format

< Y- PhyQ> Y axis physical output format

< Z- PhyQ> Z axis physical output format

0: Acceleration

1: Tilt angle

2: Tilt angle speed

0: Acceleration

1: Tilt angle

2: Tilt angle speed

0: Acceleration

1: Tilt angle

2: Tilt angle speed

Format WRPYCL=<X- PhyQ>,<Y- PhyQ>,<Z- PhyQ>

Function

Write the setting for sensor data physical output format when compound output

(acceleration, tilt angle, and tilt angle speed) is set.

28 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 31

The host writes the specified parameter <*_PhyQ> to set each format of the

sensor data physical output.

0 :Acceleration

1:Tilt angle

2:Tilt angle speed

0 :Acceleration

1:Tilt angle

2:Tilt angle speed

0 :Acceleration

1:Tilt angle

2:Tilt angle speed

Explanation

<X- PhyQ> X axis physical output format

<Y- PhyQ> Y axis physical output format

<Z- PhyQ> Z axis physical output format

NOTE: These settings are effective only when compound output is selected.

Response

<Result> OK (success)

# (failure)

Format RDFILT

Function Read the internal FIR filter setting.

Explanation

The device sends the internal FIR filter setting such as filter type, cutoff frequency,

and number of taps.

FILT=<Type>,<Fc>,<Tap>

<Result>

<Type> Filter type

<Fc> Cutoff frequency

Response

<Tap> Number of taps 128, 256, or 512

Format WRFILT=<Type>,<Fc>,<Tap>

0 : Reserved

1 : FIR Kaiser Filter(fixed)

0 : 5Hz

1 : 10Hz

2 : 20Hz

3 : 50Hz

Function Write the setting for the internal FIR filter.

M-A550AR2 Seiko Epson Corporation 29

Rev.20160704

Page 32

The host writes the specified value of the parameter <Type>, <Fc>, and <Tap> to

the internal FIR filter.

<Type> Filter type

Explanation

<Fc> Cutoff frequency

<Tap> Number of taps 128, 256, or 512

- Refer to Section 5.3, to ensure the FIR filter setting is valid according to Table 5.3

Supported Settings Output Rate and Filter Cutoff Frequency to avoid aliasing.

- When <Unit> Time unit setting for the data transmission trigger is in [s]

seconds, the FIR filter is fixed to 5Hz cutoff frequency/512Tap and averaging

process output is enabled on the output.

0 : Reserved

1 : FIR Kaiser Filter (fixed)

0 : 5Hz

1 : 10Hz

2 : 20Hz

3 : 50Hz

Response

<Result> OK (success)

# (failure)

Format RDAUTO

Function Read the status of automatic measurement mode.

Explanation

The device sends the status of automatic measurement mode (enters

measurement mode automatically after power on).

AUTO=<Auto>

Response

<Result>

<Auto> Automatic measurement mode is ON

OFF

Format

WRAUTO=<Auto>

Function Write the setting to enable/disable automatic measurement mode.

The host writes to enable or disable entering measurement mode automatically

after power supply starts by specifying the parameter <Auto>.

Explanation

<Auto> Automatic Measurement mode is ON

OFF

Response

<Result> OK (success)

# (failure)

30 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 33

Format RDBIAS

Function Read the bias correction value.

Explanation The device sends the value of the bias correction for each axis.

BIAS=<X_Bias>,<Y_Bias>,<Z_Bias>

<Result>

Response

< X_Bias> X axis bias correction value -32767 ~ 32767 (unit=uG)

< Y_Bias> Y axis bias correction value -32767 ~ 32767 (unit=uG)

< Z_Bias> Z axis bias correction value -32767 ~ 32767 (unit=uG)

Format WRBIAS=<X_Bias>,<Y_Bias>,<Z_Bias>

Function Write the setting of the bias correction value.

The host writes the bias correction value that will be applied to the sensor

measurement value for each axis by specifying the parameter <*_Bias >.

Explanation

< X_Bias> X axis bias correction value -32767 ~ 32767 (unit=uG)

< Y_Bias> Y axis bias correction value -32767 ~ 32767 (unit=uG)

< Z_Bias> Z axis bias correction value -32767 ~ 32767 (unit=uG)

Response

<Result> OK (success)

# (failure)

M-A550AR2 Seiko Epson Corporation 31

Rev.20160704

Page 34

HOST INTERFACE

7.1.4. COMMAND FORMAT

The output data of the measurement value is in binary format, whereas all other command controls and

responses are in ASCII format.

1) Command Format

The commands messages sent to the device starts with "AT" header and ends with a “<CR><LF>"

trailer. The command and parameter is separated with an "=" (equal sign). In the case the command

includes two or more parameters, the parameters are separated with a “,” (comma) delimiter.

“

“

A

T

COMMAND

"

"

“

=

"

PARAMETER

C R L

F

Figure 7-4 Command Format

2) Result Code

Return Value: "OK (command success)" or "# (command failure)"

The result code is sent by the device in response to commands starts and ends with a

“<CR><LF>".

C R L

F

Result Code

C R L

F

Figure 7-5 Result Code

3) Result Data

Return Value: Responses that do not contain “OK" or “#"

Excluding Measurement Value

The device responds to a command with result data followed by a “<CR><LF>" placed at the end.

Result Data

C R L

F

Figure 7-6 Result Data

Measurement Value

Table 7-3 - Table 7-4 show the output data packet format for the measurement values. The

measurement values (acceleration, tilt angle, tilt angle speed, and temperature) are in binary

format. The host should set the desired physical output value, axis, and temperature configuration

by using the WRDFRM and the WRPYCL command.

32 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 35

Table 7-3 UART Data Packet Format Example 1

Case: WRDFRM=0, 1, XYZ (output acceleration, temperature, and X+Y+Z axis).

Byte

No.

1 ADDRESS ADDRESS[7:0]

2 DATA_LENGTH DATA_LENGTH[7:0]

3 XACCD_3 XACCD_OUT3 [31:24]

4 XACCD_2 XACCD _OUT2 [23:16]

5 XACCD_1 XACCD_ OUT1 [15:8]

6 XACCD_0 XACCD_ OUT0 [7:0]

7 YACCD_3 YACCD_ OUT3 [31:24]

8 YACCD_2 YACCD _ OUT2 [23:16]

9 YACCD_1 YACCD_ OUT1 [15:8]

10 YACCD_0 YACCD_ OUT0 [7:0]

11 ZACCD_3 ZACCD_ OUT3 [31:24]

Name Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

HOST INTERFACE

12 ZACCD_2 ZACCD _ OUT2 [23:16]

13 ZACCD_1 ZACCD_ OUT1 [15:8]

14 ZACCD_0 ZACCD_ OUT0 [7:0]

15 TEMP_2 TEMP_OUT2 [23:16]

16 TEMP_1 TEMP_OUT1 [15:8]

17 TEMP_0 TEMP_OUT0 [7:0]

18 CHECKSUM CHECKSUM [7:0]

19 CR 0x0D

20 LF 0x0A

Three axis acceleration data, internal temperature, sensor data of X, Y, and Z are sent.

The UART data packet format is decoded as follows:

ADDRESS

Determines the measurement output format type

Acceleration: 0x80, Tilt angle: 0x81, Tilt angle speed: 0x82, Compound output: 0x83

DATA_LENGTH

Data length of the entire data packet including <CR><LF>

Data length: 20 bytes in this example

*ACCD_*

Measurement data

(1)Acceleration

Unit : G

Two's complement and four byte fixed zero point

bit31 : Sign part

bit30-24 : Integer part

bit23-0 : Fraction part

M-A550AR2 Seiko Epson Corporation 33

Rev.20160704

Page 36

HOST INTERFACE

(2)Tilt angle

Unit : Radian

Two's complement and four byte fixed zero point

bit31 : Sign part

bit30-29 : Integer part

bit28-0 : Fraction part

(3)Tilt angle speed

Unit : Radian per measurement interval

Two's complement and four byte fixed zero point

bit31 : Sign part

bit30-29 : Integer part

bit28-0 : Fraction part

TEMP

Thermal data

Unit : °C

Two's complement and three byte fixed zero point

bit23 : Sign part

bit22-10 : Integer part

bit9-0 : Fraction part

CHECKSUM

Checksum data

The checksum range of data packet is calculated from the end of the address byte up to

start of the checksum byte. The computational method of checksum simply adds the

object data in 8bit (bytes) units, and places the resulting 8-bit sum as checksum data.

NOTE: 0x63000000(+99G) is output when the maximum value of the range of

detection is exceeded, and 0x9D000000(-99G) is output when the

minimum value is exceeded.

NOTE: 0x374AC286(+99°) is output when the maximum value of the range of

detection is exceeded, and 0xC8B53D7A(-99°) is output when

minimum value is exceeded.

Radian/s in case of unit [s] seconds

Radian/ms in case of unit [ms] milliseconds

NOTE: 0x374AC286(+99°) is output when the maximum value of the range of

detection is exceeded, and 0xC8B53D7A(-99°) is output when

minimum value is exceeded.

NOTE: This reference is used for internal temperature correction, and is not

guaranteed for accuracy of the absolute internal temperature.

For example: Because the sum total is "672" when the response data is "14 00 03 1A E5

FF FF D3 E0 01 00 12 F3 00 70 35", checksum becomes "72".

34 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 37

Table 7-4 UART Data Packet Format Example 2

Case: WRDFRM=1,0,Y (Tilt angle, no temperature, and Y axis output)

Byte

No.

1 ADDRESS ADDRESS[7:0]

2 DATA_LENGTH DATA_LENGTH[7:0]

3 YANGD_3 YANGD_OUT3 [31:24]

4 YANGD_2 YANGD_OUT2 [23:16]

5 YANGD_1 YANGD_OUT1 [15:8]

6 YANGD_0 YANGD_OUT0 [7:0]

7 CHECKSUM CHECKSUM [7:0]

8 CR 0x0D

9 LF 0x0A

Name Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

HOST INTERFACE

M-A550AR2 Seiko Epson Corporation 35

Rev.20160704

Page 38

SAMPLE PROGRAM FLOW

8. SAMPLE PROGRAM FLOW

The recommended procedure for operate this product is shown below.

8.1. RS422 FLOW

7.1.1 Power-on sequence

1) Power-on.

2) Wait Power-On Start-Up Time. /* Initialization */

3) Result: “Init.M-A351¥r¥n" /* Initialization End */

7.1.2 Read sensor configuration setting

1) Change to config mode from idle mode.

Command: “ATCONFIG¥r¥n"

Result: “¥r¥nOK¥r¥n"

2) Read sensor configuration setting.

Command: “ATRDDTRG¥r¥n"

Result: “DTRG=2,00005,0¥r¥n" /* Ext.Trigger=Disable, Timer=Enable, Interval=5ms(200Sps)

*/

Result: “¥r¥nOK¥r¥n"

Command: “ATRDDFRM¥r¥n"

Result: “DFRM=0,1,XYZ¥r¥n" /* Fomat=XYZ-axis Acceleration output with Temperature */

Result: “¥r¥nOK¥r¥n"

Command: “ATRDFILT¥r¥n"

Result: “FILT=1,2,512¥r¥n" /* Filter type=FIR filter, Fc=20Hz, Tap=512 */

Result: “¥r¥nOK¥r¥n"

Command: “ATRDAUTO¥r¥n"

Result: “AUTO=OFF¥r¥n" /* Auto measure mode OFF */

Result: “¥r¥nOK¥r¥n"

Command: “ATRDBIAS¥r¥n"

Result: “BIAS=0,0,0¥r¥n" /* Bias calibration=X:0uG, Y:0uG, Z:0uG */

Result: “¥r¥nOK¥r¥n"

Command: “ATTSTSLF¥r¥n"

Result: “O1¥r¥n" /* Vdd SelfTest=OK */

Result: “O2¥r¥n" /* NVRAM SelfTest=OK */

Result: “O3¥r¥n" /* Clock SelfTest=OK */

Result: “O4¥r¥n" /* Acc.Sensor SelfTest=OK */

Result: “O5¥r¥n" /* Temp.Sensor SelfTest=OK */

Result: “O6¥r¥n" /* IRAM SelfTest=OK */

3) Change to idle mode from config mode.

Command: “ATENDCFG¥r¥n"

Result: “¥r¥nOK¥r¥n"

7.1.3 Write sensor configuration setting

1) Change to config mode from idle mode.

Command: “ATCONFIG¥r¥n"

Result: “¥r¥nOK¥r¥n"

2) Write sensor configuration setting.

Command: “ATWRDTRG=2,00005,0¥r¥n" /* Ext.Trigger=Disable, Timer=Enable, Interval =5ms(200Sps)

*/

Result: “¥r¥nOK¥r¥n"

Command: “ATWRDFRM=0,1,XYZ¥r¥n" /* Fomat=XYZ-axis Acceleration output with Temperature */

36 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 39

Result: “¥r¥nOK¥r¥n"

Command: “ATWRFILT=1,2,512¥r¥n" /* Filter type=FIR filter, Fc=20Hz, Tap=512 */

Result: “¥r¥nOK¥r¥n"

Command: “ATWRAUTO=OFF¥r¥n" /* Auto measure mode OFF */

Result: “¥r¥nOK¥r¥n"

Command: “ATWRBIAS=0,0,0¥r¥n" /* Bias calibration=X:0uG, Y:0uG, Z:0uG */

Result: “¥r¥nOK¥r¥n"

3) Change to idle mode from config mode.

Command: “ATENDCFG¥r¥n"

Result: “¥r¥nOK¥r¥n"

4) Wait

Initialization Time. /* Initialization */

5) Result: “Init.M-A351¥r¥n" /* Initialization End */

7.1.4 Measurement Mode1

1) Change to Measurement mode1 from idle mode.

Command: “ATMESMD1¥r¥n"

Result: “¥r¥nOK¥r¥n"

2) Wait Measurement Wait Time.

3) Measurement start.

/* Sensor data are output repeatedly by Internal timer. */

b) Result: HD,DL,X3,X2,X1,X0,Y3,Y2,Y1,Y0,Z3,Z2,Z1,Z0,T2,T1,T0,CS,CR,LF /* Binary data output */

[Request Command]

a) Command: “ATREQDAT¥r¥n".

b) Result: HD,DL,X3,X2,X1,X0,Y3,Y2,Y1,Y0,Z3,Z2,Z1,Z0,T2,T1,T0,CS,CR,LF /* Binary data output */

Repeat from a) to b).

4) Measurement end and change to idle mode from Measurement mode1.

Command: “ATENDMES ¥r¥n"

Result: “¥r¥nOK¥r¥n"

SAMPLE PROGRAM FLOW

/* Write to NVRAM after receiving ENDCFG command.

M-A550AR2 Seiko Epson Corporation 37

Rev.20160704

Page 40

HANDLING NOTES

9. HANDLING NOTES

9.1. CAUTIONS FOR ATTACHING

The product contains quartz crystal oscillator created by microfabrication. Take precaution to

prevent falling or excessive impact. Do not use the product after an accidental fall or it experiences

excessive impact. The possibility of a failure and risk of malfunction from failure increases.

Excessive vibration, shock, continuous stress, or sudden temperature change may increase the

possibility of failure.

Please consult us before the unit is used in an environment where there is acute vibration out of the

measurement band.

The product should be kept powered on for more than 15 minutes to measure with highest

precision and accuracy.

Do not connect the product to the network with the supply voltage turned on.

When attaching the product, ensure that the product is properly mounted to avoid mechanical

stress such as warping or twisting. In addition, ensure appropriate torque is applied when

tightening the screws but not too excessive to cause the mount of the product to deform or break.

Use screw locking techniques as necessary.

When setting up the product, ensure that the equipment, jigs, tools, and workers maintain a good

ground in order not to generate high voltage leakage. Applying over current or static electricity to

the product may be damage the product permanently.

When installing the product, ensure that metallic or other conductive material do not enter the

product. Otherwise, malfunction or damage of the product may result.

If excessive shock is applied to the product when, for example, the product falls, the quality of the

product may be degraded. Ensure that the product does not fall when you handle it.

Before you start using the product to obtain measurements, test it in the actual equipment under

the actual operating environment to confirm proper operation.

When connecting a cable to this product, tighten the screw enough after inserting it completely.

This product may not satisfy IP67 if tightening is insufficient.

Do not use the product in a situation where power is always applied to the joint of connector.

Ensure that the signals are wired correctly with attention to the name and the polarity of each

signal.

Since the product has capacitors inside, inrush current occurs immediately after power-on.

Evaluate in the actual environment in order to check the effect of the supply voltage sag caused by

inrush current in the system.

9.2. OTHER CAUTIONS

This product is water-proof and dust-proof in conformity with IP67. We do not guarantee the

operation of the product when the product is exposed to condensation, dust, oil, corrosive gas (salt,

acid, alkaline, etc), or direct sunlight which surpass IP67. Do not use this product under water.

This product is not designed to be radiation resistant.

Never use this product if the operating condition is over the absolute maximum rating. Otherwise,

permanent damage to the product may result.

If the product is exposed to excessive external noise or other similar conditions, degradation of the

precision, malfunction, or damage to the product may result. The system needs to be designed so

that the noise itself is suppressed or the system is immune to the noise.

This product is not designed to be used in equipment that demands extremely high reliability and

where its failure may threaten human life or property (for example, aerospace equipment,

submarine repeater, nuclear power control equipment, life support equipment, medical equipment,

transportation control equipment, etc.). Seiko Epson Corporation will not be liable for any damages

caused by the use of the product for those applications.

Do not apply shock or vibration to the packing box. Do not spill water over the packing box. Do not

store or use the product in an environment where dew condensation occurs due to rapid

temperature change.

Do not put mechanical stress on the product while it is stored.

38 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 41

HANDLING NOTES

Do not alter or disassemble the product.

Do not use in water except if it gets temporarily wet based on IP67. This product does not achieve

the sufficient waterproof performance if the the connector is mated incorrectly or that the mating

connector does not satisfy IP67.

The power supply to this product must satisfy the voltage rating within 2 seconds after it is turned

on.

Do not use thinner or similar liquids on this product. When cleaning this product, alcohol may be

used.

It is recommended that this product be installed horizontally (±5deg.) for normal use.

9.3. LIMITED WARRANTY

The product warranty period is one year from the date of shipment.

If a defect due to a quality failure of the product is found during the warranty period, we will

promptly provide a replacement.

M-A550AR2 Seiko Epson Corporation 39

Rev.20160704

Page 42

PART NUMBER / ORDERING INFO.

10. PART NUMBER / ORDERING INFO.

The following is the ordering code for the product:

Category Product Name Order Code Comment

RS422 interface M-A550AR20 E91E608140 -

40 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 43

11. PACKING DIMENSIONS

The following describes the packing information for the product.

11.1. PACKING MATERIAL SIZE

Name Size

Inner Box 262 (A) x 112 (B) x 56 (C) : 3pcs (Max)

Outer Box Outer Box1 : 282 (A) x 238 (B) x 81 (C) : 2 Inner Box or

Outer Box2 : 355 (A) x 280 (B) x 225 (C) 9 Inner Box with spacer.

PACKING DIMENSIONS

B

11.2. INNER BOX DESCRIPTION

C

Figure 11-1 Inner Box 1

A

M-A550AR2 Seiko Epson Corporation 41

Rev.20160704

Page 44

PACKING DIMENSIONS

11.3. OUTER BOX DESCRIPTION

Figure 11-2 Inner Box 2

11.4. PACKING LABEL

Figure 11-3 Outer Box1

Figure 11-4 Outer Box2

42 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 45

PACKING DIMENSIONS

者

)

T

)

者

)

T

)

発注

(CUST

受渡場所名

(DELIVERY POIN

納品キー番号

(TRANS.No.

品名コード

(PART No.)

品名(PART NAME)

入数/納入数量 単位

(Q'TY/TOTAL Q'TY) (UNIT)

発注者用備考(CUSTOMER'S REMARKS) 包装個数(PACKAGE COUNT)

(3N)3

(3N)4

(3N)5

F-1 F-2

SEIKO EPSON CORP.

A

B

C

D

E

G

H

I

J

/

SEIKO EPSON CORP.

P/N1

P/N2

P/N3

M

/

O

MADE IN JAPAN

K

P

PC

N

Figure 11-5 Inner Label

発注

(CUST

受渡場所名

(DELIVERY POIN

納品キー番号

(TRANS.No.

品名コード

(PART No.)

品名(PART NAME)

入数/納入数量 単位

(Q'TY/TOTAL Q'TY) (UNIT)

発注者用備考(CUSTOMER'S REMARKS) 包装個数(PACKAGE COUNT)

F-1 F-2

A

B

C

D

E

G

/

SEIKO EPSON CORP.

P/N1

P/N2

P/N3

M

/

K

P

PC

N

(3N)3

(3N)4

(3N)5

11.5. STORAGE ENVIRONMENT

Please store at room temperature, and at low humidity while avoiding direct sunlight.

Please do not store with external pressure applied to the inner and outer boxes.

H

I

J

SEIKO EPSON CORP.

Figure 11-6 Outer Label

O

MADE IN JAPAN

M-A550AR2 Seiko Epson Corporation 43

Rev.20160704

Page 46

STANDARDS AND APPROV ALS

12. ST ANDARDS AND APPROVALS

The following standards are applied only to the unit that are so labeled. (EMC is tested using the

EPSON power supplies)

Europe : CE marking

12.1. NOTICE

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

The connection of a non-shielded interface cable to this product will invalidate the EMC standards

of the device.

Any changes or modifications not expressly approved by Seiko Epson Corporation could void your

authority to operate the equipment.

12.2. CE MARKING

This product conforms to the following Derectives and Norms,

EN61326-1 Class A

EN50581

12.3. RoHS & WEEE

The crossed out wheeled bin label that can be found on your product indicates that this

product should not be disposed of via the normal household waste stream. To prevent

possible harm to the environment or human health please separate this product from other

waste streams to ensure that it can be recycled in an environmentally sound manner. For more

details on available collection facilities please contact your local government office or the

retailer where you purchased this product.

AEEE Yönetmeliğine Uygundur.

Обладнання відповідає вимогам Технічного регламенту обмеження використання деяких

небезпечних речовин в електричному та електронному обладнанні

12.4. FCC COMPLIANCE STATEMENT FOR AMERICAN USERS

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

44 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 47

ST ANDARDS AND APPROVALS

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

12.5. INDUSTRY ICES COMPLIANCE STATEMENT FOR CANADIAN USERS

CAN ICES-3(A)/NMB-3(A)

M-A550AR2 Seiko Epson Corporation 45

Rev.20160704

Page 48

REVISION HISTORY

13. REVISION HISTORY

Rev. No. Date Page Category Contents

Rev. 20160704 2016/7/4 All New

Attachment-1

46 Seiko Epson Corporation M-A550AR2

Rev.20160704

Page 49

AMERICA

EPSON ELECTRONICS AMERICA, INC.

214 Devcon Drive,

San Jose, CA 95112, USA

Phone: +1-800-228-3964 FAX: +1-408-922-0238

EUROPE

EPSON EUROPE ELECTRONICS GmbH

Riesstrasse 15, 80992 Munich,

GERMANY

Phone: +49-89-14005-0 FAX: +49-89-14005-110

SEIKO EPSON CORP.

Wearable Products Operations Division

WP Sales & Marketing Department

281 Fujimi, Fujimi-machi, Suwa-gun, Nagano-ken399-0293, JAPAN

Phone: +81-266-61-0614 FAX: +81-266-61-2045

Document Code : 3Z60-0065-01E

First Issue, July 2016

M-A550AR2 Seiko Epson Corporation 47

Rev.20160704

Loading...

Loading...