Page 1

LX-810/850

TECHNICAL MANUAL

EPSON

Page 2

NOTICE

“ All rights reserved.

Reprc~duction

of any part of this manual in any from

whatsoever without SEIKO EPSON’s express written permission is forbidden.

● The contents of this manual are subject to change without notice.

-

All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

“ The above notwithstanding SEIKO EPSON can assume no responsibility for any

errors in this manual or the consequences thereof.

9

Copyright 1989 by SEIKO EPSON CORPORATION

Nagano, Japan

I

Page 3

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury, and 2) damage

to equipment:

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

WARNING Signals a precaution which, if ignored,

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

could result in damage to equipment.

DANGER

ALWAYS DISCONNECT THE F’RODUCT FROM BOTH THE POWER SOURCE AND THE

1.

HOST COMPUTER

PROCEDURE.

2. NO WORK SHOULD BE

BASIC SAFETY MEASURES

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PERFC)RMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

WARNING

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

1.

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PROD-

UCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EP’SON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

/.LP

CHIPS AND CIRCUITRY, USE STATIC

ii

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of the LX-8 10/850.

The instructions and procedures included herein are intended for the

experienced repair technician,

precautions on the preceding page. The chapters are organized as follows:

and attention should be given to the

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 -

● The contents of this manual are subject to change without notice.

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Discusses the options

Includes a step-by-step guide for product disassembly,

assembly, and adjustment.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques and lists

lubricants and adhesives required to service the equipment.

iv

Page 5

REVISION TABLE

REVISION DATE ISSUED

I

A

IMar

27, 1989

E

CHANGE DOCUMENT

I

1st issue

I

I

fy,

-...,,.;

. . . .

v

Page 6

TABLE OF CONTENTS

REV.-A

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

OPTIONAL EQUIPMENTS

DISASSEMBLY, ASSEMBLY, AND ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

vi

Page 7

CHAPTER 1

GENERAL DESCRIPTION

REV.-A

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1

1.2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Hardware Specifications

1.2.2 Firmware Specifications

INTERFACE

1.3

DIP SWITCH AND JUMPER SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4

1.4.1 DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Jumper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5

SELECTYPE

1.6

SHEET LOADING

1.7

TEAR-OFF FUNCTION

1.8

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.1

1.8.2

1.8.3

1.8.4

1.8.5

MAIN

1.6

COMPONENTS

OVER\fl EW

FUNC1’ION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AND

Self-Test

Hexadecimal Dump Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buzzer Operation

Printer Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Lever Operation

(ESC/P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHEET EJECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

... 1-1

. 1-3

1-3

1-10

1-12

1-15

. 1-15

. 1-15

. 1-16

1-17

. 1-18

1-18

1-19

1-20

. 1-21

1-21

1-22

1.6.1

1.6.2

1.6.3

1.6.4

1.6.5

Figure 1-1.

Figure 1-2.

Figure 1-3.

Figure 1-4.

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

TAMA

Boarld

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TAPNL-W Control Panel

TA Filter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Mechanism

Housing

(M-3D1

O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 1-23

1-23

. 1-24

1-24

1-25

LIST OF FIGURES

Exterior View of the LX-810/850

Pin Configuration

Cut-Sheet Printing Area

Printing Area for Continuous Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Roll Paper Printing Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Test Printout

Hexadecimal Dump Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-3

1-6

. 1-8

. 1-12

1-18

. 1-19

,-i

:

Page 8

REV.-A

Figure 1-9.

Figure 1-10. LX-810/850 Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Figure 1-11. TAMA Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Figure 1-12.

Figure 1-13. TA Filter Unit

Figure 1-14.

Figure 1-15. Housing

Lever Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TAPNL-VV

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model-3Dl

O Printer Mechanism

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1-21

.

1-23

1-24

1-24

1-24

LIST OF TABLES

Table 1-1.

Table 1-2.

Table 1-3.

Table 1-4.

Table 1-5.

Table 1-6.

interface Options

Optional Unit

Cut-Sheet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Roll Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Envelope Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....................................................................m

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l-l

.

1-1

.

1-4

.

1-4

. 1-5

.

Table 1-7.

Table 1-8.

Table 1-9.

Table 1-10. Column Width (maximum characters/line) . . . . . . . . . . . . . . . . . . . . 1-11

Table 1-11. Connector Pin Assignments and Signal Functions ..... 1-12

Table 1-12. Printer Select/Deselect Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-13. Settings for DIP Switch 1 (SW 1)

Table 1-14. Settings for

Table 1-15. International Character Set Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-16. Lever Position

Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

printing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Size

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP

Switch 2 (SW 2)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5

. 1-10

1-1o

1-14

1-15

1-15

1-15

1-21

f:-?

.

Page 9

REV.-A

1.1

FEATURES

The LX-8 10/850 is a small, light-weight, low-cost, advanced paper handling printer comparable to the

LX-800. Its main features are:

1.

Advanced paper handling: Auto

2.

Expanded

Printing speeds: 200

3.

4.

Optional 8100 series interface

Clear, easy-to-read printing with a standard EPSON font

5.

Two built-in NLQ (Near Letter Quality) fonts (Roman and Saris Serif)

6.

Control panel switch selection of Draft, Roman, or Saris Serif font

7.

Control panel switch selection of normal or condensed printing

8.

Control panel mode settingd are saved in non-volatile memory

9.

Easy handling of cut sheets with

10.

LX-8 10/850 is equipped with the standard EPSON 8-bit parallel interface. Various interface options

The

enable users to print data from a variety

lists the optional units available for the LX-8 10/850, and Figure 1-1 shows an exterior view of the

LX-8 10/850.

ESC/P-code

printing, implemented as a standard feature

150

180

backout and cut sheet loading

cps (high speed draft)

CpS

(dri~ft

10 cpi)

CpS (dri~ft 12 cpi)

the optional cut-sheet feeder (CSF)

of computers. Table 1-1 lists the interface options, Table 1-2

Tablo

1-1. Interface Options

Model

I

Intelligent serial interface board

Enter faceboard

NOTE: Refer to the “Optional Interface Technical Manual” for details.

Model

C8061

C80006”

8310 Roll paper

8750

2* Single bin cut sheet feeder

Intelligent

I

Pull tractor unit

Ribbon cartridge (Black)

IE:EE-488 interface board

Table 1-2. Optional Units

holder

Description

Description

1-1

Page 10

REV.-A

Figure 1-1. Exterior View of the LX-81 0/850

1-2

,..

’

Page 11

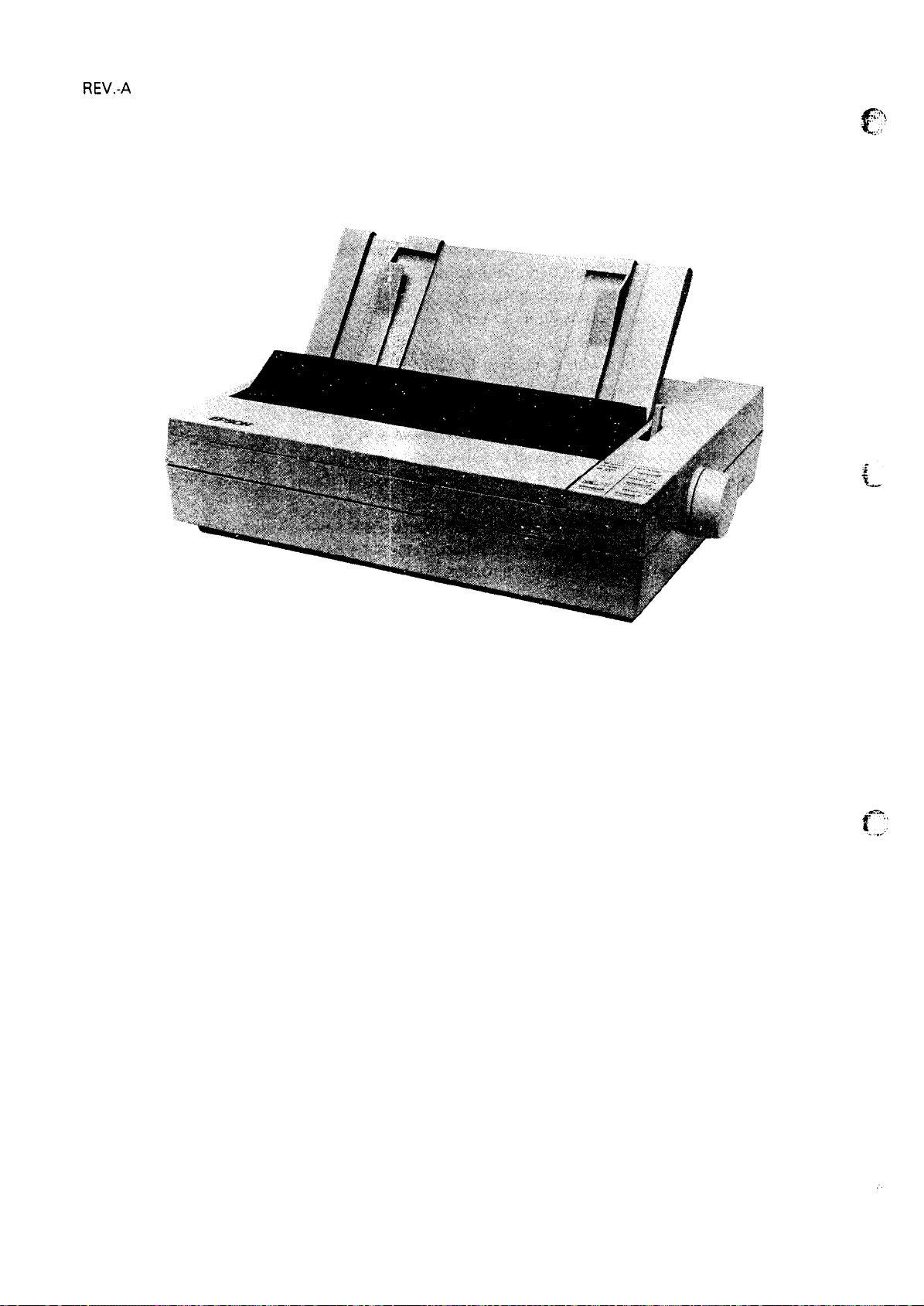

1.2 SPECIFICATIONS

REV.-A

This section describes LX-8 10/850

1.2.1

Hardware Specifications

Printing Method

Pin Configuration

Serial, impact, dot matrix

9 wires (diameter

prinlter specifications.

0.29mm)

#1

(

)

#2

(

)

#3

( )

#4

<

>

#5

<

>

#6

(

)

#7

#8

#9

t

0.29mm

!

t

0.35mm (1

f

/72”)

Figure 1-2. Pin Configuration

Feeding Method Friction

When handling paper, note the following precautions described below

Friction Feed Precautions:

1. Do not use continuous paper.

2. Do not use a single sheet shorter than 182mm or longer than

3. Do not perform any reverse paper feed within 8.5mm from the top, or 22mm from the bottom.

4. Do not perform reverse feed greater than 1/6 inch after the paper end is detected.

5. Use the pull-out unit.

6. Do not use multi-part single sheet forms.

Tractor Feed Precautions:

1. Release the friction feed mechanism.

2. Joining of copying paper must be by line or dotted pasting.

3. Copy paper must be a carbon-less, multi-part paper.

feed,

tractor feed (push tractor: standard, pull tractor: optional)

364mm.

1-3

Page 12

REV.-A

a. Push Tractor Feed

1. Use the pull-out unit.

2. Do not perform reverse

3. After paper end detection, accuracy of paper feed cannot be assured and reverse feeding cannot

be performed.

b. Push Pull Feed

1. Remove the pull-out unit and attach the pull tractor unit.

2. Do not loosen the paper between the platen and pull tractor unit.

3. Adjust precisely the horizontal position of the pull and push tractor.

4. Do not perform reverse feeding greater than 1/6 inch.

5. Do not perform reverse feeding after

c. Pull Tractor Feed

1. Remove the pull-out unit and attach the pull tractor unit.

feeding greater than 1/6 inch.

the paper end is detected.

Line Spacing

Paper Insertion

Paper-Feed Speed

Width

Length

Thickness

Si_k&lL

Width

Copies

Quality

Total Thickness

Weight

1/6 inch, 1/’8 inch, or programmable in units of 1/216 inch

From rear

Approximately 95 ins/line (1/6 inch line feeding)

Approximately 75 ins/line (1/6 inch in page feed)

Paper Specifications See Table 1-3 through 1-6

Table 1-3. Cut-Sheet Specifications

182 mm to 257

182 mm to 364 mm (7.15 in. to 14.3 in.)

0.065 mm to 0.14 mm (0.0025 in. to 0.0055 in.)

14 lb. to 24 lb. (52.3 g/mz to 90

mm (7.15 in. to 10.1 in.)

g/m2)

Table 1-4. Continuous Paper Specifications

101 mm to 254 mm (4.0 in. to 10.0 in.)

3 sheets (1 original and 2 copies)

Plain paper

0.065 mm to 0.25 mm (0.0025 in. to 0.01 in.)

1

sheet - 14 lb. to 22 lb., (52.3 g/m2 to 82

3 sheets -- 12 lb. to 15 lb., (40 g/mz to 58.2

g/m2)

g/m2)

each

Table 1-5. Roll Paper Specifications

Width

Weight 14 lb. to 17 lb. (45 kg to 55 kg)

Quality

Thickness

216 mm

Plain paper

0.07 mm to

& 3 mm (8.5 in. & 0.12 in.)

C).09

mm (0.0028 in. to 0.0035 in.)

1-4

Page 13

Table 1-6. Envelope Specifications

REV.-A

NOTES: “

Size

Weight 55Kg (68

Thickness O.19 mm (0.0075 in.) max.

Size

No.6 (166

Imm

x 92 mm), No. 10 (240 mm x 104 mm)

Quality Bond paper, Plain paper, Air mail

Thickness

0.16 mm to

0.52 mm (0.0063 in. to 0.0197 in.)

Difference of thickness within printing area must be less

than 0.25 rnm (0.0098 in.).

Weight 12 lb. to

24

lb. (45 g/m2 to 91 g/m2)

Envelope printing is only available at normal temperature.

.

Keep the long side of the envelope horizontal at setting.

*

Set the left of a

No.6 envelope at the setting mark of the sheet guide.

Table 1-7. Label Specifications

2 1/2 in. X 15/16 in. (63.5 mm X 23.8 mm)

g/m2)

Thickness excluding the base paper must be equal to or less than 0.12

mm (0.0075 in.).

NOTES:

“

Label printing is only available at normal temperature.

● Labels must be a fanfold type.

● For printing labels on pressure sensitive paper, the following conditions must be met: (1)

jointed by dotted or line pasting. (2) total thickness is equal to or less than

inch). (3) 5 degree C to 35 degree C and

10’%0

to

80’ZO

RH.

0.3mm

(0.01 18

1-5

Page 14

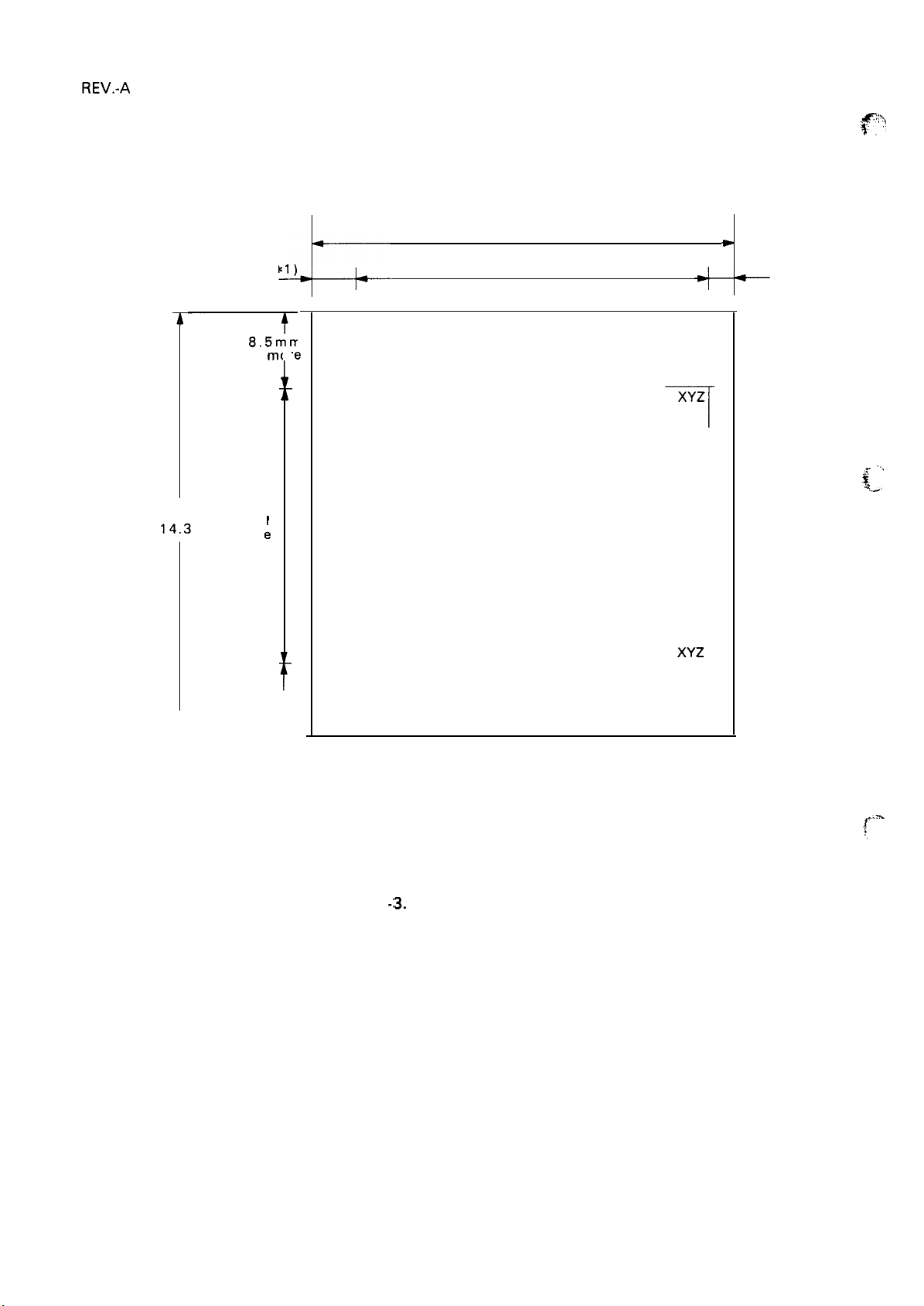

REV.-A

Printing Area

The figures

below show the printing area for cut sheets.

364mm max.

14.3

0.33 “ or

“ max.

182-257 mm(7. 2-10.1 “ )

*1 ) Printable area

4=

8.5rnrY

“e

mt

\

—

—

i

P

r

I

n

t

a

b

I

~

a

r

e

a

ABC

r

-

p)

. .

.

*

*1 )

XYZ

7

,7

““

3../

—

—

● 1 ) At least 3.0 mm (O. 12 in.) when the paper width is less than 229 mm (9 in.); at least 24 mm (0.9

in.) when the paper width is 257 mm ( 10.1 in.)

●

Printing is possible approx. 28 mm from the paper’s detected bottom edge; the 13.5 mm value

(lowest print position) is for reference only. Paper feed accuracy can not be assured within 22 mm

(0.87 in.) of either the top or bottom edge.

ABC

L

Figure 1

—

-:3.

Cut-Sheet Printing Area

XYZ

--l

~.=

~~

1-6

Page 15

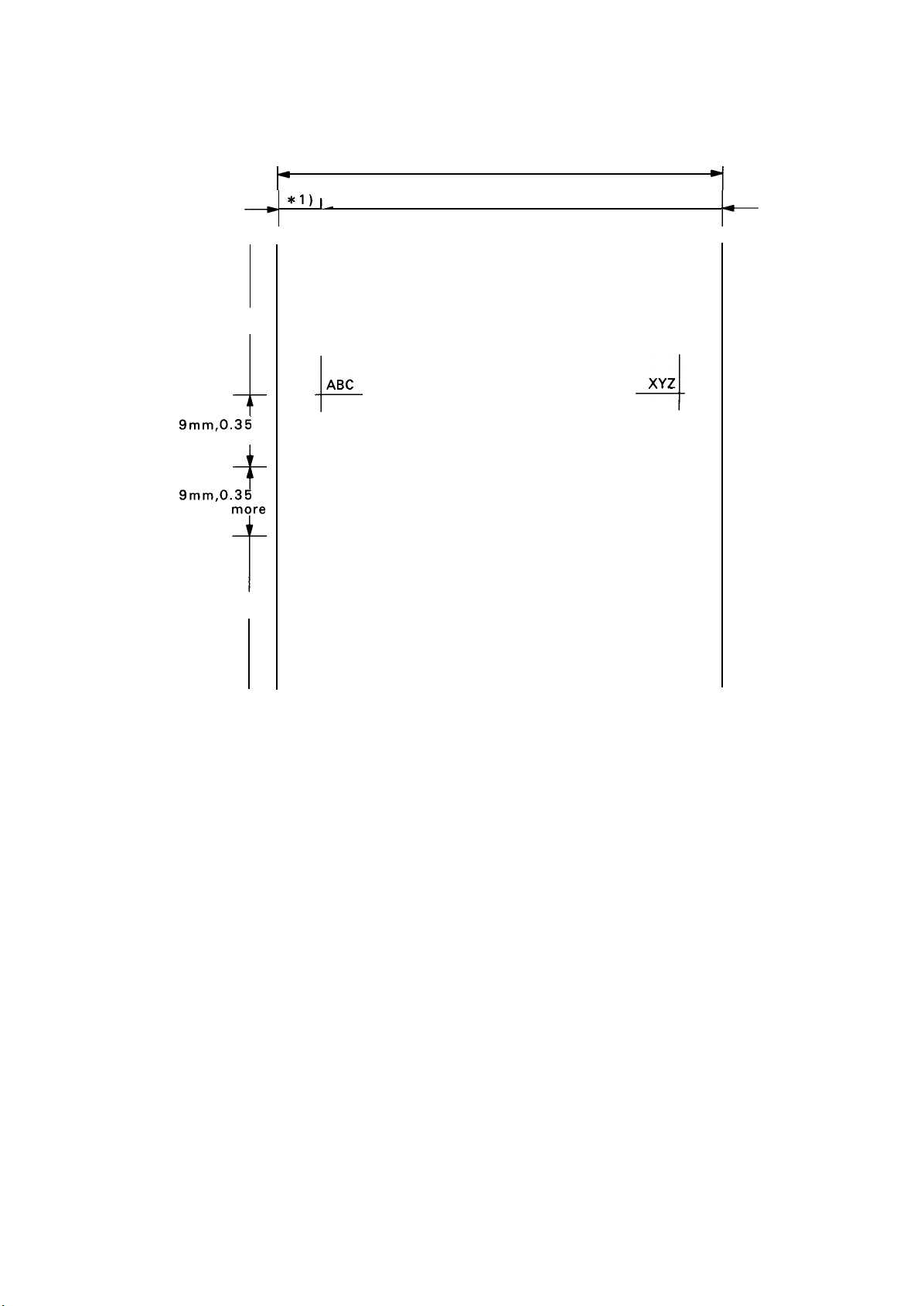

REV.-A

Printable

9mm,0.35

or more

9mm,0.35

or

Printable

area

+

“

+

“

mqre

t

area

,101 mm-254mm

Printable area

I

*1)

o

0

0

0

4.0 “ -10.0 “

1A

0

0

0

ABC

0

0

4-

0

0

0

----------------------------0

0

0

0

ABC

0

0

t

0

0

0

0

0

0

1

)(YZ

4

--------------

XYZ

i

I

*2)

I

o

0

0

0

0

0

0

0

0

0

0

0

-0

0

0

0

0

0

0

0

0

0

0

0

● 1) 13 mm or greater for paper widths of 101 - 242 mm (4 - 9.5. in.)

26 mm or greater for paper widths of 254 mm (10 in.)

*2) 13 mm or greater for paper widths of 101 - 242 mm (4 -9.5 in.)

24 mm or greater for paper widths of 254 mm (1 O in.)

Figure 1-4. Printing Area for Continuous Paper

1-7

Page 16

REV.-A

50m

min

60m

I

3rnm min.

‘1

T

1

Figure

2‘1 6mm(8.5 “)*

203.2mm

(printable area)

3mm(0.

I

AEIC

1-3.

Roll Paper Printing Area

12 “ )

3mm min.

XYZ

I

I

—

—

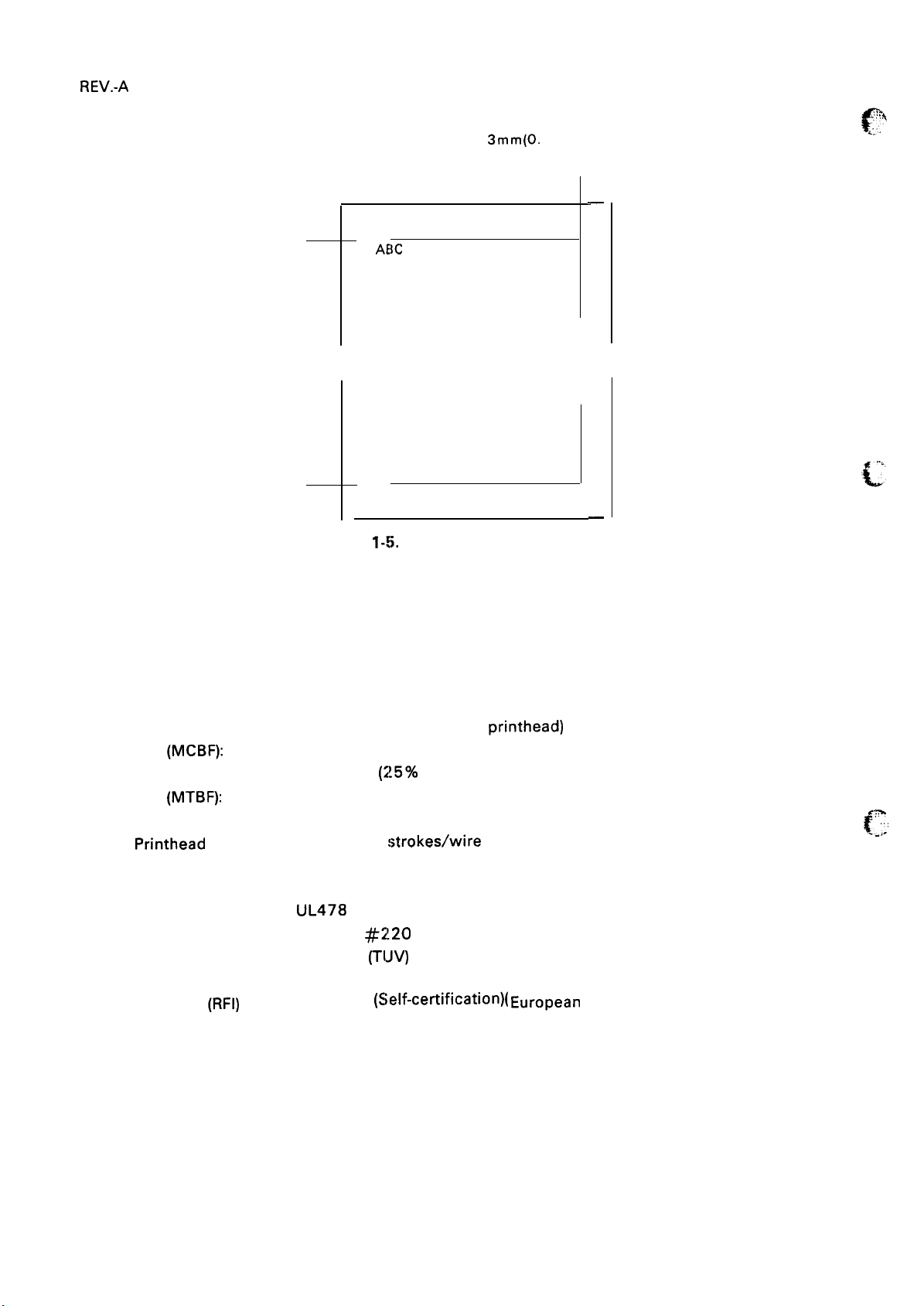

Ink Ribbon

Type:

Color:

Reliability:

Reliability

Mean Cycles Between

Failure

Mean Time Between

Failure

Life of

Safety Approval

Safety Standards

Radio Frequency

Interference

(MCBF):

(MTBF):

Printhead

(RFI)

8750 Ribbon Cartridge

Black

3 million characters at 14 dots/character

3 million lines (excluding printhead)

4000 POH

200 million

UL478

CSA22.2

VDE0806

FCC class B (U.S. version)

VDE 0871

(2!5% duty)

:;trokes\wire

(U.S. version)

#;!20

(Canada version)

(TIJV) (European version)

(Self-certification)(

EurOPean version)

,,

,,:

f-

..

”,.

1-8

Page 17

Electrical Specifications

Power Conditions

Frequency Range

Power Consumption

insulation Resistance

Dielectric Strength

120V Version

220/240V

Version

Environmental Conditions

Temperature

Humidity

Resistance to Shock

Resistance to Vibration

VAC & 10% (120V version)

120

220/240

49.5 to

VAC + 10%

60.!5 Hz

(220/240V

version)

28W (Draft self-test)

10

Mgohms min. (Between AC Line and Chassis)

(At 50 or 60 Hz, between the AC line and chassis)

1 KV AC

1.5KV AC

(rmslminute)

(rms\l

O minutes) or 1250V AC

or 1250V AC

(rms/second)

(rms\second)

5 to 35 degrees C (41 to 95 degrees F) -operating

–30 to 60 degrees C (-22 to 149 degrees F) -storage

10 to 80

5 to 85 %

1 G, within 1

2 G, within 1

YO

RH (no condensation) –operating

FIH

(no condensation) -storage

mS -operating

mS -storage

0.25 G, 55 Hz max. -operating

0.50 G, 55 Hz max. -storage

REV.-A

Physical Specifications

Weight

Dimensions

5.75 Kg

418 mm (Width) X 339 mm (Depth) X 141

excluding knobs and paper guides

mm(Height),

1-9

Page 18

REV.-A

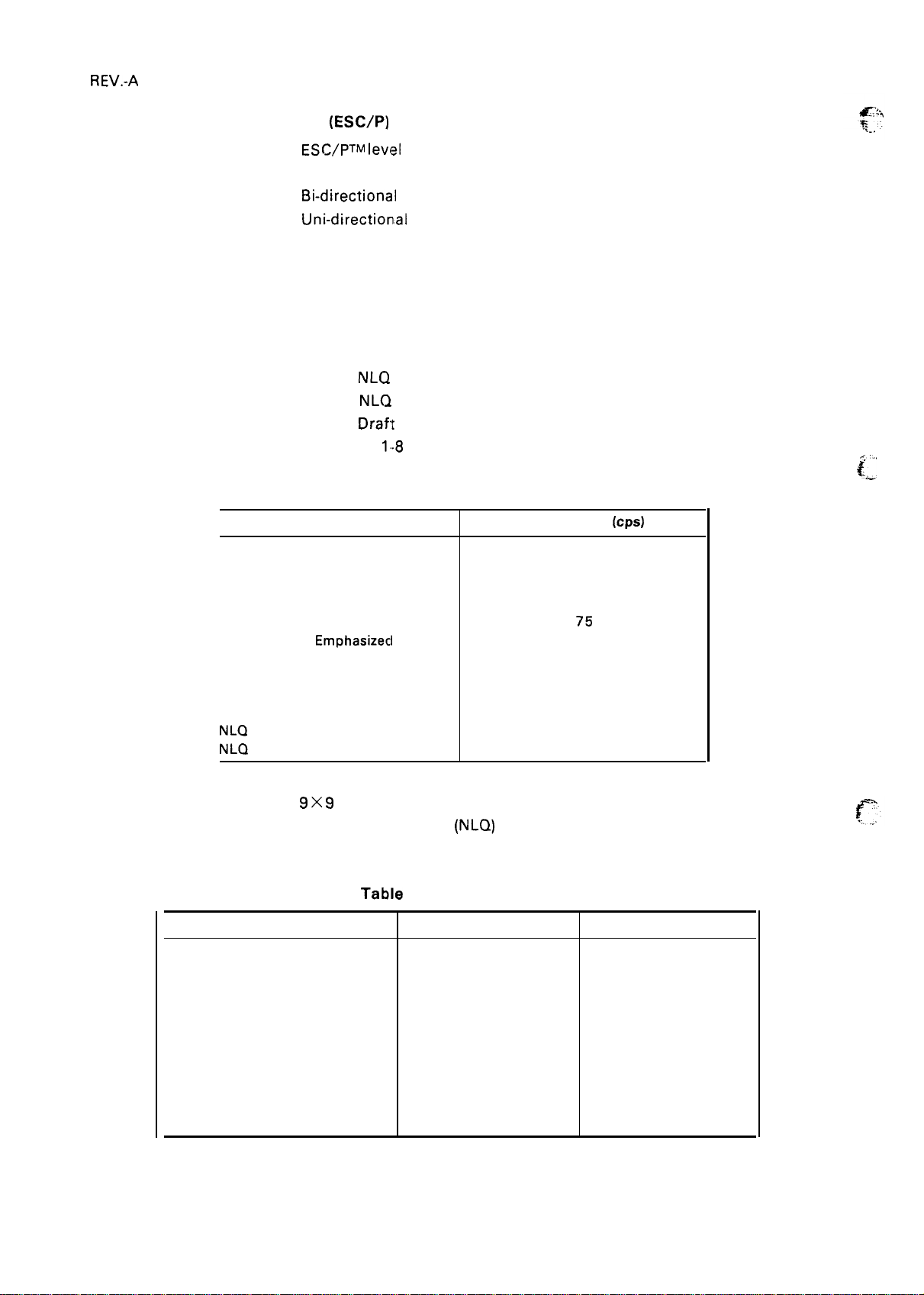

1.2.2

Firmware Specifications

(ESC/P)

Control Code

ESWPTM level ESC/P-81

(EPSON Standard Code for Printers)

Printing Direction

Bi-directional printing with logic seeking (text)

Uni-directional (left to right) printing (Bit-image)

Input data buffer

Character Set

4 K bytes

96 ASCII characters

96 Italic characters

32 International characters (13 countries)

32 International Italic characters

96 IBM Graphics characters

Font

EPSON

EPSON

EPSON

NLQ Roman

NLQ Saris Serif

Draft

Printing Speed See Table

Table 1-8. Printing Speed

Type of Letters

High Speed Draft

Pica

Elite

Double-Width

Emphasized

Double-Width Emphasizecl 37

Condensed

Double-Width condensed

Double-Width Elite

Condensed Elite

NLQ

Pica 25

NLQ

Elite

1.8

Print Speed

200

150

180

75

75

128

64

90

150

30

,,. :.,

{/-.

[cps)

Dot-matrix Format

Character Size

Pica 2.1

Elite

Condensed

Double-Width Pica

Double-Width Elite

Double-Width Condensed 2.1

Condensed Elite

Emphasized

Double-Width Emphasized

Super/Subscript Depends On Pitch

9

X $J Text mode (Draft)

18 X 20 Text mode

See Table 1-9

Type of Letters

(NLQ)

Table 1-9. Character Size

Width (mm)

1.7 3.1

1.05

4.2

3.4

0.85 3.1

2.1

4.2 3.1

1-10

Height (mm)

3.1

3.1

3.1

3.1

3.1

3.1

1.6

Page 19

REV.-A

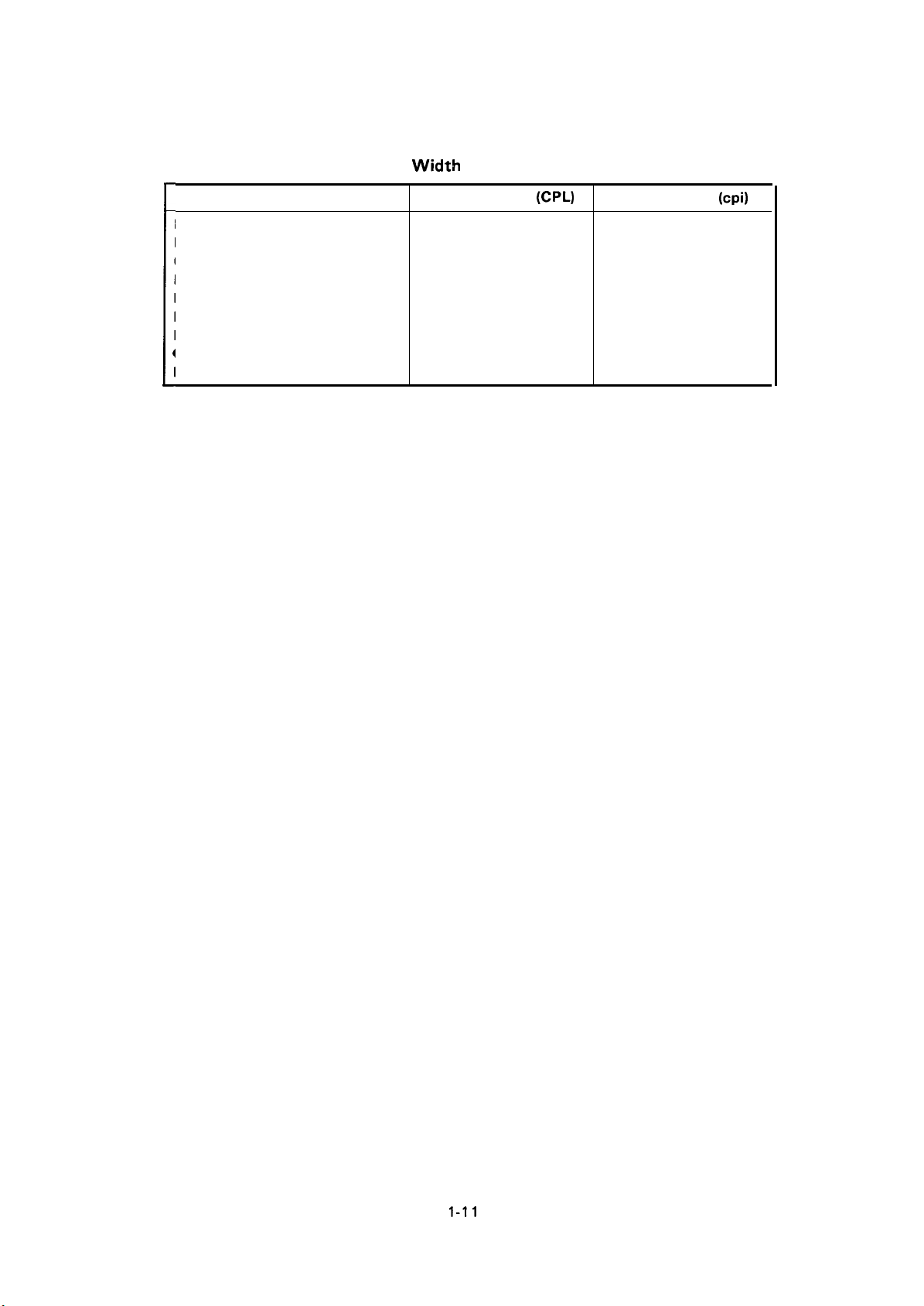

Printing Columns

Pica

Elite

Condensed

Double-Width Pica

Double-Width emphasized

Double-Width Elite

Double-Width Condensed

(

Condensed Elite

Emphasized

I

See Table 1-10

Table

1-10. Column Width (maximum characters/line)

Type of Letters

Column Width

80

96

137

40

40

48

68

160 20

80

(CPL)

Column/inch

10

12

17

5

5

6

8.5

10

(cpi)

1-11

Page 20

REV.-A

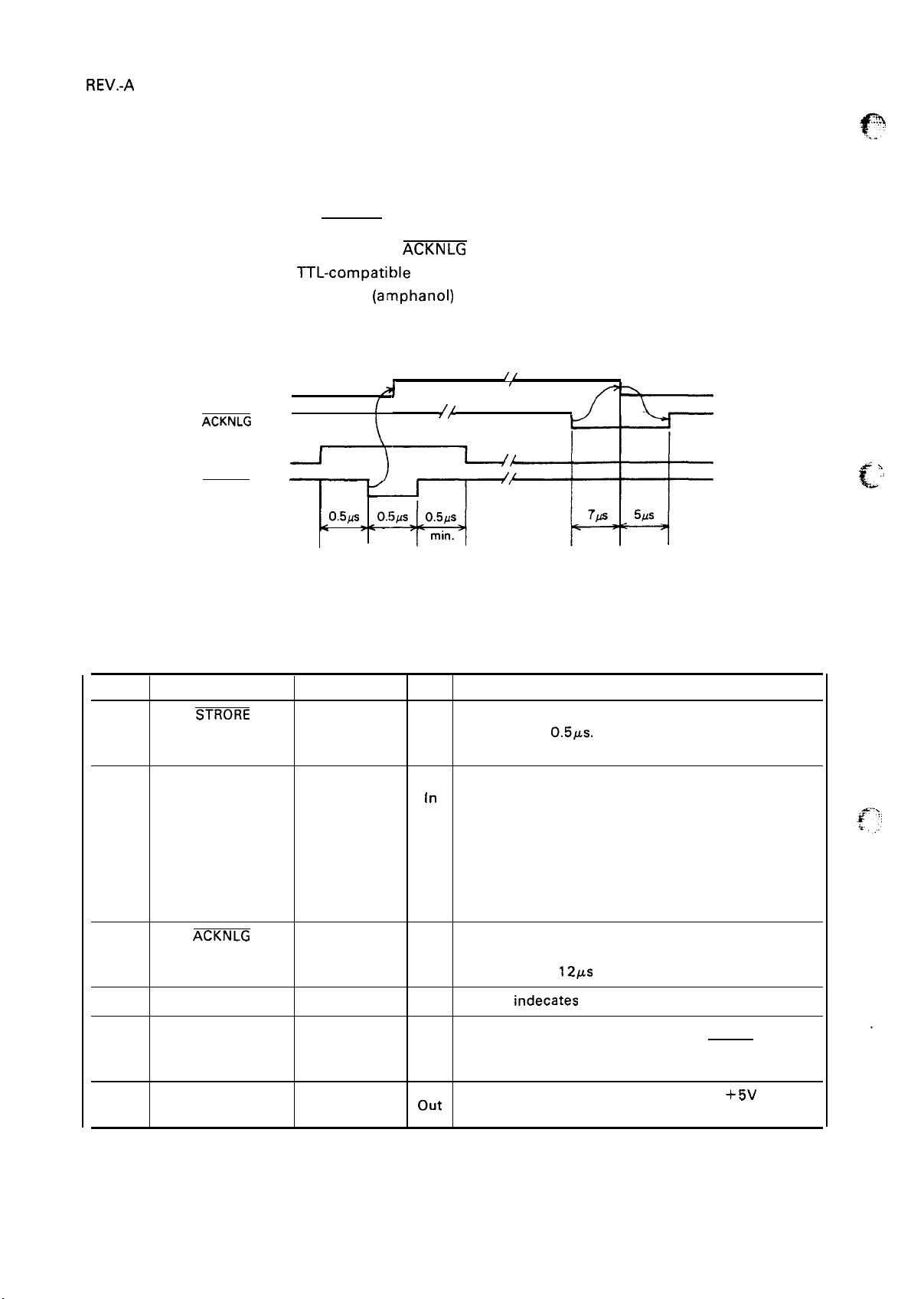

1.3 INTERFACE OVERVIEW

The standard 8-bit parallel interface provided with this printer meets the specifications described below.

Data Format

Synchronization

Handshaking

Signal Level

8-bit parallel

By STROBE pulse

By BUSY and

ACKNLG signal

TTL-compatible

Adaptable Connector 57-30360 (amphanol) or equivalent

Data Transmission Timing See Figure 1-6

/[

BUSY

A

,

{ ,/,, .

ACKNLG

DATA

STROBE

o.5#s

min.

min.

Figure 1-6. Data Transmission Timing

Table 1-11 shows the connector pin assignments and signal functions of the 8-bit parallel interface.

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Table 1-11. Connector Pin Assignments and Signal Functions

Signal Name

STRORE

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5 24

DATA 6 25

DATA 7

DATA 8

ACKNLG

BUSY

PE

SLCT

Return Pin No. DIR Functional Description

19

20

21

22

23

In

Strobe pulse to read the input data. Pulse width must

0.5,us.

be more than

of this signal.

In

Parallel input data to the printer.

[n

“HIGH” level means data “ 1“.

In

“LOW” level means data “O”.

Input data is latched at falling edge

In

In

In

26

27

In

In

28 out This pulse indicates data is received and ready to

accept next data.

29 out

30 out

Pulse width is

“HIGH”

“HIGH” indicates paper-out.

121.M

indecates

approx.

printer cannot accept next data.

This signal is effective only when ERROR signal is

“LOW”.

—

out

Always

3.3kohms register.)

“HIGH” output. (Pulled up to

+5V

through

1-12

Page 21

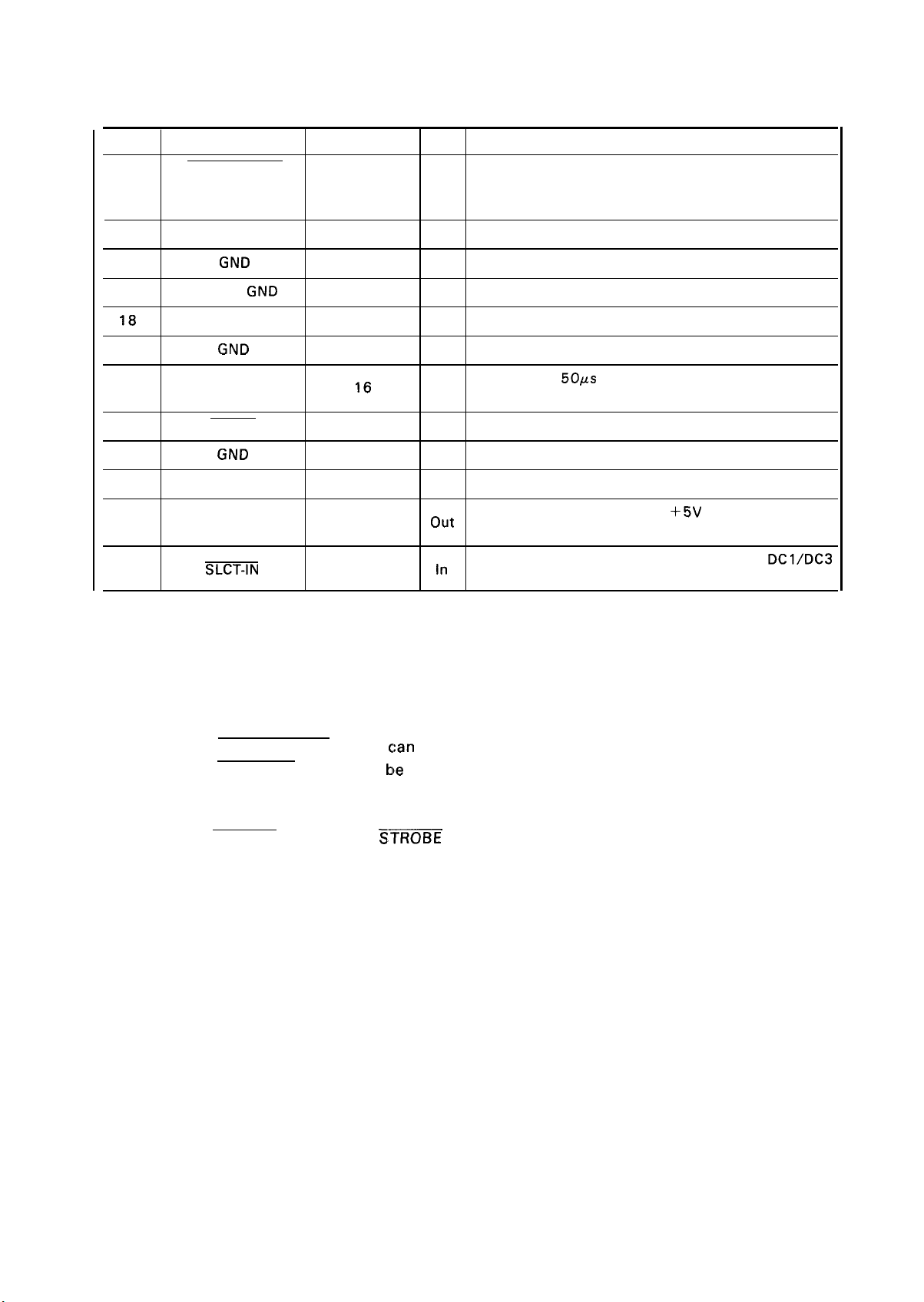

Table 1-11. Connector Pin Assignments and Signal Functions (Cont.)

REV.-A

Pin No.

14

Signal Name Return Pin No.

AUTOFEED-XT

15

16

17

Chassis

18

9 to 30

31 I NIT

32

33

34

35

36

Functional Description

feed is

—

DIR

In

if “LOW” when the printer is initialized, a line

automatically performed by input of “CR” code. (Auto

LF)

Not used

GND

GND

— —

Ground for twisted-pair grounding

Chassis ground level of printer

Not used

GND

16

ERROR out “LOW” indicates some error is occurred in the printer.

GND

—

—

—

SLCT-IN

—

Grounds for twisted-pair grounding

50#s

Pulse (Width:

In

initialization.

—

Ground for twisted-pair grounding

—

Not

used

out Always “HIGH”. (Pulled up to

min., active “LOW”) input for printer

+5V

through 3.3 Kohms

register.)

If “LOW” when prinater is initialized, the DC1/DC3

In

control is disabled.

NOTES: 1. “DIR” refers to the direction of the signal flow as viewed from the printer.

2. “Return” denotes a twisted-pair return line.

The cable used must be shielded to prevent noise.

3.

4. All interface conditions are based on TTL levels. Both the rise and fall times of all signals

must be less than 0.2 us.

5. The AUTO FEED-XT signal

6. The SELECT-IN signal can

7. Printing tests, including interface circuit tests, can be performed without using external

equipment by setting DATA 1-8 of the interface connector to certain codes and connecting

the ACKNLG signal to the

c:an

be set LOW by DIP switch 2-4.

ble

set LOW by jumper 1.

STROBE signal.

1-13

Page 22

REV.-A

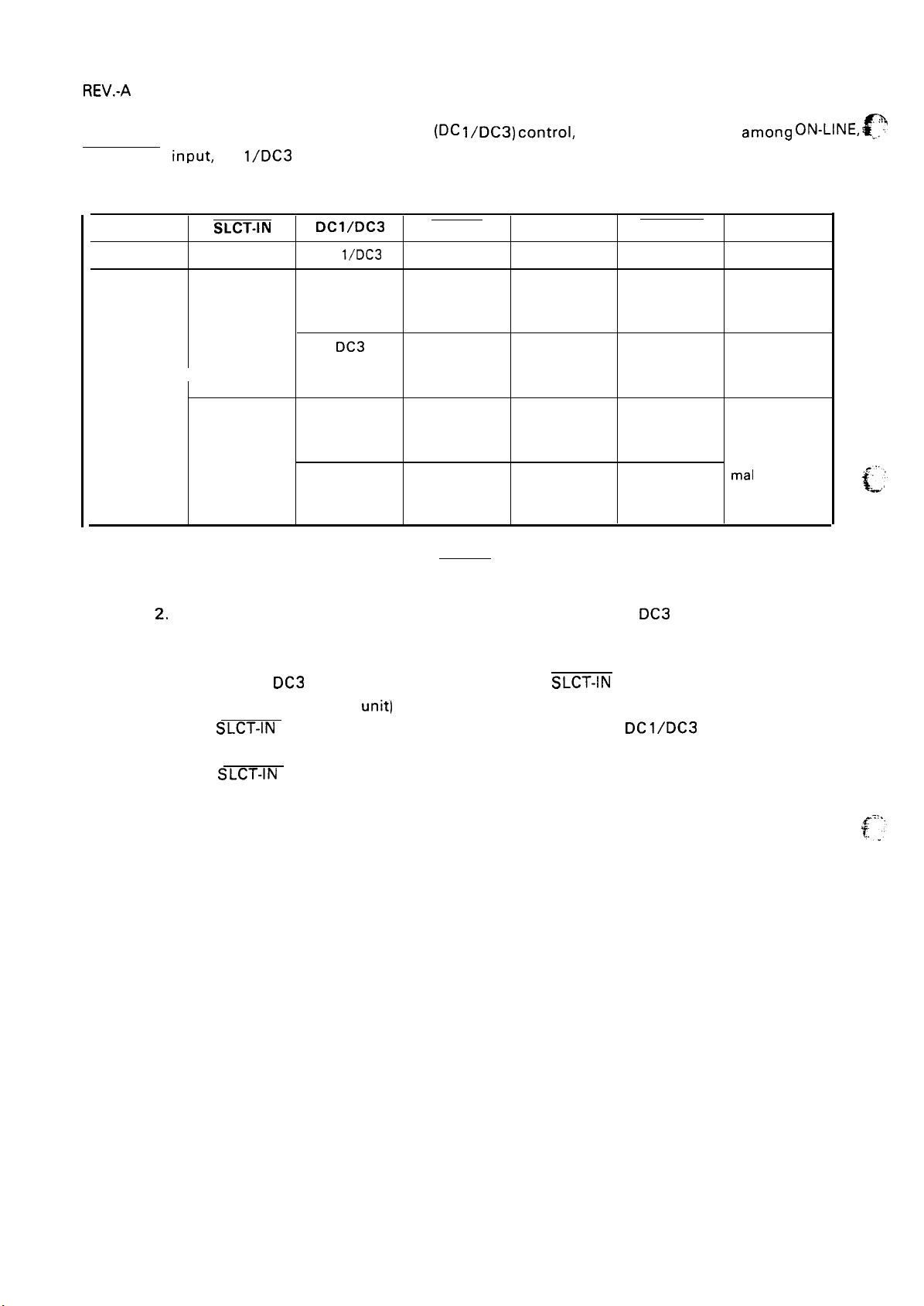

Table 1-12 shows Printer Select/Deselect (DC

SELECT-IN input, DC

l/DC3

and interface signals.

l/DC3)

controL including relations amon9 ON-LINE, .

Table 1-12. Printer Select/Deselect Control

ON-LINE SW

OFF-LINE

ON-LINE

SLCT-IN

HIGH/LOW

HIGH

LOW

Dcl/Dc3

l/DC3

DC

DC 1

DC3

DC 1

DC3 HIGH

ERROR

LOW

HIGH

HIGH

HIGH

BUSY

HIGH

LOW/HIGH

(During data after entry

entry)

LOW/HIGH

(During data after entry

entry)

LOW/HIGH

(During data

entry)

LOW/HIGH

(During data

entry)

ACKNLG

No pulse

Pulse output

Pulse output Enable (Waits

Pulse output

after entry

Pulse output

after entry

DATA ENTRY

Disable

Enable(Normal

Process)

DC 1. See Note

2)

Enable (Nor-

mal

process)

NOTES: 1. In Table 1-12, it is assumed that no ERROR status exists other than that attributable to the

OFF-LINE mode.

2, Once the printer has been put in the deselected state by the DC3 code, the printer will

not revert to the selected state unless the DC 1 code is input again. (In the deselected state,

the printer ignores input data until the DC 1 code is received.)

3. The DC 1 and

for the parallel interface

4. if the

5. If the

SLCT-IN signal is LOW when the printer is initialized,

select control is invalidated, and these control codes are ignored.

SLCT-IN signal is HIGH and is not set to LOW by jumper 1 when the printer is

initialized, the printer starts from the selected (DC 1 ) state.

DC3 codes are enabled only when the SLCT-IN signal (Input Connector No.36

unit) is HIGH and printer power is initialized.

DC1/DC3

printer select/de-

c!

.

1-14

Page 23

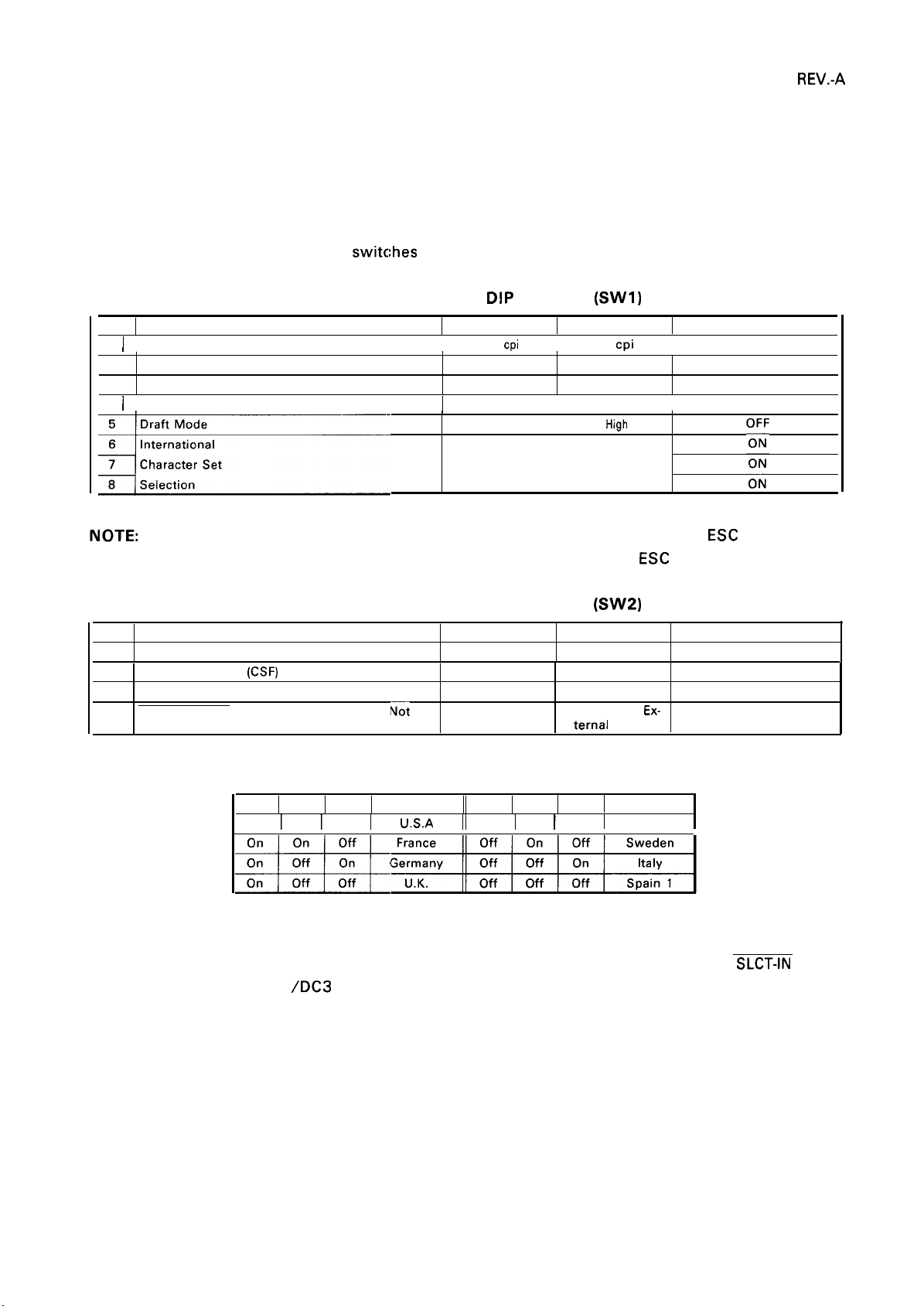

1.4 DIP SWITCH AND JUNIPER SETTINGS

This section describes DIP switch settings for the LX-8 10/850 printer.

1.4.1 DIP Switch Settings

The two DIP switches are located on the side of the printer and function as shown in Tables 1-13 through

1-15. Note that the status of the DIP

switc:hes is read only at power on or upon receipt of the I NIT signal.

Table 1-13. Settings for

No.

1 I Character Pitch

Shape of Zero

2

Table Selection (note)

3

4 I Tear Off

Description

E

When the DIP switch is set for the Italic table, at power on printer defaults to ESC 7 table. When

the switch is set for the Graphic table, at power on it defaults to

Table 1-14. Settings for DIP Switch 2

No.

1

Page length

Cut-Sheet Feeder

2

l-inch skip On

3

4 AUTO FEED XT Signal Internally Fixed or

Description

(CSF)

Mode

.-

~t

D!P

Switch 1

ON

12

I

I

‘

‘

Fixed to LOW

cpi

0

Graphics

Invalid

Normal

See Table 1-15

ON

12 in.

On

(SW1)

OFF

10

I

0

Italics

Valid

I

“gh

(SW2)

OFF

11 in.

off OFF

off

Depends On

ternal Signal

cpi

Fectory Setting

I

I

ESC 6 table.

Factory Setting

Ex-

OFF

OFF

OFF

OFF

:’

OFF

OFF

OFF

Table 1-15. International Character Set Selection

1-6 1-7 1-8

On I On I On

1.4.2 Jumper Setting

Jumper 1 (user-selectable) is located on the TAMA board. If the jumper is connected, the

is fixed to LOW, and DC 1

/DC3

printer select control is ignored.

Country

U.S.A

1-6 1-7

Off ] On I On

1-15

1-8

Country

Denmark 1

SLCT-IN

signal

Page 24

REV.-A

1.5

SELECTYPE

FUNCTION

SelecType

selection of Draft, Roman, or Saris Serif fonts and selection of normal printing or condensed printing

modes.

To select Roman or Saris Serif, press the

When it sounds twice, the Roman font is selected. When it sounds three times, the Saris Serif font is

selected.

To select the Draft font, press the DRAFT button. The buzzer will sound once, indicating that the DRAFT

font is selected.

To set for condensed printing when the printer is in the print mode, press the CONDENSED button once

(the buzzer will sound once), and the printer will enter the condensed print mode.

T

O cancel condensed printing, press the CONDENSED button again. After

buzzer sounds twice to tell you that condensed printing is cancelled.

allows the user to choose fonts and the printing mode easily. This function provides for

SelecType

is effective only when the printer is ON LINE and not printing.

NLQ button. A buzzer sounds when the NLQ button is pressed.

YOU

press the button, the ,. ~

1.6 SHEET LOADING AND SHEET EJECTION

The release lever enables disengaging of the push tractor unit drive mechanism. The printer therefore

provides some improved paper-handling functions through combination of the release-lever and

LOAD/EJECT control panel switch.

,.

‘g,,,

Cut Sheet Loading And Ejection

To load a sheet of paper, position the paper release lever back, place the sheet along the paper guide,

and press the LOAD/EJECT switch. This loads the paper to the top-of-form position.

Pressing the LOAD/EJECT switch after the paper has been loaded will cause the paper to be ejected.

Continuous Paper Loading And Ejection (Back-out)

To load fanfold paper, move the paper release Iever forward, and insert the paper into the push tractor.

~:,

Pressing the LOAD/EJECT switch will then cause paper to be automatically loaded to the top-of-form

position. Pressing the LOAD/EJECT switch after the fanfold paper has been loaded will cause the printer

to eject the paper backward from the push tractor. To back out several pages, press the LOAD/EJECT

switch several times (reverse feed is performed on a page-by-page basis).

ON-LINE LED will flash only when the paper is loaded and the ON-LINE switch pressed. This indicates

The

that the printer has entered “Top-of-form adjust” mode, and that the user may adjust the top-of-form

position, as well as the loading positions for subsequent forms. Adjustment is made using the FORM

FEED button,

which will increment the paper forward, and the LINE FEED switch, which will increment the paper in

reverse. (The minimum feed amount is 2/216 inch).

When cut sheet is used, the adjusted Top-of-form position will be lost when the printer is re-initialized,

and the Top-of from will be reset to the default value. When continuous

memory of the adjusted Top-of-form position will be retained even after

paper is used, however, the

printer initialization.

L.

.,.

1-16

Page 25

REV.-A

1.7 TEAR-OFF

The Tear-Off function

when the release-lever is set to the tractor position. In such a case,

and the printer is

LED will flash to indicate that the FORM FEED and LINE FEED switches are now available to perform

micro-adjustment. The user may then adjust the paper to the tear-off position. This position becomes

the new tear-off position default, and will remain valid even if the printer is reset and reinitialized, and

regardless of whether the main power has been interrupted. When new data are input to the printer,

the paper will automatically be returned to its original position, and printing will then start. Paper having

been advanced to the tear-off position will also be returned to its original position if the ON-LINE switch

is pressed (switching the printer from ON-LINE to OFF-LINE).

FUNCTION

can be enabled by making the appropriate DIP switch setting, and will operate

if the input data buffer is empty

ON-LINIE,

the paper

will

automatically be fed to the tear-off position, and the ON-LINE

1-17

Page 26

REV.-A

1.8 OPERATING INSTRUCTIONS

This section describes the self-test, hexadecimal dump

functions,

error states, printer initialization,

and

buzzer operation.

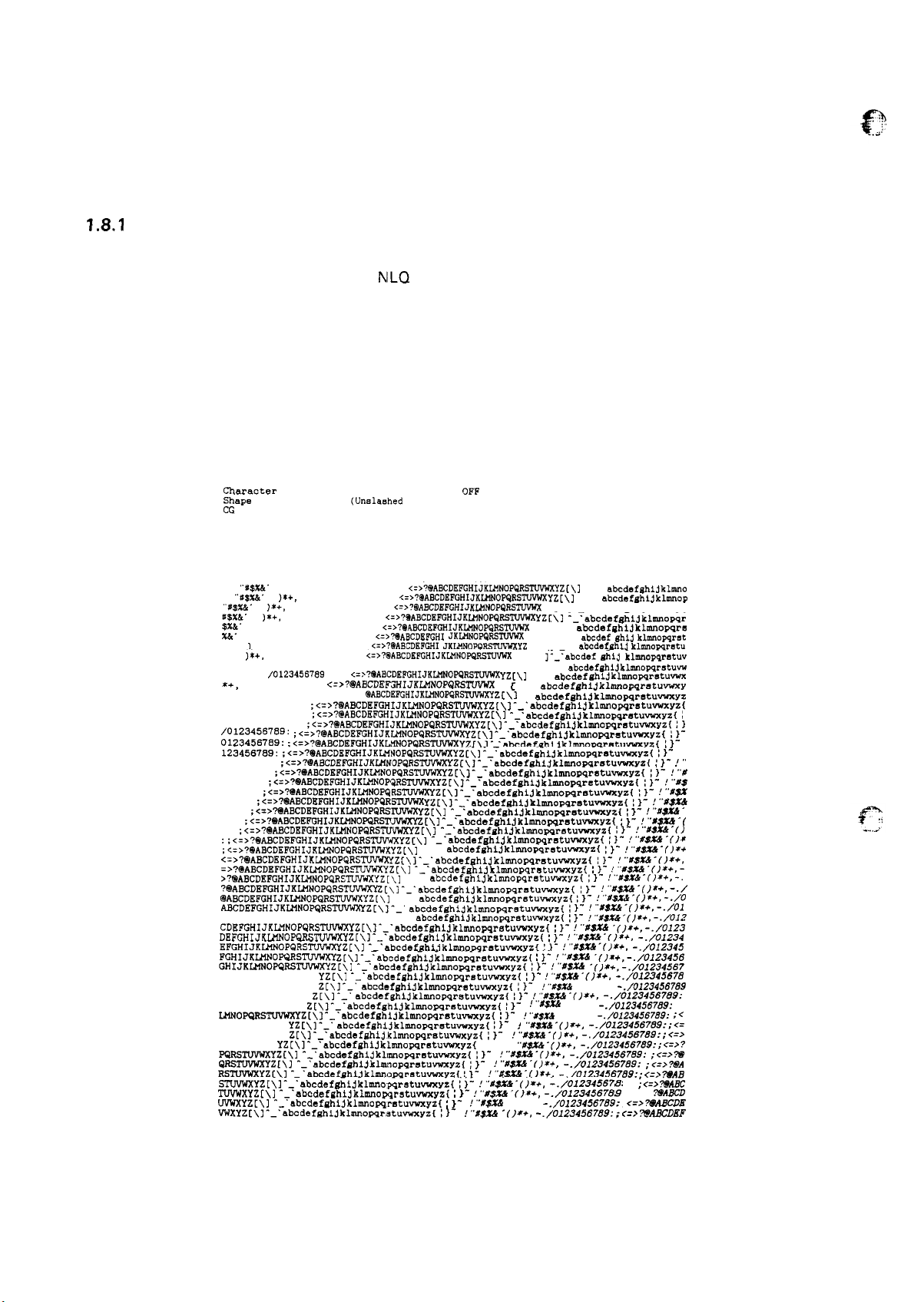

1.8.1 Self-Test

To begin printing the self-test in the Draft mode, turn the printer ON while pressing the LIN E-FEED button.

To begin printing the self-test using the

it down, then turn the printer power ON.

Self-test printing can be stopped or started by pressing ON-LINE (ON-LINE indicator is not lit). To finish

the self-test, stop the printing by pressing the ON-LINE switch then turn OFF the printer power.

The firmware revision number is printed as the first line of the self-test,

switch settings are printed.

Xxxxxxxx

Character

Shape

CG

Short Tear-off

Draft Print Speed High

Country

Page Length

CSF Mode

Skip Perforation

Auto LF

!

“’P$%&”

#$%&”

$%&”

%&’

&” ( ) *+, -./0 123456789: :

. (

( )%+, -. /0123456789: ; <=>?@ABC

)*+ ,-.

r+,

+ ,- ./0 123456769: ; <=>?

.-./0123456769: ;<=>?@ABCDEFGHIJKMOPQRSmXYZ[\l--`abcdefshijkl~0MrStU-YZ{

-./0123456769:

./0123456789:

/0123456769: ;<=>?@ABCDEFGHIJKIJlNOPQRSTWWX

0123458789: ;<=>?@ABCDEFGHIJKLKNOPQRSTUVWX

123456789: ;<.>?@ABCDEFGHIJKNNOPQRS~~YZ[i]:-=abcdefg~ij~lmopq~etuwyz{ :}-

23458789:

3456789:

456769:

56789:

6789:

769:

89:

9:

:;c.>?9ABCDEFGHIJKUlNOPQRSTUW4XYZ[\] ‘–.abcdefghijklmnopqretuv’wxyz( ;};<=>?@ABCDEFGHIJKl14NOPQRSTtIVWXYZ[\]

<=>?@ABCDKFGHIJK~NOpQRs~

=>?13ABCDEFGHIJKLM?40PQRS

>?@ABCDEFGHIJKLJ4NOpQRSTUVWXYZ[\]

?@ABCDEFGHIJKLllNOPQRSTUVWKY

@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]

ABCDEFGHIJKLMNOPQRSTUVWX

BCDEFGHIJKLMNOPQRSTUVWXYZ[\l ‘-.

CDEFGHIJKLMNOPQRSTUVWX

DEFGHIJKL4fNOPQRSTW.WKYZ[\l--’abcdefghijklmnopqrstuvwxyz( ;}- !“#$X&-()*+,- ./OlZ34

EFGHIJKLtiNOPQRS’fU%?4X

FGHIJKMINOFQFiSTWWXY

GHIJKLMNOPQESTWWXY

HIJKLHNOPQRSTUVWX

IJKLMNOPQRSTWWXY

JKLM140PQRSTWWKY

KLMNOPQRSTUVWXY

LMNOPQRS1’UWX

MNOPQRSTUV!4X YZ[\]-_” abcdefghijklmnopqretuvwxyz{ 1}NOPQRSTUVWKY

OPQRSTUVWX

PQRSTUVWKYZ[\l -_”abcdefghijklmmopqrotuvwxyz{ ;}QRSTUVWXYZ[\l --’abcdefghijklmnopqrstuvwxyz{ 1}RSTUVWXYZ[\l --’abcdefahlklmnocarstuwxyz(z( !?STUVWXYZ[il:-=abcdefgiiijklmno:a;stuvwxy;{ ~i; !“#ti’()*+,~ .>01234567,

TUVWXYZ[\l --’abcdefghijklmnopZrstuvwxyz{ ;}- !“#w&”()*+,- ./Ol2345678:

WWXYZ[\l

VWXYZ[\]–-’abcdefghijklmnoaratuvwxyz(z( ;}-

Spacing

of Zero

Table

!

“U$%&”

( )*+, -. /0123456789: ; <=>%ABCDEFGHIJKIMNOPQRSTUVWKY

“FF$.%&”

(

)*+,

-. /0123456769: ;

(

)*+,

-. /01234567.99: ;

(

)*+,

- ./0123456769: ;

( )*+, -. /0123456769: ;

( )*+, -. /0123456789: ;

)*+,

-. /0123456769, ;

/o12345678g

-. /012345.5789: ;

;<=>?SIABCDEFGHIJKUINOPQRSTW!4K

;<=>?@ABCDEFGHIJKU!NOP,WS

;<=>?@ABCDEFGHIJKLMNOPQRSTWVWX

:<=>?@ABCDEFGHIJKLtlNOPQESTUVWX

;<=>?@ABCDEFGHIJKLJlNOPQR31’UV!4K

;<=>?@ABcDEFGHIJKLrlNoPQRs17JVw’n

;<.>?@ABCDEFGHIJKLMNOPQRSTUWXYZ[\] “–’abcdefghijklmnopqrstuvwxyz{ t}- !“#3Xd-()

YZ[\l-–’abcdefghijklmnopqr6tu%wxyz{

”_’abcdefghijklmnonratuvwxyz{ 1}-

: ;

<=>?@ABCDEFOmlIJKLMNOPQRSTOVWX

;<=>7@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\l ‘–’abcdefghijklmnopqrstuvwxYz( :

:<=>?@ABCDEFGHIJK~OPQRSWXYZ[\l---abcdefghijklmonrstuwyz( ;}

;<=>?IPABCDEFGHIJKLHN3PQRSTUVWX

Z[\l ”-’abcdefghijklmnopqrc.tuvuxyz( )}- !“#$Xd” ()*.,-./Ol234567

YZ[\l ”-’abcdefghijklmnopqrstuvwxyz( ~}- !-#s%&-OZ+,-

Z[\l--’ abcdefghijklmnopqretuvwxyz( 1}-

Z[\l--’ abcdefghijklmnopqrstuvwxyz( 1}- ?“#sx.4’()*+, -./Ol23456789:

Z[\l-–’abcdefghijklmmopqratuwxyz( !}-

YZ[\]--’abcdefghijklmnopqrstuvwxyz{ ;)-

Z[\]-–’abcdefghijklmnopqratuvwxyz{ :}-

hlLQ

mode (Near Letter Quality), press FORM FEED and hold

and subsequently, current DIP

10 CPI

O

(Unalashed

Italics

Valid

U.S.A.

11 inch

Invalid

None

Depend on I/F

<=>?3ABCDEFOHIJKLMNOPQRS3’WJWX

<=>?6%W,CDEFGHIJKLMNOPQRSTUVWX

<=>?@ASCD8FGHI JKLMNoPQRSTUVWK

<.>?@tABCDEFGHI JKLMNOPQRS’fUVWXYZ

<=>?@ABCDEFGHIJKU4NOPQRSTUVWK

<=>?@ABCDEFGHIJKLMNOPQRSTOVWX

QABCDEFGHIJKLMNOPQRSTUVWXY

YZ[\l--’abcdefghijklmnopqrstuvwxyz( :}- !“#$X&-()*+,

TUTWXYZ[\l --’abcdefghijklmnopqratuvwxyz{ :}- !“#$Xd”()*+,-

Z[\]”-’abcdefghijklmnopqrstuvwxyz( ~}- !“#$xA”()*+,-./

“-.

YZ[\]”-’

YZ[\l--’abcdefghijklmnopqratuvwxyz( ;}- .I’’#$XA ”()*+,-./Ol23

YZ[\l ”–’abcdeft!hi3klmnowr8tuvwxyz{ !)- ?“#sx&-OX+.-. /O12345

Z[<l:_=abcdef~ijklmii~~ituwyz( ~j: r“#$X&”

1-1

)

<=>?@ABCDEFGHIJKLMNOPQRSTUVWX

<=>?@ABCDEFGHIJKMINOPQRSTTJVWX

DEFGHIJKLMNOPQRSTUVWXY

TUVWXYZ[\]--’abcdefghijklmnopqretuvwxyz{ ;}- !“#$

‘–.

‘-.

abcdefghijklmnopqretuwyz(

abcdefghijklmnopqrstuvwxyz{ !}- !“#s%&”OX+,-./Oli?

OFF

1-2 OFF

1-3

oFF

1-4 oFF

1-5 oFF

1-6 ON 1-7 ON 1-6 ON

2-1 OFF

2-2 OFF

2-3 OFF

2-4 OFF

YZ [\

Z [\] ‘-”

YZ[\l

YZ 1 \ 1‘_

Z[\l

YZ[\l-–”abcdefghi$klmnopqretuvwxYz{ ~}-

YZr\l- ‘abcdefghi~klmnopmstuvwwz{ :}-

YZ[\]-–’nbcdefghijklmnopqretuvwxyz{ ;?- !“

YZ[\]-_’abcdefghijklmnopqrstuvwxyz{ ;)- !“#

YZ[\l--abcdefghijklmnopqrotuwyz{

YZ[\l--’abcdef8hijklmnopqretuwxYz{ !}- !“#$Z4

YZ[\l ”–’abcdefghijklumopqrntuvwxYz{ 1}- !“#SXd”

Z[\l-–’abcdefghijklmnopqratuvwxYz{ 1}- !“#$XA’(

abcdefghijklmnopqratuvwxyz{ ;}- !“#SXA”f)*+

abcdefghijklmnopqretuvwxyz{ 1}- !“#$%&”()*+,-.

abcdefghijklmnopqretu..’wxyz{ ;}- ?“#$x&’()*+,-./O

!,,#$x’&-(),+, -./0123456789:;<=>

-

!

;}

!“#$X&-()*+, -./O123456789: ;<=>?@

!“#$Xd’()*+, -./Ol23456789: ;<=>?.9A

!’”#s.&4”()*+. -./Ol23456789:

!-X$X& -()*+.

!“#$X&o (]Jr+,- ./o1234567sg:

Z[\l

‘–’

YZ[\l

YZ[\l‘–“abcdefgbijklmopq

YZC\I ‘-=abcdefg~ijklmmopqr

YZ [\]

YZ [ \ 1‘–

[ \ 1‘–.

]:-yabcdef giij klmnopqratuv

‘-”

abcdef ghl.lklnmopqrstuvwx

abcdefghijklmnopqratuwxY

”

abcdefghijklmnopqretuvwxYz

!“#$x&”

!“#SXd”

()*+.- ./O123456769: ;

!“#$X&-

OX+,-.

! ,,#SX&-OX+,,,#$x&.OX+,- ./OIZ3456789:;<=>?

-./OlZ3456789

abcdefshijklmno

‘-’

abcdefghijklmnop

abcdefghijklmnopqre

abcdef ghij klmnopqrat

abcdefghld klmnopqratu

abcdefghi.lklmnopqratuvw

;}- !“#S.%

{“#S=-()~

1}- !-S$Xd-()*+.-./Ol

()*+,-./Ol23456

./O12345676

()*+,- ./Ol23458789

/OZZ345S789: ;<

./OLZ34567S9:;<=

:<=>?@AB

9:

;<=>WABC

: ;

<=>

;

<=>?W4ECDE

<=>?WBC7DEF

IWABCD

!

i&,””

Figure l-7. Self-Test Printout

1-18

Page 27

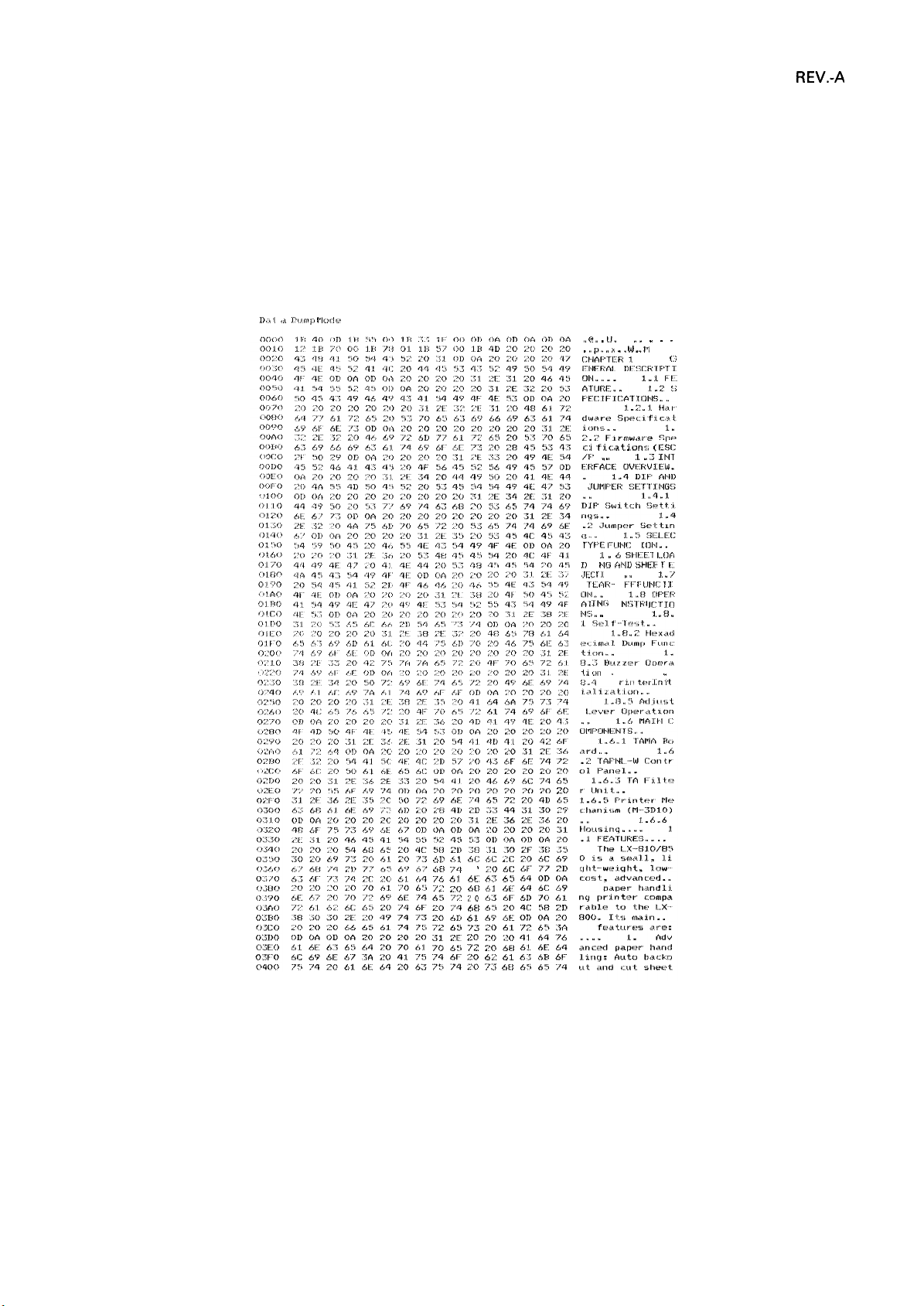

1.8.2 Hexadecimal Dump Function

REV.-A

The printer enters the HEX-DUMP mode when it is powered

on while the LINE-FEED

and FORM-FEED

buttons are pressed down.

the

In the HEX-DUMP mode, the hexadecimal representation of

input data is printed out, along with

corresponding ASCII characters. This function is valuable for checking the data the printer has received

from the host. If input data is a control code rather than a character code, a period (.) is printed in the

ASCII column.

r),<{ ,:! r?,..,.<),,:,

!“IC.,,IC:,

,,($,, ,, IL

“,’.:

,..

,, ,,,,,,, ,., ..,

Clllal,’’rr:.rv

<::~ f:i.c<at,i,cms (1+

/1,,

) ,, .,1.

fYI,r

D I

JE[::

‘11::.AI,V [.)

Al

.I’blr; ‘1’

1.1%, ,. 1.

“ .

I/J.

.,1”1

1, .

.::.:

1,1..IIw

r

[:m.t..

:1. ,, A SIH:::E!:’I

IN!:< {+141) !Wlx r’ K..

1’:l,

(.)11

,...

F’1,” l’,

1.11.1!:: ! :1’

bl!’;’l’F:ll [::’1’T1’)

I...(]fi

:1. .,7

,,0,,

.

(:;

:[i.’r

i. j.

!.,,,

.

,,

L;,,.1

1’,

!’:1.,, ?.(:,,

20

m

f,i::

.

.

[

.

20 6(::

6:?

/,[::

4(:)

<,:1

;.,, O

m

6:1.

‘7:;

:!()

‘7:!

(,2

‘;?:$ 61.;

fi:j

.’!(:

41:,’

61.

61) 61.

<!,8 ‘7.!

’74

fd

7:! ;’?()

Figure 1-8. Hexadecimal Dump Function

.1:,>$ t

,,

1-19

Page 28

REV.-A

1.8.3 Buzzer Operation

The buzzer sounds under the following conditions:

BEL

code:

Carriage trouble:

Paper-out:

Abnormal voltage:

Incorrect RAM:

The buzzer sounds for 0.1 second when a

Beeps 6 times, pausing briefly after 3rd beep.

Beeps 20 times, pausing briefly after every 4 beeps.

Beeps 5 times, pausing after every beep.

(SRAM) Beeps 8 times, pausing briefly after every 2 beeps. (Inside CPU)

Beeps indefinitely until

Recognition of panel operation:

Beeps 1 or 2 or 3 times in setting print mode.

Factory setting:

Sheet ejection failure (in CSF mode):

Illegal paper

releaselunrelease:

Beeps once when the value under micro-adjusting is equal to the

factory-set value.

Beeps 20 times, pausing briefly after every 4 beeps.

Beeps continuously when the paper release lever is changed when the

paper is in the paper path. Beeps until the lever is changed again or the

paper is completely out of the path.

power OFF.

BEL code is input.

.-

$,”.

.*

1-20

Page 29

REV.-A

1.8.4 Printer Initialization

The printer is initialized when:

1 ) AC power is turned on

2) The INIT signal is input

Here is a brief summary of the initialization sequence.

a)

Return the printhead to the Ieftmclst position.

b)

Set ON LINE mode.

c)

Clear the print buffer and input buffer.

d)

Set the line spacing to 1/6 inches.

e)

Set the page length to 11 or 12 inches according to the DIP switch setting.

Clear all vertical tab positions.

f)

Set the horizontal tab position at 13-column intervals.

9)

h)

Set the print mode according to tlhe DIP switch setting and the non-volatile memory setting of

the control panel.

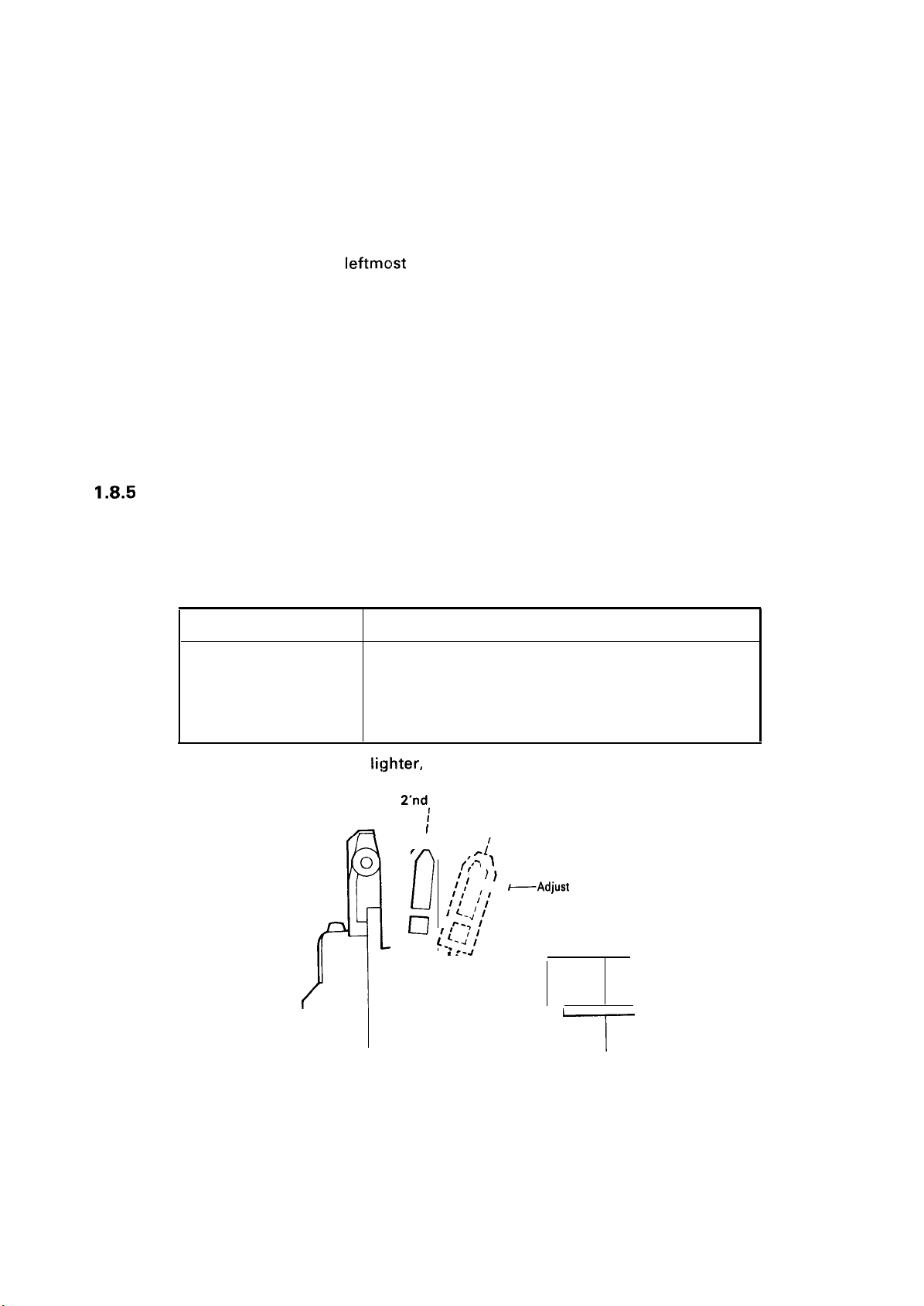

1.8.5

Adjust Lever Operation

The adjust lever must be set to the proper position according to the paper of paper you are using. Refer

to Table 1-16 and Figure 1-9 below.

Table 1-16. Lever Position

~Adjust

Paper

Lever

Lever Position

2nd step

3rd step

4th step

4th to 7th step

● If printing density becomes Ii!ghter, set the adjust lever position one step narrower.

F

Cut sheet, continuous paper (non copy, 1 + 1 copy)

Continuous paper (1 +2 copies)

Label

Envelope

2’ndl

position

4’th position

m

o

/

f;’-’

t, )}

II

o

I

<.41 I

I

l..

u

““~

l’.

$..;/’

pi,

/

~“

‘

L

I

7

Figure 1-9. Lever Position

1-21

Page 30

REV.-A

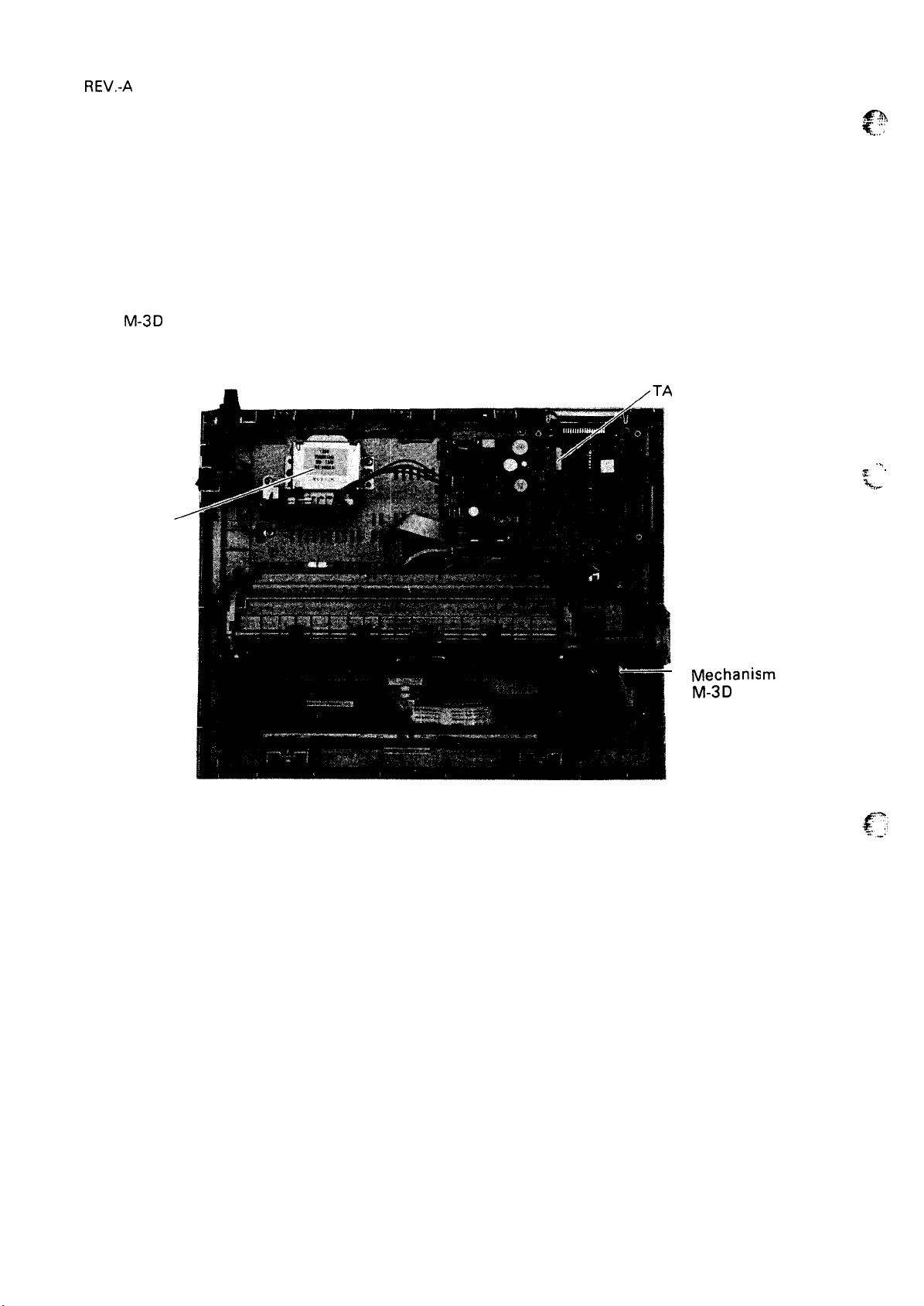

1.6 MAIN COMPONENTS

The main components of the LX-8 10/850 printer are designed for easy removal and replacement to

maintain/repair the printer.

The main components are:

1 ) TAMA board: Main control board. The CPU on this board controls all main functions.

2) TAPNL-W control panel: Control panel.

3) TA filter unit: Transformer and filter board.

M-3D 10: Printer mechanism.

4)

MA board

TA

Filter

Unit

. . .

t..

Figure 1-10. 1.X-81 0/850 Component Layout

Printer

—

Mechanis

M-3D

10

1-22

Page 31

1.6.1 TAMA Board

REV.-A

The use of the

~PD78

10HG CPU simplifies the main control board circuit design.

. PROM (3C)

(3D)

-SRAM

Gate Array

E05430 (3B)

- CPU

LPD78 10HG

(2C)

1.6.2

The

TAPNL-W

switches.

TAPNL-W

control panel is the LX-8 10/850 control panel which contains the indicator LEDs and

Figure 1-II 1.

Control Panel

Figure

TAMA

1-12.

TAPNL-W Control Panel

Main Control Board

1-23

Page 32

REV.-A

1.6.3

TA Filter Unit

The TA filter unit contains a power cord ( 120V Version) or AC inlet

fuse, filter circuit, and power transformer.

(220V

(120V Version)

Version)

Figure 1-13. TA Filter Unit

1.6.4 Printer Mechanism (M-3D1O)

The M-3D 10 printer mechanism was developed specifically

include:

Carriage motor

Carriage mechanism

Paper feed motor

Paper feed mechanism

Ribbon feed mechanism

Printhead

Sensors

for the LX-8 10/850 printer. Its components

(220/240V

(240V

Version), power switch

Version)

Figure 1-14. Nlodel-3Dl O Printer Mechanism

1-24

-.

Page 33

REV.-A

1.6.5 Housing

The LX-8 10/850 housing consists of the upper and lower cases. The upper case houses the control

panel. The lower case houses the printer mechanism and the main control board.

f:igure

1-15. Housing

1-25

Page 34

CHAPTER 2

PRINCIPLES OF OPERATION

REV.-A

2.1

OVERVIEW

2.1.1 Connector Summary

2.1.2 Outline of Printer Mechanism Operation . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.3 Circuit Overview

2.2

PRINCIPLES OF OPERATION

2.2.1 Power Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Reset Circuit

2.2.3 Carriage Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2.1 Sensors

2.1.2.2

2.1.2.3

2.2.1.1 TA Filter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.2 + 12V DC Power Supply Circuit . . . . . . . . . . . . . . . . . . . . 2-12

2.2.1.3

2.2.1.4 +5A/ DC Power Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.2.2.1 Power-on Reset

2.2.2.2 Operation at Reset

2.2.2.3 Power-off Reset

Mc~tors

Printhead

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+2!4V

DC Power Supply Circuit . . . . . . . . . . . . . . . . . . . . 2-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1

2-4

2-7

.

2-7

2-8

2-10

.

2-10

.

2-11

2-20

2-20

2-21

2-21

2-22

2.2.3.1 Carriage Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.2.3.2 Carriage Motor Specification

2.2.3.3 Carriage Motor Drive Circuit

Block Diagram

2.2.3.4 Carriage Motor Drive Circuit

2.2.3.5 Carriage Motor Software Control ................. 2-32

2.2.4 Paper Feed

2.2.4.1 Paper Feed Mechanism Operation ................ 2-35

2.2.4.2 Paper-Feed Motor Specifications ................... 2-36

2.2.4.3 Paper-Feed Motor Drive Circuit . . . . . . . . . . . . . . . . . . . . . . 2-37

2.2.4.4 Paper-Feed Motor Software Control ............. 2-38

2.2.5

Printhead

2.2.5.1

2.2.5.2

2.2.5.3

2.2.5.4 Gate Array E05A30 Operation in

Printhead

Printhead

Printhead

Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Operation

Specification

Drive Circuit Block Diagram ....... 2-40

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printhead

2-22

2-23

2-24

2-35

2-39

2-39

2-39

.

2-40

2-i

Page 35

REV.-A

2.2.5.5

2.2.5.6

2.2.6 Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.7 EEPROM Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.8 Ribbon-Feed Mechanism

Printhead

Printhead

Software Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Drive Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-41

.

2-44

.

2-45

2-46

LIST OF FIGURES

Figure 2-1.

Figure 2-2.

Figure 2-3.

Figure 2-4.

Figure 2-5.

Figure 2-6.

Figure 2-7.

Figure 2-8.

Figure 2-9. Printhead

Figure 2-10. TAMA Board Block Diagram

Figure 2-11. Power Supply Circuit Block Diagram

Figure 2-12. Transformer Circuit

Figure 2-13. + 12V DC Power Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-14.

Figure 2-15. Rectifier and Smoothing Circuit

Figure 2-16.

Figure 2-17. Voltage Feedback Circuit

Figure 2-18. Over-Current Protection Circuit

Figure 2-19. Output Transistor Drvie Waveform

Figure 2-20. Chopping Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-21.

Figure 2-22. Reset Circuit

Figure 2-23. RESET Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-24. Carriage Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-25. Carriage Drive Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-26. Carriage

Figure 2-27. SLA 7020M Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Figure 2-28. Phase Data Input Circuit (2-2 Phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Figure 2-29. Phase Signal Timing Chart (2-2 Phase) . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Figure 2-30. Phase Data Input Circuit (l-2 Phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Figure 2-31. Phase Signal Timing Chart (l-2 Phase) . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Figure 2-32. Reference Voltage Generation Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Figure 2-33. Constant Current Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Figure 2-34. Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-35. Carriage Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer

Paper-End

Paper-End Sensor

Home-Position Sensor Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Home-Position Sensor Circuit

Release Sensor Mechanism

Release Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+24V

DC Power

+24DC

+5V

Mechi~nisrn

Sensor Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SupPly

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switching Regulator Circuit

DC Power Supply Circuit

Motor

Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Block Diagram

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

2-2

2-3

.

2-4

2-5

2-6

.

2-6

2-7

2-8

2-10

2-11

2-12

2-13

2-13

2-14

2-15

2-16

2-17

. 2-18

2-19

2-20

. 2-20

.

2-22

. 2-30

.

2-33

p

.., ,.,

,,, ,

Z.ii

Page 36

REV.-A

Figure 2-36.

Figure 2-37.

Figure 2-38.

Figure 2-39.

Figure 2-40.

Figure 2-41.

Figure 2-42.

Figure 2-43.

Figure 2-44.

Figure 2-45.

Figure 2-46.

Figure 2-47.

Figure 2-48.

Figure 2-49.

Figure 2-50.

Figure 2-51.

Home-PositionSeak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Area and Printing Timing

Friction-Feed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Push Tractor Feed Operation

Paper-Feed Motor Drive Circuit

Paper-Feed Motor Drive Timing Chart

Printhead

Printing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Printhead

Printhead

Printhead Driving

Print Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/D Converter

Relationship between Head Driver Voltage and

Print Driving Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Interface

EEPROM Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon-Feed Mechanism

Drive Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveforms

(+24V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VDC Line Monitor) Circuit ..... 2-42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

2-33

2-34

.

2-35

2-36

2-37

2-38

.

2-47

2-41

.

2-42

.

2-43

2-44

.

2-45

2-46

LIST OF TABLES

Table 2-1.

Table 2-2.

Table 2-3.

Table 2-4.

Table 2-5.

Table 2-6.

Table 2-7.

Table 2-8.

Board Connecl:or Summary

Voltage Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

Phase-Excitation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Sequence (2-2 Excitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Drive Sequence (l-2 Excitation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Excitation Sequence (Clockwise : Paper Feeds

Forward)

Ribbon-Feed Gear Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voll:age

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

. 2-10

2-28

.

2-32

2-38

.

2-46

Z.iii

Page 37

REV.-A

2.1 OVERVIEW

This chapter describes the signals at the connectors linking the primary components of the LX-8 10/850.

These components include the printer mechanism and control circuits. The chapter also describes the

operation of the printer’s circuitry and

2.1.1 Connector Summary

The interconnection of the primary components is illustrated in Figure 2-1. Table 2-1 summarizes the

functions, sizes, and types of the connectors shown in the figure.

Table 2-’1. Board Connector Summary

/printer mechanism.

Board

TAMA

Board

Connector

CN

1

CN2

CN3

CN4

CN5

CN6

CN7

CN8

CN9

CN 10

Function

Host l/F (Parallel)

Optional I/F

Control Panel

Release Lever

CR Motor and PF Motor

PE Signal

Home Position Signal

Head

AC Power Input

DC Power Input (OEM)

:

Board

Pins

36 1-11

26 A-8

10

2

12

2

2 A-13

12

4

4

Reference Table

A-9

A-1 O

A-1 1

A-12

A-1 4

A-15

A-16

2-1

Page 38

REV.-A

FiiEElr

Board

Control

Panel

Model 3D 10 Printer Mechanism

Release

CR motor

PF motor

PE

HOME

HEAd

—

,

1 OPin

2Pin

TAMA Board

12Pin

2Pin

c

:

.5

: 5

co

ii~

-u

n

.5

L

-

36 Pin

m

L

J

Paralel

l/F

c

m ,-

zn

“:

n

[

Optional l/F

)

‘1

Optional

Interface

Board

l-l

I

Parallel l/F j Specific l/F

l----------~ ----------i

HOST COMPUTER

I

I

I

II

E

5

co

m

z

u

Power Input I

(OEM)

I

TA Filter

r–––––––n

I

Transformer

I

I

I

/\

I

I

Filter

I

Board

I

I

t:

I

L

AC”IN

Unit

“’?

,.

L’

I

1

I

1

‘

~-..

., .,..,.

NOTE: CR = carriage.

PF = paper feed.

HP = home position.

PE = paper end.

Figure 2-1. Cable Connections

2-2

Page 39

REV.-A

2.1.2 Outline of Printer Mechanism Operation

Model 3D 10 is a 9-pin serial dot matrix printer. Because the frame and many of the components

The

are of plastic, the mechanism is lightweight. A block diagram of the printer mechanism is shown in

Figure 2-2.

&

z

w

f

5:

:: :

U

m

$

A

u

a

~.:

(0

--(>

NE

=0

0+

Ku

v<

~~

u

1

~

2’:

$.:

~:

$

.-

CW = clockwise; CCW= counterclockwise.

HP = home position; PE= paper end.

Figure 2-2. Printer Mechanism Block Diagram

2-3

Page 40

REV.-A

“.. .

~.

,-

2.1.2.1 Sensors

The printer mechanism is equipped with the following sensors:

Paper-End

Home-Position (HP) Sensor

Friction/Tractor Sensor

(PE)

Sensor

Paper-End Sensor

Figures 2-3 and 2-4 show the paper-end sensor. This sensor switch is ON when no paper is in place

(e.g., when the paper supply has run out).

“Paper-out”

Paper present

(PE

~

ON ~ LOW

~

OFF + HIGH

sensor)

~Jq~

o

/

‘“Paper-out”

Platen

Paper guide

Paper-End Sensor

/

Paper

o

c~

/

“Paper present”

Figure 2-3. Paper-End Sensor Mechanism

+5V

&&.

7A’

Figure 2-4. Paper-End Sensor Circuit

R96

IK

2-4

Page 41

REV.-A

Home-Position Sensor (HP sensor)

Figures 2-5 and 2-6 show the home-position sensor. The sensor switch is ON when the carriage is at

the home position.

Home position + ON

Other positions + OFF - HIGH

This sensor determines the reference

-+

LOIA/

pcxsition

for the carriage drive,

age guide

iage

shaft

Figure 2-5. Home-Position Sensor Mechanism

+5V

4

CN7-1

<o—————u

R97

IK

J

Figure 2-6. Home-Position Sensor Circuit

-

HOME

2-5

Page 42

REV.-A

Friction/Tractor Sensor

The release sensor senses the position of the release lever in order to detect whether tractor feed or

friction feed is in effect.

Release Lever Position : Front + F:riction Feed + OFF + HIGH level

Release Lever Position : Rear -+ Tractor Feed ~ ON ~ LOW level

:$-2!

+.

Front

\

?“’”-

\ i,

\

~.

<

~

Figure 2-7’.

Rear

/

ease

Lever

w

Friction/Tractor Sensor

Release Sensor Mechanism

+5V

4

r’

oJKL-=

R95

IK

Figure

:2-8.

Release Sensor Circuit

2-6

Page 43

REV.-A

2.1.2.2 Motors

This printer has the following motors:

Carriage motor (step motor)

Paper-feed motor (step motor)

Carriage Motor

The carriage motor is used to move the carriage right and left along the platen. This unit employs a

4-phase, 48-step motor using either 1-2

Paper-Feed Motor

Paper feed is also driven by a 4-phase 48-step motor operating with 2-2 phase excitation. Each phase

switch causes the paper to advance by advanced 1/2 16“ for each phase switch. The gate array controls

the motor through an open loop.

or 2-2

Phase excitation.

An

open-loop system is Used for control.

2.1.2.3

Figure 2-9 shows the dot-wire operation.

When the head-driving coil is energizecl, the dot wire is pushed out. The dot wire strikes the ribbon,

causing the ribbon to impact the paper, thereby printing a dot.

Printhead

/Ribbon

Platen

Dot

‘Core

Figure 2-9.

Printhead

2-7

Page 44

REV.-A

2.1.3 Circuit Overview

h,

,.

f.

Figure 2-10 shows a block

--7rmm

ADDRESS

i

PD78 10HG

(2 c)

EEPROM

(1 c)

B

XWl

DATA/ADDRESS BUS (LOWER BYTE)

~Q=

,LE

J

‘Usir+km+=l

diagram of the TAMA board circuitry.

PROM

32KB

r

BUS

(UPPER

ADDRESS

LATCH

(3C)

BYTEI

I

GA E05A30 (36)

RAM

8KB/32KB

h

A[)DRESS

DECODER

‘3”)’

CONTROL PANEL

I

CONTROL PANEL

LED DRIVE

I

24VDC +5VDC + 12vDC

+

t

t

t,

CG = character generator; GA = gate array.

Figure 2-10.

The circuit consists mainly of the following

● ~PD7810HG CPU (2C)

The

~PD78

Upon receiving the RESET signal, the

● PROM (3C)

The PROM includes the control program (firmware) and character generators.

“

SRM

The

SRM

for expanding data, and as working area for the program.

10HG executes the program in the PROM (3C) and controls all of the printer operations,

2064C

2064C

(3D)

SRAM is external melmory for the CPU. It is used as an input data buffer and line buffer

TAMA

Board Circuit Block Diagram

ICS:

CPIJ

begins program execution from address

OOOOH.

. . . . . .

<-.,’.,

2-8

Page 45

●

E05A30

The

gate array (3B)

E05A30

functions are as follows

1. Parallel l/F

2. Address decoder

3. Data address multiplexer

4. PF motor control

5. CR motor control

6. Control panel LED drive

7. Printhead drive control

REV.-A

● EEPROM

(lC)

The EEPROM has a 256-bit memory, and remembers the current paper position.

Other control circuits are as follows:

‘ Paper feed motor drive circuit

The paper feed motor drive circuit

drive:; the paper feed motor. The paper feed motor is a 4 phase-step

motor. The rotation of the motor (position and speed) is controlled by outputting the phase switching

signal by the

● Carriage motor drive circuit

E05A30

gate array.

The carriage motor drive circuit drives the carriage motor. The carriage motor is a 4 phase-step motor.