Page 1

,’

LX-810 DOT-MATRIX PRINTER

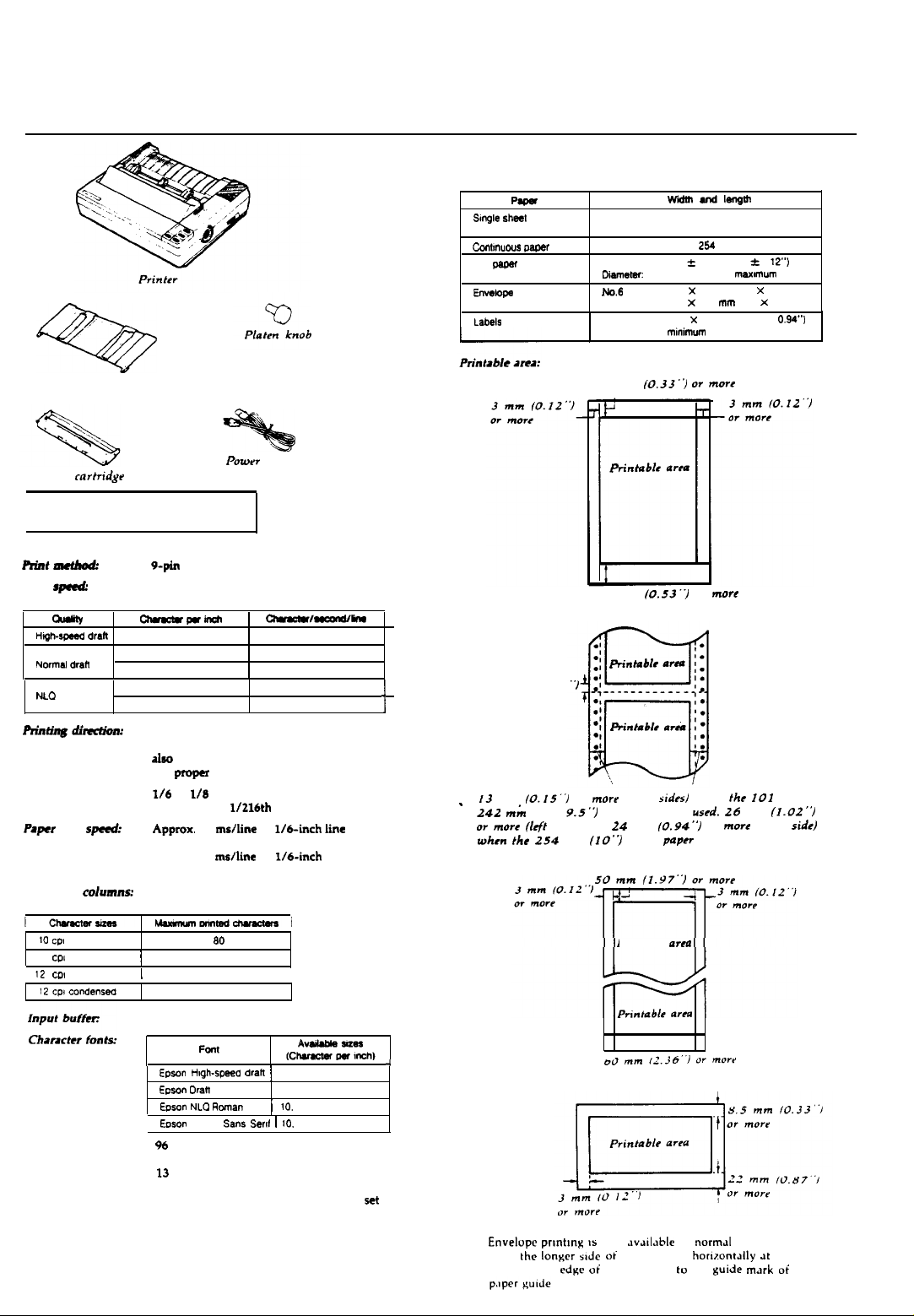

Paper

Paper width and Iength:

PIwr

Scqle

sheet

c‘ml1nuPus paper

Roll

paper

EMlope

LLb%lS

Width:

Length:

width:

Width:

Diametef:

No.6

MO.10

wm md lerqJl

162 to 257 mm (7.2 to

162 to 364 mm (7.2 to 14.3”)

101 to 264 mm (4.0 to 10.0”)

216 r 3 mm (6.5 f 0

127 mm (5.0”)

166 X 92 mm (6.5 X 3.6”)

240 X 104 mm (9.4 X 4.1”)

63.5 X 23.6 mm (2.5 X 0.94’7

mWnum

10.1")

12”)

maxw’f~“m

Q

Paper guide

Ribbon

cartridgr

Printer Specifications

Printing

Rintllwtb&

R,int

apad

w

Hv~h-weed awt

Nomal draft

NLO

Phlttngclkction:

Line spacing:

PaPer feed

Printable

spcc&

columns:

9-pin

impact dot matrix

-puinoh

10

10

12 160

10

12

Bidirectional logic-recking for text

printing. Unidirectional for graphics (can

aho

be switched to bidirectional by using

the

propa

l/6

or

l/g

increments of 1/216th of an inch.

Approx. 75

spacing during continuous feeding.

Appmx. 95

spacing during intermittent feeding.

Powrr

cable

-leaonwhu

200

150

25

30

software command).

inch, or programmable in

ms/linc

at

l/6-inch line

n&line

at

l/6-inch

line

Single sheet

8.5 mm

13.5 mm

(0.33’7 07

(0.53’7

or

more

mow

Continuous paper

(0.35)

9 mm

I

13

mm

10.1s”)

or

mmr

’

242 &I

(4 to

9.2”)

width paper is used. 26 mm

or more (left side) and 24 mm

when the

254

mm

(10’7

(both sides) when

(0.94”)

width

paper

the IOI

mm to

(l-02”)

or more fright side)

is used.

Envelope

10 cpt

10

CCI

condensed

I 12

CD!

Characters:

9 - Pin Printers

60

I

I

137

160

96

I

4K byte

I

FOnt

Epson High-Speed draft 1

Ecsan oran

Eoson NLO Reman

Eoron

NLQ Sam

96

standard ASCII character set (including

10

i IO.

Set11 1 IO.

10. 12

12

12

italic characters)

13

international character sets (including

italic characters)

Epson Extended Graphics character set

4

5/1/89

.

Envelupc

. Keep the

. Align the left

prmtmg 15 only

lonyer s& oi

Printable

I

,

area

Roll paper

.~v.Clahlc

edge oi

the envelope

the envelope to the guide mark oi the

at normal temperature.

horwontally Jt

setting

LX-810-1

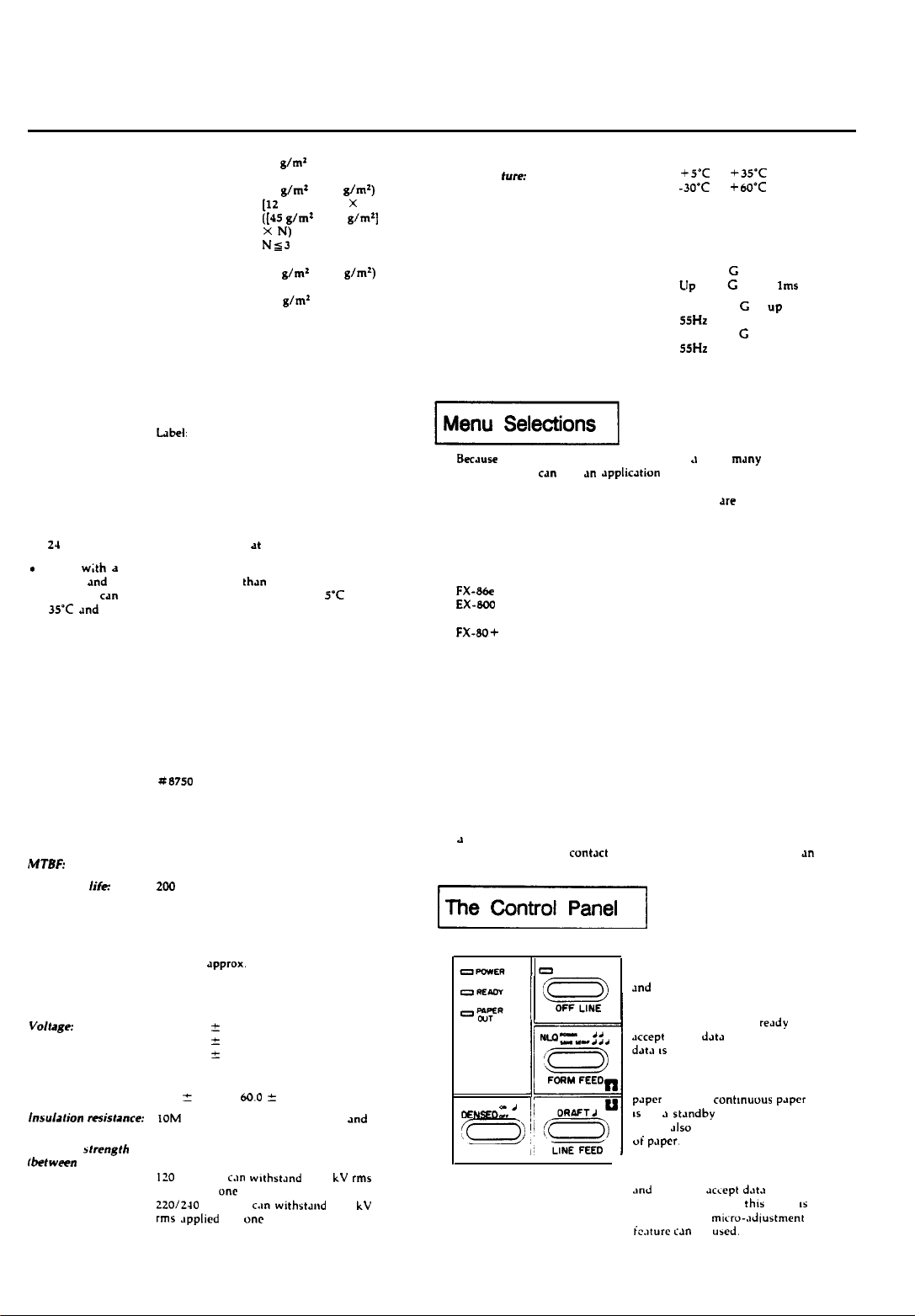

Page 2

LX - 810 DOT - MATRIX PRINTER

Paper weight:

Paper thickness:

Single sheet:

Continuous paper:

Multi-part forms:

Roll paper:

Envelope:

Single sheet:

Continuous paper:

Roll paper:

Envelope:

Abel:

14 lb to 24 lb

(52 g/m2 to 9-J g/m*)

14 lb to 22 lb

(52

g/m’

to 62

[12

lb to 15 lb]

([45 g/m* to 56 g/m*]

X

N)

Ns3

14 lb to 17 lb

(52

g/m’

to 64

12 lb to 24 lb

(45 g/m2 to 90 g/m*)

0.065 to 0.140 mm

(0.0025 to 0.0055”)

0.065 to 0.250 mm

(0.0025 to 0.0098”)

0.070 to 0.090 mm

(0.0028 to 0.0035”)

0.160 to 0.520 mm

(0.0063 to 0.0197”)

0.160 to 0.190 mm

(0.0063 to 0.0075”)

including the base

sheet

Copy capacity:

Up to 3 sheets including the original. Total

thickness must not exceed 0.25 mm

(0.0098”).

.24 lb paper printing is only available at normal temperature.

*

Label

with

pasting

a Pressure sensitive paper jointed by dotted or

and

its total thickness is less

than

or equal to 0.3 mm

(0.0118”) c.m be printed out under the condition of 5’C to

35’C

.md 10% to 80% RH.

Mechanical

Paper feeding

methods:

Friction

Push tractor

Cut sheet feeder (optional)

Pull tractor (optional)

Roll paper holder (optional)

Ribbon:

Cartridge ribbon, available in black:

se.750

Life expectancy at 14 dots/character:

3 million characters

MCBF:

For all components excluding print head:

3 million lines

MTBF:

Print head

/ifez

4000 power-on hours (duty 25%)

200 million strokes/wire

Dimensions

and wright:

Height:

Width:

Depth:

Weight: ~Pprox. 5.8 kg

141 mm

416 mm (excluding platen knob)

339 mm

Electrical

Vohge:

Power consumption:

Frequency:

lnsulalion resislance:

120 VAC

220 VAC

240 VAC

+

10% (120 V model)

c

10% (220 V model)

c

10% (240 V model)

28 W (self test printing: draft mode)

50.0

f

0.5 Hz,

6~10 2

0.5 Hz

10M ohms between AC power line

chassis

Dielectric

fbeelween

chassis):

strength

AC line and

I20 V model c.m

applied for

220/240

rms

one

V model cm

applied

for

wIthstand

minute.

onr

minute.

I 00 kV rms

withstrnd

1.25

g/m’)

X

g/m’)

and

N

kV

Environment

f5’C

to

Tempera

tore:

Humidity:

Shock:

Vibration:

Operation angle:

Operation:

Storage:

Operation:

Storage:

Operation:

Storage:

Operation:

Storage:

-3O’C to

10% to 80%

(without condensation)

5% to 65%

(without condensation)

Up to 1 C within lms

Lip

Up to 0.25 G at up to

55Hz

up to 0.50 c at up to

55Hz

Less than 15’ (without cut sheet feeder)

0’ (with cut sheet feeder)

Because the family of Epson printers shares .I great

commands. you

can

“se .m

JpplicJtion

program even if it does not

+35-z

f6o’C

to 2 C within

many

list the LX-810 on its printer selection men”. If the LX-810 is not

listed, choose one of the following printers. They

.we

listed in

order of preference.

LX-600

Lx-66

LX-80

FX-850

FX-86e

EX-600

FX-85

FX-SO+

FX-80

If none of these printers is listed, select the first one available on

the following list:

Lx

FX

EX

RX

MX

Epson printer

Standard printer

Draft printer

To “se all of the features of the LX-810, however, it is best to “se

.I

program with the LX-810 on its men”. If your program does not

list any LX printers,

contact

the software manufacturer to see if

update is available.

-1

Lights

0

ON LINE

POWER (green)

On when the power switch is on

and

power is supplied.

READY (green)

On when the printer is

accept

input d&e Flickers while

data IS

printed.

PAPER OUT (red)

On when the printer is out of

CON-

c.,

OENSE0.a.. J J

m)

LOAD/EJECT

or when

LS

in .I

printer

0i paper.

ON LINE (green)

contmuuus p.~per

standby

position. The

.~lso

beeps when it is out

paper

On when the printer is on line

.d

ready to

the computer When

flickering. the

ic.lturc

can be

accept d.lt.1

this

micro-.jdlustment

wd.

lms

ready

from

light

in

to

1s

LX-810-2

5/1/89

9 - Pin Printers

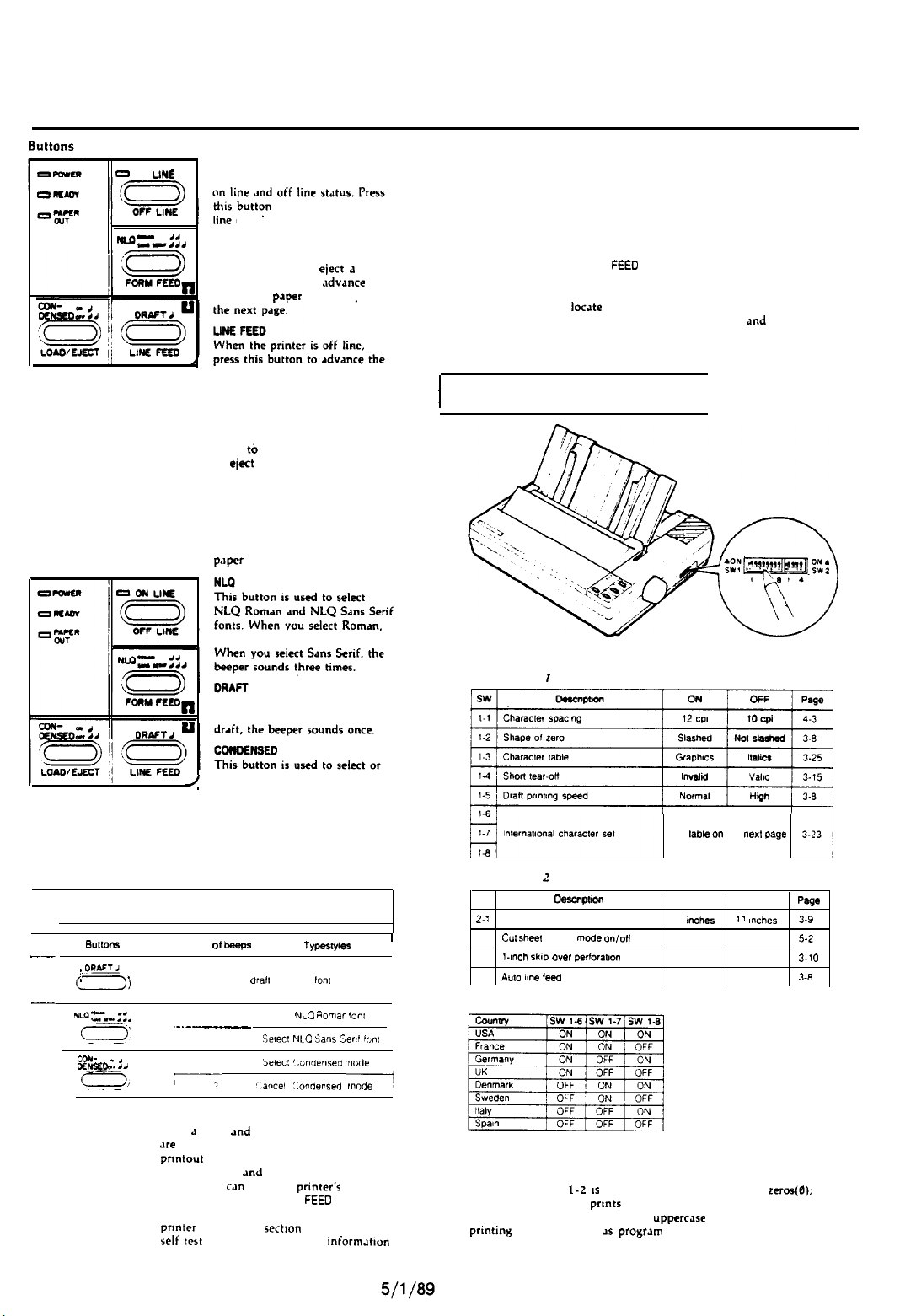

Page 3

LX - 810 DOT- MATRIX PRINTER

SelecType

0

ON UNE

Nln-

u-2,

ON LINE

This button controls the printer’s

to put the printer on

or take it off line.

FORM FEED

When the printer is off line.

press this button to eject a single

sheet of paper or to

continuous

paper

to the top of

.ldvance

paper one line, or hold it down

to advance the paper

continuously.

LOAD/EJECT

This button is used to feed the

paper to the loading position, or

to eject paper that is already

loaded. Paper is ejected forward

if the paper release lever is set to

the single sheet position and is

ejected backward (removed from

the paper path) if the release

lever is set to the continuous

paper

position.

Micro-adjustment:

By pressing the FORM FEED and LINE FEED

buttons immediately after loading paper or

when using short tear-off, you can make

fine adjustments to the loading and short

tear-off positions. See the sections on

adjusting the loading position and using

short tear-off later in this chapter.

Data dump:

By holding down both the LINE FEED and

FORM

FEE0

buttons while turning on the

printer, you turn on the data dump mode.

This feature allows advanced users to

locate

the source of communications

problems between the computer

printer. See the section on using the data

dump mode later in this chapter for more

information.

1

Setting the DIP Switches

and

the beeper sounds two times.

This button is used to select

draft printing. When you select

/

deselect the condensed mode.

When you select the condensed

mode, the beeper sounds once. In

this mode all characters are

printed at approximately 60% of

their normal width. When you

return to the normal mode, the

beeper sounds twice.

Note: Condensed mode cannot be selected when either of the

NLQ fonts have been selected.

--~

-

Buttons

-cm-

(jI t Select

N~Q~.w::d

-.

a))

CON- ^,

c.E_HqD ” i

0,

Number 01 beeps i

...-____

;

TYpesWM

drall

Ion!

Select

NL3 i(oman km!

Select NLC Sans serif fOrl1

kdec:

‘Andensed mode

‘-,ancel ConOensed InOde

Other control panel features

Self test:

Both J draft

xc

built into the printer. The self test

prmtout

switch settings

printer You can start the

by holding down the LINE

the FORM FEED button while switching the

prmter

belf tebt

and

NLQ self test function

lets you check the current DIP

and

operating status of the

prmter’s

FEE0

button or

on See the

in Chapter 1 for more

section

on running the

information

-7

self test

The DIP switch tables

DIP Switch

DIP Switch

SW

2- 1

I

2-2

2-3 I-Inch Skip over perbrahon

2-4

i

.?

Page

length

Cul sheet

feeder

Auto itne leed

-Pbm

mcde onloU

See

table on

ON

12

mches

ON

ON

ON OFF

the

next Page

OFF

1

I

inches

OFF

OFF

Page

3-9

5-2

3.10

3-0

International character set

The DIP switch functions

Slashed zeros

When DIP switch

when OFF, the printer

for clearly distinguishing between

prmting

documents such JS

l-2

1s

ON, the printer prints slashed zeros(0);

prmtr

open zeros (0). This feature is useful

upperuse

progran

0 and zero when

lists.

9 - Pin Printers

LX-810-3

Page 4

LX-810 DOT- MATRIX PRINTER

Draft printing

sp&d

When DIP switch 1-5 is OFF, the printer can print up to 200 draft

characters per second: when ON, the printer can print up to 150

characters per second. The high speed

settmg

is effective only

when printing at 10 cpi (characters per inch). When printing at

different pitch, this switch is ignored and the printer prints up to

150 characters per

Auto line

feed

second.

When auto line feed is ON (DIP switch Z-4 ON), each carriage

return code (CR) is automatically followed by a line feed code

U-F).

1

Defaults

1 Font

se1eckx

SPeml pnnnng

Graphtc

mode

I

1

effects

ass,gnmen,

1

The

cunen,

SelecTwe

ranma

1 Cano3Hed

ESC K = ESC * 0. ESC L = ESC * 1,

ESC Y = ESC * 2. ESC Z - ESC * 3

Selecting Character Sets

d

Italics

Epson Extended Graphics

i

1 councly

I

OUSA

1

France

j2Germany

3UK

, 3 Denmark 1 x $ 8 5 0 A

! 5 Sweden

/

6

;

7

~~

,23 24

1 1 $ e [ \ 1 : * C : 1 - ON ON 1

I* $

,,,;g:-:

f J

‘fafy

Span 1

It a

‘S$O’\6

/ R s e i

A.scllcPdeflex

40 58 5c 50 5E 60 78 7c 70 7E

a

e c \ 1 : ’ E : 1 :

B A Cl A 0 6 & 6 d II

R i ^ . ” fl } - OFF OFF/OFF

l-6

“,~8~EZ$“j,F

‘aa6

- t

& 6 & i OFF OFF j ON

04”FF;;;;

OFF &OFF

DIP

SW

1.7 / l-6

ON

Selecting Typestyles

HIGH-SPEED DRAFT

!"*$Xh'O*+.-./012345878S::c=>?BABCDEFOHIJK

LnNOPQRSTUVWXYZ[\l-_‘abcdsf~hijklanoWrstuv

wxuzt

: )We've

just

seen

miniature

zebras

for quantities over one. gross?

NL(1 SANS

SERIF

~~~a8%&'o~~.-./012345~789::~=~?~~BCDEFGH1JK

L~NOP~RSTUVWXVZC\l’~~bCd~fgh~Jkl~nOPqrStuv

wryrl: : 1’

your excellent ad for

in a recant back

What is the

price echedule

ioouc

of

[Papernandling

Using Short Tear-Off

When yw ,I~C

.utomatiully

tar-&f

sheet

loading

between Llocument~.

To uw thlb

paper

P!?

Using micro-adjustment

1

Make sure that the

sheet or

2.

Press the LOAD/EJECT button to feed paper to the loading

pooltion. Then press the ON LINE button: the ON LINE light then

bel5ma

r---

Note: You can use the FORM FEED

micro-adiustment

-___-

3.

Press the FORM FEED button to feed the

LINE FEED button to feed the

the desired loading position. you c.m begin printing; the ON

LINE light stops blinking

finished printing,

iccds the perior.~tion

edge of

the

printer

When you resume printing.

posahon. This

ir.ltu:e,

iedture

set DIP

the

short

t,i the

cover SO that

the piper

lets

you

,witch l-4

tear-off feature

continuous paper tu the

you cdn

feeds

tex

backward

save the paper

to OFF .md

lo.~d

~ WARNING: Never use the short tear-off feature

labels. Otherwise, labels may come off the backing and

i

jam the printer.

prmter

contmucva

is turned on

paper is ready to be loaded.

and

that either a single

to blink.

ON LINE

a

OFF LINE

and

only while the ON LINE light IS blinking.

auwmatically

LINE FEED buttons for

p.~per

paper

backward When you’ve set

forward or the

off the last

norm.llly

to the

lost

continuous

with

I

,

LX-810-4

9 - Pin Printers

Page 5

LX - 810 DOT - MATRIX PRINTER

I

PlwrhF-=

Paper (single sheele

Th,” paper

24 IO wper

~

Envelopes

@angle

AI,

PM”

Bond

Bond 124

sheets)

me,,

I20

0,

Co”t~“uous)

lb,

lb

ILevNPoMio”I

1

The Cut Sheet Feeder

Single-Bin Cut Sheet Feeder

(C&06121)

2

2

3

4 or 5

6

6

7

i

Pull Tractor Unit

(C800061)

Single-bin cut sheet feeder (optional)

Dimensions

and weight:

444 mm (W)

x

434 mm (D) x 423 mm (H)

(mounted on the printer)

Approx.

1.1 kg

Bin

capacity:

Single sheet:

(Total thickness should not exceed 15 mm)

Stacker capacity:

MCBF:

Single sheet:

100,ooLl

cycles

Environmental

condition:

Temperature

Operation:

storage:

Humidity

Operation:

Storage:

Width.

Length:

Thickness:

Storage condition

of paper:

Temperature:

Humidity.

Up to 100 sheets of

90

g/m’ (24

up to 150

82 g/m2 (22 lb) paper

lb) paper

sheets

of

Up to 185 sheets of

64

g/m’

(17 lb) paper

Up to 55 sheets of

90 g/m2 (24 lb) paper

Up to 80 sheets of

82

g/m’

(22 lb) paper

Up to 100 sheets of

64 g/m2

(17

lb) paper

+5-c

to

-3O’C to

15% to

f35’C

+wc

80%

(without condensation)

5% to 85%

(without condensation)

182 to 216 mm

(7.17 to 8.50”)

257 to 364 mm

(10.12 to 14.30”)

0.07 to 0.14 mm

(0.0028 to 0.0055”)

64

g/m’

to 90 g/m2

(17 lb to 24 lb)

+ IS’C

to

40%

+22-c

to 60%

lntelllgenl

IEEE-488

Pin

assignments for the parallel interface

cirec-

tb”

IN

STROBE pulse 10

wdth must

“w,roseco”ds at Ihe rece,w”g ferrmnal

DATA

1

--T-k

3

4

5

6

7

8

9

J--

10

I

11 ;

21

22

23

24

25

1.5

27

?8

19

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA

DATA

‘N

These

IN

the Is1 01 8 blls 01

IN

‘.3SpKtNefy

IN

Each

IN

6

logICal

tN

?

8

0

,N

OUT

OUT

OUT

Pulled up 10 + 5 volts through 3

When

automatically

(The

selltno

1 15 j - ~ NC

-

I Pnnter 5 CnaSSlS ground. wntcn IS

~soialed from me loge

Interface

read

data

be more

sjgnals represent mfotmatlobof

s,g”al IS

at HIGH level when data

1

and

LOW when

t”ls sIgnal IS

fed 1

slqnal level can

DIP

swICh Z-4 10

Pulse

than

0.5

parallel data.

I! IS logrcal

LOW

the

lane alter p”“t,“g.

be

llxed 10 lh,s

ON

ground

paper

j

3K

1s

by

9 - Pin Printers

5/1/89

LX-810-5

Page 6

LX-810 DOT - MATRIX PRINTER

IN

When

thts

level becomes LOW, the

c

-d-

33 1 - i

-

-I

! 35 1 - I

GND 1 -

-1 -

I

OUT1

This

ISame

!Pulled UP 10

level becomes

as

Ior

Pm 19.30

+ 5V

tfvough

Commands in Numerical Order

ASCII- Dec. Hex. Description

BEL 7

BS 6

HT

LF

VT

FF

CR

so

SI

DC1

DC2 18 12

DC3

DC4

CAN 24

DEL

ESC SO

ESC

SI

ESC EM

ESC

ESC

‘6

ESC L

ESC

*

ESC

-

ESC

/

ESC o

ESC

1

ESC 2

ESC 3

ESC

4

ESC

5

ESC

6

ESC 7

ESC

8

ESC

9

LX-810-6

9

10

11

12

13

14

15

17

19

20

127

I4

15

25

33

37 25

38 26

42 2A

45 2D

47

4tl 30

49

50 32

51

S2

53 35

54 36

55

56

57

07

Beeper....................................................

08

Backspace ..............................................

09

Tab Horizontally

OA

Line Feed.. .............................................

Tab Vertically

it

Form Feed

OD

Carriage Return

OE

Select Double-wide Mode

(one line) ...............................................

OF

Select Condensed Mode.

11

s&ct

Printer..

cancel

13

14

Condensed Mode

Deselect Printer

C.mcel

.................................. 9-21

.......................................

............................................

................................... 9-12

...................................... .9-8

................................... 9-9

Double-wde

Mode

(one line) ..........................................

18

Cmcel

Line

7F

Delete Character.

OE

Select

(one line) ..........

OF

Select Condensed Mode..

19

Turn Cut Sheet Feeder Mode

On/Off. ................... ....................

21

Master Select

.....................................

Double-wde

........................ o-12

Mode

.......... ...................

................................... 9-23

Select User-defined Set

Define User-defined Characters

mode)

...

...............

Define User-defined

mode) ...............................

Select

CrJphics

li8-inch

7/72-inch

Mode

Tdb

Channel

Line Spacing

Line Spacmy;.

Line

Spung..

.................

Turn Underlining Mode On/Off..

2F

Select Vertrcal

Select

31

Select

select I/b-inch Line Spacing..

33

Set

34

n/216-inch

Select Italic Mode

Cancel Italic Mode

Euble

37

38

39

Printable

En.lble Upper Control Codes.

Disable

Enable I’dper Out

Puper

Out Detection

Chxxters

Detectwn

..................

....................... .9-32

Chxxters

...................

..................... 9-29

LOW when

the

3 3K

o”m 1

.9-13

................... 9-24

.................... 9-24

.9-12

.9-25

............... 9-24

.9-11

.9-33

(draft

(NLQ

.....

..

..............

.........

....

..........

.......

..9-2

.........

.....

9-10

...

I

1

I

Page

9-11

9-20

9-15

9-17

9-25

9-25

9-33

.9-35

.9-29

.9-18

.9-15

.9-IS

Q-16

.9-lb

8

.9-32

.9-32

.9-IO

5/1/89

ASCII

ESC :

ESC

<

ESC

?

ESC

@

ESC A

ESC B

ESC C

ESC C 0

ESC D

ESCE

ESCF

ESCC

ESC H

EKJ

ESC K

ESC L

ESC M

ESC N

ESC0

ESC

I’

EXQ

ESC R

ESCSo

ESCS1

ESC T

ESC U

ESC W

ESC Y

ESC Z

ESC

ESC d

ESC b

ESC e

ESC f

ESC k

ESC I

ESC

s

ESC t

ESC x ,

...............

............

.....

Draft...9-2

Page

.9-33

9-9

9-36

9-8

.9-16

.9-17

9-13

9-13

9-21

.9-26

9-26

.9-27

.9-27

.9-17

9-34

9-23

9-14

.9-14

9-23

9-19

9-27

9-28

.,9-t 8

..9-1

9-34

.9-35

9-36

9-30

9-18

9-20

9-21

9-22

9-19

9-9

.9-31

o

2

Hex. Description

Dec.

58 3A

60 3c

63

64 40

65 41

66 42

67 43

67 ’

68 44

69 4s

70 46

71 47

72

74 4A

7s

76

77 4D

7.9

79 4F

80 so

81

82 52

83 53

83 53

a4 54

8.5

a7 57

89

90

94

-

97

Copy ROM

Select Unidirectional Mode

(one line)

Reassign Graphics Mode

3F

Initialize Printer

Set n/72-inch

Set Vertical

Set Page Length

Set page length in Inches

43

Set Horizontal Tabs

Select Emphasized

Cancel Emphasized Mode

Select Double-Strike

Cancel Double-Strike

48

Perform n/216-inch

Select Single-density Graphics

4B

Mode......................................................

Select Double-density Graphics

rc

Mode..

Select 12 cpi

Set Skip Over Perforation

4E

Cancel Skip

Select

Set Right Margin..

51

Select an International Character Set 9-31

Select Superscript

Select Subscript

Cancel Superscript/Subscript Mode

5s

Turn

Turn Double-width Mode On/Off. ..9-2 6

Select High-Speed Double-density

59

Graphics Mode

SA

Select Quadruple-density Graphics

Mode.....................................................

Select Q-pin Graphics Mode

SE

61

Select Near Letter Quality

Justification

98

101

102

107

108

11s

116

120

Set Vertical Tabs in Channels

62

Set

65

66

Horizontal/Vertical Skip

Select Typ-estyle Family

Set Left Margin

2

Turn Half-Speed Mode ON/Off..

73

74

Select Character

78

Select Near Letter Quality or

to RAM .........................

...............................................

.....................

....................................

Line Spacing ...............

Tabs .................................

in Lines.. ...................

....................

.............................

Mode.. ..................

...................

Mode.. ..............

Mode.. ............

Line Feed.. ........

.............................................. 9-34

.._

...

..........................................

...................

Over Perforation.. ..........

........................................

10

cpi..

................................

Mode.. ....................

Mode.. .......................

Unidirectional Mode On/Off.

.....................................

...........................................

Tab

Increments

..............................

.....................

.......................

....................................

Table.. ......................

9 - Pin Printers

Page 7

Installation/Support Tips

LX - 810 DOT- MATRIX PRINTER

The typs

idmtifhd

through a

program. look in

modal sohotlon.

of printer

for

mch saft+uuo packago. Thii ir dually

sotup menu. lf

installad

on your system must

this

printar

the prlnhr Usor’s

ir not

listod

Manual for

bo

in your

the

next-best

DIP Switch Settings

The dofault sottingr

but

thy

should bo

will avoid unoxpaotod raults.

will usually work for most applications,

chscked

beforo using the printor This

Optional Serial lnterface Operation

Epson’s

butthaOIPswitohosonthointMaoaboardmustbesotto

m8tch the

computer.

optionai sorlal intor&as

configuration of

the so&l

may bo

port on

uaod

in this printer,

the

host

Cut - Sheet Feeder Operation

fhe page length will

software

will ba

second

doos

linos

from the

page if

have

to be adjusted

not

propnfy

support cut-sheet

first

page printed on

the

page length is not

(shortened)

papor. Thor0

the

top of the

set correctiy.

dona

if your

’

9- Pin Printers

LX-810-7

Page 8

LX-810 DOT- MATRIX PRINTER

Information Reference List

Engineering Change Notices

None.

Product Support Bulletins

None.

Related Documentation

LX-810 Technical Manual

LX-810 Parts Price List

LX-810 User’s Manual

Technical Information Bulletins

None.

LX-810-8

5/1/89

9 - Pin Printers

Loading...

Loading...