Page 1

EPSON

IMPACT DOT MATRIX PRINTER

SERVICE MANUAL

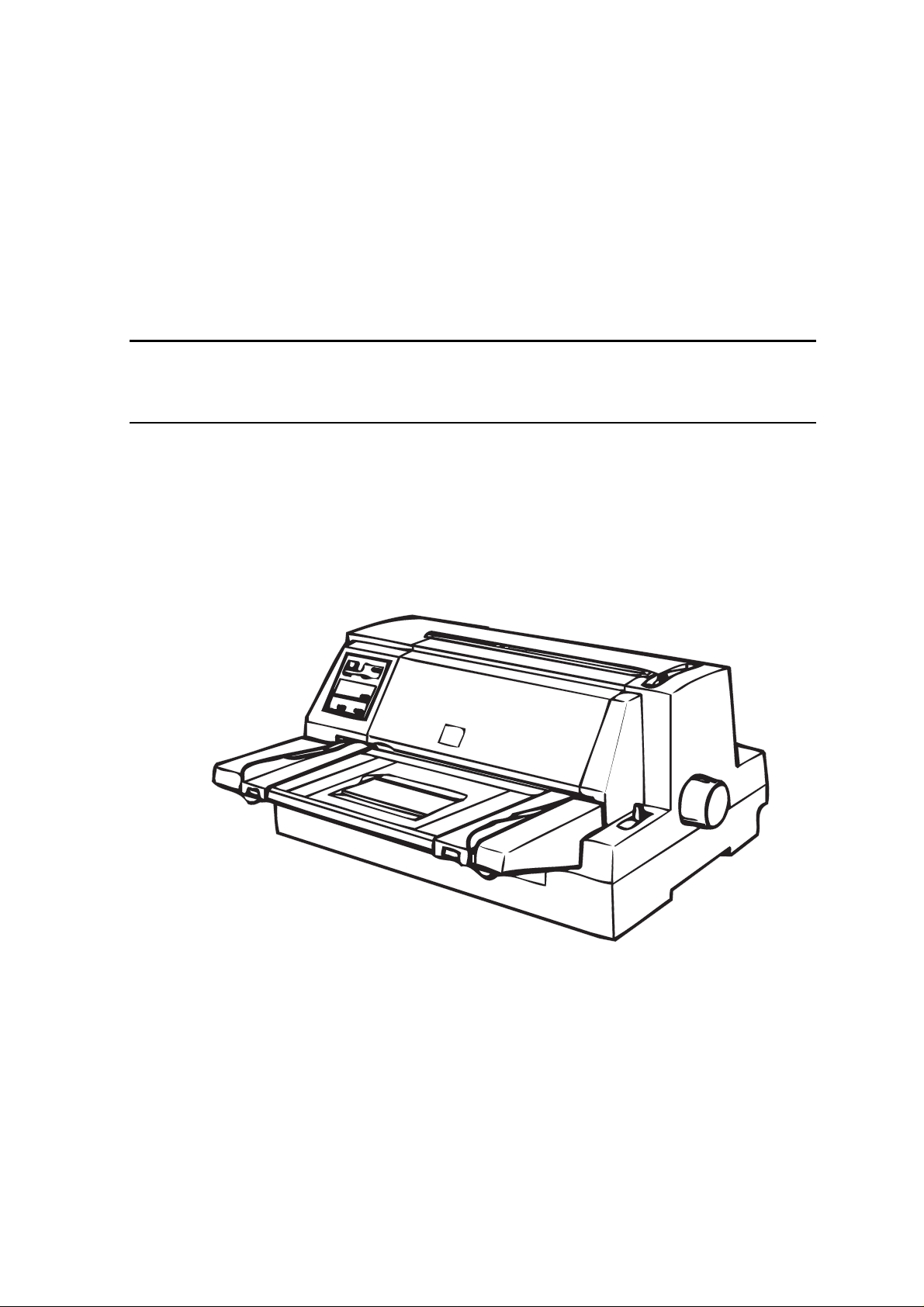

EPSON LQ-670

SEIKO EPSON CORPORATION

4007875

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever

without SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility f or any errors

in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies.

Copyright 1997 by SEIKO EPSON CORPORATION

Nagano, Japan

ii

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

WARNING

CAUTION

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by

WARNING Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

WARNING

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL. DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

POWER SUPPLY CABLE MUST BE CO NNECTED, USE EXT REME CAUT ION IN W O RKING

ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

CAUTION

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED O NLY BY EPSON CERTIFIED

REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT T HE SOURCE VOLT AGE IS THE SAME AS T HE RATED VOLT AGE,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT T HE EPSON PRODUCT HAS BEEN DISCONNECT ED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

iii

Page 4

PREFACE

This manual descr ibes functions , theory of electrical and m echanical operations , maintenanc e, and

repair of EPSON LQ-670.

The instructions and procedur es included herein are intended for the experience r epair technician,

and attention should be given to die precautions on the preceding page. The Chapters are

organized as follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the

printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENT

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides EPSON-approved techniques for troubleshooting.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to

service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and

exploded diagram.

The contents of this manual are subject to change without notice.

iv

Page 5

REVISION SHEET

Revision Issued Data Contents

Rev. A May 28, 1997 First issue

v

Page 6

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENT

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

vi

Page 7

Chapter 1

Product Descriptions

1.1 Specifications.......................................................................................................1-1

1.1.1 Features................................................................................................................................... 1-1

1.2 Hardware Specifications......................................................................................1-3

1.2.1 Printing Method ...................................................................................................................... 1-3

1.2.2 Printing Specifications........................................................................................................... 1-4

1.2.3 Paper Handling Specifications.............................................................................................. 1-5

1.2.4 Paper Specification ................................................................................................................ 1-6

1.2.5 Printable Area ....................................................................................................................... 1-10

1.2.6 Ribbon Cartridge .................................................................................................................. 1-14

1.2.7 Input data buffer................................................................................................................... 1-14

1.2.8 Electrical Specification ........................................................................................................ 1-14

1.2.9 Reliability............................................................................................................................... 1-14

1.2.10 Environmental Condition................................................................................................... 1-15

1.2.11 Safety Approvals................................................................................................................. 1-15

1.2.12 CE Marking.......................................................................................................................... 1-15

1.2.13 Acoustic Noise.................................................................................................................... 1-15

1.3 Firmware Specification ......................................................................................1-16

1.3.1 Control Codes and Fonts..................................................................................................... 1-16

1.3.2 Interface Specification ......................................................................................................... 1-18

1.3.2.1 Parallel interface (Forward channel) .......................................................................1-18

1.3.2.2 Parallel Interface (Reverse channel).......................................................................1-20

1.3.2.3 Optional Interface....................................................................................................1-21

1.3.2.4 Interface Selection................................................................................................... 1-21

1.3.2.5 Manual selection...................................................................................................... 1-21

1.3.2.6 Automatic selection .................................................................................................1-21

1.3.2.7 Interface state and interface selection.....................................................................1-21

1.3.3 Prevention Hosts from Data Transfer Timeout.................................................................. 1-21

1.4 Operation.............................................................................................................1-22

1.4.1 Control Panel ........................................................................................................................ 1-22

1.4.1.1 Usual Operation ...................................................................................................... 1-22

1.4.1.2 Switches.................................................................................................................. 1-24

1.4.1.3 Indicators(LED) ....................................................................................................... 1-25

1.4.1.4 Buzzer .....................................................................................................................1-26

1.4.2 Default Setting ...................................................................................................................... 1-27

1.4.3 Bi-d Adjustment.................................................................................................................... 1-28

1.4.4 Initialization........................................................................................................................... 1-29

1.4.5 Errors..................................................................................................................................... 1-29

1.5 Main Components...............................................................................................1-30

1.5.1 C214 Main Board .................................................................................................................. 1-30

1.5.2 C214PSB Board .................................................................................................................... 1-30

1.5.3 C214 PNL Board.................................................................................................................... 1-31

1.5.4 Printer Mechanism ............................................................................................................... 1-31

1.5.5 Housing ................................................................................................................................. 1-31

Page 8

Chapter 1 Product Description

1.1 Specifications

This specifications provide characteristics of the serial impact dot matrix printer LQ-670.

1.1.1 Features

LQ-670 is a 24pin serial impact dot matrix printer for the VAR(value added reseller) market.

The major features of this printer are;

Columns :106 columns (10cpi)

Printing Speed :High speed draft 300cps

:Draft 250cps

:LQ 83cps at 10cpi

Feeding Method :Friction feed (front manual, rear CSF)

:Push tractor feed (rear)

Feeder :Rear push tractor

CSF Bin1/Bin2 (Option)

Roll paper holder (Option)

Paper/Media :Single sheet, Continuous paper, Multi part paper, Envelope, Card,

Label and Roll paper.

Fonts :9LQ & 1 Draft Bitmap and 4 Scarable typefaces

:8 Bar code fonts

Character tables :Standard version 11 tables

NLSP version 20 tables

Input buffer :64 Kbytes

Acoustic noise :55dB(A) (ISO7779 pattern)

Reliability :Total print volume 6.5 million lines(except print head)

:(MTBF) 5000 POH

:Print head life 200 million strokes/wire

:Ribbon life 2 million characters

Interface :Bi-directional parallel interface (IEEE-1284 nibble mode supported)

Type B/I/F level 2 (Option)

Control code :ESC/P 2 and IBM 2390 Plus emulation

Copy capability :1 original + 4 copies

Control panel functions :Font, Condensed, Pause, Tear off, Bin, LF/FF, Load/Eject, Micro Adjust

and the default settings

Printable area :70 lines are available at A4.

(Top margin 0 mm setting and Bottom margin 0 mm setting are available)

Control Panel

Edge Guide

Stacker

Paper Guide

Ribbon Cartridge

Power Switch

Push Tractor

I/F Connector

Printer Cover

Print Head

Adjust Lever

Release lever

Paper Feed Knob

Figure 1-1. Exterior of LQ-670

Rev. A

1-1

Page 9

LQ-670 Service Manual

2

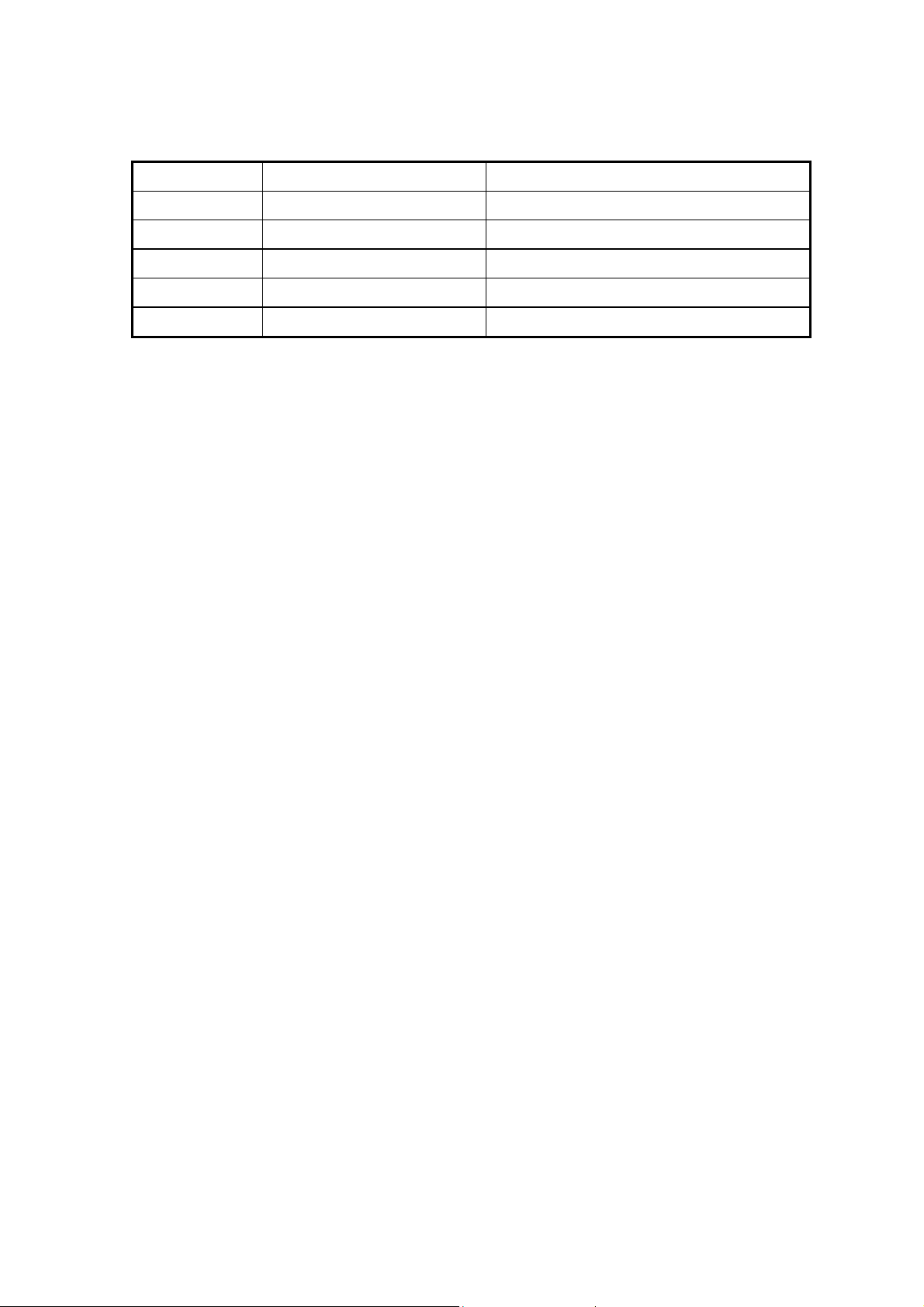

Consumables and optional units

Table 1-1. Consumables and Optional Units

Name Part Number

Ribbon cartridge S015016

High capacity cut sheet feeder (Bin1) C806781 (EAI version)

High capacity cut sheet feeder (Bin1) C806782 (Non-EAI version)

Second bin cut sheet feeder (Bin2) C806791 (EAI version)

Second bin cut sheet feeder (Bin2) C806792 (Non-EAI version)

Roll paper holder #8310

Serial I/F card C82305* / C82306*

32KB intelligent serial I/F card C82307* / C82308*

32KB intelligent parallel I/F card C82310* / C82311*

Local Talk I/F card C82312*

32KB IEEE-488 I/F card C82313*

Coax I/F card C82314*

Twinax I/F card C82315*

Ethernet I/F card C82331*

IEEE-1284 parallel I/F card C82345*

Multi Protocol Ethernet I/F card C82346*

Note*)

: The number represented by an asterisk varies, depending on the country.

1-

Rev. A

Page 10

3

1.2 Hardware Specifications

This section describes hardware specification for the LQ-670.

1.2.1 Printing Method

Printing Method : Impact dot matrix

Number of pins : 24 pins

Print pin arrangement : 12x2 staggered

Print pin diameter : 0.0079 inch (0.20 mm)

Color : Black

Print direction : Bi-direction with logic seeking

Chapter 1 Product Description

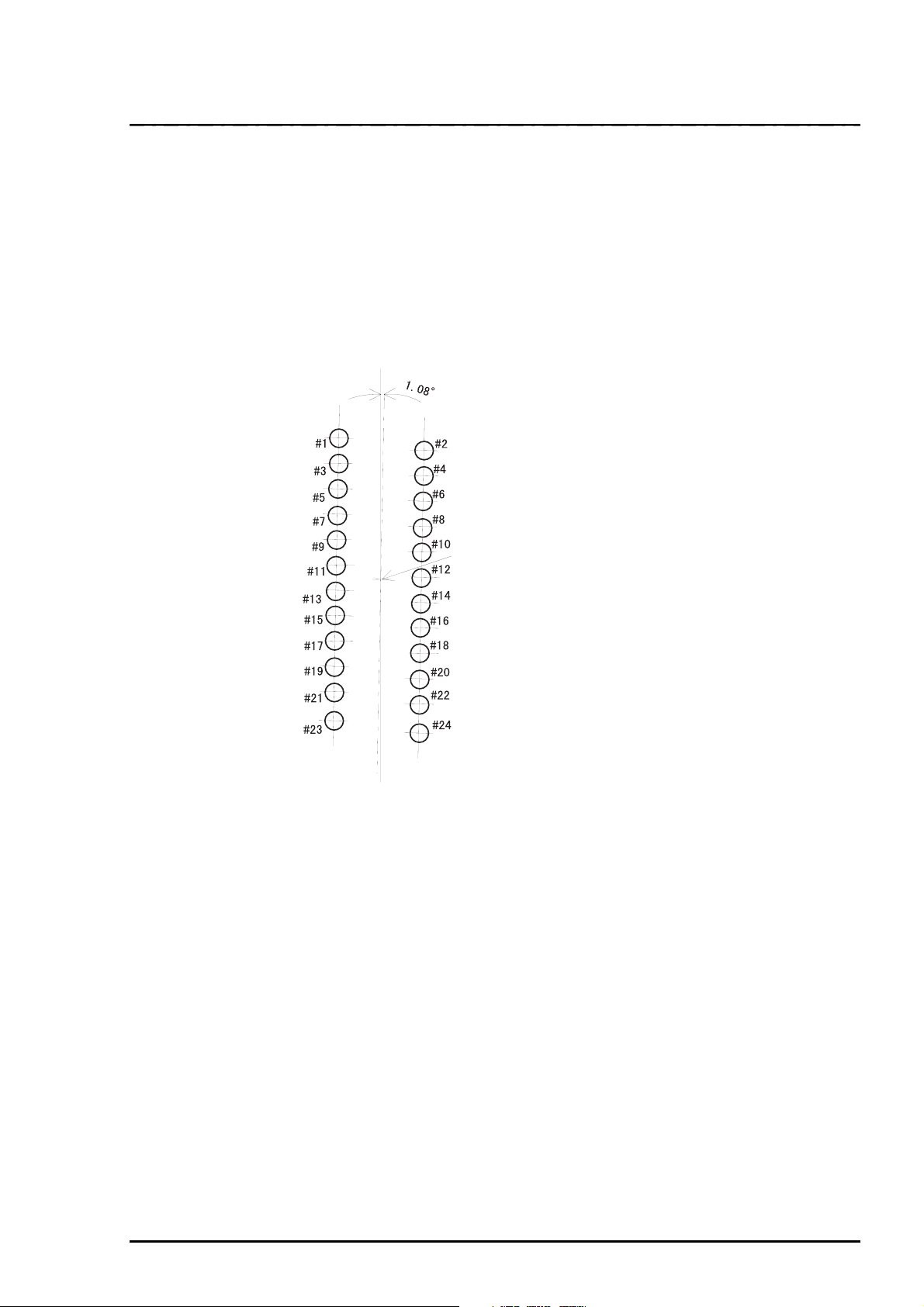

Head Center

Figure 1-2. Pin Configuration

Rev. A

1-

Page 11

LQ-670 Service Manual

4

1.2.2 Printing Specifications

Copy capability :1 original + 4 copies

Print speed and printable columns

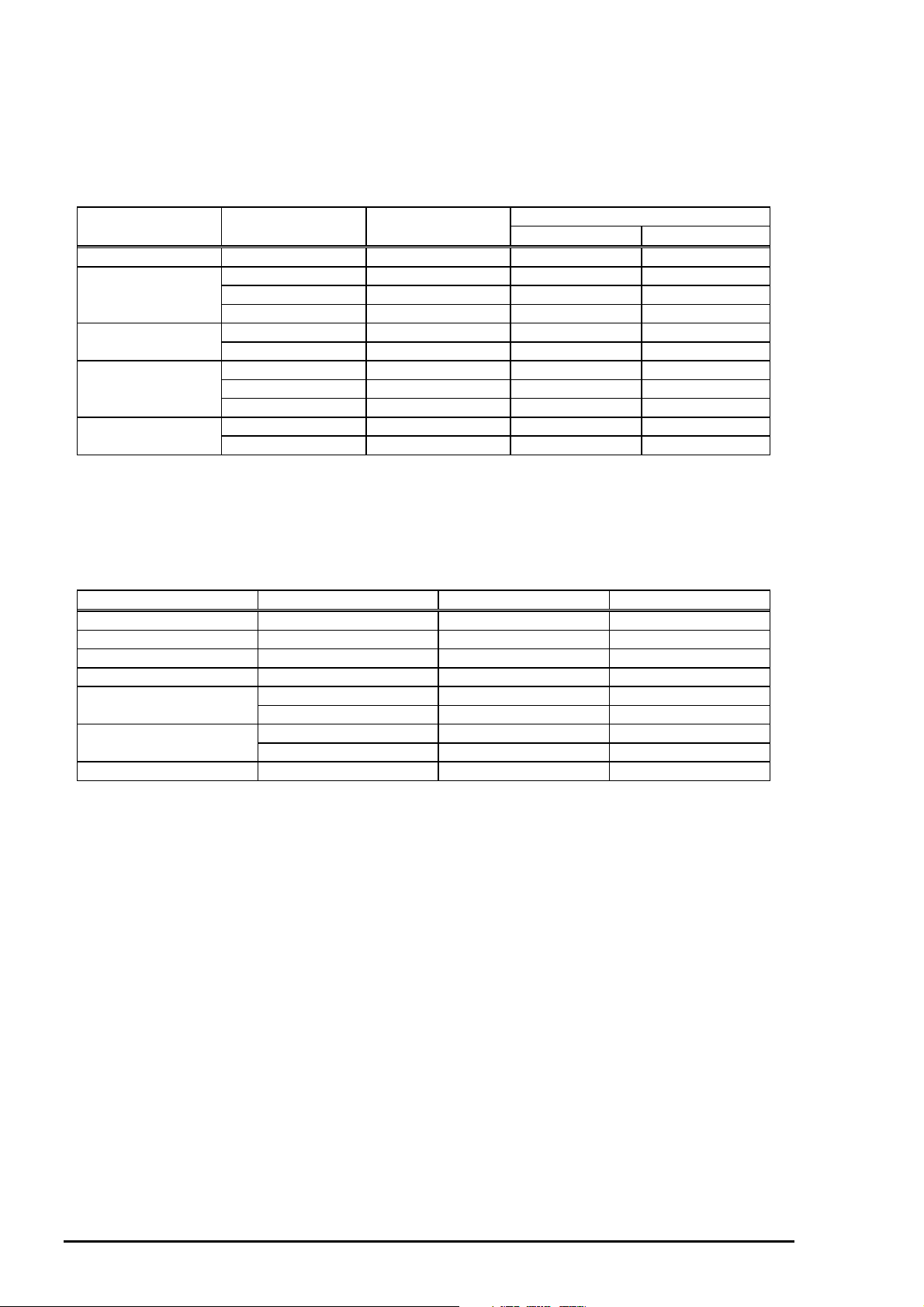

Table 1-2. Print Speed and Printable Columns

Printing Mode Character Pitch Printable Columns Print Speed(cps)

Normal Copy

High speed Draft 10cpi 106 300 200

Draft 10cpi 106 250 167

12cpi 127 300 200

15cpi 159 375 250

Draft condensed 17cpi 181 214 143

20cpi 212 250 167

LQ 10cpi 106 83 70

12cpi 127 100 83

15cpi 159 125 104

LQ condensed 17cpi 181 143 119

20cpi 212 167 139

Note)

Note)

When the power supply voltage drops to the lower limit, the printer stops printing and then starts

printing the rest of that line again but at the slower speed than before.

When the head temperature rises to the upper limit, the printer stops printing. When the head

temperature falls to the normal level, the printer starts printing again but slower than before.

Resolution

Table 1-3. Resolution

Printing Mode Horizontal density Vertical density Adjacent dot print

High speed draft 90dpi 180dpi No

Draft 120dpi 180dpi No

Draft condensed 240dpi 180dpi No

LQ 360dpi 180dpi N0

8 pins bit image 60, 80, 90 or 120dpi 60dpi Yes

120 or 240dpi 60dpi No

24 pins bit image 60,90,120 or 180dpi 180dpi Yes

360dpi 180dpi No

Raster graphics 180 or 360dpi 180 or 360dpi Yes

Control code : ESC/P 2 and IBM 2390 Plus emulation (Refer to control code)

1-

Rev. A

Page 12

Chapter 1 Product Description

5

1.2.3 Paper Handling Specifications

Feeding method :Friction feed (front manual, rear CSF)

Push tractor feed (rear)

Feeder :Rear push tractor

CSF Bin1/Bin2 (Option)

Roll paper holder(Option)

Paper path :Manual Insertion Front in, front out

CSF Rear in, front out

Tractor Rear in, front out

Line Spacing :1/6 inch or programmable in increments of 1/360 inch

Feed speed :Refer to the table 1-4.

Release Lever :The release lever must be set according to the table 1-5.

Paper thickness lever :The paper thickness lever must be set at the proper position according to the

table 1-6.

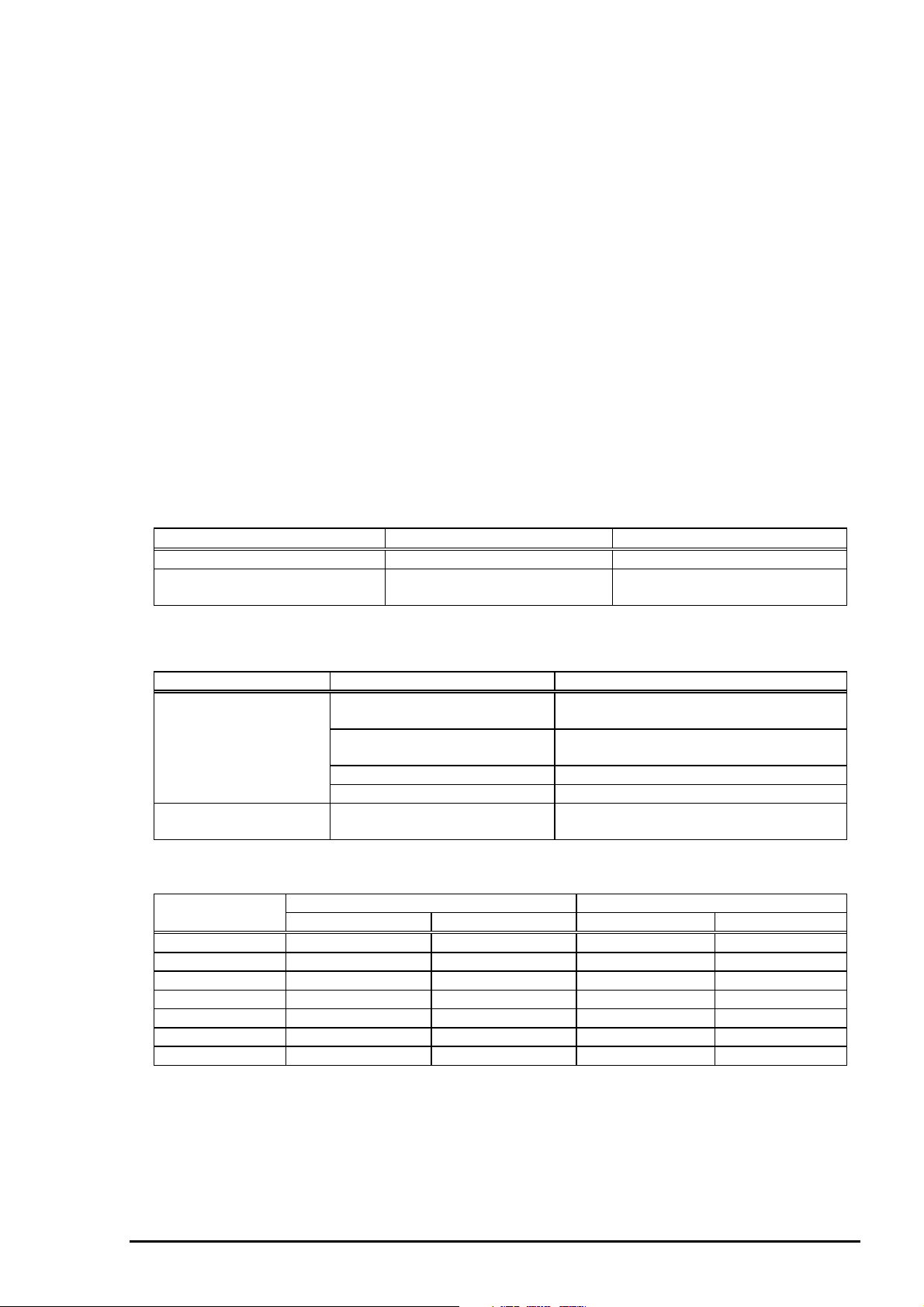

Table 1-4. Feeding Speed

Normal mode Copy mode

1/6 inch feed 60 msec 70 msec

Continuous feed 0.127MPS(m/sec)

5.0 IPS(inches/sec)

Table 1-5. Release Lever Position

Lever Position Paper path/Feeder Paper/Media

Friction Manual insertion(front) Cut sheet(Single sheet& Muti part)

Card

CSF Bin1 Cut sheet(Single sheet & Multi part)

Envelope, Card

CSF Bin2 Cut sheet(Single sheet)

Roller paper holder Roll paper

Tractor Push tractor feed(rear) Continuous paper(Single sheet & Multi

part)

Table 1-6. Paper Thickness Lever Position

Lever Position Paper thickness (inch) Paper thickness (mm)

Minimum Maximum Minimum Maximum

0 0.0024 0.0047 0.065 0.12

1 0.0047 0.0075 0.12 0.19

2 0.0075 0.0102 0.19 0.26

3 0.0102 0.0126 0.26 0.32

4 0.0126 0.0142 0.32 0.36

5 0.0142 0.0157 0.36 0.40

6 0.0157 0.0205 0.40 0.52

0.092 MPS(m/sec)

3.6 IPS(inches/sec)

Rev. A

1-

Page 13

LQ-670 Service Manual

6

1.2.4 Paper Specification

This section describes printable area and types of paper that can be used in this printer.

Cut Sheets

The following table shows specification for cut sheets.

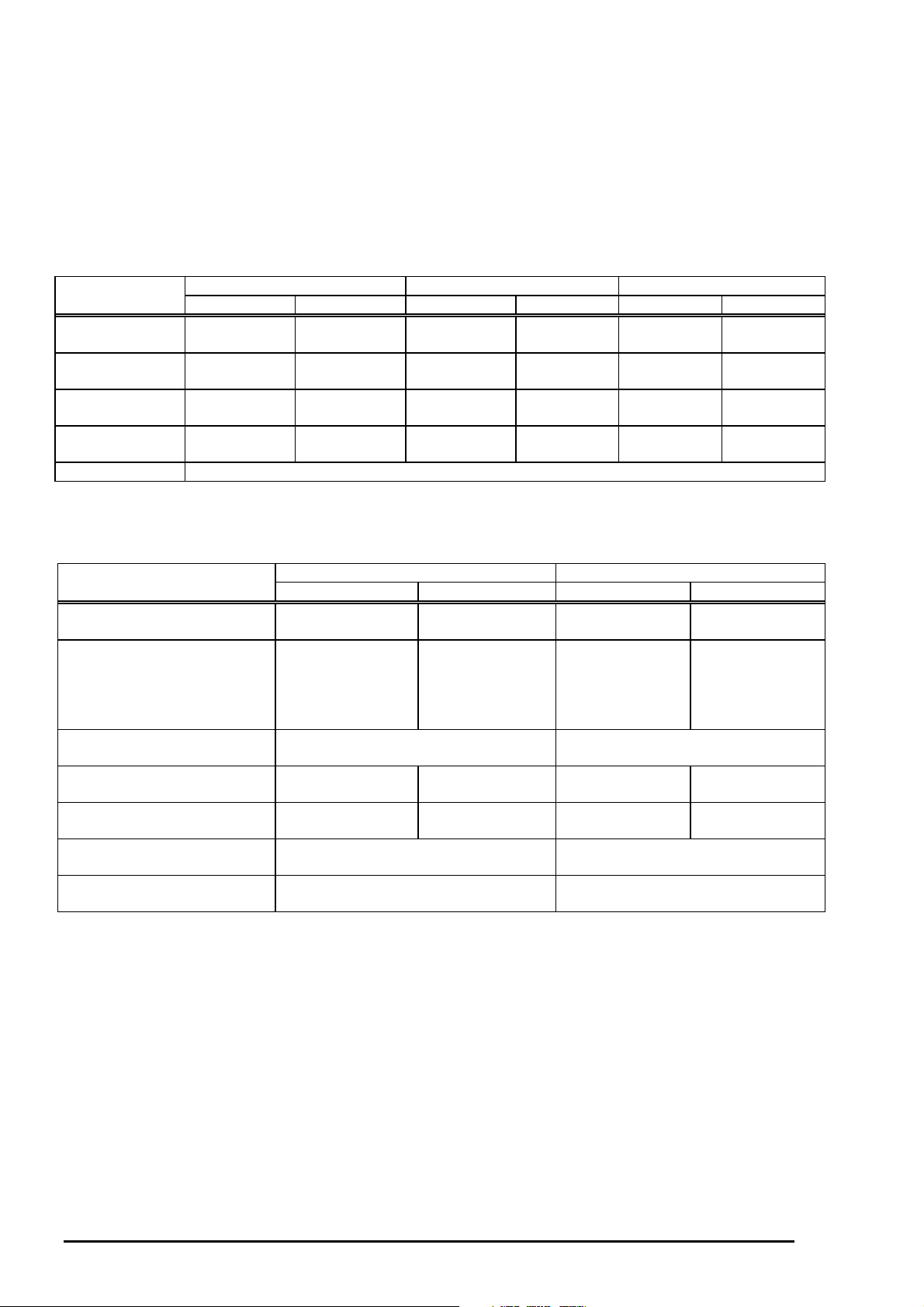

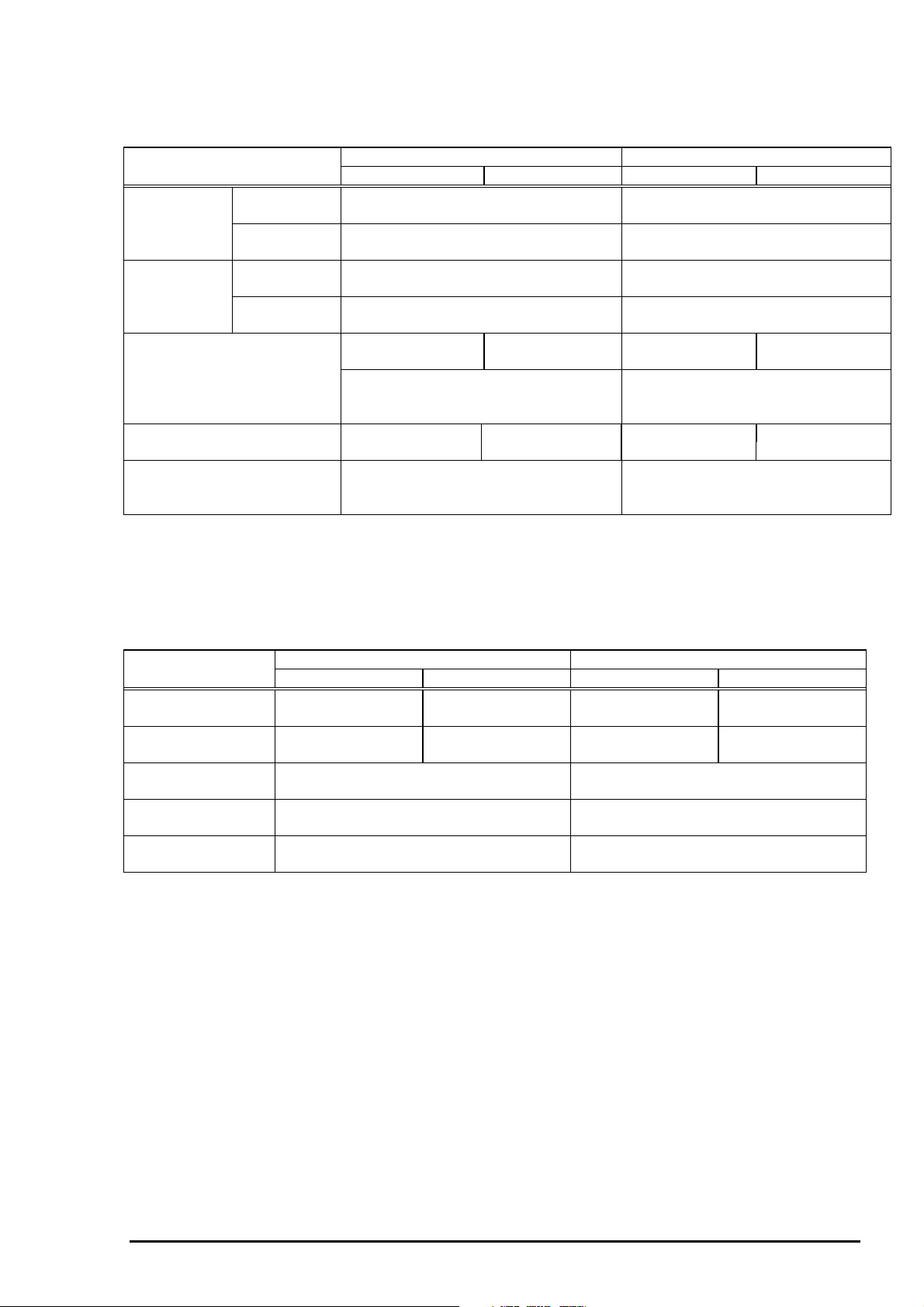

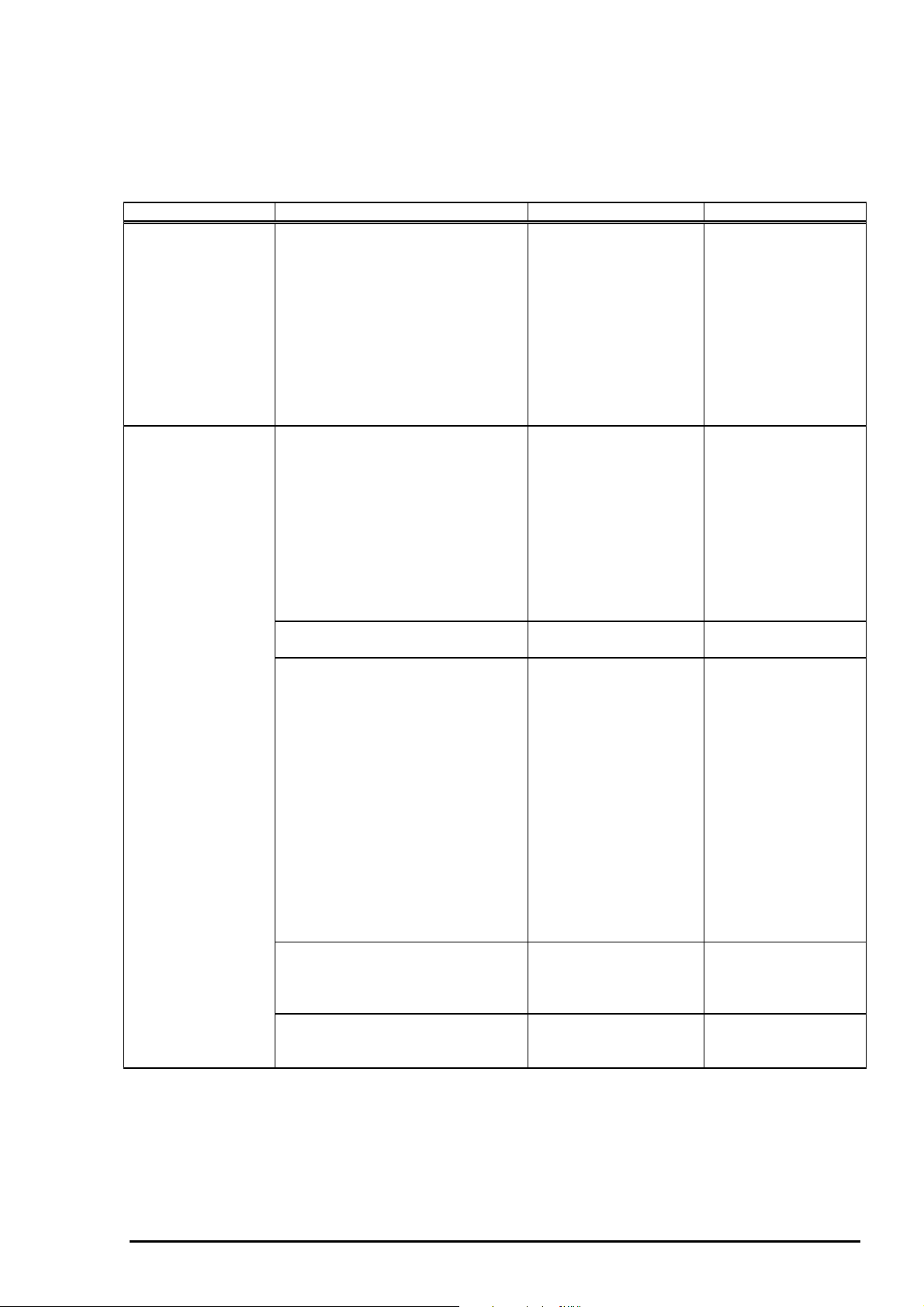

Table 1-7. Cut Sheet (Single sheet, Not Multi Part)

Front Entry(Manual Insertion) Rear Entry(CSF bin1) Rear Entry(CSF bin2)

Minimum Maximum Minimum Maximum Minimum Maximum

Width (inch) 3.6 11.7 3.9 11.7 3.9 11.7

(mm) 91 297 100 297 100 297

Length (inch) 3.5 16.5 3.6 16.5 8.3 16.5

(mm) 90 420 92 420 210 420

Thickness(inch) 0.0025 0.0055 0.0025 0.0055 0.0025 0.0055

(mm) 0.065 0.14 0.065 0.14 0.065 0.14

Weight (g/m2)529052905290

(lb) 14 24 14 24 14 24

Quality Plain paper, Reclaimed paper, Not curled, not folded, not crumpled.

Note):

Printing on reclaimed paper is available only under the normal temperature and humidity condition.

Table 1-8. Cut Sheet (Multi Part)

Front Entry (Manual Insertion) Rear Entry (CSF)

Minimum Maximum Minimum Maximum

Width (inch) 3.6 11.7 3.9 11.7

(mm) 91 297 100 297

Length (inch) 3.5 16.5(11.7) 3.6 16.5

(mm) 90 420(297)

( ):Value of line

glue one side of

form.

Copies 1 original + 4 copies 1 original + 4 copies

Total thickness (inch) 0.0047 0.015 0.0047 0.015

(mm) 0.12 0.39 0.12 0.39

Weight (g/m2)40 58 40 58

(one sheet of multi part) (lb) 12 15 12 15

Quality Plain paper, Reclaimed paper

Not curled, not folded, not crumpled

Jointing Line glue at the top or one side of

form

Note):

Printing on multi part. Don’t use CSF 2nd bin.

Plain paper, Reclaimed paper

Not curled, not folded, not crumpled

Line glue at the top of form

92 420

1-

Rev. A

Page 14

Chapter 1 Product Description

7

Envelope

Table 1-9. Envelope Specification

Front Entry (Manual Insertion) Rear Entry (CSF)

Minimum Maximum Minimum Maximum

Envelope Width (inch) 6.5 6.5

(No.6) (mm) 165 165

Length (inch) 3.6 3.6

(mm) 92 92

Envelope Width (inch) 9.5 9.5

(No.10) (mm) 241 241

Length (inch) 4.1 4.1

(mm) 105 105

Total thickness (inch) 0.0063 0.0197 0.0063 0.0197

(mm) 0.16 0.52 0.16 0.52

The difference of thickness at the

printable area is within 0.0098 inch

(0.25mm)

Weight (g/m2)45 91 45 91

(lb) 12 24 12 24

Quality BOND paper, PLANE paper or AIR

MAIL. No glue at a flap, Not curled,

not folded, not crumpled

The difference of thickness at the

printable area is within 0.0098 inch

(0.25mm)

BOND paper, PLANE paper or AIR

MAIL. No glue at a flap, Not curled,

not folded, not crumpled

Note1)

: Printing on envelope is available only under normal temperature and humidity conditions.

Note2):

Note3):

Card

Width (inch) 4.1 5.8 4.1 5.8

Length (inch) 4.1 5.83 4.1 5.8

Thickness (inch) 0.0087 0.0087

Weight (g/m2) 192 192

Quality Plain paper, Reclaimed paper

Note1)

Note2):

Set the longer side of envelope horizontally.

Don’t use CSF 2nd bin.

Table 1-10. Card Specification

Front Entry (Manual Insertion) Rear Entry(CSF)

Minimum Maximum Minimum Maximum

(mm) 105 148 105 148

(mm) 105 148 105 148

(mm) 0.22 0.22

(lb) 51 51

Plain paper, Reclaimed paper

Not curled, not folded, not crumpled

: Printing card is available only under normal temperature and humidity conditions.

Don’t use CSF 2nd bin.

Not curled, not folded, not crumpled

Rev. A

1-

Page 15

LQ-670 Service Manual

8

Continuous paper (Single sheet and Multi part)

Table 1-11. Continuous Paper (Single Sheet and Multi Part)

Rear Entry (Tractor)

Minimum Maximum

Width (inch) 4 12

(mm) 101.6 304.8

Length(one page) (inch) 4 22

(mm) 101.6 558.8

Copies 1 original + 4 copies

Total thickness (inch) 0.0025 0.015

(mm) 0.065 0.39

Weight (g/m2)52 82

(not multi part) (lb) 14 22

Weight (g/m2)40 58

(one sheet of multi part) (lb) 12 15

Quality Plain paper, Reclaimed paper

Carbonless multi part paper

Jointing Point glue or paper staple(both side)

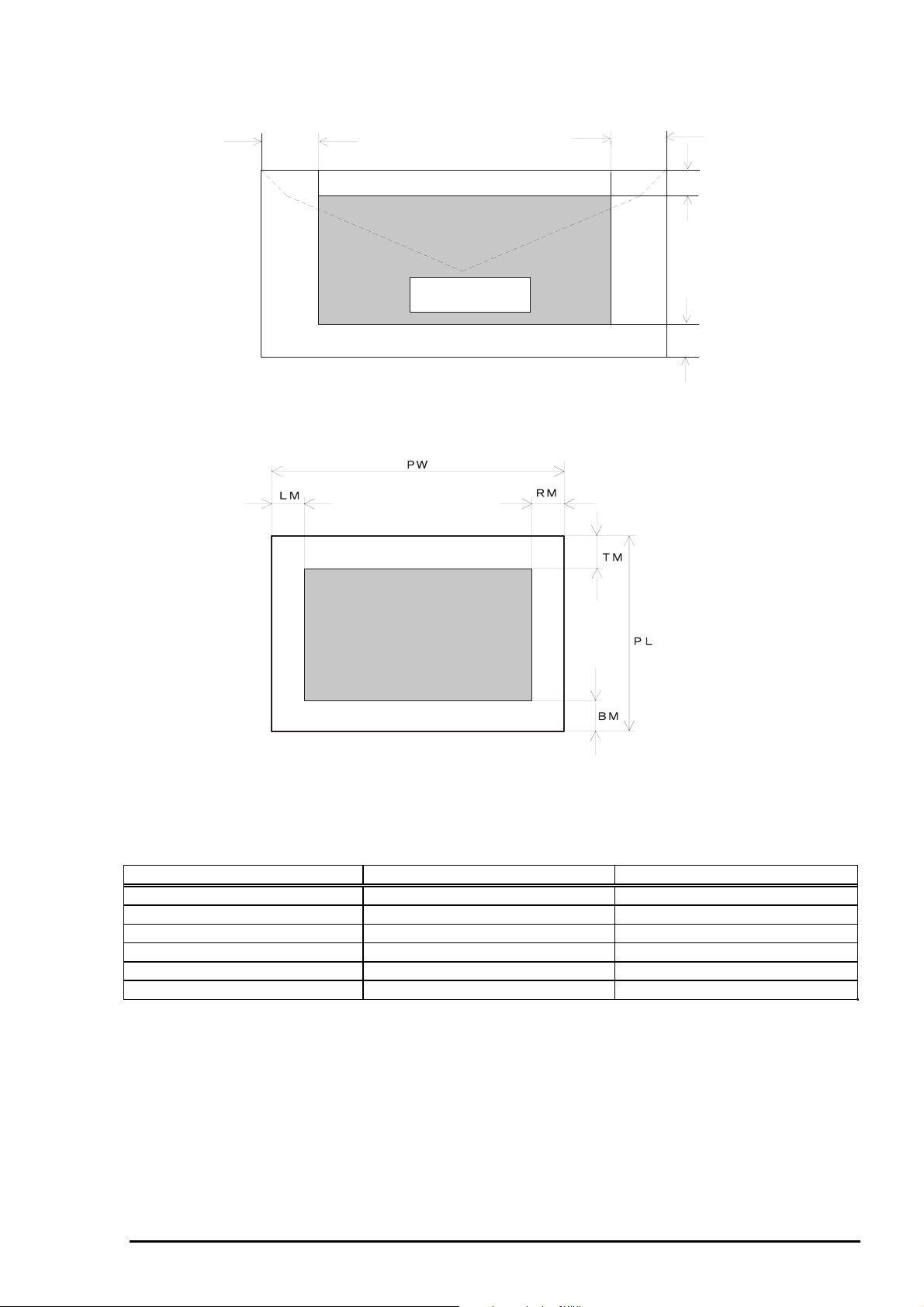

Continuous paper with Labels

Table 1-12. Continuous Paper with Labels

Rear Entry (Tractor)

Minimum Maximum

Label size See the figure below.

Base sheet width (inch) 4 12

(mm) 101.6 304.8

Base sheet length (inch) 4 22

(one page) (mm) 101.6 558.8

Base sheet (inch) 0.0028 0.0035

Thickness (mm) 0.07 0.09

Total thickness (inch) 0.0063 0.0075

0.16 0.19

Label weight (g/m2)68

(lb) 17

Quality A VERY CONTINUOUS FORM LABELS, A VERY MINI-LINE

LABELS or the same quality labels

Note)

: Printing on label is available only under the normal temperature and humidity conditions.

Note):

The base sheet of labels must be continuous paper.

2.5 inch (63.5mm) min.

15/16 inch

(23.8mm)

min.

Label

R 0.1 inch(2.5mm) min.

Figure 1-3. Label Size

1-

Rev. A

Page 16

Chapter 1 Product Description

9

Roll paper

Table 1-13. Roll Paper Specification

Rear Entry (Roll paper holder)

Minimum Maximum

Width (inch) 8.5

(mm) 216

Length (inch) -----

(mm)

Thickness (inch) 0.0028 0.0035

(mm) 0.07 0.09

Weight (g/m2)52 82

(lb) 14 22

Quality Plain paper, Reclaimed paper. Not curled, not folded, not

crumpled.

Rev. A

1-

Page 17

LQ-670 Service Manual

0

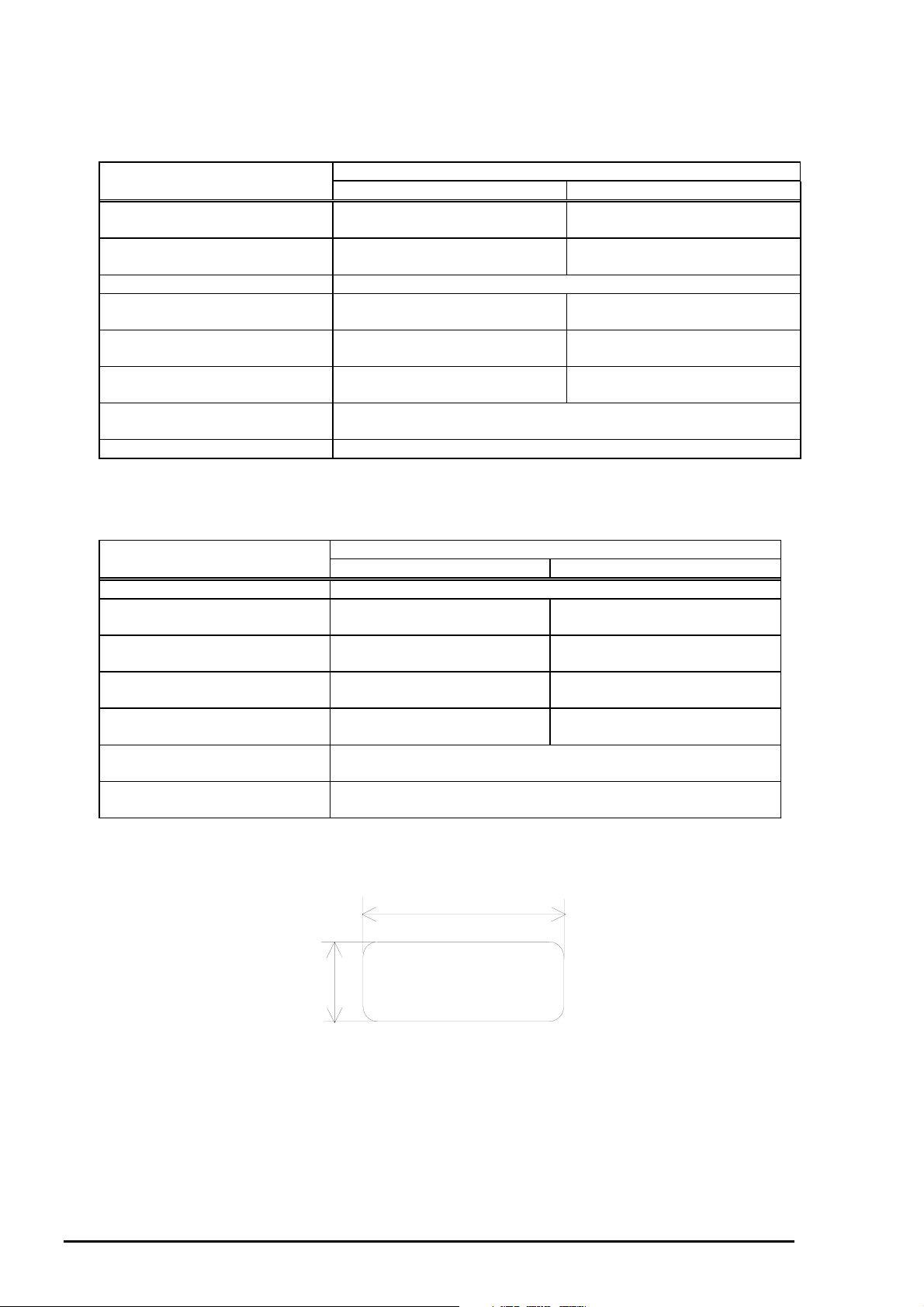

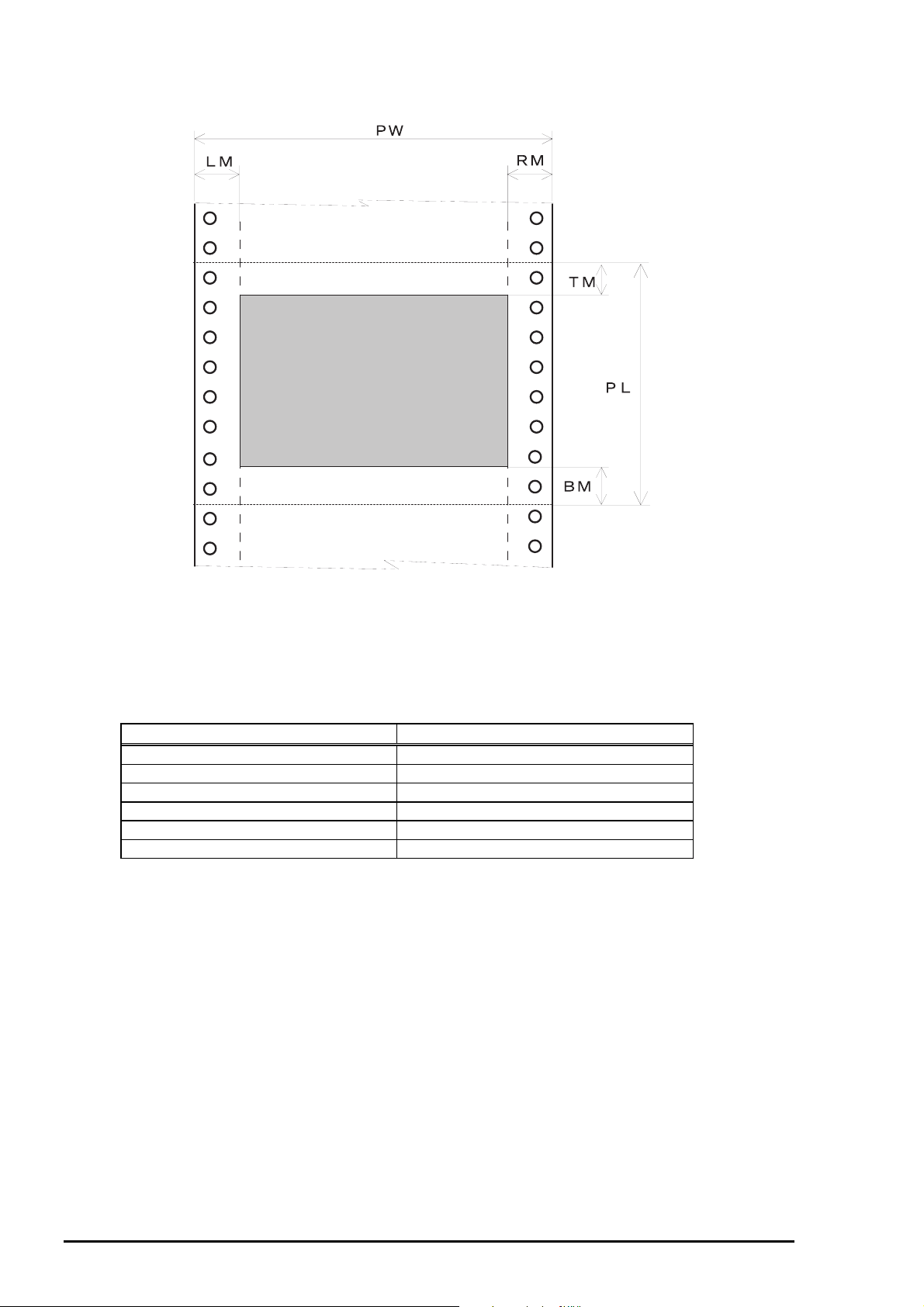

1.2.5 Printable Area

Cut sheets

Printable Area

Figure 1-4. Printable Area for Cut Sheet

Table 1-14. Printable Area for Cut Sheet

Single sheet Multi part

PW (Width) (Refer to section 1.2.4) (Refer to section 1.2.4)

PL (Length) (Refer to section 1.2.4) (Refer to section 1.2.4)

LM (Left margin)

RM (Right margin)

TM (Top margin) 0.0mm or more 0.0mm or more

BM (Bottom margi n) 0.0mm or more 0. 0mm or more

3 mm or more(PW<=297mm) 3 mm or more(PW<=297mm)

3 mm or more(PW<=297mm) 3 mm or more(PW<=297mm)

1-1

Rev. A

Page 18

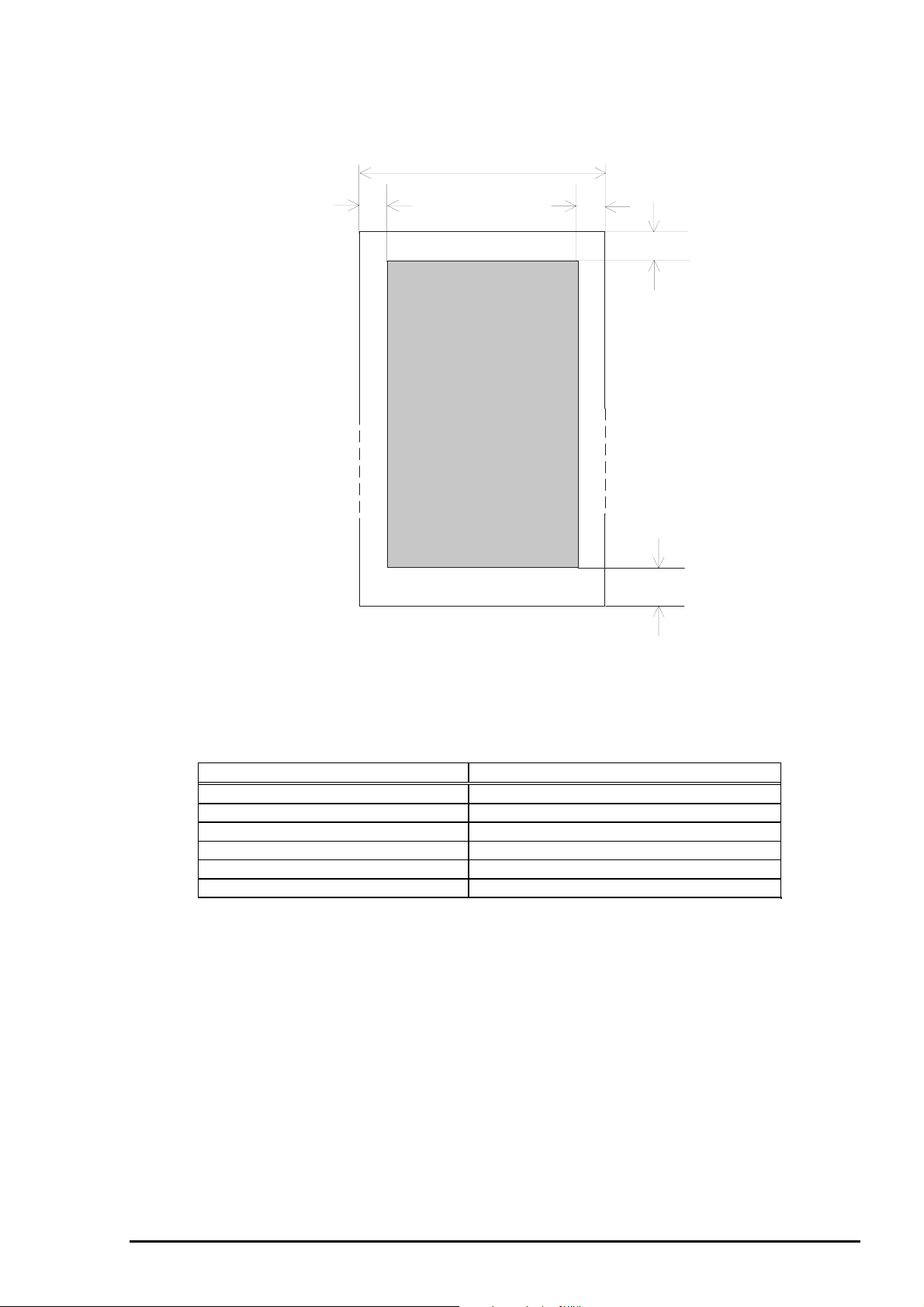

Envelope and card

Chapter 1 Product Description

LM

RM

TM

Printable Area

BM

Figure 1-5. Printable Area for Envelope

Printable Area

Figure 1-6. Printable Area for Card

Table 1-15. Printable Area for Envelope and Card

Envelope Card

PW (Width) (Refer to section 1.2.4) (Refer to section 1.2.4)

PL (Length) (Refer to section 1.2.4) (Refer to section 1.2.4)

LM (Left margin) 3 mm or more 3 mm or more

RM (Right margin) 3 mm or more 3 mm or more

TM (Top margin) 0.0mm or more *1 0.0mm or more *1

BM (Bottom margi n) 0.0mm or more 0.0mm or more

Note *1)

: When loading the paper from CSF, TM(Top margin) is 4.2 mm or more.

Rev. A

1-1 1

Page 19

LQ-670 Service Manual

2

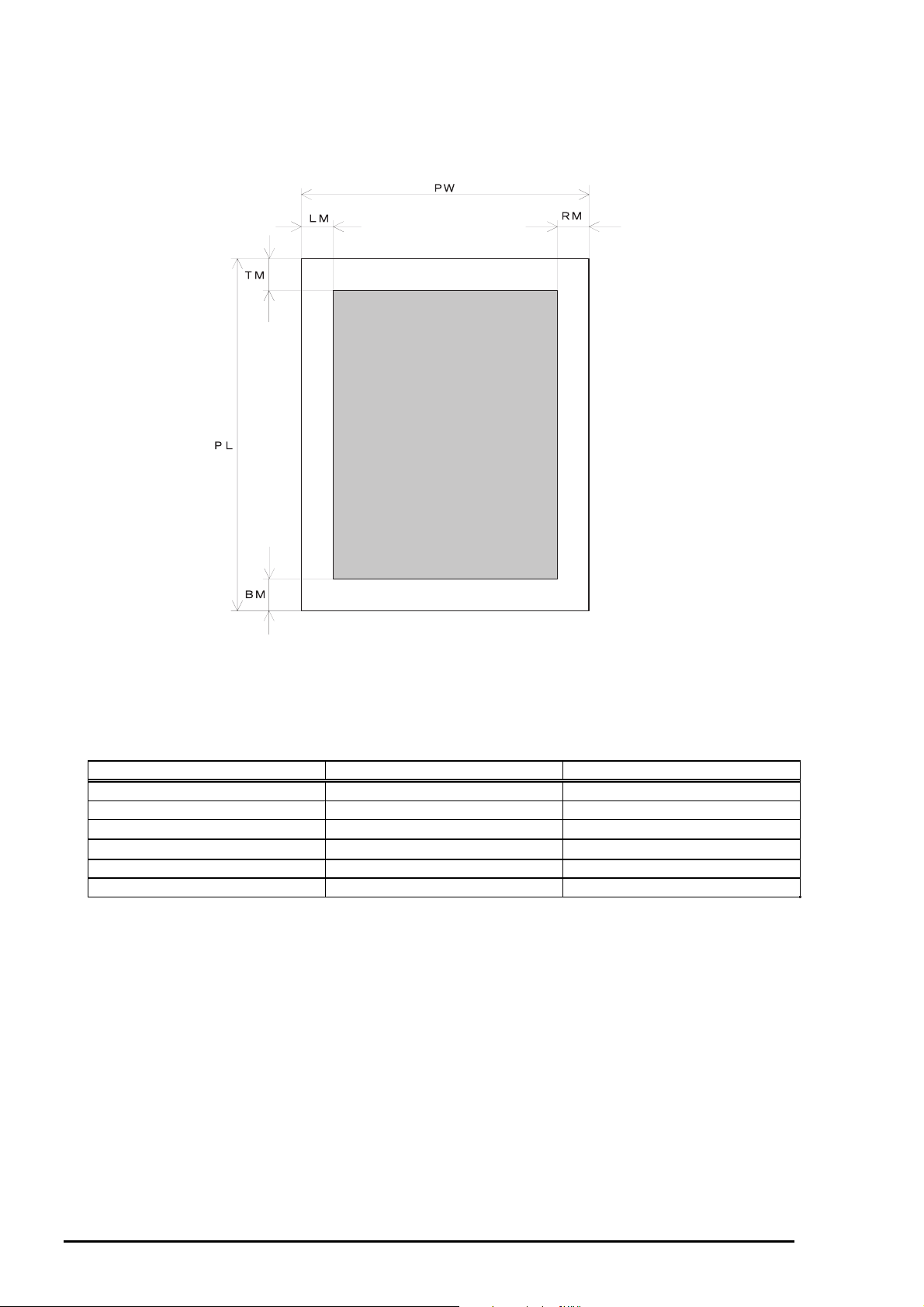

Continuous paper

Perforation

Printable Area

Perforation

Figure 1-7. Printable Area for Continuous Paper

Table 1-16. Printable Area for Continuous Paper

Continuous paper

PW (Width) (Refer to section 1.2.4)

PL (Length) (Refer to section 1.2.4)

LM (Left margin) 13mm or more

RM (Right margin) 13mm or more

TM (Top margin) 4.2mm or more

BM (Bottom margi n) 4.2mm or more

1-1

Rev. A

Page 20

3

Roll paper

Chapter 1 Product Description

PW

LM

BM

Printable Area

Figure 1-8. Printable Area for Roll Paper

TM

BM

Table 1-17. Printable Area for Roll Paper

Continuous paper

PW (Width) (Refer to section 1.2.4)

PL (Length) (Refer to section1.2.4)

LM (Left margin) 3mm or more

RM (Right margin) 3mm or more

TM (Top margin) 0.0mm or more

BM (Bottom margi n) 0.0mm or more

Rev. A

1-1

Page 21

LQ-670 Service Manual

4

1.2.6 Ribbon Cartridge

Type : Fabric

Color : Black

Ribbon life : 2 million characters (LQ 10cpi, 48 dots/character)

Dimensions :120.5mm(W) x 101.5mm(D) x 23.5mm(H)

1.2.7 Input data buffer

0 Kbyte or 64 Kbyte*

Note*)

: Depends on default settings.

1.2.8 Electrical Specification

120V version

Rated voltage : AC120V

Input voltage range : AC103.5 to 132V

Rated frequency range : 50 to 60 Hz

Input frequency range : 49.5 to 60.5 Hz

Rated current : 0.7A(max.2.2A)

Power consumption : Approx.30W (ISO/IEC10561 Letter pattern)

Energy Star Compliant

Insulation resistance : 10 MΩ min.(between AC line and chassis, DC 500V)

Dielectric strength : AC1000 Vrms. 1min.or

AC1200 Vrms. 1 sec.(between AC line and chassis)

230 V version

Rated voltage : AC220 to 240V

Input voltage range : AC198 to 264V

Rated frequency range : 50 to 60Hz

Input frequency range : 49.5 to 60.5Hz

Rated current : 0.4A (max.1.1A)

Power consumption : Approx.30W (ISO/IEC10561 Letter pattern)

Energy Star Compliant

Insulation resistance : 10MΩ min. (between AC line and chassis, DC 500V)

Dielectric strength : AC1500 Vrms. 1min.(between AC line and chassis)

1.2.9 Reliability

Total print volume : 6.5 million lines (except print head)

(MTBF) : 5000 POH

Print head life : 200 million strokes/wire

Ribbon life : 2 million characters

1-1

Rev. A

Page 22

5

1.2.10 Environmental Condition

Temperature

Operating : 5 to 35 °C(without condensation)

: 15 to 25 °C (without condensation and during printing on multi part paper,

envelope, card or label)

Non-operating : −30 to 60 °C

Humidity

Operating : 10 to 80% RH (without condensation)

: 30 to 60% RH (without condensation and during printing on multi part

paper, envelope, card or label)

Non-operating : 0 to 85% RH (without condensation)

Resistance to shock

Operating : 1G, within 1ms

Non-operating : 2G, within 2ms

Resistance to vibration

Operating : 0.25G,10 to 55 Hz

Non-operating : 0.50G,10 to 55 Hz

Chapter 1 Product Description

1.2.11 Safety Approvals

120V version

Safety standards : UL1950 with D3

CSA C22.2 No.950 with D3

EMI : FCC part15 subpart B class B

: CSA C108.8 class B

230V version

Safety standards : EN60950(VDE, NEMKO)

EMI : EN55022(CISPR pub.22) class B

: AS/NZS 3548 class B

1.2.12 CE Marking

230V version

Low Voltage Directive 73/23/EEC : EN60950

EMC Directive 89/336/EEC : EN55022 class B

: EN61000-3-2

: EN61000-3-3

: EN50082-1

: IEC801-2

: IEC801-3

: IEC801-4

1.2.13 Acoustic Noise

Level : Approx. 55 dB(A) (ISO 7779 pattern)

Rev. A

1-1

Page 23

LQ-670 Service Manual

6

1.3 Firmware Specification

This section provides detailed information about LQ-670 firmware.

1.3.1 Control Codes and Fonts

Control codes: :ESC/P 2 and IBM 2390 Plus emulation

Typefaces :Bit map font

EPSON Draft 10CPI, 12CPI, 15CPI

EPSON Roman 10CPI, 12CPI, 15CPI, Proportional

EPSON Sans Serif 10CPI, 12CPI, 15CPI, Proportional

EPSON Courier 10CPI, 12CPI, 15CPI

EPSON Prestige 10CPI, 12CPI

EPSON Script 10CPI

EPSON OCR-B 10CPI

EPSON Orator 10CPI

EPSON Orator-S 10CPI

EPSON Script C Proportional

EPSON Draft(Arabic) 10CPI, 12CPI

EPSON Draft(Hebrew) 10CPI, 12CPI

EPSON Miriam 10CPI, Proportional

EPSON David 10CPI, Proportional

EPSON Naskh 10CPI, Proportional

EPSON Kufi 10CPI, Proportional

:Scalable font

EPSON Roman 10.5pt., 8pt.-32pt.(every 2pt.)

EPSON Sans Serif 10.5pt., 8pt.-32pt.(every 2pt.)

EPSON Roman T 10.5pt., 8pt.-32pt.(every 2pt.)

EPSON Sans Serif H 10.5pt., 8pt.-32pt.(every 2pt.)

:Bar code

Ean-13

EAN-8

Interleaved 2 of 5

UPC-A

UPC-E

Code 39

Code 128

POSTNET

International character sets :14 countries and legal

U.S.A, France, Germany, U.K., Denmark 1, Sweden,

Italy, Spain 1, Japan, Norway, Denmark 2, Spain 2,

Latin America, Korea, Legal

Note)

The international and legal characters are these 12 codes;

23H, 24H, 5BH, 5CH, 5DH. 5EH, 60H, 7BH, 7CH, 7DH, 7EH.

1-1

Rev. A

Page 24

Chapter 1 Product Description

7

Character tables :The standard version has 11 character tables and the NLSP version has

20 charater tables, as shown in the following table.

Table 1-18. Character Tables

Character table Bitmap font Scalable font

Standard version

NLSP version

Italic table

PC437(US Standard Europe)

PC850(Multilingual)

PC860(Portuguese)

PC861(Icelandic)

PC863(Canadian-French)

PC865(Nordic)

Abicomp

BRASCII

Roman 8

ISO Latin 1

Italic table

PC437(US, Standard Europe)

PC850(Multilingual)

PC860(Portuguese)

PC861(Icelandic)

PC865(Nordic)

EPSON Draft

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON OCR-B

EPSON Orator

EPSON Orator-S

EPSON Script C

EPSON Draft

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON OCR-B

EPSON Orator

EPSON Orator-S

EPSON Script C

EPSON Roman

EPSON Sans Serif

EPSON Roman T

EPSON Sans Serif H

EPSON Roman

EPSON Sans Serif

EPSON Roman T

EPSON Sans Serif H

PC864(Arabic) EPSON Draft

EPSON Roman

PC437 Greek

PC852(East Europe)

PC853(Turkish)

PC855(Cyrillic)

PC857(Turkish)

PC866(Russian)

PC869(Greek)

MAZOWIA(Poland)

Code MJK(CSFR)

ISO 8859-7 (Latin/Greek)

ISO Latin 1T(Turkish)

Bulgaria(Bulgarian)

Estonia(Estonia)

PC744(LST 1283:1993)

ISO 8859-2

PC866 LAT.(Latvian)

PCAPTEC(Arabic)

PC708(Arabic)

PC720(Arabic)

PCAR864(Arabic)

Hebrew7 *1

Hebrew8 *1

PC862(Hebrew) *1

EPSON Draft

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON Draft(Arabic)

EPSON Naskh

EPSON Kufi

EPSON Draft(Hebrew)

EPSON Miriam

EPSON David

(Not supported)

(Not supported)

(Not supported)

(Not supported)

Note *1) These fonts are not selected in the default setting mode.

Note)

Rev. A

ESC R command is effective on the character tables with bold weight.

1-1

Page 25

LQ-670 Service Manual

8

1.3.2 Interface Specification

This printer provides bi-directional 8-bit parallel interface and Type-B optional interface slot as standard.

1.3.2.1 Parallel interface (Forward channel)

[Transmission mode]

[Adaptable connector]

[Synchronization]

[Handshaking]

[Signal level]

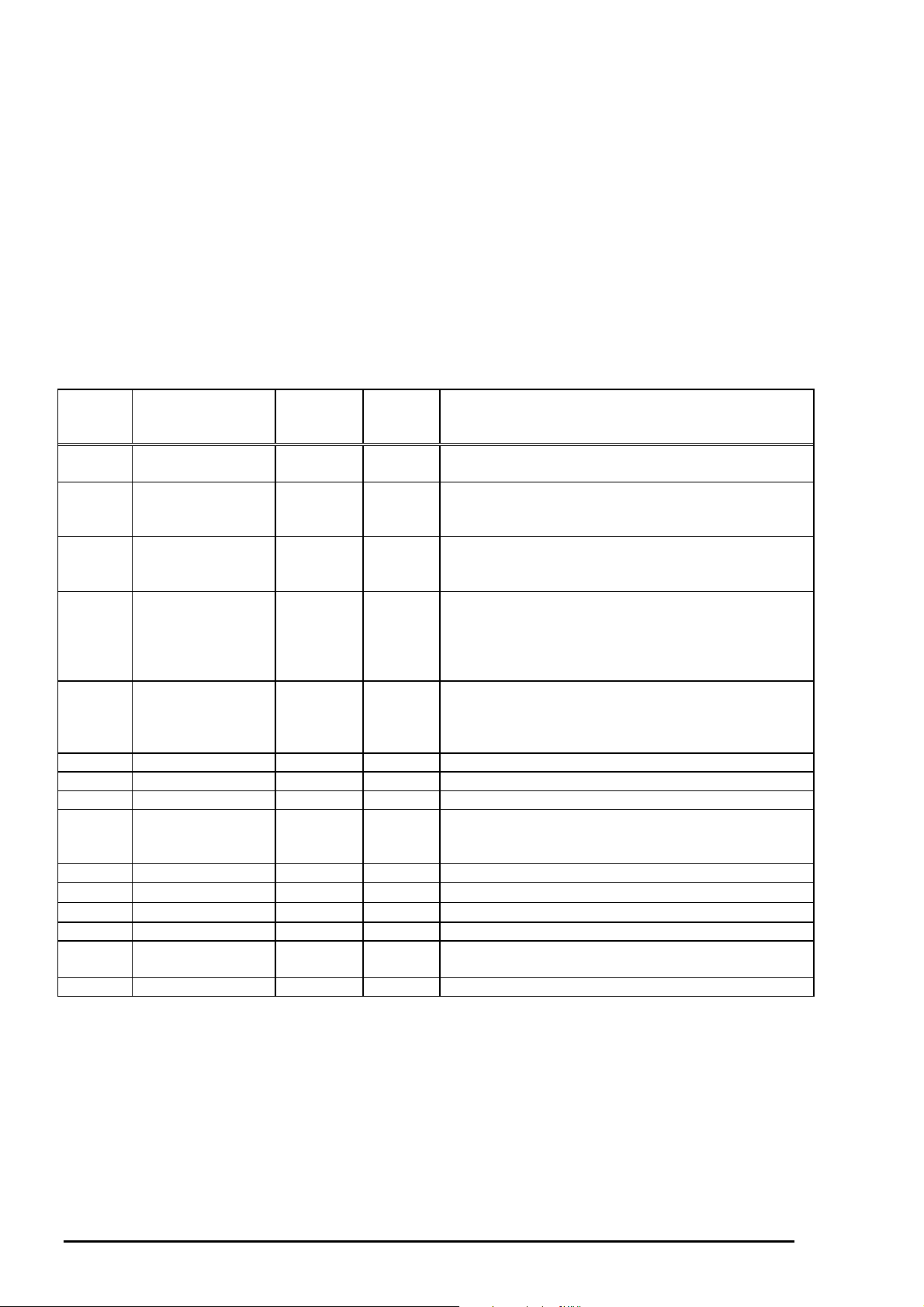

Table 1-19. Connector Pin Assignment and Signals

Pin No. Signal Name Return

1 /STROBE 19 In Stroke pulse. Input data is latched at falling edge of

2∼9DATA1∼820∼27

10 /ACKNLG 28 Out This signal (negative pulse) indicates that the printer

11 BUSY 29 Out This signal’s “HIGH” level indicates that the printer

12 PE 28 Out This signal’s “HIGH” level indicates that the printer

13 SLCT 28 Out Always at high level when the printer is powered on.

14 /AFXT 30 In Not used.

31 /INIT 30 In This signal’s negative pulse initializes printer.

32 /ERROR 29 Out This signal’s low level means the printer is in a state

36 /SLIN 30 In Not used.

18 Logic H ---- Out

35 +5V --- Out

17 Chassis --- --- Chassis GND.

16,33

19-30

15,34 NC --- --- Not connected.

GND --- --- Signal GND.

: 8 bit parallel, IEEE-1284 compatibility mode

: 57-30360 (Amphenol) or equivalent

: /STROBE pulse

: BUSY and /ACKNLG signals

: TTL compatible (IEEE-1284 level 1 device)

In/Out * Function description

GND

Pin

the signal.

In Each signal represents information of parallel data

from 1 bit to 8 bit. The data is 1 at “HIGH” and is 0

at “LOW”.

has received data and is ready to accept next one.

The pulse width is 5µs.

is not ready to accept data. On the other hand,

“LOW” means the printer can take data.

(Refer to the next page for conditions when this

signal becomes high level)

is in a state of paper-out error.(Refer to the next

page for the condition when this signal becomes

high level.)

of error. (Refer to the next page for conditions when

the signal becomes low level)

This line is pulled up to +5V through 3.9 kΩ resistor.

This line is pulled up to +5V through 1.0 kΩ resistor.

Note)

*In/Out shows the direction of signal flow from the printer's point of view.

Note)

If the signal is “LOW” and active state, the signal is marked with “/”.

1-1

Rev. A

Page 26

Chapter 1 Product Description

9

BUSY signal is active (high level) under the following conditions.

In the process of receiving data.

In the condition of being input buffer full

In the condition of being /INIT signal active(low level)

During hardware initialization

In the condition of being /ERROR or PE signal active(low level, high level, respectively)

In the self test mode

In the adjustment mode

In the default-setting mode

/ERROR signal is active(low level) under the following conditions.

In the condition of the release lever error

In the condition of the paper-out error

In the condition of the paper-jam error

PE signal is active(high level) under the following condition.

In the condition of paper-out error

Note)

It becomes possible to input the data without outside equipment by setting appropriate connecting.

Note)

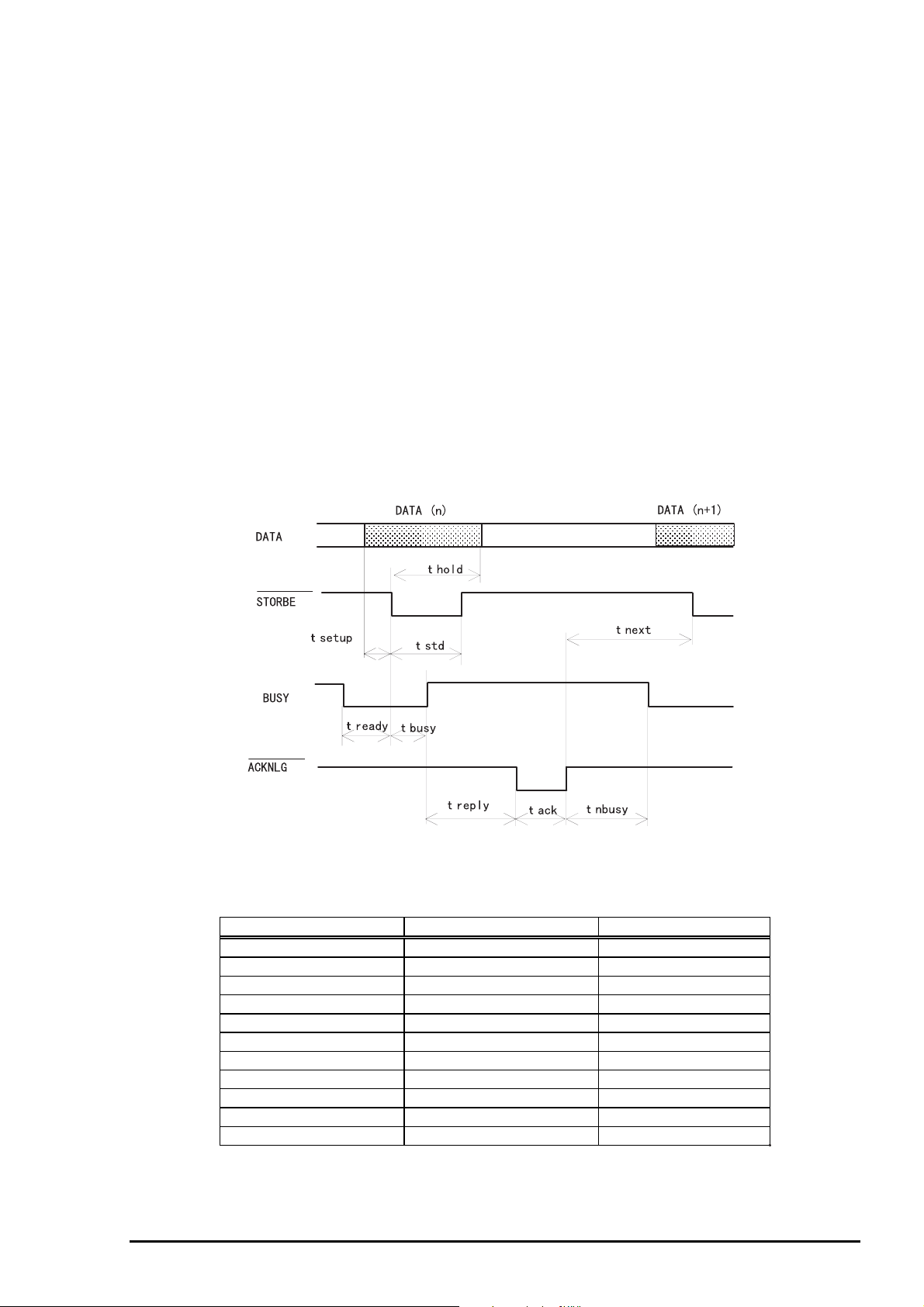

Rev. A

Figure 1-9. Data Transmission Timing

Table 1-20. Maximum and Minimum Timings for Data Transmission

Parameter Minimum Maximum

tsetup 500 nsec ---

thold 500 nsec ---

tstb 500 nsec ---

tready 0 ---

tbusy --- 500 nsec

treply --- ---

tack 500 nsec 10 us

tnbusyt 0 ---

tnext 0 ---

ttout* --- 120 nsec

ttin** --- 200 nsec

* Rise and fall time of output signals.

** Rise and fall time of input signals.

1-1

Page 27

LQ-670 Service Manual

0

1.3.2.2 Parallel Interface (Reverse channel)

[Transmission mode]

[Adaptable connector]

[Synchronization]

[Handshaking]

[Signal Level]

[Data transmission timing]

[Extensibility request]

when the request is 00H or 04H, which mean;

[Device ID]

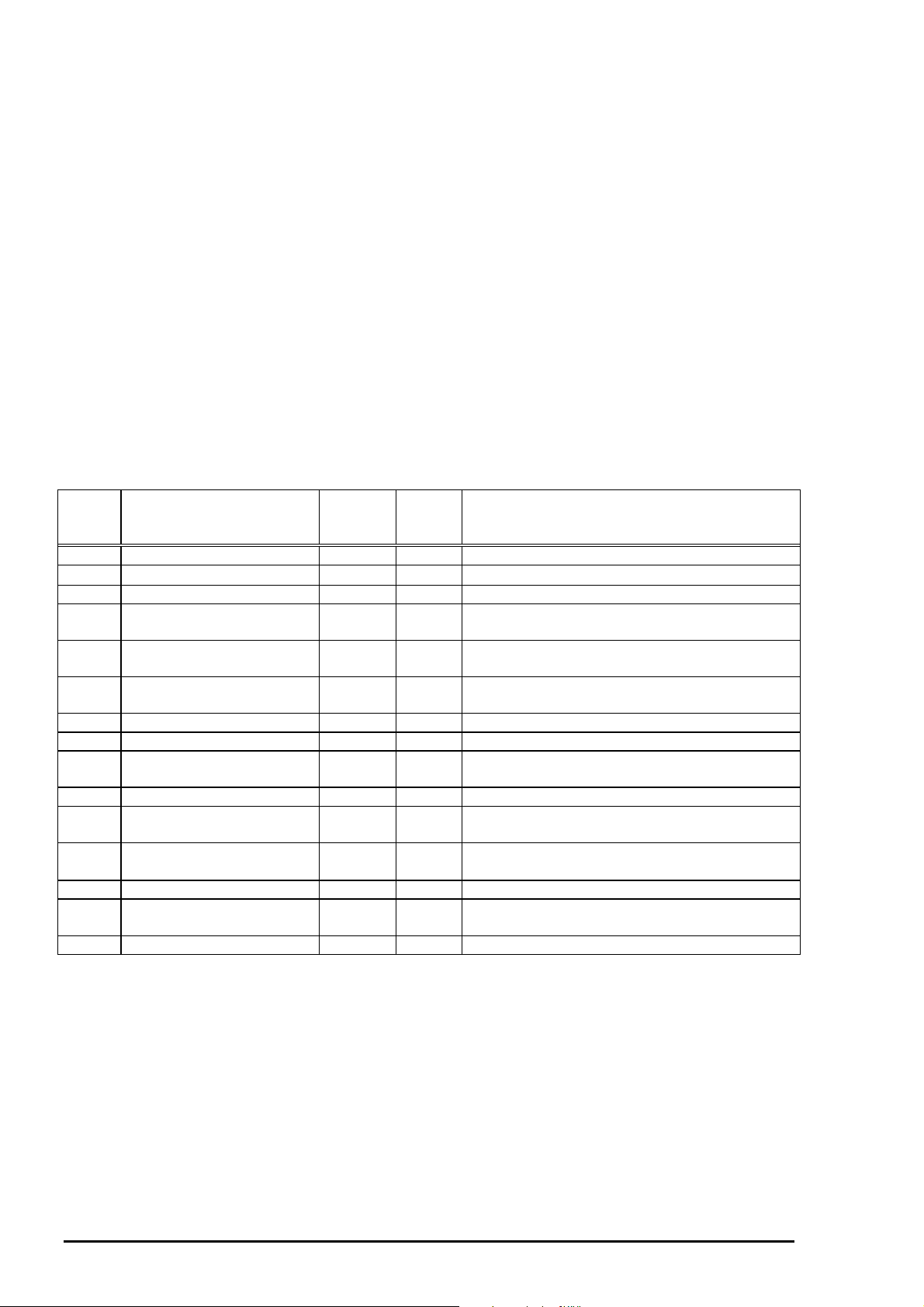

Table 1-21. Connector Pin Assignment and Signals

Pin

No.

1 HostClk 19 In Host clock signal

2∼9DATA1∼820∼27

10 PtrClk 28 Out Printer clock signal.

11 PtrBusy, DataBit-3,7 29 Out Printer busy signal and reverse channel

12 AckDataReq, DataBit-2, 6 28 Out Ack nowledge data request signal and reverse

13 Xflag, DataBit-1, 5 28 Out X-flag signal and reverse channel trans f er data

14 HostBusy 30 In Host busy signal.

31 /INIT 30 In Not used.

32 /Data Av ail, DataBit-0, 4 29 Out Data available signal and reverse channel

36 1284-Active 30 In 1284 active signal.

18 Logic-H --- Out A high signal indicates that all other signals

35 +5V --- Out

17 Ch assis --- --- Chassis GND.

16,33,

19-30

15,34 NC --- --- Not connected.

GND --- --- Signal GND.

Signal Name Return

: IEEE 1284 nibble mode

: 57-30360(Amphenol) or equivalent

: /STROBE pulse

: BUSY and /ACKNLG signals

: IEEE-1284 level 1 device

TTL compatible

: Refer to the IEEE-1284 specification

: The printer responds to the extensibility request in the affirmative,

00H:Request nibble mode of reverse channel transfer

04H:Request device ID in nibble mode of reverse channel

transfer.

: [00H] [3AH]

MFG: EPSON;

CMD:ESCPL2,PRPXL24, BDC;

MDL;LQ-670;

CLS:PRINTER;

In/Out* Function description

GND

Pin

In Parallel input data to the printer.

transfer data bit 3 or 7.

channel transfer data bit 2 or 6.

bit1 or 5.

transfer data bit0 or 4.

sourced by the peripheral are in a valid state.

This line is pulled up to +5V through 1.0 kΩ

resistor.

Note*):

1-2

In/Out refers to the direction of signal flow/from the printer’s point of view.

Rev. A

Page 28

Chapter 1 Product Description

1.3.2.3 Optional Interface

Type-B optional interface cards are available.

Table 1-22. Optional Interface

Reply message ESC/P2 IBM 2390 Plus

Main-Type MT24p,PW106cl10cpi,PRG(W0xxxx)rev MT24p,PW106c110cpi,PRG(W0xxxx)rev

Product-Name LQ-670 LQ-670

Emulation-Type ESCPL2-00 PRPXL24-01

Entity-Type EPSONLQ2 EPSONPRPXL24

1.3.2.4 Interface Selection

The printer has 2 interfaces; the parallel interface and Type B optional interface. These interfaces are

selected manually by Default setting or selected automatically.

1.3.2.5 Manual selection

Out of 2 interfaces can be selected by Default Setting.

1.3.2.6 Automatic selection

The automatic interface selection is enabled by Default Setting. In this automatic interface selection

mode, the printer is initialized to the idle state scanning which interface receives data when it is powered

on. Then the interface that receives data first is selected. When the host stops data transfer and the

printer is in stand-by state for the seconds specified by Default Setting, the printer is returned to the idle

state. As long as the host sends data or the printer interface is bus y state, the selected inter f ace is let as it

is.

1.3.2.7 Interface state and interface selection

When the parallel interface is not selected, the interface gets into a busy state. When the Type-B serial

interface card is installed and it is not s elec ted, the inter f ace s ends X OFF and s ets the DT R s ignal MARK.

When the optional interface is not selected, the printer sends disable commands to the optional interface.

When the printer is initialized or returned to the idle state, the parallel interface gets into a ready state, the

serial interface sends XON and sets the DTR SPACE and the printer sends enable commands to the

optional interface. Caution that the interrupt signal such as a /INIT signal on the parallel interface is not

effective while that interface is not selected.

1.3.3 Prevention Hosts from Data Transfer Timeout

Generally, hosts abandons data transfer to peripherals when a peripheral is in busy state for dozens of

seconds continuously. To prevent hosts from this kind of timeout, the printer receives data very slowly,

several bytes per minute, even if the printer is in busy state. This slowdown is started when the rest of the

input buffer becomes s everal hundreds of bytes. At last, when the input buffer is full, the printer is in busy

state continuously.

Rev. A

1-21

Page 29

LQ-670 Service Manual

2

1.4 Operation

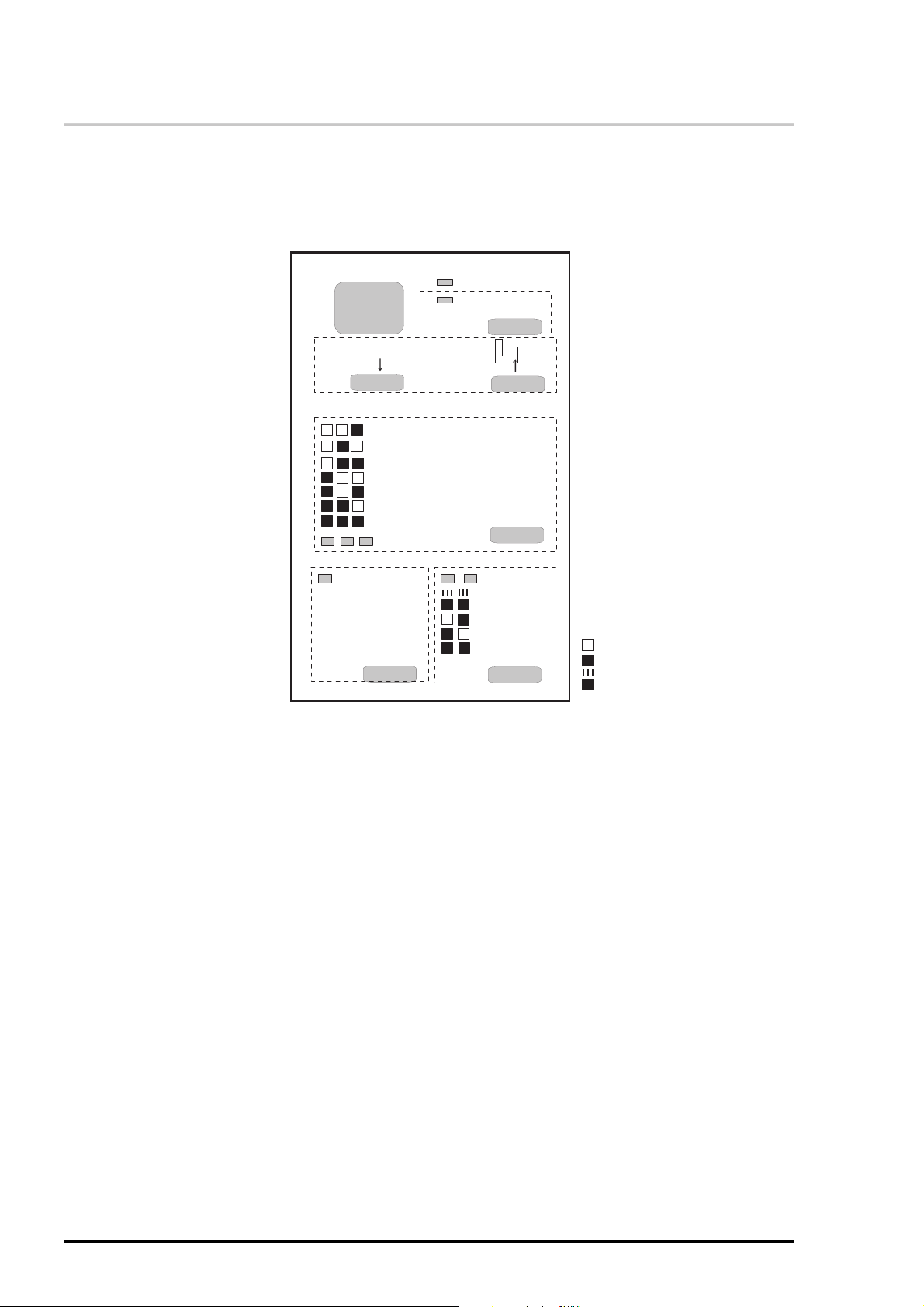

1.4.1 Control Panel

There are 7 switches and 8 LEDs on the panel as shown below.

Operate

Micro Adjust

LF/FF

Draft

Roman

Sans Serif

Courier

Prestige

Script

Others

Font

Condensed

Paper Out

Pause

Figure 1-10. Control Panel

3sec

Load/Eject

Tear Off/Bin

Tear Off

Bin 1

Bin 2

Card

LED Off

LED On

LED Blinks

1.4.1.1 Usual Operation

Operate

This switch turns the printer on and off. It is the secondary switch.

Pause

This switch alternates printer activity between printing and non-printing.

Holding it down over 3 seconds when the printer is in the stand by state, the Micro Adjust function

is enabled. Pressing it again, this function is disabled.

Load/Eject

Pressing it loads cut sheet or continuous paper when the printer is out of paper.

Pressing it ejects cut sheet to the stacker or continuous paper to the paper park.

LF/FF

Pressing it shortly executes line feed.

Holding it down for a few seconds executes form feed when continuous paper is used, or ejects cut

sheet to the stacker when cut sheet is used.

Tear Off

When continuous paper is used, pressing it moves a page to the Tear-off position. And pressing it

again moves a next page to the TOF position.

1-2

Rev. A

Page 30

Chapter 1 Product Description

3

Bin

Pressing it selects CSF bin number or the Card mode* when cut sheet is used.

Note*)

Card mode is for using post card or envelope.

Font

Pressing it selects one of following fonts.

Draft, Roman, Sans serif, Courier, Prestige, Script and Others *.

Note*)

Others means the font selected in the Default Setting Mode.

Condensed

Pressing it alternates condensed and non-condensed mode.

Micro Adjust

Micro Adjust ↑/↓ switches is effective when the Micro Adjust function is enabled by Pause switch.

Pressing the Micro Adjust ↑/↓ switches execute micro feed backward and forward by 1/80 inch.

The TOF adjustment is enabled in the TOF position after loading, and the Tear-off adjustment is

enabled in the Tear-off position.

Rev. A

1-2

Page 31

LQ-670 Service Manual

4

1.4.1.2 Switches

Operation in normal mode

In normal mode, pressing panel switches executes following function.

Table 1-23. Operation in Normal Mode

Switch Function

Operate Turn the printer on and off.

Pause Alternates printing and no-printing status.

Enables Micro Adjust function, holding it down for 3 seconds.

Load/Eject Loads or ejects the paper.

Executes micro feed forward, when this function is enabled.

LF/FF Executes line feed, pressing it shortly.

Executes form feed, holding it down for a few seconds.

Executes micro feed backward, when this function is enabled.

Tear Off/Bin Advances continuos paper to the Tear-off position.

Selects CSF bin ½ or Card mode.

Font Selects font.

Condensed Alternates condensed mode and non-condensed mode.

Operation at power on

Turning the printer on while pressing panel switches executes the function shown below.

Table 1-24. Operation in Power On

Switch Function

Load/Eject LQ self test

LF/FF Draft self test

Font Default setting

Load/Eject & LF/FF Data dump

Condensed &Tear Off/Bin Clear EEPROM

Pause Bi-d adjustment

Font & Condensed Quiet mode

The others Not available

Operation in default setting mode

The switches are used in default setting mode as follows:

Table 1-25. Operation at Default Setting Mode

Switch Function

Font Selects the Menu

Tear Off/ Bin Changes the setting

The others Not available

1-2

Rev. A

Page 32

5

1.4.1.3 Indicators(LED)

This printer displays present conditions and errors on the indicators.

Indication in normal mode

Table 1-26. LED Indicators

Chapter 1 Product Description

LED

Printer Status

Pause On --- --- --- ---

Paper out error On On --- --- --Paper jam

error

Paper eject

error

Head hot Blink --- --- --- --Micro Adjust Blink --- --- --- --Tear off --- --- *3 --- --Bin selection --- --- *3 --- --Condensed --- --- --- On --Font selection --- --- --- --- *4

Fatal error Blink Blink Blink Blink Blink

*1 Pause (Orange)

It is on when the printer is paused, and it is off when the printer is not paused.

It blinks when the Micro Adjust function is enabled or the printer is in the head hot status.

*2 Paper Out (Red)

It is on when the printer is in the paper out status, and it is off when the printer is out of this status.

*3Tear Off/Bin (Green)

2 LEDs display the status of CSF bin selection when cut sheet is used. Only a right LED is on when

Bin1 is selected, only a left LED is on when Bin2 is selected, and both LEDs are on when the Card

mode is selected.

Both LEDs blinks when continuous paper is in the Tear-off position and both LEDs are off when

continuous paper is out of the Tear-off position.

Pause

*1

On Blink --- --- --On Blink --- --- ---

Paper Out

*2

Tear Off/Bin Condensed Font

*4Font (Green)

The status of Font selection is displayed by 3 Font LEDs.

Rev. A

1-2

Page 33

LQ-670 Service Manual

6

1.4.1.4 Buzzer

When the printer detects errors, it displays errors on the LEDs and also the buzzer beeps as warning

sign.

Table 1-27. Buzzer

Warning sign Beeper sounds

Paper out error

Paper jam error

Paper eject error

Release lever operation error

Illegal panel operation

❍ ❍ ❍

● ● ● ● ●

❍ ❍ ❍

● ● ● ● ●

❍

Note

❍ : Beeper sounds approx. 100ms and interval is approx.100ms.

)

● : Beeper sounds approx. 500ms and interval is approx.100ms.

1-2

Rev. A

Page 34

Chapter 1 Product Description

7

1.4.2 Default Setting

Setting Method

Several printer settings loaded at each power-on can be changed in this operation. The method is

described in the guidance sheets (language selection sheet and printer setting sheet) which are

printed out at first in the setting mode if desired.

User is requested to operate 2 switches watching 6 LEDs on the control panel. The lights turn on and

off, and blink in one of the patterns described in the guidance sheets.

This setting mode uses the menus of 3 types as follows;

Language menu: : List of the languages to be used for the printer setting sheet

Main menu : List of items to be set(ex. “CG table”, “Auto line feed”)

Submenus : Lists of value/setting of the each item(ex. “PC437”, “ON”)

1) Language selection sheet is printed out. The s heet describes how to select a language among the

five; English, French, German, Italian and Spanish in all languages.

2) Font LEDs indicate the top item on “Language menu”.

3) The selection can be changed with Font switch.

4) When Tear off/Bin switch is pressed, the setting sheet is printed out in the language.

5) Font LEDs indicate the top item on “main menu”.

6) The selection can be changed with Font switch.

7) W hen Tear off/Bin switch is pressed, printer changes the indication to the “s ubmenu” of the selected

item.

8) Condensed & Tear off/Bin LEDs indicate the current setting/value on the submenu.

9) The setting/value can be changed with Tear off/Bin switch.

10) When Tear off/Bin switch is pressed, printer memorizes the last setting/value, and changes its

indication to the main menu.(Back to (5)).

11) The other items can be changed in the same manner.

Setting Mode (Factory setting)

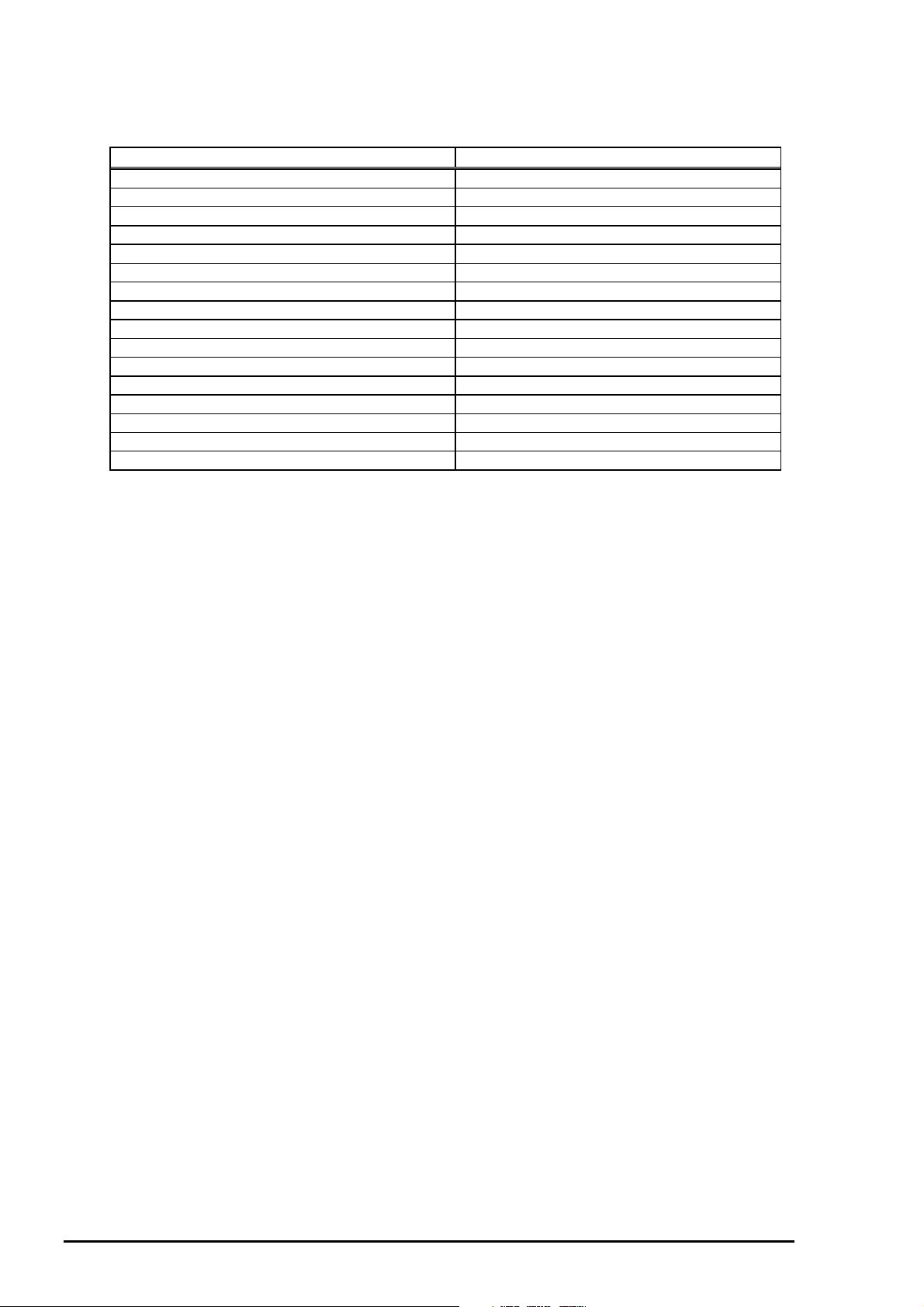

Table 1-28. Setting Menu

Item Setting/Value

Character table Standard version:

PC 437

Italic,

Abicomp, ISO Latin1, Roman8

NLSP version:

PC437

Italic,

PC864, PC866, PC869, ISO Latin 1T, ISO8859-7 MAZOWIA, Code

MJK, Bulgaria, Estonia, PC774, ISO 8859-2, PC866LAT.

PCAPTEC*5, PC708*5, PC720*5, PCAR864*5, PC860*5, PC861*5,

PC865*5

International character set for

Italic table *4

Font *1

Page Length for tractor

High speed draft

Print Direction

Software

I/f mode

Auto I/F wait time

Input buffer

Skip over perforation

Auto tear off

Auto line feed

Auto CR (IBM 2390 Plus)*2

A.G.M (IBM 2390 Plus)*2

0 slash

Buzzer

* Refer to the next page for

Notes.

Italic U.S.A

Italic Sweden, Italic Italy, Italic Spain

OCR-B, Orator, Orator-S, Script C,

3 inch, 3.5 inch, 4 inch, 5.5 inch, 6 inch, 7 inch, 8 inch, 8.5 inch,

inch

, 70/6 inch, 12 inch, 14 inch, 17 inch

On

, Off

Bi-d

Auto,

ESC/P2

Auto,

10sec

On

On,

On,

On,

On,

On,

On,

On

, IBM2390 Plus

Parallel I/F, Option I/F

., 30sec.

, off

Off,

Others

Off

Off

Off

Off

Off

, Off

, PC850, PC860, PC863, PC865, PC861, BRASCII,

, PC437 Greek, PC850, PC852, PC853, PC855, PC857,

, Italic France, Italic Germany, Italic U.K., Italic Denmark,

Roman T

, Uni-d

, Sans serif H

11

Rev. A

1-2

Page 35

LQ-670 Service Manual

8

Note*1):

Note*2)

Note*3

Note*4

Note*5):

1.

Bi-d adjustment can be adjusted by users. By using this mode, the gap of lines; line for right printing

direction and line for left printing direction can be adjusted. The setting value is stored in the EEPROM of

the main control board and retained even after the power is turned off. Bi-d adjustment method is as

follows.

1) Turning the printer on while pressing Pause switch.

2) Select most closely aligned number by pressing LF/FF(↓) and Load/Eject(↑) switches.

is also changed by according to the selection.

3) Fix the selected number by pressing Font switch.

4) Repeat 2)-3) until finishing Bi-d. adjustment for LQ mode.

5) Turn the printer off.

One of these fonts selected in the default setting is corresponding to others(=other fonts) on

the control panel. Following fonts are not selected in the default setting mode.

Draft, Roman, Sans serif, Courier, Prestige and Script

: These settings are effective when IBM 2390 Plus emulation is selected.

): Settings with bold weight mean the standard factory settings.

): “Italic Denmark” is as same as “Italic Denmark 1”, and “Italic Spain” is as same as “Italic Spain

1”.

Hebrew7, Hebrew8, PC862 are not selected in the default setting mode.

4.3

Bi-d Adjustment

The guide to adjust Bi-d alignment in this mode is printed and first alignment pattern is printed.

Font LEDs show the pattern number which is selected at that time. The selection is advanced

one by one as the switch is pressed, and the combination of On/Off/ Blink of those three LEDs

Selected number is fixed and next alignment pattern is printed.

Following adjustment is executed.

1. Bi-d adjustment for draft mode

2. Bi-d adjustment for draft copy mode

3. Bi-d adjustment for LQ mode

Note)

The setting values are stored into non-volatile memory and retained even if EEPROM is reset.

1-2

Rev. A

Page 36

Chapter 1 Product Description

9

1.4.4 Initialization

Power-On initialization

The initialization of this level is activated by power-on or cold reset command(remote RS command).

This initialization is;

to initialize the printer mechanism.

to execute Operator initialization.

Operator Initialization

The initialization of this level is activated by /INIT signal(negative pulse). This initialization is;

to clear the all buffers of data.

to cancel the download character definition.

to make the printer stand-by state, if no errors occur.

to execute Software initialization.

Software Initialization

The initialization of this level is activated by the control code ESC @. This initialization is;

to clear the unprinted data.

to make the printer’s setting defaults.

1.4.5 Errors

This printer goes to the error s tate when the following condition is detected, and changes ERROR signal

to ”LOW” and “BUSY” signal to “HIGH” , and stops taking data. Also, the printer goes unprintable condition

automatically.

Fatal errors is detected.

Paper out error or paper jam error is detected.

Paper eject error is detected.

When the present paper path and the position of release lever do not match. (Release lever

operation error)

Fatal errors

Carriage control error, Power supply voltage error and CG access error.

Paper out error

When printer fails to load a sheet, it goes paper out error.

Paper eject error

When printer fails to eject a sheet, it goes paper eject error.

Paper jam error

When printer fails to feed a sheet, it goes paper jam error.

Rev. A

1-2

Page 37

LQ-670 Service Manual

0

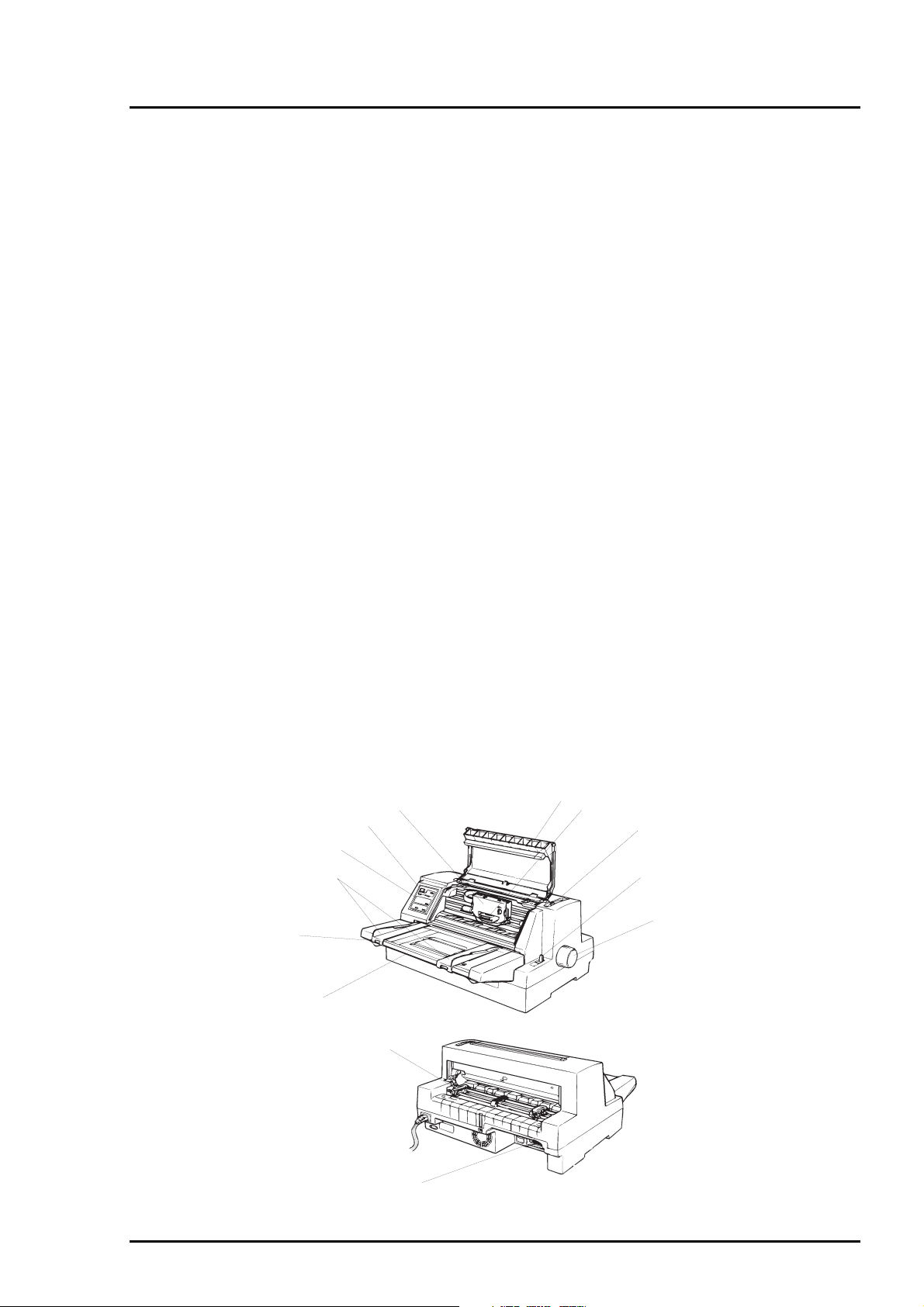

1.5 Main Components

This printer consists of the following components.

C214MAIN Board

C214 PSB/PSE Board

C214 PNL Board

Printer Mechanism(M-5060)

Housing

1.5.1 C214 Main Board

This main board consists of 16bitCPU TMP96C041AF (IC11) which is driven by 17.20MHz clock drive

frequency, Gate array E05B42(IC10), 2/4M Flash-EPROM(IC7), or 8M PROM(IC8), 4/8/32M MROM (IC4)

for CG, 8M PROM (IC5), 1MPSRAM (IC6), EEPROM 93C46(IC9), Reset IC RST592D (C12), PF Motor

drive circuit, CR motor drive circuit and print head drive circuit.

Gate Array(IC10)

PROM(IC8)

Reset IC(IC12)

PROM(IC5)

EEPROM(IC9)

PSRAM(IC5)

Flash-EPROM(IC7)

CPU(IC11)

Print Head Driver

PF Motor Driver IC

CR Motor Driver IC

Figure 1-11. C214 Main Board

1.5.2 C214PSB Board

This board consists of fuse, filter circuit, primary side diode bridge, switching FET, transformer and

chopper IC for +5V generation. Also, the secondary switch is used for power and is operated by On/Off of

the power switch on the operation panel of the printer.

Fuse

Filter Circuit

SwitchingFET

Chopper IC for +5V generation

Diode Bridge

Transformaer

Figure 1-12. C214 PSB Board

1-3

Rev. A

Page 38

Chapter 1 Product Description

1.5.3 C214 PNL Board

This panel board consists of one switch as power switch, 6 non lock type switches and 8 LEDs.

1.5.4 Printer Mechanism

This unit consists of carriage mechanism, paper feed mechanism, cut sheet/transformer change over

mechanism, platen gap adjustment mechanism and print head.

1.5.5 Housing

The housing of this printer consists of upper housing, printer cover, front sheet guide, rear sheet guide and

lower housing.

Rev. A

1-31

Page 39

Chapter 2

Operating Principles

2.1 Printer Mechanism Operation..............................................................................2-1

2.1.1 Printing Mechanism ............................................................................................................... 2-1

2.1.2 Carriage Mechanism .............................................................................................................. 2-3

2.1.3 Ribbon Advance Mechanism................................................................................................. 2-5

2.1.4 Paper Advance Mechanism...................................................................................................2-6

2.1.4.1 Paper Advance Mechanism ...................................................................................... 2-6

2.1.4.2 Paper Advance Detector Mechanism........................................................................ 2-7

2.1.4.3 Release Lever Mechanism........................................................................................ 2-9

2.1.5 Platen Gap Adjustment........................................................................................................ 2-10

2.2 Power Supply Operation....................................................................................2-11

2.2.1 Power Supply Circuit ........................................................................................................... 2-11

2.2.1.1 Power Supply Overview............................................................................................2-11

2.2.1.2 Power Supply Circuit Operation .............................................................................. 2-12

2.2.2 Control Circuit ......................................................................................................................2-13

2.2.2.1 Operating Principles of the Control Circuit ..............................................................2-13

2.2.2.2 EEPROM Control Circuit......................................................................................... 2-14

2.2.2.3 System Reset Circuit............................................................................................... 2-14

2.2.2.4 Power Off Detector Circuit....................................................................................... 2-15

2.2.2.5 Print Head Driver Circuit..........................................................................................2-15

2.2.2.6 CR Motor Driver Circuit ........................................................................................... 2-16

2.2.2.7 PF Motor Driver Circuit............................................................................................ 2-16

2.2.2.8 Operation Panel Control Circuit...............................................................................2-17

2.2.2.9 Interface(I/F) Circuit................................................................................................. 2-18

2.2.2.10 Head Temperature Detector Circuit.......................................................................2-18

2.2.2.11 Head Drive Voltage Measurement Circuit ............................................................. 2-18

2.2.2.12 Rear and Front Paper End Detector Circuit .......................................................... 2-18

2.2.2.13 Paper Width Detector Circuit................................................................................. 2-18

2.2.2.14 Carriage Home Position (HP) Detector Circuit...................................................... 2-18

2.2.2.15 Release Lever Detector Circuit ............................................................................. 2-18

2.2.2.16 Adjust Lever Detector Circuit................................................................................. 2-18

Page 40

LQ-670 Service Manual

2.1 Printer Mechanism Operation

This section describes the printer mechanism(M-5060) and explains how it works.

2.1.1 Printing Mechanism

The printing mechanism of this printer is composed of head, ink ribbon and ribbon mask.

The print head is an 24-pin(12pins X 2) head for impact dot printing.(Refer to Chapter 1)

Each wire has its own drive coil.

Actuating Plate

Actuating Spring

Head Driving Coil

Iron Core

Paper

Figure 2-1.Print Head Operation Principles

1. A drive signal, transmitted from the control circuit to the prinhead drive circuit, is converted to the

proper printhead driving voltage, which energizes a corresponding coil. The energized coil then

causes the iron core to become magnetized.

2. The magnetic force draws the actuating plate toward the core, and the dot wire, which is connected

to the core, rushes toward the platen.

3. When the dot wire impacts the platen, pressing against the ribbon and paper, it prints a dot.

4. When the driving voltage stops energizing the coil, the magnetic force vanishes from the iron core. The

actuating plate returns to its original position (the position before coil was energized) with spring action.

The dot wire also returns to its original position.

The mechanism is equipped with a built-in thermistor for head temperature detection. The temperature

detected by the thermistor is converted to an electric signal and fed back to the control circuit. In order to

keep the same print quality, the drive mode of the print head is changed over according to the paper type

and head temperature. This drive mode minimizes the degradation or damage to the dot wires in the print

head, which is caused by temperature rise of the print head from continuous printing, and also keeps print

quality when the surrounding temperature is extremely low. (Refer to section 1.2.2 for the changes of print

speed by the temperature of the head)

The next page shows print head specification.

Stopper

Wire Resetting Spring

Wire

Ink Ribbon

Ribbon Mask

Platen

Rev. A

2-1

Page 41

Chapter 2 Operating Principles

2

Category Specification

Print Method Impact dot matrix

Number of pin wires 24-pin (12X2)

Wire diameter 0.20mm

Print head life 200 million strokes/wire

Weight

Coil direct current resistance

Response Frequency Normal Mode : 1500Hz

Drive Voltage

Drive Condition

Environmental condition

Print drive method Constant voltage drive method

Table 2-1. Print Head Specification

115 ± 12g

39.3 ± 2.7 Ω (at 25 °C)

Buzzer : 1.5KHz

42 ± 3V

• Normal Drive

• Thick paper (using multipart or thick papers)

• Buzzer function

Temperature : 5∼55 °C

Humidity : 10∼85%

2-

Rev. A

Page 42

LQ-670 Service Manual

3

2.1.2 Carriage Mechanism

Carriage Mechanism consists of the carriage movement mechanism and platen gap adjustment

mechanism.

Carriage Movement Mechanism

The figure below shows carriage mechanism. The top of the carriage is supported by the CR guide

frame, and down side is by the CR guide shaft. Since the carriage motor is stepping motor, the

carriage moves freely, and the rotation of the motor is conveyed to the timing belt pulley and drive the

timing belt.

A part of the timing belt is attached to the head carriage, which is moved right and left on the carriage

guide shaft by the rotation of the carriage motor. The timing belt is pre-pressed by the spring and

adjust the elastic motion of the belt which is caused by temperature changes, and keep a certain

belt strength and tension.

The carriage home position detector uses photo coupler method and is located on the right edge of

the mechanism. The detector is detected when the carriage flag interrupts the light emitted from the

photo coupler. The carriage home position control performs open loop control after the HP detector

detects standard position. After the location is determined for the carriage to move by the printing

data, the control circuit calculates the pulse of the motor phase corresponding to the distance to move,

and outputs that information to the motor. Therefore, the detection of mis-location is detected when

the home signal is detected during printing or initialization and the printer goes to the error state.

Also, the moving speed of the carriage is controlled by carriage motor drive frequency according to the

printing data.

CR Motor

Timing Belt

Carriage

CR Guide Frame

Flag

Figure 2-2. Carriage Mechanism

Spring

CR Home Position

Detector

CR Guide Shaft

Table 2-2. Specification of the Carriage HP Detector

Category Specification

Method Photoelectric transfer method

Voltage

Switch Mode Open : In the detector range

Rev. A

5VDC ± 5%

Close : Out of the detector range

2-

Page 43

Chapter 2 Operating Principles

4

Category Specification

Type 200-pole, HB-type Stepping motor

Coil Resistance

Drive Voltage

Drive Resolution 0.106mm/step (1-2 phase)

Drive Method Constant current drive

Current Consumption Rated speed : 0.68A/phase

Drive Frequency

Table 2-3. CR Motor Specification

3.5Ω ± 10%

42V±5%

1-2 phase, W1-2 phase

At the waiting mode : 0.2A/phase

667∼7200Hz

2-

Rev. A

Page 44

LQ-670 Service Manual

5

2.1.3 Ribbon Advance Mechanism

The ribbon advance mechanism consists of the rack mounted on the carriage guide frame, the pinion

mounted on the carriage unit, planetary gear, combination gear and ratchet RD. When the carriage unit is

moved right and left on the carriage guide shaft by the CR motor, the pinion is rotated by the rack and the

motive power is conveyed to the planetary gear . When the carriage unit moves to left, the pinion is rotated

by the rack, and the motive force is conveyed to the planetary gear. Also, when the carriage unit moves to

the right side, the driving force from the planetary gear is once conveyed into the combination gear, and

the combination gear drives the ratchet RD. Then the ratchet RD rolls up the ribbon.

Ribbon Cartridge

Ink Ribbon

Carriage Unit

Combination Gear

Planetary Gear

Carriage Guide Frame

Pinion

Ratchet RD

Ribbon Advance Roller

Figure 2-3. Ribbon Advance Mechanism

Rev. A

2-

Page 45

Chapter 2 Operating Principles

6

2.1.4 Paper Advance Mechanism

The paper feed mechanism of this printer consists of the platen roller, paper feed roller, paper eject roller,

PF motor, tractor unit, PW detector, PE (rear/front) detectors, release detector, and CSF

mechanism(option). This printer performs paper advance by moving the paper horizontally.

Mechanism Frame

Roller Assembly, PF,Support

Paper Bail Roller

Roller Assembly, Paper

Eject, Drive

Roller PF Drive

Platen Roller

PF Motor

Tractor Transmission

Gear

To CSF Mechanism

Tractor Gear

Figure 2-4. Paper Advance Mechanism

2.1.4.1 Paper Advance Mechanism

Driving force of the PF motor is conveyed through the paper feed gears to roller assembly, paper eject

drive, paper bail roller, platen roller, roller assembly, PF support and roller, PF drive, and advances paper.

The driving force conveyed to the tractor gear is sent to the CSF drive gear in case the CSF is mounted.

Also, the tractor transmission gear conveys driving force to the tractor gear by the release mechanism and

enables the push tractor to feed the paper.

Friction Advance Mechanism

The paper is held between paper eject and the roller assemblies located under the carriage guide

shaft (2 for each up and down; total 4)

Paper Load : Front automatic feed (manual feed), paper load from the CSF

Paper Eject : Front paper eject

Push tractor Mechanism

By changing the release lever from the cut sheets position to the continuous paper position manually,

the mode is changed from friction mode to tractor mode. In the tractor mode, the driving force for

paper load is conveyed to the tractor side, and the contact to the roller is lost by the release

mechanism.

Paper Load : Tractor

Paper Eject : Front paper eject

Table 2-4. Paper Advance Specification

Category Specification

Type 2-phase 96 poles Hybrid type Stepping Motor

Coil Resistance

Drive Voltage

16.0Ω ± 10% (at 25 °C, per phase)

42V ± 5%

Drive Method Bi-pola constant current drive

1-2, 2-2 phase, W1-2 phase,

Micro paper sending 1/360 inch(1-2 phase)

Drive Frequency

600∼7000Hz

Rated Current 0.535A (constant speed)

2-

Rev. A

Page 46

LQ-670 Service Manual

7

2.1.4.2 Paper Advance Detector Mechanism

Paper advance detector mechanism consists of PW detector and PE (rear/front) detectors.

The function of this mechanism is to feedback information about monitoring paper edges, paper width and

paper jam, and to control paper advance. The detector’s reading operation is constantly performed. The

timing to feedback the red signals is necessarily selected by CPU according to the operation of PF motor

and CR motor. The table below shows specification of the detectors and their functions.

CR Motor

Platen

Print Head

Print Head

Rear PE Detector

Roller Assembly, PF, Support

Roller Assembly, Paper Eject,

Drive

TOP Detector

Mask Guide

Looking from

the front face.

Looking from

the top.

TOP Detector

Front PE Detector

Mask Guide

Figure 2-5. Paper Advance Detector Mechanism

Table 2-5. Detector Function and Operation

Detectors Operation Function

PW detector Paper width measurement (detects

Determines right and left margin

right and left edges)

Paper top edge detector(detects

Determines top and bottom margin

top and bottom edges)

Detects if there is any paper or not Detects paper jam after checking

paper loading and ejecting.

PE detectors (Rear/Front) Detects top and bottom margin Determines top and bottom margin

Detects if there is any paper or not Detects paper jam and paper out (if

PW detector does not detect the

paper out) after checking paper

loading and ejecting.

Front paper detector only Detects paper top margin Front entry in case of cut sheet

auto feed

Rev. A

2-

Page 47

Chapter 2 Operating Principles

8

Category Specification

Type Mechanism type

Switch Rating

Switch Mode Paper in : Open

Category Specification

Type Mechanism type

Switch Rating

Switch Mode Paper in : Open

Category Specification

Type Photoelectric transfer method

Voltage

Switch Mode Paper in : Short

Table 2-6. Front Paper End Detector

0.6∼1.0mA, 5VDC ± 5%

Paper out : Close

Table 2-7. Rear Paper End Detector

0.6∼1.0mA, 5VDC ± 5%

Paper out : Close

Table 2-8. TOP Detector Specification

5VDC ± 5%

Paper out : Close

2-

Rev. A

Page 48

LQ-670 Service Manual

9

2.1.4.3 Release Lever Mechanism

Release lever mechanism consists of the release lever, tractor transmission gear and the release

detector. The setting of the release lever enables to add or release the pressure to the paper advance

rollers and also to change over the tractor drive(continuous paper mode) which can be done by releasing

or conveying the driving force of the PF motor to the tractor transmission gear and tractor gear, and the

friction drive(cut sheet mode).

The release lever moves the rink release lever through the lever release support, and presses the roller

assembly, PF support to the paper strongly or weakly. In the cut sheet mood, the driving force of PF motor

is conveyed to the paper feed(advance) mechanism.

The roller assembly, PF support press the cut sheet actively, and paper advance is performed.

In the continuous paper mode, the paper advance is performed by conveying the driving force of PF motor

to the tractor gear through the tractor transmission gear. In this mode, the roller assembly, PF support is

just to push the paper lightly.

The release detector detects if the release mechanism is set for cut sheet mood or for continuous paper

mood. According to the detector, the main control recognizes an appropriate mode. The table below

shows specification of the release detector.

Table 2-9. Specification of the Release Detector

Category Specification

Type Mechanism type

Switch Rating

Switch mode Friction mode :Open

0.6∼1.0mA, 5VDC±5%

Tractor mode :Close

Roller, PF Drive

Figure 2-6. Release Mechanism

Tractor Gear

Release Detector

Tractor Transmission Gear

Release Lever

Rev. A

2-

Page 49

Chapter 2 Operating Principles

0

2.1.5 Platen Gap Adjustment

Platen gap (the gap between platen surface and print head) allows the printer to use different thickness of

paper by setting appropriate gap so that the different thickness of paper can avoid getting printing dirt or

picking the ribbon accidentally. Adjustment mechanism consists of the CR guide shaft, parallelism

adjustment bush, adjust lever and PG detector.

The rotating center of the CR guide shaft is angled to the rotating center of the adjust lever. Rotating the

adjust lever enables the print head to get closer to or away from the platen surface. The parallelism

adjustment bush should set the CR guide shaft parallel to the platen surface. The PG detector detects the

position of the adjust lever and changes the printing speed to the copy mode when using the thick paper

and setting the adjust lever more than 2 levels.

Adjsut Lever

CR Guide Shaft

Print Head

Rotation Center of the CR Guide Shaft

Figure 2-7. Platen Gap Adjustment Mechanism

Table 2-10. PG Detector Specification

Category Specification

Type Mechanism Type

Switch Rating

0.6∼1.0mA, 5VDC±5%

Switch Mode Normal Mode : Open

Copy Mode : Short (more than 2 levels)

PG Detector

2-1

Rev. A

Page 50

LQ-670 Service Manual

2.2 Power Supply Operation

2.2.1 Power Supply Circuit

The power supply part of this printer consists of AC cable and power supply board. The power supply

board provides CD current, which is necessary for the printer mechanism and control circuit. There are

two kinds of board according to the input voltage; C214PSB(100-120VAC) and C214PSE(220-240VAC).

Refer to the table below.

Table 2-11. Power Supply Board

Board Input voltage Input frequency range Fuse F1 Rating

C214PSB 85-138VAC 47-63Hz 4A/125V, 250V

C214PSE 187- 276VAC T2.0A/250V

2.2.1.1 Power Supply Overview

The power supply board has two power outputs for use by various control circuits and drive mechanisms.

The table below shows the output voltages and applications for the two DC output supply voltages.

Table 2-12. Output Voltages and Application

Output voltage Range of the

output voltage

+42V

+5V

39.9∼441.V

4.75∼5.25V

Rated output

current

0.8A

0.7A

Range of output

current

0∼3.0A •Print head drive

•CR motor drive

•PF motor drive

0∼0.7A •Logic line

•Detector

•Operation panel LEDs

Applications

Rev. A

2-1 1

Page 51

Chapter 2 Operating Principles

2

2.2.1.2 Power Supply Circuit Operation

In the power supply circuit, at first, the input AC power goes to the filter circuit, where removes the noise,

and goes to the diode bridge for full-wave rectification and is smoothed by the electrolytic capacitor. Then

it goes to the switching regulator on the primary side. This regulator uses ZC-RCC (ringing choke

converter) type and effectively generates +42VDC in the secondary side. Also, +42VDC generates +5VDC

by the DC-DC converter(chopper IC).

Power supply switch is mounted on the operation panel, and the PSC(power supply control signal) turns

ON/OFF the switching FET through the photo coupler in the primary side. Therefore, input voltage is in the