Epson LQ-1050, LQ-850 Service Manual

EPSON

,7

.,

. . . . . .

.

EPSON TERMINAL PRINTER

LQ-850/105O

TECHNICAL MANUAL

Y45499901

1 !

o-z

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1 ) personal injury, and 2) damage

to equipment:

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

2.

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

3.

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

/.LP

IN ORDER TO PROTECT SENSITIVE

4.

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS

OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

CHIPS AND CIRCUITRY, USE STATIC

- ii -

?!

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of the

The instructions and procedures included herein are intended for the

experienced repair technician, and attention should be given to the

precautions on the preceding page. The chapters are organized as follows:

LQ-850 and LQ-1 050.

REV.-A

—

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer

=peration.

Discusses the options

Includes a step-by-step

guide for product disassembly,

assembly, and adjustment.

Chapter 5 -

Chapter 6 -

● The contents of this manual are subject to change without notice.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques and lists

lubricants and adhesives required to service the equipment.

-

iv -

i!

REVISION TABLE

REVISION DATE ISSUED

A

Aug. 31, 1987

CHANGE DOCUMENT

1st issue

-v-

TABLE OF CONTENTS

Ml

REV.-A

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

OPTIONAL EQUIPMENTS

DISASSEMBLY, ASSEMBLY, AND ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

-

vi -

CHAPTER 1

REV.-A

—

GENERAL DESCRI

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1

1.2

SPECIFICATIONS

1.2.1 Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Firmware Specifications

INTERFACE Overflew....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3

1.3.1 8-bit Parallel Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.3.2 RS-232C Serial Interface Specifica~ions

DIP SWITCH AND JUMPER SETTINGS

1.4

1.5

SELF-TEST OPERATION

HEXADECIMAL DUMP FUNCTION

1.6

PRINTER INITIALIZATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.7

1.7.1 Hardware initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Software Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BUZZER OPERATION AND ERROR CONDITIONS . . . . . . . . . . . . . . . . . . . . . 1-22

1.8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTION

. 1- 1

1- 3

1-

3

1- 9

.

1-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-14

1-16

1-19

1-20

1-21

. 1-21

1.8.1 Buzzer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.8.2 Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

MAIN COMPONENTS

1.9

1.9.1 Printer Mechanism

1.9.1.1 Paper Leading and Paper Ejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.9.1.2 Auto-Tear-OFF Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.9.2

1.9.3

1.9.4

1.9.5

MONMA Board (Main Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

MONPS/MONPSE Board

(Power Supply Circuit Board)

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Housing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-23

1-23

1-26

1-29

1 .i

REV.-A

LIST OF FIGURES

Fig. 1-1.

Fig. 1-2.

Fig. 1-3.

Fig. 1-4.

Fig. 1-5.

Fig. 1-6.

Fig. 1-7.

Exterior Views of

Printhead Pin

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut Sheet Paper Printable Area

Fanfold Paper Printable Area

Head Adjustment Lever Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Matrix

Data transmission Timing of 8-bit Parallel interface . . . . . 1-13

the

LQ-850/l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-8. 36-Pin 57-30360 Connector

Fig. 1-9.

Hand Shaking of RS-232C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

050

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-10. Serial Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-11. Serial Interface Connector

Fig. 1-12. DIP switches 1 and 2 Factory Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-13. Self-Test Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-14. Hexadecimal Dump List

Fig. 1-15.

LQ-850/1050

Component Locations

Fig. 1-16. Model-531 0/5360 Printer Mechanism

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1- 1

. 1-

1- 5

1- 6

1-

1-11

1-13

1-14

1-15

1-15

1-18

. 1-19

1-20

1-23

1-23

3

7

Fig. 1-17. MONMA Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-18. MONPS/MONPSE Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1-19. Control PaneI

Fig. 1-20. Housings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 1-25

. 1-26

1-27

1-29

1 -ii

Ml

LIST OF TABLES

,.,

.-

REV.-A

Table 1-1.

Table

1-2. Optional Interface Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-3.

Table 1-4. Cut Sheet Paper Specified Conditions

Table 1-5.

Table 1-6.

Table 1-7.

Table 1-8.

Table 1-9.

Table 1-10. Environmental Conditions

Table 1-11. Printing Mode

Table 1-12. Character Matrix and Character Size

Table 1-13. Serial Interface Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-14. DIP Switch 1 Settings

Table 1-15. International Character Set Designation . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Table 1-16. DIP Switch 2 Settings

Table 1-17. Interface Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-18. Baud Rate Selection

Table 1-19. Jumper Setting

Table 1-20. Self-Test Operation

Optional

Line Feed Speeds

Fanfold Paper Specified Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lever Adjustment

Ribbon Cartridge Specification

Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications

Units...................................................o..mmm..mmo.mmm"""..""..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1- 2

.

1- 2

1- 4

1- 4

1-

1- 7

1- 7

. 1-

1- 8

1- 8

1-1o

1-12

1-14

1-16

1-17

.

1-17

1-17

1-18

1-19

5

8

Table 1-21. Hexadecimal Dump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

l-iii

1.1 FEATURES

The

LQ-850/

features of the these printers are:

.-—.— -

1050 printers are multifunctional,

● Upward compatibility with the

maximum print speed of 264

● A

LQ-800/l

CPS

in draft mode at 12

Zq-pin printhead,

000

● Direct selection of font, pitch, and normalfcondensed mode from the control

0 Automatic paper-10

adin9/ejectin9

function

● Low-noise acoustics

. Both 8-bit parallel and

● Push and (optional) pull tractor

RS-232C

serial interfaces

feedin9

● Advanced paper handling:

Auto backing of fanfold paper and

Auto ejecting of cut sheet paper and

autoloadin9 of cut sheet paper

autoloadin9 of fanfold paper

Printing of fanfold paper without removal of the cut sheet feeder (option)

● Optional interface for the EPSON 8100 series

● Optional low-priced,

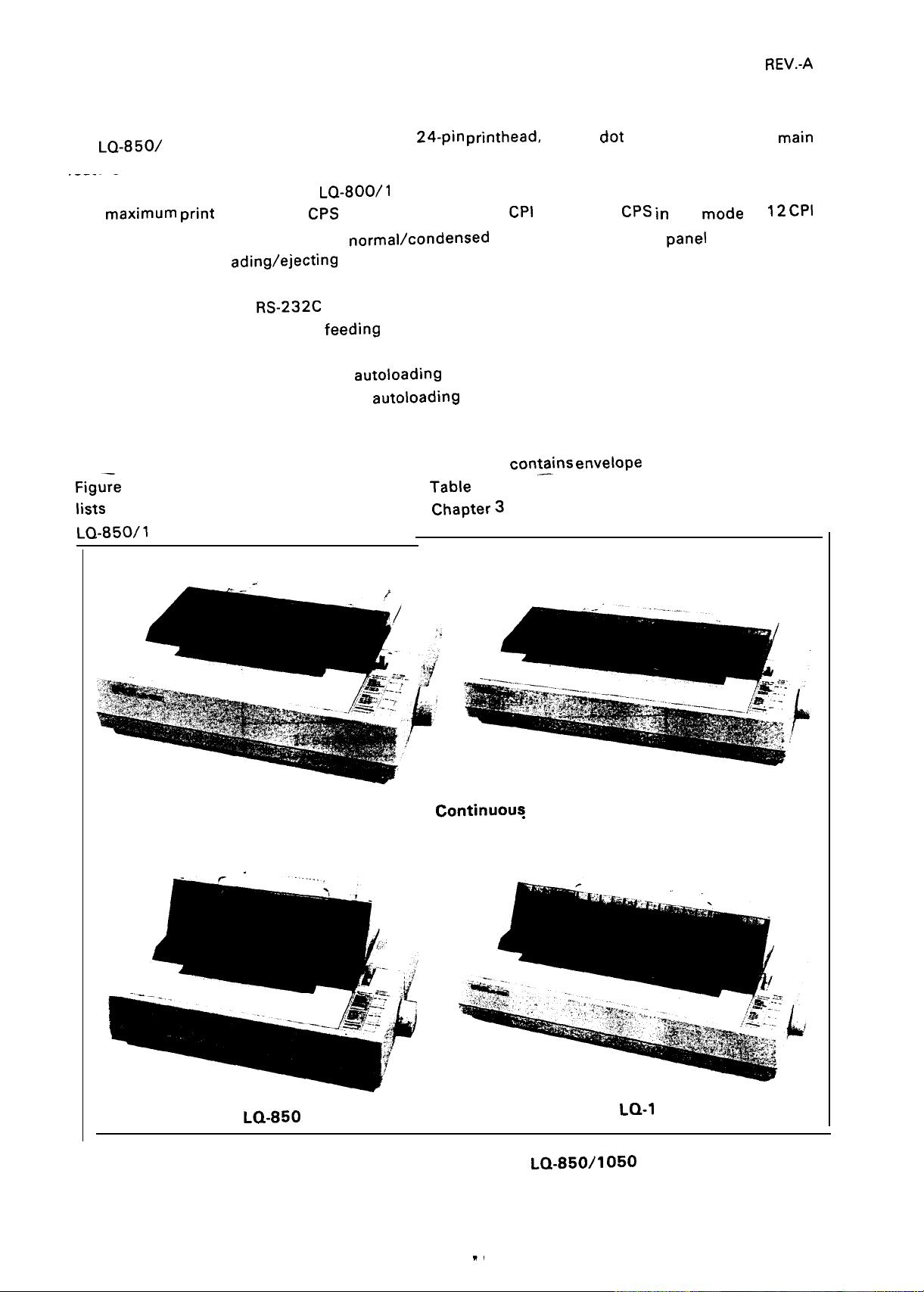

Figu~e 1-1 shows exterior views of the printers, Table 1-

lists

the optional interface boards (refer to Chapter 3 for more

LQ-8!30/l

050.

single-bin cut sheet feeder which

1 lists optional units available, and Table 1-2

impact

CPI

and of 88

cont~ins

dot

matrix printers The

CpS in

enveloPe feeding capability

detailed information) for the

REV.-A

l-Q mode at 12

panel

main

Cpl

.

LQ-850

Settings

Continuou5 Paper

for

Setting for Cut Sheet Paper

Fig. 1-1. Exterior Views of the

1-1

LQ-850/1050

LQ-1

050

“1

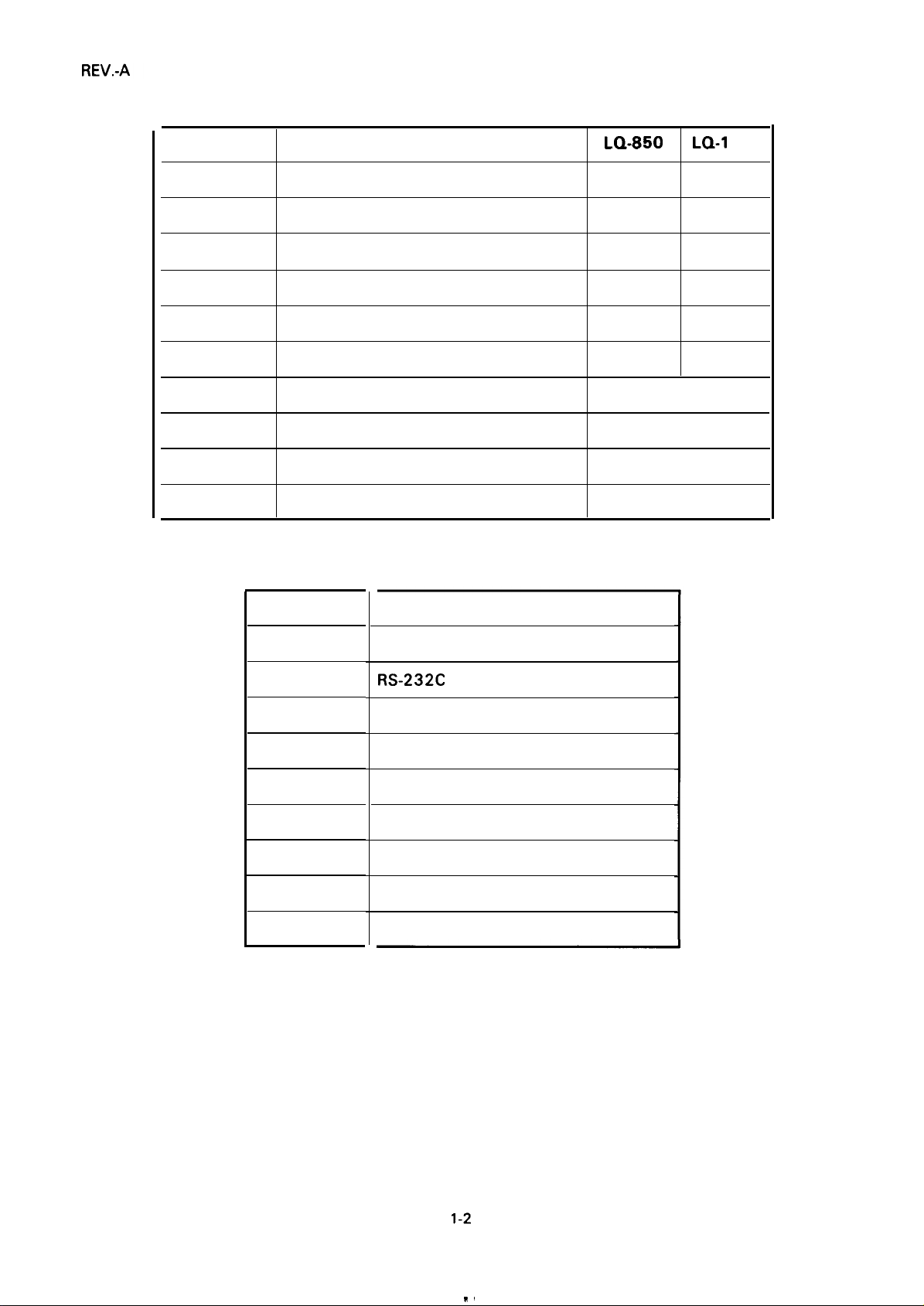

No.

ml

Table 1-1. Optional Units

Name

LQ-850

LO-1

050

#73 11

#731 2

#7339

Tractor unit

Tractor unit

Cut sheet feeder (single-bin)

#7340 Cut sheet feeder (single-bin)

#7753

Ribbon cartridge

#7754 Ribbon cartridge

#7400 Courier font-module

#7401

#7402

#7403

Prestige font-module

Script font-module

OCR-B font-module

Table 1-2. Optional Interface Boards

No.

o

o

o

o

o

o

o

o

o

o

Name

#8143

#8 145

#8148

#8 149

#8 149M

#816 1

#8 165

#8 172

#81 72M

New serial interface

RS-232C current loop interface type II

Intelligent serial interface

Intelligent serial interface type II

Intelligent serial interface type III

IEEE-488 interface

Intelligent IEEE-488 interface

32 K-byte buffer parallel interface

128K-byte buffer parallel interface

REV.-A

1.2 SPECIFICATIONS

The

LQ-850/

Module.

However, this section describes the specifications for the printer without the Identity Module option.

Specifications not affected by firmware (hardware specifications) are the same whether or not the

Identity Module is installed.

1.2.1 Hardware Specifications

1050 communicates with a wide variety of host computers, with aid of the optional Identity

Printing Method

Pin Configuration

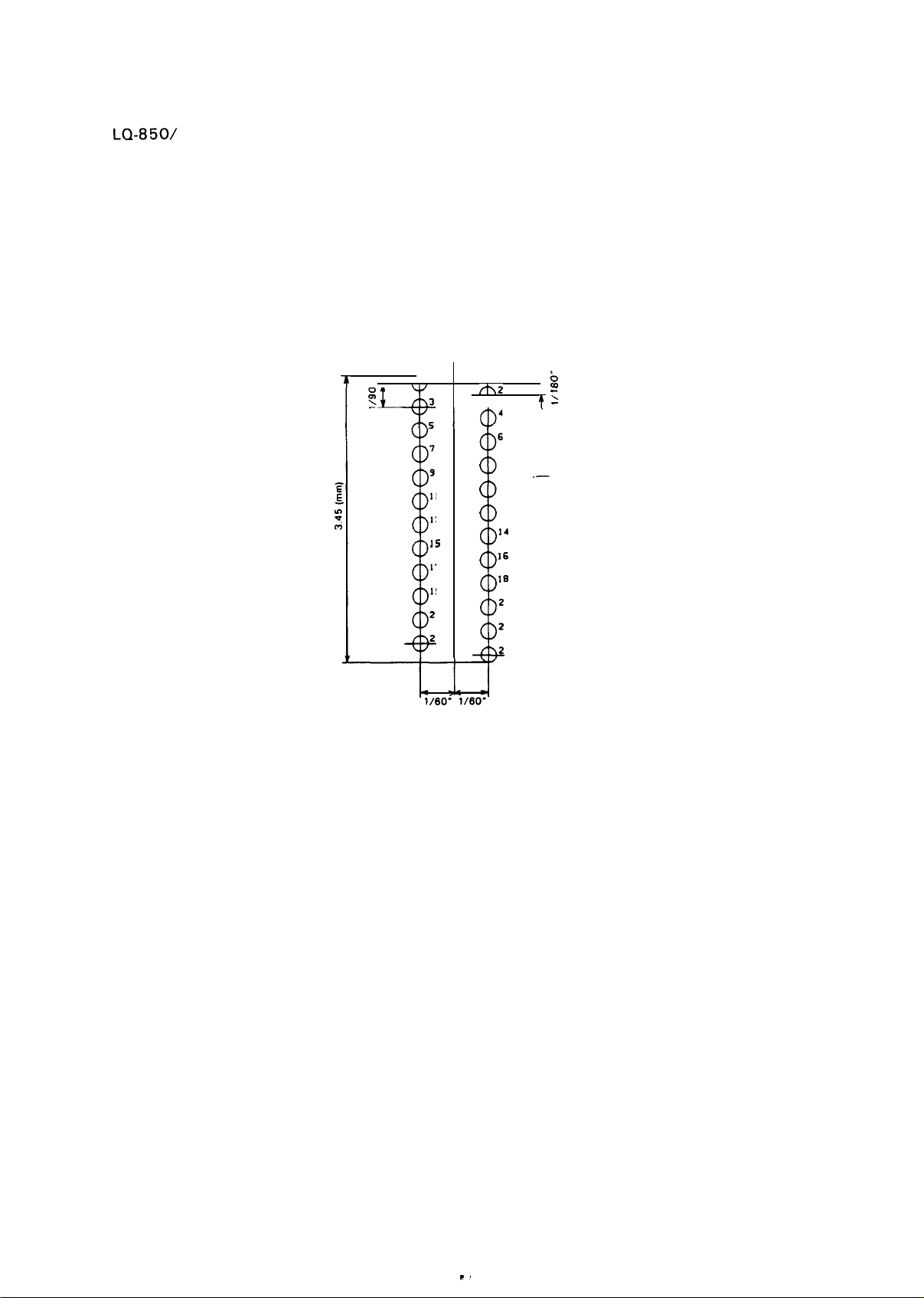

Serial, impact dot matrix

See Figure 1-2 (12X 2 staggered, diameter: 0.2

T

Fig. 1-2. Printhead Pin Configuration

I

11

13

15

17

19

21

23

I

fhz

6

10 “—

12

!

1’

16

$

18

20

22

1

o

m

:

!-

4

mm).

Feeding Method

NOTES: 1. When using friction feed:

● Use the paper tension unit.

● Do not use fanfold paper.

● Do not perform any reverse paper feed operations within the top 8.5 mm and bottom

22 mm area of the paper.

● Do not perform reverse feed beyond than 1/6 inches after the paper end has been

detected.

● Do not use multi-part, single-sheet forms.

2. When using tractor feed:

● Release the friction feed mechanism.

● Multiple copies for printing must be finished by pasting them together at the line or dots.

● Copy paper must be a carbonless multi-part paper.

a) When using push tractor feed:

● Use the paper tension unit.

Friction feed

Tractor feed (push: standard, pull: optional)

1-3

REV.-A

● Do not perform reverse feeding for more than 1/6 inches.

● Because accuracy of paper feed cannot be assured, do not perform reverse feeding

after the paper end has been detected.

b) When using pull tractor feed:

● Remove the paper tension unit and mount the pull tractor unit.

● Use the paper path when a single sheet is inserted.

c) When using push-pull tractor feed:

● Remove the paper tension unit and mount the pull tractor unit.

● Do not loosen the paper between the platen and the pull sprocket.

● Precisely the horizontal position of the pull sprocket and push tractor.

● Do not perform reverse feeding for more than 1/6”.

. Do not perform reverse feeding after the paper end has been detected.

Paper Loading Directions

Fanfold paper

Cut sheet paper

Inserted from the rear side

Inserted from the up side

Line Spacing

Line Feed Speed

Feeding Method

Friction w/o

Friction w/

Tractor

Paper specifications

Cut sheet paper

1/6” or programmable (min. 1/180”)

See Table 1-3

Table 1-3. Line Feed Speeds

CSF

CSF

1/6” Line Spacing

[ins/line]

60

65

65

Continuous

IIPS]

3.0

2.7

2.7

Refer to Table 1-4.

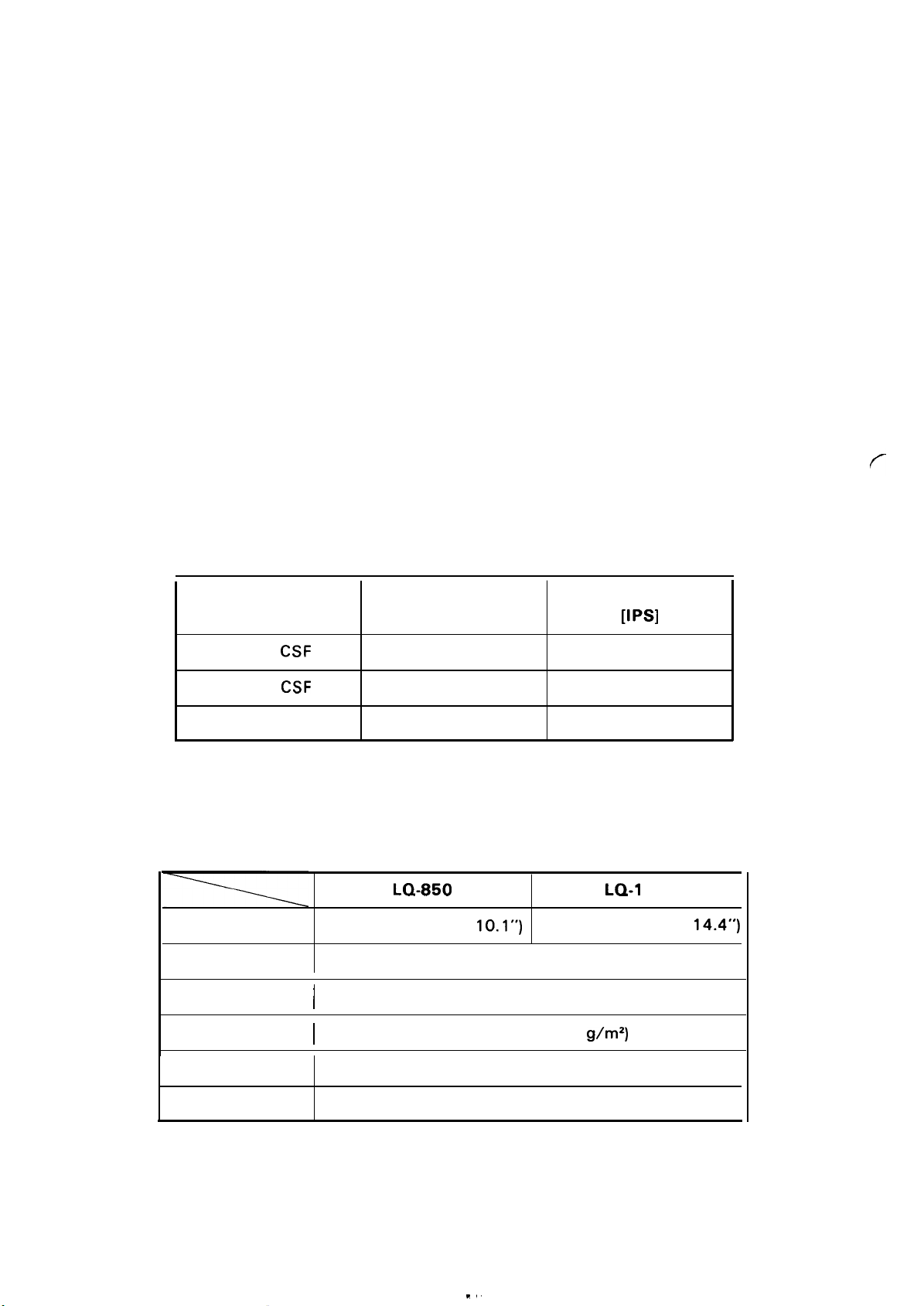

Table 1-4. Cut Sheet Paper Specified Conditions

LQ-850

LQ-1

050

Width [mm] 182-257 (7.2 -

Length

Thickness [mm]

Weight [lb]

Quality

Copies

Fanfold paper

[mm]

I

I

Refer to Table 1-5,

0.065

182-364 (7.2 -

182 -

10.1”)

305 (7.2 - 12.0”)

-0.10 (0.0025 - 0.004”)

14

-22 (52 -82

Plain paper

g\m2)

Not available

1-4

14.4”)

Table 1-5. Fanfold Paper Specified Conditions

m

,

LQ-850

LQ-1

REV.-A

050

Width

Copies [sheet]

Quality

Total Thickness

Weight

Printable Area

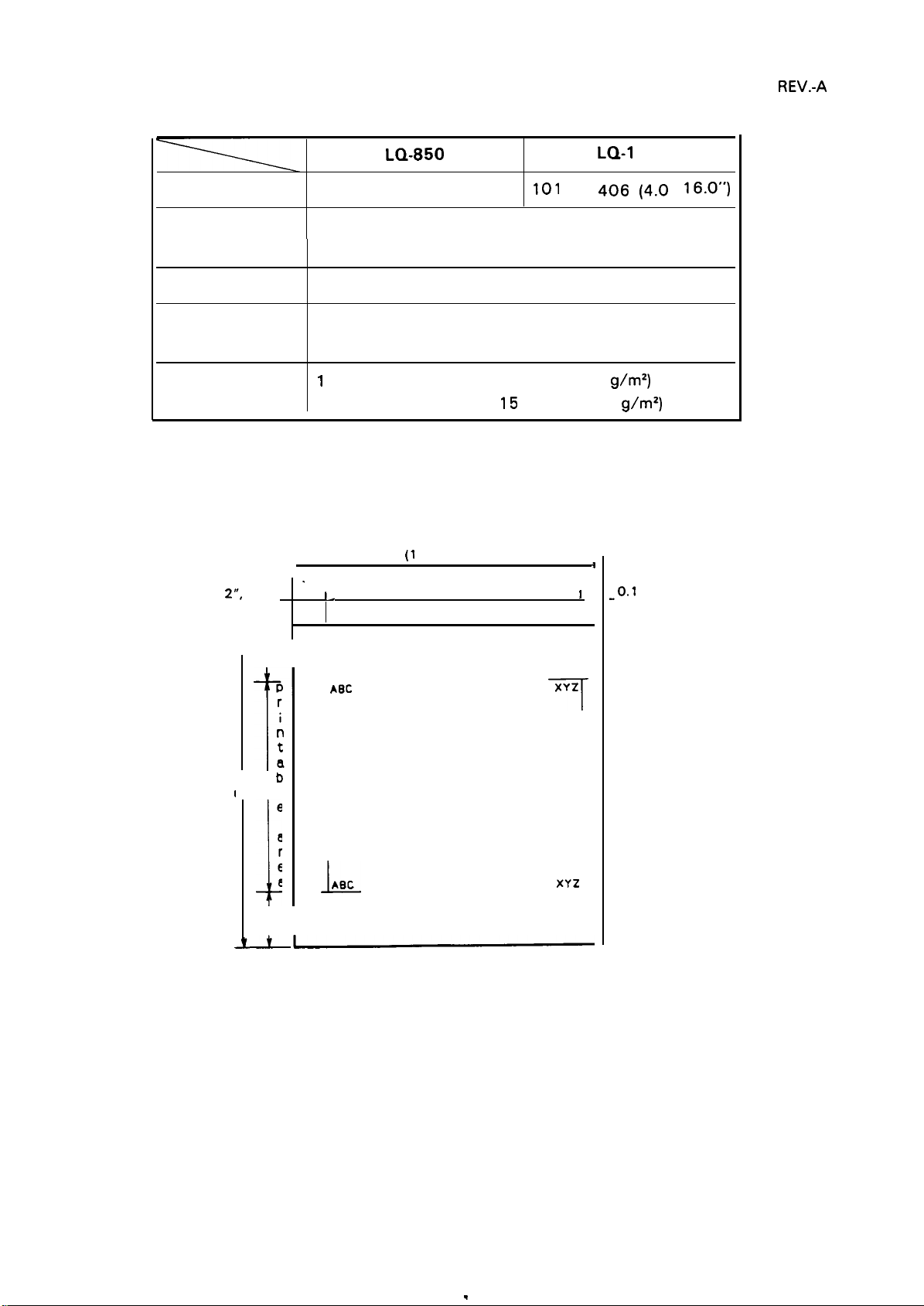

— Cut sheet paper See Figure 1-3.

[mm]

[mm]

101

4 (1 original + 3 ) at normal temperature

3 (1 original + 2 ) at all temperature range

1

sheet ..................14 - 22 (52

[lb]

4 sheets ..................12

7.2 -

1-

0.1

2“,

3 mm_

or more

‘

1-

- 254 (4.0 -

0.06 -

10,1*’

(1

4.4)”, 182- 257 (364) mm

Printable area

10. O”)

Plain paper

0.32 (0.0023 -0.01 2“)

-

101

-

- 82

15

(40 - 58.2

—

406

9

I

1

(4.0

g/m2)

g/m2)

-0.1

2“, 3 mm

or more

-

16.0”)

for each

0.33”, 8.5 mm

T-

or

more

D,

r

n

t

a

1

Max. 12“,

305

NOTES: 1. Values in the parentheses apply to the LQ-105O.

2. Printing is possible for approximately 42 mm after the bottom edge of a page has been

detected. Thus, the value 13.5 mm (lowest print position) is given for reference only. Paper

feed accuracy cannot be assured in the area approximately 22 mm (0.87”) from the bottom

edge of the page.

b

n

I

1’

e

a

r

e

a

1

0.53”,

or more

_J_~

ABC

T

ABC

L

3.5 mm

Fig. 1-3. Cut Sheet Paper Printable Area

XYZ

T

XYZ

--l

1-5

REV.-A

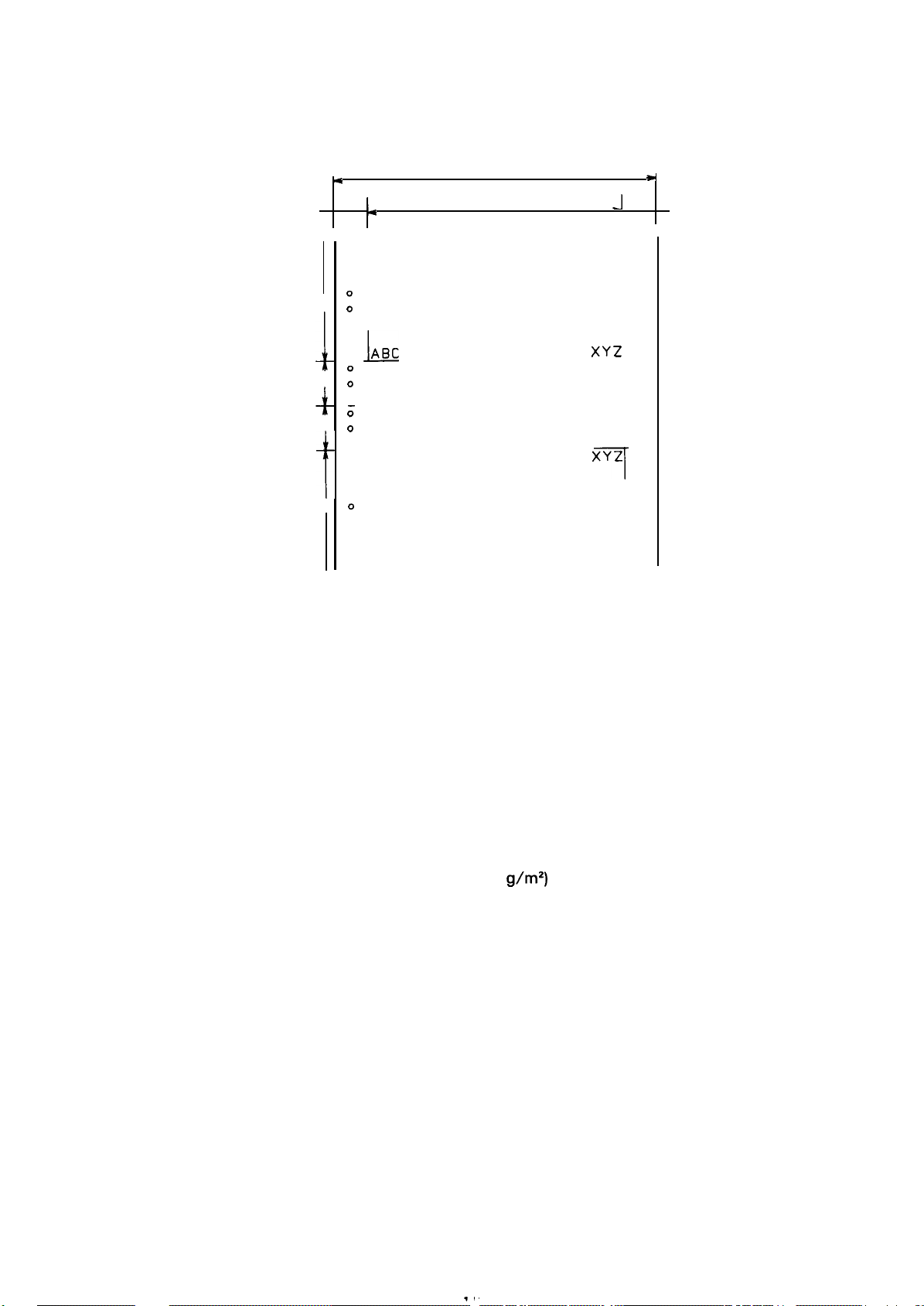

Fanfold paper

See Figure 1-4.

Printable

area

0.35”, 9 mm

or more

0.35”, 9 mm

or more

1

t

Printable

area

1O*1(1 6)”, 101

b.

4-

*2

~

o

0

0

;

0

0

0

ABC

L-

;

o

------------------ —------

;

o

o

0

ABC

0

r

0

o

o

0

0

0

Printable area

- 254 (406) mm

XYZ

-1

XYZ

7

d

*2

J

0

0

0

0

0

0

0

0

0

0

0

-0

0

0

0

0

0

0

0

0

0

0

NOTE: 1. Values in the parentheses are apply to LQ-105O.

2. 0.47”, 12 mm or more when the 101 to 242 mm (4 to 9.5”) width paper is used.

0.98”, 25 mm or more when the 254 mm (1 O“) width paper is used.

Fig. 1-4. Fanfold Paper Printable Area

Envelopes

Size

Quality

Thickness

No. 6 (166 X 92 mm), No. 10 (240 X 104 mm)

Bond paper, xerographic copier paper, airmail paper

0.16-

0.52 mm (0.0063 -0.01 97”)

NOTE: Differences in thickness within printing area must be less than 0.25 mm (0.0098”).

Weight

121 - 241 lb (45 -91

g/m2)

NOTES: 1. Envelope printing is only available at normal temperature.

2. Keep the longer side of the envelope horizontally at setting.

3. Set the left of No. 6 envelope at the setting mark of the sheet guide.

Label

Size

Thickness

2 1/2 X 15/1 6“, 4 X 15/16”, 4 X 17/16”

O.19 mm (0.0075) max.

NOTE: Thickness excluding the base paper must be less than or equal

to O.12 mm (0.0075”).

1-6

NOTES: 1. Printing of labels is only available at normal temperature.

2. Labels must be fanfold.

3. Labels with pressure-sensitive paper must be jointed by pasting along the dots or lines,

and the total thickness must be less than

under conditions that must be between 5 to 35 “C and 20 to

4. Examples of labels: AVERY CONTINUOUS FROM LABELS

AVERY MINI-LINE LABELS

or equal to 0.3 mm (O.

1 1

8“) to be printed out

80Y0

RH.

REV.-A

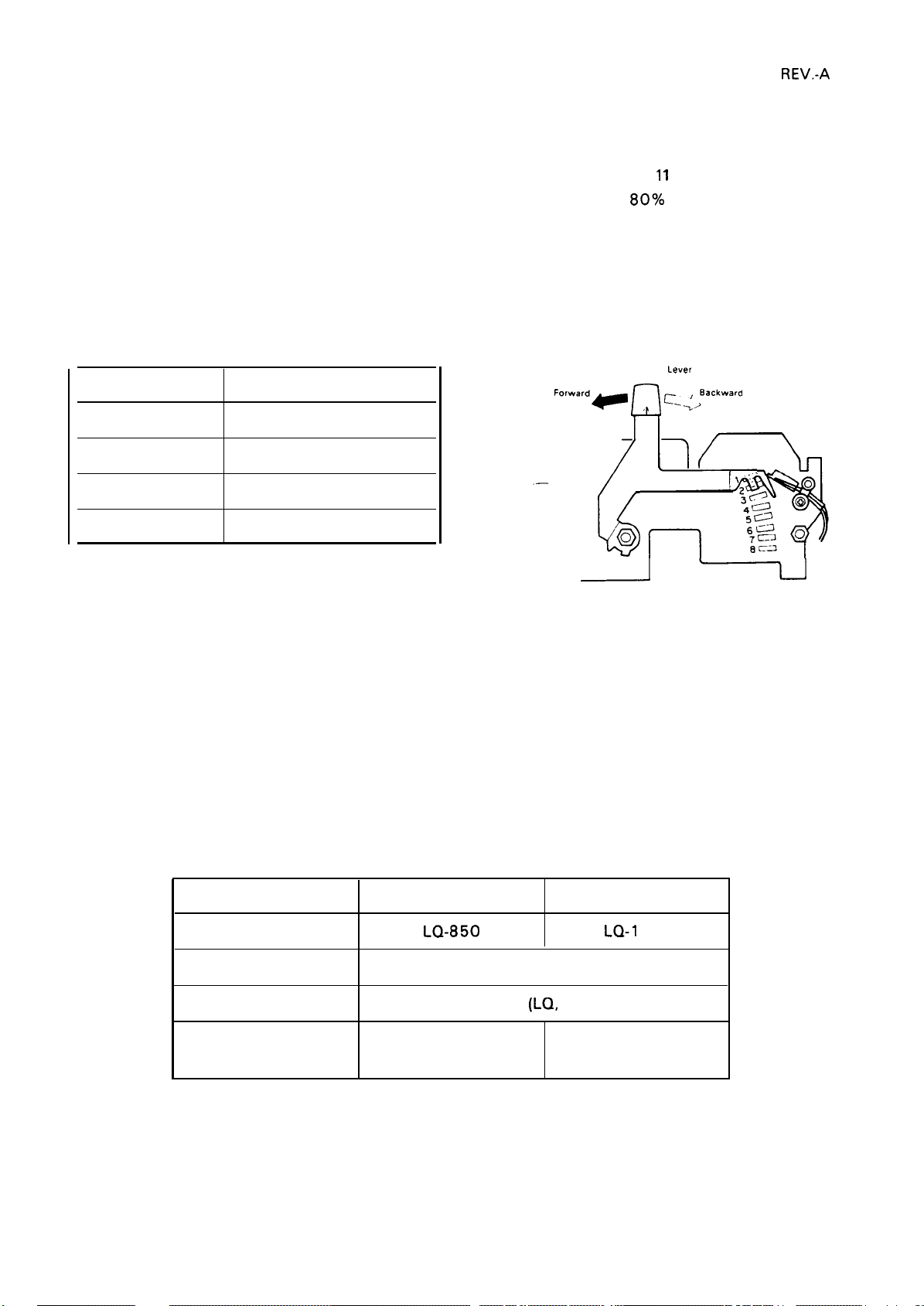

Lever Adjustment

Table 1-6. Lever Adjustment

Lever Position

2nd

3rd

—

4th

5th

NOTES: 1.

When printing density becomes lighter, set the head adjustment lever one position lower.

2. When using thicker paper than shown in the above table, set the head adjustment lever

to the 6th or higher appropriate position by performing the self-test operation.

See Figure 1-5 and Table 1-6.

Paper Thickness [mm]

0.06 - 0.12

0.13 -0.17

0.18 -0.25

0.26 -0.32

Head adjustment Lever

‘orwardw

,,

n

f=;tackwa’d

1

J——l—l

Fig. 1.5. Head Adjustment Lever Posisitioning

Ribbon Cartridge

Printer

Color

Life

Dimension

(W) X (h) X (d)

See Table 1-7.

Table 1-7. Ribbon Cartridge Specification

Ribbon Model No.

[characters]

[mm]

#7753

LQ-850

2 million

290 X 34 X 71

1-7

Black

(LQ,

#7754

LQ-1

050

self-test)

468 X 34 X 80

REV.-A

Dimensions

Weight

LQ-850

LQ-1

050

NOTE: Excluding paper feed knob and paper guide.

Electrical Specifications

L

Voltage [V AC]

Frequency range [Hz]

See Table 1-8 (Details are shown in Figures A-45 and 46.)

See Table 1-8.

Table 1-8. Dimensions and Weight

Width [mm]

430

605 142

See Table 1-9.

Table 1-9. Electrical Specifications

Height [mm] Depth [mm]

142

I

I

Weight [Kg]

198

10

12

- 264

360

360

120 V Version 220/240 V Version

108 - 132

49.5

I

- 60.5

Rating current [A]

Insulation resistance [M ohm] min.

(between AC line and chassis)

Dielectric strength [V AC, rms]

(1 minute, between AC line and chassis)

Environmental Conditions

Temperature [“C]

Humidity [% RH]

Resistance to shock [G] (within 1 ms)

Resistance to Vibration [G] (55 Hz, max.) 0.50

I

Refer to Table 1-10.

Table 1-10. Environmental Conditions

2

1250

Storage Operating

–30 - 65 5 - 35

5

- 85 10- 80

2

10

I

1

3750

1

0.25

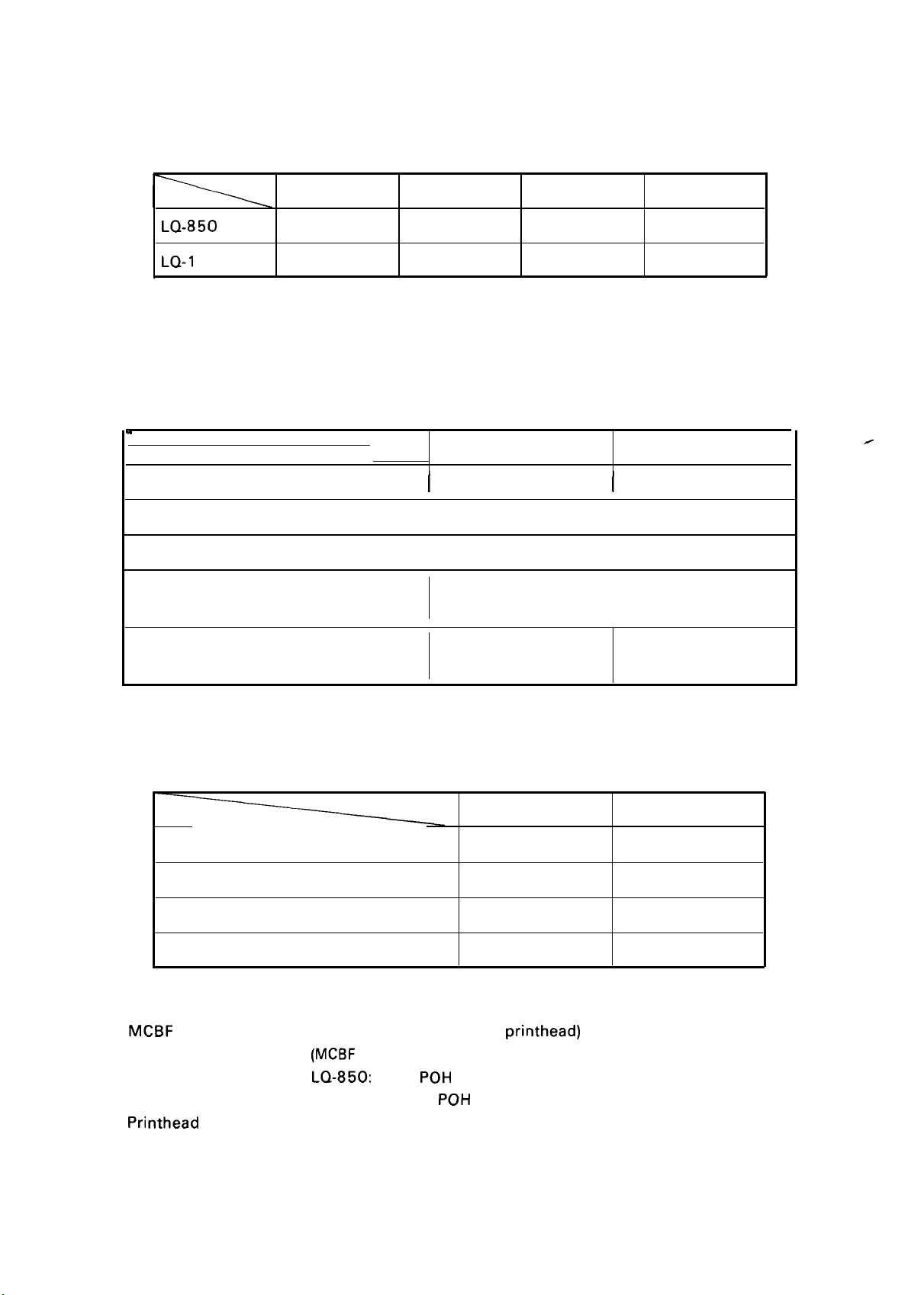

Reliability

MCBF

MTBF

Printhead

life

5 million lines (excluding

(MCBF

. . .

Mean Cycles Between Failure)

LQ-850: 4000

LQ-105O: 6000

200 million strokes/wire

POH

(duty 25%)

POH

(duty 25%)

1-8

printhead)

Safety Approvals

Safety standards

UL478 (U.S.A. version)

CSA22.2#l 54

VDE0806 (TUV)

(RFI)

Radio Frequency

Interference

FCC class B (U.S.A. version)

VDE871 (self-certification) (Europe version)

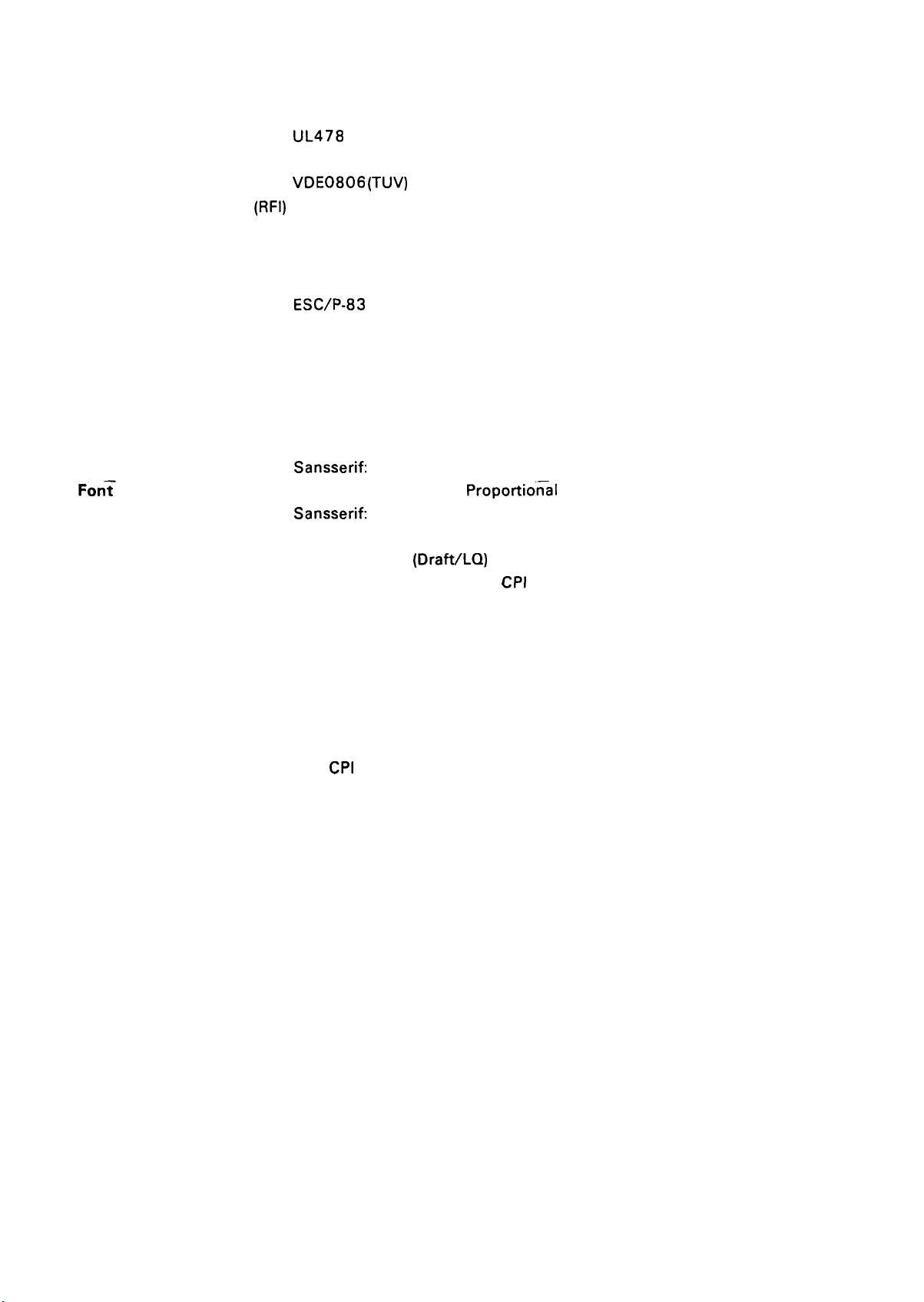

1.2.2 Firmware Specifications

REV.-A

(Europe an version)

Control Code

Printing Direction

Text

Bit-image

Character Code

Character Set

Family

Fon~

Printing Mode

NOTE: A condensed

ESC/P-83

Bidirectional with logic seeking

Unidirectional

8 bits

96 ASCII and 13 international character sets

Roman:

Sansserif: No. 1

Roman: 10, 12, 15,

Sansserif: 10, 12, 15, Proportional

Draft:

Printing quality

Character pitch (10, 12, 15 CPI or Proportional)

mode for 15

No. O

Proportio~al

10, 12, 15, Proportional

(Draft/LQ)

Condensed

Double-width

Double-height

Emphasized

Double-strike

Italic

Underlined

CPI

characters is not available.

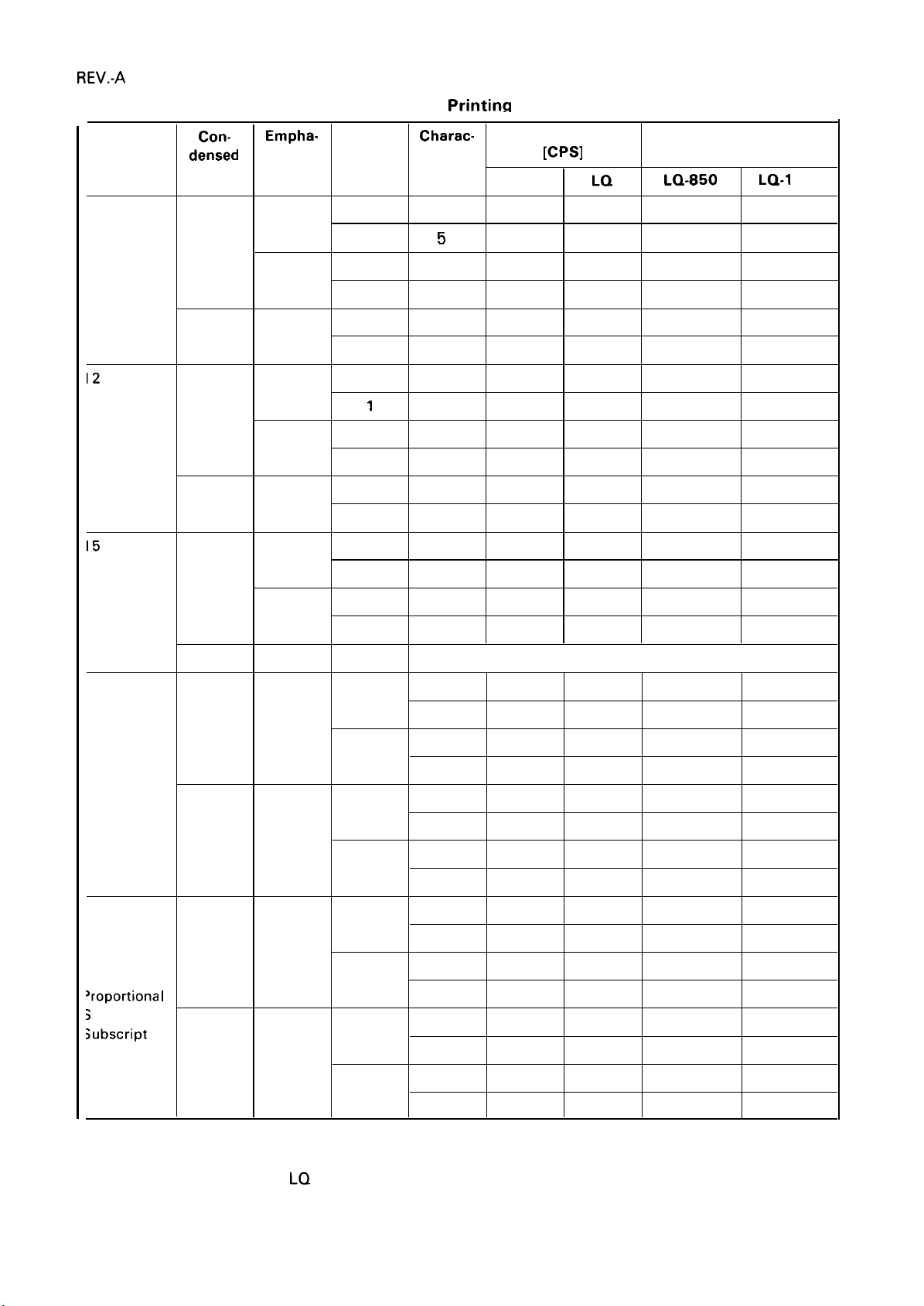

Print Speed

Print Columns

Refer to Table 1-11.

Refer to Table 1-11.

1-9

REV.-A

Table 1-11. Printirm Mode

12

15

0

Print

Pitch

Con-

densed

0

1

0 0

1

0

Empha-

sized

0

1

x

1

x

0 0

1

Double

Width

0

1

0

1

o

1

0

1

0

1

o

1

1

0

Charac-

ter Pitch

[cPI]

10

5

10

5

17.1

8.5

12

6

12

6

20 220

10

15

@7<

7.5

Printing Speed

[CPS]

Draft

220

110

110

55

188

94 62

264 88

132 44

132 88

66 44

110 73

330

165 55

165 110 60

LQ

73

36

73

36

125

146

110

Printable

Columns

LQ-850

80

40

80 136

40 68

137 233

58 116

96 163

48

96 163

48

160

80

120

120

LQ-1

050

136

68

81

81

272

136

204

204

102

‘proportional

‘roportiona

;

uper/

subscript

1

1

o

1

0

I

1

x x

x

x

x

x

o

1

o

1

o

1

o

1

7.5 82 55 60 102

Ignored

8.6 — 62 Max. 68

20 146

4.3 —

10 73

17.1

40

8.6 — 68

20

12.8 — 94

30

6.4 — 47

15

25.7 — 188

60

12.8

30

—

—

—

—

—

—

—

—

—

31

125

293

146

220 Min. 240

110

440

94

220

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Max.

Min.

Max.

Min.

Max.

Min.

Max. 116

160

Min.

34

Max. 58

80

Min.

137

Max.

320

Min.

68

Max.

160

Min.

102

Max.

Min. 408

51

Max. 87

120 Min.

204

Max.

480

Min.

102

Max.

240

Min. 204

272

136

233

544

116

272

174

204

174

816

87

NOTES: 1. Max. means the value when the maximum width characters are printed.

2. Min. means the value when the minimum width characters are printed.

3. “-”

means that LQ character set is automatically selected when proportional pitch is

specified.

1-10

REV.-A

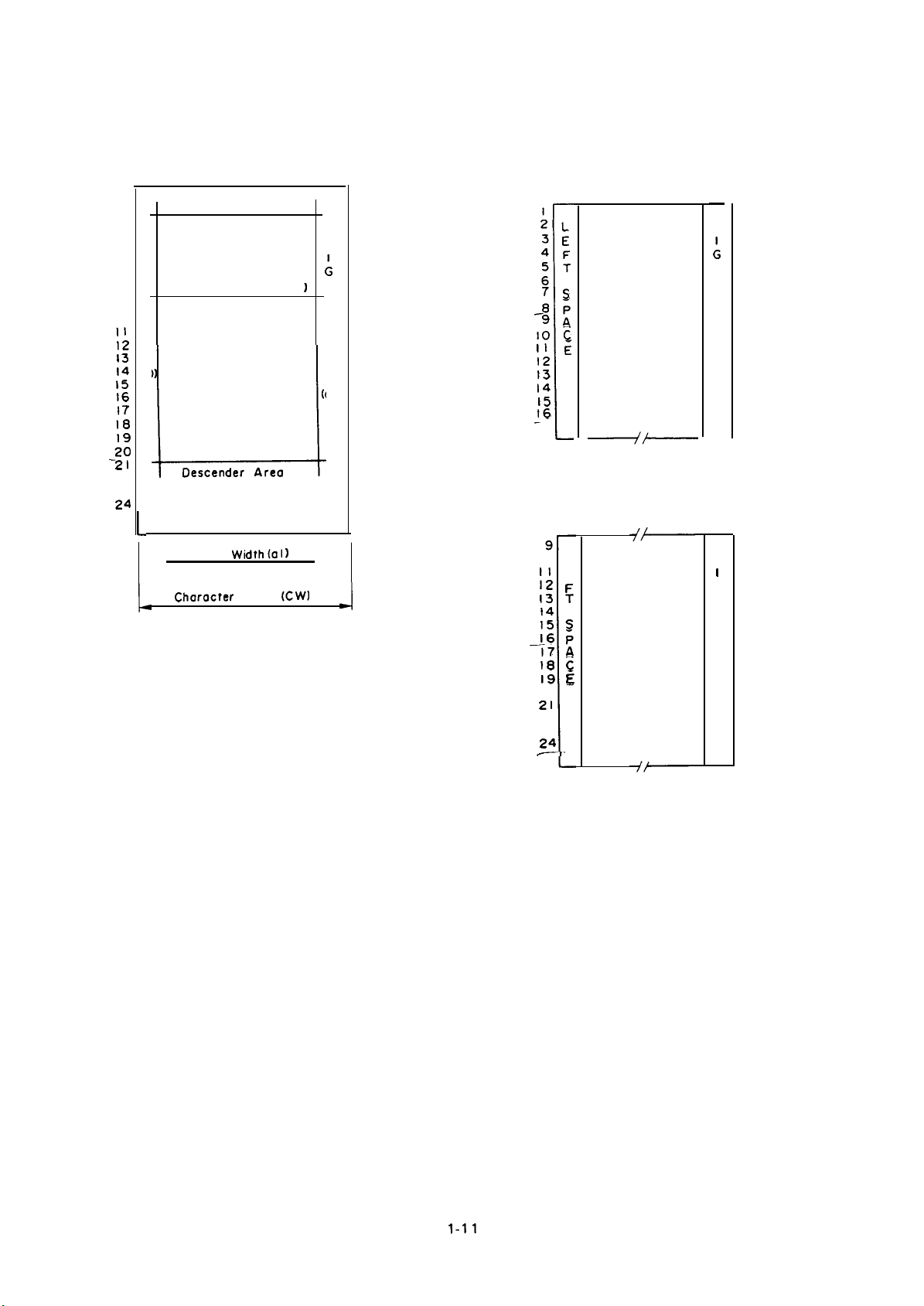

Character Matrix

(Normal Character)

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

-20

21

22

—

23

24

Ascender Area

Ascender Area (15P itch

10

Descender Area

1--1

1-

Choracrer Width

Face

Width(ol

See Figure 1-6 and Table 1-12.

R

A

H

)

T

s

P

A

c

E

(a

2

(Subscript—Character)

Pin Nos. 1 to 8 are not used when subscript printing.

)

(CWI

(Superscript Character)

Pin Nos. 17 to 24 are not used when superscript

printing.

—

2L

3E

4F

5T

6

7!j

-8P

9A

10 c

II

E

12

13

14

15

16

:[

10

L

II

E

12 F

13

T

14

15 S

16

p

~7 A

18

c

19 E

20

21

22

23

24

—-

1

R

A

H

T

s

P

A

c

E

—

R

I

G

H

T

s

P

A

c

E

Fig. 1-6. Character Matrix

1-11

REV.-A

Character Size

See Table 1-12.

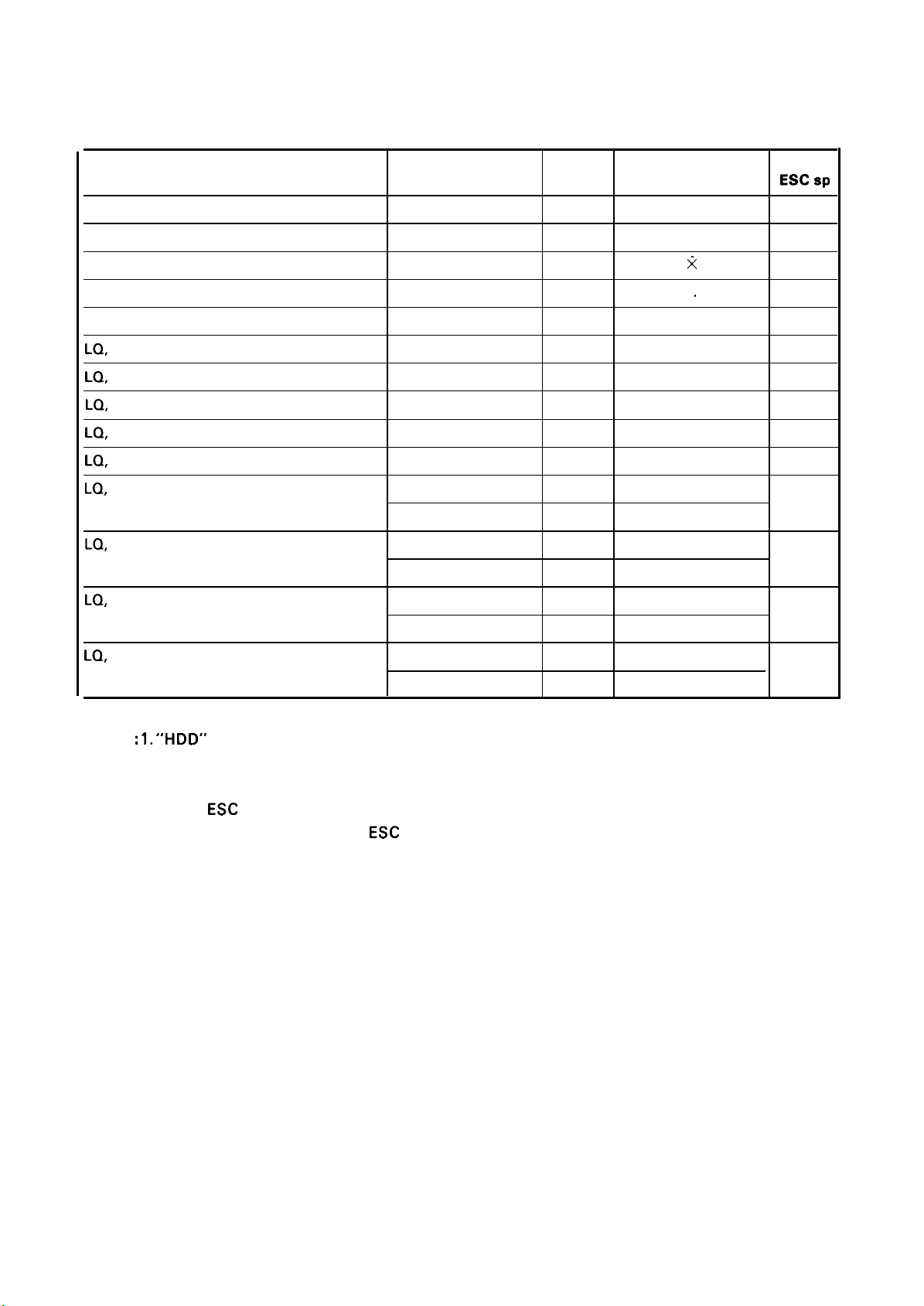

Table 1-12. Character Matrix and Character Size

Printing Mode

DRAFT, 10 pitch

DRAFT, 12 pitch

DRAFT, 15 pitch

DRAFT, 10 pitch, condensed

DRAFT, 12 pitch, condensed

LQ,

10 pitch

LQ,

12 pitch 29 X 23

LQ,

15 pitch

LQ,

10 pitch, condensed

LQ,

12 pitch, condensed

LQ,

proportional max. 39 X 23 360

LQ,

proportional, condensed

Face Matrix

9 X 23

9 X 23

9 X 16

. . .

. . .

29 X 23 360

15 X 16 360 1.0 X 2.3 180

. .

. . .

min. 18 X 23 360 1.0 X 3.2

. . .

. . .

HDD

120 1.9 X 3.2

120 1.9 X 3.2 120

120 1.0

240

240

360 2.0 X 3.2 180

360

360

360

360

Character Size

H.

X V. (mm)

~ 2.3

. . .

.

. . .

2.0’ X 3.2 180

. . .

. . .

2.6 X 3.2

. . .

. . .

Unit

ESC

120

120

240

240

360

360

180

360

Sfl

LQ,

proportional, super/subscript

LQ,

proportional, super/subscript,

condensed

NOTES

:1.

“HDD” means the Horizontal dot density, and the “Unit” shows the number of dots per inch.

2. “Face matrix” and “character size” indicate the size of maximum characters and this value

will be changed with condition of paper.

3. “Unit

4. “...”

ESC sp” indicates the minimum length which is added to the right of the character

that can be specified with

indicates that the character matrix is reformed by printer firmware. Character width

becomes half of a non-condensed character.

max. 28 X 16 360 1.8 X 2.3

min. 12 X 16

. . .

. . .

ESC sp control code.

360 0.7 X 2.3

360

360

. . .

. . .

. 180

360

1-12

REV.-A

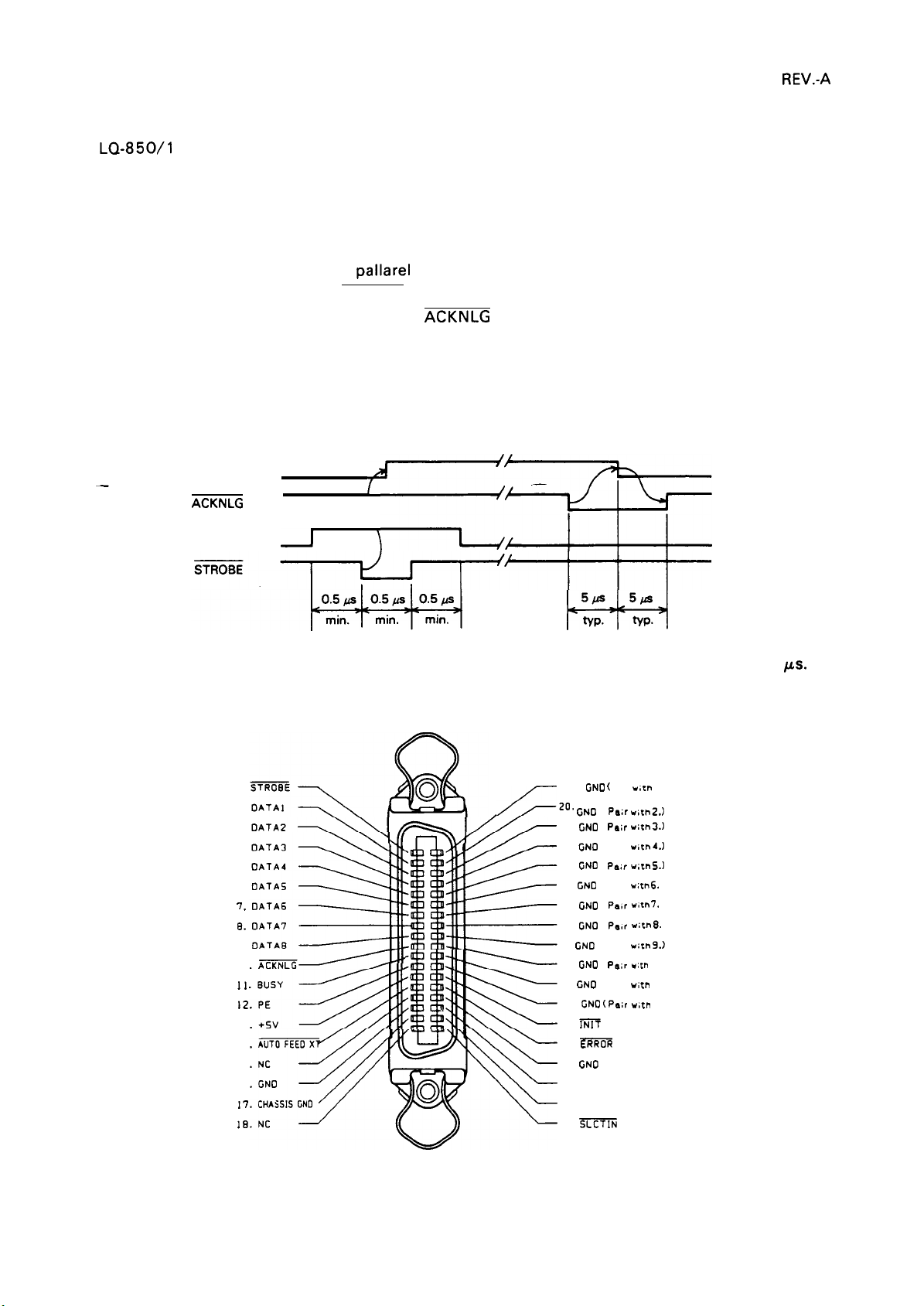

1.3 INTERFACE OVERVIEW

The

LQ-850/l

be selected by DIP switches 2-3 and 2-4 respectively. (This detail of DIP switch settings, refer to Table

1-1 7.)

1.3.1 8-bit Parallel Interface Specifications

Data Transmission Mode

Synchronization

Hand Shaking

Logic Level

Data Transmission Timing

Connector

050 has both 8-bit parallel interface and RS-232C serial interface as standard. They can

pallarel

8-bit

By STROBE pulse

By BUSY and

ACKNLG

(either or both)

TTL compatible

See Figure 1-7.

57-30360 (AMPHENOL) or equivalent

(See Figure 1-8.)

—

BUSY

[d

ACKNLG

DATA

\

=!=

NOTE: Transmission time (rising and falling time) of

Fig. 1-7. Data Transmission Timing

1.

2.

3.

4.

5.

6.

7. 25.

8.

9.

10

11

12

13

14

15

16

17

10

W

every input signal must be less than 0.2

of 8-bit Parallel Interface

19.

GNO (

Pair witn l.)

r

-20.

GNo

21.

GNO

22.

GNO

23.

GNO

24.

GNO

GNO

GNO

26.

27.

GNO

28.

GNO

29.

GNO

30.

GNO (Pair

31.

~T

32.

m

33.

GNO

34. NC

35. ● 5V

36.

m

( Pa;, with2.)

w;tl13.)

(

Pair

w;tn4.)

( Pair

W;tns.)

( Pair

w:tn6.

( Pair

witn7.

( Pair

W:tne.

( Patr

w;tf19.)

( Pair

W;th

(

Pair

W;th

( Pair

W;tn

I

o.)

1 1. )

1 2.)

)

)

)

ws.

Fig. 1-8. 36-Pin 57-30360 Connector

1-13

REV.-A

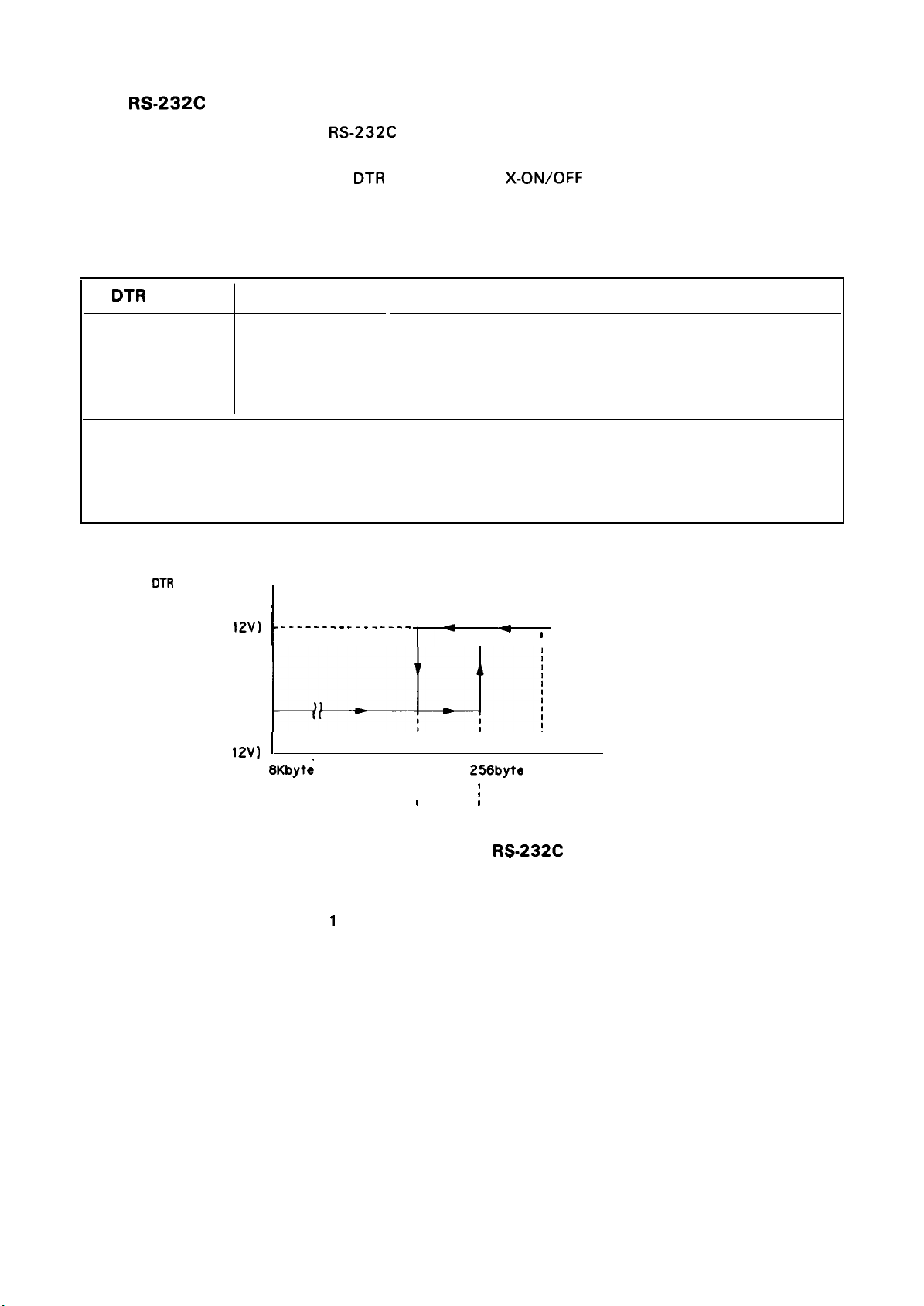

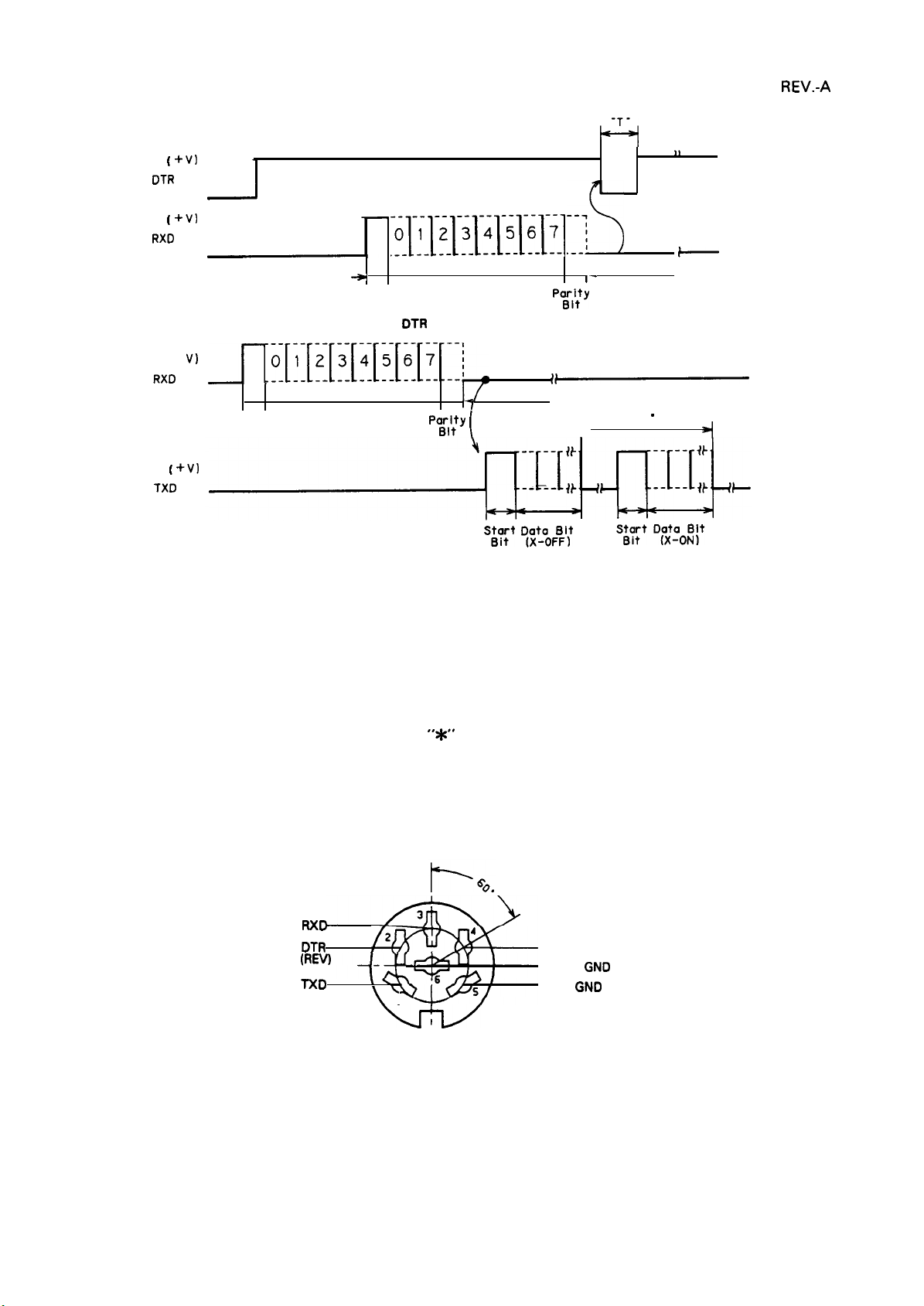

1.3.2

Data Transmission Mode

Synchronization

Handshaking

RS-232C

DTR Signal X-ON/OFF protocol

MARK

SPACE

Serial Interface Specifications

Table 1-13. Serial Interface Handshaking

X-OFF (13H)

X-ON (1 1 H)

I

RS-232C serial

Asynchronous

By

DTR

(REV) signal or X-ON\OFF protocol

Refer to Table 1-13 and Figure 1-9.

Description

When the number of bytes remaining in the input buffer

reaches 256 or less, the signal level goes to MARK, or a

X-OFF code is sent out to the host computer. This indicates

that the printer is not ready to receive data.

When the number of bytes remaining in the input buffer

reaches 512 or more, the signal level goes to SPACE, or a

X-ON code is sent out to the host computer. This indicates

that the printer is ready to receive data.

DTR

(REV) Signal

MARK ( -

12VI

I

SPASE ( +

Word Length

Start bit

Data bit

Parity bit

Stop bit

Bit Rate

Logic Level

Data Transmission Timing

IZV)

8Kbyte

----------------

‘

Fig. 1-9. Hand Shaking of

1

8

Odd, Even, or none

(selectable by DIP switches 2-3 and 2-4)

1 bit or more

300, 1200, 4800, or 9600 BPS

(selectable by DIP switches 2-5 and 2-6)

EIA level, MARK: logical 1 (–3 - –27 V)

See

512 byte

1

1

I

X-ON

SPACE: logical O (+3 - +27 V)

Figure 1-10.

I

256byte

I

I

I

X-OFF

4

I

1

O

RS-232C

byte Input Buffer Vacant Area

X-ON/X-OFF Protocol

Interface

1-14

REV.-A

------

t’+

(

+V)

DTR

( -v)

---------------------

[ +V]

RXD

[ -v]

( +

v)

( -v)

(

+V)

( –v)

–-

RXD

—

TXD

.“[I[3[4mE

Data Bit

Start

Bit

-o~j-z~3~q-g-6~j:

*

Start

Bit

DTR

Data Bit

Handshake

::17 ,,—

Stop Bit

l-l

P:rlty

[

S;:;t ;;ta&i;

X-ON/X-OFF

Protocol

---S ~

Stop Bit

1-

Pari~Y

1-

-T’

,1

“

+

NOTES: 1. The value of “T” varies according to the input data.

2. The word structure of serial data

is 1 start bit + 8 data

+ 1 or more stop bit.

Data Transmission Timing

“x” is printed.

Figure 1-1 1.)

\

1

I

NC

Chassis

Signal

Error Detection

Connector

Fig. 1-10. Serial

Parity error:

Overrun error: Ignored

Framing error: Ignored

6-pin DIN connector (See

RXD

DTR

TXD

Fig. 1-11. Serial Interface Connector

bits + parity (Odd, Even, or none)

GND

GND

1-15

REV.-A

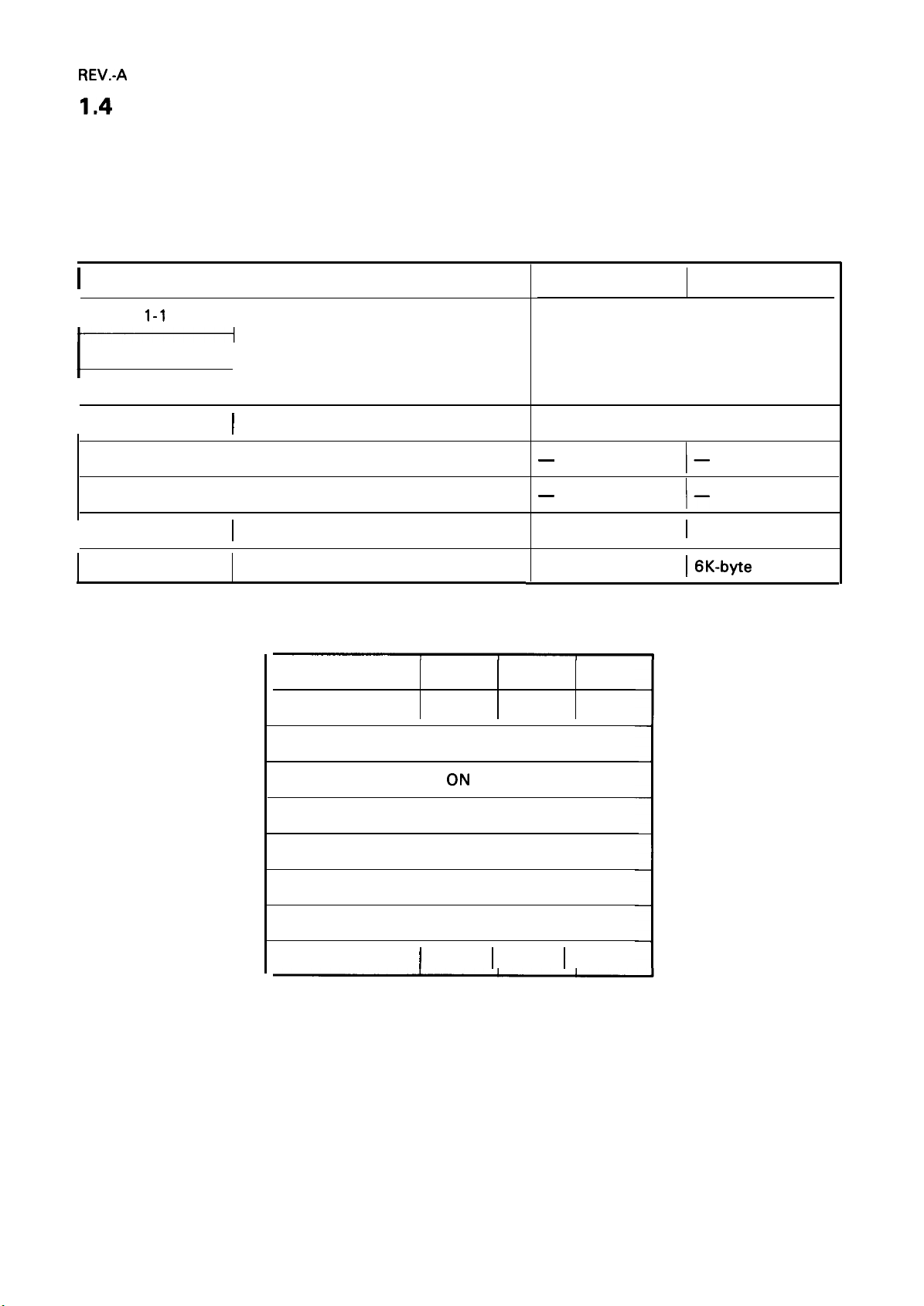

1.4

DIP Switch and Jumper Settings

The DIP switches that users can set are SW1 and SW2. These switches are positioned at the rear of

the printer, and have the functions as shown in Tables 1-14 through 1-18, (note that the status of the

DIP switches are read only when the printer power on or an INIT signal is input.)

Table 1-14. DIP Switch 1 Settings

I

DIP SW.

I

I

I

I

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

I

Function

ON OFF

I

International characher set

See Table 1-15.

I

I

Table select

Not used

Not used

I

CSF mode

Input buffer

Table 1-15. International Character Set Designation

Country

U.S.A.

1-1

ON ON

Graphic

—

—

Valid

None

1-2 1-3

ON

Italic

l–

l–

I

Invalid

I 6K-byte

NOTE: The

codes.

France

Germany

U. K.

Denmarkl

Sweden

Italy

Spain 1

above settings can be changed to any country’s characters set by inputting ESC R control

ON

I

ON

I

ON

I

OFF

I

OFF

I

OFF

I

I

OFF I OFF I OFF

ON

I

OFF

I

OFF

I

ON

I

ON

I

OFF

I

OFF

I

ON

I

OFF

I

ON

I

OFF

I

ON

I

1-16

Table 1-16. DIP Switch 2 Settings

DIP SW.

—

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

Function ON OFF

Page length

1“ skip-over perforation

I

Interface selection

Baud rate selection

Tear off mode

Auto LF

Table 1-17. Interface

2-3

OFF

I

I

2-4

OFF

Function

Parallel

See Table 1-17.

I

See Table 1-18.

I

I

Sele;tion

12“

Valid Invalid

1

Valid

Valid-

11

“

Invalid

Invalid

ON

I

OFF

I

I

ON I ON I Serial, None parity]

Table 1-18. Baud Rate Selection

2-5

I

OFF

I

I

ON I OFF I 4800

OFF

I

ON

I

OFF

I

ON

I

2-6

I

OFF

I

ON

I

ON

Serial, Even parity

I

Serial, Odd parity

Function

I

9600

1200

300

I

I

I

1

1-17

REV.-A

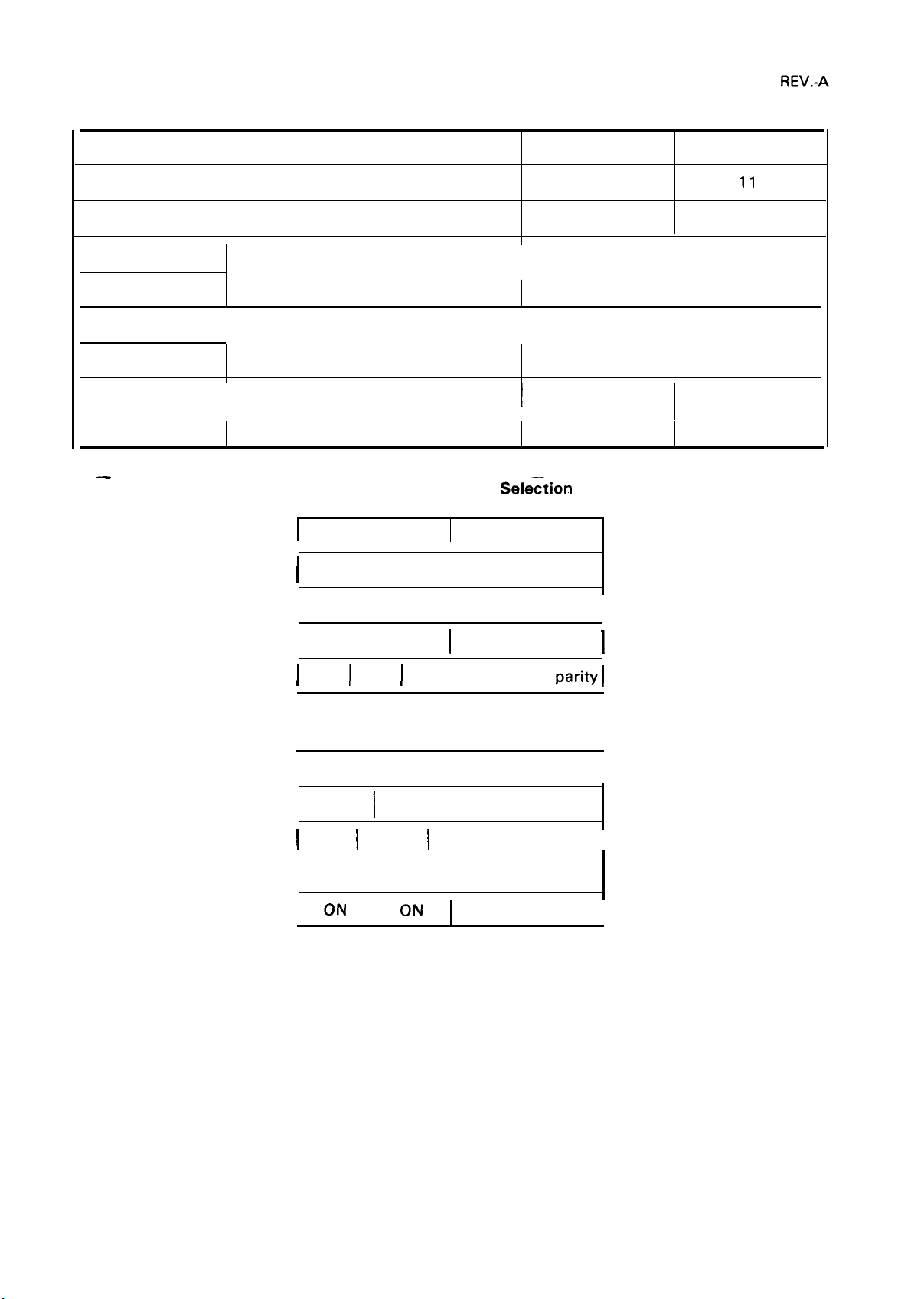

Fiugre 1-12 shows the factory settings for DIP switches SW-1 and SW-2.

Country

U. S. A., Southeast Asia,

Middle and Near East

Germany,

Northern Europe

U. K., Australia

France, Itary, Spain

White areas indicate the setting.

Fig. 1-12. DIP switches

Jamper Setting See Table 1-19.

1 and 2 Factory Settings

No.

1 M-bit

Mask-ROM P-ROM

J1 B2

J2

J3 B3

J4 ROM ROM

J5

J6 B4

J7 80

B1

4M-bit

RD

LQ-850

N.C.

B1 B1

RD

Table 1-19. Jumper Setting

Type

256 K-bit 64 K-bit

+5

RD RD RD

ROM RAM ROM

2M-bit

Mask-ROM

RD

B4

1 M-bit

B3

+5

LQ-1

136

PS-RAM

B1

WR WR

050

ST-RAM

N.C.

256 K-bit

RD

+5

Locatior

CG

1

CGO

—

27256

J8 256

J9

SICTIN

SLIN

enable

Bold indicates the factory settings.

1-18

27512

512

SLCTIN

GND

disable

PROG

—

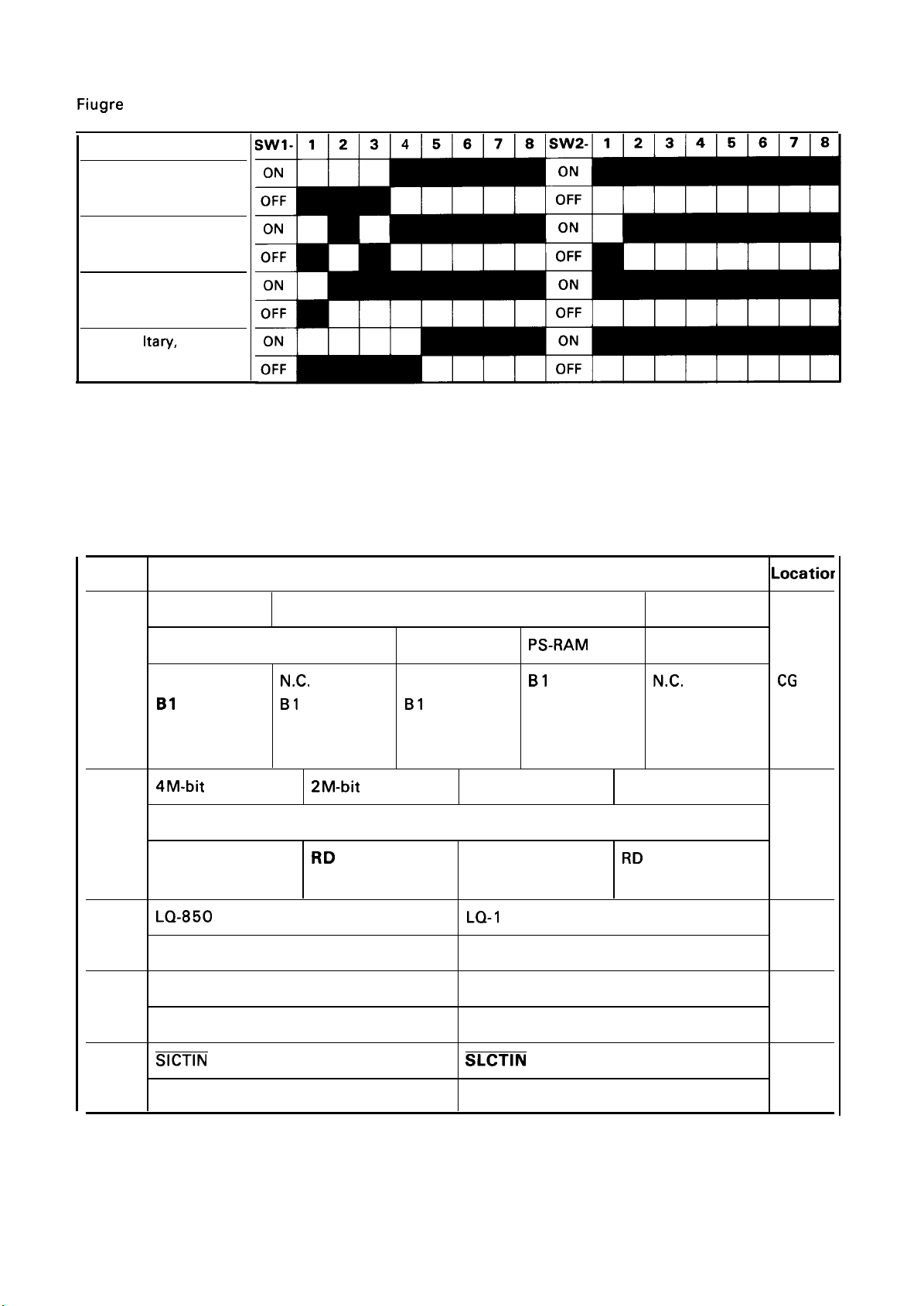

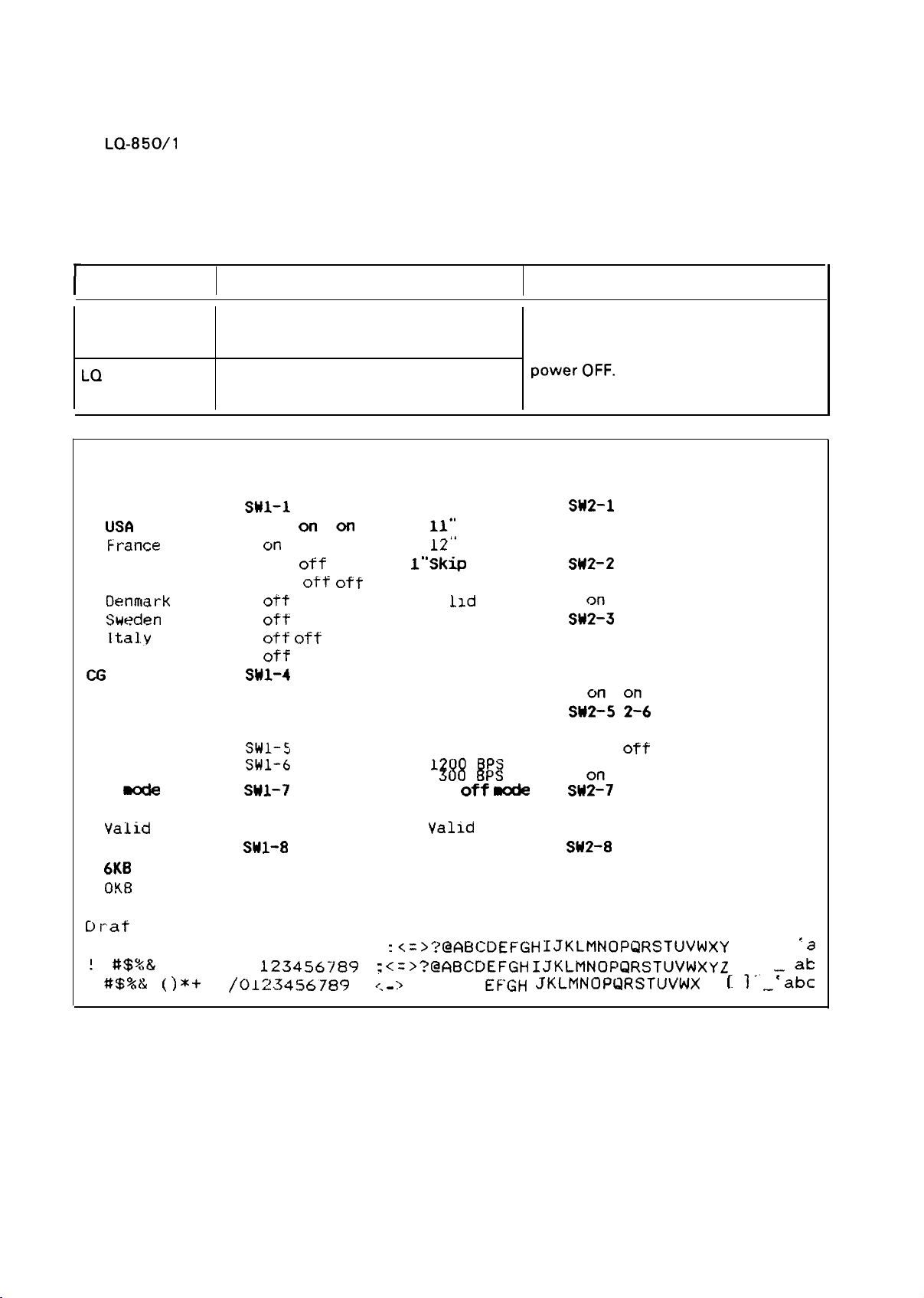

1.5 SELF-TEST OPERATION

The

LQ-850/l

DIP switch settings also printout when the self-test is performed.

Table 1-20 lists the self-test operating instructions and Figure 1-13 shows the self-test printing.

050 printer has the following self-test operation. The control ROM version No. and the

Table 1-20. Self-Test Operation

REV.-A

r

Type-face

Start

Draft Turn the power ON while pressing the

LINE-FEED switch.

LQ (Roman) Turn the power OFF while pressing the

FORM-FEED switch.

j-18-l 7 7’7

Country

USA

F“

rance

Germany

U.K.

Denmark

Sweden

1 tal.y

Spain

CG table

Italic

Graphic

not used

not used

wde

CSF

Invalid

Valid

Receive buffer

6KB

O!(B

Sul-1

On

on

on

on

o~~

oft

off off

off

SU1-4

off

on

SW1-5

SW1-6

SW1-7

off

on

SU1-8

off

on

1-2 1-3

onon

off

on

off

on

o~f off

on on

on

off off

off

on

Page Length

11”

12”

l“skip

Invalid

Va

Lld

Interface

Parallel

Serial even

Serial odd

Serial none

Baud Rate

9600

BPS

4800 BPS

Tear

Auto LF

off mde

Invalid

Valld

Invalid

Valid

stop

Push the ON-LINE switch, and turn the

power OFF”

SU2-1

off

on

SU2-2

off

SU;~3 2-4

off off

on off

off on

SU;f5 ;F6

off off

ott

on

off on

on

SU27

off

on

SU2-8

off

on

D rat

t 10

! “ #$%& ‘ ( )*+ .-. /0123456789 : ,

!

“

#$~&

‘ ( )*+ , -. /0

“ #$%& ‘ (

)*+

.-.

123456789

/ol~.3456”789

-< = >’~@ABCI)EFGH

: < = >’?@ABCDEFGH

: .

- ~ -?@ ABC DE

: ; ~.

-

Bold indicates the current DIP switch settings.

Fig. 1-13. Self-Test Printing

1-19

IJKLMNOPQRSTUVWXY Z [ \ I . . ‘

IJKLMNOpQRSTUVWXyZ [\ J”’ ‘

F-GH

I

JKLMNOPQRSTUVWX

YZ ( \ ]”

a

ak

–Tabc

REV.-A

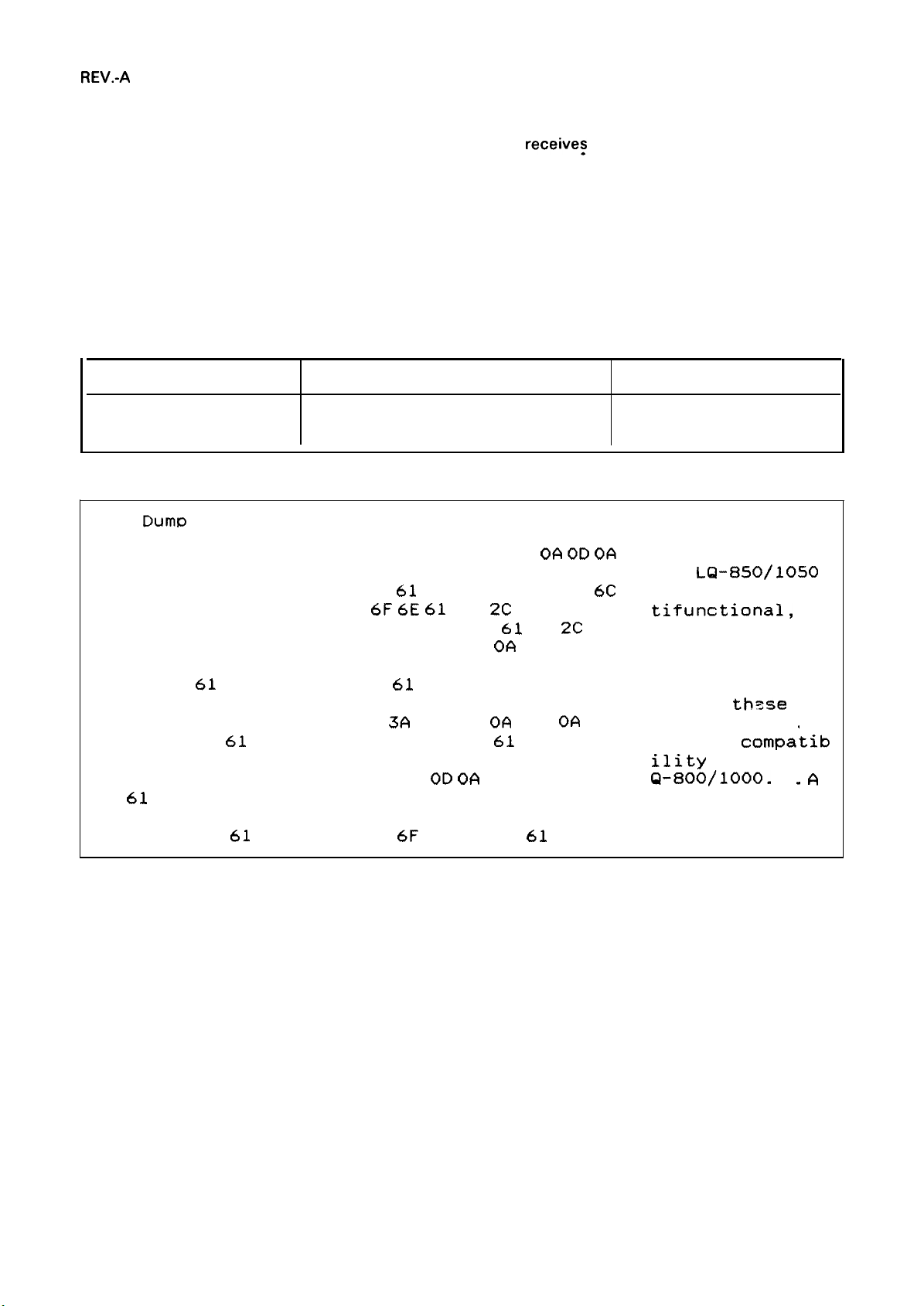

1.6 HEXADECIMAL DUMP FUNCTION

In hexadecimal dump mode, the printer prints out the data it

prints a column of 16 hexadecimal values, folIowed by a column containing the 16 corresponding ASCII

characters. If there is no corresponding printable character for a value (e.g., a control code, such as

a carriage return or line feed), a period (. ) is printed in the ASCII column in the position of the code.

Each line of the dump contains 16 values, printed in the order they were received, and any remaining

data (less than 16 values on the final line) can be printed by operating the ON-LINE switch. Table 1-21

shows the hexadecimal dump operation and Figure 1-14 shows printout of the operation.

Table 1-21. Hexadecimal Dump Operation

Function

Hexadecimal dump mode

Data

31 2E 31 20 46 45 41 54 55 52 45 53 OD

54 68 65 20 4C 51 2D 38 35 30 2F 31 30 35 30 20

70 72 69 6E 74 65 72 73 20

74 69 66 75 6E 63 74 69

2D 70 69 6E 20 70 72 69 6E 74 68 65

69 6D 70 61 63 74 20 64 6F 74 2D OD

72 69 78 20 70 72 69 6E 74 65 72 73 2E 20 54 68

65 20 6D

6F 66 20 74 68 65 20 74 68 65 73 65 20 70 72 69

6E 74 65 72 73 20 61 72 65

20 55 70 77

69 6C 69 74 79 20 77 69 74 68 20 74 68 65 20 4C

51 2D 38 30 30 2F 31 30 30 30

6D

65 65 64 20 6F 66 20 32 36 34 20 43 50 53 20 69

6E 20 64 72

Dum~ Mode

61

69 6E 20 66 65 61 74 75 72 65 73 20

61

72 64 20 63 6F 6D 70 61 74 69 62

61

78 69 6D 75 6D 20 70 72 69 6E 74 20 73 70

61

66 74 20 6D

Turn the power on while pressing both

the LF and FF switches.

Operation

61

72 65 20 6D 75 6C

6F

6E 61 6C 2C 20 32 34

3A 20 OD OA OD

OD OA

6F

64 65 20 61 74 20

2E 20 41 20

receive?

06 OD OA

61

64 2C 20

OA

6D 61 74

0($

in hexadecimal format. The printer

stop

Turn the power off.

1.1 FEATURES. . . .

The

LQ-850/1050

printers are mul

2E

tifunctional,

-pin print head,

impact dot-. mat

rix printers. Th

e main features

of the

nters are: . .

Upward

ility

Q-800/looo.

maximum print sp

eed of 264 CPS i

n draft mode at

thzse

compatib

with the L

pri

. .

24

.

. .

A

Fig 1-14. Hexadecimal Dump List

1-20

REV.-A

1.7 PRINTER INITIALIZATION

There are two initialization methods: hardware initialization and software initialization.

1.7.1 Hardware Initialization

This type of initialization occurs when printer power is turned on or when the printer receives the INIT

signal from the host via the 8-bit parallel interface.

When printer is initialized in this way, it performs the following actions:

● Initializes printer mechanism

● Clears downloaded character set

● Clears the input data buffer

● Clears the image buffer

● Sets printer selections to their default values

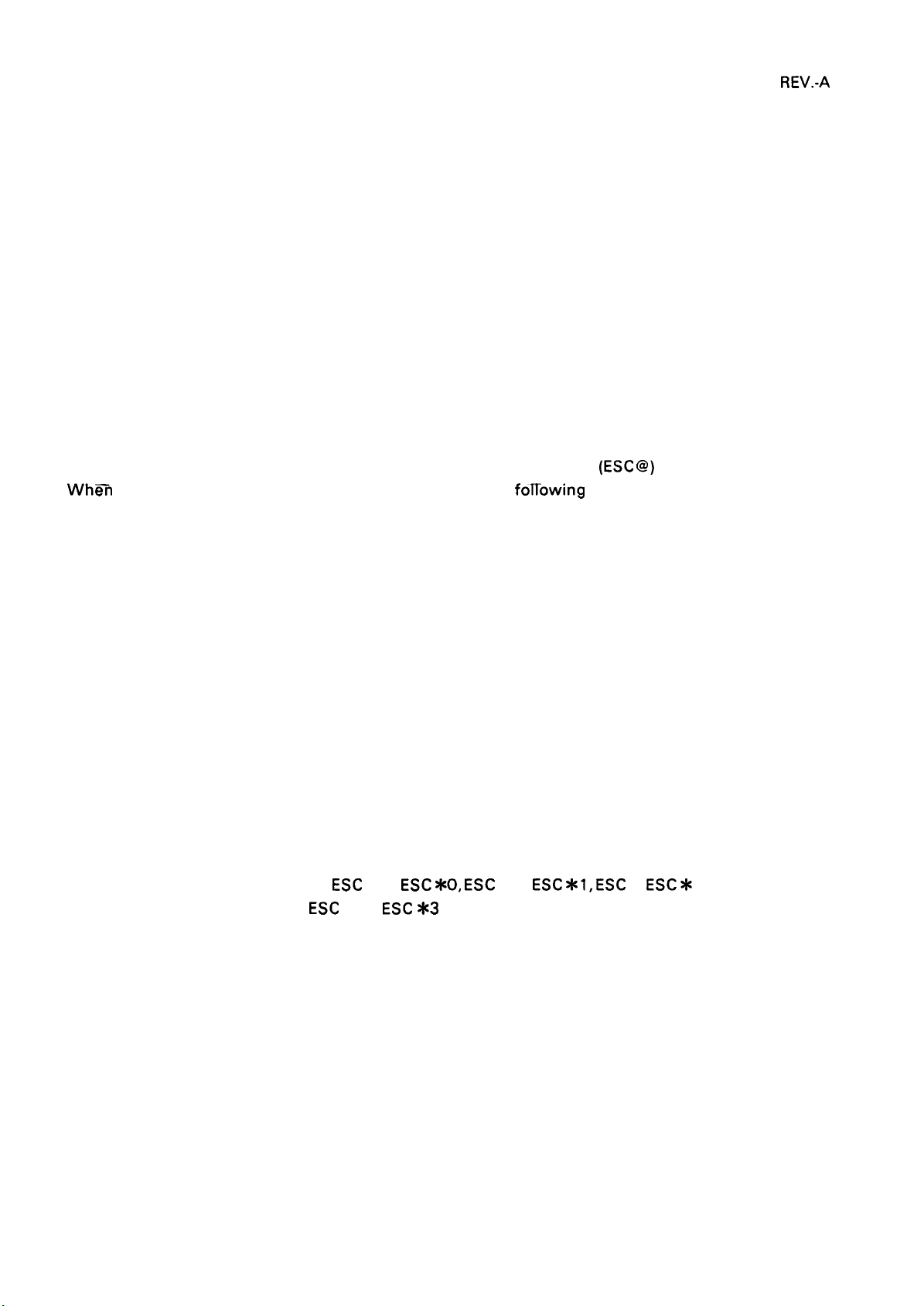

1.7.2 Software Initialization

This type of initialization occurs when the printer receives command

WhiSin

the printer is initialized in this way, it performes the fo~owing actions:

● Clears the image buffer

● Sets

NOTE: The printer’s default values are as follows:

Page Position

Left and Right Margin

Line Spacing

Vertical Tab Position

Horizontal Tab Position

VFU Channel

Family Number of Type Style Roman (Family Number O)

Downloaded Characters

Justification

Character Per Inch

Bit Image Mode Assignment

Printing Effects

printer selections to their default values.

Preset paper position becomes top of form position

Released

1/6 inches

Cleared

Every 8 characters (relative)

Channel O

Deselected: Software initialize

Cleared:

Left justification

10

ESC

K =

ESC

Z =

Cleared

Hardware initialize

ESC *O, ESC

ESC X3

L =

ESC xl, ESC

(ESC @)

=

via software.

ESC X

2,

1-21

.

REV.-A

1.8 BUZZER OPERATION AND ERROR CONDITIONS

This section describes the buzzer operation and error conditions of the printer.

1.8.1 Buzzer Operation

The buzzer ring as follows:

. When a BEL code is sent to the printer, the buzzer sounds for 0.5 seconds

. When an error has occurred

Carriage Trouble:

Paper End:

● When a panel setting is accepted, the buzzer sounds for 0.1 seconds (Refer to Section 1.9.4 for further

information concerning control panel settings.)

1.8.2 Error Conditions

If any of the following errors occur, the printer automatically enters the OFF-LINE mode.

● Home position is not detected at printer mechanism initialization.

● Home position

● The OFF-LINE switch is pressed, causing the printer to enter OFF-LINE mode.

● Paper-out is detected when forms-override is finished.

● A paper-out signal is detected and forms-override is finished.

● A paper-out signal is detected after the printer has performed a paper-loading operation with the

cut sheet feeder enabled.

For information concerning the status of the interface signals, refer to Section 2.3.2.

Sounds 5 times (rings for 0.5 seconds with 0.5 seconds interval.)

Sounds 3 times (rings for 0.1 seconds with 0.1 seconds interval.)

is detected during printing.

1-22

Loading...

Loading...