Page 1

EPSON TERMINAL PRINTER

EPL-5600

ActionLaser 1600

SERVICE MANUAL

. ‘

I

,

EPSON

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever without

SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual. However, should

any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this

manual or the consequence thereof.

Epson and Epson ESC/P are registered trademark of Seiko

General Notice: Other product names used herein are for identication purposes only and maybe

trademarks of their respective campanies.

Epson corporation.

@Copyright 1994 by SEIKO EPSON CORPORATION Nagano, Japan

-i-

Page 3

PRECAUTIONS

Precautiomry notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

DANGER

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

1.

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND

011-IER

ELECTRONIC COMPONENTS.

INSI’RUCTED

TO DO SO. WHEN

F--

4

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

AGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFEREM FROM AVAILABLE POWER SOURCE, DO

NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

NONAPPRO”VED

APPLICABLE: EPSON WARRANTY.

COMPONENTS MAY DAMAGE THE

PRODUCI’

ICS

AND VOID ANY

VOLT-

OR OTHER

,,. ,

. .

- ii -

Page 4

SAFETY INFORMATION

This printer is a page printer which operates by means of a laser. There is no possibility of danger from

the laser, provided the printer is operated according to the instructions in this manual provided.

Since radiation emitted by the laser is completely confined within protective housings, the laser beam

camot escape from the machine during any phase of user operation.

For United States Users;

[Laser Safety]

This printer is certified as a Class 1 Laser product under the U.S. Department of Health

and Human Services

tion Control for Health and Safety Act of 1968. This means that the printer does not

produce hazardous laser radiation.

(DHHS)

Radiation Performance Standard according to the Radia-

[CDRH

The Center for Devices and Radiological Health

Administration implemented regulations for laser products on August 2,1976. Compliance is mandatory for products marketed in the United States. The label shown below

indicates compliance with the

marketed in the United States.

[Internal Laser Radiation]

Maximum Radiation Power:

Wave Length:

This is a Class

unit is NOT A FIELD SERVICE ITEM. Therefore, the print head unit should not be

opened under any circumstances.

For Other Countries Users;

Regulations]

WARNING: Use of controls, adjustments or performance of procedures other

than those specified in this manual may result in hazardous radiation exposure,

WARNING: Use of controls, adjustments or performance of procedures other

than those specified in this manual may result in hazardous radiation exposure,

(CDRH)

CDRH

regulations and must reattached to laser products

5.7x

104(W)

780 nm

IIIb

Laser Diode Assay that has an invisible laser beam. The print head

of the U.S. Food and Drug

,,-

For Denmark Users;

This is a semiconductor laser.

10-4

W and the wavelen

ADVARSEL

Usynlig laserstr~ling

Undgii uds~ttelse

Klasse 1 laser produkt der opfy

ved

for

strWng.

The

gth

is 780 nm.

~bning, niir

lder

.,,

-111-

maximum power of the laser diode is 5.7

sikkerhedsafbrydere er ude af funktion.

IEC825 sikkerheds

kravene.

~

1

Page 5

VAROITLJS

Laitteen Iciiyttiminen muulla

saattaa altistaa ldiyttiijiin turvallisuusluokan

Iasersiiteiylle.

VARNING

Orn

apparaten anviinds pi%

kan anvtidaren

for laser

klass

utstittas fdr osynlig

1.

kuin

annat

tiissd Idiytt50hjeessa mainitulla tavalla

siitt ti

i

denna bruksanvisning

laserstrihin~ som

1

ylittiiv~lle niikyrniitt&r@le

sp-ificerats,

6verskrider grhser

For Norway

lhwa;

ADVARSEL

Dersom

ins kan brukeren

for laser

Dette er en

apparatet brukes p~

klasse

halvleder

utsettes

1.

for

laser.

annen

rniite

enn

spesifisert

unsyrrlig laserstriiling

Maksi@

effeckt

til Iaserdiode

i

denne bruksanvisn-

som overskrider

er 5.7 x

,balgekngde er 7S0 nm.

Laaer

Safety Labels

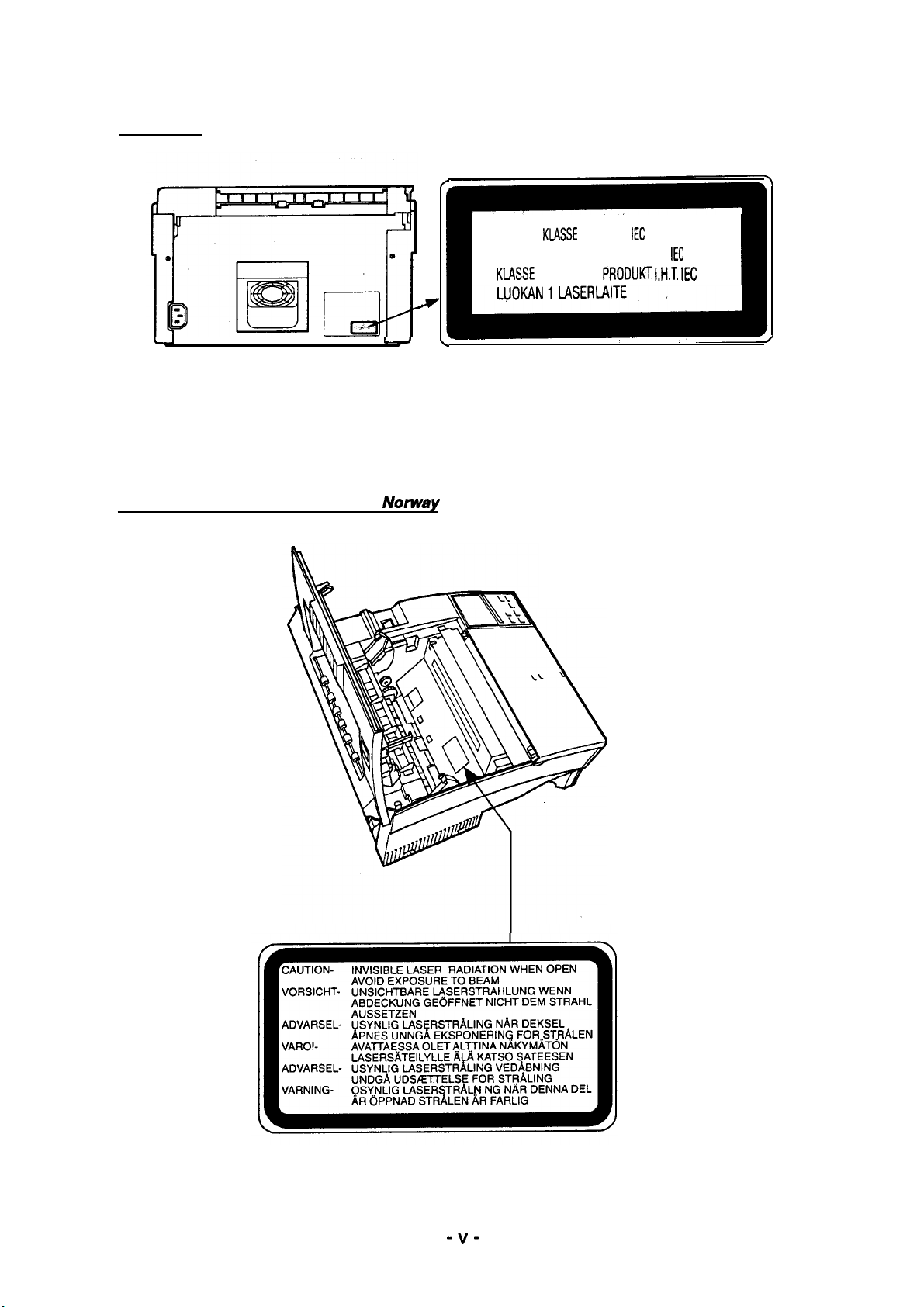

[Label on rear printer case]

A laser safety labels is attached on the outside of the printer shown below.

For United State

f

This laser product conferms to the

applicable requirement of 21 CFR

Chapter 1, subchapter J.

SEIKO EPSON CORP.

Hirooka Office

80 Hirooka,

JAPAN

MANUFACTURED:

Shiojiri-shi, Nagano-ken,

grenser

10+

W

og

\

J

-iv-

Page 6

For Europe

/

LASER

KLASSE

1 NACH

CLASS 1 LASER PRODUCT TO

KLASSE

1 LASER

w

.

IEC

825

IEC

825

PRODUKT I.H.T. IEC

825

\

[Label inside printer]

The following laser safety label will be attached inside the printer as shown below.

For Denmark, Finland, Sweden, and

Nomvay

-v-

Page 7

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of

EPL-5600 /ActionLaser 1600.

The instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are organized as

follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications and illustrates the main components of the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes

rhe

theory

of printer operation.

,..

L“:”:

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments circuit

diagmrm

circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

-

vi -

Page 8

REVISION SHEET

Revision

Rev.

A

Issue Date

Februaty 2, 1994

Revision Page

1st issue

i

-

Vll

. .

-

Page 9

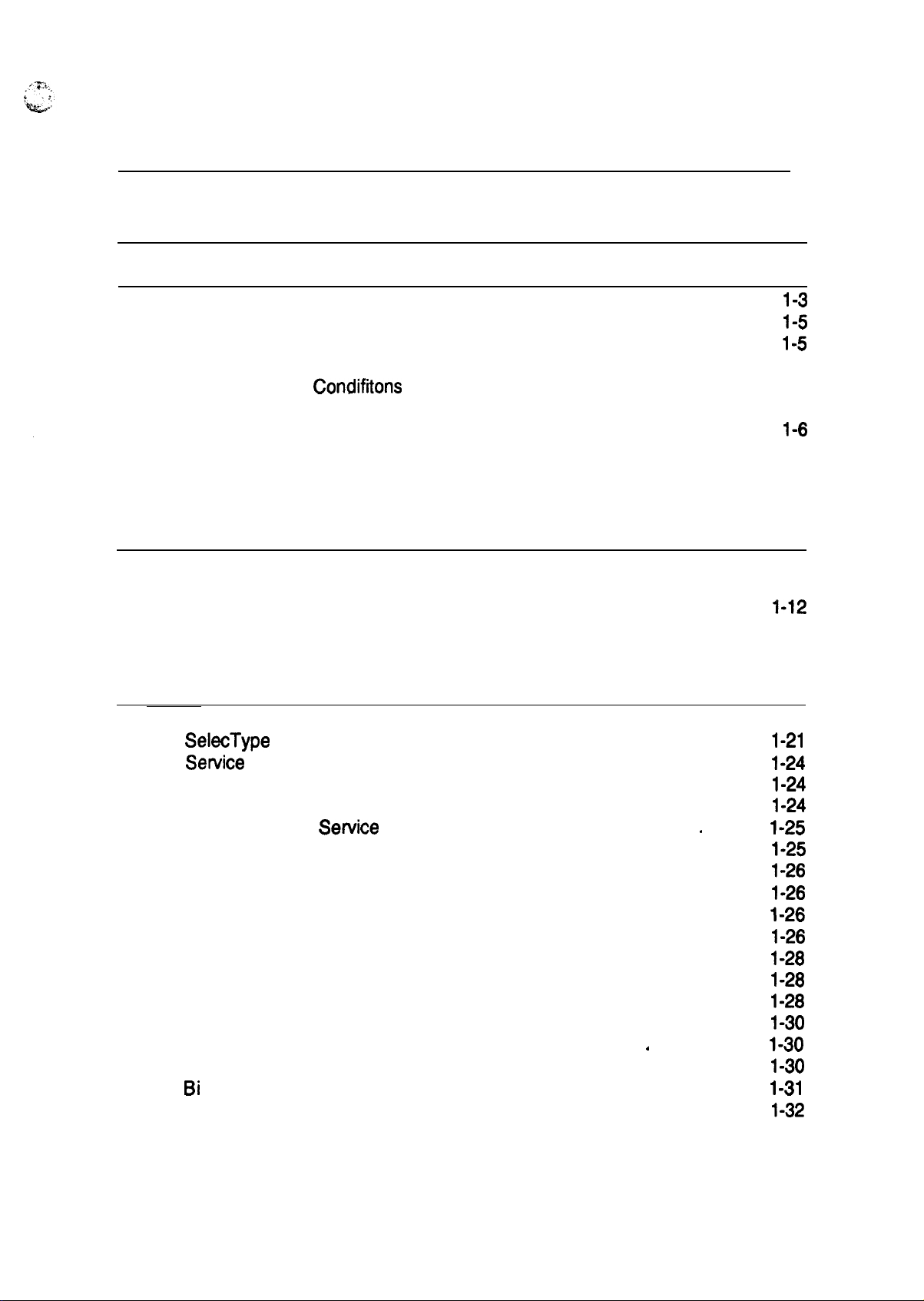

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY AND ASSEMBLY

ADJUSTMENTS

TROUBLESHOOTING

MAINTENANCE

-

,..

Vlll

-

Page 10

.

Chapter 1 General Description

Table of Contents

1.1 FEATURES

1.2 SPECIFICATIONS

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

.

.

1.2.6

1.2.7

1.2.8

1.2.9

1.3 INTERFACE SPECIFICATIONS

1.3.1 Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.3.2 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.3.3 Optional LocalTalk Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Basic Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reliability Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Conditions for Operating (including Imaging Cartridge). . 1-5

Environmental

(Excluding Image Cartridge). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Applicable Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification for Consumable (Imaging Cartridge) . . . . . . . . . . . . . . . . . 1-6

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Software Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.1.1 Compatibility Mode of Parallel InterFace. . . . . . . . . . . . . . . . . . 1-10

1.3.1.2 Reverse Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condifitons

for Storage and Transpiration

1-1

1-3

1-3

1-5

1-5

1-6

1-1o

I-12

1.4

OPERATING INSTRUCTIONS

1.4.1 Control Panel.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1.4.2

1.4.3

1.4.4

1.4.5

1.4.6

1.4.7

1.4.8

SelecType

Sewice

1.4.3.1 Hexadecimal Dump Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.2 Language Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.3 Factory

1.4.3.4 EEPROM Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display of Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4.1 Status Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4.2 Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4.3 Warning Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Sharing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.1 Port Fixed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.2 Auto Sense Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emulation Mode Switch Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.6.1 Emulation Switch by SPL . . . . . . . . . . . . . . . . .

1.4.6.2 Intelligent Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bi

Resolution Improvement Technology . . . . . . . . . . . . . . . . . . . . . . . .

Optional Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sewice

Mode. . . . . . . . . . . . . . . . . . . . . . . . . # . . . . . .

d

. . . . . . . . . . .

1-19

1-21

1-24

1-24

1-24

1-25

1-25

1-26

1-26

1-26

1-26

1-28

1-28

1-28

1-30

1-30

1-30

1-31

1-32

Page 11

1.5 MAIN COMPONENTS

1.5.1

C125

MAIN Board . . . . . . . . . . . . . . . . . . . . . . .

.‘.

. . . . . . . . . . . . . . . .

1.5.2 C82326* l/F Board (Optional LocalTalk Module). . . . . . . . . . . . . .

1-33

1-34

.‘.

. . 1-35

1.5.3 Control Panel.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

1.5.4

PWB-A

1.5.5 pWB-E

1.5.6

PWB-F

Board.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Board.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Board.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

1.5.7 Optical Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

1.5.8 Fusing Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

, 1.5.9 Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

1.5.10

1.5.11

1.5.12

lrnaging

Lower Paper Cassette . . . . . .

Face-Up Output Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

List of Figures

-1.

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

:xterior

~fintableArea. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-2.

-3.

Compatibility ModeSignalTiming. . . . . . . . . . . . . . . . J . . . . . . . . 1-10

~arallel

-4.

Timing Chart

-5.

Timing Chart

-6.

-7.

Timing Chart

Timing

-8.

-9.

2ontrol

-1o.

Port Fixed Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

-11.

Auto Sense Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

-12,

Emulation Switch by SPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

-13,

Intelligent Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

-14.

Effect of BiRITech. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

-15.

RITechAdjustment

-16.

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

-17.

C125

1-18.

1-19.

1-20.

1-21.

1-22.

1-23.

1-24.

1-25.

1-26.

1-27.

1-28.

C82326*

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

PWB-ABoard

PWB-E

PWB-FBoard

Optical Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Fusing Unit..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Imaging Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Lower PaperCassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Face-Up Output Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

View of the EPL-5600 and ActionLaser 1600 . . . . . . . . . . 1-1

1-4

Interface State Switch Diagram . . . . . . . . . . . . . . . . . . . . I-13

ofNegotiation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

ofDataTransfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

ofTermination

Chartoflnterrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1-15

Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

l/F Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Page 12

List of Tables

Table 1-1. Options for EPL-5600 and ActionLaser 1600 . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Paper Feed Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-3. Paper Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table l-4. Usability

Table l-5. Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-6. Differences between EPSON

HP LaserJet 4 Emulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table l-7. Built-in Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table l-8.

Table l-9. Parallel Interface Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Table l-10. Serial Interface Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Table l-11. LocalTalk Interface Pin Assignments. . . . . . . . . . . . . . . . . . . . . . 1-18

Table l-12. SelecType Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Table l-13. Factory Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Table l-14. Status Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Table l-15. Error Messages.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Table l-16. WarningMessages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Table 1-17. Differences in Components for the

ParalleI

ofSpecial Papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

GIJ2

and GL/2 in the

interface Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

C125

MAIN Board . . . . . . . . 1-34

Page 13

EPL-5600/ActionLaaer 1600 Service Manual

1.1 FEATURES

eeneral Deac@ion

The Epson

semi-conductor laser with

feature high-speed, high-resolution printing. Maintenance is very easy as a result of various

built-in diagnostic functions. The main features are:

Resolution — 600/300

Light weight — about 10 kg (22 lb.)

Small footprint

Easy maintenance

HP@ LaserJet@

45 built-in scalable fonts (35

~/p 2’” emulation

High-performance controller (the controller’s CPU is a 17.6 MHz

Bi Resolution Improvement Technology

jagged edges from images and characters on 600

Optional

EPSON Miao Gray Technology

Level 2 mode, refines gray scale printing to be comparable to printing on a

Small and low-cost optional LocalTalk

2 MB standard RAM and up to 64 MB RAM

Bidirectional parallel interface

High-speed serial communication rate of 57.6K bps

High-speed parallel communication rate of approximately 400

A multi-user, multi-emulation mode

IES

mode

SPL (Shared Printer Language) enables switching of the printer mode by command

@ EpL.5600 and

No

ozone

Printing speed — 6 ppm (pages per minute)

4 emulation mode

EPSONScript

(Intelligent Emulation Switch) allows switching between

the

ActionLaser

electro-photographic

dpi

(dots per inch)

Intellifonts

Level 2 (Postscript” compatible) module

TM 1600 are non-impa~

technology. These

and 10 TrueType fonts)

(BiRITech)

(EMGTech),

TM

interface module

wi’h

refines the print quality by eliminating

dpi

and 300

which is available when using

the addition of optional

page

printem

dpi

printing.

KB/second

EPSONScript

pMterS

are small and

SPARKlite (MB86930))

that

~rnbine

lighc

EPSONSaipt

1200-dpi

SIMMS

mode and another

printer

a

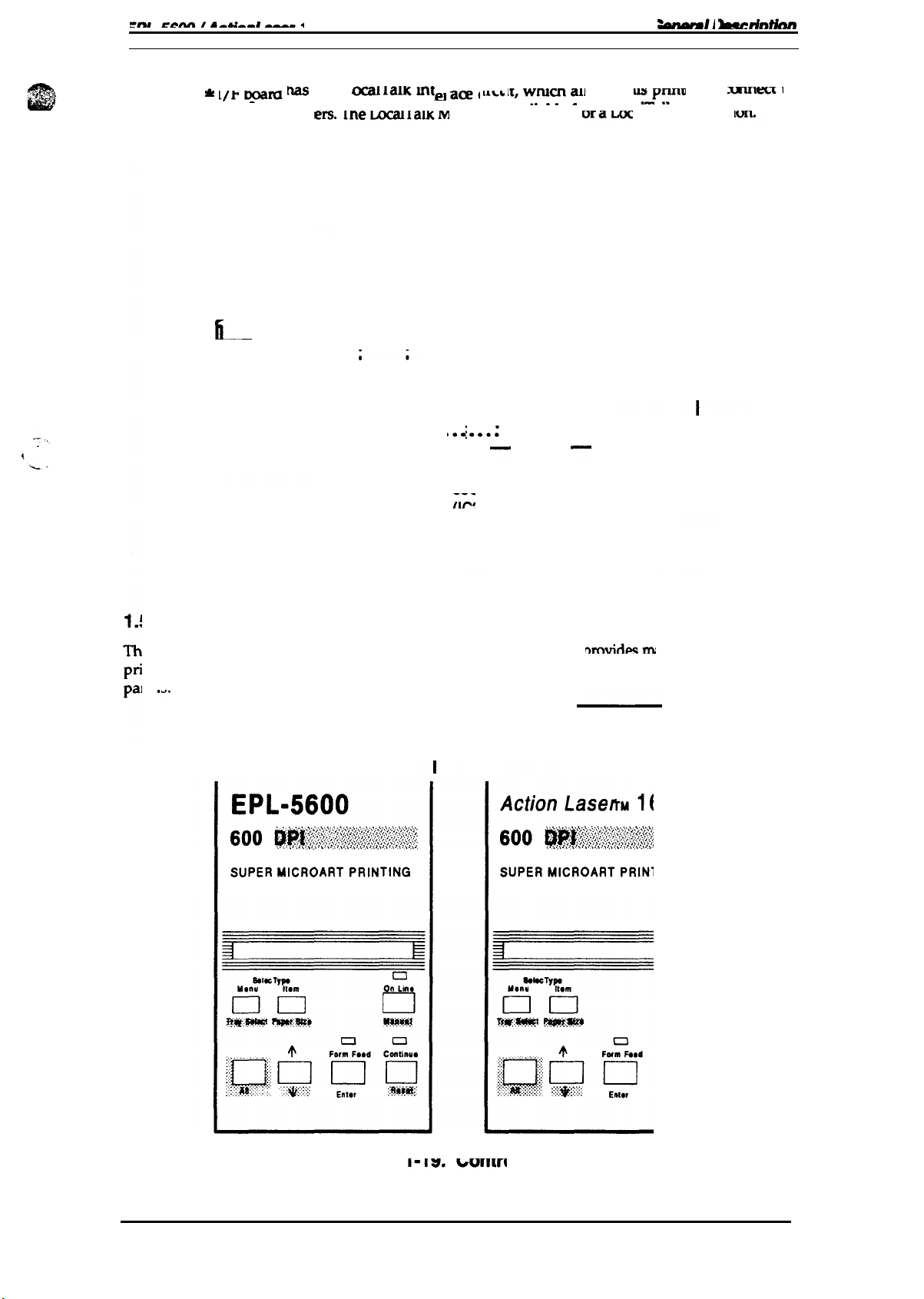

and

Figure 1-1 shows an exterior view of the

./

,,

Figure 1-1. Exterior View of the EPL-5600

EPL-5600

and

ActionLaser

and

ActionLaser

1600

1600.

Rev. A

1-1

Page 14

General Description

EPL46W/ActionLaser

1600 Service Manual

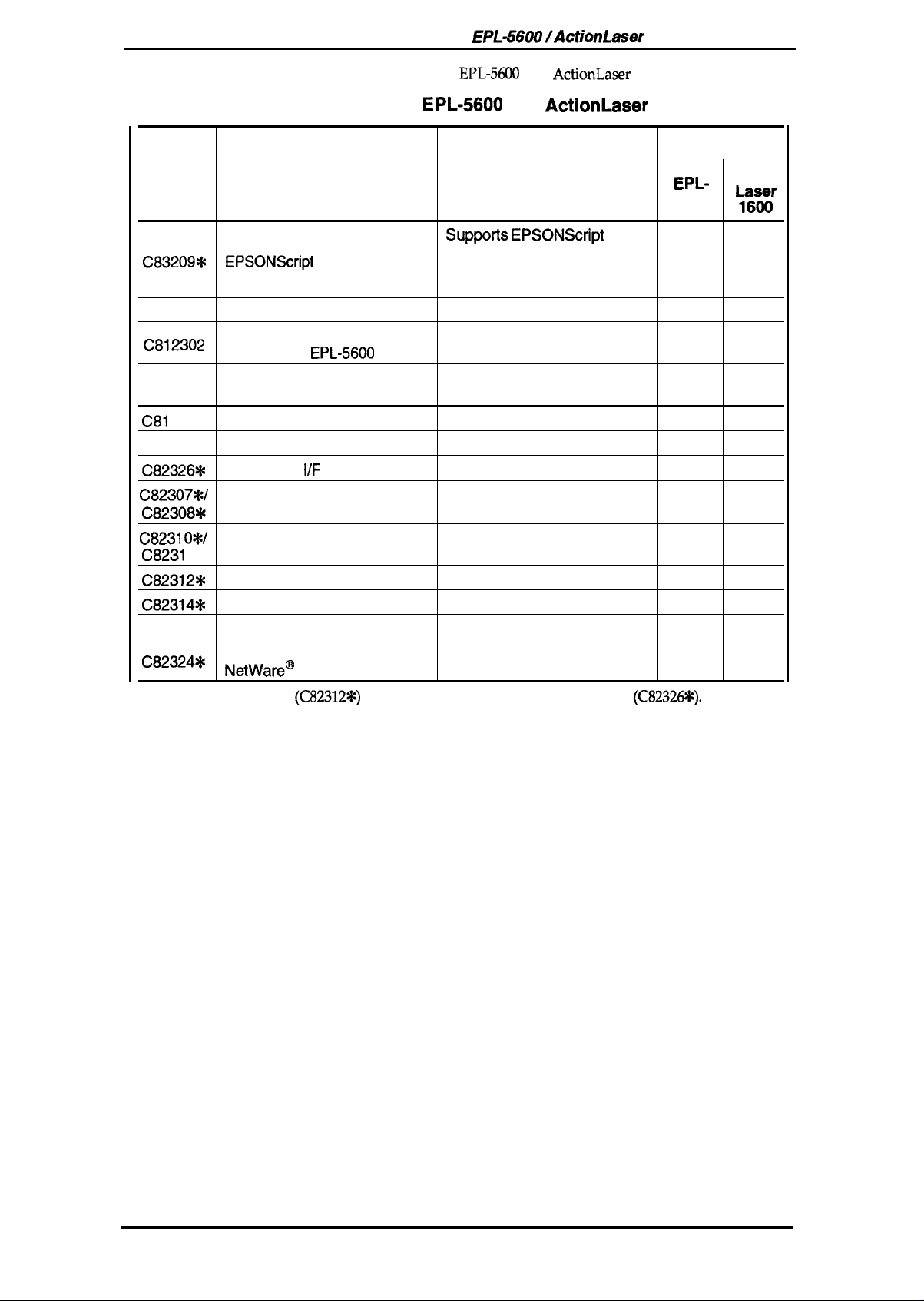

Table l-l lists the optional units available for the

Table 1-1. Options for

Cat. No.

C83209*

—

~812302

C812301

C81

231*

SO51O16

C82326*

:;:::::’

EPSONScript

Local language ROM

250 sheet lower paper

cassette for

250 sheet lower paper

cassette for AL-1 600 (Letter)

Face-up tray

Imaging cartridge

LocalTalkT”

32 KB serial interface card

Description

Level 2 Module

EPL-5600

IIF

Module

(A4)

EPL-5600

EPL-5600

sUppOrtS

Level 2 mode (PostScript

Level

commands

Supports local language fonts

Lower paper cassette

Lower paper cassette No Yes

—

Toner cartridge

—

—

and

ActionLaser

and

ActionLaser

Note

EPSONScript

2

compatible) fonts and

1600.

1600

Machine Type

EPL-

5600

Yes Yes

Yes

Yea

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Action-

~6;r

No

No

C8231 OW

C8231

C82312*

C82314*

C82315%

C82324*

Note:

, *

32 KB parallel interface card

LocalTalk card

COAX interface card

TWINAX interface card

Ethernet interface card for

NetWare@

LocalTalk card

(C82312*)

—

—

—

—

—

cannot use with LocalTalk I/F module

(C8232@).

Yes

Yes Yes

Yes

Yes Yes

Yes Yes

Yes

Yes

1-2

Rev. A

Page 15

EPL-5600

/ActionLaser 1600 Service Manual

1.2 SPECIFICATIONS

General

LM.scription

This section provides statistical data for the

1.2.1

Printing method:

Resolution:

Printing speed:

First printing time

Warm-up time:

Paper supply:

Basic Specifications

Laser beam seaming and dry

600/300 dpi

6 ppm

(A4/LT):

Less than 19 seconds (facedown output)

Less than 20

Less than 35 seconds

(at rated current and 23° C (73°

See

Table

EPL-5600

(letter/A4)

seconds

1-2.

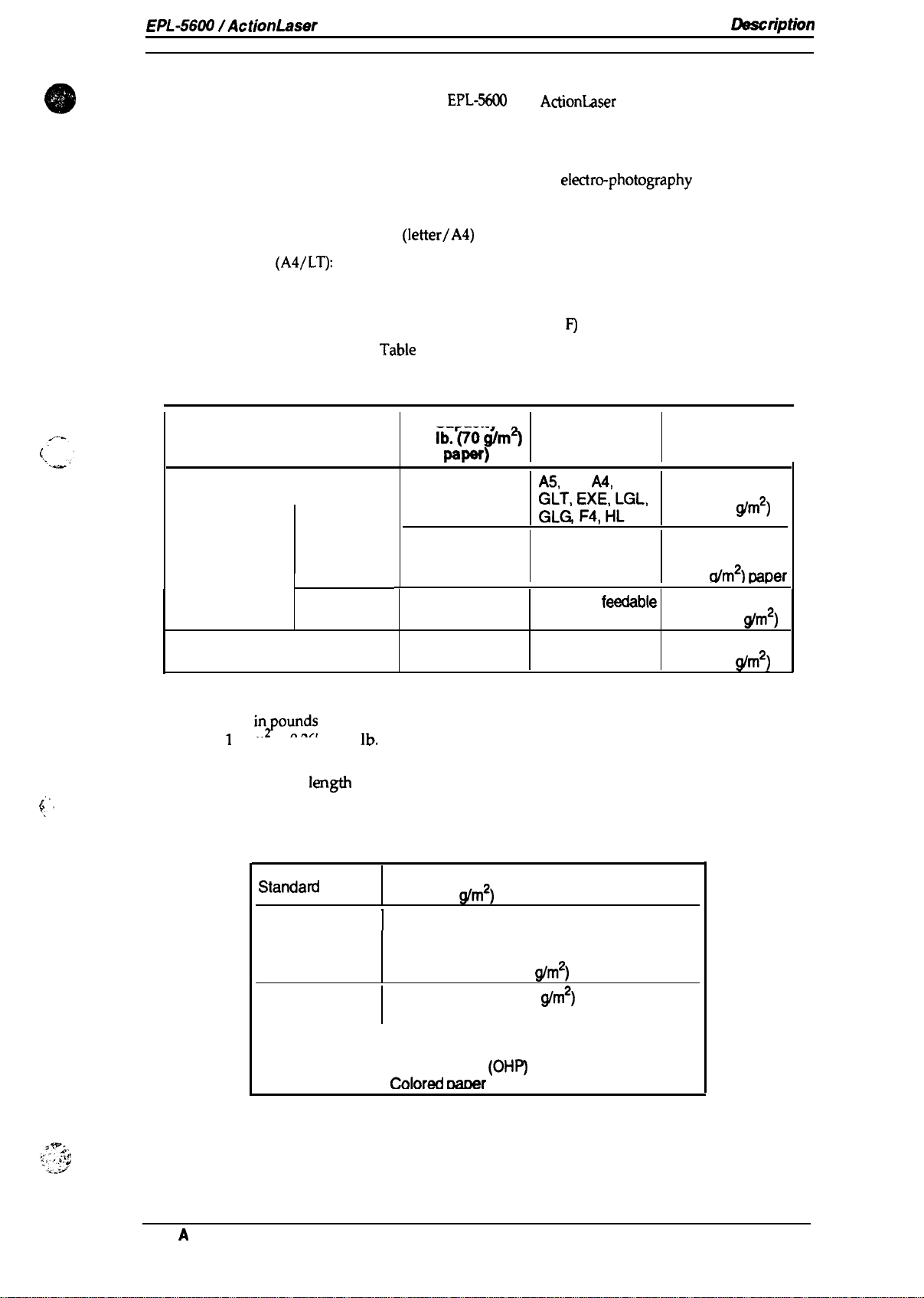

Table 1-2. Paper Feed Methods

Capacity

(20

Paper Supply

I

Auto feed

Standard built-in

paper tray

Manual feed

Lower paper cassette (optional)

lbh@7fm~

150

5 to 10

1

250

and

ActionLaser

electro-photography

(face-up output)

F)

temperature)

Paper Size

A5,

B5,

A4,

;~;

:~EH:GL’

,,

Monarch,

DL, C5,

Commercial-10

Any size

(Note 2)

A4 or LT

feedable

1600.

LT,

Usage Thickness

(Ream Weight)

16 to 24 lb.

(60 to 90

Envelopes made

of 20 to 24 b. (75

to 90

16 to 42 lb.

(60 to 157

16 to 24 lb.

(60 to 90

glm2)

ct/m2) cmer

g/m2)

@m2)

I

(’

:

Notes:

1.

The weight

weigh; 1 g/m = 0.2659763

2. Paper size range: width

Paper types:

in~ounds

Standatd

Normal paper

Special papers

(lb) is determined by how much

k?ngth

paper

500

sheets cut to 17 x 22 inch would

lb.

3.63 to 8.5 inches (92 to

5.85 to 14.0 inches (148.5 to 356 mm)

See Table 1-3.

216 mm)

Table 1-3. Paper Types

Xerox” 4024 DP paper

20 lb. (75

]

Regular photocopier paper

Bond

Recycled paper

16 to 24

Card stock (90 to 157

Envelopes

Labels

Letterhead

Transparency

Colora4 naner

@m2)

paper

lb.

(60 to 90

(OHP)

sheets

g/m2)

g/m2)

Rev.

A

1-3

Page 16

General Description

EPL-6600/ActionLaser 1600 Service Manual

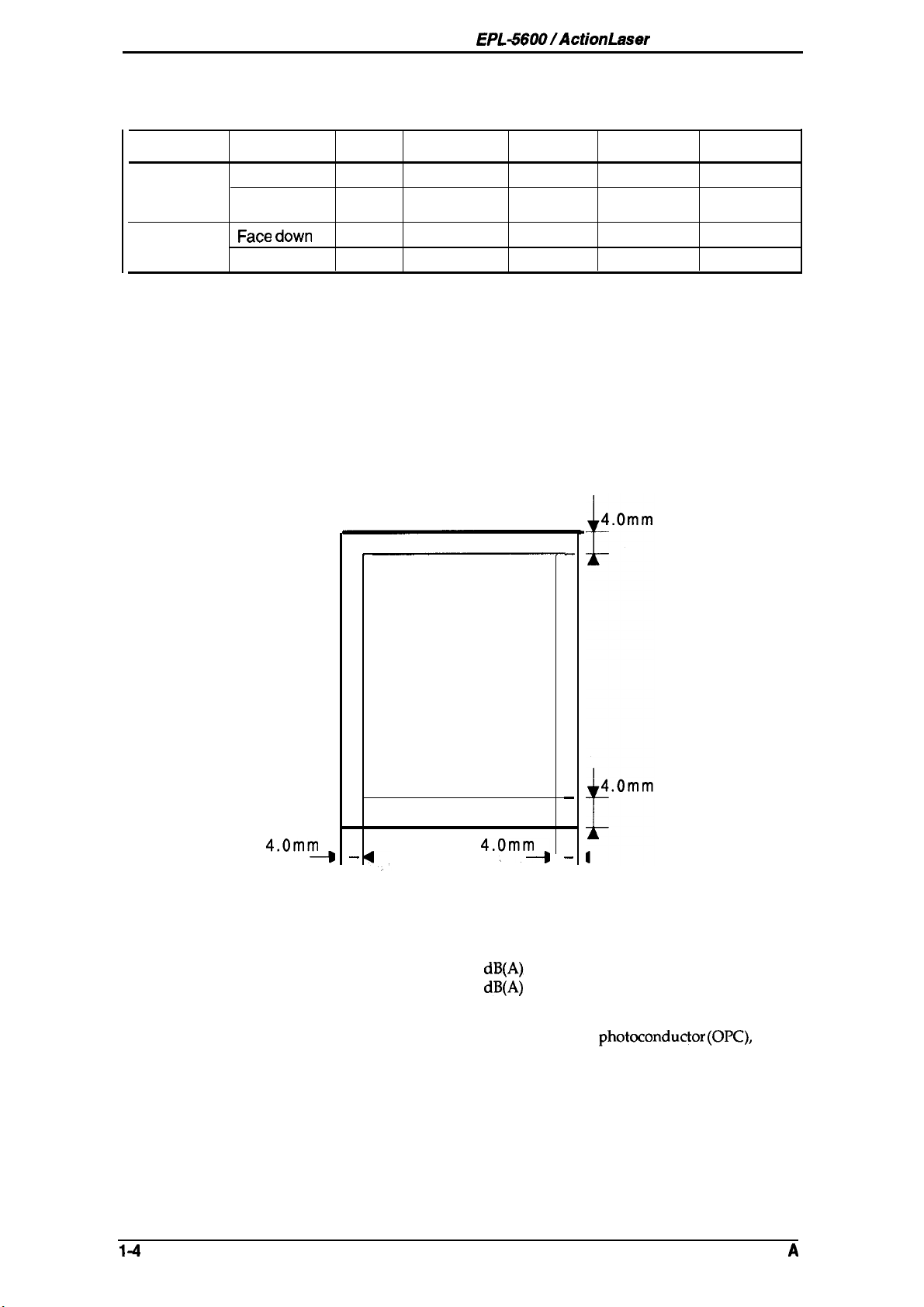

Usability of special papers:

See Table 1-4.

Table 1-4. Usability of Special Papers

Input

Standard

built-in paper

tray

Lower paper

cassette

output

Face down

Face up

Face down

Face up

R: Reliable feeding and good image quality.

P: Possible, but better avoided.

N: Not supported.

Paper feed alignment and direction: Center alignment for all sizes

Paper ejection:

Output tray capacity:

Printable area (standard paper): See Figure 1-2.

OHP Envelopes Labels Card Stock

P P

P P

R R R

N N

N

N N N P

N N P

Face down; face up (optional)

100 sheets (face down)

20 sheets (face up) (standard paper)

Letterhead

R

R

R

Note:

The actual printable area depends on the printer mode.

Noise:

Ozone density:

Toxicity:

4.Omm

—

Printable Area

—

—

4.0mm+

—

Figure 1-2. Printable Area

Less than 35

Less than 47

Less than 0.01 ppr

No toxicity exists in organic

or plastic materials

dB(A),

dB(A)

(operating)

(standby)

n

photoconductor (OPC),

toner,

1-4

Rev.

A

Page 17

EPL-5600 /ActionLaser 1600 Sawice Manual

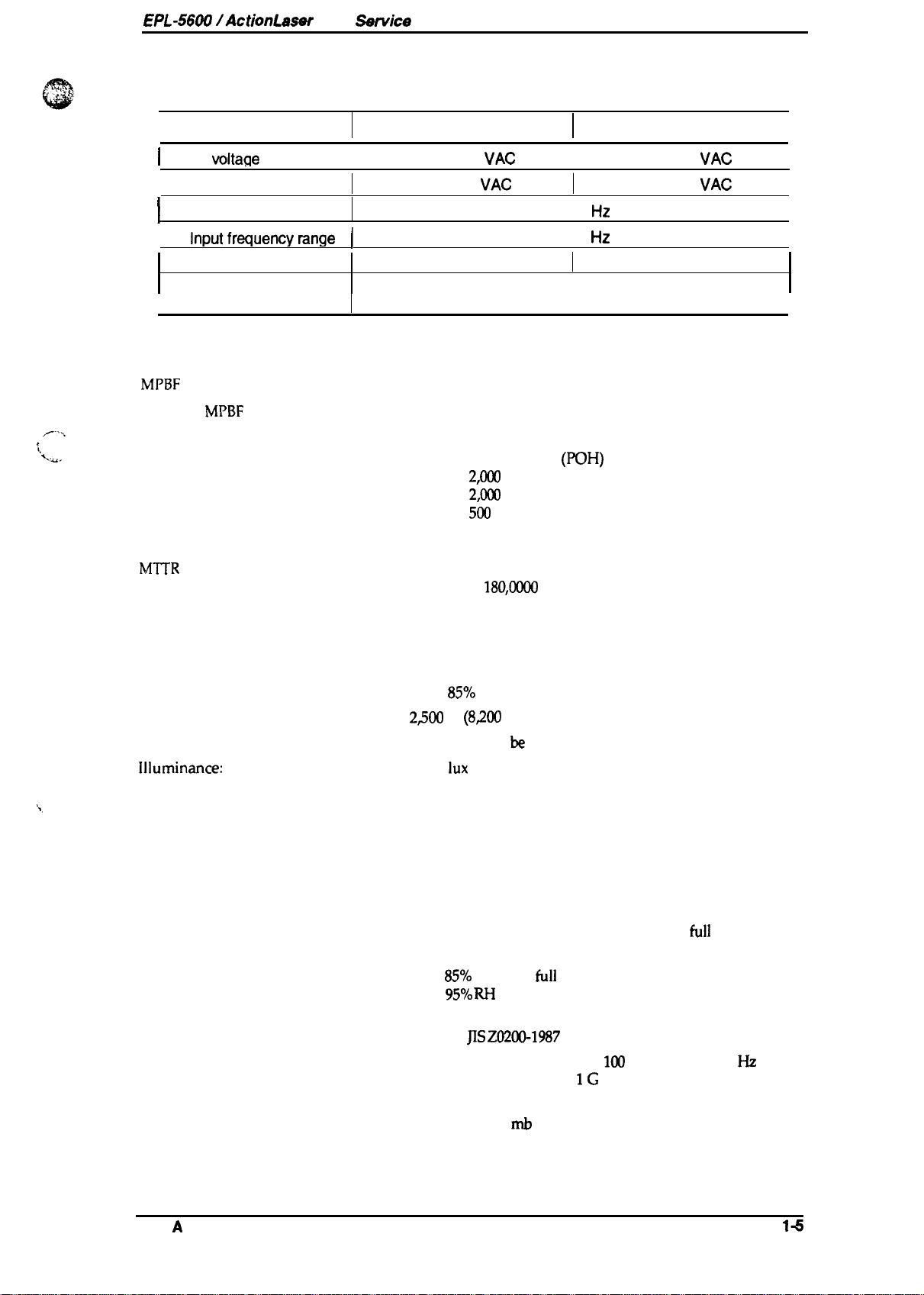

1.2.2 Electrical Specifications

Table 1-5. Electrical Specifications

General Description

,.-.,

i.

\,ti.

I

I

Rated

Input voltage range

Rated frequency range

I

Power consumption

Power consumption while Less than 30 W

in standby mode (without optional interface card and font cartridge)

Description 100 V Version

voltaae

lnPUtfWUen~YranW

I

(

100-120

90-132

Less than 500 W

VAC

VAC

I

50-60 tiz

47-63

200 V Version

220-240

198-264

tiz

Less than 600 W

VAC

VAC

1.2.3 Reliability Specifications

MPBF

(Mean Prints Between Failures): Over 25,000 sheets

MPBF

Note:

MTBF (Mean Time Between Failures): 3000 Power on hours

Jam rate:

Feed failure:

Multiple paper feeds:

Paper curl height:

Leading edge bending (1 cm or more): 1 out of 1,000 sheets

MTTR

(Mean Time To Repair):

Durability:

indicates average number of pages printed before occurrence of problem requiring

replacement or service.

(POH)

1 out of

1 out of

1 out of 5W sheets or less

30 mm (1.2 inches) or less

30 minutes or less

5 years or

2,0(XI

sheets or less (excluding multiple-sheet feeding)

2,tHXl

sheets or less (excluding multiple-sheet feeding)

180,01M(I

sheets

I

I

I

I

I

I

‘..

1.2.4 Environmental Conditions for Operating (Including Imaging Cartridge)

Temperature:

Humidity:

Altitude:

Levelness: Printer should be installed on a level plane.

Illuminance:

Surrounding space:

.

10 to 35° C (50 to 95° F)

15 to

85’340

RH

2500

m (8200 feet) or lower

3,000

Iux

or less (Must not be exposed to direct sunlight.)

Printer should have at least 100 mm of clearance on its

sides and rear.

1.2.5 Environmental Conditions for Storage and Transportation

(Excluding Imaging Cartridge)

Temperature:

Humidity:

Drop test:

Vibration:

Resistance to atmospheric pressure:

Storage term:

O to 35°

-20 to 55° C (-4 to 131°

(Extremes are allowable for up to 1/30 of

Temperature variation must be 10” C (18° F)/hour or less

30 to

10 to

(Extremes are allowable for up to 1/30 of full storage term)

Clear to

Vibration frequency 5 to

Acceleration

Acceleration direction 3 direction

More than 613

24

C (32 to 95° F) over full storage term

F) under extreme conditions

85Y0

RH over

%O/. RH

JIS Z0200-1987

months

(following date of manufacture)

full

storage term

under extreme conditions

Level 1

1(XI

Hz and 100 to 5

IG

mb

full

storage term)

Hz

Rev.

A

14

Page 18

General Description

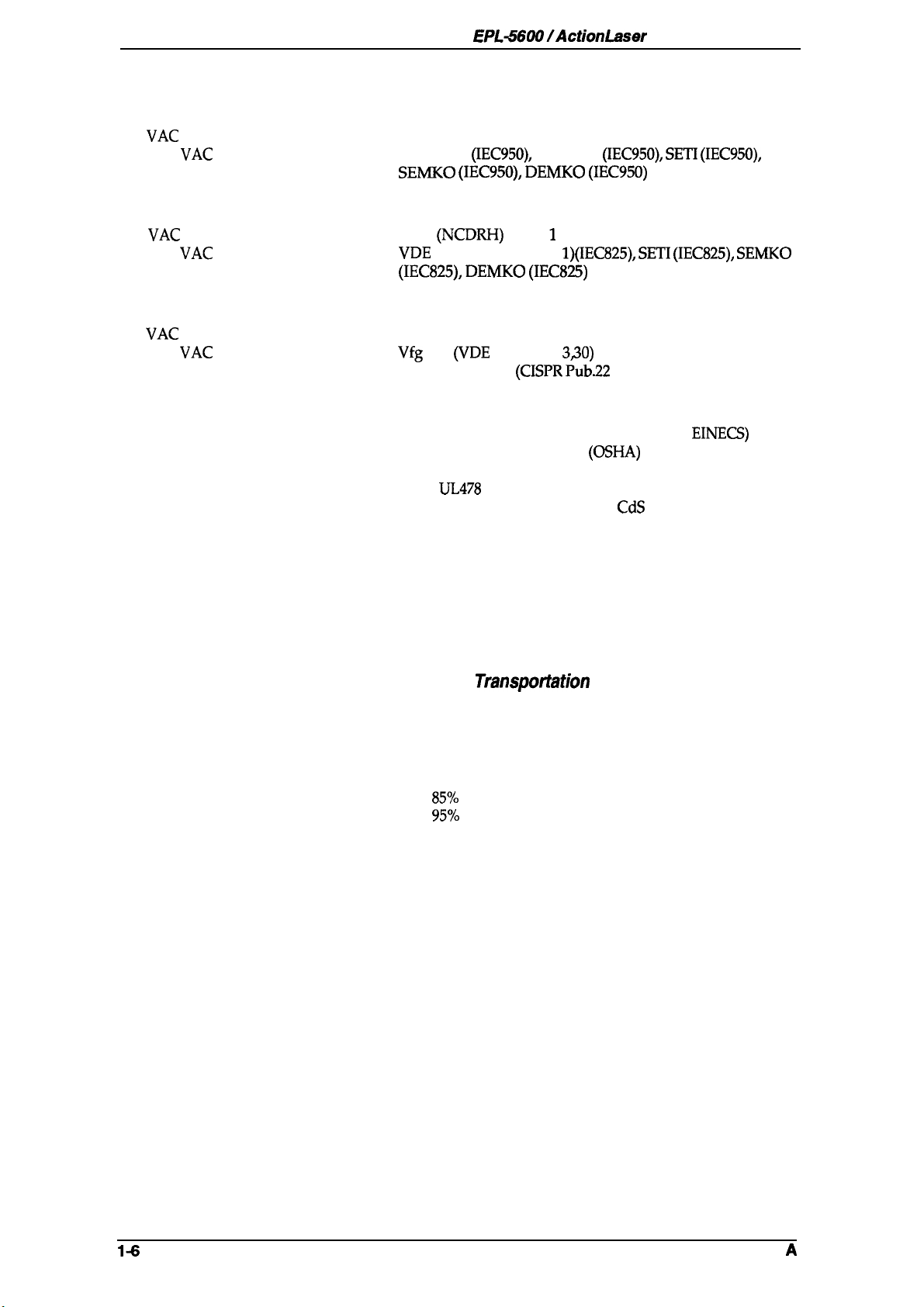

1.2.6 Applicable Standards

Safety Standards

EPL4i600/ActionLaser 1600 Service Manual

120

VAC

220/240

model:

VAC

model:

UL 1950, CSA 22.2 N0.950 Deviation 3

EN 60950

SEMKO (IEC950), DEMKO (IEC950)

(IEC950),

NEMKO

(IEC950), SETI (IEC950),

Safety Regulations (Laser radiation)

120

VAC

220/240

model:

VAC

model:

(NCDRH)

VDE

0837 (Laser Class

(IEC825), DEMKO (IEC825)

Class

1

1)(IEC825), SETI (IEC825), SEMKO

FDA

EMI

120

VAC

220/240

model:

VAC

model:

FCC Part 15 Subpart B Class B

Vfg

243

(VDE

0878 Part

EN55022 class B

(CISPR Pub.22

3s0)

class B)

Others

Toner:

OPC:

Ozone:

Materials:

No effect on human health (OSHA-TSCA,

No

effect on human health

Less than 0.01 mrnp

other

UL478

(5th edition)

SWISS Environmental Law (No

(OSHA)

CdS

1.2.7 Specification for Consumable (Imaging Cartridge)

EINECS)

must be contained)

Life:

Note:

In

continuous printing mode with A4/letter paper at a 5% image ratio (black/white

ratio). The life varies, depending on the printing mode (continuous or intermittent)

and/or the image ratio.

6,000 pages

Environmental Conditions for Storage and

Temperature:

Humidity:

Drop test:

Vibration:

Resistance to atmospheric pressure:

Storage term:

O

to 30° C

–20 to 40° C (-4 to 104” F) under extreme conditions

(Extremes are allowable for up to 1/30 of full storage term)

Temperature variations must be 10° C (18° F)/hour or less.

30 to

857.

RH over full storage term

10 to

95y0

RH under extreme conditions

(Extremes are allowable for up to 1/30 of full storage term)

Height 76 cm (30.4 inches)

Same as printer

More than 740 mb

18 months (following date of manufacture)

1.2.8 Physical Specifications

Dimensions (Width x Depth x Height):

Printer:

With lower

With face-up tray:

With lower cassette and face-up tray:

cassette:

368 x 456 x 226 mm (14.5 x 18.0x 8.9 inches)

368 x 480 x 336 mm (14.5 x 18.9x 13.2 inches)

368 x 632 x 360 mm (14.5 x 24.9 x 14.2 inches)

368 x 657 x 430 mm (14.5 x 25.9 x 16.9 inches)

Transpotiation

(32 to 86° F) over full storage term

Weight:

With lower cassette:

With face-up tray:

With lower cassette and face-up tray: Approx. 12.9 Kg (28.6 lb.)

1-6

Approx. 10 Kg (22 lb.) (consumable, excluding all options)

Approx. 12.8 Kg (28.3 lb.)

Approx. 10.1 Kg (22.3 lb.)

Rev.

A

Page 19

EPL4600

IActionLaser

16tM

Service Manual

1.2.9 Software Specifications

Built-in modes:

Note:

The EPSON

emulation. Table 1-6 shows the differences between EPSON

mode in the HP LaserJet 4 emulation. While in EPSON

enter

operator’s application software cannot send the

HP LaserJet 4 emulation

EPSON

FX (FX-670/1170,

ESC/P 2 (LQ-570/1070) mode

GL/2

GL/2

mode without sending the

GL/2

mode (LJ4-GL/2 mode and GL-like mode)

LX-1OO) emulation mode

mode is similar to the

(pCL@

ESC %#B

General ascription

Se)

GL/2

mode included in the HP LaserJet 4

GL/2

mode and the

GL/2

mode, the operator can

(Enter

ESC %#B cmnrnan

GL/2

mode) command. If the

d, then use this mode.

GL/2

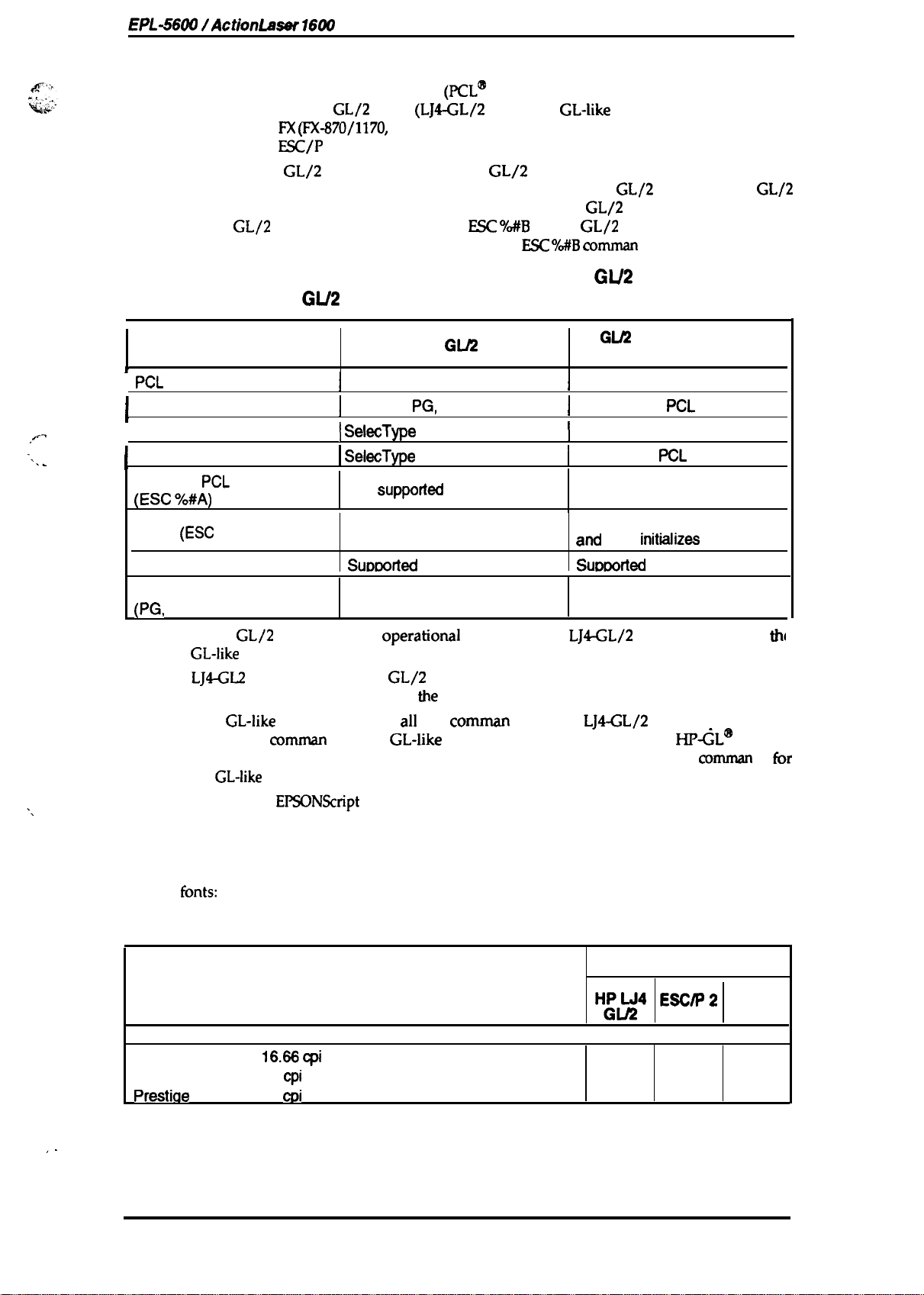

Table 1-6. Differences between EPSON

GL/2

in the HP LaserJet 4 Emulation

EPSON GU2 Mode

GU2

and

GIJ2

for HP LaserJet 4

Emulation Mode

t

I

PCL

mode

Paper eject

,,-

‘.

.

.

Auto eject

Reduced printing

Switch to

PCL

(ESC %#A)

Reset

(ESC

E)

PJL. EJL. and ES

Advance Full Page

(PG,

AF)

Notes:

EPSON

GL-like

LJ4-CX2

GL/2

mode has two

mode.

mode emulates the

Does not exist

I

Supports

,

I

SelecType

I SelecType

Not

PG,

setting

setting

Sllppdt?d

AF

commands

Ejects paper and then initializes

&JDDOdEd

supported

operatioml

GL/2

modes. One is

mode in the HP LaserJet 4 emulation. The user can

I

Exists as the initial made

I

Supported in

I

Not available

I

Available in

PCL

PCL

supported

Ejects paper, switches to PCL,

ad

then

init@[iz~

sUDDOlkd

Not supported

LJ4-GL/2

mode; the other is

th

print with software that supports me HP 7600 series plotter.

The

GL-like

additional

(HP 7475A, etc.) commands. If the application software uses unsupported

the

GL4ike

‘.

Optional modes:

mode features

comman

ds. The

all

the

GL-like

comman

mode emulates some of the HP~L@ plotter

mode, print cannot be assured.

EPSONScript

Level 2 (PostScript Level 2 emulation) mode

ds of the

LJ4-GL/2

mode, plus a few

ds

comman

fir

Auxiliary software: Hex dump

Status sheet

Font sample

Built-in

tints:

See Table 1-7

Table 1-7. Built-in Fonts

Applicable Mode

Resident Fonts

Bitmap

Line Printer

Prestige

Prestiae

S: Supported, NS: Not Supported

,.

Rev. A

fonts

16.66cpi

12

cpi

20

cmi

(Portrait)

(Portrait)

(Portrait)

H~P#

s

NS

NS

E~@

NS

s

s

2

FX

NS

s

s

1-7

Page 20

General

Descrit2tion

EPL-5600/ActitmLaser 1600 Service Manual

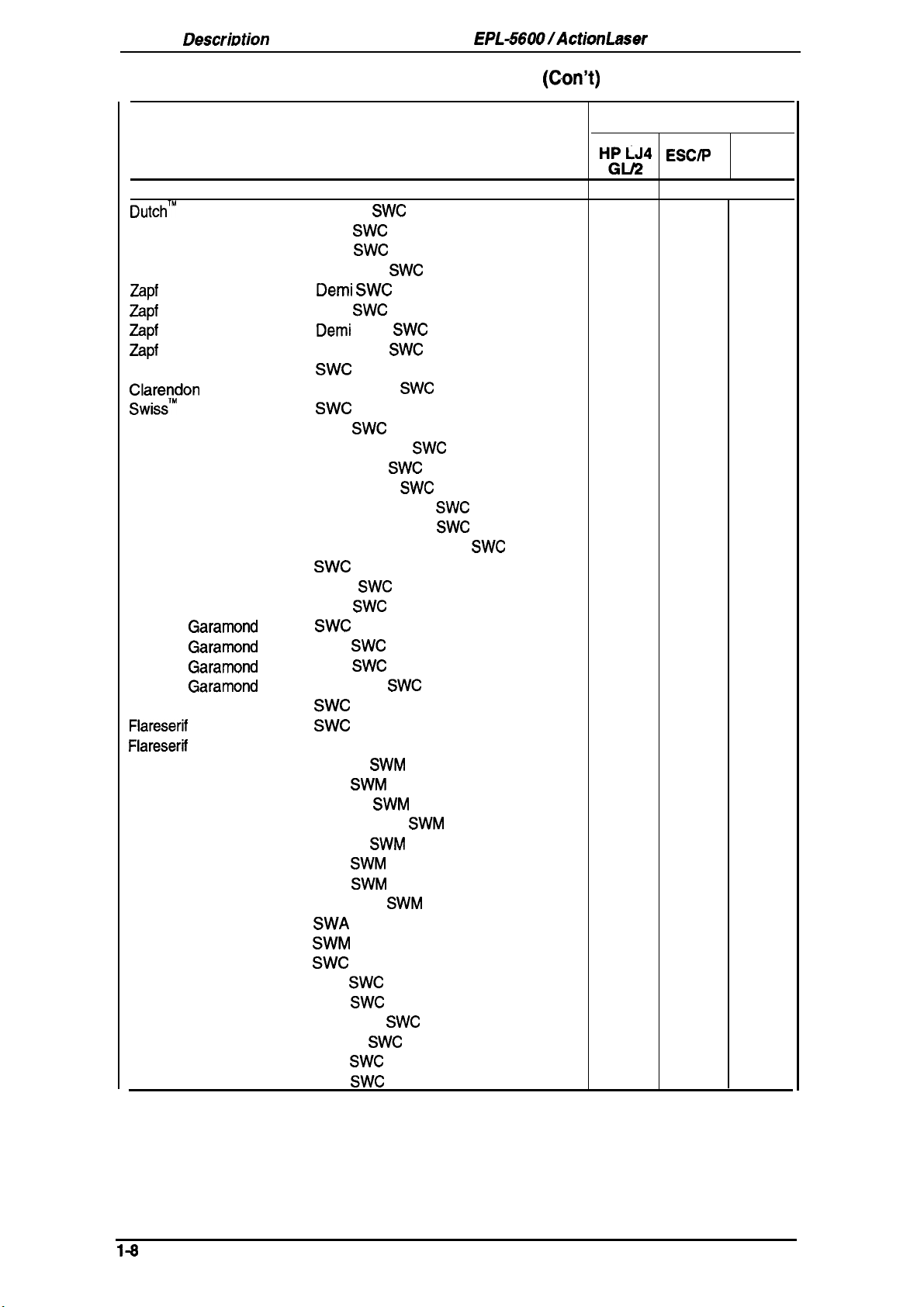

Table 1-7. Built-in Fonts

Resident Fonts

Scalable fonts

Dutch’”

801

Dutch 801

Dutch 801

Dutch 801

Zapf

Humanist 601

Zapf

Humanist 601

Zapf

Humanist 601

Zapf

Humanist 601

Ribbon 131

Clarendon

Swiss’”

742

Swiss 742

Swiss 742

Swiss 742

Swiss 742

Swiss 742

Swiss 742

Swiss 742

Incised 901

Incised 901

Incised 901

Original

Original

Original

Original

Garamond

Garamond

Garamond

Garamond

Audrey Two

Flareserif

Flareserif

821

821

Swiss 721

Swiss

721

Swiss 721

Swiss 721

Dutch 801

Dutch 801

Dutch 801

Dutch 801

Symbol Set

More WingBats

Courier

Courier

Courier

Courier

Letter Gothic

Letter Gothic

Letter Gothic

S: Supported, NS: Not Supported

Roman

Bold

SWC

Italic

SWC

Bold Italic

Demi SWC

Bold

SWC

Demi

Italic

Bold Italic

Swc

Condensed

Swc

Bold

SWC

Medium Italic

Bold Italic

Condensed

Bold Condensed

Condensed Italic

Bold Italic Condensed

Swc

Black

SWC

Italic

SWC

Swc

Bold

SWC

Italic

SWC

Bold Italic

Swc

Swc

Extra Bold

Roman

Bold

SWM

Oblique

Bold Oblique

Roman

Bold

SWM

Italic

SWM

Bold Italic

SWA

SWM

Swc

Bold

SWC

Italic

SWC

Bold Italic

Roman

Bold

SWC

Italic

SWC

SWC

SWC

SWC

SWC

SWC

SWC

SWM

SWM

SWM

SWM

SWC

SWC

SWC

SWC

SWC

SWM

SWC

SWC

SWC

(Con’t)

Applicable Mode

H~#4

s

s

s

s

s

s

s

s

s

s

s s

s“ s

s NS

s

s

EsC/p

2

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

NS

NS

NS

NS

NS

NS

NS NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS NS

NS

NS

NS

NS

NS

NS

NS

NS

s NS

s s

s

s

s

s

s s

s s s

s

s

s s

s s

s s

NS

NS

NS

NS

NS

NS

FX

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

s

NS

NS

s

s

s

1-8

Rev. A

Page 21

EPL-5600 /ActionLaser 1600 Service Manual

Font Symbol Sets

HP LaserJet 4 Mode (bitmap fonts): 15 symbol sets

General

Description

Roman-8

Roman Extension

ECM94-1

ANSI ASCII

French2

Legal

IBM@-US

PcMultilingual

HP LaserJet4 Mode (scalable fonts): 34 symbol sets

Ronam-8

Italian

Swedis2

UK

German

8859-2 1S0

PsMath

WiTurkish

VeMath

Math-8

PcTk437

PsText

IBM-DN

PcMultilingual

VeUS

PcE.Europe

WiAnsi

Norwegl

Italian

Swedis2

LJK

German

Spanish

IBM-DN

Norwegl

ECM941

ANSI ASCII

French2

Legal

Spanish

8859-9 IS0

MsPublishing

DeskTop

WiE.Europe

Windows

IBM-US

McText

VeInternational

PiFont

symbol

Wingdings

ESC./P 2 Mode: 15

USA

FRANCE

GERMANY

UK

DENMARK1

SWEDEN 1

ITALY

LEGAL

PcUSA(437)

PcPortuguese(860)

PcNordic(865)

PcE.Europe(852)

BpAbicomp

FX Mode: 13 International characters and 9 code tables

USA

FRANCE

GERMANY

UK

DENMARK1

SWEDENT

ITALY

International characters and 9

SPAIN1

JAPAN

NORWAY

DENMARK2

SPAIN2

L.AMERICA

KOREAR

PcMuItiIingual(850)

TPcCanFrench(863)

PcTurk2(857)

BpBRASCII

SPAIN1

JAPAN

NORWAY

DENMARK2

SPAIN2

L.AMERICA

code tables

PcUSA(437)

PcPortuguese(860)

PcNordic(865)

PcE.Europe(852)

BpAbicomp

Rev. A

PcMultilingual(850)

P&mFrench(863)

PcTurk2(857)

BpBRASCII

1-9

Page 22

General Description

EPL-5600 /ActionLaser 1600 Service Manual

1.3 INTERFACE SPECIFICATIONS

The EPL-5600 and ActionLaser 1600 are equipped with the following external interfaces:

■ Parallel interface

■

RS-232C/RS-422 interface

■

Optional LocalTalk interface

■

Optional Type B interface

1.3.1 Parallel Interface

The parallel interface has two modes as follows:

S

Compatibility mode (same as parallel interface of EPSON’s current page printer)

■ Reverse mode

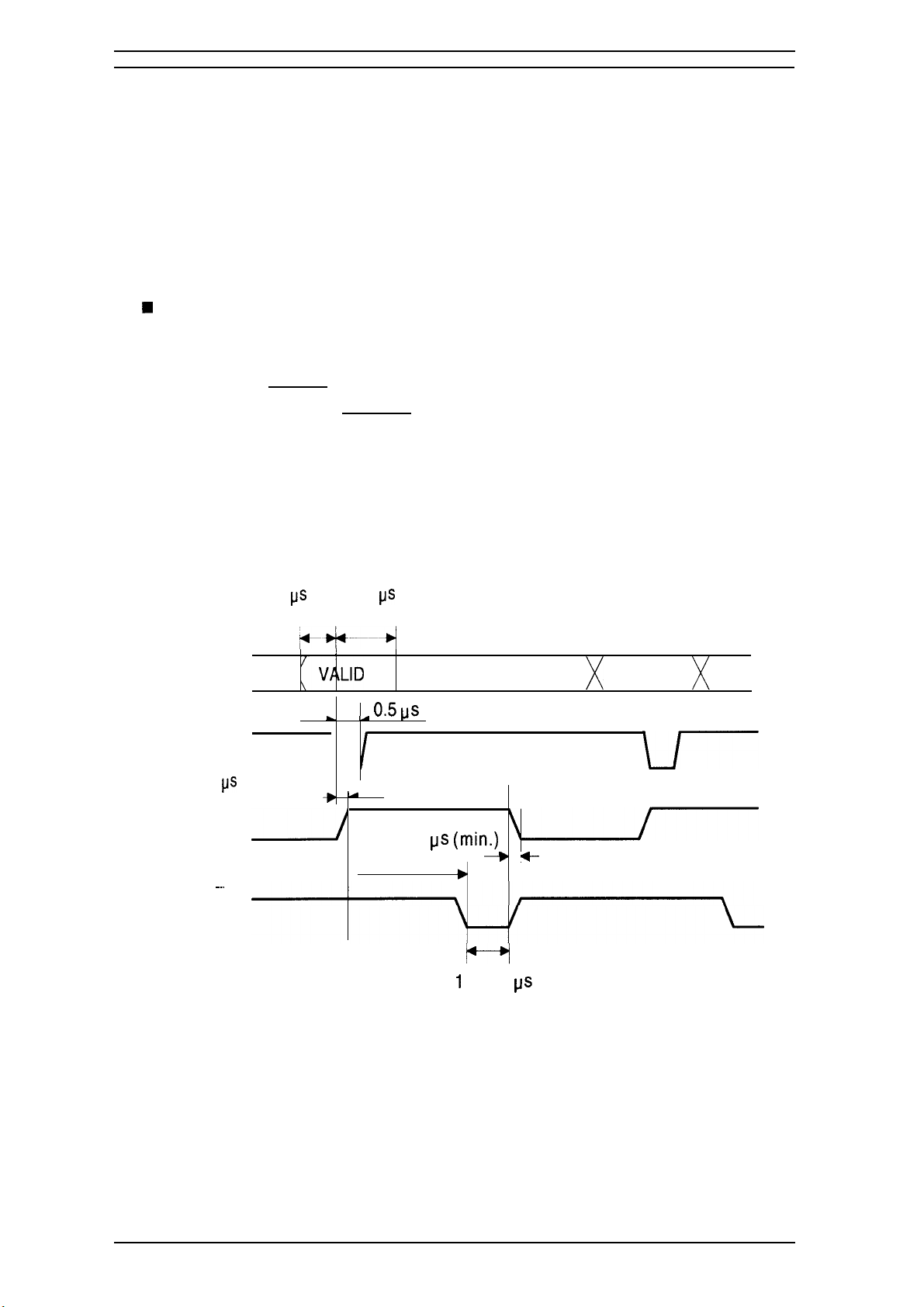

1.3.1.1 Compatibility Mode of Parallel Interface

System:

Handshaking:

Connector type:

Applicable plug:

Transfer speed:

Signal timing:

Signal description:

DATA 1-8

STROBE

0.5

ps

BUSY

-..

ACKNLG

STROBE synchronization, 8-bit parallel data transfer

BUSY and ACKNLG signals

P90-25027-1 (Amphenol) receptacle

57-30360 (Amphenol or equivalent)

Approximately 400,000 bytes/second (max.)

See Figure 1-3.

See Table 1-8.

0.5

0.5

ps

ps

(minimum) (minimum)

~+—–+

I

,

L

\-

(maximum)

+

\

/

~ 0.5 US

/

k

0.5 or 5

(minimum)

(minimum)

0s

l.lS

(min.)

4

+-

VALID

1-1o

1

or 10

(typical)

ps

Figure 1-3. Compatibility Mode Signal Timing

,

Rev. A

Page 23

EPL-561W/ActionLaser 16tW

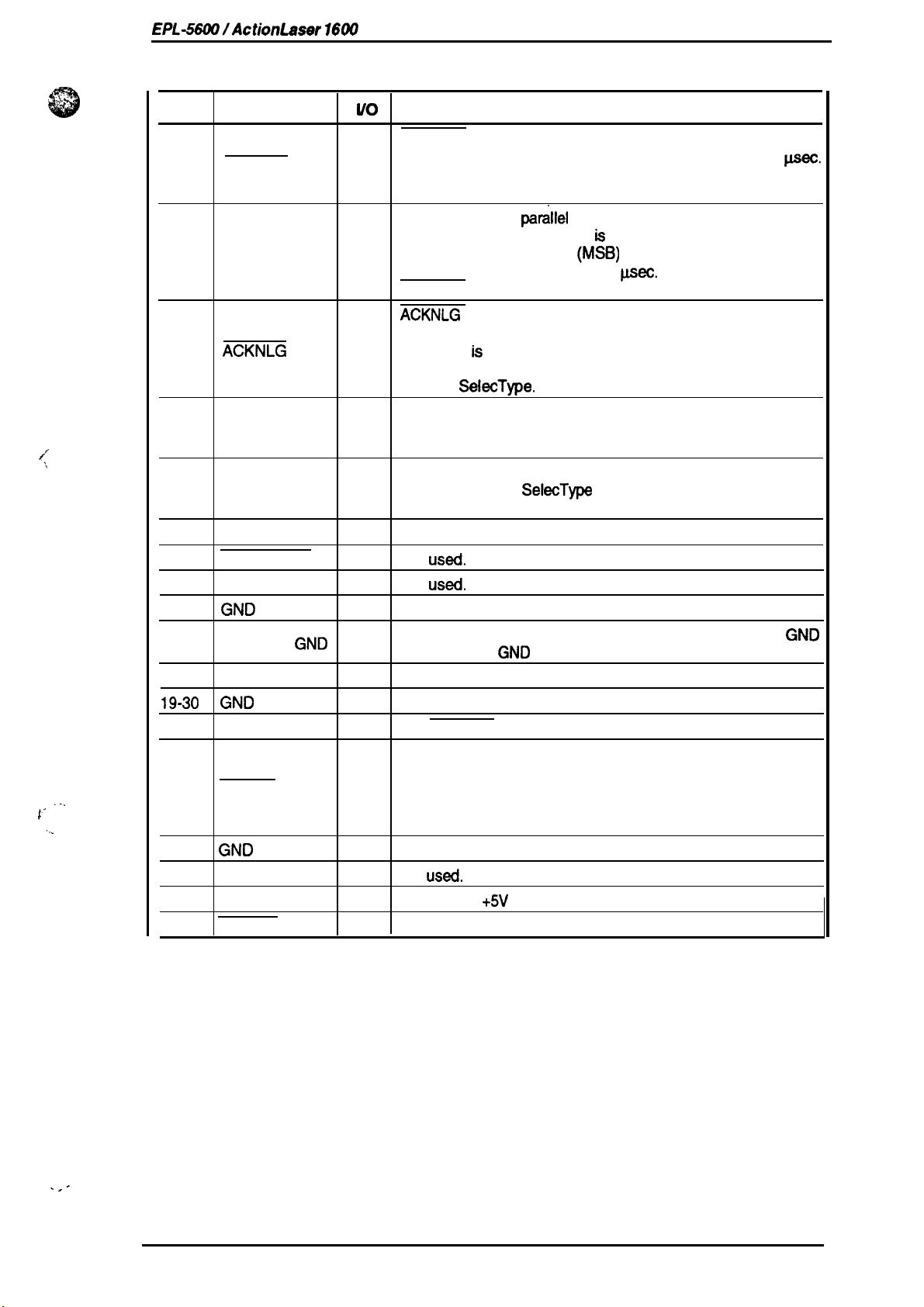

Table 1-8. Parallel Interface Pin Assignment

Service Manual

General Description

< ‘-’

(’

““

,..

Pin No.

1

2-9

10

11

12

13

14

15

16

17

18

19-30

31

32

33

34

35

36

Signal Name Vo

STROBE

DATA 1-8

IN

IN

ACKNLG OUT

BUSY OUT

PE

OUT

SLCT OUT

AUTO-FEED

NC

IN

.

GND

CHASSIS

NC

GND

.

GND

INIT

ERROR

GND

NC

5

+

s

LCT IN

IN

OUT

.

.

.

Description

STROBE

computer. The pulse width must be more than 0.5

is a strobe pulse used to read data from the host

psec.

Normally it is HIGH, and data is latched at the trailing edge of

this signal.

DATA 1 to 8 are

pa~llel data bits. When the signal is HIGH,

the data bit is 1, and when it is LOW, the data bit is O.

The most significant bit

must be maintained for 0.5

(MSB)

is DATA8. The signal state

psec.

on either side of the

STROBE signal active edge.

ACKNLG

is an acknowledge pulse with an approximate width

of 1 or 10 wee. This signal goes LOW when the data

reception

is

completed, which indicates that the printer can

accept new data. Timing with the BUSY signal is specified

through

SelecType.

The BUSY signal informs the host computer of the printer

state. When the signal is HIGH, the printer cannot accept

data.

The PE signal indicates paper empty for the standard tray

selected through

SelecType

or command, or for the optional

paper cassette. Paper empty is indicated by HIGH.

Use at reverse mode.

Not

USd.

Not

USed.

Logic ground level.

Connected to the printer chassis. The printer chassis

and the signal

GND

are connected to each other.

GND

Not connected.

Ground level for the twisted pair return signal.

The STROBE signal is ignored when this signal is LOW.

This level goes LOW when the printer is:

●

out of paper

. paper jam

. in error state

. off line

Same as for pins 19 to 30.

Not

USEd

Pulled up to

+5V

through 1.0 Kohm resistance.

Use the reverse mode.

. . ,

Rev. A

1-11

Page 24

General Description

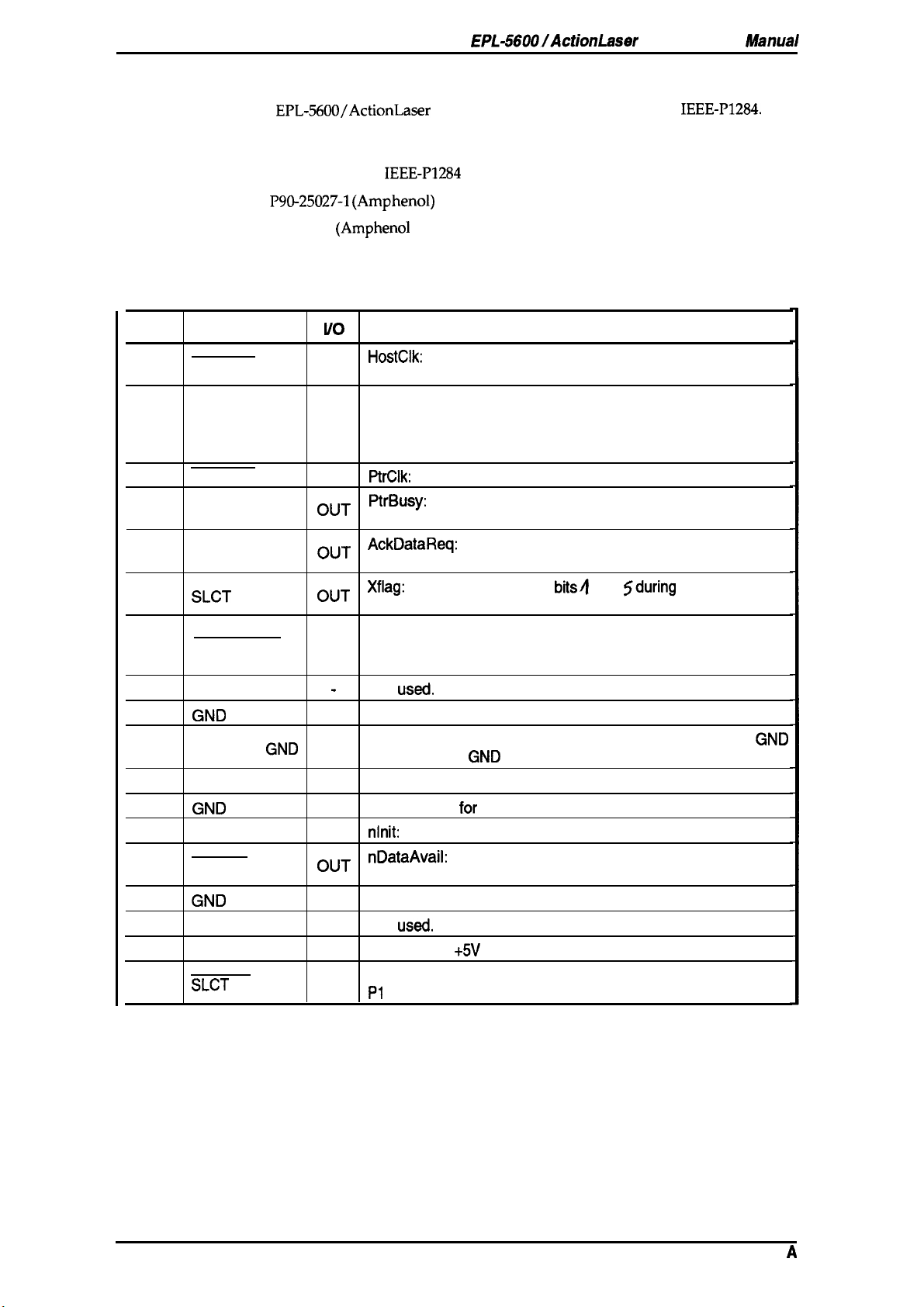

1.3.1.2 Reverse Mode

EPL-5600/ActionLaser

1600 Service

Manual

The reverse mode for

EPL-5600/ActionLaser

1600 supports the nibble mode of

IEEE-P1284.

This

printer can run in reverse mode, in which the printer can inform the computer of its status by EJL

and PJL commands.

System:

Connector type:

Applicable plug:

Signal description:

Nibble mode of

P90-25027-1 (Amphenol)

57-30360

(Amphenol

See Table 1-9.

IEEE-P1284

receptacle

or equivalent)

Table 1-9. Parallel Interface Pin Assignment

Pin No.

1

2-9

10

11

12

13

14

15

16

17

18

19-30

31

32

33

.34

35

36

Signal Name

STROBE

DATA 1-8

ACKNLG

BUSY

PE

SLCT

AUTO-FEED

NC

GND

CHASSIS

GND

NC

GND

INIT

ERROR

GND

NC

+5

SLCT

IN

I/o

HostClk:

IN

request values from the host computer during negotiation.

This signal is a strobe pulse used to read extension

The signals are data bits of extension request values during

negotiation. This printer supports following values:

IN

0000 0100: Request Device ID (by nibble mode sending)

0000 0000: Request nibble mode

OUT

OUT PtrBusy:

PtrClk:

Printer data sending clock.

Printer sending data bits 3 and 7 during data

transfer to host computer.

OUT

AckDataReq:

transfer to host computer.

OUT

Xflag:

Printer sending data bits~ and

host computer.

HostBusy: This signal informs the printer of the host computer

state. When the signal is HIGH, the host computer cannot

IN

accept data.

-

Not

US6?d.

.

Logic ground level.

Connected to the printer chassis. The printer chassis

-

and the signal

Not connected.

Ground level

nlnit:

IN

High level fixed

OUT nDataAvail:

transfer to host computer.

Same as for pins19 to 30.

.

Not

U%?d.

Pulled up to

1284Active: If this signal is set to HIGH, this printer active

IN

P1

284 (reverse mode).

Printer sending data bits 2 and 6 during data

GND

for

the twisted pair return signal.

Printer sending data bits O and 4 during data

+5V

through 1.0 Kohm resistance.

Description

Sduring

data transfer to

are connected to each other.

GND

1-12

Rev.

A

Page 25

EPL-5600 /ActionLaaer

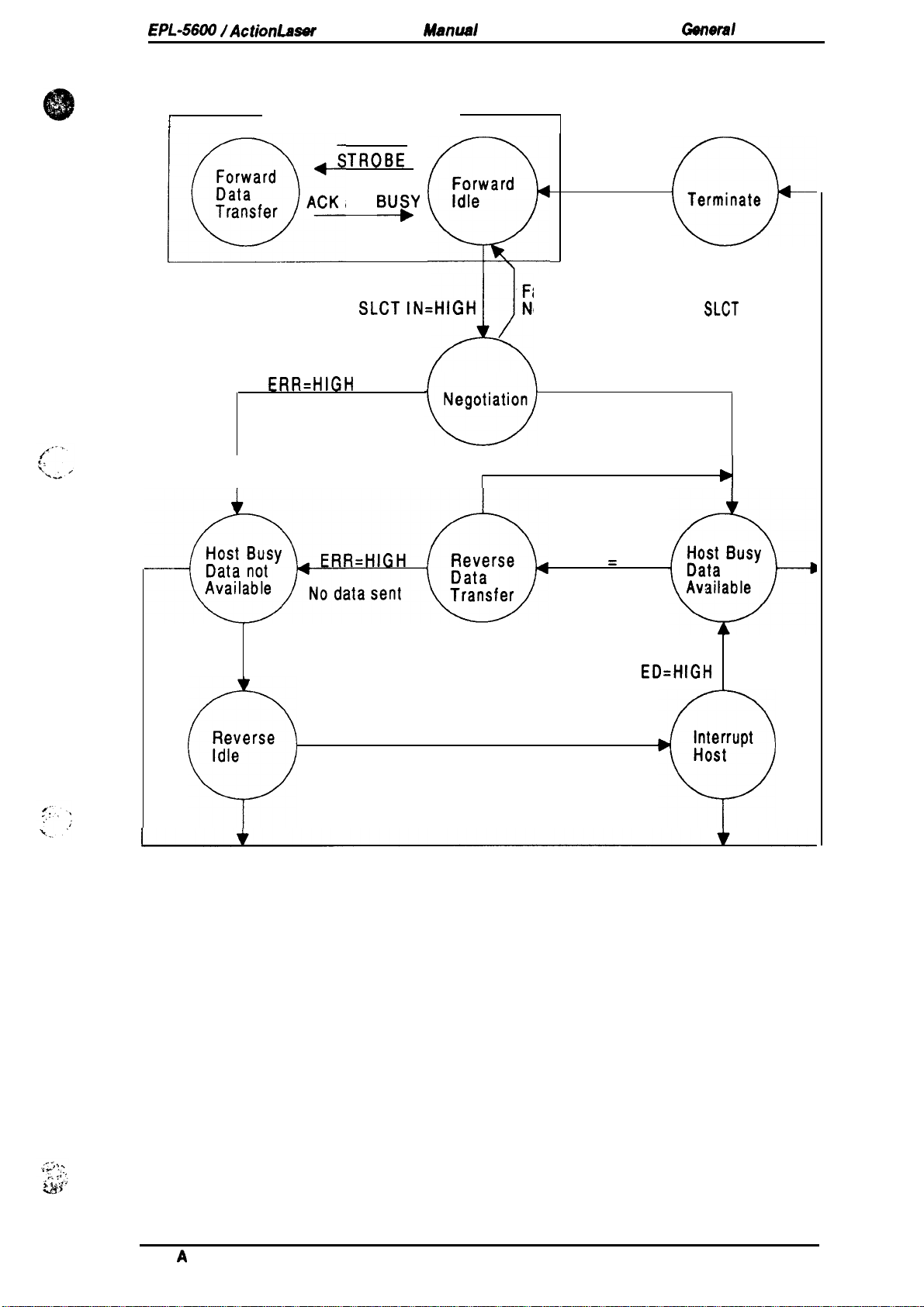

Figure 1-4 shows the parallel interface state switch diagram.

1600 Service

Manuai

Generai

Description

1

Forward

Data

Transfer

1O”s

Compatibility Mode

TROBE

Forward

ACK and

SLCT

BU~Y

Idle

Q

IN=HIGH

Failed

Negotiation

A

ERR=HIGH

No data sent Sending data

I

ERR= LOW

R= LOW

ER

Sending data

AUTO

=

FEED LOW

Terminate

o-

SLCT

IN= LOW

Request to

send data

AUTO

FE ED= LOW

FRR=LOW

Figure 1-4. Parallel Interface State Switch Diagram

AUTO

FE

ED=HIGH

Rev.

A

1-13

Page 26

General Description

EPL-5600/ActionLaser

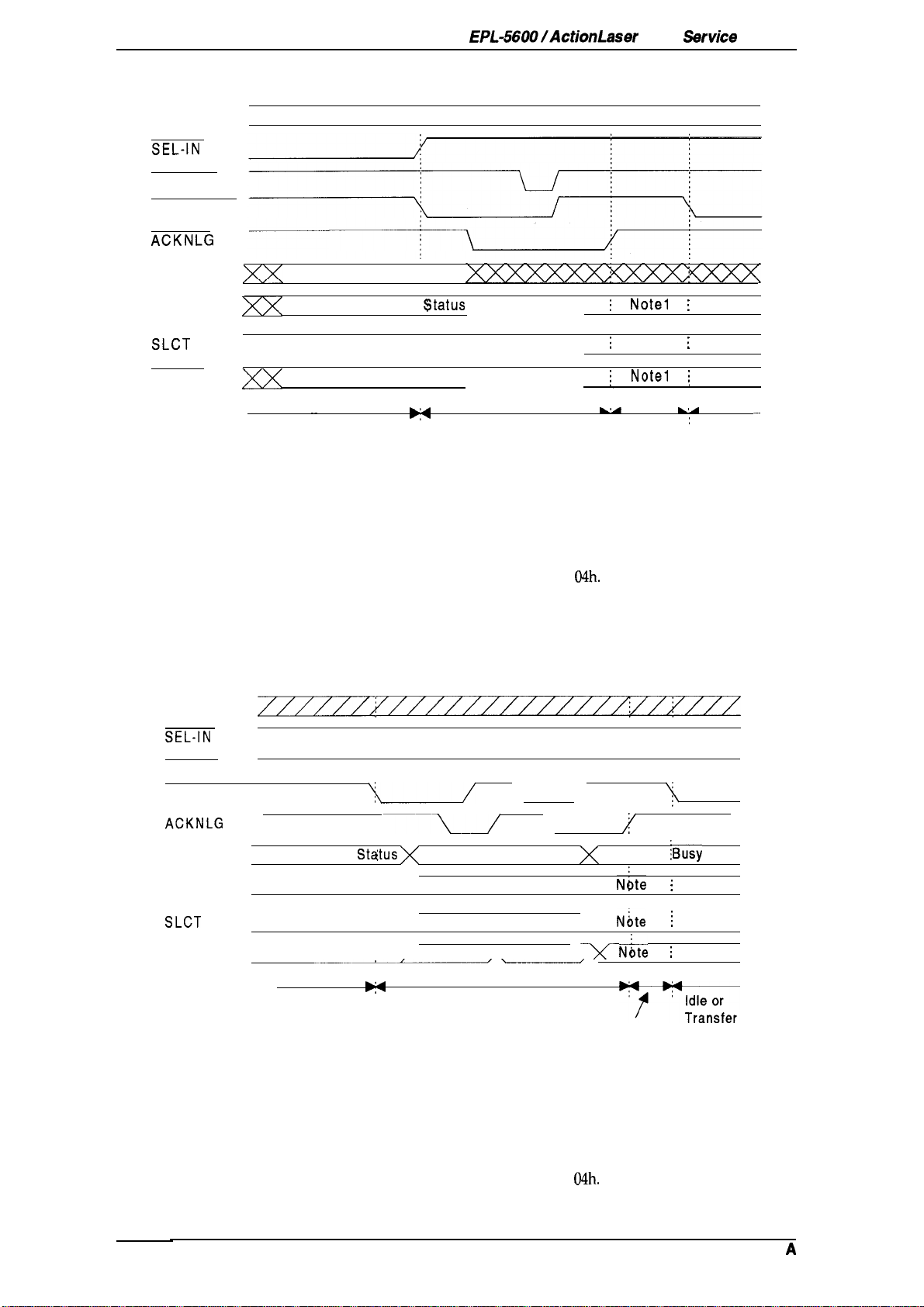

Figure 1-5 shows the timing chart of negotiation.

1600

Sarvice

Manual

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

BUSY

PE

SLCT

ERROR

Note 1:

Note

2:

Note

3:

OOh or 04 h

Peripheral Busy Status

~

Current Peripheral $tatus /

—.

\

\

~

Current Peripheral Status /

—

A,A

Compatibility

Negotiation

\

Figure 1-5. Timing Chart of Negotiation

The signal is set to HIGH when not sending data.

The signal is set to LOW when sending data.

The signal is set to HIGH, if extension request value was

HB DA: Host Busy Data Available

HB DNA: Host Busy Data Not Available

04h.

x-,

; Notel ;

I

Note 2

;

Notel 1

u

:

HB DA or : Idle or

DNA Transfer

HB

(Note 3)

i

h,A

—

Figure 1-6 shows the timing chart of data transfer.

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

BUSY

PE

SLCT

ERROR

Peripheral Busy

——————

HB DA

‘“L-J

Status X

M

Bit 3 Bit 7

Bit 2 Bit 6

Bit 1

Bit O

/

Figure 1-6. Timing Chart of Data Transfer

\ /

Bit 5

Bit 4

—

Negotiation

\

2

X

Peripheral

Njte

Note

Y Note

HB DA or

HB DNA

(Note 3)

1

2

1

$

~Busy

;

!

;

—

Status

Note 1:

Note

2:

Note

3:

1-14

The signal is set to HIGH when not sending data.

The signal is set to LOW when sending data.

The signal is set to HIGH, if extension request value was

04h.

HB DA: Host Busy Data Available

HB DNA: Host Busy Data Not Available

Rev.

A

Page 27

EPL-5600

/ActionLaaar 1600 Service Manual

Figure 1-7 shows the timing chart of termination.

DATA

SEL-IN

STROBE

Ganaralihactipthn

,/

,., -,

. . . . . .

AUTO-FEED

ACKN

LG

BUSY

PE

SLCT

ERROR

1

Note 1:

The signal is HIGH when

Note 3

~—~

Peripheral Busy St~lus / \ Peripheral Busy Status

.

Note 1

;

;

Current Peripheral Status

Note 2

Note 1

HB DNA, Idle,

I

/

H

:

Termination

\

I

Current Peripheral Status

b-

Compatibility

or HB DA

Figure 1-7.

Timing

FIB

DNA.

Chart of Termination

The signal is LOW when HB DA.

Note

Note 3:

The signal is set to HIGH, if extension request value was

2:

Idle = LOW

04h.

Figure 1-8 shows the timing chart of interrupt.

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

BUSY

—

.—

~

Peripheral Busy Status

PE

SLCT

ERROR

Note 1

Reverse Idle

;

\

;

Interrupt

!

HB DA

‘

Transfer

Note 1:

Rev.

A

Figure 1-8. Timing Chart of Interrupt

The signal is set to HIGH, if extension request value was

04h.

1-15

Page 28

General Description

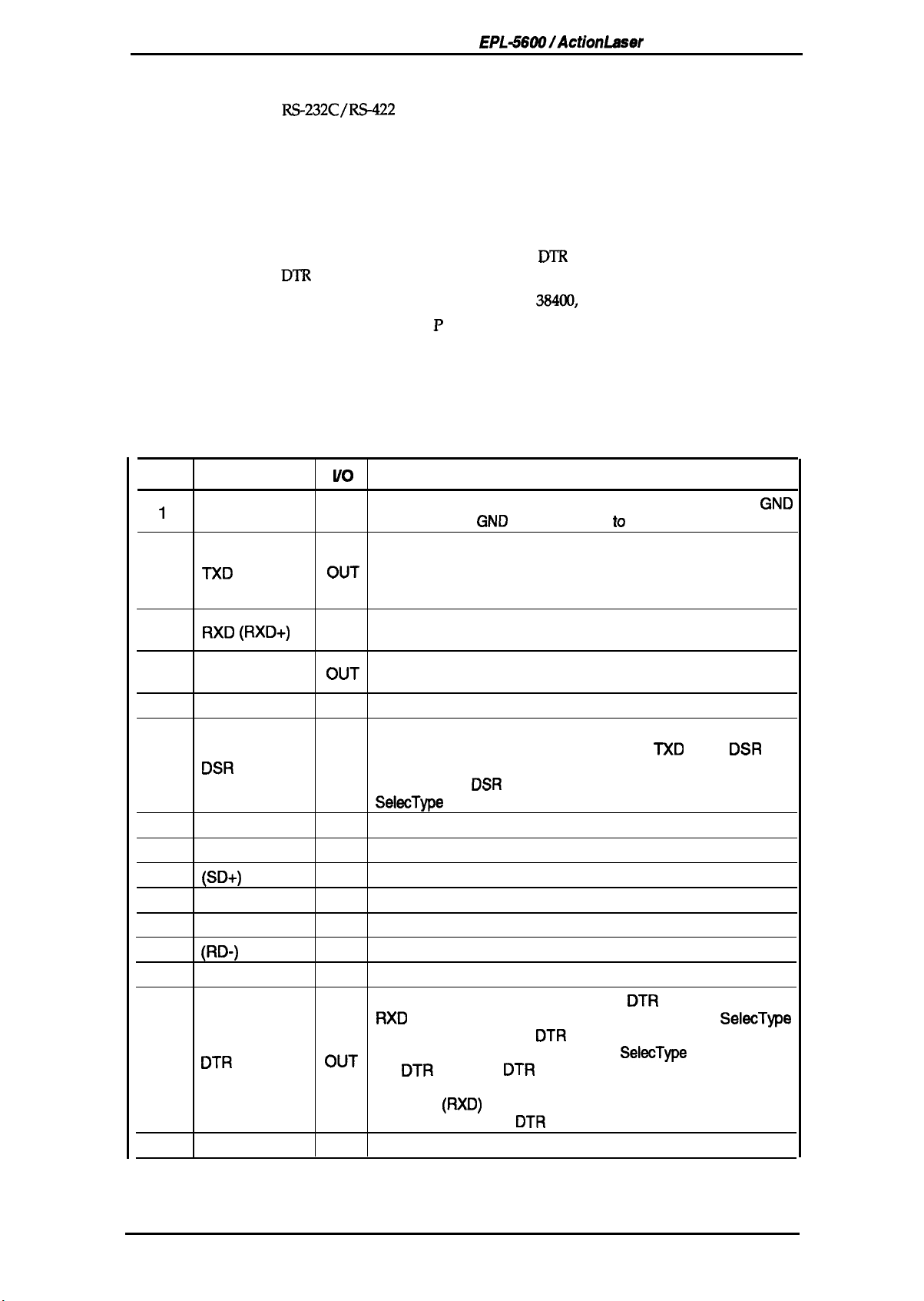

1.3.2 Serial Interface

Type: RS-232C/R%122

Transfer system:

Synchronization:

Protocol:

Transfer speed:

Error:

Signal description: See Table 1-10.

Full duplex

Asynchronous start-stop system

Start-bit:

Stop-bit:

Data length:

Parity:

X-ON/X-OFF (can be combined with

DTR

control (can be combined with X-ON/X-OFF)

300,600,1200,2400,4800, 9600,19200,

Overrun error:

Parity error:

Framing error:

Breaking character: Ignored

Table 1-10. Serial Interface Pin Assignments

EPL-6600/ActionLaser 1600 Service Manual

1 bit

1 or

2

bits

7 bits or 8 bits

Odd, even, or none

DTR

control)

384KI,

or 57600 bps

P

recessed as missing data and replaced by “*”

Replaced by “*”

Replaced by “*”

Pin No.

1

2

3

4 RTS

5

6

7

8

9

10

I 1 to 17

18

19

20 DTR

21-25

Signal Name

CHASSIS-GND

TXD

RXD (RXD+)

CTS

DSR

SIGNAL-GND

DCD

(SD+)

(SD-)

NC

(RD-)

NC

NC

Vo

-

~“T

IN

OUT

IN

IN

-

IN

OUT

OUT

IN

OUT

Description

Connected to the printer chassis. The printer chassis

and the signal

Serial ASCII data output by the printer. It maintains

state

(LOW level) between transmitted character codes.

Logic O is at HIGH level (“SPACE”) and logic 1 is at LOW

level (“MARK’).

Serial ASCII data input to the printer. It maintains “MARK”

state (LOW level) between received character codes.

Transmission request signal output from the printer. It is

always at HIGH level during power ON.

Always ignored.

Signal input to the printer.

The printer can transmit data through

HIGH level. X-ON/X-OFF, however, can be transmitted

regardless of

SelecType

Ground.

Always ignored.

See note 4.

See note 4.

No connect.

See note 4.

No connect.

Signal output by printer. When the

RXD

signal can be received by the printer. The

settings do not specify

while the printer power is on. When

for

DTR

conditions.

The data

128 characters after

No connect.

GND

are connected to each other.

DSR

state. It can always be ignored by setting

(factory setting).

DTR

control,

(RXD)

DTR

goes LOW in case of any error

from host computer must be stopped within

DTR

TXD

while

DTR

signals HIGH, the

control, the signal level is HIGH

SelecType

goes LOW.

setting is used

GND

“MARK”

DSR is at

SelecType

1-16

Rev. A

Page 29

EPL-S600

/ActionLasef 1600

Sewice

Manual

General

Lhwetiption

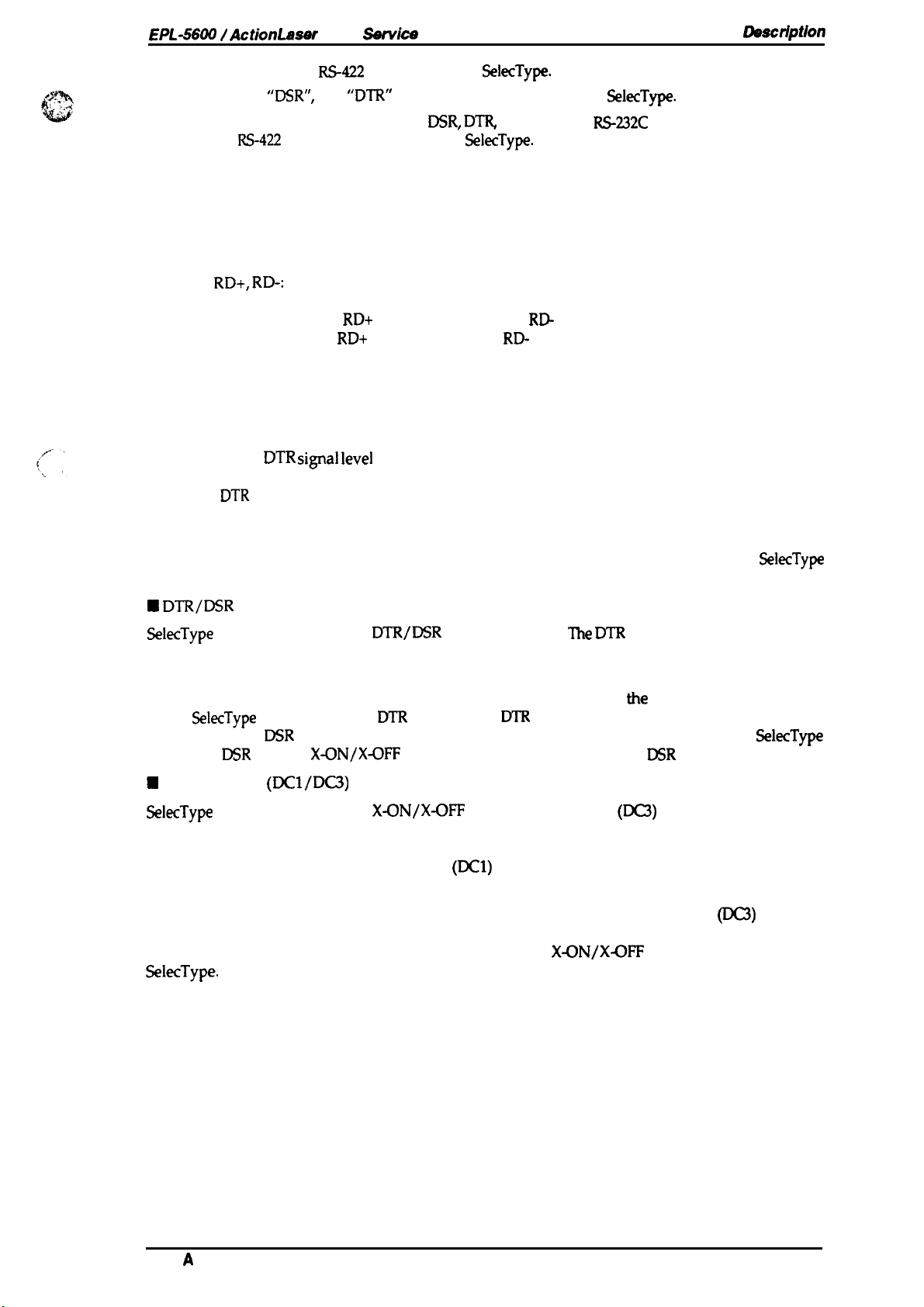

Note 1: ( )

Note

Note

Note 4: SD+, SD-:

indicates an

“CT’S’,

2:

3:

Although the signals RTS, Cl%,

for

Serial ASCII

HIGH level; when SD+ voltage is higher than SD-voltage.

LOW level; when SD+ voltage is less than SD- voltage.

Logic O is “SPACE” and logic 1 is “MARK” state must be maintained between

transmitted character codes.

RD+, RD-:

Serial ASCII data input from the computer.

HIGH level; when

LOW level; when

Logic O is “SPACE” and logic 1 is “MARK” state must be maintained between

transmitted character codes.

“DSR”,

RS-422

R%122

signal, which is

and

“DTR”

states can be selected through

DSR, Dl%

mode if selected through

data output from the printer.

RD+

voltage is higher than

RD+

voltage is less than

SPlecType.

SelecType.

and DCDare

RD-

voltage.

RD-

voltage.

SelecType.

RS-232C

level, they can be used

Handshaking

When the vacant area for data in the input buffer drops to 256 bytes, the printer outputs an X-OFF

code or sets the

Once the vacant area for data in the buffer recovers to 512 bytes, the printer outputs an X-ON code

or sets the

DTR signal level

DTR

flag to HIGH, indicating that the printer is again ready to receive data.

to LOW, indicating that the printer cannot receive more data.

Protocol

There are two types of protocols, as listed below, and each of them can be designated by

independently.

9 DTR/DSR

SelecType

the printer is ready to receive data, and to LOW when conditions indicate an error or that the

receiving buffer is full.

When the error is cleared and the printer returns to on-line mode,

When

TXD only when

setting for

9

X-ON/X-OFF

SelecType

indicates an error, and the printer warns the host to stop data transmission within 128 characters.

No further X-OFF codes are sent in response to additional data received from the host after the

X-OFF code has been sent once. The X-ON

error are cleared.

When the remaining capacity of the receive buffer reaches 256 characters, X-OFF

once. It is sent only once, even if there are multiple errors. The printer goes on line automatically at

power on, and outputs an X-ON code. Transmission of X~N/X-OFF codes can be defined by

SelecType.

protocol

is used to execute the

SelecType

is used to set the

DSR

is at the HIGH level (DSR is always considered HIGH when the

DSR

is OFF). X-ON/X~FF transmission is independent of the

(DC1/DC3)

is used to execute the

DTR/DSR

DTR

control OFF,

protocol

X-ON/X-Ow

control protocol.

DTR

is always set HIGH. The printer transmits

protocol. The X-OFF

(DCl)

code is output after all conditions given in the

l%e DTR

signal is set to HIGH when

the

signal returns to HIGH.

DSR

state.

(DC3)

code is output if status

(DC3)

SelecType

SelecType

is output

Rev.

A

1-17

Page 30

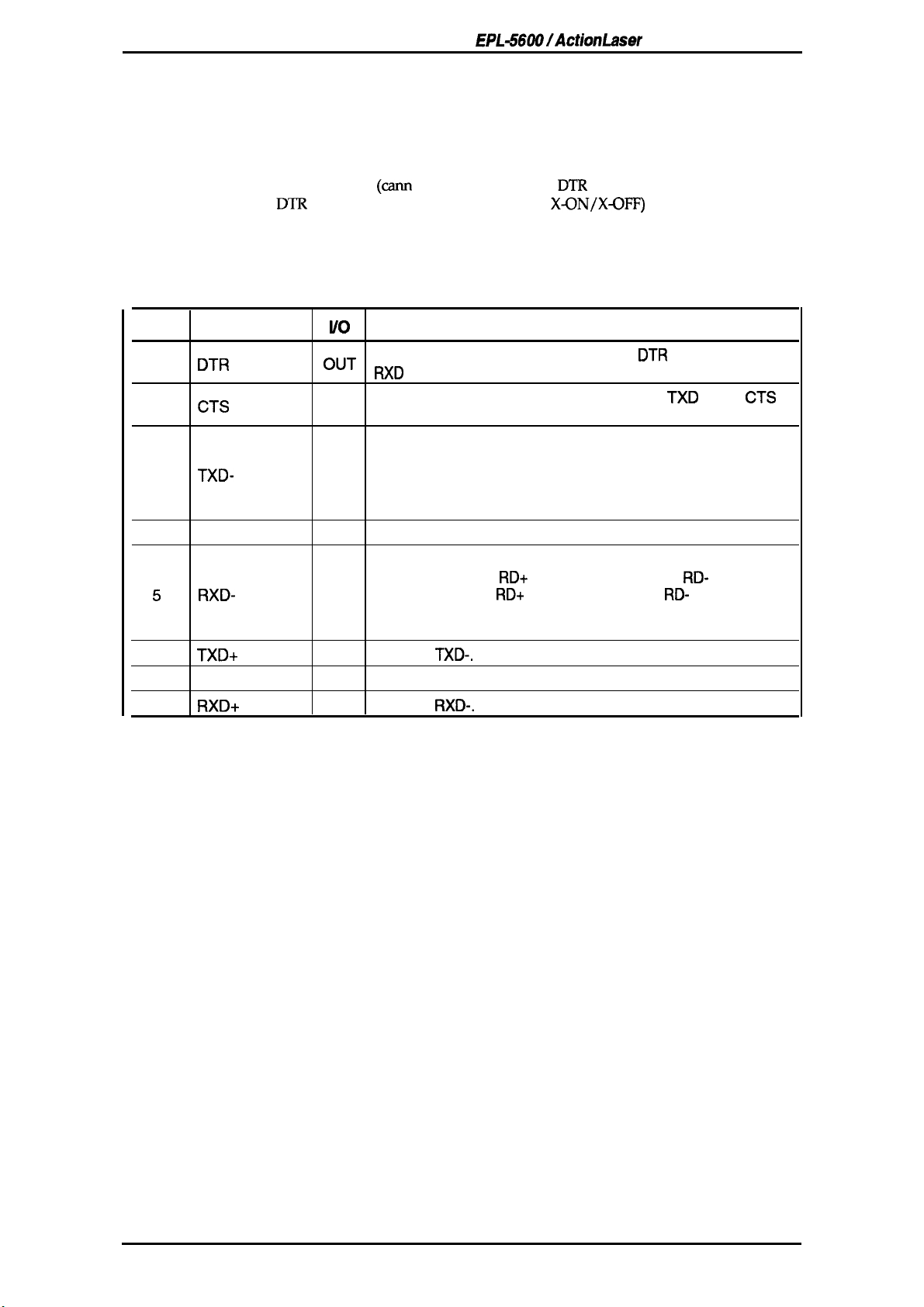

General Description

EPL4600/ActionLaser

1.3.3 Optional LocalTalk Interface

This printer can use the optional LocalTalk interface module.

1600 Service Manual

Type:

Signal level:

Protocol:

Transfer speed:

Signal description:

Table 1-11. LocalTalk Interface Pin Assignments

Pin No.

1

2

3

4

5

6

7

8

Signal Name

DTR

CTS

TXD-

GND

RXD-

TXD+

NC

RXD+

LocalTalk

Same as 179422 signal level

X-ON/X-OFF

DTR

control (cannot be combined with X~N/X43FF)

230.4 K bps

See Table 1-11.

I/o

~uT

OUT

OUT

(cann

ot be combined with

Signal output by the printer. When the

RXD

signal can be received by the printer.

The printer transmits the data through

IN

HIGH.

Serial ASCII data output from the printer.

HIGH level; when SD+ voltage is higher than SD- voltage.

LOW

level; when SD+ voltage is less than SD- voltage.

Logic O is “SPACE” and logic 1 is “MARK” state must be

maintained between transmitted character codes.

Ground.

Serial ASCII data input from computer.

HIGH level; when

IN

LOW

level; when

Logic O is “SPACE” and logic 1 is “MARK” state must be

maintained between transmitted character codes.

IN

Refer to

No connect.

Refer to

TXD-.

RXD-.

RD+

RD+

DTR

Description

voltage is higher than

voltage is less than

control)

DTR

signals HIGH, the

TXD

while

RD-

voltage.

RD-

voltage.

CTS

is

1-18

Rev. A

Page 31

,f%??>

,f.w:.:

~.y

EPL-5600

/ActionLaser

16tW Servkw

Manual

1.4 OPERATING INSTRUCTIONS

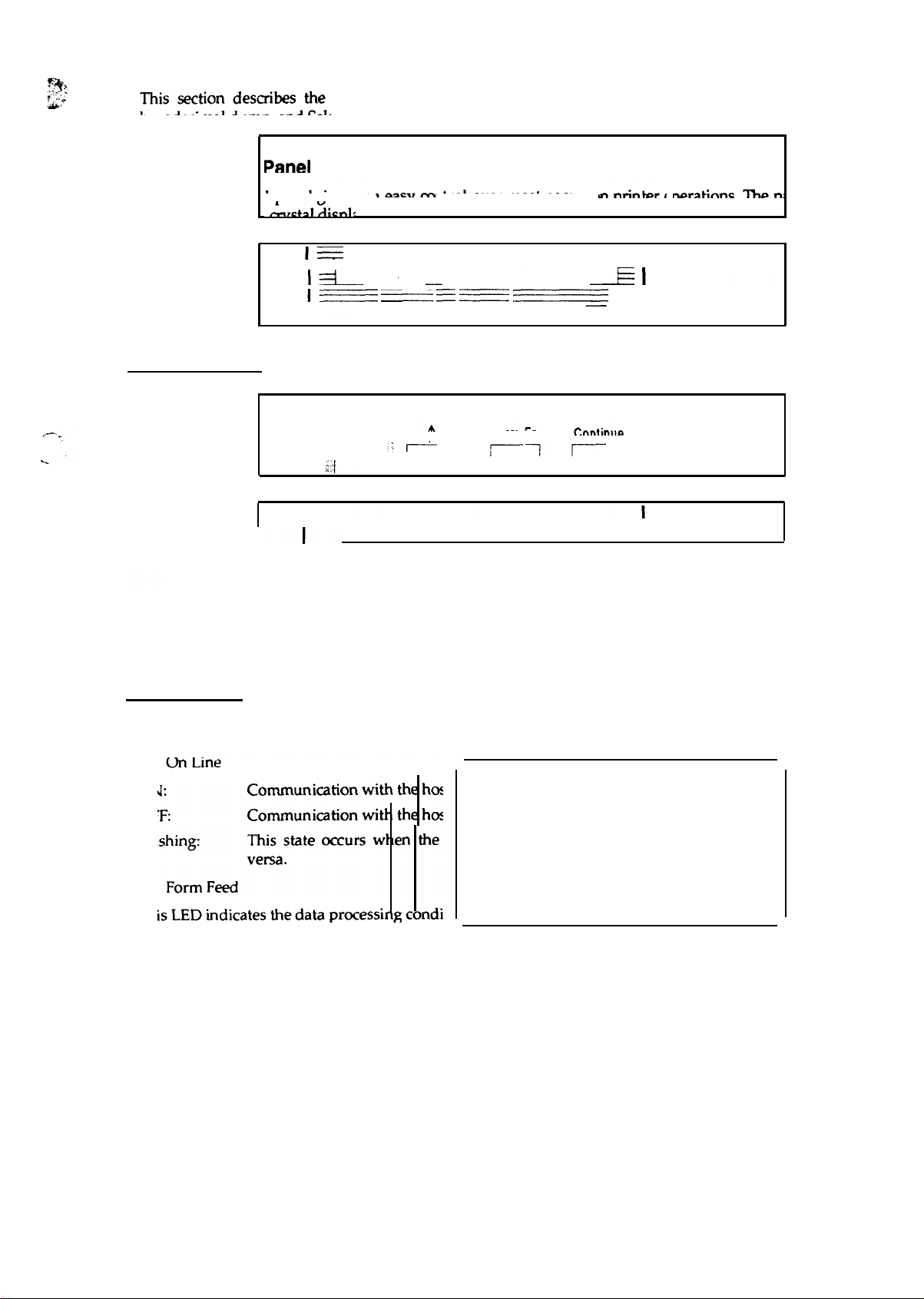

This section

hexadecimal dump, and

1.4.1 Control Panel

desaibes

the functions performed through the control panel, such as test print,

SelecType

functions.

General

Lhwctiption

The printer control panel gives you easy control over most common printer operations.

‘Me panel

consists of a liquid aystal display (LCD), indicator lights, and buttons.

SelecType

Menu

mu

Tti$::SW3 k??i@iti

. . . . . . . . . .

Item

. . . . . . .

n

u

On Line

n

tEwil#

. . . . . .

o

Figure 1-9. Control Panel

---

~..

Display (LCD)

A 20-character (5 x 7 dot matrix) by l-row liquid crystal display (LCD) unit that indicates printer

status. A variety of printer parameters can be displayed and set using

SelecType

mode.

Indicator lights

■ On Line

ON:

OFF:

Flashing:

■ Form Feed

This LED indicates the data processing condition for each interface channel: S, P, and O.

ON:

OFF:

Flashing:

H

Continue

Flashes

when

on the display at the same time.

Communication with the host is possible.

Communication with the host is not currently possible.

This state occurs when the system cannot shift from off line to on line, or vice

versa.

Received data is stored in the printer but has not been printed.

There is no printable data remaining in the printer.

The printer is processing data.

an

error is detected or a maintenance procedure is needed. An error message appears

Rev.

A

1-19

Page 32

General Description

Buttons

EPL&6001ActionLaser 1600

Service Manual

■ ON LINE

■ Manual

(ON LINE +

■ ITEM

■ Paper Size

(ITEM+

■ MENU

■ Tray Select

(MENU+

■

ALT

ALT)

ALT)

■ ’r

■

~

(~+

ALT)

■ ENTER

■ FORM FEED

■ CONTINUE

■ RESET

(CONTINUE +

ALT)

ALT)

Switches the printer between on-line and off-line mode. While in

SelecType

mode, this button exits

SelecType

mode.

Enters directly (short cut) to manual feed; this setting is the same as

the manual setting in the PRINTING MENU of

Enters

Changes the item in

SelecType

mode.

SelecType

mode.

SelecType.

Enters directly (short cut) to the paper size setting of the standard

and optional paper tray in PRINTING MENU of

Enters

Changes the menu @

SelecType

mode.

SelecType mcde.

SelecType.

Enters directly (short cut) to the paper tray select setting in

CONFIG MENU of

SelecType.

Modifies the function of other buttons.

Changes to the next available option of

Changes to the previous available option of

Sets available option of

SelecType.

SelecType.

SelecType.

When the printer is offline and the Form Feed light is lit, pressing

this button prints out data in the printer’s memory.

Pressing this button when the Continue light is flashing clears an

error.

Enter to reset operation; LCD displays “RESET”, printing stops, and

the input buffer of current interface is cleared.

If the RESET button is depressed continuously after “RESET” is

displayed, the message displayed on the LCD changes to “RESET

ALL” (about 5 seconds), and the printer enters to WARM BOOT

operation; printer clears all RAM.

1-20

Rev.

A

Page 33

EPL-66(W/ActionLaser

1600

Sendce Manuai

Generai Wription

1.4.2

The

functions,

configuration.

Table 1-12 shows the

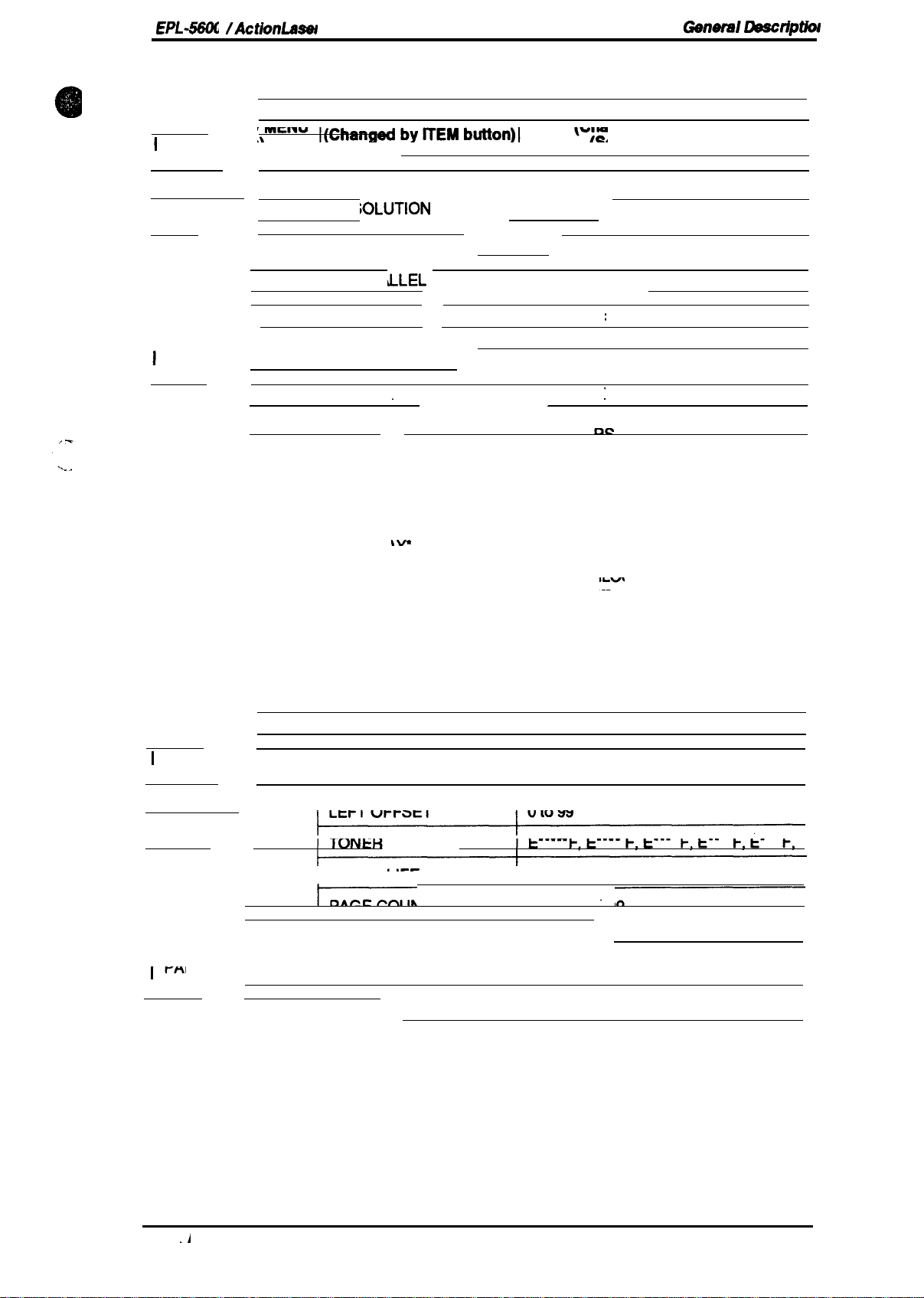

SelecType

SelecType

su&I

Menu

(Changed::)MENU

PRINTING

LJ4

Functions

function on the printer

as printing test pages, selecting a paper size, and changing the printer’s

Enter

SelecType

control

mode by pressing the MENU or ITEM button.

SekcType

options.

Tabie

(chan@ &~EM

COPIES

PAGE

ORIENTATION

MANUAL FEED OFF, ON

R!Tech

FONT SRC RESIDENT, CARTRIDGE, DOWNLOAD

FONT NUMBER

1-12.

SIZE

p~el

allows the user to control most of the printer’s

SelecType

button)

1 to 999

A4,

EXE, F4, MON, C1O, DL, C5,

PORT, LAND

OFF, LIGHT, MEDIUM, DARK

O to (available)

Functions

Available Optima

(Chan ad

(Set$y

A5, B5, LT, HLT, LGL, GLT, GLG,

by

f’or~

ENTER button)

button)

IB5

(Ps)

ESCP2

PITCH

HEIGHT

SYMSET

FORM

SRC

SYMSET’

DEST SYMSET*

— —

Font

Pitch

Condensed On, Off

0.44

to

4.00 to 999.75 PT. (Step 0.25)

Roman-8, ECM94-1, 8859-2 ISO,

IBM-US,

PcE.Europe,

WiE.Europe, WiTurkieh,

Velnternati, VeUS, MsPublishin,

PsMath, VeMath,

ASCII,

Norwegl,

5 to 128 LINES

o

to 3199

o to 3199

Courier, Prestige, Orator S, Roman-T,

Saris-H

10 CPI, 12

99.99

CPI

(step

0.01)

IBM-DN, PcMultiling,

PcTk437,

Swedis2,

Italian, Spanish, German,

French2,

CPI,

15

PiFont, Legal, UK ANSI

WiAnsi,

DeskTop,

Windows

CPI,

Prop

PsText,

Math-8,

“

With

Rev.

option

A

T-Margin

Text

CG Table

Country

0.40 to 1.50 Inch (step 0.05)

1 to (Available) LINES

Italic,

PcUSA, PcMultilin, PcPortugues,

PcCanFrenc, PcNordic,

Pc.E.Europe, BpBRASCll, BpAb-konp

USA, France,

Sweden, Italy,

Denmark2, Spain2, LatinArneric,

Legal

Gerrnsny,

Spainl,

PcTurk2,

UK, Denrnak,

Japan, Norway,

Korea,

1-21

Page 34

General Description

EPL4600/ActionLaser

1600

Service Manual

(Chan

M&MENU

!

ESCP2

FX

Menu

(Cont.)

Table 1-12.

SelecType

Functions (Cont.)

Available Options

(Chan

(Chang~ t!~~EM

Auto CR

Auto LF

Zero

Char

Bit Image

Font

Pitch

Condensed

T-Margin

button)

ON, OFF

ON, OFF

o,

($

Dark, Light,

Courier, Prestige, Orator S

10

CPI,

ON, OFF

0.40 to 1.50 Inch (step 0.05)

(Set%y

12

CPI,

ad by

ENTER button)

BarCode

15

Text 1 to (Available) LINES

Italic,

PcUSA, PcMuitilin, PcPortugues,

CG Table

PcCanFrenc,

PcNordic,

Pc.E.Europe, BpBRASCll, BpAbicomp

~or ~

CPI,

Prop

PcTurk2,

button)

GL2

Country

Auto CR

Auto LF

Zero Char

Bit Image

GLMODE

SCALE

ORIGIN

PEN

END

JOIN

PENO

PEN1

USA, France, Germany, UK, Denmak,

Sweden, Italy, Spainl, Japan, Norway,

Denmsrk2, Spain2,

LatinAmeric

ON, OFF

ON, OFF

o,@

Dark, Light,

LJ4GL2,

BarCode

GLlike

OFF, AO, Al , A2, A3

CORNER, CENTER

0, 1,2,3,4, 5,6

BUTT, SQUARE, TRIANGULAR, ROUND

MITERED, MITEREDBEVELED,

TRIANGULAR, ROUND, BEVELED,

NONE

0.05

to

5.00

mm (step 0.05)

0.05 to 5.00 mm (step 0.05)

1-22

PEN2

PEN3 0.05 to 5.00 mm (step 0.05)

PEN4

0.05 to 5.00 mm (step

0.05

to

5.00

mm (step 0.05)

0.05)

PEN5 0.05 to 5.00 mm (step 0.05)

PEN6

0.05 to 5.00 mm (step

0.05)

Rev. A

Page 35

EPL6600 /ActionLaaar

16U0 Sarvica Manual

Ganerai ~ription

n,

;.

‘. ,

- .,

Menu

(Chan

W MENu

r

utton)

JOI3

EMULATION

Table 1-12.

(chang~ $~EM button)

PAGE PROTECT

RESOLUTION

TIMEOUT

PARALLEL

SERIAL

SelecType

Functions

(ContJ

Available Options

(Chan

ad

b

~or~

(Sat%y EdTER

OFF,

LT, LGL,

300,600

5 to 300

LJ4, FX, ESCP2, PS*, GL2, PMLJ4*,

PS&FX*, PS&ESCP2*, PS&G12*

LJ4, FX, ESCP2, PS*, GL2, PS&LJ4*,

PS&FX*, PS&ESCP2*, PS&GL2*

A4

button)

button)

LJ4, FX, ESCP2, PS*, GL2, PS&LJ4*,

PS&FX*, PS&ESCP2*, PS&G12

AUX*

.“.

TRAY SIZE

STD SIZE

LJ4, FX, ESCP2, PS*, GL2, PS&LJ4*,

PS&FX*, PS&ESCP2*, PS&GU2*

A4, A5, B5,

EXE, F4, MON, C1O,

LT,

HLT,

LGL,

GLT, GLG,

01,

C5,

IB5

(-,:

----

LT,

OPT SIZE*

CONFIG

STD

TRAW

OPT TRAY*

SIZE

IGNORE

AUTO

CONT

STANDBY

DENSITY

“

PAGE COUNT

SelecType

INIT

A4

LOCK, UNLOCK

LOCK, UNLOCK

OFF, ON

OFF, ON

DISABLE, ENABLE

MEDIUM, DARK, DARKEST, LIGHTEST,

LIGHT

ON, PARALLEL, SERIAL,

o

to 99

0

to 99

E***-F,

5000 to 9000

E**** F, E-* F, p

(UT), (AUX)

F, E.

F

,

o to 99999999

PARALLEL

* With option

Rev.

A

SPEED

I BI-D

FAST, LOW

t

I

ON, OFF

1-23

Page 36

General Description

EPL-5600/ActionLaser 1600 Service Manual

Menu

(Chan M&MENIJ

f

SERIAL

TEST

Table 1-12.

I

(Changd #~~EM

SERIAL TYPE

WORD LENGTH

BAUD RATE

PARITY

STOP BIT

DTR

I XON/XOFF

DSR

STATUS SHEET

I

LJ4FONTSAMPLE

ESCP2

SelecType

FONT SAMPLE —

Functions (Cont.)

button)

I

Available Options

(Chan

ad by

%

,

RS232C,

8,7

9600, 19200,38400,57600,300, 600,

1200,2400,4800

NONE, EVEN, ODD

1,2

ON, OFF

I

ON, OFF

ON, OFF

—

(Set y ENTER button)

RS422

~or ~

button)

1-

*

With option

FX FONT SAMPLE

FACT SHEET

RITech

TEST PAGE

I

PS STATUS SHEET* I –

PS FONT SAMPLE*

PS FACT SHEET*

—

—

—

—

—

1.4.3 Service Mode

This printer has four service modes as follows:

■

Hexadecimal Dump Mode

■

Language Setting Mode

■

Factory Service Mode

■

EEPROM

1.4.3.1 Hexadecimal Dump Mode

The hexadecimal dump mode is a useful tool in trouble shooting data control problems. To enter

hexadecimal dump mode, turn on the printer while holding down the ON LINE button until

“HEX DUMP MODE” is displayed.

Format

1.4.3.2 Language Setting Mode

The

language setting mode allows the user to specify a language for panel displays and the status

sheet. To enter language setting mode, turn on the printer while holding down the MENU button

until “CONFIG LANGUAGE” is displayed. The options are changed by pressing the ~ and

buttons and are set by pressing the ENTER button. Available options areas follows:

ENGLISH,

PORTUGUI%

1-24

FRAN~AIS, DEUTCH, ITALIANO,

Espatiol,

SVENSKA, DANSK, NEDERL,

SUOMI,

~

Rev. A

Page 37

EPL-66@lActionLaser

16iUl Servke A&mud

1.4.3.3 Factory Service Mode

The

factory service mode is a useful tool

enter factory

buttons until “PRODUCT MENU” is displayed.

Table 1-13.

semice

mode, turn on the printer while holding down the ON LINE and CONTINUE

fir

service people. This mode is not available to users. To

Table 1-13. Factory Service Mode

General

The

factory service settings are shown in

Desor@ion

<...

Menu

(Chang~~~)MENU

PRODUCT

VERSION

(Chanx #~~EM

NAME

TCOUNT

I TCOUNTCLEAR

PCOUNT

PCOUNT

I JCOUNT

JCOUNT

CODE ROM

FONT ROM

LL

(Local Language ROM)*

PS ROM

Module

CLEAR

CLEAR

ROM

(EPSONScript

ROM)*

button)

Available Options

(Cha

(Set yENTERbutton)

I AL1600, EPL-5600

1

I

(Note

1

I

I

(page

I

I

(page

1

[ (jamcountervalue

I (diaplayed

I

1)

(tOfWleft COUnterCl@

countervaluedisplayed)

countafclear)

(jam counter clear)

(diaplayed

(diaplayed

(displayed version)

version)

version)

version)

by T or 4 button)

Y

displayed)

*

With option

Note 1:

1.4.3.4

EEPROM format operations are required only

,,[

board) or EEPROM is replaced and these operations are specified in the accompanying

documentation.

EEPROM format functions (printer mme, default paper size (A4 or letter), toner counter, page

counter, jam counter, and panel settings) are all stored in memory.

Defaults for the EEPROM format functions can be written to EEPROM as follows:

■

Turn on the printer while holding down the ITEM, ?, and CONTINUE buttons until

“FORMAT=EPL5600” is displayed.

H

ActionLaser

Turn on the printer while holding down the MENU, ALT, and FORM FEED buttons until

“FORMAT=AL1600”

This

counter value is

EEPROM Format

EPL-5600

1(XXI

is displayed.

Ieftof

toner weight

(pgrams)

when the

in

imagingcartridge.

Video

Ccmtroller

Board

(C125

MAIN

Rev.

A

1-25

Page 38

General Description

EPL-5600/ActionLaser

1600 Service

MAnual

1.4.4 Display of Messages

printer displays three types of messages on the LCD: status messages, error messages, and

This

power on messages.

1.4.4.1

The

Ststus

LCD panel normally indicates the printer’s status and the software mode.

Messages

Table 1-14. Status Messages

Message

SELF TEST

RESET ALL

RESET

RESET TO SAVE

WARMING UP

TONER LOW

STANDBY

READY

1.4.4.2 Error Messages

If any of the following errors occurs, it will be displayed on the LCD panel. The error must be

cleared immediately using the measures shown in the following table.

Internal self test

Warm txwt

Resetting