Page 1

EPSON TERMINAL PRINTER

EPL-5000/5200/5200+

#mLm.

1000 I15OO

SERVICE MANUAL

EPSON

4001962

Page 2

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WAHV/NG

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

Signals a

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

prwaution

which, if

ignorwl,

could result in serious or fatal personal injury.

DANGER

. .

)

(

\

. .

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

?

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

-.

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

3.

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

.

CERTIFIED REPAIR TECHNICIAN.

(

:.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLT-

AGE, LISTED

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO

NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

3.

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4.

IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

5.

BY THE MANUFACTURE; INTRODUCTION OF SECONBSOURCE

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

ON

THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON

ICS OR

PRODUCT

OTHER

c)

- ii -

Page 3

SAFETY INFORMATION

This printer is a page printer which operates by means of a laser. There is no possibility of danger from

the laser, provided the printer is operated according to the instructions in this manual provided.

Since radiation emitted by the laser is completely

coti-ined

within protective housings, the laser beam

camot escape from the machine during any phase of user operation.

For United States Users:

[Laser Safety]

This printer is certified as a Class 1 Laser product under the U.S. Department of Health

and Human Services

(DHHS)

Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968. This means that the printer does not

produce hazardous laser radiation.

[CDRH

The Center for Devices and Radiological Health

Regulations]

(CDRH)

Administration implemented regulations for laser products on August 2,1976. Compliance is mandatory for products marketed in the United States. The label shown below

indicates compliance with the

CDRH

regulations and must be attached to

marketed in the United States.

‘WARNING: Use of controls, adjustments or performance of procedures other

than those specified in this manual may result in hazardous radiation exposure.

[Internal Laser Radiation]

of the U.S. Food and Drug

laser

products

Maximum Radiation Power:

Wave Length:

This is a Class

unit is NOT A FIELD SERVICE ITEM. Therefore, the print head unit should not be

opened under any circumstances.

For Other Countries Users;

wARNING:

than those specified in this manual

?his

is a semiconductor laser. The maximum power of the laser diode is 5.7 x

-4

10

W and the wavelen

For Denmark Users;

ADVARSEL

Usynlig laserstrMng

Undg~ udsaXtelse

IKlasse

1 laser produkt der opfy

5.7 x 104 (w)

780 nm

IIIb

Laser Diode Assay that has an invisible laser beam. The print head

Use of controls, adjustments or performance of procedures other

maY

ved

for

@h

is 780

i%bning, dir

striWng.

result in hazardous radiation

nm.

sikkerhedsafbrydere er ude af

lder

IEC825 sikkerheds kravene.

exposurel

funktion.

I

. . .

-

Ill

-

Page 4

For Finland, Sweden

Users;

Laitteen kayttaminen muulla

aattaa

I

WMNING

Om

kan anvandaren utsattas

For Norway Users;

ADVARSEL

Dersom

mg,

@

algelengde

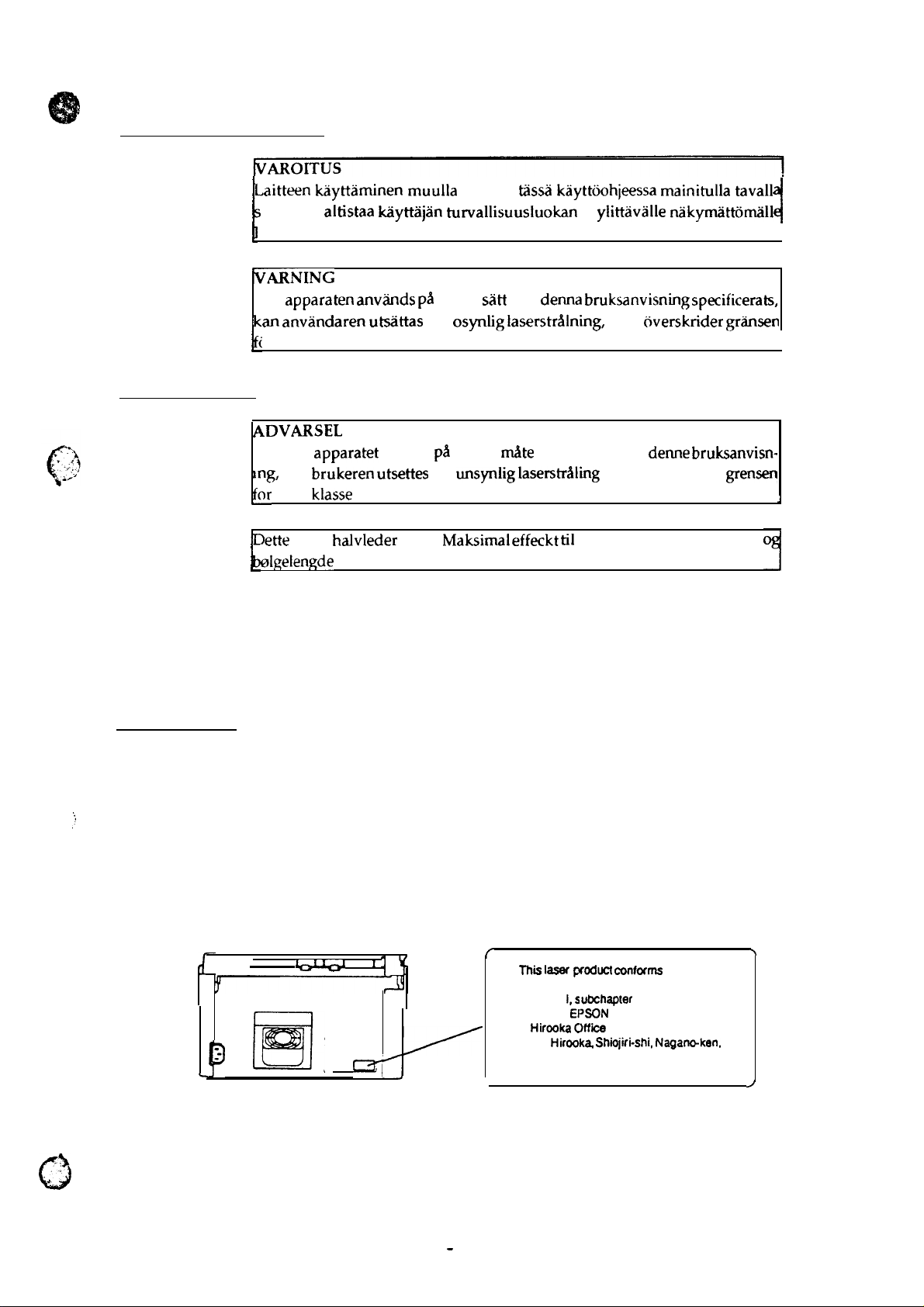

Laser Safety Labels

altistaa kiiyttajan turvallisuusluokan

apparaten anvirinds pa

kan

laser

ette

er en

apparatet

brukeren utsettes

klasse

brukes

1.

hafvleder

er 780 nm.

for

for

laser.

kuin

annat

osynlig laserstr~lning,

ptl

annen

unsynlig laserstri%ling

Maksimal effeckt til

tiissa kaytttiohjeessa mainitulla tavall

salt

an i dema

rrdte

em spesifisert i deme

1

ylittavalle nakymattomiill

bruksanvisning specificerats,

som

tiverskrider griinser

bruksanvisn-

som overskrider

laserdiode er 5.7x 10”4 W

grensen

2

1

(-”.

. . ,

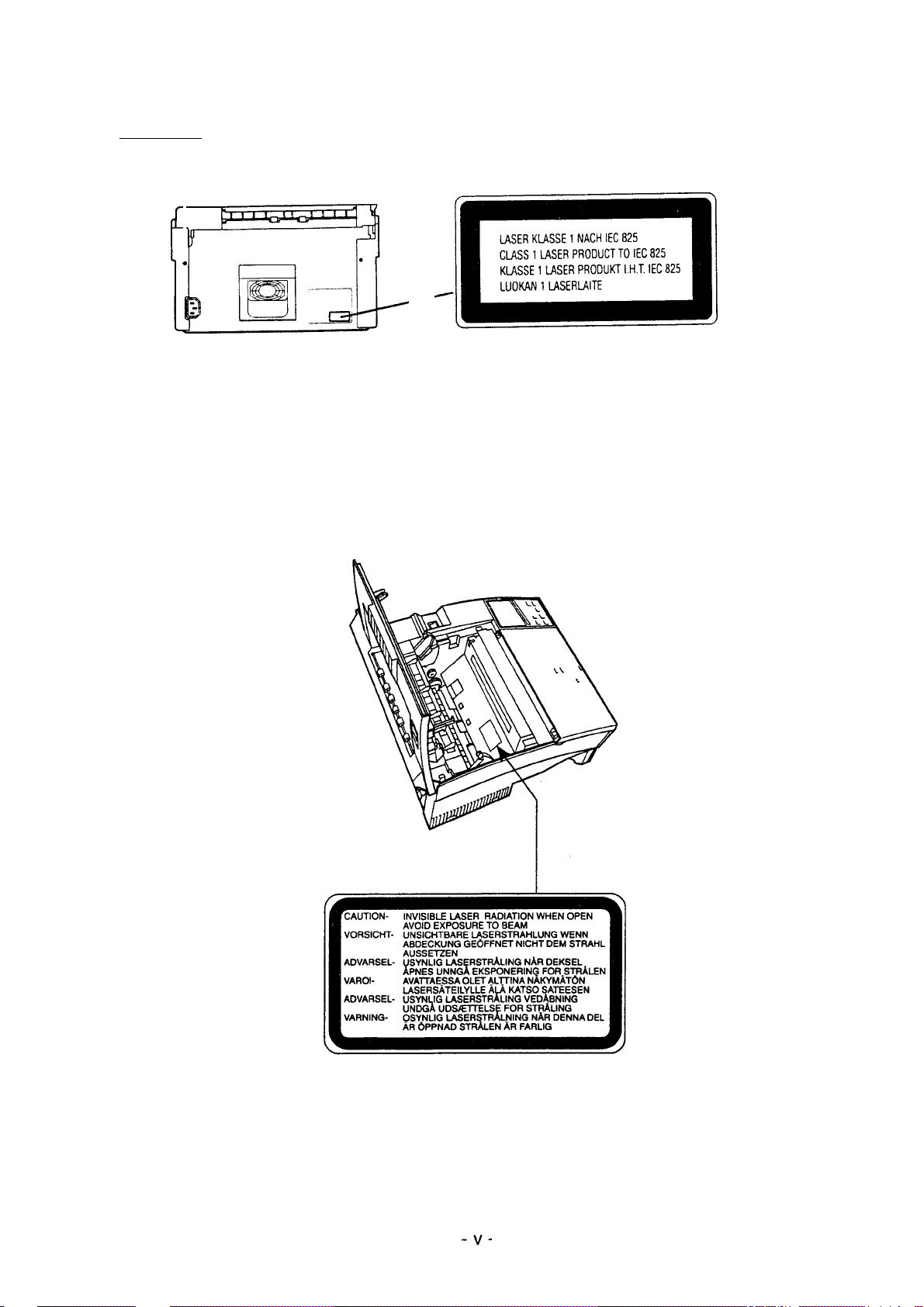

[Label on rear printer case]

A laser safety labels is attached on the outside of the printer shown below.

For United State

:

r

P

‘

~

.

-.

.

p

\

El,

‘ ‘

‘

.

-

~

;

/

r

mk laser pomct

applicable requirement of 21 CFR

Chapter 1,

MANUFACTURED:

Sued’mpler

SEIKO

EPSON

Hirooka OtSkx

Hirooka

80

JAPAN

\

rxnfcms to the

J.

CORP.

Shiojiri-shi, Nagarwken.

)

+,

(3

- iv -

Page 5

For Europe

.

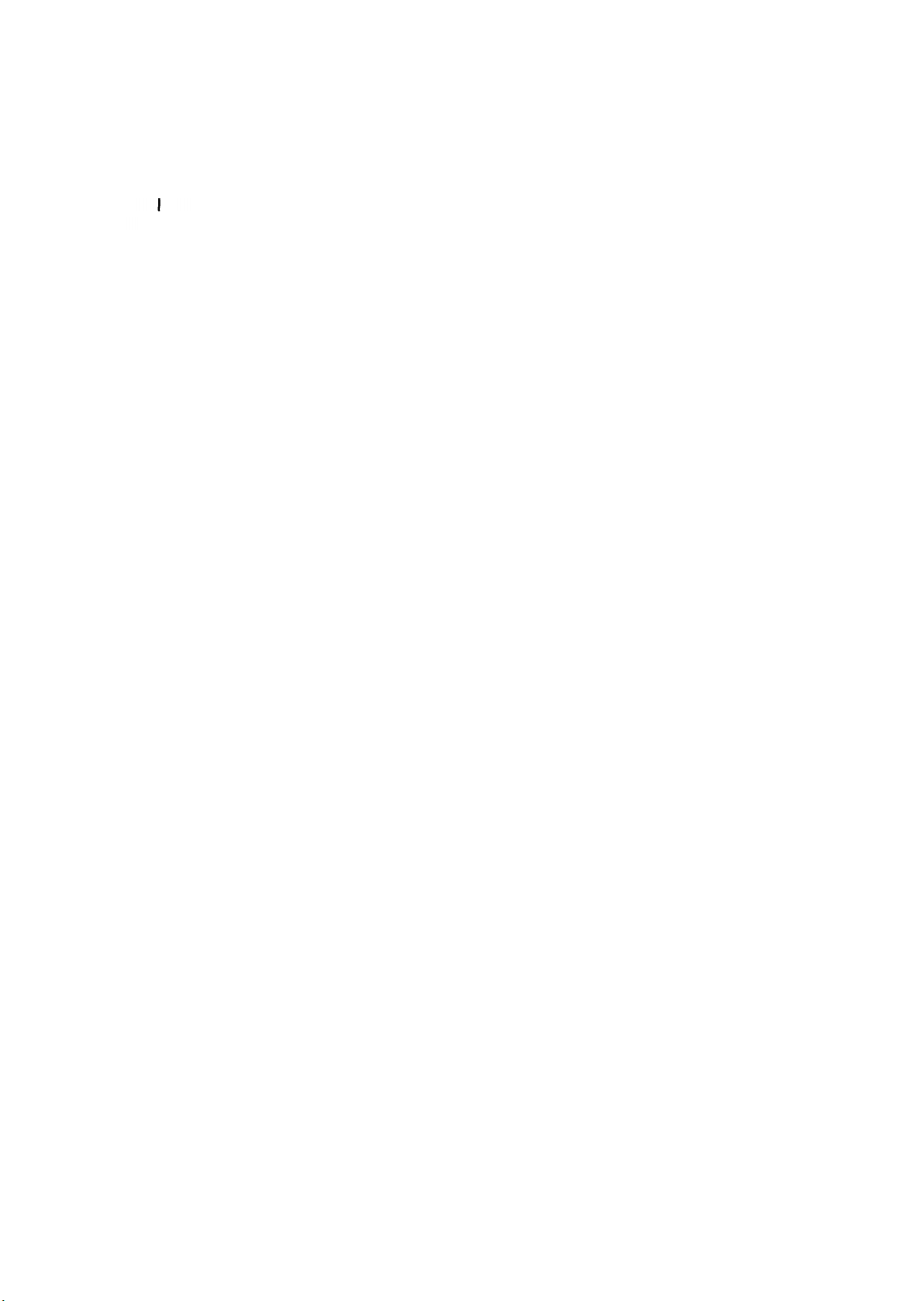

[Label inside printer]

The following laser safety label will be attached inside the printer as shown below.

-v-

Page 6

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of

EPL-5000

The

instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are organized as

follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview,

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

/5200 and Action Laser 1000/1500.

lists

specifications, and illustrates the

main components of the printer.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

-

vi -

Page 7

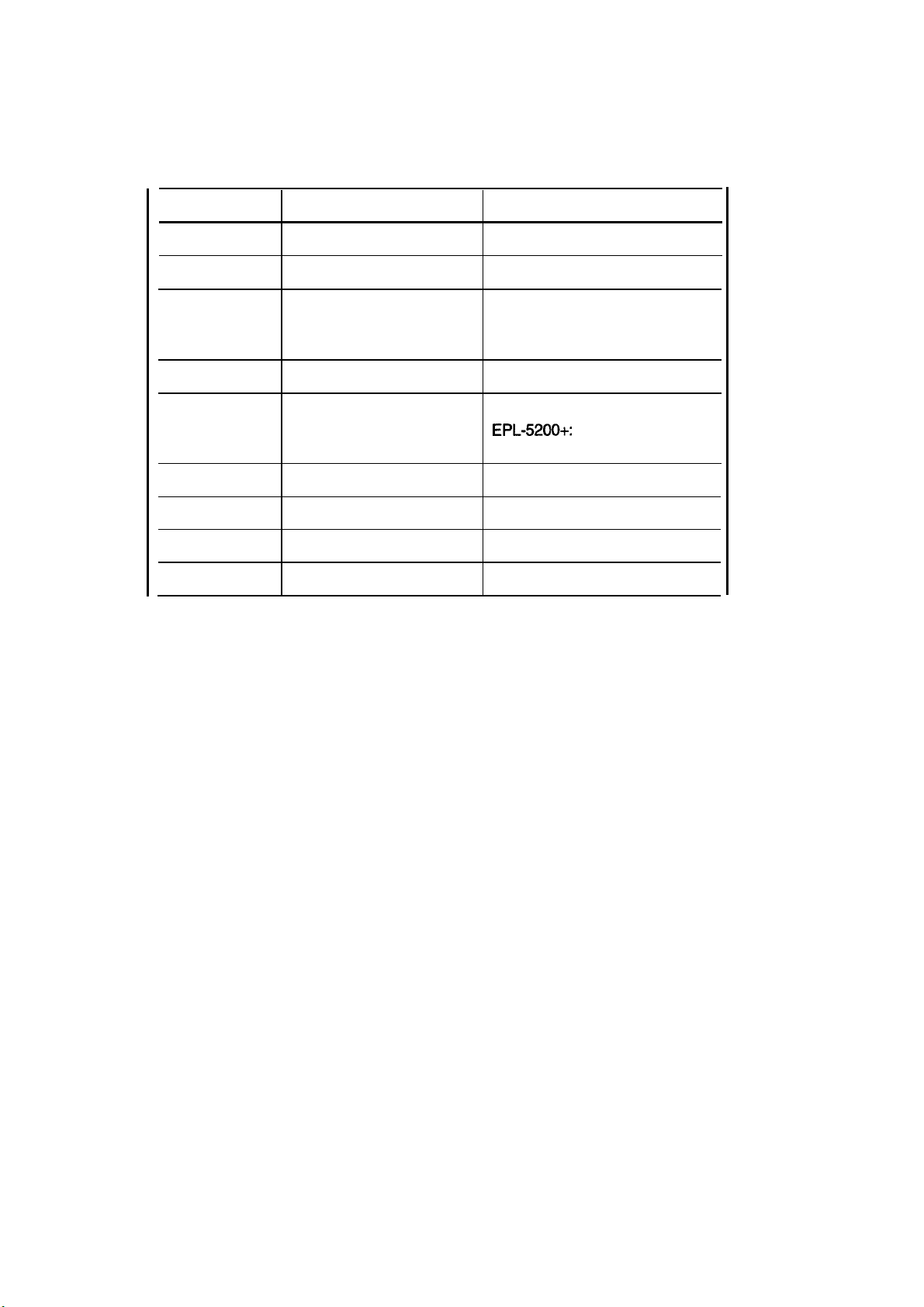

REVISION SHEET

Revision

Rev. A

Rev. B

Rev. C

Rev. D

Rev. E

Issue Date

January 8, 1993

June 28,1993

August 5, 1993

February 28, 1994

April 4, 1995

Revision Page

1st issue

Page 1-23, 1-31,2-22,3-11 ,4-1

Added information for the Cl 08

MAIN-B board: Page B-i, B-1,

through B-10

Page 1-33

Added information for the

EPL-5200+:

through C-10

Page C-i, C-1

- vii -

Page 8

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY

ADJUSTMENTS

TROUBLESHOOTING

MAINTENANCE

AND ASSEMBLY

- Vlll

. . .

-

Page 9

Chapter 1

General Description

Table of Contents

,. ,.

(

,

1.1 FEATURES

1.2 SPECIFICATIONS

1.2.1 Basic Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .1-5

1.2.2 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . ..................1-7

1.2.3 Reliability Specifications . . . . . . . . . . . . . . . . . . . . . ..................1-7

1.2.4 Environmental Conditions for Operating (Include Imaging Cartridge) .. ..1-7

1.2.5 Environmental Conditions for Storage and Transportation (Exclude

Imaging Cartridge) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......1-7

1.2.6 Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . .................1-8

1.2.7 Specifications for Consumable (Imaging Cartridge) . .................1-8

1.2.8 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . ..................1-8

1.2.9 Software Specifications . . . . . . . . . . . . . . . . . . . . . . . . ...............1-9

1.3 INTERFACE SPECIFICATIONS

1.3.1

Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .1-14

1.3.2 Serial Interface (Except for the Action Laser 1000) . . . . . . . . . . . . .....1-16

1.3.3

Optional interface C82305*/C82306* (Action Laser 1000 Only) . . .....1-18

1.4 OPERATING INSTRUCTIONS

1.4.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-19

1.4.2

1.4.3

1.4.4

1.4.5 Controller RAM Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-29

1.4.6 Optional Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ... ... ...

1.4.7

1.4.8 Resolution Improvement Technology. . . . . . . . . . . . . . . . . . . . . . . .. ...1-32

1.4.9 EEPROM Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-33

SelecType Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-21

Displayof Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..1-24

1.4.3.1 Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-24

1.4.3.2 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-25

1.4.3.3 Power On Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-26

Printer Sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-27

1.4.4.1 individual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-27

1.4.4.2 Auto Sense Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..1-28

1.4.4.3 Data Receive Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-28

Emulation Mode Switch Function . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-31

1.4.7.1 Emulation Switch by SPL. . . . . . . . . . . . . . . . . . . . . . . . . . .....1-31

1.4.7.2 Intelligent Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . .....1-31

1-1

1-5

1-14

1-19

.~-30

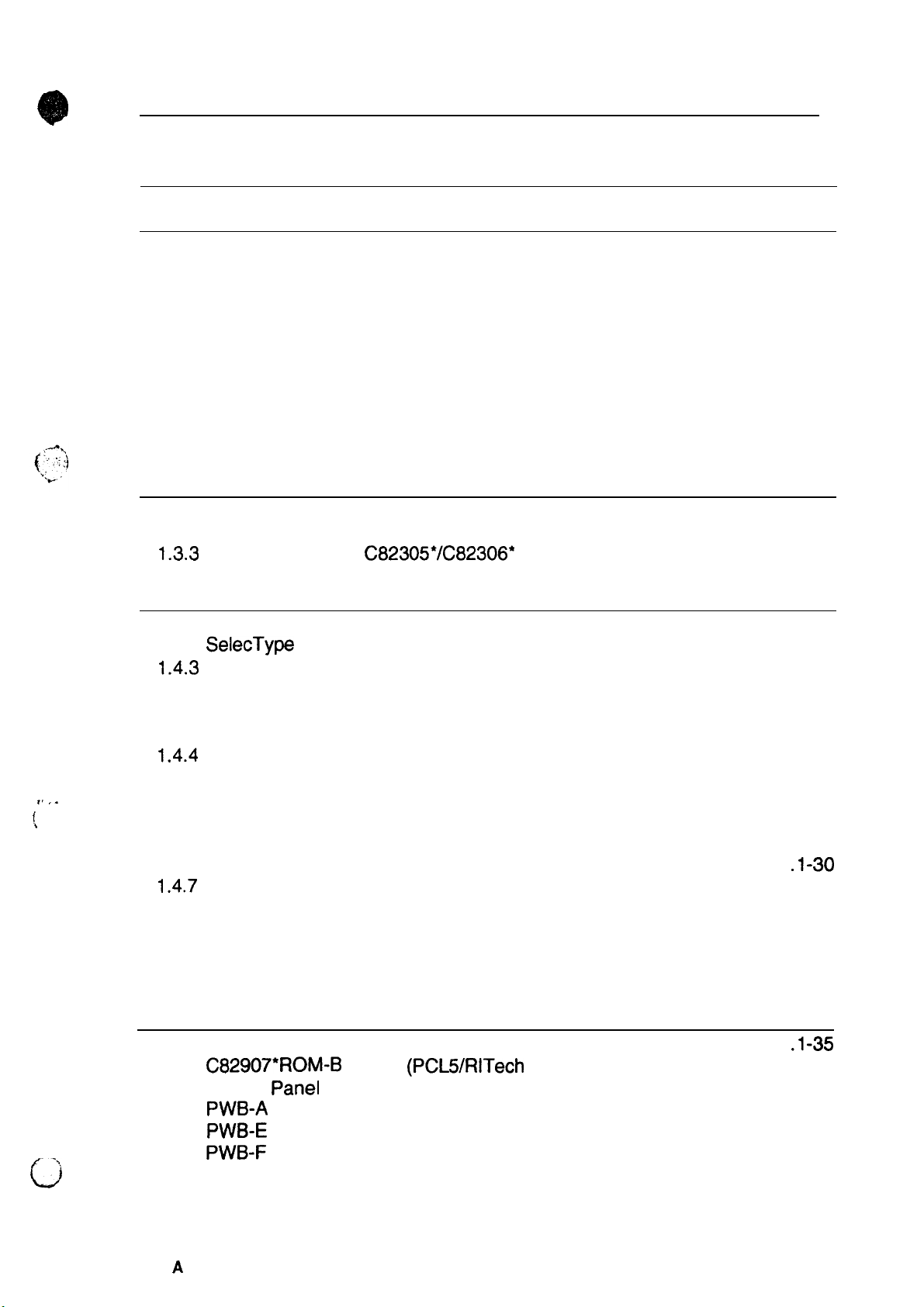

1.5 MAIN COMPONENTS

1.5.1

1.5.2

1.5.3

1.5.4

1.5.5

.

. .

?

b

1.5.6

1.5.7

1.5.8

Rev.

C108 MAIN Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-35

C82907*ROM-B Board (pCL5/RITech Upgrade Board) . .. .. . . . .....1-36

Panel

Control

PWB-A

PWB-E

PWB-F

PRINTHEAD UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..1-39

FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-40

A

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-38

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-38

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-37

1-34

l-i

Page 10

1.5.9 Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-40

1.5.10 IMAGING CARTRIDGE.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

1.5.11

Lower Paper Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

1.5.12 Face Up Output Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

List of Figures

Figure 1-1. Exterior View of the EPL-5000/5200 and Action Laser 1000/1500 . 1-1

Figure 1-2. Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure l-3. Signal Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure l-4. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Figure l-5.

Figure l-6.

Figure l-7.

Figure l-8.

Figure l-9.

SelecType

SelecType

SelecType

SelecType

SelecType Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Figurel-10.individual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Figure l-n. Auto Sense Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-28

Figure l-12. Receive Buffer Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Figure 1-13. Emulation Switch by SPL . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-31

Figurel-14.intelligent Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Figure 1-15. Effect of

Figure l-16.

RITech

Figure l-17. Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Figure l-18.

Figure 1-19.

C108MAlN Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

C82907*ROM-B Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-36

Figure l-20. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Figure l-21.

Figure 1-22.

Figure 1-23.

PWB-A Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-38

PWB-E

PWB-F

Figure 1-24. PRINTHEAD UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-39

Figure 1-25. FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Figure l-26. Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-40

Figure 1-27. IMAGING CARTRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-40

Figure l-28. Lower Paper Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

Figure l-29. Face Up Output Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Levell

Levell

Levell

Levell

RITech

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

in

LJ-2P&3/P/Si

Menu Map . . . . . . . . . .....1-21

in Epson GU2Mode Menu Map . . . . . . .....1-22

in LQand FXMode Menu Map . . . . . . . . . . . . 1-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-32

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

1-41

List of Tables

Table

Table

Table

Table

Table l-5. Usabilityof Special Papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Table l-6. Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-7

Table 1-7. Differences between EPSON

lli/lllP/illSi

Table 1-8. Built-in Fonts (EPL-5000/Action Laser 1000). . . . . . . . . . . . . .....1-10

Table l-9. Built-in Fonts

Laser 1000 with

Table 1-10. Built-in Fonts

l-ii

-1. Differences in Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-2. Options for EPL-5000/5200 and Action Laser 1000/1500 . ........1-3

-3. PaperFeed Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ....1-5

-4. Paper Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GL/2 and GU2 in the HP

LaserJet@

Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(EPL-5200/Action Laser 1500 and EPL-5000/Action

PCL5@

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-10

(EPL-5000 with GQ Chip) . . . . . . . . . . . . . . . . . . . .

Rev.

1-2

1-5

1-9

1-11

A

Page 11

Table 1-11. Built-in Fonts (EPL-5200 with GQ Chip Option and

PCL5@

Board and GQ Chip) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-12

EPL-5000

with

Table 1-12. Signal Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..1-14

Table l-13.

Centronics@

Parallel Interface Pin Assignment . . . . . . . . . . . . . .

.1-15

Table l-14. Serial interface Connector Pin Assignments . . . . . . . . . . . . .....1-16

1-15.

Table

Table

Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-24

1-16.

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Table l-17. Displayat Power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-26

Tabiel-18.

Table l-19. Differences in Components

RAM Chip Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-30

forthe

C108 MAIN Board . . . . . .....1-36

Rev.A

l-iii

Page 12

EPL4M#52tW/Act&n faser

1.1 FEATURES

l@W’lSIM Service Manual

Genera/Description

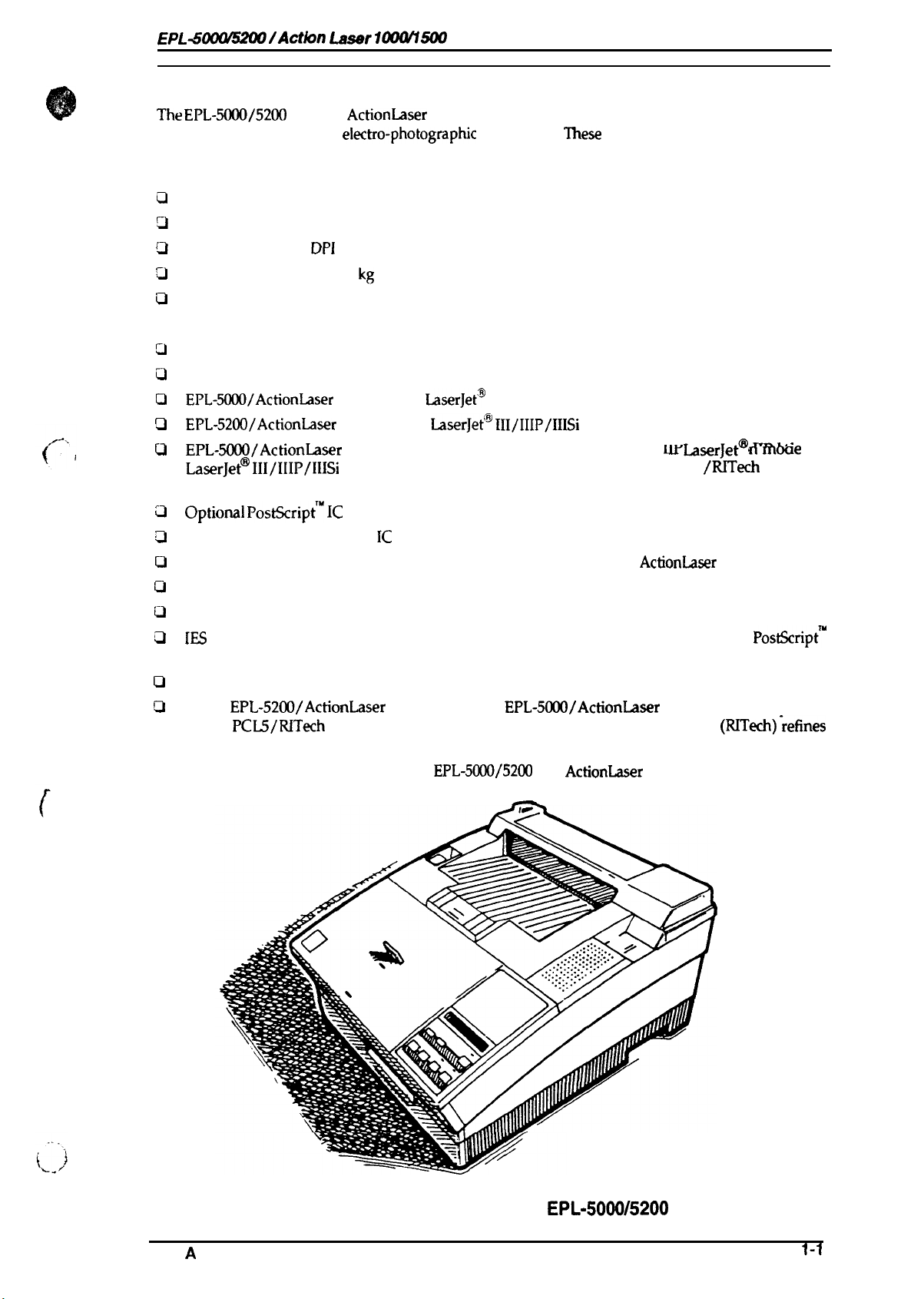

The EPL-5000/5200

semi-conductor laser with

and the

ActionLaser

electro-photographic

1000/1500 are non-impact page printers that combine a

technology.

‘Ihese

printers are small and light, and

feature high-speed, high-resolution printing. Also, maintenance is very easy, as a result of various

built-in diagnostic functions. The main features are:

it

No ozone

L1

Printing speed —6 PPM

[d

Resolution —3W

c1

Light weight — about 10 kg (22 lb.)

ii

Small footprint

Face-down tray (standard) /face-up

c1

c1

High-performance controller (the

Q

Easy maintenance

o

EPL-5000/ActionLaser

c1

EPL-5200/ActionLaser

c1

EPL-5000/ActionLaser

LaserJet@ 111/IIIP/IIISi

DPI

tray (optional)

controller’s CPU is a 16.67 MHz Motorola 68000)

1000 has HP

1500 has HP

LaserJet@

11P emulation mode

LaserJet@ 111/IIIP/IIISi

emulation mode

1000 can be upgraded from HP

emulation mode with the optional Epson

W emulanon moae

LaserJet@ ‘“ ‘ ‘-

PCL5

/RITech

Upgrade

to

‘ .

Board

c1

Optioml PostScript’” IC

a

Optional Epson GL identity IC card

High-speed serial communication rate of 38400 bps (except for the

c1

c1

A multi-user, multi-emulation mode

Cl

Various types of fonts available in font cards and cartridges

LI

IES

(Intelligent Emulation Switch) allows switching of the printer mode between

card

ActionLaser

1000)

PostScript’”

mode and another mode

o

SPL (Shared Printer Language) enables switching of

cl

In the

Epson

EPL-5200/ActionLaser

PCL5/RITech

Upgrade Board, Resolution Improvement Technology

1500 and in the

the

printer mode by command

EPL-5000/ActionLaser

1000 with the

optional

(RITech) ~efines

the print quality by eliminating jagged edges from images and characters.

Figure 1-1 shows an exterior view of the

EPL-5000/5200

Figure 1-1. Exterior View of the

Action Laser 1000/1500

Rev.

A

and

ActionLaser

1000/1500.

EPL-5000/5200

and

1-1

Page 13

General Description

EPL-5000/5200/Action Laser

iOOOl1500

Service Manual

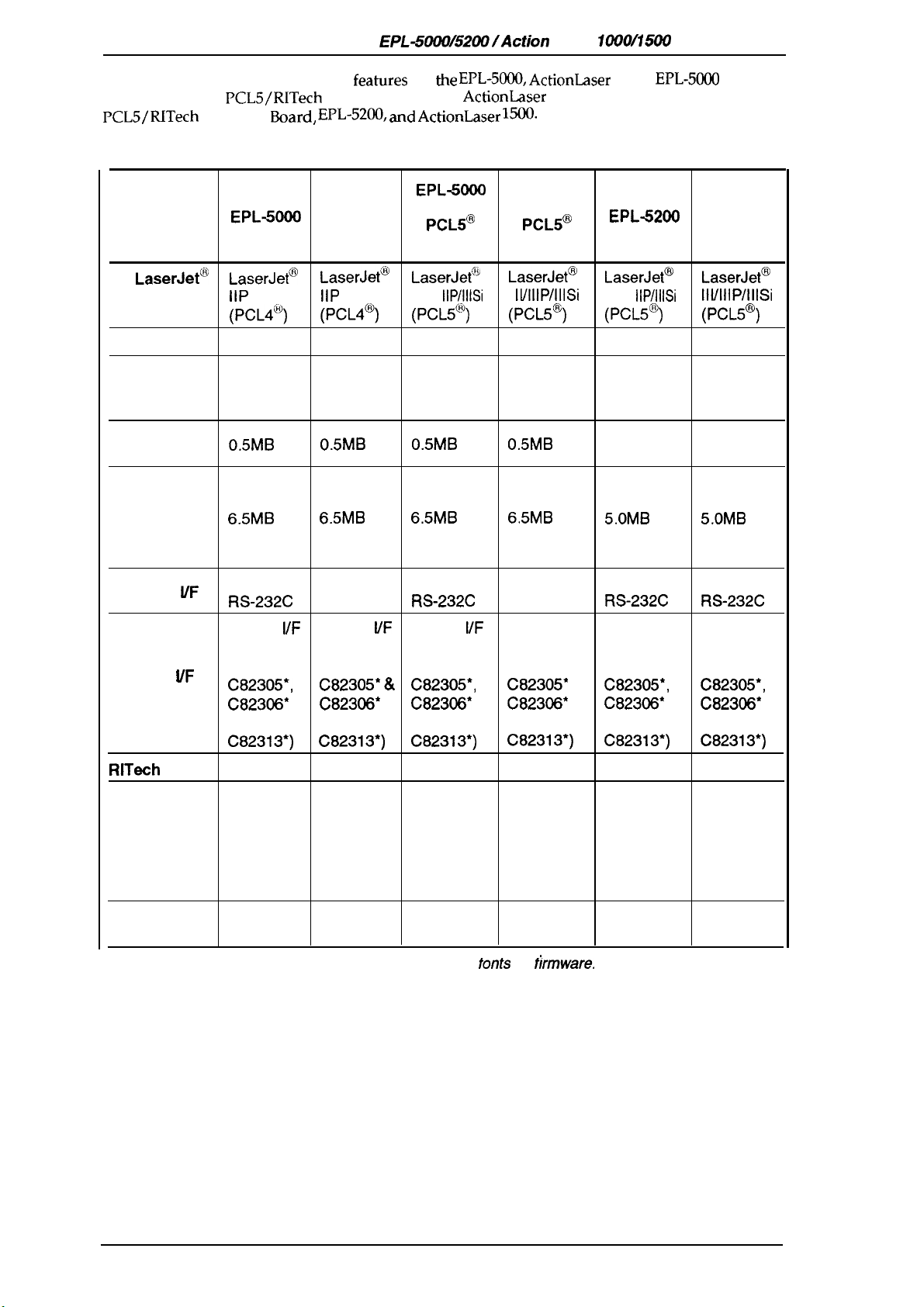

Table 1-1 shows the differences in featires for

optional Epson

PCL5/RITech

PCL5/RITech

Upgrade

Upgrade Board,

Ward, EpL-5200, and ActionLaser 1~.

Table 1-1. Differences in Features

EPL-5000

LaserJe{~

111/l llP/lllSi

(PCL5@’)

Optional No

Optional

0.5MB 0.5MB

6.5MB 6.5MB

Function/

Specification

HP

LaserJet@

Emulation

Level

GQ mode

Local

Language

ROM

Standard

RAM Size

Maximum

RAM Size

(Optional

RAM chips

installed)

EPL-5000

LaserJet@

11P

(PCL4C”)

Optional No

No

0.5MB

6.5MB

LaserJet@

11P

(PCL4@)

No

0.5MB

6.5MB

Action

Laser

1000

tie EpL-5000,

ActionLaser

Action Laser

with

PCL5°

Board

Actionhser 1000,

EPL-5000

1000 with the optional Epson

1000 with

PCL5@

Board

LaserJet@

I

11/lllP/lllSi

(PCL5@)

No

EPL%2M

LaserJet@ LaserJet@

111/l llP/lllSi

(PCL5~

Optional

Optional

1.OMB

5.OMB 5.OMB

Action Laser

with the

1500

111/lllP/lllSi

(PCL5@)

No

No

1.OMB

Standard

Optional

Cards

RITech

Resident

Bitmap Fonts

Resident

Scalable Fonts

Note:

lfF

lfF

Landscape fonts are generated from portrait

Parallel/

RS-232C

Type-B

Cards

(Except

C82305*,

C82306*

and

C82313*)

No

9 Portrait

Fonts and

None

Landscape Landscape

Fonts

(Note)

No

Parallel

Type-B IIF Type-B

IIF

Cards

(Include (Except (Include

C82305* &

C82306*

and except and

C82313*) C82313*)

No

9 Portrait

Fonts and

None Fonts and 7 Fonts and 7

Fonts

(Note)

No

Parallel/

RS-232C RS-232C RS-232C

Cards Cards

C82305*,

C82306* C82306* C82306* C82306*

Yes

9 Portrait

Landscape

Fonts Fonts

13 fonts

IIF

fonts

Parallel

Type-B l/F

C82305* &

and except

C82313*)

Yes

9 Portrait

Landscape

13 fonts

.

.

by frmware.

Parallel/ Parallel/

Type-B l/F Type-B l/F

Cards Cards

(Except (Except

C82305*, C82305*,

and

C82313*) C82313*)

Yes Yes

9 Portrait

Fonts and 7 Fonts and 7

Landscape Landscape

Fonts Fonts

13 fonts 13 fonts

and

9 Portrait

1-2

Rev. A

Page 14

EPL&XW52(W/Act&n

Laser

l(XXU1500 Senrice

Manual

Geneml Descdption

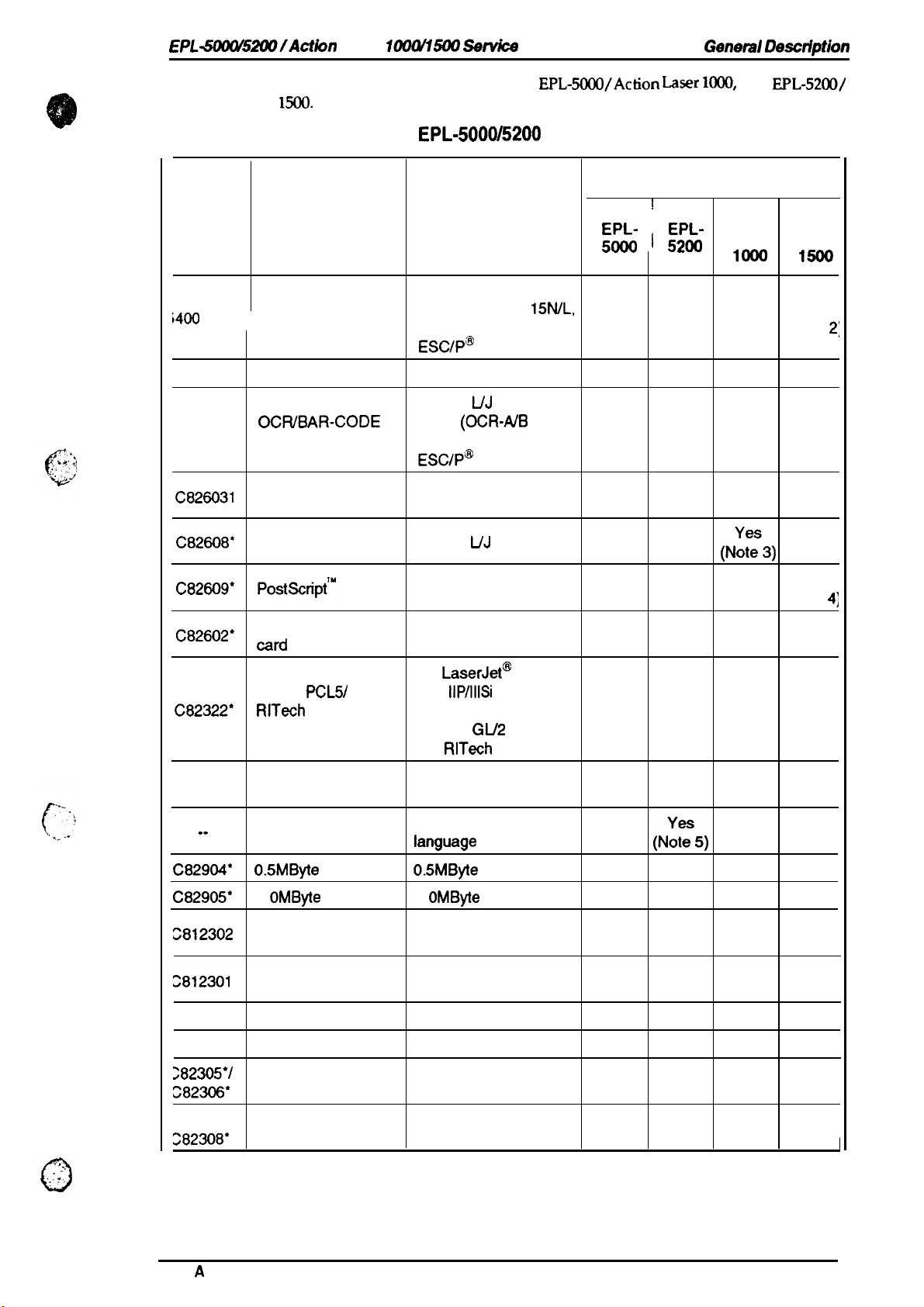

Table 1-2 lists the optional units available

Action Laser

Table 1-2. Options for

IWO.

EPL-5000/5200

Cat. No. Description Note

For GQ mode (5400

i400

-54091 Bit map font card

1410-5414

5430

C828031

C82608*

HP bit map font card For HP emulation mode

OCFVBAR-CODE

font card

22 scalable font card

51 scalable font card

Prestige 12N/L,

12 NOB are usable in

ESC/P@

For HP

mode

are also usable in

ESC/P@

For GQ mode

For HP UJ Ill mode

mode)

IJJ

(OCR-NB fonts

mode)

for the

and GQ

EPL-5000/Action Laser MlO,

and

and Action Laser 1000/1500

Machine Type

I

Action

Laser

,m

Yes

Yes

Yes

0

‘

15N/L,

EPL5000 I 52~

Yes

(Note 1),

Yes

Yes

Yes

(Note 1)

Yes

(Note 3)

(Note 1) (Note 2)

(Note 1)

EPL-

Yes

Yes

Yes

Yes

‘es (N%S3)

EPL-52@/

Action

Laser

,W

Yes

(Note

2;

Yes

Yes

0

‘

‘es

C82609*

C82602*

C82322*

--

.-

C82904*

C82905*

~812302

~812301

C81231• Face-up tray

PostScript’”

EPSON GL Identity

~rd

Epson

RITech

Board

GQ chip ROM

Local language ROM

0.5MByte

2.

250 sheet lower

paper cassette (A4)

250 sheet lower

paper cassette (A/L)

PCL5/

Upgrade

OMByte

RAM chips

RAM chips 2.

card

supports Postscript’”

language

Supports HP-GL

commands

HP

LaserJet@

111/l llP/lllSi emulation

mode (includes

EPSON GIJ2 mode)

RITech

and

Supports GQ mode

fonts and commands

supports local

Ianguage

0.5MByte

OMByte

Lower paper cassette

Lower paper cassette

support

fonts (Note 5)

RAM chip set

RAM chip set

Yes

(Note 4)

Yes

(Note 4)

Yes

Yes Yes

(Note 5)

Yes

Yes

Yes

Yes

No

Yes

Yes

(Note 4)

Yes

(Note 4)

No

(Note 5)

(N%5)

Yes

Yes

Yes

No

Yes

Yes Yes

(Note 4)

Yes Yes

(Note 4)

Yes

‘

‘

Yes Yes

Yes Yes

No

Yes

Yes Yes

(Note

(Note 4]

0

0

No

‘

0

‘

No

Yes

4]

0

.,.

,.

..:

.,

7

0

SO51O11

282305’/

:82306’

>82307’/

;82308”

Rev.

A

Imaging cartridge

Serial interface card

32KB serial interface

card

Toner cartridge

Yes

No

Yes

Yes

No

Yes

Yes Yes

Yes

Yes

No

Yes

1-3

Page 15

General

Descri@ion

EPL-5000/5200/Action

Laser 100WI5OO Service Manual

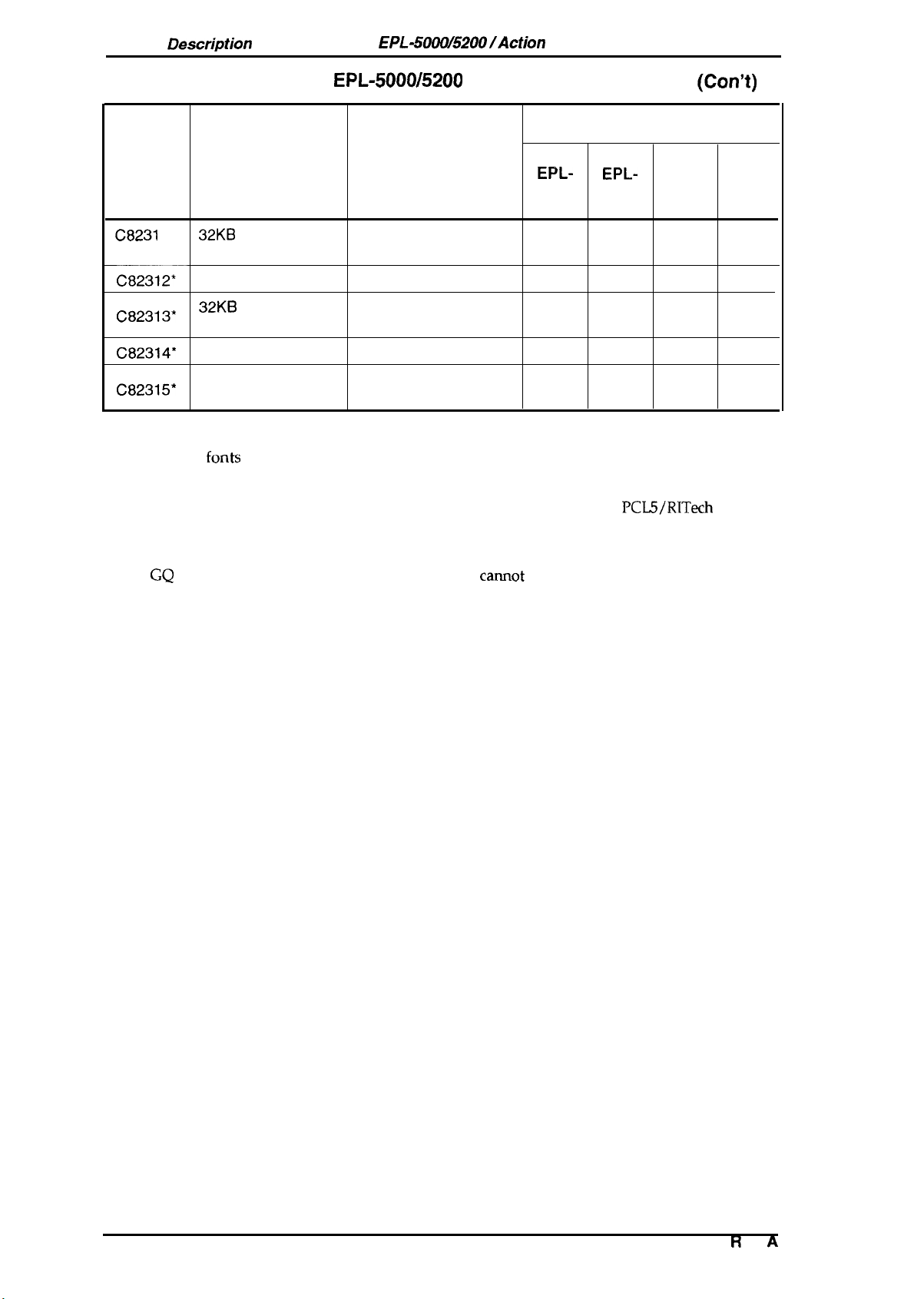

Table 1-2. Options for

Cat. No.

C8231

0’/

C82311“

C82312*–

C82313*

C82314*

C82315*

Notes:

1.

GQ mode

2.

The ActionLaser 1000/1500 uses only card 5400.

3. Scalable fonts for HP LaserJet III mode can used, if the optional Epson

Description

32KB

parallel

interface card

LocalTalk

32KB

interface card

COAX interface card

TWINAX interface

card

fonts

rM

card

IEEE-488

can be used, if the optional GQ chip is installed.

EPL-5000/5200

Note

and Action Laser 1000/1500

Machine Type

EPL-

5000

Yes

Yes Yes Yes Yes

No No

Yes Yes

Yes Yes

EPL-

5200

Yes Yes

Action Action

Laser

PCI-i5/RITech

Board is installed.

Requires added memory (RAM) over a total 1.5 MB (including standard RAM).

4.

5.

The GQ ROM chip option and local language ROM

camot

be used at the same time.

(Con’t)

Laser

1000

No No

Yes

Yes

1500

Upgrade

Yes

Yes

Yes

Page 16

EPL4WiX.Y52tXl/A ction Laaar 1(XW7SO0 Sanka

1.2 SPECIFICATIONS

Manual

Genemlf)esctfptlon

This section provides statistical data for the

1.2.1

Basic Specifications

Printing method:

Resolution:

Printing speed:

First printing time

Warm-up time:

Paper supply:

(A4/LT):

Laser beam scanning and dry

300

DP1

6 PPM (pages per minute)

Less than 19 seconds (facedown output)

Less than 20 seconds (face-up output)

Less than 35 seconds (at rated current and 23° C (73° F) temperature)

See Table 1-3.

EPL-5000/52~

(dots per inch)

Table 1-3. Paper Feed Methods

Capaoity

Paper Supply

Auto feed

Standard built-in

paper bin

(2011$7(7#m2)

150

!5

to 10

and ActionLaser

ekctro-photography

(Ietter/A4)

Paper Size

A4,LT,GLT,EXE,

LG,GLG

Monarch,D1.,C5,

Commercial-10

lW3/l!MO.

Uaage

Thkkneaa

(Beam Weight)

16 to 24 lb.

(60to

90g/m2)

Envelopes made

of 20 to 24 lb. (75

to

90gfm2)

paper

I

I

. . . .

.-”.,

:.

,

(

Y

*

Manual feed

Lower paper cassette (Optional)

Notes:

lb. (ream weight) = 500 sheets of 17x 22 inch paper; 1 g/m2 = 0.2659763 lb.

1.

2. Paper size range: width

length 5.85 to 14.0 inches (148.5 mm to 356 mm)

Paper types:

See Table

1

250

3.63to 8.5 inches (92t0216mrn)

14

Any size

(Note 2)

A4 or

feedable

LT

Table 1-4. Paper Types

Standard paper

I

Normal paper

Special

papers

Xerox”

20 lb.

Regular photocopier paper

Bond paper

16 to 24 lb. (60 to 90

Card

Envelopes

Labefs

Letterhead

Transparency

Colored

4024

(75

dm2)

stook

oaoer

W

paper

(90 to 157

(OHP)

sheets

g/m2)

@m*)

16 to 42 lb.

(60to

157g/m2)

16 to 24 lb.

(60to

90g/m2)

●

,

:;.%

c)

Rev.

A

1-5

Page 17

General Description

EPL-5000/5200 /Action Laser 1000/1500 Service Manual

Usability of special papers:

See Table 1-5.

Table 1-5. Usability of Special Papers

input

Standard

built-in paper

bin

Lower paper

cassette

output

Face down

Face up

Face down

Face up

R: Reliable feeding and good image quality.

P: Possible, but better avoided.

I: Impossible.

Paper

feed alignment and direction:

Paper ejection:

Output tray capacity:

Printable area (standard paper):

OHP

P P

R R

I

I

Center alignment for all sizes

Face down; face up (optional)

100 sheets (face down)

20 sheets (face up) (standard paper)

See Figure 1-2.

Envelopes

T

{

Labels

‘.

; “+

I

Card

#Y-

1

I

Stock

;

I

Letterhead

R

R

P

P

Note:

The actual printable area depends on the printer mode.

Noise:

Ozone density:

Toxicity:

—

Printable Area

—

I

4.00mm

Figure 1-2. Printable Area

Less than 35

Less than 47

Less than 0.01 ppm

No toxicity exists in OPC, toner, or plastic materials

4.00mm

dB(A)

dB(A)

,

—

.

(standby)

(operating)

1-6

Rev.

A

Page 18

EPL-500W5200 /Action Laser

1UOW1500

1.2.2 Electrical Specifications

Table 1-6. Electrical Specifications

I

I

Description

Semfca Manual

I

100 V Version

I

I

200 V Version

I

General Dascriptfon

1

I

(;:~

-.”

Rated voltage

Input voltage range

,

Rated frequency range

Input frequency range

Rated current

Power consumption

1.2.3

Reliability Specifications

MPBF (Mean Prints Between Failures): Over 25,000 Sheets

Note:

MTBF (Mean Time Between Failures):

Jam rate:

Feed failure:

Multiple paper feeds:

Paper curl height:

Leading edge

MTTR

Durability:

MP13F

indicates average number of pages printed before occurrence of problem requiring

replacement or

bending (1 cm or more):

(Mean Time To Repair):

semice.

100-120

90-132

3000

Power on hours

1 out of 2~ sheets or less (excluding

1 out of 2,000 sheets or less (excluding multiple-sheet feeding)

1 out of 500 sheets or less

30 mm (1.2 inches) or less

1 out of 1,000 sheets

30 minutes or less

5 years or 180,0000 sheets

VAC

VAC

5.5 A 3.3 A

Less than 600 W

50-60 Hz

47-63 Hz

(pOH)

220-240

198-264

VAC

VAC

multiph+sheet

,

I

feeding)

1.2.4 Environmental Conditions for Operating (Include Imaging Cartridge)

Temperature:

Humidity:

Altitude:

.>

(

Levelness:

Illurninance:

Surrounding space:

1.2.5 Environmental Conditions for Storage and

10to35‘C (50 to 95 ‘F)

15 to 85

2~

Printer should be installed on a level plane.

3,000 I

Printer should have at least 100 mm clearance on its sides

and rear.

YOM-I

m

(8z@

feet) or lower

UX

or less (Must not be exposed to direct sunlight.)

TranspoMion

(Exclude Imaging Cartridge)

Temperature:

Humidity:

Drop test:

Vibration:

Resistance to atmospheric pressure:

Storage term:

Oto35‘C (32 to 95 “F) over full storage term

-20 to55“C (4 to 131

(Extremes are allowable for up to

Temperature variation must be10‘C (18 ‘F)

30to85‘%oRH over full storage term

10 to 95

(Extremes are allowable for up to 1/30 of full storage term)

Clear to

Vibration frequency

Acceleration

Accelerationdirection

More than 613 mb

24

YoRH

JIS Z0200-1987

months

under extreme conditions

(following date of manufacture)

“F) under extreme conditions

l/300f

full storage term)

jhour

or less

Level 1

5 to

IW

Hz and 100 to 5 Hz

IG

3direction

Rev.

A

1-7

Page 19

General Description

1.2.6 Applicable Standards

Safefy %ndurds

120

VAC

model:

220/240

Safety Regulations (Laser radiation)

VAC

model:

EPL-5000/5200/A

ction Laser 1000/1500 Service Manual

UL 1950, CSA 22.2 Deviation 220

EN 60950

(IEC950), NEMKO (IEC950), SETI

SEMKO (IEC950), DEMKO (IEC950)

(I

EC950),

120

VAC

model:

z20/240° VAC model:

FDA(NCDRH)

VDE

O&37 (Laser Class

Class 1

1)(IEC825), SETI (IEC825), SEMKO

(IEC825), DEMKO (IEC825)

EMI

120

VAC

model:

220/240

Others

VAC

model:

Toner:

OPC:

Ozone:

Materials:

1.2.7 Specification for Consumable

Life:

Note:

Environmental Conditions for Storage and Transportation

In

continuous printing

The life varies, depending on the printing mode (continuous or intermittent)

image ratio.

mode with

FCC Part 15 Subpart B Class B

FTZ

(VDE

0871 Class B, 0875 Part 1),

No effect human health. (OSHA-TSCA,

No effect human health.

Less than 0.01 mmp

other

UL478

(5th edition)

SWISS Environmental Law (No

(Imaging

Cartridge)

6,000 pages

A4/letter

paper at a

5%

(OSHA)

CdS

image ratio

CISPR Pub22

EINECS)

must be contained)

(blacldwhite

ratio).

anoXor

the

Temperature:

Humidity:

Drop test:

Vibration:

Resistance to atmospheric pressure:

Storage term:

1.2.8 Physical Specifications

Dimensions:

Printer:

With lower cassette:

With face-up tray:

With lower cassette and

face-up tray:

Oto30“C(32

to 86 ‘F) over full storage term

-20 to40“C (-4 to 104 “F) under extreme condition

(Extremes are allowable for up to 1/30 of full storage term)

Temperature variations must be10“C (18

30 to 85

YoRH

over full storage term

OF)/hour

or less.

10to95‘%oRH under extreme conditions

(Extremes are allowable for up to 1/30 of full storage term)

Height 76 cm (30.4 inches)

Same as printer

More than 740 mb

18 months (following date of manufacture)

368(W) X 456(D) X

14.5(W) x

368(W)

14.5(W)X

368(W) x

14.5(W)X

368(W) x

18.O(D)

x

480(D) x 336(H) mm

18.9(D) x 13.2(H) inches

632(D) x 360(H)mm

24.9(D) x 14.2(H) inches

657(D) X 430(H) mm

226(H)mm

x 8.9(H) inches

14.5(W) x 25.9(D) x 16.9(H) inches

Weight:

With lower cassette;

With face-up tray;

With lower cassette and

face-up tray;

l-a

Approx. 10 Kg (22 lb.) (consumable, excluding

Approx. 12.8 Kg (28.3 lb.)

Approx. 10.1 Kg (22.3 lb.)

Approx. 12.9 Kg (28.6 lb.)

all options)

Rev.

A

Page 20

EPL&lWW52U0/Actfon Laser

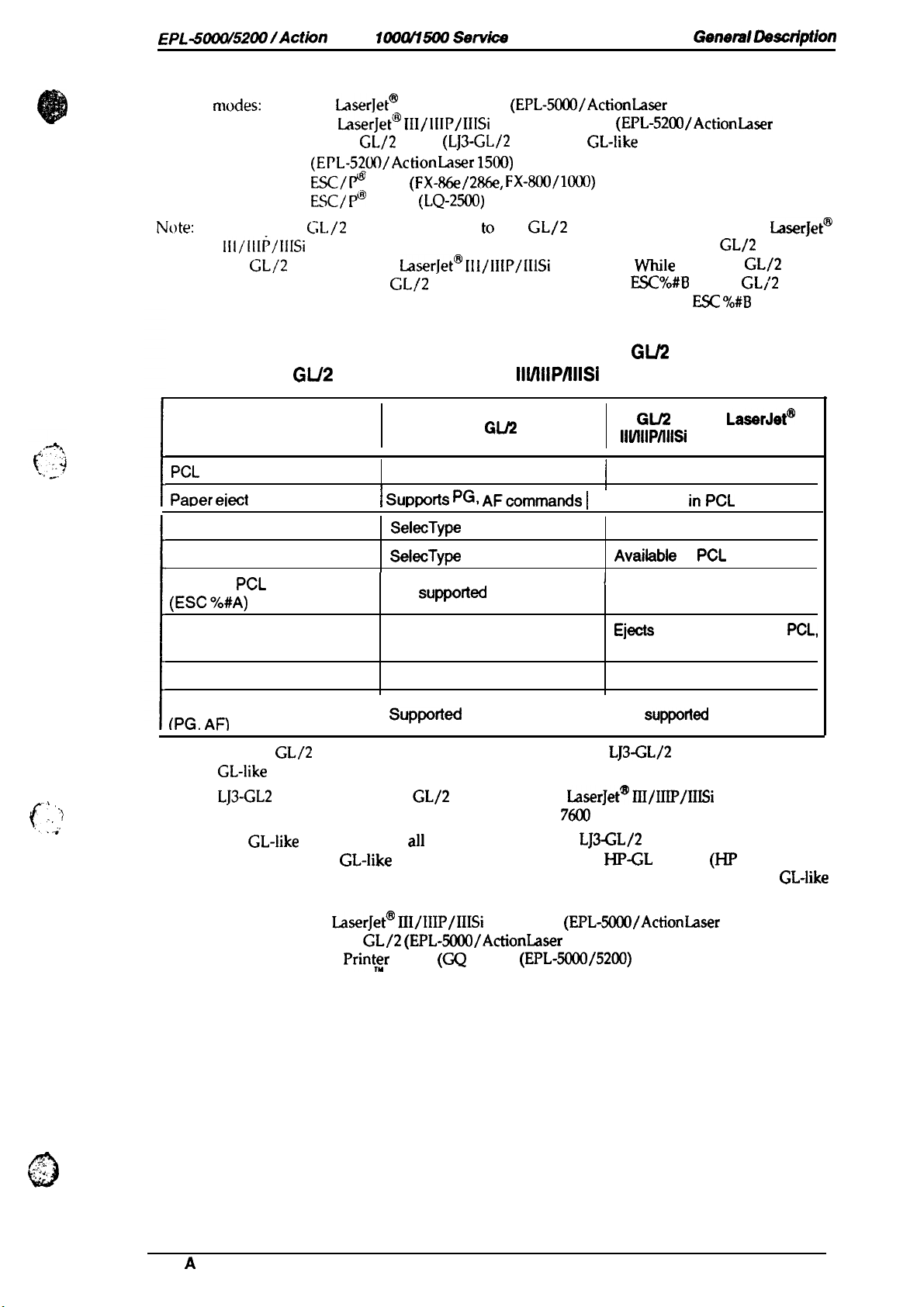

1.2.9

Software Specifications

HP

Built-in

Note:

modes:

The Epson

111/llIP/lIISi

the

GL/2

mode

the operator can enter

command. If the operator’s application software cannot send the

then use this mode.

LaserJet@

HP

LaserJet@ 111/lllP/IIISi

Epson

(EPL-5200/ActionLaser 1500)

ESC/~

ESC/ P@

GL/2

emulation.

GL/2

mode is similar to the

in the

-

1OO(W5OO Sarvfce

11P emulation:

emulation mode:

mode

9-pin

24-pin

Table

HP

GL/2

(LJ3-GL/2

(FX-86e/286e, FX-800/1000)

(LQ-25UO)

1-7

LaserJet@ 111/lIIP/IIISi

mode without sending the

mode

shows the differences between Epson

Manual

(EPL-5000/ActionLaser

(EPL-5200/ActionLaser

mode and

GL/2

GL-like

emulation mode

mode included in the HP

emulation.

1000)

mode):

While

ESC

Yo#B

GenetalDescdption

1500)

La~rJet@

GL/2

mode and

in Epson

(Enter

ESC ‘Yo#B

GL/2

mode,

GL/2

mode)

command,

r

. . .

.. .;,

Table 1-7. Differences between EPSON

GL/2

in the

PCL

mode

PaDer eiect

Auto eject

Reduced printing

Switch to

(ESC %#A)

Reset (ESC E)

PJL, EJL, and ES

Advance Full Page

(PG. AF)

Notes:

‘3

,(

Optional modes:

Auxiliary software:

Built-in fonts: See Table 1-8 through Table 1-11.

PCL

EPSON

GL-like

LJ3-GL2

user can print with software that supports the HP

The

commands. The

commands. If the application software uses unsupported co

mode, print cannot be assured.

GL/2

mode has two operational modes. One is

mode.

mode emulates the

GL-like

mode features

GL-like

HP

LaserJet@ 111/IIIP/IIISi

EPSON

Page

Prin$~r

Postscript mode (all models)

EPSON GL mode (all models)

Hex dump

Status sheet

Font sampie

HP

LaserJet”

EPSON

Does not exist

I

\ SUPPOrtS PG, AFcommands I

SelecType setting

SeiecType

Not

Ejects paper and then

initializes

Supported

Supfmled

GL/2

all

mode emulates some of the

GL/2 (EPL-5000/ActionLaser

mode

setting

SUppOftf3d

mode in the HP

the co

(GQ

mode)

IIUlllP/lllSi

GLJ2

Mode

76MI

remands of the

emulation

(EPL-5000/ActionLaser

1000)

(EPL-5000/5200)

LaserJet@ 111/IIIP/IIISi

LJ3=L/2

GU2

and

Emulation

GU2

for HP

lli/lllP/illSi

I

Exists as the initial mode

I

Supported inPCL

Not available

Avaiiable

I

supported

Ejeots

and then initializes

supported

Not

LJ3-GL/2

series plotter.

HP-GL

in

paper, switches to

SUppOrtt3d

mode; the other is the

mode, plus two additional

plotter

remands for the

LaserJet@

Emulation Mode

PCL

emulation. ‘l’he

(HP

7475A, etc.)

1000)

PCL,

GL-like

.

,+

‘$J..

‘.,.

o

Rev.

A

1-9

Page 21

General Description

EPL+OOO/5200/Action Laser 1000/1500 Service Manual

Table 1-8. Built-in Fonts

Resident Fonts

Bitmap fonts

Courier Medium

Courier

Courier Medium

Courier Medium

Courier

Courier Medium

Line printer

Presitage Medium

Presitage Medium Umiaht

i: Supported,

NS:

Not Supported

Bold Upright

Bold Upright

Medium

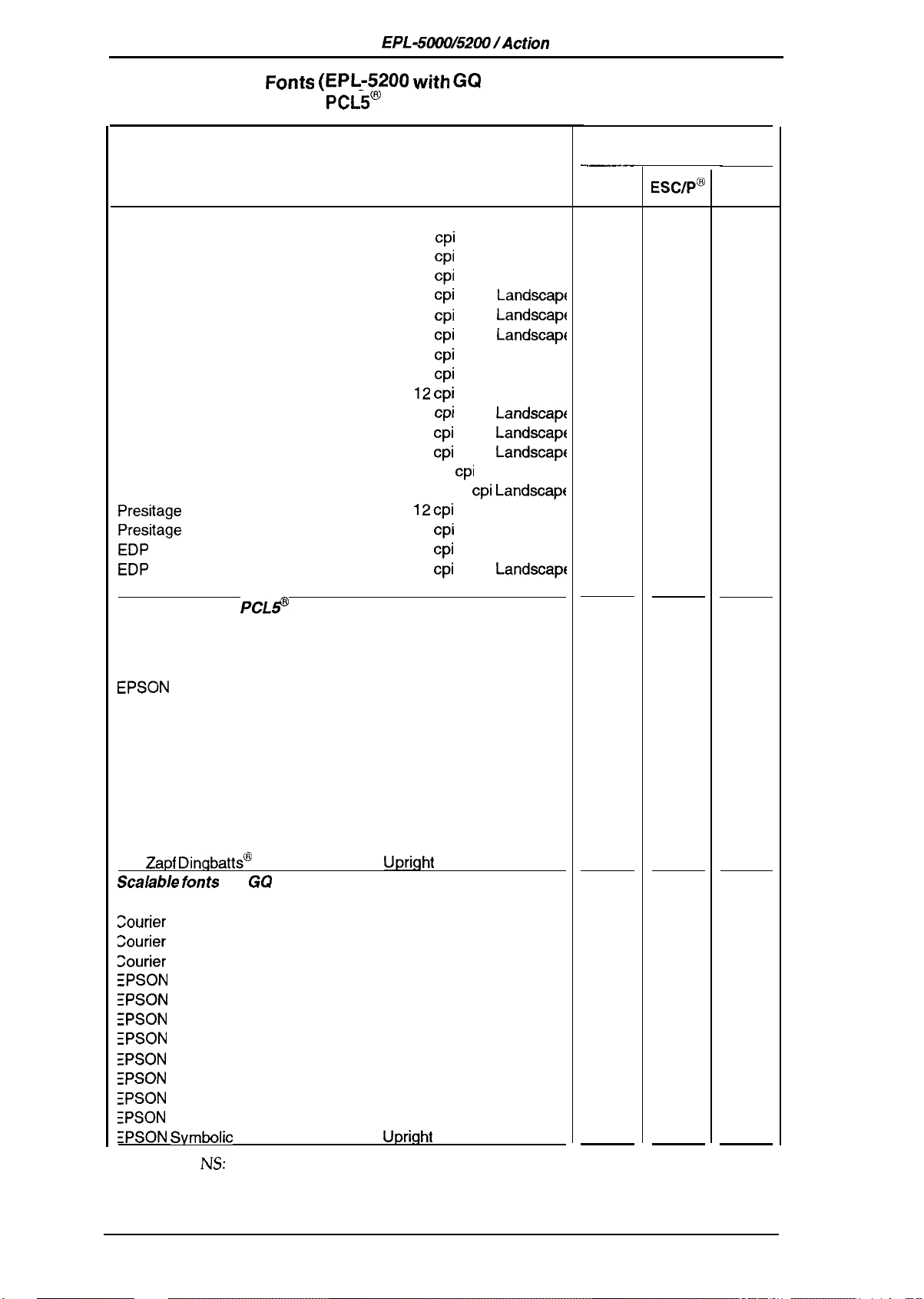

Table 1-9. Built-in Fonts

Upright

Italic

Upright

Italic

Upright

Upright

(EPL-5200/Action

Laser 1000 with

Resident Fonts

(EPL-5000/Action

10

cpi

10

cpi

10

cpi

12

cpi

12

cpi

12

cpi

16.66

cpi

12

cpi

20

c~i Portrait

Laser 1500 and

PCL5@

Board)

Laser 1000)

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

=

s

s

s

s

s

s

s

NS

Ns

s

s

NS

s

s

NS

s

s

s

EPL-5000/Action

Applicable Mode

HP LJ3

ESC/P@

Bitmap fonts

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Line printer

Line printer

Presitage

Presitage Medium

Scalable

EPSON Roman T

EPSON Roman T

EPSON Roman T Medium

EPSON Roman T

EPSON Saris Serif U

EPSON Saris Serif U

EPSON Saris Serif U

EPSON Saris Serif U

EPSON Saris Serif U

EPSON Saris Serif U

EPSON Saris Serif U

EPSON Saris Serif U

ITC

S: Supported,

fonts for

Zapf Dinqbatts@

NS:

Not Supported

PCL@

Medium

Bold

Medium

Medium

Bold

Medium

Medium

Bold

Medium

Medium

Bold

Medium

Medium

Medium

Medium

Medium

Bold Upright

Bold Italic

Medium

Bold Upright

Medium

Bold

Medium Condensed Upright

Bold

Medium Condensed Italic

Bold

Medium

Upright

Upright

Italic

Upright

Upright

Italic

Upright

Upright

Italic

Upright

Upright

Italic

Upright

Upright

Upright

Upright

Upright

Italic

Upright

Italic

Italic

Condensed Upright

Condensed Italic

Upright

10

cpi

10

cpi

10

cpi

10

cpi

10

cpi

10

cpi

12

cpi

12

cpi

12

cpi

12

cpi

12

cpi

12

cpi

16.66

16.66

12

cpi

20

cpi

cpi

cpi

Portrait

Portrait

Portrait

Landscape

Landscape

Landscape

Portrait

Portrait

Portrait

Landscape

Landscape

Landscape

Portrait

Landscape

Portrait

Portrait

s

s

s

s

s

s

s

s

s

s

s

s

s

s

NS

NS

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

NS

s

s

NS

s

s

NS

s

s

NS

s

s

s

s

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

1-1o

Rev.

A

Page 22

r..

c,’

Table 1-10. Built-in Fonts (EPL-5000 with GQ Chip)

Resident Fonts

Bitmap fonts

Courier

Courier Bold

Courier Italic

Courier

Courier Bold

Courier

Courier Bold

Courier Italic

Line printer

Line printer

Presitage

Presitage

EDP

EDP

Modern

Scabble

Courier Medium

Courier

Courier Medium Oblique

Courier

EPSON Roman T

EPSON Roman T

EPSON Roman T

EPSON Roman T

EPSON Saris serif H

EPSON Saris serif H

EPSON Saris serif H

EPSON Saris

EPSON

S:

Supported, NS: Not

fonts

Svmbolic

tbr

setif

Medium

Bold

Medium

Medium

Bold

Medium

Bold

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

G(?

H

Set

Supported

Upright

Upright

Italic

Upright

Upright

Upright

Upright

Italic

Upright

Upright

Upright

Upright

Upright

Upright

Upright

Upright

Bold Upright

Bold

Medium

Bold Upright

Medium

Bold italic

Medium

Bold Upright

Medium Oblique

Bold

Medium

Oblique

Upright

italic

Upright

Obfique

Uptiaht

10 cpi

10 cpi

10 cpi

10 cpi

10 cpi

12 cpi

12

cpi

12 cpi

16.66

16.66 cpi

12

Cp;

20

cpi

13

cpi

13 cpi

10 point Portrait

cpi

Portrait

Portrait

Portrait

Landscap[

Landscap[

Portrait

Portrait

Portrait

Portrait

Landscap[

Portrait

Portrait

Portrait

Landsqx

Applicable Mode

HP

LJ21

ESC/P@

s

s

s

NS

NS

s

s

s

NS

s

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

s

s

NS

s

s

s

s

s

s

s

s

GQ

s

s

NS

s

s

NS

NS

NS

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

.-.

Rev.

A

1-11

Page 23

General Description

EPL-50011/5200/Action Laser 1000/1500 Service Manual

Table 1-11. Built-in

Bitmap fonts

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Courier

Line printer

Line printer

Presitage

Presitage

EDP

EDP

Modern Medium

Scalable font for PCL@

EPSON Roman T

EPSON Roman T

EPSON Roman T

EPSON Roman T

EPSON Saris serif U

EPSON Saris serif U

EPSON Saris serif U

EPSON Saris serif U

EPSON Saris serif U

EPSON Saris serif U

EPSON Saris serif U

EPSON Saris serif U

ITC

Zapf Dingbatts@

Sca/ab/e fonts

Courier

Sourier

2ourier

3ourier

EPSON

=PSON

=PSON

=PSON

~PSON

EPSON

=PSON

;PSON Saris serif H

;PSON

Roman T

Roman T

Roman T

Roman T

Saris serif H

Saris serif H

Saris serif H

Svmbcdic

for

Fonts (EPL-5200 with GQ

Medium

Bold Upright

Medium

Medium

Bold

Medium

Medium

Bold Upright

Medium

Medium

Bold Upright

Medium

Medium

Medium

Medium

Medium

Medium

Medium

GQ

Set

Chip Option and EPL-5000

PCL5@

Resident Fonts

Upright

Italic

Upright

Upright

Italic

Upright

Italic

Upright

Italic

Upright

Upright

Upright 12 cpi

Upright

Upright

Upright

Upright 10 point Portrait

Medium

Bold Upright

Medium

Bold

Medium

Bold

Medium

Bold Italic

Medium Condensed Upright

Bold

Medium

Bold

Medium

Medium

Bold

Medium Oblique

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Board and GQ Chip)

10

cpi

10

cpi

10

cpi

10

cpi

10

cpi

10

cpi

12

cpi

12

cpi

12 cpi

12

cpi

12

cpi

12

cpi

16.66

cpi

16.66

20

13

13

Upright

Italic

Italic

Upright

Upright

Italic

Condensed Upright

Condensed Italic

Condensed Italic

Upriqht

Upright

Upright

Oblique

Upright

Upright

Italic

Italic

Upright

Upright

Oblique

Oblique

Upriqht

cpi Landscapf

cpi

cpi

cpi

Portrait

Portrait

Portrait

Landscap[

Landscapf

Landscap[

Portrait

Portrait

Portrait

Landscap{

Landscap(

Landscap[

Portrait

Portrait

Portrait

Portrait

Landscap(

Applicable Mode

———

HP LJ3

ESC/P@

s

s

s

s

s

s

s

s

s

s

s

s

s

s

NS

NS

NS

NS

NS

s

s

s

s

s

s

s

s

s

s

s

s

s

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

s

s

NS

s

s

NS

s

s

NS

s

s

NS

s

s

s

s

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

with

GQ

s

s

NS

s

s

NS

NS

NS

NS

NS

NS

NS

s

s

s

s

s

s

s

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

NS

s

s

s

s

s

s

s

s

s

s

s

s

s

S: Supported,

1-12

NS:

Not Supported

Rev. A

Page 24

EPL@OtY52001Act~n Laser 1000/1500 Service Manual

Font Symbol Sets

HP LaserJet@ 11P Mode: 26 symbol sets

1S02, 4,6,10,11,14,15,16,17, 21,25,57,60,61,69,84, 85

ISO1OO(ECMA94-1 )

HP German

HP Legal

IBM-US

PcMultilingual

HP LaserJet@ III/IIIP/IIISi Mode: 41 symbol sets

1S02, 4,6,10,11,14,15,16,17, 21,25,57,60,61,69,84, 85

ISO1OO(ECMA94-1)

Roman Extension

HP German

HP Spanish

HP legal

HP Roman-8

IBM-US

IBM-DN

PcMultilingual

Venture ITC Zapf Dingbatts Windows

PS ITC Zapf Dingbatts

ITC Zapf Dingbatts@ 100

ITC Zapf

ITC Zapf Dingbatts@ 300

Dingbatts@ 200

Roman Extension

HP Spanish

HP Roman-8

IBM-DN

Venture Math

Venture International

Venture US

PS Math

PS Text

Math 8

Pi Font

Microsoft Publishing

DeskTop

General Description

(

. .

\,

.j

.,

ESC/P

FRANCE

GERMANY

UK

DENMARK1

SWEDENT

ITALY

(In

GQ Mode:

USA

FRANCE *

GERMANY *

UK

DENMARK1 *

SWEDEN *

ITALY *

●

Code page 865 (PcNordic)

Code page 850 (PcMultilingual)

Code Page 437 (PcUSA)

Code Page 863 (PcCanFrench)

Code Page 857

Mode: 13

USA

addition to the above, Code Page 860,863,850,865 and 437 can also be selected by SelecType.)

:

Two types, one

International Characters

SPAIN1

JAPAN

NORWAY

DENMARK2

SPAIN2

L.AMERICA

35

symbol sets (Option)

*

*

SPAIN1 *

JAPAN *

NORWAY *

DENMARK2 *

SPAIN2 *

L. AMERICA *

with extended graphics and one without.

Code page 860 (PcPortuguese)

ECMA94-1

Symbolic

Code Page 853

Rev. A

1-13

Page 25

General Description

EPL+OOO/5200/Action Laser 1000/1500 Service Manual

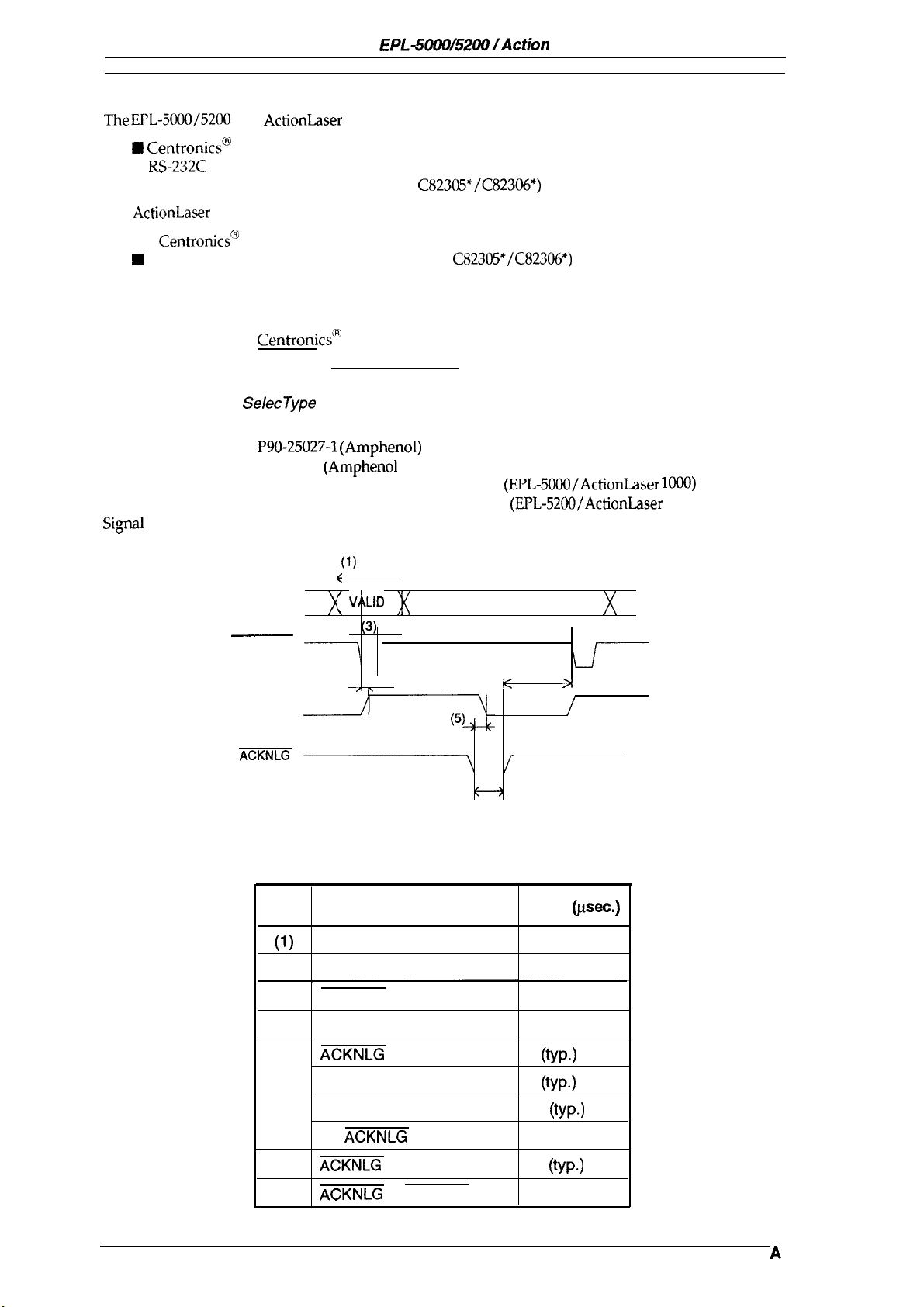

1.3 INTERFACE SPECIFICATIONS

TIW

EPL-5000/5200

and

ActionLaser

1500 are equipped with the following external interfaces:

H Centronics@

❑

RS-232C

■

Optional Type B interface (except for

The

ActionLaser

❑

Centronics@

9

Optional Type B host interface (including

1.3.1

Parallel Interface

Type:

System:

Handshaking:

Note:

While the

only.

Comector type:

Applicable plug:

Transfer speed:

parallel interface

interface

1000 is equipped with the following external interfaces:

parallel interface

CentronicsC>

STROBE synchronization, 8-bit parallel data transfer

BUSY and ACKNOWLEDGE signals

SelecType

setting for BUSY delay is “MlN,” the handshaking signal is BUSY

P90-25027-1 (Amphenol)

57-30360

About

(Amphenol

75,000

bytes/second (max.)

About 125,000 bytes/second (max.)

Siamal

timing:

See Figure 1-3.

Signal description: See Table 1-12.

(1)

(2)

(

‘r

DATA 1-8

STOROBE

BUSY

VALID VALID

)

:

,

(4)

.

C82305*/C82306*)

receptacle

or equivalent)

:3)

,

/

—

C82305*/C82306*)

(EPL-5000/ActionLaser 1000)

(EPL-5200/ActionLaser

(7)

<

>

/

1500)

\

ACKNLG

No.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

f

+--+

(6)

Figure 1-3. Signal Timing

Table 1-12. Signal Timing

Description

Data set up

DATA hold

STROBE (pulse width)

BUSY delay

ACKNLG

No

ACKNLG

ACKNLG

to BUSY –5

ACKNLG

pulse width

to STROBE

o

+5

pulse

Time

0.5 (min.)

0.5 (min.)

0.5 (min.)

4.0 (max.)

(typ.)

o

5

(typ.)

10

—

10

O (min.)

(p.sec.)

(typ.)

(typ.)

1-14

Rev.

A

Page 26

EPL+WiXV52(X1/Ac thn

Laser

l(XXV1500

Service Manual

Genendl)escrlptjon

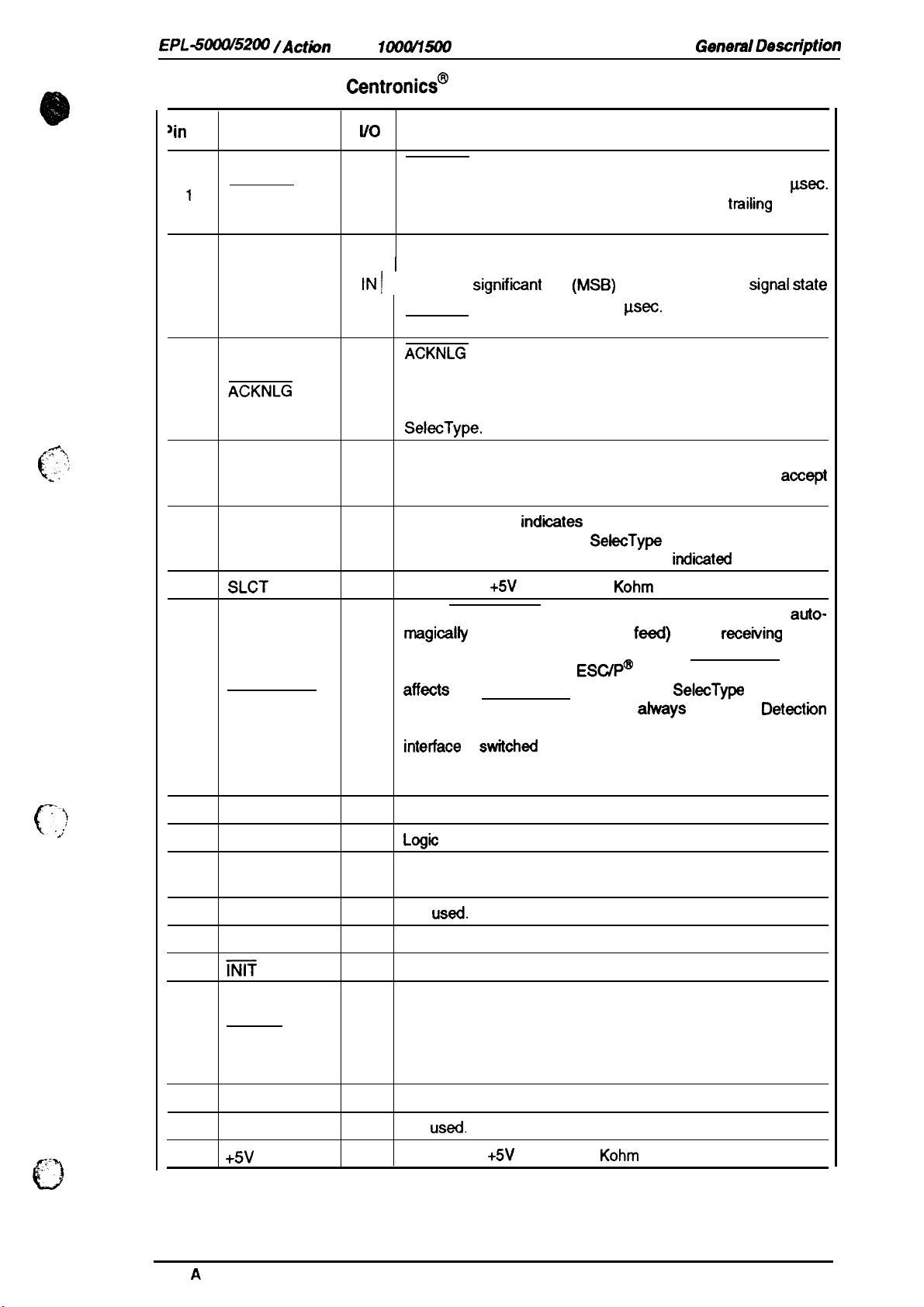

~in

2-9

No.

1

10

11

12

Table 1-13.

Signal Name

STROBE

DATA 1-8

ACKNLG

BUSY

PE

Centronics@

Parallel Interface Pin Assignment

I/o

STROBE is a strobe pulse used to read data from the host

computer. The pulse width must be more than 0.5

IN

Normally it is HIGH, and data is latched at the

this signal.

DATA 1 to 8 are parallel data bits. When the signal is HIGH,

I

the data bit is 1, and when it is LOW, the data bit is O.

IN ~

The most

must be maintained for 0.5

STROBE signal active edge.

ACKNLG

of 10 @cc. This signal goes LOW when the data reception is

OUT

OUT

OUT

completed, which indicates that the printer can accept new

data. Timing with the BUSY signal is specified through

SelecType.

The BUSY signal informs the host computer of the printer

state. When the signal is HIGH, the printer cannot

data.

The PE signal

cassette selected through

option paper cassette. Paper empty is

Description

psec.

tmiling

edge of

sjgnif~nt

is an acknowledge pulse with an approximate width

bit

(MSB)

indioates

is DATA8. The

psec.

on either side of the

paper empty for the standard

SelecType

or command, or for the

indicatd by HIGH.

signal state

acoept

>.,

“)

(

. .

‘d’

13

14

15

16

17 CHASSIS GND

18 NC

19-30

31

32

SLCT

AUTO-FEED

NC

GND

GND

~T

ERROR

OUT

IN

.

-

IN

OUT

Pulled up to +5V through a 3.3

If the AUTO FEED signal is set to LOW, the printer

magicaliy

(Carriage Return) oode from the host computer.

In GQ Mode (option) or

affeots

HP Mode, AUTO-FEED signal is

can only be done when the printer is ON or when active

intetface

This signal is detected only when the power is turned ON, or

when the printer is initialized.

performs a LF (line

the CR

is

operation according to

switohed

to parallel interface.

Kohm

ESC/P@

resistor.

auto-

fed)

upon

Mode, AUTO-FEED signal

SeleoType

afways

reoeiving

settings. In

ignored.

a CR

Deteotion

Not used.

Logio

ground level.

Connected to the printer chassis. The printer chassis

and the signal GND are connected to each other.

USeCf.

Not

Ground level for the twisted pair return signal.

The STROBE signal is ignored when this signal is LOW.

This level goes LOW when the printer is:

●

out of paper

●

paper jam

● in error state

● off line

GND

33

34

35

Rev.

GND

NC

+5V

A

Same as for pins19 to 30.

Not

USd

Pulled up to +5V through 3.3

Kohm

resistance.

1-15

Page 27

General Description

EPLGOOO/5200/Action Laser 1000/1500 Service Manual

Table 1-13.

~in

No.

36

Signal Name

SLCT-IN

Centronics@ parallel

1/0

If the

SLCT-IN

initialized, the printer enters the

DC1

and

signal is HIGH when the printer is turned on or initialized, the

select/deselect control by

receives a

until a

IN

ACKNLG

time. It is possible to disable

and keep the printer constantly in the selected state. In GQ

mode (option) or

DC3

this signal always ignored.

DC1

operation according to

Interface Pin Assignment (Continued)

Description

signal is LOW when the printer is turned on or

DC3

control codes are ignored. If the

DC1/DC3

DC3

code, any subsequent data

code is received. Handshaking with the BUSY or

signai,

however, is

ESC/P@

yerformed

SLCT-iN

mode, this

SelecType

1.3.2 Serial Interface (Except for the ActionLaser 1000)

Type:

Transfer system:

Synchronization:

RS-232C

Fuli

duplex

Asynchronous start-stop system

Start-bit:

Stop-bit:

1

1 or 2

Data length: 7 bits or 8 bits

Protocol:

Transfer speed:

Error:

Signal description:

Parity:

X-ON/X-OFF (can be combined with

DTR

control (can be combined with X-ON/X-OFF)

300,600,1200,2400,4800, 9600,19200, or 38400 bps

Overrun error:

Parity

error:

Framing error:

Breaking character:

See Table 1-14.

Odd, even, or none

DTR

control)

Processed as missing data and replaced by “*”

Replaced by “*”

Replaced by “*”

Ignored

seiectecf

state. In this state,

is valid. If the printer

wili

be thrown out

for data during this

signal with

signai

affects the

settings. In HP Mode

SLCT-IN

SelecType

DC1

or

>in

——

No

Signal Name

CHASSIS-GND I

1

2

3

RTS

4

CTS

5

Table 1-14. Serial Interface Connector Pin Assignments

I

-

1

1/0

OUT

IN

Connected to the printer chassis. The printer chassis

and the signal GND are connected to each other.

Serial ASCII data outputted by the printer. It maintains

“MARK” state (LOW

codes. Logic O is at HIGH level (“SPACE”) and logic 1 is at

LOW level (“MARK”).

Seriai ASCli

state (LOW level) between received character codes.

Transmission request signal outputted from the printer. It is

always at HiGH level during power ON.

Response signal to the

The printer transmits the data through TXD while

HIGH. It can be fixed HIGH through

When the

not be transmitted if

data inputted to the printer. it maintains “MARK”

SelecType

Description

Ievei)

between transmitted character

RTS

signal inputted to the printer.

SelecType.

setting for CTS is ON, X-ON/X-OFF will

CTS sicmal

is LOW.

GND

CTS

is

1-16

Rev. A

Page 28

EPL-500W5200/Actkm Laser llXMdMN)

Servloe

Manual

General Descdption

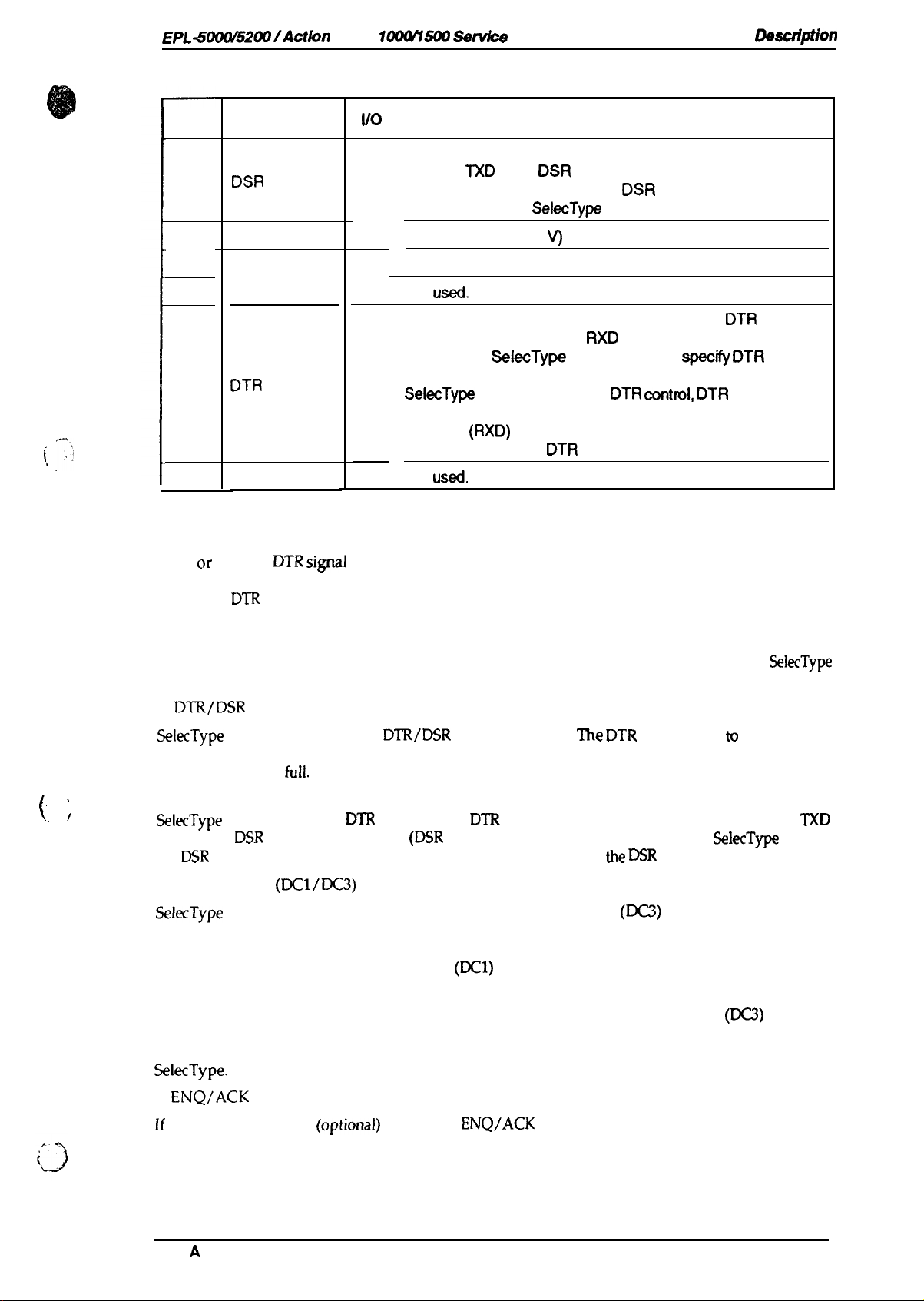

Table 1-14. Serial Interface Connector Pin Assignments (Continued)

(,

:-’!

Pin No

6

7

—.

8

9-19

20

21-25

Handshaking

Signal Name

DSR

SIGNAL GND

DCD

NC

DTR

NC

I/o

IN

IN

OUT

Signal inputted to the printer. The printer can transmit data

TXD

through

be transmitted regardless of

ignored by setting SelecType (Factory setting).

Ground reference (O

Always ignored.

Not

Used.

Signal outputted by the printer. When the

HIGH, it indicates that the

printer. The

the signal level is HIGH while the printer power is on.

SelecType

case any of the error conditions.

The date

128 characters after

USd.

Not

while DSR is HIGH. X-ON/X-OFF, however, can

SelecType

setting is used for DTR

(RXD)

from host computer must be stopped within

Description

DSR

V)

for signals.

RXD

signal can be received by the

settings do not

oontrol,

DTR goes LOW.

state. It can always be

DTR

signal is

speoify DTR

control,

When

DTR goes LOW in

When the vacant area for data in the input buffer drops to 128 bytes, the printer outputs an X-OFF

code or sets the

DTR signal

level to LOW, indicating that the printer cannot receive more data.

Once the vacant area for data in the buffer recovers to 256 bytes, the printer outputs an X-ON code

or sets the

DTR

flag to HIGH, indicating that printer is again ready to receive data.

(’

. .

Protocol

There are three types of protocols, as listed below, and each of them can be designated by

SelecType

independently.

■

DTR/DSR

SelecType

protocol

is used to execute the

DTR/DSR

control protocol.

The DTR

signal is set to HIGH when

the printer is ready to receive data, and to LOW when conditions indicate an error or that the

receiving buffer is fuk

‘

1

When the error is cleared and the printer returns to on line mode, the signal returns to HIGH. When

SelecType

only when

for

■

X-ON/X-OFF

SelwType

indicates an error, and the printer warns the host to stop data transmission within

No further

X-OFF code has been sent once. The X-ON

is used to set the

DSR

is at the HIGH level

DSR

is OFF). X-ON/X-OFF transmission is independent from

(DC1/DC3)

is used to execute X-ON/X-OFF protocol.

DTR

control OFF,

protocol

DTR

is always set HIGH. The printer transmits

(DSR

is always considered HIGH when the

The X-OFF

X-OFF codes are sent in response to additional data received from the host after the

(lXl)

code is output after all conditions given in error

the DSR

(DC3)

TXD

SelecType

setting

state.

code is output if status

128 characters.

are cleared.

When the remaining capacity of the receive buffer reaches 128 characters, X-OFF

(DC3)

is output

once. It is sent only once, even if there are multiple errors. The printer goes on line automatically at

power on, and outputs an X-ON code.

Transmission

of X-ON/X-OFF codes can be defined by

SelecType.

■

ENQ/ACK

If

the EPSON GL

Rev.

A

Protocol

mode

(optionaf)

is selected,

ENQ/ACK

protocol is also supported.

1-17

Page 29

General Description

EPL-5(XZV5200/Action Laser

1LWW1500

Service Manual

1.3.3 Optional Interface

The

ActionLaser

Type:

Synchronization:

Protocol:

Transfer speed:

Error:

1000 can use the non-intelligent serial interface card

RS-232C or current loop

Asynchronous start-stop system

Start bit:

Stop bit:

Data length:

Parity:

X-ON/X-OFF (cannot be combined with

DTR

control (cannot

300,600,1200,2400,4800, 9600, or 19200 bps

Overrun error: Processed as missing data and replaced by “*”

Parity error:

Framing error:

Breaking character: Ignored

C82305*/C82306* (ActionLaser

1000 Only)

1

1

7 bits or 8 bits

Odd, even, or none

DTR

control)

be combined with X-ON/X-OFF)

Replaced by “*”

Replaced by “*”

C82305*/C82306*.

1-18

Rev. A

Page 30

EPL4WUlY52tN1/Ac tion

Laaer

10i7tY1500

Service Manual

General

Daacdption

1.4 OPERATING INSTRUCTIONS

This section describes the functions performed through the control panel, such as test print,

hexadecimal dump, and

SelecType

functions.

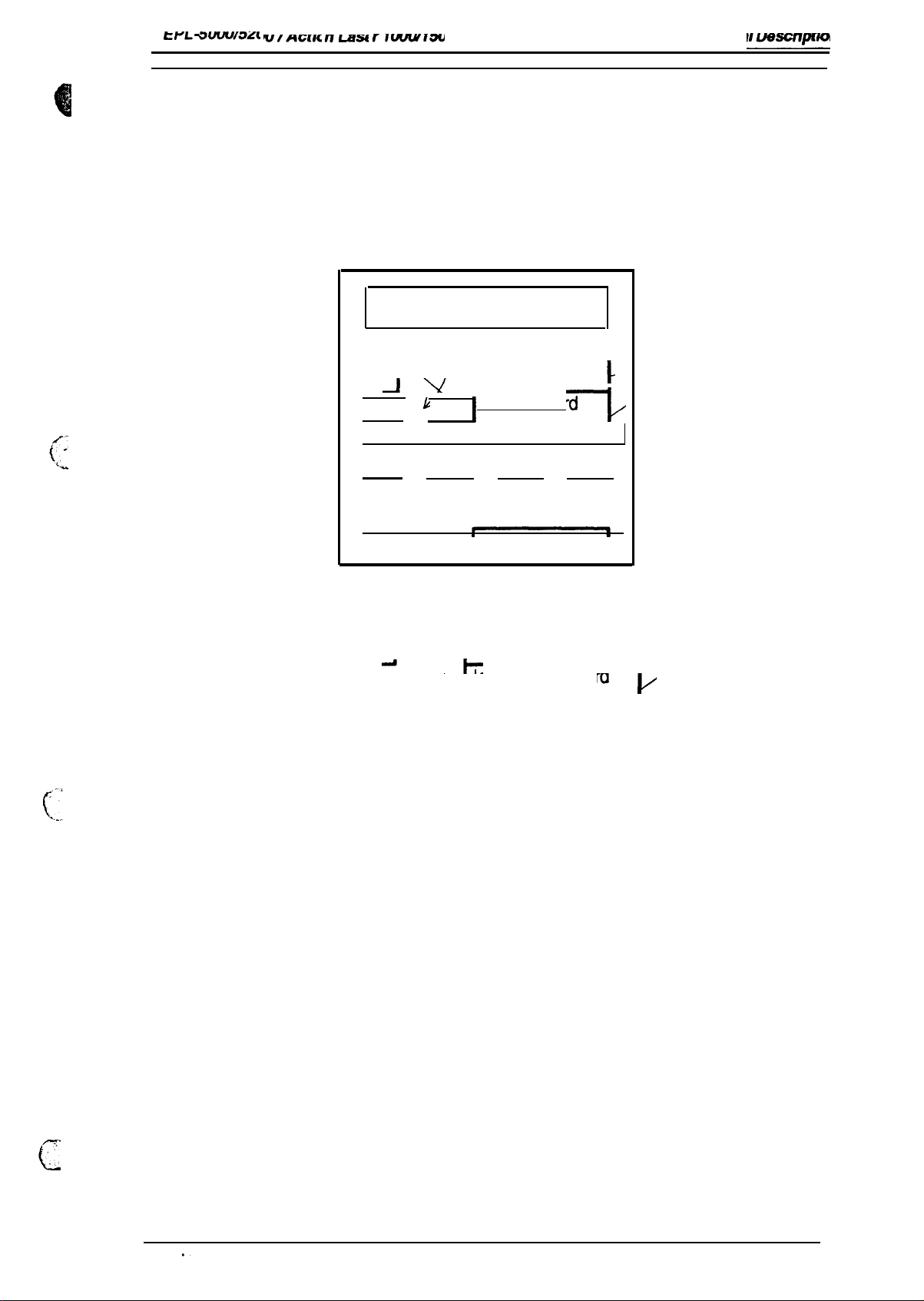

1.4.1 Control Panel

The printer control panel gives you easy control over most common printer operations. The panel

consists of a liquid crystal display (LCD), indicator lights, and buttons.

,1

c’

:\

SelecType

.EVEL

1 LEVEL 2

imu

RESET

I

o

COPY END CONTINUE

ON:NE

IJ

Figure 1-4. Control Panel

Display (LCD)

A 20-character (5 x 7 dot matrix) by l-row

status. A varie~ of printer

Indicator lights

■ ON LINE

ON:

OFF: Communication with the host is impossible.

Flashing:

Communication with the host is possible.

This state occurs when the system cannot shift from off line to on line, or vice versa.

parame~ers

liquid

crystal display (LCD) unit that indicates printer

can be displayed and &t &ing

EXIT

0

FEED

SelecType

mode.

f=.

‘:,.;

.,.

L)

■ FEED

This LED indicates the data processing condition for each interface channel: S, P, and O.

ON:

OFF:

Fast flashing:

Slow flashing: Indicates data has arrived on a non-active channel (in auto-sense operation).

H

CONTINUE

Flashes when an error is detected or a maintenance procedure is needed. An error message appears

on the display at the same time.

Rev.

A

Indicates that received data is stored in the printer that has not been printed out.

However, the LED does not light up when only non-printable data

other control codes) is stored.

Indicates there is

Indicates that the printer is in the process of receiving data from the host.

no

printable data remaining in the printer.

(comman

ds and

1-19

Page 31

General Description

Buttons

H

ON LINE/EXIT

EPL-5000/5200/Action Laser 1000/1500 Service Manual

ON LINE:

EXIT:

■

SelecType

LEVEL 1:

LEVEL 2:

This button switches the printer between on line and off line mode. This button is

invalid in

Exits

Enters

Enters

SelecType

SeIecType

SelecType

SelecType

[f printer power is turned on while this button is pressed, the printer enters hex

dump mode. (AH charnels are switched to hex dump mode.) This button is

invalid once the printer enters the hex dump mode.

■

RESET/lNI’IIALIZE

RESET:

Holding down this button until RESET appears on the display causes the printer to

finish printing the current page and then stop. The remaining data is discarded,

INITIALIZE:

and some

Continuing to hold this button down after RESET appears causes the message to

SeIecType Level 1

change to INITIALIZE.

SelecType

Level 1 and 2 settings to their power-on settings.

Holding down this button while turning on the printer, causes FACTORY RESET

to appear on the display, and all

9

COPY END/

CH

(P, S, or O) (EPL-5000/5200,

CH (P or O)

(ActionLaser

1000)

mode, but is effective in the hex dump mode.

mode.

Level 1.

Level 2.

settings return to their previously saved value.

This function clears received print data and returns

ActionLaser

SelecType

1500)

settings return to the factory settings.

COPY END:

Cancels the remaining copies when

multicopy

printing is selected and the printer is

off line.

CH (P, S, or

CH (P

or O):

❑ CONTINUE/IES

CONTINUE:

IES

(ps&xx):

■ FEED

O),If

the printer is set to auto-sense mode or individual mode, you can change the

interface charnel with this button.

(pS&xx)

Pressing this button when the CONTINUE LED is flashing

In

IES

mode, you can change the initial mode (PostScript or other mode).

cleacs

an error.

When the printer is off line and the FEED light is lit, press this button to print out data in the

printer’s memory.

1-20

Rev.

A

Page 32

EPL-5000/5200/Action Laser 1000/1500 Service Manual

1.4.2 SelecType Functions

This printer has two levels of SelecType, Level 1 and Level 2. Either level can be selected by

pressing the Level 1 or Level 2 button. SelecType Level 1 is called Mode Configuration. SelecType

Level 2 is called Printer Configuration.

The following menu maps show the possible menus options in SelecType.

General Description

Key:

SelecType Level 1

( ) - Only available with option.

[ ] - Only available with LJ-3/P/Si mode.

1“’”’

T

PAGE SIZE

COPIES

ORIENT .

FONT

STATUS SHEET

FONT SAMPLE

SUB CONFIG .

SYSTEM CONFIG .

{;;:’

A4

A5

B5

LT

HLT

1 - 999

Refer to mode menu map

Refer to mode menu map

Refer to mode menu map.

FULL PRINT

T-OFFSET

L-OFFSET

MEMORY LEFT XX

LOAD MACRO

SAVE MACRO

I

DELETE MACRO

PowerOn MACRO

F4

EXE

GLG

GLT

LGL

MON

C10

DL

C5

O

to

62

-64 to 63

-64 to

available bytes

o to

1 to 4

1 to 4

0 to

63

4

4

Figure 1-5. SelecType Level 1 Menu Map

SelecType Level 1 in LJ-2P and 3/P/Si Mode

\

i

c“

ORIE”

‘o”’

SUB

x

n;“–

CONFIG

.

Fi!!i!k

E

Roman-8

IBM-US

IBM-DN

ECM94

-1

IRV

French IBM Spa

UK Portugu

Chinese

ANSI AS

Norwegl HP Span

Swedish German

Norweg2

~~~E’—

— font number —

font number —

— font number —

0 to 128 LINES

Swedis2 Roman E

French2

JIS ASC

IBM Por

Italian

HP Germ

Spanish

Legal

PcMult

[

[

t

PcNordi

[

[

IVelnter]

[ PcText ]

[Ve US]

[PITCH or HEIGHT]

[PITCH or HEIGHT]

[PITCH or HEIGHT]

[Windows

[

i

PcPortu]

PcUSA]

]

PcCanFr]

PcMath]

PcPubli ]

[VeMath]

I DeskTop ]

[Math-8 ]

IPiFont

[VeZapfD]

[

PsZapfD]

IZd1001

[Zd200 ]

[zd300

]

]

]

. .

. . .

c)

Rev.

Figure 1-6.

A

SelecType

Level 1 in

LJ-2P & 3/P/Si

Menu Map

1-21

Page 33

General Description

SelecType Level 1 in

Epson

GIJ2

EPL-5000/5200/Action Laser 1000/1500 Service Manual

Mode

ORIENT .

FONT

SUB

CONFIG

Figure 1-7.

SelecType

Level

.

Not shown

~

Not shown

“L.

I

ORIEm. ~

I

‘c”’

I

JOIN

‘mOEJEcT ~

SelecType

LQ and FX Mode

1 in

~

~

z

Level 1

LJ3 -GL12

GL

- 1 ike

PORT

“NO

OFF

AO, Al, A2, A3, A4 or AL —

CORNER

CENTER

0/1

0.05

to

BUTT

SQUARE

TRIANGLE

ROUND