Page 1

®

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Copy Server

EPSON Color Copy Station 8200

SEOT99005

Page 2

Notice

o

All rights reserved. No p art of t his manual may be reprod uced, stored i n a ret rieval syste m, or trans mit ted in any form or by any means electronic,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

o

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

o

The contents of this manual are subject to change without notice.

o

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

o

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORA TION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

Page 4

About This Manual

CAUTION

CHECK

PO INT

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of EPSON Color Copy

Station 8200. The instructions and procedures included herein are intended for the experienced repair technici ans, and attention should be given to

the precautions on the preceding page.

Contents

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for the

troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for

disassembling and assembling the product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

APPENDIX

Provides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide

additional information on a specif ic topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read WARNING, CAUTION or NOTE

messages.

W ARNING

Indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, coul d result in in jury

or loss of life.

Indicates an operating or maintenance procedure, practice,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the results

achieved through a previous action.

Page 5

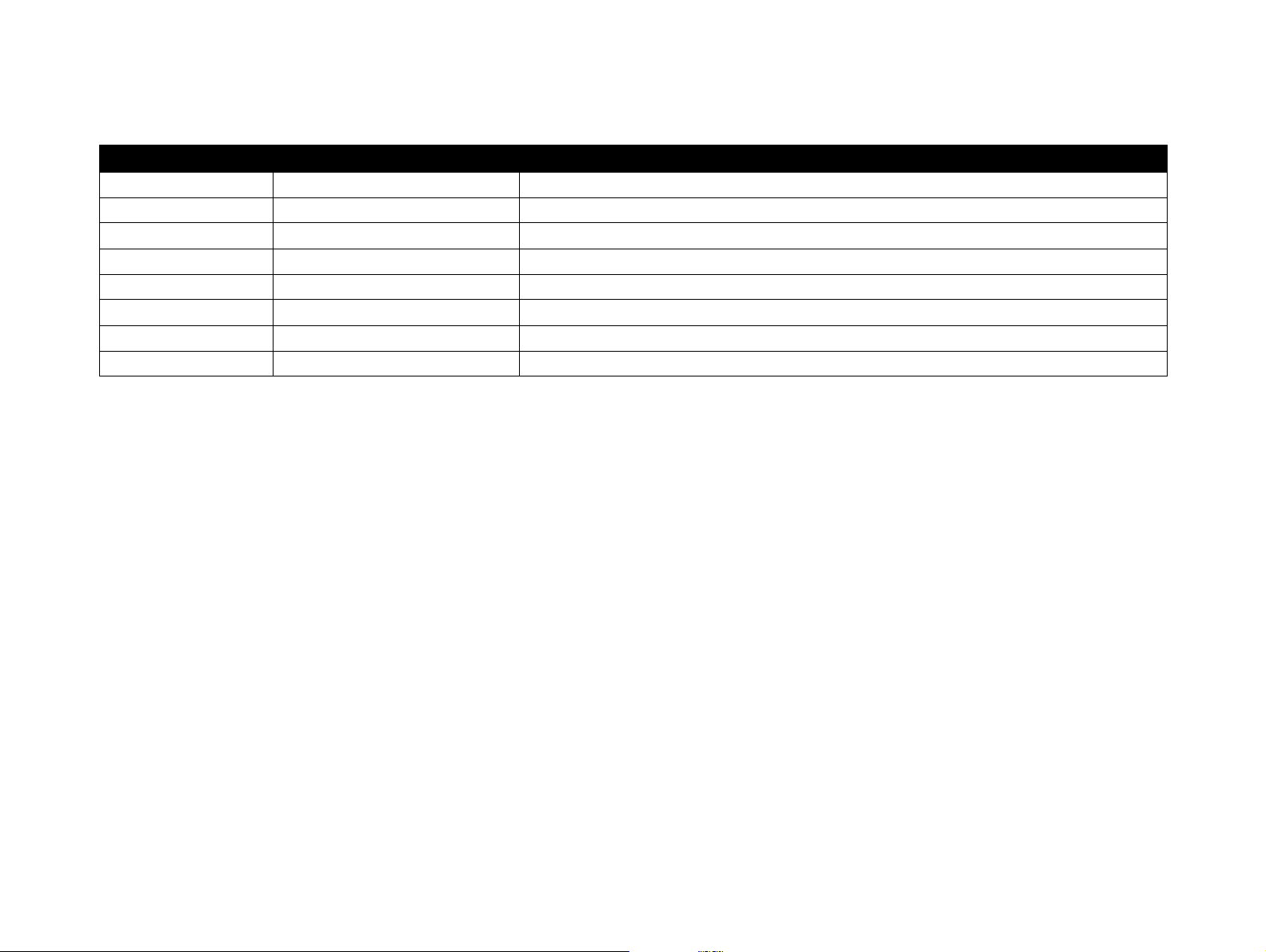

Revision Status

Revision Issued Date Description

Rev. A August 4, 1999 First Release

Page 6

EPSON Color Copy Station 8200 Revision A

Product Description

Outline .............................. ...... .............................................. ...... ....... ...... ..... 4

Features ................................................................................................... 4

System Diagram ........................ ...... ....... ...... ....... ...... ....... ...... ....... ...... ..... 5

About EPL-C8200 ..................................................... ....... ...... ....... ........... 5

Basic Specifications .. ............................................. ...... ....... ...... .................. 6

Local Copy Speed .. ............................................. ...... ....... ...... .................. 6

Electric Specifications .............................................................................. 6

Safety, EMC ............................................................................................. 6

Mechanical Specifications ........................................................................ 6

Resistance to Electric Noise ..................................................................... 6

Environment Conditions ........................................................................... 6

Reliability ...................... ....................................................................... ..... 7

Control Panel Unit .................................................................................... 7

Interfaces ...................... ............. ............. ............. ............. ............. ........... 7

SCSI ..................................................................................................... 7

Printer Interface .................................................................................... 8

Control Panel Interface ... ....... ...... .............................................. ...... ..... 8

Functions ............ ....... ...... ...... .............................................. ...... ....... ........... 9

Functions Overview .................................................................................. 9

Local Copy ............................................................................................. 11

Network TWAIN ...................................................................................... 19

Web Status ............................................................................................. 20

Web Admin ............................................................................................. 22

Web Upgrade ......................................................................................... 24

Money Recognition ................................................................................. 25

User Settings .......................................................................................... 25

User Settings on the Operational Panel ............................................. 25

Machine Functions ................................................................................. 27

H/W Check ......................................................................................... 27

Fixed IP Setting .................................................................................. 27

Firmware Update by Board to Board Copy ......................................... 28

Appearance ................................................................................................ 29

Main Unit ................................................................................................ 29

Control Panel .......................................................................................... 29

Accessories ............................................................................................... 30

Product Component ............................................................................... 30

Bundled Software ......................................... ....... ...... ....... ...... ....... ...... ... 30

Attenti on fo r forgery ................................................................................. 31

Operating Principles

Operating Principles ................................................................................. 33

Copy System .......................................................................................... 33

Control Circuit ........................................................................................ 33

ISA Board ............................................................................................... 33

ECP Board ......................................................................................... 34

Trouble Shooting

Error Message ........................................................................................... 37

Printer Error of Local Copy Mode ........................................................... 37

Scanner Error of Local Copy Mode ........................................................ 43

Network TWAIN Error ............................................................................ 43

Copy System Error ................................................................................. 43

Disassembly and Assembly

Overview .................................................................................................... 45

Precaution .............................................................................................. 45

Tools ...................................................................................................... 45

Disassembly and Assembly ..................................................................... 46

Upper Case Removal ............................................................................. 46

Optional Board Removal ........................................................................ 46

ISA Board Removal ............................................................................ 46

SCSI Board Removal ......................................................................... 47

Network Board Removal .................................................................... 47

ECP Board Removal .......................................................................... 47

Power Supply Unit Removal .................................................................. 48

Mother Board Removal .......................................................................... 48

Panel Board Removal ............................................................................ 49

Firmware Version-Up ................................................................................ 50

BIOS Re-Setting ......................................................................................... 51

Lithium Battery Volume Check ............................................................... 51

Lithium Battery Exchange ...................................................................... 51

BIOS Re-Setting ..................................................................................... 52

1

Page 7

EPSON Color Copy Station 8200 Revision A

Mother Board Jumper Setting ................................................................ 55

Adjustment

Adjustment ................................................................................................. 57

Hardware Check ..................................................................................... 57

LCD Panel Check ........... ....... ...... ....... ...... ....... ...... ....... ...... ................ 57

ISA Board Check ................................................................................ 60

ECP Board Check .............................................................................. 60

Flash ROM Sum Check ...................................................................... 62

H/W All Check Printing ....................................................................... 62

Size Collection (Adjusting the Precision) ................................................ 63

Maintenance

Maintenance ............................................................................................... 66

Appendix

Unit Connection ......................................................................................... 68

Component Layout .................................................................................... 69

Exploded Diagram ..................................................................................... 71

Electric Circuit Diagrams .......................................................................... 72

2

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

EPSON Color Copy Station 8200 Revision A

n

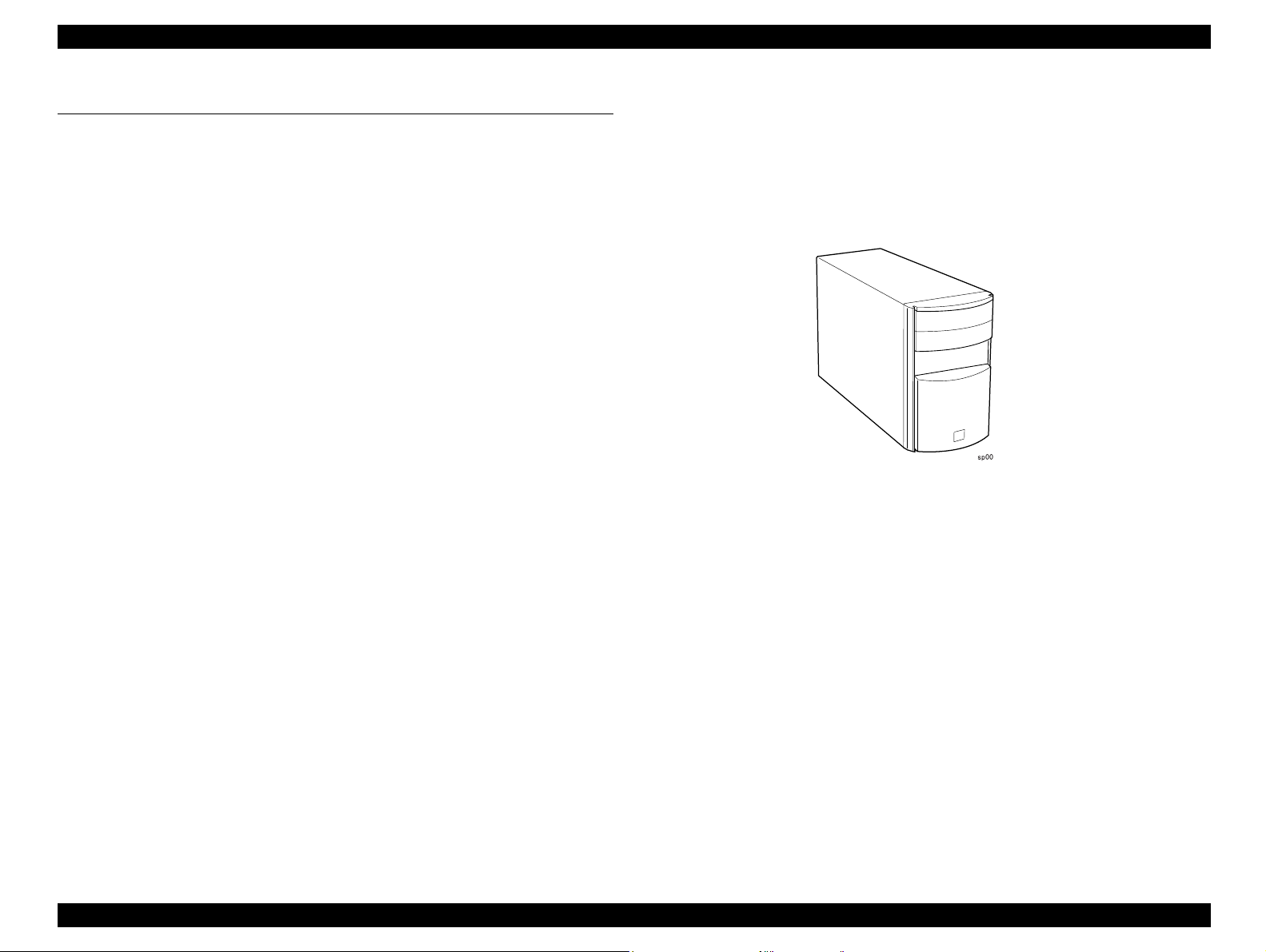

1.1 Outline

The Color Copy Station 8200 can be connected to EPSON scanner and EPSON

color laser printer. It works not only as a stand-alone copier also as network

scanner adapter. Further more, it offers some web-based functions to confirm

the status of the system, to set the initial parameters, and to update the

system firmware.

8 Job memories to save user-defined copy parameters

n

Standard copy protection for bills

n

Network Scanning via network TWAIN driver

n

Useful web-based utilities

WebStatus / WebAdmin / WebUpgrade

n

Flash-ROM update by Board to Board copy.

1.1.1 Features

o

Target Scanner and Printer

n

EPSON Color Laser Page Printer: EPL-C8200

n

EPSON A3-size Scanner: GT-10000

o

Controller

n

PC/AT architecture

n

CPU: K6-2 300MHz

n

RAM-DIMM 32MB, EEPROM 512B, Flash ROM 12MB

n

IEEE1284 ECP Bi-directional interface for printer

Figure 1-1. Exterior View of CCS 8200

n

Fast SCSI interface for scanner

n

Ethernet 100Base-TX / 10-Base-T interface

n

Special interface for control panel

n

High speed Text-enhancement processing ASIC

n

High speed Moire red uction processing ASIC

n

High speed Edge Sharpening processing ASIC

n

High speed color ma tching ASIC

o

Software

n

Copy mode matching with various kinds of documents

PHOTO / TEXT / MA GAZINE / MAP / FINE

n

Zoom 25% to 400% in increments of 1%

n

Image Quality Control

Contrast / Brightness / Sharpness / RGB Balance / Croma / Hue

Product Description Outline 4

Page 10

EPSON Color Copy Station 8200 Revision A

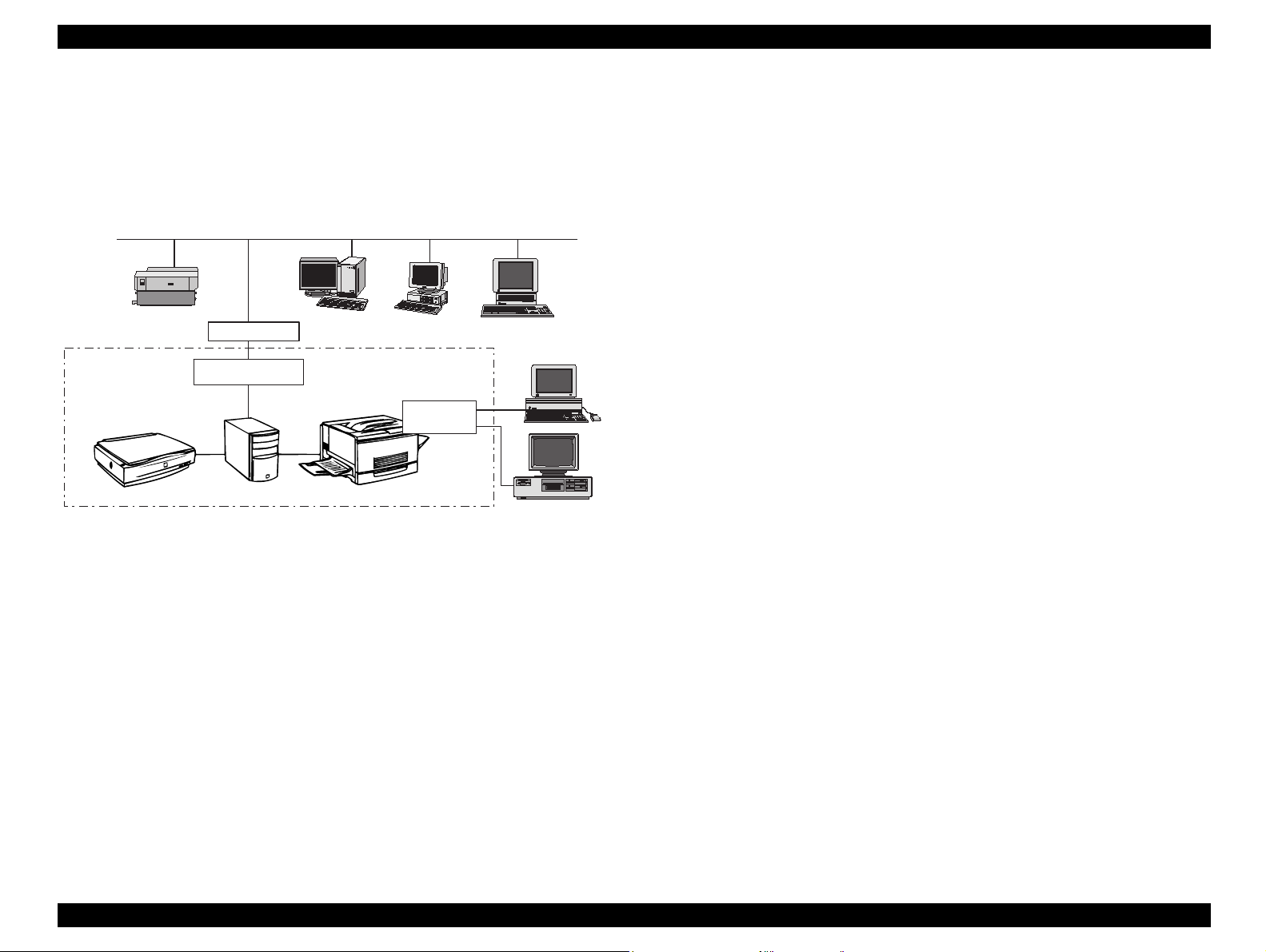

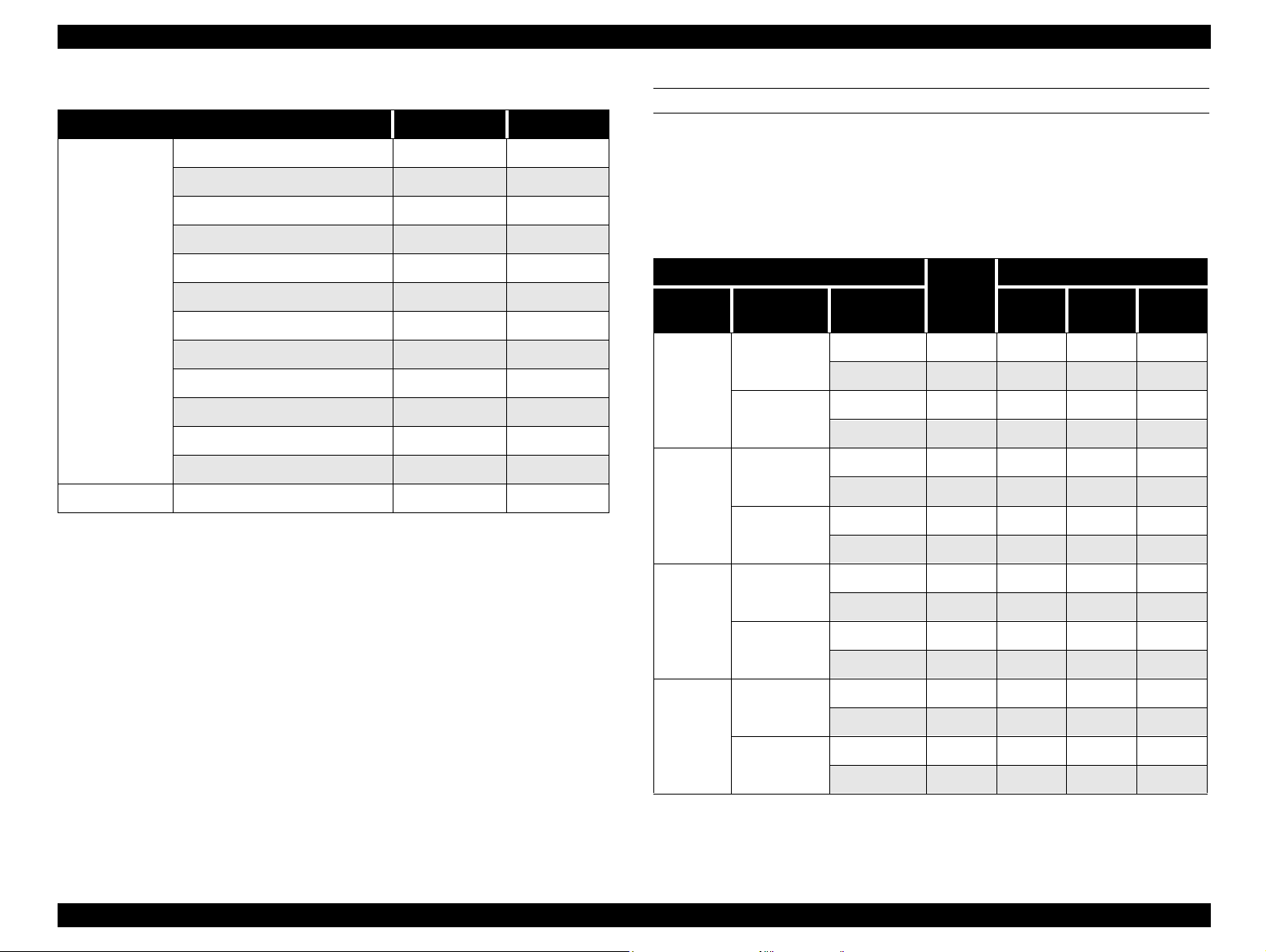

1.1.2 System Diagram

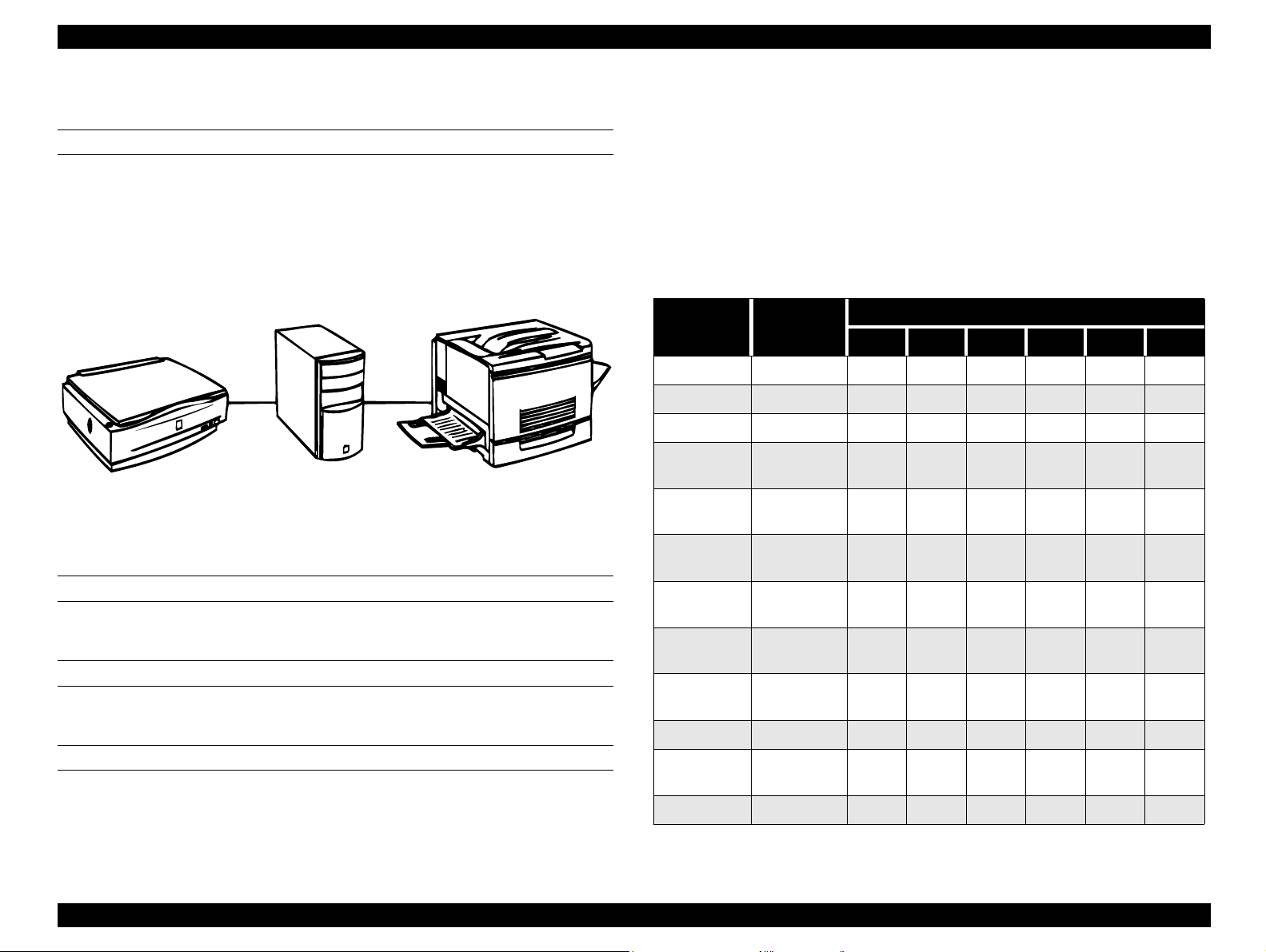

Figure 1-2 shows the color copy system diagram. The 100 base-TX

environment is recommended for using Network TWAIN on the Client PC,

because the very large amount of data flows on the network and the traffic

increases.

10Base T/100Base T

Network Printer

CCS 8200 System

GT-10000

Switching HUB

Network Board

SCSI

PC

ECP

EPL-C8200

PC PC

PC

Type-B

1.1.3 About EPL-C8200

Though EPL-C8200 has 64Mbyte memories as a default, the minimum size of

memories required for Color Copy System is 160MB. In the case that EPLC8200 has only the default memories, EPL -C8200 tries to compress the image

data to save memories, and coping speed is getting slow as a result.

Furthermore, sometimes the compressed image data is so large that the

image can’t be printed out to EPL-C8200.

CCS 8200 uses ECP mode interface with EPL-C8200. If EPL-C8200 isn’t set the

ECP mode, CCS 8200 sends the ECP set command to set this mode.

PC

Figure 1-2. System Diagram

Product Description Outline 5

Page 11

EPSON Color Copy Station 8200 Revision A

1.2 Basic Specifications

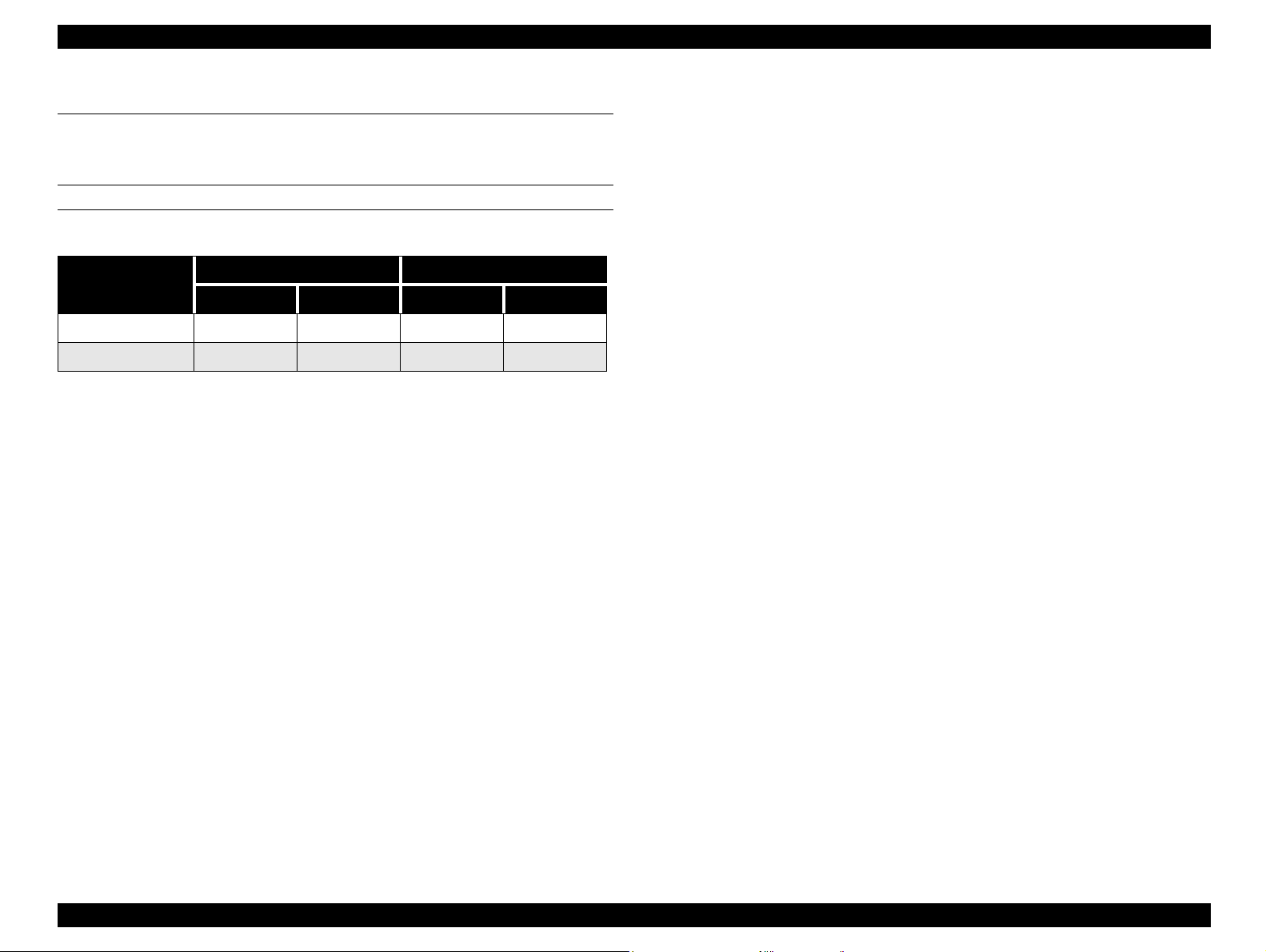

1.2.1 Local Copy Speed

THROUGH PUT

Table 1-1. Copy Speed (local copy)

Color Black and White

Copy Mode

A4/300dpi A4/600dp A4/300dpi A4/600dpi

First Copy 54sec 104sec 26sec 43sec

Multiple Copy 4ppm 4ppm 16ppm 16ppm

Multiple copy: multiple copies on scanner flatbed

Face-up: paper exit

1.2.2 Electric Specifications

Rated Voltage: AC100-120V / AC 220-240V

Input Voltage: AC100-120V 10% ± / AC220-240V ± 10%

Rated Current: 1A (Input AC100-120V) / 0.4A (Input AC220-240V)

1.2.3 Safety, EMC

Low Voltage Directive 73/23/EEC EN60950

EMC Directive 89/336/EEC EN55022 Class B

EN6100-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

AS/NZS3458 Class B

CNS13438 Class B

Korean EMC

1.2.4 Mechanical Specifications

Physical dimensions 200x460x355mm (WxDxH)

Weight Approx. 10kg

The way to connect Panel connected by shield cable (length 2.0m)

1.2.5 Resistance to Electric Noise

Static electricity 10KV/ 150pF, 150 Ohms

1.2.6 Environment Conditions

o

Rated Frequency Range: 50/60Hz

Input Frequency Range: 49.5-60.5Hz

Power Consumption: Less than 80W

Insulation resistance: 10Mohms at 500VDC

(between AC line and chassis)

Dielectic strength: AC3.0KV, 1min

Leakage Current: Less than 3.5mA

Operating

n

n

n

o

Storage

n

Temperature

10 ~ 35

Humidity

20 ~ 80%, no condensation

Vibration

0.2G

Temperature

- 20 ~ 60

°C

°C

Product Description Basic Specifications 6

Page 12

EPSON Color Copy Station 8200 Revision A

n

Humidity

10 ~ 90%, no condensation

n

Vibration

1.0G

1.2.7 Reliability

o

MTBF

10000 hours (not including the EL intensity loss)

o

Life

Approx. 5 years

(It means the life of battery on Mother Board)

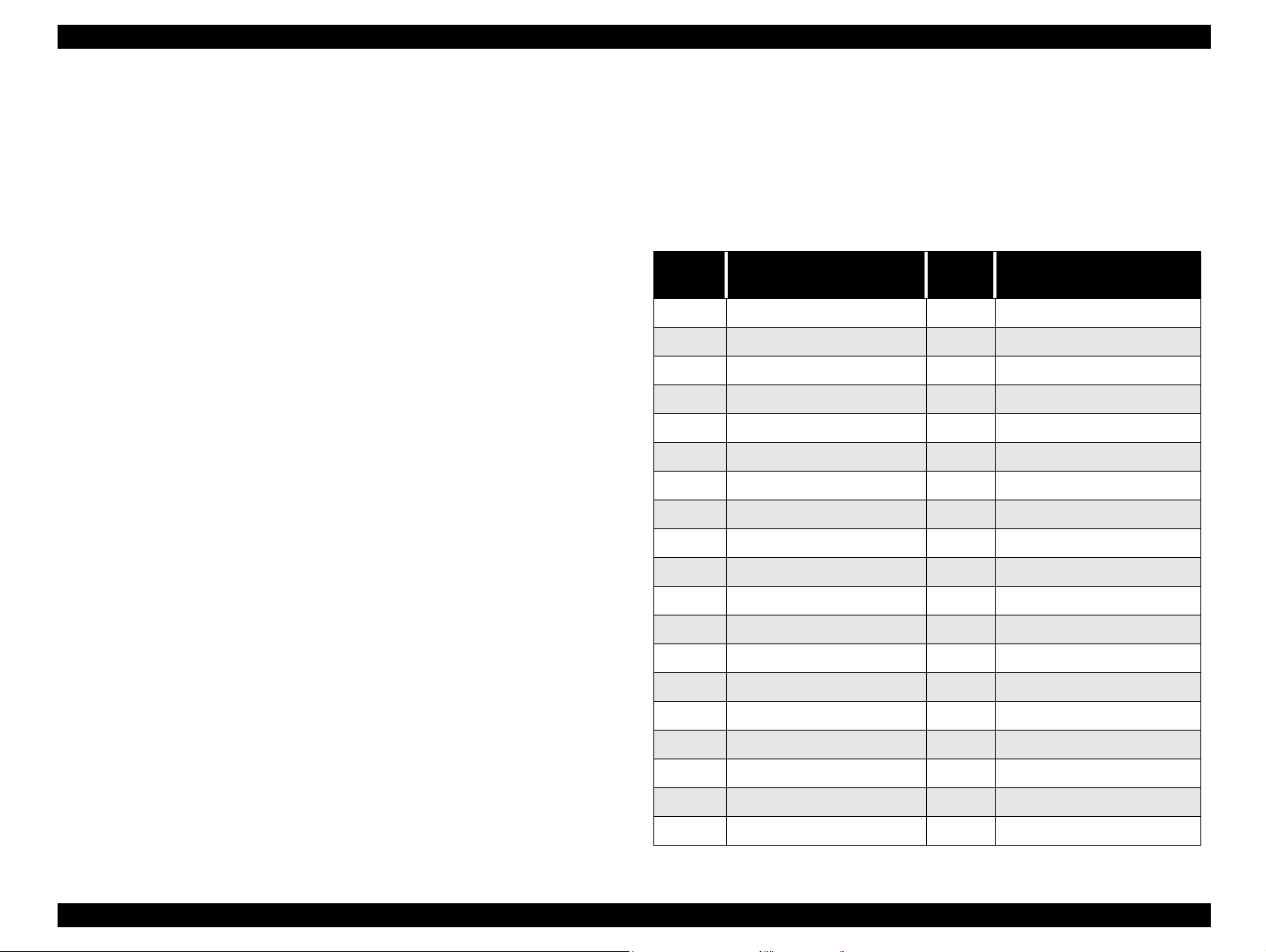

1.2.9 Interfaces

1.2.9.1 SCSI

o

Connector

D-Sub 50 pin half pitch (based on ANSI X3. 131-1986)

o

Signals

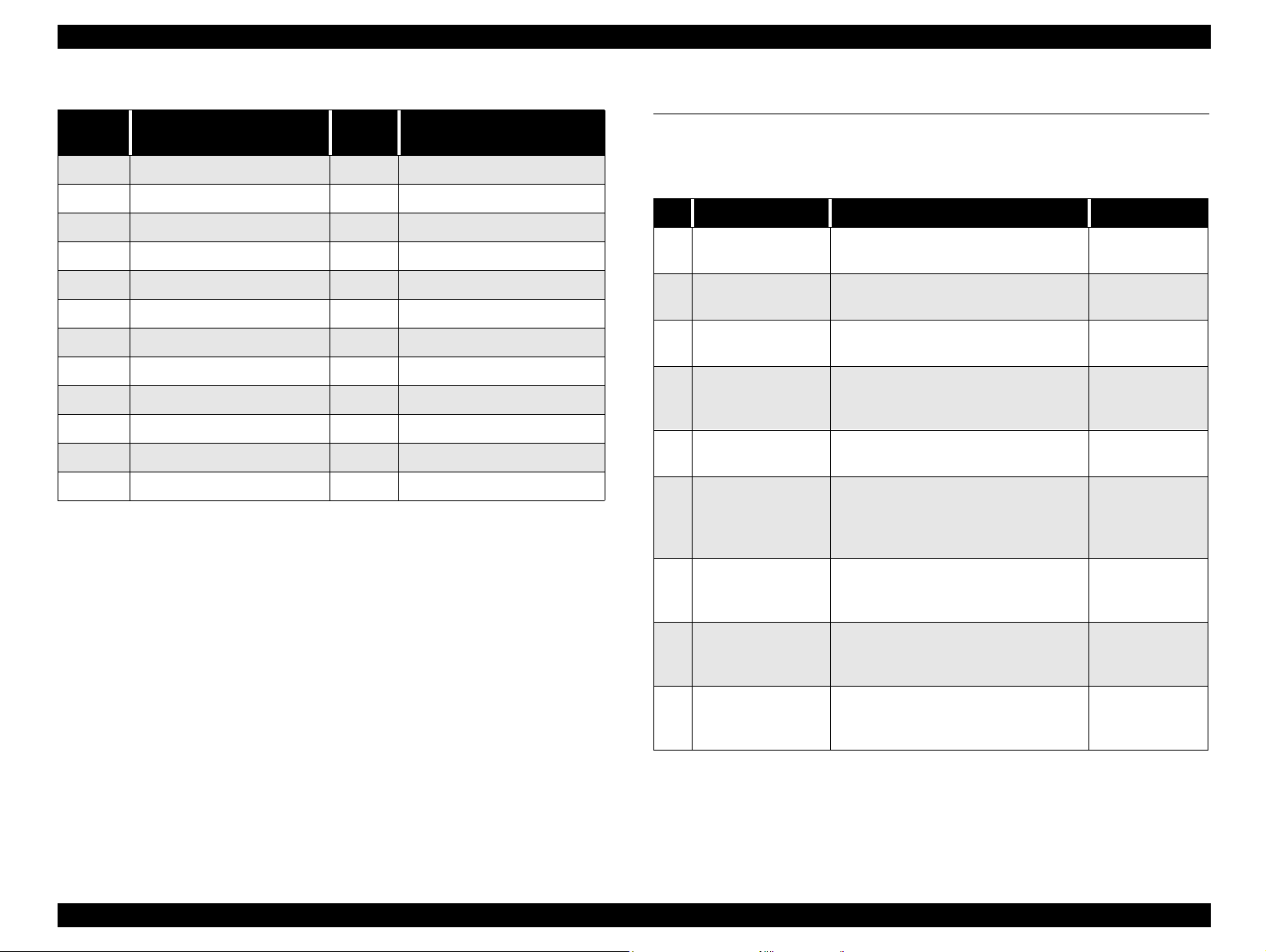

Table 1-2. Connector Pin Alignment

Pin

number

1GND26DB0

2 GND 27 DB1

Signal name

Pin

Number

Signal name

1.2.8 Control Panel Unit

LCD and Touch key with white EL-back-light

Display pixel 320 x 240

Display Area 76.785 x 57.585 (mm)

Pixel pitch 0.24 x 0.24 (mm)

Display pixel pitch 0.225 x 0.225 (mm)

Touch Key 8 x 6 matrix

Special Key Start, Stop, All Clear, 10-key (set the number)

LED lamp Power, Ready, Error

LCD contrast adjustment Volume

3GND28DB2

4 GND 29 DB3

5GND30DB4

6 GND 31 DB5

7GND32DB6

8 GND 33 DB7

9GND34DBP

10 GND 35 GND

11 GND 36 GND

12 GND 37 reserve

13 GND 38 TERM POWER

14 GND 39 reserve

15 GND 40 GND

16 GND 41 ATN

17 GND 42 GND

18 GND 43 BSY

19 GND 44 ACK

Product Description Basic Specifications 7

Page 13

EPSON Color Copy Station 8200 Revision A

Table 1-2. Connector Pin Alignment

Pin

number

20 GND 45 RST

21 GND 46 MSG

22 GND 47 SEL

23 GND 48 C/D

24 GND 49 REQ

25 GND 50 I/O

o

Cable

Signal name

GTATSCCB3 (recommended)

Pin

Number

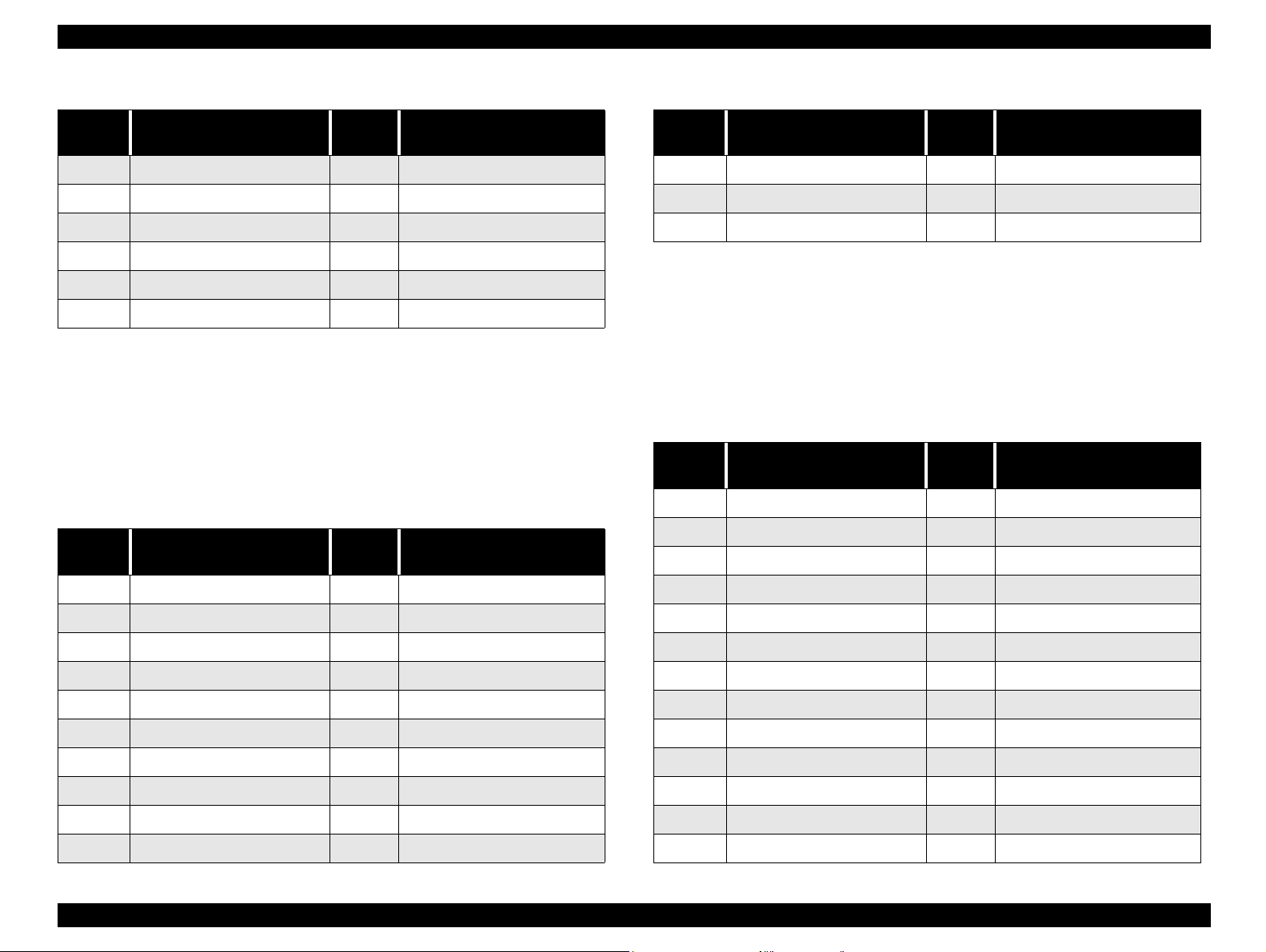

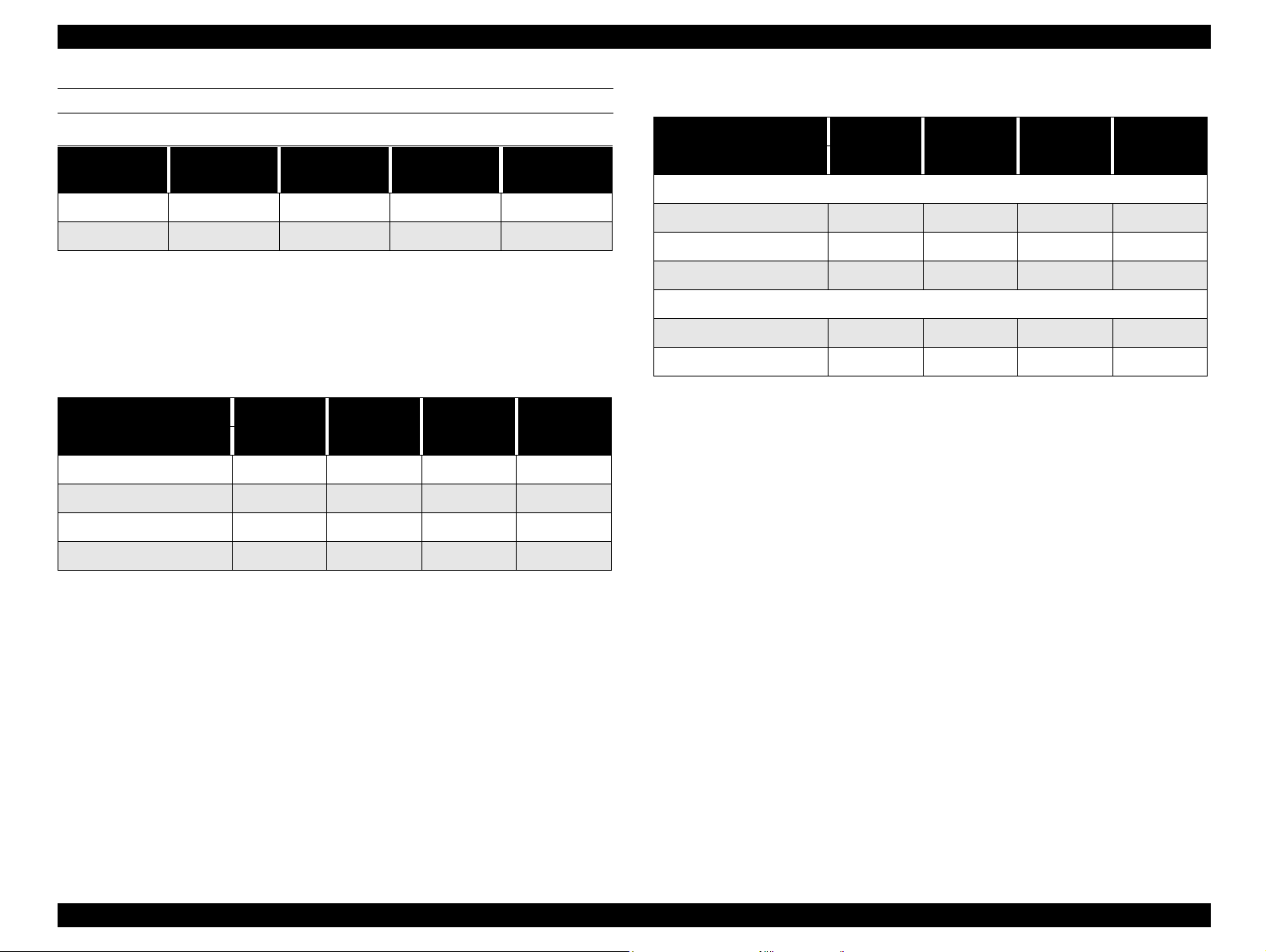

1.2.9.2 Printer Interface

o

Connector

D-Sub 25 pin (equivalent to DDK 17LE13250-27)

o

Signals

Table 1-3. Connector Pin Alignment

Pin

number

Signal name

Pin

Number

Signal name

Signal name

Table 1-3. Connector Pin Alignment

Pin

number

11 BUSY 24 GND

12 ERROR 25 GND

13 SELECT - -

o

Cable

Signal name

PRCB4N (recommended)

Pin

Number

Signal name

1.2.9.3 Control Panel Interface

o

Connector

AMP half-pitch 50pin

o

Signals

Table 1-4. Connector Pin Alignment

Pin

number

1 GND 26 VDD(+12V)

2 GND 27 VDD(+12V)

3 PAI7 (key-matrix input) 28 VDD(+12V)

Signal name

Pin

Number

Signal name

1 /STROBE 14 /SUTO FEED

2 DATA0 15 /FAULT

3 DATA1 16 /INIT

4 DATA2 17 /SELECT IN

5 DATA3 18 GND

6 DATA4 19 GND

7 DATA5 20 GND

8 DATA6 21 GND

9 DATA7 22 GND

10 /ACK 23 GND

4 PAI6 (key-matrix input) 29 GND

5 PAI5 (key-matrix input) 30 GND

6 PAI4 (key-matrix input) 31 DIN (LCD VSYNC)

7 PAI3 (key-matrix input) 32 LP (LCD HSYNC)

8 PAI2 (key-matrix input) 33 XSCL (LCD clock)

9 PAI1 (key-matrix input) 34 DOFF (LCD DIsplay ON/OFF)

10 PAI0 (key-matrix input) 35 ELON (EL ON/OFF)

11 GND 36 GND

12 GND 37 LD0 (LCD Display data)

13 PAO0 (key-matrix output) 38 LD1 (LCD Display data)

Product Description Basic Specifications 8

Page 14

EPSON Color Copy Station 8200 Revision A

Table 1-4. Connector Pin Alignment

Pin

number

14 PAO1 (key-matrix output) 39 LD2 (LCD Display data)

15 PAO2 (key-matrix output) 40 LD3 (LCD Display data)

16 PAO3 (key-matrix output) 41 LD4 (LCD Display data)

17 PAO4 (key-matrix output) 42 LD5 (LCD Display data)

18 PAO5 (key-matrix output) 43 LD6 (LCD Display data)

19 PAO6 (key-matrix output) 44 LD7 (LCD Display data)

20 PAO7 (key-matrix output) 45 GND

21 GND 46 GND

22 GND 47 ERROR (Error LED ON/OFF)

23 VCC (+5V) 48 READY (Ready LED ON/OFF)

24 VCC (+5V) 49 GND

25 VCC (+5V) 50 GND

o

Cable

Signal name

Parts Number 202637400 (recommended)

Pin

Number

Signal name

1.3 Functions

1.3.1 Functions Overview

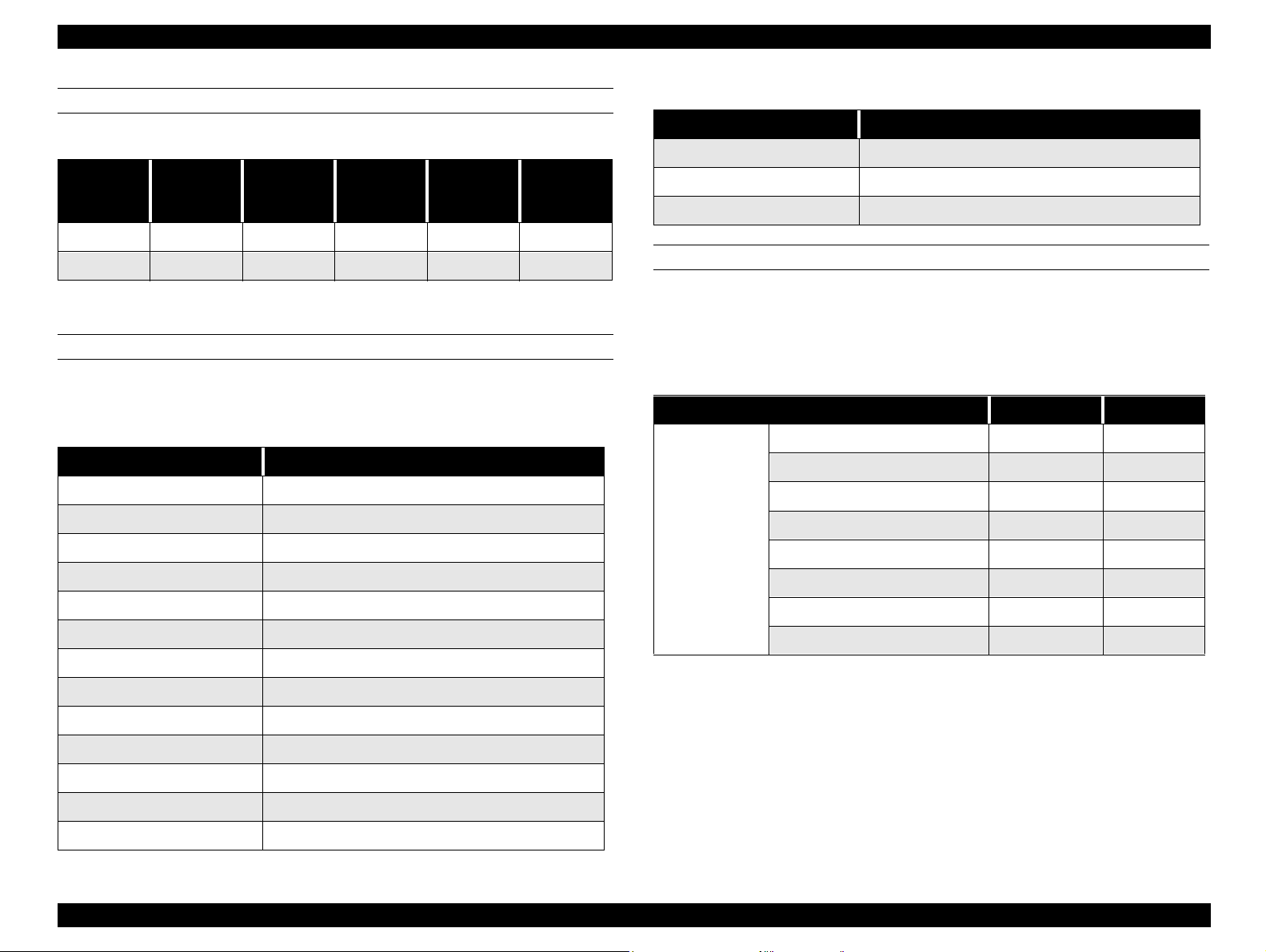

Table 1-5. The Main Functions

No. Function Name Description Target User

1 Local Copy

2 Network TWAIN

3 WebStatus

4 WebAdmin

5 WebUpgrade(*1)

User

6

Configuration

Functions for

7

Maintenance

Copy function using directly

connected scanner and printer.

Scanning function using network

TWAIN driver via network.

Web-based utility to get the status

of scanner, printer, and CCS 8200.

Web-based utility to set the initial

parameters to CCS 8200 for

administrator.

Web-based utility to upgrade

CCS 8200 firmware via network.

Initial settings for network,

Language selection of message to

display on the control panel,

Retrieving factory settings.

Checking hardware board by board

to find hardware error in the

manufacturing stage or in the fields.

End user

End User

End User

End User or

Field supporter

End User

End User

Field supporter

or

Manufacturer

Temporary IP

8

setting

Firmware Update

9

by Board to Board

copy

Starting with the fixed temporary IP

address in the manufacturing stage

or in the fields.

Copy from Master board to Target

board for CCS 8200 firmware

version-up.

Field supporter

or

Manufacturer

Field supporter

(*1) This function is not disclosed for end user at first, and not described in

the CCS 8200 manual. When the update is required after shipping, firmware

ROM file and the manual, in which the op e ration is described, will be

released.

Product Description Functions 9

Page 15

EPSON Color Copy Station 8200 Revision A

AVAILABLE COMBINATION OF EACH FUNCTION

Table 1-6. Hardware resources required for each function

Hardware

Resource

Printer

Scanner

¡

: Required

x: Not required

Local Copy

¡

¡ ¡

Note: Even if printer cannot be used, the function using scanner can be kept

alive.

Network

TWAIN

xxx

Web Admin Web Status

x x

Table 1-7. CONCURRENT USE

2nd

1st

Local Copy x x x

Network TWAIN x x x

Web Admin

Web Status

Local

Copy(*1)

¡¡

¡ ¡ ¡ ¡

Network

TWAIN

Web Admin

(*2)

x(*3)

Web Status

¡

¡

¡

Table 1-8. Scanner and Printer Option

Function

Option

Type-B x x x x

Large Capacity cassette

A3W cassette

ADF Single Side

ADF Double Side x

¡

: possible

x: impossible

Local

Copy(*1)

Printer

¡

¡

Scanner

¡ ¡

Network

TWAIN

xxx

x x x

¡

Web Admin Web Status

x x

xx

¡

: possible

x: impossible

(*1) Paper Money detection is done only for Local Copy.

(*2) Web Admin can not be used in the middle that CCS 8200 works for other

function.

(*3) When more than one Web Admin started, only the first Web Admin can

work and the time-out error occurs for the others.

Product Description Functions 10

Page 16

EPSON Color Copy Station 8200 Revision A

1.3.2 Local Copy

OPERATIONAL PRINCIPLE

Local copy function is responsible for the image data scanned by GT-1000 to

be processed by CCS 8200 and sent to the printer. Before starting copy, user

can set some parameters, number of copy, brightness, contrast and so on, on

the control pane l.

Scanner

(GT-1000)

Copy Server

CCS 8200

Figure 1-3. Local Copy Data Flow

START COPY

Press the “Start” key on the control panel to start local copy job.

CANCEL COPY

Press the “STOP” key on the control panel to cancel local copy job.

PAPER SIZE

CCS 8200 supports the following paper size.

Printer

EPL-C8200

A3W, Ledger, A3, B4, Legal, Letter (portrait), Letter (landscape), A4 (portrait),

A4 (landscape), B5 (portrait), B5 (landscape), Executive (portrait),

Executive (landscape)

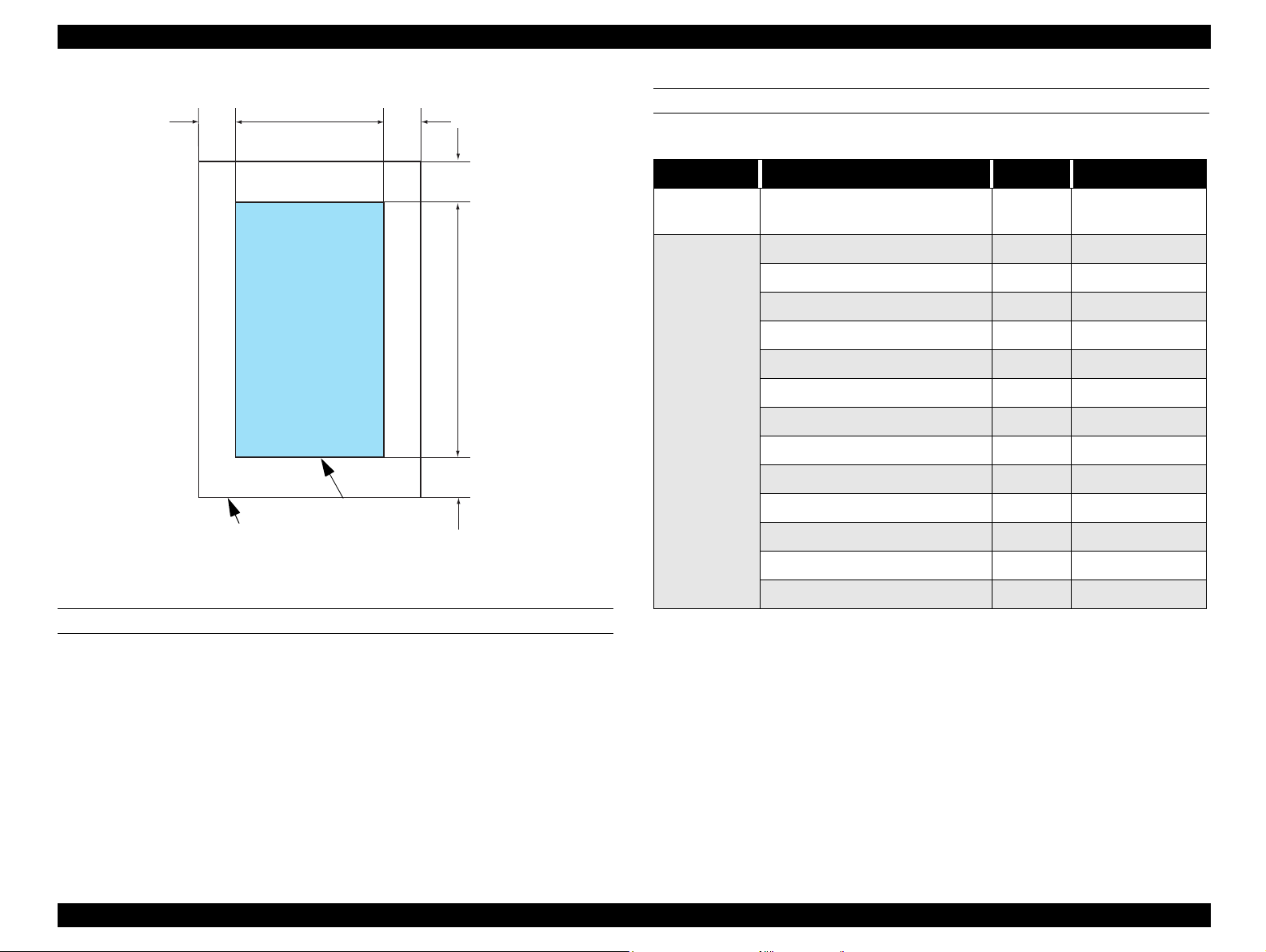

The printing maximum size shown in Figure 1-4 is exactly the same as the

size EPL-C8200 guarantees for printing

The supported paper size doesn’t depend on the language, which is set in the

user configuration mode, but depends only on the paper size in the printer

cassette.

Table 1-9. Paper Size and Effective Printing Area (mm)

Paper Type

A3W 328x453 16.5 297 14.5 5 431 17

A3 297x420 5 287 5 5 410 5

B4 257x364 5 247 5 5 354 5

A4

(Landscape)

A4

(Portrait)

B5

(Landscape)

B5

(Portrait)

Letter

(Landscape)

Letter

(Portrait)

Legal 215.9x355.6 5 205 5 5 345 5

Executive

(Portrait)

Ledger 279.4x432.0 5 269 5 5 421 5

Size

(HxV)

297x210 5 287 5 5 200 5

210x297 5 200 5 5 287 5

257x182 5 247 5 5 172 5

182x257 5 172 5 5 247 5

279.4x215.9 5 269 5 5 205 5

215.9x279.4 5 205 5 5 269 5

184.2x266.7 5 173 5 5 256 5

a1 b a2 c1 d c2

Printing Area (HxV)

Note: B4 and B5 are Japanese original paper size

Product Description Functions 11

Page 17

EPSON Color Copy Station 8200 Revision A

a1 a2

b

c1

d

c2

Printing guaranteed

Paper Size

area

Figure 1-4. Effective Printing Area

ZOOM

Table 1-10. User-defined and Pre-set Zoom

Zoom User-Setting Ratio (%) Remarks

User-defined

Zoom

Pre-set Zoom LedgeràLetter 64

A3àA4/B4àB5 70

A3àB4/A4àB5 86

B4àA3/B5àA4 115

A4àA3/B5àB4 141

- 25-400

11x15àLetter 78

LegalàLetter 7 8

B4àA4 81

100% 100

LegalàLetter 121

A4àB4 122

LetteràLedger 129

5.5x8.5àLegal 154

in increments of

1%

PAPER BIN

The user can select either Face-Up or Face-Down as a paper bin on the local

copy menu. CCS 8200 supports the paper supply from printer’s MP Tray, C1,

C2, C3, and C4.

The scanning area is calculated from output paper size according to the zoom

ratio. When scanning area is larger than maximum scan area of the scanner,

CCS 8200 scans data to maximum scan area, and printed image will be

located at the center of the paper.

Product Description Functions 12

Page 18

EPSON Color Copy Station 8200 Revision A

For all pre-set zoom, user can select just-fitting copy option by touching the

just-fitting button on the control panel. When the just-fitting is valid, whole

area of the document (including non-printed area) is scanned and the area is

printed so that it is put in the print guaranteed area.

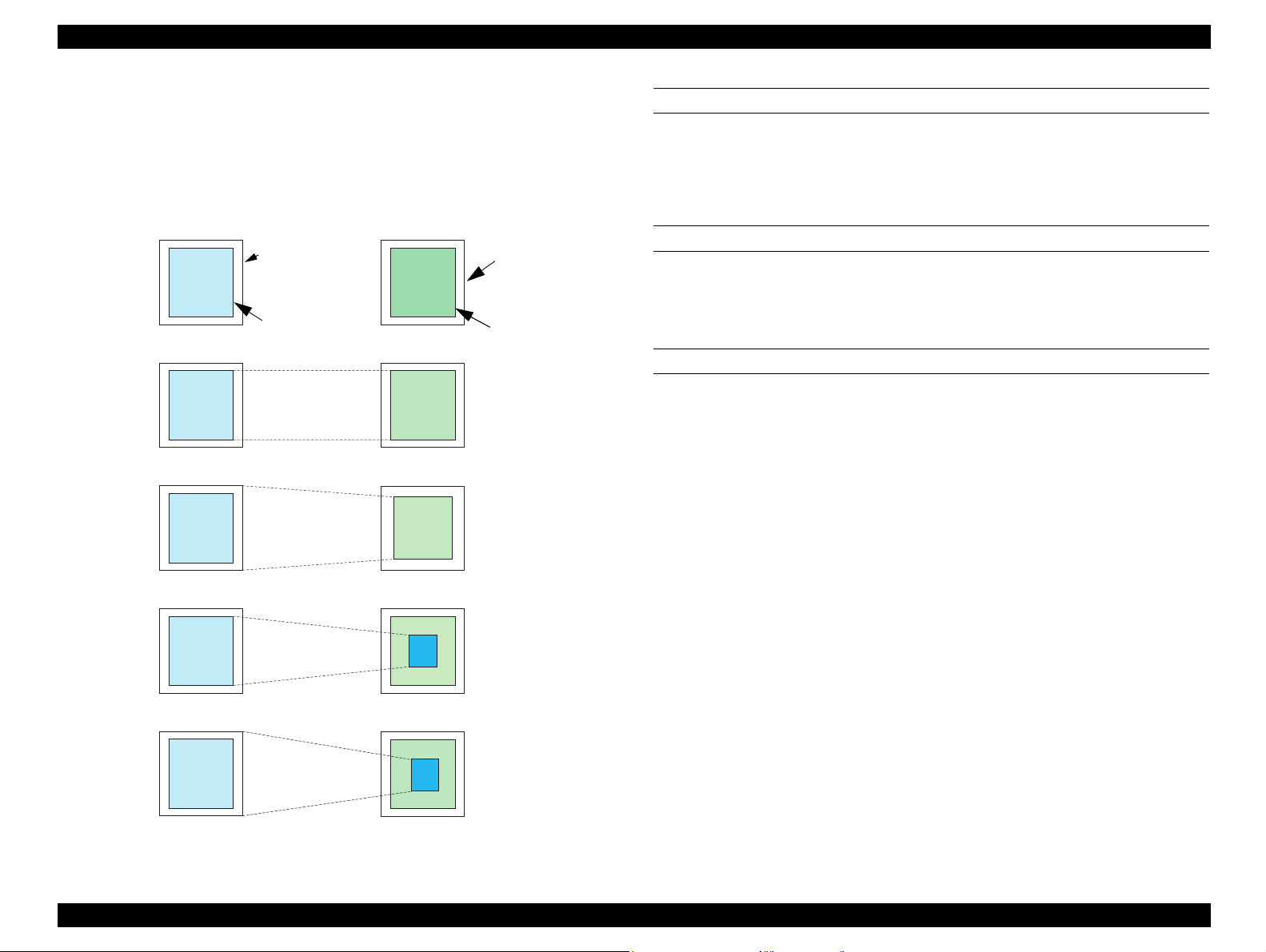

Document

(Scanner)

Document Si z e

Scanning Area

corresponding

to the

Guaranteed

Printing Area

Copy Paper

Paper Size

Guaranteed

Printing Area

Zoom 100%

(Just-fitting OFF)

Zoom 100%

(Just-fitting ON)

MULTIPLE COPIES

o

Setting Range: 1-99 (default: 1)

Scanning is done only one time.

The multiple copy function is accomplished by printer’s copy

function.

OPTION

If ADF (Auto Document Feeder) is set on the scanner, the CCS 8200 enters to

“ADF COPY” mode internally and automatically and starts copying until the

paper set on ADF comes to end.

MARGIN FOR BINDING

User can set the top, left, and right margin to keep the white area for binding.

This copy option is valid fo r all zoom ratio including pre-set and user defined

zoom.

Size-down,

size-up

(Just-fitting OFF)

Size-down,

size-up

(Just-fitting ON)

Figure 1-5. Magnification

Product Description Functions 13

Page 19

EPSON Color Copy Station 8200 Revision A

SPLIT COPY

This function enables to copy individual pages for opened-booklet located on

the flat-bed. There are limitations as follows such as pa per size must be one

of A4, B5, Letter, and Executive. The combinations of copy parameters other

than the following are not allowed and not supported by ADF either.

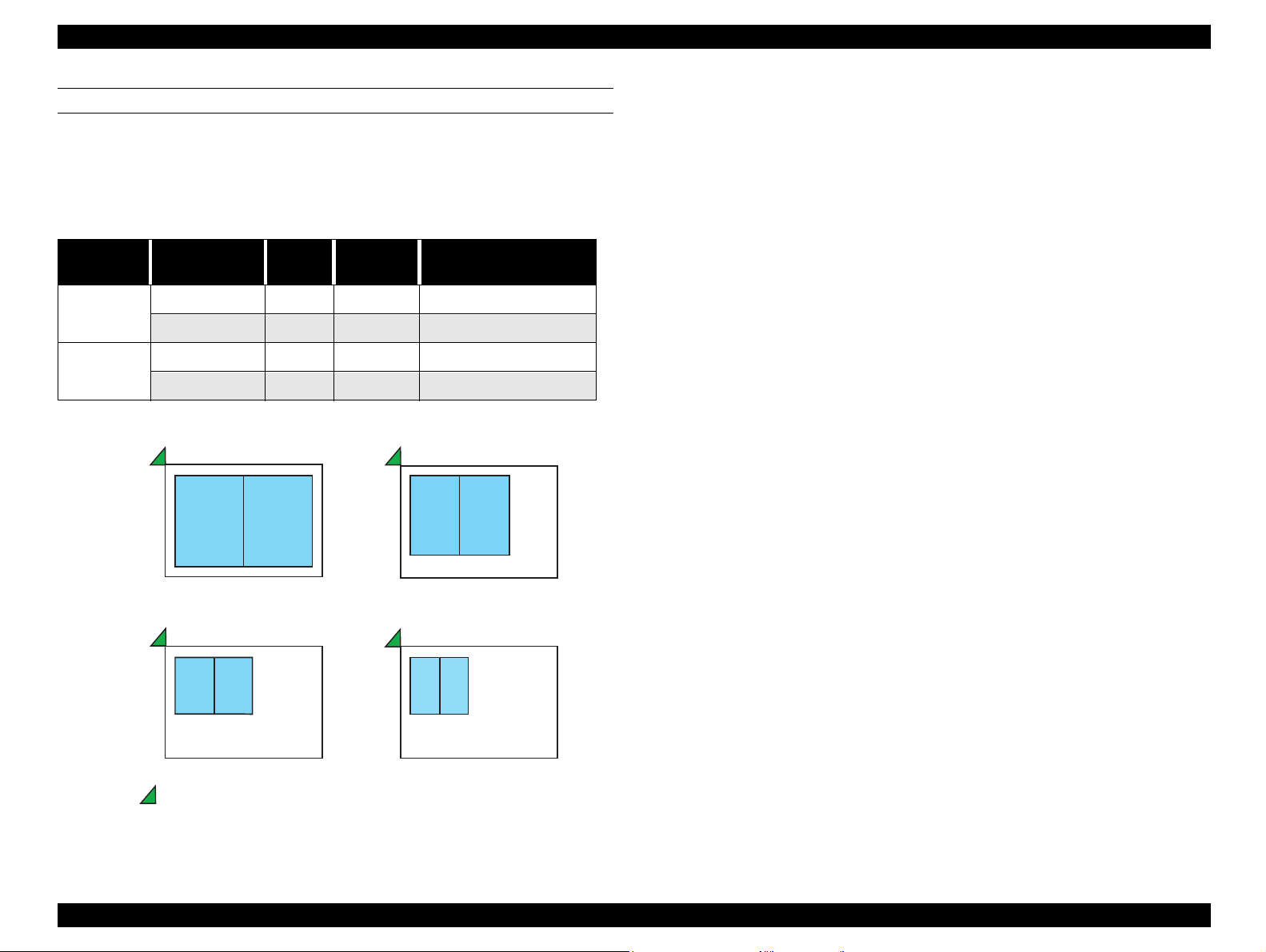

Table 1-11. Split Copy

Paper Size Scanning Area

A4 / Letter A3(A4x2) 100% (1) A4x2 pages

Letter 100% (3) Letter x 2 pages

B5 /

Executive

B4 (B5x2) 100% (2) B5 x 2 pages

Executive 100% (4) Executive x 2 pages

Zoom

Setting

(1)

A4

A4

(3)

A5

A5

Document

Location

B5

B6

B6

Copy Output

(2)

B5

(4)

Letter

Executive

Origin of Scanning

Figure 1-6. Paper Setting (Split Copy)

Product Description Functions 14

Page 20

EPSON Color Copy Station 8200 Revision A

INTERNAL PROCESSING

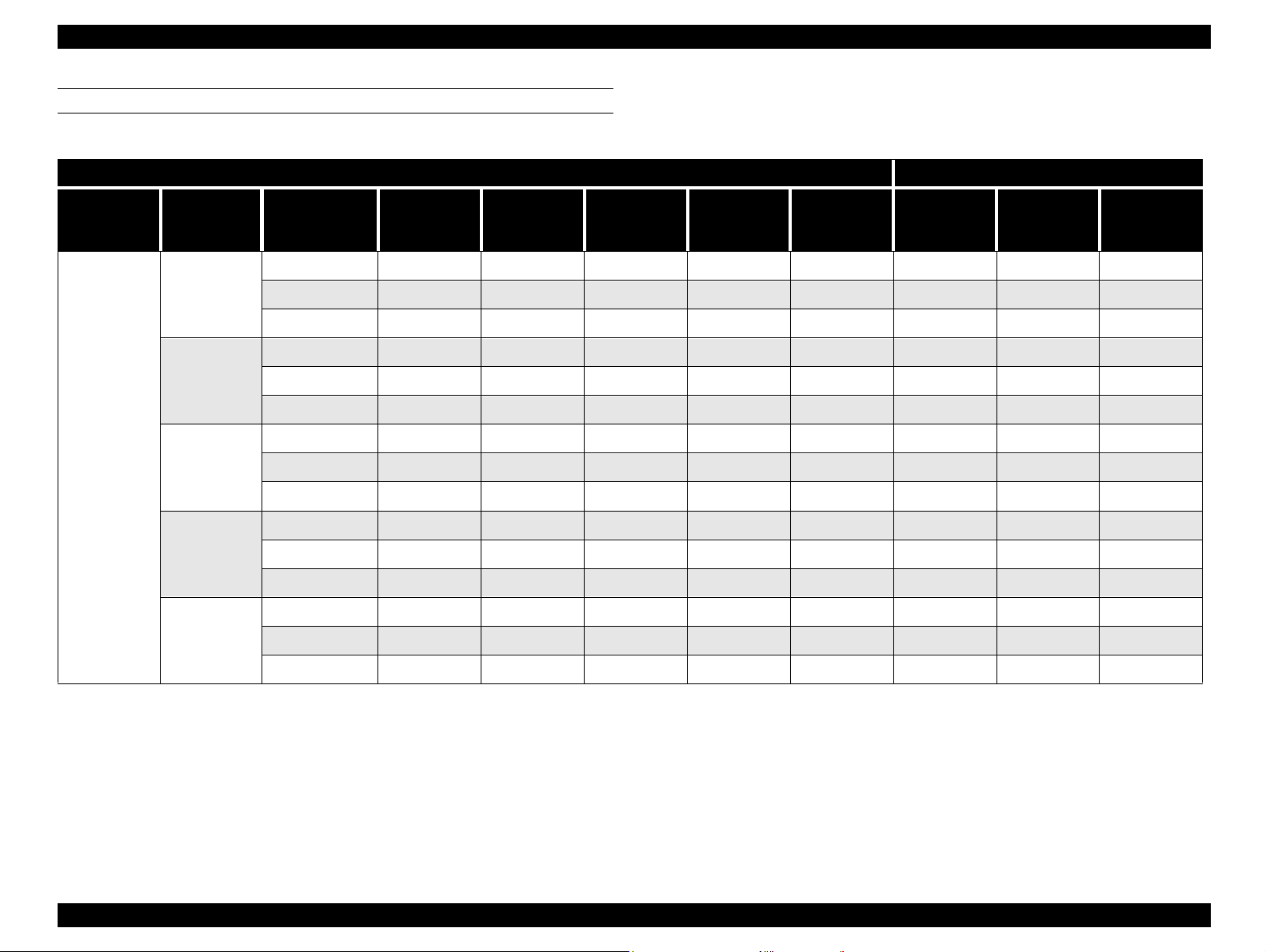

Table 1-12. Internal Processing

CCS 8200 Printer

Color/

B/W

Copy Mode Media

Color Photo Fine Paper

Thick Paper 300 300 - - Photo CPGI Transparency 300 300 - - Photo CPGI -

Text Fine Paper 300 300

Thick Paper 300 300

Transparency 300 300

Print Fine Paper 300 300

Thick Paper 300 300

Transparency 300 300

Map Fine Paper 300 300

Thick Paper 300 300

Transparency 300 300

Fine Fine Paper 600 600 - - Photo CPGI

Thick Paper 600 600 - - Photo CPGI

Scan

Resolution

c

300 300 - - Photo CPGI -

Print

Resolution

TET

(H/W)

¡

¡

¡

a

(H/W)

b

- Text CPGI

- Text CPGI

- Text CPGI

MOIRE

¡¡

¡ ¡

¡¡

¡

¡

¡

- Map CPGI

-MapCPGI

- Map CPGI

Color

Matching

Mode RIT

Table

Print CPGI Print CPGI Print CPGI -

Screen

(TBD)

¡

¡

¡

¡

¡

¡

¡

¡

Transparency 600 600 - - Photo CPGI

¡

Product Description Functions 15

Page 21

EPSON Color Copy Station 8200 Revision A

Table 1-12. Internal Processing

CCS 8200 Printer

Color/

B/W

B/W Photo Fine Paper 300 300 - - Photo CPGI -

Copy Mode Media

Thick Paper 300 300 - - Photo CPGI Transparency 300 300 - - Photo CPGI -

Text Fine Paper 300 300

Thick Paper 300 300

Transparency 300 300

Print Fine Paper 300 300

Thick Paper 300 300

Transparency 300 300

Map Fine Paper 300 300

Thick Paper 300 300

Transparency 300 300

Fine Fine Paper 600 600 - - Photo CPGI

Thick Paper 600 600 - - Photo CPGI

Scan

Resolution

Print

Resolution

TET

a

(H/W)

¡

¡

¡

¡ ¡

¡¡

¡ ¡

¡

¡

¡

MOIRE

b

(H/W)

- Text CPGI

- Text CPGI

- Text CPGI

-MapCPGI

- Map CPGI

-MapCPGI

Color

Matching

Table

Print CPGI Print CPGI Print CPGI -

Mode RIT

Screen

(TBD)

¡

¡

¡

¡

¡

¡

¡

¡

Transparency 600 600 - - Photo CPGI

¡

a.FinePaper:SpecialPaperforLaserPrinter

b.TET(H/W):TextEnhancementprocessingbyASIC

c.MOIRE(H/W):MoireReductionprocessingbyASIC

Note:ScanningConditionfromscannerisgamma=1,24bit/pixel(color,RGBx8bit),8bit/Pixel.

Product Description Functions 16

Page 22

EPSON Color Copy Station 8200 Revision A

COPY ADJUSTMENT MODE

Table 1-13. Copy Adjustment Mode

Color /

B/W

Color ±3 step ±3 step ±3 step ±3 step ±3 step

B/W ±3 step ±3 step N/A N/A N/A

Default value of each parameter is zero. (Center Value)

Brightness Contrast

RGB

Adjustmen

t

Saturation Hue

JOB MEMORY

CCS 8200 has 8 job memories to save some copy parameters.

Parameters can be saved are as follows.

Table 1-14. Job Memory

Item Value

Number of Copy 1-99 pages

Zoom Ratio 25-400%

Paper Tray MP Tray, Cassette 1-4

Media Plain Paper / Thick Paper / Transparency

Copy Mode Color / Black & White

Brightness -3 ~ +3

Contrast -3 ~ +3

Table 1-14. Job Memory

Item Value

Output Bin Face-up / Face-down

Split Copy ON / OFF

Margin for Binding Normal / Top / Left / Right

STATUS

CCS 8200 can display the status of itself, scanner, and printer on the control

panel. Furthermore, user can print the status sheet by pressing the status

button on the control panel. The items which can be displayed and printed are

as follows respectively.

Table 1-15. Status

Items Status display Status print

CCS 8200 Language NA A

Model Name A A

Current Status A NA

IP address A A

Gateway address NA A

Subnet Mask NA A

Mac address NA A

Contents of job memory NA A

R Balance -3 ~ +3

G Balance -3 ~ +3

B Balance -3 ~ +3

Croma -3 ~ +3

Hue G+3 ~ R+3

Document Type TEXT / PHOTO / MAGAZINE / MAP / FINE

Product Description Functions 17

Page 23

EPSON Color Copy Station 8200 Revision A

Table 1-15. Status

Items Status display Status print

Printer Model Name A A

Current status A NA

Tray 1 paper size A A

Tray 2 paper size A A

Tray 3 paper size A A

Tray 4 paper size A A

Toner Balance A A

Oil Roll Balance A A

Status of Waste Toner Box A A

Status of Photoconductor A A

Memory Capacity A A

Output bin A A

Scanner Model Name A A

A: available, NA: not available

PRINTER CONTROL

The maximum memories which can be allotted to the printer is 256MB and it

is not enough to print some combinations of paper size and copy mode. As

shown below, CCS 8200 sends image data to the printer in two different ways;

non-compressed and compressed data, according to the paper size and copy

mode.

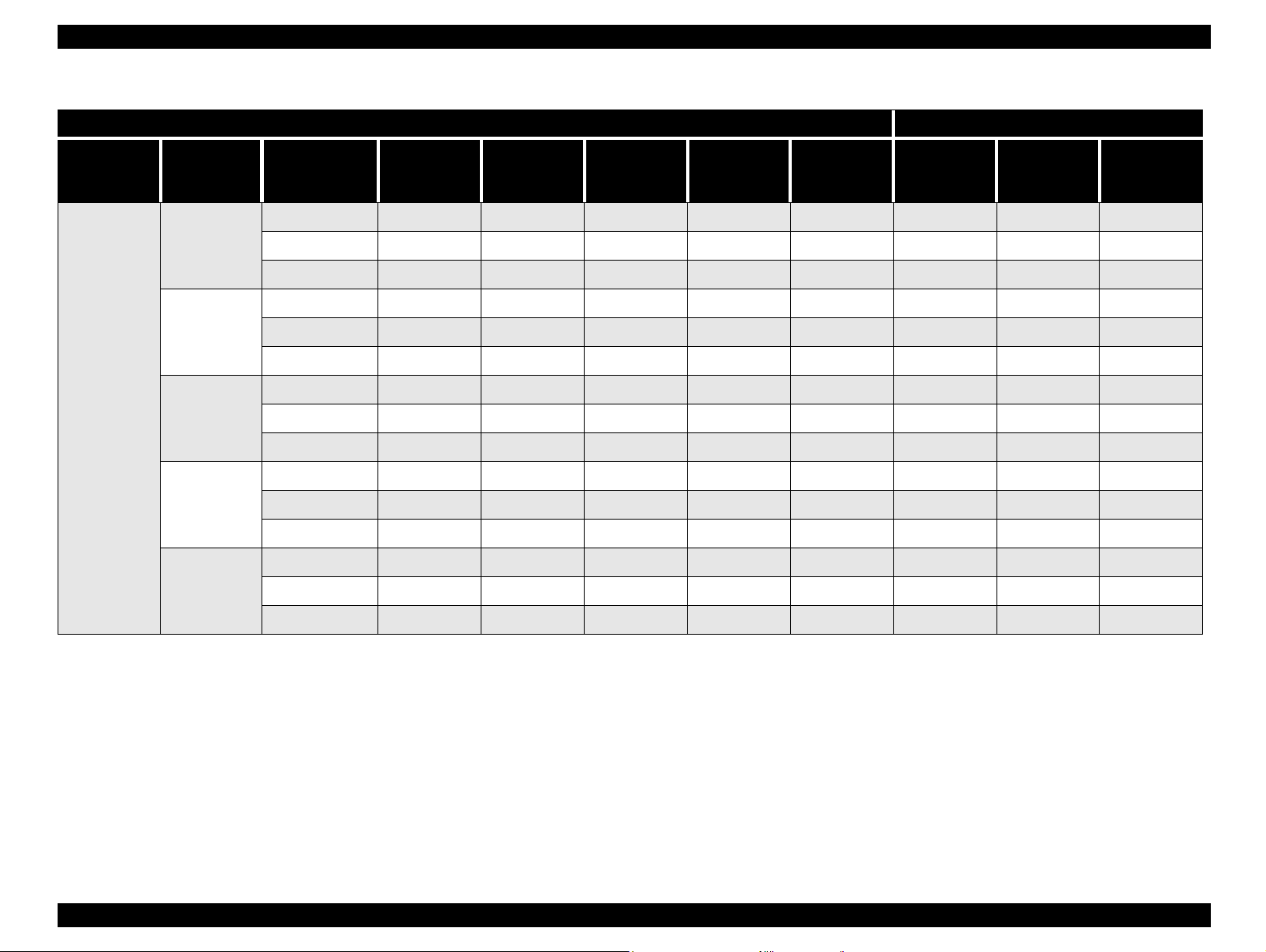

Table 1-16. Printer Control

Copy Mode

Paper

Size

A3W B&W 300dpi 18 NC NC NC

A3 B&W 300dpi 16 NC NC NC

Color/

B/W

Color 300dpi 54 NC NC NC

Color 300dpi 49 NC NC NC

Resolution 192 224 256

600dpi 71 NC NC NC

600dpi 214 C C C

600dpi 66 NC NC NC

600dpi 197 C C C

Amount

of Data*

[MB]

Printer Memory [MB]

A4 B&W 300dpi 8 NC NC NC

600dpi 32 NC NC NC

Color 300dpi 24 NC NC NC

600dpi 96 NC NC NC

Letter B&W 300dpi 8 NC NC NC

600dpi 31 NC NC NC

Color 300dpi 23 NC NC NC

600dpi 93 NC NC NC

Product Description Functions 18

Page 24

EPSON Color Copy Station 8200 Revision A

Table 1-16. Printer Control

Copy Mode

Paper

Size

Legal B&W 300dpi 10 NC NC NC

Legal B&W 300dpi 16 NC NC NC

Legal B&W 300dpi 6 NC NC NC

Color/

B/W

Color 300dpi 30 NC NC NC

Color 300dpi 48 NC NC NC

Color 300dpi 19 NC NC NC

Resolution 192 224 256

600dpi 40 NC NC NC

600dpi 119 NC NC NC

600dpi 63 NC NC NC

600dpi 190 C C C

600dpi 25 NC NC NC

600dpi 75 NC NC NC

Amount

of Data*

[MB]

*: This rough value contains only image data, not control data.

192MB Printer Memory: Minimum memory size to use CCS 8200.

Printer Memory [MB]

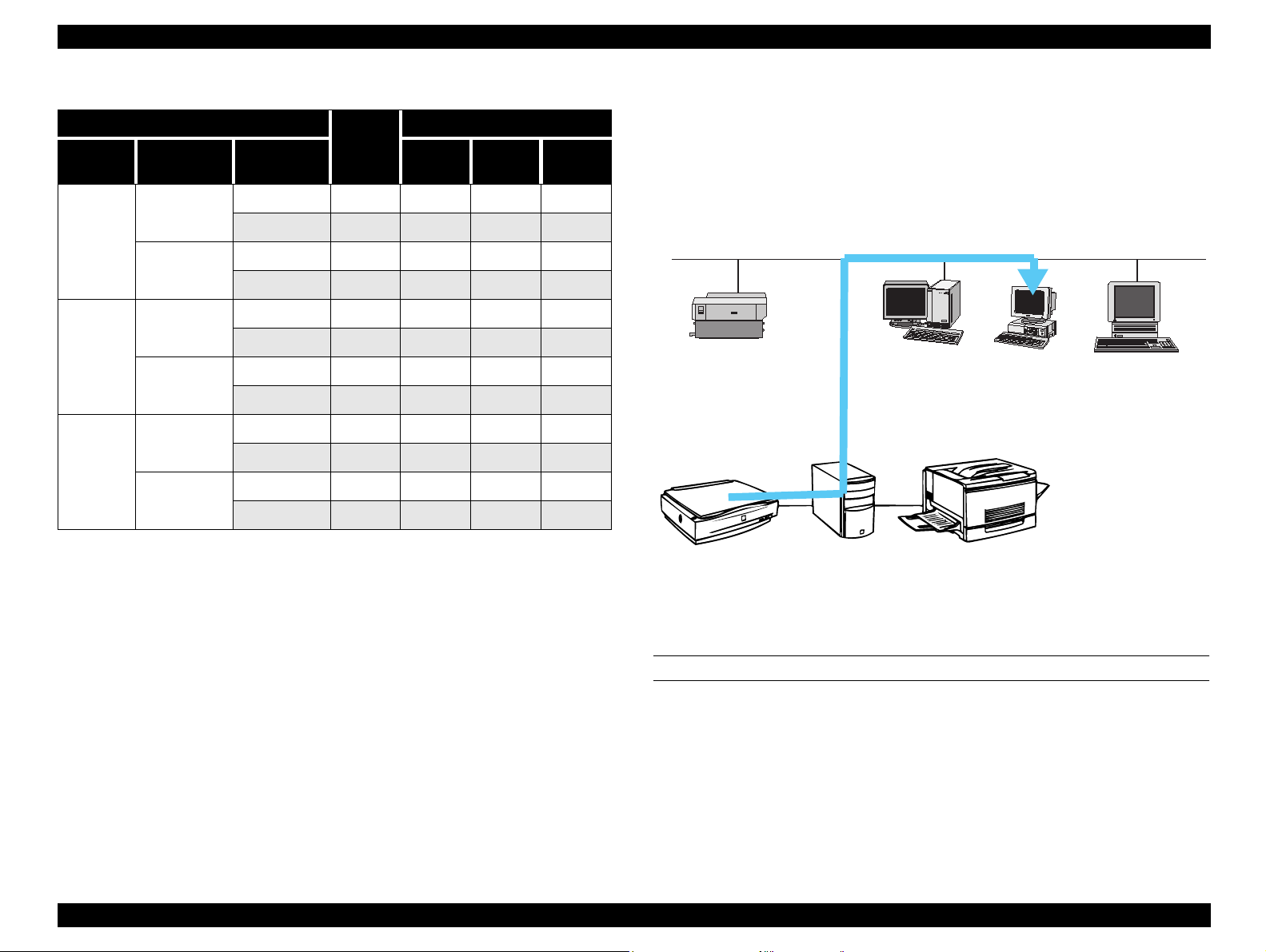

1.3.3 Network TWAIN

Network TWAIN scans image data from scanner connected with CCS 8200 via

network. The user interface on network TWAIN driver is just th e same as the

one on the local TWAIN, and the only difference between local and network

TWAIN driver is device inter fac e, namely SCSI for local and TCP/IP for

network.

10/100 base

Client PC

Scanner

GT-10000

Copy Server

CCS 8200

Printer

EPL-C8200

Figure 1-7. Network TWAIN Data Flow

START COPY

Two ways to start scanning:

1) Press the scanning button on the TWAIN at the client PC.

2) Press START key on the control panel of CCS 8200.

In the case of (1), the scanning is processed using the scanning parameters

set on the TWAIN driver. Therefore the user must open TWAIN and set the

parameters on the client befor e scanning. In the case of (2), on the other

hand, the scanning parameters must be set on the control panel. In this copy

system, scan-navi button located on the scanner is not available.

Product Description Functions 19

Page 25

EPSON Color Copy Station 8200 Revision A

PROTOCOL

EPSON original protocol on TCP/IP (Peer to Peer connection)

CLIENT OS

Table 1-17. Client OS

Software Name EPSON TWAIN Pro Network

Client OS PC/AT

Compatible

machine

Windows95, Widows98

WindowsNT3.51 Workstation

WindowsNT4.0 Workstation

SCANNER OPTION

ADF: Available

TPU: Not Available (Scanner does not support TPU.)

TWAIN FUNCTIONS

Other functions including scanning mode, scanning size are just the same as

local TWAIN functions.

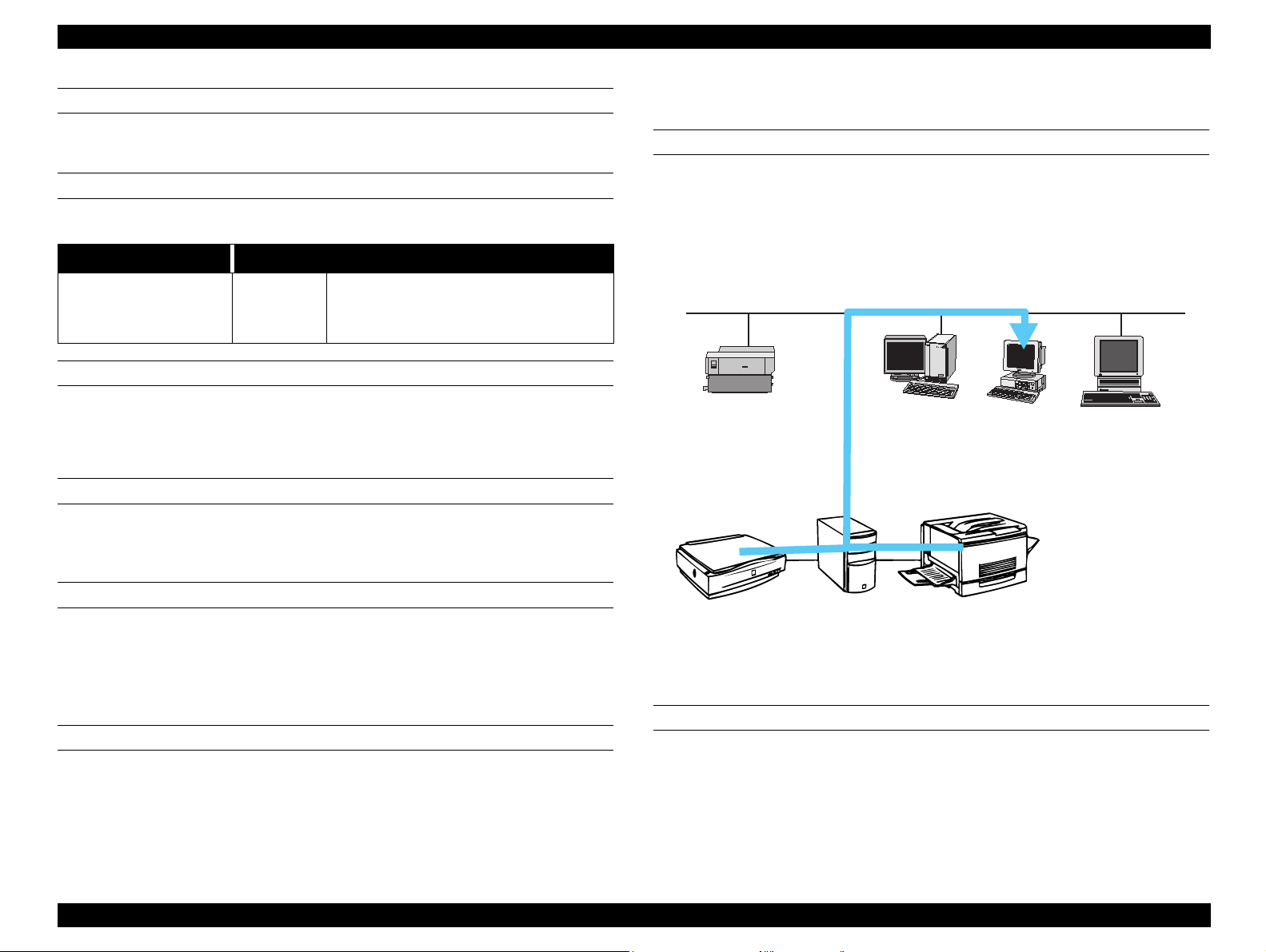

1.3.4 Web Status

OPERATIONAL PRINCIPLES

Web Status functions is the one of thr ee web-based utilities. Web Status

module is JAVA applet written by JAVA language and works on the web

master. When the user starts WebStatus, browser accesses to CCS 8200,

loads WebStatus applet, and executes it. By using this function, the user can

get the current status about scanner, printer, and CCS 8200.

10/100 base

Client PC

TIME OUT

After trying to connect, if no replay comes even after the fixed time passed,

the TWAIN driver disconnects the communication with CS-8200. This fixed

value is 30 seconds as a default in the initial setting . But the user can change

it on the TWAIN environment setting.

Scanner

GT-10000

Copy Server

CCS 8200

Printer

EPL-C8200

Figure 1-8. Web Status Data Flow

PROTOCOL

LOCALIZATION

HTTP on TCP/IP

TWAIN does not detect th e language used on OS and is localized for each

language as individual release.

Product Description Functions 20

Page 26

EPSON Color Copy Station 8200 Revision A

CLIENT OS

Table 1-18. Client OS

Software Name EPSON TWAIN Pro Network

Client OS PC/AT

Compatible

machine

Windows95, Widows98

WindowsNT3.51 Workstation

WindowsNT4.0 Workstation

URL

http://<host name>/WebStatus.html

host name: Name of CCS 8200

LOCALIZATION

WebAdmin detects the language used on OS, and uses the language if it is

one of the following: German, French, Spanish, Italian, and Portugue se. For

the other languages, WebAdmin uses English.

Table 1-19. Localization

Client PC OS Localization WebAdmin Localization

German German

French French

Spanish Spanish

Italian Italian

Portuguese Portuguese

All other local areas English

STATUS ITEMS

Table 1-20. Status Items

Items Remarks

CCS 8200 Registered Name Name registered by WebAdmin

Division Division registered by WebAdmin

IP address

Current Status

Printer Model Name

Current Status

Font Card Information Slot A, Slot B

Interface Card Information Slot A, Slot B

MP Tray Paper Size, Balance

C1 Cassette Paper Size, Balance

C2 Cassette Paper Size, Balance

C3 Cassette Paper Size, Balance

C4 Cassette Paper Size, Balance

Photo Conductor Life

Oil Roll Balance

Waste Toner Box status

Scanner Model Name

Current Status

ADF

Existence of document on ADF

Product Description Functions 21

Page 27

EPSON Color Copy Station 8200 Revision A

STATUS UPDATE TIMING

The status displayed on Web Status is updated at the timing below.

(Web Status doesn’t get the status from CCS 8200 periodically by itself)

n

When Web Status starts

n

When user clicks the icon of registered CCS 8200 on the WebStatus

n

When user press the re-load button on the web browser

1.3.5 Web Admin

OPERATIONAL PRINCIPLES

Web Admin function is the one of three web-based utilities for administrator.

WebAdmin module is JAVA applet written by JAVA language as is the case of

WebStatus. By using this function, the administrator can set some

parameters to CCS 8200.

10/100 base

Client PC

Scanner

GT-10000

Copy Server

CCS 8200

Printer

EPL-C8200

Figure 1-9. Web Admin Data Flow

PROTOCOL

HTTP on TCP/IP

Product Description Functions 22

Page 28

EPSON Color Copy Station 8200 Revision A

CLIENT OS

Table 1-21. Client OS

Software Name EPSON TWAIN Pro Network

Client OS PC/AT

Compatible

machine

Windows95, Widows98

WindowsNT4.0 Workstation

URL

http://<host name>/WebStatus.html

host name: Name of CCS 8200

CERTIFICATION

Web Admin is protected by certification mechanism.

The user name and password is fixed as follows as a default.

User Name: Administrator

Default Password: Administrator

LOCALIZATION

Web Admin detects the language used on OS, and uses it for German, French,

Spanish, Italian, and Portuguese. For the other languages, WebAdmin uses

English.

Table 1-22. Localization

Client PC OS Localization WebAdmin Localization

German German

French French

Spanish Spanish

Italian Italian

Portuguese Portuguese

All other local areas English

SETTING ITEMS

Table 1-23. Setting Items

Items Remarks

Main Unit Name of CCS 8200 possible (necessary)

Division possible

Model Name impossible

Memory Capacity of CCS 8200 impossible (32MB fixed)

Administrator Name possible

Administrator Login Name possible (necessary)

Administrator Password possible (necessary)

Administrator E-mail Address possible

Administrator Telephone Number possible

Product Description Functions 23

Page 29

EPSON Color Copy Station 8200 Revision A

Table 1-23. Setting Items

Items Remarks

TCP/IP IP Address possible (necessary)

Subnet Mask possible (necessary)

Mac Address impossible

Gateway Address possible

Registratio

n of

Machine

Printer

Initial

Settings

Name of Machine possible (necessary)

Division possible

a

IP Address possible (necessary)

Administrator Name possible

Administrator E-mail Address possible

Administrator Telephone Number possible

Output Tray

Right Margin

Left Margin

Upper Margin

possible

(Face-up/ Face-down)

possible(0~15mm, in

increments of 1mm)

possible (0~15mm, in

increments of 1mm)

possible 80~15mm, in

increments of 1mm)

1.3.6 Web Upgrade

OPERATIONAL PRINCIPLES

Web Admin function is the one of three web-based utilities for administrator.

WebAdmin module is JAVA applet written by JAVA language as well as

WebStatus. By using this function, the administrator can set some

parameters to CCS 8200.

10/100 base

Client PC

Scanner

GT-10000

Copy Server

CCS 8200

Printer

EPL-C8200

Figure 1-10. Web Admin Data Flow

a.Theusercanconfirmthestatusfortheregisteredmachine.

Themaximumnumberofmachineswhichcanberegisteredis8.

DATA VALID TIMING

PROTOCOL

HTTP on TCP/IP

The parameters are sent to the CCS 8200 after pressing SUBMIT button on the

Web Admin. After the CCS 8200 receives them and restarts by itself, those

parameters are valid.

Product Description Functions 24

Page 30

EPSON Color Copy Station 8200 Revision A

CLIENT OS

Table 1-24. Client OS

Software Name EPSON TWAIN Pro Network

Client OS PC/AT

Compatible

machine

Windows95, Widows98

WindowsNT4.0 Workstation

URL

http://<host name>/WebStatus.html

host name: Name of CCS 8200

LOCALIZATION

WebUpgrade doesn’t detect the language used on OS, and its language is

English only. (not localized)

1.3.7 Money Recognition

When CCS 8200 detects the feature of paper money in the scanned image in

the middle of local copy job, it cancels the job. Depending on the detection

timing, the copy output may be made and the printer outputs the image. But

even in this case, its image will not be complete money.

The specification of this fun ction is not open to the public.

1.3.8 User Settings

1.3.8.1 User Settings on the Operational Panel

HOW TO MOVE TO USER SETTING MODE

To enter the user setting mode, turn on the power switch while holding down

“start” and “stop” key on the operational panel simultaneously.

ITEMS

In the user setting mode, user can set the following parameters.

n

Language

n

IP address

n

Gateway address

n

Subnet mask

n

Network Speed (10 base / 100 base)

n

Retrieve factory settings

LANGUAGE SELECTION

At the user configuration mode, user can select the language from the ones

that CCS 8200 displays. At the same time, localization about operational

panel, web utilities, and pap e r size is determined according to the selec ted

language. The relation between the area and the localization for each function

is in the table below.

Table 1-25. Language Selection

Language Control Panel

English (default) English English English

French French French English

Italy Italy Italy English

Web Status

Web Admin

a

Web Upgrade

Product Description Functions 25

Page 31

EPSON Color Copy Station 8200 Revision A

Table 1-25. Language Selection

Language Control Panel

German German German English

Spain Spain Spain English

Portuguese Portuguese Portuguese English

a.These three web utilities detect OS language by itself and changes

its language to be used for user interface. For CCS 8200 the

languages which are not shown in the upper table, English is

selected.

Web Status

Web Admin

a

Web Upgrade

RELATIVE FACTORY SETTING

The menu “Retrieve Factory Settings” initializes all parameters about

CCS 8200.

n

Language Selection

n

Job Memory data

n

Parameters used in we b-based utilities

Factory settings are shown in the table below.

Table 1-26. Control Panel (No 1)

Parameters Default Value

Paper Size Paper Size of Cassette 1

Copy Mode Color

Document Type Magazine

Output Tray Face Up

Split Copy OFF

Print Margin Standard (Top, Left, Right = 100mm)

Forced continuation(*1) clear

Job memory clear for all

(*1) CCS 8200 can work even if scanner and /or printer is not connected to

CCS 8200. In this case, CCS 8200 doesn’t ask user because CCS 8200

remembers the previous setting of the existing scanner and printer. Forced

continuation indica tes this mark.

Table 1-27. Operational Panel (No.2)

Parameters Initial Value

Job memory clear for all

Table 1-26. Control Panel (No 1)

Parameters Default Value

Language English

IP address 000.000.000.000

Subnet Mask 000.000.000.000

Network Negotiation Automatic

Image Quality Parameters All 0 (standard settings)

Number of Copy 1

Zoom 100%

Parameters Initial Value

Main Unit - Name Color Copy Station

Main Unit - Division clear

Main Unit - Model CCS 8200

Main Unit - Administrator Name Clear

Main Unit - Administrator Login Name Administrator

Main Unit - Administrator Password Administrator

Main Unit - Administrator E-mail Address clear

Main Unit - Administrator Telephone clear

Table 1-28. Web Admin

Product Description Functions 26

Page 32

EPSON Color Copy Station 8200 Revision A

Table 1-28. Web Admin

Parameters Initial Value

Registered Machine clear for all registered machines

Output Tray Face Up

Print Margin 0mm for Upper, Left, Right margin

Server Scan Enable / Disable disable

1.3.9 Machine Functions

1.3.9.1 H/W Check

This function is used for manufacture and field supporter.

o

How to enter this mode

To enter user setting mode, turn on the power switch while holding

down “0”, “.”, and “stop” key on the operational panel

simultaneously.

o

Items to be checked

n

Panel unit check

n

ISA board check

n

ECP board check

n

Sum check for flash ROM

n

Print out the result of all H/W check

1.3.9.2 Fixed IP Setting

This function is used for manufacturer or field supporter. In this mode,

CCS 8200 starts with fixed IP address temporarily and user can use some

functions as well as in the normal mode. Once user turns CS-8200 off, the IP

address is cleared.

o

How to enter this mode

To move to user setting mode, turn on the power switch with pressing

“1”, “2”, and “3” key on the control panel simultaneously.

Product Description Functions 27

Page 33

EPSON Color Copy Station 8200 Revision A

o

Available functions

n

Local Copy

n

Network TWAIN

n

WebStatus

(WebAdmin and WebUpgrade can not be used in this mode.)

1.3.9.3 Firmware Update by Board to Board Copy

CCS 8200 supports two ways to upgrade the firmware, one is by

WebUpgrade, and the other is by Board to Board copy. The board to board

copy can execute the copy from master to target board even if target is just

brand-new board, but WebUpgrade supports the previous version of

firmware is written and runs in the CCS 8200. Please refer to Chapter 4 for

details.

UPGRADE SEQUENCE

1. O pen the ca se of CCS 8200, and insert two ISA boards setting the

MASTER mode and the Target mode. MASTER or TARGET is set by

jumper on the ISA Board as shown below.

Table 1-29. Jumper set on ISA BOARD

Jumper No. JP20 JP30 JP31 JP32

3. The LED lamp on the Control Panel turns on according to the sequence

below.

Table 1-30. Sequence turn on the LED

LED

Power

ON

Time

“Error”

LED (Red)

ll¡

l ¡ ¡

¡¡¡

l ¥ ¡

¥l¡

After the data in the flash ROM area is rewritten by executing WebUpgrade,

Board to Board, or Retrieve factor settings, the state in the ROM is changed as

follows.

“Ready”

LED (Green)

“Power”

LED (Green)

meaning

Power ON

Erasing the old firmware

Reading from MASTER,

and writing to TARGET

Finished successfully

Finished by failure

Table 1-31. ROM Area after rewritten

Control

Web Upgrade

ROM Area (*1)

Program Area Overwrite Overwrite Keep Previous State

Board to

Board Copy

Retrieve Factory

Settings

Master Mode 1-2 1-2 2-3 1-2

Target Mode 1-2 1-2 1-2 2-3

2. T urn on the power switch of CCS 8200.

Control Panel No. 1 Keep previous state Overwrite Overwrite

Control Panel No. 2 Keep previous state

Web Admin Keep previous state Overwrite Overwrite

Keep previous

state

Overwrite

(*1) Refer “User Settings” on page 25

Product Description Functions 28

Page 34

EPSON Color Copy Station 8200 Revision A

1.4 Appearance

1.4.1 Main Unit

Card Slot 6 (ISA Target Board)

Figure 1-11. CS-6000N Back

Table 1-32. Parts List

Power Switch

Power Connector

Card Slot 3 (ECP Board)

Card Slot 4 (SCSI Board)

Card Slot 5 (Network Board)

Table 1-32. Parts List

Name Remarks

Printer interface connector

Scanner interface connector

Network interface connector

Control Panel Interface connector

1.4.2 Control Panel

F

Doc Type

Zoom

Paper Size

Image

Density

G

Color

Adjust

CLR/

B&W

All Color

Start

H

I

1 2 3

4 5 6

7 8 9

0 . C

Name Remarks

Power Switch

AC inlet

Card Slot 1 (Blank)

Card Slot 2 (Blank)

Card Slot 3 PCI-bus ECP Card

Card Slot 4 PCI-bus SCSI Card

Card Slot 5 PCI-bus Network Card

Card Slot 6 ISA-bus ISA Board (Flash, Panel)

Card Slot 7 ISA-bus (Blank)

(A) Error Lamp (Red)

(B) Ready lump (Green)

B

A

CD

E

Figure 1-12. Appearance of Operational Panel

ON: means the error occurs in scanner, printer, or CCS 8200.

OFF: means no error occurs in scanner, printer, or CCS 8200.

ON: means the scanner, printer, and CCS 8200 are all standby.

OFF: means one of the scanner, printer, or CCS 8200 is not standby.

BLINK: means CCS 8200 is doing some job.

Product Description Appearance 29

Page 35

EPSON Color Copy Station 8200 Revision A

(C) Power lump (Green)

ON: means CCS 8200 is powered on.

OFF: means CCS 8200 is powered of.

(D) Intensity Adjustment volume

A volume switch to adjust LCD intensity.

(E) Ten key

There are keys to set copy numbers, zoom, and so on.

“C” key is used to clear copy numbers and so on for default.

(F) LCD and Touch key

LCD is 320x240 dot matrix, and Touch key is 8x6 matrix scan sensor.

LCD is used to display parameters, and Touch key is used to set

parameters.

(G) All Clear key

The parameters for local copy are all cleared by pressing this key.

(H) Start key

Local copy or Network TWAIN starts to copy or scan by pr essing this

key.

(I) Stop key

Local copy or Network TWAIN stops to copy or scan by pressing this

key.

1.5 Accessories

1.5.1 Product Component

The typical configuration contains the following components.

1. CC S 8200

2. Operational Panel

3. Operational Panel Cable

4. EPL-C8200

5. GT-10000

6. Printer Cable

7. Scanner C able (SCSI Cable)

8. Sys tem Rack (2 large capacity paper cassette type)

9. Power Supply Code for System Rack

10. Code Manuals (English Version)

11. Bundled Software CD-ROM

1.5.2 Bundled Software

1. EPSON TWAIN Pro Network for Windows

2. Microsoft Internet Explore for Windows

Product Description Accessories 30

Page 36

EPSON Color Copy Station 8200 Revision A

1.6 Attention for forgery

EPSON Color Copy Station 8200 is a Color Copier, and user can copy all kind

of documents. But the admin istrator must forbid all users from copying bills,

securities and so on which are inhibited by law. The system administrator has

duty not to make illegal copies.

Product Description Attention for forgery 31

Page 37

OPERATING PRINCIPLES

CHAPTER

2

Page 38

EPSON Color Copy Station 8200 Revision A

2.1 Operating Principles

This section explains the operating principles of CCS 8200. Refer to

each Service Manual for the operating principles of printer and scanner.

2.1.1 Copy System

Copy system of CCS 8200 is as follows.

CPU

L2

PCI

Bridge

ISA Board

ISA

Board

Control Panel

ISA

Bridge

Figure 2-1. System Connection

Main

Memory

32MB

NIC

DE-500B

Ethernet

10/100BaseT

PCI Bus

SCSI Board

AVA-290E

Scanner

ECP Board

Printer

2.1.2 Control Circuit

Hardware architecture of this product is PC/AT personal computer, and

interfaces of ISA and PCI for extension exist respectively.

CPU adopts AMD K6-2 processor, which is driven by 300 MHz Clock,

and has one 32MB RAM-DIMM on the mother board. On the mother

board, CMOS, which records the setting values of BIOS, and a lithium

battery for backing-up are mounted.

2.1.3 ISA Board

On the ISA Board (C85010 I/F), ASIC E02A27, Flash ROM (8Mbit x 12),

EEPROM (AT93C66) and SRAM (256 KB x 1) are mounted. ISA board

is connected to the mother board through ISA bus s lot. The figure bel ow

is ISA board block diagram.

ISA Board

E02A27

Flash ROM

8Mbitx12

SRAM

256kx1

Control Panel

ISA BUS

ROM

Control

LCD

Control

Touch Panel

Button Control

CCS-8200 connects the network by 10/100 Base Network Interface

Board (DE-500B) through the switching pab and operate copy server

function. Due to this, each PC on the network can use the common

Figure 2-2. ISA Board Block Diagram

scanner and printer.

Operating Principles Operating Principles 33

Page 39

EPSON Color Copy Station 8200 Revision A

o

ASIC E02A27:

Controls I/F of ISA board and ROM (to start the system), LCD of the

control panel (panel module), and the touch panel and control

bottom on the LCD.

o

Flash-ROM:

Stores firmware, table etc.

2.1.3.1 ECP Board

ECP Board (Image Processing Board, C850101/F-B) connects to the

mother board through the PCI bus of Color Copy Station 8200.

PCI bus

TO update firmware, connect the master ISA board to an open ISA

slot. Flash-ROM uses Board to Board copy function, which copies

the firmware from the master board to the target board. Also, FlashROM can be updated from the Web page.

o

SRAM:

Memory for LCD indicator

o

EEPROM:

Keeps the setting of the ISA board.

WAIT

WAIT

WAIT

PCI E09A06AB

176 pin (3.3v, 5V)

WAIT

INT

WAIT

WAIT

LOCAL BUS (ADDRESS)

LOCAL BUS (DATA)

INT

Clock

Super I/O

FDC87W23 (SMSC), 100pin (5V)

BILL

CPU, E09A12AA

DRAM

SRAM

TET

E09A12AA

144pin(3.3V)

RGB

STRB

BUSY

MOIRE

E09A09AB

144pin(3.3V)

RGB

SHARPNESS

E09A11EA

RGB

E09A11EA

RGB

E09A10AA

208pin(3.3V,5V)

STRB

CMM

STRB

DMA

BUSY

STRB

BUSY

BUSY

STRB

BUSY

RGB

SRAM (3.3V)

(32KWx8bit )x4

BUSY

STRB

Regulator

1284 Driver

IEEE1284

25pin

DSUB Connector

Figure 2-3. ECP Board Block

Operating Principles Operating Principles 34

Page 40

EPSON Color Copy Station 8200 Revision A

FUNCTIONAL EXPLANATION

GENERAL DESCRIPTION OF THE BOARD FUNCTION

o

PCI:

o

The board processes image data sent through PCI bus, and stores

Controls PCI BUS, LOCAL BUS, and RGB BUS.

the image processed data to the SRAM (total memory: 1Mbit)

o

mounted on the board. (DMA IN)

BILL (Bill recognition circuit):

BILL uses CPU, ASIC, and the program and data stored on the ISA

o

The board sends on the image processed data to the printer through

Super I/O. (DMA OUT)

ECP board processes image data by BILL (bill recognition circ uit), TET

board. When the system started, the programs and data are loaded

and stored in the DRAM inside BILL. The image data is input

through RGB BUS, and in case BILL recognizes it as a bill, BILL

informs this by interrupting into the LOCAL BUS.

(Text Enhancement Technology), MOIRE (deleting moire),

o

SHARPNESS (emphasizing edges), CMM (changing color). Each

treatment does not support al l r esol ution power. The ta ble below sho ws

whether respective treatment is valid at each resolution power.

Table 2-1. Resolution Power of Each Treatment

Resolution

Power** (dpi)

300 x 300

600 x 600

BILL TET MOIRE

¡

*

¡

¡(¡

)

x*(¡) x(¡)

¡(¡

)

SHARPNESS

¡(¡

)

¡(¡

)

CMM

¡(¡

¡(¡

)

)

TET (TEXT ENHANCED TECHNOLOGY):

Performs TET process.

o

MOIRE:

Performs MOIRE clearing process.

o

SHARPNESS:

Performs edge emphasizing treatment.

o

CMM:

Performs color translation process from RGB TO R’G’B’.

o

Note: *¡: supported x: Not supported

** Resolution Power: main-scanning x sub-scanning

(): when using processing by-pass

As shown in the table above, when using A3 wide (600 x 600 dpi), the

DMA:

Storing data sent from CMM in SRAM. (DMA IN)

Four 32Kw x 8bit SRAMs are mounted and total memory amounts

to 32Kw x 8bit.

ASIC (TET, MOIRE) treatment on the board are not supported, and

therefore it is supported by software. When the software is used to

process image data, in order to prevent input of the data processed by

TET and MOIRE against BILL (for processed image data cannot be

input to BILL), PCI output is provided with two types of strobe signal.

When performing this process, the software should alternately transmit

one line data processed by TET and MOIRE to PCI.

Operating Principles Operating Principles 35

Page 41

TROUBLE SHOOTING

CHAPTER

3

Page 42

EPSON Color Copy Station 8200 Revision A

3.1 Error Message

Color Copy Station 8200 is equipped with a self-error-detection function, and

when an error occurs, it is in dicated by LCD on the control panel or an error

lamp.

3.1.1 Printer Error of Local Copy Mode

Table 3-1. Alert Message

Cause Copy Server Panel Screen Printer Panel Screen

A write-enabled ROM

module is inserted that

is not formatted.

Due to a memory

shortage, printing at the

specified resolution is

not possible, and the

printing resolution is

lowered..

Memory is insufficien t

during data processing

and memory

compression and

expansion is applied.

Selected paper size is

mismatched.

Selected paper size is

mismatched and printed

on a different size of

paper.

Printer Alert

ROM module

Press the Stop button

Job will Continue

Printer Alert

Insufficient Memory

Press the Stop button

Job will Continue

Printer Alert

Insufficient memory

Press the Stop button

Job will Continue

Printer Alert

Paper Size Error

Press the Stop button

Job will Continue

Printer Alert

Paper Size Error

Press the Stop button

Job will Continue

Format Error ROM A

or

Format Error ROM B

Image Optimum

Need Memory

Check Paper Size

Check Paper Type

Table 3-1. Alert Message

Cause Copy Server Panel Screen Printer Panel Screen

This message appears

only if selected paper

type is mismatched and

printed at different

cassette

Informs the user t hat th e

photoconductor unit has

almost reached the end

of its serv ice life.

The Waste Toner

Collector is nearly full.

There is on ly a little

fuser oil re maining.

Asigned number of

pages are not printed.

The remaining toner of

each color (Y, M, C, K) is

low.

A warning has been

generated which the

user cannot resolve.

Paper is prefed, but

since the print data is

not prepared within the

engine’s setting time,

the paper was forced to

be fed without printing.

Printer Alert

Paper Size Error

Press the Stop button

Job will Continue

Printer Alert

Photoconductor

Press the Stop button

Job will Continue

Printer Alert

Waste Toner Box

Press the Stop button

Job will Continue

Printer Alert

Oil Roll

Press the Stop button

Job will Continue

Printer Alert

Collate disabled

Press the Stop button

Job will Continue

Printer Alert

Toner Cartridge

Press the Stop button

Job will Continue

Printer Alert

Service Required

Press the Stop button

Job will Continue

Printer Alert

Pre-feed Error

Press the Stop button

Job will Continue

Outbin Select Error

Warning

Photoconductr

Waste T Box Nearfull

Oil Roll Near Empty

Collate was disabled

uuuu Toner Low

uuuu = CMYK

Maintenance Req

hhhh

Time exceeded

Trouble Shooting Error Message 37

Page 43

EPSON Color Copy Station 8200 Revision A

Table 3-2. Auto Recovery Error Message

Cause

During the printing procedure,

the print data were too compl ex

for image processing to keep

up with the printer engine

speed.

Memory was insufficient for a

processing task, and operation

cannot continue.

Selected paper size is

mismatched.

Table 3-3. Unrecoverable Error Message

Cause

The front cover is open.

A ROM module that cannot

be used with this printer is

inserted in slot.

The write process was not

completed successfully, or

there is no R O M module

inserted in slot.

Copy Server Panel

Screen

Printer Error

Printer Overrun

After Error Recovery

Job will Continue

Printer Error

Insufficient Memory

Press the Stop button

Printer Error

Printer Size Error

After Error Recovery

Job will Continue

Copy Server Panel

Screen

Printer Error

Cover Open

After Error Recovery

Job will Continue

Printer Error

ROM Module

After Error Recovery

Press the Stop

button

Printer Error

ROM Module

After Error Recovery

Press the Stop

button

Printer Panel

Screen

Print Overrun Continue

Mem Overflow Cancel

Paper Set sss ttt Cancel

Printer Panel

Screen

Front Cover Open Continue

Invalid ROM A

or

Invalid ROM B

Write Error ROM A

or

Write Error ROM B

Copy

Activity

Copy

Activity

Cancel

Cancel

Table 3-3. Unrecoverable Error Message

Cause

A paper concurred at the

location indicated.

(Feed, Fuser, Exit)

Printer attempted paper feed

but there was no pape r in t he

paper feed unit.

Printer attempted paper feed

but there was no pape r in t he

paper feed unit.

The OHP sheet was set

upside dow n and fed into the

printer, or an unspecified

OHP sheet was fed into the

printer.

An interface card that cannot

be used with this printer is

inserted.

The photoconductor unit is

not set or it is not set

correctly.

A Waste Toner Collector is

not set.

Copy Server Panel

Screen

Printer Error

Paper Jam

After Error Recovery

Job will Continue

Printer Error

Paper Out

After Error Recovery

Job will Continue

Printer Error

Paper Size Error

After Error Recovery

Job will Continue

Printer Error

Paper Size Error

After Error Recovery

Job will Continue

Printer Error

Aux I/F Error

After Error Recovery

Press the Stop

button

Printer Error

Photoconductor

After Error Recovery

Press the Stop

button

Printer Error

Waste Toner Box

After Error Recovery

Job will Continue

Printer Panel

Screen

Jam xxxxxxxxxxx

xxxxxxxxxxx =

Feed, Fuser, Exit

Paper Out sss ttt Continue

Manual Feed sss

ttt

Check OHP Sheet Continue

Invalid AUX I/F

Card

Insert

Photocondctr

Insert Waste T

Box

Copy

Activity

Continue

Continue

Cancel

Cancel

Continue

Printer Error

Oil Roll

After Error Recovery

Job will Continue

Insert Oil Roll Continue

The appointed cassette does

not exist.

Printer Error

Paper Out

After Error Recovery

Job will Continue

Insert sss Continue

The Fuser Oil Roll is not set.

Trouble Shooting Error Message 38

Page 44

EPSON Color Copy Station 8200 Revision A

Table 3-3. Unrecoverable Error Message

Cause

The paper output cover is

open.

The Fuser cover is open.

The paper feed unit is open.

Engine’s photoconductor

service life is detected to end.

The waste toner box is

sensed to be full of waste

toner from the engine.

Toner sensor detects there is

no fuser oil. .

Copy Server Panel

Screen

Printer Error

Cover Open

After Error Recovery

Job will Continue

Printer Error

Fuser Unit Open

After Error Recovery

Job will Continue

Printer Error

Paper Unit Open

After Error Recovery

Job will Continue

Printer Error

Photoconductor

After Error Recovery

Press the Stop

button

Printer Error

Waste Toner Box

After Error Recovery

Job will Continue

Printer Error

Oil Roll

After Error Recovery

Job will Continue

Printer Panel

Screen

Exit Cover Open Continue

Fuser Unit Open Continue

Paper Unit Open Continue

Replace

Photocondctr

Replace Waste T

Box

Replace Oil Roll Continue

Copy

Activity

Cancel

Continue

Table 3-3. Unrecoverable Error Message

Cause

The proper Photoconductor

Unit is not set.

The Photoconductor Unit is

malfunctioning.

The paper feed cover is ope n.

A Toner Cartridge is not set.

It is detected that there is no

toner remaining by the toner

and sensor for each engine

color.

Copy Server Panel

Screen

Printer Error

Photoconductor

After Error Recovery

Press the Stop

button

Printer Error

Photoconductor

After Error Recovery

Press the Stop

button

Printer Error

Cover Open

After Error Recovery

Job will Continue

Printer Error

Toner Cartridge

After Error Recovery

Job will Continue

Printer Error

Toner Cartridge

After Error Recovery

Job will Continue

Printer Panel

Screen

Wrong

Photoconductor

Photoconductor

Trouble

Feeder Cover

Open

uuuu Toner Crtg

Out

uuuu = CMYK

uuuu Toner Out

uuuu = CMYK

Copy

Activity

Cancel

Cancel

Continue

Continue

Continue

At the top of paper feed

direction, print data with a

YMCK total print da ta d ens it y

of 280% or greater exits, with

a printing high density error

occurring.

Printer Error

Paper Thickness

After Error Recovery

Press the Stop

button

Irregular Density Cancel

Trouble Shooting Error Message 39

Page 45

EPSON Color Copy Station 8200 Revision A

Table 3-3. Unrecoverable Error Message

Cause

The PostScript card that

cannot be used with this

printer is inserted.

HDD is in trouble.

An Error has been generated

which the user cannot

resolve.

Table 3-4. Details of Service Call Error

Error CategoryeError Code

ffff

E 0003 Fuser Unit Malfunction (Service Life)

E 0008 Engine NVRAM Malfunction

E 0014 Engine Communications Error

E 0020 ADC Sensor Dirty

E 0022 PCDC Defective

E 0023 IBT Cleaner Service Life

E 0024 Second BTR Service Life

E 0025 Spare

E 0030 Fuser Unit Malfunction (Time Out)

E 0031 Fuser Unit Malfunction (no Fuser Unit)

Copy Server Panel

Screen

Printer Error

Post Script Error

After Error Recovery

Press the Stop

button

Printer Error

HDD Error

After Error Recovery

Press the Stop

button

Printer Error

Service Required

After Error Recovery

Press the Stop

button

Printer Panel

Screen

Invalid PS3 Cancel

Invalid HDD Cancel

Service Req effff

effff: See the table

below

Explanation

Copy

Activity

Cancel

Table 3-4. Details of Service Call Error

Error CategoryeError Code

ffff

E 0032 Fuser Unit Malfunction (Overheat)

E 0033 Fuser Unit Malfunction (Lamp)

E 0034 Fuser Unit Malfunction (Low Temperature)

E 0035 Large Capacity Paper Unit Malfunction

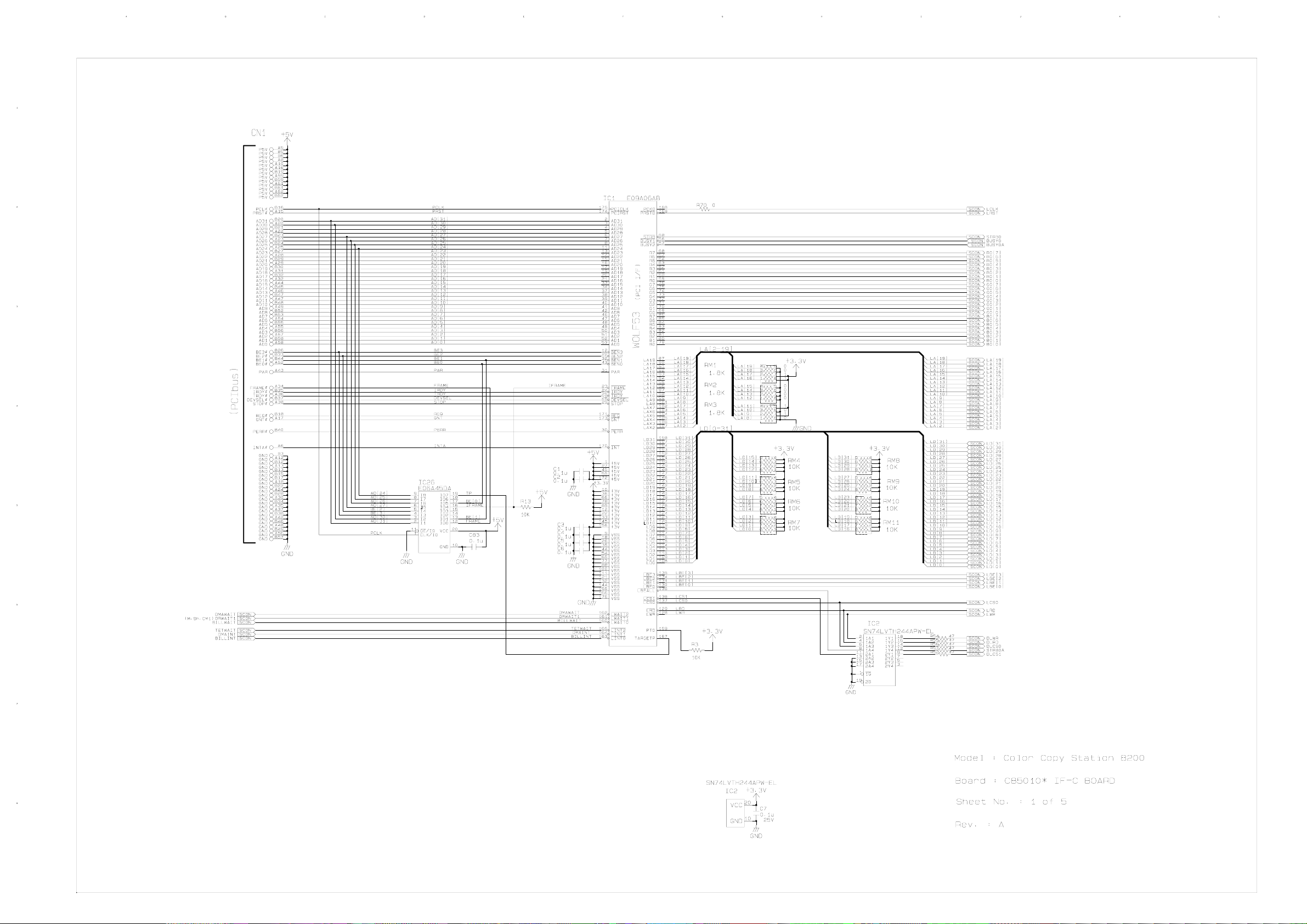

E 0036 Second BTR Resistance Abnormal