Page 1

Roller Conveyor

Models

❑ RC-length-AF (5 ft. min.)

example RC-15-AF

Roller conveyors are specifically designed for

centralized food service systems where trays

are moved manually along a straight assembly

line. An optional electrical system is available

to supply power to accessory serving units.

FEATURES

• Available in 5' to 24' lengths

in one foot intervals. Contact

factory for lengths greater

than 24 feet.

• Flexibility — Conveyors

may be used separately or

joined together to form

longer assembly line.

• Quiet operation — Trays

roll smoothly and quietly on

rollers constructed of nonmarking plastic.

• Easy to clean and maintain

— the entire stainless steel

conveyor can be steam or hot

water cleaned.

• Conveyor is mounted on

sturdy stainless steel legs,

with adjustable bullet feet.

• Optional correctional package available.

■ Construction: Shall be stainless steel, sup-

ported as necessary with aluminized steel

to provide maximum strength and rigidity.

■ Conveyor: Manual feed. Trays move on

rollers constructed of non-marking plastic.

■ Legs: Shall be 1

5

⁄8" O.D. stainless steel with

1

1

⁄4" cross braces equipped with adjustable

bullet feet. Optional casters are available

and add

1

⁄2" to overall height of 37".

■ Electrical: Construction shall be such that

a separate, stainless steel, drip-resistant

wire raceway is located below the conveyor

top deck. Electric outlets shall be mounted

in the raceway and shall be furnished with

water resistant covers. A circuit breaker

panel shall be furnished with water resistant covers. A circuit breaker panel shall be

furnished located at the loading end of the

conveyor. Standard wiring shall be

120/208/240 volt, single phase, 125 amp

load center with four standard electrical

outlets (up to 30 amps each) with a maximum of 100 amperes, full load. Additional

outlets will require an optional electrical

system.

PRODUCT INFORMATION

Savannah, TN 38372 www.americanfoodserviceco.com

731-925-2200 / 800-447-4693 / FAX 731-925-2840

Project: Quantity: Item #:

Meal Delivery Systems

Page 2

Roller Conveyor

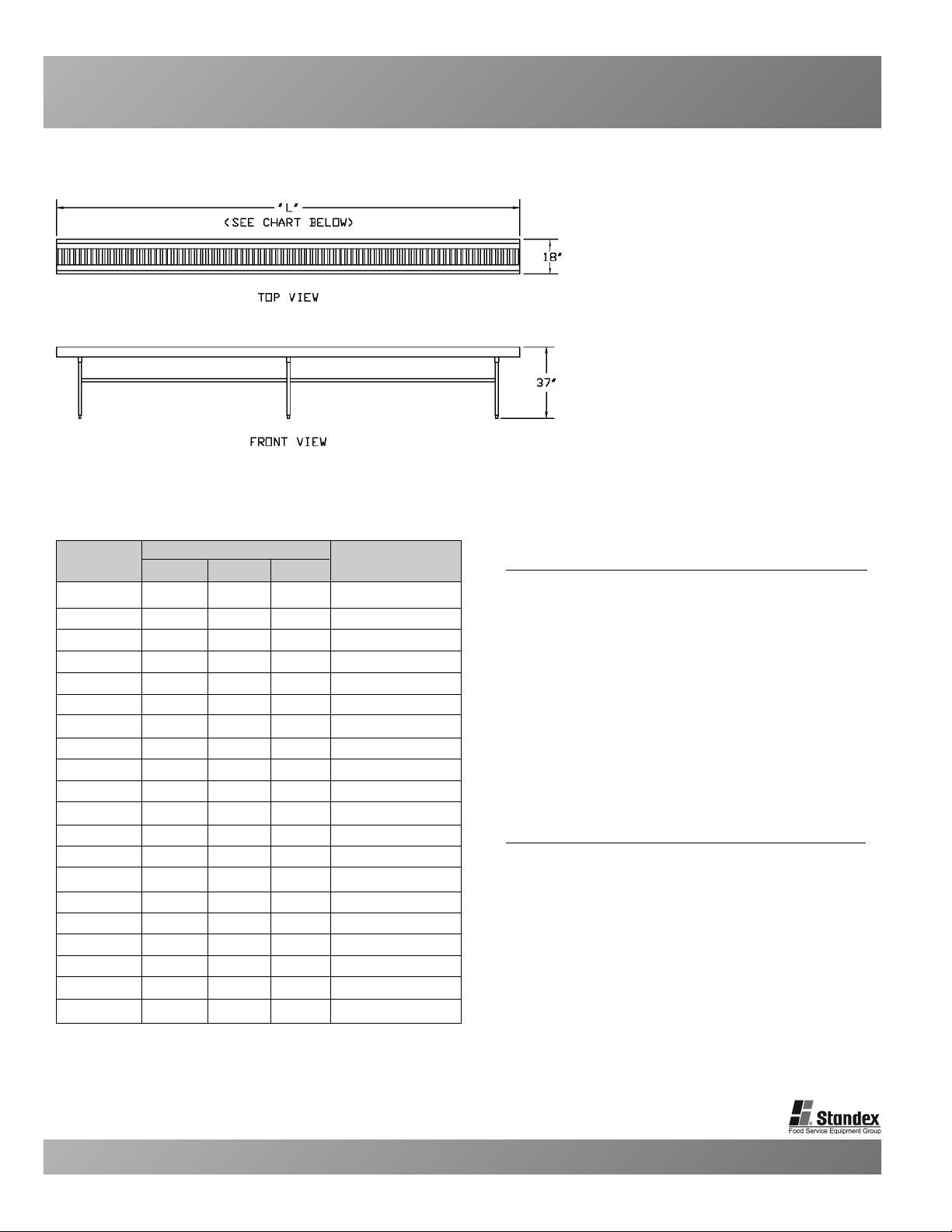

TECHNICAL SPECIFICATIONS

BID SPECIFICATIONS

Savannah, TN 38372 www.americanfoodserviceco.com

731-925-2200 / 800-447-4693 / FAX 731-925-2840

RC-length-AF (RC-15-AF)

Model _______ Roller Conveyor. Overall dimensions

shall be __" wide x __" long x __" high. All seams

shall be continuously welded and polished. Leg

stands shall be 1

5

⁄8" O.D. stainless steel with 11⁄4" cross

braces and have adjustable bullet feet. Tray rollers

shall be constructed of non-marking plastic. Electric

shall be separate in a stainless steel drip-resistant

wireway with water resistant cover furnished on all

outlets mounted in the raceway.

Model #

Approx. Shipping

L W H** Weight (lbs.)

RC-05-AF

RC-06-AF

RC-07-AF

RC-08-AF

RC-09-AF

RC-10-AF

RC-11-AF

RC-12-AF

RC-13-AF

RC-14-AF

RC-15-AF

RC-16-AF

RC-17-AF

RC-18-AF

RC-19-AF

RC-20-AF

RC-21-AF

RC-22-AF

RC-23-AF

RC-24-AF

5'

6'

7'

8'

9'

10'

11'

12'

13'

14'

15'

16'

17'

18'

19'

20'

21'

22'

23'

24'

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

18"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

260

302

344

386

428

470

512

554

596

638

630

652

674

696

718

740

762

784

806

828

Due to continued product improvement, specifications are subject to change without notice. 4/01/10 USA

Dimensions

OPTIONAL ACCESSORIES

• Three shelf starter station shelves on 8" spacing.

First and second shelves cut out for 12" x 20" pans.

(Pans not included.)

• Circuit breaker panel and electric raceway.

• Casters in lieu of legs with adjustable feet. Add

1

⁄2"

to overall height.

• Optional correctional package available.

NOTE:

*For conveyors mounted on optional casters add suffix “C” to

model number. For optional electrical raceway add suffix “E”.

**Height with casters is 371⁄2".

Loading...

Loading...