Epco 35-10-AF, 35-12-AF, 35-16-AF, 35-18-AF, 35-20-AF Specifications

...

Bandveyor™ Powered

Tray Conveyor

Models

❑ 35-XXA-AF

XX= total length

of conveyor

The Series 35 powered tray conveyors are designed

for heavy duty use in institutions. They provide

cost savings over conventional powered conveyors

due to low maintenance cost.

FEATURES

• Heavy duty stainless steel

construction throughout.

• Electronic, low maintenance

variable speed drive.

• Moving bands are of FDA

approved material requiring no

alignment or slack adjustments.

• All bearings are lubricated for

life and sealed.

• Electrical outlets in lower

raceway provide power on either

side of the tray line.

• Bands are cleanable using a

hand-held cloth.

• Significant cost savings over

conventional powered conveyors.

• All seams are continuously

welded and polished.

• Integrated loading and unloading surfaces are designed for ease

of tray assembly and inspection.

• Optional starter station available.

• Optional correctional package

available.

PRODUCT INFORMATION

Savannah, TN 38372 www.americanfoodserviceco.com

731-925-2200 / 800-447-4693 / FAX 731-925-2840

35-XXA-AF

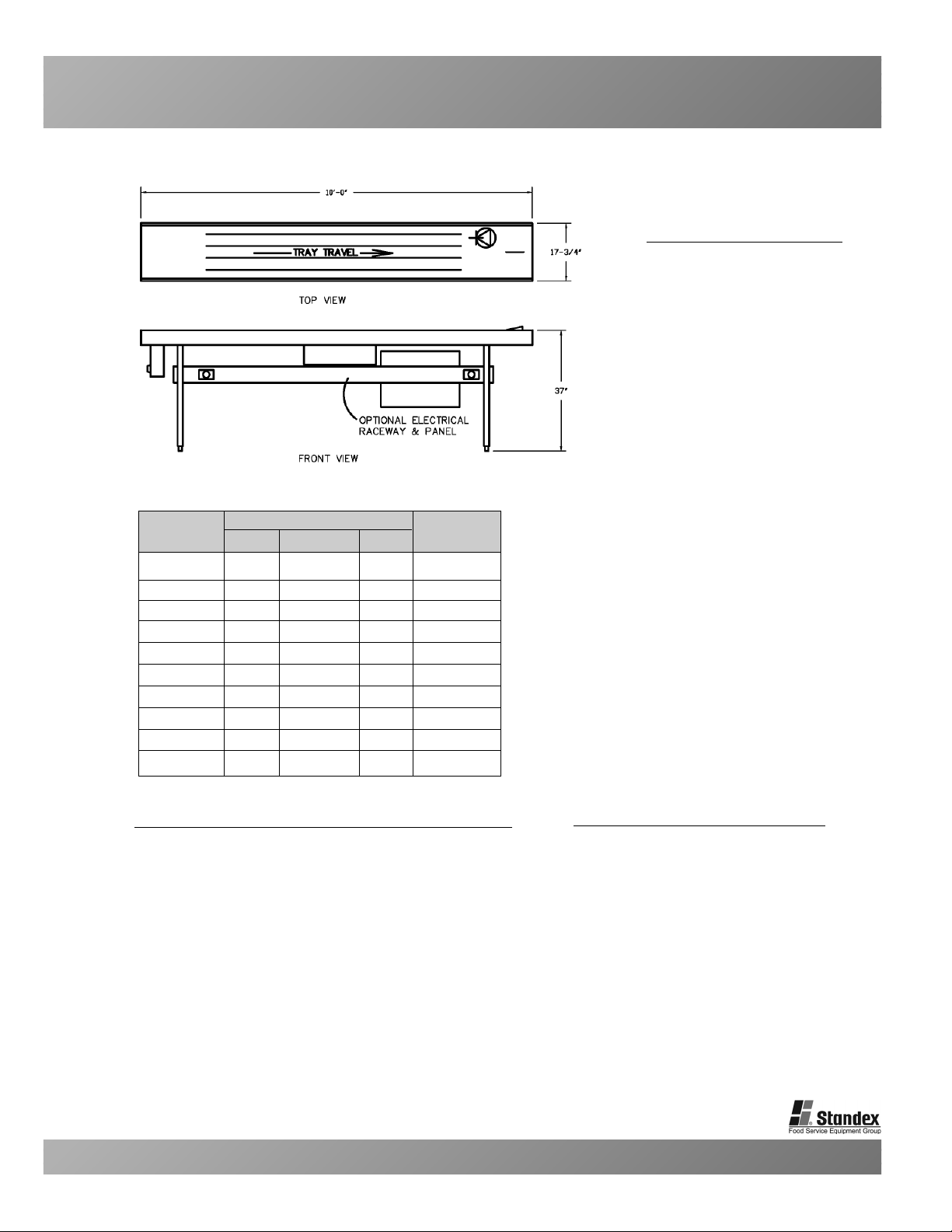

■ Construction: Two full-length load-bearing channels

formed of 12 gauge aluminized steel shall be positioned

beneath the top deck to give maximum strength and

rigidity. The top deck shall be one piece 18-gauge stainless steel fabricated to cover support channels on exterior

and interior sides and both ends. All seams shall be continuously welded and polished. Top deck shall be provided with continuous “V” type marine edge and shall

accommodate trays up to 17

3

⁄

4

" wide. A 20" loading and a

28" unloading shelf shall be integral with top deck.

■ Conveyor Bands: Trays shall be conveyed on four con-

tinuous bands of FDA approved material. Bands shall

require no adjustments for alignment or slack takeup.

■ Legs: Leg stands shall be 1

5

⁄8" O.D. stainless steel with

1

1

⁄4 " braces equipped with adjustable leveling bullet feet.

■ Electrical: Construction shall be such that a separate,

stainless steel, drip-proof wire way is located below the

conveyor top deck. Electrical outlets shall be mounted in

the raceway and shall be furnished with waterproof

covers. A circuit breaker panel shall be furnished located

at one end of the wire way with a separate breaker for

each outlet.

Note: Customer should advise total number and location of

electrical outlets required, voltage and wattage (or amperage) indicated for each. Customer should also indicate preferred location for optional circuit breaker panel if specified.

No cord set will be provided unless specified. Customer

should also advise manufacturer and model number of cord

caps to be connected to conveyor electrical outlets.

Project: Quantity: Item #:

Meal Delivery Systems

Bandveyor™ Powered Tray Conveyor

BID SPECIFICATIONS

Savannah, TN 38372 www.americanfoodserviceco.com

731-925-2200 / 800-447-4693 / FAX 731-925-2840

35-XXA-AF (XX=Total length of conveyor)

35-10-AF

35-12-AF

35-16-AF

35-18-AF

35-20-AF

35-22-AF

35-24-AF

35-26-AF

35-28-AF

35-30-AF

173⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

17

3

⁄4"

10'

12'

16'

18'

20'

22'

24'

26'

28'

30'

37"

37"

37"

37"

37"

37"

37"

37"

37"

37"

Due to continued product improvement, specifications are subject to change without notice. 4/01/10 USA

Provide (1) model _________ Bandveyor™ tray conveyor.

Overall dimensions shall be _____" wide x ______" long x

______" high. Top deck shall accommodate trays up to

17

3

⁄4" wide and shall have continuous V type marine edge

formed to cover exterior and interior sides of support

channels. All seams shall be continuously welded and

polished. A 20" loading and 28" unloading shelf shall be

integral with top deck. Adjustable legs shall be 1

5

⁄8" O.D.

stainless steel with 1

1

⁄4" braces. Drive and control shall be

3

⁄4 H.P. DC powered with integral worm. Speed control

shall be of the SCR type for 115V, with variable speed

adjustment up to 30 feet per minute. Conveyor bands

shall be four (4) continuous bands of FDA approved

material. Electrical shall be separate in a stainless steel

drip-proof wire way with waterproof covers furnished

on all outlets mounted in the raceway.

TECHNICAL SPECIFICATIONS

Model

Shipping

W L (overall) H Weight (lbs.)

600

650

725

825

900

975

1075

1150

1250

1350

Dimensions

• Casters in lieu of legs

• 3-shelf starter station

• Circuit breaker panel and

electrical raceway

• Optional correctional package

available

OPTIONAL ACCESSORIES

Refer to bid specifications

ELECTRICAL

Loading...

Loading...