Page 1

April 15, 1989

THIS BULLETIN COVERS:

I

. EPS DIAGNOSTICS

.

EPS - THE 7501 MAIN BOARD AND THE 10002 MAIN BOARD

EPS DIAGNOSTICS

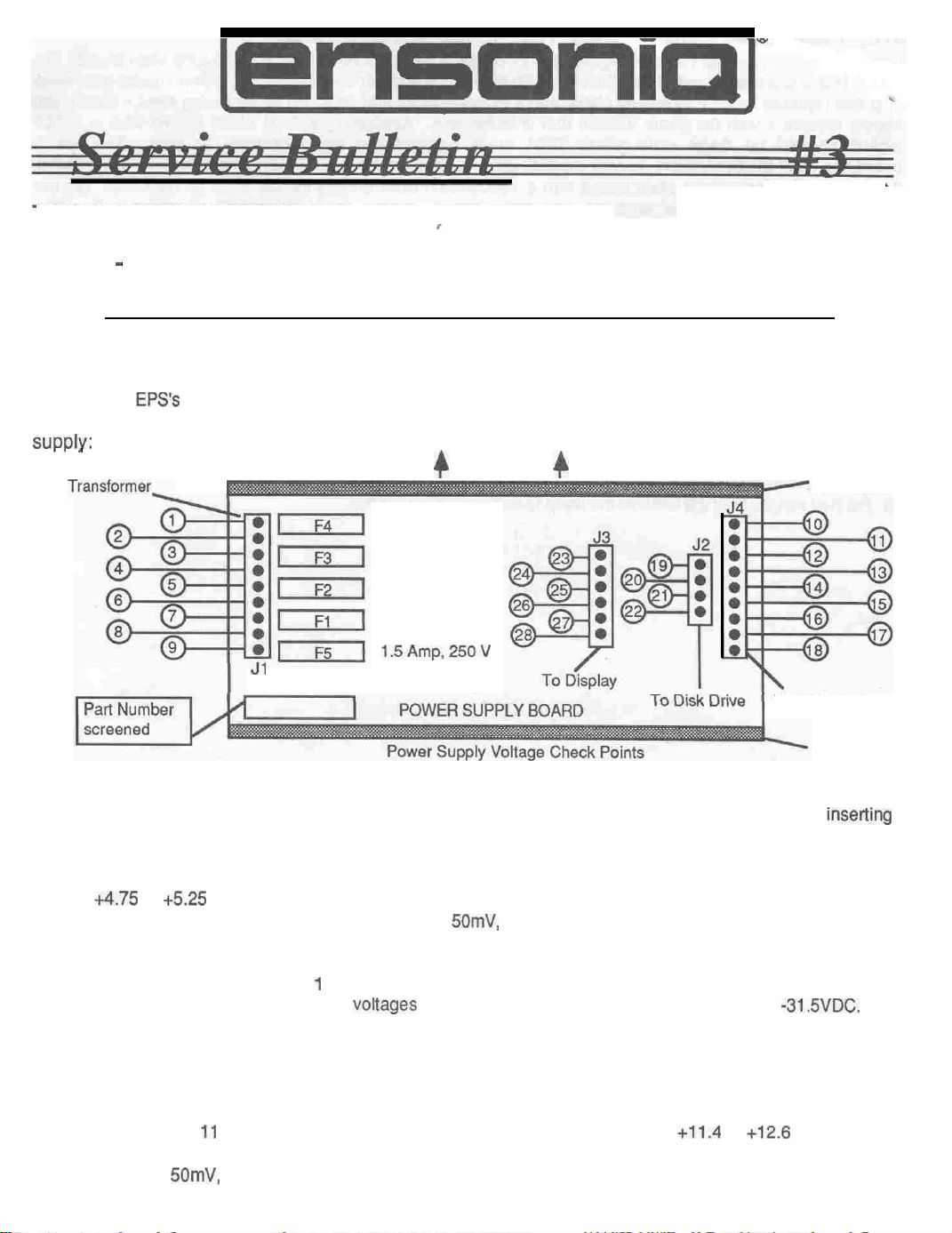

A number of

a faulty power supply. The following are the most common problems which could be caused by a faulty power

SUDDIV:

,. ,

To Transformer-

EPS’s

have been incorrectly diagnosed as having a faulty main board when the real problem was

4

Back

4.0

Amp, 250 V

4.0 Amp, 250 V

of Unit

4

Heat Sink

1.5 Amp,

1.5 Amp,

Jl

1 .

PROBLEM: Hum or buzz in audio output; EPS crashes randomly; or problems develop after

memory expander.

SOLUTION: Check the voltages on the power supply at J4 with the power supply loaded (main board

and display board connected). Using pin 11 as ground, the voltages on pins 14, 16, and 16 (of J4) should

be

+4.75

to

+5.25

VDC. The AC ripple on these pins should be less than 50mV. If the voltages are not

within this range or the AC ripple is greater than

2. PROBLEM: EPS is dead on power up.

SOLUTION: Perform solution I above. If no problem is found, check the voltages on the power supply

at J3.

voltages are not within this range, replace the power supply.

pin 25 (of J3).

3. PROBLEM: EPS has disk drive loading problems.

SOLUTION: Perform solution 1 above. If no problem is found, check the voltages on the power supply

at J2. Using pin 11 of J4 as ground, the voltage on pin 22 (of J2) should be

ripple on this pin should be less than 50mV.

greater than

Using pin 23 as ground, the

It should be -29 to -37.2 VDC. If the voltage is not in this range, replace the power supply,

50mV,

replace the power supply.

1.5Amp.250V

VOltageS

250 V

250 V

To Main Harness

Heat Sink

inserting

50mV,

replace the power supply.

on pins 27 and 28 (of J3) should be -22.7 to -315VDC. If the

If no problem is found, check the voltage at

+11.4

to

+12.6

VDC. The AC

If the voltage is not within this range or the AC ripple is

a

Page 2

THE 7501

Unitswnh &&al

-lWtlN

BOARD AND THE 10002 MAIN BOARD

numbers 16582 or higher (240V- 502603) contain a new version of the EPS Main Board. The

10002 board is a new layout of the 7501 Main Board with: the tower board included: a new square gate array

chip that replaces several individual chips; and a different size RAM chip. When replacing a main board, you

should replace ii with the same version that is in the unit. Replacing a 7501 Maln Board

board should be done only when 7501 maln boards are not

,avallable

to you. The 10002

with

a 10002

board has all of the connectors (except the disk drive connector, J2) in a different place from the 7501 board.

If you must replace a 7501 Main Board with a 10002 Main Board, three cables must be replaced. D

attempt to switch boards without

acqulrlng

these cables from

ENSONIQ Cbstomer

O

not

Servlce:

Keyboard Cable, Main Board Power Cable (attached lo main harness), and SCSI Cable (if applicable),

1.

Remove the 7501 Main board as described in the EPS Service Manual.

2.

Clip the four wire ties that hold the main board power cable

3.

Insert

the new 10002 Main Board as described in the EPS Service Manual.

4.

Attach the new main board power cable to the power supply at J4 and to the main board at

5.

Reconnect the cables from the display board

6.

Use two wire ties to bundle the new main board power cable out of the way. NOTE: Leave the wheels

(J8),

wheels

(g-pin)

to the main harness.

(J9),

and disk drive (J2).

Discard this cable.

JlO.

cable out of the wire ties.

7.

If applicable, install the new longer SCSI cable (the

34-pin

ribbon cable from the SCSI board to the auxiliary

expansion, connector J6 on the main board).

8. Replace the existing keyboard cable on the keyboard with the new longer keyboard cable.

9.

Re-install the keyboard as described in the EPS Service Manual.

10. For best results, boot the unit with the latest OS. disk (2.35 or higher).

Page 3

March 20, 1991

This Bulletin Covers:

l

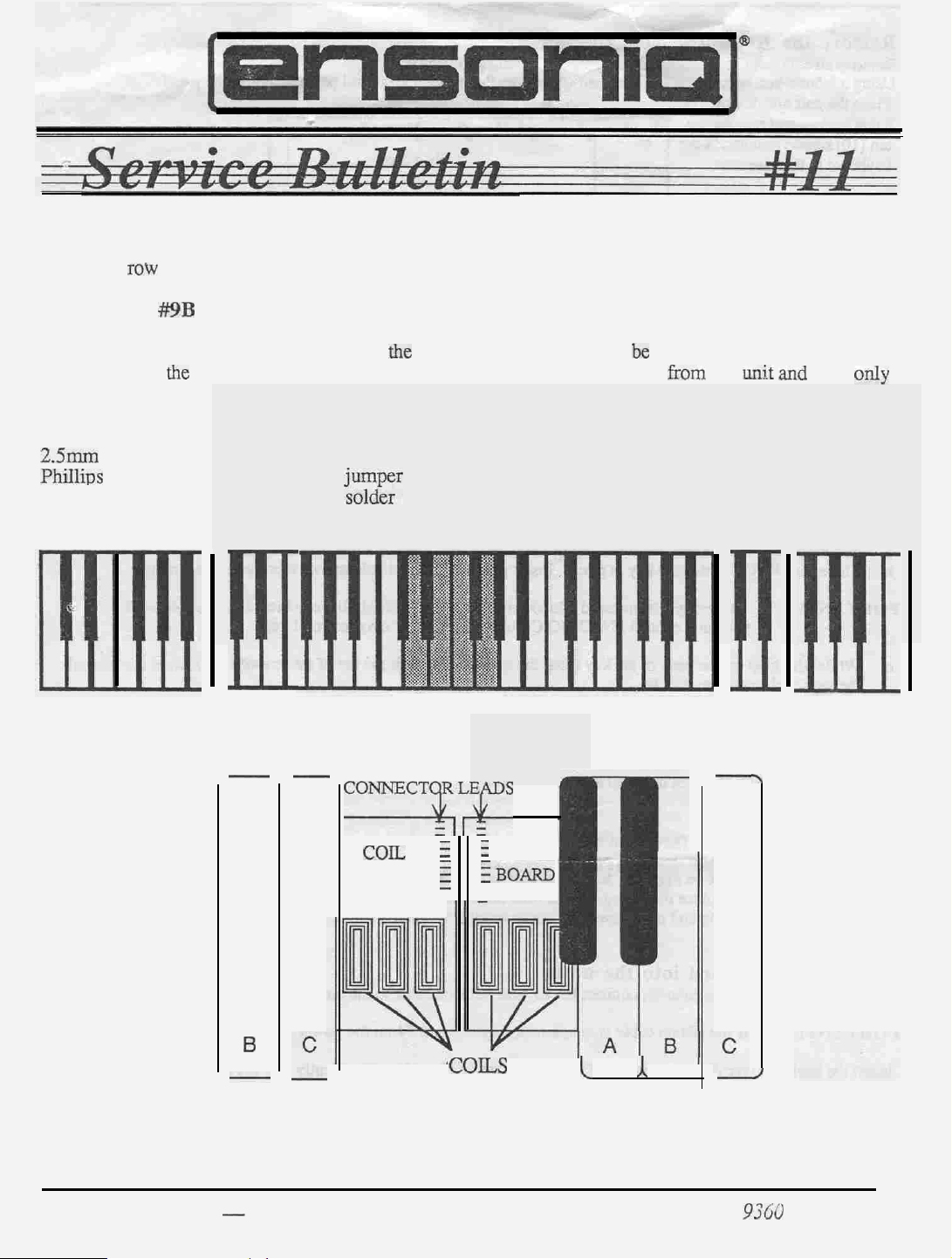

Soldering jumper wires between the two Poly-Key Keyboard Coil Boards that have a twelve-pin

single

not need to be hardwired.) This bulletin should only be done after performing Service

Bulletin

row

connector. (A twenty-pin dual-row connector was used after November 1990 and does

#9B

to ensure that the unit has the latest KPC version and resistors.

To form an absolute connection between

together using

remove six keys from the middle of the keyboard to expose the solder side of the connectors.

Tools Needed:

2.5mm

PhiIlius

soldering iron

hex wrench

screwdriver

the

wires provided. You will need to remove the keyboard

n

I

-

-

the

two coil boards, you

small flat blade screwdriver

zynr

CONNECT(QDS

wires from ENSONIQ

Remove

these six keys

SINGLE-ROW

(12)

COlL :

BOARD

i

q

f

COIL

iBOARD

3

will be hardwiring the coil boards

from

the

uu;t and

then

only

II

,

B

COILS

Service Bulletin #I I - Poly-Key Keyoard Coil

(over)

Boards

I

A

PIN

J

9TGC

CO86 01 -A

Page 4

A. Remove the Keyboard from the unit

;;

3)

Remove

Using a

Place

all

external cables connected to the unit. including the Power cord.

2.5mm

hex wrench, remove the four (4)

the

unit upside

down

on

scr~s

that fasten the control panel and raise

the

panel.

Carefully mm the unit right side op. Raise the

4)

the main board. paying particular attention to the polarity.

Remove the keyboard from the case by gently lifting up

5)

Once the

keyboard cavity.

B . Remove Middle D through

rear

of the keyboard has

cleared the

(

contxol panel

control

(see figure on p. 1)

1)

Place

the

keyboard with the keys up on

2)

Remove

a.

b. Push

3)

Remove

a.

b.

IMPORTANT!

c. While

the

key springs:

Insen a small Phillips screwdriver

down

to

expand the

the springs in a

the

keys to expose the coil boara connecmrs

Just below the key number (near the

There is a clip that holds

lifting up on the back of the key (near

the

keyboard to release

safe

These.

pressure, contact

spring,

place. they

the

clips do not need a lot of pressure to be released.

the

d

hz

spring

key in place.

ENSONlQ

clip.

hole) on

Insert

Customer Service for a replacement key.

C. Solder the connector leads together

1)

Hardwire

a.

the connector leads together

If there are two rows of leads on each

a better

co~ector and does

not need to be

(horizontally).

board.

do not solder them together.

hardwised.

and disconnect

the

front of it while pulling it toward

panel

mounting tabs, the keyboard can be removed

(wnxe Keys nrst):

the

key there is a

a small/thin flat blade

the

spring hole) push

the Z&pin

rectnngular

scmwdriver

If a clip breaks due to

the

top

of

The

keyboard ribbon cable

opening.

into the opening.

the

screwdriver toward

twenty-pin dual-row connector is

the

front of the unit

from the

tco

much

the

f?om

back of

D. Reinstall the keys:

1)

Put the black keys on

2)3)Place the

Place

4)

To reinstall

screwdriver into the spring and push down and out to expand it. Then move the bottom

frame.

front

of the key on fast, then press

the

white keys back on in order. Make

the

first.

They go on where

springs, place the spring

there are

the

sure that

into

its hole on the key (open side up). Insert the

single keystops.

back of the

kejj

down

zm!i! the c!ip

the clip for each key is engaged.

catches and holds it in place.

small/thin

the

spring into

Phillips

the

keyboard

E. Install the Keyboard into the unit

1)

Making note of

IMPORTANT!

2)

Insmt

the keyboard rear fust

rear

of the unit, lowering the

slightly to be sure that the keyboard cable lies flat beneath the keyboard and is not pinched under the keyboard frame.

3)

Tom

the unit upside down on a soft surface and replace

4)

Power up, test the unit, and close

page

2

the

proper polarity, connect the keyboard ribbon cable to the main board.

If the ribbon cable is

into the

front

of

the

mispirmed,

unit at

the front

the

keyboard as needed to clear the control panel mounting tabs. Lift the keys

control panel.

fuses F3 and F4 on

of

the

keyboard cavity. Gently slide the keyboard toward the

the

ten (10) screws

the

power supply will blow.

that secure rhe

keyboard to

the

case.

Service Bulletin #II

Page 5

July 25, 1991

This Bulletin Covers:

The latest information on the Poly-Key

previously contained in Service Bulletins

you will be up to date on current developments. This bulletin completely replaces Service

Bulletins #9B AND #11.

IMPORTANT!

.

If the coil board-to-coil board connector is

six keys as described in Section E). hardwire it together (follow

both foam and foamless keyboards.

.

If the

coil bard-to-coil board connector is a 20-pin dual-row connector (remove the middle

six keys as described in Section E), call ENSONIQ Customer Service for a replacement

keyboard assembly.

Tools Needed:

#0 Phillips screwdriver

small flat blade screwdriver

2.5mm hex wrench

jumper wires from ENSONIQ

Keyboard.

#9B

and #11.

a 12-pin single-row connector (remove the middle

safety glasses

soldering iron and sol&r

scribe (see Section K)

Some information is new and some was

Please take the time to read this bulletin so

this bulletin). This is for

History . . . . . . . . . . . . .

A

D

F

H

K

Service Bulletin #I2 -- Poly-Key Keyboard Coil Boar&

Types of Keyboards, KPC Versions, and Coil Boards . . . . . . .

Troubleshooting a Unit with a Poly-Key Keyboard Problem (flowchart)

Removing the Keyboard from the unit . . . . . . . . . . . . 5

Remove Keys . . . . . . . . . .

Solderthe Connector Leads Together . . . . . . . . . . . . . .

Reinstall

Installing the Keyboard into the unit . . . . . . . . . . . . . .

Checking the KPC O.S. Version .

Keyboard Ribbon Cable Problems . . . . . . . . . . . . . . .

the

Keys

.

Page

2

4

5

6

6

7

PIN 9360 0091 01 -A

Page 6

A. History

Keyboard failures have been caused by two problems.

coil boards is intermittent, it may cause a keyboard calibration failure, random notes to be played,

or ERROR 144.

two coil boards together).

wire harnesses.

While investigating Keyboard Calibration errors, it was found that a break in the interconnection of

the two coil boards can cause a variety of problems.

horizontal plane while the

one pin doesn’t make contact or loses contact briefly, the keyboard might not calibrate, might

freeze up (button presses have no effect), show an ERROR 144, or might start playing random

notes. Hardwiring the two boards together forms an absolute connection.

The

tin

connectors (most commonly used coating/material for connectors) builds up some oxide

over time.

would be horizontally).

ONLY (no movement horizontally at all) and therefore the oxide would not be cleared off.

oxide buildup could cause one or more pins to lose contact over time.

The fix is to make a reliable connection between the two coil boards

Second, a few failures have been caused by faulty ribbon cables and

force

exerted on the connector by playing is in a vertical direction.

This oxide is cleared by a wiping action when the pins are moved in their plane (here it

However, the force on the coil board-to-coil board connector is vertical

First, when the connector between the two

(hardwire

The coil board connectors move in a

If

This

the

This problem was masked by the type of flux that we use (Service Bulletin #9B). This flux

leave some residue and we now clean

example the Keypad/Display connector) or hand solder them into the board

connectors helped temporarily because

reconnecting them broke through the oxide buildup on the connector.

This oxide buildup problem was very difficult to find, because shipping a unit from a customer to

the factory could cause the coil board-to-coil board connector to shift enough to break through the.

oxide so that the unit would work fine when it reached the factory.

keyboard from the unit would shift

making contact.

or have a calibration error.

In the investigation of the keyboard failures, it was also found that

the design of the

terms of heat dissipation and clock generation.

sufficient for many keyboards.

board connector.

assembly as it contains information specific to its particular coil boards and keys in its memory.

Other small things were found and corrected as well but the main cause of failure is

to-coil board connector breaking contact.

the keyboard software more reliable, but does not correct the basic problem Changing two

resistor

therefore the resistors are no longer included in the KPC EPROM Update Kit

values

Losing contact on just one pin, even briefly, can cause a unit to lock up (freeze)

KPC

board

Remember that a KPC board can only be replaced with the whole keyboard

(described in Service Bulletin

Changes made to the KPC board make the design more robust in

all

connectors that hang over the edge of the board

Cleaning the

the

wiping action of separating the coil boards and then

Sometimes removing the

the

connector and break through the oxide so that all pins were

there

were some weaknesses in

However, just updating the KPC only is not

The main failure on keyboards is caused by the coil board-to-coil

the

Changes were made to the KPC O.S. EPROM to make

#9B)

helped but does not correct the basic problem,

does

(for

coil board-

All new units from the factory will have the KPC board changes and the coil boards hardwired

together until newly designed coil boards am in production.

for repair will also have this done as a routine part of the service.

page 2

Any units that come into the factory

Service Bulletin #I2

Page 7

B. Types of Keyboards

As you may or may not be aware, there are two types of Poly-Key keyboards: ones with foam

pads on the under sides of the keys and foamless (ones without the foam pads). We currently

manufacture foamless keyboards with coil boards that have reference coils.

Types of WC Versions

The

Each type of Poly-Key keyboard uses a different KPC O.S. version.

versions are shown below.

current KPC O.S.

KPC version

150

203

227

233

The KPC O.S. version is typed on

KPC board is the small circuit board (3.75’: x 4.25”) located on the underside of the keyboard

assembly.

Types of Coil Boards

There are

different

removed from the unit, the reference coil(s) may be seen on the top edge of the coil board below

the lowest key (the left side of the keyboard, see below).

key (see Section E) to get a better view of the coil board

See Section J for information on how to check the KPC O.S.

two types of foamless keyboards:

row than the other coils) and ones without reference coil(s).

Keyboard and Coil Boards

white foam pads on the undersides of the keys

grey foam pads on the undersides of the

foamless -no reference coil

foamless -with reference coil

the

white label on

ones with a reference coil(s) (extra coil(s) in a

Coil Board-

to-Coil Board KPC Version

-

12-pin

._I_-

the

EPROM (U2) on the KPC board.

If

you wish, you may remove the lowest

Current

227

single-row

keys

With the keyboard assembly

Comments

We used more than one

Coil board part number for

this version KPC 227. The

only

a foamless keyboard with

no reference coil.

The

absolute reference is

Service Bulletin

#I2

12-pin

single-row

233

You may use

number as a reference if

you have dismantled the

keyboard.

Call

ENSONIQ for a

replacement keyboard.

You may use the part number

as a reference if you have

dismantled the keyboard.

the

part

page

3

Page 8

C. Troubleshooting a Unit with a Poly-Key Keyboard Problem:

keys

from

the keyboard

(see Section

E).

Hardwire

connector together (see Section

the coil board-to-coil board

No

Make sure

EPROM is 233 or higher

(see Section

that the KPC

J).

F).

KPC

EPROM is 203

I

Page 4

Figure 2

Keyboard Problem

-

Service Bulletin

#I2

Page 9

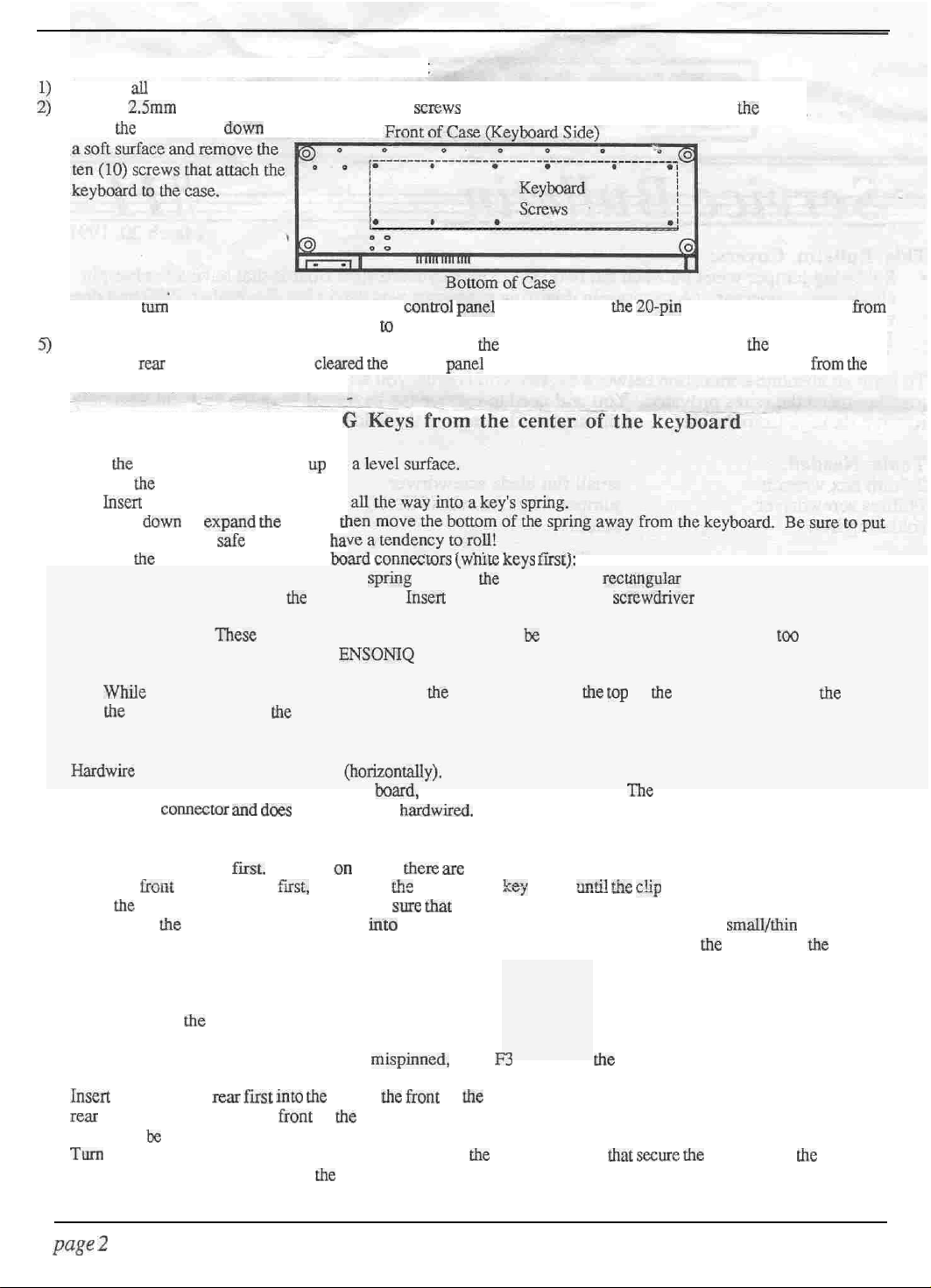

D. Removing the Keyboard from the unit

Remove all cables connected to the unit, including the Power cable.

1)

Using a 2.5mm hex wrench, remove the four (4) screws that fasten the control panel and raise

2)

the panel.

Place the unit upside

3)

down on a soft surface

and remove the ten (10)

screws that attach the

keyboard to the case.

Figure 3 -Bottom of

Carefully turn the unit tight side up. Raise the control panel and disconnect the

4)

Case

20-pin

keyboard ribbon cable from the main board (using a scribe or similar tool, see Section K),

paying particular attention to the Polarity.

Remove the keyboard from the case by gently lifting up the front of it while pulling it toward

5)

the front of the unit.

Once

the rear of the keyboard has cleared

the

control panel mounting

tabs, the keyboard can be removed from the keyboard cavity.

E. Remove Middle D through G Keys from the center of the keyboard

these six keys

Place the keyboard with the keys up on a level surface.

Remove the key springs:

a. Insert a small Phillips screwdriver all the way into a key’s spring at the tear of the key.

b. Push down to expand the spring, then move the bottom of the spring away from the

keyboard.

Remove the keys to expose the coil board connectors (white keys first):

a. Just below the key number (near the spring hole) on the key there is a rectangular opening.

b. There is a clip that holds the key in place.

opening.

Be sure to put the springs in a safe place, they have a tendency to roll!

Insert a small/thin

flat blade screwdriver into the

IMPORTANT!

These clips do not need much pressure to be released If a clip breaks due to

too much pressure, contact

ENSONIQ

Customer Service for a replacement key.

c. While lifting up on the back of the key (near the spring hole) push the top of the

screwdriver toward the back of the keyboard to release the clip.

d. Remove the white keys first then the black keys.

We suggest keeping the keys in order to

make them easier to put back on.

Service Bulletin

#I2

page 5

Page 10

With the middle D through G keys removed from the center of the keyboard:

B

C

Figure 5- 12-pin coil board-to-coil

board

C

connector

F. Solder the Connector Leads Together

Using

the

jumper

IMPORTANT!

wires

provided, hardwire the connector leads together (horizontally).

If

there

are two rows

the connector is a twenty-pin dual-row, contact ENSONIQ Customer Service

for a replacement keyboard.

of leads on each board, do not solder them together

G. Reinstall the Keys

Put the black keys on first They go on where there are single keystops.

1)

Place the front of the key on first sliding the slot in the front of the key over the keystop on the

2)

keyboard frame, then press the back of the key down until the clip catches and holds it in

place.

Place the white keys back on in order. Make sure that the clip for each key is engaged

3)

To reinstall the springs, place the spring into its hole on the key (open side up). Insert the

4)

small/thin Phillips screwdriver into the spring and push down and out to expand it.

move the bottom the spring into the keyboard frame and remove the screwdriver from the

spring to lock it in place.

If

Then

H. Installing the Keyboard into the unit

Making note of the proper polarity, connect the keyboard ribbon cable to the main board

1)

IMPORTANT!

Insert the keyboard rear first into the unit at the front of the keyboard cavity. Gently slide

2)

keyboard toward the rear of the unit, lowering the front of the keyboard as needed to clear the

control panel mounting tabs. Lift the keys slightly to be sure that the keyboard cable (and disk

drive cable when present) lies flat beneath the keyboard and is not pinched under the keyboard

frame.

Turn the unit upside down on a soft surface and replace the ten (10) screws that secure the

3)

keyboard to the case.

Power up, test the unit, and close the control panel.

4)

page

6

If ribbon cable is mispinned, fuses F3 and F4 on the power supply will

Service Bulletin

the

#I2

Page 11

J. Checking the KPC O.S. Version Number

SD-l,

While holding down Presets, press

VFXSD

and VFX

Master.

The display shows ENSONIQ

-

SOFTWARE - ROM V X.XX KPC YYY. X.XX denotes the main operating system and YYY

indicates the KPC O.S. version. See note in Section K for VFXSD keyboard ribbon

cable problems.

EPS-16 PLUS and EPS

Press

Command,

right arrow button until the display shows

then

Env1. The display shows NO COMMANDS ON PAGE. Press the

SOFTWARE

INFORMATION. Press Enter.Yes

until the display shows KPC VERSION YYY.

K. Keyboard Ribbon Cable Problems

We have found that some units have developed further problems once a keyboard is installed

has been a result of improper handling of the keyboard ribbon cable. We suggest removing the

cable connector using the angled end of a scribe (see below).

Figure 6 -

Scribe

These can be found in the following catalogs:

l

Techno-Tool catalog 38, page 204, part number 400PR144

l

Newark catalog 110, page 1024, part number 76-1510

This

Note for

Be sum to route the keyboard ribbon cable around the square

VFXSD

Only:

68-pin

gate array on the main board.

After you insert the keyboard into place, lift the keys slightly and visually check to make sure that

the cable is not over

Bottom view of ferrite

the

gate array.

New

Keyboard Cable

Routing for the VFX-SD

A misplaced or crimped cable can result in what seems to be a keypad/display problem because

keypad/display information is passed

through

the KPC board to the main board.

You may call

ENSONIQ Customer Service for a new cable with these folds.

Service Bulletin #I2

page 7

Loading...

Loading...