Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

L2988 Rev. C 02/11

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Finnish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Norwegian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Swedish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

日本語 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

2.0 SAFETY

2.1 General Hydraulic Safety Precautions

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

when in doubt as to the safety precautions and operations. If you

have never been trained on high-pressure hydraulic safety,

consult your distribution or service center for a free Enerpac

Hydraulic safety course.

Failure to comply with the following cautions and warnings could

cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction

of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

Never

set the relief valve (pumps equipped with useradjustable relief valve only) to a higher pressure than the

maximum rated pressure of the pump. Higher settings

may result in equipment damage and/or personal injury.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated component

in the system. Install pressure gauges in the system to

monitor operating pressure. It is your window to what is happening

in the system.

Model ZUTP-1500

1500 Bar Electric Pump

CAUTION: Avoid damaging hydraulic hose. Avoid

sharp bends and kinks when routing hydraulic hoses.

Using a bent or kinked hose will cause severe back-pressure.

Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

Do not drop heavy objects on hose. A sharp impact

may cause internal damage to hose wire strands.

Applying pressure to a damaged hose may cause it

to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or

other means of safe transport.

CAUTION: Keep hydraulic equipment away from

fl ames and heat. Excessive heat will soften packings

and seals, resulting in fl uid leaks. Heat also weakens

hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C [150°F] or higher.

Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualifi ed hydraulic technician. For repair

service, contact the Authorized ENERPAC Service Center

in your area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fi t properly and withstand high

loads.

WARNING: Do not use electric pumps in an explosive

atmosphere. Adhere to all local and national electrical

codes. A qualifi ed electrician must do installation and

modifi cation.

1

WARNING: Keep hands clear of moving parts and

pressurized hoses.

WARNING: These pumps have internal factory

adjusted relief valves, which must not be repaired or

adjusted except by an Authorized Enerpac Service

Center.

WARNING: To prevent damage to pump electric motor,

check specifi cations. Use of incorrect power source

will damage the motor.

2.2 Safety Precautions - Model ZUTP-1500 Pump

DANGER:

may result in serious personal injury or death!

• Always wear eye protection, gloves and boots when operating

the pump.

• High pressure hydraulic equipment can be very dangerous if

misused. Keep away from oil leakages at high pressure. Liquid

escaping from highly pressurized equipment has suffi cient

power to penetrate the skin, which can cause blood poisoning.

In the case of such an accident, seek IMMEDIATE medical

attention.

• Never attempt to disconnect a hydraulic

coupler while it is under pressure.

• Never attempt to repair leaks while the

system is pressurized. Be sure system

pressure gauge indicates zero (0) psi/

bar before making any repairs.

• Never pressurize the back of a

disconnected male coupler.

Serious personal injury could

result if the coupler fails while

under pressure.

• Use caution when pressurizing a

system. Pressure can rise faster

than anticipated. Continuously

monitor the pressure gauge during pressurization. Be prepared

to stop pressurization immediately at any time.

• Before operation, ensure that quick-disconnect couplings are

properly connected by physically pulling on them.

Failure to observe the following precautions

0

0

• Allow only trained and experienced personnel to operate the

pump. Be especially careful to avoid accidental pump start-up.

• Never leave the pump pressurized and unattended. Always

depressurize before leaving the system unattended.

• Never exceed the safe working pressure for the hydraulic

hoses, tools or pump.

• The Model ZUTP-1500 pump is designed to operate at a

maximum working pressure of 21,750 psi [1500 bar]. Do not

exceed this pressure setting.

WARNING:

Do not operate the pump at pressure settings

above 21,750 psi [1500 bar]. Hydraulic components

could rupture or burst. Serious personal injury and

property damage may result!

3.0 SPECIFICATIONS

(See technical data charts at bottom of page)

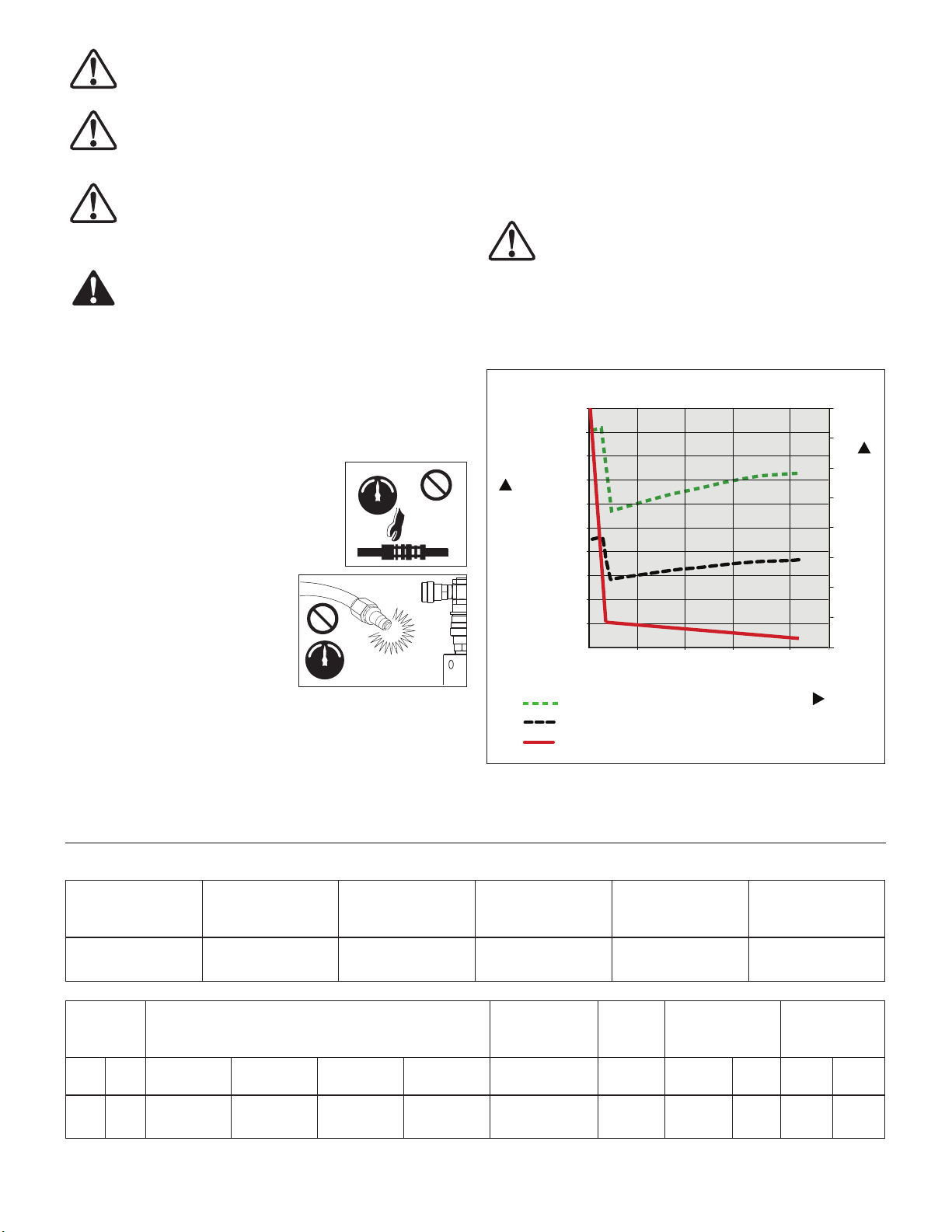

3.1 Flow, Pressure and Current Draw (typical)

in /min3L/min

200 [3,27]

180 [2,94]

160 [2,62]

140 [2,29]

120 [1,96]

100 [1,63]

Flow

80 [1,31]

60 [0,98]

40 [0,65]

20 [0,32]

115 V

230 V

0

0 5,000

[350]

Amps (115 V)

Amps (230 V)

10,000

[700]

15,000

[1000]

21,750

[1500]

Pressure psi

[bar]

16

14

12

10

8

6

4

2

0

Current Draw (amps)

Flow

Note: Actual fl ow, pressure and current draw will vary, depending

on power supply, application, pump condition and other factors.

Technical Data – Model ZUTP-1500

Temperature

Range

-20ºF to +140ºF

[-29ºC to +50ºC]

Motor

Size

hp kW

1.7 1.25

0 psi

[0 bar]

180 in3/min

[2,94 L/min]

Oil Viscosity

Range

150 -165 S.U.S.

[15 - 25 C.S.T.]

Output Flow Rate Motor

10,000 psi

[700 bar]

15 in3/min

[0,24 L/min]

Hydraulic

Oil Type

(recommended)

Enerpac HF

15,000 psi

[1000 bar]

12 in3/min

[0,19 L/min]

21,750 psi

[1500 bar]

8 in3/min

[0,13 L/min]

Seal Materials Max. Hydraulic

Buna, Viton

& Polyurethane

Electrical

Working Pressure

21,750 psi

[1500 bar]

Sound

Level

Reservoir

Oil Capacity

Current Draw

Specifi cations

Volts-Ph-Hz dBA gallons liters lbs kg

115-1-50/60

230-1-50/60

2

89 1 3,8 65 29,4

Electric

(Refer to graph

in Section 3.1)

Weight

With Oil

4.0 INSTALLATION

Install or position the pump to ensure that air fl ow around the

motor and pump is unobstructed. Keep the motor clean to

ensure maximum cooling during operation.

4.1 Air Breather (See Figure 1)

A shipping plug (A) is installed in the breather port on the top of

the reservoir. Before using the pump, replace the shipping plug

(A) with the air breather (B) and adapter fi tting (C).

B

A

C

Figure 1, Air Breather

4.2 Oil Level (See Figures 2 and 3)

Check the pump oil level prior to start-up. The reservoir is full

when the oil level is as shown in Figure 2. If necessary, remove

the oil fi ll plug from the cover plate as shown in Figure 3 and add

oil as required.

IMPORTANT: Add oil only when all system components are fully

retracted, or the system will contain more oil than the reservoir

can hold. Reservoir capacity is approximately 1 gallon [3,8 liters].

4.3 Electrical Connections

WARNING: The pump is factory equipped with the

common electrical plug for a given voltage. Altering the

plug type should only be done by a qualifi ed electrician,

adhering to all applicable local and national codes.

• The disconnect and line circuit protection is to be provided by

customer. Line circuit protection is to be 115 percent of motor full

load current at maximum pressure of application.

• For additional information, refer to power rating on pump name

plate. Also refer to graph in Section 3.1.

4.4 Hydraulic Connections

• A female quick-disconnect fi tting (Enerpac Model BR150) is

installed at the pump oil outlet. This fi tting is rated at 21,750 psi

[1500 bar].

• Enerpac recommends the use of Enerpac HT 1500 Series

thermoplastic hoses with the Model ZUTP-1500 pump. These

hoses are rated at 21,750 psi [1500 bar]. Refer to Enerpac

instruction sheet L2733 for use, safety and maintenance

information.

WARNING: The Model ZUTP-1500 pump must be

operated only with hoses and fi ttings rated to operate

at 21,750 psi [1500 bar] working pressure. Hydraulic

hoses and fi ttings of a lower pressure rating will rupture or burst.

Serious personal injury could result!

• Before connecting hose to pump oil outlet, check that pump

pressure gauge indicates zero (0) psi/bar. If any pressure is

indicated, fully open the pressure release valve to relieve

pressure. See Section 5.1.

5.0 OPERATION

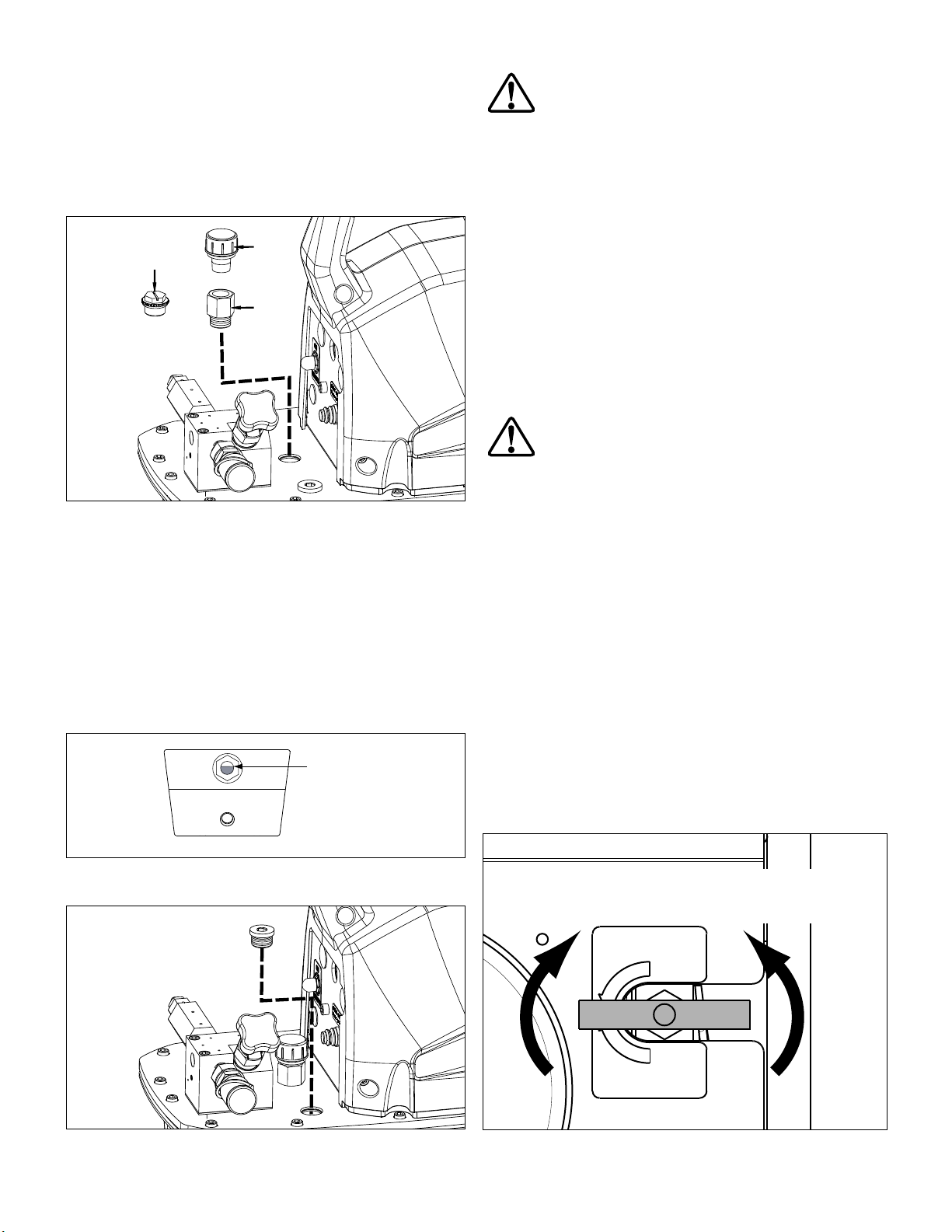

5.1 Pressure Release Valve (See Figure 4)

Valve Positions:

1. CLOSED - Flow directed to pump hydraulic outlet port.

Pressure builds when pump motor is turned on. Pump holds

pressure when motor is turned off.

2. OPEN - Pressure released to pump hydraulic reservoir.

Pressure will not build when motor is turned on.

Tank is full

when oil level

is here.

Figure 2, Oil Level Sight Glass

Figure 3, Oil Fill Plug

IMPORTANT: Close the pressure release valve using hand force

only. Overtightening and/or use of tools may result in damage to

the valve and/or valve seat.

CLOSED

(oil fl ow to tool)

OPEN

(pressure release

to reservoir)

PRESSURE RELEASE VALVE

OPEN SLOWLY

OPEN

CLOSE

DO NOT CLOSE

USING EXCESSIVE FORCE

Figure 4, Pressure Release Valve

3

5.2 Pendant and Motor Jog Buttons

(See Figures 5 and 6)

The pump motor can be controlled either by the pendant button

or by the motor jog button (located on the pump front panel).

Relief Valve

Knob

Pendant Button

MOTOR

JOG

Figure 6, Motor Jog Button

Operation is the same for both

buttons:

Button pressed:

Motor starts. System pressure

builds and tool is actuated for as

long as button is held down.

Button released:

Motor stops. Check valve holds

Figure 5, Pendant

Note: Pressure release valve (see Figure 4) must be fully closed

to allow pressure to build while motor is running.

5.3 Adjusting the Relief Valve Setting (See Figure 7)

1. Remove hose (if connected) from the quick disconnect

coupler at the oil outlet port.

2. Fully close the pressure release valve. See Figure 4.

3. Loosen the relief valve locknut to allow pressure adjustment.

See Figure 7.

4. Turn the relief valve knob several turns counter-clockwise, so

that the relief valve is set lower than the desired setting.

Notes:

• When adjusting relief valve setting, always start at a low

pressure and slowly increase the pressure to the desired setting.

• If desired, the motor jog button can be used in place of the

pendant button during the following steps.

5. Check that pump is connected to electrical power.

6. Press and hold the pendant button. See Figure 5. The pump

motor will start and pressure will begin building immediately.

7. While continuing to press and hold the pendant button,

slowly turn the relief valve knob clockwise (as required) until

the desired pressure reading is shown on the pump pressure

gauge.

WARNING: Pump maximum working pressure is

21,750 psi [1500 bar]. Do not set the relief valve

pressure above 21,750 psi [1500 bar].

8. Release the pendant button. The pump motor will stop.

pressure until pressure release

valve is opened.

Locknut

Figure 7, Relief Valve

Notes:

• Rotating the relief valve knob counter-clockwise will NOT

reduce or relieve existing system pressure.

• If pressure is adjusted too high, relieve pressure by opening the

pressure release valve (see Figure 4) until the pump pressure

gauge indicates zero (0) psi/bar. Then, fully close the pressure

release valve and repeat steps 6 through 8.

9. After verifying that setting is correct, tighten the relief valve

locknut (hand tight only - do not overtighten) to lock the

setting. See Figure 7.

10. Slowly open the pressure release valve to relieve pressure

in the oil outlet line. See Figure 4. Verify that pump pressure

gauge indicates zero (0) psi/bar.

5.4 Pressurizing the System

1. Adjust the relief valve setting. Refer to Section 5.3.

2. Connect hydraulic hose(s) and tool(s). Refer to Section 4.4.

3. Close the pressure release valve. See Figure 4.

4. Check that pump is connected to electrical power.

CAUTION: Before pressurizing the system, read and

understand all instructions and safety precautions

applicable to the hydraulic tool(s) being used. Follow

safe work practices in accordance with all applicable laws,

regulations and industry standards.

CAUTION: Continuously monitor the pump pressure

gauge while pump is running. Pressures can rise faster

than anticipated.

5. Press and hold the pendant button. See Figure 5. The pump

motor will start and pressure will begin building immediately.

6. When the desired reading is shown on the pump pressure

gauge, release the pendant button. The pump motor will

stop.

Note: Time required to pressurize the hydraulic circuit will vary,

depending on the number and type of tools connected, hydraulic

hose lengths and other factors.

4

5.5 Depressurizing the System

1. Slowly open the pressure release valve to relieve system

pressure. See Figure 4.

2. Verify that the pump pressure gauge indicates zero (0) psi/bar.

5.6 Circuit Breaker

The pump circuit breaker is

located on the pump front

panel, beside the pump jog

button.

In the event of an electrical

overload, the pump circuit

breaker will trip. After

investigating and correcting

the source of the overload,

push the circuit breaker

button to reset.

WARNING: To avoid injury and equipment damage, do

not continue pressurizing hydraulic tools after they

reach maximum travel or maximum operating pressure.

(See Figure 8)

CIRCUIT BREAKER

Press to Reset

Figure 8, Circuit Breaker

6.0 MAINTENANCE

Frequently inspect all system components for leaks or damage.

Repair or replace damaged components. Electrical components,

such as the power cord, may only be repaired or replaced by a

qualifi ed electrician, adhering to all applicable local and national

codes.

WARNING: Disconnect pump from electrical power

before performing any maintenance or repairs. Be sure

all hydraulic pressure is completely relieved (0 psi/bar).

6.1 Check Oil Level

Check the pump oil level prior to start-up. If oil level is low,

remove the oil fi ll plug from the cover plate and add oil as needed.

See fi gures 2 and 3. Always be sure that hydraulic tools are fully

retracted before adding oil to the reservoir.

6.2 Change Oil and Clean Reservoir

Enerpac HF oil is a crisp blue color. Frequently check oil condition

for contamination by comparing pump oil to new Enerpac oil. As

a general rule, completely drain and clean the reservoir every 250

hours, or more frequently if used in dirty environments.

Note: The following procedure requires that you remove the

pump from the reservoir. Work on a clean bench and dispose of

used oil in accordance with all applicable laws and regulations.

1. Disconnect pump from electrical power.

2. Remove the drain plug and drain all oil from the reservoir.

Clean and reinstall the drain plug.

3. Unscrew the 13 bolts holding the cover plate to the reservoir

and lift the pump unit out of the reservoir. Be careful not to

damage the oil intake fi lter screen.

4. Thoroughly clean the reservoir with a suitable cleaning agent.

5. Remove the oil intake fi lter screen for cleaning. (Do not pull

on the screen or the bottom of the intake to avoid possible

damage.) Clean the screen with solvent and a soft brush.

Reinstall.

6. Reassemble the pump and reservoir, installing a new reservoir

gasket.

7. Disassemble the hydraulic return line fi lter. Clean and

reinstall (or replace) the fi lter element. Refer to Section 6.3 for

additional information.

8. Fill the reservoir with clean Enerpac HF hydraulic oil. The

reservoir is full when oil level is as shown in Figure 2.

6.3 Hydraulic Return Line Filter (See Figure 9)

Remove and inspect the hydraulic return line fi lter element at

every oil change. The element can be cleaned and reused if it is

in good condition. However, a new element should be installed if

the old element is damaged or has been cleaned more than three

times.

2

1

OIL OUT OIL IN

Key:

1. End Cap

2. O-Ring

3. Spring

4. Housing

5. Spring

6. Element, 90 Micron (Arrow P/N EK9052V-90)

7. Gasket

7

Note: For additional information,

go to www.arrowpneumatics.com.

Figure 9, Hydraulic Return Line Filter

3

4

5 6

6.4 Motor Brush Replacement (See Figure 10)

To prevent motor damage, the pump motor brushes incorporate

an automatic motor stop when one of the brush carbons wears

to a length of 0.25" [6 mm]. Inspect both brushes.

1. Disconnect pump from electrical power.

DANGER: To avoid possible electrocution, pump must

be completely disconnected from electrical power

before brush servicing is attempted.

2. Remove both brush caps (A) by defl ecting the brush cap latch

(B) and gently prying outward. See Figure 10.

3. Remove motor brushes by turning black cap counter-

clockwise.

4. Replace both brushes and reverse procedure to reassemble.

A

B

Figure 10, Brush Cap Removal

A. Brush Cap B. Brush Cap Latch

5

7.0 TROUBLESHOOTING

Only qualifi ed hydraulic technicians should service the pump or system components. A system failure is not necessarily the result of

a pump malfunction. To determine the cause of the problem, the complete system must be considered in any diagnostic procedure.

The following troubleshooting chart is intended to be used only as an aid in determining if a problem exists. For repair service, contact

your Enerpac Authorized Service Center.

Troubleshooting Guide

Problem Possible Cause Action

Pump will not start. No power. Connect power.

Pump circuit breaker tripped. Push pump circuit breaker button to reset.

Low voltage. Turn off other electric loads.

Use heavier gauge extension cord.

Motor brushes worn to end of life. Replace brushes per Section 6.4.

Pump element jammed. See authorized service center.

Pendant damage. Repair pendant.

See authorized service center.

Motor stops under load. Low voltage. Turn off other electric loads.

Use heavier gauge extension cord.

Pump fails to build pressure or

builds less than full pressure.

Low oil level in reservoir. Add oil per Section 4.2.

Relief valve setting too low. Adjust per Section 5.3.

External system leak. Inspect and repair or replace.

Pump pressure release valve open or not fully

closed.

Pump hydraulic intake screen dirty. Clean or replace hydraulic intake screen.

Close pressure release valve.

Change hydraulic oil. See Section 6.2.

Internal leak in pump pressure release valve. See authorized service center.

Internal leak in system component. See authorized service center.

Pump builds full pressure, but tool

does not move.

Low oil fl ow. Pump hydraulic intake screen dirty. Clean or replace hydraulic intake screen.

Tool drifts back on its own. External system leak. Inspect all hydraulic connections and replace or repair.

Tool will not return when

pressure is relieved.

Load greater than tool capacity at full pressure. Reduce load or add tool capacity.

Flow to tool blocked. Check hydraulic couplers for full engagement.

Check hose for blockage or kinks.

Change hydraulic oil. See Section 6.2.

Pump check valve malfunctioning. See authorized service center.

Internal leak in a system component. See authorized service center.

Tool is not spring return. Manually retract tool as required.

Flow restricted or blocked. Check hydraulic couplers for full engagement.

Check hose for blockage or kinks.

Pump hydraulic return fi lter dirty. Clean or replace hydraulic return fi lter element.

Pressure release valve malfunction. See authorized service center.

Return spring broken.

(tools equipped with return spring only)

Pump runs hot. Flow restricted. Check hydraulic couplers for full engagement.

6

See authorized service center.

Check hose for blockage or kinks.

NOTES:

7

A

A

A

A

A

Enerpac Worldwide Locations e-mail: info@enerpac.com internet: www.enerpac.com

ustralia and New Zealand

ctuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 297 438 988

F +61 297 438 648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

ctuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China (Taicang)

ctuant (China) Industries Co. Ltd.

No. 6 Nanjing Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

sales-cn@enerpac.com

China (Beijing)

ctuant (China) Industries Co. Ltd.

709B Diyang Building

Xin No. 2, Dong San Huan North Rd.

Beijing City, 100028 China

T +86 10 845 36166

F +86 10 845 36220

sales-cn@enerpac.com

France, Switzerland, North Africa

and French speaking African

countries

ENERPAC

Une division d’ACTUANT France

S.A.S.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Office 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. office Enerpac

Russian Federation

Admirala Makarova Street 8

125212 Moscow, Russia

T +7 495 98090 91

F +7 495 98090 92

sales-ru@enerpac.com

Singapore

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363 7722

sales-sg@enerpac.com

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 800

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P.O. Box 421

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

South Africa and other English

speaking African countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 525 613

sales-za@enerpac.com

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

6100 N. Baker Road

Milwaukee

WI 53209 USA

T +1 262 781 6600

F +1 262 783 9562

User inquiries:

+1 800 433 2766

Distributor inquiries/orders:

+1 800 558 0530

sales-us@enerpac.com

All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

01/25/11

Loading...

Loading...