Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

L4242 Rev. B 10/18

ZC-Series Cordless Electric Pumps

EN

ZC3308J

ZC3408J ZC3908J

TABLE OF CONTENTS:

1.0 SAFETY .........................................................................................3

1.1 Introduction ......................................................................3

1.2 General Hydraulic Safety Precautions ...........................3

1.3 Battery Operated Pump Safety Precautions .................4

2.0 MAJOR FEATURES AND COMPONENTS ..................................5

3.0 PRODUCT DATA ........................................................................... 6

3.1 Specifications ..................................................................6

3.2 Pressure and Flow Graphs ..............................................6

3.3 External Dimensions .......................................................7

4.0 PRODUCT DESCRIPTION ...........................................................8

4.1 Introduction ......................................................................8

4.2 Additional Information - Battery and Charger ..............8

4.3 Conformance to National and International Standards ..8

4.4 Electromagnetic Compatibility (EMC) ..........................8

5.0 IMPORTANT RECEIVING INSTRUCTIONS ................................8

5.1 Hydraulic Reservoir Breather .........................................8

6.0 HYDRAULIC CONNECTIONS......................................................8

7.0 BATTERY ......................................................................................9

7.1 Battery Capacity Indicator ..............................................9

7.2 Battery Installation ..........................................................9

7.3 Battery Removal ............................................................10

7.4 Battery Management System .......................................10

7.5 Additional Battery and Charger Information ...............10

8.0 OPERATION ................................................................................ 10

8.1 Before Start-up ..............................................................10

8.2 Starting the Pump Motor ..............................................10

8.3 Stopping the Pump Motor .............................................10

8.4 Operating Precautions ..................................................10

8.5 Manual Valve Operation ................................................10

8.5.1 VM33 Operation ..........................................................10

8.5.2 VM43 Operation ..........................................................11

8.5.3 VM43LPS Operation

(post-tensioning applications only) ...........................11

8.6 Air Removal ....................................................................11

8.7 Disconnecting Hydraulic Hoses ...................................12

8.8 Transporting the Pump ..................................................12

9.0 MAINTENANCE ..........................................................................12

9.1 Check Oil Level ..............................................................12

9.2 Hydraulic Oil Information ..............................................12

9.3 Adding Oil .......................................................................12

9.4 Oil Change ......................................................................12

10.0 PRESSURE RELIEF VALVE ADJUSTMENT ............................13

10.1 VM33 and VM43 Only ...................................................13

10.2 VM43LPS Only ..............................................................13

11.0 TROUBLESHOOTING ..............................................................14

Troubleshooting Guide .....................................................................14

1.0 SAFETY

WARNING

NOTICE

1.1 Introduction

Read all instructions carefully. Follow all recommended safety

precautions to avoid personal injury as well as damage to the

pump and/or damage to other property. Enerpac cannot be

responsible for any damage or injury from unsafe use, lack of

maintenance or incorrect operation. Do not remove warning

labels, tags, or decals. In the event any questions or concerns

arise, contact Enerpac or a local Enerpac distributor for

clarification.

If you have never been trained on high-pressure hydraulic safety,

consult your distributor or service center for information about an

Enerpac hydraulic safety course.

This manual follows a system of safety alert symbols, signal

words and safety messages to warn the user of specific hazards.

Failure to comply with these warnings could result in death or

serious personal injury, as well as damage to the equipment or

other property.

The Safety Alert Symbol appears throughout this

manual. It is used to alert you to potential physical

injury hazards. Pay close attention to Safety Alert

Symbols and obey all safety messages that follow this symbol to

avoid the possibility of death or serious personal injury.

Safety Alert Symbols are used in conjunction with certain Signal

Words that call attention to safety messages or property damage

messages and designate a degree or level of hazard seriousness.

The Signal Words used in this manual are WARNING, CAUTION

and NOTICE.

Indicates a hazardous situation that, if not

avoided, could result in death or serious

personal injury.

CAUTION

1.2 General Hydraulic Safety Precautions

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Do not remove or disable the pressure relief valve.

• Never set the pressure relief valve to a higher pressure than

the maximum rated pressure of the pump.

• Stay clear of loads supported by hydraulics. To avoid personal

injury, keep hands and feet away from cylinder and work piece

during operation.

• Do not handle pressurized hoses. Escaping oil under pressure

can penetrate the skin. If oil is injected under the skin, see a

doctor immediately.

Indicates a hazardous situation that, if not

avoided, could result in minor or moderate

personal injury.

Indicates information considered important,

but not hazard related (e.g. messages relating

to property damage). Please note that the

Safety Alert Symbol will not be used with this

signal word.

WARNING

• A cylinder when used as a load lifting device, should never be

used as a load holding device. After the load has been raised

or lowered, it always must be blocked mechanically.

• Do not pressurize disconnected couplers.

• Only use hydraulic cylinders in a coupled system. Never use

a cylinder with uncoupled couplers. If the cylinder becomes

extremely overloaded, components can fail catastrophically.

• Use only rigid pieces to hold loads. Carefully select steel or

wood blocks that are capable of supporting the load. Never

use a hydraulic cylinder as a shim or spacer in any lifting or

pressing application.

• Avoid situations where loads are not directly centered on the

cylinder plunger. O-center loads produce considerable strain

on cylinders and plungers. In addition, the load may slip or fall.

• The system operating pressure must not exceed the pressure

rating of the lowest rated component in the system. Install

pressure gauge(s) in the system to monitor operating pressure.

It is your window to see what is happening in the system.

• Do not exceed equipment ratings. Never attempt to lift a load

weighing more than the capacity of the cylinder. Overloading

causes equipment failure and possible personal injury.

• Wear personal protective equipment (P.P.E.) when operating

hydraulic equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

• Be sure setup is stable before lifting load. Cylinders should

be placed on a flat surface that can support the load. Where

applicable, use a cylinder base for added stability. Do not

weld or otherwise modify the cylinder to attach a base or other

support.

• Immediately replace worn or damaged parts with genuine

ENERPAC parts. Standard grade parts will break causing

personal injury and property damage.

CAUTION

Failure to observe and comply with the following precautions

could result in minor or moderate personal injury. Property

damage could also occur.

• Do not use or repair damaged hydraulic hose. Avoid sharp

bends and kinks when routing hydraulic hoses. Using a bent

or kinked hose will cause severe back-pressure. Sharp bends

and kinks will internally damage the hose, leading to premature

hose failure.

• Do not drop heavy objects on hose. A sharp impact may cause

internal damage to hose wire strands. Applying pressure to a

damaged hose may cause it to rupture.

• Distribute the load evenly across the entire saddle surface.

Always use a saddle to protect the plunger.

• Do not lift hydraulic equipment by the hoses or swivel couplers.

Use the carrying handle or strap.

• Keep hydraulic equipment away from flames and heat.

Excessive heat will soften packings and seals, resulting in

fluid leaks. Heat also weakens hose materials and packings.

For optimum performance, do not expose equipment to

temperatures of 150˚F [65˚C] or higher. Protect all hydraulic

equipment from weld spatter.

3

• Immediately replace worn or damaged parts with genuine

NOTICE

Enerpac parts. Enerpac parts are designed to fit properly and

to withstand high loads. Non-Enerpac parts may break or

cause the pump to malfunction.

Hydraulic equipment must only be serviced by a

qualified hydraulic technician. For repair service, contact the

Enerpac Authorized Service Center in your area.

1.3 Battery Operated Pump Safety Precautions

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Do not use the pump if the remote pendant rocker switch

cannot turn the pump on or o. Have the remote pendant

repaired before using the pump.

• Do not operate the pump near combustible materials, such as

flammable liquids, gases, or dust.

• Remove the battery from the pump before making any

adjustments, performing maintenance or storing the pump.

• Do not attempt to disable or modify the safety key interlock

feature.

• Remove safety key when pump is unattended to prevent

unauthorized persons from operating pump.

• Do not probe the battery or battery charger with conductive

materials.

• Do not allow metal items or material such as steel wool,

aluminium foil or other foreign objects into the battery or

battery charger cavity or charger terminals.

• Do not use the pump if the motor assembly is loose or

damaged. Have the motor assembly inspected and repaired

by an Enerpac Authorized Service Center before using the

pump.

• Do not attempt to charge non-specified batteries in the

charger.

• Do not expose the battery or battery charger to wet conditions

or excessive humidity.

• Do not immerse the battery or battery charger.

• Use the Enerpac ZC-Series pump only with the specified

Briggs & Stratton 82V LI-ION batteries. Refer to Section 3.1 for

approved battery model numbers.

• Recharge battery only with the charger specified by Briggs &

Stratton for the battery being used.

• Do not deliberately short circuit battery or battery charger.

• If battery liquid leaks and contact occurs, flush with water and

seek medical help.

• Do not attempt to disassemble, repair or modify the battery or

battery charger.

• Unplug battery charger when cleaning or not in use.

• Do not burn, crush or damage battery.

• Do not cover ventilation slots in the top of the charger or sides

of the battery.

• Do not place battery charger on a soft surface, such as a

blanket or pillow.

• Do not allow battery or battery charger to become too warm.

Allow these items to cool before attempting to charge the

battery.

• Store battery and battery charger in a cool, dry place. Keep

these items in a secured area, away from children and pets.

• Battery and battery charger may under no circumstances be

opened. If the cover is damaged, then these items should no

longer be used and must be replaced.

• Pump motor assembly (“powerhead”) is not serviceable and

should not be opened. Electric shock may result.

4

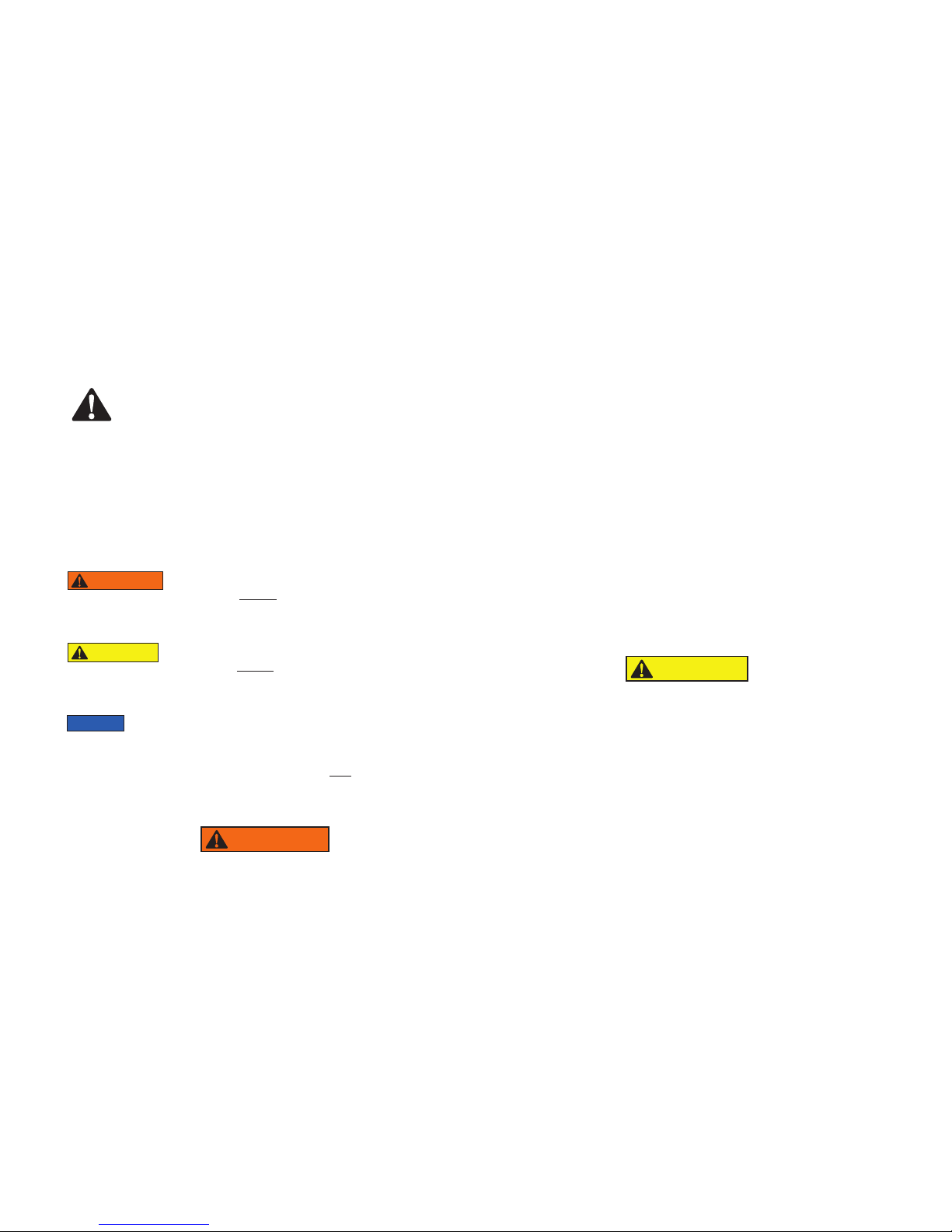

2.0 MAJOR FEATURES AND COMPONENTS

2

ZC-3308J

9

1

10

7

12

11

ZC-3408J

9

15

14

13

11

8

12

ZC-3908J

9

6

3

5

4

16

17

19

18

13

11

14

Key:

1. Remote Pendant

2. Carrying Handle/Roll Bar

3. Hydraulic Reservoir Sight Glass

4. Hydraulic Reservoir Drain Plug

5. Oil Fill Plug

6. Hydraulic Reservoir

7. Pump Motor

8. Directional Control Valve

9. Valve Handle

10. Advance/Retract Port

11. User-adjustable Relief Valve

12. Gauge Port

13. Advance Port

14. Retract Port

15. Auxiliary Tank Return Port

16. Battery Door

17. Battery Release Button

18. Battery

19. Safety Key

Figure 1, Major Features and Components, ZC-Series

5

3.0 PRODUCT DATA

3.1 Specifications

Pump

Model

Number

ZC3308J

ZC3408J

ZC3908J

Pump Model

Number

ZC3308J

ZC3408J

ZC3908J

Control Valve

Model Number and Function

Enerpac VM33

(Advance / Neutral / Retract)

Enerpac VM43

(Advance / Neutral / Retract)

Enerpac VM43LPS

(Advance / Neut. Hold / Retract)

Maximum Hydraulic

Pressure

psi bar

10,000

[+300 / -50]

10,000

[+300 / -50]

10,000

[+300 / -50]

700

[+20.7 / -3.4]

700

[+20.7 / -3.4]

700

[+20.7 / -3.4]

Operating Temp

˚ F ˚ C hp kW dBA

+40 to

+120

+40 to

+120

+40 to

+120

For Use With:

Single-acting

Cylinder

Double-acting

Cylinder

Power Seater

Post-Tensioning

Tools

Hydraulic

Connections

3/8" NPTF

3/8" NPTF

3/8" NPTF

Flow Rate (Refer to Section 3.2)

At

No Load

in³/

min

l/min

At 4,000 psi

[276 bar]

in³/

l/min

min

At 10,000 psi

[700 bar]

in³/

l/min gal l lb kg

min

310 5.0 80 1.3 32 0.52

Range

+4 to

+49

+4 to

+49

+4 to

+49

Reservoir

Size*

Motor Rating

1.4 1.0 75

1.4 1.0 75

1.4 1.0 75

Pump

Weight**

1.75 6.6 65.5 29.7 Enerpac HF

Sound

Pressure

Hydraulic Oil

Type

310 5.0 80 1.3 32 0.52 1.75 6.6 65.5 29.7 Enerpac HF

310 5.0 80 1.3 32 0.52 1.75 6.6 73.4 33.3 Enerpac HF

* Approximate usable capacity of oil reservoir.

** Approximate weight of pump with oil in reservoir and with battery installed.

Weight of battery is approximately 2.4 lb [1.1 kg].

Pump Series Item

Enerpac Briggs & Stratton

Battery Charger, 115V AC, 50/60 Hz Input NA ZC115VC 1760263

ZC-Series

Battery Charger, 230V AC, 50/60 Hz Input EU/AU ZC230VC 1760264

Battery, Lithium Ion, 82V, 4Ah, NA ZC82V4NA 1760265

Battery, Lithium Ion, 82V, 4Ah, EU/AU ZC82V4EUAU 1760515

Batteries and chargers can be purchased from an Enerpac distributor or Briggs & Stratton retailer.

*

3.2 Pressure and Flow Graphs

/min)

3

FLOW/RATE (in

400

350

300

250

200

150

100

FLOW VS. PRESSURE

50

6

5

4

3

FLOW/RATE (il/min)

2

1

FLOW VS. PRESSURE

Model Numbers

FLOW VS. PRESSUREFLOW VS. PRESSURE

*

0

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000

PRESSURE (PSI) PRESSURE (BAR)

NOTE: All product data is subject to change without notice. Graphs in Section 3.2 show typical pump pressure/flow curves.

0

100 200 300 400 500 600 700 800

6

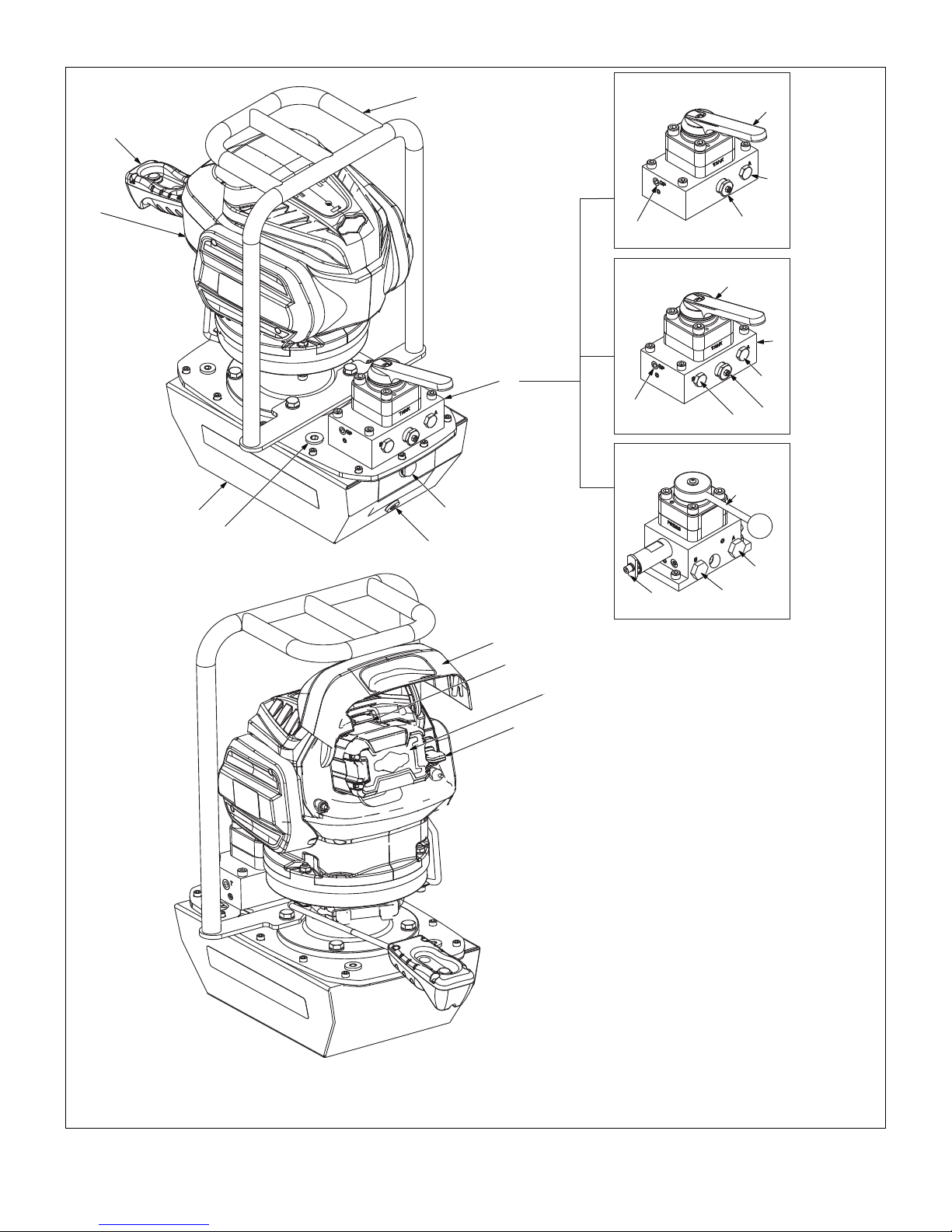

3.3 External Dimensions

B

A

F

E

H

G

D

C

I J K

ZC3308J ZC3408J ZC3908J

Item

A 25.48 647 G 16.28 414

B 14.00 356 H 10.92 277

C 9.69 246 I 11.74 298

D 8.09 205 J 11.74 298

E 4.22 107 K 10.43 265

F 5.66 144

Dimension

in mm in mm

Item

7

Dimension

4.0 PRODUCT DESCRIPTION

NOTICE

NOTICE

4.1 Introduction

The Enerpac ZC-Series combines the high performance of an

electric AC-powered pump with the convenience of a cordless,

battery powered pump. It is an ideal solution for remote locations,

where electrical or pneumatic power sources are not available.

Major features include a brushless DC electric motor, three-stage

pump element and 1.75 gallon [6.6 liter] hydraulic reservoir. Three

dierent control valves are available.

The pump is powered by a rechargeable 82V lithium-ion battery,

manufactured by Briggs & Stratton Corporation. The lithium-ion

battery is capable of providing impressive run times, even under

extreme job site conditions.

4.4 Electromagnetic Compatibility (EMC)

The ZC-Series cordless electric pump has been tested and

certified to conform to CE-EMC emission and immunity

standards.

5.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

5.1 Hydraulic Reservoir Breather

A shipping plug is installed in the breather port on the top of the

reservoir. Before using the pump, replace the shipping plug with

the adapter fitting and breather.

Check oil level before operating pump. Refer to

Section 9.1.

1

2

Figure 1, Battery and Charger

4.2 Additional Information - Battery and Charger

• The Briggs & Stratton logo is trademarked and intellectual

property of Briggs & Stratton.

• Portions of this publication are subject to copyright of Briggs

& Stratton Corporation.

4.3 Conformance to National and International Standards

Enerpac declares that the ZC-Series cordless electric pump

has been tested and conforms to applicable standards and is

approved to carry the CE, TUV C and US certification marks. An

EU Declaration of Conformity is enclosed separately.

3

4

Key:

1. Breather

2. Adapter Fitting

Figure 2, Breather and Oil Fill Plug Locations

3. Shipping Plug

4. Oil Fill Plug (SAE #8)

6.0 HYDRAULIC CONNECTIONS

WARNING

tightly bending hoses. If a hose becomes kinked or otherwise

damaged, it must be replaced. Damaged hoses may rupture at

high pressure. Serious personal injury may result.

The pump comes equipped with a 3-way, 3-position control

valve (VM33); 4-way, 3-position control valve (VM43); or a control

valve specifically designed for foundation tensioning (VM43LPS).

is strongly recommended. All hoses and fittings must be rated to

at least 10,000 psi [700 bar].

To ensure proper operation, avoid kinking or

Installation of a pressure gauge in each hydraulic line

8

Figure 3, Hydraulic Connections

NOTICE

NOTICE

1

1. Battery Capacity Indicator Button

2. Indicator Lights

2

As hoses, components and fittings are assembled, apply 1-1⁄2

wraps of PTFE thread sealing tape to all threaded NPT or NPTF

fittings, leaving the first complete thread free of tape as shown in

Figure 3. Use care to prevent pieces of tape from entering the

hydraulic system.

Make hydraulic connections as described in the following steps.

The pumps equipped with the VM43 and VM43LPS control

valves will have ports “A” and “B”. Pumps equipped with the

VM33 control valve will only have port “A”.

1. To prevent the pump from starting, be sure that the battery is

removed from the pump.

2. Remove the plugs from pump ports “A” and “B” (if equipped).

3. As required, install hydraulic fitting(s) at pump port(s). Tighten

fittings(s) finger tight. Then tighten fitting(s) two additional full

turns. Couplings or other hydraulic fittings (user-supplied)

must have 3/8" NPTF threads.

4. Make connections as described for each model:

ZC3308J only:

• Connect the cylinder advance/retract hose to pump port “A”.

ZC3408J and ZC3908J only:

• Connect the hose from the advance side of the cylinder to

pump port “A”.

• Connect the hose from the retract side of the cylinder to

pump port “B”.

5. Pumps equipped with VM43LPS control valve only: some

post-tensioning equipment may require the connection of

a third hydraulic hose. Refer to the manuals provided with

your post-tensioning equipment. Also refer to the Enerpac

VM43LPS instruction sheet.

7.0 BATTERY

7.1 Battery Capacity Indicator

New batteries should be charged before use. Each battery

contains four indicator lights. The battery capacity indicator

lights show the approximate battery capacity level.

Press the battery capacity indicator button to display the lights.

The battery capacity indicator lights will stay lit for two seconds

after the button is pressed. Refer to Figure 4 to determine the

level of charge.

Run time between battery charges is dependent on the

application, pump run time, pressure setting and other factors.

If none of the battery capacity indicator lights illuminate

when the battery capacity indicator is pressed, place the battery

on the charger and charge as needed.

When Battery Capacity Indicator

Button is pressed:

4 Lights ON 80 - 100%

3 Lights ON 60 - 80%

2 Lights ON 40 - 60%

1 Lights ON 25 - 40%

0 Lights ON < 25%

Figure 4, Battery Capacity Indicator

7.2 Battery Installation

1. Ensure that remote pendant switch is in the OFF (O) position.

2. Lift battery door and hold it open.

3. Align ribs on battery and battery bracket. Then, slide the

battery fully into the battery compartment until it stops.

4. Ensure battery release button snaps in place and that

the battery is fully seated and secured before beginning

operation.

5. Close the battery door.

Percent Charge:

(approximate)

1

3

2

4

Key:

1. Battery Door

2. Battery

3. Battery Release Button

4. Safety Key

Figure 5, Battery Installation

9

NOTICE

To ensure compatibility and proper operation, use only

NOTICE

Briggs & Stratton 82V lithium-ion batteries with the pump. Refer

to Section 3.1 for battery model number information.

7.3 Battery Removal

1. Ensure pump motor is switched o.

2. Lift the battery door and hold it open.

3. Press the battery release button located above battery.

4. Slide the battery outwards and remove it from the battery

compartment. Refer to Figure 5.

7.4 Battery Management System

The battery management system monitors and controls battery

operation:

• A low voltage cut-o feature will shut down the battery when

the battery voltage drops to below acceptable limits.

• A high temperature shut down feature will shut down the

battery if its internal temperature rises to above acceptable

limits.

• If the low voltage cut-o or high temperature shut down feature

is activated while the pump is operating, the pump motor will

emit a beeping sound and the pump will stop.

• If the high temperature shut down feature is activated, the

battery must cool down to an acceptable internal temperature

before the pump can be restarted.

7.5 Additional Battery and Charger Information

• The battery is not shipped fully charged. It is recommended

that battery be fully charged before first use to ensure

maximum run time can be achieved.

• For best results, the battery should be charged in a location

with a temperature between 43°F [6.1°C] and 104°F [40°C].

The battery is a lithium-ion device. It will not develop a memory

and may be charged at any time.

• If the battery charger light glows green and blinks when the

battery is placed in the battery charger, this indicates that the

battery is being charged. A solid green light indicates that the

battery is fully charged.

• If the battery charger light glows solid red when the battery is

placed in the battery charger, this indicates that the battery

temperature is above acceptable limits. Leave the battery in

the charger and allow time (up to 30 minutes) for the battery

to cool. The charger should resume charging after the battery

has cooled.

• If the battery has been stored with little to no charge for a long

period of time, the charger will go into recovery mode, which

will take 20 hours to fully charge the battery. This will enhance

the life of the battery. Once the battery is fully charged, the

next charge will return to standard charging.

8.0 OPERATION

8.1 Before Start-up

1. Check all hydraulic fittings and connections to be sure they

are tight and leak free.

2. Install hydraulic reservoir breather. Refer to Section 5.1.

3. Check the hydraulic oil level. Add oil if necessary. Refer to

sections 9.1, 9.2 and 9.3.

4. Install a fully charged battery on the pump. Refer to Section

7.2.

5. Verify safety key is installed.

6. Connect hydraulic hose(s) to pump as described in Section

6.0. Remove air from system before placing pump into

operation. Refer to instructions in Section 8.6.

8.2 Starting the Pump Motor

1. Place control valve lever in the neutral position (“3”). Refer to

sections 8.5.1, 8.5.2 and 8.5.3 for control valve details.

2. To start the pump motor, press the upper half of the remote

pendant rocker switch.

8.3 Stopping the Pump Motor

To stop the pump motor, press the lower half of the remote

pendant rocker switch.

In an emergency, the pump motor can also be stopped

by removing either the safety key or the battery.

1

2

1. On Position

2. O Position

Figure 6, Remote Pendant

8.4 Operating Precautions

WARNING

Failure to observe the following precautions and instructions

could allow load to drop on persons working in the area.

Death or serious personal injury could result.

• Keep persons away from area under load during lifting,

lowering and whenever the control valve lever is moved.

• To prevent the lifted load from dropping, always immediately

support it with jack stands or other mechanical blocking

devices of adequate rated capacity.

• Be certain that blocking is fully in place before moving

the control valve lever from one position to another. An

unsupported load can drop when the control valve is shifted.

• Do not rely on the pump hydraulics to hold lifted loads (pumps

equipped with VM33 or VM43 control valves). The pump is

not designed as a load holding device. The control valve does

NOT contain a safety locking valve in any of its three positions.

• Although in some instances the pump hydraulics may

temporarily hold the load, be aware that the load can drift

downward or drop suddenly at any time without warning if it is

not mechanically supported.

• Pump model ZC3908J is designed exclusively for post-

tensioning applications and should only be used with

compatible post-tensioning equipment. To prevent possible

loss of load and serious personal injury, do not use model

ZC3908J for lifting applications.

8.5 Manual Valve Operation

Each ZC-Series cordless electric pump is equipped with a control

valve. It is operated by a rotary lever located at the front of the

pump. Refer to Figures 7, 8 and 9 for control valve positions.

8.5.1 VM33 Operation

To advance the cylinder:

1. Be sure that control valve is in the neutral position (“3”).

10

1. Advance

2. Retract

3. Neutral

2

3

1

1. Advance

1. Advance

2. Retract

2. Retract

3. Neutral

3. Neutral

2

3

1

Figure 7, VM33 Control Valve Positions

2. Turn pump on by pushing upper half of remote pendant

rocker switch.

3. Move control valve lever to the advance position (“1”). The

cylinder will begin advancing.

The cylinder will continue to advance until the pump is switched

o or the cylinder is fully extended.

To retract the cylinder:

1. Move control valve to the neutral position (“3”).

2. If pump is on, turn pump o by pushing lower half of remote

pendant rocker switch.

3. Move control valve lever to the retract position. The cylinder

will begin retracting.

The cylinder will continue to retract until the control valve lever

is placed in the neutral position (“3”) or until the cylinder is fully

retracted. Additional hydraulic devices may be required to control

the rate of cylinder retraction.

The VM33 control valve blocks hydraulic flow in the cylinder hose

when the lever is moved to the neutral position (“3”). However, the

valve is not designed for holding loads. After lifting is completed,

the load must be mechanically supported. Refer to warning

statements and related information in Section 8.4.

8.5.2 VM43 Operation

To advance the cylinder:

1. Be sure that the control valve lever is in the neutral (“3”)

position.

2. Turn pump on by pushing upper half of remote pendant

rocker switch.

3. Move control valve lever to the advance (“1”) position. The

cylinder will begin advancing.

The cylinder will continue to advance until the control valve is

moved to the neutral position (“3”), the pump motor is switched

o or the cylinder s fully extended.

To retract the cylinder:

1. Be sure that the control valve lever is in the neutral (“3”)

position.

2. Turn pump on by pushing upper half of remote pendant

rocker switch. Pump must be on to retract cylinder.

3. Move control valve lever to the retract (“2”) position. The

cylinder will begin to retract.

Figure 8, VM43 Control Valve Positions

The cylinder will continue to retract until the control valve lever

is moved to the neutral position (“3”) or until the cylinder is fully

retracted. Additional hydraulic devices may be required to control

the rate of cylinder retraction.

The VM43 control valve blocks hydraulic flow in both cylinder

hoses when the lever is moved to the neutral position (“3”).

However, the valve is not designed for holding loads. After lifting

is completed, the load must be mechanically supported. Refer to

warning statements and related information in Section 8.4.

8.5.3 VM43LPS Operation (post-tensioning applications only)

For detailed operating instructions, refer to the separate

instruction sheet provided with the VM43LPS control valve. Also

refer to the operation manuals supplied with the post-tensioning

equipment being used.

2

1. Advance/Stressing

1

2. Retract/Seating

3. Neutral/Hold

3

Figure 9, VM43LPS Control Valve Positions

8.6 Air Removal

When hydraulic components are connected for the first time,

air will be trapped in the components. To ensure smooth, safe

operation, run the cylinder through several complete advanceretract cycles before placing the pump into service. Do this with

no load on the cylinder and with the pump positioned higher than

the cylinder.

When the cylinder advances and retracts smoothly and without

hesitation, the air has been vented from the system.

11

NOTICE

Trapped air purged from system components will return

NOTICE

NOTICE

NOTICE

NOTICE

to reservoir. Oil level may drop. Add additional oil (if required) to

reservoir after purging air. Refer to Section 9.3.

8.7 Disconnecting Hydraulic Hoses

Disconnect hydraulic hoses after use as described in the

following steps:

1. Fully retract the cylinder or tool. Be sure that the load is

completely removed from the device.

2. Move the control valve lever back and forth between the

advance (“1”) and retract (“2”) positions several times to

relieve any trapped pressure.

3. If pressure gauges have been installed, verify that the gauges

indicate zero (0) psi/bar.

4. Disconnect hydraulic hoses from pump.

5. To prevent contamination, cap or plug all open hydraulic

couplings and ports.

8.8 Transporting the Pump

Always transport the pump using the built-in carrying handle.

Never attempt to transport or reposition the pump by dragging

it by the hoses. Damage to the pump and/or hoses may result.

9.0 MAINTENANCE

9.1 Check Oil Level

1. Be sure hydraulic cylinder or other tool is fully retracted.

2. Rotate the control valve lever back and forth several times

between the advance and retract positions (“1” and “2”) to

remove any trapped pressure.

3. Remove the battery from the pump. Refer to Section 7.2.

4. Place the pump on a level surface.

5. Visually check the oil level by looking through the hydraulic

reservoir sight glass. Reservoir is FULL when oil level is

about halfway between the top and bottom of the sight

glass. Refer to Figure 10.

If oil level is low:

Add oil as described in Section 9.3. Refer to Section 9.2 for

oil requirements.

9.2 Hydraulic Oil Information

Use only Enerpac HF hydraulic oil when adding additional oil

or when performing an oil change. Enerpac HF hydraulic oil is

available from Enerpac distributors and Enerpac authorized

service centers.

Use only Enerpac HF hydraulic oil. Use of other oils

may result in damage to pump components. Such damage is not

covered under the Enerpac product warranty.

9.3 Adding Oil

1. Be sure hydraulic cylinder or tool is fully retracted.

2. Rotate the control valve lever back and forth several times

between the advance and retract positions (“1” and “2”) to

remove any trapped pressure.

3. Disconnect hydraulic hoses.

4. Remove the battery from the pump. Refer to Section 7.3.

5. Place the pump on a level work surface.

6. Remove SAE #10 plug from cover plate. Refer to Figure 2.

7. Slowly fill the reservoir with new oil until level is about halfway

between the top and bottom of the hydraulic reservoir sight

glass. Refer to Section 9.2 for oil requirements.

Do NOT overfill. Be certain that all hydraulic cylinders

are fully retracted before adding any oil. Over filling hydraulic

reservoir may cause damage to the pump.

9.4 Oil Change

Change the hydraulic oil in the pump reservoir at least once

a year, or whenever it is suspected that the oil has become

contaminated.

To properly drain and refill the reservoir, change the oil as

described in the following steps. Refer to Figure 10.

1. Be sure hydraulic cylinder or tool is fully retracted.

2. With the pump o, rotate the control valve lever back

and forth several times between the advance and retract

positions (“1” and “2”) to remove any trapped pressure.

3. Remove the battery from the pump.

4. Disconnect hydraulic hoses from pump.

1

Key:

1. Hydraulic Reservoir Sight Glass

2. Drain Plug

Figure 10, Hydraulic Reservoir

ZC-Series pumps are equipped with a 1.75 gallon [6.6

liter] hydraulic reservoir. Be sure the pan or container is large

enough to hold all the drained oil.

5. Place a suitable pan or container of appropriate capacity

under the hydraulic reservoir drain plug. Refer to Figure 10.

6. Remove hydraulic reservoir drain plug.

7. Allow used oil to drain completely from reservoir.

8. Clean hydraulic reservoir drain plug and remove any metal

shavings (plug is magnetic).

9. Reinstall hydraulic reservoir drain plug.

Dispose of used oil in accordance with all applicable

laws and regulations.

10. Refill hydraulic reservoir with new oil. Refer to Section 9.3.

2

Full

12

10.0 PRESSURE RELIEF VALVE ADJUSTMENT

NOTICE

NOTICE

NOTICE

WARNING

Never adjust the pressure relief valve setting above 10,000 psi

[700 bar]. Be certain that the pressure setting does not exceed

the maximum rated pressure of the cylinder (or tool) being

used. Failure to observe these precautions may result in failure

of cylinder or tool and related components. Death or serious

personal injury could occur.

10.1 VM33 and VM43 Only

1. Install a 0-15,000 psi [0-1035 bar] gauge in the “A” port. Refer

to Figure 11.

2. VM43 Only: Install a 3/8" pipe plug in the “B” port and torque

to 25 ft-lbs [33 Nm].

3. Loosen the relief valve locknut to permit adjustment of set

screw.

4. Rotate the control valve handle to the neutral position (“3”).

Refer to Figures 7 and 8 for valve handle positions.

5. Start the pump and allow the oil to warm.

6. Rotate the control valve handle to the advance position (“1”).

Allow pressure to build.

7. To increase pressure: SLOWLY turn the relief valve set screw

clockwise until pressure increases to the desired setting.

An internal check valve in the manifold will prevent the

pressure from dropping when the set screw is turned counterclockwise. To lower the pressure setting, follow steps 8a through

8e.

8. To decrease pressure:

a. Be sure the pump is running.

b. Rotate the control valve handle to the neutral position

(“3”) to relieve pressure on the “A” port.

c. Turn the relief valve set screw counter-clockwise one

turn.

d. Rotate the control valve handle to the advance position

(“1”).

e. SLOWLY turn the relief valve set screw clockwise until “A”

port pressure increases to the desired setting.

9. When the desired pressure setting is reached, lock the set

screw with the locknut. DO NOT overtighten.

10. Before turning o pump, rotate the control valve handle

momentarily to the retract position (“2”) to relieve pressure at

the “A” port. Then, rotate the handle to the neutral position

(“3”). Check that gauge indicates zero (0) psi/bar.

11. Shut o the pump.

10.2 VM43LPS Only

1. Install a 0-15,000 psi [0-1035 bar] gauge in the stressing

pressure gauge “A” port. Refer to Figure 12.

2. Install a 3/8" pipe plug in the seating port “B” port and torque

to 25 ft-lbs [33 Nm].

3. Loosen the relief valve locknut to permit adjustment of set

screw.

4. Rotate the control valve handle to the neutral/hold position.

Refer to Figure 9 for valve handle positions.

5. Start the pump and allow the oil to warm.

6. Rotate the control valve handle to the advance position (“1”).

Allow pressure to build.

Use a 5mm Allen wrench to adjust the relief valve set

screw.

7. To increase pressure: With the pump running, SLOWLY turn

the relief valve set screw clockwise until stressing “A” port

pressure increases to the desired setting.

A pilot-operated check valve in the locking valve block

will prevent the pressure from dropping when the set screw is

turned counter-clockwise. To lower the pressure setting, follow the

procedure in steps 8a through 8e.

8. To decrease pressure:

a. Be sure the pump is running.

b. Rotate the control valve handle to the retract/seating

position momentarily. This will activate the pilotoperated check valve and relieve pressure at the

stressing “A” port. Then, rotate the handle to the neutral/

hold position.

c. Turn the relief valve set screw counter-clockwise one

turn.

d. Rotate the control valve handle to the advance/stressing

position.

e. SLOWLY turn the relief valve set screw clockwise until

stressing port “A” pressure increases to the desired

setting.

9. When the desired pressure setting is reached, lock the set

screw with the locknut. DO NOT overtighten.

10. Before turning o pump, rotate the control valve handle

momentarily to the retract position to relieve pressure at the

stressing “A” port. Then, rotate the handle to the neutral/

hold position. Check that stressing pressure gauge (“A” port)

indicates zero (0) psi/bar.

11. Shut o the pump.

Relief Valve Body (DO NOT TURN)

“B” Port

(VM43 Only)

Figure 11, Relief Valve - VM33 and VM43

Locknut

Set screw

AB

“A” Port

Relief Valve Body

(DO NOT TURN)

Locknut

Set Screw

13

“A” Port

“B” Port

Figure 12, Relief Valve - VM43LPS

11.0 TROUBLESHOOTING

The information in the Troubleshooting Guide is intended as an

aid to help diagnose and correct various possible problems that

may occur.

For repair service, contact your nearest Enerpac Authorized

Service Center. Only an Enerpac Authorized Service Center

should be permitted to service the pump and its components.

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Never tighten or loosen hydraulic fittings while the pump

hydraulic system or connected components are pressurized.

Escaping oil under pressure can penetrate the skin, causing

serious personal injury.

• Keep hands, fingers and other body parts clear of pinch

points and moving parts when observing operation during

troubleshooting.

• To prevent accidental start-up of pump during servicing,

always remove battery from pump before performing any

maintenance or repair procedures.

WARNING

TROUBLESHOOTING GUIDE

Symptom Possible Cause Solution

1. Pump will not start. a. Battery is not installed. Install battery.

b. Safety key is not inserted. Insert safety key.

c. Battery is discharged. Charge battery.

d. Electrical contacts are dirty or

corroded.

2. Pump clicks when

remote pendant switch

is on, but does not

start.

3. Low fluid output. a. Pump needs priming. To prime the pump, be sure that the pump reservoir is filled

4. Pump does not build

pressure.

5. Noisy and/or vibrating

pump operation.

6. Battery charge is

reduced after more than

one month of use.

a. Battery is discharged. Charge battery.

b. Battery is damaged or not

functioning.

c. Electrical contacts are dirty or

corroded.

d. Pump is jammed due to

obstruction. Possible internal

damage to pump.

b. Bypass valve malfunction. Contact Enerpac Authorized Service Center.

c. Oil intake screen is clogged with

debris.

d. Internal damage to pump. Contact Enerpac Authorized Service Center.

Pressure relief valve is set too

low.

a. Pump element piston is sticking. Contact Enerpac Authorized Service Center.

b. Motor is damaged. Contact Enerpac Authorized Service Center.

The battery has automatically

performed self-maintenance to

extend its life.

Clean contacts on the battery, pump and charger.

Replace battery.

Clean contacts on the battery, pump and charger.

Contact Enerpac Authorized Service Center.

with oil. Then, run the pump with the control valve in the

neutral position (“3”) while gently rocking the pump from

side-to-side.

Contact Enerpac Authorized Service Center.

Adjust pressure relief valve pressure setting. Refer to

Section 10.

Fully recharge battery before use.

(continued on next page)

14

Symptom Possible Cause Solution

7. Cylinder will not

advance or retract.

8. Pump slows down and

stops.

9. Cylinder advances and

retracts erratically.

TROUBLESHOOTING GUIDE (continued)

a. Valve handle in wrong position. Move valve handle to position “1” to advance.

Move valve handle to position “2” to retract.

b. Oil level low. Add oil until reservoir is full.

c. Pump needs priming. To prime the pump, be sure that the pump reservoir is filled

with oil. Then, run the pump with the control valve in the

neutral position (“3”) while gently rocking the pump from

side-to-side.

d. Oil intake screens are clogged

Contact Enerpac Authorized Service Center.

with debris.

Battery is discharged. Charge battery.

a. Air is in the system. Advance and retract the cylinder until operation is smooth.

b. External hydraulic leak. Tighten connections. Replace damaged components.

c. Internal leakage in valve. Contact Enerpac Authorized Service Center.

d. Internal damage to valve. Contact Enerpac Authorized Service Center.

e. Internal damage to pump. Contact Enerpac Authorized Service Center.

15

POWERFUL SOLUTIONS. GLOBAL FORCE.

http://www.enerapac.com

41

L1057 Rev. C 08/12 www.enerpac.com

3 - In Use

42

B

A

2

3

1

B

43

A

A

PT

A

PT

A

PT

A

PT

A

PT

A

PT

VM33

VM33L

P

T

A

"GA"

"GP"

"GP"

T

P

T

A

"GP"

"GP"

"GA"

T

44

4

APTB

PT

A B

AB

APTB

APTB

PT

A B

VM43

VM43

P

T

A

B

"GA"

"GB"

"GP"

"GP"

T

P

T

"GP"

"GP"

T

A

B

"GA"

"GB"

45

PT

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

T +61 (0)2 9743 8988

F +61 (0)2 9743 8648

sales-au@enerpac.com

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

customer.service@actuant.com

China

Actuant (China) Industries Co. Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free: +86 400 885 0369

sales-cn@enerpac.com

France, Switzerland, North Africa

and French speaking African

countries

ENERPAC

Une division d’ACTUANT France S.A.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

sales-fr@enerpac.com

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf, Germany

T +49 211 471 490

F +49 211 471 49 28

sales-de@enerpac.com

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore, 560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

sales-in@enerpac.com

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

sales-it@enerpac.com

Japan

Applied Power Japan LTD KK

Besshocho 85-7

Kita-ku, Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

sales-jp@enerpac.com

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Oce 423, LOB 15

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

sales-ua@enerpac.com

Russia

Rep. oce Enerpac

Russian Federation

Admirala Makarova Street 8

125212 Moscow, Russia

T +7 495 98090 91

F +7 495 98090 92

sales-ru@enerpac.com

Singapore

Actuant Asia Pte Ltd.

83 Joo Koon Circle

Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free: +1800 363 7722

sales-sg@enerpac.com

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi,

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

sales-kr@enerpac.com

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

sales-es@enerpac.com

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

scandinavianinquiries@enerpac.com

The Netherlands, Belgium,

Luxembourg,

Central and Eastern Europe,

Baltic States, Greece, Turkey

and CIS countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

sales-nl@enerpac.com

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P. O. B o x 42 1

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

integratedsolutions@enerpac.com

South Africa and other English

speaking African countries

Enerpac Africa Pty Ltd.

No. 5 Bauhinia Avenue

Cambridge Oce Park

Block E

Highveld Techno Park

Centurion 0157

South Africa

T: +27 12 940 0656

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

sales-uk@enerpac.com

USA, Latin America and Caribbean

ENERPAC

P.O. Box 3241

Milwaukee WI 53201 USA

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

T +1 800 433 2766

Distributor inquiries/orders:

T +1 800 558 0530

F +1 800 628 0490

Technical inquiries:

techservices@enerpac.com

sales-us@enerpac.com

Enerpac Worldwide Locations e-mail: info@enerpac.com internet: www.enerpac.com

All Enerpac products are guaranteed

against defects in workmanship and

materials for as long as you own them.

For the location of your nearest authorized

Enerpac Service Center, visit us at

www.enerpac.com

101711

Loading...

Loading...