Page 1

Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

LCD Control Panel Operation - Firmware 7.x

L2940 Rev. A 07/09

1.0 SAFETY ISSUES

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

when in doubt as to the safety precautions and operations. If you

have never been trained on high-pressure hydraulic safety,

consult your distribution or service center for a free Enerpac

Hydraulic safety course.

Failure to comply with the following cautions and warnings could

cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction

of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: Stay clear of loads supported by

hydraulics. A cylinder, when used as a load lifting device,

should never be used as a load holding device. After the

load has been raised or lowered, it must always be blocked

mechanically.

WARNING: USE ONLY RIGID PIECES TO HOLD

LOADS. Carefully select steel or wood blocks that are

capable of supporting the load. Never use a hydraulic

cylinder as a shim or spacer in any lifting or pressing application.

DANGER: To avoid personal injury keep hands

and feet away from cylinder and workpiece

during operation.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated component

in the system. Install pressure gauges in the system to

monitor operating pressure. It is your window to what is happening

in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid

sharp bends and kinks when routing hydraulic hoses.

Using a bent or kinked hose will cause severe back-pressure.

Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

Do not drop heavy objects on hose. A sharp impact

may cause internal damage to hose wire strands.

Applying pressure to a damaged hose may cause it

to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or

other means of safe transport.

Z-Class Electric Pumps

CAUTION: Keep hydraulic equipment away from

fl ames and heat. Excessive heat will soften packings

and seals, resulting in fl uid leaks. Heat also weakens

hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C [150°F] or higher.

Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected couplers. If

the cylinder becomes extremely overloaded, components

can fail catastrophically causing severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a fl at

surface that can support the load. Where applicable, use

a cylinder base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially dangerous

results.

IMPORTANT: Hydraulic equipment must only be serviced

by a qualifi ed hydraulic technician. For repair service,

contact the Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fi t properly and withstand high

loads.

WARNING: Do not use electric pumps in an explosive

atmosphere. Adhere to all local and national electrical

codes. A qualifi ed electrician must do installation and

modifi cation.

Page 2

WARNING: Keep hands clear of moving parts and

pressurized hoses.

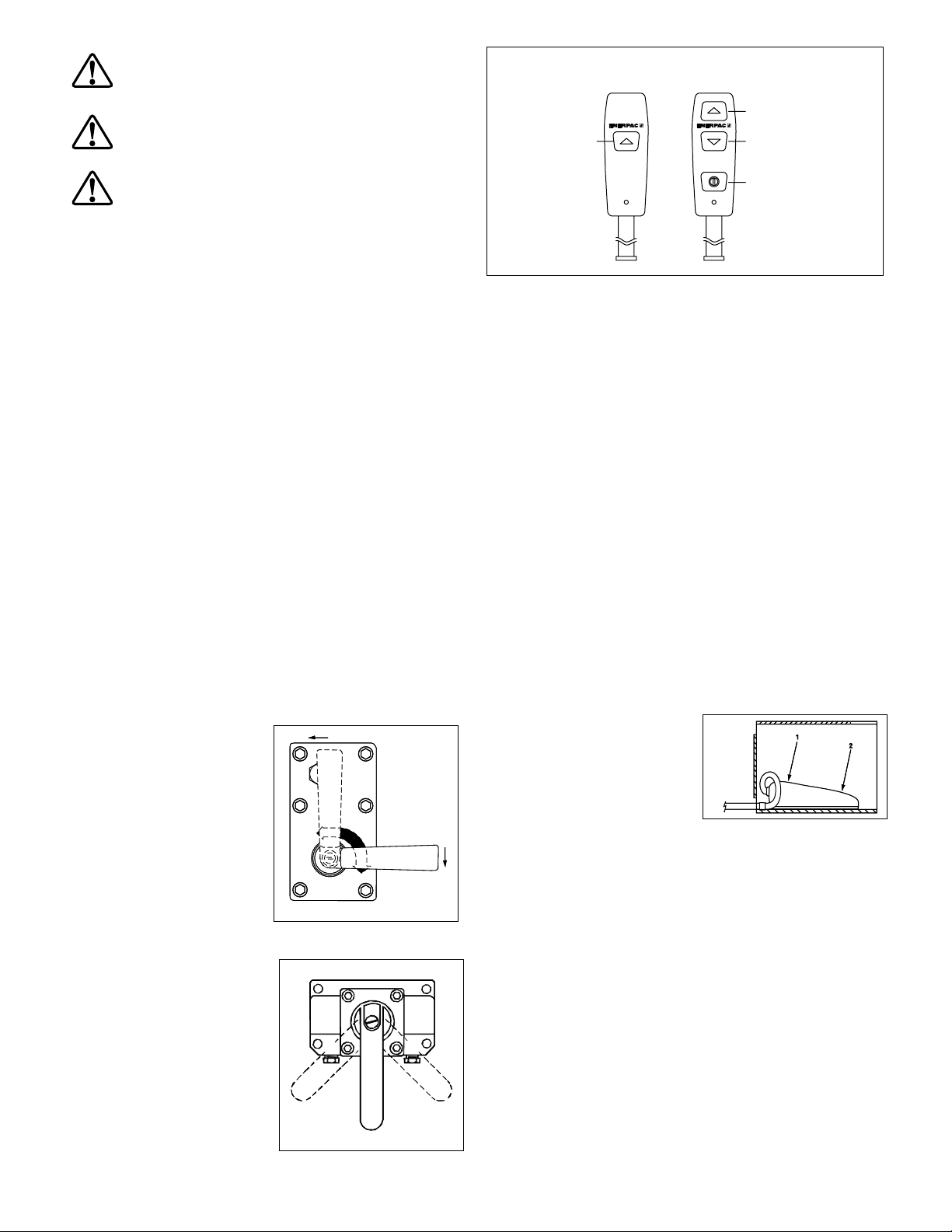

One

Button

Three

Button

WARNING: These pumps have internal factory adjusted

relief valves, which must not be repaired or adjusted

except by an Authorized Enerpac Service Center.

WARNING: To prevent damage to pump electric motor,

check specifi cations. Use of incorrect power source

will damage the motor.

2.0 STARTUP

IMPORTANT:

• Pumps with optional pressure transducer: Review Automode

information in sections 4.0 and 5.0 before starting pump.

• Pumps with optional pressure switch: Review section 6.7 G

before starting pump.

1. Check the oil level of pump and add oil if necessary. Refer to

pump instruction sheet.

2. Make sure the shipping plug has been removed and the

breather cap is installed. Refer to pump instruction sheet.

3. Place manual control valve (all models NOT equipped with

electric valve) in the Neutral position.

4. Connect unit to power. Wait about 2 seconds - until “READY” is

displayed - before pressing any button on shroud or pendant.

Refer to section 6.2 for additional boot sequence information

Note: During the boot sequence, the microprocessor will identify

operation of any button as a potential malfunction and will

prevent the motor from starting. Reset by disconnecting power

for 10 seconds.

5. Adjust relief valve as described in section 5.0.

6. For Motor On/Off and valve operation: refer to sections 3.1

through 3.4 for instructions applicable to your specifi c valve

and pendant confi guration. For models equipped with a foot

switch, refer to section 3.5.

3.0 VALVE, PENDANT AND FOOT SWITCH

OPERATION

2

2

3.1 Manual Valve

Operation

VM32 (See Fig. 1)

1. Advance

2. Retract

Shroud On/Off=

Toggle Motor On or Off

Tank

Tank

Pressure

Pressure

Figure 1

Figure 1

1

1

® ®

Up Arrow/

ON/OFF

Up Arrow

Down Arrow

ON / OFF

Figure 3, Pendant Button Variations

3.3 VE33, VE43 and VEW43P Electric Valves with

3-Button Pendant Operation

Also known as a Remote Pump - oil fl ow and motor are both

controlled by the pendant (see Fig. 3).

1. Up Arrow = Momentary Advance

2. Down Arrow = Momentary Retract

3. On/Off = Toggle Motor On or Off

Shroud On/Off = Toggle motor On or Off

3.4 VE32D Electric Valve with 1-Button Pendant

Operation

Also known as a Dump Pump - Oil fl ow and motor are both

controlled by the pendant. The pump will run and the cylinder

will advance when the pendant button is pressed. Releasing the

button will stop the pump and the cylinder will retract automatically

(see Fig. 3).

1. Up Arrow = Momentary Advance

Shroud On/Off = Toggle Motor Off Only

3.5 Valves with foot switch (See Fig. 4)

A. All valves except VE32D

1. Momentary advance or motor

on

2. Momentary retract (if

applicable)

Shroud On/Off = Toggle Motor

On or Off

Figure 4Figure 4

B. VE32D valves

1. Not used

2. Momentary advance

Shroud On/Off = Toggle Motor Off

3.2 VM33, VM33L, VM43,

and VM43L

(See Fig. 2)

1. Advance

2. Retract

3. Neutral

Shroud On/Off =

Toggle Motor On or Off

3 - In Use

3 - In Use

A

B

B

2

2

Figure 2

Figure 2

A

1

1

3

3

2

Page 3

4.0 AUTOMATIC PUMP OPERATION

(Pumps equipped with pressure transducer option)

Pumps equipped with the pressure transducer option have the

ability to react automatically at a user-defi ned upper and lower

pressure value. This feature is called “Automode”.

Automode can be turned on or off as desired, at the LCD control

panel.

Automode controlled operation of the motor and electric valve

(if equipped) will vary, depending on pump type . The pump type

appears briefl y on the LCD when power is connected to the

pump.

Refer to Table 1 for a list of the pump types covered in this

manual. Refer to Table 4, Pump Model Matrix, (located near the

end of this document) for a description of the specifi c operational

characteristics for each pump type.

Table 1 - Pump Types

Number Pump/Valve Description

1 . . . . . . . . . . . . . . . . . . . Manual w/LCD (manual valve)

2 . . . . . . . . . . . . . . . . . . . Advance/Hold /Retract (electric valve)

3 . . . . . . . . . . . . . . . . . . . Dump (electric valve)

6 . . . . . . . . . . . . . . . . . . . Remote 3 or 4-Way (electric valve)

8 . . . . . . . . . . . . . . . . . . . Jog (manual valve)

10 . . . . . . . . . . . . . . . . . . 3 or 4-Way Manual Momentary

. . . . . . . . . . . . . . . . . . . Local Mode Default (electric valve)

4.1 Overview of Automode Operation

Refer to paragraphs A through D of this section for an overview

of Automode operation and features.

4.1 A. If Automode is ON, and LO PRESS setting is

greater than zero (Pump types 1, 2, 6, 8 and 10)

I. Before the HI PRESS value is reached:

• The pendant buttons and shroud On/Off button will function as

described in sections 3.1 – 3.4.

• The text “AUTO” will be shown on the LCD, reminding the

operator that Automode is active, and that the pump will take

control when system pressure rises to the HI PRESS value.

II. After the HI PRESS value is reached:

• Pump types 1 and 8: The pump motor will stop.

• Pump type 2: The pump motor will stop and the electric valve

will shift.

• Pump types 6 and 10: The pump motor will keep running and

the electric valve will shift.

• The LCD text will change from “AUTO” to “AUTO ON” and the

LCD backlight will begin fl ashing on and off. This indicates that

Automode is now controlling pump operation automatically as

required to maintain the set pressure range.

WARNING: All personnel must be aware that motor can

start and/or valve can shift at any time when backlight

is fl ashing and “AUTO ON” is displayed on the LCD.

WARNING: Always set Automode to OFF and

disconnect electrical power to pump before

disconnecting hoses or performing any

adjustments, maintenance or repairs.

III. When system pressure drops to the LO PRESS value:

• Pump types 1 and 8: The pump motor will restart.

• Pump types 6 and 10: The electric valve will shift.

• Pump type 2: The pump motor will restart and the electric

valve will shift.

4.1 B. If Automode is ON, and LO PRESS setting is set

to zero (0) or OFF (Pump types 1, 2, 3, 6, 8 and 10)

Note: On pump type 3 only, the LO PRESS function is not used,

and is automatically set to zero (0) by the microcontroller.

I. Before the HI PRESS value is reached:

• The pendant buttons and shroud On/Off button will function

as described in sections 3.1 – 3.4.

• The text “AUTO” will be shown on the LCD, reminding the

operator that Automode is active, and that the pump will take

control when system pressure rises to the HI PRESS value.

II. After the HI PRESS value is reached:

• Pump types 1, 2, 3 and 8: The pump motor will stop and the

electric valve will shift.

• Pump types 6 and 10: The pump motor will keep running and

the electric valve will shift.

• The LCD will continue to display “AUTO” and the LCD backlight

will remain turned on (will not fl ash on and off).

4.1 C. If Automode is OFF

(Pump types 1, 2, 3, 6, 8 and 10)

• The LCD will display “READY” in the text area.

• The LCD will indicate system pressure as a simple pressure

gauge, no additional actions will be performed regardless of

previously set HI PRESS and LO PRESS values.

4.1 D. Additional Information

• Pressing and releasing any button on the pendant (if equipped)

or shroud will stop the automatic cycle. Pressing the pendant

Down-Arrow (if applicable) will also retract the cylinder. Pressing

the motor On/Off button will also de-energize the motor if it is

running.

• To restart the automatic cycle, press and release the pendant

Up-Arrow button (if applicable) or the motor On/Off button (See

section 3.1– 3.4).

• Refer to sections 6.1 through 6.5 later in this document for

and detailed LCD operating instructions and descriptions of the

Automode LCD screens.

3

Page 4

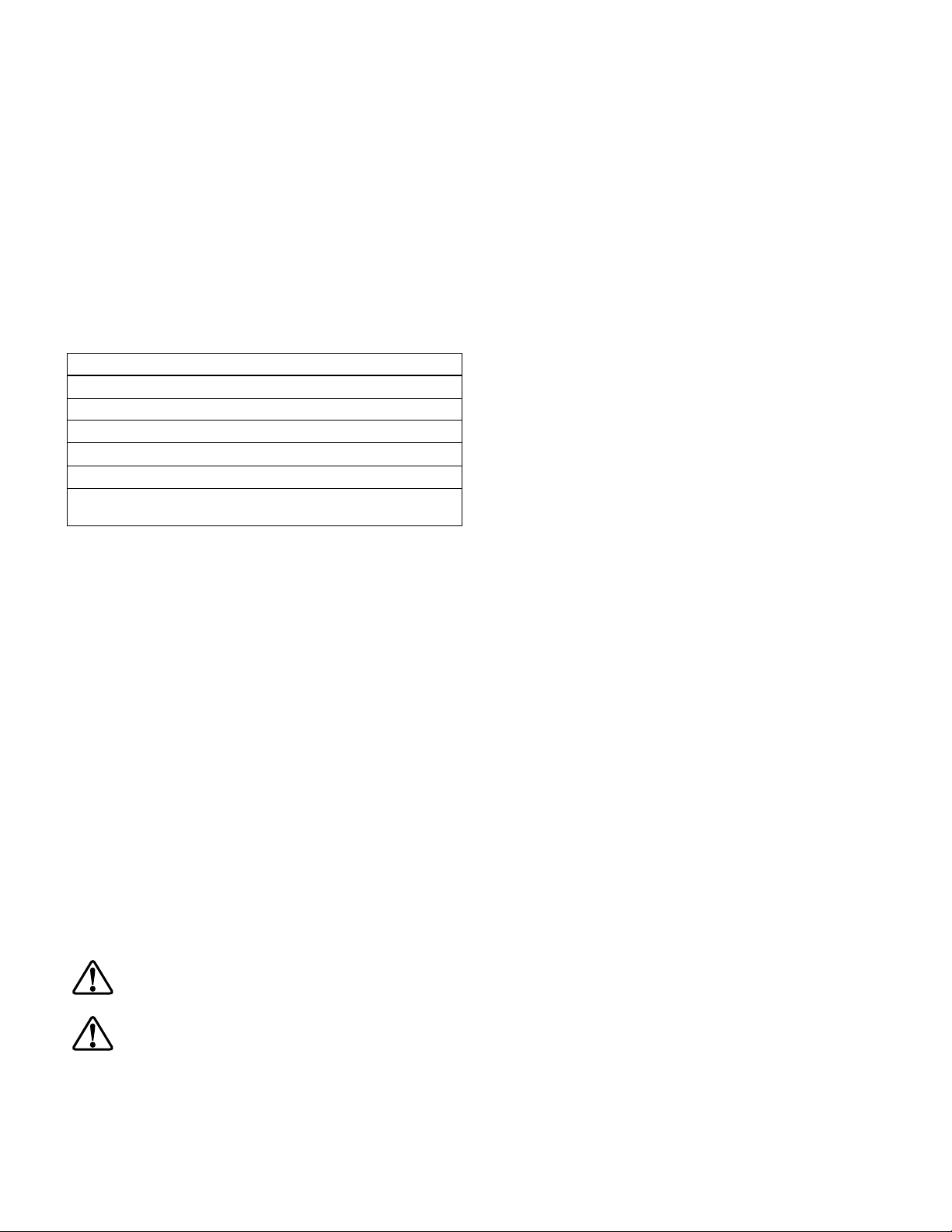

5.0 RELIEF VALVE ADJUSTMENT

Z-Class pumps are equipped with one user adjustable relief valve

(see Figure 5.)

IMPORTANT: To ensure proper pump operation:

• On pumps equipped with the optional pressure transducer, the

relief valve must be set at least 200 psi [13.7 bar] above the HI

PRESS value.

• On pumps equipped with the optional pressure switch (see

section 7.0), the relief valve must be set at least 200 psi [13.7 bar]

above the pressure switch setting.

To adjust the relief valve pressure setting:

1. Install a gauge on the pump.

2. If the pump is equipped with the optional pressure transducer,

verify AUTOMODE is off (See section 6.5C for additional

details).

3. Start the pump to allow the oil to warm.

4. Loosen the set screw locking nut.

5. Shift the control valve and build pressure in the system. Using

an Allen wrench, turn the set screw counter-clockwise to

decrease pressure and clockwise to increase pressure.

Note: To obtain an accurate setting, decrease the pressure

to a point below the fi nal setting and then slowly increase the

pressure until it reaches the fi nal setting.

6. Tighten the locking nut when the desired pressure is set.

7. Shift the control valve to the neutral position, allowing the

system pressure to return to 0 psi.

8. Recheck the fi nal pressure setting by shifting the control valve

and pressurizing the system.

Relief valve body

(DO NOT TURN)

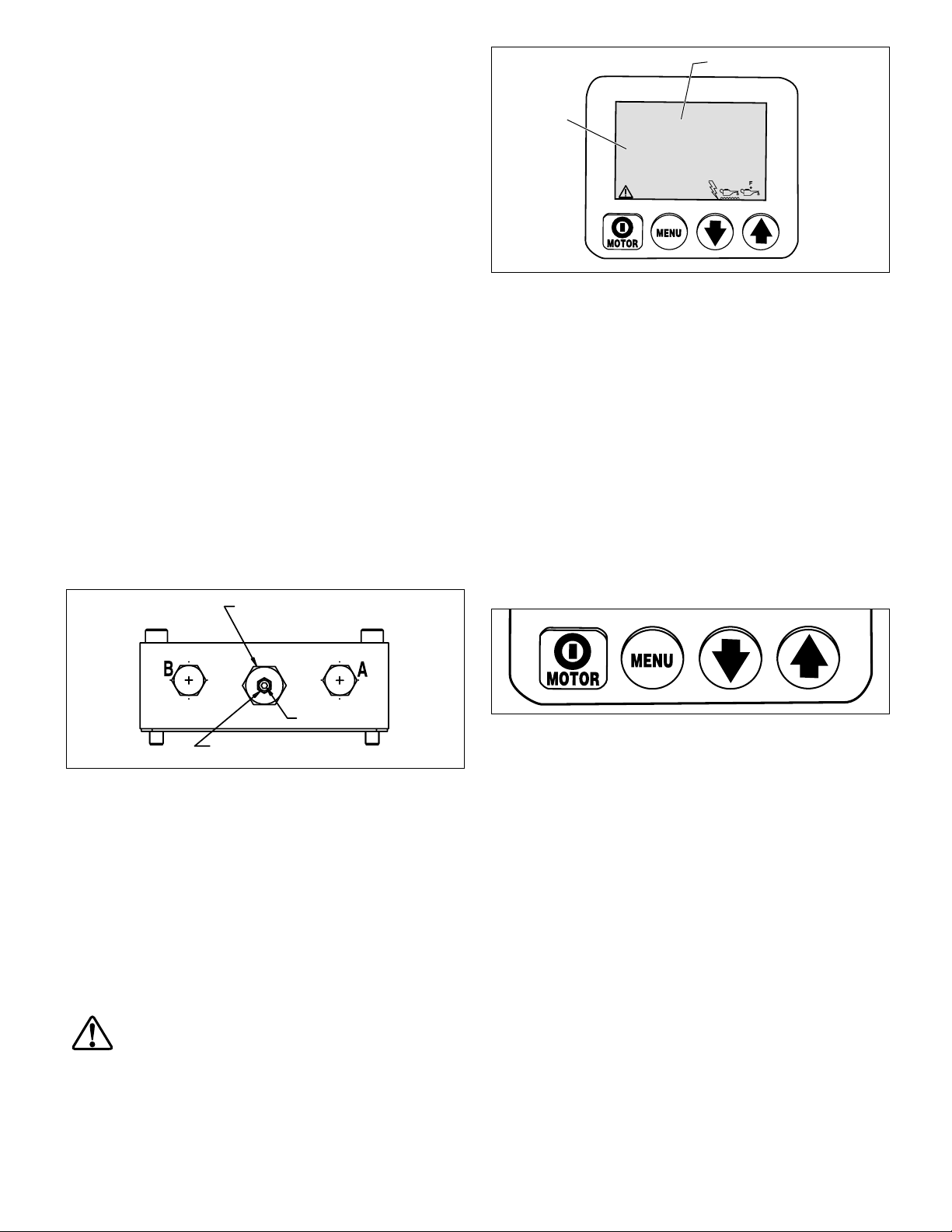

Text Display

Numeric

Display

6.2 Boot Sequence

When the pump is connected to electrical power, the LCD screen

will show: “FIRMWARE 7.x” for 1 second, then “Model XX” for

0.5 seconds. Following these messages, “Motor UN”, “Motor

1P” or “Motor 3P” will appear for 0.5 seconds. This information

may be useful if the pump ever requires servicing or repairs.

Additional information may appear, depending on pump model

and installed accessories.

The boot sequence is successfully completed when the text

display on the LCD screen shows “READY” (sequence takes

approximately 3 seconds). On pumps equipped with the pressure

transducer option, the current system pressure (typically “0” if

motor is not running) will also appear on the numeric display.

SET

00000000

0000.0

HOURS CYCLES

LOW MOTOR

VOLTAGE OVERLOAD

Figure 6, LCD Control Panel

PSI MPa

BAR

6.3 LCD Operation Buttons

The LCD control panel is equipped with four button switches:

Set Screw

Locknut

Figure 5, Relief Valve

6.0 LCD ELECTRONIC CONTROLS

6.1 LCD Control Panel Overview

The LCD control panel serves as an interface between the

operator and the pump. By using the LCD control panel's fourbutton switches, and the additional button switches located on

the pendant, all functions and settings described in sections 6.3

through 6.6 of this document can be activated.

In the event of an abnormal condition, the LCD also displays

fault codes and warning alerts as described in sections 6.7 and

6.8.

CAUTION: Make sure that the plastic overlay that

protects the LCD screen and the button switches is

not broken or otherwise damaged. Never punch the

button switches with a sharp or pointed instrument, use fi ngertips

only. Clean the overlay regularly with a damp cloth. Never use

aggressive or abrasive detergents.

On/Off / Menu / Down Arrow / Up Arrow

• Pressing the MOTOR on/off button shuts-off the motor during

normal operation. The motor OFF function is available on this

button even if the pump is being operated by the pendant.

However, the MOTOR on/off button will not turn the motor

ON except if the LCD is in Local mode (See section 6.5 K).

• Pressing the MENU button enables the operator to step from

normal operational mode into a series of menus. Repeated

pressing allows the operator to step through all available

menus. Pressing the Menu button also saves any changes

made. To return to the normal operational mode, press and

hold the Menu button for three seconds or do not push any

button for 60 seconds.

• The Down Arrow and Up Arrow buttons serve two purposes.

For most LCD menus, the Down Arrow and Up Arrow buttons

are used to step through the menu options. Also, when the

pump is placed in Local mode, pressing the Up Arrow button

switches the valve solenoid on and off (the pendant is nonoperational in Local mode).

4

Page 5

6.4 LCD Menu Overview

The LCD contains the following available menus:

• Normal Operation – Default start-up screen. Appears

immediately after power is connected and microcontroller

has booted.

Note: The Units, Automode, Hi Press and Lo Press menus are

available only on pumps equipped with a pressure transducer

(optional equipment)

• Units – Sets the pressure units to PSI / BAR / MPa. PSI is the

default setting.

• Automode – Switches the Automode function ON or OFF.

• Hi Press – (Available only when Automode is ON) Sets the high

pressure limit at which pump de-energizes motor / electric

valve.

• Lo Press – (Available only when Automode is ON - Not used

on pump type 3) Sets the low pressure limit at which pump

energizes motor / electric valve.

• Main – Displays pump status after the desired pump

operational parameters have been input by the user and

saved in the microcontroller memory.

• Motor – Displays the motor hour meter and on/off cycle

counter (non-resettable).

• Low Volt – Displays the low voltage hour meter

(non-resettable).

• Advance – Displays the solenoid hour meter and on/off cycle

counter for the advance solenoid (non-resettable).

• Retract – Displays the solenoid hour meter and on/off cycle-

counter for the retract solenoid (non-resettable).

• Local – Switches the pump Local mode ON or OFF.

• Language – Sets the language of the display to English,

Spanish, French, Italian, German or Portuguese, with English

being the default setting.

• Diagnose – Displays input signals from the pendant and other

electrical accessories.

6.5 LCD Menus

See the following paragraphs for descriptions of the LCD menus.

Also refer to Table 2, Quick Reference Chart (QRC), located at the

end of this document.

6.5 A Normal Operation Menu

(See Screen 1) LCD screen “READY”

indicates that the microcontroller has

booted successfully.

For pumps equipped with a pressure

transducer, the pressure reading will

be displayed as “0” when pump is

fi rst connected to power and motor is

off. Enter into the remaining menus by

pressing the Menu button. Refer to QRC step #1.

6.5 B “Units” Menu

(See Screen 2) This screen allows the

operator to set the unit of pressure

measurement by pressing the Up or

Down Arrow buttons. PSI, BAR and

Mpa are the available choices, with

PSI being the default. Save setting

and step forward by pressing the

Menu button. Refer to QRC step #2.

Screen 1

READY

PSI

0

Screen 2

SET

PSI MPa

UNITS

BAR

6.5 C “Automode” Menu

(See Screen 3) This screen allows the

operator to activate or de-activate

automatic operation of the pump

motor and electric valve (if equipped).

Toggle Automode ON or OFF by

pressing either the Up or Down Arrow

button. Save setting and step forward

by pressing the Menu button. Refer to QRC step #3A.

Notes:

• The UNITS and AUTOMODE menus are available only on

pumps equipped with the pressure transducer option. These

menus will not appear on pumps not equipped with a pressure

transducer.

• When Automode is on, the pump will de-energize the motor

/ electric valve when the hydraulic pressure reaches operator

defi ned levels. This parameter is set using the Automode “HI

PRESS” menu.

• The pump can be set to re-energize the motor / electric valve

when the hydraulic pressure falls to an operator defi ned level.

This parameter is set using the Automode “LO PRESS” menu.

Note: the LO PRESS menu is not functional for pump type 3.

• The specifi c operation of the motor and electric valve while

Automode is activated is determined by the pump type (factory

set). For additional information, refer to Table 4, Pump Model

Matrix, located at the end of this document. Also refer to sections

4.0 and 4.1 for an overview of Automode operation.

• If Automode is OFF: The HI PRESS and LO PRESS menus will

not be available, and any previously set HI or LO PRESS values

will have no effect on pump operation.

Screen 3

SET

AUTOMODE

ON

6.5 D “HI PRESS” Menu

(Available only when Automode is ON)

(See Screen 4) This screen allows the

operator to set the high-pressure limit

at which the pump de-energizes the

motor / electric valve. Make changes

in increments of 50 psi [3.5 bar] by

pressing either Down or Up Arrow

button once. Press and hold either

button to scroll quickly through the

available settings. Maximum pressure value is 10,500 psi [724

bar]. Save setting and step forward to the Main menu (See

section 6.5 F) by pressing the Menu button for 3 seconds. Refer

to QRC step #3B.

Note: If the menu button is pressed for less than 3 seconds, the

selected HI PRESS value will be saved and the LO PRESS menu

(See section 6.5 E) will appear.

CAUTION: Due to motor coast down, valve shift time

and system oil capacitance, always set the user-

adjustable relief valve 200 psi above the HI PRESS

value to prevent pressure spikes. Refer to pump instruction

sheet for relief valve setting instructions.

Screen 4

SET

HI PRESS

7500

PSI

5

Page 6

6.5 E “LO PRESS” Menu (Available only when

Automode is ON - All except pump type 3)

(See Screen 5) This screen allows

the operator to set the low-pressure

limit at which the pump energizes the

motor / electric valve. Make changes

in increments of 50 psi [3.5 bar] by

pressing either Down or Up Arrow

button once. Press and hold either

button to scroll quickly through the

available settings. Default pressure value is OFF (or “0” on some

pump models). Save setting and step forward to the Main menu

(See section 6.5 F) by pressing the Menu button for 3 seconds.

Refer to QRC step #3C.

Note: If the menu button is pressed for less than 3 seconds, the

selected LO PRESS setting will be saved. However, the Motor

menu (See section 6.5 G) will appear instead of the Main menu.

CAUTION: The LO PRESS value should be set at least

400 PSI below the HI PRESS value to prevent excessive

pump cycling. Use appropriate valving in the hydraulic

circuit to ensure that the pump does not cycle on and off more

than three times per minute. For circuits equipped with sequence

valves, the LO PRESS setting should be at least as high as the

fi rst stage sequence valve pressure.

6.5 F Main Menu

(See Screen 6A) When Automode is

fi rst turned on, the screen will display

“AUTO”.

(See Screen 6B) During pump

operation, and after Automode has

taken control of the pump, the text will

change from “AUTO” to “AUTO ON”.

All except pump type 3: If a LO

PRESS value has been entered, the

pump backlight will begin to fl ash on

and off. This fl ashing will continue

until system pressure drops to the LO

PRESS value.

Note: Details of Automode operation

will vary, depending on pump type and

model. Refer to sections 4.0 and 4.1

for additional information. Also refer to

the pump model matrix in Table 4 near

the end of this document.

(See Screen 6C) If Automode is OFF, the

screen will display “READY” instead of

“AUTO”, and the system pressure will

appear on the numeric display.

Note: For pumps NOT equipped with

a pressure transducer, the screen will

display “READY” and no pressure will

be indicated. The “AUTO” and “AUTO

ON” screens will not be available.

6.5 G “Motor” Menu

(See Screen 7) This screen allows the

operator to read the number of hours

or on/off cycles the motor has been

operated. Toggle between hours and

cycles by pushing either the Down

or Up Arrow button. Step forward by

pressing the Menu button. Refer to

QRC step #5.

Screen 5

SET

LO PRESS

OFF

Screen 6A

AUTO

0

Screen 6B

AUTO ON

0

Screen 6C

READY

0

Screen 7

MOTOR

4.8

HOURS CYCLES

PSI

PSI

PSI

__________________________________________________________

General note for all hour and cycle displays:

HOURS DISPLAYED

- up to 9999.9 the display will show decimal hours.

- between 10,000 - 99,999 whole hours will be

displayed (decimal “.” is not displayed).

- over 99,999 hours the meter starts over at 0.0 reading

decimal hours.

CYCLES DISPLAYED

- over 99,999 cycles the meter starts over at 0.

__________________________________________________________

6.5 H “Low Volt” Menu

(See Screen 8) This screen allows the

operator to read the number of hours

the pump has been operated in a lowvoltage condition. Step forward by

pressing the Menu button. Refer to

QRC step #6.

6.5 I “Advance” Menu

(See Screen 9) This screen allows the

operator to read the total number of

hours that the advance valve solenoid

has been operated. It also displays

the total number of advance solenoid

cycles. Toggle between hours and

cycles by pushing either the Down or

Up Arrow buttons. Step forward by

pressing the Menu button. Refer to

QRC step #7.

6.5 J “Retract” Menu

(See Screen 10) This screen allows

the operator to read the total number

of hours that the retract solenoid has

been operated. It also displays the

total number of retract solenoid cycles.

Toggle between hours and cycles by

pushing either the Down or Up Arrow

buttons. Step forward by pressing the

Menu button. Refer to QRC step #8.

6.5 K “Local” Menu

(See Screen 11) This screen allows the

operator to toggle the Local mode ON

or OFF (default is OFF). Local mode

allows operation of the pump if the

pendant or pendant cord is damaged.

With Local mode ON, the shroud

buttons replace the pendant buttons

as the method of operating the pump,

and the pendant buttons become deactivated. Toggle Local

mode ON or OFF by pressing the Down or Up Arrow button.

When Local mode is ON, the text “LOCAL” replaces “READY” on

the “Normal Operation” menu. Save setting and step forward by

pressing the Menu button. Refer to QRC step #9.

6

Screen 8

LOW VOLT

.0

HOURS

Screen 9

ADVANCE

188

HOURS CYCLES

Screen 10

RETRACT

334

HOURS CYCLES

Screen 11

SET

LOCAL

OFF

Page 7

6.5 L “Language” Menu

(See Screen 12) This screen allows

the operator to change the LCD display

language. When a language is shown on

the LCD, press the Down or Up Arrow

buttons to select a different language. Save

setting and step forward by pressing the

Menu button. Refer to QRC step #10.

6.5 M “Diagnose” Menu

(See Screen 13) This screen allows

the operator to troubleshoot various

pendant problems. If the number “1”

does not appear when a pendant button

is pushed, problems with the pendant

button switches and/or pendant cord

may be present (See Screens 14, 15 and

16). Use Local mode to operate pump

until problem can be corrected. Refer to

QRC step #11.

Pendant on/off button

Pendant advance button

Pendant retract button

(not used)

(not used)

Diagnose screen

with pendant

on/off button

pushed.

Press

Screen 12

SET

ENGLISH

Screen 13

DIAGNOSE

PSI MPa

PSI MPa

BAR Nm

Ft-lb

BAR Nm

Ft-lb

00001

Screen 14

DIAGNOSE

01001

6.6 LCD Hidden Menus

6.6 A “Calibration” Menu

(See Screen 17) This screen allows the

operator to adjust the pressure value

shown on the LCD to match a master

gauge.

To access this menu, go to the “UNITS”

menu.

Then, press and hold the shroud

Motor on/off button in for 7 seconds. ENTRY CODE will appear.

Then, press and hold both the Down Arrow and Up Arrow button

for 7 seconds. See Table 3, “Z-Class Pressure Transducer

Calibration” for adjustment steps.

Screen 17

SET

CAL PT A

0

PSI

6.7 LCD Fault Conditions

Any fault condition will shut down the pump and prevent it from

starting.

6.7 A Clearing a Fault Condition from the LCD

After the fault causing problem has been corrected, clear the fault

message from the LCD by disconnecting electrical power from

the pump. Wait until all characters clear the LCD (~ 10 seconds),

then reconnect power.

6.7 B Power Failure

Display: “POWER OFF”

(See Screen 18) The Power Off fault is

displayed when the main power supply

drops to 65% or less of nominal voltage.

The pump will automatically shut-off

the valve solenoid and the motor, and

display “Power Off” on the LCD. Note:

Power Off is also displayed for several

seconds after the unit is disconnected

from electrical power.

Screen 18

POWER

OFF

Diagnose screen

with pendant

advance button

.

pushed

Diagnose screen

with pendant

retract button

.

pushed

Press

Press

Screen 15

DIAGNOSE

10001

Screen 16

DIAGNOSE

00101

PSI MPa

BAR Nm

Ft-lb

PSI MPa

BAR Nm

Ft-lb

6.7 C Button Fault

Display: “BUTTON FAULT”

(See Screen 19) The Button Fault

message is displayed when the

microcontroller detects that any button

is pressed during the boot sequence

or if the shroud Motor on/off button is

pressed for more than 3 seconds.

Screen 19

BUTTON

FAULT

6.7 D Motor Overload

Display: “MTR OVLD” and

“Motor Overload”

(See Screen 20) The Motor Overload

fault is displayed when the electric

current draw exceeds the pre-set limit

of the pump’s internal circuit breaker.

The circuit breaker will automatically

reset in about 2 to 3 minutes after the

condition has been corrected. However,

before the pump can be restarted, the

operator must clear the fault by disconnecting and reconnecting

electrical power as described in section 5.7 A.

Screen 20

MTR OVLD

MOTOR

OVERLOAD

7

Page 8

6.7 E Oil Level

(requires optional fl oat / temperature switch)

Display: “OIL LEVEL”

(See Screen 21) The Oil Level fault is

displayed when the oil level inside the

reservoir drops below 1.3" (34 mm)

from bottom.

Screen 21

OIL LEVEL

6.8 LCD Warning Conditions

LCD Warnings notify the operator of abnormal operating

conditions, but allow the pump to continue operating. Warnings

will automatically clear once the abnormal condition has been

resolved.

6.8 A Low Voltage Warning

Display: “LOW VOLT” and “Low Voltage”

6.7 F Oil Temperature

(requires optional fl oat/temperature switch)

Display: “OIL TEMP”

(See Screen 22) The Oil Temperature

fault is displayed when the temperature

of the oil inside the reservoir exceeds

175 ºF [80 °C].

Screen 22

OIL TEMP

6.7 G Oil Pressure

(requires optional pressure switch)

Display: “P SWITCH OPEN”

(Screen 23) The “P SWITCH OPEN”

fault is displayed when the high pressure

limit is reached and the pressure switch

opens.

Screen 23

P SWITCH

OPEN

(See Screen 23) A “Low Voltage”

condition is defi ned as an operating

condition when the main power supply

is at or below 80% of nominal voltage.

While running the pump under this

condition, the “Low Voltage” signal will

fl ash on the LCD and the Low Voltage

hours will be counted and stored by the

microcontroller. Normal pump operation

is still permitted.

IMPORTANT: Pump operation during a Low Voltage condition

is not recommended. Motor RPM and hydraulic fl ow will be

reduced. The pump's internal circuit breaker may trip due to high

current draw, resulting in a Motor Overload fault (see section

6.7 D).

Screen 24

LOW VOLT

LOW

VOLTAGE

Pressure Switch Notes:

• The pressure switch does not provide real time pressure data

to the LCD. For this reason, no pressure indication will be shown

on the “READY” screen unless a pressure transducer is also

installed.

• Factory installed pressure switches are typically installed in the

valve manifold “GA” port. However, if desired, the pressure switch

can be installed in the valve manifold “GB” or “GP” ports.

“GA” measures “A” port pressure.

“GB” measures “B” port pressure (if applicable).

“GP” measures pump pressure before the control valve.

8

Page 9

(Continued on next page)

Units Comments

digital display

Start calibration process.

PSI, BAR or MPa. Default is PSI.

Firmware version 7.x, pump type (1, 2, 3, 6, 8 or 10)

and motor type (UN, IP or 3P) will briefl y appear on LCD.

or MPa

Save previous setting and step forward to select units,

“READY” appears after power on and boot sequence has completed.

PSI, BAR or MPa. Default is PSI.

Toggle between “ON” and “OFF” using the Arrow buttons.

See Table 2, calibration reference chart for further instructions.

or MPa

Note: To step to #5 Motor screen, turn Automode OFF

If Automode is ON.

and press Menu button.

default value is 10,500 psi [724 bar].

Set maximum pressure (upper Automode limit),

Note: Pressure not adjustable when Automode is OFF.

or MPa

PSI, BAR

If Automode is ON.

default value is OFF.

hold down button for 4 sec. minimum.

hold down button for 4 sec. minimum.

Set minimum pressure (lower Automode limit),

" Only if pressure transducer is detected,

" Only if pressure transducer is detected,

or MPa

PSI, BAR

hold down button for 4 sec. minimum.

Note: Pressure not adjustable when Automode is OFF.

" Only if pressure transducer is detected,

hold down button for 4 sec. minimum.

" Only if pressure transducer is detected,

Expected reading / symbol / status

Display

Table 2, QRC: Quick Reference Chart • Pump Firmware Version 7.x • Pump Types 1, 2, 3, 6, 8 and 10

Step Switch Text

1 READY 0 PSI, BAR,

2A X SET UNITS PSI

X" BAR

X" MPa

X Save and step to #3 by pressing Menu button.

CAL PT A 0 PSI, BAR,

X X " Hold for 7 Seconds

2B X SET UNITS Hold for 7 Seconds Save previous setting and step forward to select units,

XXXXX (PSI, BAR or MPa)

Then up 50 psi [4 bar] every 0.05 sec.

Then down 50 psi [4 bar] every 0.05 sec.

HI PRESS

X " Up 50 psi [4 bar] per 0.5 sec. for fi rst 3 sec.

XON

X Save and step to #3B by pressing Menu button.

3A X AUTOMODE OFF

9

3B SET

X " Down 50 psi [4 bar] per 0.5 sec. for fi rst 3 sec.

X Save and step to #3C by pressing Menu button.

3C SET

XXXXX (PSI, BAR or MPa)

Then up 50 psi [4 bar] every 0.05 sec.

Then down 50 psi [4 bar] every 0.05 sec.

LO PRESS

X " Up 50 psi [4 bar] per 0.5 sec. for fi rst 3 sec.

X " Down 50 psi [4 bar] per 0.5 sec. for fi rst 3 sec.

X Save and step to #5 by pressing Menu button.

Page 10

Text Display:

Units Comments

digital display

“AUTO” if Automode ON

“READY” if Automode OFF

Select hour meter function (motor).

Select cycle counter function (motor).

Numeric display will show “0” when system pressure is zero.

or MPa

PSI, BAR

0 PSI

0 BAR

0 MPa

Select “LOCAL” mode.

Toggle between “ON” and “OFF”.

Pressure or torque units will appear,

indicating that pressure transducer is connected.

When pendant buttons are pushed, the digital display

is expected to show processor inputs that are “turned on”.

MPa,

10001 With pendant On/Off button pushed.

01001 With pendant ADVANCE button pushed.

00101 With pendant RETRACT button pushed.

Expected reading / symbol / status

Display

Table 2, QRC: Quick Reference Chart • Pump Firmware Version 7.x • Pump Types 1, 2, 3, 6, 8 and 10

(Continued from previous page)

Step Switch Text

or

4 AUTO

READY

X " Number of cycles. CYCLES Select cycle counter function (solenoid advance).

X " Number of cycles. CYCLES Select cycle counter function (solenoid retract).

X" ON

X " Number of cycles. CYCLES

6 X LOW VOLT Number of hours at low voltage, displayed as 0.0. HOURS Select hour meter function (low voltage condition).

7 X ADVANCE Number of hours, displayed as 0.0. HOURS Select hour meter function (solenoid advance).

5 X MOTOR Number of hours 0.0. HOURS

8 X RETRACT Number of hours, displayed as 0.0. HOURS Select hour meter function (solenoid retract).

X " OFF

9 X LOCAL OFF

X ESPANOL

X FRANCAIS

X ITALIANO

X DEUTSCH

X PORTUGUES

X ENGLISH Save and step to #11 with Menu button.

10 X ENGLISH Select language, default is English.

10

11 X DIAGNOSE 00001 PSI, BAR, or

12 X - - - Hold for 3 seconds to return to step 4.

Page 11

Comments

LCD Reading

Boot sequence.

psi is the current unit of pressure measurement.

0 psi

psi

FIRMWARE 7.x,

then “READY”

UNITS

Table 3 , Z-Class Pressure Transducer Calibration, Firmware 7.x • Pump Types 1, 2, 3, 6, 8 and 10

Step into the hidden calibration mode.

Start of calibration process. The advance-solenoid will be powered up to access the pressure transducer

CODE

O psi

ENTRY

CAL PT A

through valve-port A.

[O bar]

Calibrate the zero-offset, point “A”.

O psi

[O bar]noyes

CAL PT A

SAVE A

Confi rm the pressure data should be stored to memory.

SAVE A

Calibrating gain is done with two points, starting with point “B”.

5000 psi

[345 bar]

CAL PT B

First obtain the pressure value on the master gauge (ie 5000 psi). Then use the arrow buttons to match the

LCD value to the master gauge.

5000 psi

[345 bar]noyes

CAL PT B

SAVE B

Confi rm the pressure data should be stored to memory.

SAVE B

Calibrating gain is done with two points, fi nishing with point “C”.

8000 psi

[548 bar]

CAL PT C

First obtain the pressure value on the master gauge (ie 8000 psi). Then use the arrow buttons to match the

LCD value to the master gauge.

8000 psi

[548 bar]noyes

CAL PT C

SAVE C

Confi rm the pressure data should be stored to memory.

SAVE C

Re-confi rm calibration data. Leave “off” to proceed with new calibration data. Only set to “on” to change

off

USE DFLT

calibration data back to factory default settings. Press Arrow button to change.

Save calibration data to permanent memory.

Calibration complete, motor stops and electric valve releases pressure.

O psi

[O bar]

O psi

CAL PT A

READY

[O bar]

Operator action

No.

Connect a master gauge to port A (Advance port)

1

Connect electrical power to pump.

At main screen, press the Menu button once to display “UNITS” screen.

2

3

Press and hold the ON/OFF button for seven seconds.

Press and hold the Arrow-up and Arrow-down buttons together for seven seconds.

Open the pump’s user-adjustable relief valve and verify both pump LCD and master

gauge read zero.

Press the Menu button to accept the pressure value into temporary memory.

Press one Arrow button to change from “no” to “yes”.

Press the Menu button once.

Press and release the shroud’s ON/OFF motor-button to switch the pump motor on.

Reading the master gauge, apply a pressure of 5000 psi by closing the pump’s user-

4

5

6

7

8

9

10

adjustable relief valve.

Press the Menu button to accept the pressure value into temporary memory.

Press one Arrow button to change from “no” to “yes”.

11

12

11

Press the Menu button once.

Reading the master gauge, apply a pressure of 8000 psi.

Press the Menu button to accept the pressure value into temporary memory.

Press one Arrow button to change from “no” to “yes”.

13

14

15

16

Press the Menu button once.

Press the Menu button once.

Press and hold the Menu button for three seconds to step out of the calibration mode.

17

18

19

Page 12

Additional comments

3 button pendant used but only Up and Down

Arrow buttons are active

up-arrow now on the middle button-position,

using pin #2 of pendant

Pump type 6 is the default factory setting. 0

means LO_PRES is turned off. Default

manufacturer setting is AUTO MODE off &

LO_PRESS is 0

safety feature: Arrow-up and arrow-down

buttons switch off motor when pump is running

on toggle-on

(Continued on next page)

turned off.

On/Off

value. 0 means LO_PRESS is

50 psi less than HI_PRESS current

on

10,500 psi

off

on/off

toggle

na -

no pendant

50 psi less than HI_PRESS current

on

10,500 psi

off

off

(advance)

momentary on

Max value for LO_PRESS

value is reached

Action when LO_PRESS

Operation with Automode ON

Max value

for HI_PRESS

Pumps Equipped with Pressure Transducer Option Only

Action when HI_PRESS

value is reached

LCD Panel

Button

Motor

Arrow up

na - can not change

LO_PRESS value from off

off

off

(advance)

momentary on

na

na

10,500 psi

only the valve shuts off,

when HI_PRESS is reached

on/off

toggle

no change

50 psi less than HI_PRESS current

on

off

motor continues running

off

momentary on

turned off.

value. 0 means LO_PRESS is

na

off

off

na - disabled

value from off

na - can not change LO_PRESS

na - can not change

LO_PRESS value from off

10,500 psi

off

off

(advance)

momentary on

turned off

value. 0 means LO_PRESS is

(advance)

na

turned off.

value. 0 means LO_PRESS is

50 psi less than HI_PRESS current

off

on

10,500 psi

off

off

off

off

toggle

on/off

momentary on

Pendant Button

What happens when _____ button is pushed in

normal operation mode (“READY” is displayed on LCD)

Table 4, Z-Class Pump Model Matrix • Firmware 7.x • Pump Types 1, 2, 3, 6, 8 and 10

down

Arrow

Motor

On/Off

Item

foot

switch

pendant

valve

code

Pump type

type

Pump

Type

Pump

na -

no pendant

no

na -

(if attached)

Motor & Fan

NA

none

any manual

ZxxxxxLx

ZxxxxxHx

w/LCD

manual

1

pendant

na - disabled

na -

disabled

(if attached)

Motor & Fan

Option

3-button

VE32

Zxx2xxSx

Adv /

Hold /

2

Ret

momentary

na -

Solenoid B

on (retract)

na - disabled

na -

disabled

Motor & Fan

Option

1-button

VE32-D

Zxx1xxDx

Dump

3

disabled

(if attached)

12

na - disabled

na -

disabled

Solenoid A

no change

on/off

toggle

(if attached)

Motor & Fan

Option

3-button

VE33 / VE43

Zxx3xxSx

Zxx4xxSx

remote

3/4-way

6

off

no

change

Solenoid A

none

none

ZxxxxxWx

momentary

no

Solenoid B

on (retract)

change

on

momentary

on/off

toggle

(if attached)

Motor & Fan

Option

button

1or2-

any manual

8 Jog ZxxxxxKx

Page 13

Additional comments

Similar to pump No. 6 execpt that LOCAL MODE

is the default at start-up. Pendant buttons are

disabled.

(See Note 2)

na

Max value for LO_PRESS

na

value is reached

Action when LO_PRESS

Operation with Automode ON

Max value

for HI_PRESS

Pumps Equipped with Pressure Transducer Option Only

reached

(SET_PRESS) value is

Action when HI_PRESS

Button

LCD Panel

Motor

Arrow up

On/Off

10,500 psi

when HI_PRESS is reached

toggle

no change

only the valve shuts off,

on/off

motor continues running

50 psi less than HI_PRESS current

on

off

off

(see note 1)

momentary on

turned off

value. 0 means LO_PRESS is

(advance)

na

off

off

off

off

be on or off

Note: Motor may

Notes - Pump Type 10:

1. if Automode is OFF, motor is momentary on (no toggle).

2. If Automode is OFF, solenoids can be operated manually when motor is off or on.

What happens when _____ button is pushed in

normal operation mode (“READY” is displayed on LCD)

Table 3, Z-Class Pump Model Matrix • Firmware 7.x • Pump Types 1, 2, 3, 6, 8 and 10

Table 4, Z-Class Pump Model Matrix • Firmware 7.x • Pump Types 1, 2, 3, 6, 8 and 10

(Continued from previous page)

Pendant Button

down

Arrow

Motor

On/Off

Item

foot

switch

pendant

valve

code

Pump type

type

Pump

Type.

Pump

no change

On

(no toggle)

Momentary

(if attached)

Motor & Fan

Option

3-button

VE33 / VE43

ZxxxxxWx

Manual

Momen-

tary

10

Pump

off

no

Solenoid A

none

none

change

13

momentary

no

Solenoid B

(retract)

on

change

may be

on or off

Note: Motor

Page 14

Enerpac Worldwide Locations

Africa

ENERPAC Middle East FZE

Office 423, JAFZA 15

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Australia, New Zealand

Actuant Australia Ltd.

Block V Unit 3

Regents Park Estate

391 Park Road

Regents Park NSW 2143

(P.O. Box 261) Australia

Tel: +61 297 438 988

Fax: +61 297 438 648

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

Tel: +55 11 5687 2211

Fax: +55 11 5686 5583

Toll Free in Brazil:

Tel: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

Tel: +1 905 564 5749

Fax: +1 905 564 0305

Toll Free:

Tel: +1 800 268 4987

Fax: +1 800 461 2456

Technical Inquiries:

techservices@enerpac.com

China

Actuant Industries Co. Ltd.

No. 6 Nanjing Road

Taicang Economic Dep Zone

Jiangsu, China

Tel: +86 0512 5328 7529

+86 0512 5328 7500 7529

Fax: +86 0512 5335 9690

Actuant China Ltd. (Beijing)

709B Diyang Building

Xin No. 2

Dong San Huan North Rd.

Beijing City

100028 China

Tel: +86 10 845 36166

Fax: +86 10 845 36220

e-mail: info@enerpac.com

&

Central and Eastern Europe, Greece

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse13

D-40549 Düsseldorf

Germany

Tel: +49 211 471 490

Fax: +49 211 471 49 28

France, Switzerland francophone

ACTUANT - ENERPAC

France S.A., ZA de Courtaboeuf

32, avenue de la Baltique

91140 Villebon / Yvettte

France

Tel: +33 1 60 13 68 68

Fax: +33 1 69 20 37 50

Germany, Austria

and Switzerland and Baltic States

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse13

D-40549 Düsseldorf

Germany

Tel: +49 211 471 490

Fax: +49 211 471 49 28

India

ENERPAC Hydraulics

(India) Pvt. Ltd.

No. 1A,

Peenya Industrial Area,

llnd Phase

Bangalore, 560 058 India

Tel: +91 80 40 792 777

Fax: +91 80 40 792 792

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

Tel: +39 02 4861 111

Fax: +39 02 4860 1288

Japan

Applied Power Japan LTD KK

Besshochou 85-7

Kita-ku,

Saitama-shi 331-0821

Japan

Tel: +81 48 662 4911

Fax: +81 48 662 4955

Middle East, Turkey and

Caspian Sea

ENERPAC Middle East FZE

Office 423, JAFZA 15

P.O. Box 18004

Jebel Ali, Dubai

United Arab Emirates

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Russia and CIS

(excl. Caspian Sea Countries)

Actuant LLC

Admiral Makarov Street 8

125212 Moscow, Russia

Tel: +7-495-9809091

Fax: +7-495-9809092

Sweden, Denmark, Norway,

Finland and Iceland

ENERPAC Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg

Sweden

Tel: +46 31 7990281

Fax: +46 31 7990010

Singapore

Actuant Asia Pte. Ltd.

37C, Benoi Road Pioneer Lot,

Singapore 627796

Tel: +65 68 63 0611

Fax: +65 64 84 5669

Toll Free: +1800 363 7722

Technical Inquiries:

techsupport@enerpac.com.sg

South Korea

Actuant Korea Ltd.

3Ba 717,

Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi, Kyunggi-Do

Republic of Korea 429-450

Tel: +82 31 434 4506

Fax: +82 31 434 4507

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 DAGANZO DE ARRIBA (Madrid)

Spain

Tel: +34 91 661 11 25

Fax: +34 91 661 47 89

&

internet: www.enerpac.com

The Netherlands, Belgium,

Luxembourg

ENERPAC B.V.

Galvanistraat 115, 6716 AE Ede

P.O. Box 8097, 6710 AB Ede

The Netherlands

Tel: +31 318 535 800

Fax: +31 318 525 613

+31 318 535 848

Technical Inquiries Europe:

techsupport.europe@enerpac.com

United Kingdom, Ireland

Enerpac Ltd

Bentley Road South

Darlaston, West Midlands

WS10 8LQ, United Kingdom

Tel: +44 (0)121 50 50 787

Fax: +44 (0)121 50 50 799

USA, Latin America

and Caribbean

ENERPAC

P.O. Box 3241

6100 N. Baker Road

Milwaukee, WI 53209 USA

Tel: +1 262 781 6600

Fax: +1 262 783 9562

User inquiries:

+1 800 433 2766

Inquiries/orders:

+1 800 558 0530

Technical Inquiries:

techservices@enerpac.com

ENERPAC

704 W. Simonds

Dallas, TX 75159 USA

Tel: +1 972 287 2390

Fax: +1 972 287 4469

All Enerpac products are guaranteed against defects in workmanship and materials for as long as you own them.

For your nearest authorized Enerpac Service Center, visit us at www.enerpac.com

062609

Loading...

Loading...