Page 1

1

YPA3174D

Instruction Manual

Page 2

Hydraulic Technology Worldwide

AIR DRIVEN HYDRAULIC PUMPS

YPA3174D 1500bar

INSTRUCTION MANUAL

3

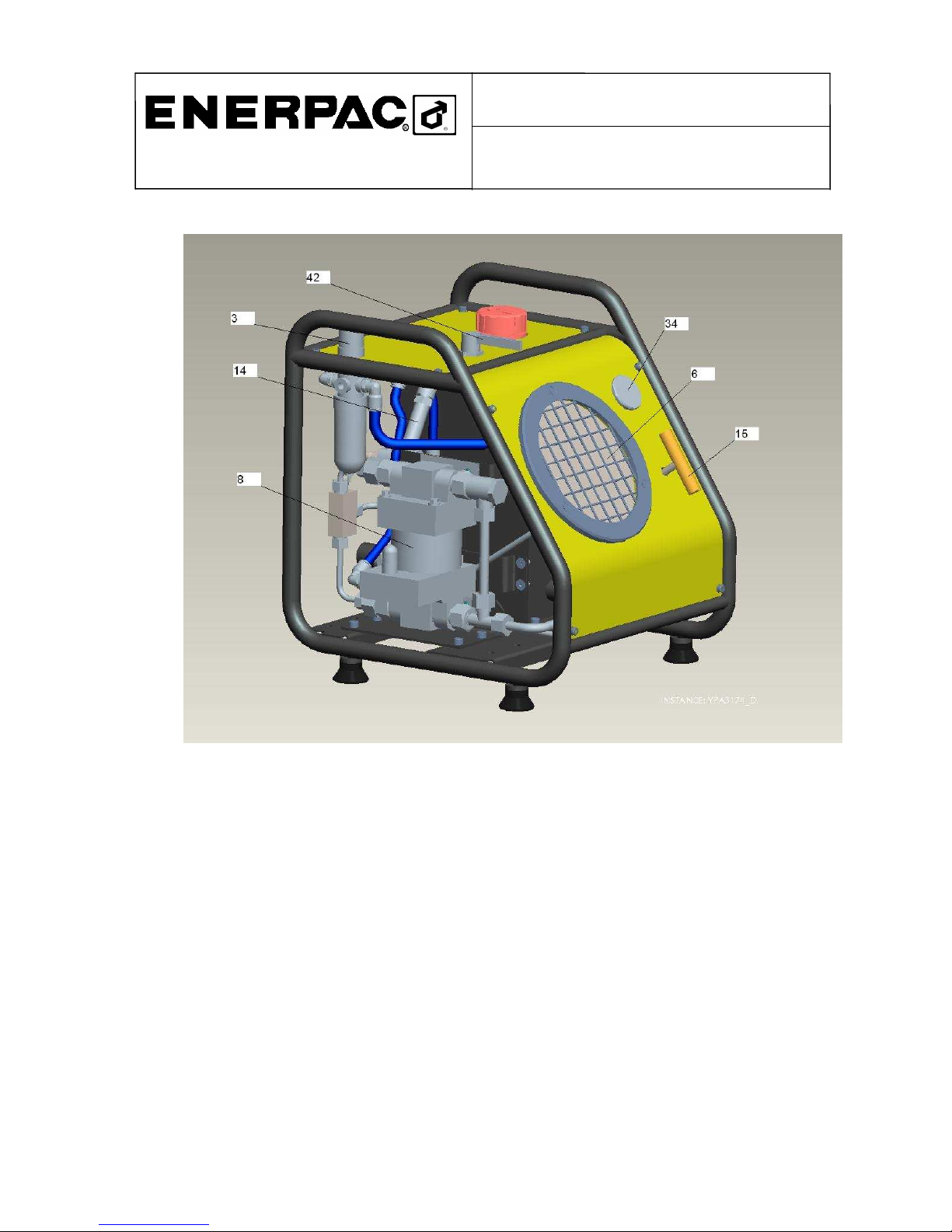

Figure 1

Parts list:

3 AIR PRESSURE FILTER REGULATOR UNIT

6 GLYCERINE FILLED GAUGE D160 mm SCALE 0-2000 bar

8 MAXIMATOR PUMP UNIT M-189D

11 OUTPUT OIL PORT

14 SAFETY VALVE

15 SHUT OFF VALVE

21 OIL RESERVOIR CAPACITY 10 L

25 INPUT AIR PORT 1/2 BSP

34 AIR GAUGE

42 AIR BALL VALVE

Page 3

Hydraulic Technology Worldwide

AIR DRIVEN HYDRAULIC PUMPS

YPA3174D 1500bar

INSTRUCTION MANUAL

4

Figure 2

Page 4

Hydraulic Technology Worldwide

AIR DRIVEN HYDRAULIC PUMPS

YPA3174D 1500bar

INSTRUCTION MANUAL

5

1.0 SAFETY FIRST !!!

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during

system operation. Enerpac cannot be

responsible for damage or injury resulting from

unsafe product use, lack of maintenance or

incorrect product and/or system operation.

Contact Enerpac when in doubt as to the safety

precautions and operations.

IMPORTANT: Before using the product

it’s important for the operator to read the

instructions and to understand the precautions,

the warnings, and to apply the local codes of

security.

2.0

DESCRIPTION OF THE PRODUCT :

The “ENERPAC” air driven hydraulic pumps

model YPA3174D , are manual pumps realised for

single acting tensioners, the components are

described in fig. 1 and 2, while the characteristics of

the pump M189D are indicated in the graph page 7.

In fig.2 we find the air input for alimentation of the

pump (pos.25), made of a fitting with ½ BSP thread

to be equipped with an air fitting, not include,

compatible with the equipment where the pump will

be used. The oil output(pos. 11) is a female rapid

coupler

.

3.0 INSTALLATION

3.1 GENERAL: The Enerpac pumps are supplied

ready to use, complete with hydraulic oil. The

safety valve is preset as the relief valves.

These values can be changed only by qualified

personal.

3.2 PRELIMINARY OPERATIONS:

1

Position the pump near the work area, assure

that the hoses and the pendant can reach easily

the wrench.

2 Check that the alimentation of the

compressed air is able to give a

minimum of 300 Nl/min at 6.5 bar

3

Check the pressure setting as described at point

3.3

4 Check that the couplers are well connected..

ATTENTION: Always mount the protection

caps on the couplers when not used. Do not

pressurise flexible hoses without connecting the

couplers.

3.3 REGULATION PRESSURE:

Verify what is the working pressure needed for

the tensioning

Connect the alimentation hose to the fitting for

air alimentation pos. 25

Connect the flexible oil hose at the output of the

pump (pos. 11) leaving the other hose end with

the coupler free(the hose must be able to be

pressurized)

ATTENTION: avoid that the hose free end,

during the pressure regulation is pointing towards

persons or animals; an eventual break of the coupler

could eject metal parts which could be harmful.

Lift and turn counterclockwise the air tap on the air

regulator(pos.3) until it is completely open

Shut the the relief valve(pos. 15) turning clockwise.

Open the air valve(pos. 42).

Turn clockwise the air tap (pos.3) slowly until you

reach the working pressure of the oil(see the

performance graph pag.7) shown on the gauge of

the front panel(pos. 6), while trough the air valve it

is possible to the air pressure

When the working pressure is reached close the air

valve(pos. 42)

Lock the air tap, lowering it(pos.3) and open the

relief valve(pos. 15) turning counterclockwise to set

the pressure of the circuit to zero

Page 5

Hydraulic Technology Worldwide

AIR DRIVEN HYDRAULIC PUMPS

YPA3174D 1500bar

INSTRUCTION MANUAL

6

ATTENTION:

Please consult the

tensioner manual.for the correct use.

Note:

do not change the settings of the safety valve

4.0

OPERATIONS :

4-1

TENSIONING :

Verify that the hose has no air in it, if not, go

to procedure 6

Verify that the coupler is clean

Attach the hose at the oil output of the

pump(pos.11) and to the tensioner which we

suppose correctly positioned and ready for the

tensioning.

Verify that the coupler is correctly attached

Start the tensioning operation:

•

Close the relief valve (pos.15)

•

Open the air valve(pos. 42)

•

Wait until the final pressure is

reached, looking at the gauge(pos.6)

•

Tighten the bolts with the correct

tensioning procedure.

4.2 LOOSENING:

• Close the air valve(pos.42)

• Open the relief valve(pos.15)

Before disconnecting the hose

5-0

STORAGE

Disconnect hoses both from the pump and from the

tensioner

Clean the pump with a soft rag.

Protect the couplers with the dust caps.

Roll up the hose and put them away in a place not

near to heat sources.

Check that the tensioner does not leak oil, place it

in a dry place and not near to heat sources

Respecting this procedure is essential to operate

in security and prevents malfunctions.

6-0 PROCEDURE FOR AIR BLEEDING

HOSES

•

Find a compatible coupler like the on

on the hose

•

Mount the coupler on one end of the

hose

•

Mount the hose on the output port of

the pump(pos.11)

•

Close the relief valve(pos.15)

•

Open the air valve(pos.42)

•

Wait to see the oil leaking from the

free end of the hose

•

Close the air valve and dismount the

hose

Page 6

YPA3174D - PERFORMANCE GRAPH

0

500

1000

1500

2000

2500

0,00

0,04

0,08

0,12

0,16

0,20

0,24

0,28

0,32

0,36

0,40

0,44

Oil Flow (l/min)

Pressure (bar)

0

100

200

300

400

500

600

700

Air Consumption (l

N

/min)

Air Pressure at 4 bar Air Pressure at 6 bar

Air Pressure at 8 bar Air Consumption at 4 bar

Air Consumption at 6 bar Air Consumption at 8 bar

8 bar

6 bar

8 bar

4 bar

6 bar

4 bar

Page 7

Page 8

Loading...

Loading...