Page 1

POWERFUL SOLUTIONS. GLOBAL FORCE.

L3085 Rev. C 12/12

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-20

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Hollands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Português . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Suomalainen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Norsk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Svensk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

日本語 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

2.0 SAFETY ISSUES

Read all instructions, warnings and precautions

carefully. Follow any recommended safety

precautions to avoid personal injury or damage to

the jack. Enerpac cannot be responsible for any damage or injury

from unsafe use, lack of maintenance or incorrect operation. Do

not remove warning labels, tags, or decals. In the event any

questions or concerns arise, contact ENERPAC or a local Enerpac

distributor for clarifi cation.

The maximum working pressure of the jack hydraulic system

varies between 6,000 and 10,200 psi [414 and 703 bar],

depending on jack model. Refer to pressure listings in Table 1,

General Specifi cations.

If you have never been trained on high-pressure hydraulic safety,

consult your distributor or service center for a free Enerpac

Hydraulic Safety Course.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

Failure to comply with the following safety precautions could

result in equipment damage and/or personal injury:

Instruction Sheet

Pow’r-Riser

®

Lifting Jacks

PR Series Air Operated Models

DANGER: To avoid serious personal injury, keep

hands and feet away from hydraulic cylinder and

related components during jack operation.

DANGER: Do not handle pressurized lines. Escaping oil

under pressure can penetrate the skin, causing serious

injury. If oil is injected under the skin, see a doctor

immediately.

WARNING: The jack's internal relief valve must not be

repaired or adjusted except by an authorized service

center. Never tamper with overload protection devices.

Higher settings may result in equipment damage and/or personal

injury.

CAUTION: When jack is not in use, fully retract the

cylinder and protect the entire unit from external damage.

Keep the jack clean, avoid weld splatter, and store in a

clean dry area. INSPECT ALL JACK COMPONENTS BEFORE USE.

CAUTION: Keep the jack away from fl ames and

heat. For optimum performance, do not expose the

jack to temperatures above 65 °C [150 °F].

WARNING: BE SURE LIFTING ARRANGEMENT IS

STABLE BEFORE LIFTING LOAD. Use jack only on a

solid and level surface, capable of supporting the load

and the base of the jack. Always center the load on the lifting

saddle of the jack. If the jack is not perpendicular to the load,

slipping or loss of load is possible.

WARNING: Distribute the load evenly when performing

lifts with multiple jacks. Failure to heed this warning may

cause loss of load and/or failure of the jack, resulting in

property damage and/or personal injury.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualifi ed hydraulic technician. For repair

service, contact the Authorized ENERPAC Service Center

in your area. To protect your warranty, use only ENERPAC oil.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: The jack is to be used for lifting only! Support

the load after completing the lift using approved

accessories or by other appropriate means. Never get

under a load being supported only by the jack.

WARNING: Never exceed the rated capacity of the jack.

Allow for a margin of safety that accounts for possible

shifting loads or side loading conditions.

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fit properly and withstand high

loads.

CAUTION: To avoid damage to jack internal

components, do not continue pressurizing the jack

cylinder after it reaches maximum extension or

retraction.

Page 2

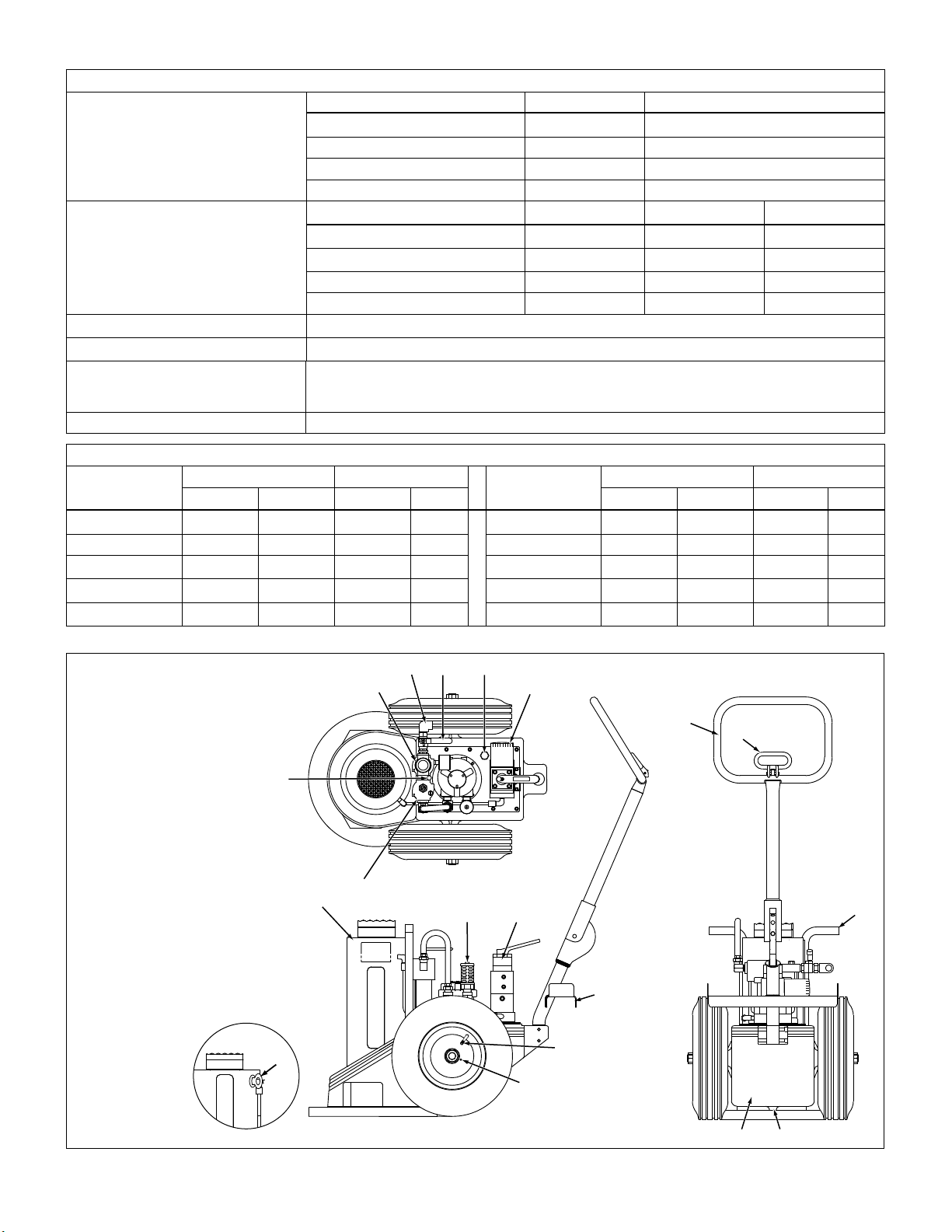

3.0 PRODUCT DATA

17

Table 1 - General Specifi cations

Model psi bar

PRAMA060_ _L 6,000 414

Maximum Operating Pressure

Load Rating

Hydraulic Oil Type Enerpac HF (Refer to Table 8 for oil specifi cations)

Maximum Hydraulic Oil Temperature 170 ºF [76 °C]

Hydraulic Reservoir Oil Capacity

(approximate - when fi lled to

proper level)

Air Requirements (minimum) 50 CFM @ 80 psi [1416 l/min @ 5,5 bar]

Short Stroke

Models

Stroke Length Weight

inches mm Pounds Kg inches mm Pounds Kg

PRAMA06014L 14 356 390 177 PRAMA06027L 27 686 600 272

PRAMA10016L 16 406 510 231 PRAMA10027L 27 686 600 272

PRASA10016L 16 406 510 231 PRASA10027L 27 686 600 272

PRASA15016L 15.5 394 570 258 PRASA15027L 26.5 673 708 321

PRASA20016L 15.5 394 640 290 PRASA20027L 26.5 673 825 374

Note: Refer to Enerpac catalog for product external dimensions.

PRAMA100_ _L & PRASA100_ _L 9,700 669

PRASA150_ _L 10,200 703

PRASA200_ _L 10,200 703

Model US Tons Metric Tons kN

PRAMA060_ _L 60 54 533

PRAMA100_ _L & PRASA100_ _L 100 90 889

PRASA150_ _L 150 136 1333

PRASA200_ _L 200 181 1778

4.2 gallons [15,9 liters]

Table 2 - Stroke Lengths and Weights

Long Stroke

Models

Stroke Length Weight

Key:

1. Handle Lock Lever

2. Handle Assembly

3. Lifting Bar

*

4. Air Supply Valve

5. Control Valve, Manual

7. Air Line Lubricator

8. Reservoir Air Breather

9. Air Line Filter/Regulator

10. Air Inlet Connection (1/2" NPT)

11. Oil Fill Plug

12. Oil Filter

13. Hydraulic Cylinder

14. Hydraulic Reservoir

15. Oil Drain Plug

16. Air Mu er

17. Lifting Eyebolt*

18. Wheel Bearing Grease Fitting

19. Tire Air Valve

20. U-Ring Storage

Not present on all models.

*

11

410

9

12

2

1

8

7

7

13

16

RAISE

LOWER

5

3

20

19

18

15

14

Figure 1, Major Features and Components - PRAMA Series Models

2

Page 3

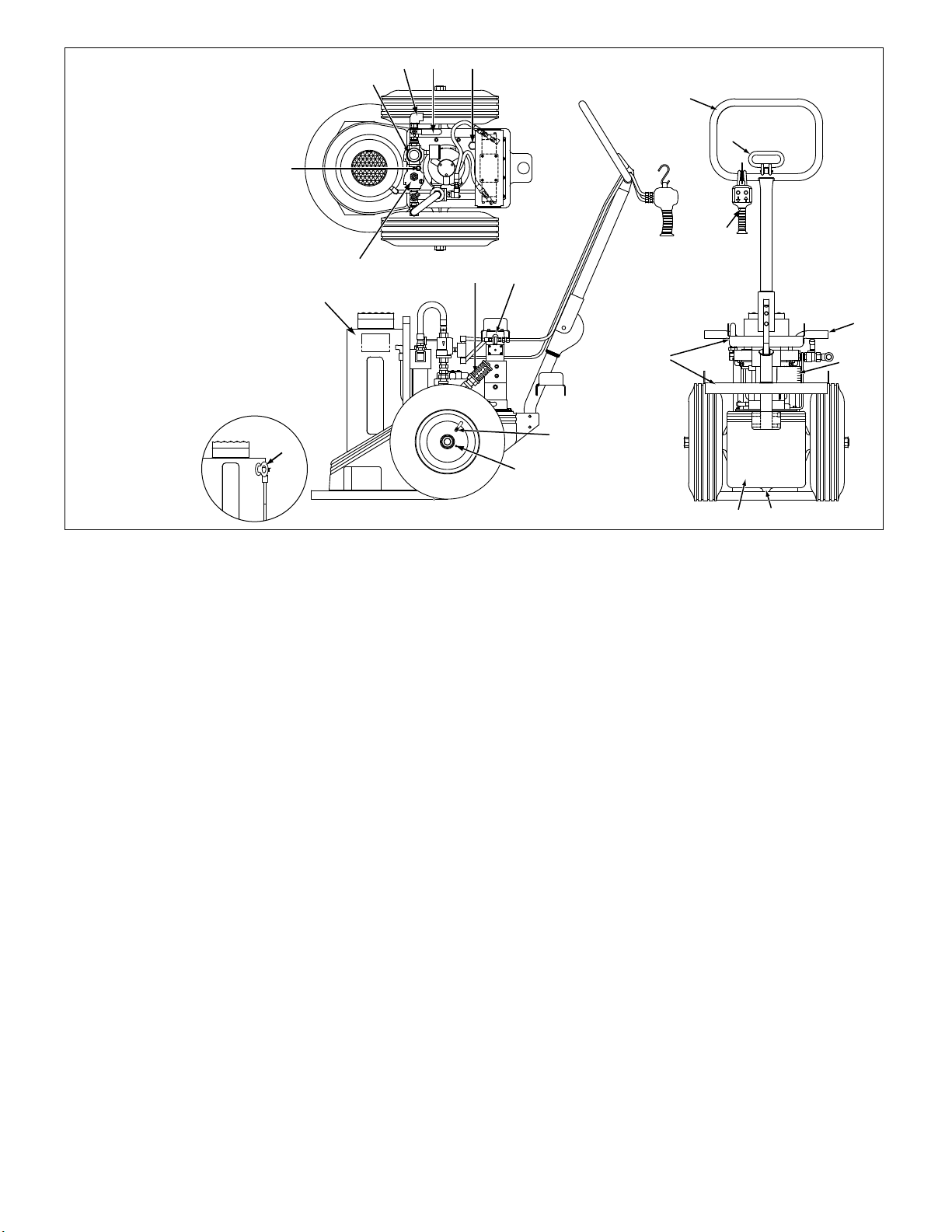

17

Key:

1. Handle Lock Lever

2. Handle Assembly

3. Lifting Bar*

4. Air Supply Valve

5. Control Valve, Air Operated

6. Pendant

7. Air Line Lubricator

8. Reservoir Air Breather

9. Air Line Filter/Regulator

10. Air Inlet Connection (1/2" NPT)

11. Oil Fill Plug

12. Oil Filter

13. Hydraulic Cylinder

14. Hydraulic Reservoir

15. Oil Drain Plug

16. Air Mu er

17. Lifting Eyebolt

18. Wheel Bearing Grease Fitting

19. Tire Air Valve

20. U-Ring Storage

Not present on all models.

*

*

9

8

7

13

410 11

16

2

1

6

5

3

18

19

19

20

12

Figure 2, Major Features and Components - PRASA Series Models

4.0 INITIAL SETUP

4.1 Adding Oil

Before startup, remove the oil fi ll plug (callout #11) and check

oil level. Oil level should be about 1 inch [25 mm] below top of

reservoir. Add Enerpac HF hydraulic oil to reservoir if necessary.

See Section 6.1 for additional information.

4.2 Air Requirements

Lubricated air is necessary to provide shaft seal lubrication for the

air motor, and to prevent rust. All models are equipped with an

automatic air line lubricator set to feed approximately 3 drops per

minute.

Before startup, check the level in the air line lubricator (callout #7)

and add additional lubricant if needed. Use an SAE 10 [ISO 32]

detergent oil or an approved antifreeze lubricant. See Section 6.4

for additional information.

A fi lter/regulator with moisture trap (callout #9) is installed in the

air line ahead of the motor. For e ciency of output and control

of speed, use an air line of not less than 3/4 inch pipe size. Air

pressure and fl ow must be at least 50 CFM @ 80 psi

[1416 l/min

@ 5,5 bar]. The air inlet connection is a 1/2" NPT female thread.

Be certain that compressed air is clean and dry. Moisture in the

air line can cause rust formation in the air motor and may result

in reduced performance. Allowing excessive moisture or foreign

particles to enter the air motor will void the Enerpac warranty.

4.3 Using the Jack for The First Time

Note: Refer to Section 5.0 for detailed jack operation instructions.

1. On PRAMA Series models, be sure that the control valve lever

is in the center (neutral/hold) position.

Note: On PRASA Series models, the air operated control valve

automatically returns to the center (neutral/hold) position when

the pendant buttons are not depressed.

15

14

2. Connect an air hose at the air inlet connection (callout #10).

Note: On PRAMA Series models, the motor will start immediately

when the air supply valve is opened. On pendant controlled

PRASA Series models, the motor will start automatically when

either pendant button is depressed.

3. Open the air supply valve (callout #4). Using the regulator

knob, adjust the air pressure to a minimum of 80 psi [5,5 bar].

IMPORTANT: Perform the following step with no load on jack.

4. Check for proper operation by fully extending and retracting

the cylinder (callout #13). Use the lever on the manual control

valve (callout #5 - PRAMA Series models) or the buttons on

the pendant (callout #6 - PRASA Series models) to control

cylinder movement. To remove air from system, cycle the

cylinder as needed until operation is smooth.

4.4 Using the Handle Assembly to Position the Jack

1. Push handle lock lever (callout #1) to release lock pin.

2. With lock pin released, position handle assembly (callout #2)

to desired location and release handle lock lever (callout #1)

to engage lock pin.

3. The jack can now be tilted back onto the wheels and pushed

or pulled to the work area. Use caution when walking

backwards.

4. If needed, the jack can be lifted using the lifting bar (callout

#3 - if equipped) or the lifting eyebolt(s) (callout #17 - if

equipped).

Note: Lifting bars are installed on short stroke PRAMA060, PRA_

A100 and PRASA150 Series models. Lifting bars are not used on

any long stroke models or on short stroke model PRASA20016L.

All long stroke models are equipped with one lifting eyebolt.

The short stroke model PRASA20016L is equipped with two

lifting eyebolts. Lifting eyebolts are not present on short stroke

PRAMA060, PRA_A100 and PRASA150 Series models.

3

Page 4

WARNING: Lift the jack using only lifting eyebolt(s) or

lifting bar. Never attempt to lift the jack by using the

handle assembly. The handle assembly is to be used

only for transporting the jack on its wheels and for positioning

the jack under the jacking point.

5. Using the handle assembly, adjust the jack position so that

the cylinder load cap is centered under the jacking point of

the load.

WARNING: Be sure that the jack is positioned on a

solid and level support surface, with the lifting cylinder

perpendicular to the ground. Jacking at an angle can

allow the jack to slip out of position, resulting in loss of load. As

required, use a swivel load cap to properly engage angled lifting

points. Refer to Section 5.5 for additional information.

5.0 OPERATION

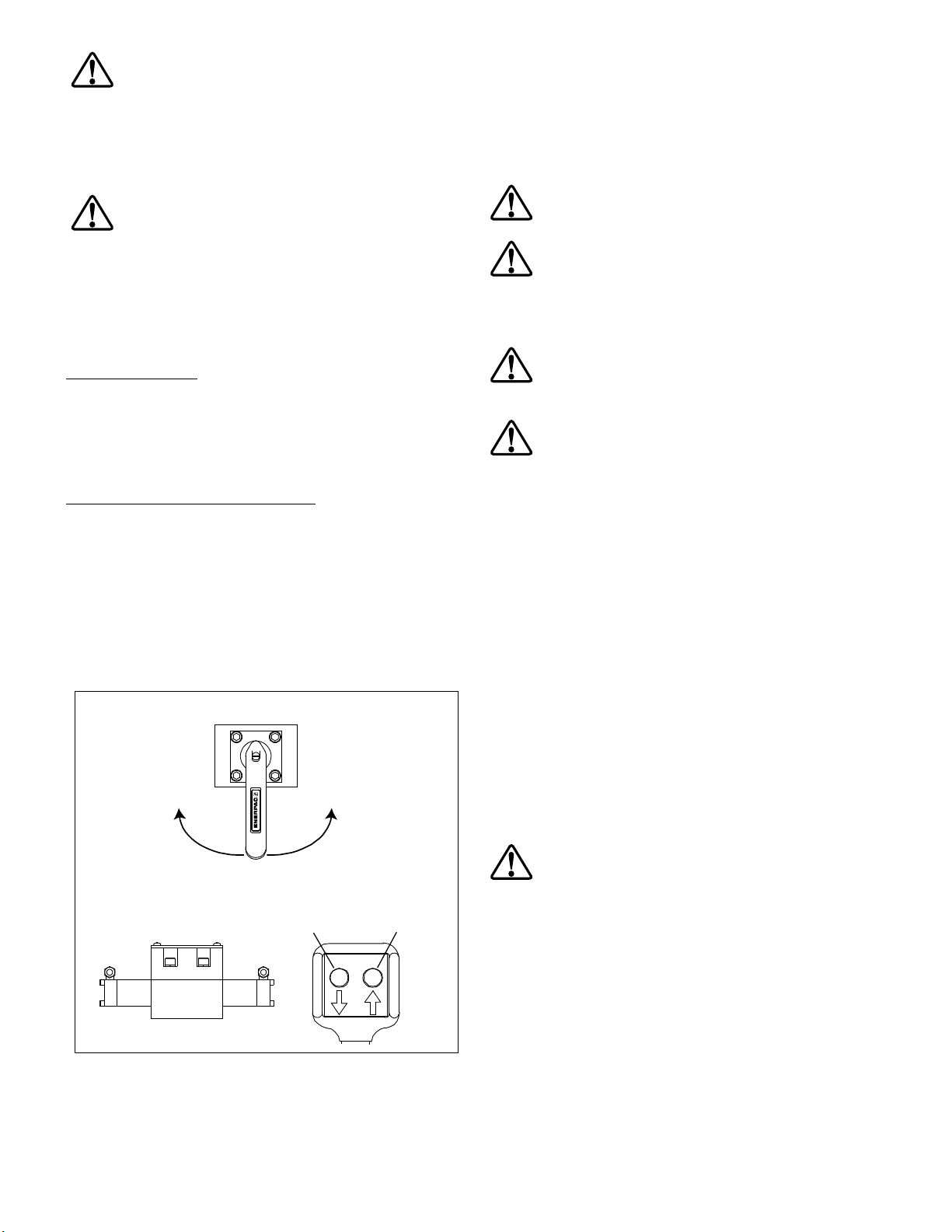

5.1 Control Valves (See Figure 3)

4-Way Manual Valve:

With pump motor running:

• Move lever to the extend position to raise the cylinder.

• Move lever to the retract position to lower the cylinder.

• Center position is neutral/hold. Cylinder stops and holds the

load. This is also referred to as the “idle” position.

4-Way Air Operated Valve with Pendant:

• To start motor and extend cylinder - press up-arrow button.

• To start motor and retract cylinder - press down-arrow button.

•

For neutral/hold - release both pendant buttons. Motor will stop.

Lifting speed and torque can be regulated by using the air

pressure regulator. The regulator should be adjusted to 100 psi

[7 bar] maximum with air motor running and air supply valve

completely open.

IMPORTANT: Pressure settings of above 100 psi [7 bar] will

result in reduced air motor life and will void product warranty.

Manual Valve: Center position is NEUTRAL/HOLD.

RETRACT

(lower)

Air Operated Valve: Stays in center neutral/hold position

until pendant down-arrow or up-arrow button is pressed.

(

Figure 3, Control Valve and Pendant Details

RETRACT

(lower)

)

EXTEND

(raise)

EXTEND

(raise)

5.2 Jacking Safely

You must know the weight of what you intend to lift and choose

a jack with at least 20 percent additional capacity.

All persons operating the jack should obtain and be familiar with

the American National Standards Institute rules that apply to

hydraulic rams and jacks (ASME ANSI B30.1) or the equivalent

standards used in your country or region.

WARNING:

Never place any part of your body under the

load at any time while it is being lifted, lowered, or

hydraulically supported by the Pow'r-Riser jack.

WARNING: The Pow'r-Riser jack is intended for lifting

purposes only and should not be used to hydraulically

support the load for any period of time after the lift has

been completed. Support the load with U-Rings or other suitable

load supports immediately after it has been lifted to the desired

height.

WARNING: Never leave the

Pow'r-Riser

jack

unattended during operation, even for a brief period of

time. Closely monitor jack operation at all times and be

prepared to stop lifting or lowering immediately.

WARNING: Do not use the

Pow'r-Riser

jack outdoors in

windy conditions. Changes in wind direction or velocity

could cause the load to become unstable and fall.

5.3 Operating Instructions (See Figures 3, 4 and 5)

TO RAISE THE LOAD:

1. Be certain that the jack is positioned on a solid and level

surface, capable of supporting the load and the base of

the jack. Be sure that the lifting cylinder is perpendicular to

the ground. See Section 4.4 for additional jack positioning

instructions.

2. If a high jacking point requires a taller jack, install extensions

and spacers (optional accessories) on the cylinder as

required. Refer to Section 5.4 for installation instructions

and additional information about extensions and spacers.

3. Place a piece of plywood or other compression material

(approximately 1/4" [6,3 mm] thick with good friction

characteristics) between the cylinder load cap and the

jacking point. This will provide a small amount of cushioning

and will also help prevent damage to the jacking point.

4. To raise the load, open the air supply valve to start the motor.

Then, move the control valve lever to the extend position. If

jack is equipped with pendant, depress the up-arrow button

to start motor and extend cylinder.

CAUTION: When lifting with more than one jack, be

especially careful to keep the load level. Leveling is best

accomplished by throttling with the air supply valve or

by alternating and stopping jacks to keep the load level enough

so it remains stable.

5. When load has reached the desired height, move the control

valve lever to the center (neutral/hold) position. If jack is

equipped with pendant, release up-arrow button to return

valve back to the center (neutral/hold) position.

6. Be sure that the proper Enerpac U-Rings are installed on

the cylinder (refer to Section 5.6 for U-Ring installation and

stacking instructions). If U-Rings are not used, be sure that

other load supports of appropriate load rating are in place.

7. Move the control valve lever to the retract position. Allow the

load to lower until it is supported by the U-Rings or other

load supports. Then, return the lever to the center (neutral/

hold) position. If jack is equipped with pendant, depress and

release the down-arrow button as required, until the load is

supported by the U-Rings or load supports.

4

4

Page 5

WARNING: After lifting is completed, always support

the load using the proper Enerpac U-Rings or

appropriately rated load supports. Never rely on the

cylinder's hydraulic pressure to support the lifted load.

WARNING: Wait an appropriate amount of time before

working under the load after it is supported by U-Rings

or load supports. Any settling of jack base or load

supports into the ground below must not exceed 1/4 inch [6.4

mm]. If additional settling occurs, reposition jack or load supports

on solid ground.

IMPORTANT: if there is to be no cylinder movement for more

than one minute, it is recommended that the motor be turned

o to prevent overheating of pump and air motor (models with

manual control valve only).

TO LOWER THE LOAD:

1. Be sure the control valve lever is in the center (neutral/hold)

position. If jack is equipped with pendant, be sure that both

buttons are released (not pressed) so that valve returns back

to the center position.

2. Open the air supply valve. On models equipped with a

manual control valve, the motor will start.

3. Move the control valve lever to the extend position or depress

the pendant up-arrow button. Allow cylinder to advance a

small amount, so that load is lifted o of U-Rings or clears

the load supports. Then place the control valve lever in the

center (neutral/hold) position or release the up-arrow button.

4. After the U-Rings or load supports are removed, move the

control valve lever to the retract position or depress the

pendant down-arrow button to retract the cylinder.

CAUTION: Be careful while lowering to ensure that the

load is lowered evenly, so that load shifting does not

occur.

5. When load has been fully lowered, place the control valve

lever in the center (neutral/hold) position or release the

pendant down-arrow button. On models with manual control

valve, close the air supply valve to stop the motor.

AFTER COMPLETING THE JOB:

Fully retract the cylinder and close the air supply valve.

With the

motor o , shift the control valve several times between the extend

and retract positions to relieve system pressure.

Disconnect the air supply hose and remove any extensions or

spacers from the cylinder. Place U-Rings (if used) on the storage

rack provided on the jack.

Always store the jack and its accessories in a clean and dry area,

free of moisture and direct sunlight.

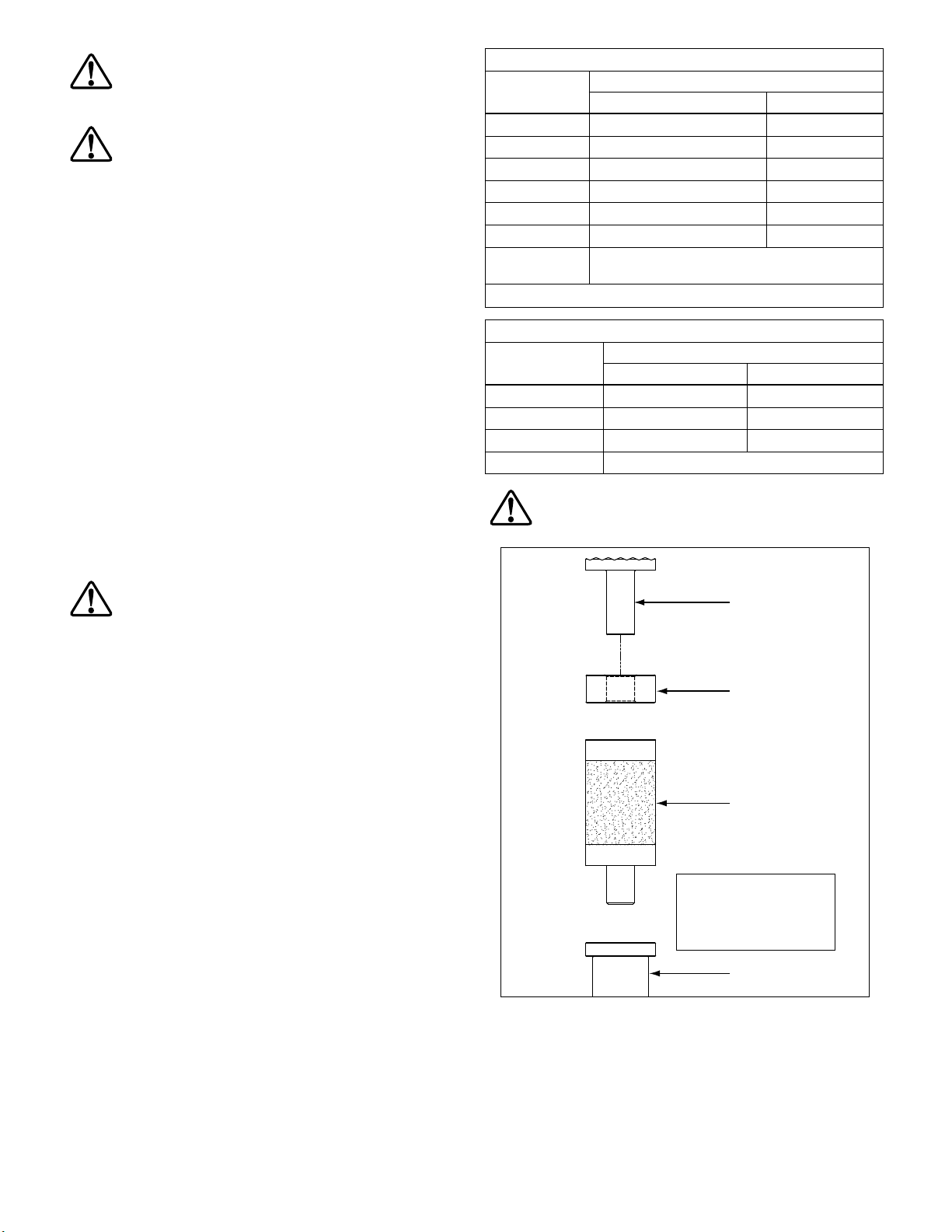

5.4 Stacking Instructions - Extensions and Spacers

(See Figure 4)

Extensions and spacers are available as optional accessories

from your Enerpac authorized distributor. They may be ordered

individually or in sets. Refer to tables 3 and 4 for additional

information.

PRE Series extensions allow the jack's useful lifting height to

be increased in increments of 5, 7, 9 or 11 inches [127, 178,

229 or 279 mm]. On short stroke Pow'r-Riser models only, larger

extensions can also be used, allowing the useful lifting height to

be increased in increments of 14 or 18 inches [356 or 457 mm].

PRS Series spacers allow additional fi ne adjustment of the

extension stack height. They may be used alone or in conjunction

with PRE Series extensions.

Table 3 - PRE Series Extensions (optional accessories)

Extension

Model

PRE5 5 127

PRE7 7 178

PRE9 9 229

PRE11 11 279

PRE14 * 14 356

PRE18 * 18 457

PRES6024

Extension Set

Includes PRE5, PRE7, PRE11 and PRE18 (1 each).

Thickness (each)

inches mm

* For use on short stroke jacks only (models ending in “14L” or “16L”)

Table 4 - PRS Series Spacers (optional accessories)

Spacer Model

PRS1 1 25

PRS2 2 51

PRS3 3 76

PRS4 Spacer Set Set includes PRS1, PRS2 and PRS3 (1 each).

CAUTION:

Never exceed the maximum additional stack

height for your jack model. Refer to Table 5 for additional

information.

Figure 4, Extension and Spacer Installation (typical)

Thickness (each)

inches mm

Load Cap

(see Table 6)

PRS Series Spacer

(see Table 4)

PRE Series

Extension

(see Table 3)

Important: Refer to

Table 5 for maximum

additional stack height

information.

Cylinder Rod

5

Page 6

WARNING: Failure to observe the following instructions

could allow load to shift or drop. Serious personal injury

and/or property damage may result.

When using PRE Series extensions and/or PRS Series spacers,

always obey the following rules:

• For loads up to 60 tons [54 metric tons]: Any two PRE Series

extensions may be included in the stacking arrangement,

provided that the maximum stack height (See Table 5) is not

exceeded and the following exceptions are observed:

1) Jack model

PRAMA06014L: Only one PRE18 extension

can be included in the stacking arrangement.

2) All jack models ending in “16L”:

Only one PRE11, PRE14

or PRE18 extension can be included in the stacking arrangement.

3) All jack models ending in “27L”: Extensions PRE14 and

PRE18 cannot be included in the stacking arrangement. These

extensions are designed for short stroke jacks only (models

ending in “14L” and “16L”).

• For loads over 60 tons [54 metric tons], or strokes over

14 inches [356 mm]: Only one PRE Series extension and

one PRS Series spacer can be included in the stacking

arrangement.

• Never exceed 3 inches [76 mm] in total spacer height.

• Never exceed the maximum additional stack height for your

jack model. Refer to Table 5, dimension “X”.

Table 5 - Maximum Additional Stack Height Using

Optional PRE Series Extensions and PRS Series Spacers

Maximum Additional Stack

Jack Model

PRAMA06014L 32 813

PRAMA06027L 11 279

PRAMA10016L 21 533

PRAMA10027L 11 279

PRASA10016L 21 533

PRASA10027L 11 279

PRASA15016L 21 533

PRASA15027L 11 279

PRASA20016L 21 533

PRASA20027L 11 279

Height (dimension “X”)

inches mm

X

5.5 Load Caps

A non-swivel load cap is included with the jack as standard

equipment. A swivel load cap is available as an optional

accessory. Refer to Table 6 for a list of load cap model numbers.

IMPORTANT: Use a swivel load cap to properly engage angled

lifting points. A swivel load cap should always be used when the

amount of misalignment between the standard load cap and the

lifting point is too large to be compensated for by use of plywood

or other suitable compression material alone.

Table 6 - Load Caps

Load Cap Model Numbers

Jack Model

PRAMA06014L

PRAMA06027L

PRAMA10016L

PRAMA10027L

PRASA10016L

PRASA10027L

PRASA15016L

PRASA15027L

PRASA20016L

PRASA20027L

Non-Swivel

Load Cap (standard)

42208E PRTS60

42208E PRTS60

42208E PRTS150

42208E PRTS200

Swivel Load Cap

(optional accessory)

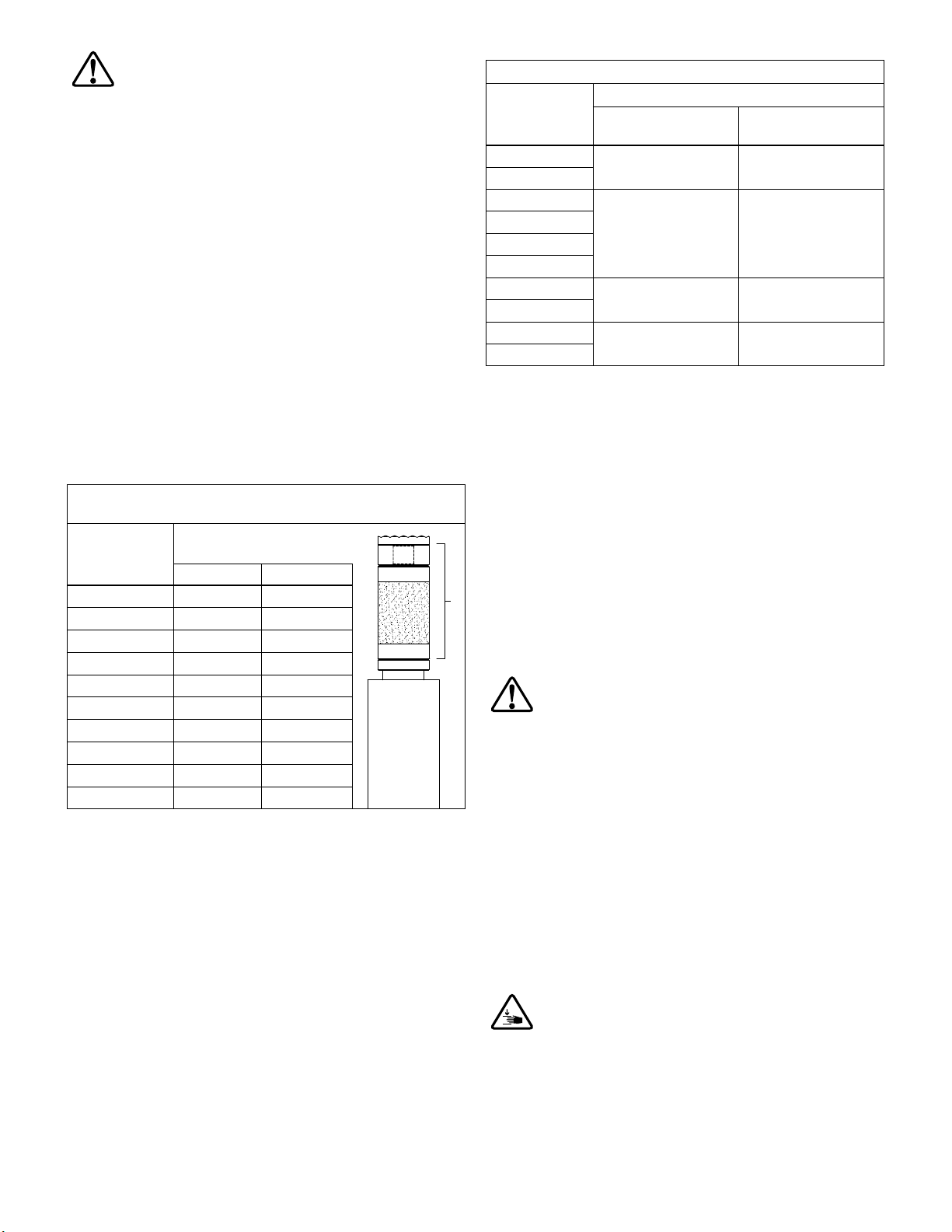

5.6 U-Ring Stacking Instructions (See Figure 5)

Pow'r-Riser U-Rings (optional accessories) allow positive

mechanical load holding of a lifted load. The U-Rings are placed

on top of the cylinder housing and around the extended cylinder

rod. They are available in fi ve di erent lengths for each Pow'rRiser model.

To help ensure proper alignment and installation, the top surface

of the cylinder housing and the top surface of each U-Ring

contains a raised locator. The bottom surface of each U-Ring

contains a mating recess.

The U-Rings are made of steel and aluminum. A steel U-Ring

must always be positioned at the top and bottom ends of the

U-Ring stack. The aluminum U-Rings must always be located

in the middle of the stack, between the two steel U-Rings. This

stacking arrangement helps prevent damage to the aluminum

U-Rings.

CAUTION:

top or bottom end of the U-Ring stack.

Install U-Rings as described in the following steps:

1. Using the jack, raise the load to the desired lifting height.

Refer to the instructions in Section 5.3 of this manual.

2. Place one steel U-Ring on top of the cylinder housing,

around the extended cylinder rod.

3. As required, place one or more aluminum U-Rings on top

of the steel U-Ring, around the extended cylinder rod.

The quantity of aluminum U-Rings to be installed will vary,

depending on jack model, lifting height and the U-Ring set

being used. Refer to Table 7 for additional information.

4. Place a second steel U-Ring at the top of the U-Ring stack.

IMPORTANT: Be sure the arrow on each U-Ring is pointing up.

Be sure all locators are fully engaged in the mating recesses of

the U-Rings.

CAUTION: Pinch point hazard: In the following step,

keep hands and fi ngers clear of area between load

support ring and top of U-Ring stack.

Never position an aluminum U-Ring at the

6

Page 7

Jack Model

1 inch

[25 mm]

Table 7 - U-Ring Information

U-Ring Size and Model Number

3 inch

[76 mm]

4-1/2 inch

[114 mm]

5-1/2 inch

[140 mm]

10 inch

[254 mm]

U-Ring

Set Model

Number

Items Included in Each U-Ring Set

2x 1x 2x 1x

PRAMA06014L

PRAMA06027L

PRAMA10016L PRU11 PRU13 PRU14 - PRU110 PRUS126 PRU11 PRU13 PRU14 PRAMA10027L PRU11 PRU13 PRU14 - PRU110 PRUS137 PRU11 PRU13 PRU14 PRU110

PRASA10016L PRU11 PRU13 PRU14 - PRU110 PRUS126 PRU11 PRU13 PRU14 PRASA10027L PRU11 PRU13 PRU14 - PRU110 PRUS137 PRU11 PRU13 PRU14 PRU110

PRASA15016L PRU151 PRU153 - PRU155 PRU1510 PRUS1526 PRU151 PRU153 PRU155 PRASA15027L PRU151 PRU153 - PRU155 PRU1510 PRUS1537 PRU151 PRU1510 PRU155 PRASA20016L PRU201 PRU203 - PRU155 PRU1510 PRUS2026 PRU201 PRU203 PRU205 PRASA20027L PRU201 PRU203 - PRU155 PRU1510 PRUS2037 PRU201 PRU2010 PRU205 -

5. Slowly lower the cylinder rod until the weight of the load

PRU11 PRU13 PRU14 - PRU110 PRUS126

PRU11 PRU13 PRU14 - PRU110 PRUS137 PRU11 PRU13 PRU14 PRU110

PRU11 PRU13 PRU14 -

6.0 MAINTENANCE

is supported by the U-Rings. Refer to the information in

Section 5.3 for jack operating instructions.

IMPORTANT: Follow all applicable work rules and regulations

in e ect at your facility or worksite. The use of auxiliary stands,

blocking or other additional load supports may be required even

when U-Rings are installed.

6.1 Maintain Oil Level in Hydraulic Reservoir

Check the hydraulic oil level every 30 days. Oil level should be

approximately 1 inch [25 mm] below top of reservoir, with cylinder

fully retracted and motor o .

If oil level is low, add Enerpac HF hydraulic oil as required. If

Enerpac HF is not available at the work site, use an equivalent

Steel U-Ring

(top)

Aluminum U-Rings

hydraulic oil that meets the specifi cations shown in Table 8.

Table 8 - Oil Specifi cations

Locator (on each

U-Ring and at

top of cylinder

housing)

ISO Grade

Viscosity Index

Viscosity at 210 °F

Viscosity at 100 °F

Viscosity at 0 °F

API Gravity

Flash, C.O.C. °F

Pour Point, °F

Para nic Base Color

32

100 min

42-45 S.U.S.

150-165 S.U.S.

<12000 S.U.S.

31.0-33.0

400

-35

Blue

Steel U-Ring

Load

Cap

Load

Support

Ring

(bottom)

Recess of U-Ring

Assembled View

Figure 5, U-Ring Stacking Arrangement (typical)

CAUTION: Failure to use the proper oil may result in

damage to jack hydraulic components and will void the

product warranty. Use of Enerpac HF oil is strongly

recommended.

IMPORTANT: Be sure that the oil is clean. If the oil has a milky,

cloudy or dark appearance, it should be changed immediately as

described in Section 6.2.

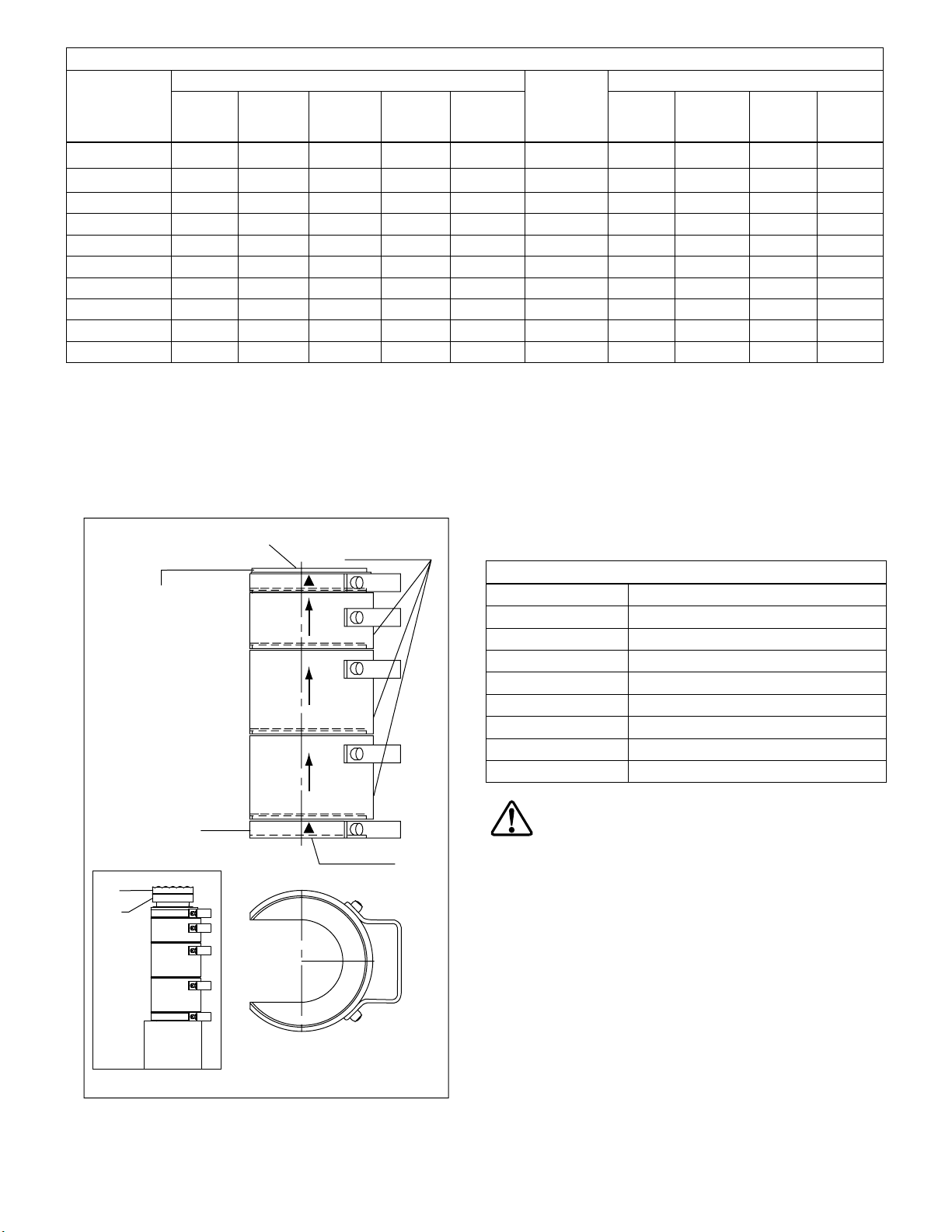

6.2 Changing the Oil (See Figure 6)

Change the oil at least every 12 months.

Note: The following conditions will require more frequent oil

changes:

• Rigorous duty, where oil temperature may reach 150 °F

[60 °C].

• A high humidity environment and/or extreme changes in

temperature that can result in condensation inside the

reservoir.

• Dirty or dusty environments that may contaminate the oil.

7

Page 8

Change the oil as described in the following steps:

1. Be sure that cylinder is fully retracted and that the air line is

disconnected.

IMPORTANT: The 5 gallon [18,9 liter] hydraulic reservoir holds

approximately 4.2 gallons [15,9 liters] of oil when fi lled to the

proper level with cylinder fully retracted and motor o . Dispose

of used oil in accordance with all applicable laws and regulations.

2. Loosen and remove oil drain plug at bottom of reservoir.

Allow used oil to drain into a suitable container.

3. Clean and reinstall oil drain plug.

4. Remove, clean and reinstall the reservoir air breather. It is

located on the reservoir top cover plate, under the air fi lter/

regulator assembly.

5. Loosen oil fi ll plug at top of reservoir. Slowly fi ll the reservoir

until the oil level is about 1 inch [25 mm] below top of reservoir.

Use Enerpac HF hydraulic oil or a suitable equivalent that

meets the specifi cations shown in Table 8.

6. Reinstall oil fi ll plug.

7. Remove the old oil fi lter and replace it with a new one of

the proper specifi cations. Catch any spilled oil in a suitable

container.

8. Raise and lower the cylinder several times to check for

proper operation before placing the jack back into service.

Air Breather

(under fi lter/

regulator)

Oil Fill Plug

Oil

Filter

RAISE

LOWER

Drip Adjustment

Fill Plug

Air Regulator

Air Line

Lubricator

Filter Bowl

Lubricant

Reservoir

Water Drain

Figure 7, Air Line Lubricator and Filter/Regulator

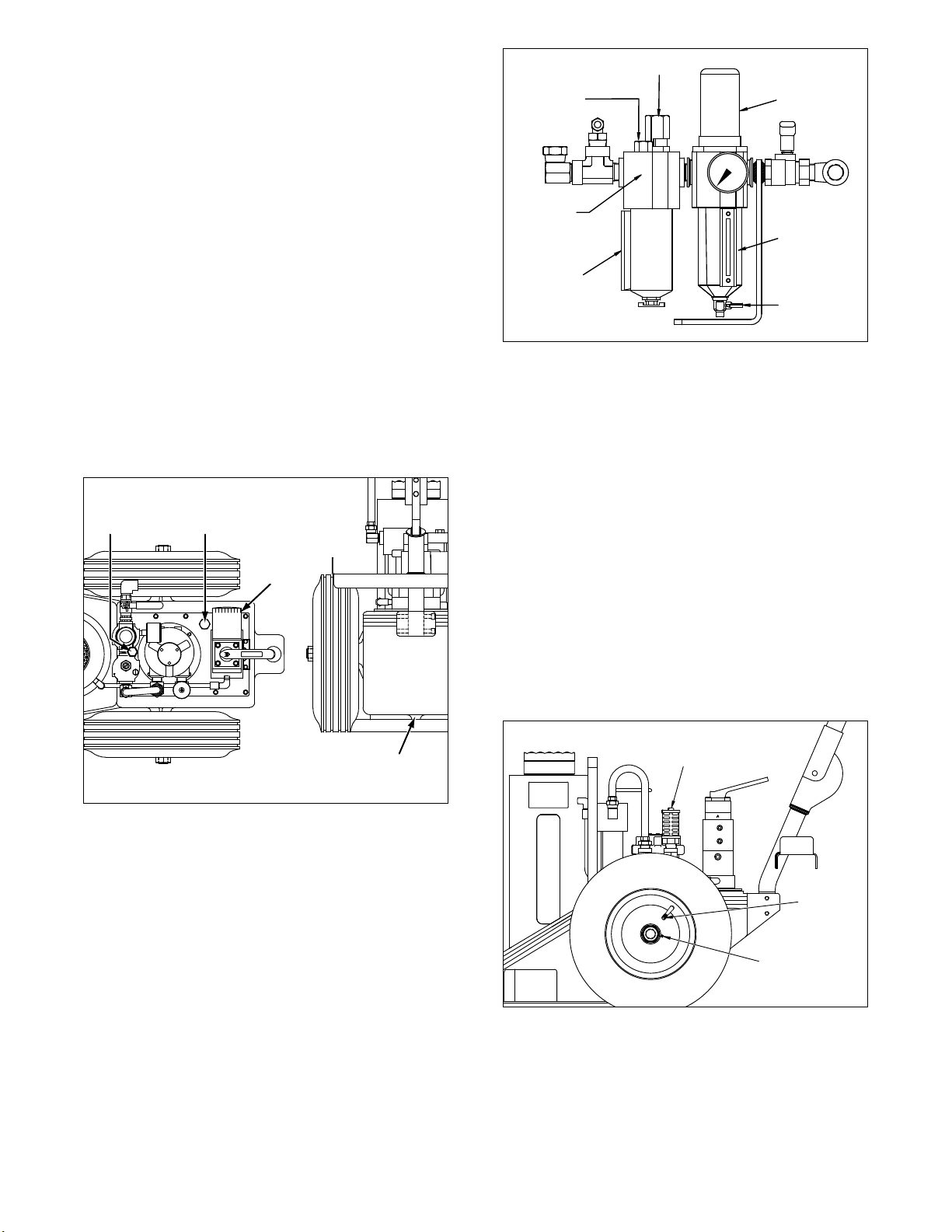

6.5 Air Mu er (See Figure 8)

Every 30 hours of operation:

• Check the air mu er for dirt or debris. If clogged, replace the

mu er with a new one of the same specifi cations.

Note: Air mu er design and appearance will vary. On jacks

equipped with a Gast manufactured air motor, the felt pads

inside the mu er can be removed, cleaned and replaced.

6.6 Wheels and Tires (See Figure 8)

Every 30 hours of operation:

• Check the tires for wear or damage. Replace as required.

• Check the tire infl ation pressure. Each tire should be infl ated to

90 psi [6,2 bar].

Every 12 months:

• Lubricate both wheel bearings with a high quality wheel

bearing grease. Each wheel hub contains a grease fi tting.

Oil Drain

Plug

Figure 6, Oil Change

6.3 Air Line Filter/Regulator (See Figure 7)

Every 30 hours of operation:

• Check the fi lter bowl for water. Drain any water if present.

• Inspect air fi lter element (inside fi lter bowl). Replace fi lter

element if dirty.

6.4 Air Line Lubricator (See Figure 7)

Before each use, check the fl uid level in the air line lubricator

and add additional lubricant if needed. Use an SAE 10 [ISO 32]

detergent oil or an approved antifreeze lubricant.

Check for an oil drip speed of approximately 3 drops per minute.

Adjust if necessary.

Air Mu er

(appearance may vary)

Tire Air

Valve

Wheel Bearing

Grease Fitting

Figure 8, Additional Maintenance Items

8

Page 9

7.0 TROUBLESHOOTING

The information in the Troubleshooting Guide (refer to Table 9) is

intended as an aid to help diagnose and correct various possible

problems that may occur.

For repair service, contact your local Enerpac Authorized Service

Center. Only an Enerpac Authorized Service Center should

service the jack and its components.

Table 9 - Troubleshooting Guide

Symptom Possible Cause Solution

1. Sporadic cylinder

action.

2. Noisy operation. Air trapped in hydraulic system. Cycle cylinder up and down several times to bleed trapped air.

Air trapped in hydraulic system. Cycle cylinder up and down several times to bleed trapped air.

Low oil level in hydraulic reservoir. Add Enerpac HF oil as required.

Seal wear and/or other internal damage. Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Low oil level in hydraulic reservoir. Add Enerpac HF oil as required.

Air leaks in hydraulic system. Check all points where air might leak into system.

CAUTION: Never tighten or loosen hydraulic fi ttings

while jack hydraulic system is pressurized.

Clogged or blocked pump intake

screen.

3. Oil is overheating. Low oil level in hydraulic reservoir. Add Enerpac HF oil as required.

Oil viscosity too high or too low. Drain and refi ll reservoir with Enerpac HF oil.

High pressure leakage at the pump. Have hydraulic system inspected by Enerpac Authorized Service Center.

4. Pump runs but will not

pump oil.

OR

Cylinder moves but

will not lift load.

5. Cylinder extends but

will not retract.

6. Pump does not run. Insu cient compressed air volume. Check air regulator setting. Increase volume of compressed air or increase

Seal wear and/or other internal damage. Have hydraulic system inspected by Enerpac Authorized Service Center.

Control valve needs repair. Have control valve inspected by Enerpac Authorized Service Center.

Insu cient compressed air volume. Check air regulator setting. Increase volume of compressed air or increase

Internal pressure leaks, or leaking retract

hoses.

Internal relief valve setting or retract side

relief valve setting too low.

Defective over-center valve, secondary

lock valve or control valve.

Pump not developing enough pressure. Have hydraulic system inspected by Enerpac Authorized Service Center.

Moisture in compressed air. Be sure that compressed air is clean, dry and free of water.

Have hydraulic reservoir and intake screen fl ushed and cleaned by

Enerpac Authorized Service Center.

Repair or replace components as required.

Repair or replace components as required.

Repair or replace as required.

size of supply air line to meet airfl ow and pressure requirements.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Repair or replace components as required.

size of supply air line to meet airfl ow and pressure requirements.

7. Jack is di cult to

roll on wheels.

Air mu er frozen or clogged with ice. Clean the air mu er. Be sure compressed air is clean, dry and free of

Air motor frozen or clogged with ice. Be sure compressed air is clean, dry and free of water. Check lubricant level

Air motor corroded, damaged, worn or

seized.

Pump element damaged, worn or

seized.

Low tire infl ation pressure. Check tire infl ation pressure. Add air if low.

Wheel bearings need lubrication. Apply grease to wheel bearings. See Section 6.6.

Wheel locknut out of adjustment. Loosen locknut until wheel rotates freely.

water. Check lubricant level in air line lubricator. Use only SAE 10 [ISO 32]

detergent oil or an approved antifreeze lubricant.

in air line lubricator. Use only SAE 10 [ISO 32] detergent oil or an approved

antifreeze lubricant.

Have air motor inspected by Enerpac Authorized Service Center. Repair or

replace as required.

Have pump element inspected by Enerpac Authorized Service Center.

Repair or replace as required.

Pressure should be 90 psi [6,2 bar].

9

Page 10

NOTES:

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

10

Page 11

Hoja de instrucciones

POWERFUL SOLUTIONS. GLOBAL FORCE.

Modelos de la serie PR accionados por aire

L3085 Rev. C 12/12

1.0 IMPORTANTES INSTRUCCIONES DE RECEPCIÓN

Inspeccione visualmente todos los componentes para verifi car

si hay daños producidos en el transporte. Debido a que la

garantía no ampara daños en transporte, si los hubiese, informe

inmediatamente a la empresa de transportes, puesto que ésta es

responsable de todos los gastos de reparaciones o reemplazo

que resulten por daños producidos en el transporte.

2.0 ASPECTOS DE SEGURIDAD

Lea atentamente todas las instrucciones,

advertencias y precauciones. Siga las precauciones

de seguridad recomendadas para evitar lesiones

personales o daños al gato. Enerpac no puede responsabilizarse

por daños o lesiones derivados del uso inseguro del producto,

falta de mantenimiento o uso incorrecto. No quite las etiquetas de

seguridad, las pegatinas ni las calcomanías. Si necesita resolver

alguna duda, póngase en contacto con ENERPAC o con algún

distribuidor local de Enerpac.

La presión máxima de trabajo del sistema hidráulico del gato

oscila entre 6000 y 10 200 psi [414 y 703 bar], en función del

modelo de gato. Consulte las listas de presión en la Tabla 1,

Especifi caciones generales.

Si nunca ha recibido formación sobre seguridad hidráulica de

alta presión, consulte con su distribuidor o con el centro de

servicio técnico para recibir un curso gratuito de seguridad

hidráulica de Enerpac.

Una PRECAUCIÓN se utiliza para indicar procedimientos y

prácticas de uso o mantenimiento correctos para evitar daños o

la destrucción de equipo u otra propiedad.

Una ADVERTENCIA indica un potencial peligro que requiere de

procedimientos o prácticas correctos para evitar lesiones.

Un PELIGRO se utiliza sólo cuando su acción u omisión podría

causar lesiones graves o incluso la muerte.

El incumplimiento de las siguientes precauciones de seguridad

podría causar daños en el equipo y/o lesiones personales:

ADVERTENCIA: Use el equipo de protección personal

adecuado cuando use equipo hidráulico.

ADVERTENCIA: ¡El gato solo debe utilizarse para

elevar cargas! Soporte la carga después de completar

la elevación con accesorios autorizados u otros medios

apropiados. Nunca se ponga debajo de una carga que está

soportada únicamente con el gato.

ADVERTENCIA: Nunca exceder la capacidad

certifi cada del gato. Permitir un margen de seguridad

que prevenga la posibilidad de desplazamiento o

desviación de la carga.

PELIGRO: Para evitar lesiones personales,

mantenga las manos y los pies alejados del cilindro

hidráulico y de los componentes relacionados

durante su funcionamiento.

Gatos de elevación Pow’r-Riser

PELIGRO: No manipule mangueras bajo presión. El

aceite que escape bajo presión puede penetrar la piel y

causar lesiones graves. Si se inyecta aceite bajo la piel,

consulte a un médico inmediatamente.

ADVERTENCIA: La válvula de descarga interna del gato

solo debe repararse o ajustarse por un centro de servicio

técnico autorizado. Nunca intente forzarla con

dispositivos de protección contra sobrecarga. Ajustes mayores

pueden provocar daños en el equipo y/o lesiones personales.

PRECAUCIÓN: Cuando no se utilice el gato, repliegue

completamente el cilindro y proteja toda la unidad de

daños externos. Mantenga el gato limpio, evite las

salpicaduras de las soldaduras y guárdelo en un lugar limpio y

seco. INSPECCIONE TODOS LOS COMPONENTES DEL GATO

ANTES DE USARLO.

PRECAUCIÓN: Mantener el gato alejado de llamas

y calor. Para un rendimiento óptimo, no exponer el

gato a temperaturas superiores a 65 ºC [150 ºF].

ADVERTENCIA: ASEGURARSE DE QUE LA

DISPOSICIÓN DE LA ELEVACIÓN ES ESTABLE

ANTES DE ELEVAR CARGAS. Utilice el gato sobre una

superfi cie sólida y nivelada, capaz de soportar la carga y la base del

gato. Coloque siempre la carga en el centro del asiento elevador

del gato. Si el gato no está en posición perpendicular a la carga,

esta podría deslizarse o perderse.

ADVERTENCIA: Distribuya la carga de manera uniforme

cuando efectúe elevaciones con múltiples gatos. Si no

cumple esta advertencia, podría perderse la carga o

podría darse un fallo del gato que resulte en daños a la

propiedad y/o lesiones personales.

IMPORTANTE: Únicamente técnicos califi cados en

sistemas hidráulicos habrán de prestarle servicio al

equipo hidráulico. Comuníquese con el Centro de

Servicio ENERPAC autorizado en su zona para prestarle servicio

de reparaciones. Use únicamente aceite ENERPAC a fi n de

proteger su garantía.

ADVERTENCIA: Reemplace inmediatamente las piezas

gastadas o dañadas por piezas ENERPAC genuinas. Las

piezas de calidad corriente se romperán, llo que causará

lesiones y daños a la propiedad. Las piezas ENERPAC están

diseñadas para encajar debidamente y resistir grandes cargas.

11

®

Page 12

PRECAUCIÓN: Para evitar daños en los componentes

internos del gato, no continúe presurizando el cilindro

cuando alcance su máxima extensión o retracción.

3.0 DATOS DEL PRODUCTO

Tabla 1: Especifi caciones generales

Modelo bar psi

PRAMA060_ _L 414 6,000

Presión máxima de funcionamiento

Límite de carga

Aceite de tipo hidráulico Enerpac HF (consulte la Tabla 8 para obtener las especifi caciones del aceite)

Temperatura máxima del aceite

hidráulico

Capacidad de aceite del depósito

hidráulico (aproximada, cuando se

llena hasta el nivel adecuado)

Requisitos de aire (mínimos) 1416 l/min @ 5,5 bar [50 CFM @ 80 psi]

PRAMA100_ _L & PRASA100_ _L 669 9,700

PRASA150_ _L 703 10,200

PRASA200_ _L 703 10,200

Modelo

PRAMA060_ _L 54 533 60

PRAMA100_ _L & PRASA100_ _L 90 889 100

PRASA150_ _L 136 1333 150

PRASA200_ _L 181 1778 200

76° C [170º F]

15,9 litros [4,2 galones]

Toneladas

métricas

kN

Toneladas EE.

UU.

Tabla 2: Longitud de carrera y pesos

Modelos de

carrera corta

PRAMA06014L 356 14 177 390 PRAMA06027L 686 27 272 600

PRAMA10016L 406 16 231 510 PRAMA10027L 686 27 272 600

PRASA10016L 406 16 231 510 PRASA10027L 686 27 272 600

PRASA15016L 394 15.5 258 570 PRASA15027L 673 26.5 321 708

PRASA20016L 394 15.5 290 640 PRASA20027L 673 26.5 374 825

Nota: Consulte el catálogo de Enerpac para consultar las dimensiones externas de los productos.

4.0 CONFIGURACIÓN INICIAL

4.1 Añadir aceite

Antes de comenzar, retire el tapón de llenado de aceite (anotación

#11) y compruebe el nivel de aceite. El nivel de aceite debería

encontrarse aproximadamente a 25 mm [1 pulgada] de la parte

superior del depósito. Añada aceite hidráulico HF de Enerpac al

depósito si es necesario. Consulte la Sección 6.1 para obtener

información adicional.

4.2 Requisitos de aire

Se necesita aire lubricado para proporcionar lubricación al sello del

eje para el motor de aire y para prevenir la oxidación. Todos los

modelos están equipados con un lubricador automático para línea

de aire que sirve para suministrar aproximadamente 3 gotas por

minuto.

Longitud de carrera Peso

mm Pulgadas Kg Libras mm Pulgadas Kg Libras

Modelos de

carrera larga

Antes de comenzar, compruebe el nivel del lubricador para línea de

aire (anotación #7) y añada más lubricante si es necesario. Utilice

un aceite detergente SAE 10 [ISO 32] o un lubricante anticongelante

autorizado. Consulte la Sección 6.4 para obtener información

adicional.

Un fi ltro/regulador con colector de humedad (anotación #9) se

instala en la línea de aire por delante del motor. Para conseguir

efi ciencia en la salida de aire y controlar la velocidad, utilice una

línea de aire que no sea inferior a ¾ pulgadas del tamaño de la

tubería. La presión y el fl ujo del aire deben ser al menos de 50 CFM

@ 80 psi [1416 l/min @ 5,5 bar]. La conexión de entrada de aire es

una rosca hembra interna de 1/2" NPT.

Asegúrese de que el aire comprimido es limpio y seco. La presencia

de humedad en la línea de aire puede causar la aparición de óxido

en el motor de aire y puede reducir su rendimiento. Si entra excesiva

humedad o partículas extrañas en el motor de aire, la garantía de

Longitud de carrera Peso

Enerpac quedará invalidada.

12

Page 13

17

Referencias:

17

1. Palanca de bloqueo de la manija

2. Conjunto de manija

3. Barra de elevación*

4. Válvula de suministro de aire

5. Válvula de control, manual

7. Lubricador para línea de aire

8

8. Conducto de aireación del depósito

9. Filtro/regulador para línea de aire

10. Conexión de entrada de aire (1/2" NPT)

11. Tapón de llenado del aceite

12. Filtro del aceite

13. Cilindro hidráulico

14. Depósito hidráulico

15. Tapón de drenado del aceite

16. Silenciador

17. Cáncamo para izar*

18. Accesorio para la grasa de los cojinetes

de las ruedas

19. Válvula de aire del neumático

20. Almacenamiento de los anillos en U

*No disponible en todos los modelos.

.

13

11

410

9

12

2

1

RAISE

LOWER

7

7

16

5

3

20

19

18

Figura 1, Características y componentes principales - Modelos de la serie PRAMA

Referencias:

1. Palanca de bloqueo de la manija

2. Conjunto de manija

3. Barra de elevación*

4. Válvula de suministro de aire

5. Válvula de control,

8

accionada por aire

6. Mando remoto

7. Lubricador para línea de aire

8. Conducto de aireación del depósito

9. Filtro/regulador para línea de airer

10. Conexión de entrada de aire (1/2" NPT)

11. Tapón de llenado del aceite

12. Filtro del aceite

13. Cilindro hidráulico

14. Depósito hidráulico

15. Tapón de drenado del aceite

16. Silenciador

17. Cáncamo para izar*

18. Accesorio para la grasa de los cojinetes

de las ruedas

19. Válvula de aire del neumático

20. Almacenamiento de los anillos en U

*No disponible en todos los modelos.

13

15

14

410 11

9

2

1

6

7

16

5

3

19

19

20

12

18

15

14

Figura 2, Características y componentes principales - Modelos de la serie PRASA

13

Page 14

4.3 Uso del gato por primera vez

Nota: Consulte la Sección 5.0 para ver las instrucciones de

funcionamiento detalladas del gato.

1. En los modelos de la serie PRAMA, asegúrese de que la

palanca de la válvula de control esté en la posición central

(neutral/de retención).

Nota:

En los modelos de la serie PRASA, la válvula de control

accionada mediante aire vuelve a la posición central (neutral/

de retención) cuando los botones del mando remoto no están

pulsados.

2. Conecte una manguera de aire a la conexión de entrada de

aire (anotación #10).

Nota: En los modelos de la serie PRAMA, el motor arrancará

inmediatamente cuando se abra la válvula de suministro de

aire. En los modelos de la serie PRASA controlados por mando

remoto, el motor arrancará automáticamente cuando se pulse

cualquiera de los botones del mando remoto.

3. Abra la válvula de suministro de aire (anotación #4). Ajuste la

presión del aire a un mínimo de 5,5 bar [80 psi] mediante el

botón de regulación.

IMPORTANTE: Realice el siguiente paso sin carga en el gato.

4. Compruebe el buen funcionamiento extendiendo y replegando

totalmente el cilindro (anotación #13). Utilice la palanca en la

válvula de control manual (anotación #5 - modelos de la serie

PRAMA) o los botones del mando remoto (anotación #6 modelos de la serie PRASA) para controlar el movimiento del

cilindro. Para retirar el aire del sistema, cicle el cilindro según

sea necesario hasta que funcione suavemente.

4.4 Uso de la manija para posicionar el gato

1. Pulse la palanca de bloqueo de la manija (anotación #1) para

liberar el pasador de bloqueo.

2. Al liberar el pasador de bloqueo, posicione la manija

(anotación #2) en la posición deseada y libere la palanca de

bloqueo de la manija (anotación #1) para colocar el pasador

de bloqueo.

3. El gato podrá entonces inclinarse hacia las ruedas y se

podrá tirar o empujar hacia el área de trabajo. Tenga cuidado

al caminar de espaldas.

4. Si lo necesita, podrá elevar el gato con la barra de elevación

(anotación #3 - si la hubiere) o con el cáncamo o cáncamos

de elevación (anotación #17 - si los hubiere).

Nota: Los modelos de carrera corta de la serie PRAMA060,

PRA_A100 y PRASA150 tienen instaladas barras de elevación.

La barras de elevación no se utilizan en ningún modelo de carrera

larga ni en el modelo de carrera corta PRASA20016L.

Todos los modelos de carrera larga están equipados con un

cáncamo para izar. El modelo de carrera corta PRASA20016L

está equipado con dos cáncamos para izar. Los modelos de

carrera corta de la serie PRAMA060, PRA_A100 y PRASA150 no

tienen instalados cáncamos para izar.

ADVERTENCIA: Eleve el gato utilizando únicamente

uno o más cáncamos de elevación o barras de

elevación. Nunca intente elevar el gato utilizando la

manija. La manija solo debe utilizarse para transportar el gato

sobre las ruedas y para colocarlo bajo el punto de elevación.

5. Con la manija, ajuste la posición del gato para que la

plataforma de carga del cilindro esté centrada bajo el punto

de elevación de la carga.

ADVERTENCIA: Asegúrese de que el gato está situado

en una superfi cie de soporte sólida y nivelada, con el

cilindro de elevación en posición perpendicular al

suelo. El uso del gato en una superfi cie desnivelada podría

provocar su desplazamiento y la pérdida de la carga. Según sea

necesario, utilice una plataforma de carga giratoria para ajustar

correctamente los puntos de elevación desnivelados. Consulte

la Sección 5.5 para obtener información adicional.

5.0 FUNCIONAMIENTO

5.1 Válvulas de control (véase la Figura 3)

Válvula de 4 vías accionada manualmente:

Con funcionamiento del motor de la bomba:

• Mueva la palanca a la posición extendida para elevar el

cilindro.

• Mueva la palanca a la posición de repliegue para descender el

cilindro.

• La posición central es neutral/de retención. El cilindro deja de

moverse y retiene la carga. Esta también se conoce como la

posición "de reposo".

Válvula de 4 vías accionada mediante aire con mando remoto:

• Para arrancar el motor y extender el cilindro, presione el botón

de la fl echa hacia arriba.

• Para arrancar el moto y replegar el cilindro, presione el botón

de la fl echa hacia abajo.

• Para una posición neutral/de retención, libere los dos botones

del mando remoto. El motor se detendrá.

La velocidad de elevación y del par de torsión se pueden regular

mediante el regulador de presión de aire. El regulador debería

ajustarse a un máximo de 7 bar [100 psi], con el motor de aire

encendido y la válvula de suministro de aire completamente

abierta.

IMPORTANTE: Los ajustes de presión superiores a 7 bar [100 psi]

reducirán la vida útil del motor de aire y anulará la garantía del

producto.

Válvula accionada manualmente: La posición central es

neutral/de retención.

RETROCESO

(descender)

Válvula accionada por aire: Permanece en posición central, neutral/

de retención,hasta que se pulse el botón de fl echa hacia arriba o

fl echa hacia abajo del mando remoto.

(

Figura 3, Válvula de control y detalles del mando remoto

EXTENSIÓN

(elevar)

RETROCESO

(descender)

)

EXTENSIÓN

(elevar)

14

Page 15

5.2 Seguridad en la elevación

Debe conocer el peso de aquello que desea elevar y elegir un

gato que tenga una capacidad adicional de, al menos, un 20 por

ciento.

Todos aquellos que hagan uso del gato deberán adquirir y estar

familiarizados con las normas del American National Standards

Institute (Instituto Nacional Estadounidense de Estándares) que

se aplican a los cilindros y gatos hidráulicos (ASME ANSI B30.1)

o los estándares equivalentes que se aplican en su país o región.

ADVERTENCIA: Nunca coloque ninguna parte del

cuerpo por debajo de la carga mientras está se está

elevando, descendiendo o soportando hidráulicamente

con el gato de elevación Pow'r-Riser.

ADVERTENCIA: El gato Pow'r-Riser está diseñado

únicamente para fi nes de elevación y no debería

utilizarse para soportar carga durante ningún período

de tiempo después de que la elevación se haya completado.

Soporte la carga con anillos en U o con otros soportes de carga

adecuados inmediatamente después de que la carga se haya

elevado hasta la altura deseada.

ADVERTENCIA: Nunca deje el gato Pow'r-Riser

desatendido durante su funcionamiento, aunque se

trate de un corto período de tiempo. Vigile atentamente

el funcionamiento del gato en todo momento y esté preparado

para detener la elevación o para descender de manera inmediata.

ADVERTENCIA: Nunca utilice el gato Pow'r-Riser en

espacios abiertos cuando haga viento. Cualquier

cambio en la dirección del viento podría causar

inestabilidad en la carga y, en consecuencia, su caída.

5.3 Instrucciones de funcionamiento (consulte las

fi guras 3, 4 y 5)

PARA ELEVAR LA CARGA:

1. Asegúrese de que el gato está situado en una superfi cie

sólida y nivelada, capaz de soportar la carga y la base del

gato. Asegúrese de que el cilindro elevador se encuentra en

posición perpendicular al suelo. Véase la Sección 4.4 para

obtener instrucciones adicionales sobre el posicionamiento

del gato.

2. Si un punto de elevación alto requiere un gato más alto,

instale extensiones y piezas de distancia (accesorios

opcionales) en el cilindro, según sea necesario. Consulte la

Sección 5.4 para ver las instrucciones y precauciones.

3. Coloque una pieza de contrachapado u otro tipo de material

comprimido (aproximadamente 6,3 mm [1/4"] de ancho, con

características de fricción buenas) entre la plataforma de

carga del cilindro y el punto de elevación. Esto proporcionará

un poco de amortiguación y ayudará a prevenir daños al

punto de elevación.

4. Para elevar la carga, abra la válvula de suministro de aire

para arrancar el motor. Después, mueva la palanca de la

válvula de control hacia la posición de extensión. Si el gato

tiene un mando remoto, presione el botón de la fecha hacia

arriba para arrancar el motor y extender el cilindro.

PRECAUCIÓN: Tenga especial cuidado para mantener

el nivel de la carga cuando se efectúe la elevación con

más de un gato. La mejor manera de conseguir la

nivelación adecuada, es regularla con la válvula de suministro de

aire o alternando y deteniendo los gatos para mantener el nivel

de carga estable.

5. Cuando la carga haya alcanzado la altura deseada, mueva la

palanca de la válvula de control a la posición central (neutral/

de retención). Si el gato tiene un mando remoto, libere el

botón de la fl echa hacia arriba para que la válvula vuelva a la

posición central (neutral/de retención).

6. Asegúrese de que se instalan los anillos en U de Enerpac

correctos en el cilindro (consulte la Sección 5.6 para ver las

instrucciones de instalación y apilamiento). Si no se utilizan

los anillos en U, asegúrese de que el resto de soportes de

carga con certifi cado de carga apropiada están en el lugar

correspondiente.

7. Mueva la palanca de la válvula de control hasta la posición

de repliegue. Deje que descienda la carga hasta que esté

soportada por los anillos en U o por otros soportes de carga.

A continuación, vuelva a colocar la palanca en la posición

central (neutral/de retención). Si el gato tiene un mando

remoto, presione y libere el botón de la fl echa hacia abajo,

según sea necesario, hasta que la carga esté soportada por

los anillos en U o los soportes de carga.

ADVERTENCIA: Una vez completada la elevación,

soporte la carga con los anillos en U apropiados o con

soportes de carga debidamente certifi cados. Nunca se

sirva de la presión hidráulica del cilindro para soportar la carga

elevada.

ADVERTENCIA: Espere durante un período de tiempo

apropiado antes de comenzar a trabajar debajo de la

carga cuando esté soportada por anillos en U o por

otros soportes. La instalación por debajo del suelo de la base del

gato o de los soportes de carga no debe exceder los 6,4 mm [1/4

pulgadas]. Si se instala algún elemento adicional, vuelva a

colocar el gato o los soportes de carga en suelo sólido.

IMPORTANTE: Si el cilindro no se va mover durante más de un

minuto, se recomienda que se apague el motor para evitar el

recalentamiento de la bomba y del motor de aire (solo para los

modelos con válvula accionada manualmente).

PARA DESCENDER LA CARGA:

1. Asegúrese de que la palanca de la válvula de control esté

en la posición central (neutral/de retención). Si el gato tiene

un mando remoto, asegúrese de que ambos botones estén

liberados (no presionados), para que la válvula vuelva a la

posición central.

2. Abra la válvula de suministro de aire. En los modelos que

tienen una válvula de control manual, el motor arrancará.

3. Mueva la palanca de la válvula de control a la posición

extendida o pulse el botón de la fl echa hacia abajo del

mando remoto. Deje que el cilindro avance un poco, de

modo que la carga se eleve y deje de estar apoyada en los

anillos en U o en los soportes de carga. A continuación,

coloque la palanca de la válvula de control en la posición

central (neutral/de retención) o libere el botón de la fl echa

hacia arriba.

4. Después de retirar los anillos en U o los soportes de carga,

mueva la palanca de la válvula de control hasta la posición

de repliegue o pulse el botón de la fl echa hacia abajo del

mando remoto para replegar el cilindro.

PRECAUCIÓN: Proceda con cuidado durante el

descenso y asegúrese de que la carga desciende de

manera uniforme para evitar que esta se desplace.

5. Cuando la carga haya descendido por completo, coloque

la palanca de la válvula de control en la posición central

(neutral/de retención) o libere el botón de la fl echa hacia

abajo del mando remoto. En los modelos con válvula de

control manual, cierre la válvula de suministro de aire para

detener el motor.

15

Page 16

DESPUÉS DE FINALIZAR EL TRABAJO:

Repliegue completamente el cilindro y cierre la válvula de

suministro de aire. Con el motor apagado, cambie repetidas veces

la posición de la válvula de control a las posiciones de extensión y

de repliegue para liberar la presión del sistema.

Desconecte la manguera de suministro de aire y retire cualquier

extensión o pieza de distancia del cilindro. Coloque los anillos

en U (en caso de utilizarse) en el bastidor de almacenamiento

suministrado con el gato.

Guarde el gato y sus accesorios en un lugar limpio y seco, sin

humedad y sin luz solar directa.

5.4 Instrucciones de apilamiento –. Extensiones y

piezas de distancia (véase Figura 4)

Las extensiones y piezas de distancia se encuentran disponibles

como accesorios opcionales en su distribuidor autorizado de

Enerpac. Pueden solicitarse de manera individual o en conjunto.

Consulte las tablas 3 y 4 para obtener información adicional.

Las extensiones de la serie PRE permiten que la altura de la

elevación útil del gato aumente en longitudes de 127, 178, 229

o 279 mm [5, 7, 9 o 11 pulgadas]. Únicamente en los modelos

Pow'r-Riser de carrera corta se pueden utilizar extensiones más

largas, de manera que la altura de elevación útil aumente en

longitudes de 356 o 457 mm [14 o 18 pulgadas].

Las piezas de distancia de la serie PRS permiten ajustes precisos

adicionales en la extensión de la altura. Se pueden utilizar

individualmente o junto con las extensiones de la serie PRE.

Plataforma de

carga (véase la

Tabla 6)

Piezas de distancia

de la serie PRS

(véase la Tabla 4)

Extensión de la

serie PRE (véase la

Tabla 3)

Importante: Consulte

la Tabla 5 para obtener

información sobre la altura

adicional máxima.

Vástago del cilindro

Figura 4, Instalación de las extensiones y

piezas de distancia (ejemplo típico)

Tabla 3: Extensión de la serie PRE (accesorios opcionales)

Modelo de extensión

PRE5 127 5

PRE7 178 7

PRE9 229 9

PRE11 279 11

PRE14 * 356 14

PRE18 * 457 18

Conjunto de la

extensión PRES6024

* Únicamente para gatos de carrera corta (modelos que terminan

por “14L” y “16L”)

Incluye PRE5, PRE7, PRE11 y PRE18

(1 cada uno).

Anchura (de cada uno)

mm Pulgadas

Tabla 4: Piezas de distancia de la serie PRS

(accesorios opcionales)

Modelo de piezas de

distancia

PRS1 25 1

PRS2 51 2

PRS3 76 3

Conjunto de piezas de

distancia PRS4

El conjunto incluye PRS1, PRS2 y PRS3

(1 cada uno).

Anchura (de cada uno)

mm Pulgadas

PRECAUCIÓN: Nunca exceda la altura adicional

máxima establecida para el modelo de su gato.

Consulte la Tabla 5 para obtener información adicional.

ADVERTENCIA: El incumplimiento de las siguientes

instrucciones podría provocar el desplazamiento o la

caída de la carga. Puede provocar una lesión personal

grave y/o daños a la propiedad.

Siga las siguientes instrucciones cuando utilice extensiones de

la serie PRE y/o piezas de distancia de la serie PRS:

• Para cargas de hasta 60 toneladas [54 toneladas métricas]:

Se pueden incluir dos extensiones de la serie PRE en el

apilamiento, siempre y cuando no exceda la altura máxima

(véase la Tabla 5) y se observen las siguientes excepciones:

1) Modelo de gato PRAMA06014L: Solo se puede incluir

una extensión PRE18 en el apilamiento.

2) Todos los modelos de gato que terminan por “16L”:

Solo se puede incluir una extensión PRE11, PRE14 o

PRE18 en el apilamiento.

3) Todos los modelos de gato que terminan por “27L”:

No se pueden incluir las extensiones de PRE14 y PRE18

en el apilamiento. Estas extensiones están diseñadas

únicamente para gatos de carrera corta (modelos que

terminan por “14L” y “16L”).

• Para cargas de hasta 60 toneladas [54 toneladas métricas]

o carreras de más de 356 mm [14 pulgadas]: Solo se puede

incluir una extensión de la serie PRE y una pieza de distancia

de la serie PRS en el apilamiento.

• Nunca deje que la altura total de las piezas de distancia

sobrepase los 76 mm [3 pulgadas].

• Nunca exceda la altura adicional máxima establecida para el

modelo de su gato. Consulte la Tabla 5, dimensión “X”.

16

Page 17

Tabla 5: Altura adicional máxima con extensiones

de la serie PRE y piezas de distancia de la

serie PRS opcionales

Tabla 5: Altura adicional

Modelo de gato

PRAMA06014L 813 32

PRAMA06027L 279 11

PRAMA10016L 533 21

PRAMA10027L 279 11

PRASA10016L 533 21

PRASA10027L 279 11

PRASA15016L 533 21

PRASA15027L 279 11

PRASA20016L 533 21

PRASA20027L 279 11

máxima (Dimensión “X”)

mm Pulgadas

X

5.5 Plataformas de carga

Se incluye una plataforma de carga no giratoria con el gato

como parte del equipo. Hay una plataforma de carga giratoria

disponible como accesorio opcional. Consulte la Tabla 6 para ver

una lista de los números de modelo de las plataformas de carga.

Anillo en U de acero

(parte superior)

Posicionador

(en cada anillo

en U y en la

parte superior

de la carcasa del

cilindro)

Anillo en U

de acero

(parte inferior)

Plataforma

de carga

Anillo

de

soporte

de carga

Anillo en U de

aluminio

Anillo en U de

aluminio

IMPORTANTE: Utilice una plataforma de carga giratoria, para

ajustar correctamente los puntos de elevación desnivelados.

La plataforma de carga giratoria deberá utilizarse siempre que

el desalineamiento entre la plataforma de carga estándar y el

punto de elevación sea tan grande que no pueda compensarse

solo con el uso de contrachapado u otro material comprimido

adecuado.

Tabla 6: Plataformas de carga

Números de modelo de las plataformas de carga

Modelo de

gato

PRAMA06014L

PRAMA06027L

PRAMA10016L

PRAMA10027L

PRASA10016L

PRASA10027L

PRASA15016L

PRASA15027L

PRASA20016L

PRASA20027L

Plataforma de

carga no giratoria

(estándar)

42208E PRTS60

42208E PRTS60

42208E PRTS150

42208E PRTS200

Plataforma de carga

giratoria (accesorio

opcional)

5.6 Instrucciones de apilamiento del anillo en U (véase

la Figura 5)

Los anillos en U de Pow'r-Riser (accesorios opcionales) permiten

una carga mecánica efectiva de una carga ya elevada. Los anillos

en U se colocan en la parte superior de la carcasa del cilindro y

alrededor del vástago del cilindro extendido. Están disponibles

en 5 longitudes diferentes para cada modelo de Pow'r-Riser.

Assembled View

Figura 5, Apilamiento para el anillo en U (ejemplo típico)

Para asegurar el alineamiento e instalación adecuados, la

superfi cie superior de la carcasa del cilindro y la superfi cie

superior de cada anillo en U contienen posicionadores. La parte

inferior de la superfi cie de cada anillo en U contiene acopladores.

Los anillos en U están hechos de acero y de aluminio. Un anillo

en U de acero siempre debe estar al principio y al fi nal de la pila

de anillos en U. Los anillos en U de aluminio siempre deben estar

en el medio del bloque, entre los dos anillos en U de acero. Este

apilamiento ayuda a evitar daños a los anillos en U de aluminio.

PRECAUCIÓN: Nunca ponga un anillo en U de aluminio

al principio o al fi nal de la pila de anillos en U.

Instale los anillos en U como se describe en los siguientes pasos:

1. Eleve la carga a la altura deseada con ayuda del gato.

Consulte las instrucciones de la Sección 5.3 de este manual.

2. Coloque un anillo en U de acero en la parte superior de

la carcasa del cilindro, alrededor del vástago del cilindro

extendido.

3. Según sea necesario, coloque uno o más anillos en U de

aluminio encima del anillo en U de acero, alrededor del

vástago del cilindro extendido. La cantidad de anillos en U

de aluminio que habrá que instalar puede variar, en función

del modelo de gato, de la altura de elevación y del conjunto

de anillos en U que se van a utilizar. Consulte la Tabla 7 para

obtener información adicional.

4. Coloque un segundo anillo en U de acero en la parte superior

de la pila de anillos en U.

17

Page 18

Tabla 7: Información sobre los anillos en U

Tamaño y número de modelo de los anillos en U

Modelo de gato

PRAMA06014L

PRAMA06027L

PRAMA10016L PRU11 PRU13 PRU14 - PRU110 PRUS126 PRU11 PRU13 PRU14 PRAMA10027L PRU11 PRU13 PRU14 - PRU110 PRUS137 PRU11 PRU13 PRU14 PRU110

PRASA10016L PRU11 PRU13 PRU14 - PRU110 PRUS126 PRU11 PRU13 PRU14 PRASA10027L PRU11 PRU13 PRU14 - PRU110 PRUS137 PRU11 PRU13 PRU14 PRU110

PRASA15016L PRU151 PRU153 - PRU155 PRU1510 PRUS1526 PRU151 PRU153 PRU155 PRASA15027L PRU151 PRU153 - PRU155 PRU1510 PRUS1537 PRU151 PRU1510 PRU155 PRASA20016L PRU201 PRU203 - PRU155 PRU1510 PRUS2026 PRU201 PRU203 PRU205 PRASA20027L PRU201 PRU203 - PRU155 PRU1510 PRUS2037 PRU201 PRU2010 PRU205 -

25 mm

[1 pulg]

PRU11 PRU13 PRU14 - PRU110 PRUS126

PRU11 PRU13 PRU14 - PRU110 PRUS137 PRU11 PRU13 PRU14 PRU110

76 mm

[3 pulg]

114 mm

[4-1/2 pulg]

140 mm

[5-1/2

pulg]

254 mm

[10 pulg]

Número de

modelo del

conjunto de

anillos en U

Elementos incluidos en cada conjunto

de anillos en U

2x 1x 2x 1x

PRU11 PRU13 PRU14 -

IMPORTANTE: Asegúrese de que la fl echa de cada anillo en U

está enfocada hacia arriba. Asegúrese de que los posicionadores

están totalmente enganchados a los acopladores de los anillos

en U.

PRECAUCIÓN: Peligro de lesión: En el siguiente paso,

mantenga las manos y los dedos alejados del área entre

los anillos de soporte de la carga y la parte superior de la

pila de anillos en U.

5. Descienda lentamente el vástago del cilindro hasta que

el peso de la carga esté soportado por los anillos en U.

Consulte la información de la Sección 5.3 para ver las

instrucciones de funcionamiento del gato.

IMPORTANTE: Siga todas las normas de trabajo y normativas

aplicables vigentes en su empresa o lugar de trabajo. Puede que

se requiera el uso de soportes o bloques auxiliares u otros soportes

de carga, incluso cuando los anillos en U están instalados.

6.0 MANTENIMIENTO

6.1 Mantenga el nivel del aceite en el depósito

hidráulico

Compruebe el nivel de aceite hidráulico cada 30 días. El nivel

de aceite debería encontrarse aproximadamente a 25 mm

[1 pulgada] de la parte superior del depósito, con el cilindro

completamente replegado y el motor apagado.

Si el nivel de aceite es bajo, añada aceite hidráulico HF de

Enerpac, según sea necesario. Si no hay aceite HF de Enerpac

en su lugar de trabajo, utilice un aceite hidráulico equivalente

que cumpla las especifi caciones que se muestran en la Tabla 8.

Tabla 8: Especifi caciones del aceite

Calidad ISO

Índice de viscosidad

Viscosidad a 99º C

Viscosidad a 38º C

Viscosidad a 17º C

Gravedad API

Flash, C.O.C. ° C 204

Punto de fl uidez, º C

Color de la base parafínica

32

100 min

42-45 S.U.S.

150-165 S.U.S.

<12000 S.U.S.

31.0-33.0

-35

Azul

PRECAUCIÓN: No utilizar el aceite adecuado podría

provocar daños en los componentes hidráulicos del

gato e invalidar la garantía del producto. Se recomienda

encarecidamente el uso del aceite HF de Enerpac.

IMPORTANTE: Asegúrese de que el aceite está limpio. Si el

aceite tiene una apariencia oscura, nebulosa o lechosa, debe

cambiarse de inmediato, como se describe en la Sección 6.2.

6.2 Cambio del aceite (véase la Figura 6)

Cambie el aceite al menos cada 12 meses.

Nota: Las condiciones expuestas a continuación requerirán

cambios de aceite más frecuentes:

• Será preciso cuando la temperatura del aceite alcance los

60° C [150º F].