Page 1

POWERFUL SOLUTIONS. GLOBAL FORCE.

L4075 Rev. B 07/14

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-36

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-54

日本語 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

1.0 SAFETY

1.1 Introduction

Read all instructions carefully. Follow all recommended safety

precautions to avoid personal injury as well as damage to the jack

and/or damage to other property. Enerpac cannot be responsible

for any damage or injury from unsafe use, lack of maintenance

or incorrect operation. Do not remove warning labels, tags, or

decals. In the event any questions or concerns arise, contact

Enerpac or a local Enerpac distributor for clarifi cation.

If you have never been trained on high-pressure hydraulic safety,

consult your distributor or service center for a free Enerpac

Hydraulic Safety Course.

This manual follows a system of safety alert symbols, signal

words and safety messages to warn the user of specifi c hazards.

Failure to comply with these warnings could result in death or

serious personal injury, as well as damage to the equipment or

other property.

The Safety Alert Symbol appears throughout this

manual. It is used to alert you to potential physical

injury hazards. Pay close attention to Safety Alert

Symbols and obey all safety messages that follow this symbol to

avoid the possibility of death or serious personal injury.

Safety Alert Symbols are used in conjunction with certain Signal

Words that call attention to safety messages or property damage

messages and designate a degree or level of hazard seriousness.

The Signal Words used in this manual are DANGER, WARNING,

CAUTION and NOTICE.

DANGER

WARNING

CAUTION

NOTICE

or

NOTICE:

Indicates a hazardous situation that, if not

avoided, will result in death or serious personal

injury.

Indicates a hazardous situation that, if not

avoided, could result in death or serious

personal injury.

Indicates a hazardous situation that, if not

avoided, could result in minor or moderate

personal injury.

Indicates information considered important,

but not hazard related (e.g. messages relating

to property damage). Please note that the

Safety Alert Symbol will not be used with this

signal word.

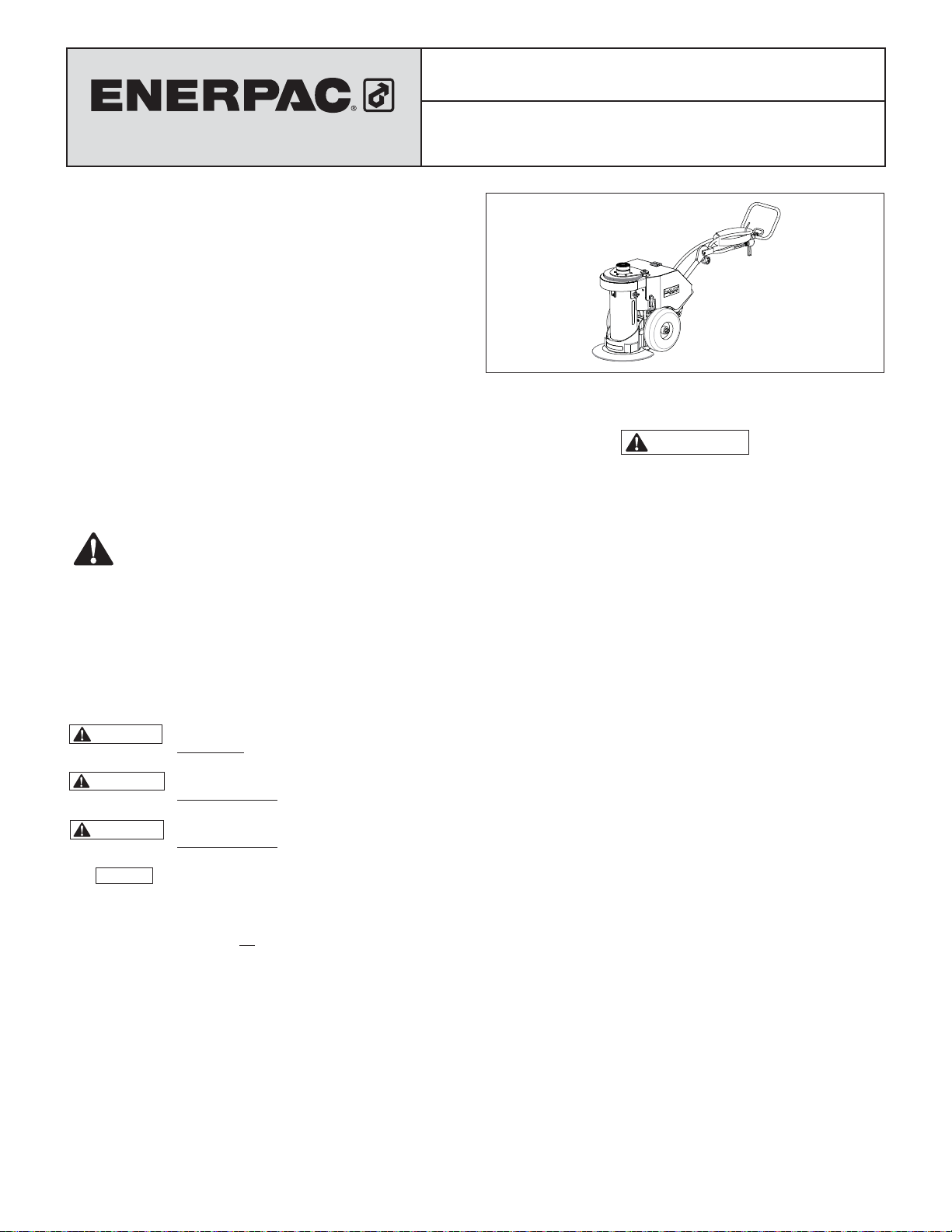

Instruction Sheet

Pow’R-LOCK

™

Portable Lift System

PL200 Series Models (air-operated)

1.2 Safety Precautions - Pow'R-LOCK

System

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Keep hands and feet away from hydraulic cylinder and

related components during jack operation.

• Always wear proper personal protective equipment (PPE)

when operating hydraulic equipment (such as gloves, eye

protection, head protection, protective footware, etc.).

• Do not handle pressurized lines. Escaping oil under

pressure can penetrate the skin, causing serious personal

injury. If oil is injected under the skin, see a doctor

immediately.

• The jack is to be used only for lifting loads and for

supporting lifted loads. Never use the jack for pushing

or separating objects, or for other non-lifting related

purposes.

• Never exceed the rated capacity of the jack. Allow for a

margin of safety that accounts for possible shifting loads

or side loading conditions. Failure to follow this warning

could cause the jack to fail.

• Never tamper with overload protection devices. The jack's

internal relief valve must not be repaired or adjusted

except by an authorized service center. The maximum

rated hydraulic pressure of the jack hydraulic system is

10000 psi [700 bar]. Higher settings may result in personal

injury and/or equipment damage.

• Be sure lifting arrangement is stable before lifting load.

Use jack only on a solid and level surface, capable of

supporting the load and the base of the jack. Always

center the load on the load cap of the jack. If the jack is

not perpendicular to the load, slipping or loss of load is

possible.

• Distribute the load evenly when performing lifts with

multiple jacks. Failure to heed this warning may cause loss

of load and/or failure of the jacks.

• Be aware of external events and acts of nature (wind,

storms, fl ooding, earthquakes or other seismic activity,

etc.) that could occur either while the jack is in active use,

or while it is left loaded and unattended. Do not use the

jack if it is likely that such conditions will occur.

1

™

Portable Lift

Page 2

CAUTION

Failure to observe and comply with the following precautions

could result in minor or moderate personal injury. Property

damage could also occur.

• When jack is not in use, fully retract the cylinder and protect

the entire unit from external damage. Keep the jack clean,

avoid weld splatter, and store in a clean dry area. Failure

to observe these precautions may cause erratic operation,

reduced performance, increased wear and/or damage to

jack.

• Keep the jack away from fl ames and heat. For optimum

performance, do not expose the jack to temperatures

above 150 °F [65 °C]. Failure to observe these precautions

may cause erratic operation, reduced performance,

increased wear and/or damage to jack.

• Immediately replace worn or damaged parts with genuine

Enerpac parts. Enerpac parts are designed to fi t properly

and to withstand high loads. Non-Enerpac parts may break

or cause the jack to malfunction.

NOTICE

• The jack is not designed for long-term support of lifted objects.

If the load must remain supported for more than 30 days, use

appropriately rated load support devices to support the load.

• Hydraulic equipment must only be serviced by a qualifi ed

hydraulic technician. For repair service, contact the Enerpac

Authorized Service Center in your area.

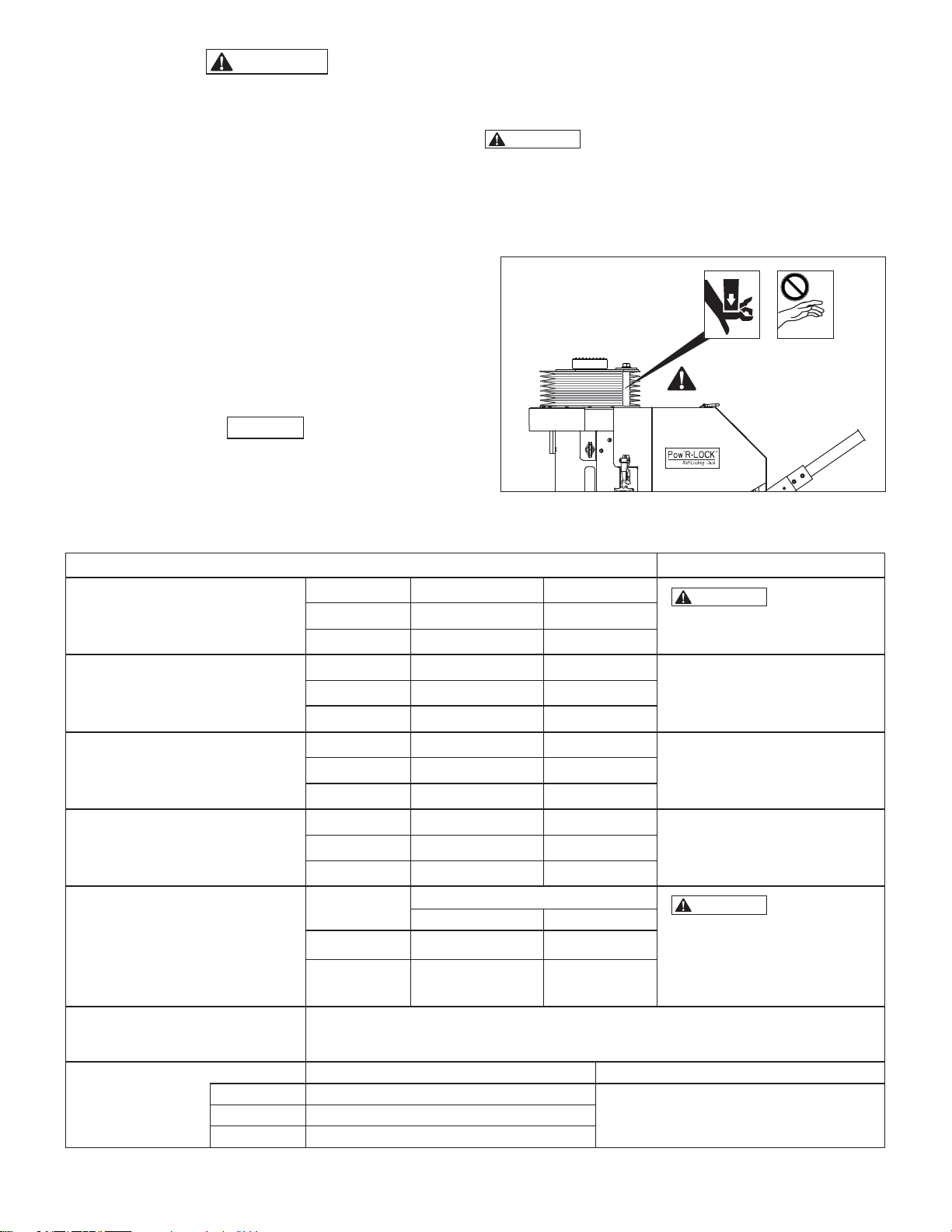

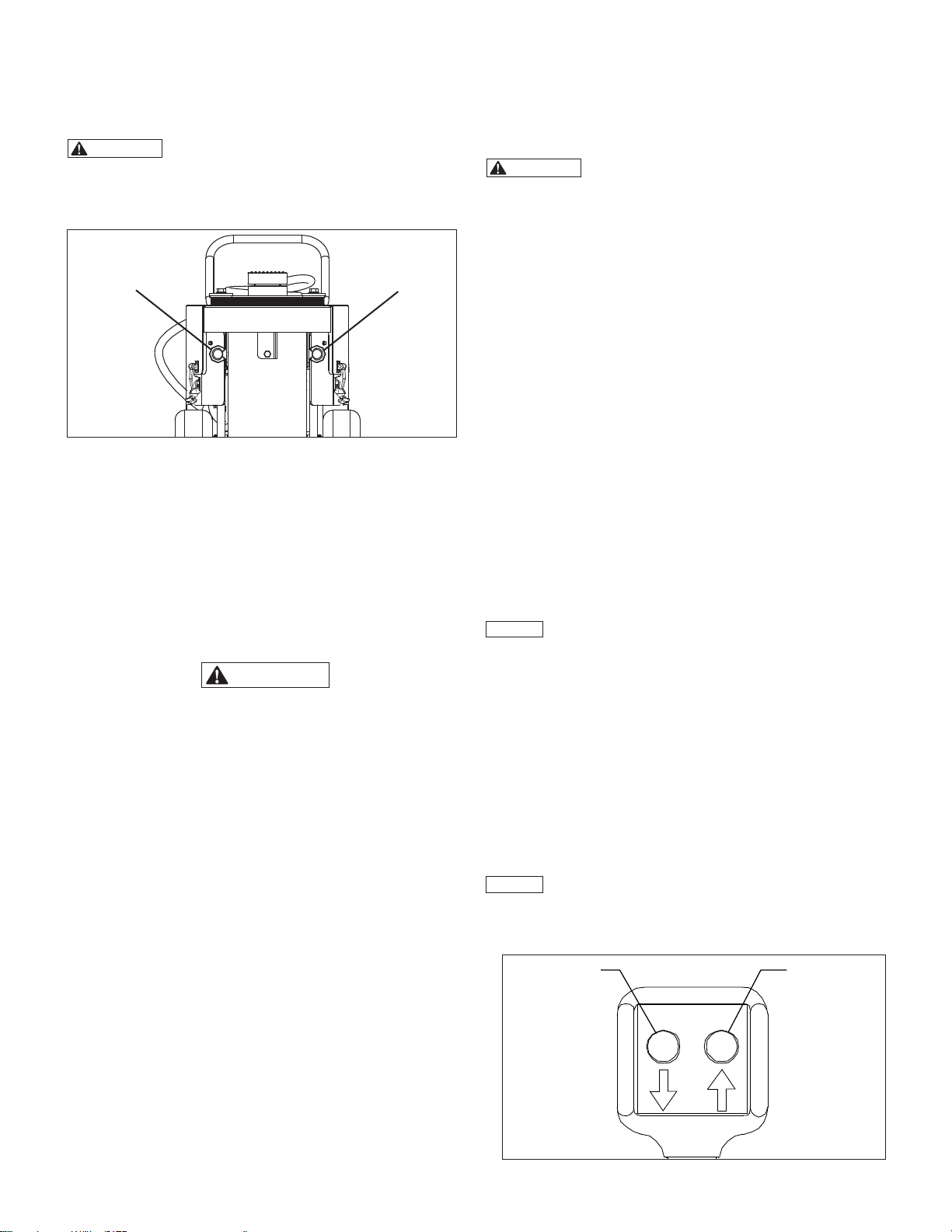

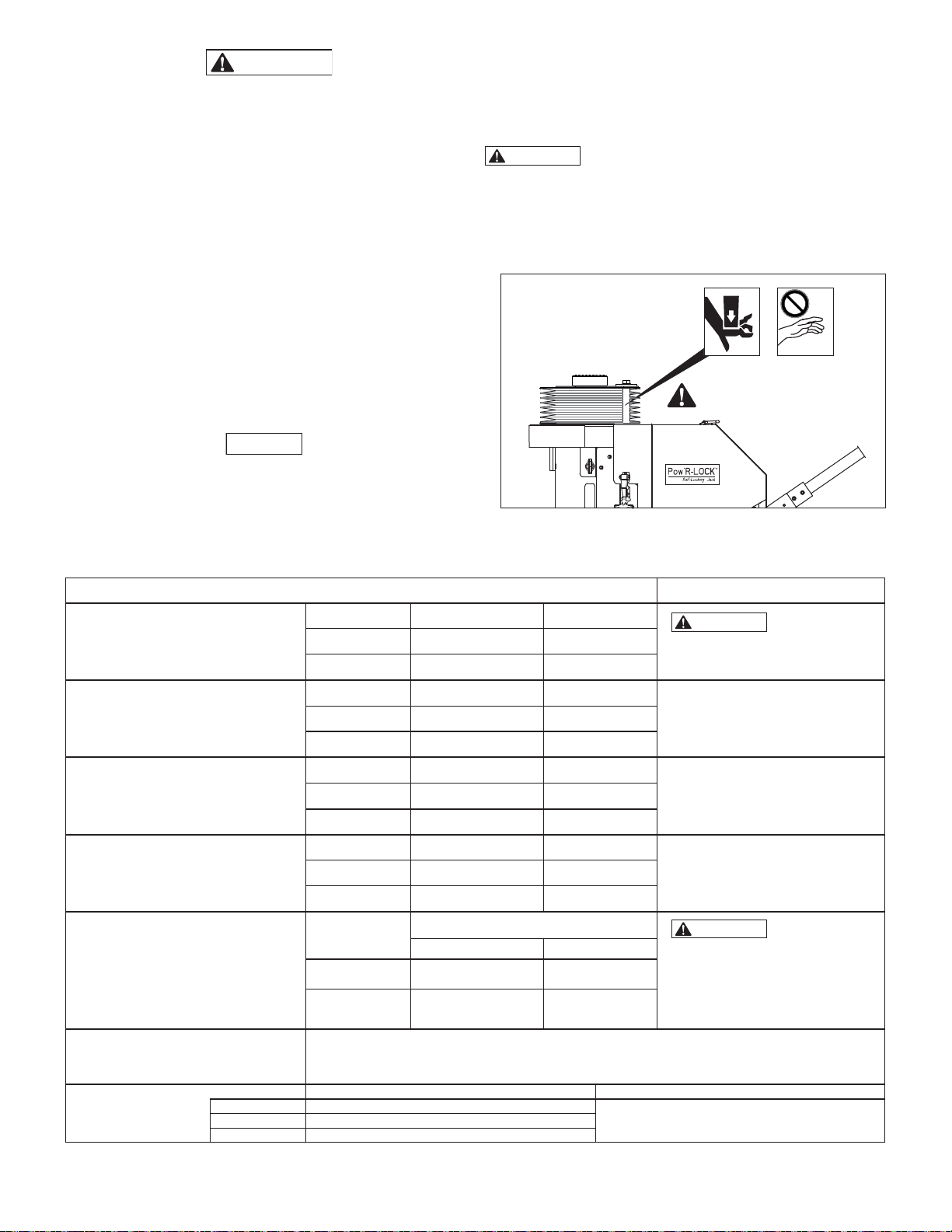

1.3 Crush and Pinch Point Hazard

WARNING

reach in between the cylinder anti-rotation plate and the jack

front access cover. Do not touch or grab the anti-rotation

rods. Do not place hands in or on the cylinder protective

bellows. Serious personal injury can occur if cylinder is

lowered and hands, fi ngers or other body parts are present in

these areas. See Figure 1.

CRUSH AND PINCH POINT HAZARD! Never

Crush and Pinch Point Hazard

Do not reach in this area!

Figure 1, Pinch Point Hazard

2.0 PRODUCT DATA

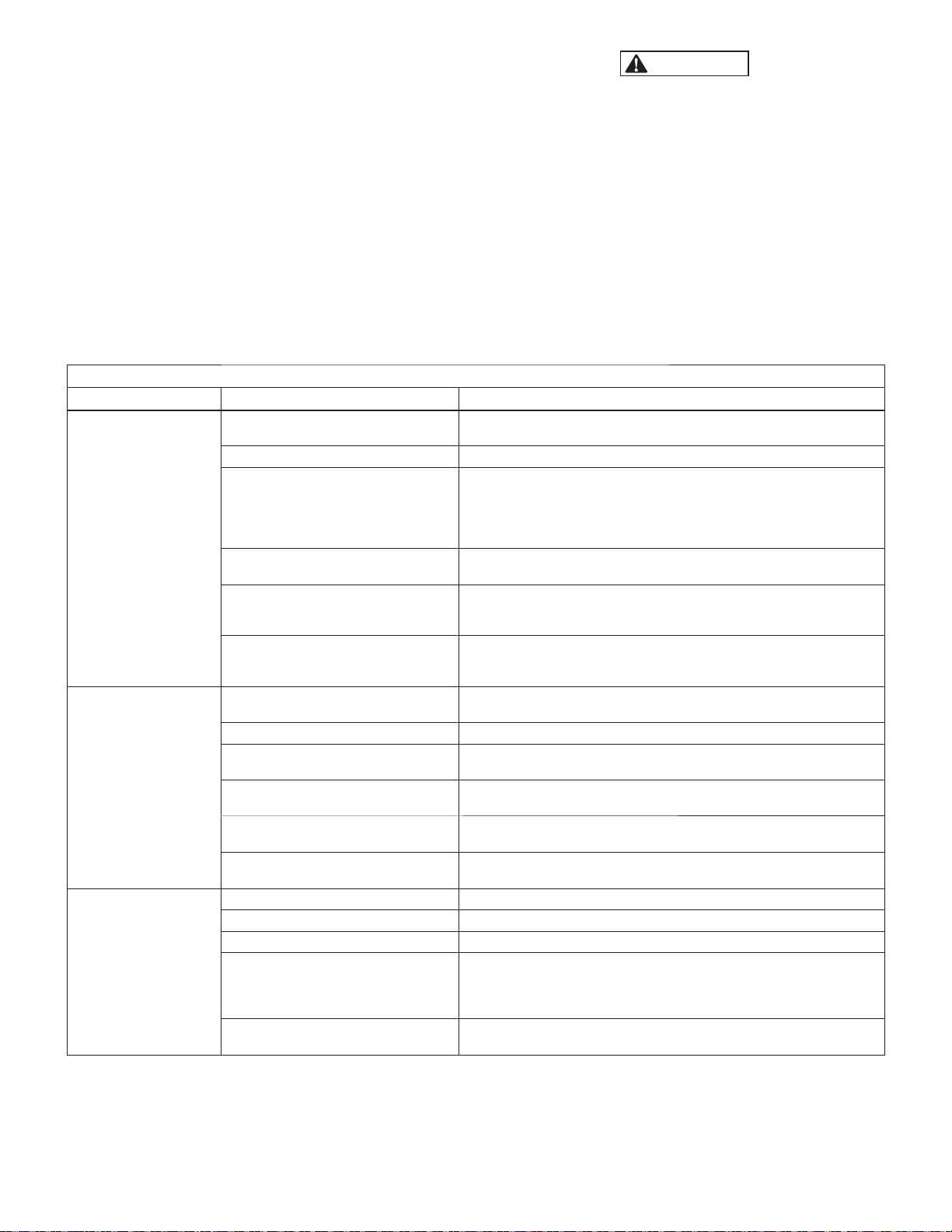

Table 1 - General Specifi cations (notes and precautions)

Model US Tons kN

Load Rating

(Maximum Capacity)

Weight

Collapsed Height (fully retracted)

Maximum Stroke (fully extended)

Hydraulic Pressure

Cylinder Advance Speed

Compressed Air

Requirements

NOTICE: Specifi cations are subject to change without notice.

Typical 90 - 100 psi [6,2 - 6,9 bar]

Maximum 120 psi [8,3 bar]

PL20014-ASA 200 1779

PL20025-ASA 200 1779

Model Pounds kg

PL20014-ASA 1105 501

PL20025-ASA 1320 599

Model inches mm

PL20014-ASA 34.0 864

PL20025-ASA 45.5 1156

Model inches mm

PL20014-ASA 14.0 356

PL20025-ASA 24.5 622

Model

PL20014-ASA 9898 682

PL20025-ASA 9898 682

Approximately 2.0 to 2.4 inches [51 - 61 mm] per minute.

NOTICE: Actual advance speed will vary depending on available air fl ow, pressure regulator setting,

pump speed, load weight, diameter of incoming air supply line and other variables.

Dynamic Air Pressure Air Flow Volume

Max. Working Pressure at Load Rating

psi bar

130 - 150 CFM [3681 - 4247 l/min]Minimum 50 - 60 psi [3,4 - 4,1 bar]

2

WARNING

jack load rating. Death, serious

personal injury and/or property

damage could result.

Weight includes reservoir fi lled with

oil but does not include accessories,

such as cylinder adapter, extensions

or spacers.

Refer to tables 2 and 3,

item E1.

Refer to tables 2 and 3,

item E2.

WARNING

pressure of the jack hydraulic

system is factory set at 10000 psi

[700 bar]. Do not attempt to

readjust pressure relief valve.

Death, serious personal injury and/

or property damage could result.

Do not exceed

The maximum

Page 3

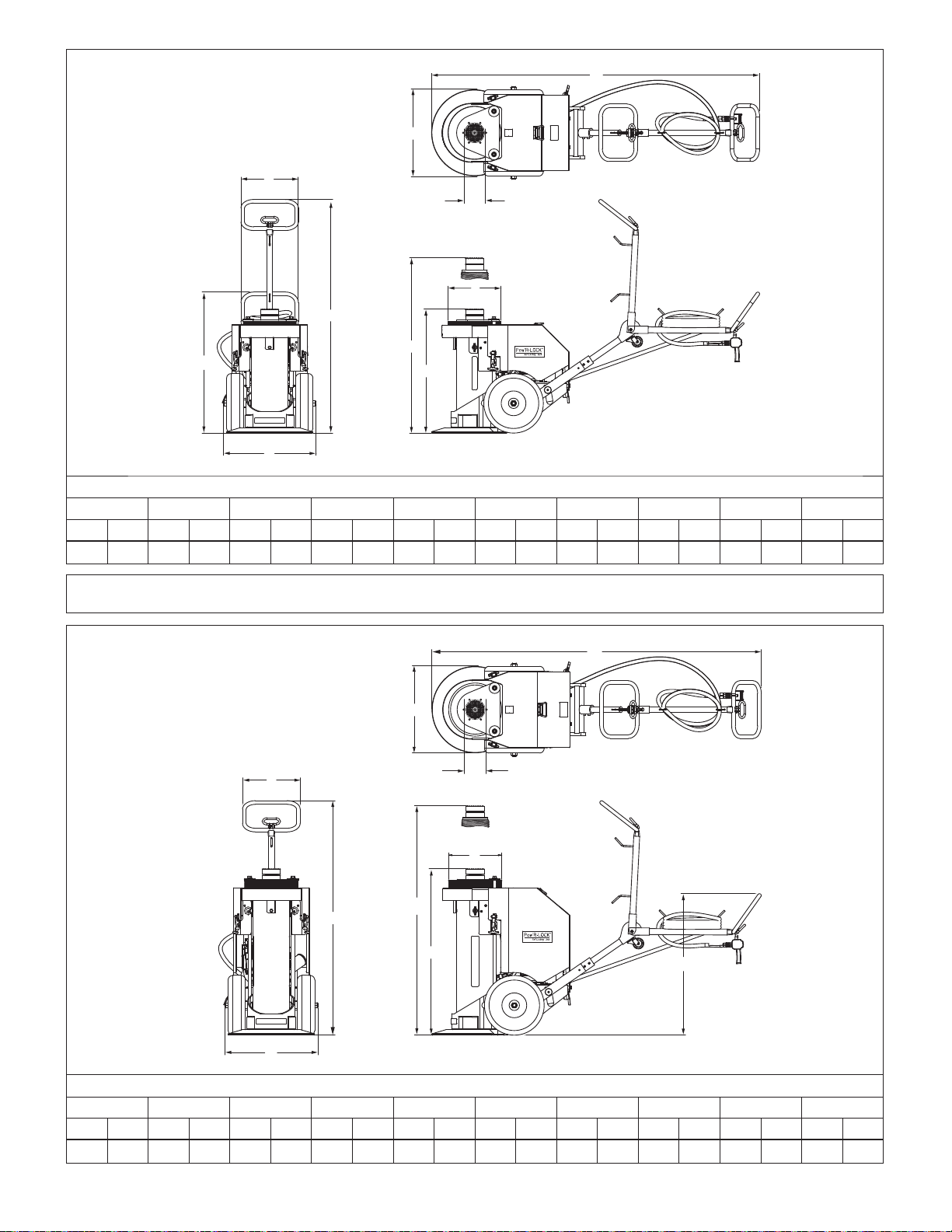

D

H

B

G

F

A2

E2

A1

C

E1

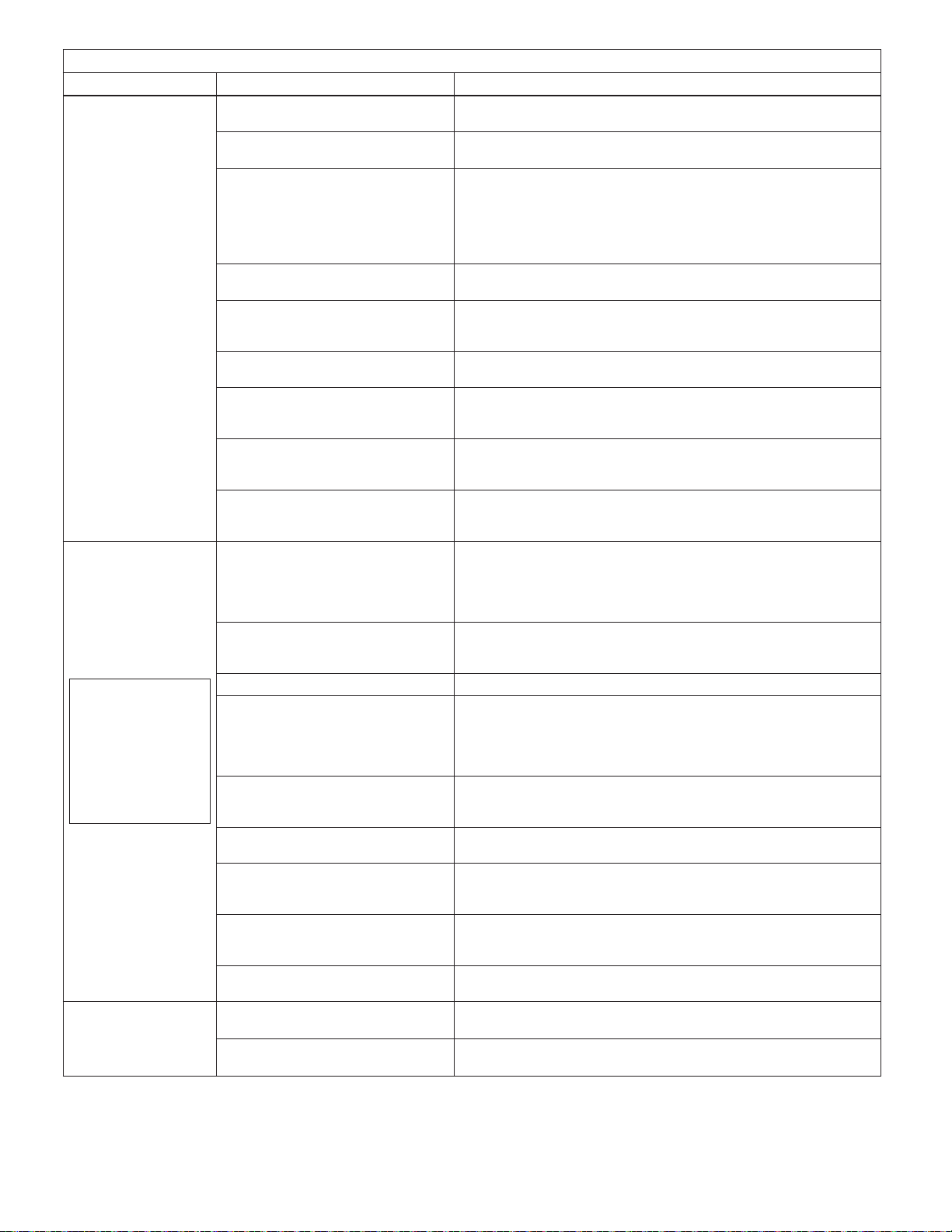

Table 2 - External Dimensions, PL20014-ASA

A1 A2 B C D E1 E2 F G H

inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

38.6 980 64.0 1626 15.7 399 25.4 645 89.9 2283 34.0 864 48.0 1219 14.5 368 5.0 127 23.6 599

NOTICE: Height of items E1 and E2 is with swivel load cap installed. Subtract 2 inches (51 mm) if non-swivel load cap is used.

Dimensions shown are approximate and subject to change without notice.

D

H

E1

G

F

A1

B

A2

E2

C

Table 3 - External Dimensions, PL20025-ASA

A1 A2 B C D E1 E2 F G H

inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

38.6 980 64.0 1626 15.7 399 25.4 645 89.9 2283 45.5 1156 70.0 1778 14.5 368 5.0 127 23.6 599

33

Page 4

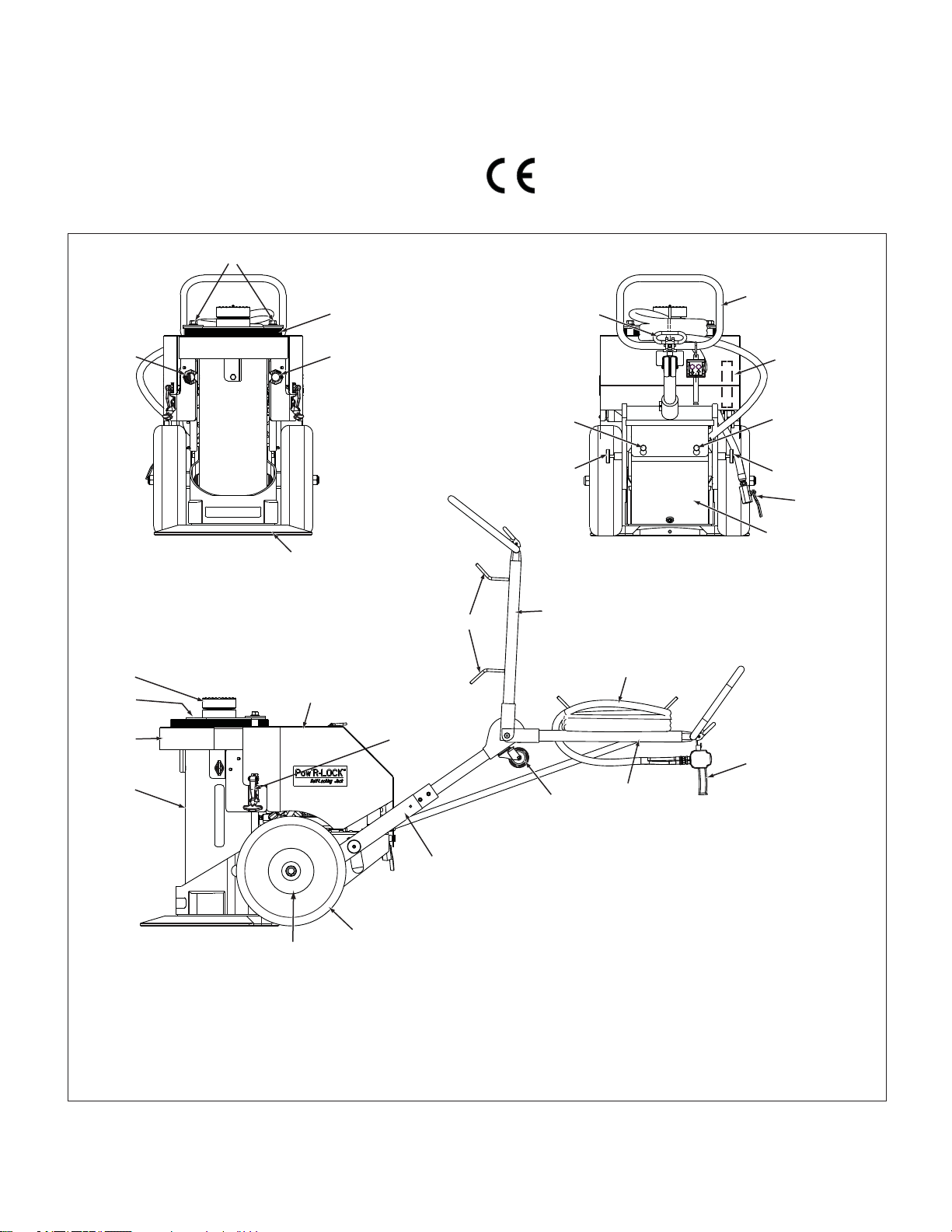

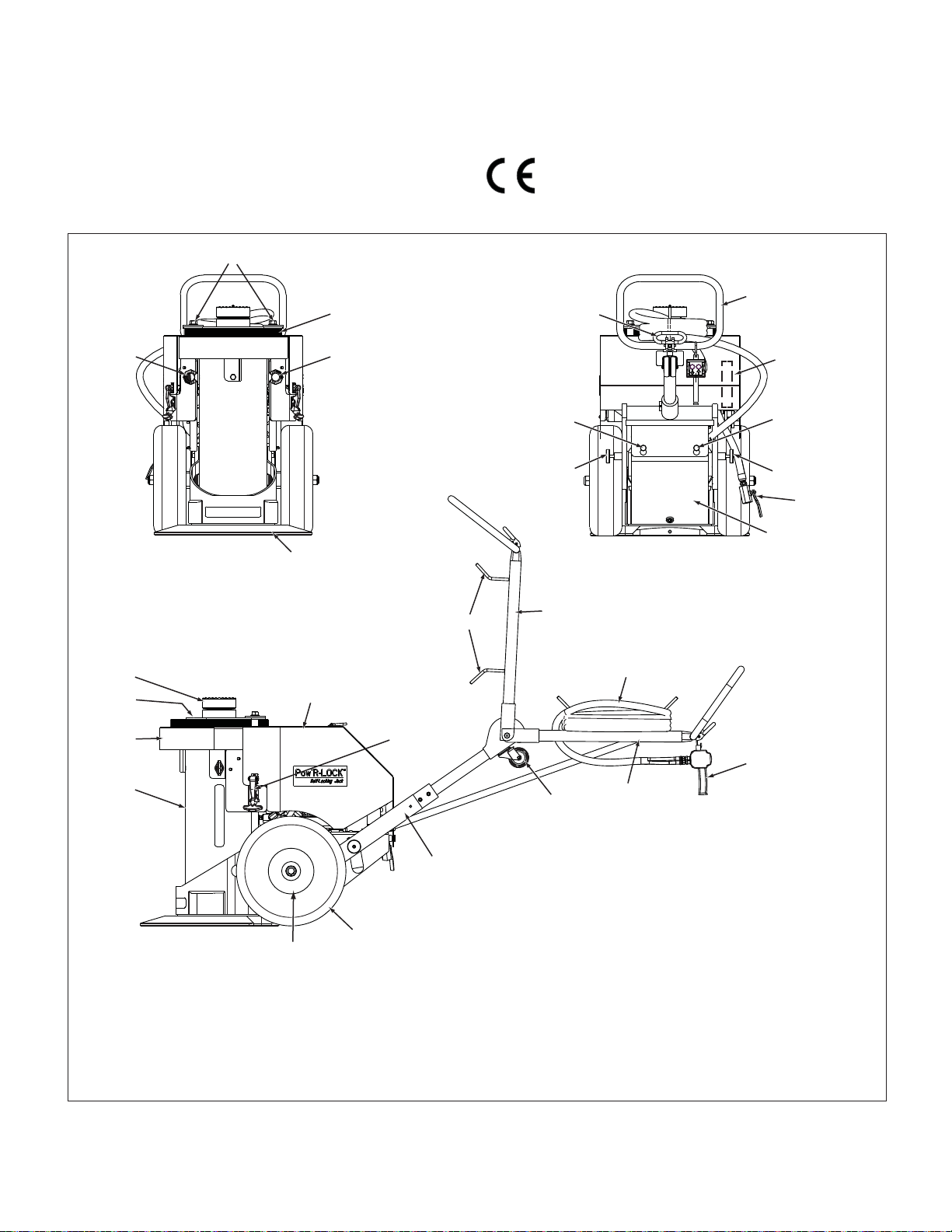

3.0 PRODUCT DESCRIPTION

The Pow’R-LOCK ™ lifting jack provides continuous positive

locking of the load through all stages of lifting and lowering. No

operator intervention is required to activate or de-activate the

automatic locking system.

Two di erent stroke lengths are available. Both models are

powered by an external compressed air system (user-supplied).

A convenient two-button pendant controls operation of the jack's

air motor and directional control valve.

02

03

Refer to Section 2.0 for specifi cations, dimensions and other

product data. See Figure 2 for a list of major features and

components.

4.0 CONFORMANCE TO NATIONAL AND

INTERNATIONAL STANDARDS.

Enerpac declares that this product has been tested and

conforms to applicable standards and is approved to

carry the CE mark. An EU Declaration of Conformity is

enclosed separately.

06

05

01 01

04

24

23

22

21

18

19

13

12A

16

08

09

See Fig. 3

08

09

07

10

14

15

12B

11

20

17

Key:

01. Lifting Eye

02. Anti-Rotation Tubes

03. Protective Bellows

04. Jack Base

05. Handle Lock Lever

06. Positioning Handle

07. Air Shut-o Valve

08. Rear Cover Supports

09. Detent Pin

10. Hydraulic Reservoir

11. Wheel and Hub

12A. Upper Handle (raised)

12B. Upper Handle (lowered)

13. Hose Storage Hooks

14. Pendant Hose

15. Pendant Control

16. Caster Wheel

17. Lower Handle

18. Rear Access Cover

19. Rubber Latch

20. Tire

21. Hydraulic Cylinder

22. Front Access Cover

23. Anti-Rotation Plate

24. Load Cap

Figure 2, Major Features and Components, PL200 Series Models (PL20014-ASA shown, PL20025-ASA similar)

4

4

Page 5

5.0 ASSEMBLY AND SETUP

5.1 Important Receiving Instructions

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

NOTICE

The jack rear access cover must be removed to gain

access to various components and service items discussed in

sections 5.2 through 5.4. Refer to Section 7.1 for cover removal

instructions.

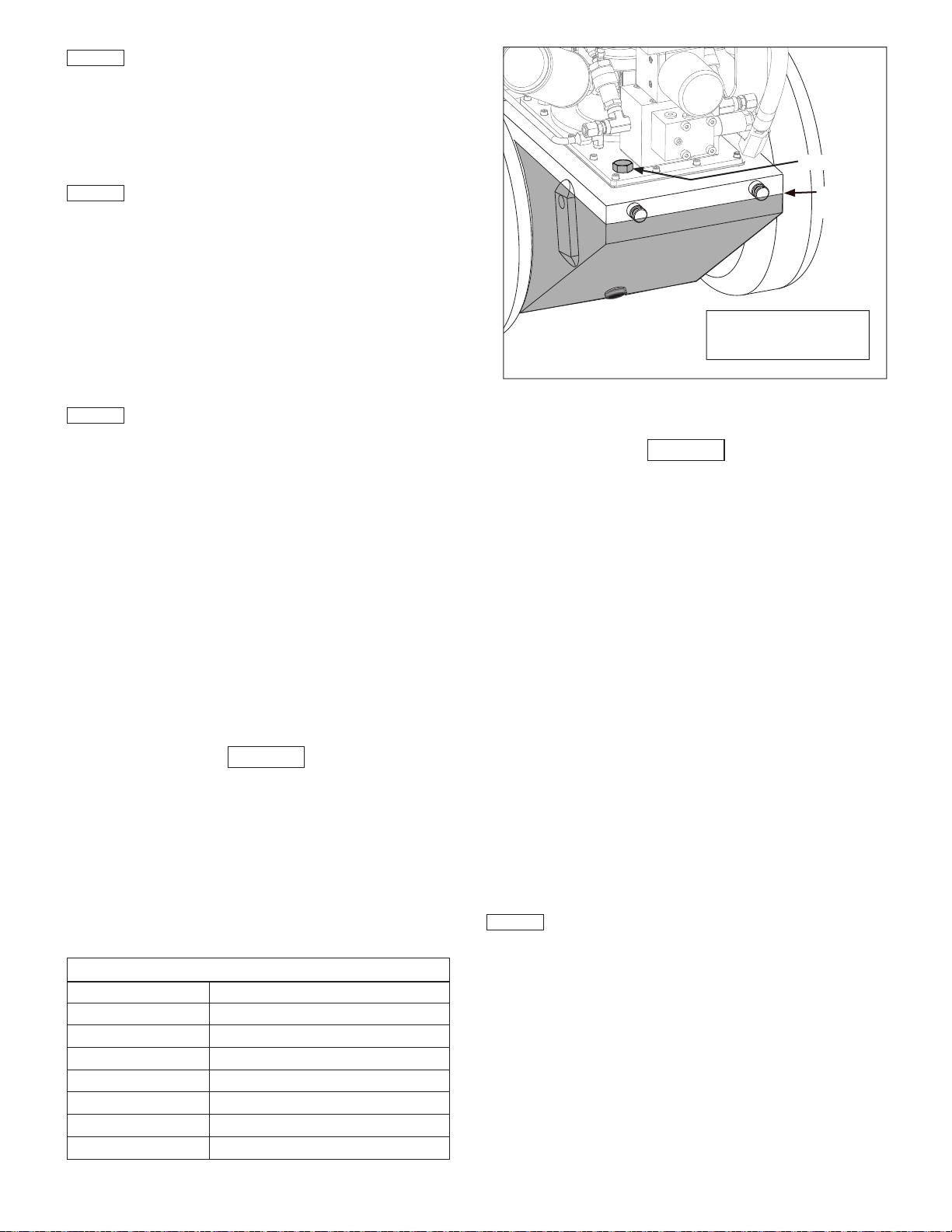

5.2 Hydraulic Oil Level

Before using the jack or connecting the air supply, remove the

oil fi ll plug from the hydraulic reservoir and check the oil level.

Add additional hydraulic oil to reservoir if oil level is low. See

Section 7.3 for oil level diagram, oil specifi cations and additional

instructions.

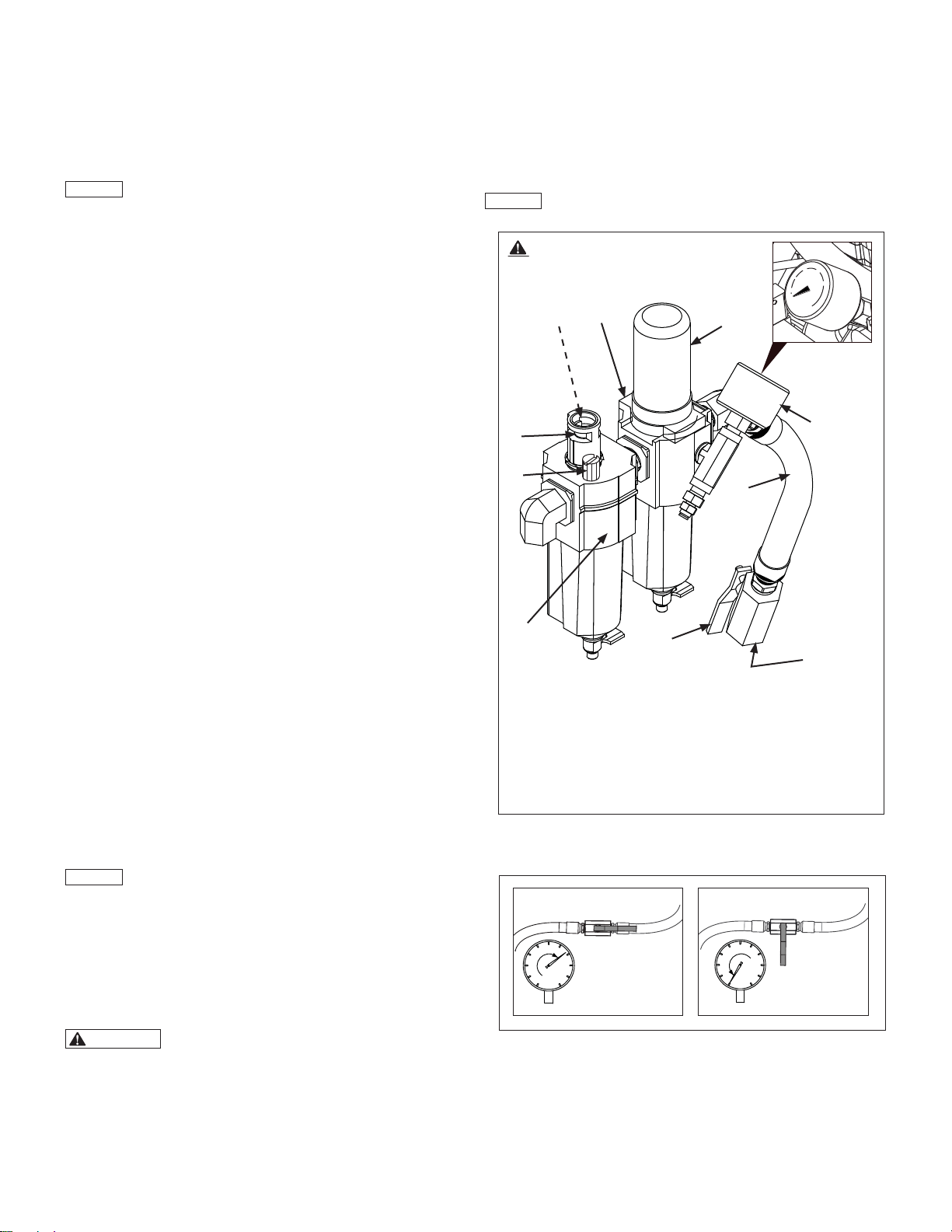

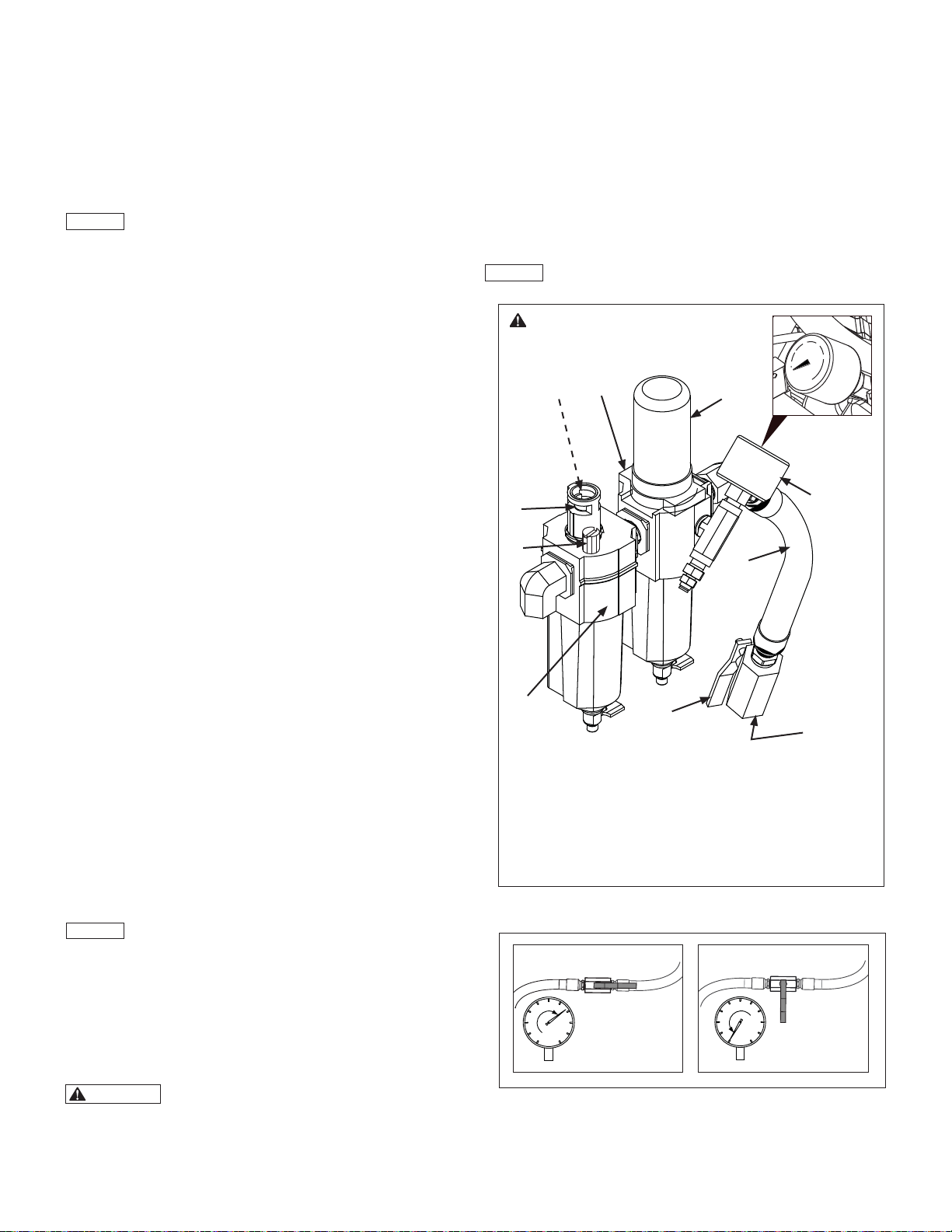

5.3 Compressed Air Requirements

The compressed air system used with the jack must be capable

of providing 80 - 100 psi [5,5 - 6,9 bar] @ 130 CFM [3681 l/min].

The jack is equipped with an air fi lter/regulator assembly, which

consists of an air regulator, pressure gauge and moisture trap.

See Figure 3, items A, B and F.

A short hose connects the fi lter/regulator to the air-shuto valve.

The air inlet connection is a 1/2 inch NPT female thread. See

Figure 3, items C, D and E. Refer to Figure 4 for shut-o valve

positions.

For e ciency of output and reliable operation, an air supply

line of not less than 0.82 inch [20,8 mm] internal diameter is

recommended. (Nominal Pipe Size - 3/4 inch pipe).

Check the air pressure gauge with the pendant UP button

depressed and the jack air motor running. Be sure there is NO

load on the cylinder. This will provide an accurate dynamic air

pressure reading.

The minimum dynamic air pressure required to operate the jack

will vary, but is typically about 50 to 60 psi [3,4 - 4,1 bar].

Approximately 90 to 100 psi [6,2 to 6,9 bar] dynamic air pressure

will be needed for the jack to achieve its rated 200 ton [1779 kN]

lifting capacity.

Lifting speed and torque can be adjusted using the knob located

at the top of the fi lter/regulator. To prevent damage to jack

pneumatic components, the regulator air pressure setting should

not exceed 120 psi [8,3 bar].

NOTICE

in reduced air motor life and will void the Enerpac product

warranty.

Pressure settings of above 120 psi [8,3 bar] will result

Before using the jack, check the lubricant level in the sight gauge

on the air line lubricator. Add additional lubricant if low. Refer to

Section 7.6 for air lubricant recommendations and additional air

lubricator information.

After the air supply hose has been connected, observe the oil

fl ow through the oil drip window while the cylinder is in motion.

Verify that the lubricator drip speed is set at 4 to 5 drops per

minute.

NOTICE

Air motor must be running and cylinder must be

moving up or down when checking lubricator oil drip speed.

Be sure air pressure gauge (item B)

indicates zero (0) psi/bar before

removing lubricator fi ll plug (item H).

0

F

J

I

A

B

H

C

G

E

D

Key:

A. Air Regulator Knob

B. Air Pressure Gauge

C. Air Inlet Hose

D. Air Inlet Connection

(1/2 inch NPT)

E. Air-shuto Valve

F. Air Filter/Regulator

(with moisture trap)

G. Air Line Lubricator

H. Lubricator Fill Plug

I. Oil Drip Window

J. Oil Drip Speed Control

(inside oil drip housing)

Figure 3, Filter/Regulator, Air Line Lubricator

and Air Shut-off Valve

5.4 Air Lubrication

The jack pneumatic system is equipped with an automatic air

line lubricator.

is necessary to provide lubrication for the air motor and to help

prevent rust formation.

WARNING

indicates zero (0) psi/bar before removing lubricator fi ll plug.

Lubricant may spray from fi ll opening if fi ll plug is removed

while system is pressurized, even when air hose has been

disconnected and air shut-o valve is in the closed position.

Serious eye injury and/or skin penetration could result. If any

pressure is indicated, relieve pressure as described in

Section 7.2 of this manual.

See Figure 3, items G, H, I and J.

Lubricated air

Be certain that regulator air pressure gauge

OPEN

CLOSED

Figure 4, Air Shut-Off Valve Positions

5

5

Page 6

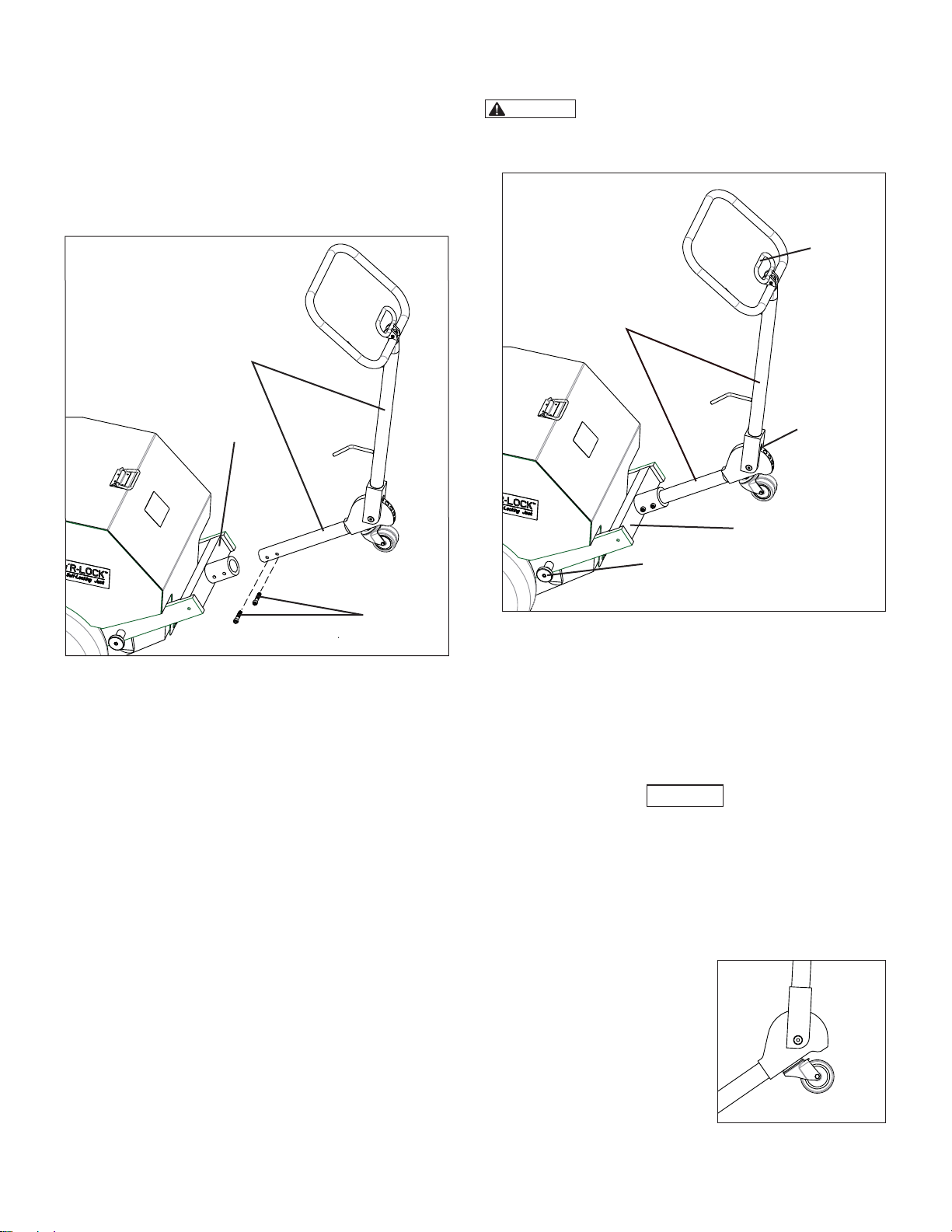

5.5 Upper Handle Installation

The upper handle is shipped unassembled. Install it as described

in the following steps. See Figure 5 for assembly details.

1. Align end of upper handle with opening in lower handle.

Slide upper handle into lower handle until it stops.

2. Secure upper handle with two 3/8-16 inch screws (shipped

loose). Tighten screws to approximately 150 in-lbs [16,9

Nm].

3. Wrap the pendant hose loosely around the hose storage

hooks and hang the pendant control on the upper handle.

Upper Handle

4. After engaging the lock pin and both detent pins, the jack

can now be tilted back onto the wheels and pushed or pulled

to the work area.

CAUTION

Do not walk backwards while pulling the jack.

Always look toward the direction where the jack is being

pulled. Failure to observe this precaution may cause you to

trip and fall, resulting in possible personal injury.

Handle

Lock Lever

Upper Handle

Lower Handle

Screws

(shipped loose)

Figure 5, Upper Handle Installation

5.6 Using the Handle Assembly

The handle assembly is used for transporting the jack on its

wheels and also serves as an aid for positioning the jack under

the jacking point. See Figure 6 for adjustment details.

UPPER HANDLE ADJUSTMENT

1. Push the handle lock lever to release the lock pin.

2. With the lock pin released, position the upper handle to

the desired location. Then, release the handle lock lever to

engage the lock pin.

DETENT PINS - LOWER HANDLE

The detent pins on the lower handle should be engaged in the

corresponding holes on the hydraulic reservoir before tilting the

jack back on its wheels.

To engage the detent pins:

1. Be sure that the detent pins are pulled-out on both sides of

the lower handle.

2. Push down fi rmly on the upper handle. The jack will tilt

forward slightly. Align the detent pins with the detent pin

holes (located on each side of the hydraulic reservoir).

3. While continuing to push down on the upper handle, push

both detent pins inward until they are fully engaged in the

detent pin holes.

Lock Pin

Lower Handle

Detent Pin

(one on each side

of lower handle)

Figure 6, Handle Adjustments

(pendant and hose not shown)

To disengage the detent pins:

1. Push down fi rmly on the upper handle to remove weight

from the detent pins.

2. Pull out the detent pins on both sides of the lower handle.

3. Slowly release hand pressure on the upper handle until the

jack base is resting on the fl oor or ground.

NOTICE

• Be certain that both detent pins are disengaged before using

the jack to lift, support or lower a load. Failure to observe this

precaution may result in damage to the lower handle, wheels,

or axles.

• To closely position the jack under the load, push down on the

upper handle with the detent pins disengaged.

5.7 Caster Wheel

A caster wheel is mounted at the

top end of the upper handle. It

allows the jack to be tilted back

and pushed or pulled to the desired

work location. The caster wheel

can also be used to help maneuver

the jack when it is being positioned

under the jacking point.

For best results, the upper handle

should be adjusted to the most

upright (vertical) position before

using the caster wheel.

6

6

Figure 7, Caster Wheel

Page 7

5.8 Lifting and Supporting the Jack

Two lifting eyebolts are located on the cylinder housing. Use only

these eyebolts when it is necessary to lift or support the jack

for any reason. Always use a suitable lifting device of adequate

capacity. Refer to Section 2.0 for jack weights.

WARNING

support the jack. The handle assembly is not designed for

this purpose. Jack will drop if failure of handle assembly

occurs. Death, serious personal injury and/or property

damage may result.

Lifting

Eyebolt

Never use the handle assembly to lift or

Lifting

Eyebolt

Figure 8, Lifting Eyebolts

6.2 Calculating Load Floor Pressure Requirements

Before the jack is used, it must be verifi ed that the surface

below the jack is capable of supporting the load. The following

calculation will determine the approximate maximum pressure

that will be exerted by the jack against the surface of the fl oor or

ground, based on the load being lifted.

WARNING

fl oor and/or ground can safely support the load to be lifted,

the jack should not be used in that location. Avoid using jack

on overburden or ballast that can shift or crush under load.

Consult a qualifi ed professional, such as a licensed civil

engineer or building architect If there are any questions

or concerns regarding load fl oor pressure requirements.

Failure to observe this instruction may cause an unstable

lifting arrangement, resulting in loss of load, personal injury

and/or property damage.

LOAD FLOOR PRESSURE CALCULATION:

Weight of Load x Load Factor = Load Floor

• The load factor to be used for the imperial system is 0.0125.

• The load factor to be used for the metric system is 0.00194.

If any doubt exists regarding whether the

Pressure Requirement

6.0 OPERATION

6.1 Jacking Safely

You must know the weight of what you intend to lift and choose

a jack with at least 20 percent additional capacity.

All persons operating the jack should obtain and be familiar with

the American National Standards Institute rules that apply to

hydraulic rams and jacks (ASME ANSI B30.1) or the equivalent

standards used in your country or region.

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury:

• Never place any part of your body under the load at any

time while lifting or lowering is in progress. The load could

drop suddenly if it becomes unstable.

• Never leave the jack unattended during operation, even

for a brief period of time. Closely monitor jack operation

at all times and be prepared to stop lifting or lowering

immediately. Load could drop if it is not monitored while

jack is in use.

• Avoid placing external forces on the lifted load while it

is being supported by the jack. The load may become

unstable and fall.

• Do not use the jack outdoors in windy conditions.

Changes in wind direction or velocity could cause the load

to become unstable and fall.

• When lifting with more than one jack, be especially careful

to keep the load level. Leveling is best accomplished by

throttling with the air shut-o valve or by alternating and

stopping jacks to keep the load level enough so it remains

stable and does not drop.

• Never operate the jack with the jack front access cover

raised or removed. Serious personal injury could result

if fi ngers, hands or other body parts become entangled

in the lock nut drive chain mechanism, or in the cylinder

threads.

These load factors are applicable to all Pow’R-LOCK ™ jack

models.

EXAMPLE:

For a 100000 pound [45359 kg] load, the following equations

would apply:

Imperial System: 100000 x 0.0125 = 1250 psi

Metric System: 45359 x 0.00194 = 87.99 kg/cm

NOTICE

of side loading. Excessive side loading will reduce the jack's

e ective foot print on the load fl oor and will increase the jack

contact pressure. Damage to jack components may occur.

The jack is designed to withstand only a limited amount

2

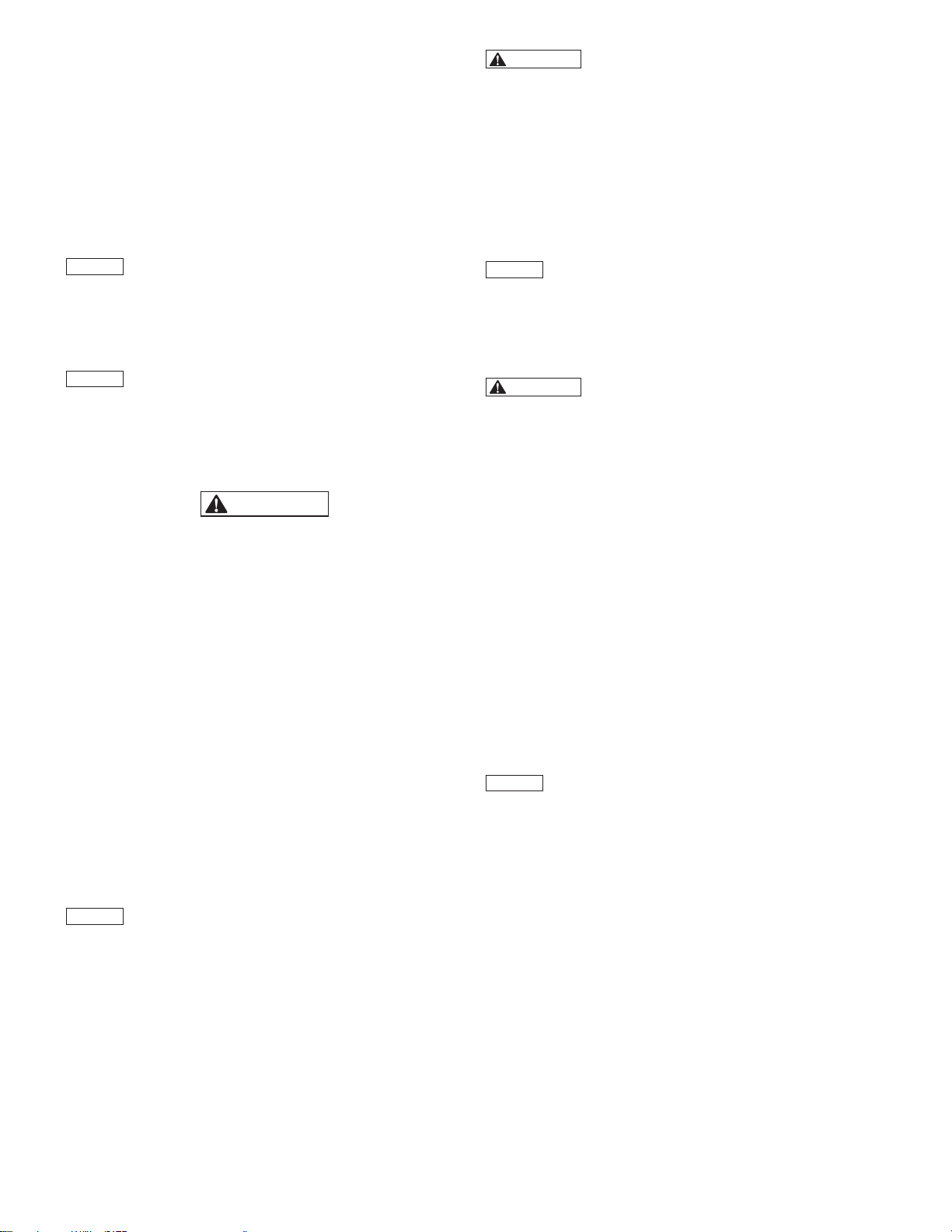

6.3 Pendant Controls

The air motor will start automatically when either pendant button

is depressed. See Figure 9.

• To extend (raise) the cylinder

press and hold the pendant UP button.

• To retract (lower) the cylinder press and hold the pendant DOWN button.

• To stop

release both pendant buttons.

NOTICE

there may be a brief delay until the desired action occurs. A small

amount of time (up to one second) is required for the jack's

pneumatic control circuit to respond to pendant commands.

7

7

the

cylinder and hold the load -

When depressing or releasing either pendant button,

DOWN

BUTTON

Figure 9, Pendant Controls

-

UP

BUTTON

Page 8

6.4 Checking Jack Operation Before Use

Before using the jack for the fi rst time, or if the jack has been

in storage for more than 30 days, check the jack operation as

described in the following steps:

1. If not already done, check the oil level in the hydraulic

reservoir. Refer to Section 7.3 for additional information.

2. Verify that the jack is connected to the compressed

air supply, and that the air pressure setting is correct.

Refer to section 5.3 for air pressure requirements and

recommendations.

3. Be sure that the jack air shut-o valve is in the OPEN position.

NOTICE

to Section 6.3 for pendant control information.

4. Fully extend and retract the cylinder to verify proper

NOTICE

supply is connected and the air-shuto valve is in the OPEN

position. This sound is normal, and indicates that the jack

pneumatic system is pressurized.

Perform the following step with no load on jack. Refer

operation. If needed, continue cycling the cylinder until

operation is smooth, and any trapped air has been removed

from the system.

The jack will make a “hissing” sound when the air

6.5 Operating Instructions

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Load may

become unstable or drop. Property damage could also occur.

• Always lift, support and lower the load in accordance with

all applicable work rules and regulations in e ect at your

worksite or facility.

• Wait an appropriate amount of time before working under

the load. Any settling of jack base or load supports (if used)

into the ground below must not exceed 1/4 inch [6,4 mm].

If additional settling occurs, lower the load and reposition

jack on solid ground.

BEFORE BEGINNING THE LIFT:

1. Using the handle assembly, adjust the jack position so that

the cylinder load cap is centered under the jacking point of

the load. Be sure that the jack base is positioned on a solid

and level support surface, with the cylinder perpendicular to

the fl oor or ground.

2. After positioning the jack, be sure that both detent pins on

the lower jack handle are fully pulled out (disengaged).

NOTICE

using jack to lift, support or lower a load. Failure to observe this

precaution may result in damage to the lower handle, wheels, or

axles.

3. If a high jacking point requires a taller jack, install extensions

4. Place a piece of good quality plywood or other compression

Be certain that both detent pins are disengaged before

and/or spacers (optional accessories) on the cylinder as

required. Refer to Section 6.6 for installation instructions and

additional information about extensions and spacers.

material (approximately 1/4 inch [6,4 mm] thick with high

friction characteristics) between the cylinder load cap

and the jacking point. This will provide a small amount of

cushioning and will also help prevent damage to the jacking

point.

WARNING

out of position, resulting in possible loss of load, personal

injury and/or damage to jack. As required, use a swivel load

cap to properly engage an angled lifting point. The slope of

the angled lifting point must not exceed 5 degrees.

TO RAISE THE LOAD:

1. Depress and hold the pendant UP button. The air motor will

start and the cylinder will begin extending.

2. When the load has reached the desired height, release the

pendant UP button. The cylinder will stop and the load will

remain supported.

NOTICE

load holding device, the use of auxiliary stands, blocking or other

additional load supports may be required in your location. Follow

all applicable work rules and regulations in e ect at your facility

or worksite.

TO LOWER THE LOAD:

WARNING

load is lowered evenly, so that load shifting does not occur.

Load shifting could cause instability, which could result in

loss of load and/or failure of the jack. This could cause death,

serious personal injury and/or property damage.

1. Be certain that no persons are working under the load. Alert

all personnel that the load is about to be lowered.

2. Depress and hold the pendant DOWN button. The air motor

will start and the cylinder will advance a slight amount to

raise and release the cylinder lock nut. The cylinder will then

begin to retract.

3. When the load has been lowered to the desired height,

release the pendant DOWN button. The air motor will stop.

AFTER COMPLETING THE JOB:

1.

Fully retract the cylinder.

the jack air-shuto valve.

2. To remove trapped pressure from the jack pneumatic system,

depress and hold the pendant UP button. The air motor may

run for a few seconds but will stop when pressure is relieved.

3. Always store the jack and its accessories in a clean and dry

area, free of moisture and direct sunlight.

NOTICE

top of the cylinder when jack is not in use. This will prevent water

from accumulating inside the recessed area at the top of the

cylinder.

Jacking at an angle can allow the jack to slip

Although the Pow’R-LOCK ™ jack is designed to be a

Be careful while lowering to ensure that the

Disconnect the air supply hose from

Always keep a load cap or extension installed in the

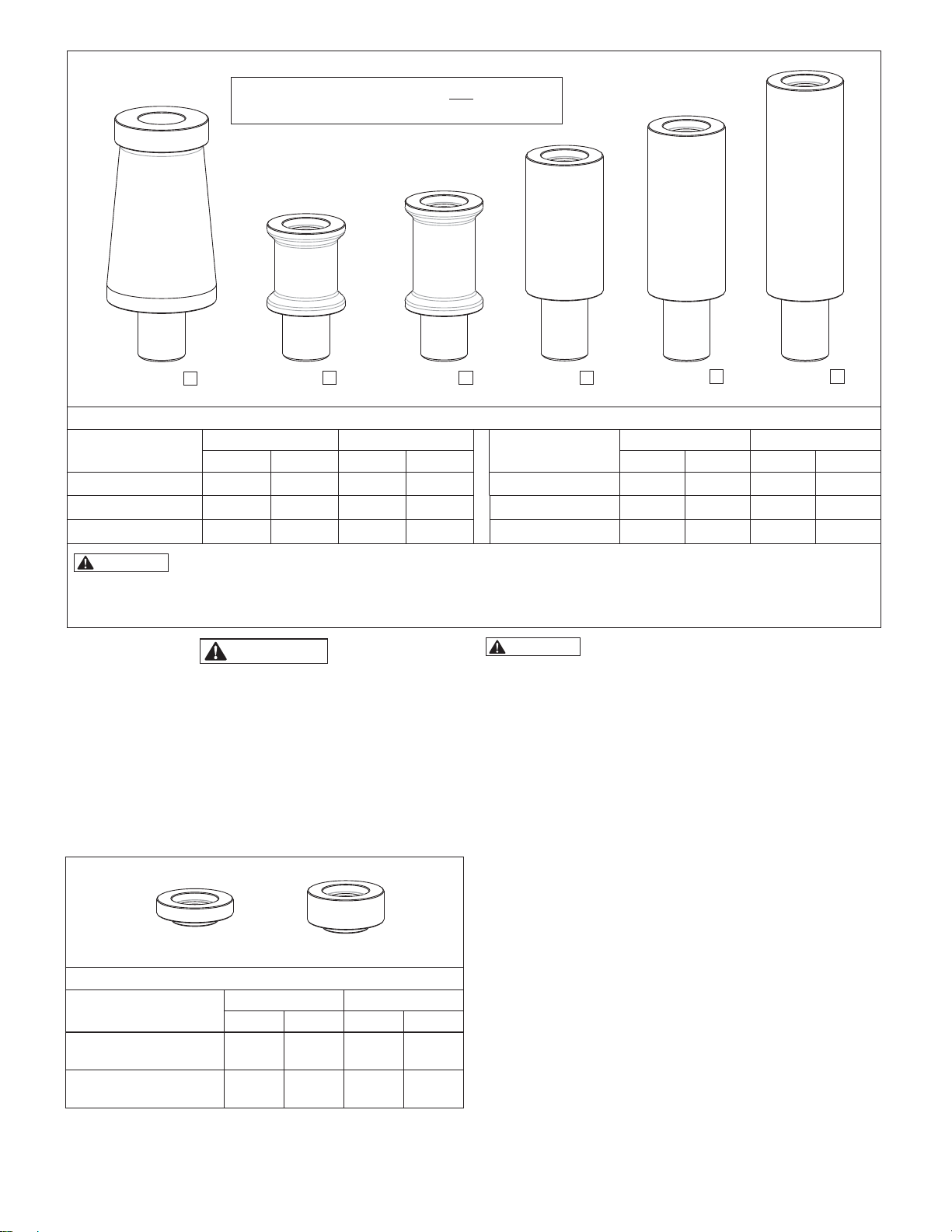

6.6 Stacking Instructions - Extensions and Spacers

Extensions and spacers are available as optional accessories

from your Enerpac authorized distributor. Refer to tables 4 and

5 for additional information.

PLE Series extensions allow the jack's usable lifting height to be

increased up to 9 inches [229 mm] for model PL20025-ASA and

up to 28 inches [711 mm] for model PL20014-ASA.

PLS Series spacers allow additional fi ne adjustment of the usable

lifting height. They may be used alone or in conjunction with

PLE Series extensions. Spacers of 1 and 2 inch [25 and 51 mm]

heights are available.

8

Page 9

▲

Use with jack model PL20014-ASA only.

▼

Use with jack model PL20014-ASA or PL20025-ASA.

PLB12 PLE5 PLE7 PLE9 PLE11 PLE14

▲

▼ ▼ ▼

▲

▲

Table 4 - PLB and PLE Series Extensions (optional accessories)

Extension

Model

PLB12 12 305 44.2 20,0 PLE9 9 229 28.0 12,7

PLE5 5 127 24.6 11,2 PLE11 11 279 31.7 14,4

PLE7 7 178 29.9 13,6 PLE14 14 356 37.4 17,0

WARNING

Extensions PLE11, PLB12 or PLE14 are to be used with the “short” jack model PL20014-ASA only. Use of

Height (each) Weight (each)

inches mm pounds kg inches mm pounds kg

Extension

Model

Height (each) Weight (each)

these extensions on “tall” jack model PL20025-ASA will result in an excessive maximum lifting height. Load could become

unstable and drop, resulting in possible personal injury and/or property damage.

NOTICE: Dimensions and weights shown are approximate.

WARNING

Failure to observe the following precautions and instructions

may allow the load to shift or drop, resulting in possible

personal injury and/or property damage.

• Use only genuine Enerpac PLB, PLE and PLS Series

extensions and spacers with the Pow’R-LOCK ™ jack.

Never use extensions or spacers that are fabricated or that

are designed for use with another lifting device.

• Never exceed the maximum additional stack height for your

jack model. Refer to Table 6 for additional information. An

excessive stack height will reduce the stability of the jack.

WARNING

precautions, and conditions could result in an unstable lifting

arrangement. Load could shift or drop, resulting in possible

personal injury and/or property damage.

When using PLB, PLE or PLS Series extensions and spacers,

always obey the following rules, precautions, and conditions:

• Table 6 shows the maximum additional stack height (dimension

“X”) that is allowed. When installing extensions and spacers,

do not exceed this dimension for your jack model.

• The total height of the PLS Series spacers installed in the stack

must not exceed 2 inches [51 mm].

Failure to observe the following rules,

• Jack model PL20014-ASA: Only one PLB12 base extension

(if used) must be present in the stack, and the PLB12 must

always be located at the bottom of the stacking arrangement.

Do not attempt to stack two or more PLB12's together.

• Extensions PLE11, PLB12 and PLE14 are designed for use

PLS1

PLS2

with model PL20014-ASA only. To prevent unsafe operation,

do not use these extensions on jack model PL20025-ASA (see

Table 5 - PLS Series Spacers (optional accessories)

Spacer Model

Height (each) Weight (each)

inches mm pounds kg

warning statement at bottom of Table 4).

• Be especially careful to avoid o -center loads and side loads

when using extensions and spacers.

PLS1 1.0 25 4.5 2,0

PLS2 2.0 51 9.1 4,1

NOTICE: Dimensions and weights shown are approximate.

9

Page 10

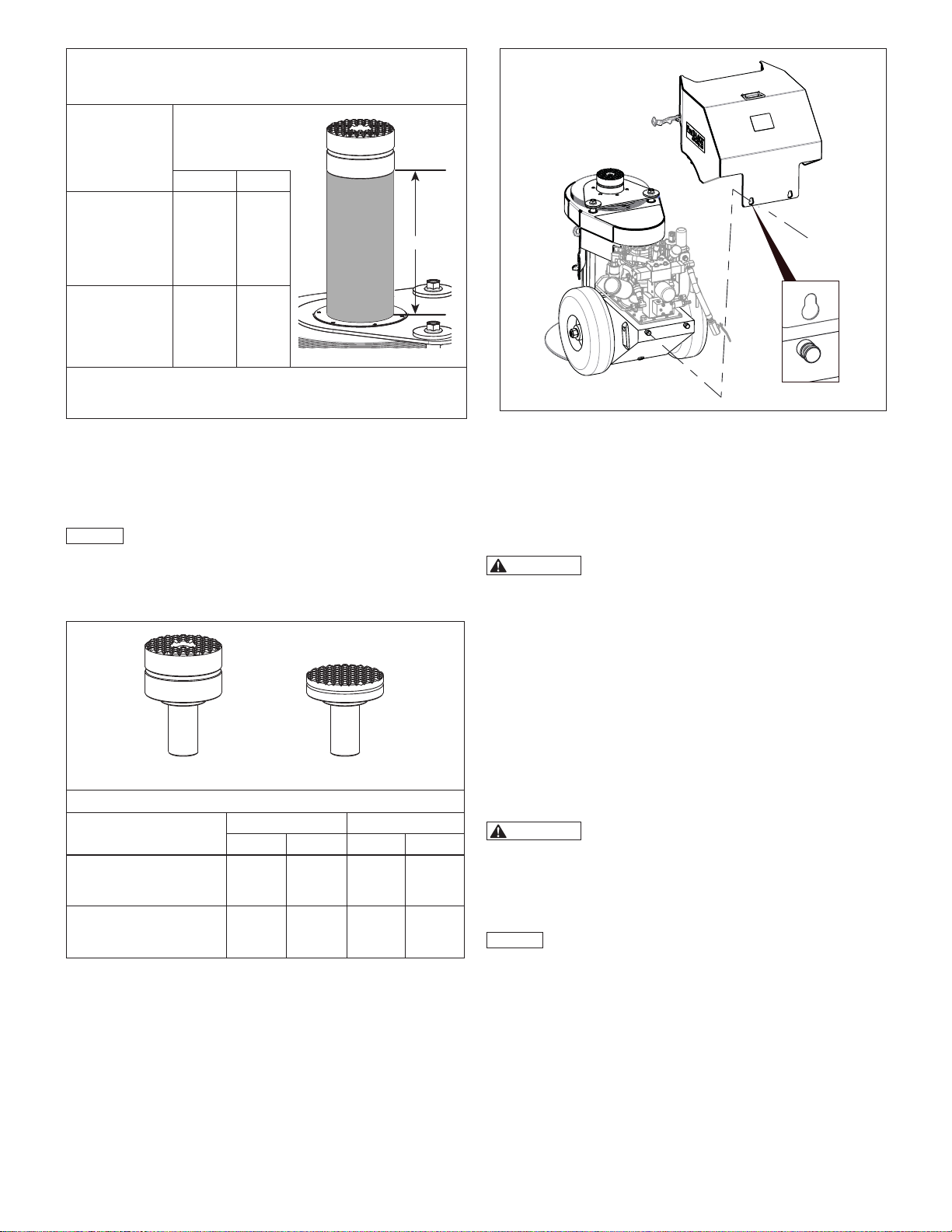

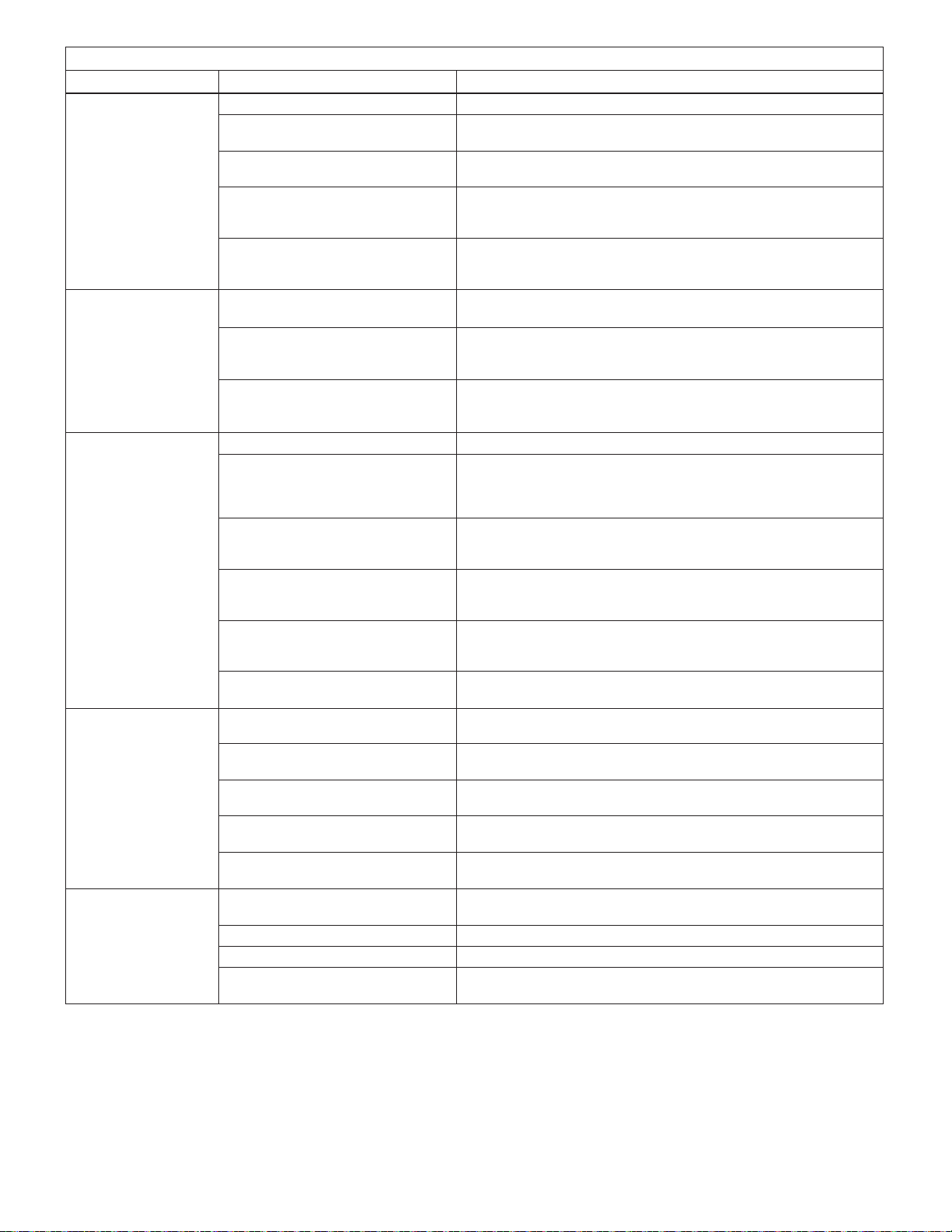

Table 6 - Maximum Additional Stack Height

(Using optional PLB and PLE Series

extensions and PLS Series spacers)

Maximum

Additional

Jack Model

Stack Height

(dimension “X”)

inches mm

PL20014-ASA 28.0 711

PL20025-ASA 9.0 229

Stack height (dimension “X”) includes total combined height of all

installed extensions and spacers. Load cap height is NOT included in

the stack height.

X

6.7 Load Caps

A swivel load cap is included with the jack as standard equipment.

A non-swivel load cap is available as an optional accessory, and

is for use in applications where a reduced collapsed height is

needed. Refer to Table 7 for load cap model numbers.

NOTICE

points. A swivel load cap should always be used when the

amount of misalignment between a non-swivel load cap and the

lifting point is too large to be compensated for by use of plywood

or other suitable high-friction compression material alone.

Use a swivel load cap to properly engage angled lifting

Figure 10, Rear Access Cover Removal

3. Gently guide the cover rearward until it has cleared the pins

and then lift the cover o of the jack.

4. Reverse steps 1, 2 and 3 to reinstall the cover. At the keyway

openings, be sure the groove in each cover support pin is

aligned with the cover sheet metal before fully installing the

cover onto the jack.

WARNING

Always reinstall the jack rear access cover

before using the jack. Except as necessary for maintenance

procedures, do not operate jack with cover removed. Serious

personal injury could occur if persons make contact with hot

surfaces or pressurized lines and components while cover is

removed. Damage could also occur if falling objects drop

onto exposed components.

DD4880045SR PLC1

Table 7 - Load Caps

Load Cap Model

DD4880045SR

Swivel Load Cap

(standard)

PLC1

Non-swivel Load Cap

(optional accessory)

NOTICE: Dimensions and weights shown are approximate.

Height (each) Weight (each)

inches mm pounds kg

3.3 84 20.2 9,2

0.88 22 10.4 4,7

7.0 MAINTENANCE

7.1 Rear Access Cover Removal

The jack rear access cover must be removed to gain access to

various inspection, lubrication and maintenance points. Remove

the jack rear access cover as described in the following steps:

1. Unhook the rubber latches on each side of the cover.

2. Pull up on the cover until the round openings on the cover

keyways align with the cover support pins on the rear of the

hydraulic reservoir.

7.2 Depressurizing the Jack Hydraulic and Pneumatic

Systems

For some maintenance procedures contained in Section 7 of

this manual, it is required that the jack hydraulic and pneumatic

systems be depressurized before the procedure can begin. These

operations are necessary to ensure the safety of the maintenance

personnel.

WARNING

steps may result in unexpected start-up of jack while

maintenance and repair procedures are being performed.

Uncontrolled release of pressure may also occur if

pressurized components are opened or pressurized fi ttings

are loosened. Serious personal injury could result.

NOTICE

before the pneumatic system is depressurized. Always be sure to

depressurize both systems.

1. Depressurize the jack hydraulic system, as described in

steps 1a through 1c:

a. Check that the jack is connected to the air supply and the

air-shuto valve is in the OPEN position.

b. Be sure the cylinder is in the fully retracted position.

c. Depress the pendant UP button while watching the

cylinder. Release the UP button IMMEDIATELY when the

cylinder starts advancing (usually after about 1 or 2 seconds).

This procedure will relieve any trapped pressure in the jack

hydraulic system.

10

Failure to follow the procedure in the following

The hydraulic system must be depressurized fi rst,

Page 11

NOTICE

To prevent hydraulic pressure from re-building in the

system, do not depress the pendant DOWN button at any time

during the following steps.

2. Depressurize the jack pneumatic system, as described in

steps 2a through 2f:

a. Move the jack air-shuto valve to the CLOSED position.

b. Disconnect air supply hose at jack air-shuto valve.

NOTICE

Jack may start and run briefl y in the following step, as

trapped air is expelled from the jack pneumatic system.

c. Depress and hold the pendant UP button. Continue

holding button until jack air motor stops running. Motor will

usually stop after about 2 to 6 seconds, depending on length

of air supply hose.

d. Verify that there is no audible “air hiss” sound coming

from the jack.

e. Remove the jack rear access cover (if not already

removed). Refer to Section 7.1.

f. Check the air pressure gauge on the jack fi lter/lubricator.

Verify that it indicates zero (0) psi/bar.

NOTICE

If any pressure is indicated on gauge, be certain that

air-shuto valve is in the CLOSED position and that air hose is

disconnected from air shut-o valve. Then, repeat steps 2c

through 2f.

3. Proceed with desired maintenance or repair procedure.

7.3 Checking Oil Level

Check the hydraulic oil level every 90 days.

1. Be sure that cylinder is fully retracted and that the jack is

positioned on a fi rm and level surface.

2. Remove the jack rear access cover. Refer to Section 7.1.

3. Be sure the air shut-o valve is in the CLOSED position.

4. Unscrew and remove the oil fi ll plug. See Figure 11.

5. Check the oil level in the reservoir. Oil level should be

approximately 1 inch [25 mm] below top of reservoir, with

cylinder fully retracted and air motor turned o . See Figure 11.

6. If oil level is low, add Enerpac HF hydraulic oil as required.

Use a funnel to avoid spillage.

NOTICE

• Reservoir is vented. To prevent oil leakage through the air

breather, do not fi ll reservoir completely to the top.

• To help avoid accidental overfi lling of reservoir, always make

sure that cylinder is fully retracted before checking oil level or

adding additional oil.

• If Enerpac HF is not available at the worksite, use an equivalent

hydraulic oil that meets the specifi cations shown in Table 8.

7. Reinstall oil fi ll plug.

8. Reinstall the jack rear access cover. Refer to Section 7.1.

Table 8 - Hydraulic Oil Specifi cations - ISO 32

ISO Grade

Viscosity Index 100 min

Viscosity at 210

Viscosity at 100

Viscosity at 0

API Gravity

Flash, C.O.C.

Pour Point,

°F

°F

°F

°F

°F

32

42-45 S.U.S.

150-165 S.U.S.

<12000 S.U.S.

31.0-33.0

400

-35

Oil Fill Plug

Oil Level

(FULL)

FULL = 1 inch [25 mm]

below top of reservoir

Figure 11, Oil Level - Hydraulic Reservoir

(handle assembly removed to show detail)

NOTICE

• Failure to use the proper oil may result in damage to jack

hydraulic components and will void the product warranty. Use

of Enerpac HF oil is strongly recommended.

• Be sure that the oil is clean. The oil cleanliness should be

maintained to a maximum level of 18/16/13 per the ISO4406

standard. If the oil has a milky, cloudy or dark appearance, it

should be changed immediately as described in Section 7.4.

7.4 Changing the Oil

Change the oil in the hydraulic reservoir every 12 months or 500

hours of use. See Figure 12.

The following conditions will require more frequent oil changes:

• Rigorous duty, where oil temperature may reach 150 °F

[60 °C].

• A high humidity environment and/or extreme changes in

temperature that can result in condensation inside the reservoir.

• Dirty or dusty environments that may contaminate the oil.

Change the oil as described in the following steps:

1. Be sure that cylinder is fully retracted.

2. Remove the jack rear access cover. Refer to Section 7.1.

3. Completely relieve any trapped pressure in the jack hydraulic

and pneumatic systems. Disconnect the air supply hose

from the air shut-o valve. Follow procedure in Section 7.2.

NOTICE

[18,9 liter] of oil when fi lled to the proper level with cylinder fully

retracted and air motor o . Dispose of used oil in accordance

with all applicable laws and regulations.

4. Loosen and remove oil drain plug at bottom of reservoir.

5. Clean and reinstall oil drain plug.

6. Remove, clean and reinstall the reservoir air breather.

7. Using a strap wrench, unscrew and remove the old oil fi lter.

11

The hydraulic reservoir holds approximately 5 gallons

Allow used oil to drain into a suitable container. It may be

necessary to tip the jack back slightly to completely drain all

oil and any debris from the bottom of the reservoir.

Replace the air breather if clogged or damaged.

Catch any spilled oil in a suitable container. Dispose of spilled

oil in accordance with all applicable laws and regulations.

Page 12

NOTICE

Use only a new 10 micron oil fi lter of the proper

specifi cations (Enerpac Part No. 69670E or equivalent).

8. Before installation, lubricate the new oil fi lter's rubber seal

with a small amount of oil. Tighten fi lter hand tight only (do

not use tools).

4

1

2.

Key:

1. Air Breather

2. Oil Fill Plug

Figure 12, Oil Change

(handle assembly removed to show detail)

9. Remove the oil fi ll plug and add Enerpac HF hydraulic oil as

required. Use a funnel to avoid spillage. Oil level should be

approximately 1 inch [25 mm] below top of reservoir, with

cylinder fully retracted and air motor turned o . See Figure

11 for oil level diagram.

3.

3. Oil Drain Plug

4. Oil Filter

NOTICE

• Reservoir is vented. To prevent oil leakage through the air

breather, do not fi ll reservoir completely to the top.

• To help avoid accidental overfi lling of reservoir, always make

sure that cylinder is fully retracted before checking oil level or

adding additional oil.

• If Enerpac HF is not available at the worksite, use an equivalent

hydraulic oil that meets the specifi cations shown in Table 8.

10. Clean the oil fi ll plug and apply thread sealant to the threads.

Reinstall oil fi ll plug.

WARNING

In the following step, it will be necessary to

extend and retract the cylinder several times. Stay clear of

the cylinder and related components. Keep hands and fi ngers

away from pinch and crush points. Serious personal injury

could occur if these precautions are not observed. Refer to

Section 1.3 of this manual for additional hazard information.

11. With no load on the jack, extend and retract the cylinder

several times to check for proper operation, and to remove

any trapped air in the hydraulic system.

12. With the cylinder fully retracted and the pump motor o ,

re-check oil level to be sure that it has not dropped. Add

additional oil if required. See Figure 11 for oil level diagram.

13. Reinstall the jack rear access cover. Refer to Section 7.1.

7.5 Air Line Filter/Regulator (See Figure 13)

Every 30 hours of operation:

1. Remove the jack rear access cover. Refer to Section 7.1.

2. Completely relieve any trapped pressure in the jack hydraulic

and pneumatic systems. Disconnect the air supply hose

from the air shut-o valve. Follow procedure in Section 7.2.

3. Check the fi lter bowl sight gauge for water. A manual drain is

located at the bottom of the fi lter/regulator bowl. If water is

present, drain it into a suitable container and dispose of it in

accordance with all applicable laws and regulations. Be sure

the drain is fully closed after draining is completed.

Rear View

K

Key:

A. Air Regulator Knob

B. Air Pressure Gauge

C. Air Inlet Hose

D. Air Inlet Connection

(1/2 inch NPT)

E. Air-shuto Valve

Figure 13, Routine Service and Maintenance Items - Air Filter/Regulator and Air Line Lubricator

F

G

(item B) indicates zero (0) psi/bar

before removing lubricator fi ll

plug (item H) or performing

maintenance activities.

M

L

F. Air Filter/Regulator

(with moisture trap)

G. Air Line Lubricator

H. Lubricator Fill Plug

I. Oil Drip Window

J. Oil Drip Speed Control

Be sure air pressure gauge

K. Filter Bowl Sight Gauge

L. Drain Valves

M. Lubricant Bowl Sight Gauge

N. Lubricant Bowl

O. Filter Bowl

12

J

A

B

I

H

N

O

Front View

C

E

D

Page 13

4. Remove fi lter bowl and inspect the air fi lter element (inside

fi lter bowl). Replace fi lter element if dirty.

NOTICE

Norgren for detailed maintenance instructions, fi lter elements

and replacement parts.

Filter/regulator is manufactured by Norgren. Contact

7.6 Air Line Lubricator (See Figure 13)

Every 30 hours of operation:

1. Remove the jack rear access cover. Refer to Section 7.1.

2. Check the sight gauge on the air line lubricant bowl. The

lubricant level should be at least 1/2 full.

NOTICE

described in steps 3 through 6. If lubricant level is OK, skip these

steps and go to step 7.

3. Completely relieve any trapped pressure in the jack hydraulic

completely depressurized and regulator air pressure gauge

indicates zero (0) psi/bar before removing lubricator fi ll plug.

Lubricant may spray from fi ll opening if fi ll plug is removed

while system is pressurized, even when air hose has been

disconnected and air shut-o valve is in the closed position.

Serious eye injury and/or skin penetration could result.

4. Remove the lubricator fi ll plug. Add additional lubricant as

For ambient temperatures above 32°F [0°C], use a high quality

NOTICE

gauge. Do not operate jack with excess lubricant in lubricant

bowl. If lubricant bowl is overfi lled, jack air logic circuit may

become fl ooded with lubricant, preventing normal operation

of jack.

5. Reinstall the lubricator fi ll plug.

6. Reconnect the air supply hose. Be sure the air shut-o valve

7. Check the lubricator drip speed in the drip window:

• Drip speed should be 4 to 5 drops per minute. Always check

• If drip speed is too slow or too fast, readjust the drip speed

NOTICE

Norgren for detailed maintenance instructions, fi lter elements

and replacement parts.

8. Reinstall the jack rear access cover. Refer to Section 7.1.

If lubricant level is low, add additional lubricant as

and pneumatic systems. Disconnect the air supply hose

from the air shut-o valve. Follow procedure in Section 7.2.

WARNING

required, until the level reaches the top of the lubricant bowl

sight gauge. DO NOT OVERFILL!

SAE 10 [ISO 32] air tool lubricant. For ambient temperatures

below 32°F [0°C], use only a glycol-based anti-freeze air tool

lubricant (Enerpac part number DD5142835 or equivalent).

is in the OPEN position.

the drip speed while the cylinder is advancing or retracting.

as required. Use a fl at blade screwdriver to turn the drip

speed adjustment screw.

Be certain that jack pneumatic system is

Lubricant level must not be higher then top of site

Air line lubricator is manufactured by Norgren. Contact

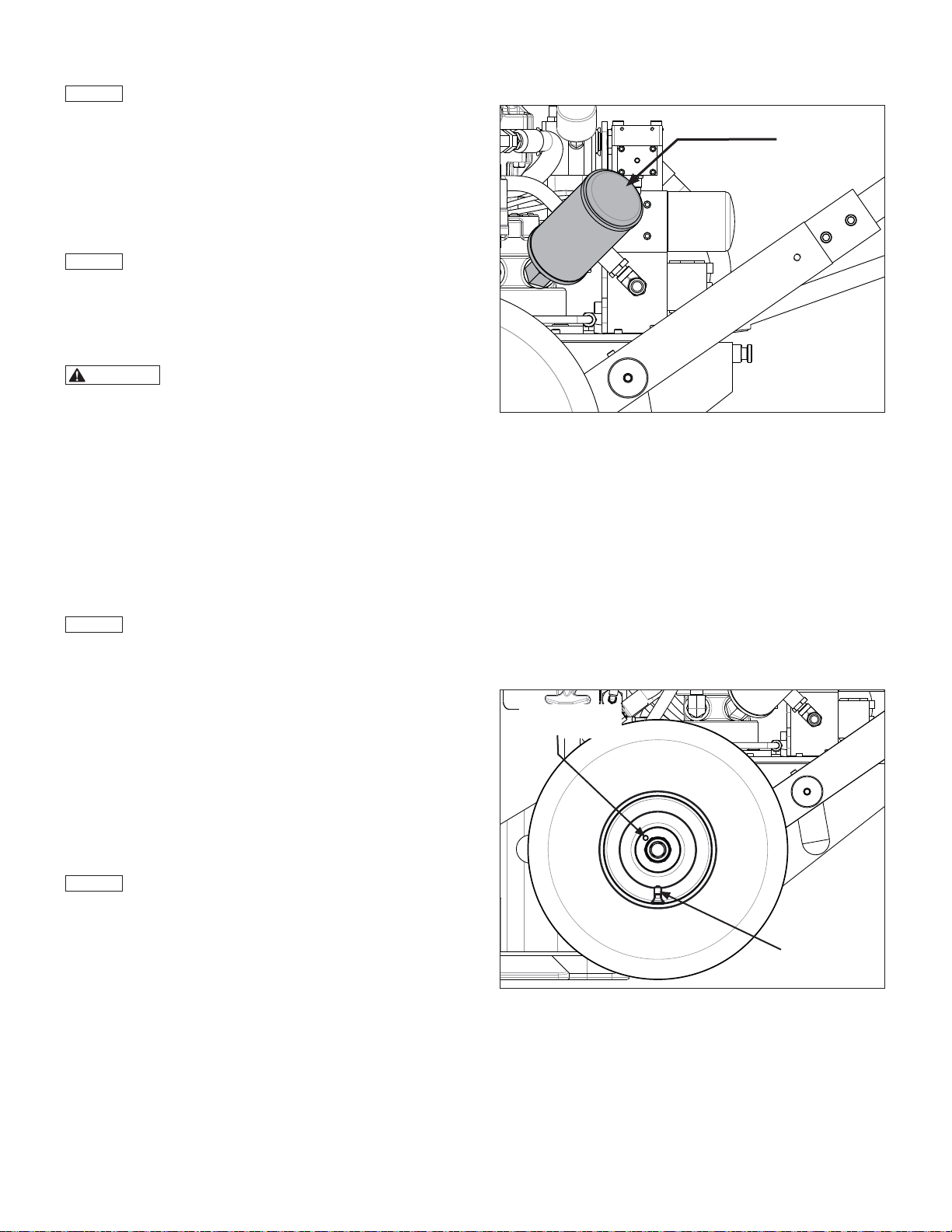

7.7 Air Mu er (See Figure 14)

Every 30 hours of operation:

1. Remove the jack rear access cover. Refer to Section 7.1.

2. Disconnect the air supply hose from the air shut-o valve.

Completely relieve any trapped air in the jack pneumatic

system. Follow procedure in Section 7.2.

3. Inspect the air mu er. Remove any loose dirt or debris.

4. If old air mu er is very dirty or clogged, replace it with a new

air mu er. Use only a 25 micron air mu er of the original

specifi cations (Enerpac Part No. DD4791116 or equivalent).

Air Mu er

Figure 14, Air Muffler

7.8 Wheels and Tires (See Figure 15)

Every 30 hours of operation:

• Check the tires for wear or damage. Replace as required.

• Check the tire infl ation pressure. Each tire should be infl ated

to 90 psi [6,2 bar].

Every 12 months:

• Each wheel hub contains a grease fi tting. Lubricate both wheel

bearings with a high quality wheel bearing grease.

• Inspect the caster wheel for damage and check that it turns

and pivots freely. Remove any loose dirt and lubricate bearings

with oil. Refer to Figure 7 in Section 5.7 of this manual.

Wheel Bearing

Grease Fitting

Tire Air Valve

Figure 15, Wheels and Tires

13

Page 14

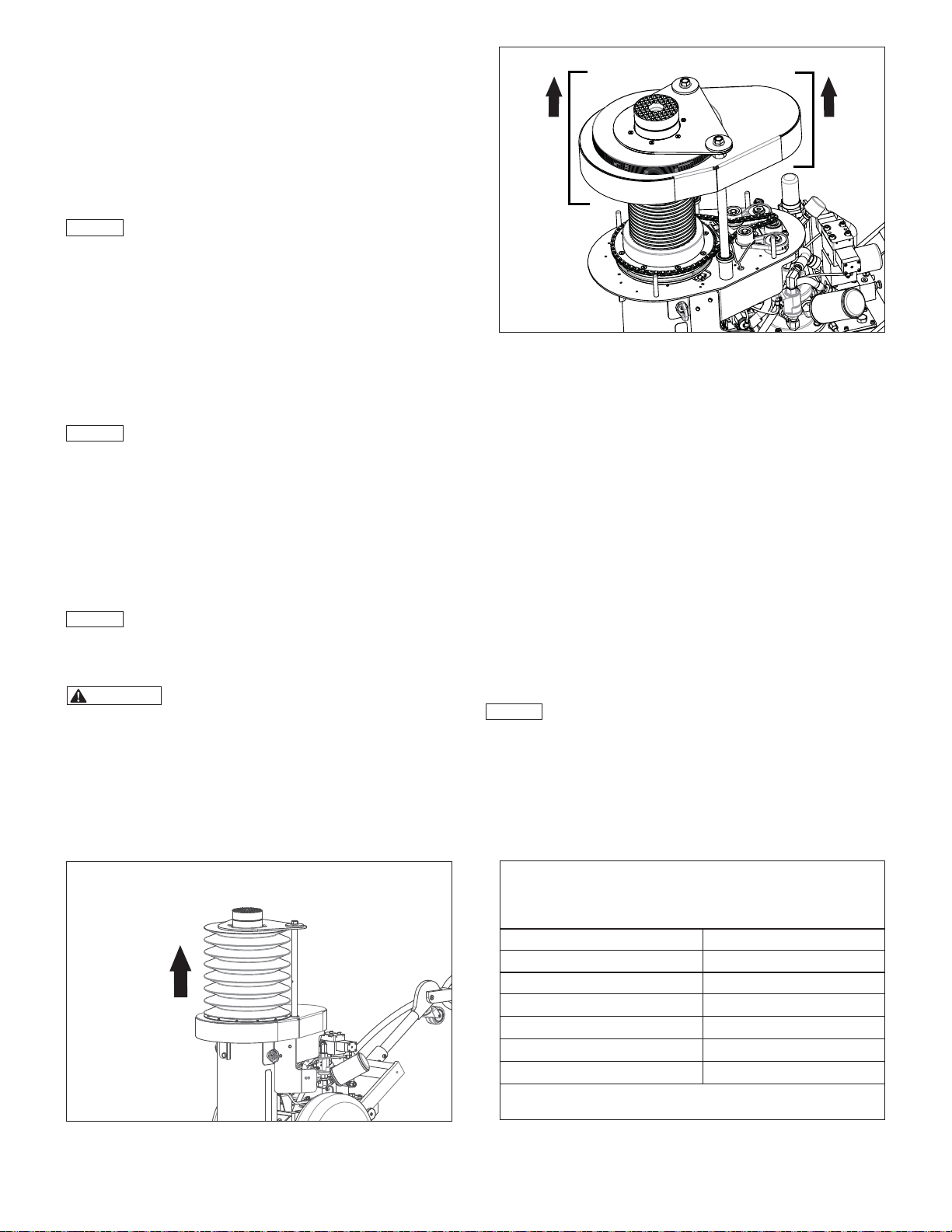

7.9 Lubrication of Cylinder Threads and Lock Nut

Chain Drive (See Figures 16-19)

The cylinder threads and lock nut drive chain should be lubricated

approximately every 30 hours of operation. Both lubrication

activities can be performed at the same time, as described in the

following steps:

1. Be sure there is no load on the jack.

2. Unhook the rubber latches and remove the jack rear access

cover. See Section 7.1 for procedure.

NOTICE

must be fully extended and the jack pneumatic system must be

depressurized. Follow instructions in steps 3a-3f.

3. Fully extend the cylinder and depressurize the jack pneumatic

a. Depress and hold the pendant UP button to raise the

b. Move the jack air-shuto valve to the CLOSED position.

c. Disconnect air supply hose at jack air-shuto valve.

NOTICE

trapped air is expelled from the jack pneumatic system.

d. Depress and hold the pendant UP or DOWN button.

e. Verify that there is no audible “air hiss” sound coming

f. Check the air pressure gauge on the jack fi lter/lubricator.

NOTICE

air-shuto valve is in the CLOSED position and that air hose is

disconnected from air shut-o valve. Then, repeat steps 2d

through 2f.

and that air regulator pressure gauge indicates zero (0) psi/

bar before continuing with this procedure. Jack will start

immediately if air pressure is indicated on gauge, and either

pendant button is depressed. Lock nut and chain will begin

turning. Serious personal injury could occur if jack is started

while persons are performing lubrication procedures.

4. Raise the jack front access cover so that the cylinder threads

Before performing lubrication procedures, the cylinder

system:

cylinder. Continue holding the button until the cylinder is

fully extended and the jack air motor stops running. See

Figure 16.

Jack may start and run briefl y in the following step, as

Continue holding button until jack air motor stops running.

Motor will usually stop after about 2 to 6 seconds, depending

on length of air supply hose.

from the jack.

Verify that it indicates zero (0) psi/bar.

If any pressure is indicated on gauge, be certain that

WARNING

Be certain that air supply hose is disconnected

are exposed as much as possible. See Figure 17.

Figure 17, Lifting Front Access Cover to Expose Threads

5. Attach a lifting sling to the front access cover. Wrap the sling

around the anti-rotation plate and load cap, so that the cover

is held in the raised position. Be certain that the sling is strong

enough to support the weight of the cover (approximately 15

lbs [5,6 kg] ) and that it is securely fastened.

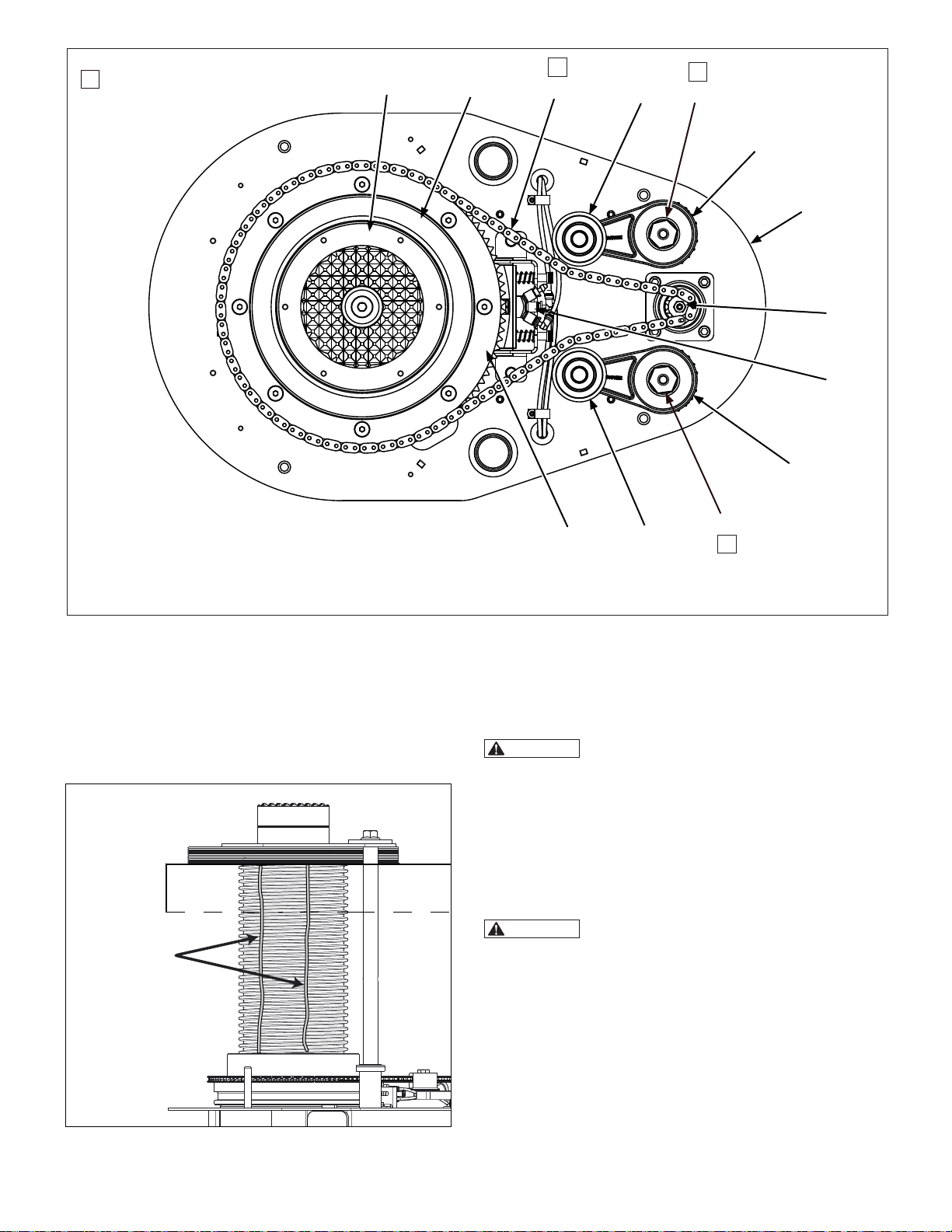

6. Perform the following inspection and lubrication tasks. See

Figure 18.

• Remove any loose dirt or debris from the chain drive

assembly.

• Check each chain tensioner to verify that it is applying

fi rm spring tension against the chain. If the tensioner does

not move freely, or if spring tension is weak, it should be

replaced. The tensioners are not adjustable or repairable.

• Check the tensioner rollers for obvious indications of wear

or damage. Replace rollers as required. The rollers are

available as a separate replacement part.

• Check all teeth on the lock nut and drive sprockets for

obvious indications of wear or damage. Replace these

parts as required.

NOTICE

Refer to Table 9 for gear oil specifi cations.

• Apply a fi lm of SAE 80w-90 gear oil [ISO 150] to the links

of the lock nut drive chain.

• At each tensioner, apply a small amount of 80w-90 gear

oil [ISO 68] to the exposed areas of the tensioner pivot

bushing, located under the tensioner retaining nut. Some

of the oil will fl ow past the bushing and onto the tensioner

pivot shaft. Removal of nut is not required.

Figure 16, Fully Extending the Cylinder

Table 9 - Gear Oil Specifi cations - SAE 80w-90 [ISO 150]

(Use for lubricating cylinder threads, lock nut drive

chain, sprockets and tensioner pivot shaft.)

SAE Grade

ISO Grade

Viscosity Index 103

Viscosity at 40

Viscosity at 100

Flash Point.

Pour Point,

NOTICE: Specifi cations shown in this table are typical. Exact

specifi cations may di er slightly, depending on oil brand.

14

°C, cSt

°cSt

°C

°F

80w-90

150

136

14.5

202

-30

Page 15

Lubricate with gear oil.

✽

(see Section 7.9 for

detailed instructions)

A

B

✽

C

D

✽

E2

E1

F

G

H

E1

Key:

A. Hydraulic Cylinder

B. Lock Nut

C. Drive Chain

D. Roller

E 1. Chain Tensioner

7. Remove any loose dirt or debris from the cylinder threads

and inspect the threads for obvious wear or damage. If the

old lubricant has dried-up, clean the threads with a brush

and some solvent before applying new lubricant.

8. Using an oil bottle with spout, apply two vertical streams

of SAE 80w-90 gear oil [ISO 150] on the exposed cylinder

threads, from top to bottom of cylinder. See Figure 19.

Apply two

streams of

gear oil to threads.

(see Section 7.9 for

detailed instructions)

Figure 19, Cylinder Thread Lubrication

E 2. Tensioner Pivot Shaft

F. Chain Drive Plate

G. Drive Sprocket

H. Proximity Sensors

I. Lock Nut Sprocket

Figure 18, Lock Nut Chain Drive Assembly

I

9. Remove the lifting sling and lower the jack front access

cover to its normal position, so it is supported by the chain

drive plate. The front access cover and protective bellows

should now completely cover the cylinder threads and chain

drive mechanism.

WARNING

installed and fully lowered before starting the jack. Never

operate the jack with the front access cover removed or

raised, either during lubrication and maintenance procedures

or when the jack is in use. Failure to observe this precaution

may result in persons becoming entangled in the moving

parts of the chain drive mechanism. Serious personal injury

could result.

10. Reconnect the air supply hose and move the air-shuto

valve to the OPEN position.

WARNING

extend and retract the cylinder several times. Stay clear of

the cylinder and related components. Keep hands and

fi ngers away from pinch and crush points. Serious personal

injury could occur if these precautions are not observed.

Refer to Section 1.3 of this manual for additional hazard

information.

11. With no load on the jack, fully extend and retract the cylinder

several times to distribute the gear oil on the cylinder

threads, and on the chain and drive components. Verify

proper operation.

12. Reinstall the jack rear access cover. Refer to Section 7.1.

Be certain that jack front access cover is

In the following step, it will be necessary to

D

E2

✽

15

Page 16

8.0 TROUBLESHOOTING

The information in the Troubleshooting Guide (refer to Table 10) is

intended as an aid to help diagnose and correct various possible

problems that may occur.

For repair service, contact your local Enerpac Authorized Service

Center. Only an Enerpac Authorized Service Center should

service the jack and its components.

Table 10 - Troubleshooting Guide

Symptom Possible Cause Solution

1. Sporadic cylinder

action and/or sluggish

operation.

a. Air trapped in hydraulic system. Cycle cylinder up and down several times to bleed trapped air.

b. Low oil level in hydraulic reservoir. Add Enerpac HF oil as required.

c. Insu cient compressed air pressure

or volume.

Check air pressure at fi lter/regulator. Increase regulator setting if pressure

shown on gauge is too low.

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Never tighten or loosen hydraulic fi ttings while jack hydraulic

system is pressurized. Escaping oil under pressure can

penetrate the skin, causing serious personal injury.

• Keep hands, fi ngers and other body parts clear of pinch

points and moving parts when observing operation during

troubleshooting.

• To prevent injury, always be sure the jack air shut-o valve

is in the CLOSED position and that the air supply hose is

disconnected before beginning any maintenance, adjustment

or repair procedures. Be certain that any trapped pressure is

completely relieved as described in Section 7.2 of this manual.

If necessary, increase volume of compressed air or increase size of supply

air line to meet airfl ow and pressure requirements.

d. Clogged or blocked pump intake

screen.

e. Pneumatic control circuit components

leaking, worn, damaged or out of

adjustment.

f. Seal wear, internal leakage, worn

components and/or other internal

damage.

2. Noisy operation. a. Air trapped in hydraulic system. Cycle cylinder up and down several times to bleed trapped air.

b. Low oil level in hydraulic reservoir. Add Enerpac HF oil as required.

c. Air mu er missing or damaged. Replace air mu er.

d. Air leaks in hydraulic system. Check all points where air might leak into system. Tighten, repair or replace

e. Clogged or blocked pump intake

screen.

f. Air motor worn or damaged. Have air motor inspected by Enerpac Authorized Service Center. Repair or

3. Oil is overheating. a. Low oil level in hydraulic reservoir. Add Enerpac HF oil as required.

b. Oil viscosity too high or too low. Drain oil from reservoir and refi ll with Enerpac HF oil.

c. Excessive cycling of cylinder. Reduce cycling of cylinder. Allow time for oil to cool between lifts.

d. Jack is overloaded. Reduce load or use a di erent jack of higher capacity.

Have hydraulic reservoir and intake screen fl ushed and cleaned by

Enerpac Authorized Service Center.

Have pneumatic control circuit inspected by Enerpac Authorized Service

Center. Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

components as required.

Have hydraulic reservoir and intake screen fl ushed and cleaned by

Enerpac Authorized Service Center.

replace components as required.

NOTICE: Oil may overheat if jack is overloaded, and oil runs over the relief

valve for a prolonged period of time.

e. High pressure leakage at the pump. Have hydraulic system inspected by Enerpac Authorized Service Center.

(Continued on next page)

Repair or replace components as required.

1616

Page 17

Table 10 - Troubleshooting Guide (Continued)

Symptom Possible Cause Solution

4. Motor does not run

when either pendant

button is depressed.

5. Motor starts when

pendant UP or DOWN

button is depressed,

but cylinder does not

move, or moves only a

small amount.

a. Air supply valve in the CLOSED

position.

b. Insu cient compressed air pressure. Check air pressure at fi lter/regulator. Increase regulator setting if pressure

c. Insu cient compressed air volume. If necessary, increase volume of compressed air or increase size of supply

d. Air mu er restricted by ice or debris. Check air mu er for ice or debris. Replace mu er if clogged.

e. Moisture in compressed air causing

ice formation in motor.

f. Pendant damaged. Have pendant assembly inspected by Enerpac Authorized Service Center.

g. Pneumatic control circuit components

leaking, worn, damaged or out of

adjustment.

h. Hydraulic system components

leaking, worn, damaged or out of

adjustment.

i

. Motor physically locked and/or pump

element seized.

a. Insu cient compressed air pressure

or volume.

b. Air mu er restricted by ice or debris. Check mu er for ice or debris. Replace mu er if clogged.

Move valve lever to the OPEN position. Check that fi lter/regulator gauge

indicates pressure.

shown on gauge is too low. Do not exceed 120 psi [8,3 bar].

air line to meet airfl ow and pressure requirements.

NOTICE: If pressure gauge reading drops a large amount (more than about

40 psi [2,75 bar]) when either pendant button is depressed, it is an indication

that the available compressed air volume may be too low.

Refer to step 10 of Troubleshooting chart if ice is present.

Be sure that compressed air is clean, dry and free of water.

Refer to step 10 of Troubleshooting chart if ice formation is present or

suspected.

Repair or replace components as required.

Have pneumatic control circuit inspected by Enerpac Authorized Service

Center. Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Have air motor, hydraulic pump and related components inspected by

Enerpac Authorized Service Center. Repair or replace components as

required.

Check air pressure at fi lter/regulator. Increase regulator setting if pressure

shown on gauge is too low. Do not exceed 120 psi [8,3 bar].

If necessary, increase volume of compressed air or increase size of supply

air line.

NOTICE: When

pendant DOWN

button is depressed,

the cylinder will

move upward a

small amount before

retraction begins. This

is normal operation.

6. Cylinder advances

when pendant DOWN

button is depressed.

Refer to step 10 of troubleshooting if ice formation is present.

c. Jack is overloaded. Reduce load or use a di erent jack of a higher capacity.

d. Cylinder hydraulic control valve not

shifting.

e. Lock nut spin-up sensor dirty

or plugged (this symptom is applicable

to the cylinder advance circuit only).

f. Cylinder lock nut not turning. Refer to step 9 of troubleshooting.

g. Pneumatic system air line lubricator is

overfi lled.

h. Pneumatic control circuit components

leaking, worn, damaged or out of

adjustment.

i. Hydraulic system components leaking,

worn, damaged or out of adjustment.

a. Proximity-2 lock nut position sensor

dirty or plugged.

b. Pneumatic system air line lubricator

is overfi lled.

(Continued on next page)

Have control valve inspected by Enerpac Authorized Service center. Repair

or replace components as required.

NOTICE:

overrides can be used to shift the valve to test cylinder retract and extend

operation.

Have lock nut spin-up sensor checked by Enerpac Authorized Service

Center. Verify that sensor ports and air lines are not dirty or blocked.

Drain excess lubricant from air line lubricant bowl. Do not operate jack for

8 to 12 hours to allow excessive lubricant to clear from jack pneumatic

control circuit.

Have pneumatic control circuit inspected by Enerpac Authorized Service

Center. Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Have Proximity-2 sensor checked by Enerpac Authorized Service Center.

Verify that sensor ports and air lines are not dirty or blocked.

Drain excess lubricant from air line lubricant bowl. Do not operate jack for 8

to 12 hours to clear excessive lubricant from jack pneumatic control circuit.

A manual override pin is located on each end of the valve. These

1717

Page 18

Table 10 - Troubleshooting Guide (Continued)

Symptom Possible Cause Solution

7. Cylinder stops

retracting when lock

nut contacts cylinder

housing. Does not fully

retract.

8. Lock nut turns too

slowly when cylinder is

retracted.

Cylinder stops part-

way and will not fully

retract.

9. Lock nut not turning. a. Cylinder threads need lubrication. Clean and lubricate cylinder threads. Refer to Section 7.9.

a. Lock nut not turning. Refer to Step 9 of troubleshooting.

b. Lock nut spin-up sensor dirty or

plugged.

c. Pneumatic system air line lubricator is

overfi lled.

d. Pneumatic control circuit components

leaking, worn, damaged or out of

adjustment.

e. Hydraulic system components

leaking, worn, damaged or out of

adjustment.

a. Lock nut not turning freely on cylinder

threads.

b. Lock nut drive train components are

worn or loose.

c. Cylinder lowering too fast. Have Enerpac Authorized Service Center inspect the counterbalance

b. Lock nut drive chain derailed, broken

or worn.

Have lock nut spin-up sensor checked by Enerpac Authorized Service

Center. Verify that sensor ports and air lines are not dirty or blocked.

Drain excess lubricant from air line lubricant bowl. Do not operate jack for 8

to 12 hours to clear excessive lubricant from jack pneumatic control circuit.

Have pneumatic control circuit inspected by Enerpac Authorized Service

Center. Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

Clean and lubricate cylinder threads. Refer to Section 7.9.

Have Enerpac Authorized Service Center inspect condition of lock nut drive

chain, sprockets and related components. Repair or replace components

as required.

valve and related hydraulic system components. Adjust, repair or replace

components as required.

Inspect lock nut drive chain. Reinstall or replace chain as required.

Determine if other problems may have caused drive chain wear or failure.

10. Ice formation at

pump air mu er.

or

Ice formation at lock

nut position sensors.

11. Jack is di cult to

roll on wheels.

c. Lock nut drive components are worn

or loose.

d. Lock nut position sensors dirty or

plugged.

e. Pneumatic control circuit components

leaking, worn, damaged or out of

adjustment.

f. Hydraulic system components leaking,

worn, damaged or out of adjustment.

a. Water in the air fi lter bowl. Check air fi lter bowl for water. Drain water from bowl if present.

b. Air fi lter element dirty. Clean or replace air fi lter element (inside fi lter/regulator).

c. Air line lubricator is empty. Fill lubricant bowl with anti-freeze lubricant. Refer to Section 7.6 for

d. Air line lubricator drip speed

incorrect.

e. Air supply contains excessive water. Reduce amount of water in air supply.

a. Low tire infl ation pressure. Check tire infl ation pressure. Add air if low.

b. Wheel bearings need lubrication. Apply grease to wheel bearings. See Section 7.8.

c. Wheel lock nut out of adjustment. Loosen lock nut until wheel rotates freely.

d. Caster wheel worn or stuck. Inspect caster wheel for wear and verify that it rotates and pivots freely.

Have Enerpac Authorized Service Center inspect condition of lock nut drive

chain, sprockets and related components. Repair or replace components

as required.

Check the spin-up sensor and Proximity-2 sensor. Verify that sensor ports

and air lines are not dirty or blocked. Refer to step 10 of troubleshooting if

ice has formed on or inside sensors.

Have pneumatic control circuit inspected by Enerpac Authorized Service

Center. Repair or replace components as required.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

additional information.

Adjust the lubricator drip speed to 4 to 5 drops per minute.

Pressure should be 90 psi [6,2 bar].

Lubricate bearings with oil if necessary. Replace caster wheel if required.

18

18

Page 19

Hoja de instrucciones

POWERFUL SOLUTIONS. GLOBAL FORCE.

Pow’R-LOCK ™ Sistema de elevación portátil

Modelos de la serie PL200 (neumáticos)

L4075 Rev. B 07/14

1.0 SEGURIDAD

1.1 Introducción

Lea atentamente todas las instrucciones. Siga todas las precauciones de

seguridad recomendadas para evitar daños personales, así como daños

al gato y/o daños a otros bienes. Enerpac no puede responsabilizarse

por daños o lesiones derivados del uso inseguro del producto, falta de

mantenimiento o uso incorrecto. No quite las etiquetas, pegatinas ni

calcomanías de advertencia. Si tiene alguna pregunta o duda, póngase

en contacto con Enerpac o con algún distribuidor local de Enerpac.

Si nunca ha recibido formación sobre seguridad hidráulica de alta

presión, consulte con su distribuidor o con el centro de servicio técnico

para recibir un curso gratuito de seguridad hidráulica de Enerpac.

En este manual se emplea un sistema de símbolos de alerta de

seguridad, palabras de advertencia y mensajes de seguridad para avisar

al usuario de riesgos específi cos. El incumplimiento de las siguientes

advertencias podría causar la muerte o lesiones graves, así como daños

al equipo u otros bienes.

El Símbolo de alerta de seguridad aparece a lo largo de

este manual. Se utiliza para avisarle de posibles riesgos de

lesiones físicas. Preste especial atención a los símbolos de

alerta de seguridad y obedezca todos los mensajes de seguridad que

siguen este símbolo para evitar la posibilidad de muerte o lesiones

personales graves.

Los símbolos de alerta de seguridad se utilizan en combinación con

ciertas palabras de advertencia que llaman la atención sobre mensajes

de seguridad o mensajes de daños materiales, e indican un grado o nivel

de gravedad del riesgo. Las palabras de advertencia utilizadas en este

manual son PELIGRO, ADVERTENCIA, PRECAUCIÓN y ATENCIÓN.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ATENCIÓN

o

ATENCIÓN:

Indica una situación peligrosa que, si no se evita,

ocasionará la muerte o lesiones graves.

Indica una situación peligrosa que, de no evitarse,

puede ocasionar la muerte o lesiones graves.

Indica una situación peligrosa que, de no evitarse,

puede ocasionar lesiones menores o moderadas.

Indica información que se considera importante,

pero no relacionada con peligro (por ejemplo,

mensajes relacionados con daños materiales).

Tenga en cuenta que el símbolo de alerta de

seguridad no se utiliza en combinación con esta

palabra de advertencia.

1.2 Medidas de seguridad - Sistema de elevación portátil

Pow’R-LOCK

El incumplimiento de las siguientes precauciones de seguridad

podría ocasionar la muerte o lesiones graves. También podrían

producirse daños materiales.

• Mantenga las manos y los pies alejados del cilindro hidráulico y

sus componentes durante el funcionamiento del gato.

• Lleve siempre equipo de protección personal (PPE) al operar el

equipo hidráulico (como guantes, gafas protectoras, protección

de la cabeza, calzado de protección, etc.).

• No toque mangueras bajo presión. El aceite saliente bajo presión

puede penetrar la piel y causar lesiones graves. Consulte

inmediatamente a un médico, si se ha inyectado aceite debajo

de la piel.

• El gato debe utilizarse solo para la elevación de cargas y para

soportar cargas elevadas. Nunca utilice el gato para empujar o

separar objetos, o para otros fi nes que no estén relacionados

con la elevación.

• Nunca exceda la capacidad certifi cada del gato. Permita

un margen de seguridad que prevenga la posibilidad de

desplazamiento o desviación de la carga. El incumplimiento de

esta advertencia podría causar un fallo del gato.

• Nunca intente forzarlo con dispositivos de protección contra

sobrecarga. La válvula de alivio interna del gato solo debe ser

reparada o ajustada por un centro de servicio técnico autorizado.

La presión máxima de trabajo del sistema hidráulico del gato es

10000 psi [700 bar]. Ajustes mayores pueden provocar lesiones

personales y/o daños al equipo.

• Asegúrese de que el equipo está estable antes de levantar la

carga. Utilice el gato sobre una superfi cie sólida y nivelada,

capaz de soportar la carga y la base del gato. Coloque siempre

la carga en el centro de la silleta del gato. Si el gato no está

en posición perpendicular a la carga, esta podría deslizarse o

soltarse.

• Distribuya la carga de manera uniforme cuando efectúe

elevaciones con múltiples gatos. Si no cumple esta advertencia,

podría soltarse la carga y/o podría darse un fallo de los gatos.

• Tenga en cuenta los posibles acontecimientos externos y actos

de la naturaleza (viento, tormentas, inundaciones, terremotos

u otra actividad sísmica, etc.) que podrían ocurrir mientras el

gato está en uso, o mientras se deje cargado sin supervisión.