Enerpac PL User Manual [en, de, es, fr, it]

PRODUCTION AUTOMATION

L2057 Rev. O 1/96

CONTENTS

Instruction Sheet

®

Pull Cylinders -- Metric

ENGLISH .... ....... ............. ......... ....... ....1 - 8

DEUTSCH......................... ................12-15

FRANCAIS.......... .. ... .. ... .. .... . .... . .. .... . .16-19

IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all compone nts for shipping damage . If any shipping damage is found,

notify carrier at once. Shipping damage is

responsible fo r all repair or replacement cos t resulting from damage in shipment.

DESCRIPTIO N

These pull cylinders are designed to push/pull in a straight direction with no

side loading. Single- and double-acting models are available in most c apac i ties. Plunger

bolts are not supplied with cylinders. Plunger bolts must be quality Gra de 8

(8.8 DIN 912).

ESPAÑOL.................... ............ .........20-23

ITALIANO ................... ................. ....24-27

NEDERLANDS...... . ..........................28-31

NOT covered by warranty. The carrier is

Upper Flange Lower Flange Threaded Body

Model Number Code

1 2 3 4 5 6 optional

P = pull

cylinder

T = threaded body

U = upper flange

L = lower flange

S = straight S = single-acting

D = double-acting

2 = 2,2 kN

5 = 5,6 kN

9 = 9,0 kN

35 = 35,0 kN

2 = metric V = Viton

SPECIFICATIONS

Capacity [kN (lbs.)]

Body Style

Cylinder Type

Hydraulic Stroke

[mm (in.)]

Effective Area

2

[cm

(in2 )]

Oil Capacity

3

[cm

(in3 )]

Max. Pressure

[bar (psi)]

Max. Flow at 350 bar (5000 psi)

3

[cm

/min (in.3/min)]

clamp/

unclamp

clamp

unclamp

clamp

unclamp

PRELIMINARY INFORMATION

IMPORTANT: Failure to read and follow these instructions may lead to

system malfunction or pr oduct failure, and could invalidate your wa rranty.

Cylinder Specifications

-22 Series -52 Series -92 Series -352 Series

2,2 (500) 5,6 (1250) 9,0 (2000) 35,0 (7900)

threaded body, lower flange, or upper flange mounting

single-acting and double-acting double-act ing double-a cting

16,7 (0.658) 23,0 (0.906) 22,0 (.867) 30,0 (1.182)

0,75 (0.116) 1,79 (0.278) 3,13 (0.485) 12,42 (1.925)

1,54 (0.238) 3,80 (0.589) 8, 04 (1.246) 23,76 (3.683)

1,25 (0.076) 4,12 (0.251) 6,88 (0.420) 37,20 (2.269)

2,57 (0.157) 8,74 (0.533) 17,69 (1.079) 71,28 (4.348)

350 bar (5000 psi)

393 (24) 820 (50) 122 (2000) 7867 (480)

(1)Hi gh flow rates can lead to excessive cylinder speed which can cause cylinder damage.

Hydraulic pressure and cyli n der speed must be adjusted to match the parti cular

cylinder. The push/pull force also varies wit h the system pressure. Refer to the

operating specifications above.

(2)Flow controls with return checks may be required to reduce pull cyli n der speed to the

recommended rate. The return checks help minimize back pressure that could l e ad to

an unclamp malfunction on single-acting systems.

(3)When using single-acting pull cylinders, limit the return flow back pre ssure to

3,45 bar (50 psi) maximum. Large diameter tubing (10 mm O.D. or larger) and f low

controls with free flow return checks help minimize back pr essure. Consult Enerpac for

proper system design.

2

MOUNTING SPECIFICATIONS

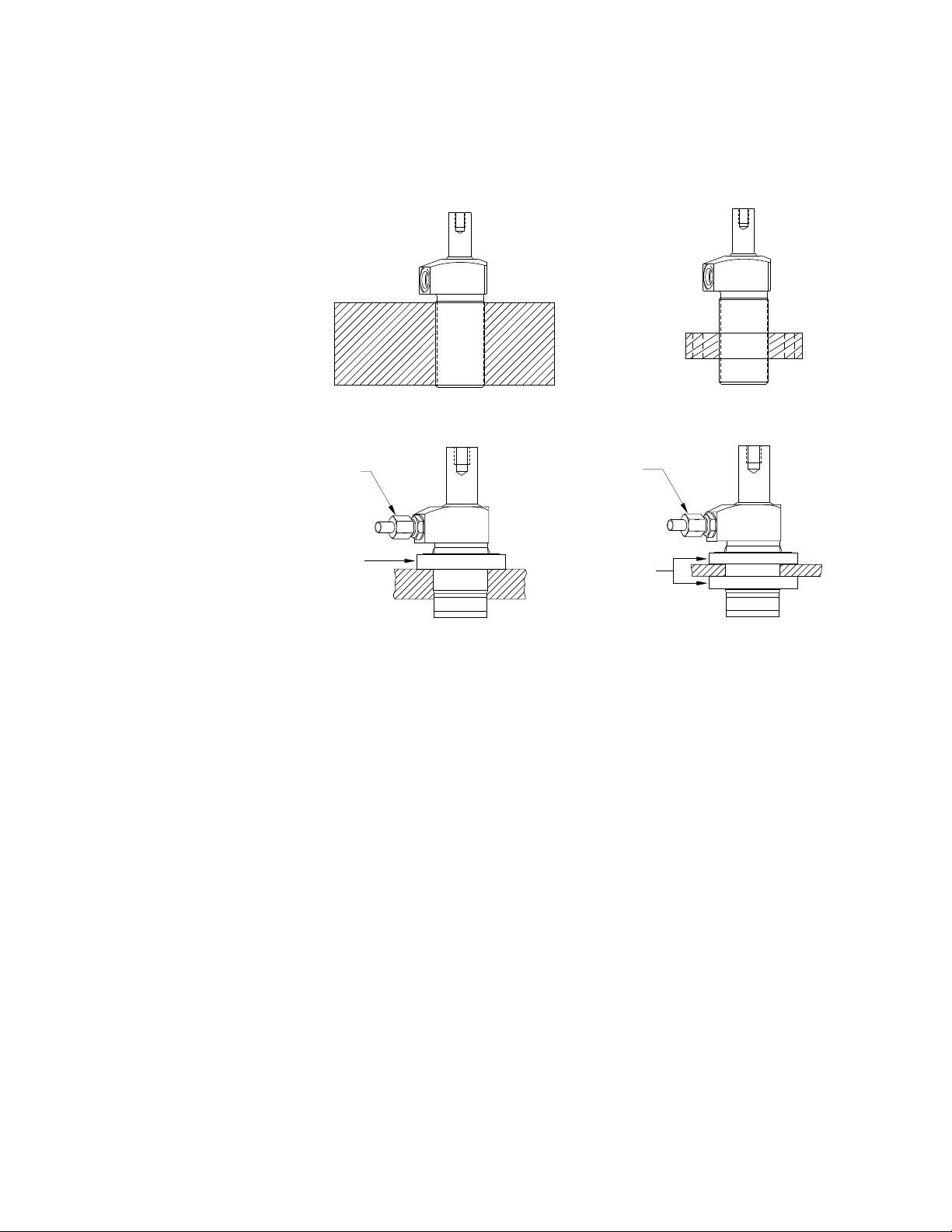

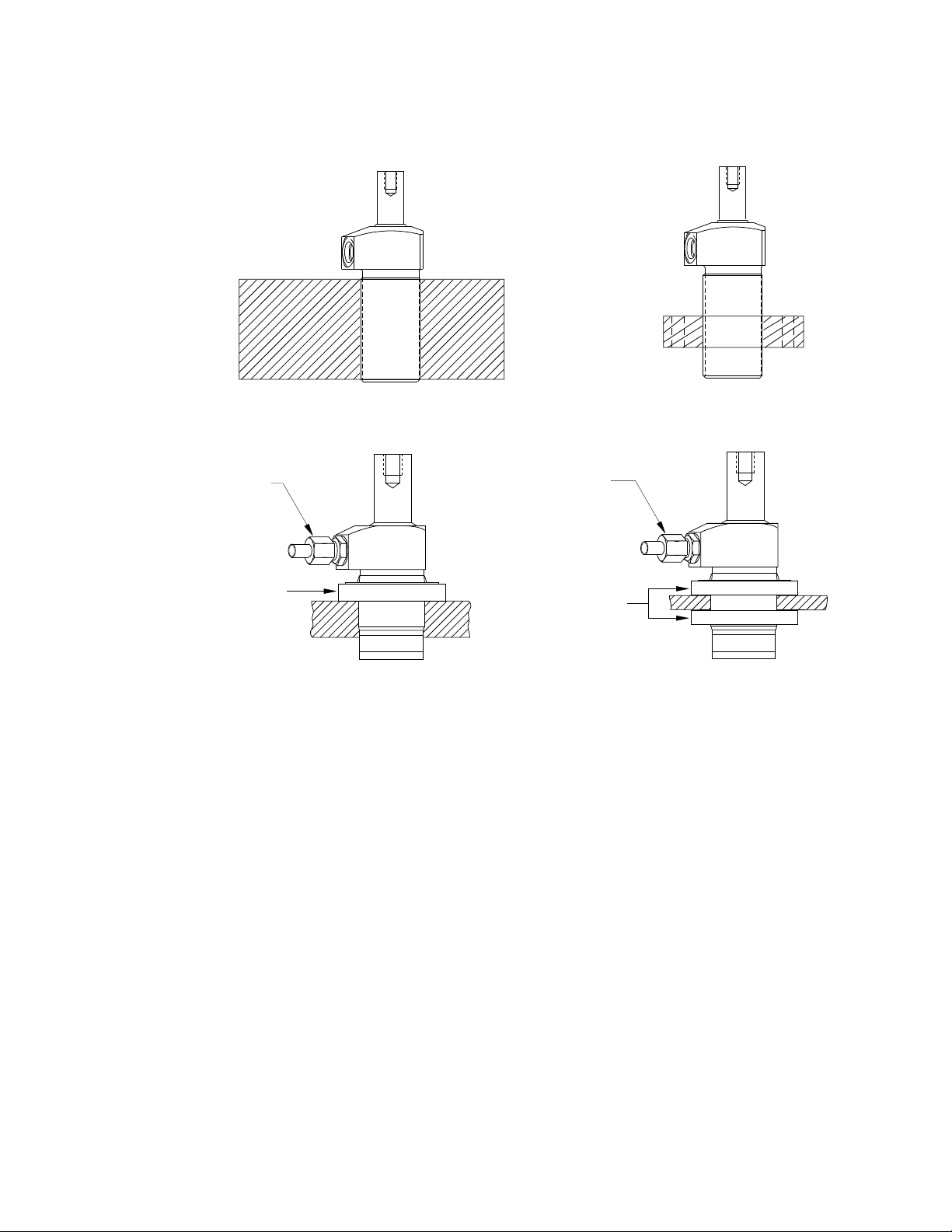

Mounting Threaded Body Cylinder s

Threaded body cylinders can be threaded into a tapped hole, s ecured to the fixture using

a mounting flange, threaded into the fixture and secured with a jam nut, or mounted

through a c learance hole and secured with jam nuts. See illustrations below.

threaded into fixture

mounting flange

oil connection

jam nut

oil connection

jam nuts

Figure 1

When a threaded body pull cylinder is being installed in a fixture, the thread engagement

should be no less than the thread engagement f or the standard Enerpac mounting flange.

If a cylinder is being mounted using just the lower portion of the threads , the engagement

should be increased f o r additional support. See table below for minimum thread

engagement.

Cylinder Capacity Minimum Thread Engagement

2,2 kN 500 lb 13 mm .50"

5,6 kN 1250 lb 13 mm .50"

9 kN 2000 lb 16 mm .63"

35 kN 7900 lb 30 mm 1.25"

3

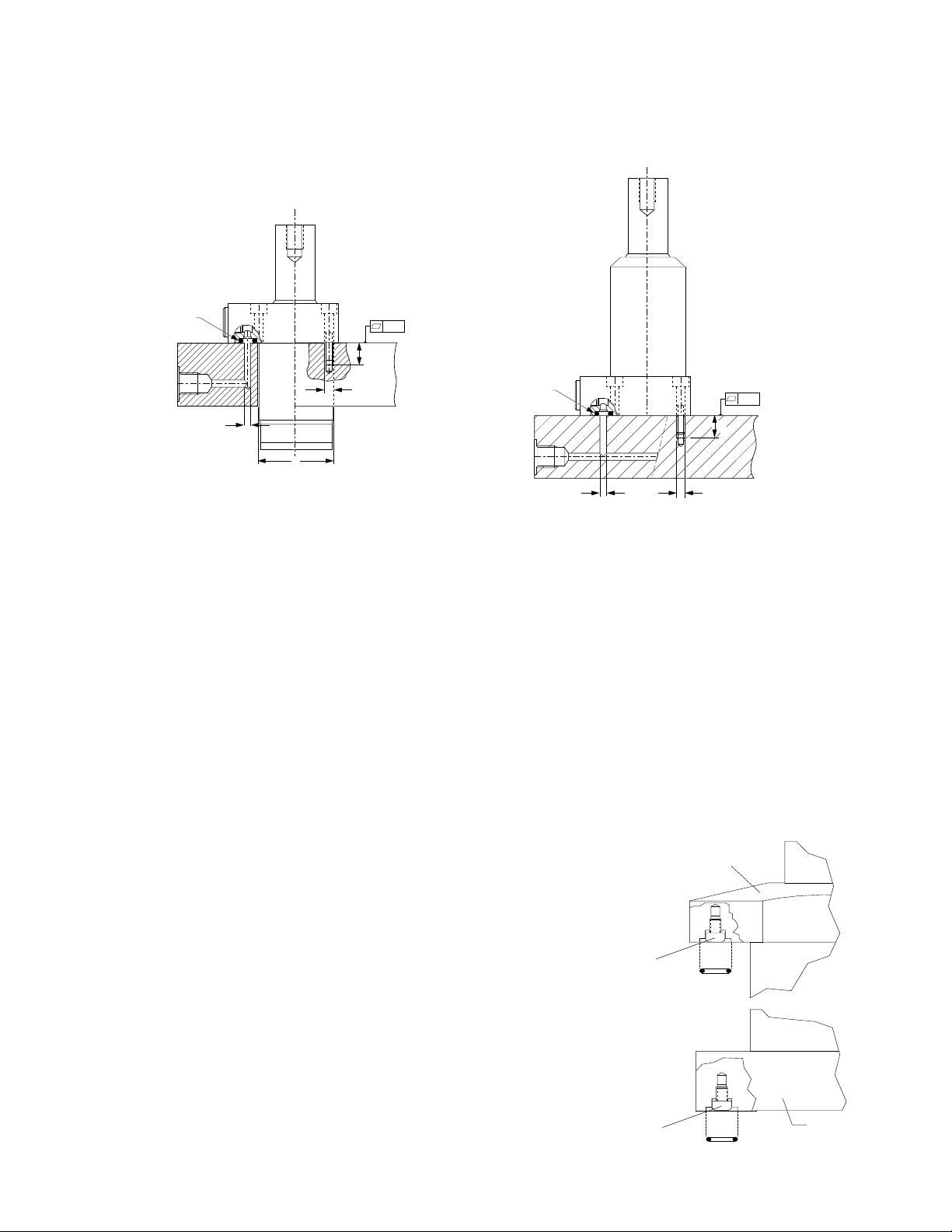

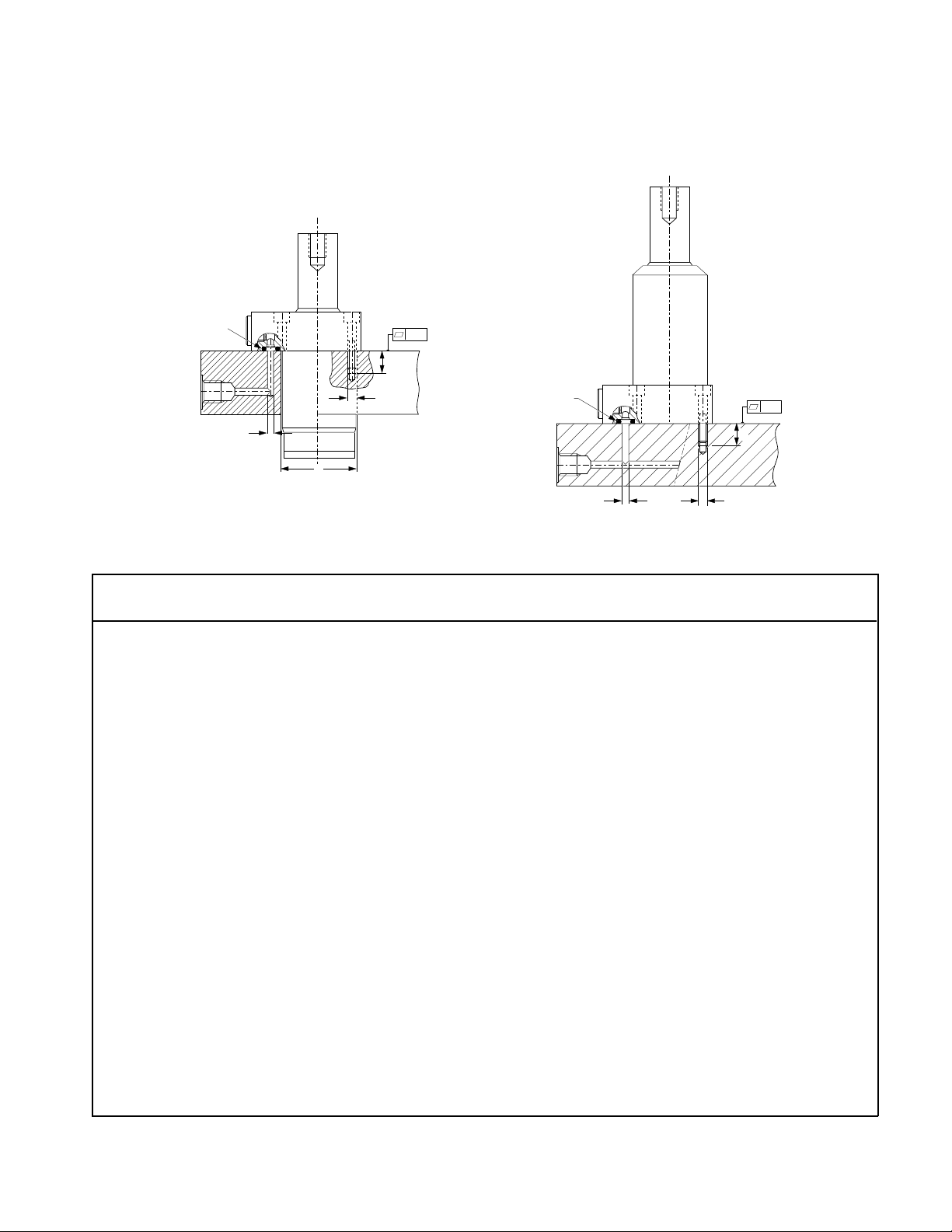

Mou ntin g Upp er and Lower Fl ange Cylinders

A WARNING

The fi xture must be capable of withstanding 350 bar (5000 psi ) hydraulic

working pressure when cylinders are manifold mounted.

Manifold

O-ring

Cylinder

Capacity

2,2 kN

500 lb

5,6 kN

1250 lb

9 kN

2000 lb

A

Max. Oil

Channel

Diameter

B

Ø A

4mm

0.156"

4mm

0.156"

4mm

0.156"

0.003

0,1

D

C

Manifold Specifications

Fixture

Hole Diameter

Ø B

29,2 ± 0,8

1.15 ±.03

36,0 ± 0,8

1.42 ± .03

49,1 ± 0,8

1.93 ± .03

Figure 2

Mounting

Threads

C

M5 15 mm

M6 15 mm

M6 15 mm

Manifold

O-ring

A

Minimum

Thread

Depth

D

0.59"

0.59"

0.59"

Lubricated

Mounting Bolt

Torque

4,5-5 ,4 Nm

40-48 in-lbs.

12,2-14,9 Nm

9-11 ft-lbs.

13,5-15 Nm

10-11 ft-lbs.

0.003

0,1

D

C

Manifold

O-Ring

Dimensions

I.D. x w.

6,07 x 1,78 mm

0.239 x 0.070"

7,65 x 1,78 mm

0.301 x 0.070"

4,34 x 3,53 mm

0.171 x 0.139

35 kN

7900 lb

4mm

0.156"

77,5 0,3

3.05 ± .01

M10 15 mm

Before manifold mounting the pull c ylinder, remove

the port screw plugs and copper ga ske ts or o-rings.

Prior to mounting and bolting down the pull cylinder,

lubricate the o-rings provided and install them in the

counter-bore around the port.

Be sure that the o-ring does not get pinched or

damaged during mounting as leakage c ould result. T o

prevent leakage from the manifold mounting, provide

a fixture mounting surface with flatness within 0.08

mm (0.003 in.) and a surface roughness not to exc eed

Ra 1, 6.

4

0.59"

65-7 2 Nm

48-53 ft-lbs.

Remove port

screw plug.

Remove port

screw plug.

4,34 x 3,53 mm

.171 x .139"

Upper Flange

o-ring

o-ring

Lower

Flange

INSTALLATION

Hydraulic Connect ions

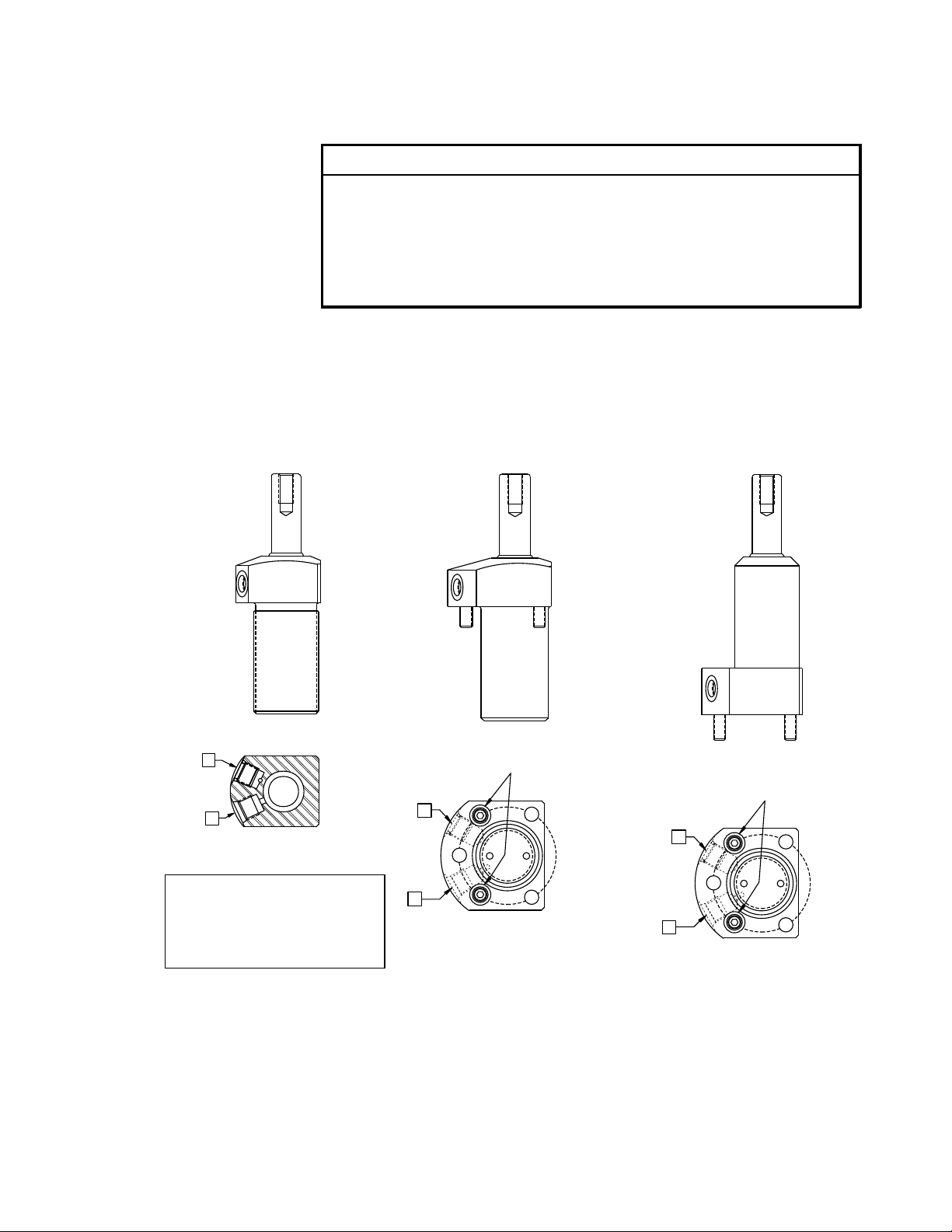

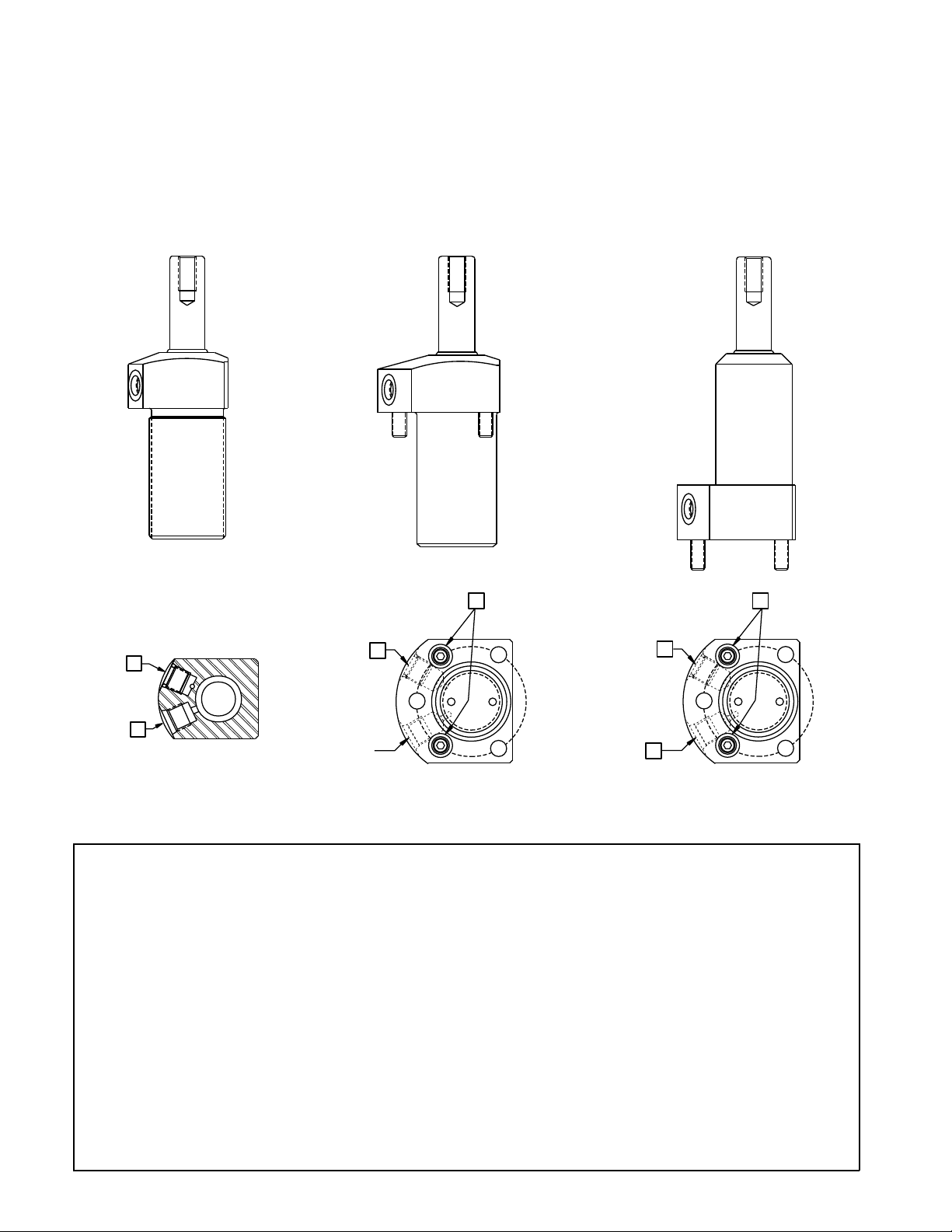

Port Identification

To make port connections, install fittings rated for 5000 psi (350 bar).

Cylinder Ports

Cylinder Capacity 350 bar (5000 psi) Fitting

2,2 kN (500 lbs.)

5,6 kN (1250 lbs.)

9 kN ( 2000 lbs.)

35 kN (7900 lbs.)

1

/8 BSPP

1

/8 BSPP

1

/4 BSPP

1

/4 BSPP

DO NOT us e thread seala nt. Sealing is accomplis hed by using an o-ring on the fitting

boss. Lubricate the o-ring prior to assembly.

NOTE: When designing your hydraulic circuit, cons ider the factors listed in

PRELIMINARY INFORMATION on p age 2. For mo re informa tion about plumbing

hydraulic circuits, see your Enerpac Production Automation Catalog.

Threaded

Body Style

Side View

A

B

Bottom View

KEY

A: Clamp Port

B: Vent Port (Single-acting Models)

Unclamp Port (Double-acting Models)

NOTE: Do not remove vent plug except

to attach tubing (See vent plug section).

OPERATI ON

Upper Flange

Body Style

A

B

Bottom View

Lower Flange

Body Style

Side View

Side View

Manifold Ports

Manifold Ports

A

B

Bottom View

A CAUT ION

—To ensure maximum cylinder performance and safety; be sure all hydraulic

connections, hoses, and fit tin gs are properl y sealed and fully tightened.

—Be sure al l items are rated to withstan d system pr essures. Under-rated

components will not wit hstand higher pressure. Using under-rated

components will lead t o equipment damage and possible personal i njury.

5

Vent Plug

Single-acting cylinders have a vented plug on the left side of the cylinder when you a re

facing the hydraulic ports. To prevent entry of chips and coolant, the vent plug must not

be removed. If the vent plug is subjec ted to a continuous coolant flood c ondition, attac h

tubing to the port using a BSPP fitting and run the tubing to a non-contaminated area o f

the fixture.

Pressure and Flow Settings

A CAUTION

It i s very i mportant that you use the correct pressure and flow setti ngs.

Operating outside these limits will cause damage to the cylinder. Damage

caused by exceeding rated pressur e and maximum flow is NOT COVERED BY

WARRANTY.

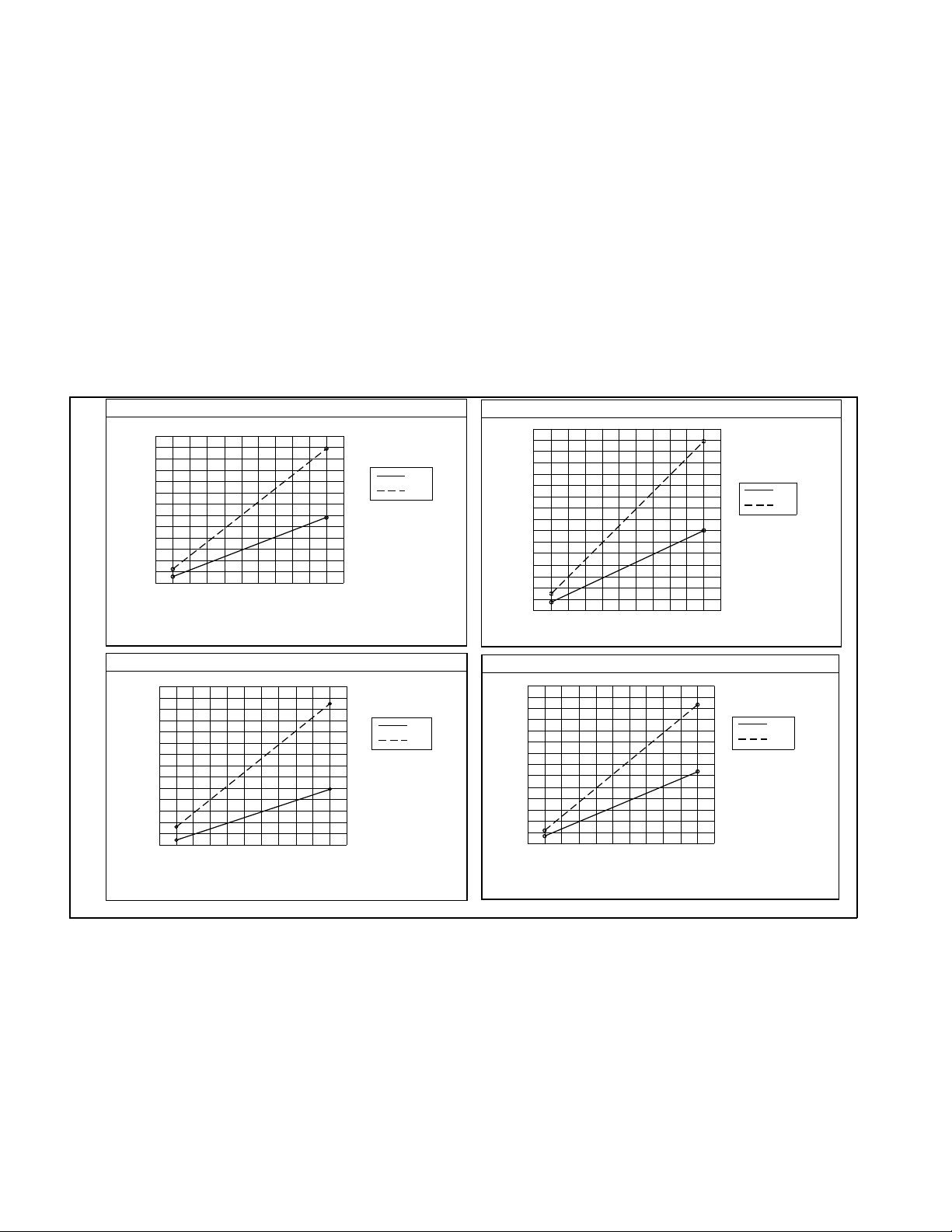

Push/Pull Fo rce s vs. Syste m Pressure

NOTE: Push forces are for double-acting cylinders only.

2,2 kN [500 lbs.]

4,9

[1100]

4,0

[900]

3,1

[700]

2,2

[500]

1,3

Force kN [lbs.]

[300]

0,4

[100]

0

[1000]

206,8

137,968,9

[3000][2000] [4000]

Pressure bar [psi]

275,8

344,7

[5000]

Pull Force:

Push Force:

Stroke

Pull

Push

0,75 x pressure

1,54 X pressure

13,3

[3000]

11,6

[2600]

9,8

[2200]

8,0

[1800]

6,2

Force kN [lbs.]

[1400]

4,5

[1000]

2,7

[600]

0,9

[200]

137,968,9

[1000]0[2000]

Pressure bar [psi]

5,6 kN [1250 lbs.]

206,8 275,8

[3000] [4000]

344,7

[5000]

Stroke

Pull Force:

Push Force:

Pull

Push

1,79 x pressure

3,80 x pressure

26,7

[6000]

22,2

[5000]

17,8

[4000]

13,3

[3000]

Force kN [lbs.]

8,9

[2000]

4,4

[1000]

137,968,9

[1000]0[2000]

Pressure bar [psi]

MAINTENANCE

9,0 kN [2000 lbs.]

206,8 275,8

[3000] [4000]

344,7

[5000]

Stroke

Pull Force:

Push Force:

Pull

Push

3,13 x pressure

8,04 x pressure

86,7

[19500]

73,4

[16500]

60,0

[13500]

46,7

[10500]

33,3

[7500]

Force kN [lbs.]

20,0

[4500]

6,7

[1500]

0

68,9

[1000]

35,0 kN [7900 lbs.]

137,9

[2000]

[3000] [4000]

Pressure bar [psi]

Stroke

Pull Force: 12,42 x pressure

Push Force: 23,76 x pressure

344,7206,8 275,8

[5000]

Pull

Push

Figure 3

Maintenance is required when wear or lea kage is noticed. Oc casionally inspec t all

components to detect any problem requiring s ervice and maintena nce. Enerpac offers

ready-to-us e Repair Parts Kits. Repair Parts Sheets are available with assembly drawing

and parts list. Contact Enerpac.

IMPORTANT: Consult the Repair Parts Sheet for se rvice information as to correct

assembling and disasse mbling. Incorrect maintenance and servic e such as wrong torque

values may cause product malfunctions a nd/or personal injury.

6

TROUBLESHOOTING

The following information is inte nded to be used only as an aid in determining if a

problem exists. For repair s ervice, contact your Distributor or Authorized Enerpac

Service Center.

Problem Possible Cause Solution

1. Cylinder will not

clamp/unclamp.

2. Cylinder

advances

part way.

3. Cylinder

clamps/unclamps

slower than

norma l.

4. Cylinder

clamps/unclamps

but will not hold

pressure.

5. Cylinder leaks

oil.

A.pump release valve open

B.no oil in pump re servoir

C.air in syste m

D.couplers not fully tightened

E.blocked hydraulic line

F. spring broken in c ylinder

A.oil level in pump too low

B.plunge r binding

A.leaking connection

B.restricted hydraulic line

C.pump malfunction

A.seals damaged

B.leaking connection

C.pump malfunction

A.seals damaged

B.plunge r worn or damaged

A.close pump release valve

B.fill pump reservoir

C.remove air from hydraulic system

D.re-tighten couplers

E.check valves, fittings, and tubing

F.replace spring

A.fill pump reservoir

B. replace damaged parts

—refer to Repair Parts Sheet

A.re-tighten fittings, couplers, and tubing

B. check valves, fittings, and tubing

C.refer to pump Instruction Sheet

A.replace seals

—refer to Repair Parts Sheet

B.re-tighten fittings, couplers, and tubing

C.refe r to pump Instr uction Sheet

A.replace seals

—refer to Repair Parts Sheet

B. replace damaged parts

—refer to Repair Parts Sheet

7

Mont age von Zyl in dern mit Auß engewinde

Montage des Vérin s à Corps Fileté

Montaje de Cilindros de Cuerp o Roscado

Montaggio dei Cilindri a Corpo Filettato,

Monteren van cilinders met Schroefdraadlichaam

threaded into fixture

oil connection

C

jam nut

Abbil dung, Figure, Ilustració n, Fig ura, Afbeelding, 1

A

mounting flange

oil connection

D

C

jam nuts

D

B

AB C

In die Vorrichtung

geschraubt

vérin vissé sur la machine bride de fixation raccord d’huile écrou de

atorinil lado en el apar ejo brida de montaje conexión de aceite contratuerca (contratuercas)

avvitato nel supporto fisso flangia di montaggio raccordo del olio controdado (controdadi)

in appendage geschroefd montageflens oileaansluiting tegenmoer (tegenmoeren)

Montageflansch Ölanschluß Gegenmutter

blocage

(écrous de blocage)

D

(Gegenmuttern)

écrou de blocage

8

Montage vo n Kopf- und Fußflanschzylind ern

Montage des Vérins Par Bride Supérieure ou Inférieure

Montaje de Cilindros Con Brida Superior y Brida Inferior

Mont aggio dei Cilindri a Flangia Superio re ed Inf eriore

Monteren van Onder- en Bovenflens van Cilinders

Manifold

Especificaciones del colector,Specifiche del collettore, Specificaties verdeelstuk

Zylinderkapazität

Capacité du

vérin

Capacidad

del cilindro

Forza

sviluppata

dal cilindro

Cilinder-

capaciteit

E

O-ring

Max. Ölkanal-

durchmesser

Diamètre maxi.

du passage

d’huile

Diámetro máx.

de conducto

de aceite

Diametro max.

condotto olio

Max. diameter

oliekanaal

0.003

0,1

D

C

A

B

Manifold

O-ring

E

A

0.003

0,1

D

C

Abbil dung, Figure, Ilustració n, Fig ura, Afbeelding, 2

Anschlußspezifikatio nen, Carac téristi ques du bloc foré,

Durchmesser

der Öffnung

Diamètre

du trou

de la machine

Diámetro de

agujero en

aparejo

Diametro foro

supporto fisso

Diameter gat

appendage

Ø A Ø B C D E

Befestigungs-

gewinde

Filets de

montage

Roscas de

montaje

Filetti di

montaggio

Montage-

schroefdraad

Mindest-

Einschraubtiefe

Profondeur

minimum

Profundidad

mín. de rocas

Profunditá

min. dei filetti

Minimale

scroefdraad-

diepte

Anzug-Dreh-

moment der

Befestigungs-

schrauben

(geschmiert)

Couple de

serrage du

boulon de

montage

lubrifié

Apriete de

pernos de

montaje

lubricatos

Coppia di

montaggio

bullone

lubrificato

Aandraai-

moment

gesmeerde

montagebaut

O-Ring-Anschluß

Innendurch-

messer x B

Dimensions du

joint torique

D.I. x I.

Dimensiones de

anillo "O"

de colector

D. I. x ancho

Dimensioni

O-Ring

collettore

D.I. x s

Afmeting

O-Ring

verdeelstuk

binnendiam. x b

2,2 kN 4 mm 29,2 ± 0,8 M5 15 mm 4,5-5,4 Nm 6,07 x 1,78 mm

5,6 kN 4mm 36,0 ± 0,8 M6 15 mm 12,2-14,9 Nm 7,65 x 1,78 mm

9 kN 4mm 49,1 ± 0,8 M6 15 mm 13,5-15 Nm 4,34 x 3,53 mm

35 kN 4mm 77,5 ± 0,3 M10 15 mm 65-72 Nm 4,34 x 3,53 mm

9

Anschlußbeschreibung

Identific ation d’oriface

Identificación de Lumbreras

Identificazione degli Attacchi

Identificatie Poorten

Zylinder mit Außengewinde

Corps fileté

Cuerpo roscado

Corpo filettato

Schroefdraadlichaam

Seitenansicht, Vue de côté, Vista lateral, Vista laterale, Zijaanzicht

Zylinder mit Kopfflansch

Corps á bride supérieure

Cuerpo con brida superior

Corpo a flangia superiore

Lichaam met bovenflens

C C

Zylinder mit Fußflansch

Corps á bride inférieure

Cuerpo con brida inferior

Corpo flangia inferiore

Lichaam met onderflens

A

A

B

B

Ansicht von unten, Vue de dessous, Vista inferior, Vista dal basso, Onderaanzicht

A

B

Abbildung, Figure, Ilustració n, Figura, Afbeelding, 3

AB C

Spannenanschluß Entlüftungsanschluß (einfach wirkende Modelle)

Entspannungsanschluß (doppelt wirkende Modelle)

oriface de bridage oriface d’aération (modèles simple effe t)

oriface de débridage (modèel es double effet)

Lumbrera de fijición Lumbrera de ventilación (modelos de acción única )

Lumbrera de soltado (modelos de acción doble)

attacco di serraggio attacco di sfiato (modelli a dffetto semplice)

attacco di rilascio (modelli a doppio effetto)

Klempoort Ontluchtingspoort (enkelwerkende modellen)

Afspanpoort (dubbelwerkende modellen)

HINWEISE: Den Entlüftungsstopfen nicht entfernen, es sei denn zum Anschließen von Rohren. (Siehe den Abschnitt Entlüftungsstopfen.)

REMARQU E: Ne pas retirer le bouchon à é vent, sauf pour brancher la conduite. (Voir la section bouchon à évent.)

NOTA: No saque el tapón ventilado sakvi oara c ibectar tybería en su lugar (vea la sección Tapón ventilado).

NOTA: non rimuovere il tappo di sfiato, fuorché per il collegamento di tubi (vedere la sezione sul tappo di dfiato).

N.B . : Verwijder de ontluchtingsstop alleen voor het bevestigen van slangen. (Zie het gedeelte Ontluchtingsstop).

Verteilerkopfanschlüsse

Orifaces du bloc foré

Lumbreras del colector

Attacchi del collettore

Porten verdeelstuk

10

Loading...

Loading...