Page 1

1

®

Hydraulic Technology Worldwide

Instruction Sheet

P-392FP

Hydraulic Foot Pump

EIS 63.107-1 09/2004

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If shipping

damage is found, notify carrier at once. The carrier is

responsible for all repair and replacement costs resulting from

damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to

avoid personal injury or property damage

during system operation. Enerpac cannot be responsible for

damage or injury resulting from unsafe product use, lack of

maintenance or incorrect product and/or system operation.

Contact Enerpac when in doubt as to the safety precautions

and operations. If you have never been trained on highpressure hydraulic safety, consult your distribution or service

center for a free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and warnings

could cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent damage to,

or destruction of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action

may cause serious injury or even death.

WARNING: Wear proper personal protective gear

when operating hydraulic equipment.

WARNING: Stay clear of loads supported by

hydraulics. A cylinder, when used as a load lifting

device, should never be used as a load holding

device. After the load has been raised or lowered, it must

always be blocked mechanically.

WARNING: USE ONLY RIGID PIECES TO HOLD

LOADS. Carefully select steel or wood blocks that are

capable of supporting the load. Never use a hydraulic

cylinder as a shim or spacer in any lifting or pressing

application.

DANGER: To avoid personal injury keep hands and

feet away from cylinder and workpiece during

operation.

WARNING: Do not exceed equipment ratings. Never

attempt to lift a load weighing more than the capacity

of the cylinder. Overloading causes equipment failure

and possible personal injury. The cylinders are designed for a

max. pressure of 700 bar [10,000 psi]. Do not connect a jack

or cylinder to a pump with a higher pressure rating.

DANGER: Never set the relief valve to a higher

pressure than the maximum rated pressure of the

pump. Higher settings may result in equipment

damage and/or personal injury. Do not remove relief valve.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated

component in the system. Install pressure gauges in

the system to monitor operating pressure. It is your window to

what is happening in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid

sharp bends and kinks when routing hydraulic hoses.

Using a bent or kinked hose will cause severe backpressure. Sharp bends and kinks will internally damage the

hose leading to premature hose failure.

Do not drop heavy objects on hose. A sharp impact

may cause internal damage to hose wire strands.

Applying pressure to a damaged hose may cause it to

rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or

other means of safe transport.

CAUTION: Keep hydraulic equipment away from

flames and heat. Excessive heat will soften packings

and seals, resulting in fluid leaks. Heat also weakens

hose materials and packings. For optimum performance do

not expose equipment to temperatures of 65 °C [150 °F] or

higher. Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses.

Escaping oil under pressure can penetrate the skin,

causing serious injury. If oil is injected under the skin,

see a doctor immediately.

Index:

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

®

®

®

Page 2

2

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected

couplers. If the cylinder becomes extremely

overloaded, components can fail catastrophically causing

severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a flat

surface that can support the load. Where applicable,

use a cylinder base for added stability. Do not weld or

otherwise modify the cylinder to attach a base or other

support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially

dangerous results.

Distribute the load evenly across the entire saddle

surface. Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualified hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or damaged

parts by genuine ENERPAC parts. Standard grade

parts will break causing personal injury and property

damage. ENERPAC parts are designed to fit properly and

withstand high loads.

CAUTION: Always use the handle to carry the pump.

Carrying the pump by the hose may damage the hose

and/or the pump.

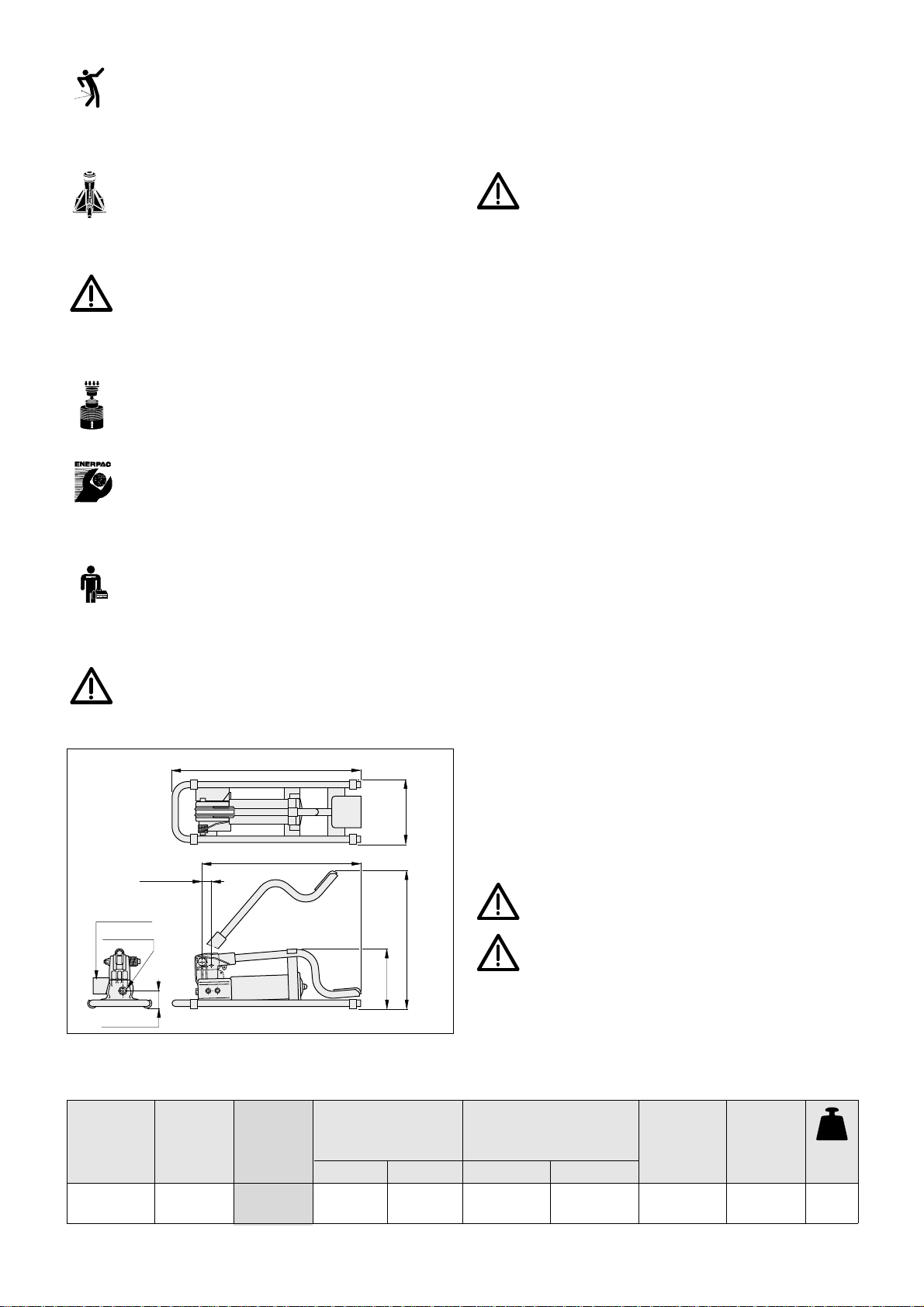

3.0 DESCRIPTION

The P-392FP is a two-speed pump which can be used to

power single-acting cylinders and tools with an oil capacity up

to 490 cm3. It has an internal pressure relief valve for overload

protection. For dimensions see Figure 1. Figure 2 shows the

specifications of the pump.

WARNING: The P-392FP is operated with a nonvented reservoir. If the reservoir is subjected to

high pressure, the casing may rupture, causing

personal injury and/or equipment damage. NEVER

attempt to return more oil to the reservoir than it is

capable of holding.

4.0 INSTALLATION

4.1 Connecting the Pump

1. Thread hose into pump outlet. Use 1 1/2 wraps of Teflon tape

(or suitable thread sealant) on hose fitting, leaving the first

complete thread free of tape to ensure that tape does not

shed into hydraulic system, causing damage. Trim loose

ends.

2. Install a pressure gauge in-line from the pump for added

safety and better control.

3. Connect the hose(s) to your cylinder or tool.

NOTE: For single-acting cylinders, connect one hose from

the pump to the cylinder. For double-acting cylinders,

connect two hoses. Connect one hose from the pressure

port of the pump to the pressure port of the cylinder.

Connect another hose from the retract port of the pump to

the retract port of the cylinder.

4.2 Pump Venting

The P-392FP is operated with a non-vented reservoir. If the

reservoir is subjected to high pressure, the casing may

rupture, causing personal injury and/or equipment damage.

NEVER attempt to return more oil to the reservoir than it is

capable of holding.

5.0 OPERATION

5.1 Before Using the Pump

1. Check all system fittings and connections to be sure they

are tight and leak free.

2. Check oil level in reservoir before operating pump. See

paragraph 7.1 "Adding Oil to the Pump" on page 3.

CAUTION: NEVER add extensions to pump handle.

Extensions cause unstable pump operation.

WARNING: In certain situations the pump handle

can "kick back". Always keep your body to the side

of the pump, away from the line of force of the

handle.

NOTE: To reduce handle effort at high pressure, take short

strokes. Maximum leverage is obtained in the last 5° of stroke.

Release valve

FIGURE 2 - SPECIFICATIONS

Figure 1

Single-

Acting

Usable Oil

Capacity

cm

3

[in3]

Used

with

cylinder

Pressure Rating

bar [psi]

Model

Number

Oil Displacement

per Stroke

cm3 [in3]

Max.

Handle

Effort

kg

[lbs]

Piston

Stroke

mm

[inch]

1ststage 1ststage 2ndstage 2ndstage

kg

[lbs]

492

[30]

15

[220]

700

[10,000]

11,26

[.687]

2,47

[.151]

42

[93]

25,4

1.00

7,0

[15.4]

P-392FP

®

30 [1.18"]

600 mm [23.6 inch]

3/8"-18NPT

52 [2.04"]

504 [19.8"]

193 [7.60"]

433 [17.05"]

187 [7.36"]

Page 3

3

5.2 Using Two-Speed Pumps

These pumps provide 2-stage flow. Under no-load, the pump

operates in the high flow first stage for rapid advance. When

the load is contacted, the pump automatically shifts to the

second stage for building pressure.

NOTE: For best performance, operate pump handle at

moderate speed during the high flow first stage. Rapid handle

speed in the first stage will prevent the pump from delivering

full volume of oil.

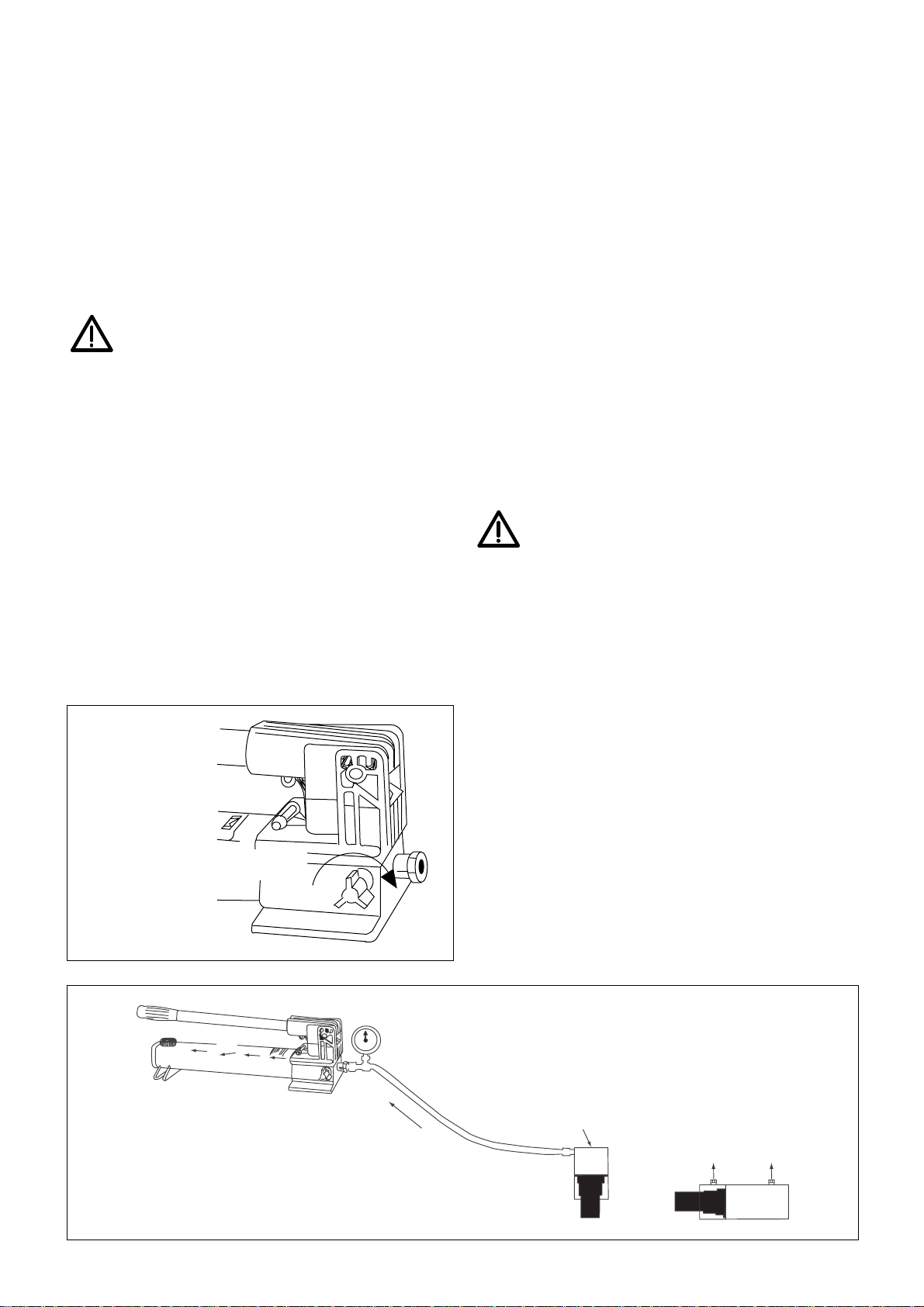

5.3 Single-Acting Applications with Release Valve

1. Close release valve by turning clockwise, as shown in

Figure 3.

CAUTION: Close release valve finger tight ONLY.

Using tools on release valve can damage it and

cause the pump to malfunction.

2. Operate pump handle to deliver hydraulic power to system.

Pressure will be maintained until release valve is opened.

3. Open release valve (turn counter-clockwise) to release

pressure, allowing oil to flow back to the reservoir.

5.6 Relief Valve Adjustment

All pumps contain a factory set relief valve to prevent overpressurization of the system. Lower pressure settings can be

obtained. Contact your Authorized Enerpac Service Center.

6.0 AIR REMOVAL

Removing air from the hydraulic system will help the cylinder to

advance and retract smoothly (see figure 4).

6.1 Pump With Single-Acting Cylinder (A)

1. Vent pump reservoir (for vented pumps only) and close

release valve.

2. Position pump at higher elevation than cylinder.

3. Position cylinder with the plunger end down (up if using pull

cylinder). See Figure 4 below.

4. Operate pump to fully extend the cylinder (retract if using

pull cylinder).

5. Open release valve to retract cylinder (extend if a pull

cylinder). This will force the trapped air to move up to the

pump reservoir.

6. Repeat the above steps as necessary.

7. Add oil if necessary. See paragraph 7.1 (page 3)

8. Return vent/fill cap to operating position.

7.0 MAINTENANCE

Use only Enerpac hydraulic oil with these pumps to promote

long pump life and to protect your warranty. Viton and EPR seal

kits are available for some hand pumps. Contact your Enerpac

representative for more information

7.1 Adding oil to pump

Check oil level regularly.

WARNING: Always add oil with cylinders fully

retracted (extended if pull cylinders) or the system

will contain more oil than the reservoir can hold.

1. Remove vent/fill cap from reservoir.

2. Fill reservoir only to level mark shown on pump.

3. Remove air from system if necessary. See page 6. Recheck

oil level after removing air.

4. Return vent/fill cap to proper position.

NOTE: Non-vented hand pumps require air in the reservoir to

function properly. If the reservoir is completely filled, a vacuum

will form preventing oil from flowing out of the pump.

7.2 Keeping Oil Lines Clean

When coupler halves are disconnected, always screw on dust

caps. Use every precaution to guard unit against entrance of

dirt because foreign matter may cause pump, cylinder, or

valve failure.

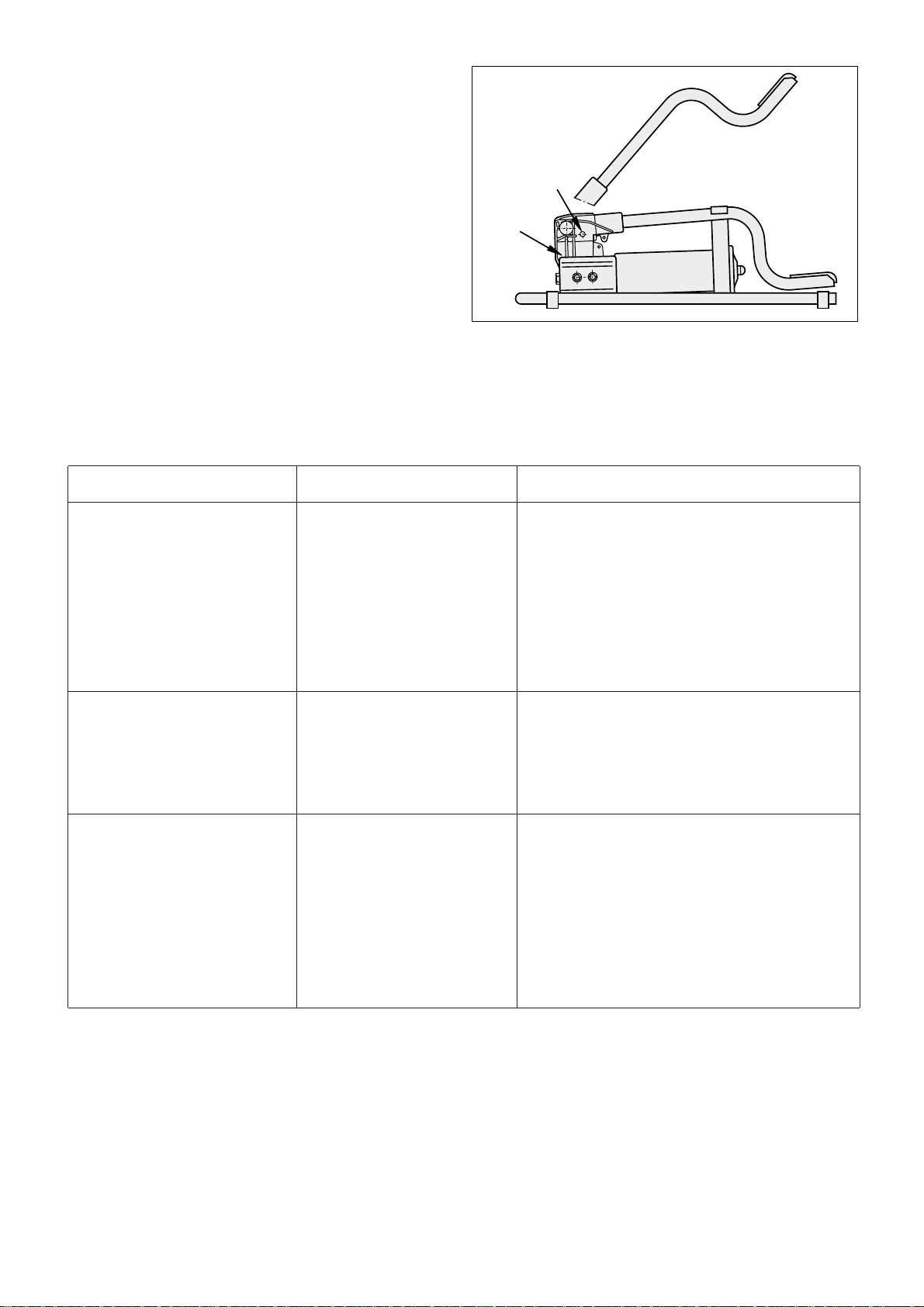

7.3 Lubricating the Pump

To extend pump life and improve performance, lubricate the

beam pin (A), cross pin (B), and piston head (C) regularly, using

roller bearing grease. See Figure 5 on page 4.

Release valve

Figure 3

AIR

Figure 4

Page 4

4

1. Cylinder does not advance,

advances slowly, or advances

in spurts.

1. Oil level in pump reservoir is

low.

2. Release valve open.

3. Loose hydraulic coupler.

4. Load is too heavy.

5. Air trapped in system.

6. Cylinder plunger binding.

1. Add oil according to the Maintenance

instructions on page 3 (paragrapgh 7.1).

2. Close the release valve.

3. Check that all couplers are fully tightened.

4. Do not attempt to lift more than rated tonnage.

5. Remove air according to the instructions on

page 3 (paragraph 6.0).

6. Check for damage to cylinder. Have cylinder

serviced by a qualified hydraulic technician.

1. Leaking connection.

2. Leaking seals.

3. Internal leakage in pump.

1. Check that all connections are tight and leak

free.

2. Locate leak(s) and have equipment serviced by

a qualified hydraulic technician.

3. Have pump serviced by a qualified hydraulic

technician.

3. Cylinder does not retract,

retracts part way, or retracts

more slowly than normal..

1. Release valve closed.

2. Pump reservoir is over-filled.

3. Loose hydraulic coupler.

4. Air trapped in system.

5. Hose internal diameter too

narrow.

6. Cylinder retraction spring

broken or other cylinder

damage.

1. Open release valve.

2. Drain oil level to full mark. See page 3

instructions for adding oil (paragrapg 7.1).

3. Check that all couplers are fully tightened.

4. Remove air according to the instructions on

page 3 (paragraph 6.0).

5. Use larger diameter hydraulic hose.

6. Have cylinder serviced by a qualified hydraulic

technician.

2. Cylinder advances, but does

not hold pressure.

Problem Possible Cause Solution

8.0 TROUBLE SHOOTING

7.4 Changing the Oil

1. Drain all oil and refill with clean Enerpac oil every 12

months. If pump is used in dirty environments, change the

oil more often.

2. Remove vent/fill cap or plug from reservoir.

3. Tilt pump to drain out old oil.

4. Fill reservoir only to level mark shown on pump.

5. Replace the vent/fill cap or plug.

6. Dispose of used oil properly.

8.0 TROUBLESHOOTING GUIDE

The following information is intended as an aid in determining

if a problem exists. For repair service, contact the Authorized

Enerpac Service Center in your area.

A

B+C

Figure 5

Page 5

5

®

Hydraulic Technology Worldwide

Fiche d’instructions

P-392FP

Pompe à pied

EIS 63.107-1 09/2004

1.0 INSTRUCTIONS IMPORTANTES RELATIVES À LA

RÉCEPTION

Inspecter tous les composants pour vous assurer qu’ils n’ont

subi aucun dommage en cours d’expédition. Les dommages

subis en cours de transports ne sont pas couverts par la

garantie. S’ils sont abîmés, aviser immédiatement le

transporteur, qui est responsable des frais de réparation et de

remplacement résultant de dommages en cours de transport.

LA SÉCURITÉ AVANT TOUT !

2.0 SÉCURITÉ

Lire attentivement toutes les instructions et

mises en garde et tous les avertissements.

Suivre toutes les précautions pour éviter

d’encourir des blessures personnelles ou de provoquer des

dégâts matériels durant le fonctionnement du système.

Enerpac ne peut pas être tenue responsable de dommages ou

blessures résultant de l’utilisation risquée du produit, d’un

mauvais entretien ou d’une application incorrecte du produit et

du système. En cas de doute sur les précautions ou les

applications, contacter Enerpac.

Respecter les mises en garde et avertissements suivants sous

peine de provoquer des dégâts matériels et des blessures

corporelles.

Une mise en garde ATTENTION sert à indiquer des

procédures d’utilisation et de maintenance correctes qui

visent à empêcher l’endommagement voire la destruction du

matériel ou d’autres dégâts.

Un AVERTISSEMENT indique un danger potentiel qui exige la

prise de mesures particulières visant à écarter tout risque de

blessure.

La mention DANGER n’est utilisée que lorsqu’une action ou

un acte de négligence risque de causer des blessures graves,

voire mortelles.

AVERTISSEMENT: Porter un équipement de

protection personnelle adéquat pour utiliser un

appareil hydraulique.

AVERTISSEMENT : Rester à l’écart de charges

soutenues par un mécanisme hydraulique. Un

vérin, lorsqu’il est utilisé comme monte-charge, ne

doit jamais servir de support de charge. Après avoir monté ou

abaissé la charge, elle doit être bloquée par un moyen

mécanique.

AVERTISSEMENT : UTILISER SEULEMENT DES

PIÈCES RIGIDES POUR SOUTENIR LES

CHARGES. Sélectionner avec précaution des blocs

d’acier ou de bois capables de supporter la charge. Ne jamais

utiliser un vérin hydraulique comme cale ou intercalaire

d’appui pour les applications de levage ou de pressage.

DANGER: Pour écarter tout risque de blessure

personnelle, maintenir les mains et les pieds à

l’écart du vérin et de la pièce à usiner durant

l’utilisation.

AVERTISSEMENT: Ne pas dépasser les valeurs

nominales du matériel. Ne jamais essayer de soulever

une charge d’un poids supérieur à la capacité du

vérin. Une surcharge entraînera la panne du matériel et risque

de provoquer des blessures corporelles. Les vérins sont

conçus pour une pression maximale de 700 bar. Ne pas

connecter de cric ou de vérin à une pompe affichant une

pression nominale supérieure.

AVERTISSEMENT: Ne jamais régler la soupape de

sûreté à une pression supérieure à la pression

nominale maximale de la pompe sous peine de

provoquer des dégâts matériels et/ou des blessures

corporelles. Ne pas retirer le limiteur de pression.

AVERTISSEMENT: La pression de fonctionnement

du système ne doit pas dépasser la pression

nominale du composant du système affichant la plus

petite valeur. Installer des manomètres dans le système pour

surveiller la pression de fonctionnement. Ils permettent de

vérifier ce qui se passe dans le système.

ATTENTION: Éviter d’endommager les tuyaux

hydrauliques. Éviter de les plier et de les tordre en les

mettant en place. Un tuyau plié ou tordu entraînera un

fort retour de pression. Les plis et coudes prononcés

endommageront par ailleurs l’intérieur du tuyau, provoquant

son usure précoce.

Ne pas faire tomber d’objets lourds sur le tuyau.

Un fort impact risque de causer des dégâts intérieurs

(torons métalliques). L’application d’ une pression sur

un tuyau endommagé risque d’entraîner sa rupture.

®

®

®

Page 6

6

IMPORTANT: Ne pas soulever le matériel hydraulique

en saisissant ses tuyaux ou ses raccords articulés.

Utiliser la poignée de trans-port ou procéder d’une

autre manière sûre.

ATTENTION: Garder le matériel hydraulique à

l’écart de flammes et d’une source de chaleur. Une

forte température amollira les garnitures et les joints

et provoquera par conséquent des fuites. La chaleur affaiblit

également les matériaux et les garnitures du tuyau. Pour une

performance maximale, ne pas exposer le matériel à une

température supérieure ou égale à 65 °C [150 °F]. Protéger

tuyaux et vérins de projections de soudure.

DANGER: Ne pas manipuler les tuyaux sous

pression. L’huile sous pression qui risque de s’en

échapper peut pénétrer dans la peau et provoquer

des blessures graves. En cas d’injection d’huile sous la peau,

contacter immédiatement un médecin.

AVERTISSEMENT: Utiliser des vérins hydrauliques

uniquement dans un système couplé. Ne jamais utiliser

un vérin en présence de raccords déconnectés. La

surcharge du vérin peut avoir des effets désastreux sur ses

composants, qui peuvent causer des blessures graves.

AVERTISSMENT : S'assurer de la stabilité de

l'ensemble avant de lever une charge. Le vérin doit

être placé sur une surface plane capable de

supporter la charge. Lorsqu'applicable, utiliser une

base de vérin pour accroître la stabilité. Ne pas souder ou

modifier le vérin de quelque façon que ce soit pour y fixer une

base ou un autre dispositif de support.

Éviter les situations où les charges ne sont pas

directement centrées sur le piston du vérin. Les

charges décentrées imposent un effort considérable

au vérins et pistons. En outre, la charge risque de glisser ou

de tomber, ce qui crée un potentiel de danger.

Répartir la charge uniformément sur toute la surface

d'appui. Toujours utiliser un coussinet d'appui si des

accessoires non filetés sont utilisés.

IMPORTANT: Le matériel hydraulique doit

uniquement être réparé par un technicien hydraulique

qualifié. Pour toute réparation, contacter le centre de

réparation ENERPAC agréé le plus proche. Pour assurer la

validité de la garantie, n’utiliser que de l’huile ENERPAC.

AVERTISSEMENT: Remplacer immédiatement les

pièces usées ou endommagées par des pièces

ENERPAC authentiques. Les pièces de qualité

standard se casseront et provoqueront des blessures et des

dégâts matériels. Les pièces ENERPAC sont conçues pour

s’ajuster parfaitement et résister à de fortes charges.

PRÉCAUTION: Toujours porter la pompe par son

levier. Si la pompe est portée par le flexible, le flexible

ou la pompe risque d’en souffrir.

3.0 DESCRIPTION

P-392FP à deux vitesses par vérins de simple effet. Valve de

pression interne, protège des surcharges. Voir figure page 6

pour le dimensions et figure 2 pour le specifications.

AVERTISSEMENT: Ces pompes fonctionnent avec

un réservoir non aéré. Si le réservoir est soumis à

une pression élevée, le carter risque d’éclater et

de causer des blessures et (ou) des dégâts matériels. NE

JAMAIS essayer de renvoyer au réservoir plus d’huile qu’il

ne peut en contenir.

4.0 INSTALLATION

4.1 Raccordement de la pompe

1. Visser le flexible dans l’orifice de la pompe. Entourer le

raccord de flexible de 1 1/2 tour de ruban Téflon (ou utiliser

un matériau d’étanchéité qui convient), en ne couvrant pas le

premier filet afin d’éviter que des lambeaux de ruban

pénètrent dans le circuit hydraulique et causent des dégâts.

Couper les parties qui dépassent.

2. Par mesure de prudence et pour permettre de surveiller la

pression plus aisément, poser un manomètre sur la conduite

sortant de la pompe.

3. Raccorder le ou les flexibles au vérin ou outil.

NOTE : Dans le cas des vérins à simple effet, brancher un

flexible entre la pompe et le vérin. Pour les vérins à double

effet, raccorder deux flexibles. Connecter un flexible entre

l’orifice de pression de la pompe et l’orifice de pression du

vérin. Brancher l’autre entre l’orifice de rentrée de la pompe

et l’orifice de rentrée du vérin.

Valve de

décharge

FIGURE 2 - SPECIFICATIONS

Figure 1

Simple

effet

Capacité

d’huile utile

cm

3

[pouce3]

Utilisé

avec

vérin

Pression nominale

bar [psi]

Référence Débit par course

cm3 [pouce3]

Effort

maximal

sur le levier

kg

[lbs]

Course du

piston

mm

[pouce]

1er étage 1er étage2ème étage 2ème étage

kg

[lbs]

492

[30]

15

[220]

700

[10,000]

11,26

[.687]

2,47

[.151]

42

[93]

25,4

1.00

7,0

[15.4]

P-392FP

600 mm [23.6 inch]

®

193 [7.60"]

504 [19.8"]

30 [1.18"]

3/8"-18NPT

433 [17.05"]

187 [7.36"]

52 [2.04"]

Page 7

7

4.2 Aération de la pompe

Ces pompes fonctionnent avec un réservoir non aéré. Si le

réservoir est soumis à une pression élevée, le carter risque

d’éclater et de causer des blessures et (ou) des dégâts

matériels. NE JAMAIS essayer de renvoyer au réservoir plus

d’huile qu’il ne peut en contenir.

5.0 FONCTIONNEMENT

5.1 Avant d’utiliser la pompe

1. Vérifier tous les raccords et toutes les connexions du circuit

pour s’assurer de leur intégrité et leur étanchéité.

2. Vérifier le niveau d’huile dans le réservoir avant de faire

fonctionner la pompe. Voir § 7.1 "Appoint d’huile dans la

pompe", page 8.

PRÉCAUTION : NE JAMAIS ajouter de rallonges

au levier de la pompe, sous peine de déstabiliser

le fonctionnement de la pompe.

AVERTISSEMENT : Il peut arriver que le levier de la

pompe revienne brusquement en arrière. Toujours

se tenir sur le côté de la pompe, hors de portée du

levier.

NOTE: Pour réduire l’effort à exercer sur le levier aux

pressions élevées, pomper par petits coups. L’effet de levier

maximum est obtenu dans les cinq derniers degrés de la

course du levier.

5.2 Utilisation des pompes à deux vitesses

Ces pompes fournissent un débit en deux étapes. À vide, la

pompe fonctionne en première étape à débit élevé pour

assurer une sortie rapide du vérin. Quand il y a contact avec

la charge, la pompe passe automatiquement à la deuxième

étape afin de donner de la pression.

NOTE: Pour optimiser les performances, actionner le levier de

la pompe à vitesse modérée durant la première étape à débit

élevé. Si l’on pompe trop vite dans la première étape, le

volume d’huile fourni ne sera pas suffisant.

5.3 Applications à simple effet avec robinet de décharge

1. Fermer le robinet de décharge en le tournant vers la droite,

comme l’illustre la figure 3.

PRÉCAUTION : Serrer le robinet de décharge à la

main UNIQUEMENT. L’emploi d’outils sur le

robinet de décharge peut l’endommager et risque

de causer un mauvais fonctionnement de la pompe.

2. Actionner le levier de la pompe afin d’alimenter le circuit en

puissance hydraulique. La pression est maintenue jusqu’à

ce que le robinet de décharge soit ouvert.

3. Ouvrir le robinet de décharge (en le tournant vers la gauche)

pour dissiper la pression, ce qui permet le retour de l’huile

vers le réservoir.

5.6 Réglage du robinet de décharge

Toutes les pompes sont munies d’un robinet de décharge

réglé en usine qui permet d’empêcher le circuit de se

pressuriser plus que nécessaire. Il est possible de régler ce

robinet sur une pression moins élevée. Contacter le Service

après-vente agréé Enerpac le plus proche.

6.0 PURGE DE L’AIR

L’élimination de l’airdu circuit hydraulique aide le vérin à sortir et

rentrer en douceur. Voir figure 4.

6.1 Pompe associée à un vérin à simple effet (A)

1. Aérer le réservoir de la pompe (pompes aérées uniquement)

et fermer le robinet de décharge.

2. Positionner la pompe plus haut que le vérin.

3. Positionner le vérin côté piston vers le bas (ou le haut s’il

s’agit d’un vérin à traction). Voir figure 4.

4. Actionner la pompe pour faire sortir le vérin jusqu’au bout

(le faire rentrer s’il s’agit d’un vérin à traction).

5. Ouvrir le robinet de décharge pour faire rentrer le vérin (le

faire sortir s’il s’agit d’un vérin à traction). L’air piégé est

ainsi forcé à remonter vers le réservoir de la pompe.

6. Répéter les opérations ci-dessus, au besoin.

7. Ajouter de l’huile si nécessaire. Voir § 7.1 page 8.

8. Remettre le reniflard en position de service.

Valve de décharge

Figure 3

AIR

Figure 4

Page 8

8

7.0 ENTRETIEN

Utiliser uniquement de l’huile hydraulique Enerpac avec ces

pompes afin d’en prolonger la durée de vie et de protéger la

validité de la garantie. Des jeux d’étanchéité Viton et EPR

peuvent être fournis pour certaines pompes à main. Demander

plus d’informations sur ces produits et leurs applications au

représentant Enerpac.

7.1 Appoint d’huile à la pompe

Vérifier régulièrement le niveau d’huile.

AVERTISSEMENT : Les vérins doivent être

complètement rentrés (ou sortis si vérins de

traction) quand l’huile est ajoutée, sinon le circuit

risque de renfermer plus d’huile que le réservoir ne peut

en contenir.

1. Retirer le bouchon reniflard du réservoir.

2. Remplir le réservoir en s’arrêtant au repère marqué sur la

pompe.

3. Éliminer l’air du circuit si nécessaire. Voir § 6 Figure 4.

Revérifier le niveau d’huile après cette opération.

4. Remettre le bouchon reniflard sur la position qui convient.

NOTE : Les pompes à main non aérées ont besoin d’air dans

le réservoir pour fonctionner correctement. Si le réservoir est

rempli à ras bord, un effet de vide se crée empêchant l’huile

de sortir de la pompe.

7.2 Protection des conduites d’huile contre les saletés

Quand les deux moitiés d’un raccord sont séparées, toujours

protéger les ouvertures par des capuchons anti-poussière.

Prendre toutes les mesures nécessaires pour protéger

l’appareil contre la pénétration de saletés, car les corps

étrangers peuvent provoquer une défaillance au niveau de la

pompe, du vérin ou des soupapes.

7.3 Lubrification de la pompe

Pour prolonger la durée de vie de la pompe et en améliorer les

performances, lubrifier l’axe du balancier (A), l’axe transversal

(B) et la tête de piston (C) régulièrement en utilisant de la

graisse pour roulements à rouleaux. Voir figure 5.

7.4 Vidange d’huile

1. Vider toute l’huile et faire le plein d’huile Enerpac propre

tous les 12 mois. Si la pompe est utilisée dans des

conditions de grande saleté, changer l’huile plus souvent.

2. Retirer le bouchon reniflard ou le bouchon de remplissage

du réservoir.

3. Pencher la pompe pour faire partir toute l’huile usée.

4. Remplir le réservoir en s’arrêtant au repère marqué sur la

pompe.

5. Remettre le bouchon reniflard ou de remplissage.

6. Jeter l’huile usée selon les méthodes appropriées.

8.0 GUIDE DE DÉPANNAGE

Les informations (voir page 9) qui suivent sont à utiliser à titre

de guide pour déterminer l’existence d’un problème. Pour les

réparations, contacter le Service après-vente agréé Enerpac

le plus proche.

Figure 5

B+C

A

Page 9

1. Le vérin ne sort pas, sort

lentement ou sort par àcoups.

1. Niveau d’huile insuffisant

dans le réservoir de la

pompe.

2. Robinet de décharge ouvert.

3. Raccord hydraulique

desserré.

4. Charge trop importante.

5. Air piégé dans le circuit.

6. Piston du vérin coince.

1. Ajouter de l’huile suivant les instructions

d’entretien de la § 7.1 page 8.

2. Fermer le robinet de décharge.

3. Vérifier que tous les raccords sont bien serrés.

4. Ne pas tenter de soulever plus que la charge

nominale.

5. Éliminer l’air suivant les instructions de la § 6

page 7.

6. Vérifier l’état du vérin. Faire réparer le vérin par un

technicien qualifié en hydraulique.

1. Fuite aux connexions.

2. Fuite aux joints.

3. Fuite interne dans la pompe.

1. Vérifier l’intégrité et l’étanchéité de toutes les

connexions.

2. Localiser la ou les fuites et faire réparer le matériel

par un technicien qualifié en hydraulique.

3. Faire réparer la pompe par un technicien qualifié

en hydraulique.

3. Le vérin ne rentre pas, rentre

partiellement ou rentre plus

lentement qu’il ne devrait.

1. Robinet de décharge fermé.

2. Réservoir de la pompe trop

rempli.

3. Raccord hydraulique

desserré.

4. Air piégé dans le circuit.

5. Diamètre intérieur du flexible

trop petit.

6. Ressort de rappel du vérin

cassé ou autre problème de

vérin.

1. Ouvrir le robinet de décharge.

2. Vider de l’huile pour redescendre au repère plein.

Instructions pour l’appoint d’huile à la § 7.1

page 8.

3. Vérifier que tous les raccords sont bien serrés.

4.

Éliminer l’air suivant les instructions de

la § 6

page 7.

5. Utiliser un flexible hydraulique à plus grand

diamètre.

6. Faire réparer le vérin par un technicien qualifié en

hydraulique.

2. Le vérin sort mais ne

maintient pas la pression.

Problème Cause possible Solution

8.0 GUIDE DE DÉPANNAGE

9

Page 10

10

®

Hydraulic Technology Worldwide

Bedienungsanleitung

P-392FP

Hydraulische Fußpumpe

EIS 63.107-1 09/2004

1.0 WICHTIGE VERFAHRENSHINWEISE FÜR DEN

EMPFANG:

Alle Komponenten auf sichtbare Transportschäden inspizieren.

Transport-schäden sind nicht von der Garantie gedeckt.

Werden solche Schäden festgestellt, ist unverzüglich das

Transportunternehmen zu verständigen. Das

Transportunternehmen ist für alle Reparatur- und Ersatzkosten,

die auf Transportschäden zurückzuführen sind, verantwortlich.

SICHERHEIT GEHT VOR

2.0 SICHERHEITSFRAGEN

Alle Anleitungen, Warnungen und

Vorsichtshinweise sorgfältig durchlesen.

Beachten Sie alle Sicherheitsvorkehrungen,

um Verletzungen oder Sachschäden während des

Systembetriebs zu vermeiden. Enerpac ist weder für Schäden

noch Verletzungen haftbar, die durch einen fahrlässigen

Gebrauch des Produkts, mangelhafte Instand-haltung oder

eine unvorschriftsmäßige Anwendung des Produkts und/oder

des Systems verursacht werden. Bei evtl. Fragen in bezug auf

Sicherheitsvorkehrungen und Betriebsabläufe wenden Sie sich

bitte an ENERPAC. Wenn Sie an keinerlei

Sicherheitsschulungen im Zusammenhang mit Hochdruckhydraulikanlagen teilgenommen haben, fordern Sie von Ihrer

Vertriebs- und Kundendienstzentrale einen kostenlosen

Enerpac-Hydraulik-Sicherheitskurs an.

Ein Mißachten der folgenden Vorsichtshinweise und

Warnungen kann zu Geräteschäden und Verletzungen führen.

Mit einem VORSICHTSHINWEIS wird auf ordnungsgemäße

Betriebs- oder Wartungsverfahren und –praktiken

hingewiesen, um Schäden an den Geräten oder anderen

Sachwerten bzw. deren Zerstörung zu vermeiden.

Eine WARNUNG verweist auf eine potentielle

Verletzungsgefahr, die durch ordnungsgemäße Verfahren oder

Praktiken vermieden werden kann.

Ein GEFAHRENSHINWEIS wird nur dann gegeben, wenn eine

bestimmte Handlung oder die Unterlassung einer bestimmten

Handlung schwere oder tödliche Verletzungen zur Folge

haben kann.

WARNUNG: Beim Betrieb hydraulischer Anlagen

geeignete Schutzkleidung und –ausrüstung tragen.

WARNUNG: Von Lasten fernhalten, die durch ein

Hydrauliksystem abgestützt werden. Ein als

Lastenhebegerät eingesetzter Zylinder darf niemals

als ein Lastenhaltegerät verwendet werden. Nach Heben oder

Senken der Last muß diese stets auf mechanische Weise

gesichert werden.

WARNUNG ZUM SICHERN VON LASTEN STETS

NUR STARRE TEILE VERWENDEN. Zum Abstützen

von Lasten sorgfältig dazu geeignete Stahl- oder

Holzblöcke auswählen. Bei Hebe- oder Drückanwendungen

keinesfalls einen Hydraulikzylinder als Abstandsstück oder

–halter verwenden.

GEFAHR: Zur Vermeidung von Verletzungen

während des Betriebs Hände und Füße von

Zylinder und Werkstück fernhalten.

WARNUNG: Die zugelassene Nennleistung der

Geräte nicht überschreiten. Keine Last zu heben

versuchen, deren Gewicht das Hebevermögen des

Zylinders übersteigt. Überlasten verursachen

Maschinenausfälle und können zu Verletzungen führen. Die

Zylinder wurden für einen max. Druck von 700 bar konstruiert.

Keinen Heber oder Zylinder an eine Pumpe mit einer höheren

nominalen Druckleistung anschließen.

GEFAHRENSHINWEIS: Das Überdruckventil

keinesfalls auf einen höheren Druck als den maximal

zulässigen Druck der Pumpe einstellen. Höhere

Einstellungen können zu Geräteschäden und/oder

Verletzungen führen. Nicht das Druckbegrenzungs-Ventil

entfernen!

WARNUNG: Der System-betriebsdruck darf den

zulässigen Nominaldruck der System-komponente

mit der niedrigsten Nennleistung nicht überschreiten.

Zur Überwachung des Betriebsdrucks sind Manometer im

System zu installieren. Dies ist das Fenster zu den Abläufen im

System.

VORSICHT: Beschädigungen am

Hydraulikschlauch vermeiden. Beim Verlegen der

Hydraulik-schläuche enge Bögen und Abknicken

vermeiden. Der Einsatz eines gebogenen oder geknickten

Schlauchs führt zu einem hohen Rückstau. Starke Biegungen

und Knickstellen schädigen den Schlauch auf der Innenseite

und führen zu dessen vorzeitigem Ausfall.

Keine schweren Gegenstände auf den Schlauch fallen

lassen. Starke Erschütterungen können Schäden an

den im Schlauchinnern verlaufenden Drahtlitzen

verursachen. Ein Schlauch, auf den Druck ausgeübt wird,

kann bersten.

®

®

®

Page 11

11

WICHTIG: Hydraulische Geräte weder an den

Schläuchen noch den Gelenkanschlüssen anheben.

Dazu den Tragegriff oder eine andere sichere

Transportmethode verwenden.

VORSICHT: Hydraulische Geräte von Flammen

und Hitzequellen fernhalten. Zu hohe Temperaturen

weichen Füllungen und Dichtungen auf und bewirken

Flüssigkeitslecks. Große Hitze schwächt außerdem die

Schlauchmaterialien und –dichtungen. Zur Gewährleistung

einer optimalen Leistung darf die Anlage keinen Temperaturen

über 65°C ausgesetzt werden. Außerdem müssen Schläuche

und Zylinder beim Schweißen vor Funkenschlag geschützt

werden.

GEFAHR: Nicht mit unter Druck stehenden

Schläuchen hantieren. Unter Druck austretendes Öl

kann in die Haut eindringen und schwere

Verletzungen verursachen. Falls Öl unter die Haut gelangt, ist

sofort ein Arzt aufzusuchen.

WARNUNG: In einem gekoppelten System dürfen

nur Hydraulikzylinder verwendet werden. Niemals

einen Zylinder mit unverbundenen Kupplungen

verwenden. Bei einer extremen Überlastung des Zylinders

können dessen Komponenten einen Sprungvollausfall erleiden,

was schwere Verletzungen hervorrufen kann.

WARNUNG: Sicherstellen, dass die anlage

stabilisiert, bevor eine last angehoben wird. Der

Zylinder sollte auf einer ebenen Oberfläche aufsitzen,

die fest genug ist, um die Last abzustützen. Wenn

möglich einen Zylinderfuß verwenden, um größere Stabilität zu

gewährleisten. Keine Schweißarbeiten oder andere

Änderungen am Zylinder vornehmen, um einen Zylinderfuß

oder andere Abstützungen anzubringen.

Situationen vermeiden, in denen die Lasten nicht

direkt über dem Kolben des Zylinders ausgerichtet

sind. Seitlich versetzte Lasten führen zu erheblicher

Belastung der Zylinder und Kolben. Außerdem könnte die Last

ins Rutschen geraten oder fallen, was zu äußerst gefährlichen

Situationen führen kann.

Die Last gleichmäßig über die gesamte Fläche des

Druchstückes verteilen. Den Kolben immer mit einem

Druckstück schützen, wenn keine Zusatzgeräte mit

Gewinde benutzt werden.

WICHTIG: Hydraulische Geräte müssen von einem

qualifizierten Hydrauliktechniker gewartet werden.

Bei Reparaturarbeiten an die autorisierte ENERPACKundendienstzentrale der jeweiligen Region wenden. Zur

Aufrechterhaltung der Garantie nur ENERPAC-Öl verwenden.

WARNUNG: Abgenutzte oder beschädigte Teile

unverzüglich durch ENERPAC-Originalteile ersetzen.

Standardteile anderer Hersteller versagen und

verursachen Verletzungen und Sachschäden. ENERPAC-Teile

werden so konstruiert, daß sie richtig passen und hohen

Lasten standhalten.

VORSICHT: Benutzen Sie zum Tragen der Pumpe

stets den Griff. Wird die Pumpe beim Tragen am

Schlauch gehalten, kann der Schlauch und/oder

die.Pumpe beschädigt werden.

3.0 BESCHREIBUNG

Fußpumpe mit Zwei-Stufenbetrieb für Anwendung mit

einfachwirkende Zylinder und Werkzeuge. P-392FP hat ein

internes Druckbegrenzungsventil für Überlastungsschutz.

Siehe Abbildung 1 für die Abmessungen und Tabelle 2 für die

Technische Daten.

ACHTUNG: Diese Pumpen werden mit einem nicht

entlüfteten Tank betrieben. Falls der Tank hohem

Druck ausgesetzt wird, kann das Gehäuse

brechen. Verletzungen und/oder Schäden können die

Folge sein. NIEMALS versuchen, mehr Öl in den Tank

zurückzuleiten, als dieser fassen kann.

4.0 INSTALLATION

4.1 Anschließen der Pumpe

1. Schrauben Sie den Schlauch mit dem Gewinde in den

Ausgang der Pumpe ein. Benutzen Sie für die

Schlauchanschlüsse 1 1/2 Lagen Teflonband (oder ein

anderes geeignetes Gewindedichtungsmittel), wobei der

erste volle Gewindegang frei bleiben muß, um zu verhindern,

daß das Band reißt und in das System gelangt und Schaden

verursacht. Lose Enden abschneiden.

2. Installieren Sie in der von der Pumpe kommenden Leitung

ein Druckmeßgerät, um erhöhte Sicherheit und verbesserte

Kontrolle zu gewährleisten.

3. Schließen Sie den Schlauch (bzw. die Schläuche) an den

Zylinder oder das Werkzeug an.

Ablaßventil

TABELLE 2 - TECHNISCHE DATEN

Abbildung 1

Einfachwirkend

Nutzbares

Ölvolumen

cm

3

[in3]

Für

Zylindertyp

Max. Druckstufe

bar [psi]

ModellNummer

Fördervolumen

pro Kolbenhub

cm3 [in3]

Max.

Hebelkraft

kg

[lbs]

Kolbenhub

mm

[Zoll]

1. Stufe 1. Stufe2. Stufe 2. Stufe

kg

[lbs]

492

[30]

15

[220]

700

[10,000]

11,26

[.687]

2,47

[.151]

42

[93]

25,4

1.00

7,0

[15.4]

P-392FP

600 mm [23.6 inch]

®

193 [7.60"]

504 [19.8"]

30 [1.18"]

3/8"-18NPT

433 [17.05"]

187 [7.36"]

52 [2.04"]

Page 12

12

HINWEIS: Bei einfachwirkenden Zylindern wird ein

Schlauch von der Pumpe zum Zylinder angeschlossen. Bei

doppeltwirkenden Zylindern werden zwei Schläuche

angeschlossen. Schließen Sie einen Schlauch vom

Druckanschluß der Pumpe am Druckanschluß des

Zylinders an. Schließen Sie einen zweiten Schlauch vom

Einfahranschluß der Pumpe an den Einfahranschluß des

Zylinders an.

4.2 Entlüften der Pumpe`

ACHTUNG: Diese Pumpen werden mit einem nicht entlüfteten

Tank betrieben. Falls der Tank hohem Druck ausgesetzt wird,

kann das Gehäuse brechen. Verletzungen und/oder Schäden

können die Folge sein. NIEMALS versuchen, mehr Öl in den

Tank zurückzuleiten, als dieser fassen kann.

5.0 BETRIEB

5.1 Vor Inbetriebnahme der Pumpe

1. Prüfen Sie alle Systemanschlüsse und Verbindungen, um

sicherzustellen, daß diese fest sitzen und dicht sind.

2. Prüfen Sie den Ölstand im Tank, bevor die Pumpe betrieben

wird. Siehe 7.1 "Auffüllen der Pumpe mit Öl" auf Seite 13.

VORSICHT: Bringen Sie NIEMALS eine

Verlängerung am Pumpengriff an. Verlängerungen

führen dazu, daß die Pumpe beim Betrieb instabil

wird.

ACHTUNG: Unter gewissen Umständen kann der

Pumpengriff "zurückschlagen". Achten Sie darauf,

daß Sie stets seitlich zur Pumpe stehen, und daß

sich Ihr Körper außerhalb der Reichweite des Griffs

befindet.

HINWEIS: Um bei der Betätigung des Griffs bei hohem Druck

Kraft zu sparen, führen Sie kurze Züge aus. Die größte

Pumpwirkung wird in den letzten 5 Grad des Zuges erzielt.

5.2 Verwendung von Pumpen mit zwei Geschwindigkeiten

Diese Pumpen bieten einen zweistufigen Förderstrom. Ohne

Belastung arbeitet die Pumpe in der ersten Stufe mit hohem

Förderstrom für schnelles Ausfahren. Sobald Kontakt mit der

Last besteht, stellt sich die Pumpe automatisch in die zweite

Stufe um, um Druck aufzubauen.

5.3 Einfachwirkende Anwendungen mit Ablassventil

1. Schließen Sie das Ablassventil durch Drehen im

Uhrzeigersinn, wie in Abbildung 3.

VORSICHT: Das Ablassventil NUR fingerfest

schließen. Wird das Ablassventil mit einem

Werkzeug umgestellt, so kann es beschädigt

werden und einen Ausfall der Pumpe verursachen.

2. Betätigen Sie den Pumpengriff, um Hydraulikdruck in das

System einzubringen. Der Druck wird solange gehalten, bis

das Ablassventil geöffnet wird.

3. Öffnen Sie das Ablassventil (Drehung gegen den

Uhrzeigersinn), um den Druck abzulassen. Das Öl fließt nun

wieder in den Tank zurück.

5.6 Einstellung des Druckbegrenzungsventils

Alle Pumpen sind mit einem werkseitig eingestellten

Druckbegrenzungsventil ausgestattet, um Überdruck im

System zu verhindern. Das Ventil kann auf niedrigere

Druckwerte eingestellt werden. Wenden Sie sich an Ihr

autorisiertes Enerpac Service Center.

6.0 ENTLÜFTUNG

Durch das Entfernen von Luft aus dem Hydrauliksystem wird

geschmeidiges Ausfahren und Einfahren des Zylinders erreicht.

Siehe Abbildung 4.

Ablaßventil

Abbildung 3

LUFT

Abbildung 4

Page 13

13

6.1 Pumpe mit einfachwirkendem Zylinder (A):

1. Pumpentank entlüften (nur bei entlüfteten Pumpen) und

Ablassventil schließen.

2. Die Pumpe in einer höheren Lage als den Zylinder

positionieren.

3. Den Zylinder so aufstellen, daß das Kolbenende nach unten

zeigt (nach oben bei Zugzylinder). Siehe Abbildung 9.

4. Pumpe betätigen, um den Zylinder voll auszufahren

(Zugzylinder voll einfahren).

5. Druckentlastungsventil öffnen, um den Zylinder einzufahren

(Zugzylinder ausfahren). Dadurch wird die eingeschlossene

Luft nach oben in den Pumpentank gepreßt.

6. Die obigen Schritte so oft wie nötig wiederholen.

7. Wenn erforderlich, Öl auffüllen. Siehe Seite 21.

8. Den Entlüftungs-/Einfülldeckel wieder in die

Betriebsstellung bringen.

7.0 MAINTENANCE

Benutzen Sie für diese Pumpen nur Enerpac-Hydrauliköl, um

eine lange Lebensdauer der Pumpen zu erreichen und den

Garantieschutz aufrecht zu erhalten. Viton- und EPRDichtungssätze sind für einige Pumpen erhältlich. Wenden Sie

sich an die zuständige Enerpac Vertriebsstelle, um

Informationen über diese Produkte und ihre Anwendung zu

erhalten.

7.1 Auffüllen der Pumpe mit Öl

Prüfen Sie den Ölstand regelmäßig.

ACHTUNG: Füllen Sie nur dann Öl auf, wenn die

Zylinder voll eingefahren (bzw. bei Zugzylindern

ausgefahren) sind, andernfalls enthält das System

mehr Öl, als der Tank aufnehmen kann.

1. Entfernen Sie den Entlüftungs-/Einfülldeckel vom Tank.

2. Füllen Sie den Tank nur bis zur Füllmarkierung an der

Pumpe.

3. Wenn erforderlich, entfernen Sie die Luft aus dem System.

Siehe 6.0 auf Seite 12. Prüfen Sie den Ölstand nach dem

Entlüften nochmals.

4. Bringen Sie den Entlüftungs-/Einfülldeckel wieder in der

vorschriftsmäßigen Stellung an.

HINWEIS: Nicht entlüftete Handpumpen benötigen Luft im

Tank, um ordnungsgemäß zu funktionieren. Ist der Tank

vollständig gefüllt, so bildet sich ein Vakuum, das verhindert,

daß Öl aus der Pumpe abfließen kann

7.2 Reinhalten der Ölleitungen

Werden die Kupplungsteile getrennt, so müssen stets

Staubkappen aufgeschraubt werden. Führen Sie alle

erforderlichen Vorsichtsmaßnahmen aus, um das Eindringen

von Verunreinigungen in die Pumpe zu verhindern, da

Fremdkörper zum Versagen der Pumpe, des Zylinders oder

des Ventils führen können.

7.3 Schmierung der Pumpe

Um die Lebensdauer der Pumpe zu verlängern und die

Leistung zu erhöhen, schmieren Sie den Tragbolzen (A), den

Querbolzen (B) und den Zylinderkopf (C) regelmäßig mit

Rollenlager-Schmierfett. Siehe Abbildung 5.

7.4 Ölwechsel

1. Lassen Sie alle 12 Monate das gesamte Öl ab und füllen die

Pumpe mit reinem Enerpac-Öl auf. Führen Sie den

Ölwechsel öfter aus, wenn die Pumpe in schmutziger

Umgebung eingesetzt wird.

2. Nehmen Sie den Entlüftungs-/Einfülldeckel vom Tank ab.

3. Kippen Sie die Pumpe, um das Altöl abzulassen.

4. Füllen Sie den Tank nur bis zur Füllmarkierung an der

Pumpe.

5 Entlüftungs-/Einfülldeckel bzw. -stopfen wieder anbringen.

6. Das Altöl ist vorschriftsmäßig zu entsorgen.

8.0 ANLEITUNG ZUR FEHLERSUCHE

Die folgende Information soll helfen, um feststellen zu können,

ob eine Fehlfunktion vorliegt. (Seite 14) Für die Durchführung

von Reparaturarbeiten wenden Sie sich an das autorisierte

ENERPAC Service-Center in Ihrem Gebiet.

Abbildung 5

B+C

A

Page 14

1. Zylinder fährt nicht aus, fährt zu

langsam aus, oder setzt beim

Ausfahren aus.

1. Zu niedriger Ölstand im Tank

der Pumpe.

2. Ablassventil offen.

3. Hydraulikkupplung lose.

4. Zu schwere Last.

5. Eingeschlossene Luft im

System.

6. Zylinderkolben klemmt.

1. Öl gemäß Wartungsanweisungen auf 7.1 Seite 13.

2. Ablassventil schließen.

3. Überprüfen, ob alle Kupplungen vollständig

festgezogen sind.

4. Nicht versuchen, eine größere Last als die

Nennlast zu heben.

5. Luft gemäß Anweisungen auf 6.0 Seite 12.

6. Auf Schaden am Zylinder prüfen. Zylinder von einem

zugelassenen Hydrauliktechniker warten lassen.

1. Undichte Verbindung.

2. Undichte Dichtungen.

3. Innere Leckage in der Pumpe.

1. Prüfen, ob alle Verbindungen festgezogen und dicht

sind.

2. Leckstellen auffinden und das Gerät von einem

qualifizierten Hydrauliktechniker warten lassen.

3. Pumpe von einem qualifizierten Hydrauliktechniker

warten lassen.

3. Zylinder fährt nicht ein, fährt nur

teilweise ein oder fährt

langsamer als normal ein.

1. Ablassventil geschlossen.

2. Tank der Pumpe überfüllt.

3. Lose Hydraulikkupplung.

4. Eingeschlossene Luft im

System.

5. Zu geringer

Schlauchdurchmesser.

6. Rückstellfeder des Zylinders ist

gebrochen, oder anderer

Schaden am Zylinder liegt vor.

1. Ablassventil öffnen.

2. Ölstand durch Ablassen bis zur Vollmarkierung

senken Anweisungen zum Auffüllen von Öl, siehe 7.1

Seite 13.

3. Überprüfen, ob alle Kupplungen vollständig

festgezogen sind.

4. Luft entfernen, gemäß Anweisungen auf 6.0 Seite 12.

5. Hydraulikschlauch mit größerem Durchmesser

benutzen.

6. Zylinder von einem qualifizierten Hydrauliktechniker

warten lassen.

2. Zylinder fährt aus, hält den

Druck aber nicht.

Fehlfunktion Mögliche Ursache Behebung

8.0 FEHLERSUCHE

14

Africa

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

Australia

Tel: +61 297 438 988

Fax: +61 297 438 648

Brazil

Tel: +55 11 5687 2211

Fax: +55 11 5686 5583

Toll Free in Brazil:

Tel: 0800 891 5770

vendasbrasil@enerpac.com

Canada

Tel: +1 905 564 5749

Fax: +1 905 564 0305

Toll Free:

Tel: +1 800 268 4987

Fax: +1 800 461 2456

Te chnical Inquiries:

techservices@enerpac.com

China

Tel: +86 21 5866 9099

Fax: +86 21 5866 7156

Beijing

Tel: +86 10 845 36166

Fax: +86 10 845 36220

Central and Eastern Europe

Tel: +31 318 535 936

Fax: +31 318 535 951

France

Te l: +33 1 601 368 68

Fax: +33 1 692 037 50

Germany, Austria, Switzerland,

Greece, Russia and CIS

(excl. Caspian Sea Countries)

Te l: +49 211 471 490

Fax: +49 211 471 49 28

India

Te l: +91 22 2778 1472

Fax: +91 22 2778 1473

Italy

Te l: +39 02 4861 111

Fax: +39 02 4860 1288

Japan

Te l: +81 484 30 1055

Fax: +81 484 30 1066

The Netherlands, Belgium, Luxembourg,

Sweden, Denmark, Norway, Finland and

Baltic States

Te l: +31 318 535 911

Fax: +31 318 525 613

+31 318 535 848

Technical Inquiries Europe:

techsupport.europe@enerpac.com

Singapore

Tel: +65 64 84 5108

+65 64 84 3737

Fax: +65 64 84 5669

Toll Free:

Tel: +1800 363 7722

Technical Inquiries:

sales@enerpac.com.sg

South Korea

Tel: +82 31 434 4506

Fax: +82 31 434 4507

Spain, Portugal

Tel: +34 91 661 11 25

Fax: +34 91 661 47 89

Middle East, Turkey,

Caspian Sea

Tel: +971 (0)4 8872686

Fax: +971 (0)4 8872687

United Kingdom, Ireland

Tel: +44 01527 598 900

Fax: +44 01527 585 500

USA, Latin America

and Caribbean

Tel: +1 262 781 6600

Fax: +1 262 783 9562

User inquiries:

+1 800 433 2766

Distributor inquiries/orders:

+1 800 558 0530

Technical Inquiries:

techservices@enerpac.com

EIS63107-1_P392FP

Mac, printed in Holland

Loading...

Loading...