Page 1

Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

L2923 Rev. B 09/09

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Finnish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Norwegian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Swedish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

日本語 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Repair Parts Sheets for this product are available from the

Enerpac web site at www.enerpac.com, or from your nearest

Authorized Enerpac Service Center or Enerpac Sales offi ce.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

SAFETY FIRST

2.0 GENERAL HYDRAULIC SAFETY PRECAUTIONS

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

when in doubt as to the safety precautions and operations. If

you have never been trained on high-pressure hydraulic safety,

consult your distribution or service center for a free Enerpac

Hydraulic safety course.

Failure to comply with the following cautions and warnings

could cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent damage to,

or destruction of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action

may cause serious injury or even death.

WARNING: Wear proper personal protective gear

when operating hydraulic equipment.

WARNING: Do not exceed equipment ratings.

Overloading causes equipment failure and possible

personal injury. The nut splitter is designed for a

maximum pressure of 700 bar [10,000 psi]. Do not connect the

nut splitter to a pump with a higher pressure rating.

Never set the relief valve to a higher pressure than the

maximum rated pressure of the pump. Higher settings

may result in equipment damage and/or personal

injury.

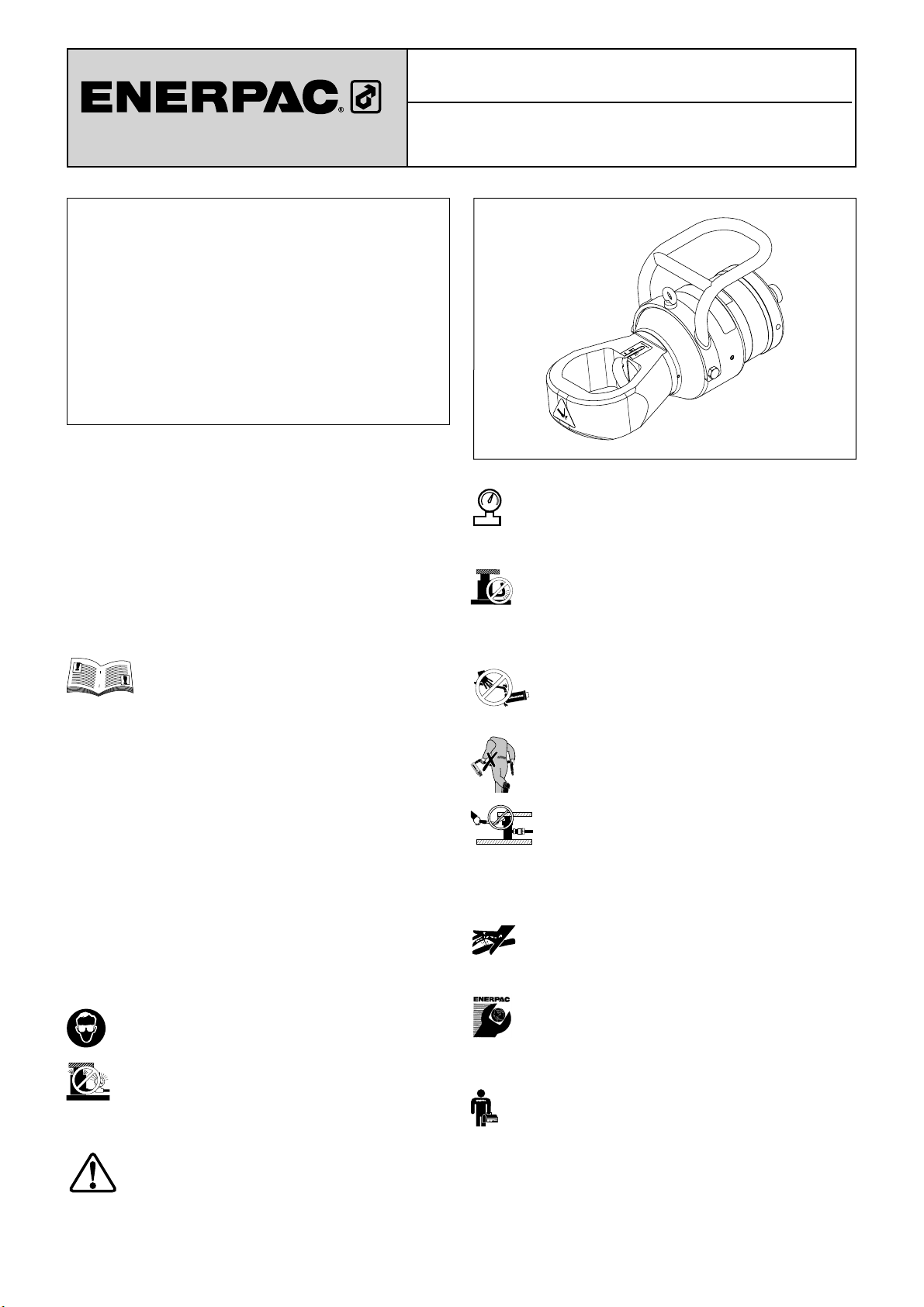

NS Series Hydraulic Nut Splitter

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated

component in the system. Install pressure gauges in

the system to monitor operating pressure. It is your window to

what is happening in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid

sharp bends and kinks when routing hydraulic hoses.

Using a bent or kinked hose will cause severe back-pressure.

Sharp bends and kinks will internally damage the hose leading

to premature hose failure.

Do not drop heavy objects on hose. A sharp

impact may cause internal damage to hose wire

strands. Applying pressure to a damaged hose

may cause it to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or

other means of safe transport.

CAUTION: Keep hydraulic equipment away from

fl ames and heat. Excessive heat will soften

packings and seals, resulting in fl uid leaks. Heat

also weakens hose materials and packings. For optimum

performance do not expose equipment to temperatures of

65°C [150°F] or higher. Protect hoses and cylinders from weld

spatter.

DANGER: Do not handle pressurized hoses.

Escaping oil under pressure can penetrate the skin,

causing serious injury. If oil is injected under the skin,

see a doctor immediately.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualifi ed hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only ENERPAC

oil.

WARNING: Immediately replace worn or damaged

parts with genuine ENERPAC parts. Standard grade

parts will break causing personal injury and property

damage. ENERPAC parts are designed to fi t properly and

withstand high loads.

1

Page 2

2.1 Hydraulic Nut Splitter Safety Precautions

WARNING: Failure to observe the following precautions

may result in serious personal injury or death!

• Personal protective equipment must be worn at all times. Use

of safety footwear, thick gloves, overalls and safety glasses

is mandatory. These items are in addition to any other safety

equipment required at your site.

• Keep personnel clear while pressurizing the system. Allow

only relevant personnel to be within the work zone.

• Never exceed the maximum working pressure of the nut

splitter or any associated ancillary equipment. The maximum

working pressure of the nut splitter is 10,000 psi [700 bar].

• Do not place fi ngers or any part of the body between the nut

splitter and the nut. Keep hands clear of the nut splitter head

at all times and especially in the vicinity of the blade.

• Do not place fi ngers or hands underneath the body of the

nut splitter to support the weight, as hands or limbs could be

trapped when the pressure is applied.

• Lift the nut splitter using only the provided lifting eyebolt.

Always use appropriate lifting equipment. See Section 3.1 for

weights.

• The nut splitter handle is provided for positioning and

maneuvering purposes only. Do not use the handle to carry the

nut splitter.

• Do not strike the nut splitter (or any of its components) with a

hammer or other objects in an attempt to shock or impact the

nut.

• Do not attempt to move or reposition the nut splitter while it

is in operation.

• Do not apply heat to the nut while the nut splitter is positioned

on the nut.

• When in operation, do not stand along the axis of the nut

splitter. Always stand to the side.

• Do not cut the nut into small pieces. Use a maximum of two

cuts. The second cut must always be at 180º (opposite) to the

fi rst.

• Hydraulic couplers are susceptible to knocks and damage.

Therefore, be careful when handling the equipment. A damaged

coupler or fi tting may burst or eject fl uid under pressure.

• Always allow the nut splitter cylinder to fully retract before

disconnecting hydraulic hose(s). High-pressure fl uid may be

ejected from an unretracted cylinder if a coupler has been

damaged during handling.

• Fully release hydraulic pressure and disconnect hydraulic

hose(s) from nut splitter cylinder before applying lubricant to

blade or performing any other work inside the cutting zone.

• Be careful when handling severed nuts. Sharp edges can

cause lacerations.

• Always use the correct size cutting head for the nut to be

cut.

• Do not insert packing pieces or shims behind the nut or

blade in an attempt to split a nut that is not within the specifi ed

size range for the cutting head.

• Use the nut splitter to cut hexagonal nuts only. Do not attempt

to cut square, round, bi-hex or 12-point nuts.

• Do not use the nut splitter to cut chains or bolts.

• Do not use the nut splitter to rotate nuts.

• Do not use the nut splitter's hydraulic cylinder for jacking,

lifting, pushing or any other purpose than that for which it is

intended.

• Sparks can be emitted at the blade tip when the nut fractures.

To minimize the risk of sparks or hot metal fragments, a water

spray can be directed over the entire nut and blade area.

However if there is any doubt as to whether sparks can be

effectively arrested, then the nut splitter should not be used.

• Never attempt to disconnect or retighten any part of the

hydraulic system while under pressure. Be sure pressure

gauge indicates zero (0) psi/bar before attempting to connect,

disconnect or tighten hydraulic fi ttings.

• Treat hydraulic hoses with care. Do not kink, twist or sharply

bend any hydraulic hose. Never exceed the hose manufacturer's

specifi ed minimum bend radius. Never use a damaged, worn

or split hose.

• Read and understand the operating instructions, maintenance

instructions and safety precautions contained in this instruction

sheet.

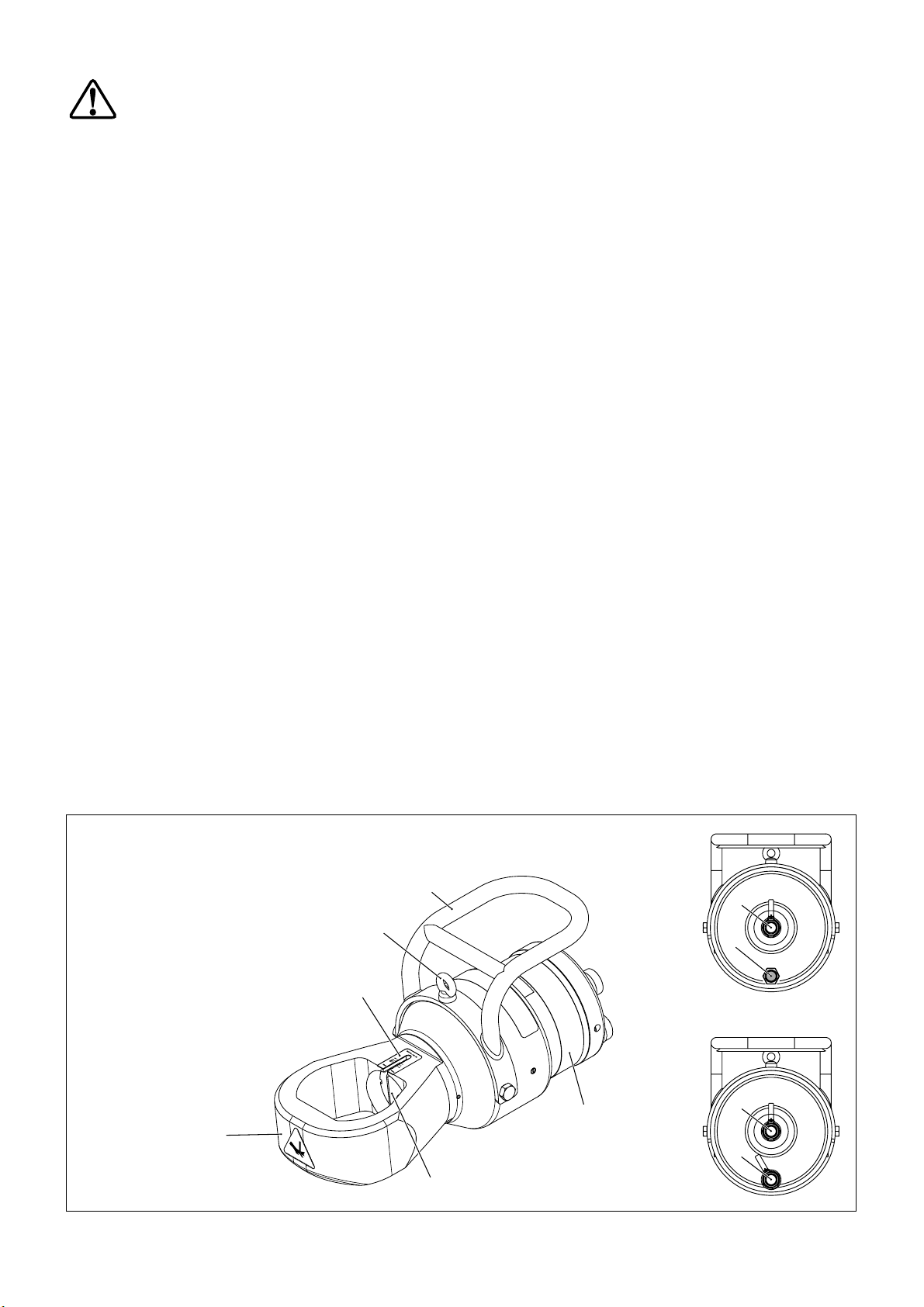

1. Cutting Head

2. Blade Cutting Depth Scale

3. Lifting Eyebolt

4. Handle

5. Hydraulic Coupler

6. Vent Plug

(single acting NS70 models only)

7. Pipe Plug

(single acting NS110 models only)

8. Hydraulic Coupler

(double acting models only)

9. Hydraulic Cylinder

10. Cutting Blade

1

4

3

2

9

10

Figure 1, Features and Components, NS Series Nut Splitter

2

Single

Acting

Models

Double

Acting

Models

5

6,

7

(rear view)

5

8

Page 3

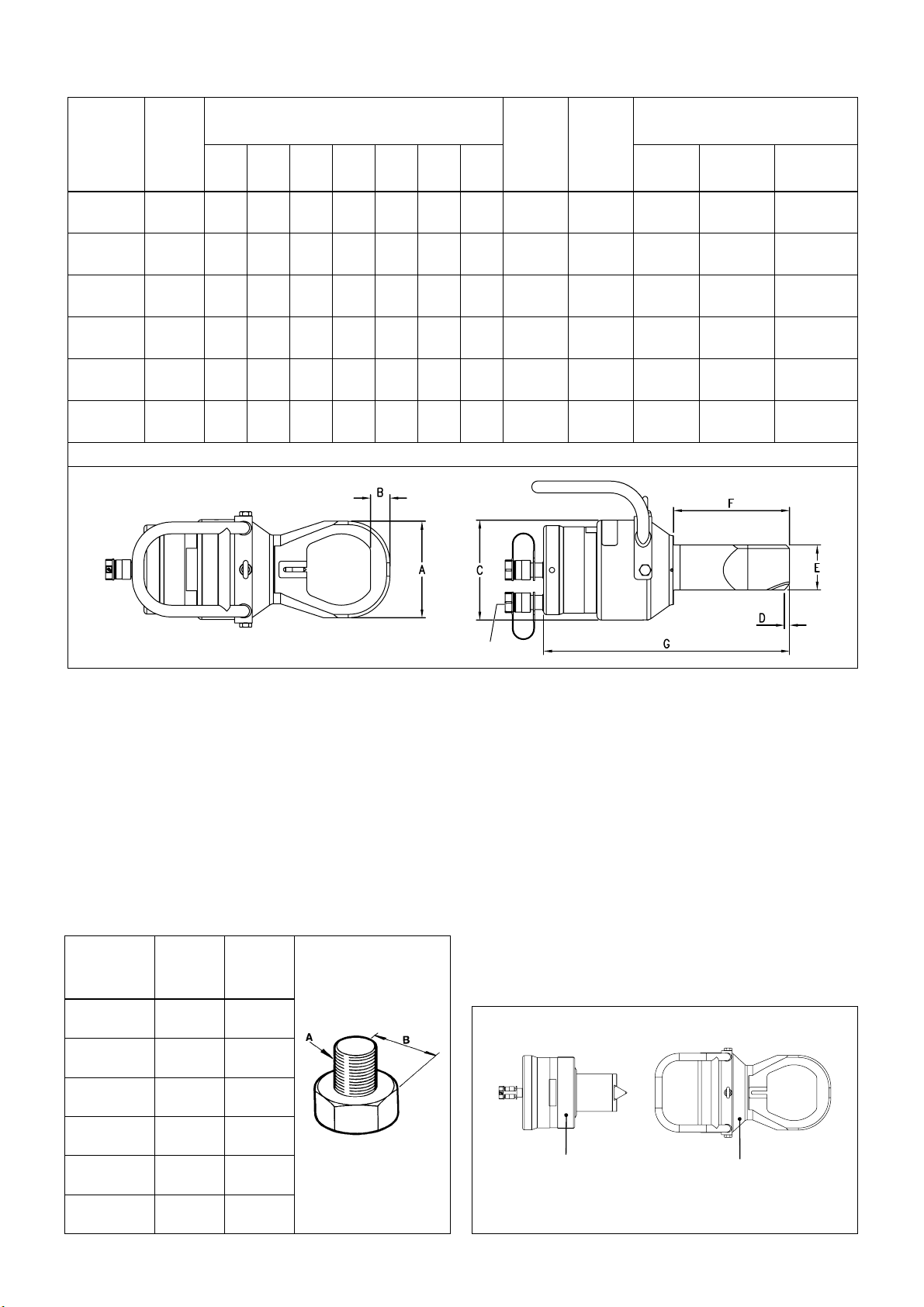

3.0 SPECIFICATIONS

3.1 Product Data

Nut Splitter

Model

Number

NS-7080

NS-7080D

Capacity

tons [kN]

103.2

[918]

Dimensions

inch [mm]

ABCDEFG

5.2

1.1

7.1

0.3

3.2

7.3

[132]

[28]

[180]

[8.0]

[81]

[186]

16.2

[412]

Weight

lb [kg]

81.4

[37.0]

Minimum

Pump Oil

Capacity

3

in

[cm3]

23.0

[377.0]

Additional Model Numbers

Cylinder

Sub-

Assembly

NSC-70

NSC-70D

Cutting

Head Sub-

Assembly

NSH-7080 NSB-70

Replacement

Blade

NS-7085

NS-7085D

NS-7095

NS-7095D

NS-70105

NS-70105D

NS-110115

NS-110115D

NS-110130

NS-110130D

Note: A model number ending with “D” indicates double acting.

103.2

[918]

103.2

[918]

103.2

[918]

192.5

[1712]

192.5

[1712]

5.7

[145]

6.3

[160]

6.9

[174]

7.4

[189]

8.6

[219]

1.2

[30]

1.3

[32]

1.4

[35]

1.4

[36]

1.6

[41]

7.1

[180]

7.1

[180]

7.1

[180]

9.2

[234]

9.2

[234]

0.3

[8.0]

0.3

[8.0]

0.4

[9.0]

0.1

[3.7]

0.1

[2.5]

3.2

[81]

3.2

[81]

3.2

[81]

4.4

[111]

4.4

[111]

7.7

16.6

[196]

[422]

7.9

[201]17[432]

17.5

8.2

[209]

[443]

9.2

18.6

[234]

[472]

9.5

19.4

[242]

[493]

Double Acting Only

82.7

[37.5]

84.9

[38.5]

87.1

[39.5]

151.6

[68.8]

158.3

[71.5]

23.0

[377.0]

23.0

[377.0]

23.0

[377.0]

50.0

[819.5]

50.0

[819.5]

NSC-70

NSC-70D

NSC-70

NSC-70D

NSC-70

NSC-70D

NSC-110

NSC-110D

NSC-110

NSC-110D

NSH-7085 NSB-70

NSH-7095 NSB-70

NSH-70105 NSB-70

NSH-110115 NSB-110

NSH-110130 NSB-110

Notes:

• The NS Series is available in both single and double acting

models. Single acting models use spring force to retract the

blade. Double acting models use hydraulic force to retract the

blade.

• A model number ending with “D” indicates that the nut

splitter (or cylinder sub-assembly) is double acting. Refer to

Section 3.1 for model numbers and additional information.

• Both single and double acting models use the same NSH

series cutting heads shown in Section 3.1.

3.2 Nut and Bolt Ranges

Cutting Head

Subassembly

Model Number

NSH-7080 1.75-2.00

NSH-7085 1.75-2.25

NSH-7095 1.75-2.50

NSH-70105 1.75-2.75

NSH-110115 2.75-3.00

NSH-110130 2.75-3.50

AB

Bolt Range

inch [mm]

[M45-M52]

[M45-M56]

[M45-M64]

[M45-M72]

[M76-M80]

[M76-M90]

Hexagon

Nut Range

inch [mm]

2.75-3.13

[70-80]

2.75-3.50

[70-85]

2.75-3.88

[70-95]

2.75-4.25

[70-105]

4.25-4.63

[110-115]

4.25-5.38

[110-130]

4.0 DESCRIPTION

The NS Series nut splitter is a hydraulically operated industrial

power tool, designed to quickly remove seized or heavily

corroded nuts from threaded studs.

See Figure 1 for an overview of NS nut splitter major features

and components.

A complete nut splitter consists of two separate subassemblies:

1) a single or double acting hydraulic cylinder and 2) a

matching cutting head designed for use with a specifi ed nut

size range. The replaceable cutting blade is installed in a blade

holder mounted on the shaft of the cylinder subassembly.

See Figure 2.

One cutting head is provided with each nut splitter. If desired,

additional cutting heads for different nut size ranges can be

purchased separately from Enerpac.

Refer to sections 3.1 and 3.2 for nut splitter specifi cations and

additional information.

Cylinder

Subassembly

Cutting Head

Subassembly

3

Figure 2, Nut Splitter Subassemblies

Page 4

5.0 ASSEMBLY

5.1 Assembling Cutting Head and Cylinder

The cutting head is shipped disassembled from the cylinder.

Assemble as described in the following steps:

1. Be sure that cylinder is fully retracted and disconnected

from the hydraulic pump.

2. Loosen the plastic set screw (Figure 3, item A) located on

the cutting head barrel.

3. Insert the cylinder into the head, aligning the axial slots

in the blade holder (Figure 3, item B) with the spring pins

(Figure 3, item C) in the cutting head bore. Once aligned,

rotate the cylinder in the direction shown in order to engage

the screw threads.

4. Continue rotating the cylinder until NO threads are visible on

the outside of the cylinder body (threads fully engaged).

WARNING:

Never use the nut splitter if any of the

cylinder threads are visible.

5. Install the cutting blade. Refer to Section 7.0 for installation

instructions.

Enerpac PU Series

Electric Pump

Enerpac P Series

Hand Pump

Enerpac PA Series

Air-Hydraulic Pump

0-10,000 psi

[0-700 bar]

Pressure Gauge

Note:

Hose arrangement for

single acting nut splitter

models is shown.

Double acting nut splitter

models require TWO

hoses, one for extend

and one for retract.

B

C

B

C

A - Set Screw

B - Grooves

A

Figure 3, Assembling the Cylinder and Cutting Head

5.2 Hydraulic Pump

A 10,000 psi [700 bar] hydraulic pump is required to operate

the nut splitter.

If a single acting nut splitter is used, the pump must be

equipped with a pressure release valve. If a double acting nut

splitter is used, the pump must be equipped with a suitable

4-way 3-position directional control valve.

Always check the pump hydraulic relief valve setting before

connecting the nut splitter. Maximum pressure must not exceed

10,000 psi [700 bar].

If an air-powered hydraulic pump is used, an air regulator must

be installed in the air supply line, limiting the air pressure to the

recommended range for the pump being used.

If the pump is not equipped with a hydraulic pressure gauge,

install a 0-10,000 psi [0-700 bar] gauge between the pump

outlet and the hydraulic hose.

5.3 Hose Connections

Be sure to use only high pressure hoses and fi ttings designed

for 10,000 psi [700 bar] operation. See Figure 4 for typical

pump and hose arrangements.

Single acting nut splitters are equipped with one Enerpac

CR-400 3/8" female coupler. Double acting nut splitters are

equipped with two Enerpac CR-400 3/8" female couplers.

C - Spring Pins (inside bore)

Enerpac XA Series

Hydraulic Pump

Figure 4, Hydraulic Connections (typical pumps shown)

Connect the hydraulic hose(s) between the pump and the nut

splitter cylinder. Check that couplers on both ends of hose(s)

are fully screwed together. Firmly tighten couplers by hand to

prevent restricted oil fl ow.

IMPORTANT: Be sure that all couplers are fully connected.

Loose or partially connected couplers will block the fl ow of oil

between the pump and the nut splitter.

To remove any air trapped in the system, advance and retract

the cylinder several times.

6.0 OPERATION

6.1 Adjusting Blade Cutting Depth

(If bolt diameter is shown on the scale)

The blade cutting depth scale allows the user to set the nut

splitter's maximum stroke, and the corresponding depth of

the cutting blade. This feature helps prevent bolt damage from

occurring due to excessive blade penetration.

Adjust the cutting depth as described in the following steps:

1. Ensure that the nut splitter cylinder is fully retracted.

2. Check that the bolt diameter is within the range of the

cutting head to be used (bolt diameter range is indicated

on the scale). See Section 3.2 for additional information.

Note: The cutting depth scale is calibrated only for the following

thread, bolt and nut types:

Imperial threads - Unifi ed (UN) bolt threads with heavy series

nuts.

Metric threads - Metric (M) bolt threads with standard series

nuts.

If any other thread, bolt or nut type is present, skip the following

steps in this section and refer to Section 6.2 for additional

instructions.

4

Page 5

Note: Scale markings will vary

depending on cutting head size.

Figure 5, Blade Cutting Depth Scale

3. If tight, loosen the plastic set screw located on the cutting

head barrel. See Figure 3, item A.

4. Rotate the cutting head until the red marker line on the

blade holder is aligned with the required bolt size marker

line on the scale. See Figure 5.

5. Retighten the plastic set screw.

6.2 Adjusting Blade Cutting Depth

(If bolt diameter is NOT shown on the scale)

1. Measure the distance from the fl at of the nut to the furthest

side of the bolt. See Figure 6.

2. Advance and hold the nut splitter cylinder at full stroke.

3. If tight, loosen the plastic set screw located in the barrel

portion of the cutting head. See Figure 3, item A.

4. Rotate the cutting head until the distance from the head

fl at to the tip of the blade is the same as the nut to

bolt distance previously measured in Step 1 PLUS an

additional 1 to 2 mm (1/16"). See Figure 7.

IMPORTANT: Ensure that the cylinder threads are not exposed.

If the threads are visible, a larger cutting head and possibly a

larger cylinder is required. Refer to Section 3.1 for additional

information.

5. Retighten the plastic set screw.

6. Retract the nut splitter cylinder.

“X” mm

“X” + 1-2 mm

5. To help prolong blade life, lubricate the blade cutting edge

and fl anks with a molybdenum disulphide based lubricant

or other high quality lubricant.

CAUTION:

prevent contact with skin.

Wear gloves when applying lubricants to

ABC

Figure 8, Positioning the Cutting Head

6. Position the cutting head over the nut, ensuring that the

fl at surface of the blade rests against one of the nut fl ats.

Centrally position the nut within the head so that the blade

will cut in the center of the nut fl at. See Figure 8, view “A”.

7. Ensure that the underside of the cutting head is seated

against the fl ange, as the blade must cut as close to the

bottom of the nut as possible. However, if a washer is

present under the nut, position the nut splitter so that the

cutting blade will not contact the washer. See Figure 9.

IMPORTANT: Improper positioning of the nut splitter may

cause damage to the cutting blade, blade holder and piston.

8. Vented pumps only: open the vent/fi ll plug or loosen the

vent screw to provide venting.

9. Air or electric powered pumps only: Set the pump to

deliver a nominal pressure of 1000 psi [69 bar].

Blade

Washer

Figure 9, Blade Position

Figure 6 Figure 7

6.3 Nut Splitting Procedure

1. Verify that the nut splitter cutting head is the correct size

(bolt range) for the nut to be cut. See Section 3.2.

2. Ensure that the nut splitter blade is in good condition and

that the cutting edge is not worn, chipped or damaged.

Rotate or replace blade as required.

3. Adjust the blade cutting depth to prevent damage to the

bolt threads. Refer to sections 6.1 and 6.2 for adjustment

instructions.

4. Connect hydraulic hose(s) as described in Section 5.3.

Check that hydraulic pump reservoir is fi lled to the correct

level.

WAR

NING:

To prevent personal

injury, do not place hands or

fi ngers in the cutting area.

WAR

NING:

reposition nut splitter during

operation.

10. Operate the pump to slowly advance the nut splitter blade

until it makes contact with the nut. Check that the blade is

resting squarely on the nut fl at.

5

Do not move or

Page 6

Notes:

• Air or electric powered pumps only: Once the blade has

stopped cutting at 1000 psi [69 bar], the pressure should be

gradually increased using the pressure regulator on the pump.

Allow adequate time for the blade to cut before increasing

pressure.

• If pressure is increased too quickly, blade damage may result.

Excessive pressure may also cause the nut splitter's internal

relief valve to open, resulting in oil leakage from the oil bleed

hole located on the underside of the blade holder.

• On larger nuts, it may be helpful to periodically retract and relubricate the blade. This will reduce friction and increase blade

effi ciency.

11. Continue to apply hydraulic pressure until the nut is

completely severed. As the nut splits, a loud “crack” will be

heard, indicating that the nut has been severed.

12. If necessary, a second cut

may be applied, at 180° to

the fi rst, completely severing

the nut in half. See Figure

10.

IMPORTANT: Do not cut the

nut into small pieces. Use a

maximum of two cuts and always

at 180º (opposite) to the fi rst.

Otherwise, nut metal fragments

Fig. 10, Making Two Cuts

may be released.

13. After the cut is completed:

• Single acting models: Release the pressure to retract

the nut splitter blade.

• Double acting models: Move the control valve to the

retract position to retract the nut splitter blade.

14. Stop the pump. Check that pressure gauge indicates zero

(0) psi/bar.

15. Remove nut splitter from the nut.

16. Remove the severed nut from the stud.

6.4 If Nut Does Not Split at Full Hydraulic Pressure

If the nut splitter is at full pressure, 10,000 psi [700 bar], and

the nut does not split:

WARNING

: Fully release hydraulic pressure and

disconnect hydraulic hose(s) from nut splitter cylinder

before applying lubricant to blade or performing any

other work inside the cutting zone.

1. Ensure that the blade cutting depth setting is correct. Also,

check that the cylinder is not at full stroke.

2. If the blade cutting depth setting is correct and cylinder

is not at full stroke: Release hydraulic pressure and rotate

the cylinder clockwise one full turn. This will allow the blade

to advance 1 to 2 mm further. Then, re-apply hydraulic

pressure and try again to split the nut.

3. If step 2 did not work: Release hydraulic pressure. Re-

lubricate the blade and the groove in the nut where the

blade has penetrated. Then, re-apply pressure, ensuring

that the blade is positioned back in the same nut groove.

4. If step 3 did not work: Re-lubricate the blade and the

nut groove again. Lift and position the nut splitter above

the fl ange surface so that the blade will penetrate the nut

approximately ²⁄³ the height of the nut, and in the same

groove. Then, re-apply pressure.

5. If step 4 did not work: Install a larger cutting head (if

available) or use a larger nut splitter model. Be certain

that the nut size is within the larger equipment's operating

range.

6.5 After Using the Nut Splitter

1. Ensure that the nut splitter cylinder is fully retracted. If it

is fully or partially advanced, reconnect the cylinder to

the pump and allow time for full retraction to occur. After

ensuring that there is no pressure present in the system,

disconnect the hydraulic hose(s) from the cylinder.

2. Using a clean cloth, wipe away any debris from the nut

splitter components. Pay particular attention to the cutting

head and blade area. Remove all traces of lubricant from

the blade.

3. Reinstall dust caps and/or plugs on all hydraulic couplers.

4. If the nut splitter is to be stored in damp conditions or will

not be used for a long period of time, coat exterior surfaces

with a water-repellent spray or similar removable protective

coating.

5. Store the nut splitter subassemblies in their storage cases.

7.0 CUTTING BLADE REPLACEMENT

The blade features three separate cutting edges. If one edge

becomes damaged or severely chipped, the blade can be

removed, rotated 120 degrees, and reinstalled to provide a

new cutting edge.

IMPORTANT: After all three edges are worn, the blade should

be replaced. Do not attempt to sharpen worn or damaged

blades.

Replace the blade as described in the following steps. See

Figure 11.

1. Be sure that nut splitter cylinder is fully retracted and that

pressure gauge indicates zero (0) psi/bar. Disconnect

hydraulic hose(s) from cylinder coupler(s).

2. Slide the blade from the holder and out through the

underside of the head. If the blade is tight, a light tap on the

top surface of the blade should free it from the ball detent

mechanism.

C

AUTION: Be careful when handling blades. Fractured

edges can be sharp. Wear appropriate hand protection

when removing and installing blades.

3. Determine if the old blade has any reusable edges. If a new

blade is to be installed, refer to Section 3.1 for replacement

blade part numbers. Be sure to use the proper blade for the

cutting head used on your nut splitter model.

Ball Detent

Blade

(removed)

Blade

(installed)

Figure 11, Cutting Blade Replacement

6

Page 7

4. From the underside of the head, slide the new or rotated

blade into the dovetail shaped groove in the blade holder,

until the ball detent snaps into position. The blade is fully

installed when the bottom of the blade is fl ush with the fl at

W

ARNING: Fully release hydraulic pressure and

disconnect hydraulic hose(s) from nut splitter cylinder

before performing any adjustments, repairs or

maintenance.

bottom of the blade holder.

8.0 TROUBLESHOOTING

The Troubleshooting Chart is intended as a guide to help you

diagnose and correct various possible problems.

Only qualifi ed hydraulic technicians should troubleshoot

and service the nut splitter. For repair service, contact the

CAUTION: Piston retract spring and other internal

parts may eject from cylinder suddenly during

disassembly. To avoid personal injury, use caution if

cylinder disassembly is necessary. Cylinder

disassembly and repairs should be performed only by

qualifi ed personnel.

Authorized Enerpac Service Center in your area.

Troubleshooting Chart

Problem Possible Cause Action

1. Nut splitter cylinder will not

hold pressure.

2. Nut splitter cylinder builds

pressure, but piston and blade

do not move or move only a

partial amount.

3. Nut splitter cylinder will not

build pressure.

Piston seal leaking. Replace seal.

Coupler leaking. Replace coupler.

Cylinder internal relief valve malfunction. Check relief valve and replace if required.

Hydraulic pump malfunction.

Pump reservoir not vented.

Check hydraulic pump for proper operation.

Repair or replace pump as required.

If using a vented pump, loosen vent/fi ll cap

or vent screw as required to provide venting.

Coupler not fully assembled. Check couplers.

Both hoses not connected.

(double acting models only)

Be sure that both hoses are connected.

Piston at full stroke. Allow piston to retract.

Blocked hose. Replace hose.

Pump release valve open. Close pump release valve.

Piston seal leaking. Replace seal.

Cylinder internal relief valve malfunction. Check relief valve and replace if required.

Insuffi cient oil in pump. Add oil to pump reservoir as required.

4. Nut splitter cylinder will not

retract or retracts very slowly.

5. Nut splitter builds full pressure,

but will not split nut.

6. Hose is diffi cult to assemble.

7. Frequent blade replacement.

8. Leakage from nut splitter oil

bleed hole on underside of

blade holder.

Coupler leaking. Replace coupler.

Loose coupler. Check coupler and tighten if loose.

Restricted or blocked hose. Replace hose.

Incorrect coupler being used. Install correct coupler.

Incorrect hose being used. Install correct hose.

Pump release valve closed. Open pump release valve.

Broken or weak piston return spring.

(single acting models only)

Replace return spring.

(See Section 6.4 of instructions.) (See Section 6.4 of instructions.)

Damaged coupler. Replace coupler.

Internal pressure within hose. Vent hose.

Lubricant not used. Use lubricant.

Pressure above 10,000 psi [700 bar].

7

Release system pressure to allow cylinder

internal relief valve to reset.

Loading...

Loading...