Page 1

Instruction Manual for MODEL EDI62SInstruction Manual for MODEL EDI62S 1/12

ED-34828

2008.10

1 Before Using the Unit

Thank you for purchasing our quality designed and manufactured EDI62S

Series. Before unpacking the unit, check for damages during transportation. If you have noticed any damage, directly contact us or our distributor.

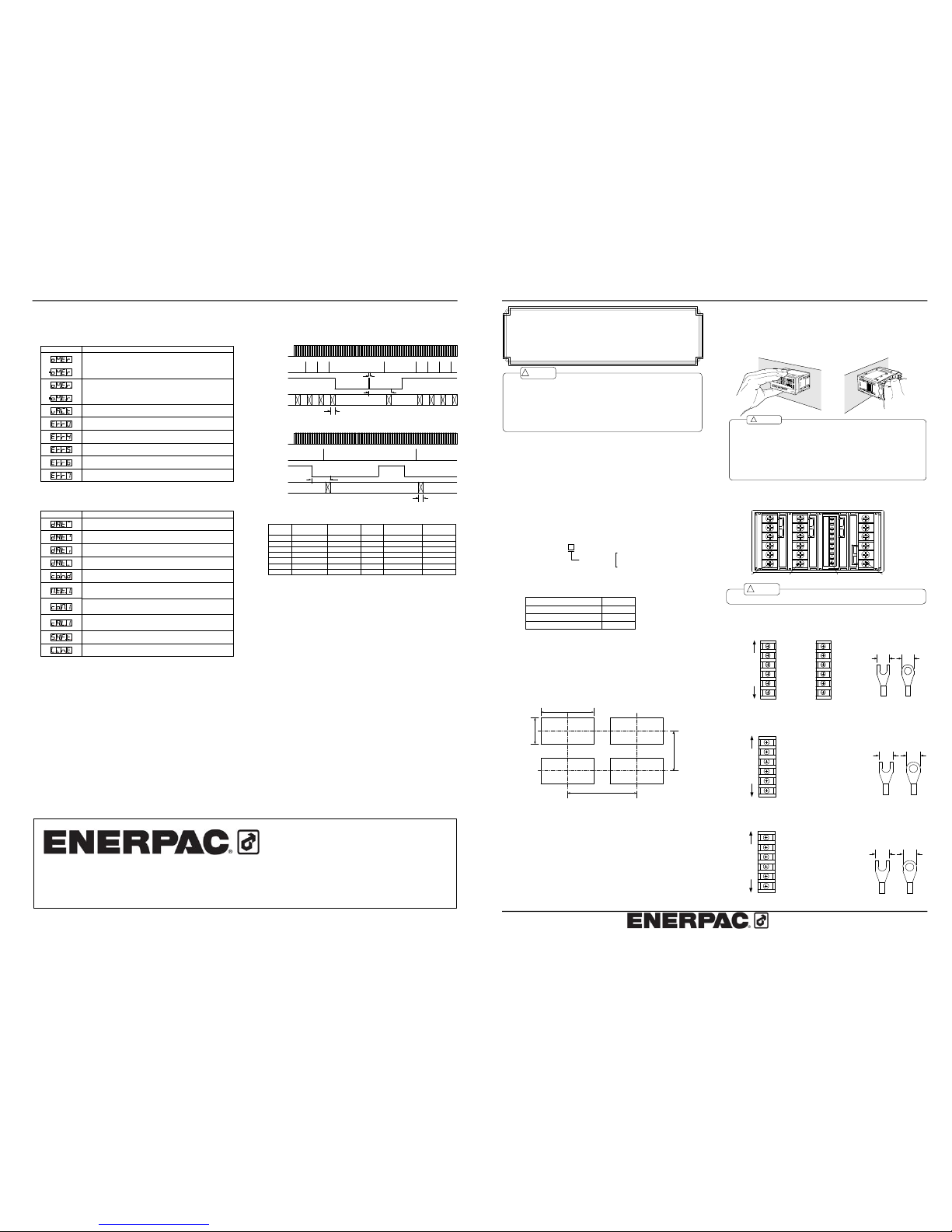

1.1 Type Identification

Each model number of the EDI62S series ha s its general spe cifications, and the following describes each note and the meaning. Before

using the unit, check that the mod el number and specifications of the

delivered unit match th ose of the pr oduct you ordere d. For optional

units, see the sepa rate instruction Manuals.

1.2 Accessories

2 Mounting Method

2.1 Panel Cut Size

Cut th e panel to moun t the ED I62S ser ies in a ccordance with th e

illustration b elow:

The recommended panel thickness is 0.8 to 5.0mm.

2.2 How to Mount the Unit on the Panel

Mount the EDI62S series to the panel in accordance with the illustra tion belo w:

3 Terminals and Connections

3.1 Power supply connections

3.2 Input Signal Connections

3.3 Comparator Output Connections

Each unit is not replaceable by the customer.

Caution

!

⑤AC POWER

⑥AC POWER

③NC

④NC

①NC

②NC

⑤NC

③NC

④NC

①DC POW(+)

②DC POW(-)

⑥NC

Top

Bottom

5.8 mm or

less

5.8 mm or

less

Suitable solderless terminals

AC power supply DC power supply

(1) Remove the mounting band and insert the case

from the front of the panel.

(2) Fix the case using the mounting band from the

rear of the panel.

(1)

Th e re c om m en d ed p a ne l th i ck ne s s is 0 .8 to 5 m m.

(2)

Do n o t in st al l th e u ni t in lo ca ti o ns w h er e it i s e xp os e d to di re ct s u nl ig ht ;

wh e re a m bi en t e mp e ra tu re or h um i di ty d o es n' t m ee t t he r eq u ir em e nt s b el ow ;

or w h er e a d ra st ic c h an g e in t em p er a tu re m a y au s e c on de n sa ti o n.

Am b ie nt t em p er a tu re : 0 t o 50 ℃

Am b ie nt h u mi di ty : 3 5 to 8 5 %

(3)

Do n o t in st al l th e u ni t w he re it i s ex po s ed t o d us t , pa rt ic le s , ch e mi ca ls ha rm f ul t o

el ec tr ic c o mp o ne n ts , co r ro si ve ga se s , et c.

(4)

Do n o t in st al l th e u ni t w he re it i s ex po s ed t o e xc e ss iv e v ib ra ti o n or s h oc k.

(5)

In st al l th e u ni t ho r iz on t al ly ; ot he r wi se , v en ti la t io n wi ll b e a dv e rs el y a ff ec te d a nd

ma y re s ul t in d e te ri o ra ti on .

(6)

Wh e n th is u n it i s in s ta ll ed i ns i de o th e r eq u ip me n t, p a y at te nt io n t o th e h ea t

ra di at io n a nd ke ep th e h ea t in si d e th e e qu ip m en t 5 0℃ o r b el ow .

Ca ution

!

Caution

!

(1) Applying a voltage or current exceeding its maximum permissible value may cause the unit to be

damaged.

(2)

(3)

(4)

(5)

For the purpose of functional improvement, the information written herein may be changed without

prior notice.

Always use the unit within the specified voltage range; otherwise, it may cause a fire, electric

shock or personal/equipment damage.

Information contained herein is considered accurate to the best of our knowledge. If you have any

question or comment on the information, please contact us or our distributor.

Read this manual carefully and thoroughly before starting to operate the unit, and keep the

manual available for future refer ence.

120 mm or more

70 mm or more

+0.6

-0

45

92

-0

+0.8

Instruction Manual for EDI62S Series

Digital Straingauge Meters

12/12

(ED-34824)

Unit in dication la bel

Access ory Quantit y

6-p ter minal cove r 3 piece s

1 each

Mounti ng band 2 piece s

Suitable solderles s termin als

5.8 mm or

less

5.8 mm or

less

Top

Bottom

①+SIG (D) sens or input ( +)

②-SIG ( B) sens or input (- )

③+EXC (A) sens or supply power ( +)

④-EXC (C) sens or supply power (- )

⑤AG (E ) anal og ground

⑥NC space termina l

Display Descrip tion

Indicate s that ea ch judgm ent value of compa rator dat a or the s ize of

hysteres is param eters doe s not me et the con ditions.

Indicate s that a signal ex ceeding th e measu rement ra nge has been

applied .

Indicate s that an input sig nal once exceeded the mea surement

range, b ut has re turned to the mea surable ra nge with the peak hold

function activate d.

Indicate s that th e unit is w aiting for an A/D c onverter input or t hat

power-O N delay time is v alid.

Indicate s that dig ital limite r HI and digital lim iter LO o f scaling data

have the same v alue.

Indicate s that an alog outp ut HI and analog o utput LO of scalin g data

have the same v alue.

Lineariz e data er ror

Indicate s that fu ll-scale in put value and off-s et input v alue of s caling

data ha ve the sa me value .

* Turning power O N with th e Enter k ey and M ode key held dow n causes all the

paramet ers to retu rn to the initial va lues (de faults).

Memory switch a rea, chec ksum err or of main memory

Calibrat ion data a rea, che cksum er ror of ma in memor y

Memory switch a rea, chec ksum err or of sub -memory

Calibra tion data area, che cksum e rror of su b-memory

Conditio n data a rea, chec ksum err or

Press th e Mode key for a prolonged time to l oad the i nitial valu es.

Scaling data area , checksu m error (f or each p attern)

Press the Mode k ey for a p rolonged time to lo ad the ini tial value s of each

pattern.

Compara tor data area, chec ksum erro r (for eac h pattern )

Press the Mode ke y for a pr olonged time to loa d the ini tial value s of each

pattern.

Calibrat ion data a rea, chec ksum erro r (for eac h pattern)

Press the Mode k ey for a p rolonged time to lo ad the ini tial value s of each

pattern.

Shift da ta area, checksum error

Press th e Mode key for a prolonged time to l oad the i nitial valu es.

Lineariz e data ar ea, chec ksum err or

Press th e Mode key for a prolonged time to l oad the i nitial valu es.

Display Descrip tion

*2 + time delay +(*1 ×2)+500μ s+*3

*2

*3

Time dela y +(*1×2) +500μs+* 3

*3

Internal

sampling

Specified

sampling

S/H term inal

Compara tor

output up date

Start/hold type A

*1

Internal

sampling

Specified

sampling

S/H term inal

Compara tor

output up date

Start/hold type B

*1

10 Error Message

10.1Error Indication during Measurement or Setup

10.2Memory Failure Error Indication

11 Timing Charts

12 Warranty and Service

12.1Warranty

The warrant y peri od of the product is one ye ar fro m the date of

delivery. If a failure occurs during this perio d that is clearly judged to

be cau sed by a defect asc ribable to Asahi Keiki , we will repair th e

failure or replace any defective parts without charge.

12.2After Sales Service

Under strict quality control measure s, this produc t was m anufactured, tested, inspected and shipped. Should a defect in manufacture

or workm anship be identified, please retu rn the pro duct to our distributor or directly to us. It would be highly appreciated i f you could

give a detail ed account of the faul t and enclose it with t he product.

*1 Specified sampling

AVG

setting

1

Sampling speed

1041.65 times/sec

2 520.825 times/sec

4

8

10 104.165 times/sec

205052.0825 times/sec

20.833 times/sec

AVG

setting

100

Sampling speed

10.4165 times/sec

200 5.20825 times/sec

400 2.604125 times/sec

800

1000 1.04165 times/sec

2000

5000

0.520825 times/sec

0.20833 times/sec

*2 External start signal

*3 Time delay for alarm outp ut

Relay output: 10 ms max.

The width of the external start signal must be from betwee n 500μs to a specified s ampling cycle. A time

delay can be set for the ex ternal start using the S/H dela y time parameter of the condi tion data.

The sampling speed is determined by the AVG parameter setting of condition data as shown in the table below:

1.3020625 times/sec

260.4125 times/sec

130.20625 times/sec

Sampling cycle

Approx. 48 ms

Approx. 19.2 ms

Approx. 960 s

Approx. 1.92 ms

Approx. 3.84 ms

Approx. 7.68 ms

Approx. 9.6 ms

Sampling cycle

Approx. 4.8 sec

Approx. 1.92 sec

Approx. 96 ms

Approx. 192 ms

Approx. 384 ms

Approx. 768 ms

Approx. 960 ms

Photo coupler output: Maxi mum 200μs

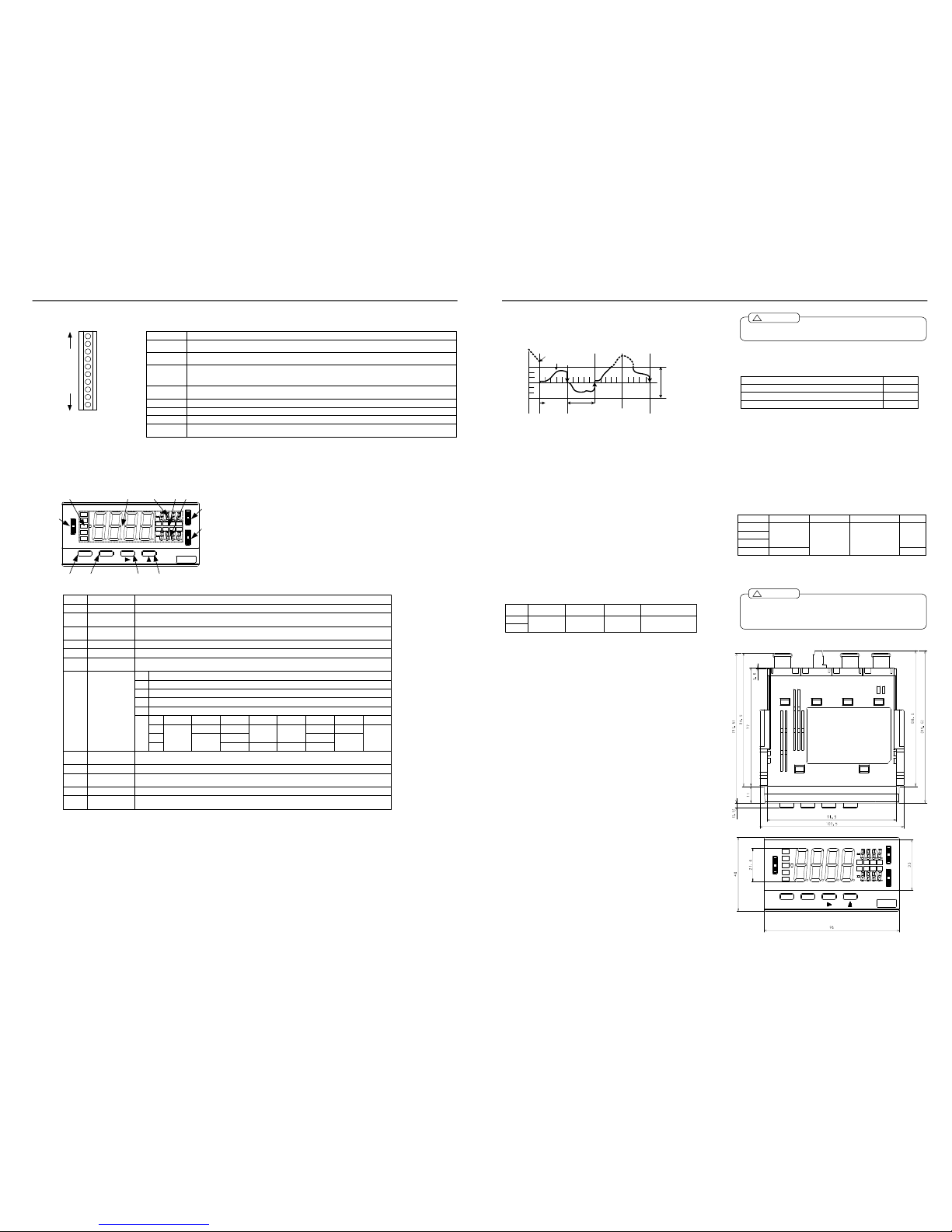

Illustrat ion of the r ear

Input un it Compar ator output unit Anal og output unit Pow er supply un it

EDI6 2S

Power s upply

AC:100 t o 240V AC ±10%

DC:12 t o 48V DC± 10%

-

Suitable solderles s termina ls

5.8 mm or

less

5.8 mm or

less

Top

Bottom

①HI a ( HI output a contac t)

②HI c ( HI output COM)

③GO a (GO outp ut a cont act)

④GO c (GO outp ut COM)

⑤LO a ( LO outpu t a conta ct)

⑥LO c (LO outpu t COM)

Cust omer servi ce

Bessh o-chou 8 5-7, Saita ma-shi, kit a-ku

TEL +81-04 8-662- 4911

Saita ma-ken 33 1-0821, J apan

ENERPAC JAPAN

FAX +81-04 8-662-495 5

WEB http:// www.a pj.ne.jp

Page 2

Instruction Manual for MODEL EDI62SInstruction Manual for MODEL EDI62S 2/12 11/12

3.4 Analog Output connections

4 Parameter Settings

4.1 Display Unit

Names and major functions

①HOLD

②PH

③DZ

④R.RE SET

⑤NC

⑥NC

⑦COM

⑧A.OU T V(+)

⑨A.OU T I(+)

⑩A.OU T COM(-)

Top

Bottom

Termina l Function

S/H

PH

DZ

R.RESE T

"Start/ho ld" contro l termina l. The "hold " state is turned on when this terminal i s at the sa me poten tial as the COM

termina l or short-c ircuited.

"Peak h old" contr ol termina l. The pea k hold func tion is tur ned on wh en this ter minal is a t the sam e potential as the

COM te rminal or short-circu ited.

"Digital zero" con trol termin al. The dig ital zero f unction is turned on when this terminal is at the s ame poten tial as the

COM te rminal or short-circu ited. This setting is valid only when the e xternal co ntrol term inal is sel ected as th e control

method for digital zero using condition data.

"Relay r eset" con trol termin al. The re lay reset f unction is turned on (only for t he meter relay) whe n this term inal is at

the sam e potentia l as the C OM termin al or shor t-circuited .

COM

External control’s common terminals, which are at the sa me potenti al as the L O or AG terminal f or the inp ut circuit.

A.OUT V (+)

A.OUT I(+)

A.OUT COM(-)

Voltage output ter minal of a nalog outp ut.

Current output ter minal of a nalog outp ut.

Common terminal of analog output.

Insulated from inp ut LO or AG termin al/external control CO M termi nal.

⑨ ⑩ ⑪ ⑫

H H

H I

G O

L O

L L

R E P H D Z TZ

M E P 1 P 2 P 3

Enter Mode

④ ⑤ ⑥ ⑦ ⑧

①

②

③

Jog 3

Locatio n Name Major fu nction

①

②

③

Display s results o f judgmen t when u sed with m eter rela y.Judgmen t monito r

Main m onitor Displays a measur ed value, menu na me or a v alue at the time of parameter setting.

Sub mo nitor 1

④

Display s a judgme nt value when used with met er relay; displays a maximu m value, etc. when used witho ut

meter r elay.

⑤

Sub mo nitor 2

Display s a judgme nt value when used with met er relay; displays a maximu m value, etc. when used witho ut

meter r elay.

⑥

⑦

⑧

⑨

⑩

⑪

⑫

Jog 1

Jog 2

Enter

Mode

Shift

Increme nt

Menu a nd value s election a t the time of param eter setti ng; patter n selectio n when us ed with In crement.

Change s judgmen t values w hen used with the m eter rela y; sets a current m easurem ent value to a

judgme nt value; s witching maximum values, e tc. when u sed witho ut meter relay.

Change s judgmen t values w hen used with the m eter rela y; sets a current m easurem ent value to a

judgme nt value; s witching maximum values, e tc. when u sed witho ut meter relay.

Switche s to the p arameter setting m ode.

Change s modes a t the time of param eter sett ing; switch es to the memory mode at t he time o f normal

measur ements (w hen this button is pushed and held.)

Selects digits at the time o f parame ter setting ; DZ contr ol at the t ime of no rmal mea surement s.

Change s values a t the time of param eter setti ng; patter n selection at the ti me of nor mal mea surements

(when t his button is pushed and held ); special operation s

R E

P H

D Z

T Z

M E

P 1

P 2

P 3

Illumina tes when the unit is set to th e remote mode via communic ation fun ction.

Illumina tes when peak hold , valley h old, or pe ak-valley hold is tur ned on.

Illumina tes when Digital Ze ro is turn ed on.

Illumina tes when Tracking Zero is tu rned on.

Illumina tes when Digital Ze ro Backu p is turned on.

P 1

P 2

P 3

Pattern 1 Pattern 2 Pattern 3 Pattern 4 Pattern 5 Pattern 6 Pattern 7 Pattern 8

O F F

O F F

O N

O N

O F F

O F F

O N

O F F O N

O FF

O N

O N

O F F

O N

O F F

O N

Function monitor

8 Output Functions

8.1 Comparison Output Function

The ser ies allows tow judgm ent values of HI, L O to be set up wit h

respect to the m easured valu e (indica ted value) and the judgment

result to be output by relay contact output. For the contact rating, etc.,

see the ou tput specifications.

8.2 Analog Output Function

The series ca n output an analog signal with respect to the indicated

value. There are four types of outputs: 0 to 1V, 0 to 10V, 1 to 5V, and

4 to 20mA, whi ch can be select ed using conditio n data. Als o, any

scaling can be applied.

9 Specifications and External Dimensions

9.1 Input Specifications

9.2 General Specifications

Digital z ero ON. ( T he displ ay is Zero .)

The dis play vani shes to t he correc tion at th e fifth tim es of sam pling be cause

of 3 dig it or less the displ ay.

It doesn 't correct it becau se it com es off fro m the co rrection v alue.

The dis play vani shes to t he correc tion beca use of 3d igit or le ss it.

①

②③

④

⑤

Setting example

Tracking zero co rrection ti me 5( It co rrects it e very five times of samplin g.)

Tracking zero co rrection w idth 3( Correc tion valu e 3digit)

* It beco mes bas ic sampl ing (abou t 960µs)× averag ing times with sam pling.

When the avera ge freque ncy is 5 0 in this example , it becom es a cor rection o f

each a bout 240 ms (abo ut 960µs× 50 time s ×5).

Trackin g

zero sta rt

Five tim es of sa mpling

(Trackin g zero c orrection cycle)

Digital z ero ON

Display value

Trackin g zero wi dth

① ② ③ ④ ⑤

0

-1

-2

-3

1

2

3

(Displa y)

9.3 Output Specifications

9.3.1 Compa rison Output

9.3.2 Analog Output (PWM)

9.4 External Dimensions

The PS voltage must b e applie d or shu t down a t once (n ot gradu ally).

Take a t least a 10-seco nd inter val betw een a s hutdown and sta rtup.

Ca ution

!

10kΩ or more

Load r esistan ceOutpu t type

Resolu tion

:

Maxim um eq uivalent to 14 b its

(I depe nd on o utput indicatio n setti ng.)

Scalin g : Digita l scalin g

Respo nse spe ed

Conve rsion sy stem:PWM conver sion

Accura cy

0 to 1 V

0 to 10 V

1 to 5 V

4 to 20 mA

±(0.5 % of F S)

Appro x. 0.5 s econd

550Ω or less

Ripple

50mVp -p

25mVp -p

(1) Ana log outp ut circui ts and ex ternal co ntrol circ uits are i nsulated.

(withst and volta ge 500V DC, one minute)

(2) CO M termin als of ext ernal co ntrol circ uits and L O termin als of in put

circuits have th e same e lectric p otential a t direct c urrent.

Ca ution

!

Enter Mode

0.5 μV/dig it (Sen sor p owe r : 5V) , 1μV/digit (S ens or po wer : 10V)

:

:

Sensor

power

5V

10V

Zero ad justing

range

-1 to +1 mV/V

Span ad justing

range

1 to +3 mV/V

Measur ement

range

-4 to +4 mV/V

Error

(23℃ ±5℃;35 to 85%)

±(0.1% of FS +2d igit)

Sa mpli ng ra te M axi mum ap prox. 100 0 time s/secon d

Min imu m in put

sen sitivity

:

Sen sor p owe r 5V DC ±5% 60m A, 1 0V D C ±5% 3 0mA

* The e rror is a ppl ied w hen the sa mpli ng ra te is 2 0 time s/second or les s.

Display :

Main displ ay : Red/green 7 -segment disp lay

(character h eight : approx . 20 mm)

Sub displa y : Red 7-segm ent display

(character h eight : approx . 6 mm)

Display ra nge : -9999 to 9999

Operationa l temperature :

:

0 to 50℃ 35 to 85%RH

-10 to 70 ℃ , 60%RH or less

Storage te mperature

External d imension :

48mm (H) x 96mm (W) x 9 9.5mm

Withstand voltage :

PS-input, o utput : 1500V A C, 1 minute

PS-input, o utput : 500V D C, 1 minute

Input-outpu t : 500V DC, 1 minute

AC PS

DC PS

Input-outpu t : 500V DC, 1 minute

Output-outp ut : 500V DC, 1 minute

Output-outp ut : 500V DC, 1 minute

Power sup ply : AC PS

100 to 240V AC ±10%

DC PS

12 to 48V D C ±10%

Power con sumption : A C PS

Maximum lo ad : Approx. 8 VA at 100V AC

DC PS

Maximum lo ad : Approx. 7 W at 24V DC

Weight : Ap prox. 450g

Insulation resistance : AC PS

DC PS

Among the above termina ls : 500V DC 10 0MΩ or more

Among the above termina ls : 500V DC 10 0MΩ or more

Case-PS, in put, output : 1 500V AC, 1 min ute

Case-PS, in put, output : 1 500V AC, 1 min ute

Indicated value > Upper limit judgment value

Conditions for comparison

Hysteresis

: Can be set in the range of 1 to 999 digits for each judgme nt value

Operating speed : Depends on the sampling rate

Judgment value setup range : -9999 to +9999

HI

Lower limit judgment value ≦ Indicated value ≦ Upper limit judgment value

Lower limit judgment value > Indicated value

Judgment result

GO

LO

Contact quantity

Contact rating::

Relay contact ×3

250V AC 2A, 30V DC 2A

●Relay contact output

●Photo coupler output

Output quantity

Contact rating::

Photo coupler ×3

Output rating:Sink current 20mA max. Voltage applied 30V max.

Output saturation voltage: 1.2V or less at 20mA

Page 3

Instruction Manual for MODEL EDI62SInstruction Manual for MODEL EDI62S 10/12 3/12

6 Memory Mode

It is possi ble to display ma ximum value, minim um value, (maximu m

value - minimum val ue) and in put value on the main monitor. Long

pressing the Mode Key results in displaying the maximum value. Press

the Enter Key to return to normal d isplay.

Measured maximum value, minimum value and (maximum value - mini-

mum value) are a lways stored in memory (with the power turned on)

and these data values are cleared by long pressing the Mode Key. In

addition, each of these maximum value, minimum value and (maximum

value - minimum val ue) is displ ayed in red, while the in put value i s

displayed in green.

7 Each Control Functions

7.1 About Each Control Function

If any optional unit is installed, the Start/Hold, digital zero, peak hold

and pattern select control functions can be used. In addition, the digital

zero and pattern se lect functions can be co ntrolled through front key

operation.

* Caution : The COM terminal of the external control circuit and the LO

terminal of the inpu t circuit have the same potential in terms of direct

current .

7.2 Start / Hold Function

The Start/Hold function ho lds the display at any timing, which can be

set in type A or typ e B usin g conditi on data. Type A is the fr ee run

mode, in which you short the S/H terminal with terminal COM or make

these ter minals have th e same potentia l from the free-run status to

hold the indicated value and comparison judgment value. Type B is the

one-shot mode. In this mode, you short the S/H terminal with terminal

COM or m ake these term inals have th e same potent ial from a h old

status to outp ut the indicated val ue and comparison ju dgment value

once. For this, see the timing chart below.

7.3 Digital Zero Function

The Digital Zero functi on is used to set the displayed value to zero at

any timing and then display deviation from that point. Additionally, the

Digital Zero function is activated or deactivated by terminal control o r

through fron t key operation.

* Terminal control or front key opera tion is selected (set) by using

condition data. If the o ptional unit i s not installe d, only the fron t key

operation becomes valid.

7.4 Peak hold Function

The peak h old function is used to hold m aximum value (peak hold),

minimum value ( valley hold), and (maximum value - minimum value)

(peak valley hold ) and generate the outp ut corresponding to each of

these values. In addition, maximum value (peak value), minimum value

(valley hold) or (maximum value - minimum value) (peak valley hold) is

selected (set) b y using condition data. B oth types of peak hold func-

tion are available: Type A and Type B. Type A is of the progressing type

which activa tes the peak ho ld function with the PH terminal shorted

with the COM terminal or the PH and COM terminals set to the same

potenti al to d isplay each of the se measur ed peak values (P H/VH/

PVH). Each peak value is cleared with the PH terminal opened. On the

other hand, Type B is of the result type which conducts measurement

while the PH terminal is shorted with the COM terminal or the PH and

COM terminals are set to the same potential to display, by opening the

PH terminal, each of these measured peak values (PH/VH/PVH) while

the PH terminal is shorted with the COM terminal or these terminals are

set to the same potential.

* If the displayed value overflows during peak hold measure ment, no

overflow display can be released as far as that display is not returned

to normal display once.

7.5 Pattern Select Function

The pattern select function is used to store scaling data and compara-

tor data up to 8 pat terns and be able to set any pattern to be used.

Pattern select contro l selects th e number o f patterns which can b e

used by the pattern select setting in condition data. In addition, I oper-

ate the co ntrol of the patte rn select functi on with front key.

7.6 Tracking Zero Function

The tracking zero function is used to inter nally and digital ly conduct

the a utomatic correcti on of a zero-p oint shi ft. Thi s functi on start s

functioning fro m the time when the digital zero function is activated.

Interna l circuit : P ull-up at a pprox. 5V

(resistance value : ap prox. 10k Ω)

Contro l signal HI level : 4.2 to 5V wit h respect to termina l COM

Contro l signal HI level : 0 to 0.4V wit h respect to termina l COM

Mode

Mode

Mode

Mode

Mode

Mode

Enter

If the m ode key is pushed, it become s

maximu m value d isplay.

*The d isplay cha nges sequ entially.

Max imum → Mnimum → ( M aximum

ーMni mum) → Input → Maxim um

Opera tion Meth od

Measur ement ope ration

The ma ximum va lue is disp layed.

( Red)

The mn imum val ue is displ ayed.

( Red)

The val ue in whic h minimum value is

pulled f rom the m aximum v alue is

display ed.

( Red)

The inp ut value is displayed .

( Green)

All the values are cleared.

*"cLE r" is displa yed in the main mon itor

for abo ut one sec ond.

Display usually.

Push a nd hold( A bout 3 sec onds)

Push a nd hold( A bout 3 sec onds)

Front ke y control :

The dis play at that time is a ssumed to be 0 by pu shing the

shift key for about three sec onds. Digit al zero fun ctions are

released again by p ushing the shift key for three s econds.

Termina l control :

The dis play at that time is a ssumed to be 0 by ma king it to

the term inal DZ, th e termina l COM sho rt-circuit o r this

potentia l. 0 digital functions are release d by openi ng the

termina l DZ.

Opera tion proc edure dia gram (J og lever : Operatio n of front switch c ombinatio n)

●Expla nation of a figure o f jog lever

push tilt downside tilt u pside

1

1 1

Enter

1

1

1

1

1

1

1

1

1

Scaling data patte rn select ion

Compar ator data pattern se lection

1

1

1

1

2or3

Set low layer val ues of the condition data.

Set low layer val ues of the scaling da ta.

Set low layer val ues of the comparato r data.

Judgme nt value s etting

Set a m easured v alue as a reference .

Digit se lection (fr om the

lowest digit to hi ghest digit)

* Retur ns to mea surement

after th e highest digit.

2or3

Pattern selection

+ 2or3

+ 1 or + 1

Norma l operation

1 1

1

1

Shift da ta setting

Digit se lection (fr om the hig hest

digit to the lowes t digit)

2

2 2

Increase or decre ase a valu e.

1

1

Calibra tion data p attern se lection

Set low layer valu es of the Calibratio n data.

* I can set it by v alidating a linearize function b y

conditio n data.

Decreas e a value .

Increase a value.

2or3

2or3

Change the param eter sele cted.

1

1 1

Select a paramet er to chan ge.

Change the param eter sele cted.1

1 1

Select a paramet er to chan ge.

Change the param eter sele cted.1

1 1 Select a paramete r to chang e.

Return s to measu rement

after th e highest digit.

2or3

Mode

Shift da ta is refle cted upon the

measur ement dat a on the M ain Moni tor.

Change the param eter sele cted.1

1 1 Select a paramete r to chang e.

How to set a lo w layer v alue (Co ndition d ata / sca ling data / compar ator data / Calibra tion data)

To chan ge the se lected par ameter, p ush the ce nter of Jo g 1 or us e the Mod e key to m ove from the menu selection

mode t o value ch ange mode .

Select the name of a param eter (sho wn on Sub monitor 2) you wa nt to chan ge by turn ing Jog 1 up or dow n.

11or

Mode

*While Sub mon itor 2 flash es in the menu sele ction mod e, Main m onitor wi ll flash in the value change mo de.

or 1 1 1

Push th e center o f Jog 1 t o choose th e digit yo u want to change, and turn J og 1 up or down to change th e value.

1 1

If the p arameter requires a value ent ry:

Turn Jo g 1 up or down to choose a s election.

If the p arameter requires a selection :

1 or

Mode

Push th e center o f Jog 1 or use the M ode key to shift fr om the va lue change mode to the menu selection mode.

* While Sub mon itor 2 flash es in the menu sele ction mod e, Main monitor w ill flash in the value change m ode.

1 or

Enter

Turn Jo g 1 up or down to select the menu nam e of the p arameter you want to change (shown in Sub mon itor 2) or

return to measur ement by pushing th e Enter ke y.

Front ke y control :

The patt ern can be switched from P-1 to maximu m P-8 by

pushing the increm ent key fo r about th ree second s.

P1

P2

P3

Pattern 1 Pat tern 2 P attern 3 Pattern 4 Pattern 5 P attern 6 Pattern 7 Pattern 8

OFF

OFF

ONONOFF

OFFONOFF ON

OFF

ON

ON

OFF

ON

OFF

ON

Function monitor

Page 4

Instruction Manual for MODEL EDI62SInstruction Manual for MODEL EDI62S 4/12 9/12

* I can set it by v alidating a linearize function by

conditio n data.

Change the param eter sele cted.

Opera tion proc edure dia gram (O peration only with front sw itch)

Enter

Select a paramete r to chan ge.

Change the param eter sele cted.

Select a paramete r to chan ge.

Change the param eter sele cted.

Select a paramete r to chan ge.

Set low layer valu es of the condition data.

Set low layer valu es of the scaling da ta.

Set low layer valu es of the comparat or data.

Setting low layer values of the lineari zed data.

Pattern selection

Mode

Shift d ata is refl ected upon the meas urement

data on the Main Monitor.

Change the param eter sele cted.

Select a paramete r to chan ge.

Memor y mode

Mode

Push an d hold

Push an d hold

Push an d hold

Keep on pushing t he button for autom atic incre ments.

When y ou push th e Mode k ey, mode s will cha nge in the order of the

maximu m value, minimum value, (ma ximum v alue-minim um valu e)

and inp ut value. If you pus h and hold the Mode key whe n you are in

the me mory mod e, all the values in m emory w ill be clea red.

Mode

Mode

Mode

Mode

Mode

Mode

Mode

Mode

Mode

Mode

Digit se lection

Value ch ange

Mode

5.7 Linearization Data Setting Examples

* Linearization data setti ng function

Linearization dat a can be used as a functi on to set 2, 4, 8, or 16 li nearity correction points.

Input data are displayed when the linearization function is OFF. The value to be displayed in response to the input data is output data. For each linearity

correction point, input an d output data must be set.

For example, whe n the linearization f unction is OFF, and you wish to c hange the displayed val ue on the meter from 0 - 1000 to 0 - 1 200, set N01.I

(Correction Point 1 Input Data) and N01.O (Correction Point 1 Output Data) to 0, N02.I (Correction Point 2 Input Data) to 1000, and N02.O (Correction Point

2 Output Data) to 1200.

In this case, the line between Correction Points 1 and 2 behaves according to the linearity correction setting. When the value of the input data exceeds

that at Correction Point 2, the behavior of the output data is no longer affected by the setting (the value of the output data changes from 1200 to 1001).

When more than two co rrection points are set, the behavior of a line connecting two sequential correction points is d ifferent from that of the next two

in sequence.

* Conditions for setting linearization data

To set linearization data, the value of th e input data at one correction point mus t be larger than that at the previous on e.

N01.I < N02.I < N03.I < N04.I ??< N15.I < N16.I

How to calibrat e the zer o input (Z RIN) val ue and th e span in put (SPIN ) value u sing an a ctual loa d or the e quivalen t input

Push th e center o f Jog 1 to choose th e digit you want

to chan ge, and m ove it up o r down to change th e

value. I n the left figure, pus hing the jo g1 while the

least sig nificant d igit of “1.0 00” is se lected, cau ses

the low er digits to also be d isplayed.

Push an d hold the Shift key , then the current

measur ed value w ill be rea d as the se tting.

Equival ent input c alibration

Actual load calibr ation

Push an d hold

1 or

Mode

1 1 1

Caution

* Comp arator jud gment val ues can be set not o nly from J og 2 and J og 3 but also from the low la yers of the comparat or data.

1

1

Press m ultiple tim es

1

1

1

1

1

1

1

Select a digit to change

Increas e a value

Decrea se a value

Mode

Change the selec ted digit

Save an d return to measur ement

Enter

Return to measu rement

Oper ation Met hod

Measur ement op eration

* Not d isplayed u nless the v alue of th e protect l evel param eter of t he conditio n data is PL0.

* Not d isplayed u nless the linearizati on param eter of the condition data is en abled.

Correc tion Point 1 Output D ata Setti ng (setting method i s the sam e as above )

Correc tion Point 2 Input Da ta Setting (setting m ethod is the same as above)

Correc tion Point 1 Input Da ta Setting

Correc tion Point 2 Output D ata Setti ng (setting method i s the sam e as above )

Correc tion Point 16 Output Data Set ting (setti ng method is the sa me as abo ve)

1

* Not d isplayed w hen the va lue of the lineariza tion param eter of th e conditio n data is s maller th an 16.

Page 5

Instruction Manual for MODEL EDI62SInstruction Manual for MODEL EDI62S 5/128/12

0 1 2 3 4 5 6 7 8 9

A B C D E F G H I J K L M N O P Q

R S T U V W X Y Z

-

4.2 Numeric and Character Indications

4.3 Protection Levels

Each parameter of the EDI62S has an individual protection level, and by setting the protection level of the condition data, you can set an access level.

(For the protect level of each parameter, see the P.L. column of the tables in Section 4.4.)

The higher the protection level is, the less the number of settable parameters will be. If you set the protection level to the strictest LV3, you can change

the protection level only, and all the other parameters may not be changed. (No comparator judgment value can be changed using the jog switches in

this cas e.)

*The pr otec tio n l evel set at the tim e of sh ipm ent is LV1. (Se tti ngs of dis play co lor s, s cali ng and jud gmen t-r elate d va lues onl y ar e

avai labl e.)

5.6 Calibration Data Setting Examples

How to calibrat e the zero input (Z RIN) valu e and the span inp ut (SPIN ) value us ing an ac tual load or the equ ivalent in put

Push th e center o f Jog 1 to choose the digit you want

to chang e, and mo ve it up o r down to change the

value. I n the left figure, push ing the sh ift while th e

least sig nificant d igit of “1.0 00” is sele cted, caus es

the low er digits to also be d isplayed.

Push an d hold the Shift key , then the c urrent

measur ed value w ill be read as the set ting.

Equivale nt input c alibration

Actual l oad calibra tion

Push an d hold

Mode

&

* The EDI6 2S series does not add the zer o input value to the span input v alue.

Namely , the gradient an d offset values for y=ax+b are obtained as foll ows:

Gradient (a ) =

(SPAN - ZE RO)

(SPIN - ZR IN)

Offset (b) =

(SPAN - Z ERO) ×ZRIN

(SPIN - ZRI N)

- ZERO

1

Calibration data pattern se lection

Select a pa ttern to set.

* Patterns cannot be selec ted when the nu mber of availab le patterns is se t to 1 using co ndition data.

1 1

1

Sensor pow er supply selec tion

1

1

1 1

1

Zero input value setting1

Mode

1 Select a digit to set.

1 1

Change the value for the s elected digit

(equivalent input calibration ).

the curren t measurement as the setting ( actual load calib ration).

Zero indica tion value settin g1

Mode

1 Select a digit to set.

1 1 Change t he value for the selected digit.

1

1

1

Mode

1

1 1

Change the value for the s elected digit

(equivalent input calibration ).

1

1

Mode

1 Select a digit to set.

1 1 Change t he value for the selected digit.

Select a di git to set.

Operati on Method

Press the Shift key for pro longed time to automatically r ead

the curren t measurement as the setting ( actual load calib ration).

Press the Shift key for pro longed time to automatically r ead

How to set a lo w layer v alue (Co ndition d ata/scali ng data/c omparato r data)

Mode

Mode

Enter

Select the name of a param eter you want to c hange by p ushing the Increme nt key.

Use th e Shift ke y to choos e the digit you want to change , and pus h the Incr ement key to set the value.

If the parameter requires a value ent ry:

Use th e Increme nt key to choose a s election.

If the parameter requires a selection :

Use th e Mode ke y to shift f rom the v alue chan ge mode to the men u selectio n mode.

Use th e Increme nt key to s elect the menu nam e of the p arameter you want to change or return to

measur ement by pushing t he Enter k ey.

To chan ge the se lected par ameter, use the Mo de key to move from the men u selectio n mode to the value

change mode.

&

or

Page 6

Instruction Manual for MODEL EDI62SInstruction Manual for MODEL EDI62S 6/12 7/12

4.4 List of the Parameters

The para meters for the process sign al measurement unit can b e roughly divi ded into thre e types: conditi on data which deal with b asic functions

including sampling time; s caling data which control measure ment including i nput range; com parator data which deal with compa rator output; and

calibration da ta which relating to cal ibration with a sensor.

4.4.1 Condit ion Data

4.4.2 Scaling Data

4.4.3 Compar ator Data

4.4.4 Calibra tion Data

5 Setting Examples and Use Examples

5.1 Scaling Data Setting Examples

Set digital liniter,analog output and decimal point by 4.4.2 scaling data.

Set it in below of operation procedure diag ram.

The digital limiter is the function that limits an input value to the relevant

set value even if a signal higher than or lower than the indicated value

set to DLHI or DLLO respectively is input. The setting condition is DLHI

> DLLO, and if th is condition is not met, Err5 is c aused, returning the

display to DLHI.

5.2 Analog output Scaling Setting Examples

The analog output sets the output value to the display value.

5.3 Comparator Data Setting Examples

● High and Low Judgment Type

The high and low judgme nt type allows you to directly set judgment

values in nu merical values, which are checked against the in dicated

value for judgment. It allows setting of two stages of judgment points: HI

and LO.

* The setting conditions are (HI judgment value - HI hysteresis) > (LO

judgment value + LO hysteresis). If any of these conditions is not met,

Err0 is caused, returning the display to the HI jud gment value setting.

Jog SW 0

P.L.

PH Selec tion 0

Average times

Average times of

moveme nts

Step wid e

Display color type

HI displa y color

GO displ ay color

LO displa y color

Display blank level

DZ backu p

Linearize

TZ time

TZ corre ction rang e

Power on delay tim e

Protectio n level

Unit num ber indic ation

DZ contr ol

0

0

0

1

1

1

1

0

0

0

0

0

0

3

0

0

P.SEL 0

Start/hold type 0

PH type 0

S/H dela y time 0

Setting ra nge or alt ernativesParamet er name

Menu ind ication

Conversi on rate (a verage ti mes of int ernal sam pling; s ampling time: app rox. 1ms ) is selec ted.

Major se tting purpo se and rem arks

Selects t he average times of movemen ts.Filt ering effec ts: Sma ll<1(OFF )-2-4-8-1 6-32>Big

Selects t he range o f display c hanges to maintain image disp lay consi stency .

(If this p arameter i s set to 5, the low est digit w ill displa y either 0 or 5 on ly).

Selects au tomatic (red in th e HI or LO mode or green in t he GO mo de) or manual setting for display c olor type .

Selects r ed or gree n as displa y color at the time of HI judg ment .*Only w hen CLR .T is MAN U.

Selects r ed or gree n as displa y color at the time of GO jud gment .*Only when CLR .T is MA NU.

Selects r ed or gree n as displa y color at the time of LO judg ment .*Only w hen CLR .T is MA NU.

Selects t he display brightnes s. <brig ht OFF- LV1-LV2- LV3-ON >turned o ff

Selects w hether the jog SW i s used or not.

Selects a type that o perates w hen the P H function is turned on (peak hol d/valley hold/pea k-valley hold).

Selects w hether the digital ze ro value i s backed u p or not a t the time when the u nit is turn ed off .

Selects t he number of pattern s availabl e for the p attern sele ction func tion .

Selects w hether the linearize function i s enabled /disab led and s ets the num ber of co rrection p oints .

Selects whether the tracking zero function is enabled/disabled and sets the correction time (setup value/conversion rate).

Sets the t ime betwe en the sta rtup and a ctual star t of measu rements (se tup value x 1 seco nd).

Sets the c orrection range of th e tracking zero func tion .*Only w hen TR.T is set to a value oth er than 000.

Selects t he protecti on level to prevent o peration m istakes .High < LV3-LV 2-LV1-LV 0 >Low

Selects w hether the code of a unit moun ted at the time of st artup is di splayed or not .

Selects a n operatio n type of s tart/ho ld (A: fre e run; B : one shot ).

Sets the d elay time at the tim e of startu p (set up value x 1 ms).

Selects a n operatio n type of p eak hold (A: re al-time di splay; B: results d isplay).

Selects a control method of Digital Zero (SW: front key; TERM: external control terminal).

Initial valu e

(AVG)

(MAV)

(S.WD)

(CLR.T)

(HI.CL)

(GO.CL)

(LO.CL)

(BLNK)

(DZ.BU)

(LINE)

(TR.T)

(P.ON)

(PRO)

(U-NO.)

(S/H.T)

(PVH)

(PS)

(TR.W)

(S/H.D)

(PVH.T)

(DZ.C)

(J.SW)

~

~

~

~

Sets the upper lim it of the displaya ble range .

(Any va lue equal to or exc eeding th e digital limiter H I setting will not be update d and kep t at the s etup valu e .

Selects an analog output r ange .

Sets the relations hip betw een indic ations an d analog outputs .

Sets the position of the de cimal po int.

Sets the lower li mit of the displaya ble rang e.

(Any va lue equal to or belo w the di gital lim iter LO se tting wil l not be u pdated an d kept at the setup value .

1

1

2

1

0

0

Analog o utput HI

Analog o utput LO

Decima l point

Analog o utput type

Digital li miter LO

Digital li miter HI

P.L. Set ting rang e or alter nativesParame ter nameMenu in dication Major se tting pur pose and remarksInitial va lue

(DLHI)

(DLLO)

(AOHI)

(AOLO)

(DP)

(A.OUT )

Each dig it can be set

independ ently

~

~

~

~

(SPIN) S pan inpu t value 2 ~

(ZERO) Z ero in dica tion 2 ~

(SNSR) Senso r pow er sup ply 1

(ZRIN) Z ero in put va lue 2 ~

(SPAN) S pa n indic ation 2 ~

Sele cts a se nsor p owe r sup ply.

Sets the relatio nship betw een in put sig nal s and their in dicatio ns .

P.L. Sett ing range or alternativ esParameter name

Menu indi cation

Major set ting purpos e and rem arksInitial valu e

0

5000

4mA

20mA

10V

20000

-2000

When t he indicati on varies b etween 0 to 5000,

corresp onding ana log output values sh ould be 4 to 20mA .

Analog output

Indicati on value

Example 1

Analog o utput HI ( AOHI)

Analog o utput LO (AOLO)::

5000

0

Example 2

When t he indicati on varies b etween 2 00.0 to -2 00.0,

corresp onding ana log output values sh ould be 0 to 10V.

Analog o utput

Indicatio n value

Analog o utput HI ( AOHI)

Analog output LO (AOLO)::

-2000

2000

Example 1

Above and below set up mode

GO GOHI GO LO

Indication values

Judgment

700

500

0

1000

400

900

200

LO judgm ent value

HI judgm ent value

Hysteresi s range

* The hyst eresis is e ffective ei ther in th e range low er than t he HI judg ment valu e or that h igher tha n the LO

judgment value.

●Tolerance Judgment Type

The tolerance judgment type allows you to set a nominal value and its

tolera nces (XX%) to make judgment on the basis of the jud gment

values calculated fr om these valu es within the instrument. You can

set one nominal value and one tolerance values.

For example, if the nominal value is set t o 1000 and tolerances 10%

respectively, internal judgment values are 1100 for HI judgment value,

900 for LO judgment value.

5.4 How to Switch the Sensor power

5V DC or 10V DC ca n select by 4. 4.4 Calibrati on data. Initi al value

become 5V DC.

5.5 Shift Data Setting Examples

The s hift fun ction allo ws you to arbitrar ily shift the disp lay withou t

changing the inclination of an input s ignal. A setting example below

shows how to shift the in dicated value b y 100 digits.

Example 2

Error judg ment mode

GO GOHI GO LO

Indication values

Judgment

1000

900

0

1100

Nominal v alue

Hysteresis range

Upper side error

Lower side error

* Error is to be set a s a percen tage of th e nominal value.

* The hyst eresis is to be set as an x-th di git of the indication value.

* The hyst eresis is e ffective eit her in the range lowe r than the upper side error or that higher than the

lower side error.

1

1

Press mu ltiple tim es

1

Mode

It is me morized.

Opera tion Meth od

Measure ment ope ration

*It is n ot display ed, except when the

protectin g level of the condi tion data is PL0.

Shift da ta setting

2 2 2oror

2

2

2

The digit is moved , and the d igit

that wan ts to chan ge is sele cted.

Increase a value.

Decrease a value .

Enter

Return t o measure ment

HI judgm ent value

LO judgm ent value

HI logic

LO logic

HI hyster esis

LO hyste resis

Error 1

Nominal value

2

2

2

2

1

1

0

0

Compara tor output type 1

Error 1 h ysteresis 1

GO logic 0

Select ei ther [abo ve or bel ow] or e rror comp arator ty pes.

Sets a H I judgmen t value . *Only w hen COM .T is O/ U.

Sets a LO judgme nt value . *Only w hen COM .T is O /U.

Sets a no minal val ue. *On ly when COM.T is ERR.

Sets an e rror. *O nly when COM.T is ERR.

Sets a H I hysteres is value (smalle r than the setup val ue.) *O nly when COM.T is O/U.

Sets a LO hystere sis value (larger than the s etup valu e.) *O nly when COM.T is O/U.

Sets an e rror hyst eresis ( smaller o r larger t han the se tup value s.) *O nly when COM.T is ERR.

Sets a H I output log ic (N. O.=norma lly open or N.C. =normall y closed)

*Output w hen the p ower is O FF is al ways open .

Sets a G O output l ogic (N .O.=nor mally ope n or N.C .=norma lly closed )

*Output w hen the p ower is O FF is al ways ope n.

Sets a LO output lo gic (N .O.=norm ally open or N.C .=norma lly closed )

*Output w hen the p ower is O FF is al ways ope n.

P.L. Set ting range or altern ativesParameter name

Menu ind ication

Major se tting purp ose and r emarksIni tial value

(LO-L)

(GO-L)

(HI-L)

(ER1.H)

(LO-H)

(HI-H)

(ERR1)

(N.VAL)

(LO-S)

(HI-S)

(COM.T )

~

~

~

~

~

~

~

Loading...

Loading...