Page 1

1

Instruction and

Repair Parts Sheet

BHP Puller Sets

and Attachments

EIS 65.100-1 05/14 Rev. F

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

SAFETY FIRST

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for

damage or injury resulting from unsafe use of

product, lack of maintenance or incorrect product

and/or system operation. Contact Enerpac when in

doubt as to the safety precautions and applications.

TO PROTECT YOUR WARRANTY, USE ONLY

ENERPAC HYDRAULIC OIL.

2.0 PRODUCT DESCRIPTION

Enerpac BHP-series puller sets consist basically of a

handpump, single-acting cylinder, gauge, gauge

adaptor, hose, couplers and specific tools and

attachments. The pullers are designed for installing

and removing all press fitted and heat fitted parts

such as gears, pulleys, wheels, bearings, sleeves,

sprockets, pins and other stubborn parts.

The Enerpac BHP-series puller sets are available as:

Grip Puller Sets (see paragraph 2.1), Cross-Bearing

Puller Sets (see paragraph 2.2) and Multi-Purpose

Puller Sets (see paragraph 2.3).

Puller set attachments are additional parts to

increase on-the-job flexibility further with the use of

grip pullers and cross-bearing pullers. See tables D

and E on the pages 11 and 12 for the individual

components of puller set attachments.

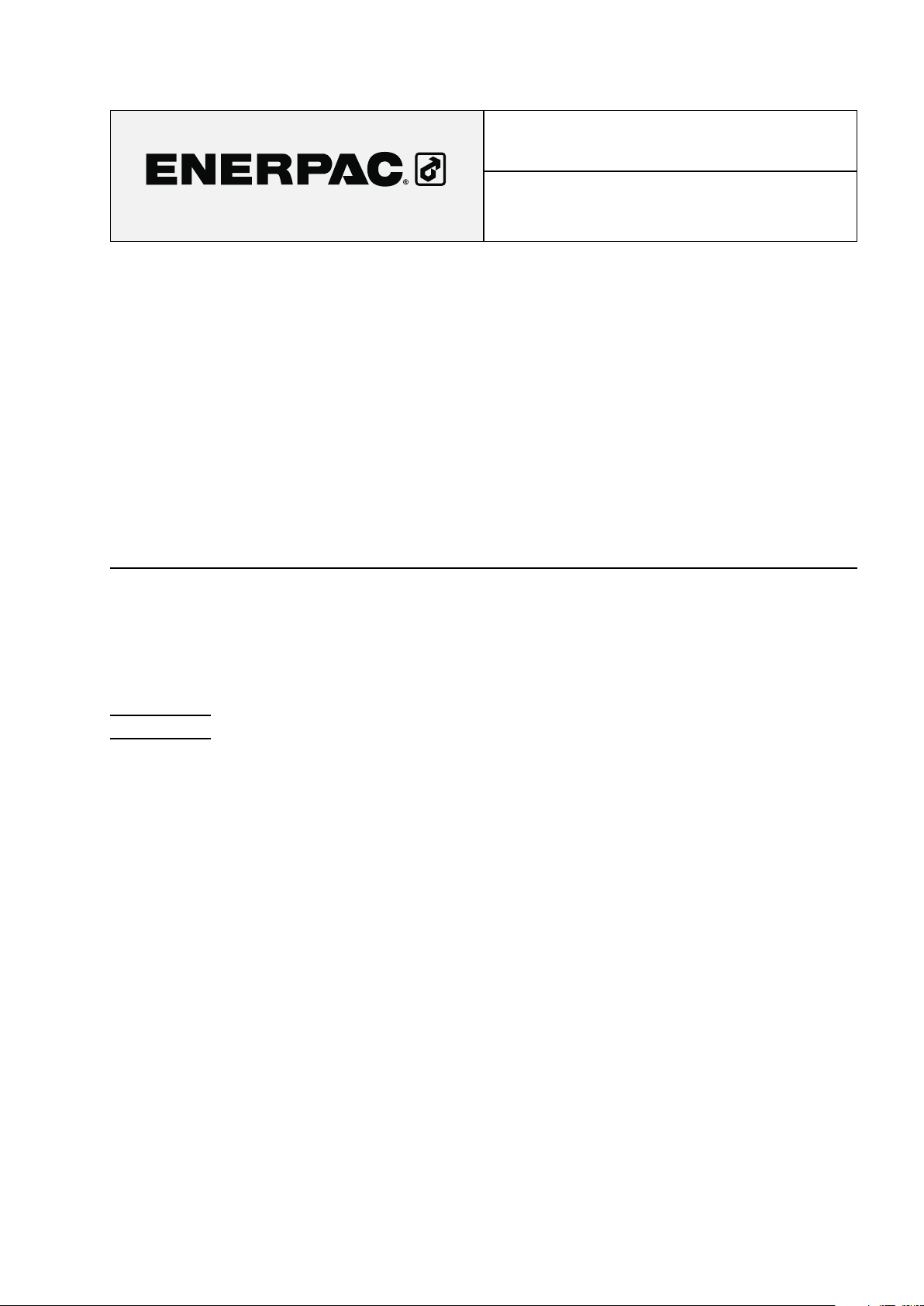

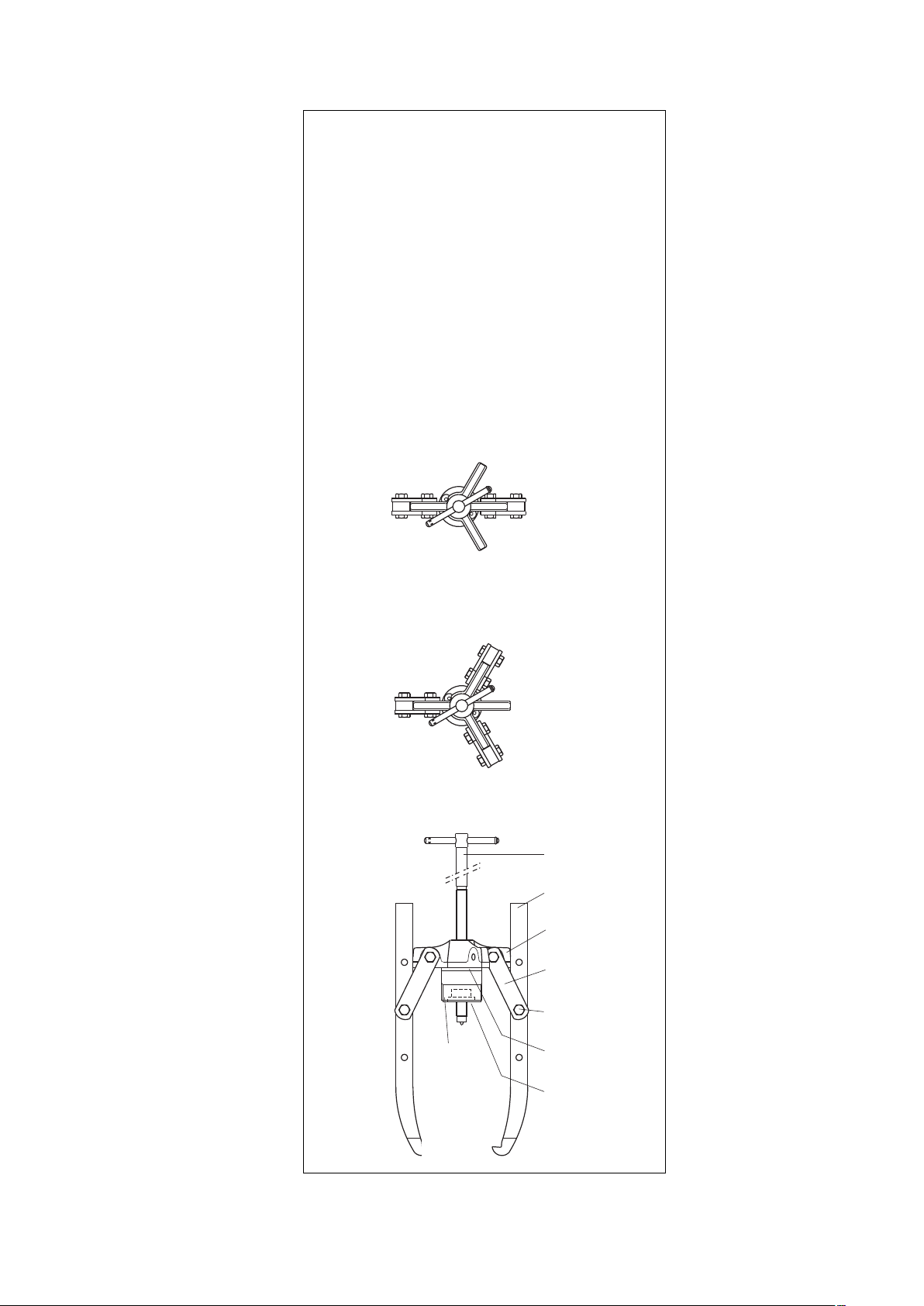

2.1 Grip Puller Sets

The grip puller sets BHP-152, BHP-251G, BHP-351G

and BHP-551G can be used to remove and install

gears, bearings, pulleys and similar parts. See

illustration 1 on page 3: grip pullers can be used with

a double crosshead (2 grip arms) or a triple cross head (3 grip arms). For individual parts see table A

on page 7.

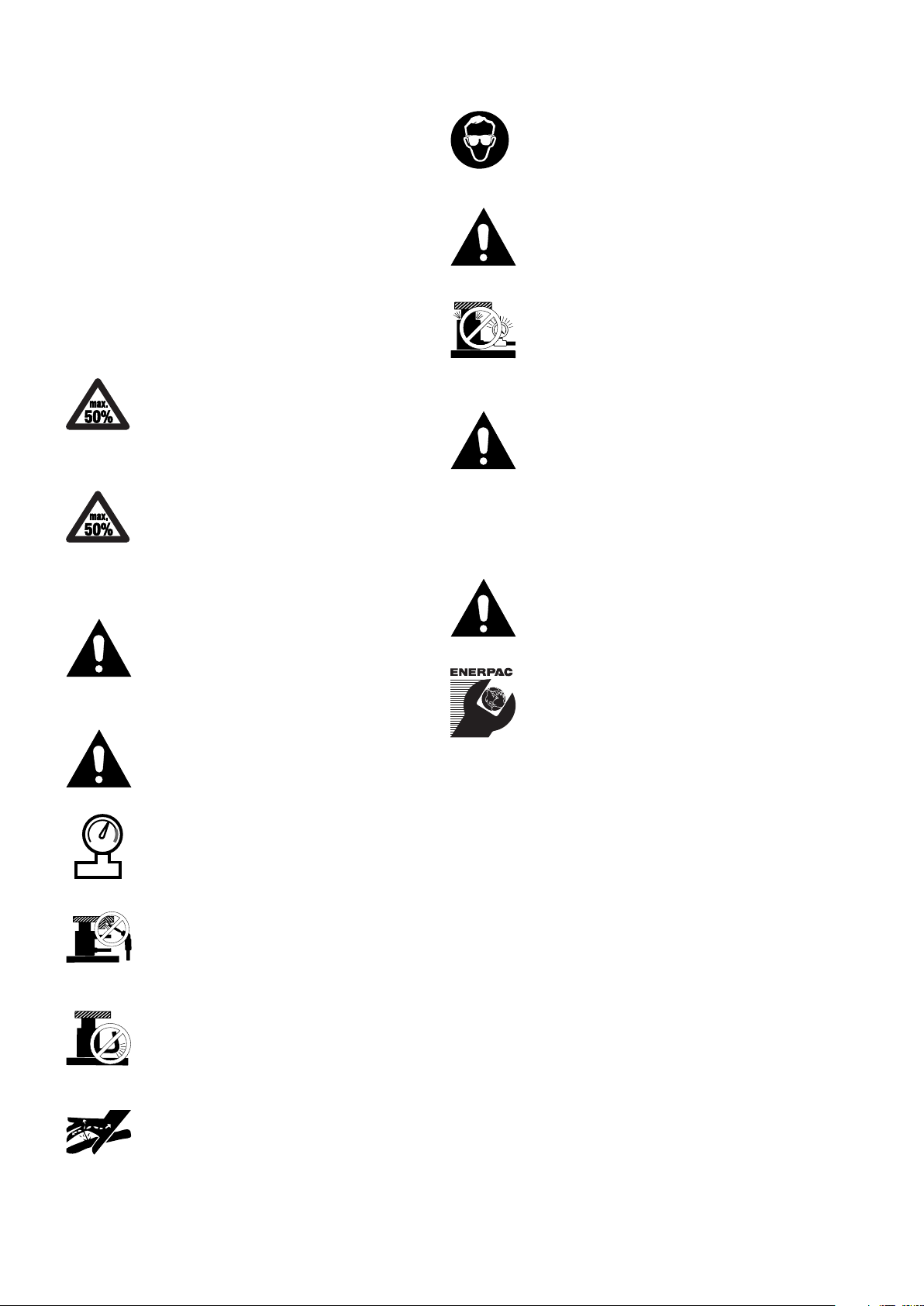

2.2 Cross Bearing Puller Sets

The cross bearing puller sets BHP-162, BHP-261G,

BHP-361G and BHP-561G can be used to remove

and install gears, pulleys, sleeves and bushings.

These pullers can also be used as bearing cup

pullers (internal grip pullers) as shown in illustr. 2 on

page 3 or as bearing pullers as shown in illustration 3

on page 3.

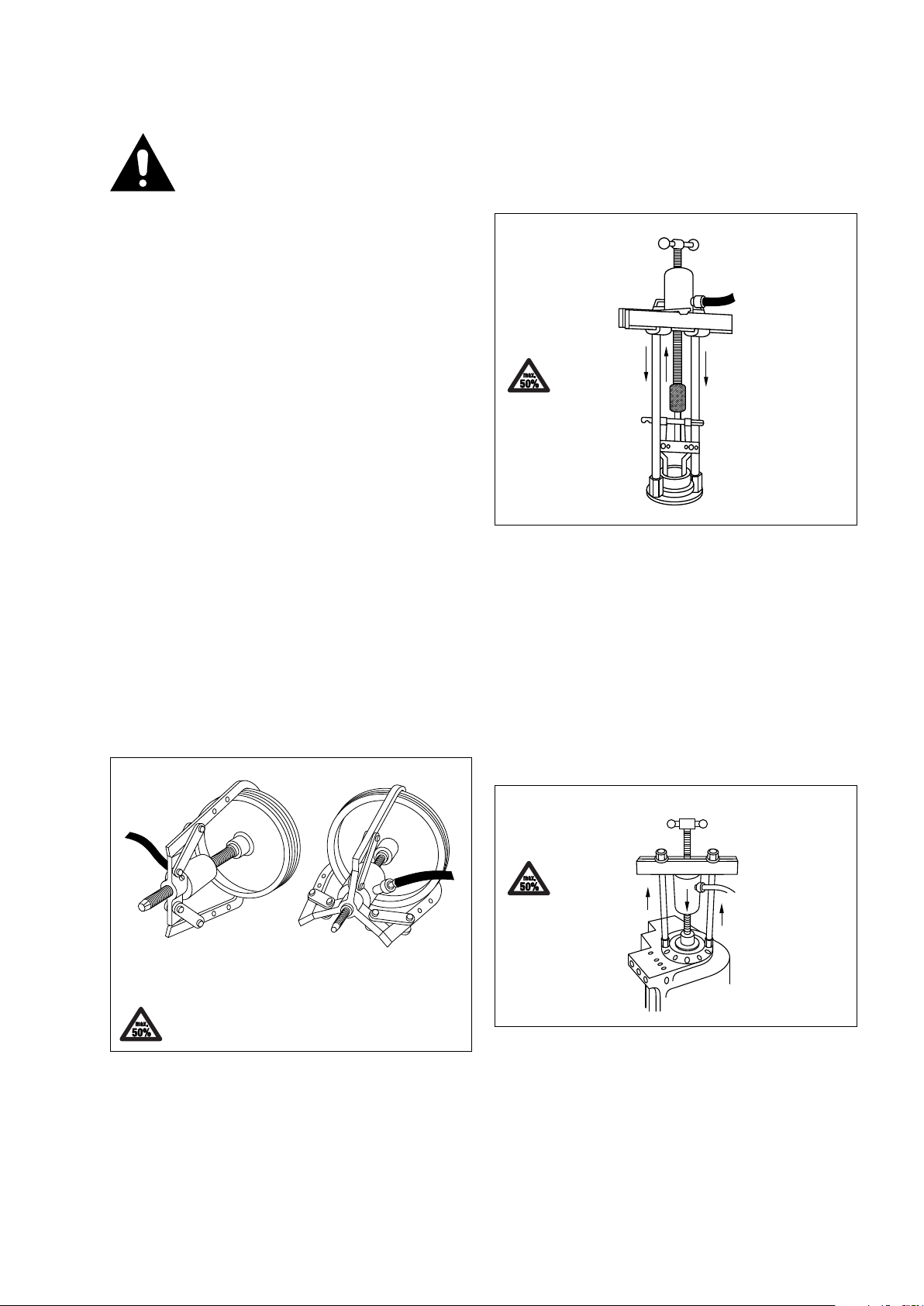

In situations where clearance prevents a direct

application of grip puller arms, it is possible to use the

puller in combination with bearing puller attachment

as shown in illustration 4 on page 4. Bearing puller

attachments have wedge shaped edges to place the

puller behind the hard to reach the gear or bearing.

See table B on page 9 for individual components.

index:

English

Instruction Sheet.............................................................pages.............1-4

Repair Parts Sheet.......................................................................pages...........5-12

Française

Notice d’Emploi...........................................................pages .........13-16

Deutsche

Bedienungsanleitung...................................................Seiten ........17-20

Italiano

Manuale Istruzioni...........................................................pagine........21-24

Español

Instrucciones .................................................................páginas ......25-28

Nederlandse Gebruikershandleiding.......................................blz.............29-32

Русская инструкция

.................................................................

страница

.....33-36

POWERFUL SOLUTIONS. GLOBAL FORCE.

Page 2

2

2.3 Multi-Purpose Puller Sets

BHP-1752, BHP-2751G, BHP-3751G and BHP-5751G

multi-purpose puller sets are a combination of the

above mentioned grip puller sets and cross bearing

puller sets to provide maximum application flexibility

in pulling and pushing applications in maintenance

and repair. See table C (page 10) for individual

components.

3.0 GENERAL SAFETY ISSUES

Failure to comply with the following cautions and

warnings could cause equipment damage or

personal injury.

WARNING: DO NOT exceed 50% of the

rated puller capacity when using a

double crosshead (2 grip arms): do not

exceed 350 bar (5,000 psi) when using

a hydraulic puller in this application.

WARNING: DO NOT exceed 50% of the

rated puller capacity when using the

puller legs in combination with bearing

puller attachment: do not exceed 350

bar (5,000 psi) when using a hydraulic

puller in this application.

IMPORTANT: It is recommended to use

the triple crosshead (3 grip arms) which

gives a more secure grip, a more even

pulling force and is more stable than the

double crosshead (2 grip arms).

WARNING: To avoid personal injury and

equipment damage, make sure all

hydraulic components withstand the max.

hydraulic pressure of 700 bar (10,000 psi).

IMPORTANT: Use hydraulic gauges in

each hydraulic system to indicate safe

operating loads.

WARNING: Make sure that all system

components are protected from external

sources of damage, such as excessive

heat, flame, moving machine parts, sharp

edges and corrosive chemicals.

CAUTION: Avoid sharp bends and kinks

that which will cause severe back-up

pressure in hoses. Bends and kinks lead

to premature hose failure.

WARNING: DO NOT handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin causing serious injury.

If oil is injected under the skin see a doctor

immediately.

WARNING: The operator must take

precaution against injury due to flying

debris caused by failure of the tool or

workpiece.

WARNING: DO NOT use this equipment

in circumstances where a sudden release

of pressure can result in loss of balance

causing damage or injury.

WARNING: DO NOT overload equip ment. Use the right size puller. When you

have applied maximum force, but the part

will not move, go to a larger capacity

puller. Resist sledging.

IMPORTANT: It is impossible to predict

the exact force needed for every pulling

situation. The amount of press fit and

force of removal can vary greatly between

jobs. Set-up requirements along with the size, shape

and condition of the parts being pulled are variables

which must be considered. Study each pulling

application before you select your puller.

IMPORTANT: Apply force gradually. Align

puller legs and grip arms. Be sure the

setup is rigid and puller is square with the

work.

WARNING: Immediately replace worn or

damaged parts with genuine Enerpac

parts. Enerpac parts are designed to fit

properly and withstand rated loads.

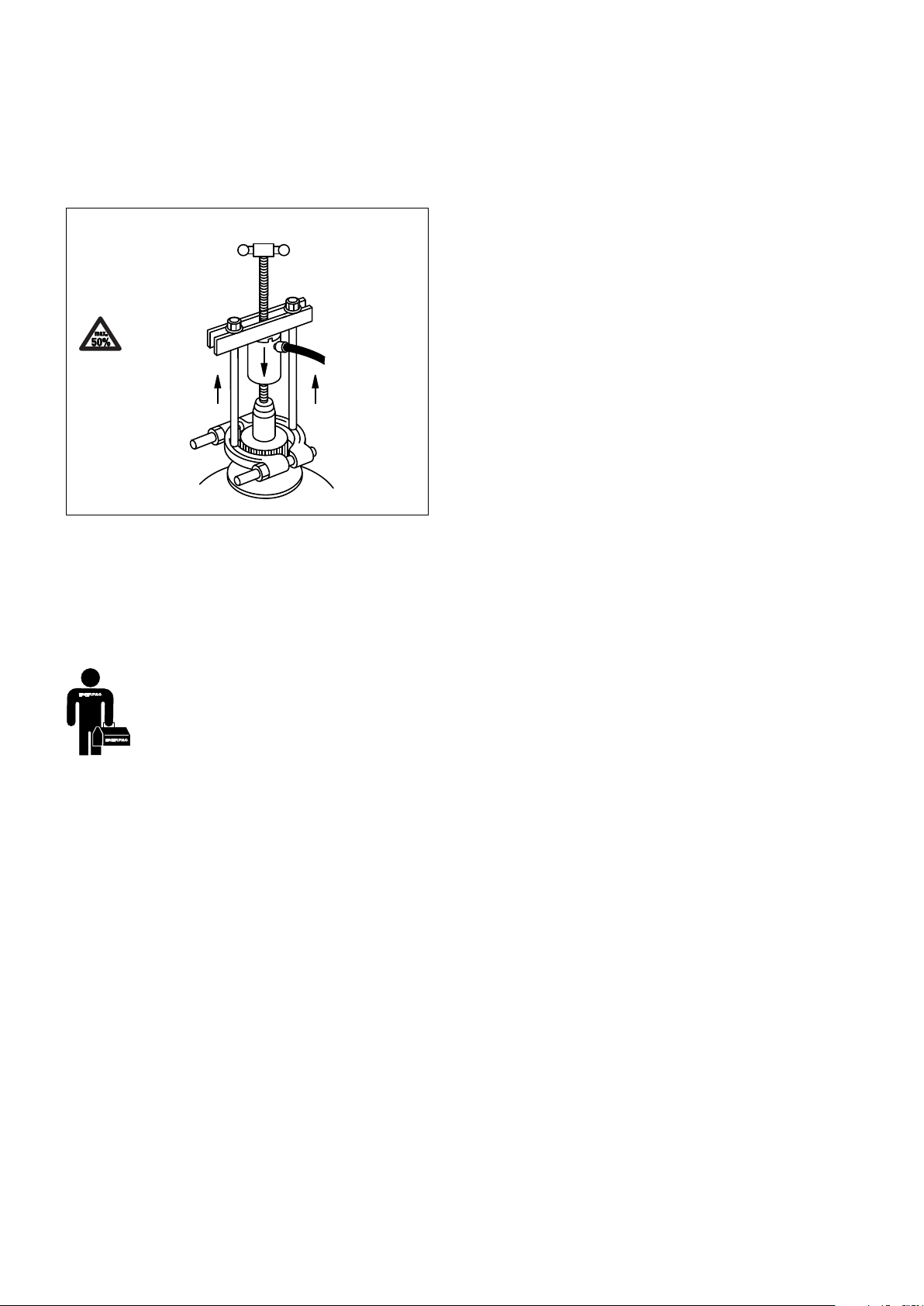

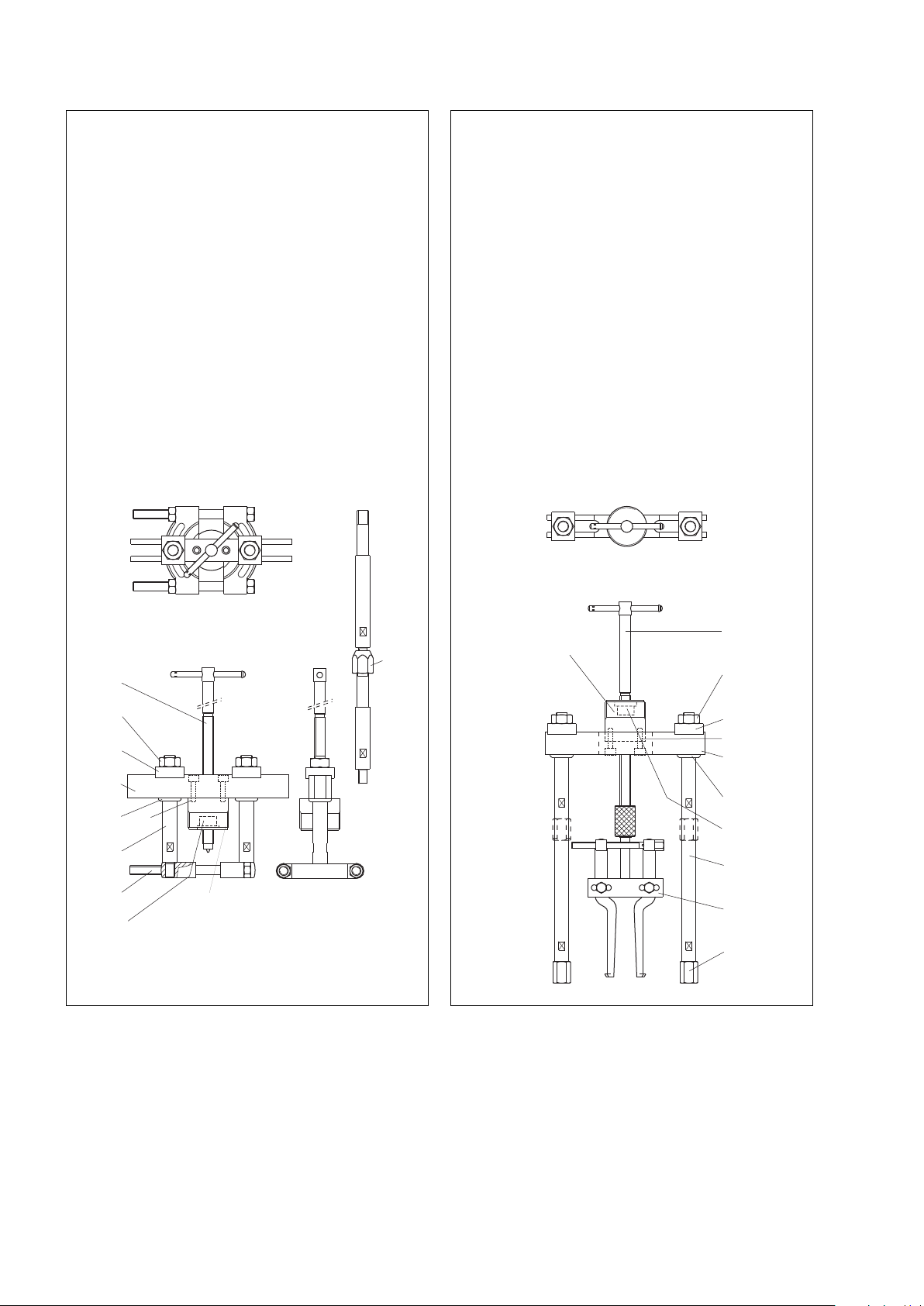

4.0 INSTALLATION

4.1 Grip pullers

Illustration 5 on page 6 shows how to build-up your

grip puller. The numbers in illustration 5 correspond

with the parts numbered in table A on page 7.

4.2 Cross bearing pullers

Illustration 6 on page 8 shows how to build-up your

cross bearing puller. The numbers in illustration 6

correspond with the parts numbered in table B on

page 9.

4.3 Internal pullers

Illustration 7 on page 8 shows how to build-up your

internal puller. The numbers in illustr. 7 correspond

with the parts numbered in table B on page 9.

Page 3

5.0 OPERATION

IMPORTANT: It is mandatory that the

operator has a full understanding of all

instructions, safety regulations, cautions

and warnings, before starting to operate

any of this high force tool equipment. When in doubt,

contact Enerpac.

5.1 Advancing and retracting the cylinder

All BHP Puller Sets are equipped with a singleacting, spring return cylinder and a handpump. For

complete operating instructions refer to the instruc tion sheet included with each pump and cylinder.

Handpumps to operate single-acting cylinders are

equipped with a release valve to release pressure.

Close the release valve, raise and lower the pump

handle to advance the cylinder. To retract the

cylinder, open the release valve.

5.2 Air removal

Advance and retract the cylinder several times

avoiding pressure build-up. Air removal is complete

when the cylinder motion is smooth.

5.3 Using grip pullers

Build up your application as shown in illustr. 1 below

and illustration 5 on page 6. Remember that the triple

grip puller provides a more stable and secure grip,

with a more even pulling force than the double grip

puller. Do not exceed 50% of the rated puller capacity

with a double grip puller. Start pumping and apply

hydraulic pressure gradually to remove the part.

5.4 Using bearing cup puller

Build up your application as shown in illustration 2

with the internal grip puller. See also illustr. 7 page 8.

Align puller legs and arms and apply hydraulic

pressure gradually to remove the part.

5.5 Using cross bearing pullers

To pull: The cylinder must be positioned above the

slotted crosshead. Align puller legs and adjusting

screw and apply hydraulic pressure gradually to

remove the part.

To push: Build up the application as shown in

illustration 3. Notice that the cylinder must be

positioned under the slotted crosshead. Align puller

legs and adjusting screw and apply hydraulic

pressure gradually to remove the part.

3

illustration 1 - Grip Pullers

Removing pulley with

2-jaw grip puller

(double crosshead)

Do not exceed

50% of rated

capacity.

Removing pulley with

3-jaw grip puller

(triple crosshead)

illustration 2 - Cross head puller with bearing cup

puller attachment

Do not

exceed

50% of

rated capacity.

illustration 3 - Pushing with cross bearing puller

Do not

exceed

50% of

rated capacity.

Page 4

5.6 Using bearing puller attachment

The bearing puller attachment can be used in

combination with the crosshead puller shown in the

illustration 4 below and illustration 6 on page 8.

6.0 MAINTENANCE AND SERVICE

Maintenance is required when wear or leakage is

noticed. Periodically inspect all components to detect

any problem requiring service and maintenance.

Enerpac offers ready-to-use spare parts kits for

repair and/or replacements. Contact Enerpac.

IMPORTANT: Hydraulic equipment must

be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized Enerpac Service Center in

your area.

• Periodically inspect all components to detect any

problem requiring maintenance and service.

Replace damaged parts immediately.

•

Do not exceed oil temperature of 60˚C [140˚F]

.

• Keep all hydraulic components clean.

• Keep your pulling equipment in shape. Clean and

lubricate the puller’s adjusting screw and puller

legs frequently, from thread to tip, to ensure good

operation and long life.

• Periodically check the hydraulic system for loose

connections and leaks.

• Change hydraulic oil in your system as recom mended in the pump instruction sheet.

illustration 4 - Bearing puller attachment with

Crosshead Puller

Do not

exceed

50% of

rated capacity.

4

Page 5

5

Note: See pages 6 through 12 for repair parts lists and diagrams.

Hinweis: Siehe Seiten 6 bis 12 für Ersatzteillisten und Schemata.

Nota: Véanse las páginas 6-12 para las listas de piezas de recambio y diagramas.

Remarque : Voir les pages 6 -12 pour les listes des pièces de rechange et les schémas.

Nota: Per consultare i diagrammi e gli elenchi dei pezzi di ricambio, fare riferimento alle

pagine 6 - 12.

N.B.: Zie pagina's 6 tot en met 12 voor reparatielijsten en schema's.

Замечание: См. стр. 6-12 для запасных частей и схем.

Repair Parts Sheet

BHP Puller Sets

and Attachments

Page 6

illustration 5 - How to set up a Grip Puller. Numbers

correspond with table A on page 7.

figure 5 - Comment assembler un extracteur à griffes.

Les números correspondent à ceux de la table A page 7.

Abbildung 5 - Montieren der Abzugsätze.

Die Zahlen stimmen mit Tabelle A auf Seite 7 überein.

figura 5 - Come montare un estrattore a griffe. I numeri

corrispondono con quelli della tabella A a pagina 7.

ilustración 5 - Modo de colocación de un extractor de

garras. Los números corresponden con el cuadro A en la

página 7.

illustratie 5 - Opbouwen van Trekkersets met trekarmen.

De nummers komen overeen met tabel A op bladzijde 7.

Рис. 5. Сборка зажимного съемника. Числа на

рисунке соответствуют числам в таблице A (стр. 7).

2 grip arms

Tête à 2 griffes

Kreuzkopf 2-armig

Traversa 2 griffe

Cruceta doble

2-armig juk

Зажим с 2 лапами

3 grip arms

Tête à 3 griffes

Kreuzkopf 3-armig

Traversa 3 griffe

Cruceta triple

3-armig juk

Зажим с 3

лапами

6

Цилиндр

RWH или

RCH

RWH

or

RCH

Cyl.

12

2

3-4

15

13+14

19

17

Page 7

7

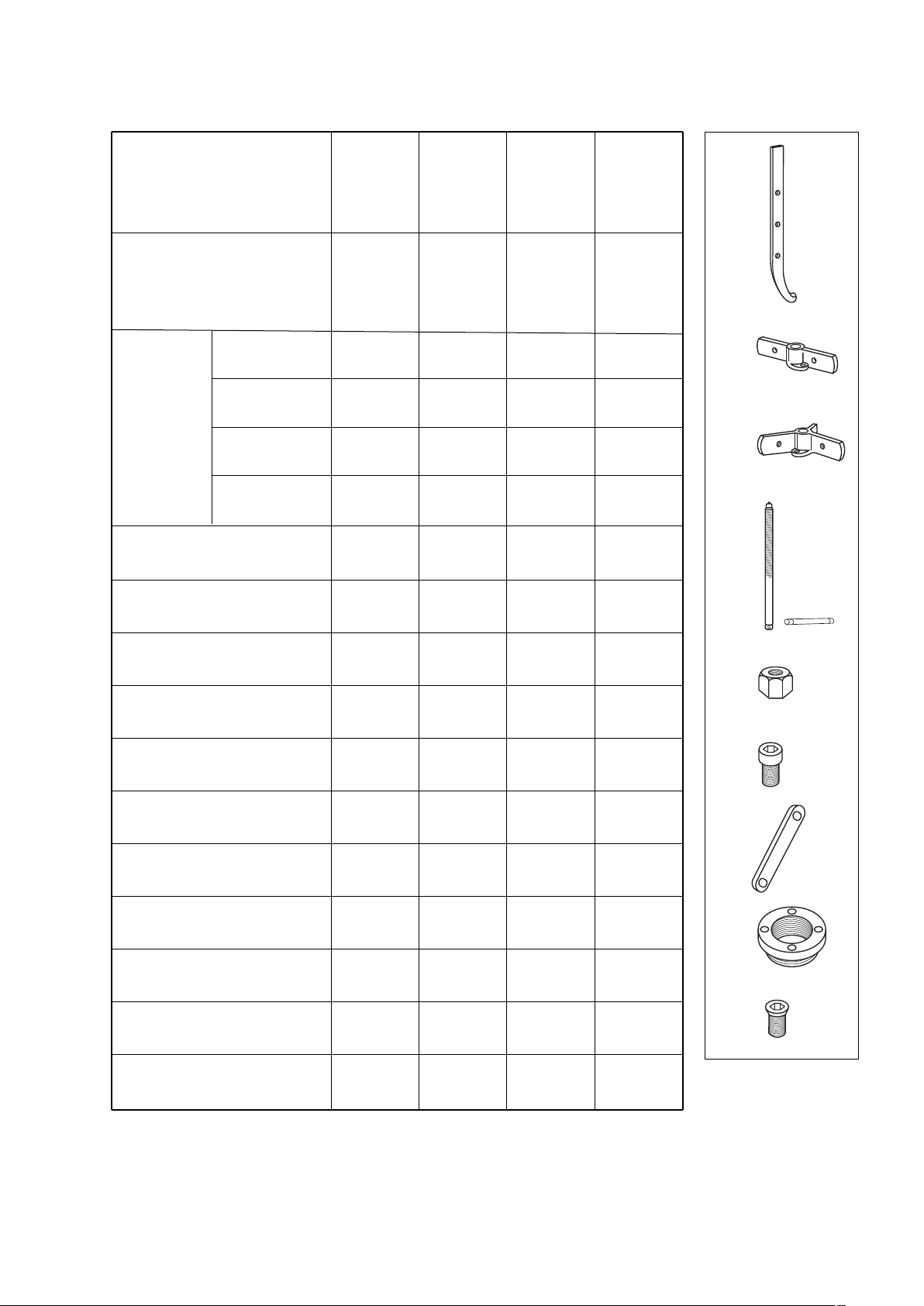

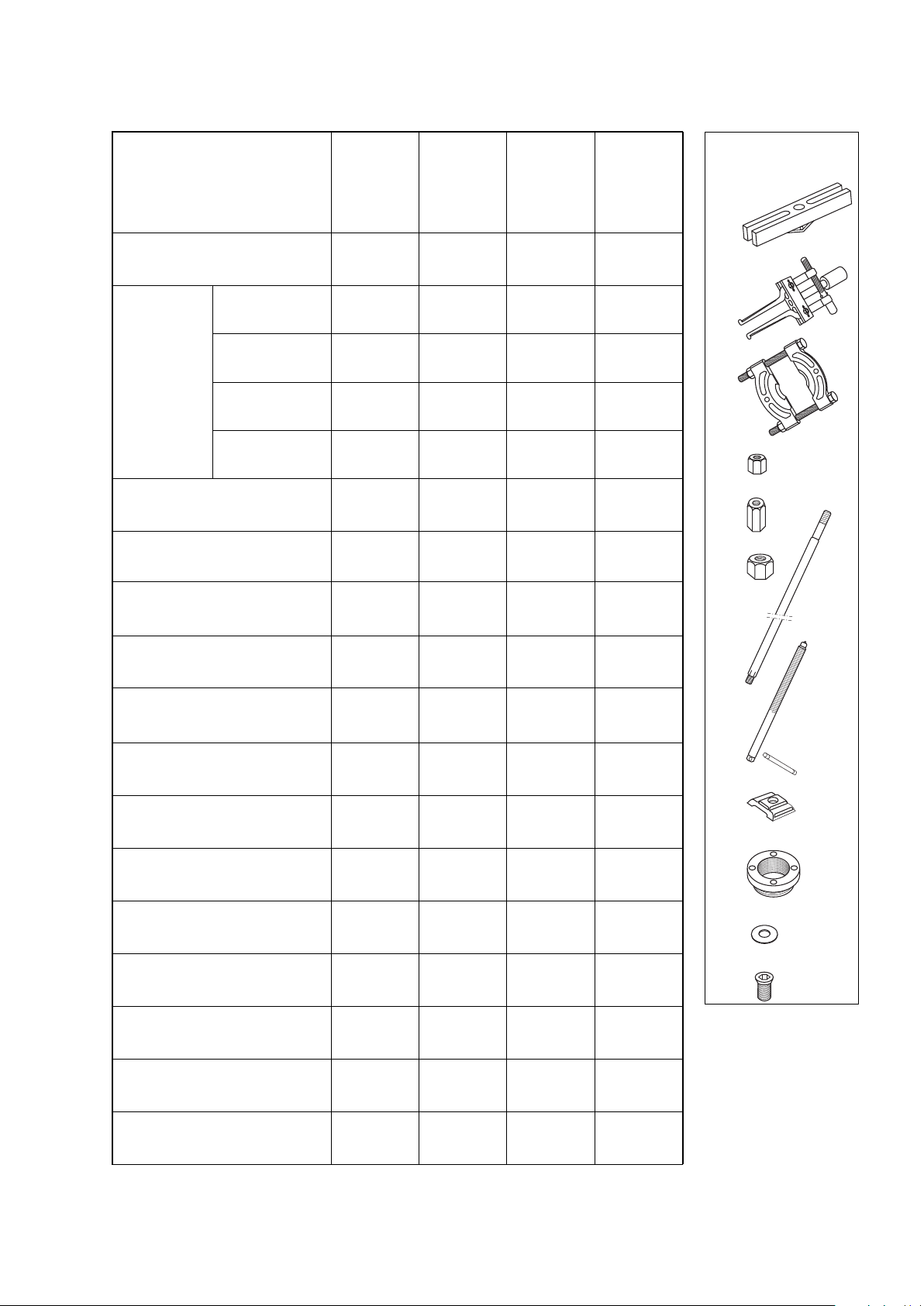

Model Number - Grip Puller Sets

BHP-152

Cyl. Adapter

1

2

Grip Arms

3

Double Crosshead

4

Triple Crosshead

12

Adjusting Rod

13

Strap Nut Kit

(Includes 6 nuts)

14

Strap Screw Kit

(includes 6 screws)

15

Straps

17

Threaded Saddle

Mounting Screw Kit

(includes 2 screws)

Weight / Poids

Pump

Cylinder

Gauge

Hose

Hydraulic

Components

2

4

12

13

14

15

17

3

19

TABLE A - INDIVIDUAL COMPONENTS OF GRIP PULLER SETS

8 ton

P-142

RWH-121

GF-120P (US)

GF-120B (Eur)

+ GA-4

1)

HB-7206QB

HC-7206

BHP-251G

20 ton

P-392

RCH-202

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

BHP-351G

30 ton

P-392

RCH-302

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

BHP-551G

50 ton

P-80

RCH-603

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

--

HP-1125 (3x) HP-2125 (3x) HP-3125 (3x) HP-5125 (3x)

--

HP-2120

HP-3120

HP-5120

HP-1130 HP-2130 HP-3130 HP-5130

HP-1111 HP-2111 HP-3111 HP-5111

HP-1123 HP-2023 HP-3123 HP-5023

HP-1122 HP-2122 HP-3122 HP-5122

HP-1121 (6x) HP-2121 (6x) HP-3121 (6x) HP-5121 (6x)

-- HP-2015 HP-3015 HP-5016

HP-1120 HP-2213 HP-2013 HP-5013

22 kg

48 lbs

56 kg

123 lbs

91 kg

200 lbs

160 kg

353 lbs

1) GA = Gauge Adaptor

19

Maximum Capacity

HC-7206 HC-7206

-- -- --

Note: Refer to

Illustration 5

(page 6)

Page 8

8

illustration 7 - How to set up a Internal Puller. Numbers

correspond with table B on page 9

figure 7 - Comment assembler un extracteur intérieur.

Les números correspondent à ceux de la table B page 9.

Abbildung 7 - Montieren der Lagerschalen abzieher. Die

Zahlen stimmen mit Tabelle B auf Seite 9 überein.

figura 7 - Come montare un estrattore per interni. I

numeri corrispondono con quelli della tabella B a pagina

9.

ilustración 7 - Modo de colocación de un extractor

interior. Los números corresponden con el cuadro B en la

páguina 9.

illustratie 7 - Opbouwen van inwendige lagertrekkers. De

nummers komen overeen met tabel B op bladzijde 9 .

Рис. 7. Сборка съемника с внутренним захватом

Числа на рисунке соответствуют числам в таблице B

(стр. 9).

illustration 6 - How to set up a Cross Bearing Puller.

Numbers correspond with table B on page 9

figure 6 - Comment assembler un extracteur à tirants.

Les números correspondent à ceux de la table B page 9.

Abbildung 6 - Montieren der Jochabzieher.

Die Zahlen stimmen mit Tabelle B auf Seite 9 überein.

figura 6 - Come montare un estrattore a tiranti. I numeri

corrispondono con quelli della tabella B a pagina 9.

ilustración 6 - Modo de colocación de un extractor de

cojinetes. Los números corresponden con el cuadro B en

la página 9.

illustratie 6 - Opbouwen van brugstuk-lagertrekkers. De

nummers komen overeen met tabel B op bladzijde 9.

Рис. 6. Сборка съемника-хомута. Числа на рисунке

соответствуют числам в таблице B (стр. 9).

RWH или

RCH

Цилиндр

RWH / RHC

Цилиндр

12

10

16

18

11

7

17

RWH

or

RCH

12

Cylinder

9

10

16

20

5

5

18

20

17

11

RWH / RCH

Cylinder

6

8

Page 9

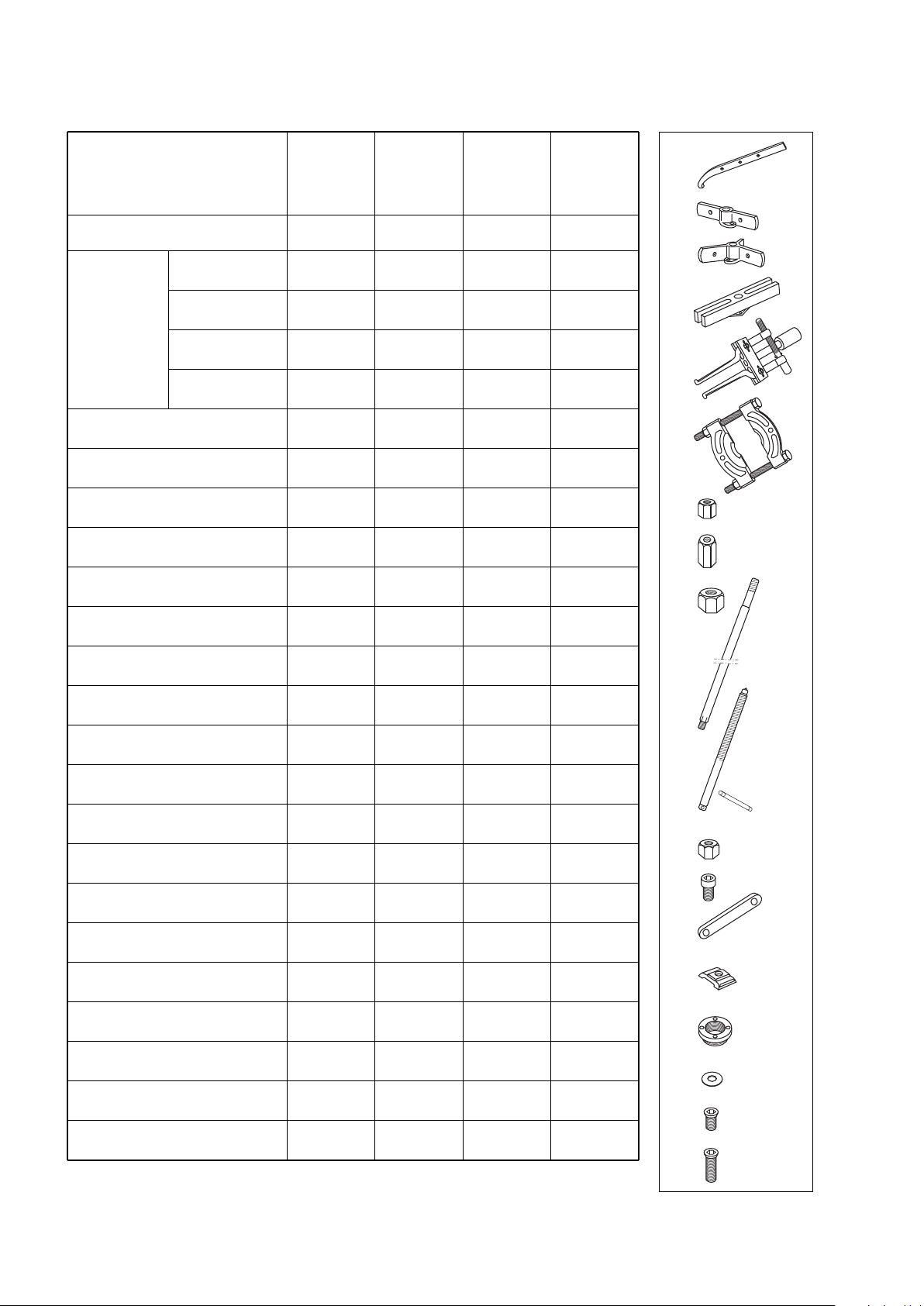

9

Max. Capacity

Cross-Bearing Puller Sets BHP-162

Weight

5

Slotted Crosshead

8

Leg End Kit

(includes 2 leg ends)

9

Leg Reducer Kit

(includes 4 reducers)

Leg Nut Kit

(includes 2 nuts)

11

Leg

2)

12

Adjusting Rod

16

Slide Plate

17

Threaded Saddle

18

20

Washer Kit

(includes 2 washers)

Mounting Screw Kit

(includes 2 screws)

6

Bearing Cup Pull.

Pump

Cylinder

Gauge

Hose

Hydraulic

Components

TABLE B - INDIVIDUAL COMPONENTS OF CROSS-BEARING PULLER SETS

8 ton

P-142

RWH-121

GF-120P (US)

GF-120B (Eur)

+ GA-4

1)

HB-7206QB

HC-7206 HC-7206 HC-7206

BHP-261G

20 ton

P-392

RCH-202

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

BHP-361G

30 ton

P-392

RCH-302

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

BHP-561G

50 ton

P-80

RCH-603

GF-813P (US)

GF-813 (Eur)

+ GA-3

1)

26 kg

57 lbs

62 kg

164 lbs

121 kg

267 lbs

185 kg

408 lbs

HP-1103 HP-2103 HP-3104 HP-5103

HP-2009 HP-2009 HP-3039 --

HP-2031 HP-2031 HP-3041 --

HP-2001 HP-2001 HP-3031 HP-5001

HP-1136 (2x)

HP-1137 (2x)

HP-2006 (2x)

HP-2007 (2x)

HP-2008 (2x)

HP-2012 (2x)

HP-3036 (2x)

HP-3037 (2x)

HP-3038 (2x)

HP-5007 (2x)

HP-5008 (2x)

HP-1111 HP-2111 HP-3111 HP-5111

HP-1105 (2x) HP-2105 (2x) HP-3135 (2x) HP-5102 (2x)

-- HP-2015 HP-3015 HP-5016

HP-1102 HP-2002 HP-3032 HP-5132

HP-1213

BHP-180 BHP-280 BHP-380 BHP-580

7

Bearing Puller BHP-181 BHP-282 BHP-382 BHP-582

HP-2213 HP-3113 HP-5113

1) GA = Gauge Adaptor 2) See Leg Lengths table on page 11 for additional information.

10

Note: Refer to

Illustration 6 or 7

(page 8)

5

6

7

8

9

10

11

12

16

17

18

20

Page 10

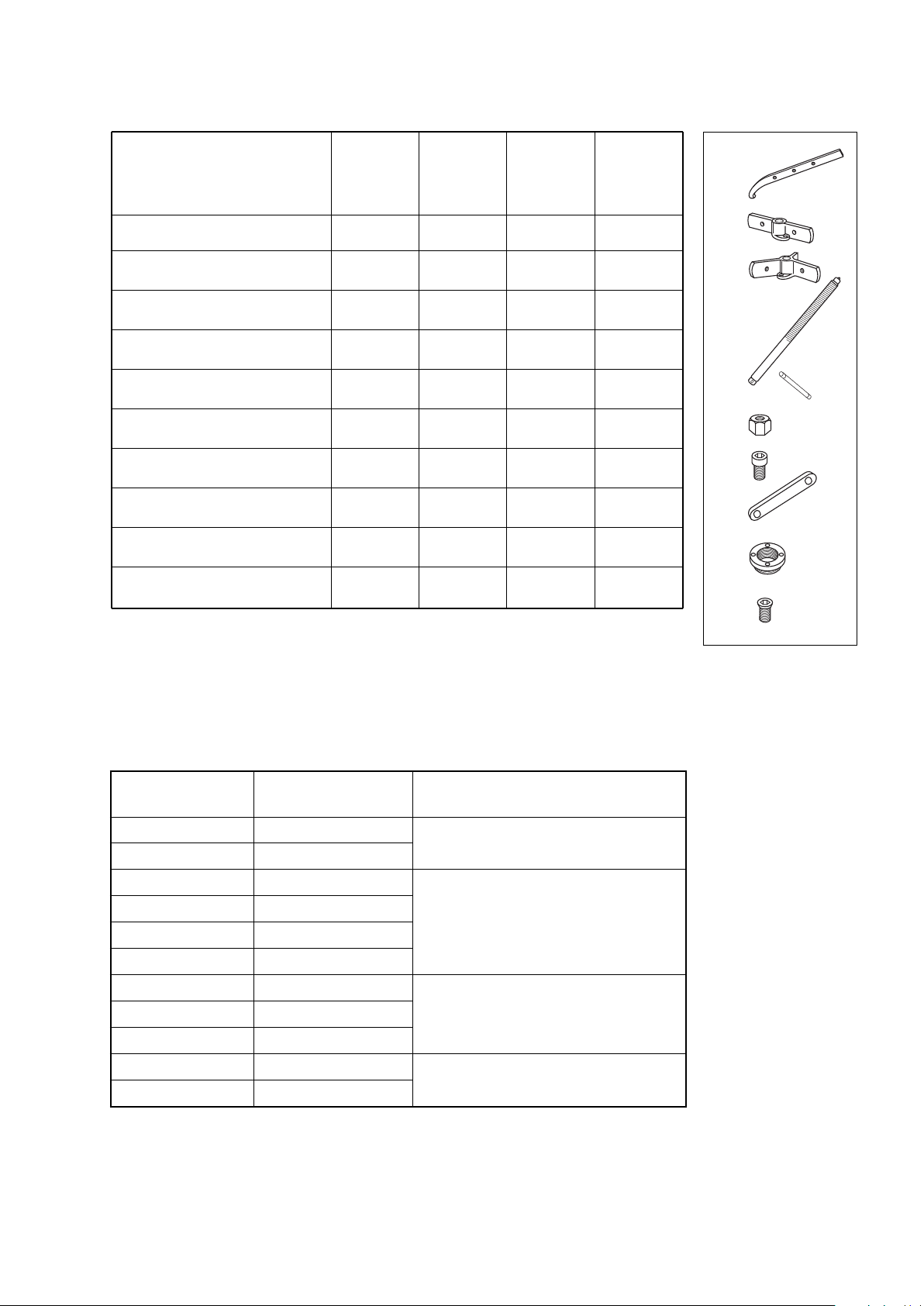

10

8

9

12

13

10

11

17

16

18

2

4

5

6

7

14

15

3

19

20

Capacity

Multi-Purpose Puller Sets

BHP-1752

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Pump

Cylinder

Gauge

Hose

Hydraulic

Components

TABLE C - INDIVIDUAL COMPONENTS OF MULTI-PURPOSE PULLER SETS

8 ton

P-142

RWH-121

HB-7206QB

HC-7206 HC-7206 HC-7206

BHP-2751G

20 ton

P-392

RCH-202

BHP-3751G

30 ton

P-392

RCH-302

BHP-5751G

50 ton

P-80

RCH-603

Grip Arms

HP-1125 (3x) HP-2125 (3x) HP-3125 (3x) HP-5125 (3x)

Double Crosshead

-- HP-2120 HP-3120 HP-5120

Triple Crosshead

HP-1130 HP-2130 HP-3130 HP-5130

Slotted Crosshead

HP-1103 HP-2103 HP-3104 HP-5103

Bearing Cup Pull.

BHP-180 BHP-280 BHP-380 BHP-580

Bearing Puller

BHP-181 BHP-282 BHP-382 BHP-582

Leg End Kit

(includes 2 leg ends)

HP-2009 HP-2009 HP-3039 --

Leg Reducer Kit

(includes 4 reducers)

HP-2031 HP-2031 HP-3041 --

Leg Nut Kit

(includes 2 nuts)

HP-2001 HP-2001 HP-3031 HP-5001

Leg

2)

HP-1136 (2x)

HP-1137 (2x)

HP-2006 (2x)

HP-2007 (2x)

HP-2008 (2x)

HP-2012 (2x)

HP-3036 (2x)

HP-3037 (2x)

HP-3038 (2x)

HP-5007 (2x)

HP-5008 (2x)

Adjusting Rod

HP-1111 HP-2111 HP-3111 HP-5111

Strap Nut Kit

(includes 6 nuts)

HP-1123 HP-2023 HP-3123 HP-5023

Strap Screw Kit

(includes 6 screws)

HP-1122 HP-2122 HP-3122 HP-5122

Straps

HP-1121 (6x) HP-2121 (6x) HP-3121 (6x) HP-5121 (6x)

Slide Plate

HP-1105 (2x) HP-2105 (2x) HP-3135 (2x) HP-5102 (2x)

Threaded Saddle

-- HP-2015 HP-3015 HP-5016

Washer Kit

(includes 2 washers)

HP-1102 HP-2002 HP-3032 --

Short Mounting Screw Kit

(includes 2 screws)

HP-1213

HP-2113 HP-2013 HP-5013

1) GA = Gauge Adaptor 2) See Leg Lengths table on page 11 for additional information.

20

Long Mounting Screw Kit

(includes 2 screws)

HP-2213 HP-3113 HP-5113

HP-1120

GF-120P (US)

GF-120B (Eur)

+ GA-4

1)

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

GF-813P (US)

GF-813B (Eur)

+ GA-3

1)

GF-813P (US)

GF-813 B (Eur)

+ GA-3

1)

Note: Refer to

Illustration 5 (page 6) or

illustrations 6 & 7 (page 8)

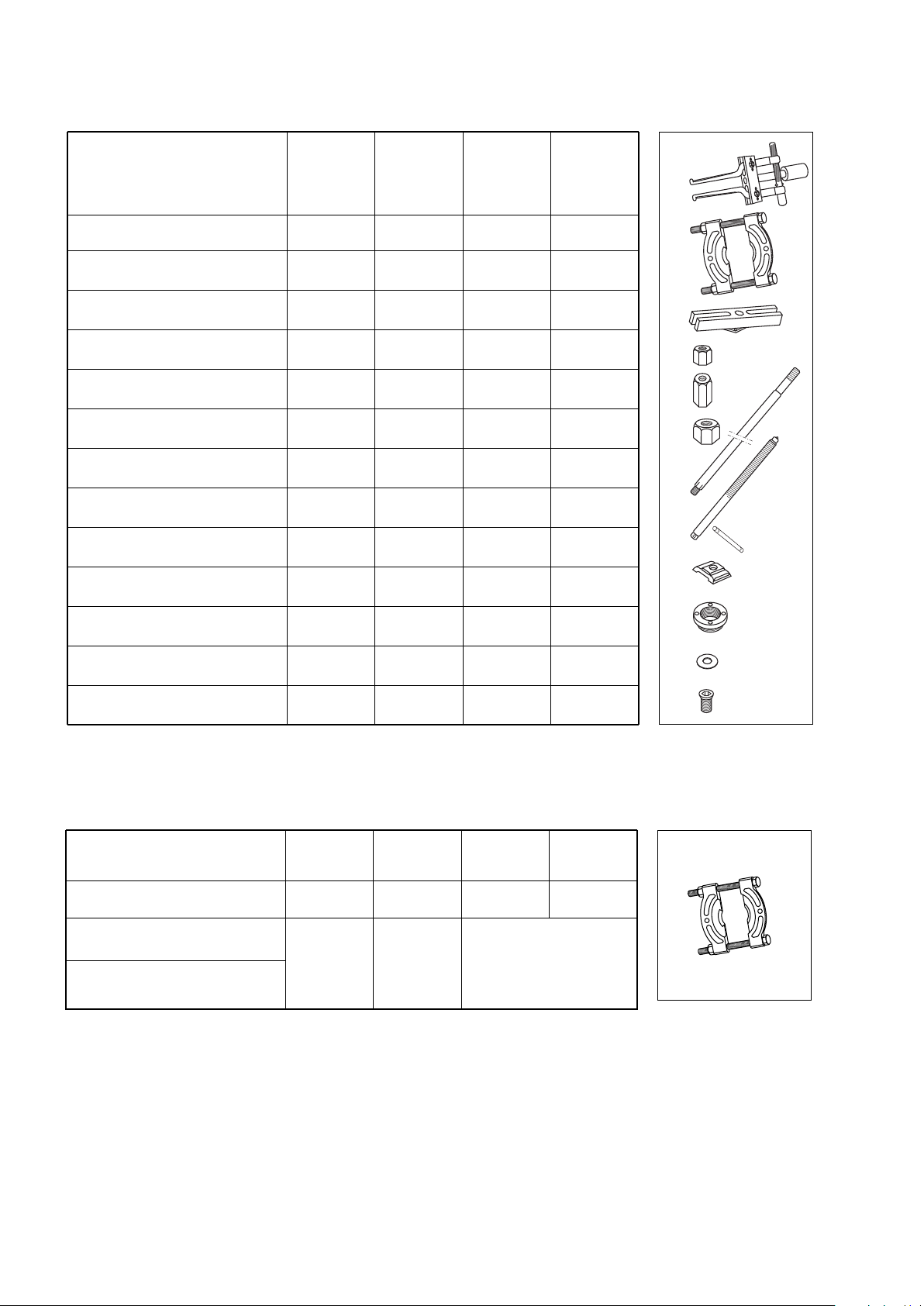

Page 11

11

12

13

17

19

2

4

14

15

3

Capacity

Grip Puller Attachments

BHP-1762

TABLE D - INDIVIDUAL COMPONENTS OF GRIP PULLER ATTACHMENTS

8 ton

BHP-252

20 ton

BHP-352

30 ton

BHP-552

50 ton

2

3

4

Grip Arms

HP-1125 (3x) HP-2125 (3x) HP-3125 (3x) HP-5125 (3x)

Double Crosshead

-- HP-2120 HP-3120 HP-5120

Triple Crosshead

HP-1130 HP-2130 HP-3130 HP-5130

12

13

14

15

Adjusting Rod

HP-1111 HP-2111 HP-3111 HP-5111

Strap Nut Kit

(includes 6 nuts)

HP-1123 HP-2023 HP-3123 HP-5023

Strap Screw Kit

(includes 6 screws)

HP-1122 HP-2122 HP-3122 HP-5122

Straps

HP-1121 (6x) HP-2121 (6x) HP-3121 (6x) HP-5121 (6x)

17

Threaded Saddle

-- HP-2015 HP-3015 HP-5016

19

Mounting Screw Kit

(includes 2 screws)

HP-1120 HP-2213 HP-2013 HP-5013

LEG LENGTHS (See item #11, tables B, C and E)

Leg Part Number

Leg Length

inch [mm]

Used on Puller Models:

HP-1136 4.2 [106]

BHP162, BHP-1752, BHP-1772

HP-1137 14.1 [357]

HP-2006 9.4 [240]

BHP-261G, BHP-2751G, BHP-262

HP-2007 16.5 [420]

HP-2008 22.4 [570]

HP-2012 4.5 [115]

HP-3036 8.0 [204]

BHP-361G, BHP-3751G, BHP-362HP-3037 18.1 [18.1]

HP-3038 28.0 [710]

HP-5007 24.0 [608.5]

BHP-561G, BHP-5751G, BHP-362

HP-5008 34.0 [863.5]

Note: Refer to

Illustration 5

(page 6)

Page 12

12

Capacity

Puller Set Attachments

BHP-1772

TABLE E - INDIVIDUAL COMPONENTS OF PULLER SETS ATTACHMENTS

8 ton

BHP-262

20 ton

BHP-362

30 ton

BHP-562

50 ton

6

7

Bearing Cup Pull.

BHP-180 BHP-280 BHP-380 BHP-580

Bearing Puller.

BHP-181 BHP-282 BHP-382 BHP-582

5

Slotted Crosshead

HP-1103 HP-2103 HP-3104 HP-5103

8

9

10

11

Leg End Kit

(includes 2 leg ends)

HP-2009 HP-2009 HP-3039 --

Leg Reducer Kit

(includes 4 leg ends)

HP-2031 HP-2031 HP-3041 --

Leg Nut Kit

(includes 2 nuts)

HP-2001 HP-2001 HP-3031 HP-5001

Leg

1)

HP-1136 (2x)

HP-1137 (2x)

HP-2006 (2x)

HP-2007 (2x)

HP-2008 (2x)

HP-2012 (2x)

HP-3036 (2x)

HP-3037 (2x)

HP-3038 (2x)

HP-5007 (2x)

HP-5008 (2x)

12

Adjusting Rod

HP-1111 HP-2111 HP-3111 HP-5111

16

17

18

20

Slide Plate

HP-1105 (2x) HP-2105 (2x) HP-3135 (2x) HP-5102 (2x)

Threaded Saddle

-- HP-2015 HP-3015 HP-5016

Washer Kit

(includes 2 washers)

HP-1102 HP-2002 HP-3032 --

Mounting Screw Kit

(includes 2 screws)

HP-1213 HP-2113 HP-3113 HP-5113

Bearing Puller BHP-181 BHP-282 BHP-382 BHP-582

Capacity 8 ton 20 ton 30 ton 50 ton

Rod

BHP181K BHP282K BHP582K

Rod Nut

TABLE F - INDIVIDUAL COMPONENTS OF BEARING PULLER

Refer to Illustration

6 or 7 (page 8)

1) See Leg Lengths table on page 11 for additional information.

6

7

5

8

9

10

11

12

16

17

18

20

Page 13

13

Notice d’Emploi et

Liste de pièces

Extracteurs BHP

et accessoires

EIS 65.100-1 05/14 Rev. F

1.0 INSTRUCTIONS IMPORTANTES LORS DE LA

RECEPTION

Inspecter visuellement tous les composants afin de

détecter d’éventuels dommages causés pendant le

tran sport. Les dommages causés pendant le trans port ne sont pas couverts par la garantie. S’il y a des

degats matériels en avertir immédiatement le trans porteur. Le transporteur est responsable pour tous

les frais de réparation et de remplacement qui résul teraient de dommages causés pendant le transport.

SECURITE D’ABORD

Lire attentivement toutes les instructions, les infor mations marquées ”avertissement” et “attention”.

Pour éviter les blessures et la détérioration du

matériel pendant l’utilisation du système, suivre

toutes les recommandations pour la sécurité.

Enerpac ne peut être tenu responsable en cas de

blessures et de détériorations qui résulteraient d’une

manipulation dangereuse du produit, d’un manque

de maintenance ou d’une utilisation incorrecte du

produit et/ou du système. En cas de doute

concernant les précautions recommandées ou les

applications, contacter Enerpac. POUR

BENEFICIER DE VOTRE GARANTIE, N’UTILISER

QUE DE L’HUILE HYDRAULIQUE ENERPAC.

2.0 DESCRIPTION DU PRODUIT

Les extracteurs Enerpac de la série BHP sont

composés essentiellement d'une pompe à main, d'un

vérin simple effet, d'un manomètre, d’un adaptateur

manomètre, d'un flexible, de raccords rapides,

d'outils spécifiques et d'accessoires.

Les extracteurs sont conçus pour monter ou

démonter toutes les pièces montées à la presse ou à

chaud telles engrenages, poulies, roues,

roulements, manchons, pignons, axes et autres

pièces récalcitrantes.

Les extracteurs Enerpac de la série BHP sont

disponibles en divers ensembles: extracteur à griffes

(voir paragraphe 2.1), extracteur à tirants (voir

paragraphe 2.2) et extracteur universel (voir

paragraphe 2.3).

En option, des jeux d'accessoires permettent

d'augmenter la souplesse d'exécution du travail lors

de l'utilisation des extracteurs à griffes et des

extracteurs à tirants. Pour les composants des

accessoires pour extracteurs voir les tables D et E

pages 11 et 12.

2.1 Ensembles extracteur à griffes

Les ensembles extracteur à griffes BHP-152,

BHP-251G, BHP-351G et BHP-551G s'utilisent pour

enlever et installer engrenages, roulements, poulies

et autres pièces similaires. Voir fig.1 page 15: les

extracteurs à griffes peuvent s'utiliser avec une tête à

2 griffes ou une tête à 3 griffes. Pour les composants

voir table A page 7.

2.2 Ensembles extracteur à tirants

Les ensembles extracteur à tirants BHP-162,

BHP-261G, BHP-361G et BHP-561G s'utilisent pour

enlever et installer engrenages, poulies, manchons

et douilles. Ces extracteurs peuvent également

s'utiliser pour extraire les roulements par leur cage

intérieure (au moyen de l'extracteur intérieur) comme

indiqué fig.2 page 15 ou avec un collier extracteur

voir fig.3 page 15.

Lorsque l'absence d'espace libre empêche une

utilisation directe des griffes de l'extracteur, il est

possible d'utiliser l'extracteur en combinaison avec

l'accessoire collier extracteur comme illustré fig.4

page 16. Les colliers extracteurs ont les bords

biseautés pour permettre de placer les griffes de

l'extracteur derrière l'engrenage ou le palier difficile à

atteindre. Voir les composants table B page 9.

2.3 Ensembles extracteur universel

Les ensembles extracteur universel BHP-1752,

BHP-2751G, BHP-3751G et BHP-5751G sont une

combinaison de l'ensemble extracteur à griffes et de

l'ensemble extracteur à tirants cités ci-dessus, ils

permettent un maximum de souplesse en matière de

dépose et de remontage dans les opérations de

maintenance et de réparations. Voir les composants

table C page 10.

Page 14

14

3.0 MESURES GENERALES DE SECURITE

L’inobservation des mesures de sécurité et des

mises en garde peuvent entraîner la détérioration du

matériel et occasionner des dommages corporels.

AVERTISSEMENT: NE PAS dépasser

50% de la capacité nominale de

l'extracteur lorsque ce dernier est

utilisé avec une tête à deux griffes, et

ne pas dépasser 350 bars (5,000 psi) de pression

lorsque l'extracteur hydraulique est utilisé dans

cette application.

AVERTISSEMENT: NE PAS dépasser

50% de la capacité nominale de

l'extracteur lorsque les tirants sont

utilisés en combinaison avec

l'accessoire collier extracteur, et ne pas dépasser

350 bars de pression (5,000 psi) lorsque

l'extracteur hydraulique est utilisé dans cette

application.

IMPORTANT: Il est recommandé d'utiliser

la tête à trois griffes, elle permet une prise

plus sûre, une répartition plus égale de la

force de traction et est plus stable que la

tête à deux griffes.

AVERTISSEMENT: Pour éviter les

blessures et une possible détérioration de

l’équipement, s’assurer que tous les

composants hydrauliques sont capables

de résister à une pression de travail de 700 bars

(10,000 psi).

IMPORTANT: Installer des manomètres

dans chaque système hydraulique pour

pouvoir contrôler et ne pas dépasser les

charges admises pour travailler en toute

sécurité.

AVERTISSEMENT: S’assurer que tous

les composants du système sont à l’abri

d’influences extérieures telles

échauffement excessif, flamme, partie

mobile d’une machine, bord coupant, produit

chimique corrosif, pouvant causer des détériorations.

PRECAUTION A PRENDRE: Afin d’éviter

des contraintes et des surpressions dans

les circuits, éviter les courbures à rayon

faible ainsi que les torsions sur les

flexibles. Ces conditions d’utilisation entraînent une

usure prématurée des tuyauteries.

AVERTISSEMENT: Ne pas toucher aux

flexible sous pression. En cas de fuite,

l’huile sous pression peut pénétrér la

peau, causant des blessures graves. En

cas d’injection d’huile sous la peau, consulter

immédiatement un médecin.

AVERTISSEMENT: L'utilisateur doit se

prémunir contre les blessures que

pourraient provoquer des débris projetés

lors de la casse de l'outil ou de la pièce.

AVERTISSEMENT: NE PAS utiliser cet

équipement dans des circonstances où

une chute de pression soudaine pourrait

provoquer une perte d'équilibre source de

détérioration ou de blessure.

AVERTISSEMENT: NE PAS surcharger

l'équipement. Utiliser l'extracteur de

capacité adéquate. Si après avoir

appliqué la force maximale la pièce ne

bouge pas, utiliser un extracteur de plus grande

capacité. Ne pas exercer de chocs répétés.

IMPORTANT: Il est impossible de prevoir

la force d'extraction exacte nécessaire

dans chaque situation. Elle peut varier

grandement d'un travail à l'autre. Les

configurations du montage ainsi que la dimension, la

forme et l'état de la pièce à extraire sont variables et

doivent être prises en considération. Etudier chaque

application avant de sélectionner l'extracteur.

IMPORTANT: Appliquer la force

graduellement. Aligner les tirants et les

griffes de l'extracteur. S'assurer de la

rigidité du montage, l'extracteur doit être

d'équerre avec la pièce.

AVERTISSEMENT: Remplacer immédia -

te ment les pièces usées ou endomma -

gées par des pièces d'origine Enerpac.

Les pièces de qualité ordinaire casseront

et seront cause de détériorations et de blessures.

Les pièces Enerpac sont conçues pour s'adapter

parfaitement et pour résister aux charges élevées.

4.0 INSTALLATION

4.1 Extracteurs à griffes

La figure 5 page 6 montre comment assembler votre

extracteur à griffes. Les numéros repère de la fig. 5

correspondent aux numéros de pièces de la table A

page 7.

Page 15

15

4.2 Colliers extracteurs

La fig. 6 page 8 montre comment assembler votre

collier extracteur. Les numéros repère de la fig. 6

correspon dent aux numéros de pièce de la table B.

4.3 Extracteurs intérieurs

La figure 7 page 8 montre comment assembler votre

extracteur intérieur. Les numéros repère de la fig. 7

correspondent aux numéros de pièce de la table B.

5.0 OPERATION

IMPORTANT: L’opérateur doit impérati -

ve ment avoir une connaissance complète

de toutes les instructions, règles de

sécurité et des précautions à prendre

avant de commencer à manipuler une partie quel conque de cet équipement de grande puissance. En

cas de doute, contacter Enerpac.

5.1 Avance et retour de la tige du vérin

Tous les ensembles extracteur BHP sont équipés

d'un vérin simple effet, à rappel par ressort, et d'une

pompe à main. Pour les instructions d'utilisation

complètes, voir le feuillet d'instruction fourni avec

chaque pompe et vérin.

Pour actionner les vérins simple effet, les pompes à

main sont munies d'une valve de décharge

permettant de libérer la pression. Fermer la valve de

décharge, actionner le levier de la pompe pour

avancer la tige du vérin. Le retour de la tige du vérin

s'obtient en ouvrant la valve de décharge.

5.2 Désaérer le système

Faire sortir et rentrer la tige du vérin plusieurs fois en

évitant de monter en pression. Lorsque la tige du

vérin se déplace sans discontinuité le système est

désaéré.

5.3 Utilisation des extracteurs à griffes

Monter l'extracteur comme indiqué fig.1 et 5 page 6.

L'extracteur à trois griffes permet une prise plus

stable et plus sûre, une force d'extraction plus

équilibrée, que l'extracteur à deux griffes. Avec un

extracteur à deux griffes ne pas dépasser 50 % de sa

capacité nominale. Commencer à pomper, appliquer

graduellement la pression hydraulique pour enlever

la pièce.

5.4 Utilisation de l'extracteur intérieur

Monter l'extracteur, muni de l'extracteur intérieur,

comme indiqué fig.2 et fig.7 page 8. Positionner les

tirants et les griffes, appliquer graduellement la

pression hydraulique pour enlever la pièce.

5.5 Utilisation de l'extracteur à tirants

Pour tirer: Le vérin doit être placer au dessus de la

tête de l'extracteur. Positionner les tirants et la tige

filetée réglable, appliquer graduellement la pression

hydraulique pour enlever la pièce.

Pour pousser: Monter l'extracteur comme indiqué

figure 3 à page 15. Observer que le vérin doit être

placer sous la tête de l'extracteur. Positionner les

tirants et la tige filetée réglable, appliquer

graduellement la pression hydraulique pour enlever

la pièce.

figure 1 - Extracteurs à griffes

Extraction d’une poulie

avec un extracteur à

2 griffes (tête double)

Ne pas dépasser

50% de la capa cité

nominale.

Extraction d’une poulie

avec un extracteur à

3 griffes (tête triple)

figure 2 - Tête d’extracteur avec accessoire

extracteur intérieur

Ne pas

dépasser

50% de la

capacité

nominale.

figure 3 - Pousser avec l’extracteur à tirants

Ne pas

dépasser

50% de la

capacité

nominale.

Page 16

16

5.6 Utilisation de l'accessoire collier extracteur

L'accessoire collier extracteur peut être utiliser en

combinaison avec l'extracteur à tirants, comme

indiqué figure 4 et figure 6 page 8.

figure 4 - Accessoire collier extracteur

Ne pas

dépasser

50% de la

capacité

nominale.

6.0 MAINTENANCE ET SERVICE

Une opération de maintenance est nécessaire en cas

de fuite d'huile ou d'usure. Il faut inspecter

régulièrement tous les composants pour détecter

toute anomalie nécessitant une intervention de

maintenance ou de service. Enerpac propose des

jeux de pièces de remplaçement ou pour la

réparation. Contacter Enerpac.

IMPORTANT: La maintenance d'un

équipement hydraulique ne doit être

effectuée que par un technicien qualifié.

Pour une réparation, contacter l’atelier

agrée Enerpac de votre région.

• Vérifier périodiquement tous les composants afin

de détecter toute anomalie nécessitant une inter vention de maintenance et de service. Remplacer

immédiatement les pièces endommagées.

• La température de l'huile ne doit pas dépasser

60˚C [140 ˚F].

• Maintenir les composants hydrauliques dans un

état de propreté.

• Veiller à garder votre équipement en bon état.

Nettoyer et lubrifier fréquemment la tige filetée

réglable et les griffes de l'extracteur, du filetage à

l'extrémité, pour obtenir un bon fonctionnement et

une longue durée de vie.

• Inspecter périodiquement le système hydraulique,

à la recherche de fuites éventuelles et de raccords

desserrés.

• Changer l'huile hydraulique du système comme il

est conseillé dans la notice d’emploi de la pompe.

Page 17

17

Bedienungsanleitung

und Ersatzteilliste

BHP Abzugsätze

und Zubehör

EIS 65.100-1 05/14 Rev. F

1.0 WICHTIG FÜR DIE ÜBERNAHME

Alle Bestandteile visuell überprüfen, da Transport schäden nicht in der Garantie enthalten sind. Sollten

Sie Transportschäden feststellen, benachrichtigen

Sie bitte sofort die Speditionsfirma. Diese haftet für

alle Reparatur- und Austauschkosten, die durch eine

Beschädigung während des Transport entstehen.

SICHERHEIT IST OBERSTES GEBOT

Lesen Sie alle Anleitungen, Warnungen und

Vorsichts maßnahmen sorgfältig durch. Befolgen Sie

sämtliche Sicherheitsvorschriften, um Personenoder Sachschäden während des Betriebs zu

vermeiden. Enerpac haftet nicht für Schäden oder

Verletzungen, die durch ungenügende Beachtung

der Sicherheitsvorschriften, unzulängliche Wartung

oder schlechte Produkt- bzw. Systembedienung

entstanden sind. Wenn Sie noch Fragen zu den

Sicherheits- und Anwendungsvorschriften haben,

wenden Sie sich bitte an Enerpac.

AUS GARANTIEGRÜNDEN DARF NUR ENERPAC

HYDRAULIKÖL VERWENDET WERDEN.

2.0. PRODUKTBESCHREIBUNG

Die BHP-Abzugsätze von Enerpac bestehen im

Prinzip aus einer Handpumpe, einem

einfachwirkenden Zylinder, einem Manometer, einem

Manometer-Zwischenstück, einem Schlauch,

Kupplungen, spezifischen Werkzeugen und Zubehör.

Die Abzugsätze sind geeignet für die Installation und

Entfernung aller Druck- und Schweißverbindungen

wie Getriebe, Riemenscheiben, Räder, Kugellager,

Buchsen, Kettenradzähne, Nägel und andere

hartnäckige Teile.

Die BHP-Abzugsätze von Enerpac sind erhältlich als

Abzugsätze mit Zugarmen (siehe Absatz 2.1),

Jochabzugsätze (siehe Absatz 2.2) und UniversalAbzugsätze (siehe Absatz 2.3). Zubehör für

Jochabzugsätze sind zusätzliche Teile, die den

Anwendungsbereich von Abzugsätzen mit Zugarmen

und Jochabzugsätzen vergrößern. Siehe Tabelle D

und E auf Seite 11 und 12 für die einzelnen

Komponenten der Jochabzugsätze.

2.1 Abzugsätze mit Zugarme

BHP-152, BHP-251G, BHP-351G und BHP-551G

sind geeignet für die Entfernung und Installation von

Getrieben, Lagern, Buchsen und ähnlichen Teilen.

Siehe Abbildung 1 auf Seite 19: Abzugsätze mit

Zugarmen können mit zweiarmigem Kreuzkopf (2

Zugarme) oder dreiarmigem Kreuzkopf (3 Zugarmen)

eingesetzt werden. Für einzelne Teile siehe Tabelle

A auf Seite 7.

2.2 Jochabzugsätze

BHP-162, BHP-261G, BHP-361G und BHP-561G

sind geeignet für die Installation und Entfernung von

Getrieben, Riemenscheiben, Buchsen und Muffen.

Sie können ebenfalls als Lagerschachtabzieher

(eingebaute Abzieher) eingesetzt, siehe Abbildung 2

auf Seite 19, oder als Lagerabzieher, siehe

Abbildung 3 auf Seite 19 verwendet werden.

In Situationen, wo der Spielraum die direkte

Anwendung von Abziehern mit Zugarmen verhindert,

kann ein Abzieher in Kombination mit Zubehör für

Jochabzugsätze (siehe Abbildung 4 auf Seite 20)

eingesetzt werden.

Das Zubehör für Jochabzugsätze hat keilförmige

Kanten, damit der Abzieher hinter dem schwer

erreichbaren Getriebe oder Lager plaziert werden

kann. Siehe Tabelle B auf Seite 9 für

Einzelkomponenten.

2.3 Universal-Abzugsätze

BHP-1752, BHP-2751G, BHP-3751G und

BHP-5751G Universal-Abzugsätze sind eine

Kombination der genannten Abzugsätze mit Zug armen und Jochabzugsätzen, die zur Erweiterung

des Anwendungsbereiches im Hinblick auf Zug- und

Preßkraft bei Wartung und Temperaturen beitragen.

Für einzelne Teile siehe Tabelle C auf Seite 10.

3.0 ALLGEMEINE SICHERHEITSVORSCHRIFTEN

Die Nichtbeachtung folgender Vorsichtsmaßnahmen

und Warnungen kann Materialschäden oder

Verletzungen von Personen zur Folge haben.

WARNUNG: Überschreiten Sie niemals

50% der Nominalleistung des

Zylinders, wenn Sie einen zweiarmigen

Page 18

18

Kreuzkopf (2 Zugarme) verwenden. Über schreiten Sie niemals 350 bar, wenn Sie einen

hydraulischen Abzieher verwenden.

WARNUNG: Überschreiten Sie niemals

50% der Nominalleistung des

Zylinders, wenn Sie die Zugarme in

Kombination mit Zubehör für

Lagerabzieher verwenden. Überschreiten Sie

niemals 350 bar, wenn Sie einen Hydraulik abzieher verwenden.

WICHTIG: Es empfiehlt sich, für einen

sichereren Griff und eine größere Zugkraft

einen dreiarmigen Kreuzkopf (drei

Zugarme) zu benutzen . Außerdem ist er

stabiler als der zweiarmige Kreuzkopf mit zwei

Zugarmen.

WARNUNG: Vergewissern Sie sich, daß

alle hydraulischen Komponenten einem

Höchstdruck von 700 bar standhalten

können. Andernfalls könnten Personen

und Geräteschaden die Folge sein.

WICHTIG: Benutzen Sie in Jedem

hydraulischen System Hydraulik-

Manometer. Dies ermöglicht eine

Kontrolle des Hydrauliksystems und zeigt

die Abläufe an.

WARNUNG: Vergewissern Sie sich, daß

alle Systemkomponenten vor äußeren

Schadenquellen geschützt sind, wie z.B.

übermäßige Hitze, Feuer, bewegende

Maschinenteile, scharfe Kanten und korrosive

Chemikalien.

VORSICHT: Hydraulikschläuche niemals

knicken. Niemals über die Schläuche

fahren und schwere Gegenstände auf die

Schläuche fallen lassen.

VORSICHT: Keine Schläuche anfassen,

die unter Druck stehen.

Öl, das unter

Druck ausspritzt, kann die Haut

durchdringen und schwere Verletzungen

verursachen. Falls Öl unter die Haut gelangt, sofort

eine Arzt befragen.

WARNUNG: Der Bediener muß sich

gegen Verletzungen durch herum fliegende Teile auf Grund fehlerhaften

Funktionierens des Werkzeugs oder des

Materials schützen.

WARNUNG: Benutzen Sie die Geräte

nicht in Situationen, in denen ein

plötzlicher Druckausstoß zu Gleich gewichtsverlust und/oder zu Verletzungen

und Sachschäden führen kann.

WARNUNG: Überlasten Sie die Geräte

nicht. Verwenden Sie den richtigen

Abzieher. Wenn Sie die maximale

Zugkraft eingesetzt haben und sich das

Teil nicht entfernen läßt, müssen Sie einen Abzieher

mit einer höheren Kapazität verwenden. Forcieren

Sie nicht.

WICHTIG: Es ist unmöglich, für jede

Abzugsituation die genaue Zugkraft

einzuschätzen. Die Festigkeit der

Druckverbindungen und die Kraft zur

Entfernung kan pro Arbeit variieren. Montage bedingungen sowie Größe, Umfang und Kondition

der Teile die abgezogen werden müssen, sind

Variablen, die berücksichtigt werden müssen. Unter suchen Sie die Anwendungsmöglichkeiten, bevor Sie

Ihren Abzieher wählen.

WICHTIG: Dosieren Sie die Zugkraft.

Richten Sie Abziehbeine und Zugarme.

Vergewissern Sie sich, daß die

Aufstellung stabil ist und der Abzieher mit

dem Teil übereinstimmt.

WARNUNG: Ersetzen Sie sofort alle

verschlissenen oder beschädigten Teile

mit original Enerpac Ersatzteilen. Andere

Teile würden auseinanderbrechen und

Verletzungen und Sachschäden

verursachen. Die Enerpac Teile passen und können

hohen Belastungen ausgesetzt werden.

4.0 INSTALLATION

4.1 Abzieher

Abbildung 5 auf Seite 6 zeigt, wie der Abzieher

montiert werden muß. Die Zahlen in Abb. 5 stimmen

mit den numerierten Teilen in Tabelle A überein.

4.2 Jochabzugsätze

Abbildung 6 auf Seite 8 zeigt, wie der Jochabzugsatz

montiert werden muß. Die Zahlen in Abbildung 6

stimmen mit den numerierten Teilen in Tabelle B

überein.

4.3 Eingebaute Abzieher

Abbildung 7 auf Seite 8 zeigt, wie der eingebaute

Abzieher montiert werden muß. Die Zahlen in

Abbildung 7 stimmen mit den numerierten Teilen in

Tabelle B überein.

Page 19

19

5.0 BEDIENUNG

WICHTIG: Der Bediener muß alle

Anleitungen, Sicherheitsvorschriften,

Vorsichts maßnahmen und Warnungen

kennen, bevor er eines dieser Hochdruck

Arbeitsgeräte bedient. Setzen Sie sich im Zweifelsfall

mit Enerpac in Verbindung.

5.1 Aus- und Einfahren des Zylinders

Alle BHP-Abzugsätze sind mit einem einfach wirkenden, Federrückzug-Zylinder sowie einer Hand pumpe ausgerüstet. Für vollständige Instruktionen

verweisen wir auf die Bedienungsanleitung, die jeder

Pumpe mitgeliefert wird.

Handpumpen zur Bedienung einfachwirkender

Zylinder besitzen ein Wegeventil zur Betätigung der

Funktionen Ausfahren/Halt/Einfahren. Wird dieses

Ventil auf Ausfahren gestellt und der Pumpengriff

zunächst hochgezogen und dann hinuntergedrückt,

fährt der Zylinder aus. Öffnet man das Ventil, fährt

der Zylinder ein.

5.2 Entlüften des Systems

Fahren Sie den Zylinder mehrmals ohne Last ein und

aus und stellen Sie dabei die Pumpe höher als den

Zylinder. Das System ist entlüftet, wenn der Zylinder

gleichmäßig ein- und ausfährt.

5.3. Die Anwendung von Abzieher

Montieren Sie das Gerät wie in Abb. 1 unten und

Abb. 5 Seite 6 angegeben wird. Der Abzieher mit drei

Armen bietet einen stabileren und sichereren Griff mit

mehr Zugkraft als der Abzieher mit zwei Armen.

Überschreiten Sie mit dem zweiarmigen Abzieher

niemals 50% der geltenden Zugkraftkapazität.

Fangen Sie an zu pumpen und dosieren Sie den

Druck, damit Sie das Teil entfernen können.

5.4 Die Anwendung von Lagerschalenabziehern

Montieren Sie das Gerät wie in Abb. 2 unten und

Abb. 7 Seite 8 mit dem eingebauten Abzieher mit

Zugarmen. Bringen Sie die Zugarme und

Einstellmuttern an und dosieren Sie den Druck zur

Entfernung des Teils.

5.5 Die Anwendung von Jochabziehern

Abziehen: Sorgen Sie dafür, daß sich der Zylinder

über dem Joch befindet. Bringen Sie die Zugarme

und Einstellmuttern an und dosieren Sie den Druck

zur Entfernung des Teils.

Pressen: Montieren Sie das Gerät wie in Abb. 3.

Sorgen Sie dafür, daß sich der Zylinder unter dem

Joch befindet. Bringen Sie die Zugarme und Einstell muttern an und dosieren Sie den Druck zur

Entfernung des Teils.

Abbildung 1 - Abzieher mit Zugarmen

Entfernung der Riemen -

scheibe mit Hilfe eines

Abziehers mit zwei

Klemmbacken

(2-armiger Kreuzkopf)

Überschreiten

Sie niemals 50%

der Nominal leistung.

Entfernung der Riemen -

scheibe mit Hilfe eines

Abziehers mit drei

Klemmbacken

(3-armiger Kreuzkopf)

Abbildung 2 - Kreuzkopfabzieher mit Zubehör des

Lagerschalenabziehers

Über schreiten

Sie niemals

50% der

Nominal leistung

Abbildung 3 - Pressen mit dem Jochabzieher

Über schreiten Sie

niemals 50% der

Nominal leistung

Page 20

20

5.6 Die Anwendung mit dem Lagerabziehvor richtung

Das Zubehör der Lagerabzieher kann eingesetzt

werden in Kombination mit dem Jochabzieher aus

Abbildung 4 unter und Abbildung 6 Seite 8.

Abbildung 4 - Befestigungen für Lagerabzieher mit

Kreuzkopfabzieher

Über schreiten

Sie niemals

50% der

Nominal leistung

6.0 WARTUNG UND SERVICE

Die Wartung ist erforderlich, wenn Verschleiß oder

Leckage festgestellt werden. Kontrollieren Sie

regelmäßig alle Teile, um wartungs- und service bedürftige Teile zu entdecken. Enerpac liefert

gebrauchsfertige Ersatzteil-Ausstattungen für

Reparatur und/oder Auswechslungen. Nehmen Sie

Kontakt mit Enerpac auf.

WICHTIG: Ein hydraulisches Gerät darf

nur von einem qualifizierten Hydraulik techniker gewartet werden. Für Repara tur arbeiten wenden Sie sich bitte an das

zuständige Enerpac Service Center in

Ihrem Bezirk.

• Kontrollieren Sie regelmäßig alle Teile, um

wartungs- und servicebedürftige Teile zu

entdecken. Ersetzen Sie umgehend schadhafte

Teile.

• Die Öltemperatur sollte 60˚C nicht überschreiten.

• Sorgen Sie für die Sauberkeit aller hydraulischen

Teile.

• Halten Sie Ihre Ausrüstung in guter Kondition.

Reinigen und schmieren Sie die Einstellmutter und

Zugarme regelmäßig vom Gewinde bis zur Spitze,

damit ein guter Betrieb und eine lange

Lebensdauer gewährleistet sind.

• Prüfen Sie das hydraulische System regelmäßig

auf lockere Verbindungen und Leckage.

• Wechseln Sie das Öl in Ihrem hydraulischen

System, wie in der Pumpen-Betriebsanleitung

angegeben.

Page 21

21

Manuale Istruzioni e

Tavola Parti di Ricambio

Estrattori BHP e Accessori

EIS 65.100-1 05/14 Rev. F

1.0 ISTRUZIONI AL RICEVIMENTO

Controllare visivamente tutti i componenti per

accertare eventuali danni derivanti dal trasporto. Se

del caso, sporgere subito reclamo al trasportatore.

I danni di trasporto non sono coperti dalla garanzia. Il

trasportatore è responsabile degli stessi e deve

rispondere di tutte le spese e costi per la rimessa in

efficienza del materiale.

SICUREZZA, anzitutto !!!

Leggere attentamente tutte le ISTRUZIONI, le

PRECAUZIONI ed ATTENZIONI che si devono

osservare per ciascun prodotto. Seguire fedelmente

tutte le prescrizioni di SICUREZZA per evitare

infortuni alle persone e danni alle cose.

L’ENERPAC non è responsabile per incidenti e danni

causati dal mancato rispetto delle Norme di

Sicurezza, dall’uso e dall’applicazione impropria del

prodotto o della sua mancata manutenzione. In caso

di dubbio contattare direttamente l’ENERPAC o i suoi

rappresentanti.

PER SALVAGUARDARE LA VOSTRA

GARANZIA, USARE SEMPRE E SOLO OLIO ENERPAC.

2.0 DESCRIZIONE DEL PRODOTTO

Gli estrattori oleodinamici della serie BHP dell'

Enerpac sono normalmente composti da una pompa

a mano, un cilindro a semplice effetto, un

manometro, un adattatore per manometro, un tubo

flessibile, raccordi speciali ed accessori.

Gli estrattori sono raccomandati per l'installazione e

la rimozione di tutte le parti accessorie a pressione e

a caldo come ingranaggi, pulegge, ruote, cuscinetti,

manicotti, perni ed altre parti difficilmente rimovibili.

Gli estrattori oleodinamici della BHP dell' Enerpac

sono disponibili nei tipi: estrattori oleodina mici a griffe

(consultare paragrafo 2.1), estrattori oleo dina mici a

tiranti (paragrafo 2.2) e estrattori oleodinamici

universali (paragrafo 2.3).

Gli accessori sono parti addizionali che consentono

l'ulteriore aumento della flessibilità d'impiego sul

lavoro degli estrattori oleodinamici a griffe e a tiranti.

Per informazioni dettagliate sugli accessori degli

estrattori vedere tabelle D e E sulle pagine 11 e 12.

2.1 Estrattori oleodinamici a griffe

Gli estrattori oleodinamici a griffe BHP-152,

BHP-251G, BHP-351G e BHP-551G, sono racco man dati per la rimozione e l'installazione di ingra naggi, cuscinetti, pulegge e altri particolari simili.

Consultare l'illustrazione 1 a pagina 23: gli estrattori

a griffe sono utilizzabili sia con la traversa a 2 che

con quella a 3 griffe. Consultare la tabella A a pag. 7

per i componenti singoli.

2.2 Estrattori oleodinamici a tiranti

Gli estrattori oleodinamici a tiranti BHP-162,

BHP-261G, BHP-361G e BHP-561G sono racco mandati per la rimozione e l'installazione di ingra naggi, cuscinetti, pulegge, manicotti e boccole.

Questi estrattori possono anche essere dotati di

morsetto per interni, come mostra l'illustrazione 2 a

pagina 23 o come morsetto per esterni come

mostrano le illustrazione 3 a pagina 23.

In situazioni dove lo spazio impedisce l'impiego

diretto di estrattori oleodinamici a griffe, è possibile

usare l'estrattore in combinazione con un morsetto

per esterni come mostra l'illustrazione 4 a pagina 24.

Gli accessori del morsetto per esterni sono dotati di

orlo a for ma di cuneo per posizionare l'estrattore

dietro l'ingra naggio o il cuscinetto di difficile accesso.

Consul tare la tabella B a pagina 9 per i componenti

singoli.

2.3 Estrattori oleodinamici universali

Gli estrattori oleodinamici universali BHP-1752,

BHP-2751G, BHP-3751G e BHP-5751G sono una

combinazione tra gli estrattori oleodinamici a griffe e

gli estrattori oleodinamici a tiranti sopra citati, per una

maggiore flessibilità di operazioni di spinta o di

trazione durante le manutenzione e riparazioni.

Consultare la tabella C a pagine 10 per singoli

componenti.

3.0 NORME SULLA SICUREZZA

L’inosservanza delle Norme di Sicurezza (a pag. 22)

può causare infortuni e danni all’attrezzatura.

Page 22

22

AVVERTENZA: Quando si impiega la

traversa per 2 griffe, il carico non può

eccedere il 50% della capacità

massima dell'estrattore. Non superare i

350 bar quando si impiega un estrattore

oleodinamico.

AVVERTENZA: Se si usano i tiranti con

l'attacco del morsetto per esterni, il

carico non deve superare il 50% della

capacità massima dell'estrattore. Non

superare i 350 bar quando si impiega un

estrattore oleo dinamico.

IMPORTANTE: Si raccomanda di usare

la traversa a 3 griffe. Qeusta offre una

presa più sicura, una forza di trazione più

bilanciata e maggiore stabilità.

AVVERTENZA:

Per evitare lesioni perso nali o danni all’attrezzatura, assicurarsi che

tutti i componenti oleodinamici siano idonei

ad operare alle pressione di 700 bar.

IMPORTANTE: Impiegare sempre

manometri per il controllo della pressione

e della forza sviluppata dal cilindro. Un

manometro è la Vostra ‘finestra’ sul

sistema. Vi permette di vedere cosa sta succedendo.

AVVERTENZA: Proteggere tutti i compo nenti da fonti di calore eccessivo, fiamme

libere, parti macchine in movimento,

spigoli taglienti ed aggressivi chimici.

PRECAUZIONE: Evitare curve strette e

serpentine ai tubi flessibili. Curve troppo

strette, causano strozzature nelle tuba zioni che possono dar luogo a pericolose

contropressioni le quali ne compromettono la durata.

PRUDENZA: Non maneggiare tubi

flessibili sotto pressione. Spruzzi d’olio

sotto pressione perforano la pelle,

causando, serie complicazioni. Se l’olio è

penetrato sotto pelle consultare immediatamente un

medico.

AVVERTENZA: Indossare indumenti

prote tivi appropriati quando si impiegano

attrezzature oleodinamiche.

AVVERTENZA: Non usare questa

apparecchiatura in circostanze dove un

improvviso rilascio di pressione può

causare uno sbilanciamento con

conseguenti danni o lesioni personali.

AVVERTENZA: Non sovraccaricare le

apparecchiature. Usare l'estrattore delle

giuste dimensioni. Se si usa la forza

massima e la parte non si muove, usare

un estrattore di maggiore capacità.

IMPORTANTE: Non è possibile preve dere esattamente la forza necessaria per

ogni estrazione. Il valore di pressione e di

forza di rimozione può variare molto fra le

diverse operazioni. Le esigenze di posiziona mento,

le dimensioni, la forma e le condizioni delle parti da

estrarre sono variabili da considerare. Valutare ogni

singola applicazione di trazione prima di scegliere il

vostro estrattore.

IMPORTANTE: Aumentare gradualmente

la forza. Mettere in linea i tiranti dell'estrat -

tore e le griffe. Assicurarsi che il posizio -

na mento sia ben fisso e che l'estrattore

sia idoneo all'operazione.

AVVERTENZA:

Sostituire immediata mente i pezzi logorati o danneggiati con

ricambi originali Enerpac. Parti usurate

possono causare ferimenti a persone o

danni alle apparecchiature. I componenti

Enerpac sono progettati per resistere a carichi elevati.

4.0 INSTALLAZIONE

4.1 Estrattori a griffe

L'illustrazione 5 a pagina 6 mostra come montare

l'estrattore a griffe. Le posizioni dell'illustrazione 5

corrispondono con le parti della tabella A a pagine 7.

4.2 Estrattori a tiranti

L'illustrazione 6 a pagina 8 mostra come montare

l'estrattore a tiranti. Le posizioni dell'illustrazione 6

corrispondono con le parti della tabella B a pagine 9.

4.3 Estrattori per interni

L'illustrazione 7 a pagina 8 mostra come comporre

l'estrattore per interni. Le posizioni dell'illustrazione 7

corrispondono con le parti della tabella B a pagine 9.

5.0 FUNZIONAMENTO

IMPORTANTE: E’ indispensabile che

l’ope ra tore prima di impiegare le attrez zature, comprenda bene tutte le istruzioni,

precauzioni, avvertimenti e norme di

sicurezza. In caso di dubbio contattare l’ENERPAC.

5.1 Avanzamiento e ritorno del cilindro

Tutti gli estrattori BHP sono dotati di un cilindro con

ritorno a molla a semplice effetto e di una pompa a

mano. Per la completezza delle istruzioni operative

consultare anche quelle delle centraline o delle pompa.

Page 23

23

5.4 Uso morsetto per interni

Montare l'estrattore come illustra la figura 2 e figura 7

a pagine 8. Allineare i tiranti dell'estrattore e le griffe

per interni, aumentare gradualmente la pressione

idraulica per rimuovere la parte.

5.5 Uso dell'estrattore a tiranti

Per rimuovere: Tenere presente che il cilindro deve

essere posizionato sotto al giogo dei tiranti. Allineare

i tiranti dell'estrattore e la vite di regolazione,

aumentare gradualmente la pressione idraulica per

rimuovere la parte.

Per calettare: Montare l'estrattore come illustra la

figura 3. Tenere presente che il cilindro deve essere

posizionato al di sotto del giogo per tiranti. Allineare i

tiranti dell'estrattore e la vite di regolazione,

aumentare gradualmente la pressione idraulica per

calettare la parte.

Le pompe manuali utilizzate per il funzionamento di

cilindri a semplice effetto sono dotate di una valvola

di comando per il rilascio della pressione. Chiudere la

valvola di comando, sollevare e abbassare la leva

della pompa per fare avanzare il cilindro. Per il ritorno

del cilindro, aprire la valvola di comando.

5.2 Spurgo dell’aria

Per spurgare l’aria dai cilindri e tubazioni, far

compiere alcuni cicli, senza carico, al cilindro (esten sione e rientro). L’aria sarà spurgata completamente

quando il cilindro si muoverà in modo uniforme.

5.3 Uso degli estrattori a griffe

Montare l'estrattore come illustra la figura 1 e figura 5

a pagine 6. Ricor darsi che la traversa a 3 griffe

fornisce una presa più stabile e più sicura alla forza

max. nominale dell'estrattore. Quando si impiega la

traversa a 2 griffe, il carico non può superare il 50%

della capacità nominale dell'estrat tore. Iniziare a

pompare ed aumentare la pressione idraulica

gradualmente per rimuovere la parte.

figura 1 - Estrattori a griffe

Rimozione di una

puleggia con estrattore

a 2 griffe

(traversa per 2 griffe)

Non eccedere il

50% della capa cità massima

dell’estrattore!

Rimozione di una

puleggia con estrattore

a 3 griffe

(traversa per 3 griffe)

figura 2 - Traversa con morsetto per interni

Non ecce dere il 50%

della capa cità massima

dell’estrattatore!

figura 3 - Calettare con estrattore a tiranti

Non ecce -

dere il 50%

della capa cità massima

dell’estrattatore!

Page 24

24

5.6 Uso del morsetto per esterni con accessori

Gli accessori del morsetto per esterni si usano in

combinazione con un estrattore a tiranti o con una

traversa come illustrato in figura 4 e figura 6 a pag. 8.

6.0 MANUTENZIONE

La manutenzione deve intervenire quando si notano

usure o perdite d’olio. Periodicamente controllare e

ispezionare tutti i componenti per accertarne il loro

gradi di efficienza. L’ENERPAC offre kit di parti di

ricambio pronti all’uso. Documentazioni ed elenchi

delle parti di ricambio sono disponibili.

IMPORTANTE: La manutenzione o ripa ra zione delle attrezzature oleodina miche

deve essere demandata a tecnici esperti e

qualificati. Per ogni necessità contattare

l’ENERPAC o il Centro di Assistenza più

vicino alla Vostra Sede.

• Periodicamente controllare tutti i componenti per

accertarne lo stato di efficienza. Sostituire

immedia tamente le parti danneggiate.

• La temperatura dell’olio non deve superare i 60˚C.

• Mantenere puliti tutti i componenti oleodinamici.

• Mantenere l'attrezzatura di trazione in buone

condi zioni. Per un buon funzionamento ed una

lunga durata, pulire e lubrificare regolarmente la

vite di regolazione dell'estrattore ed i tiranti dalla

filettatura fino alla sommità.

• Controllare periodicamente tubi, raccordi ed in nesti per prevenire le perdite d’olio.

• Sostituire l’olio idraulico nell’impianto come meglio

specificato nelle istruzioni delle pompe.

figura 4 - Morsetto per cuscinetti con traversa a

tiranti

Non ecce dere il 50%

della capa cità massima

dell’estrattatore!

Page 25

25

Instrucciones y

Hoja de despiece

Extractores BHP

y Accesorios

EIS 65.100-1 05/14 Rev. F

1.0 INSTRUCCIONES IMPORTANTES DE ENTREGA

Inspeccione todos los componentes por si hay daños

de transporte. Los daños de transporte no están

cubiertos por la garantía. Si los hay, deberá

comunicarlo de inmediato al transportista. El

transportista es responsable de todos los gastos de

reparación y repuesto que surjan a consecuencia de

los daños de transporte.

LA SEGURIDAD EN PRIMER LUGAR

Lea atentamente todas las instrucciones, notas y

advertencias. Tome todas las precauciones

necesarias para evitar lesiones y averias durante el

funcionamiento del sistema. Enerpac no se

responsabiliza por los daños y lesiones que pudieran

resultar del uso del producto sin medidas de

seguridad, falta de mantenimiento o aplicaciones

incorrectos. Póngase en contacto con Enerpac si

tiene dudas sobre las precauciones y aplicaciones de

seguridad.

PARA MANTENER LA GARANTIA, USE

EXCLUSIVAMENTE ACEITE HIDRAULICO ENERPAC.

2.0 DESCRIPCION DEL PRODUCTO

Los juegos de extractores de la serie BHP de

Enerpac constan básicamente de un bomba manual,

un cilindro de simple efecto, un manómetro,una

adaptador de manómetro, una manguera,

acopladores y herramientas específicas y

accesorios. Los extractores han sido diseñados para

instalar y extraer toda clase de piezas fijadas a

presión o en caliente, tales como engranajes, poleas,

ruedas, cojinetes, camisas, manguitos, pernos y

demás piezas difíciles de mover.

Los juegos de extractores de la serie BHP de

Enerpac se pueden suministrar como: juego de

extractores de garra (véase párrafo 2.1), juego de

extractores de cojinetes (véase párrafo 2.2) y juegos

de extractores polifuncionales (véase párrafo 2.3)

Los accesorios son piezas adicionales para

aumentar aún más la flexibilidad durante el trabajo

de los extractores de garras y de cojinetes. Véanse

los cuadros D y E en las páginas 11 y 12 para una

lista de componentes de los juegos de extractores.

2.1 Los extractores de garras

Los extractores de garras BHP-152, BHP-251G,

BHP-351G y BHP-551G se pueden usar para extraer

y colocar engranajes, cojinetes, poleas y piezas

similares. Véase la ilustración 1 en la página 27: los

extractores de garra pueden usarse con una cruceta

doble (2 garras) o una cruceta triple (3 garras).

Véase cuadro A en la página 7 para una lista de los

componentes.

2.2 Conjuntos para extracción de cojinetes

Los conjuntos para extracción de cojinetes BHP-162,

BHP-261G, BHP-361G y BHP-561G se pueden usar

para extraer y calar engranajes, poleas, manguitos y

cojinetes. Estos extractores también se pueden usar

como extractores de cubos de cojinete (garra

interior) como se muestra en la ilustración 2 en la

página 27 o como extractores de cojinetes como se

muestra en la ilustración 3 de la página 27.

En situaciones en las que el espacio no permite una

aplicación directa de las garras, se puede utilizar el

extractor en combinación con un accesorio, como se

muestra en la ilustración 4 de la páguina 28. Los

accesorios de los extractores de cojinetes tienen

bordes en forma de cuña para calzar el extractor

detrás del engranaje o cojinete de difícil acceso.

Véase el cuadro B de la página 9 para una lista de

los componentes.

2.3 Los extractores polifuncionales

Los extractores polifuncionales BHP-1752,

BHP-2751G BHP-3751G y BHP-5751G son una

combinación de los extractores arriba descritos y

ofrecen una flexibilidad máxima en las aplicaciones

de extracción e instalación en trabajos de

mantenimiento y reparación. Véase el cuadro C de la

página 10 para una lista de los componentes.

3.0 SEGURIDAD

El incumplimiento de las siguientes precauciones y

avisos (de la página 26) podría causar averías al

equipo o lesiones al operador.

Page 26

26

AVISO: No exceda la fuerza nominal

del extractor cuando use un extractor

de cruceta doble (2 garras): no exceda

los 350 bar (5,000 psi) cuando use un

extractor hidráulico en esta aplicación.

AVISO: No exceda la fuerza nominal

del extractor cuando use tirantes en

combinación con un accesorio de

extracción de cojinetes: no exceda los

350 bar (5,000 psi) cuando use un extractor

hidráulico en esta aplicación.

IMPORTANTE: Se recomienda usar una

cruceta triple (3 garras) lo que presta un

agarre más firme, más fuerza de tiro y

más estabilidad que una cruceta doble (2

garras).

¡

ATENCION!: Para evitar lesiones y

averías, asegúrese de que todos los

componentes hidráulicos resisten la

presión máxima de 700 bar (10,000 psi).

IMPORTANTE: Use siempre un

manómetro en cada sistema hidráulico

para asegurar fuerzas de trabajo seguras.

Un manómetro es su ‘ventana’ al interior

del sistema. Le permite saber que está

pasando.

ADVERTENCIA: Asegúrese de que todos

los componentes del sistema están

protegidos contra posibles causas de

averías, tales como temperatura

excesiva, llamas, piezas móviles, bordes afilados y

productos químicos corrosivos.

PRECAUCION: No doble las mangueras.

El radio de curvatura deberá ser mayor de

115 mm. No haga pasar vehículos sobre

las mangueras ni deje caer objetos

pesados en ellas.

PRECAUCIÓN: No manipule las

mangue ras presurizadas. El chorro de

fluido hidráulico apresión tiene fuerza

suficiente para penetrar la piel, causando

lesiones graves. Si el fluido penetra en la piel,

consulte a un médico de inmediato.

ADVERTENCIA: Lleve ropa protectora

adecuada y use siempre gafas de

seguridad mientras trabaja con

extractores.

PRECAUCION: NO use este equipo en

circunstancias en las que una repentina

caída de la presión pueda resultar en un

desequilibrio; esto podría causar lesiones

o daños.

AVISO: NO sobrecargue el equipo. Use el

extractor de la medida adecuada. Si

después de aplicar la fuerza máxima, aún

no se mueve la pieza, tome un extractor

de mayor capacidad. Evite que resbale.

IMPORTANTE: Es imposible prever la

fuerza exacta necesaria para cada

extracción. La presión de la fijación y la

fuerza necesaria para retirar una pieza

puede variar mucho según el trabajo. Seleccione el

equipo de acuerdo con las medidas, la forma y las

condiciones de las piezas a extraer que pueden ser

muy diversas, lo que se debe tener en consideración.

Estudie cada aplicación de extracción antes de

seleccionar un extractor.

IMPORTANTE:

Aplique la fuerza gradual mente. Alinee los tirantes y las garras.

Ase gúrese de que la colocación es rígida y

que el extractor se adapta bien al trabajo.

ADVERTENCIA: Sustituya de inmediato

piezas torcidas o rotas por piezas

originales de Enerpac. Las piezas

corrientes pueden romperse causando

lesiones y averías. Las piezas de Enerpac

han sido diseñadas para un ajuste correcto y para

resistir grandes fuerzas.

4.0 INSTALACION

4.1 Extractores de garras

La ilustración 5 en la página 6 muestra como debe

colocar su extractor de garras. Los números en la

ilustración 5 corresponden con las piezas numeradas

en el cuadro A en la página 7.

4.2 Extractores de cojinetes

La ilustración 6 (pág. 8) muestra como debe colocar

su extractor de cojinetes. Los números en la

ilustración 6 corresponden con las piezas numeradas

en el cuadro B (pág. 9).

4.3 Extractores interiores

La ilustración 7 (pág. 8) muestra como debe colocar

su extractor interior. Los números en la ilustración 7

corresponden con las piezas numeradas en el

cuadro B (pág. 9).

Page 27

27

5.0 FUNCIONAMIENTO

IMPORTANTE: Es indispensable que el

ope rador conozca a fondo todas las

instrucciones, normas de seguridad, pre cauciones y advertencias antes de

empezar a trabajar con cualquiera de estas

herramientas de gran fuerza. En caso de duda,

póngase en contacto con Enerpac.

5.1 Avance y retracción del cilindro

Todos los conjuntos de extractores BHP están

equipados con un cilindro de simple efecto con

retorno por muelle y una bomba de mano. Para

instrucciones completas del funcionamiento,

refiérase a las hojas de instrucción incluidas en cada

bomba o cilindro.

Bombas manuales

Las bombas manuales para gobernar cilindros de

simple efecto, tienen una válvula de descarga para la

presión. Cierre la válvula de descarga, y mueva la

palanca para extender el cilindro. Para retraer el

cilindro, abra la válvula de descarga.

5.2 Purga

Haga avanzar y retroceder el cilindro varias veces,

sin que aumente la presión. El aire habrá salido

cuando el movimiento del cilindro sea suave.

5.3 Uso de los extractores de garras

Coloque su aplicación como se muestra en la

ilustración 1 y ilustración 5 página 6. No olvide que

una cruceta triple ofrece un agarre más firme y

estable con una fuerza de tiro más uniforme que una

cruceta doble. No exceda la mitad de la capacidad

nominal del extractor cuando use un extractor con

cruceta doble. Empiece a bombear y aplique la

presión hidráulica gradualmente para extraer la

pieza.

ilustración 1 - Extractores de garras

Polea de extracción con

un extractor de 2 garras

(cruceta doble)

No exceda la

50% de la

fuerza nominal

Polea de extracción con

un extractor de 3 garras

(cruceta triple)

5.4 Uso de los extractores de cubos de cojinetes

Coloque su aplicación como se muestra en la

ilustración 2 y ilustración 7 págine 8 con el extractor

interior. Alinee los tirantes y las garras y aplique la

presión hidráulica gradualmente para extraer la

pieza.

5.5 Uso de los extractores de cojinetes

Para extraer: Tenga en cuenta que el cilindro tiene

que quedar posicionado encima de la cruceta

ranurada. Alinee los tirantes y los tornillos de ajuste

y aplique la presión hidráulica gradualmente para

extraer la pieza.

Para empujar: Coloque su aplicación como se

muestra en la ilustración 3. Tenga en cuenta que el

cilindro tiene que quedar posicionado debajo de la

cruceta ranurada. Alinee los tirantes y los tornillos de

ajuste y aplique la presión hidráulica gradualmente

para quitar la pieza.

ilustración 3 - Empuje con un extractor de

cojinetes

ilustración 2 - Cruceta con accesorio de extracción de cubos de cojinete

No exceda

la 50% de

la fuerza

nominal

No exceda

la 50% de

la fuerza

nominal

Page 28

28

5.6 Uso de los accesorios del extractor de

cojinetes

Los accesorios del extractor de cojinetes se usan en

combinación con una cruceta como se muestra en la

ilustración 4 y ilustración 6 página 8.

illustración 4 - Accesorio para extracción de

cojinetes con cruceta

No exceda

la 50% de

la fuerza

nominal

6.0 MANTENIMIENTO Y SERVICIO

Se precisará mantenimiento cuando se observe

algún desgaste o fuga. Inspeccione regularmente

todos los componentes para comprobar si existe

algún defecto que precise mantenimiento y servicio.

Enerpac dispone de piezas de recambio listas para

realizar reparaciones y/o sustituciones. Tome

contacto con Enerpac.

IMPORTANTE: Sólo personal cualifi cados deberá cuidar del servicio del

sistema hidráulico. Para el servicio de

reparaciones, póngase en contacto con

un Centro de Servicio Autorizado de

Enerpac en su zona.

• Inspeccione regularmente todos los componentes

para comprobar si existe algún defecto que