Page 1

Repair Parts Sheets for this product are available from the Enerpac

web site at www.enerpac.com, or from your nearest Authorized

Enerpac Service Center or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions carefully.

Follow all safety precautions to avoid personal injury or

property damage during system operation. Enerpac

cannot be responsible for damage or injury resulting from unsafe

product use, lack of maintenance or incorrect product and/or system

operation. Contact Enerpac when in doubt as to the safety

precautions and operations. If you have never been trained on highpressure hydraulic safety, consult your distribution or service center

for a free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and warnings could

cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: Stay clear of loads supported by hydraulics.

A cylinder, when used as a load lifting device, should never

be used as a load holding device. After the load has been

raised or lowered, it must always be blocked mechanically.

WARNING: USE ONLY RIGID PIECES TO HOLD LOADS.

Carefully select steel or wood blocks that are capable of

supporting the load. Never use a hydraulic cylinder as a

shim or spacer in any lifting or pressing application.

DANGER: To avoid personal injury keep hands and

feet away from cylinder and workpiece during

operation.

WARNING: Do not exceed equipment ratings. Never

attempt to lift a load weighing more than the capacity of the

cylinder. Overloading causes equipment failure and

possible personal injury. The cylinders are designed for a max.

pressure of 700 bar [10,000 psi]. Do not connect a jack or cylinder

to a pump with a higher pressure rating.

Never set the relief valve to a higher pressure than the

maximum rated pressure of the pump. Higher settings may

result in equipment damage and/or personal injury.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated component

in the system. Install pressure gauges in the system to

monitor operating pressure. It is your window to what is happening

in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid sharp

bends and kinks when routing hydraulic hoses. Using a

bent or kinked hose will cause severe back-pressure.

Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

Do not drop heavy objects on hose. A sharp impact may

cause internal damage to hose wire strands. Applying

pressure to a damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic equipment by the hoses

or swivel couplers. Use the carrying handle or other means

of safe transport.

CAUTION: Keep hydraulic equipment away from

flames and heat. Excessive heat will soften packings

and seals, resulting in fluid leaks. Heat also weakens

hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C [150°F] or higher.

Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping oil

under pressure can penetrate the skin, causing serious

injury. If oil is injected under the skin, see a doctor

immediately.

®

Instruction Sheet

Air/Hydraulic Booster

B2009, 2009V B3006, 3006V B5003,5003V

L1356 Rev. A 01/03

Index:

English: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Français: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Deutsch: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Italiano: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Español: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Nederlands: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .N/A

Por tuguese: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .N/A

®

®

®

Page 2

2

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected couplers.

If the cylinder becomes extremely overloaded,

components can fail catastrophically causing severe personal

injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a flat

surface that can support the load. Where applicable, use a

cylinder base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered on

the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In addition,

the load may slip or fall, causing potentially dangerous results.

Distribute the load evenly across the entire saddle surface.

Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be serviced

by a qualified hydraulic technician. For repair service,

contact the Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

by genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fit properly and withstand high

loads.

3.0 SPECIFICATIONS

Note: Shipping box contains fittings for NPT hook-up. The fitting

with the tapered male threads goes into the 3/8 BSPT air inlet.

Ambient Temperature Range..............-4˚F (-20˚C) to +176˚F (80˚C)

Recommended Oil Temperature ......+59˚F (15˚C) to +131˚F (55˚C)

Minimum Operating Air Pressure ................................40 psi (3 bar)

Maximum Operating Air Pressure..............................125 psi (9 bar)

Air Consumption ..............................................0.95 cu. ft. per stroke

Reservoir Capacity ..............................................................50 cu. in.

Usable Oil Capacity ..........................................................13.4 cu. in.

Maximum Cycle rate ........................................10 cycles per minute

Air Piston Retract Speed (from full extend)

@ 86 psi (6 bar)............................................................Max. 3.2 sec.

Return Spring Force @ Initial Position....................................57 lbs.

Return Spring Force @ Maximum Compression ..............1041 lbs.

Stroke Sensing Position Before Full Stroke ..........................1.04 in.

Sensing Contact Capacity ......................................30 VDC, 3 amps

4.0 INSTRUCTIONS

4.1 General Description

Air operated hydraulic boosters convert low pressure air to high

pressure hydraulic oil for operating hydraulic cylinders, clamps or

similar devices. Primary booster components are, the air piston and

the hydraulic cylinder plunger. Air pressure, into the booster, exerts

a force against the air piston causing it to move forward. The forward

motion compresses the piston return spring and moves the hydraulic

plunger in the oil cylinder. The plunger compresses the oil in the

cylinder developing high pressure at the outlet port.

Pressure intensification is determined by the air piston to hydraulic

plunger ratio. If the booster ration is 20:1 100 psi air pressure will

produce 2000 psi hydraulic pressure. Air pressure of 80 psi will

produce 1,600 psi hydraulic pressure. To determine actual holding

forces, multiply the effective area of a working cylinder by the

hydraulic pressure being produced. The result is holding force

in pounds.

4.2 Selecting Cylinders and Boosters

1. Determine the holding force required for the application.

2. Determine input air pressure available.

3. Determine volume of oil required in the hose or pipe from the

booster to the working hydraulic cylinder or clamping devices.

Note: Any cylinder can be matched with any pump or booster as

long as the pump or booster has enough useable oil capacity (cubic

inches) to transmit and fully extend the cylinder or cylinders.

Your only other consideration is knowing the maximum Hydraulic

Pressure Range (psi) of the selected pump or booster for

determining the "Cylinder Holding Force" of the cylinder or

cylinders.

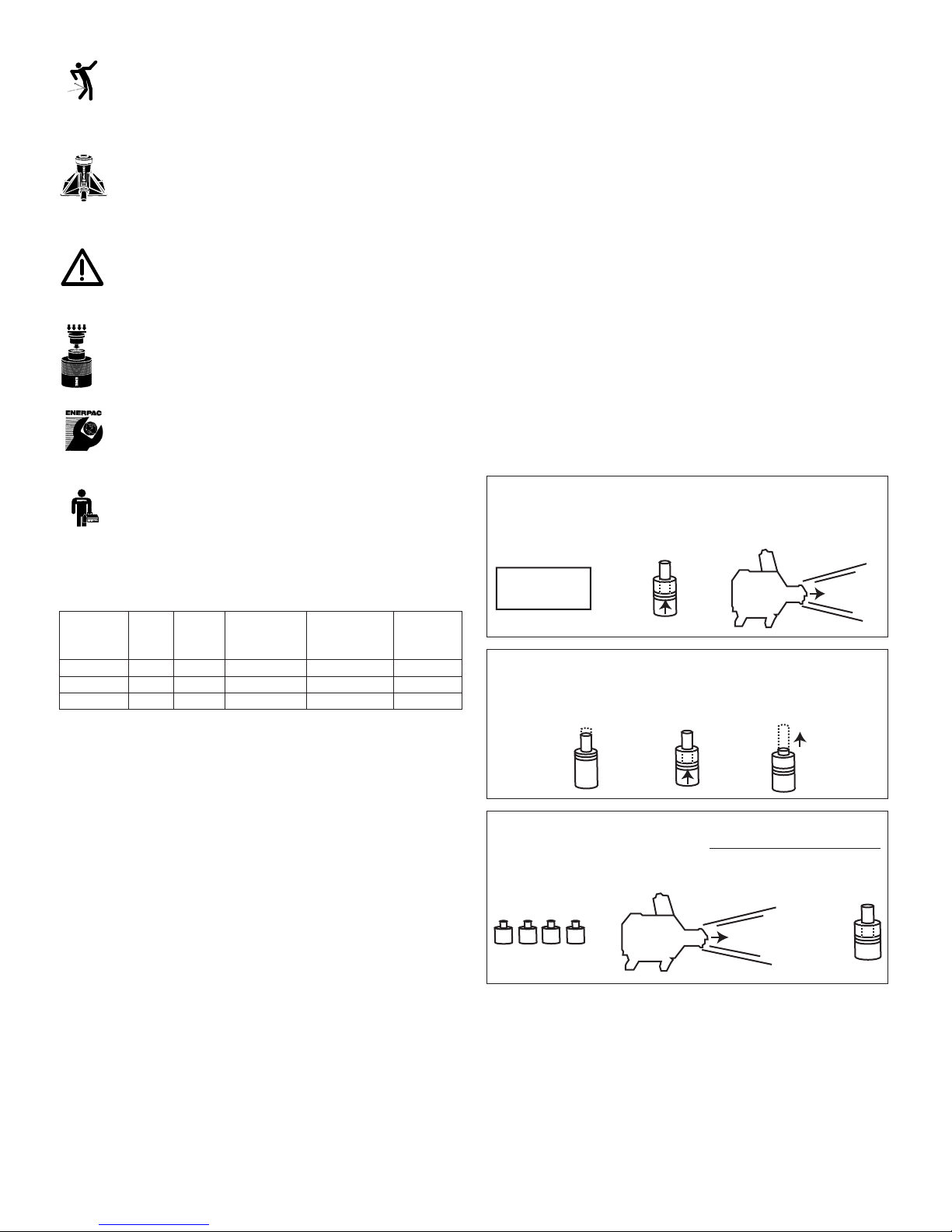

Model No. Ratio Oil Per Oil Pressure Max

Piston Stroke Oil at 100PSI Oil

Stroke Output Air Pressure Pressure

B-2009 20:1 5.20 in. 9.30 cu. in. 2000 psi 2500 psi

B-3006 30:1 5.20 in. 6.20 cu. in. 3000 psi 3750 psi

B-5003 50:1 5.20 in. 3.70 cu. in. 5000 psi 6250 psi

®

TO FIND: Cylinder Holding = Cylinder Effective x Hydraulic Working

Force (lbs) Area (sq. in.) Pressure (psi)

Force

(lbs)

TO FIND: Cylinder Oil Capacity = Cylinder Effective x Cylinder Stroke

(cu. in.) Area (sq. in.) (inches)

TO FIND: Total number of Cylinders Useable Oil Capacity of Pump

that can be used with = (or) Booster oil Output (cu. in.)

Booster or Pump Oil Capacity of Cylinder (cu. in.)

=x

=x

OIL

Pump or

= ÷

Booster

Pump or

Booster

Useable Oil

Capacity

Working

Pressure

OIL

Page 3

3

The selected pump or booster will operate at various desired

pressure ranges within its maximum rated capacity. Therefore, the

"Workholding Cylinders" will operate at many desired workholding

forces by merely regulating the hydraulic operating pressure (psi) of

the pumps or boosters.

5.0 INSTALLATION

1. Install the booster in a location which is higher than the working

cylinders. The booster can be mounted in the horizontal or one

vertical position. When mounting vertically, the hydraulic output

end (port) must face up.

2. To mount the booster, remove the capscrew and acorn nuts

securing the bracket to the booster.

3. Re-position the booster bracket using any of the six positions

around the circumference of the booster. Be sure all capscrews

are firmly tightened.

4. Install four mounting screws through the bracket and into the

mounting plate (figure 1).

Note: When mounting the booster, the air fill cap and sight gauge

should always remain visible and useable to permit checking and

re-filling the reservoir.

Figure 1

6.0 INCOMING AIR SUPPLY

Compressed air, to the booster, must be clean, dry and lubricated to

protect the booster components. If properly treated air is not

available, install an Enerpac regulator/filter/lubricator in the air line

leading to the booster control valve. The regulator/filter/lubricator

provides the following advantages:

1. Removes dirt and moisture from the air

2. Provides a mist of lubrication in the air supply which protects

control valves and booster internal parts. Filter lubricators use

Enerpac hydraulic oil.

3. Contains an air regulator valve and gauge to adjust air pressure

to the booster.

7.0 AIR AND OIL CONNECTIONS

Caution: Teflon tape is an excellent thread sealer, however,

if not properly applied small pieces can tear loose and

enter the hydraulic system causing restrictions and

potential malfunctions. Use 1

1

/2 wraps and leave the 2 threads, at

the end of fitting, without tape.

1. A 3-way, 2-position directional control valve (VA-42) is required

to operate booster. Locate the valve within six feet of the

booster, between the regulator/filter/lubricator and the booster

inlet port. Valve port sizes are 3/8” - 18 NPT.

2. Connect the air supply line to the input port on the

regulator/filter/lubricator (

3

/

8” - 18 NPT).

3. Install an air line from the regulator/filter/lubricator outlet port to

the VA-42 valve, port No. 3 (

3

/8” - 18 NPT).

4. Mount the VA-42 control valve to a solid base. Use the three

mounting holes in the valve body.

5. Connect an air line from the VA-42 control valve, port No. 4, to

the booster inlet port (figure 2). Valve port No. 1 remains open

for exhausting air.

Figure 2

6. Attach a hydraulic line from the booster to the system working

components (ie. cylinder, clamps or valves).Fill booster hydraulic

reservoir with ENERPAC oil, approximately 1.75 quart.

8.0 BOOSTER OPERATION

Booster operating speed depends on factors including working

cylinder strokes, valving, hose lengths and port sizes.

1. Keep hose or pipe lengths reasonably short.

2. Provide clean, dry, lubricated air supply at 40 psi minimum to

125 psi maximum.

3. All hoses, fittings, piping and associated components must be

pressure rated to withstand maximum system pressure.

4. Maintain booster oil level in the reservoir. Check sight gauge

frequently. Repair leaks immediately.

5. Prior to operation, bleed system to remove air trapped in

hydraulic components.

6. Bleeding Hydraulic System

(a) Check booster reservoir level. Fill to capacity.

(b) Activate booster to complete 2 or 3 cycles and pump oil

into entire system.

(c) Loosen a fitting (furthest from booster). Cover fitting with

rags to prevent oil splatter.

(d) Activate booster to full advance, tighten fitting,

retract booster.

(e) Add hydraulic oil to booster reservoir.

7. MAGNETIC SENSOR: The sensor connections are available to

connect optional indicator lights or buzzers which actuate upon

completion of the hydraulic plunger stroke. Figure 3 illustrates

a typical light connection.

Figure 3

Booster

Capscrews

Fill Cap

Mounting Bracket

Filter

Lubrication

3

VA-42

Valve

5

24

Booster

Gauge

Cylinder

Hydraulic Line

Incoming

Air

Booster

Magnetic

Sensor

Cylinder

Lamp

Page 4

4

8.1 Operation

1. Position all working components and ensure oil connections

are complete.

2. Adjust air supply to provide required booster pressure.

3. Booster is activated by pulling handle on the control valve.

When handle is released, the booster retracts via return spring.

Working cylinders or clamps also retract unless a shut-off valve

has been installed to maintain pressure beyond the booster.

9.0 MAINTENANCE

1. Frequently check booster reservoir sight gauge to ensure oil

level remains at proper level. Small red circle, in sight gauge, is

maximum level.

2. After system repairs or oil changes, the hydraulics must be bled

to remove trapped air.

(a) Loosen a fitting furthest from the booster.

(b) Activate booster to fully advance the hydraulic plunger.

Tighten the fitting.

(c) Re-fill booster reservoir. If working system components

continue to function erratically or very slow, bleed system,

check for leaks, repair or replace faulty items.

3. Changing Hydraulic Oil

(a) Change intervals are: every 150 hours during normal

operating conditions, every 50 hours under dirty, dusty or

extremely humid conditions.

(b) Place a drain pan under booster outlet port. Remove

hydraulic line. Tip booster to drain oil into the pan.

(c) Re-install hydraulic line, Remove red fill cap and re-fill

reservoir (1

3

/4 quart). When oil appears in sight glass red

circle, reservoir is full.

Loading...

Loading...