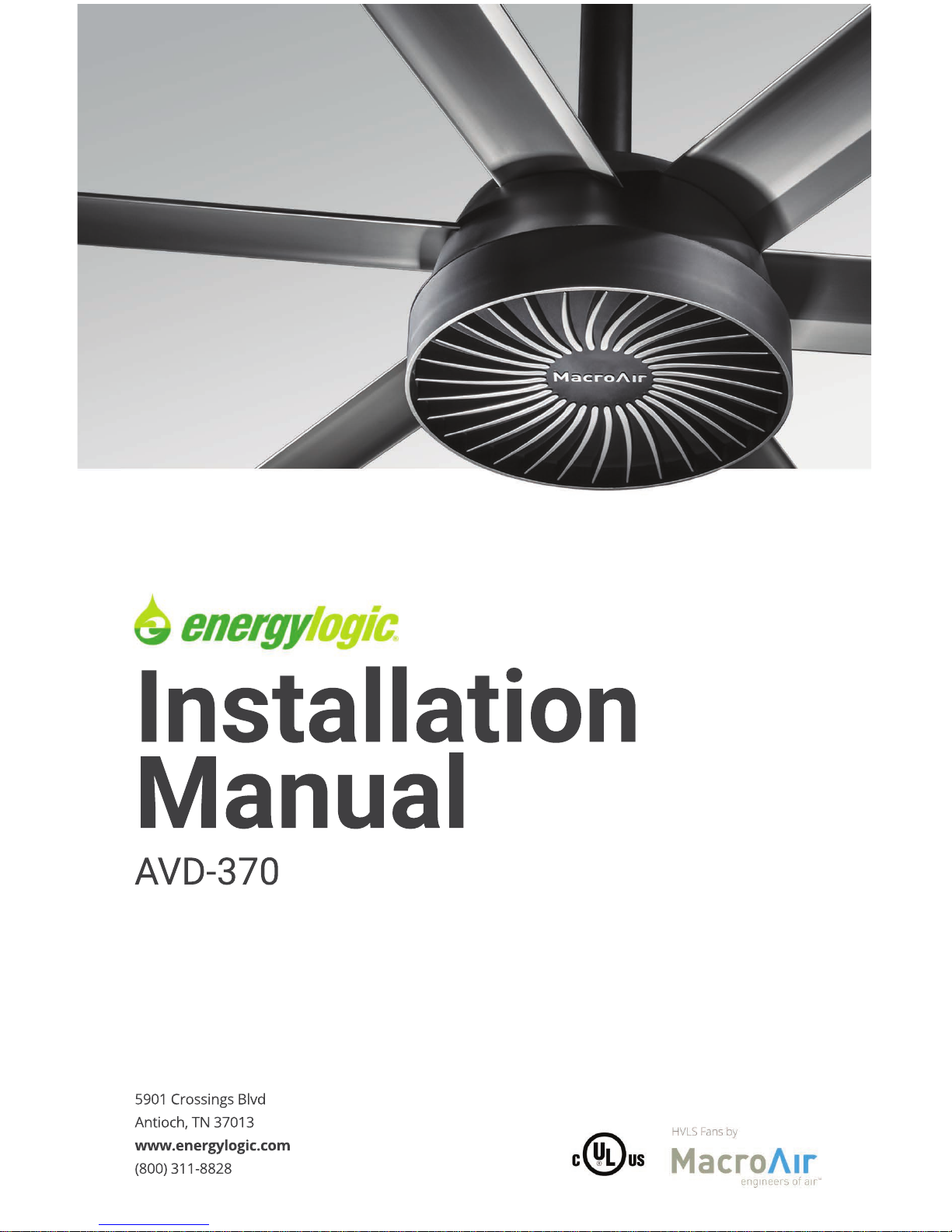

EnergyLogic MacroAir AVD-370 Installation Manual

Installation

Manual

AVD-370

5901 Crossings Blvd

Antioch, TN 37013

www.energylogic.com

(800) 311-8828

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 1

Rev. Date 062718

Table of Contents

Caution & Safety ................................................................................................................................. 2

Fusing Chart ....................................................................................................................................... 5

Fan Placement & Clearance .............................................................................................................. 6

Fan Dimensions .................................................................................................................................. 9

Components (Rapid Mount Commercial) .......................................................................................... 10

Components (Fixed Angle Mount) ..................................................................................................... 11

Fan Components & Tools .................................................................................................................. 12

Mounts ................................................................................................................................................ 13

1 - Rapid Mount Commercial

1.1 Rapid Mount Commercial Motor & Extension Tube............................................................ 14

1.2 Rapid Mount Commercial Bolt Kits ..................................................................................... 17

1.2.1 Rapid Mount Commercial Glulam (Direct Mounting) ................................................... 18

1.2.2 Rapid Mount Commercial Glulam (with Glulam Brackets).......................................... 21

1.2.3 Rapid Mount Commercial I-Beam (Steel Truss Mounting) .......................................... 25

1.2.4 Rapid Mount Commercial Unistrut ............................................................................... 29

2 - Fixed Angle Mount

2.1 Fixed Angle Mount Motor & Extension Tube ....................................................................... 32

2.2 Fixed Angle Mount Bolt Kits ................................................................................................. 35

2.2.1 Fixed Angle Mount Glulam ............................................................................................ 36

2.2.2 Fixed Angle Mount I-Beam (Steel Truss Mounting) ..................................................... 39

2.2.3 Fixed Angle Mount Unistrut ........................................................................................... 43

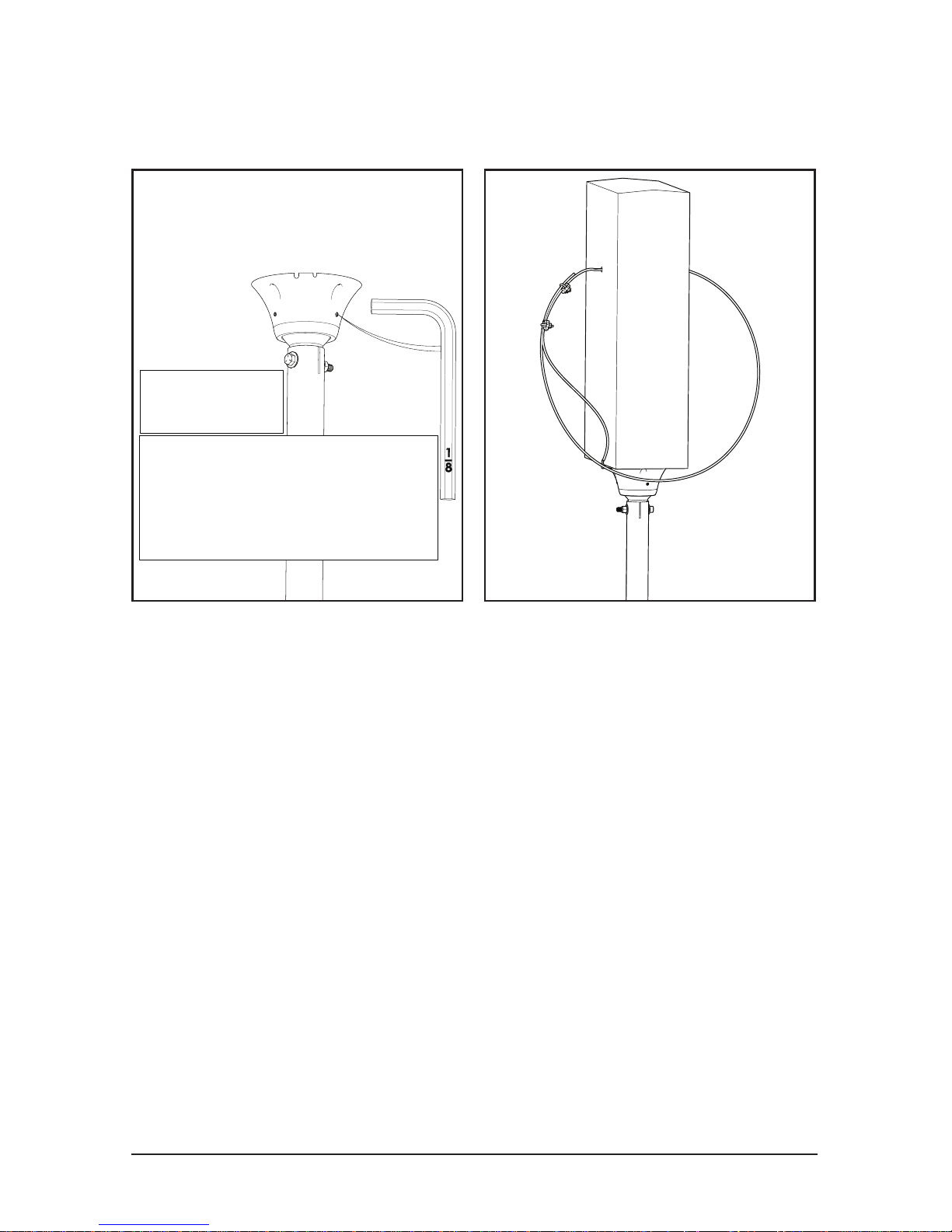

2.3 Guy Wire Installation (Fixed Angle Mount ONLY) ................................................................ 46

3 - Airfoil Installation

3. Airfoil Installation .................................................................................................................. 50

4 - Disconnect Switch

4.1 Fuse Disconnect Switch Installation .................................................................................... 53

4.2 Emergency Disconnect Schematic ...................................................................................... 54

5 - Touchpad Remote Setup

5.1 Touchpad Remote Mounting ................................................................................................ 55

5.2 Touchpad Remote Navigation .............................................................................................. 58

5.2 Touchpad Remote Operations .............................................................................................. 59

Maintenance Information ................................................................................................................... 60

Mounting Plate Dimensions ............................................................................................................... 61

Mounting Bracket Dimensions .......................................................................................................... 62

Touchpad Remote Dimensions .......................................................................................................... 63

Troubleshooting ................................................................................................................................. 64

Warranty and Technical Support ....................................................................................................... 69

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 2

Rev. Date 062718

Caution & Safety

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning

use of the appliance in a safe way and understand the

hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

READ AND SAVE THE ENTIRE MANUAL BEFORE OPERATING THE FAN. Ensure that all safety

practices and instructions are followed during the installation, operation and servicing of the

fan. Failure to apply these safety practices could result in death or serious injury. If you do not

understand the instructions please call EnergyLogic for guidance (contact information can be

found on page 69).

The fan installation should follow the recommendations outlined in this manual. EnergyLogic

is not responsible for any injury or damage to people or property as a result of the user and/or

installer not complying with the recommendations outlined in this manual.

All fan controls and incoming power should only be installed by qualied technicians familiar

with the requirements of the Natural Electric Code (NEC) and local codes. Refer to appropriate

portions of this manual for other important requirements. Failure to follow these guidelines will

void the manufacturer’s warranty.

NOTICE: All electrical controls are congured at the factory and are ready to use. No user

adjustments are available. Follow the included wiring schematics and installation instructions

when installing this device to ensure proper operation. Do not make any changes to any part of

the fan without rst consulting EnergyLogic.

Installation is to be in accordance with the national electrical code, ANSI/NFPA 70-1999 and local

codes.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for their

safety.

Children should be supervised to ensure that they do not play with the appliance.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH.

Read and understand this manual before installing or operating a fan unit. Installation,

adjustment, repair, or maintenance must be performed by qualied personnel.

The user is responsible for compliance with all international and National Electrical Code

requirements with respect to the grounding of all equipment.

Many of the parts of this unit operate at live voltage. DO NOT TOUCH.

Install all covers before applying power or starting and stopping the unit.

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 3

Rev. Date 062718

Caution & Safety

WARNING - TO REDUCE THE RISK OF ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

a) Use this unit only in the manner intended by the manufacturer. If you have questions, contact

the manufacturer.

b) Before servicing or cleaning the unit, switch power off at the service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such as a

tag, to the service panel.

WARNING: If unusual oscillating movement is observed, immediately stop using the ceiling fan

and contact the manufacturer, its service agent or suitably qualied persons.

WARNING: Make sure to power the fan off and lock it out using the IEC/CE approved disconnect

when doing any cleaning and or maintenance to the equipment.

PRIOR TO THE INSTALLATION, ENSURE:

• That the mounting of the suspension system shall be performed by the manufacturer, its

service agent or suitably qualied persons;

• That the fan is to be installed so that the blades are more than 2,3 m above the oor;

• The model or type reference of a luminaire that may be installed in a fan constructed for

this purpose.

DAMAGED EQUIPMENT

Do not operate or install any fans or fan accessories that appear to be damaged. Failure to follow

this instruction can result in death, serious injury, or equipment damage.

SERVICE:

If the fan does not operate properly using the procedures in this manual, BE CERTAIN TO

REMOVE ALL POWER TO THE UNIT and contact our technical department for further assistance.

Keep all body parts clear of moving part at all times. All electrical troubleshooting and repair

must be done by a qualied technician and meet all applicable codes.

Ensure that the replacement of parts of the safety suspension system device shall be performed

by the manufacturer, its service agent or suitably qualied persons.

Key Safety System Components

EnergyLogic fans are engineered with key safety features to prevent pieces of the fan from

falling in the unlikely event of a catastrophic failure. Used together, these features provide

comprehensive protection of people, equipment and property. Follow the detailed instructions

precisely when installing fans, including the following:

• Install the safety cable on EVERY fan. The safety cable, if installed per EnergyLogic

specications, will prevent the fan from falling in the unlikely event that the mounting

system should fail. An EnergyLogic fan should never be run without a properly installed

safety cable, which is supplied with every fan along with all required hardware. You must

install a safety cable for the warranty to be in effect.

• Install guy wires on every fan, unless otherwise specied. Properly installing the guy wires

is required for proper stabilization during normal operation for some fan and mounting

types (Fixed Angle and Universal Mounts). In addition, guy wires keep the fan stable in case

of earthquakes or in “outdoor” installations where high wind conditions may occur.

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 4

Rev. Date 062718

Caution & Safety

Mark the Floor to Alert Personnel

When mounting a fan in an area where materials may be elevated into its path, EnergyLogic

recommends marking or painting the oor with a large crosshatched circle to alert personnel of

the overhead location of fans.

Weight Considerations

Ensure the xing means for attachment to the ceiling such as hooks or other devices shall be

xed with a sufcient strength to withstand 4 times the weight of the ceiling fan. The maximum

hanging weight for the Model 370 is 79 lbs [36 kg] including the weight of an additional drop

length. If there is any uncertainty in the strength of the building structure, a professional

structural engineer should perform a thorough evaluation of the building prior to purchasing the

fans. EnergyLogic provides guidelines for mounting fans; however, it is the sole responsibility of

the building owner and installer to ensure the safety of the mounting system, that the building

structure is sound and that the installation complies with all federal, state, and local codes.

Torque

The maximum torque (twisting force) during normal operation that must be handled by the

mounting system, including the building structure. For a Model 370, the maximum potential

torque is 20 ft-lbs [27 N-m].

Check Federal, State, and Local Codes

Check all relevant codes to make sure that all product certications, product listings, and

building regulations are met. Code compliance is the responsibility of the installer.

Windy Conditions

Fans should not be operated when wind is present.

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 5

Rev. Date 062718

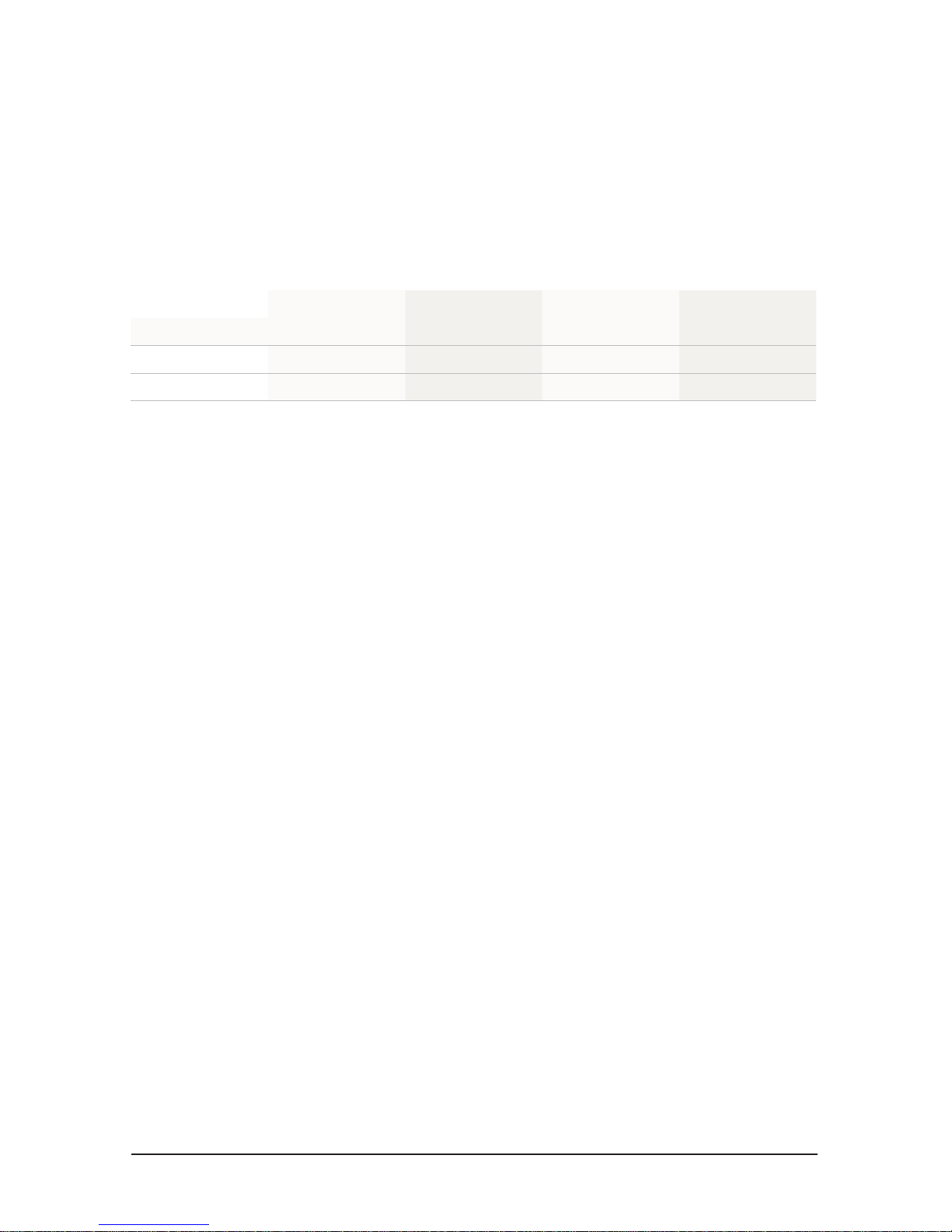

Fusing Chart

BRANCH CIRCUIT PROTECTION IS REQUIRED TO PROTECT THE ELECTRICAL COMPONENTS

AND COMPLY WITH UL 507.

Use the table below to select the correct fast acting fuse size for your application. The optional

fuse disconnect switch provided by EnergyLogic uses class CC fast acting fuses. Fuses must be

purchased separately.

Max Amp Draw / Recommended Fuse

Voltage and Phase 6ft 8ft 10ft 12ft

110 VAC 1-Phase 1.5A / 5 5.9A / 7.5 3.8A / 5 2.0A / 5

120 VAC 1-Phase 1.4A / 5 5.4A / 7.5 3.5A / 5 1.8A / 5

208/240 VAC 1-Phase 0.8A / 5 3.1A / 5 2.0A / 5 1.0A / 5

Reference page 53 for installation.

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 6

Rev. Date 062718

Fan Placement & Clearance

Sprinkler Systems and Fan Placement

In any installation where re sprinklers are in place, fans should not interfere with their correct

operation. Fans should be located no less than 3 feet below a sprinkler, and placed central to

each sprinkler quadrant. Our AirBrain motor controller can be connected to a re suppression

control system which will emergency-stop fans in case of re. Prior to installing fans, review all

codes applicable to sprinkler systems and fans to ensure code compliance (refer to NFPA 13).

Please call EnergyLogic for guidance (contact information can be found on page 69). However, it

is your sole responsibility to see that the installation is completed to code and that it is correct.

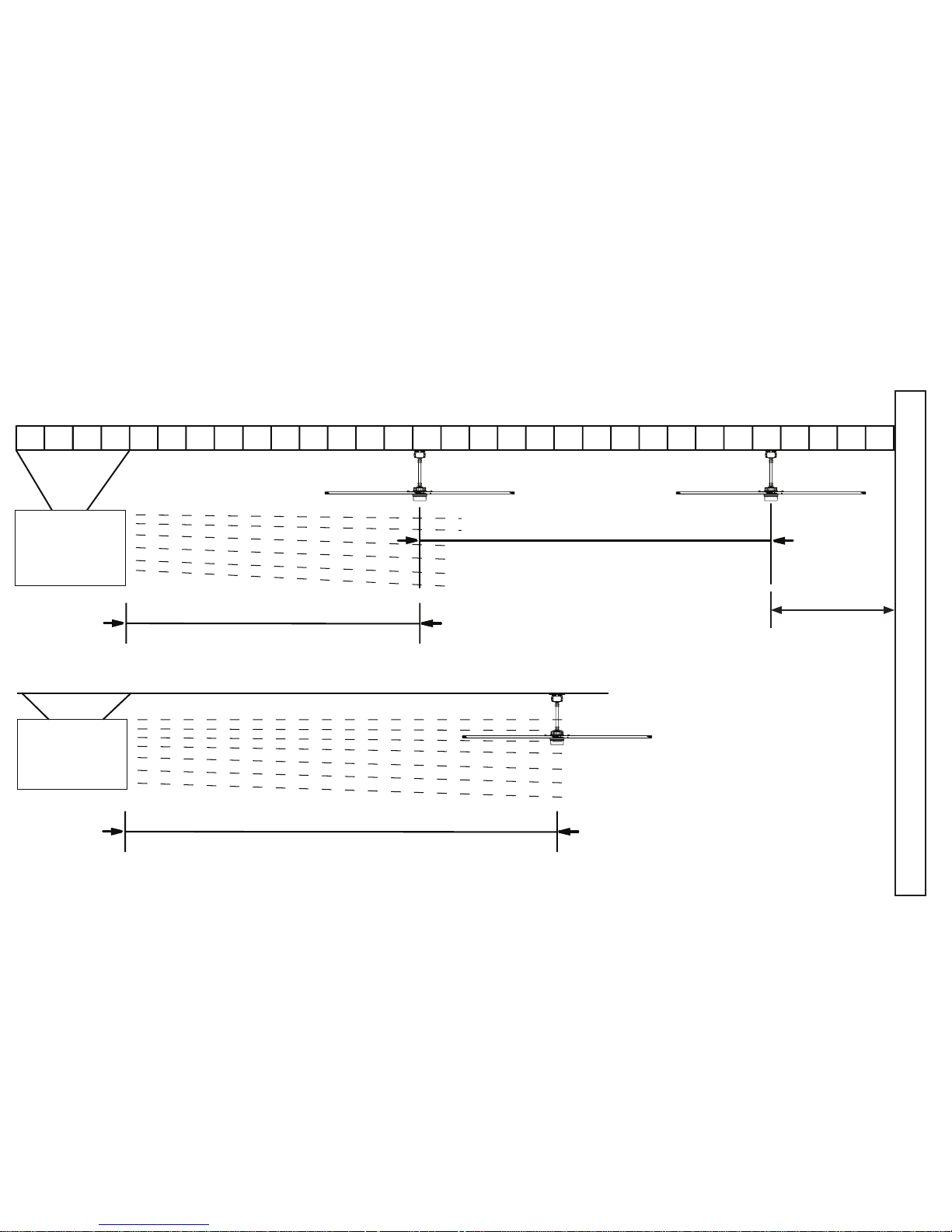

Other Information on Placement and Spacing

If possible, avoid mounting fans directly below lights or skylights to avoid any strobe effect

caused by moving airfoils.

If the building has a mezzanine, fans should be mounted so a person cannot reach a fan in any

way from the upper level/deck. Make certain that fans are positioned so that the airfoil tips are at

least 3 feet away from any area where a person may be able to extend outward to reach them.

HVLS fans should not be located near to air supply outlets or exhausting inlets of other HVAC

equipment. Supply air outlets can be congured to deliver air away from the HVLS fan or the fan

location should be oriented such that the outlet is pointing away from the fan and outside the

swept area of the fan. Exhaust fan inlets or other return air points creating a negative pressure

should not be within 1.5 times the diameter of the fan. These system will diminish the capacity of

the HVLS fan. Proper systems orientation will provide an enhancement to the Indoor Air Quality

(IAQ) and occupant comfort. Refer to next page for illustration.

© 2018 EnergyLog ic, LLC Toll Fre e: 80 0 311 882 8 Fax: 615 471 52 02 w ww.ener gylogic.com 7

Rev. Date 062718

HVAC Diffuser

with airflow

UNDER fan

HVAC Diffuser

with airflow

ABOVE fan

Fan Placement & Clearance

space from diffuser

space from diffuser

at least 1.5 x diameter away from

intake/discharge

at least 2 x diameter away from intake/discharge

spacing between fans

space from

wall

at least 1.5 x

diameter away

from the wall

at least 3 x diameter of the fans apart

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 8

Rev. Date 062718

WARNING: FANS ARE NOT MEANT TO BE OPERATED IN WINDY CONDITIONS.

The minimum distance of a fan to a wall or similar obstruction should be no less than 1.5 times

the diameter of the fan.

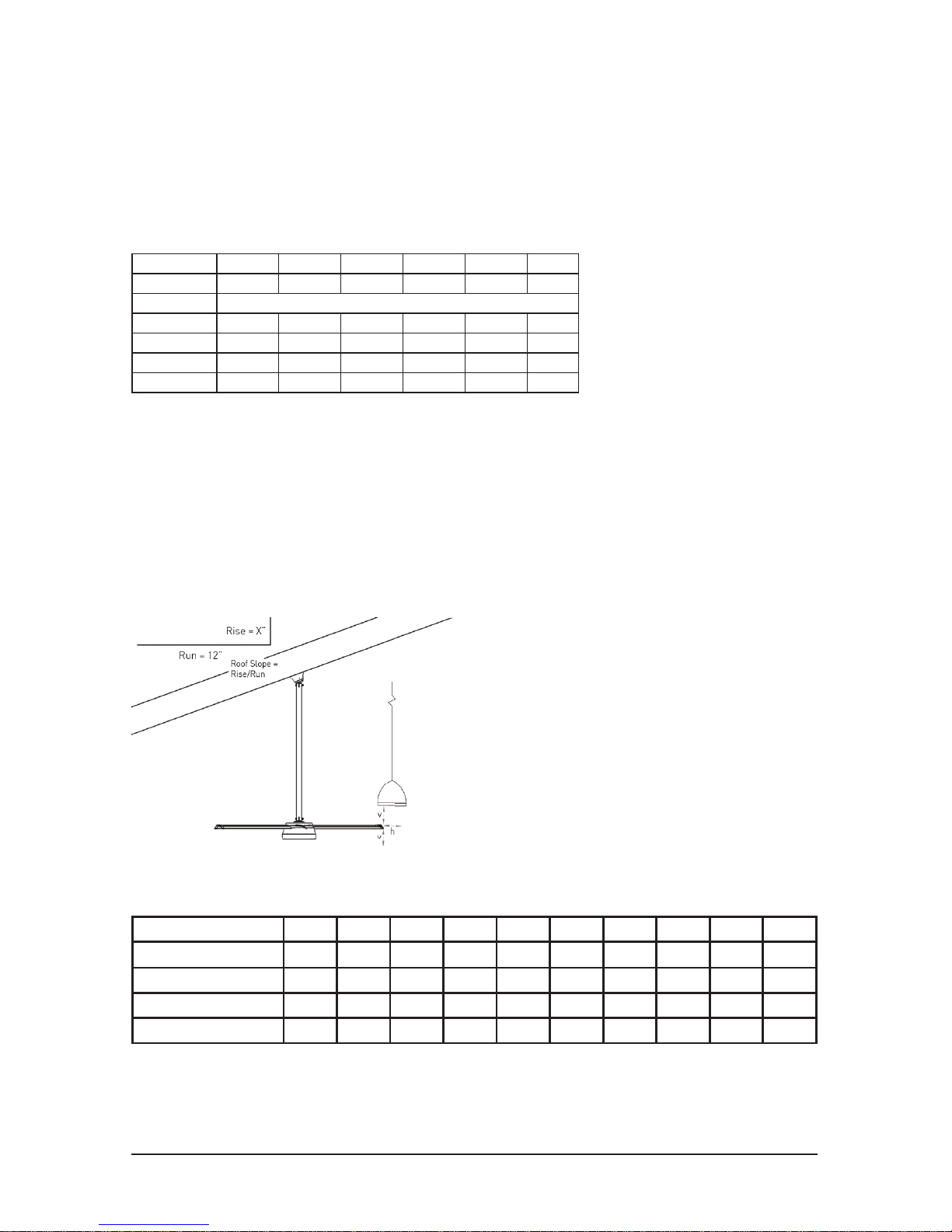

Maximum Angle for Mount (feet)

Slope (in) 0 2/12 4/12 6/12 8/12 10/12

Roof Angle 0 9.5

o

18.4

o

26.6

o

33.7

o

39.8

o

Diameter Recommended Total Drop (Mount to Airfoil) Length (ft)

6 feet 2 2 2 3 4 4

8 feet 2 2 3 3 4 5

10 feet 2 2 3 4 5 6*

12 feet 2 2 3 5 6* 8*

*The Rapid Mount Commercial does not support this angle. Use Fixed Angle Mount for drop

lengths over 5 feet.

The drop lengths above are minimum recommendations only / based solely on roof pitch and fan

diameter. Other factors / such as allowing for proper air ow into the fan must be evaluated when

determining drop length requirements. In addition / EnergyLogic strongly recommends that the

fan airfoils must be a minimum of 10 feet (3.05 meters) above the oor. Contact EnergyLogic for

assistance with fan placement and drop length selection (contact information can be found on

page 69).

The table below shows the clearance

needed from the fan to obstructions such

as lighting / conduit / etc.

Minimum Clearance (Horizontal / Vertical inches):

Airfoil / Drop Length (ft) 1 2 3 4 5 6* 7* 8* 9* 10*

6 feet 7 / 7 7 / 7 7 / 7 8 / 8 9 / 8 8 / 7 9 / 8 10 / 8 12 / 9 14 / 9

8 feet 7 / 7 7 / 7 7 / 8 8 / 8 9 / 9 8 / 8 9 / 8 10 / 9 12 / 10 14 / 10

10 feet 7 / 7 7 / 8 7 / 8 8 / 9 9 / 10 8 / 9 9 / 9 10 / 10 12 / 11 14 / 11

12 feet 7 / 8 7 / 8 7 / 9 8 / 10 9 / 11 8 / 10 9 / 10 10 / 11 12 / 12 14 / 13

Fan Placement & Clearance

needed from the fan to obstructions such

*Drop Lengths over 5 feet require the xed angle mount

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 9

Rev. Date 062718

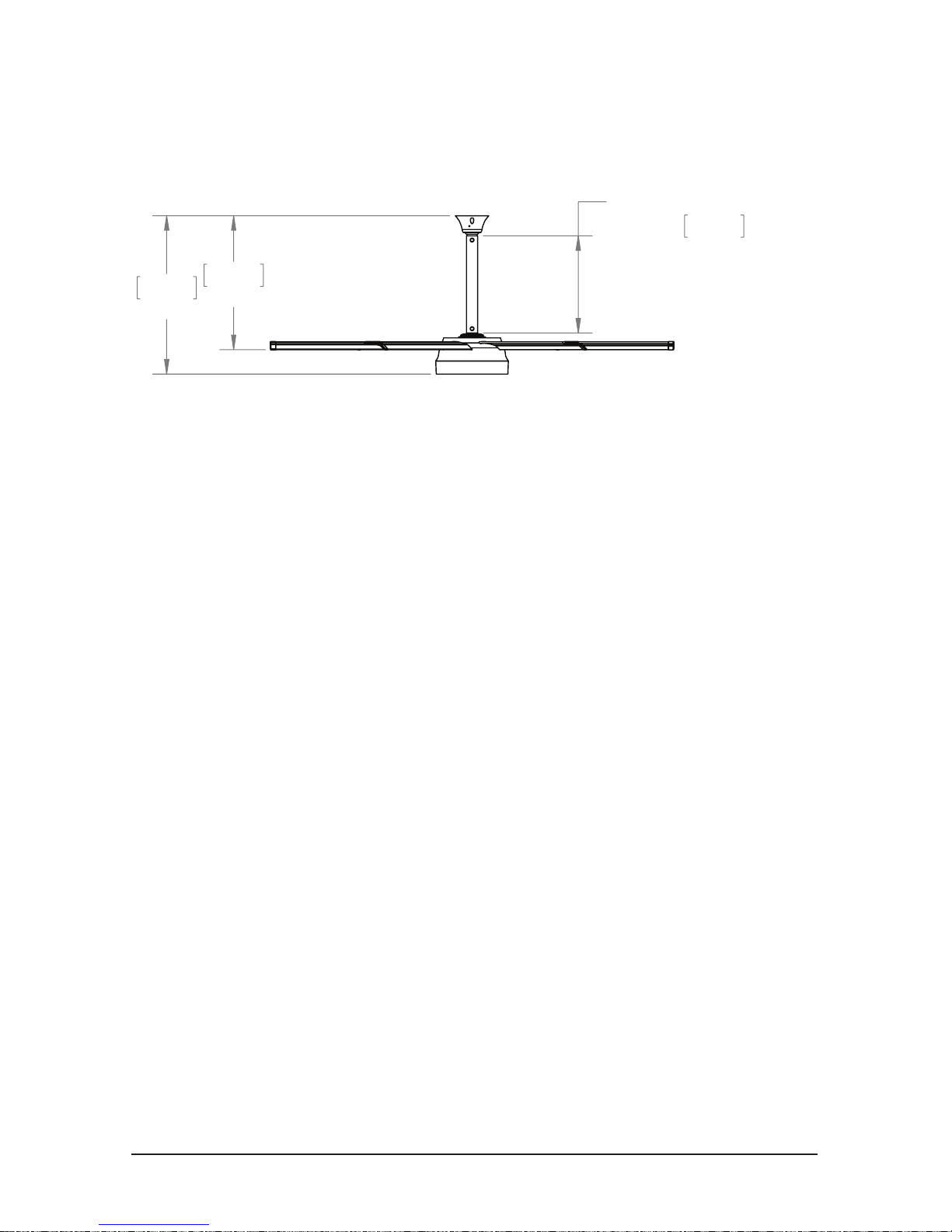

The Model 370 has a standard airfoil to mounting point clearance of 2 feet [0.61 m] with the Rapid

Mount Commercial. Refer to the Fan Clearance & Placement charts on pages 6-8 for required

fan clearance and mounting conditions.

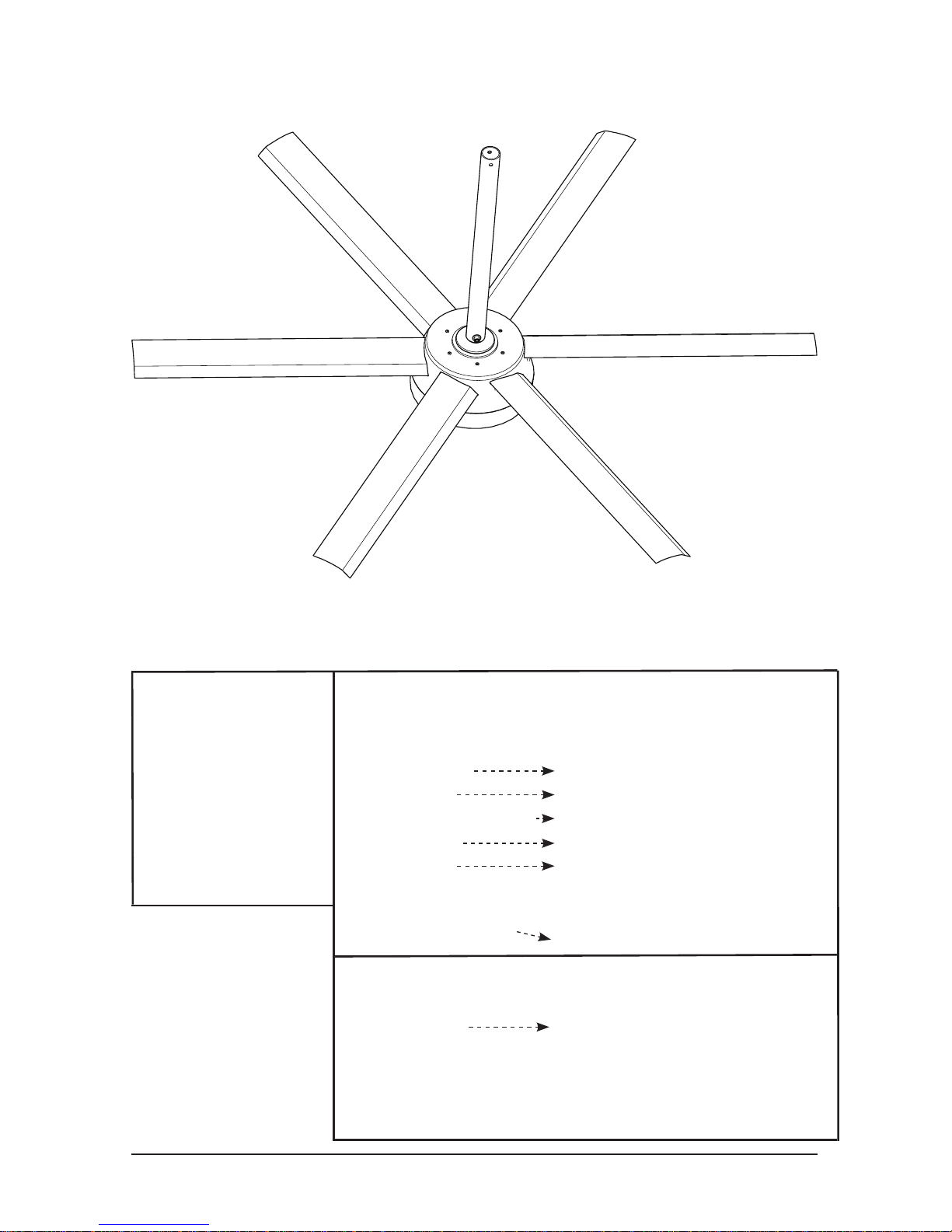

Fan Dimensions

ILLUSTRATION

SHOWN WITH

STANDARD EXTENSION

0.441

1'5.375"

0.609

2'0"

0.720

2'4"

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 10

Rev. Date 062718

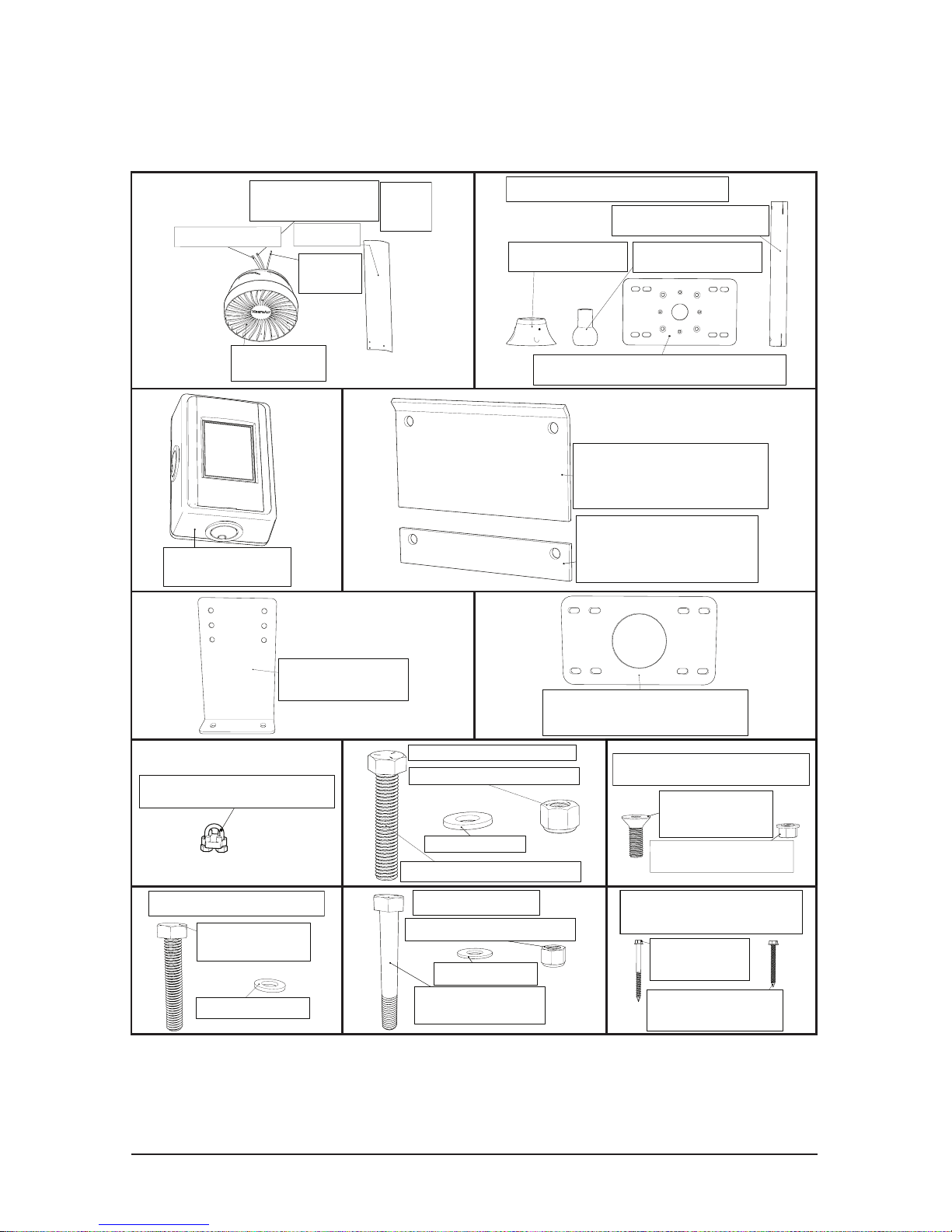

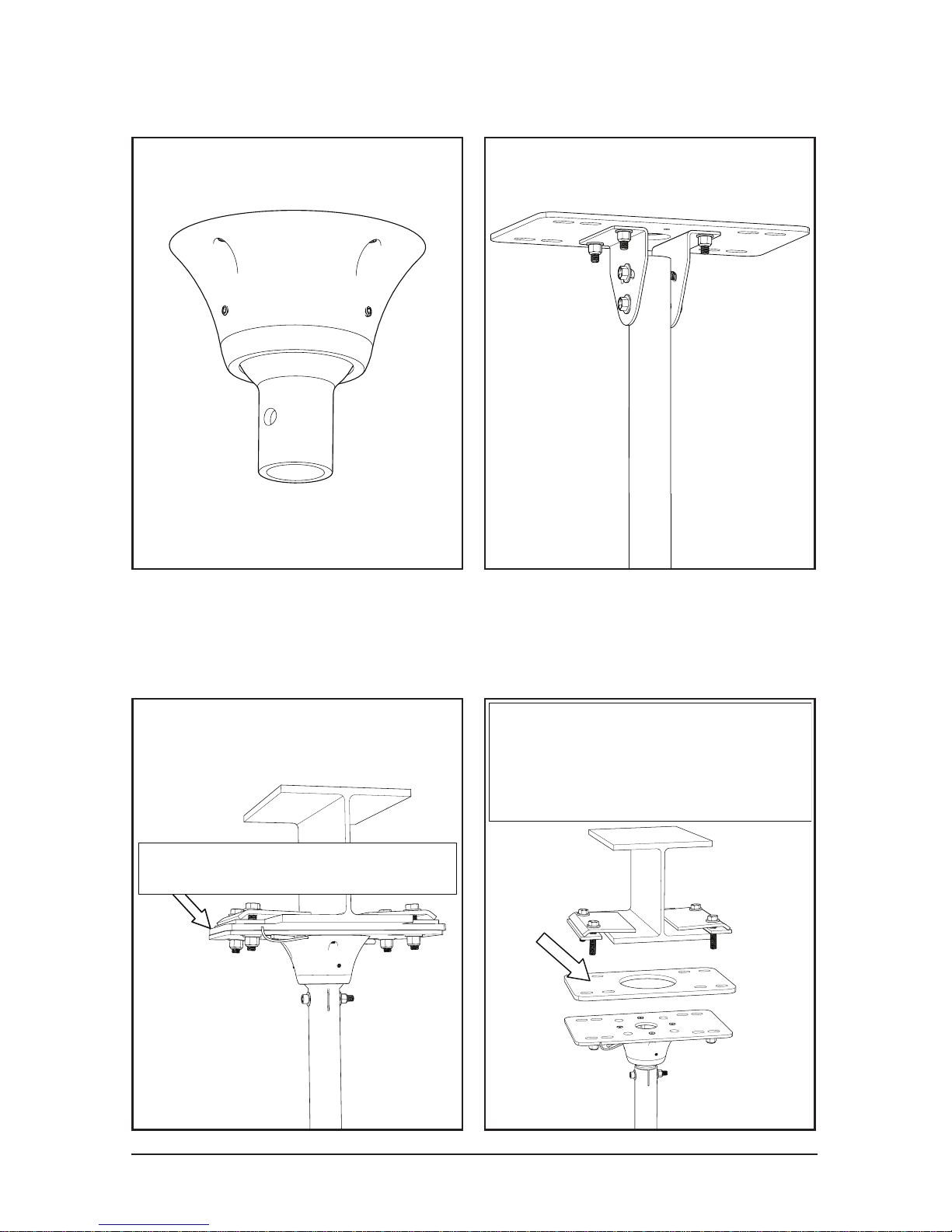

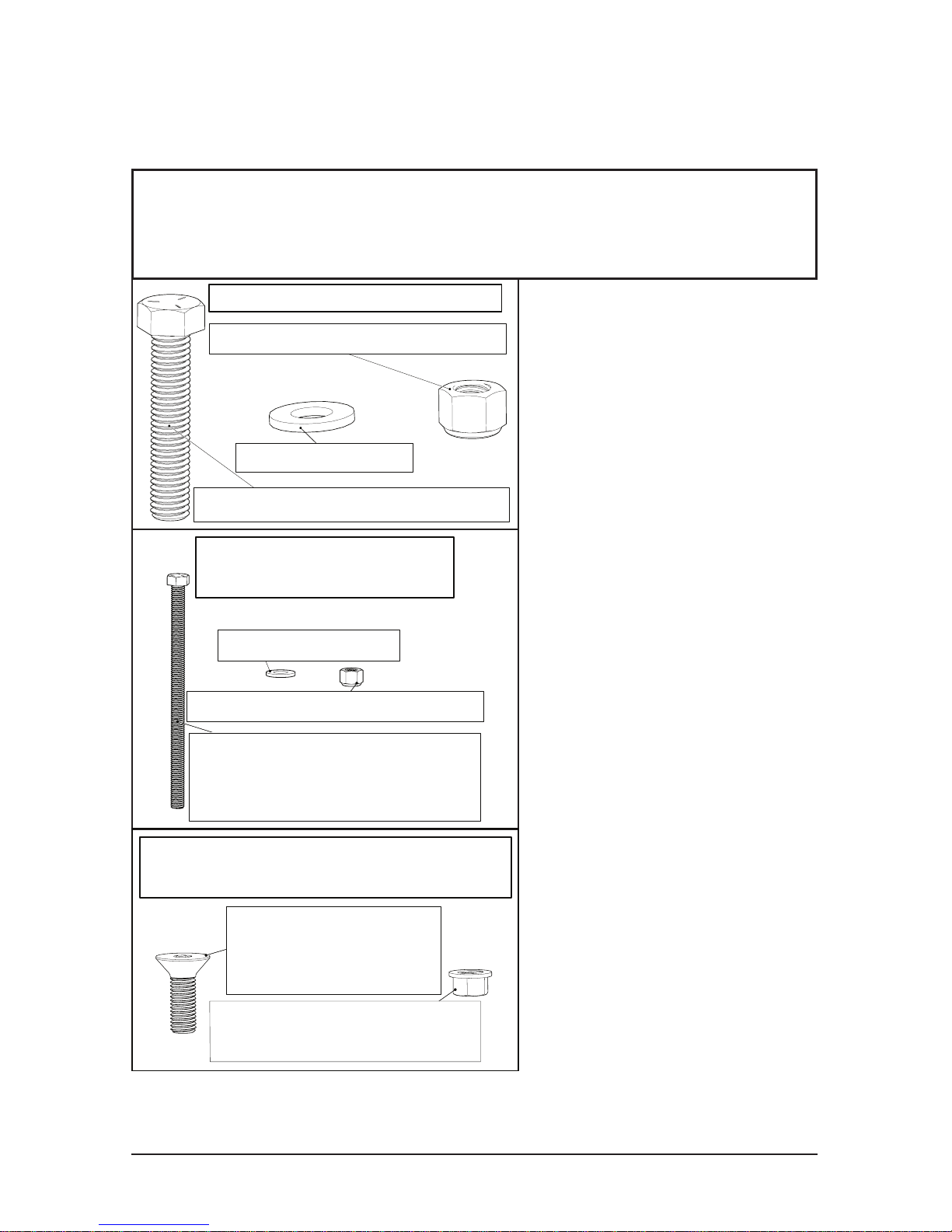

Glulam Bracket (2)

(Optional)

Noise Dampening Pad (1)

(Optional)

Top Mount Plate (1) (Optional)

Extension Tube (1)

Mount Cap (1)

Mount Shaft (1)

Rapid Mount Commercial Parts

Touchpad Digital

Remote (1)

Wire Rope Clamp (2)

M5 x 32mm Hex

Head Bolt (18)

AVD 370 Blade Bolt Kit

M5 Washer (18)

1/2"-13 x 2 1/2" Hex Bolt (4)

1/2"-13 Nylon Lock Nut (4)

1/2" Washer (8)

I-Beam Bolt Kit (Optional)

3/8" Washer (4)

3/8"-16 Nylon Lock Nut (2)

3/8"-16 x 2 3/4" Hex

Head Bolts (2)

3/8" Washer (4)

Extension Bolt Kit

1/4"-28 x 3/4"

Countersunk Socket

Head Cap Screw (4)

1/4"-28 Flanged Distorted

Thread Locknut (4)

Rapid Mount Commercial Mounting

Plate Bolt Kit (Optional)

Components

(Rapid Mount Commercial)

Make sure all parts listed above are included if you purchased the Rapid Mount

Commercial. Read the entire manual before beginning the installation of the

fan. Additional parts may be required, including, but not limited to, guy wire

attachment hardware, extra cable, Unistrut, and bolts for Glulam mounting.

#10 2-1/2"

Lag Screw (4)

#10 1-3/4"

Concrete Screw (4)

Rapid Mount Commerical

Mounting Screws

I-Beam Shim (2)

(Optional)

I-Beam Clamp (2)

(Optional)

AVD 370

Motor Unit (1)

Airfoil (6)

Safety

Cable (1)

Sheilded Stranded

CAT5e Cable (1)

Power Cable (1)

RJ45

Pin-Out

Type “B”

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 11

Rev. Date 062718

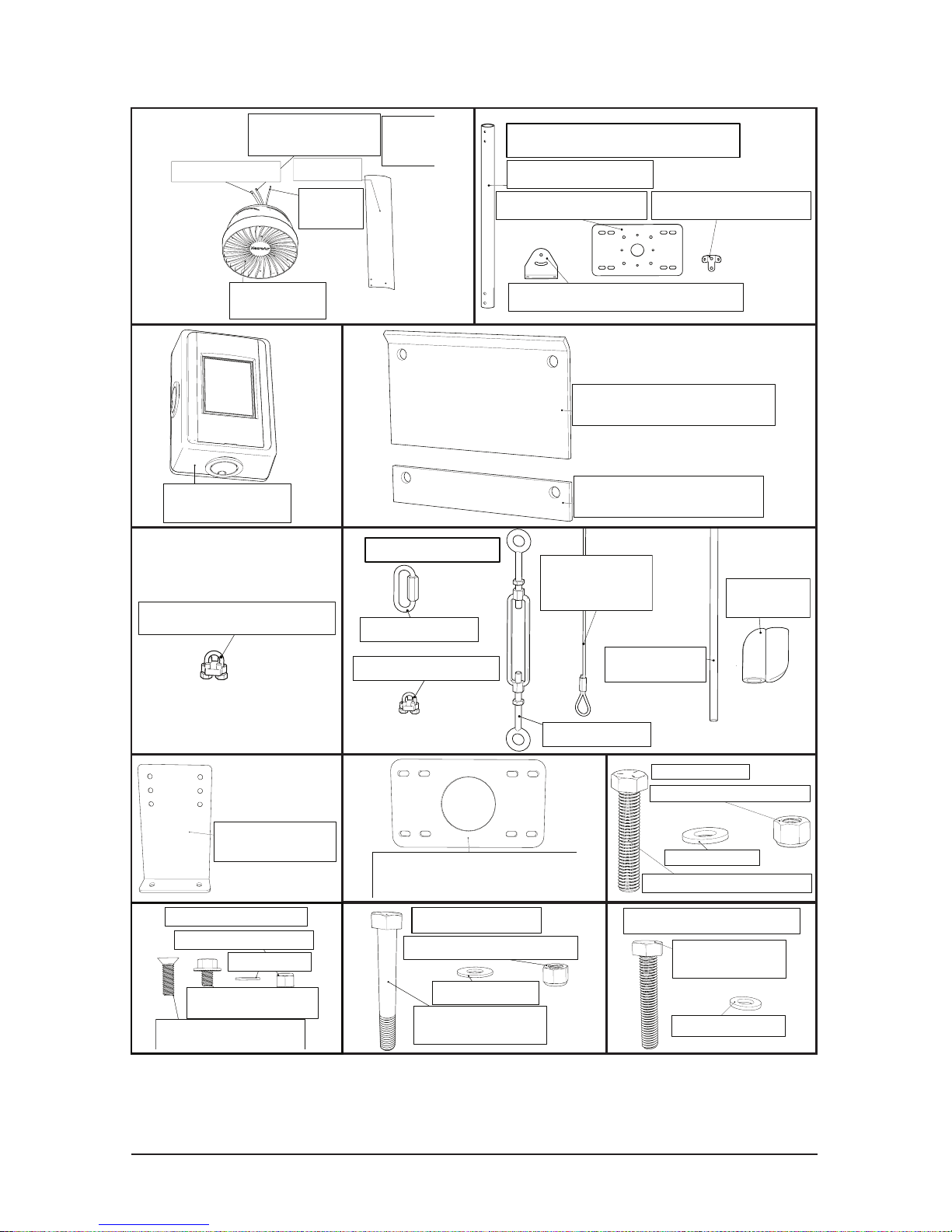

Glulam Bracket (2)

(Optional)

Noise Dampening Pad (1)

(Optional)

Fixed Angle Mount Bracket (2)

Guy Wire Bracket (2)

Top Mount Plate (1)

Extension Tube (1)

Fixed Angle Mount Parts

Wire Rope Clamp (2)

M5 x 32mm Hex

Head Bolt (18)

AVD 370 Blade Bolt Kit

M5 Washer (18)

1/2"-13 x 2 1/2" Hex Bolt (4)

1/2"-13 Nylon Lock Nut (4)

1/2" Washer (8)

I-Beam Bolt Kit

3/8" Washer (4)

3/8"-16 Nylon Lock Nut (2)

3/8"-16 x 2 3/4" Hex

Head Bolts (2)

3/8" Washer (4)

Extension Bolt Kit

3/8" Washer (4)

3/8"-16 x 1 1/4"Countersunk

Socket Head Cap Screw (4)

3/8"-16 Nylon Lock Nut (4)

3/8" Washer (4)

3/8"-16 x 1 1/4"Countersunk

Socket Head Cap Screw (4)

3/8"-16 x 1/2" Serrated

Flange Hex Head bolt (4)

Fixed Angle Mount Bolt Kit

Components (Fixed Angle Mount)

Make sure all parts listed above are included if you purchased the Fixed

Angle Mount. Read the entire manual before beginning the installation of the

fan. Additional parts may be required, including, but not limited to, guy wire

attachment hardware, extra cable, Unistrut, and bolts for Glulam mounting.

Guy Wire Assembly

Wire Rope (4)

19ft (A), 23ft (B),

or 33ft (C)

Turn Buckle (4)

1/4" Quicklink (4)

Wire Rope Clamp (8)

AVD 370

Motor Unit (1)

Airfoil (6)

Safety

Cable (1)

Sheilded Stranded

CAT5e Cable (1)

Power Cable (1)

RJ45

Pin-Out

Type “B”

I-Beam Shim (2)

I-Beam Clamp (2)

Guy Wire

Elastic Band (1)

Elastic Band

Clip (1)

Touchpad Digital

Remote (1)

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 12

Rev. Date 062718

Fan Components and Tools

Tools Required:

For All Mounts:

-Torque Wrench

-Level

-Phillips Screwdriver

-3/8’’ Wrench

-9/16 Wrench

-5/16’’ Socket

-9/16’’ Socket

For Rapid Mount Commercial:

-Needle Nose Pliers

-Cordless Drill For Glulam Mounting

-1/4” Socket For Direct Glulam Mounting

-3/16’’ Hex Bit Socket For Unistrut Mounting

-3/4’’ Wrench For I-Beam & Glulam Brackets

-3/4’’ Socket For I-Beam & Glulam Brackets

-1/8’’ Allen Wrench (Provided)

-5/32’’ Allen Wrench (Provided)

For I-Beam & Glulam Brackets

For Fixed Angle Mount:

-Cordless Drill For Glulam Mounting Only

-1/2” Wrench

-3/4’’ Wrench

-3/4’’ Socket

-7/32” Allen Wrench (Provided)

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 13

Rev. Date 062718

If using the Universal Mount, please refer to the AVD 550/780

manual for proper mounting instruction, which can be found at

www.EnergyLogicfans.com/resources/

Mounts

Noise Dampening Pad

Place Noise Dampening

Pad between mount and

mounting surface for all

mounts and mounting styles.

If you purchased the Noise/Vibration Dampening Pad (optional):

Rapid Mount Commercial

Turn to page 14

Fixed Angle Mount

Turn to page 32

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 14

Rev. Date 062718

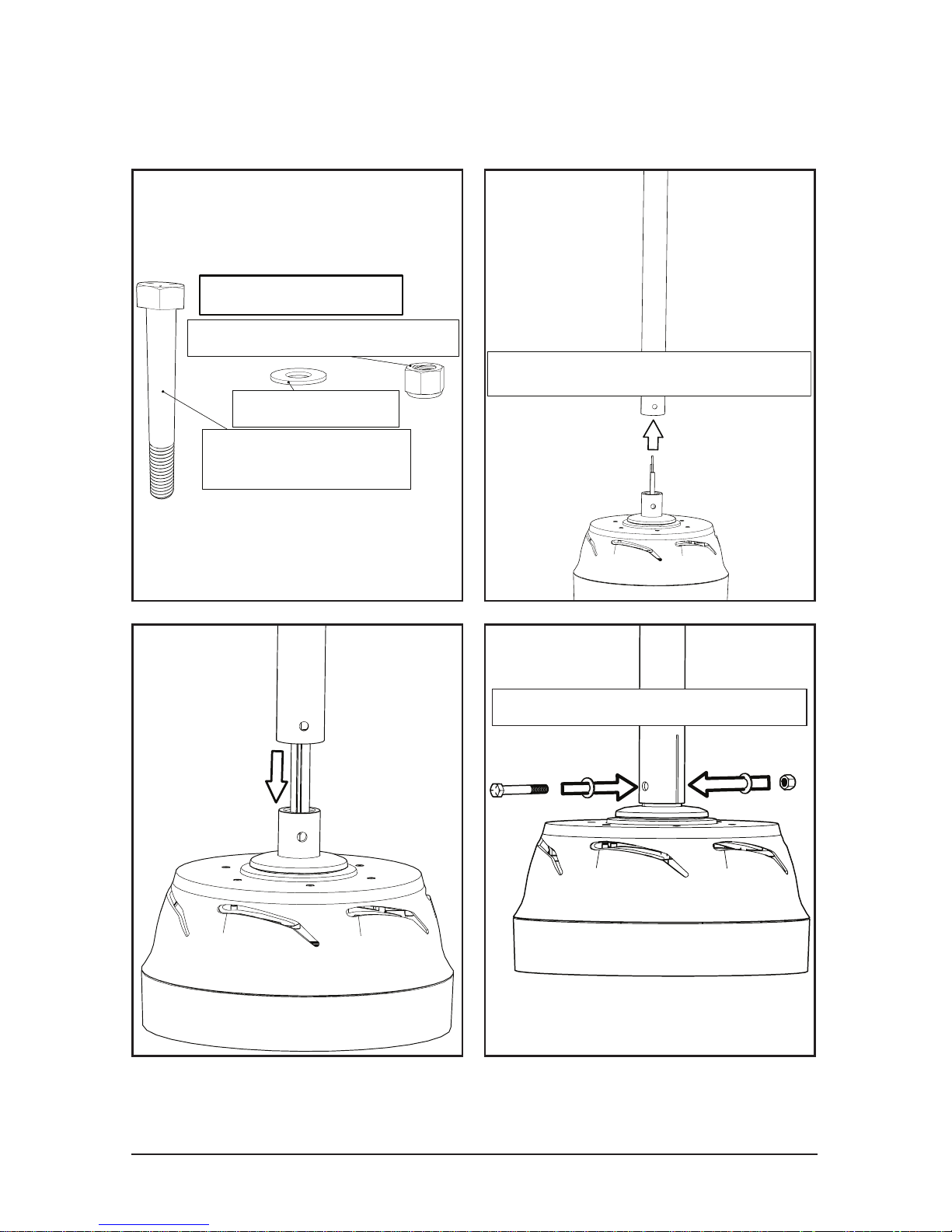

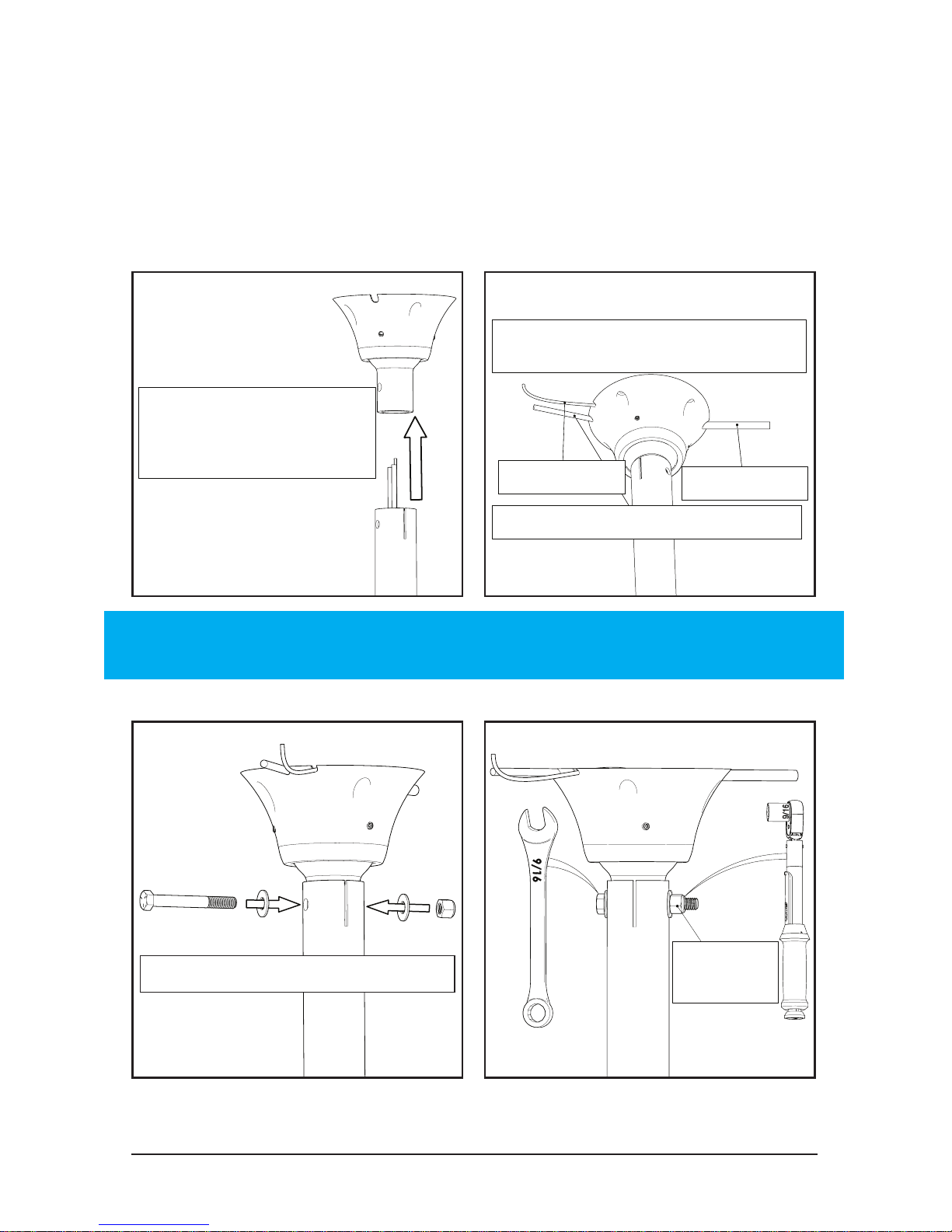

1.1 Rapid Mount Commercial

Motor & Extension Tube

3/8" Washer (4)

3/8"-16 Nylon Lock Nut (2)

3/8"-16 x 2 3/4" Hex

Head Bolts (2)

3/8" Washer (4)

Extension Bolt Kit

Feed cables through tube

Feed cables through tube

Be careful of wires

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 15

Rev. Date 062718

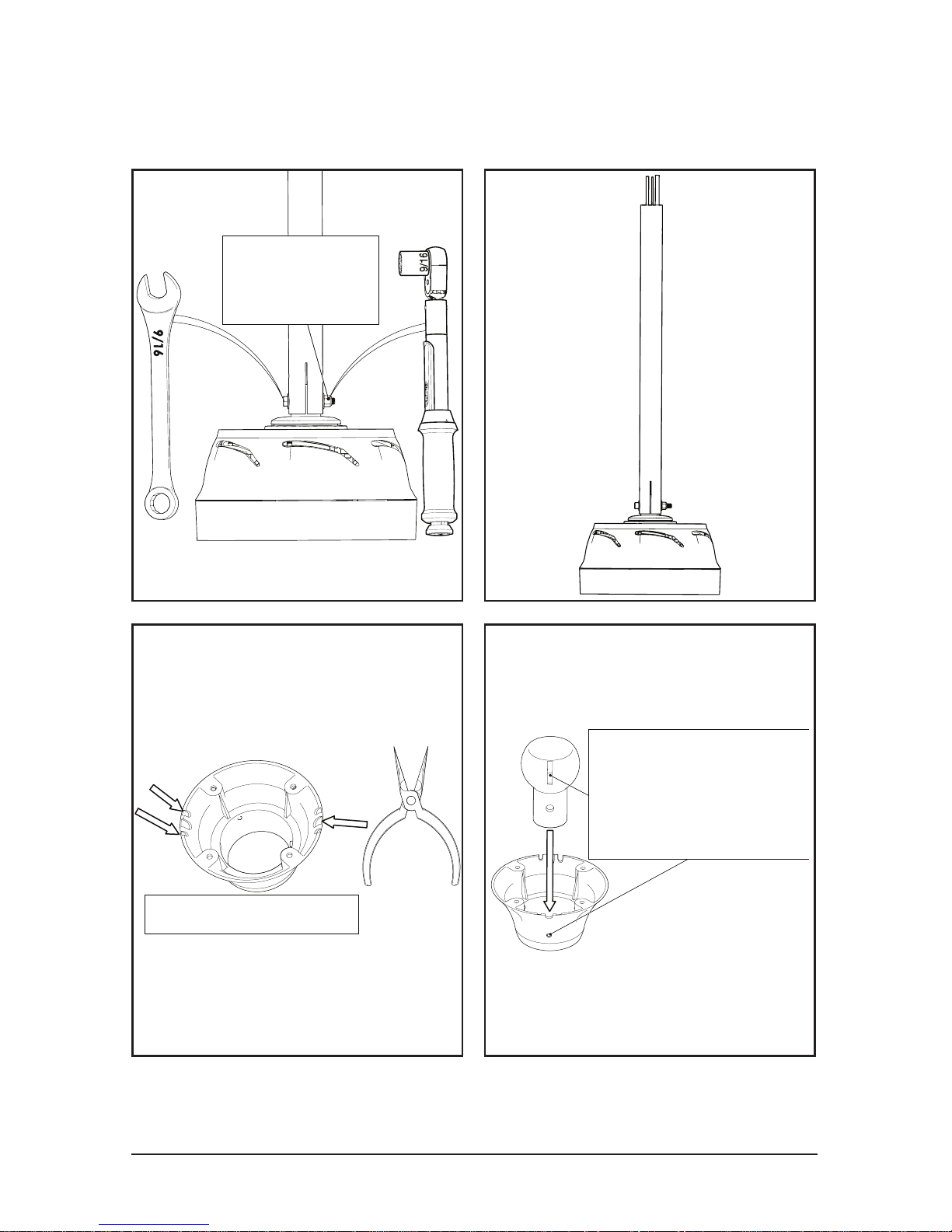

30 ft-lbs

30 ft-lbs

[41 N-m]

9/16”

Remove Breakouts

Line-up pin and

groove to ensure

no rotational

movement

Line-up pin and

groove to ensure

no rotational

movement

1.1 Rapid Mount Commercial

Motor & Extension Tube

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 16

Rev. Date 062718

30 ft-lbs

30 ft-lbs

[41 N-m]

Be careful of wires

The set screws in the mount will be tightened once the mount is

securely fastened to the building.

9/16”

1.1 Rapid Mount Commercial

Motor & Extension Tube

Run cables

through mount

Power Cable

Stranded Sheilded CAT5e Cable

Safety Cable

Power Cable

Stranded Shielded CAT5e Cable

Safety Cable

The power cable must be opposite

of the safety and CAT5e cables

NOTE: Power cable must be routed into the mount on the

opposite side from safety cable and CAT5e cable.

CAT5e Shielded must be used at a minimum. No unshielded comm cables.

The communications cable MUST be routed at least 1 foot away from

power cables, high voltage power wires, and uorescent lighting. The

only point where the power cable should be near the comm wire is

when they are in the mount and extension tube.

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 17

Rev. Date 062718

1/2"-13 Grade 5 Hex Bolt

at least 2 1/2" longer than

width of Glulam (2)

1/2" Washer (4)

1/2"-13 Nylon Lock Nut (2)

Glulam Required Parts

(NOT PROVIDED)

1.2 Rapid Mount Commercial

Bolt Kits

The I-Beam Bolt Kit is included with both I-Beam and Glulam

brackets. Additional parts must be purchased if mounting to

a Glulam (with the glulam bracket) or Unistrut.

For mounting to steel

trusses over 3 inches in

width, use the I-Beam

mounting method. For

widths under 3 inches,

use Unistrut span

mounting.

If you wish to mount to

a different surface than

these listed here, contact

a structural engineer.

1/2"-13 x 2 1/2" Hex Bolt (4)

1/2"-13 Nylon Lock Nut (4)

1/2" Washer (8)

I-Beam Bolt Kit (Optional)

1/4"-28 x 3/4"

Countersunk Socket

Head Cap Screw (4)

1/4"-28 Flanged Distorted

Thread Locknut (4)

Rapid Mount Commercial Mounting

Plate Bolt Kit (Optional)

Direct Glulam mounting

starts on page 18

Glulam Bracket mounting

starts on page 21

I-Beam mounting

starts on page 25

Unistrut mounting

starts on page 29

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 18

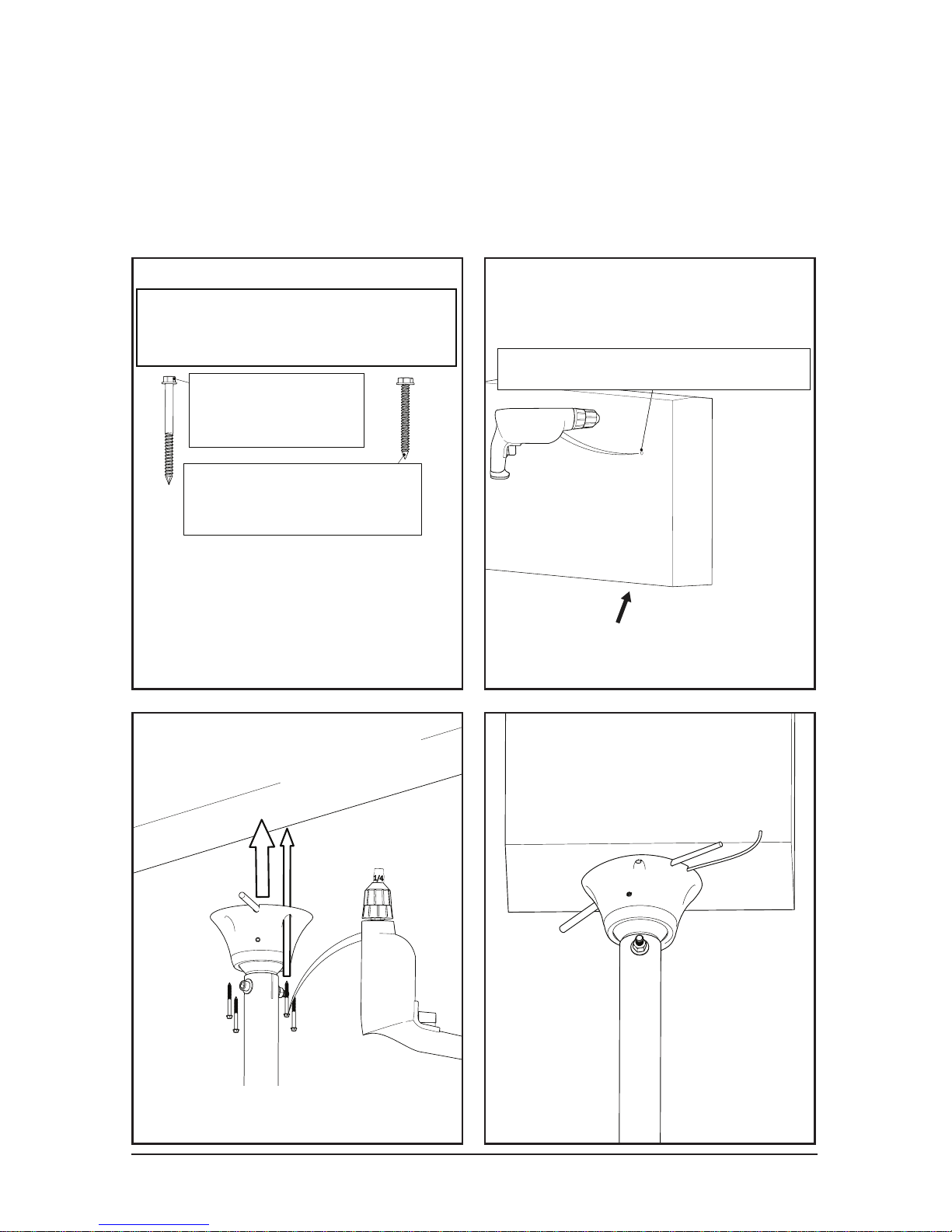

Rev. Date 062718

#10 2-1/2"

Lag Screw (4)

#10 1-3/4"

Concrete Screw (4)

Rapid Mount Commerical

Mounting Screws

1/8" safety cable clearance1/8" safety cable clearance

Glulam / Wood Beam

1.2.1 Rapid Mount Commercial

Glulam (Direct Mounting)

While concrete screws

are provided, contacting a

structual engineer is required

for mounting to Concrete.

Position the mount so that the

screws are as far away from the

edge of the beam as possible

Glulams and wood beams must be at least 6” wide to use this mounting

method. For narrower beams, use Glulam Brackets (sold separately) or

span across two or more beams using the Unistrut mounting method.

1/4”

Drill a pilot hole before

installing screws

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 19

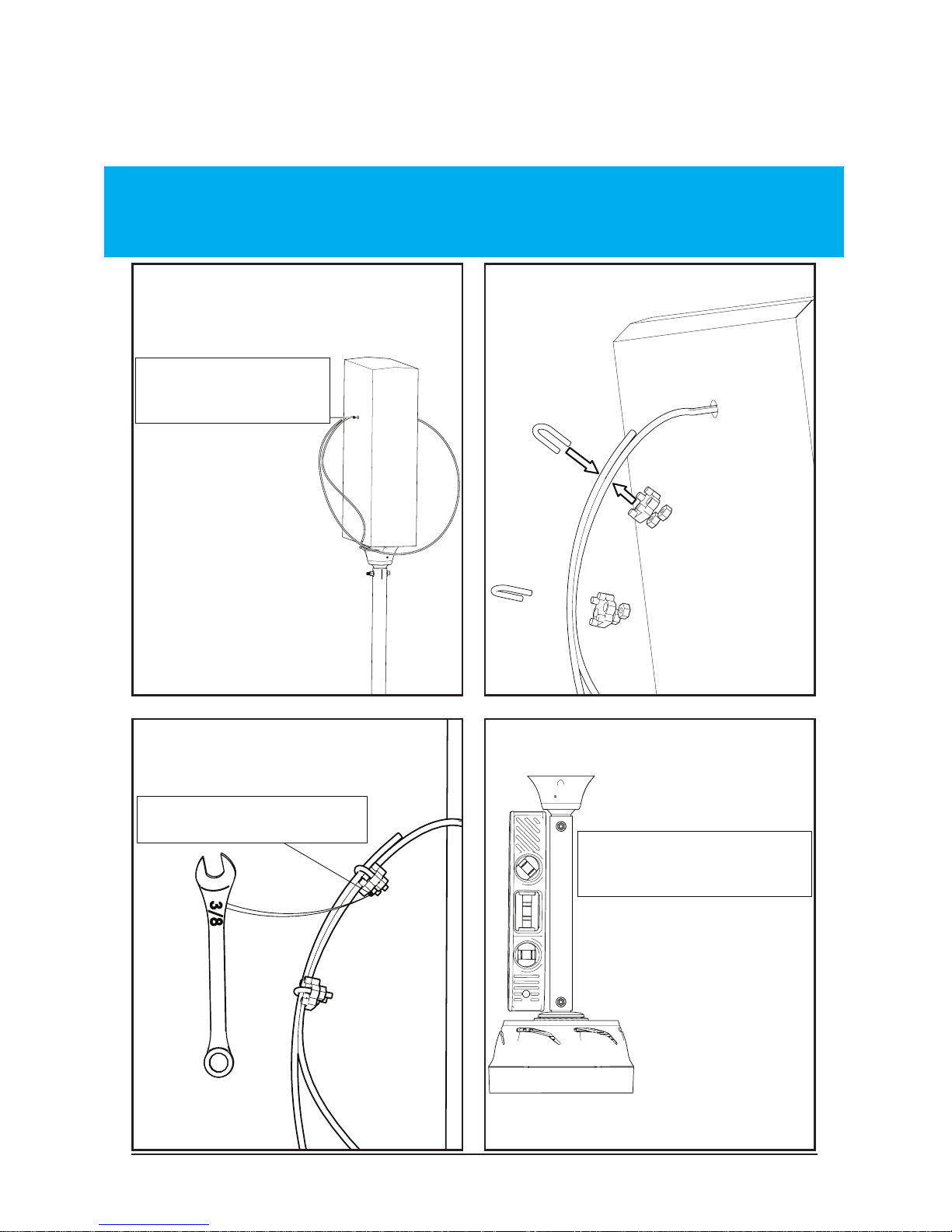

Rev. Date 062718

Run safety cable

though hole

Run safety cable

through hole

Tighten both nuts

Level Mount

1.2.1 Rapid Mount Commercial

Glulam (Direct Mounting)

WARNING: Do not put too much tension on the safety cable. There

needs to be a small amount of slack present in the safety cable for

proper functioning. Avoid sharp edges.

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 2 0

Rev. Date 062718

Tighten both

set screws

After tightening, move the

extension tube back and

forth, then tighten the set

screws again

1.2.1 Rapid Mount Commercial

Glulam (Direct Mounting)

1/8”

Complete safety cable installation and turn to page 50

© 2018 EnergyLogic, LLC Toll Free: 800 311 8828 Fax: 615 471 5202 www.energylogic.com 21

Rev. Date 062718

10 ft-lbs

10 ft-lbs

[14 N-m]

5/16”

5/32”

1/8" safety cable clearance

Holes can be oversized

for leveling the mount

1/2" bolt clearance

Use the two holes closest to

the center line of the glulam.

The bracket can be below the bottom

of the glulam if necessary but

is not recommended if it is avoidable.

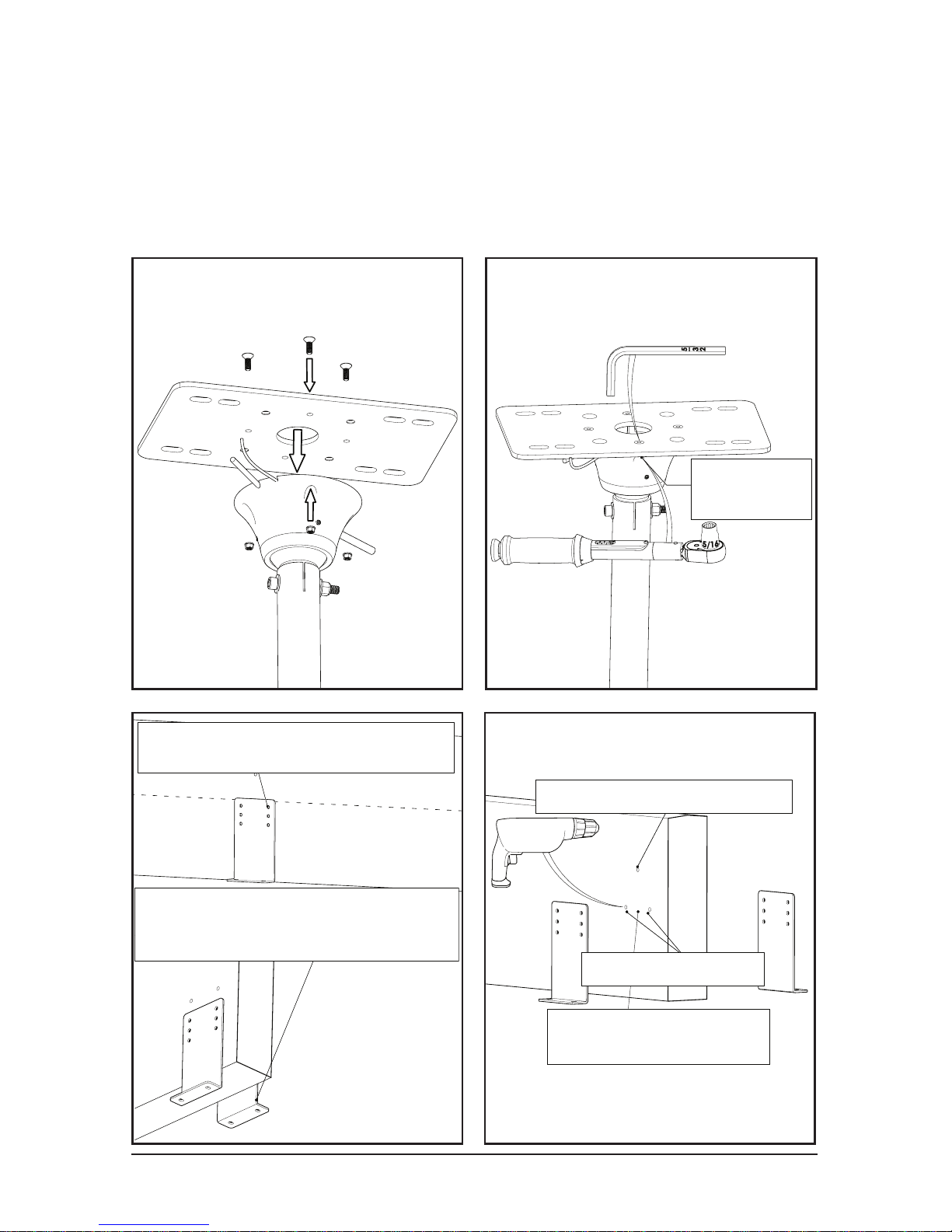

1.2.2 Rapid Mount Commercial

Glulam (with Glulam Brackets)

This method is recommended for Glulams or wood beams between

4-1/8” or wider. For narrower beams, span across two or more beams

using the Unistrut mounting method.

Loading...

Loading...