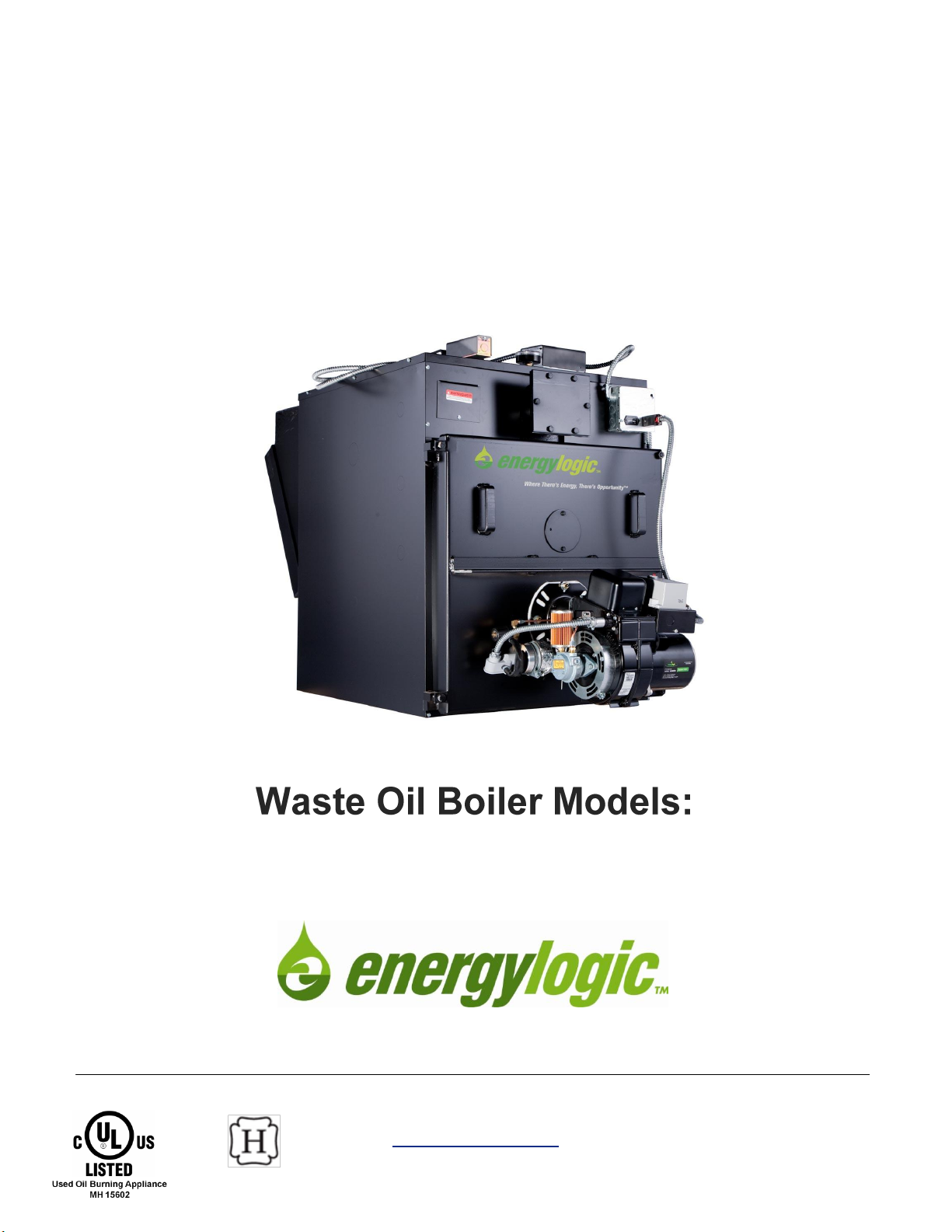

Energylogic EL-500B, EL-200B, EL-375B User Manual

Installation &

Operation Manual

EL-200B, EL-375B, and EL-500B

115V/60Hz

5901 Crossings Boulevard

Nashville, TN 37013

www.energylogic.com

(615) 471-5290

ASME Certified

Designed to save. Built to last. ™

Item # 98030034

Issue date: 26 March 2014

I.D. Number:

(Located on the vessel skins,

near the spec. label.)

Installed By:

(Service Company, Address,

Contact Name, Phone Number)

Date of Installation:

Ta

bl

e

of

C

on

Caution!

Before you begin installation and operation

of your boiler, read this manual completely,

and save it for future reference!

IMPROPER INSTALLATION, OPERATION, OR

MAINTENANCE OF THE BOILER SYSTEM CAN CREATE

HAZARDOUS CONDITIONS AND WILL VOID THE

WARRANTY AND U.L. LISTING

This boiler is UL listed for commercial and industrial use only.

Refer to Section 1 for safety information and precautions.

Installation of the unit shall be made in accordance with all state and local codes which

may differ from information provided in this manual. Installations in Canada shall be in

accordance with the regulations of authorities having jurisdiction and installation

practice shall be made according to CSA standard B139, Installation Code for Oil

Burning Equipment.

Product improvements are occurring regularly, so the products may vary slightly from

what is shown in this manual.

If you have any questions or concerns during the installation or operation of the boiler,

contact your local service representative or EnergyLogic.

Thank you for purchasing an EnergyLogic boiler. Record the Unit I.D. Number below for future

reference. Please register your unit to activate your warranty by visiting EnergyLogic’s website

at www.energylogic.com/register . If you have any issues registering, please contact us at

615-471-5200.

Call 1-615-471-5290 for Technical Support

i

Table of Contents

Before you begin ................................................................................................................................... i

Table of Contents ................................................................................................................................... ii

1. Safety, Codes and Regulations ......................................................................................................... 1

1.1 Conventions Used in this Manual................................................................................................. 1

1.2 General Warnings ........................................................................................................................ 2

1.3 Safety Hazards ............................................................................................................................ 2

1.4 Codes and Regulations ................................................................ ............................................... 4

1.5 Fuels and Fuel Management ....................................................................................................... 5

1.5.1 Fuels ..................................................................................................................................... 5

1.6 Clearances to Combustible Surfaces ........................................................................................... 6

2. Installation Considerations ................................................................................................................ 7

2.1 Technical Guidelines ................................................................................................................... 7

2.2 Tools Required ............................................................................................................................ 8

2.3 Boiler Placement Guide ............................................................................................................... 8

3. Assembly and Installation –Vessel, Tank, Pump and Suction Fuel Line .......................................... 10

3.1 Unpacking and Inspection ......................................................................................................... 10

3.2 Warranty Registration ................................................................................................................ 10

3.3 Boiler Vessel Installation ............................................................................................................ 12

3.3.1 Vessel Installation ............................................................................................................... 12

3.4 Preparing the EnergyLogic Used-Oil Tank ................................................................................. 13

3.4.1 Tank Vent Installation – EnergyLogic Tanks ........................................................................ 13

3.4.2 Drain Valve Installation – EnergyLogic Tanks ..................................................................... 13

3.4.3 Low Fuel Cutoff Switch – EnergyLogic Tanks ..................................................................... 13

3.5 Fuel Metering Pump and Filter Installation – EnergyLogic Tank (continue to section 3.6 if you

don’t have EL tank). .......................................................................................................................... 14

3.5.1 Fire Stop Valve and Filter Head Installation – EL Tank. ....................................................... 14

3.5.2 Metering Pump Installation – EL Tank ................................................................................. 14

3.5.3 Gauge and Pump Tubing Installation – EL Tank ................................ ................................. 15

3.6 Metering Pump Installation – Non-EL Tank (skip if you have EL tank) ........................................ 16

4. Installation of Boiler Components .................................................................................................... 17

4.1 Vessel Panel and Insulation Assembly ...................................................................................... 17

Call 1-615-471-5290 for Technical Support

ii

4.2 Boiler Wire Harness and Controls Installation ............................................................................ 18

4.2.1 Low Water Cutoff Probe and Control Installation. ................................................................ 18

4.2.2 Triple Aquastat Temperature Controller Installation. ............................................................ 19

4.2.3 High-Limit Temperature Controller Installation. ................................................................... 20

4.2.4 Vessel Wire Box installation. ............................................................................................... 21

4.3 Pressure Relief Valve and Combination Gauge Installation ....................................................... 22

4.4 Domestic Coil (optional accessory) ............................................................................................ 22

4.5 Preheater Assembly .................................................................................................................. 23

4.6 Burner/Vessel Assembly ............................................................................................................ 24

4.7 Pump Discharge (Outlet) Tubing Installation .............................................................................. 27

4.7.1 Pump Discharge Tubing Installation ..................................................................................... 27

4.7.2 Pump Discharge (Outlet) Tubing Installation – Guidelines ................................................... 28

4.8 Hydronics Connection and Boiler Mixing Valve Installation ........................................................ 28

4.8.1 Hydronics Installation – Key Points ..................................................................................... 28

4.8.2 Hydronics Set Up ................................................................................................................ 29

4.8.3 Boiler Mixing Valve Set Up .................................................................................................. 30

4.9 Filling the System ...................................................................................................................... 30

5. Exhaust Flue System Installation .................................................................................................... 31

5.1 Barometric Damper Tee Installation ........................................................................................... 31

5.2 Flue Piping Installation ............................................................................................................... 31

5.3 Draft Gauge Installation (included with some packages) ............................................................ 34

6. Electrical System Installation ........................................................................................................... 35

6.1 Wall Thermostat and Low Fuel Cut-Off Switch Installation (Optional Accessories) .................... 35

6.1.1 Wall Thermostat Installation ................................................................................................ 35

6.1.2 Low Fuel Cut-Off Installation ............................................................................................... 35

6.2 Fuel Pump Power Connection ................................................................................................... 36

6.3 Main Electrical Connection ........................................................................................................ 37

7. Startup and Operation ..................................................................................................................... 38

7.1 Do’s and Don’ts/Tech Tips ......................................................................................................... 38

7.2 Burner Primary Control Operation.............................................................................................. 38

7.3 Safety Systems and Warnings ................................................................................................... 40

7.4 Boiler Startup ............................................................................................................................. 40

7.4.1 Fuel System Priming ........................................................................................................... 41

7.4.2 Starting the Boiler ................................................................................................................ 42

7.4.3 Burner System Checkout ................................................................ .................................... 43

Call 1-615-471-5290 for Technical Support

iii

7.5 Everyday Operation of Your EnergyLogic Used Oil Boiler ...................................................... 46

8. Maintenance ................................................................................................................................... 47

8.1 Service Contracts ...................................................................................................................... 48

8.2 Safety Warnings – Lockout/Tagout ................................................................ ............................ 48

8.3 Monitoring System Performance over Time ............................................................................... 48

8.4 Maintenance Schedule and Parts .............................................................................................. 48

8.5 Maintenance Procedures ........................................................................................................... 50

8.5.1 Heat Exchanger Cleaning / Door and Access Insulation Checks ......................................... 50

8.5.2 Low Water Cut Off Testing and Probe Inspection ................................................................ 52

8.5.3 Fuel Oil Filter Replacement ................................................................................................. 54

8.5.4 Preheater Cleaning ............................................................................................................. 55

8.5.5 Nozzle Line Assembly Cleaning .......................................................................................... 57

8.5.6 Retention Head and Electrode Settings ............................................................................... 60

8.5.7 Solenoid Valve Cleaning ..................................................................................................... 62

8.5.8 Air Compressor Maintenance .............................................................................................. 64

8.6 Seasonal Shut Down & Start Up ................................................................................................ 66

9. Troubleshooting .............................................................................................................................. 67

9.1 Troubleshooting Condition Table ............................................................................................... 68

9.2 Troubleshooting Trees ............................................................................................................... 69

9.3 Testing Procedures ................................................................................................................... 72

9.3.1 Wall Thermostat (if equipped) and Burner Thermostat Circuit Testing .................................. 72

9.3.2 Water Circulator Pump Testing ............................................................................................ 73

9.3.3 Cad Cell Testing................................................................................................................... 74

9.3.4 Metering Pump Assembly Testing ........................................................................................ 75

9.3.5 Preheater and Nozzle PTC Testing Procedure ..................................................................... 77

9.3.6 Primary Control Testing........................................................................................................ 79

9.3.7 Solenoid Valve Testing......................................................................................................... 80

9.3.8 Top Suction Kit Testing ........................................................................................................ 81

9.3.9 Iron Core Transformer Testing ............................................................................................. 82

9.3.10 Boiler Control Testing / Wiring Troubleshooting.................................................................. 84

10. Appendices ................................................................................................................................... 86

10.1 Boiler Wiring and Oil Schematic............................................................................................... 86

10.2 Boiler Specifications ................................................................................................................ 89

10.3 Limited Warranty ..................................................................................................................... 93

iv

Call 1-615-471-5290 for Technical Support

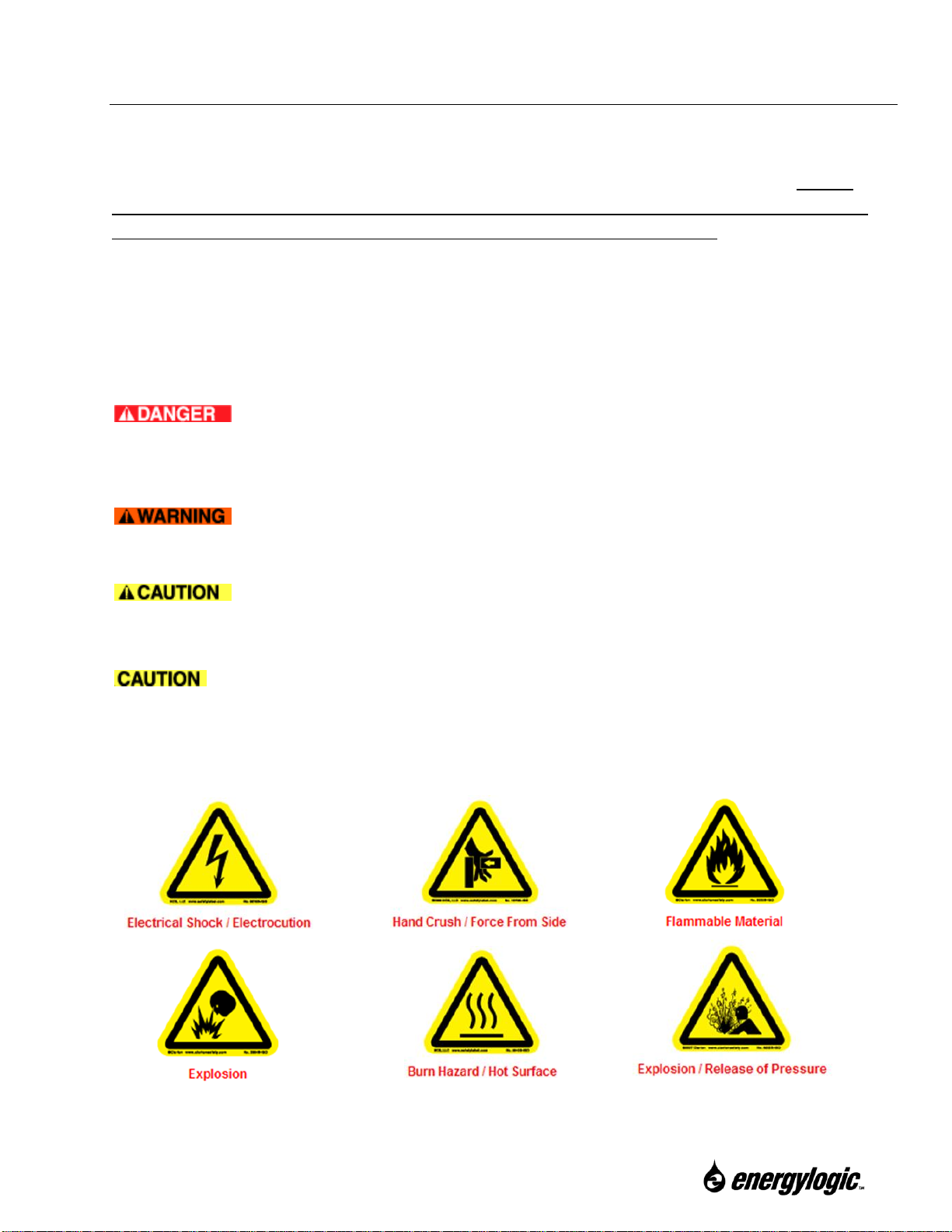

Danger: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury. This signal word is limited to the most extreme

situations.

Warning: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

Caution (without alert symbol): Indicates an unsafe practice which, if not

avoided, may result in product or property damage. Also used for general

alerts.

1. Safety, Codes and Regulations

Thank you for the purchase of an EnergyLogic used oil boiler. EnergyLogic boilers are

thoroughly tested for safe, long-term operation. However, proper installation, fuel quality

control, and regular maintenance are required to ensure safe, long-term operation. Please

read and understand this manual completely before attempting to install, operate, or service

the boiler. Post this instruction manual and maintain it in legible condition. If you have any

questions, call your local service provider or the number below for EnergyLogic Technical

Service.

1.1 Conventions Used in this Manual

For your safety, this manual uses the following definitions and signal words to identify hazards:

Product safety labels and their meaning (labels not used on all products):

Call 1-615-471-5290 for Technical Support

1

1.2 General Warnings

The EnergyLogic burner is to be used only in the EnergyLogic boiler

provided. Do not attempt to use the burner for other purposes.

Do not tamper with the unit or controls – call your service technician.

Do not attempt to use unit with broken or damaged components.

Do not allow unqualified personnel to install or service the boiler,

electrical system, or flue system. Contact EnergyLogic for help with finding a qualified

installation and service company. Failure to install and maintain your boiler properly will

void your warranty and the UL listings.

Do not attempt to start the burner when excess oil has accumulated,

when the boiler is full of vapor, or when the combustion chamber is very hot.

Do not start the burner unless all cleanout panels are secure in place.

KEEP THE FUEL VALVE NEAREST THE SUPPLY TANK SHUT OFF

WHEN THE BURNER IS SHUT OFF FOR EXTENDED PERIODS.

Turn off power to the burner when the burner is off for extended periods.

The boiler is designed to be installed in a manner that restricts its access.

USED OILS CONTAIN HEAVY METALLIC COMPOUNDS AND

FOREIGN MATERIALS. WHEN BURNED, THESE COMPOUNDS ARE EMITTED

FROM OR DEPOSITED WITHIN THIS HEATING APPLIANCE AND THEREFORE

CARE SHOULD BE TAKEN WHEN USING, CLEANING AND MAINTAINING THIS

EQUIPMENT.

EnergyLogic recommends that the building, domestic hot water system or

process have a secondary heat source during times the boiler is down for maintenance

or service. Used oil boilers require maintenance. Also, used oil may sometimes be

unavailable or burn poorly due to contaminants (such as water) in the oil.

1.3 Safety Hazards

There are potential hazards associated with operation of this or any other boiler. In addition to

the codes and regulations listed in the following section, general safety rules and precautions

should be followed at all times to prevent accidents that could lead to personal injury, death or

property damage. Only those qualified should perform the tasks. Specific safety hazards

include:

Electricity: The EnergyLogic boiler operates on 115V/60Hz electrical power.

Turn power off at the circuit breaker and lock it out prior to performing any work on the boiler

system or any of the components. Make sure covers are in place during normal use. Use only

copper conductors.

Liquid Fuels: Used oils must be handled properly to prevent spills. Uncontained

oil leaks may contaminate the local water supply. Ensure that all national and local codes are

Call 1-615-471-5290 for Technical Support

2

followed in regards to the requirements for spill containment and SPCC paperwork. Oil leaks

pose slip/fall hazards, and pose a risk for fires. DO NOT USE GASOLINE OR ANY OIL

CONTAINING GASOLINE. Do not add any cleaning fluids or oil additives to the used oil

burned in this appliance. The use of unauthorized fuels will void the warranty and U.L. listing.

See section 1.5.1 for a list of allowable fuels. The end user of the boiler is responsible for

ensuring that all correct precautions are taken in managing their used oil.

Combustion Exhaust Gases: The exhaust products from the combustion are

dangerous to breathe. The boiler must be attached to a flue which properly vents the exhaust

out of the building to the atmosphere at all times, to assure safe and proper operation of the

burner. If proper draft cannot be established, changes to the building construction or a draft

inducer will be required in order to provide adequate make-up air.

Safe Maintenance: Used oil contains mineral additives and deposits called

“ash” that will not burn. Ash collects in the boiler and flue with regular use over time. Ash must

be cleaned out of the combustion chamber/heat exchanger and flue pipe on a scheduled

basis. Follow the minimum maintenance instructed in section 8. Wear proper protective

clothing; including gloves, safety glasses, and a dust mask or respirator whenever any

cleaning is performed, including the cleaning of the heat exchanger, flue piping and exhaust

stack.

Vapor/Dust Ignition: Do not store or use gasoline or other flammable liquids or

vapors near this boiler, as they may be ignited by the burner. Do not operate the boiler in dusty

or otherwise dangerous environments.

Flammable liquids: Do not create a fire or explosion hazard by using or placing

flammable liquids such as gasoline or solvents near the boiler. A flammable liquid is any liquid

that has a closed-cup flash point below 100°F (37.8°C), as determined by the test procedures

and apparatus set forth in 1.7.4 of NFPA 30.

Minimum Clearance – Safe clearance to combustibles (Section 1.6) shall be

adhered to.

Height, Weight, Guarding and General Safe Practices: The boilers are installed

with flue systems at heights which pose a risk for injuries due to a fall. Many of the

components are heavy, and pose the risk of injury with improper lifting and handling. Always

follow safe practices and use proper equipment. Never climb on the equipment. Do not take

risks when installing or servicing the equipment. All cover plates, enclosures, and guards must

be maintained in place at all times, except during maintenance and servicing. Failure to

observe general safety rules and to follow safety rules specific to the tools and equipment used

or being worked on may result in product/property damage, personal injury or death.

Call 1-615-471-5290 for Technical Support

3

1.4 Codes and Regulations

The installation, operation, and maintenance of the boiler system in the United States must be

performed by qualified personnel in accordance with this manual and all national, state, and

local codes / regulations, as well as the following standards of the National Fire Protection

Association (NFPA) and the American Society of Mechanical Engineers (ASME):

ASME Boiler Code Section IV

ASME CSD-1 Controls and Safety Devices for Automatically Fired Boilers

NFPA 31 Standard for the Installation of Oil Burning Equipment

NFPA 30 Flammable and Combustible Liquids Code

NFPA 30A Code for Motor Fuel Dispensing Facilities and Repair Garages

NFPA 70 National Electric Code

NFPA 88A Standard for Parking Structures

NFPA 88B Standard for Repair Garages

NFPA 211 Standard for Chimneys, Fireplaces, Vents and Solid Fuel Burning

Appliances

These standards are available from the NFPA at www.nfpa.org, and from the ASME at

http://www.asme.org/.

Similarly, the installation, operation, and maintenance of the boiler system in Canada must be

performed by qualified personnel in accordance with this manual and in accordance with all the

regulation authorities having jurisdiction, as well as CSA Standard B 139, Installation Code for

Oil Burning Equipment, B140.0 – General Requirements for Oil Burning Equipment, B140.7.2

– Oil Fired Steam and Hot Water Boilers for Commercial and Industrial Use, B214 –

Installation Code for Hydronic Heating Systems. Electrical installation in Canada shall be in

accordance with C22.1 - Canadian Electrical Code, Part I. CSA standards are available at

www.csa.ca.

A qualified installer is an individual or agency who is responsible for the installation and

adjustment of the equipment and who is properly licensed and experienced to install oil

burning equipment in accordance with all codes and ordinances.

In the United States, make sure you comply with all EPA regulations concerning the gathering

and storing of used oil, and operation of the boiler. Specifically, CFR Title 40 Part 279 covers

managing used oil. As well, make sure you comply with local codes and regulations.

In Canada, only used oil generated on the premises of the owner may be used in this

equipment unless written authorization is obtained from the regulatory authority. Comply with

Canadian regulations regarding the management and storing of used oil, as well as any local

codes and authorities having jurisdiction

Call 1-615-471-5290 for Technical Support

4

1.5 Fuels and Fuel Management

The boiler system is composed of several components and subsystems that work together for

efficient and safe operation. In order for the system to function as designed, good fuel

management practice must be followed.

1.5.1 Fuels

EnergyLogic boilers are listed by Underwriters’ Laboratories (U.L.) for the U.S. and Canada,

operating on the following fuels:

Used Crankcase Oil.

Used Automatic Transmission Fluid.

ASTM D396 No. 2 Fuel Oil.

DO NOT USE GASOLINE OR ANY OIL CONTAINING GASOLINE.

Fuel mixtures must have a minimum flash point of 140°F (60°C) and the maximum flash point

of approximately 400°F (204°C). Mixtures shall not contain hazardous waste.

Never mix inappropriate or hazardous material with the used oil. Examples of

substances that should never be added include but are not limited to:

Gasoline

Kerosene

Hazardous Waste

Anti-freeze

Carburetor Cleaner

Any Chlorinated Material

Parts Washer Solvents

Oil Additives

Animal Fats

Brake Fluid

Paint Thinner

The addition of inappropriate substances to the fuel is not approved and can

lead to poor equipment performance, premature product failure, and/or explosive/hazardous

conditions. Burning of fuels that contain unapproved substances will void the product warranty

and the UL listing. If you have any question about what is contained in your used oil, it is your

responsibility to have the oil analyzed prior to burning.

Contact EnergyLogic Technical Services if you have questions about a particular fuel type, or if

you need fuel analysis. For a nominal fee, EnergyLogic Technical Services will provide a

professional fuel analysis. You will be provided with instructions in order to collect an oil

sample to be sent out for analysis. Specify the type of analysis that is needed.

Call 1-615-471-5290 for Technical Support

5

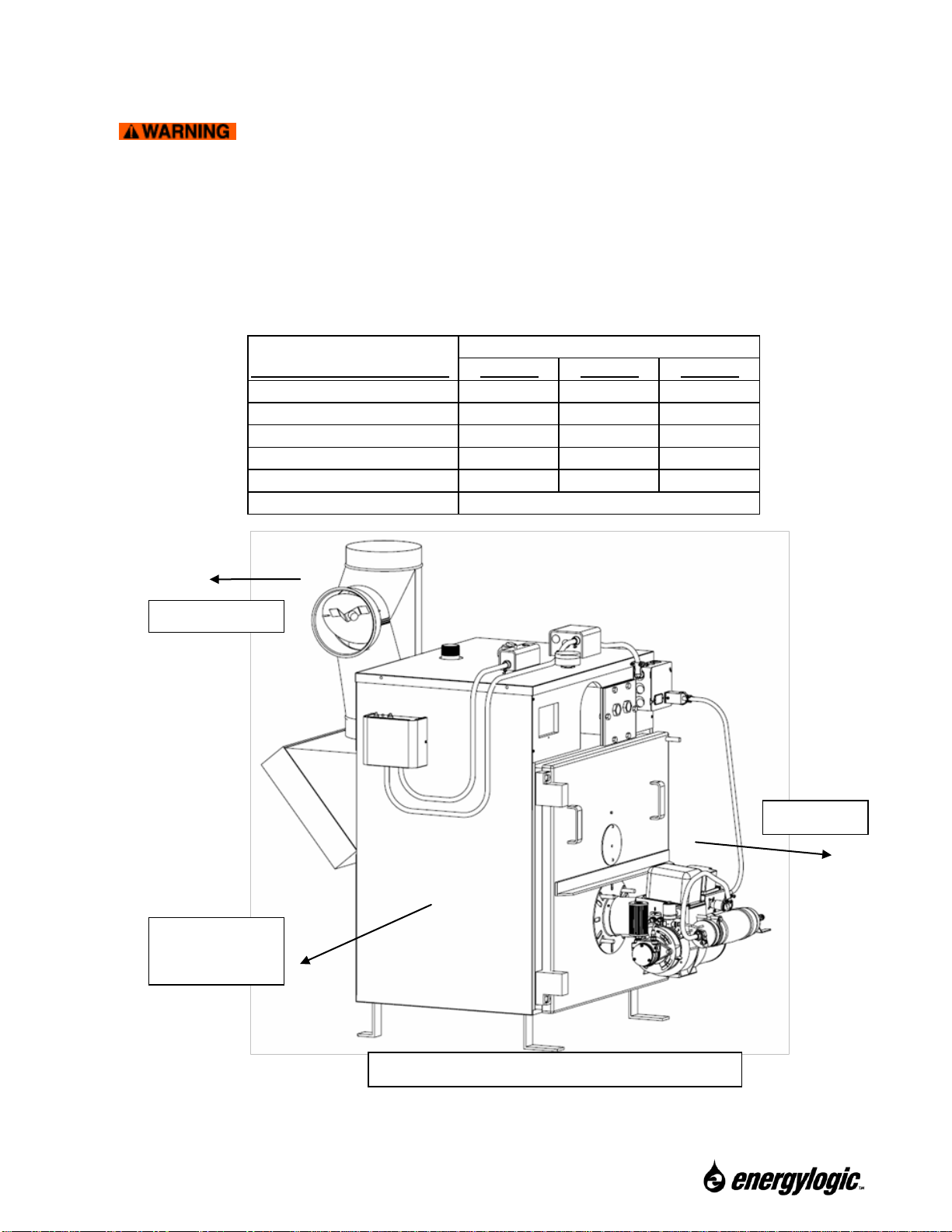

EL-200B EL-375B EL-500B

Top & pipe connections 18" 18" 18"

Front - (burner location) 48" 48" 48"

Sides 18" 18" 18"

Rear 18" 18" 18"

Flue Pipe 18" 18" 18"

Bottom

Must be on non-combustible flooring.

Model

Minimum clearance from:

48” Front

18” Sides, Top

and Rear

18” Flue Pipe

Non-combustible Flooring

Minimum Clearances

1.6 Clearances to Combustible Surfaces

It is of the utmost importance that the installation conform to the minimum

clearances to combustible surfaces (Material made of or surfaced with wood, compressed

paper, plant fibers, plastics, or other material that can ignite and burn, whether flame proofed

or not, or whether plastered or unplastered). Consult applicable codes and regulations for

precedence. Non-compliance to minimum clearances may result in fire, explosion, personal

injury or death. The U.L. Listing specifies: “For all boilers rated for 50 psi or less and for all

water boilers, installation clearances are Form III.” & “The boilers are intended for installation

on noncombustible flooring.” The clearances for each model follow:

Call 1-615-471-5290 for Technical Support

6

2. Installation Considerations

EnergyLogic boilers are designed to operate reliably over a wide range of conditions. However,

it is important to read this section before installation to prevent unnecessary work or problems.

2.1 Technical Guidelines

1. Most components of your boiler are factory-tested to ensure proper operation. Do not

tamper with factory settings or fittings. The settings on the triple aquastat may be

adjusted.

2. Pre-assembled fittings are sealed with thread-locker sealant and do not require

additional tightening.

3. Always supply power through a dedicated, hard-wired (copper only), 115VAC/60Hz

circuit with a 25 Amp maximum breaker. Check local codes.

4. Do not use the provided thread-locker sealant on flare fittings. Use the provided

sealant on all NPT fuel line connections only.

5. Do not use Teflon tape on any fuel connections. Loose strands may block small

orifices, affecting unit operation or may damage components.

6. Route all fuel lines inside building to prevent exposure to cold weather. If this is not

practical, call EnergyLogic for application support.

7. Locate boiler and tank in a dry area above 50°F (10°C) at all times.

8. If not installing the pump to an EnergyLogic Tank, mount it according to guidelines in

the EnergyLogic Top Suction Kit packaging instructions.

9. Do not kink copper tubing. Route tubing as straight and vertical as possible to avoid

air pockets.

10. Maximize vertical run of flue, and minimize horizontal run. Allow access for clean-out.

11. Do not allow your tank to run out of fuel. If the tank runs out of fuel, air and

contamination will be introduced into the fuel delivery system. An optional EnergyLogic

low-level cut off switch is recommended to prevent low fuel operation.

12. Never use compression fittings for fuel tubing connections, as they will leak and cause

the burner to shut down.

13. Care should be taken not to over tighten or cross thread brass fittings.

14. Applying a thin film of anti-seize compound to burner gasket may reduce gasket

sticking to vessel when servicing.

15. Another source of heat is recommended for periods when the boiler may be off-line for

maintenance or for any other reason.

Call 1-615-471-5290 for Technical Support

7

5/16” Combination Wrench Pipe Wrench Set

3/8” Combination Wrench Flat Blade Screwdriver

7/16” Combination Wrench (x2) 1/4” Hex Wrench or Driver

1/2” Combination Wrench Wire Cutter (to remove tie straps)

5/8” Combination Wrench Lift Device

11/16” Combination Wrench Safety Ladder or Lift

3/4” Combination Wrench (Tools Required for Flue Kit Installation)

2.2 Tools Required

Below is a recommended list of tools and equipment that may be used to aid in the installation

of the EnergyLogic boiler. This is a minimum list for a simple system, excluding the hydronics

and plumbing.

2.3 Boiler Placement Guide

It is important to plan the boiler and tank placement, wiring, piping and flue prior to installation.

Electrical Wiring - Will the layout of your building allow safe routing and installation of

electrical wiring to the boiler? Check your local building codes. The EnergyLogic boiler requires

115VAC/60Hz power, supplied through a dedicated, hard wired, circuit breaker - 25Amp

maximum. Use copper conductors only. Electricity is very dangerous. Wiring

must be installed by a qualified electrician. In the U.S., consult the National Electric Code

(NEC) and local building codes for additional requirements. In Canada, consult the Canadian

Electrical Code, Part I.

Flue Pipe - Is ceiling/roof or wall location suitable for a flue pipe to pass through? Are any

obstacles present at interior or exterior locations? Check your roof warranty about penetration

of the flue pipe. Check your local building and fire codes.

Combustion and Make Up Air Requirements – It is necessary to ensure that

adequate air for safe combustion is provided for oil-burning appliances and equipment. Refer

to NFPA 31, Chapter 5 for requirements based on the total input BTU rating of all appliances in

the space. In Canada, reference CSA Standard B139/CGA B149.

Tanks - The oil tank is to be vented to the outside of the building. Oil

temperature should be maintained at 50°F (10°) and above. Tank shall be

at least 5 feet away from any source of heat and should not obstruct

service meters, electrical panels, or shut off valves. Check building,

environmental and fire codes for containment and other restrictions.

Minimum Clearance – Safe clearances to combustibles (Section 1.6) shall be

adhered to. A non-combustible flooring structure is required for the boiler.

Call 1-615-471-5290 for Technical Support

8

Distance from Flammable Liquids – Do not create a fire or explosion hazard

by using or placing flammable liquids such as gasoline or solvents near the boiler. A flammable

liquid is any liquid that has a closed-cup flash point below 100°F (37.8°C), as determined by

the test procedures and apparatus set forth in 1.7.4 of NFPA 30.

Access - Position the used oil storage tank to provide adequate access to filling ports, filter,

drain valve and pump. Leave an unobstructed path for shop vehicles and equipment. Consider

access needed for service (heat exchanger cleaning, flue cleaning, removal of breech panels,

burner access, etc.). Installation of system piping should not hinder required access for

service.

Vessel Placement in Motor Fuel Dispensing Facilities and Repair Garages – Heat

producing appliances shall not be allowed unless installed with provisions outlined in NFPA

30A, section 7.6.

Structural requirements (Canada) – In Canada, the structure in which the used oil burning

appliance is housed shall be no less than 4.6m (15ft) high at the point where the appliance is

situated and have a minimum length and width of 6m (20ft) and a minimum floor area of 37m2

(400ft2). In addition, the installation including flue stack height requirements and distance from

property line shall be in accordance with the authorities having jurisdiction concerning

environmental quality as well as fuel, fire, and electrical safety and Table 7 in CSA B140.0-03

(clause 22.3.2).

Other Considerations for EnergyLogic Boilers:

They are constructed with ASME certified pressure vessels (30 psi maximum pressure).

The ASME

stamp is located on boiler plate on the vessel under a removable panel.

They have Canadian Registration. The CRN number is located on the boiler plate.

They are UL Listed in the US and Canada. The UL mark and specification label are on a

boiler panel.

They are fire-tube boilers. This means that hot combustion gases flow through tubes,

transferring heat to water that surrounds the tubes.

They are carbon steel boilers. With a ¼” steel shell, they are of a durable construction,

and much lighter than cast iron models. Since they are carbon steel however, there are

some restrictions on the return water temperature to prevent corrosion (minimum return

temperature of 140°F).

They are wet-based boilers. This means that the combustion chamber and tubes are

surrounded by water that keeps the steel cool and prevents chamber deterioration.

They are non-condensing boilers. This means that the flue gases are not allowed to

cool enough to create condensation. Due to sulfur in the oil, condensation would create

sulfuric acid which would quickly corrode the boiler tubes and chamber.

Call 1-615-471-5290 for Technical Support

9

3. Assembly and Installation –Vessel,

Tank, Pump and Suction Fuel Line

This section instructs installing the fuel delivery system (side suction or top suction) and

mounting the vessel.

3.1 Unpacking and Inspection

After unpacking your new boiler, make sure you have received the proper parts and quantities

shown in the checklist on the following page. For missing parts, contact EnergyLogic. If any

parts were damaged during shipment, please contact your shipping carrier.

3.2 Warranty Registration

IMPORTANT: You must register your boiler with EnergyLogic for the warranty to become

active and to receive technical service.

Please take a few minutes to fill out the Warranty Registration Card.

Note: Your Warranty Registration Card may be found in the accessory box where you located

this manual. You may fax the completed card to us at (615) 251-0682, or mail it. You may also

register online at www.energylogic.com.

Call 1-615-471-5290 for Technical Support

10

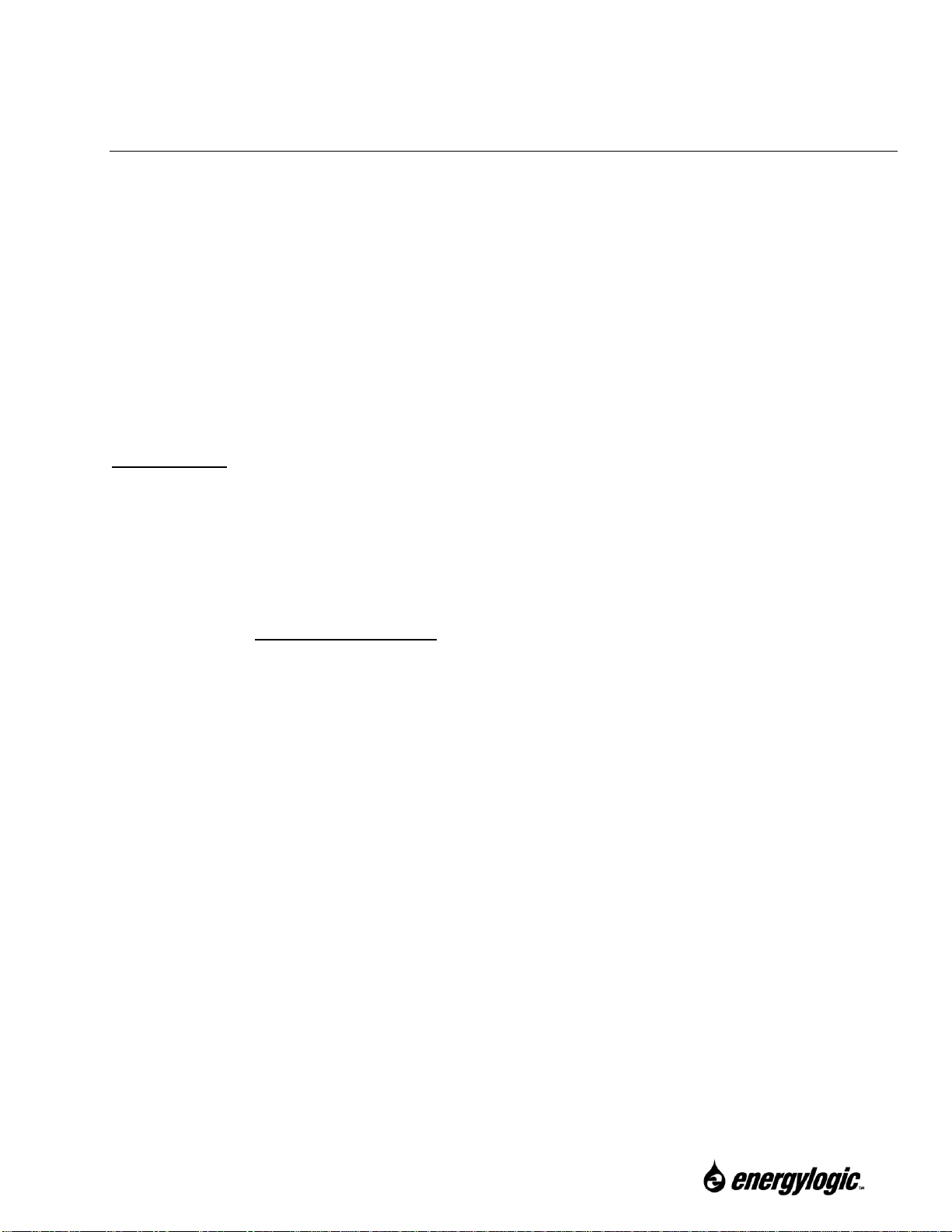

No. Item Qty.

1

Boiler Vessel Assembly

1a. Boiler Vessel (with trim

kit)

1b. Boiler panels and

Insulation panels.

1c. Controls/ Wire Harness.

1 set

2

Preheater Assembly 1

3

Burner Assembly 1

4

Air Compressor Filter 1

5

Burner Gasket 1

6

Alligator Clips 2

7

Filter Head and Fuel Filter 1

8

Fuel Pump Assembly 1

9

Vacuum Gauge 1

10

Pressure Gauge 1

11

Barometric Damper and Tee

Assembly

1

12

Draft Gauge (provided with

bundles only)

(1)

13

Draft Gauge Probe

(provided with bundles

only)

(1)

14

Thread Sealant Tube (not

shown)

1

15

EnergyLogic Workbench

Tank

1

16

Drain Valve Assembly 1

17

Swing-Arm Fuel Gauge 4

18

3/8" Copper Suction Line

with Flare Nuts

1

19

Low Fuel Cut Off Switch

Assembly

1

20

FireStop Valve Assembly 1

Boiler Assembly with Side Suction Fuel Pick Up

Boiler complete (minus flue kit)

Tank Assy

Side Suction Kit

Included with EnergyLogic Boiler

Tank and Tank Options

20

17

Checklist

Call 1-615-471-5290 for Technical Support

11

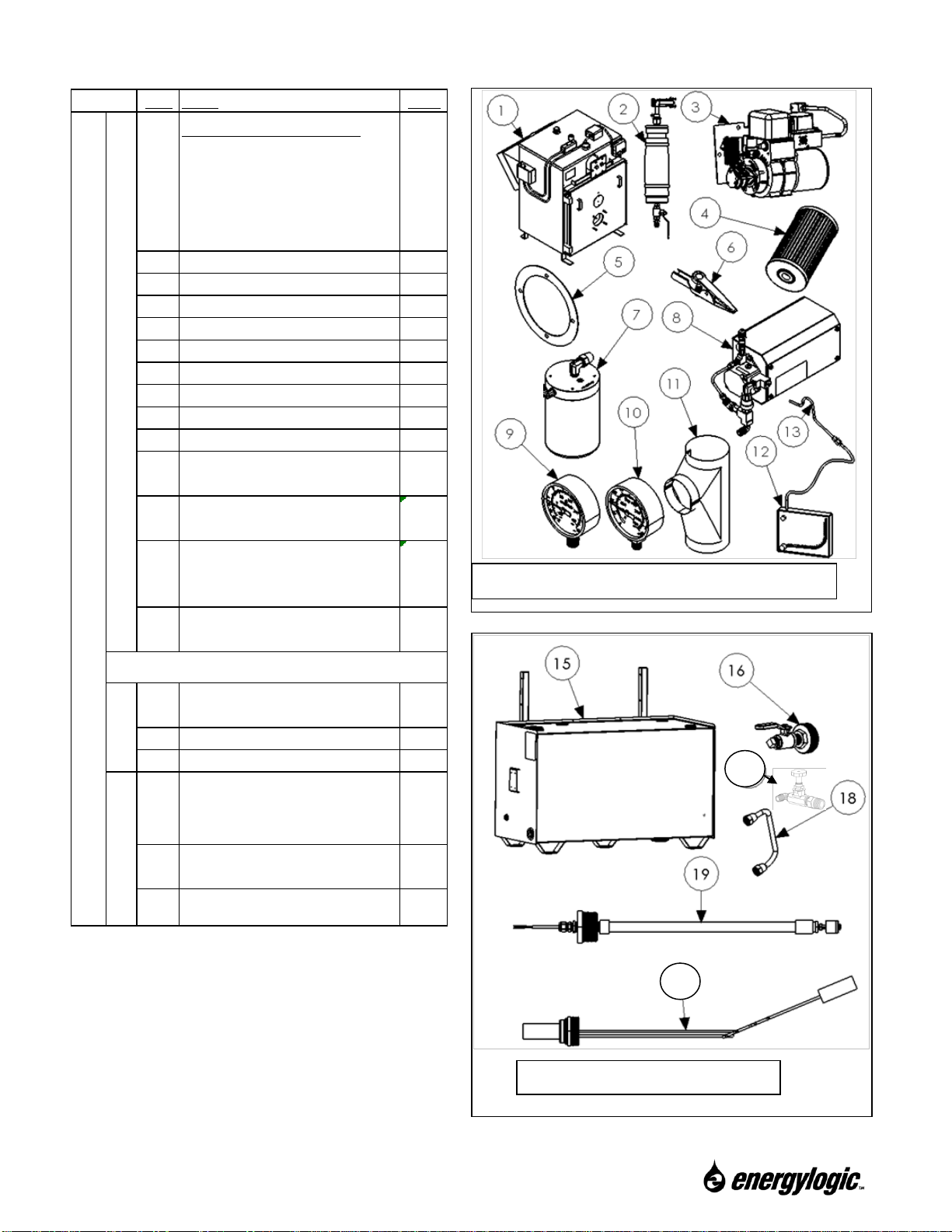

EnergyLogic Boiler with EnergyLogic Tank

3.3 Boiler Vessel Installation

Note: This manual covers the installation of a single boiler and pump. If you are installing

multiple boilers in the same building, contact your local dealer or EnergyLogic for additional

installation options.

3.3.1 Vessel Installation

1. Uncrate and locate the vessel near the desired location.

2. Once the boiler vessel is in place, the vessel may be anchored.

3. Be sure to remove the trim package that contains the fittings and gauges. This is to be

found in the rear breech / chimney connector.

4. Consider the following:

Prior to placement, a licensed electrician shall install a dedicated 115vac/60Hz

service junction box (switchable and lockable) in close proximity to the vessel

location (preferably within 5 feet).

A non-combustible platform or flooring structure is required.

Pay special attention to Codes and Regulations in Section 1.4, and all local codes

and regulations.

Refer to section 2.3 for placement guidelines / restrictions for the boiler. The

placement is critical for proper operation and efficient servicing.

Call 1-615-471-5290 for Technical Support

12

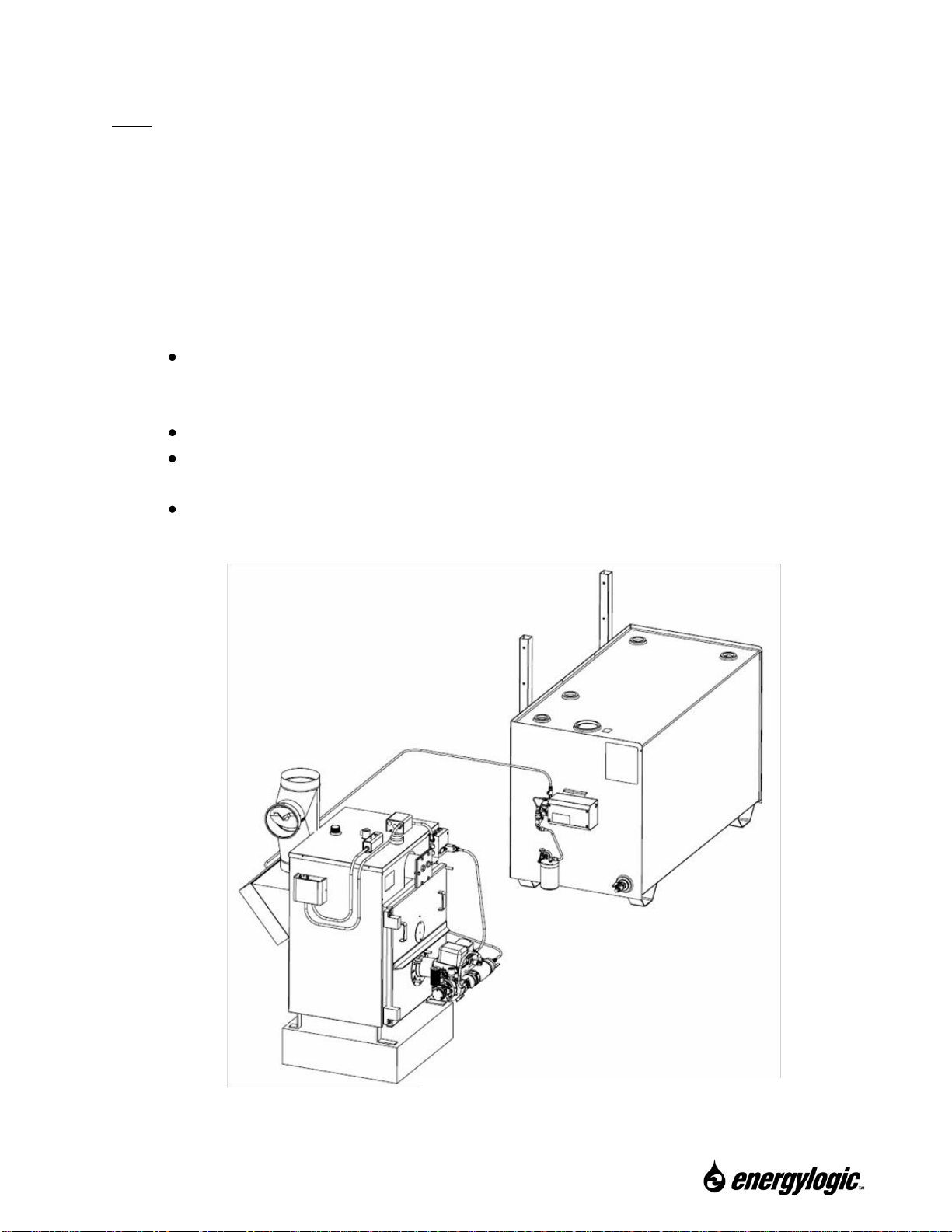

Exterior Wall

Emergency Vent Cap

(sold separately).

Min. 1.25” NPT

Steel Pipe

Drain Valve

2” NPT Port in

Tank Side

Apply Thread

Sealer

Drain valve installation.

3.4 Preparing the EnergyLogic Used-Oil Tank

If you are not installing an EnergyLogic Tank, first verify that your used oil storage system

meets all applicable codes and requirements, then proceed to the instructions for installing the

metering pump.

3.4.1 Tank Vent Installation – EnergyLogic Tanks

Once the tank is in place, install a tank

vent (not included). This requires a

minimum 1.25 inch NPT steel pipe

routed through an exterior wall,

terminated with a 90° elbow turned

down (figure). A mushroom-style cap

may be used to terminate the vent as

an alternative to the down-turned

elbow. Install appropriate Emergency

Venting. EnergyLogic offers an

emergency vent cap with capacity of

53,000 cu. ft./hr./1501 cu. m/hr. This

optional accessory can be installed into

a 4 inch NPT port (figure).

3.4.2 Drain Valve Installation – EnergyLogic Tanks

Install the tank drain valve in a port along the bottom of the tank as shown in figure. Use the

provided thread sealer on the threads during

installation. Note: Some tanks come with the drain

valve already installed. The drain valve is

necessary for draining water from the bottom of the

tank. The drain valve is shown in closed position in

figure. A plug should be installed in the drain valve to

prevent accidental spills.

After all components have been installed on

the tank, make sure that all unused tank openings are

properly plugged.

3.4.3 Low Fuel Cutoff Switch – EnergyLogic Tanks

The low fuel cutoff switch is an optional accessory that will automatically shut

off the burner if the tank is nearly out of fuel. This prevents the pump from

losing prime. The float switch operates by interrupting the thermostat circuit

when the fuel level is too low. Install the accessory according to the

packaged instructions.

Call 1-615-471-5290 for Technical Support

13

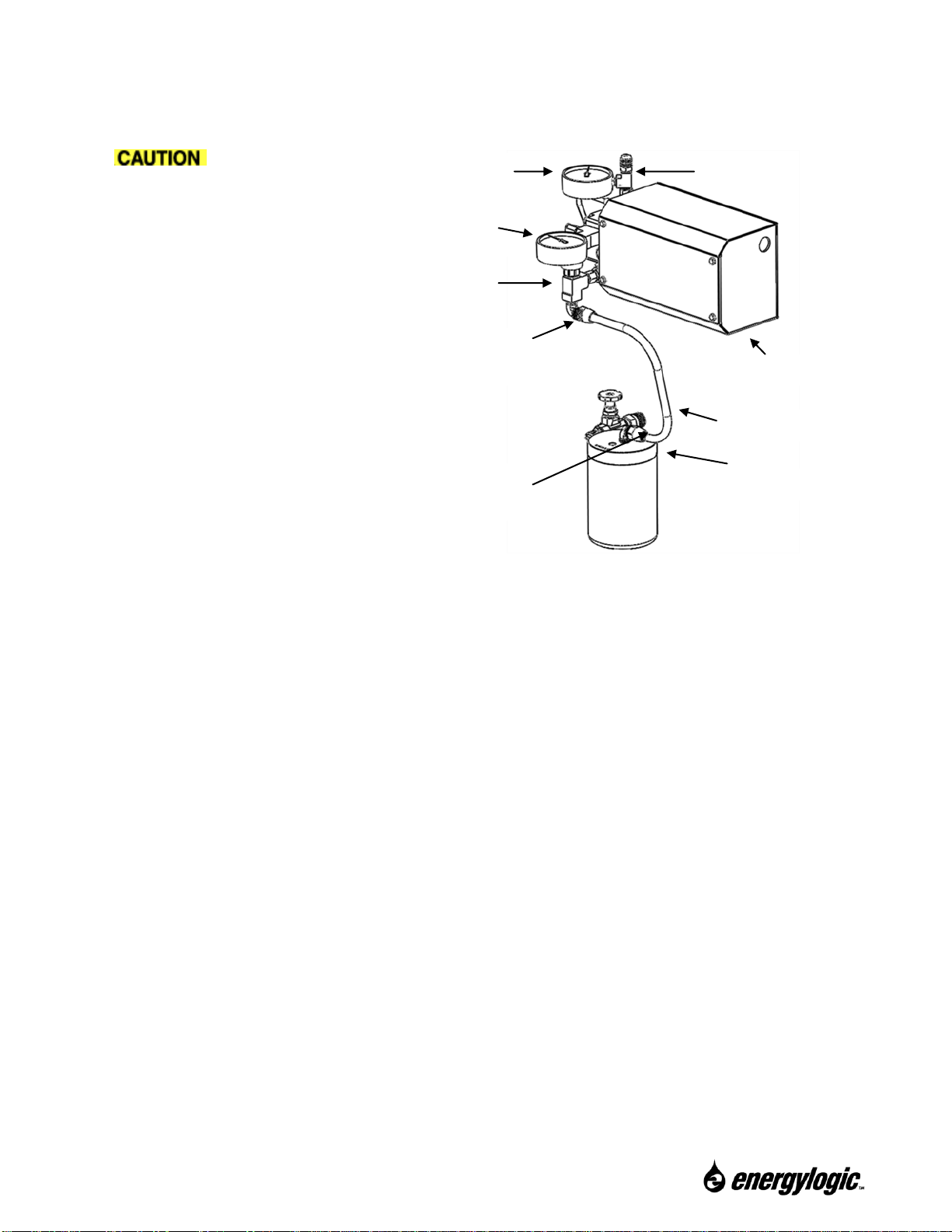

Fire-Stop Valve

Filter Head Assembly

Spin On Fuel Filter

Metering Pump

Assembly

Fuel system – EL Tank

Gasket

sealer here,

then tighten.

FireStop Valve

Filter Head

Assy.

(4) 1/4 - 20 Bolts

Remove cover to

install bolts. Replace

cover after pump has

been wired.

Fuel Pump Assembly

Mount Pump to Tank

3.5 Fuel Metering Pump and Filter Installation – EnergyLogic Tank

(continue to section 3.6 if you don’t have EL tank).

On EnergyLogic Tanks, the fuel pump components are mounted on the side as shown. Follow

the steps below to first install the firestop valve and filter head, and then install the pump.

3.5.1 Fire Stop Valve and Filter Head Installation – EL

Tank.

Decide which end of the tank is the best location for your

pump. On EL 250 gallon and 500 gallon tanks, the pump may

be mounted to either end. To install the firestop valve, first

apply gasket sealer to the ¼” NPT fitting and screw the fire

stop valve to the fuel filter head, fully tighten the NPT threads

using a back up wrench. Then, apply sealer to the ½” NPT

fitting and screw the entire filter head assembly with firestop

valve into the ½” NPT port in the side of the tank (located

about 10” up from the floor).

3.5.2 Metering Pump

Installation – EL Tank

Mount the pump to the

integrated bracket on the

EnergyLogic tank using (4)

1/4-20 bolts.

Call 1-615-471-5290 for Technical Support

14

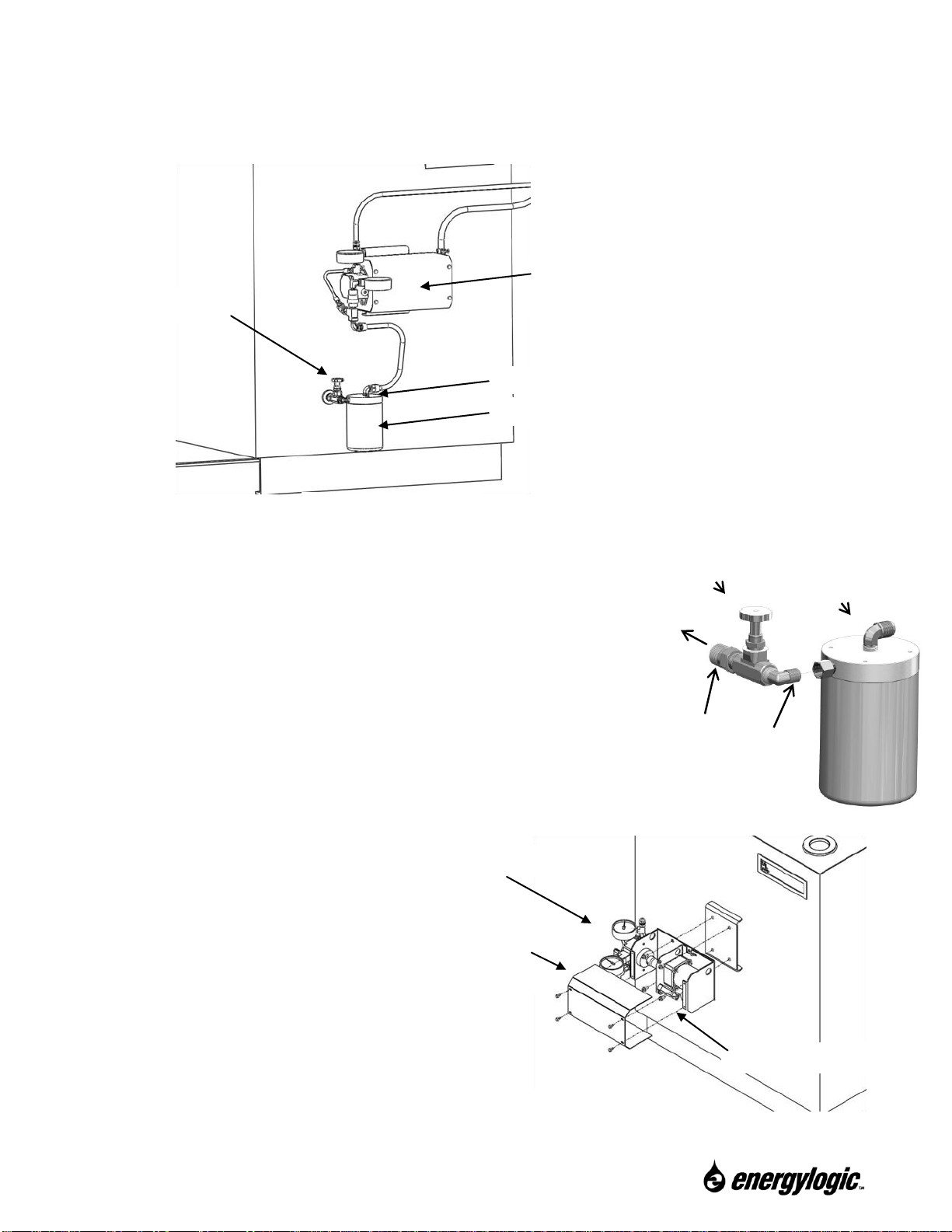

Fuel Pump Assembly

Filter Head Assembly

3/8” Copper Tube

Inlet Tee

Vacuum

Gauge

Pressure

Gauge

Outlet Tee

Upper Flare

Fitting

Lower Flare

Fitting

Gauge and Suction Tubing Installation.

3.5.3 Gauge and Pump Tubing Installation – EL Tank

Install the gauges and tubing

as follows:

The pump fittings

are sealed and leak tested at

the factory. Use a backup

wrench when installing the

gauges and flare fittings to

ensure that you do not turn the

pump fittings and create a

leak.

1. Remove the plugs on

the inlet and outlet tees

(refer to figure). Note:

The pumps are tested

at the factory, so a

small amount of oil may

be present.

2. Using the gasket sealer

provided, install the

pressure gauge on the

outlet tee, and the

combination vacuum/pressure gauge on the inlet tee.

3. Locate the short 3/8” copper tube assembly. Carefully bend the tube (without kinking)

into position as shown.

4. Thread (do not tighten) upper 3/8 inch flare nut onto the flare fitting on the fuel pump

inlet. Do not apply gasket sealer to the flare fittings.

5. Thread lower fitting onto the filter head fitting.

6. Tighten both flare nuts. Use a backup wrench - do not over-tighten.

Call 1-615-471-5290 for Technical Support

15

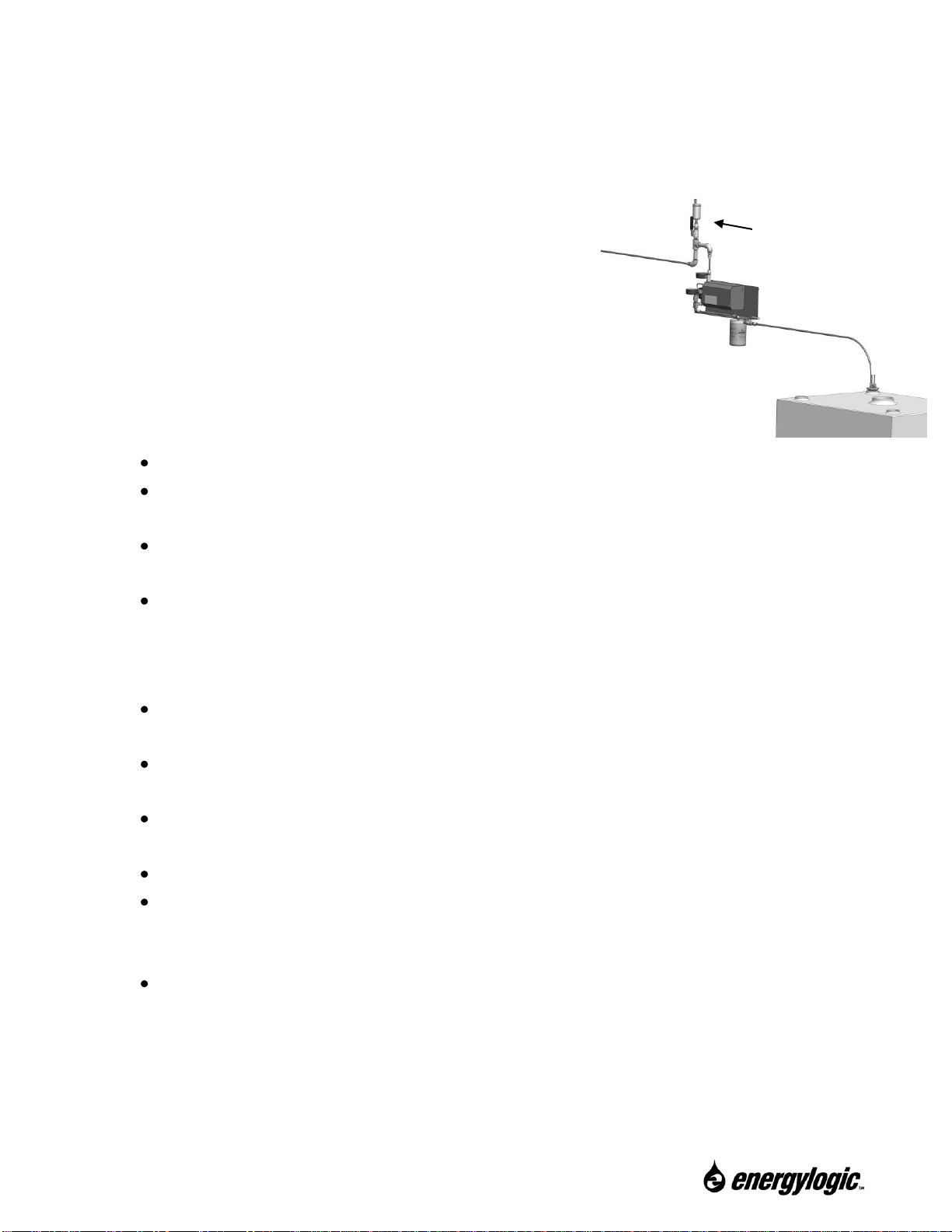

EL Top Suction Kit Installed

AirScape Accessory

(Optional)

3.6 Metering Pump Installation – Non-EL Tank (skip if you have EL tank)

If you are metering fuel directly from a tank not supplied by EnergyLogic, the top suction

method may be used. Verify regulations prior to installation. Contact your authorized

EnergyLogic dealer to purchase an EnergyLogic Top Suction Kit if one was not included in

your original purchase. The use of a genuine EnergyLogic Top Suction Kit (figure) will help to

avoid common fuel delivery issues with this type of

installation.

Installation of the Top Suction System:

1. Install the vacuum and pressure gauges on the

pump. Follow steps 1 & 2 in previous section.

2. If you purchased an EnergyLogic Top Suction Kit,

follow the instructions included in the packaging.

Refer to the following for general guidelines.

Guidelines for Top Suction Method:

Purchase an EL Top Suction Kit (if your package did not include one).

Keep in mind that the main storage tank will need to have enough capacity to allow for

separation of water from the used oil. Never meter oil directly from oil drums or totes.

EnergyLogic’s fuel pump is designed for interior use only (must be mounted inside a

protective structure). The minimum recommended fuel temperature is 50oF.

The pump may be mounted to a nearby wall, within 6’ of the tank. The ideal placement

of pump is with the inlet above the filter head assembly, which should be mounted

above the tank fitting. Maximum vertical lift for the suction line should not exceed 6 feet

(2m). This includes the portion of line inside of the tank.

The EL Filter Head Assembly is to be placed such that it filters the oil prior to pump. A

shut off valve should be placed prior to the filter head in order to do a vacuum check.

The pump assembly and wiring connections must be at least 18 inches (46 cm) above

the floor to meet National Fire Protection Association (NFPA) codes for repair garages.

The inlet to the suction line should be at least 8 inches (20 cm) off the bottom of the

tank, to prevent water and sludge from entering the system.

Use minimum 3/8” OD x 1/32” wall thickness copper tubing. Never create loops.

Use 45 degree flares on the copper tubing. Loose fittings or cracked flares cause

problems. Suction leaks cause air to get sucked into the fuel system. All suction leaks

must be eliminated.

Used-oil contains water from condensation. A drain valve on the bottom of the tank

should be used regularly to remove water and sludge that separates out of the oil and

settles to the bottom of the tank. If your tank does not have a drain valve, you must

have the tank pumped out completely (periodically) to remove the water and sludge.

Call 1-615-471-5290 for Technical Support

16

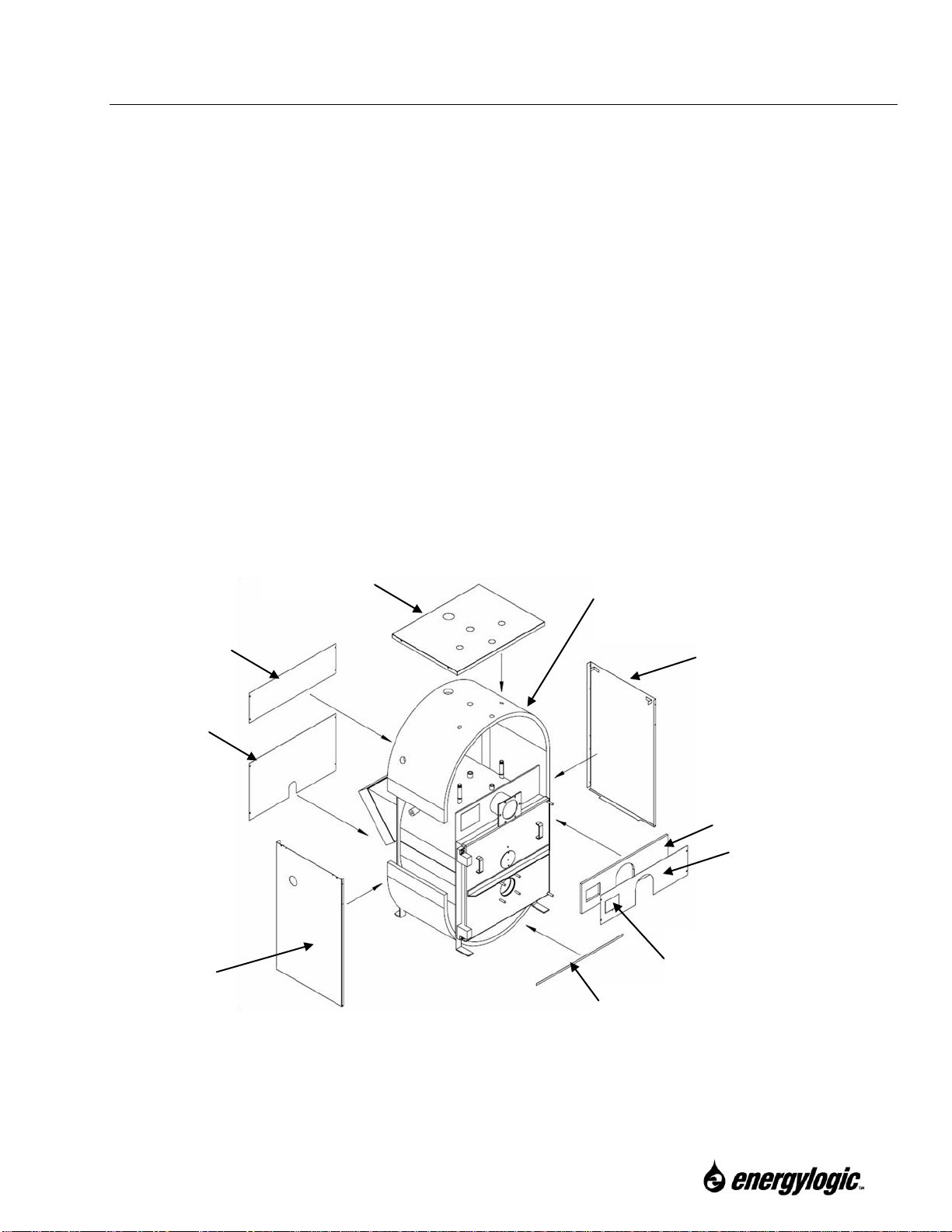

Side Panel

Wrap insulation around

the vessel and secure

using two ribbons.

Front Panel

Front Insulation

ASME Boiler Plate

Access Panel.

Brace

Side Panel

Rear Panel

Lower Panel

Top Panel

Assembling Insulation and Panels (EL-200B shown)

4. Installation of Boiler Components

With the vessel in place, you are ready to attach the vessel panels and insulation, the wire

harness and controls, the optional domestic coil, and the burner/preheater assembly. Then,

you will install the fuel tubing from the pump discharge to the preheater. Finally, your hydronics

professional will connect the hydronic piping system to the boiler – and fill the system.

4.1 Vessel Panel and Insulation Assembly

Install the vessel panels and insulation as follows:

1. Open the box containing the insulation, panels, and hardware.

2. Wrap the insulation around the boiler vessel. Use the ribbon provided to secure the

insulation around the vessel. Install the insulation for the front panel. Note: Make sure to

cut out the insulation for ports and drains as needed. On front panel, make sure that the

insulation is cut out to provide a view of the ASME boiler plate.

3. After the insulation is in place, install the panels as they are shown in the figure below,

securing using the sheet metal screws provided. Install the side panels to the front and

rear panels first. Then, install the remaining panels.

Call 1-615-471-5290 for Technical Support

17

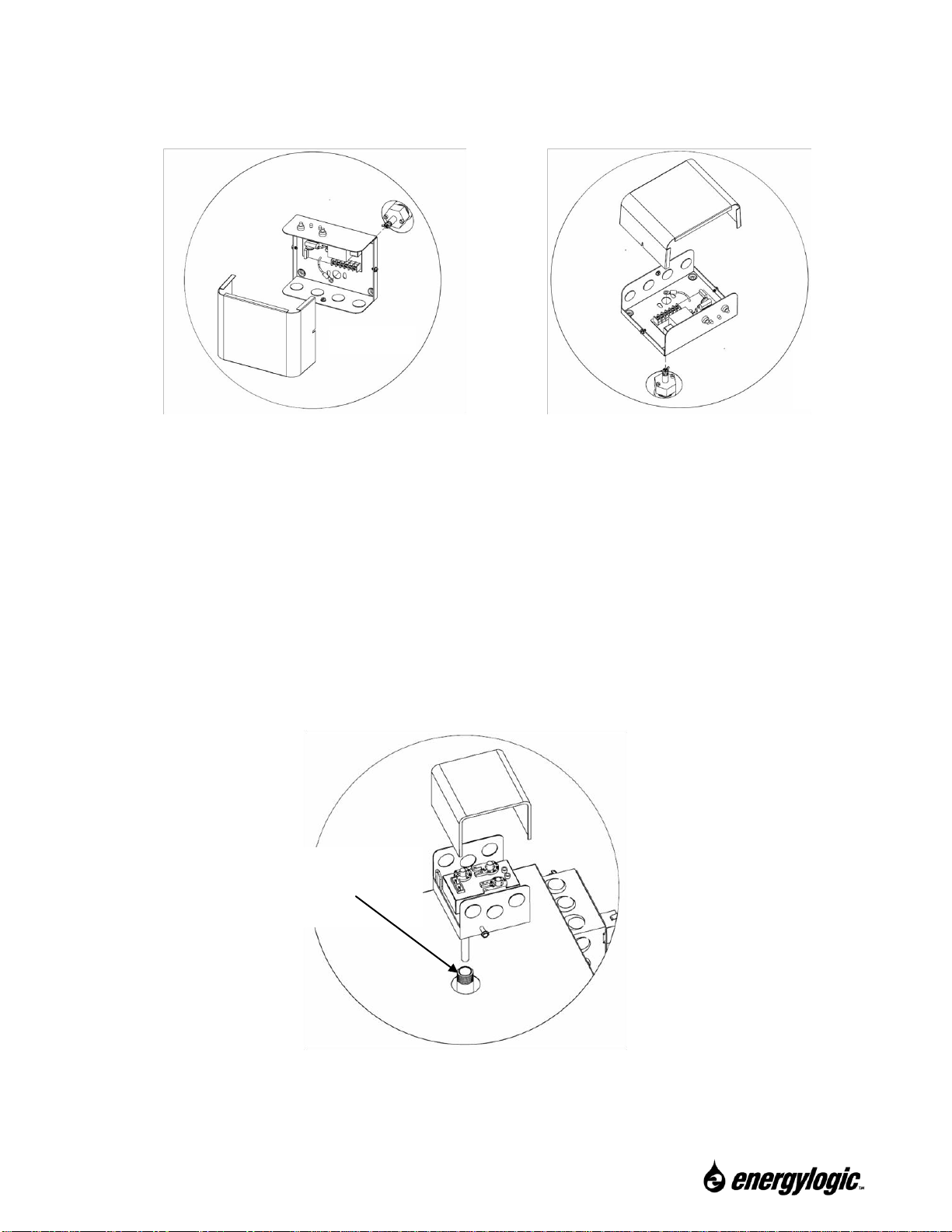

Low Water Cut Off

High Temp Limit

Press. Relief

Gauge

Triple Aquastat

Vessel Wire Box

Installing Controls on EL-200B

EL-200B

EL-375B

EL-500B

Low Water Cut Off

Triple Aquastat

High Temp Limit

Vessel Wire Box

Gauge

Press. Relief

Installing Controls on EL-375B or EL-500B

4.2 Boiler Wire Harness and Controls Installation

The boiler controls are pre-wired at the factory. You will install the pre-wired, steel conduit, wire

harness to the vessel. Install the boiler wire harness and controls as follows:

4.2.1 Low Water Cutoff Probe and Control Installation.

1. Remove the probe from the Low Water Cutoff packaging. Locate the proper port as

shown in figures above.

2. Prior to threading the probe into the port, use pipe dope on the first threads.

Do not use Teflon tape and do not cover all of the threads as metal-to-metal contact is

necessary for proper electrical conduction and function of the probe.

3. Thread the probe into the port ( Do not use grease on this probe). Tighten.

Align the probe so that the mounting screws are in a location that situates the

installation of the control for best appearance (use the control as a guide). Loosen the

probe mounting screws a couple of turns.

4. Remove the LWCO control from the packaging. Remove the cover from the control.

Call 1-615-471-5290 for Technical Support

18

Fill Triple Aquastat Well with

Thermal Conductive Grease

before inserting probe.

EL-200B

EL-375B

EL-500B

5. Install the control over the probe, guiding the probe through the opening. With the

mounting screws on the probe loosened, guide the screws into the slots, and tighten the

screws securely to the base of the control.

6. Secure the “Probe” lead wire coming from the circuit board to the probe using the

provided wing nut.

7. Install the cover to the control.

8. Note: An EL factory installed on-off switch is provided as part of this control. This switch

may be used to turn power on and off to the boiler.

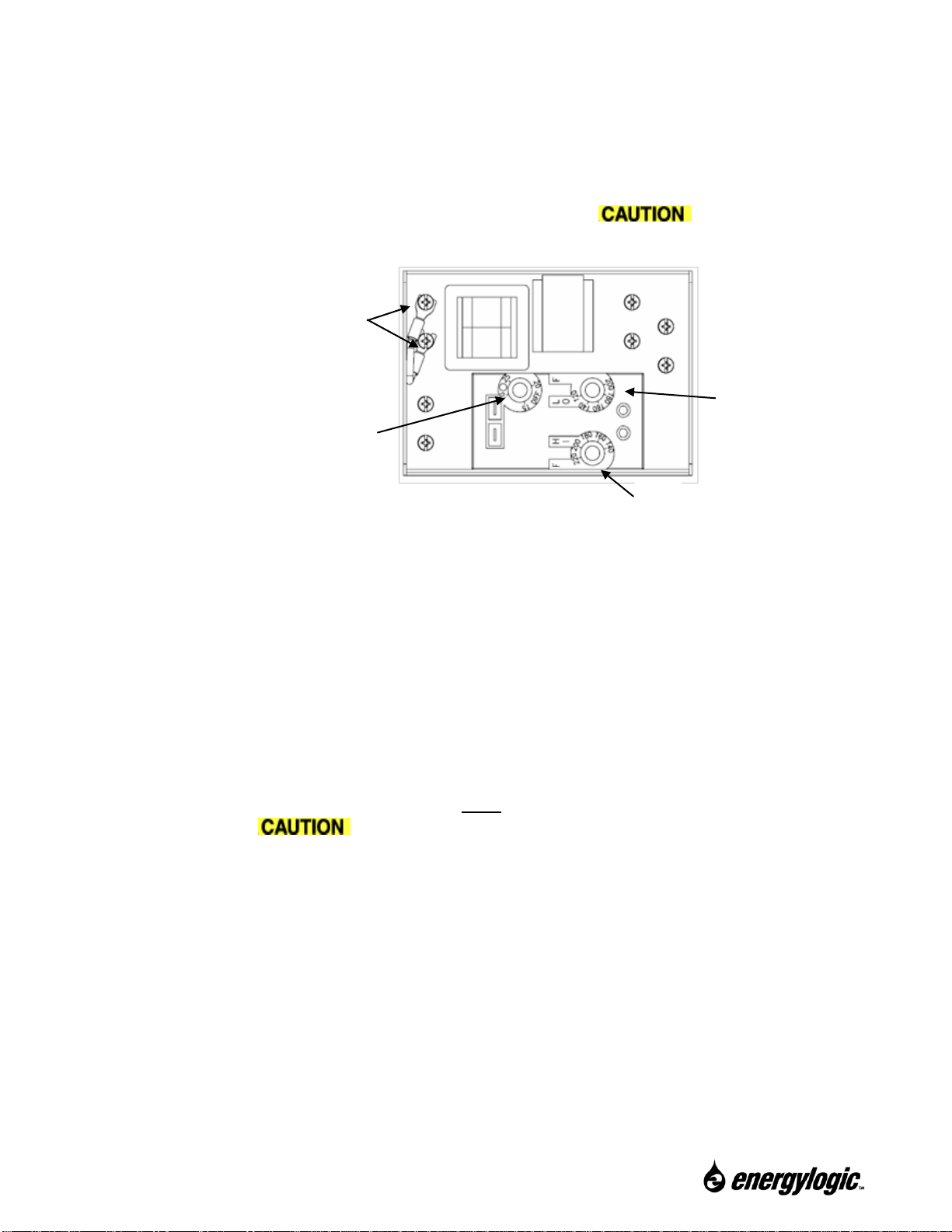

4.2.2 Triple Aquastat Temperature Controller Installation.

1. Remove the cover from the triple aquastat control.

2. Fill the triple aquastat thermal well (refer to figures) with thermal conductive grease

(provided), as follows: Fold the plastic bag of compound lengthwise and twist it gently.

Then snip off end of bag and work the open end of the bag all the way into the well.

Slowly pull out the bag while squeezing it firmly to distribute compound evenly in the

well. Wipe excess compound from the outer end of the well.

3. Loosen but do not remove the clamp screw on the case. Insert the aquastat probe into

the thermal well until it bottoms out.

Call 1-615-471-5290 for Technical Support

19

Remove jumper wire

and install room

thermostat here, if used.

HI

Lo

DIFF

4. Fit the case onto the well so that the clamp on the case slides over the well. Securely

tighten the clamp screw. Note: Align the controller prior to tightening securely.

5. Set the control settings to the desired temperatures. Set HI to the temperature that you

want the water to reach during a call for heat. Set Lo to the temperature that you want

the water to maintain in the vessel when there is not a call for heat. Set DIFF to an

amount that you want the Lo setting temperature to cycle between. Note: The Hi limit

must be set at least 20°F above the Lo limit setting. Do not set the low limit

below 140°F.

6. If a room thermostat (or other device) is to be used to call for heat, the factory-installed

jumper wire will need to be removed from the triple aquastat and replaced with wiring

(24VDC) from the thermostat (refer to figure above) If the jumper is not removed, the

control will always sense a call for heat. If this is the case, the burner will always cycle

between the high temperature limit and its fixed differential of 10°F, and the water

circulation pump will be powered (if this control is used for the circulation pump).

7. If using the circulation pump control on the aquastat, wire the pump control across

terminals C1 and C2 using a 115V coil relay to provide separate power to the pump.

The amperage rating of the controller is limited to a total load of 8 amps, which is mostly

consumed by the burner itself. The relay is necessary to make sure that the controller is

not overloaded by the addition of the pump. Make sure to connect according to NEC

code, with approved metal conduit. Note: Many installations use separate controls for

the pump. Regardless of the pump control method used, be aware of the

requirement for a minimum of 140°F return water temperature. If this requirement is not

met, the vessel warranty is void.

8. Install the cover to the control.

4.2.3 High-Limit Temperature Controller Installation.

1. Remove the cover from the high-limit temperature aquastat control.

2. Fill the high-limit temperature aquastat thermal well (locate well according to figures)

with thermal conductive grease following the same procedure as in section 4.2.2.

Call 1-615-471-5290 for Technical Support

20

Fill High-Limit Controller Well

with Thermal Conductive

Grease before inserting probe.

EL-200B

EL-375B

(EL-500B is

similar)

Boilers complete with Controls

3. Insert the aquastat probe into the thermal well until it bottoms out.

4. Install the control over the thermal well. Using the clamp provided on the bottom of the

control, secure the control to the well. The screws to tighten the clamp are located

inside of the control, on either side of the probe opening.

5. Make sure that the control is set to 230°F. Do not increase the setting.

6. Install the cover to the control.

4.2.4 Vessel Wire Box installation.

1. Mount the wire box to the upper-right front panel (panel #4) using the sheet metal

screws provided. Refer to figures for location of box.

2. Secure the conduit to the vessel panels using clamps and sheet metal screws provided.

Call 1-615-471-5290 for Technical Support

21

Domestic Coil Location

Optional Accessory

4.3 Pressure Relief Valve and Combination Gauge Installation

1. Install the 30 psi pressure relief valve in the port shown in figures in the beginning of this

section. Use pipe dope on the threads. Make sure to install metal piping from the relief

valve; routed according to code to a safe place for discharge.

2. Install the combination temperature / pressure gauge in the port shown in the beginning

of this section. Use pipe dope on the threads.

4.4 Domestic Coil (optional accessory)

The boiler vessel has provision for an optional domestic coil (2 on EL-500B), which can be used for

heating potable water in an open loop circuit.. Call if you have a need for this accessory.

Call 1-615-471-5290 for Technical Support

22

Plug in

preheater.

Install Fuel

Tubing

Install

Preheater

Install Long

Bolt

Install Air

Filter

Long Bolt (goes here)

EL-200B Preheater Assembly (to burner).

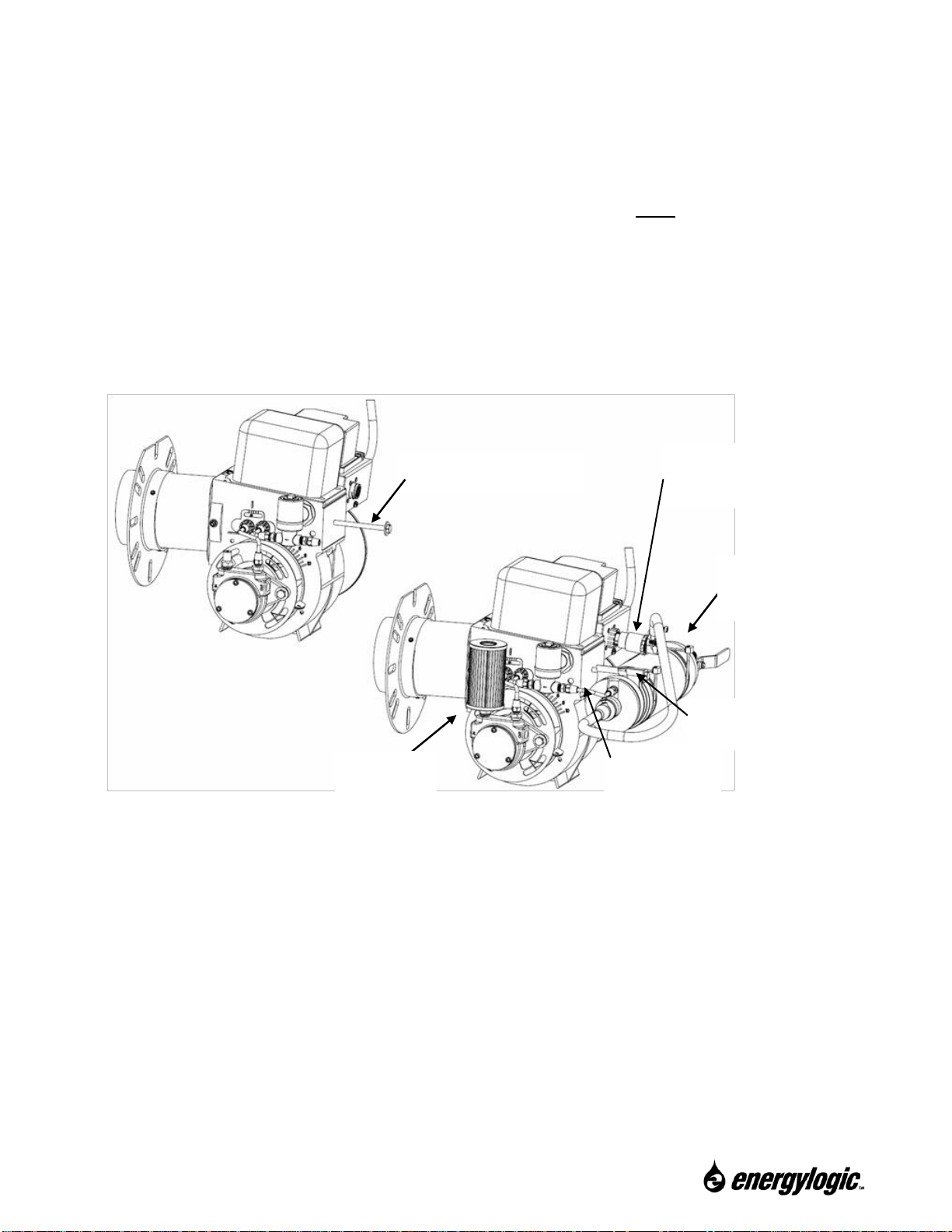

4.5 Preheater Assembly

Before installing the burner to the vessel, install the preheater, as follows:

Instructions for Model EL-200B:

1. Use the long bolt (provided with the preheater) to install the preheater. For the EL-200B,

the preheater installs to the burner assembly as shown in figure below.

2. Remove the shipping caps on the preheater and burner. Note: The preheater and

burner are tested during manufacturing, so a small amount of oil may be present when

the caps are removed.

3. Cut the tie strap holding the 1/8” copper tubing, and thread (do not tighten) the fittings

onto the burner solenoid valve and preheater, as shown in the figure.

4. Tighten the fuel tubing fittings and the long preheater bolt.

5. Screw the plug end of the conduit into the receptacle on the burner wire box.

6. Install the air filter by pressing it onto the compressor inlet.

Instructions for Model EL-375B and EL-500B:

1. Use the long bolt (provided with the preheater) to install the preheater. For the EL-375B

2. Align the preheater with a slight upward slope to allow air to escape. Do not tighten the

Call 1-615-471-5290 for Technical Support

and the EL500B, the preheater installs directly to the vessel door. NOTE: The

preheater installs on top of the bolt.

bolt completely until you have installed the fuel tubing to the preheater in the next

section.

23

Install

Preheater

Long Bolt (goes

here)

Installation of Preheater (to vessel door) for EL-375B and EL-500B

NOTE: The Preheater Mounts on Top of the Bolt.

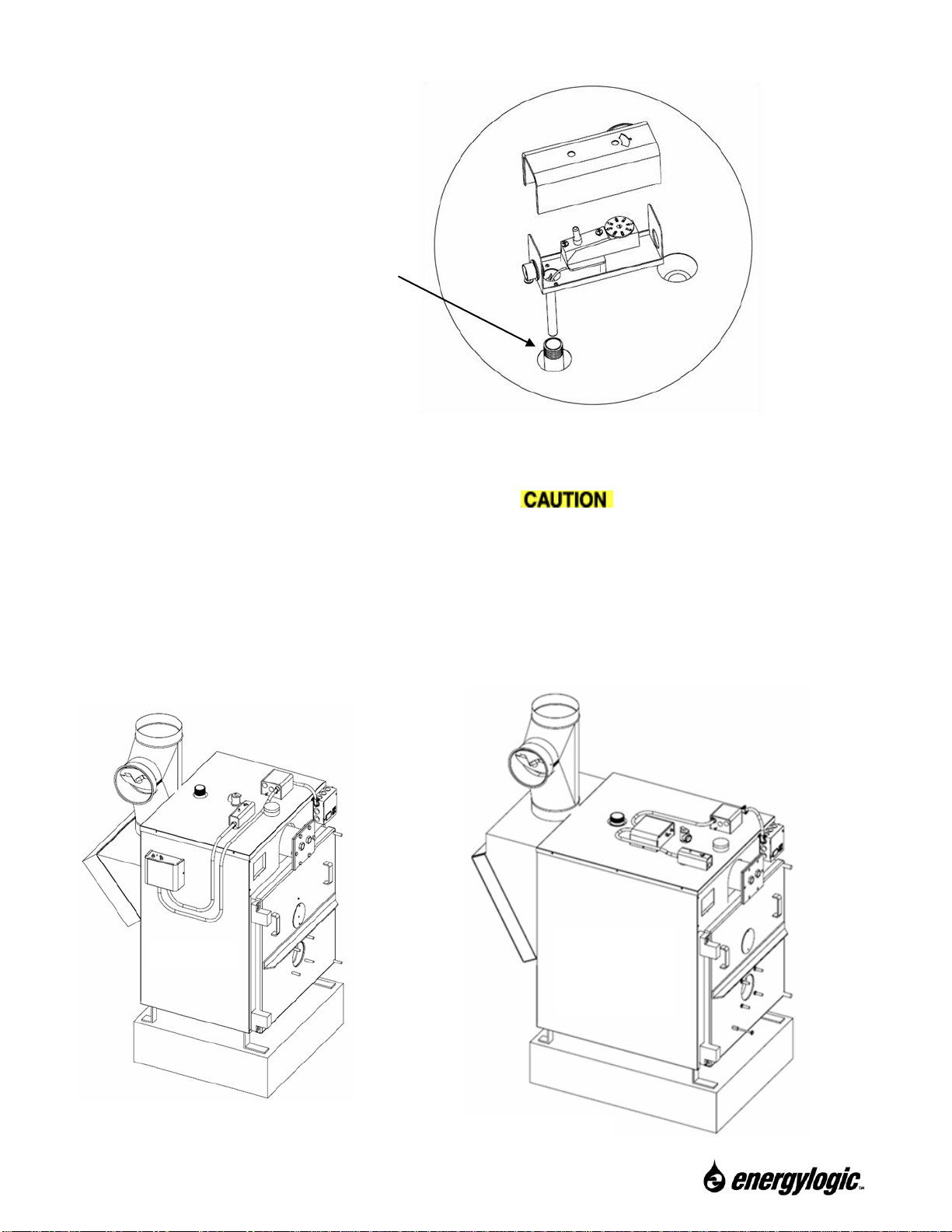

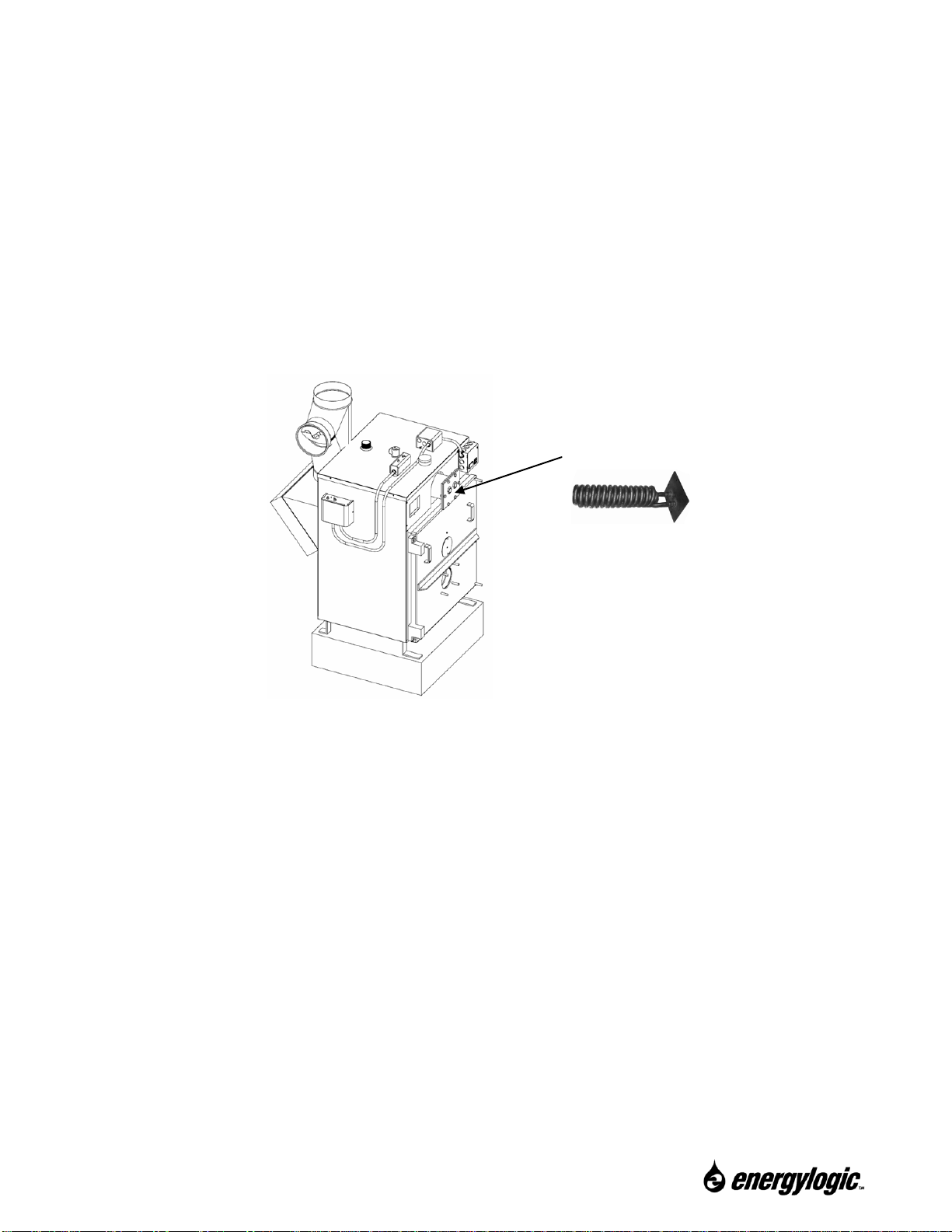

4.6 Burner/Vessel Assembly

Now, the burner can be installed on the boiler vessel. This is done as follows:

The burner assembly is heavy. Handle with care.

1. Remove the four (4) nuts from the studs on the boiler door

2. Install the burner gasket onto the studs. NOTE: Gasket sealer should not be used on

this gasket. Apply a thin film of anti-seize compound to the vessel side of the burner

gasket to help reduce gasket sticking when servicing.

3. Inspect the retention head and electrodes for proper settings (refer to Section 8.5.6).

4. Mount the burner assembly onto the vessel by inserting the burner over the studs.

5. Reinstall and tighten the four (4) nuts.

6. Plug the burner harness into the vessel wiring box (refer to figure). The plug fits only

one way. This completes this step for the EL-200B. If you are installing an EL-375B or

EL-500B, continue to step 7 to connect the preheater to the burner.

Always unplug the burner before doing any service work on it. Attempting to swing the

vessel door open while the burner is plugged in may damage the plug or cable.

Call 1-615-471-5290 for Technical Support

24

Loading...

Loading...