Energenics MLF-1015 User Manual

www.energenics.com

1470 Don Street Naples, Florida 34104 Telephone: (239) 643-1711

Fax: (239) 643-6081

Customer Service: (800) 944-1711

2009 Installation & Operation Manual

For MILNOR MLF-1004/1010/1015 On-board or Remote mounted

Individual Lint Filters

Descriptions Page

Table of Contents 1

Description of Lint Filter Operation 2

Important Installation Considerations

Receiving and Installation 3

Warnings/Cautions 4

Start Up and Operation Instructions

Typical On-Board Installation 5

Typical Remote Installation 6

Utilities Installation 7

Sheet Metal Installation 8

Compressed Air Requirements 9

Fire Suppression Water System 10

Dryer/Filter Utility Requirements 11

Side View Connection Location 12

IMPORTANT WARNING/GATE VALVE MAINTENANCE 13

Optional 6” Vacuum with 150 Gallon Lint Storage 14

Motor Starter Wiring for Optional Vacuum 15

Maintenance Requirements 16

1

DESCRIPTION OF LINT FILTER OPERATION

Your new Milnor Lint Filter represents the most advanced features available in

the laundry industry to date. The following list the functions and mode of

operation:

Blowdown (cleaning) – The Lint Filter will automatically blowdown (clean) when

the dryer blower motor stops at the end of the drying cycle. 30 seconds after the

dryer blower stops the 6 second blowdown occurs. When the dryer is off (thus

no airflow) a blowdown cycle will occur removing the Lint from the screen.

Fire Control – A normally open sensor located inside of the filter at the top of the

inlet will close at 360 degrees F. The dryer control will open the water solenoid,

An audible/visual signal will occur simultaneously opening the water solenoid

allowing water to flow inside the filter to extinguish any fire. The Alarm will be

active until the temperature has dropped bellow 360 degrees F. After 60

seconds the alarm will automatically reset.

IMPORTANT INSTALLATION CONCERNS

All Energenics Lint Collectors can be mounted indoors or outdoors. If it is

mounted outdoors we recommend our Side Discharge or a field installed swept

radius elbow (Gooseneck). Do not use a “China type” cap on the discharge.

All solenoids are mounted on the filter. If the filter is mounted outside the

building all solenoids should be mounted indoors as close to the Lint Filter as

possible. This will insure that the air and water piping will remain pressure

charged for most efficient operation. The fire sensor should remain mounted on

the lint filter as installed by manufacturing.

The 4” x 4” junction box located on top of the Lint Filter will contain 3 sets of

wires. Each solenoid valve will have 3 wires and the fire sensor will have 2

wires. The wires are labeled for termination with their counterpart wires supplied

with the dryers.

Since the Filter uses compressed air it is important that the air receiver tank be

located as close to the filter as possible. The longer the pipe, the more

restrictive. You will need to increase the pipe diameter if the run is over 50 feet

long.

After everything is mounted and utilities activated manually start the dryer and

turn it off. The rotor on the inside the lint filter should spin. Make sure that the air

pressure at the filter starts out at 100 and ends at about 60 at the end of the

blowdown cycle. If it is too low the rotor won’t spin.

2

RECEIVING AND INSTALLATION

Before you sign the Bill of Lading:

1. Receiving- Inspect units inside and out for signs of damage

Verify all components are delivered per the Bill of Materials.

Report damage to the carrier IMMEDIATELY.

Note ALL damage on the Bill of Lading.

This is your responsibility and you must file all claims.

The filter is fully assembled and ready for installation. If the

optional vacuum system is not ordered there will be a box with

the Lint Bag and Installation Manual.

2. Installation- Follow instructions attached:

Determine the location with reference to minimum duct work from the tumbler

and ease of access for inspection. In most cases the Lint Filter will be

mounted directly to the dryer.

If using a lint drop extension allow enough room for lint to travel down 4’

before the first bend. Max bend angle is 30 degrees.

If using lint bag or container make sure adequate clearance is allowed.

Conduit or Sealtight between filter junction boxes should be ¾ inch.

When mounting the filter overhead, mount the control below the filter where it

can be easily accessed.

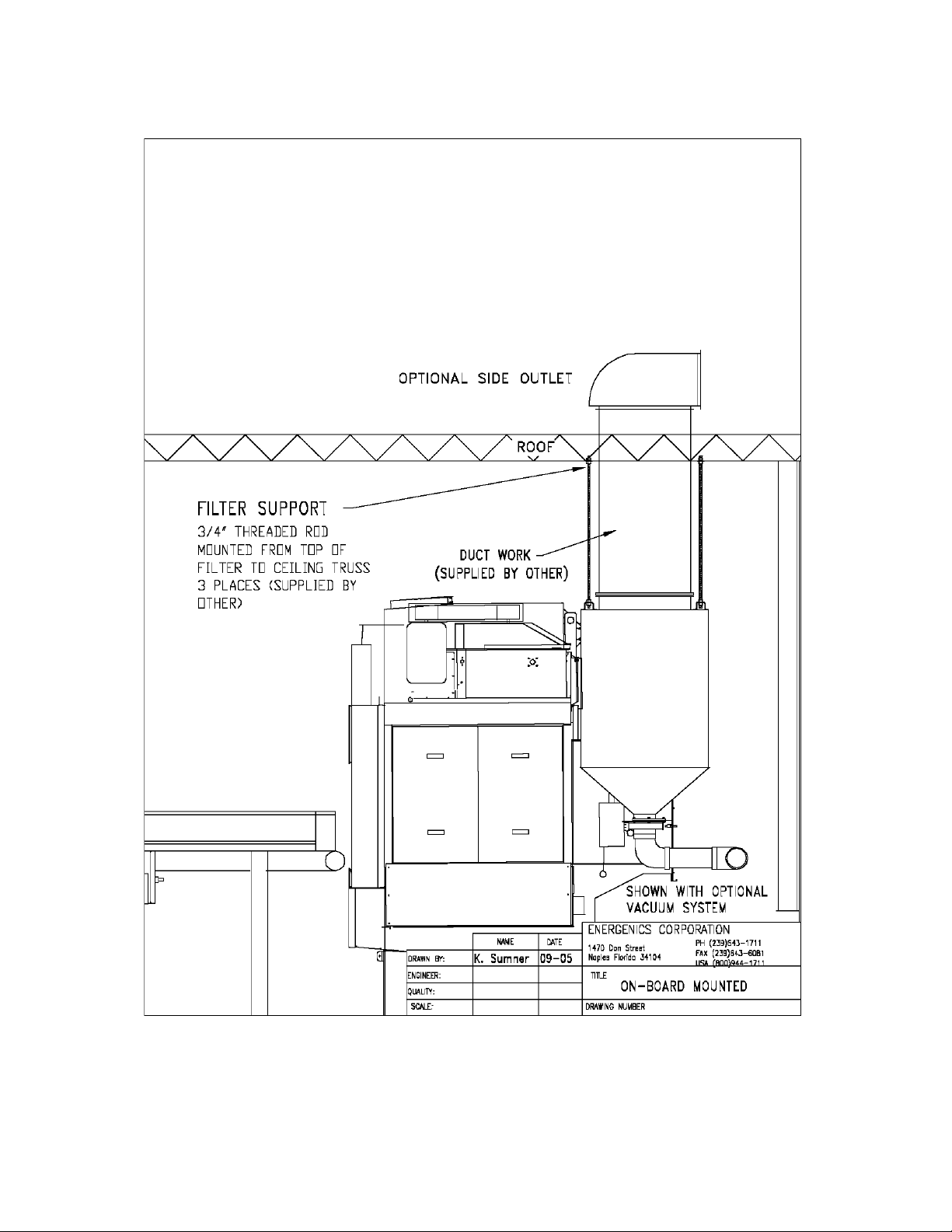

SUPPORT THE LINT FILTER EXTERNALLY FROM THE

DRYER. DO NOT EXPECT THE DRYER TO SUPPORT THE

LINT FILTER. DO NOT SUPPORT THE DUCTWORK WITH THE

LINT FILTER. ALL DUCTING SHOULD BE SUPPORTED

EXTERNALLY, IN NO CASE BY THE DRYER OR LINT FILTER.

USE THREADED ROD TO STABALIZE THE FILTER AT THE 3

CONNECTION POINTS ON TOP OF THE FILTER TO A

SUPPORT POINT AT THE CEILING.

3

WARNING AND CAUTION

IF INSTALLING OPTIONAL VACUUM PAY

ATTENTION TO PAGE 15

You have purchased the finest lint filter available for your facility. Please follow

these instructions to ensure a safe long life for your filter and facility.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN AN UNSAFE

OPERATING CONDITION, INCLUDING THE POSSIBILITY OF FIRE.

DO NOT OPERATE ANY DRYER CONNNECTED TO THIS FILTER

WITHOUT BEING CERTAIN THE FILTER STARTUP HAS BEEN

COMPLETED AND THE FILTER IS IN OPERATING CONDITION.

Insure it is installed in compliance with local codes.

Step 1. Install the compressed air (Fire suppression plumbing if ordered), and

piping system(s) including solenoid valves. If the filter is in position,

make all final connections.

Step 2. Install sheet metal and ducting.

START UP AND OPERATION INSTRUCTIONS

Inspect the filter installation. Is it complete? Review the entire installation

requirements prior to startup.

1. Test the blow down cycle (turn the dryer on and off).

Watch the pressure gauge. It should start at 100psi and should not drop below

60psi during the 6-10 second cycle.

The rotor should turn 6-12 times during blow down. The rotor propulsion is

adjustable by increasing the number of horizontal holes on the top horizontal

portion of the rotor end.

3. Review maintenance requirements and establish a regular PM schedule.

4

5 6 7 8

Loading...

Loading...