Energenics Air Wash User Manual

The dyers are vented to inlets (arranged per your order) on the upper half of the AIRWASHER. Immediately

to the spray pipes, each a full ¼’ fully open. The water discharged from each pipe shoots at a “target” which

Immediately opposite the inlets is a curved baffle. This baffle turns the exhaust air, now full of wet lint, down

THE AIRWASHER - HOW IT WORKS

below each inlet is a “target spray outlet”. Re-circulated water is pumped through a manifold under pressure

disperses –splatters- the water up into the air stream of the dryer exhaust. The dryer exhaust passes

through the water spray twice, as the water is splattered up, and as the water splashes down again,

resulting in higher efficiency lint removal.

into the conical bottom half.

The conical bottom is dimensioned to provide space to slow the exhaust below the velocity at which wet lint

transported, so the wet lint tends to fall out of the air stream.

A tubular exhaust fan located on top of the AIRWASHER draws the exhaust up, out of the conical bottom

through a space where the velocity is slowed still further. The AIRWASHER exhaust fan is sized to

overcome the resistance to the airflow through the AIRWASHER; the dyer fans are responsible for

overcoming the resistance in the dryer exhaust ducts.

The wet lint, being heavier than the air it displaces, tends to fall. The wet lint then impinges on the baffle

and on the interior surfaces of the AIRWASHER. Water from the “target sprays” floods the entire interior

and is washed down and out the bottom drain.

In the sump there are separation screens, which remove most of the lint from the water, so the water can be

recirculated. There is a float assembly connected to your water supply to replace that quantity of water

entrained in the air stream leaving the AIRWASHER.

The AIRWASHER may optionally include one barometric damper, to stabilize the negative pressure at the

collector inlets regardless of the number of dryers operating. The barometric damper works like a one-way

air valve between the atmosphere and inside the AIRWASHER, allowing air to rush into the AIRWASHER

from atmosphere when dryers turn off, thereby preventing excessive vacuum on the dryers that remain

operating. The barometric damper swings passively on a single hinge, and is maintenance free.

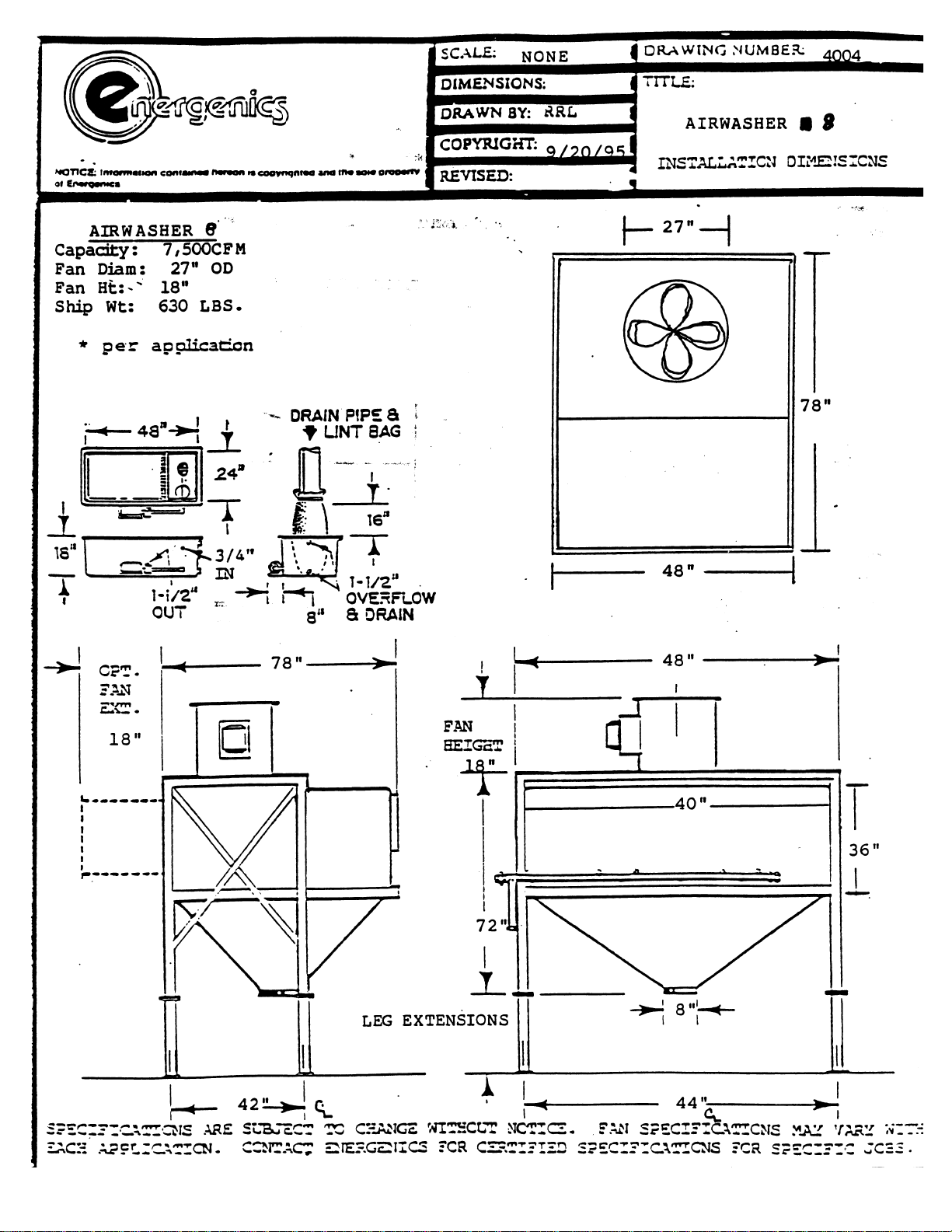

INSTALLATION DESCRIPTION

RECEIVING, ERECTION, SHEET METAL,

AND ELECTRICAL

I. RECEIVING

A. Inspect unit(s) inside and out for damage. Report any damages immediately

to the delivering carrier. THIS IS YOUR RESPONSIBILITY AND YOU MUST FILE ALL

CLAIMS. Please be certain you receive all the items on the Bill of Lading. Please send copy of the

Receiving Report.

B. The filter is fully assembled and shipped on its own pallet with the Target

Spray Assembly and leg extensions.

C. The Reservoir Assembly and pump are shipped on one pallet.

D. The Fan is shipped units own pallet.

II. ERECTION REQUIREMENTS

A. Determine the location with reference to minimum duct work to the tumbler,

ease of access, and inspection. Minimize the requirement for the horizontal duct.

B. If Filter is located outdoors, allow for the possibility of freezing.

C. Install fan on top of Airwasher with motor toward the outlet (rear) end to

balance the entire Airwasher weight over the 4 legs (or, if optional horizontal outlet is ordered, install

fan with motor hanging down and run a thick bead of rubberized caulk along the flanges to provide a

watertight seal). Dryer ducts must have 5% slope into the filter per drawing #4005.1.

D. Raise unit onto leg extensions, level unit to within ½’ over the length of the

unit, and bolt the feet to the base constructed by others.

E. If a Lint Bag is to be attached directly to the Filter, be sure the clearance

Below is adequate for easy removal. If Lint Bag is to be downstairs from the Airwasher, connect 8’

PVC using a transition to 12’ lint outlet/drain.

III SHEET METAL REQUIREMENTS

A. Duct design is properly done by licensed professional engineers.

Energenics accepts no responsibility or liability for duct design or installation.

B. For indoor installation all exhaust ducting must be properly sealed from the inside of unit

(watertight).

factory installed if requested). Duct each dryer individually to Airwasher inlet to allow water to drain into

Vanes in exhaust ductwork because of lint build up and consequent

flexible connectors have been provided on pump suction and pressure connections to protect the pump

C. The Airwasher inlet can accommodate up to 4-30’ diameter ducts (inlet flanges and openings can be

the Airwasher. If you’re cutting your own inlet(s) into the Airwasher, place them as high as

possible in the fiberglass inlet to have best filtering possible and properly seal each duct from

the inside of the unit.

D. Provide clean outs in all horizontal ductwork. The booster blower in the Airwasher is designed to

overcome the resistance inside the Airwasher itself and will not necessarily prevent lint fallout in

horizontal ducts.

E. The length and size of the dryer exhaust ductwork should be per dryer manufacture’s

recommendations. Use round duct for minimum pressure drop, minimum lint build-up and maximum

strength. Do not use Turing

fire hazard. Use elbows with a radius of not less than 1.5 times the diameter of the duct.

F. Add at least 3 ft. of round exhaust duct to booster fan outlet to act as a guard.

IV PLUMBING REQUIREMENTS

A. Set reservoir in a position convenient for easy removal of lint bag.

B. Install Target Spray Manifold Assembly through the holes in the front of the fiberglass body of caulk

around gaps between nozzle tips and fiberglass.

C. Use 1’ PVC pipe to connect pump pressure connection to Target Spray Manifold. Plastic shockproof

housing form stress or torque shock.

D. Connect ¾’ cold water to the float assembly coupling on the reservoir. Water fill should shut off at a

level of 1’ below the overflow.

E. Connect ¾’ overflow to the 1 ½’ drain after the manual cock drain valve (valve by others).

F. Pump instructions were shipped with the pump.

V. ELECTRICAL REQUIREMENTS

A. Consult the fan motor and pump nameplates for voltage and power

requirements.

B. Provide circuit breakers and motor starters in a location convenient for daily on/off operation. Motor

Starters are available from Energenics as an option .

Loading...

Loading...