Page 1

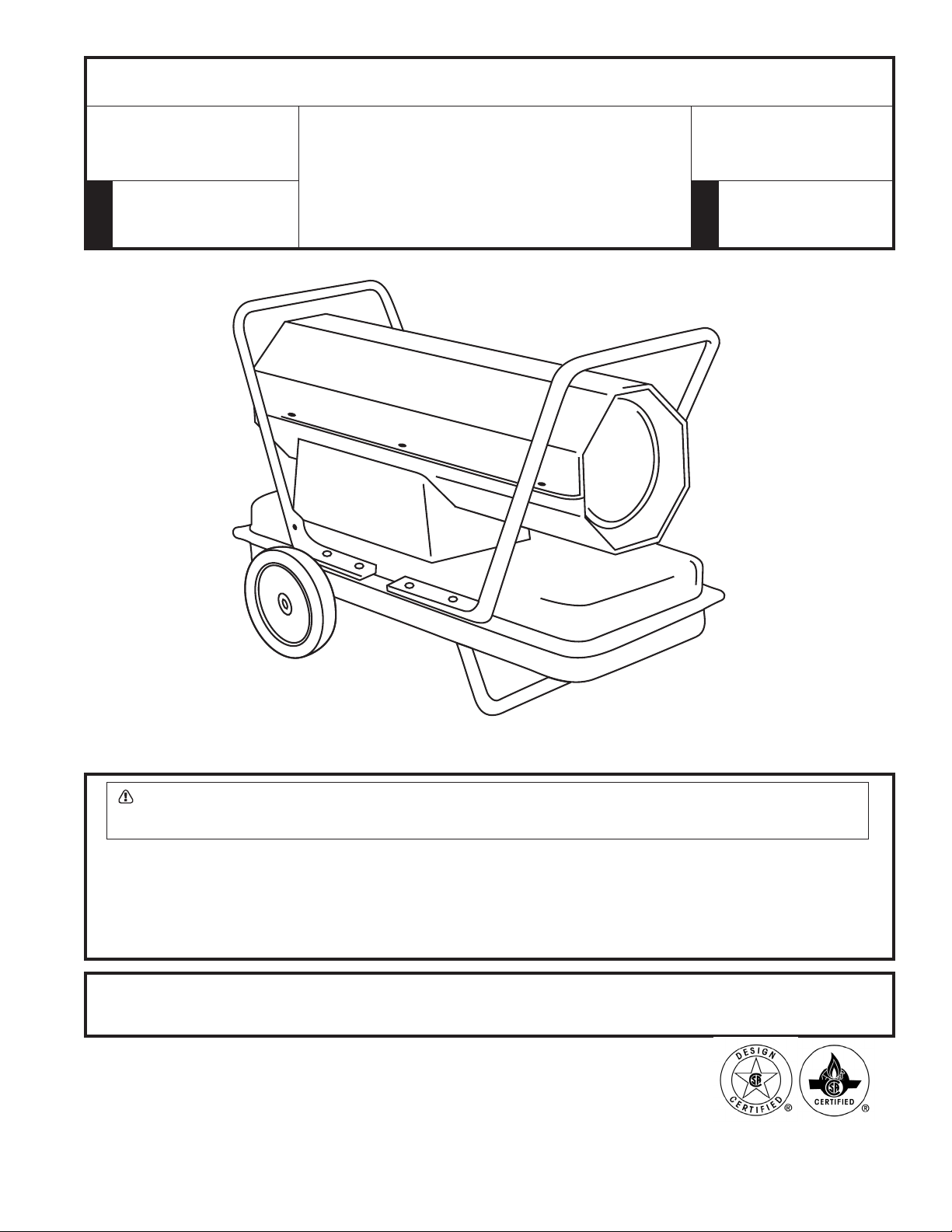

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read

MR. HEATER

MODEL

MH50KT, MH75KT,

MH125KT, MH175KT,

MH210KT

and follow all instructions. Place instructions

in a safe place for future reference. Do not

allow anyone who has not read these instructions to assemble, light, adjust or

operate the heater.

HEATSTAR

MODEL

HS50KT, HS75KT,

HS125KT, HS175KT,

HS210KT

KEROSENE

FORCED-AIR HEATER

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

—Service must be performed by a qualified service agency.

This is an unvented portable heater. It uses air (oxygen) from the area in which it is used.

Adequate combustion and ventilation air must be provided. Refer to page 3.

UL-733, &CSA/CAN3-B140.9.3

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

04/05 70276 Rev. A

Page 2

WARNING:YOUR SAFETY IS IMPORT ANT

TO YOU AND TO OTHERS, SO PLEASE READ

THESE INSTRUCTIONS BEFORE YOU

OPERA TE THIS HEATER.

GENERAL HAZARD W ARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH

THIS HEATER, CAN RESULT IN DEATH, SERIOUS BODILY INJURY AND PROPERTY LOSS

OR DAMAGE FROM HAZARDS OF FIRE,

EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL

SHOCK.

ONLY PERSONS WHO CAN UNDERST AND AND

FOLLOW THE INSTRUCTIONS SHOULD USE

OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER

INFORMATION SUCH AS AN INSTRUCTIONS

MANUAL, LABELS, ETC. CONTACT THE MANUFACTURER.

W ARNING: NOT FOR HOME OR

RECREA TIONAL VEHICLE USE

W ARNING: FIRE, BURN, INHALATION,

AND EXPLOSION HAZARD. KEEP SOLID

COMBUSTIBLES, SUCH AS BUILDING

MA TERIALS, PAPER OR CARDBOARD, A SAFE

DIST ANCE AW A Y FROM THE HEA TER AS

RECOMMENDED BY THE INSTRUCTIONS

NEVER USE THE HEATER IN SPACES WHICH

DO OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES, OR PRODUCTS

SUCH AS GASOLINE, SOLVENTS, PAINT

THINNER, DUST PARTICLES OR UNKNOWN

CHEMICALS.

The State of California requires the following warning:

WARNING:COMBUSTION BY-PRODUCTS

PRODUCED WHEN USING THIS PRODUCT

CONT AIN CARBON MONOXIDE, A CHEMICAL

KNOWN TO THE ST ATE OF CALIFORNIA TO

CAUSE CANCER AND BIRTH DEFECTS (OR

OTHER REPRODUCTIVE HARM).

W ARNING:

• DO NOT USE GASOLINE, NAPHTHA OR

VOLATILE FUELS.

• STOP HEATER BEFORE ADDING FUELS.

• ALWAYS FILL OUTDOORS AWAY FROM OPEN

FLAME

• DO NOT USE EXTERNAL FUEL SOURCE.

• DO NOT OPERATE HEATER WHERE

FLAMMABLE LIQUIDS OR V APORS MAY BE

PRESENT.

• DO NOT START HEATER WHEN CHAMBER IS

HOT

• DO NOT START HEATER WHEN EXCESS

FUEL HAS ACCUMULATED IN THE CHAMBER.

• DO NOT PLACE COOKING UTENSILS ON TOP

OF THE HEATER.

• PLUG ELECTRICAL CORD INTO A PROPERLY

GROUNDED THREE-PRONG RECEPTACLE.

50K & 75KT WARNING:

Not suitable for use on wood floors or other

combustible materials. When used the heater

should rest on a suitable insulating material at

least 1 inch thick and extending 3 feet or more

beyond the heater in all directions.

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’ s Manual

CONTENTS

WARNINGS .......................................................................... 2

HEATER SPECIFICATIONS................................................. 3

OPERA TING PRECAUTIONS.............................................. 3

SAFETY PRECAUTIONS ..................................................... 3

OPERA TING INSTRUCTIONS............................................. 4

MAINTENANCE, STORAGE AND SERVICE....................... 5

WIRING DIAGRAM............................................................... 6

PARTS LIST.......................................................................... 6

EXPLODED VIEW ................................................................ 7

WARRANTY ......................................................................... 8

INSTRUCTIONS FOR ORDERING P ARTS......................... 8

2

Page 3

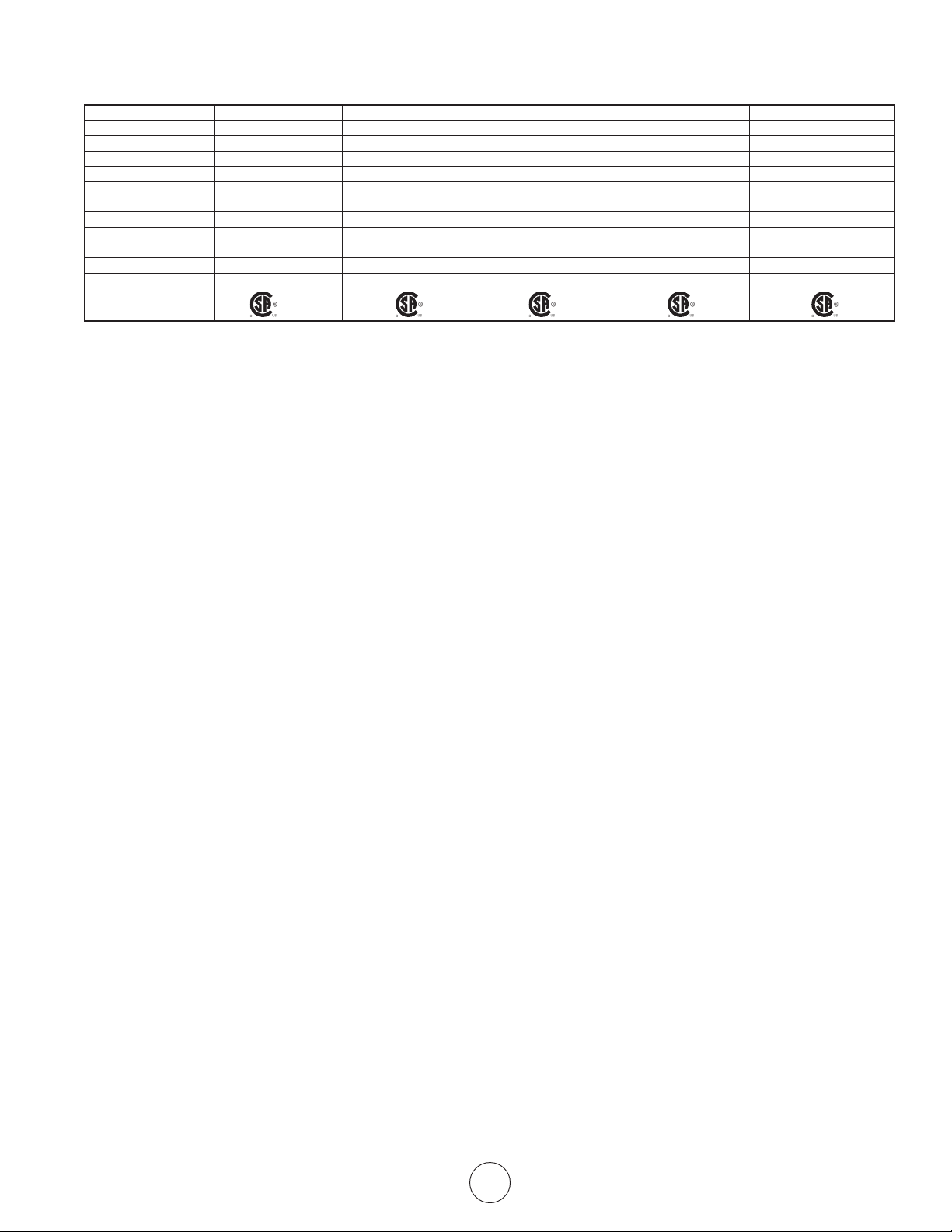

SPECIFICATIONS

Type of Fuel: For use with Kerosene or #1 Fuel Oil ONLY on ALL models.

Model 50K 75KT 125KT 175KT 210KT

Burn Rate: 50,000 Btu/hr (22 kW) 75,000 Btu/hr (22 kW) 125,000 Btu/hr (37 kW) 175,000 Btu/hr (51 kW) 210,000 Btu/hr (61.5 kW)

Fuel Rate: 0.37 gal/hr (1.4 L/hr) 0.55 gal/hr (2.1 L/hr) 0.96 gal./hr (3.5 L/hr) 1.3 gal/hr (5.0 L/hr) 1.6 gal/hr (6.0 L/hr)

Electrical Input: 1 15V, 60Hz, 3.5a 115V, 60Hz, 4a 115V, 60Hz, 5.5a 115V, 60Hz, 5.5a 115V, 60Hz, 5.5a

Line Protection: 10 amps 10 amps 20 amps 20 amps 20 amps

Min. Operating Voltage: 110V 110 V 110 V 1 10V 110 V

Pressure Setting: 3.5 psig (24 kPa) 4.2 psig (29 kPa) 5.0 psig (34 kPa) 5.8 p sig (40 kPa) 8.5 psig (58.6 kPa)

Max. Outlet T emperature: 1300oF (704oC) 1300oF (704oC) 1300oF (704oC) 1300oF (704oC) 1300oF (704oC)

Fuel T ank Capacity: 4 gallons (15.1 L) 6 gallons (22.7 L) 14 gallons (53 L) 14 gallons (53 L) 14 gallons (53 L)

Ignition: Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous

Spark Generator: Igniter 13 kV, 10ma Igniter 13 kV, 10ma Igniter 13 kV , 10ma Igniter 13 kV, 10ma Igniter 13 kV, 10ma

Primary Safety Control: Solid State Control Solid State Control Solid State Control Solid State Control Solid State Control

Certification:

OPERATING PRECAUTIONS

This is a kerosene, direct-fired, forced air heater. It's intended

use is primarily temporary heating of buildings under construction, alteration or repair.

Direct-Fired means that all of the combustion products enter

the heated space. Even though this heater operates very

close to 100 percent combustion efficiency, it still produces

small amounts of carbon monoxide. Carbon monoxide (called

CO) is toxic. We can tolerate small amounts but not a lot. CO

can build up in a heated space and failure to provide adequate ventilation could result in death. The symptoms of

inadequate ventilation are:

• headache

• dizziness

• burning eyes and nose

• nausea

• dry mouth or sore throat

So, be sure to follow advice about ventilation in these

operating instructions.

Forced Air means that a blower or fan pushes the air through

the heater. Proper combustion depends upon this air flow;

therefore, the heater must not be revised, modified or

operated with parts removed or missing. Likewise, safety

systems must not be circumvented or modified in order to

operate the heater.

When the heater is to be operated in the presence of other

people the user is responsible for properly acquainting those

present with the safety precautions and instructions, and of

the hazards involved.

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT

operate a damaged heater.

2. DO NOT modify the heater or operate a heater which

has been modified from its original condition.

3. Use only Kerosene. Never use gasoline, naphtha,

paint thinner, alcohol or other fuels of any kind.

4. For indoor use only. Not for use where exposed to

weather.

5. Use in well ventilated areas, provide at least 2 sq. ft.

(0.19 sq. m.) of opening near the floor and 2 sq. ft.

(0.19 sq. m.) near the ceiling directly to outdoors.

Increase air openings as marked for each additional

heater.

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’ s Manual

6. Always keep combustibles, like paper and wood at

least 8 ft. (2.4 m) from the heater outlet and 3 ft. (1.0 m)

from the top, sides and inlet. Locate 10 ft. (3.0 m) from

canvas or plastic coverings and secure them to prevent

flapping movement.

7. Caution: Due to the high surface and exhaust

temperatures, adults and children must observe

clearances to avoid burns or clothing ignition. Do Not

Touch. Keep Children, Clothing, and Combustibles

away.

8. Install the heater such that it is not directly exposed to

water spray, rain and / or water.

9. Never use in areas normally for habitation and /or

where children may be present.

10. Operate only on a stable, level surface. (MH50K &

MH75KT – See wood floor warning).

11. Do not use with duct work. Do not restrict inlet or exit.

12. Use only with electrical power specified. The electrical

connection and grounding must comply with National

Electrical Code – ANSI/NFPA 70 (USA) and CSA C22.1

Canadian Electrical Code, Part 1 (Canada).

13. Use only a properly grounded 3-prong receptacle or

extension cord.

14. Do not move, handle, or service while hot or burning.

15. Use only in accordance with local, state (provincial) or

National requirements, ordinances and codes.

OPERATING INSTRUCTIONS

UNPACKING

1. Remove all protective material which may have been

applied to the heater for shipment.

2. Remove heater from carton.

3. Check the heater for possible shipping damage. If any

damage is found immediately notify the dealer from

whom you purchased the heater.

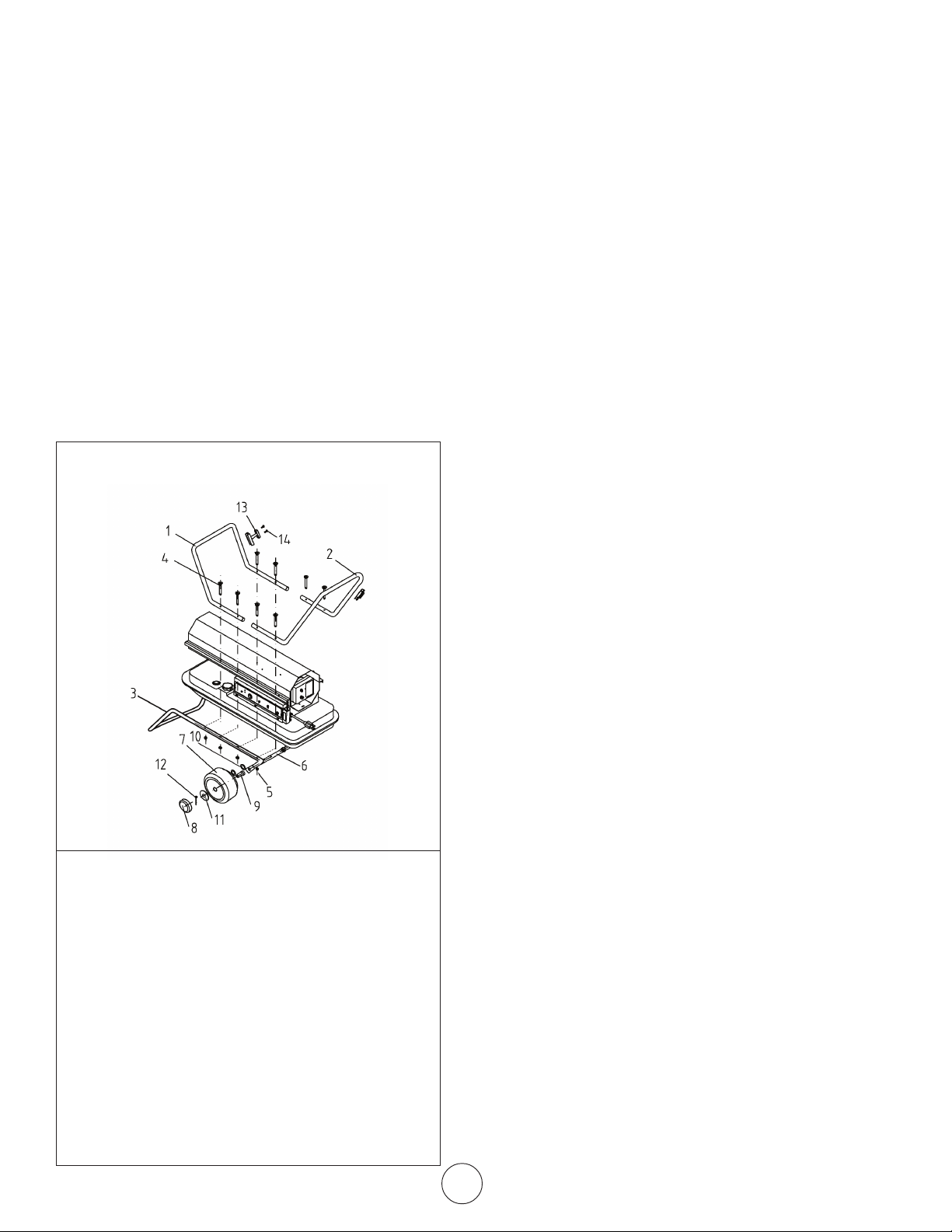

ASSEMBLY (For 125,000, 175,000 and 210,000 BTU/hr

models only)

Wheel and handles are found in the shipping carton along

with mounting hardware. The wheels, axle and mounting

hardware are in a package. Tools required are a 5/16"

nutdriver, 3/8" open or adjustable wrench and standard pliers.

1. Assemble the wheels onto the wheel support frame as

follows:

a.Install one of the cotter pins into the hole on one end

of axle.

b.Slide the large washer, then wheel onto the axle next

to the cotter pin.

3

04/05 70276 Rev. A

Page 4

c.Slide a small washer, spacer, small washer onto the

axle next to the wheel.

d.Slide the partially assembled axle through the wheel

support frame.

e.Slide the small washer, spacer, and small washer onto

the axle next to the wheel support.

f. Slide the wheel then large washer onto the axle and

hold in place with the remaining cotter pin.

g.Install the caps over the larger washers to finish the

wheel assembly.

2. Position the heater on the wheel support frame

assembly with the exit end over the wheels.

3. Use eight screws and nuts to attach the handles to the

top of the tank flange. The screws will go through the

handles, tank flange and wheel support frame. Install

the nuts and finger tight only until all nuts are installed.

4. Tighten all the nuts.

5. Attach cord caddies to handles using No. (14) & No. (5)

screws and nuts.

Handle assembly for 125KT, 175KT& 210KT only.

PREPARING FOR OPERATION

1. Check the heater for possible shipping damage. If any

is found, immediately notify the factory.

2. Follow all of the "Precautions".

3. Fill the fuel tank with clean kerosene. In extremely cold

weather, condensation may develop in the tank and it is

recommended that a tablespoon of de-icer be added

for each gallon (4 liters) of fuel in the tank. When filling

the heater, use at least 2 gallons (8 liters) of fuel. Be

sure heater is level and do not overfill. Use a funnel or

can with a long fill spout.

IMPORTANT: Before filling fuel tank the first time or after

extended storage periods, drain the fuel tank of any

moisture or condensation.

4. Locate heater at a safe distance from combustible

materials. Models 50K & 75KT is not suitable for use on

wood floors or other combustible materials. When

used, the heater should rest on suitable insulating

material at least 1 inch thick and extending 3 ft. or more

beyond the heater in all directions.

ST ART

1. 50K: Plug the heater into a grounded 115V, 60 Hz, 1 Ø

outlet.

75KT, 125KT, 175KT & 210KT:

lowest setting, make sure “On/Off” switch is “Off”. Plug

the heater into a grounded 115V, 60 Hz, 1 Ø outlet.

Turn thermostat to highest setting. Start heater by

push toggle switch to “On” position (light signifies

switch is in “ON” position). Adjust thermostat to

desired setting. Heater will cycle on/off as heat is

required.

For all models: In cold weather, starting may be improved by

holding a finger over the end of the pressure adjusting screw

until the heater starts. This unit is equipped with an interrupt

circuit. The reset is located near the power cord. If the unit

does not start, press the reset button.

Turn thermostat to

ITEM P ART NO. DESCRIPTION QTY

1 24338 Handle, Front 1

2 24338 Handle,Rear 1

3 24339 Wheel Support Frame 1

4 26977 Machine Screw Blk (long) 8

5 26037 Kep Nut Blk 12

6 28746 Axle 1

7 28752 Wheel (8’’ Dia.) 2

7 22110 Wheel (13’’ Dia. 210KT only) 2

8 28751 Cap 2

9 28748 Spacer 2

10 28747 Washer, Small 4

11 28749 Washer, Large 2

12 28750 Cotter Pin 2

13 28754 Ext. Cord Caddy 2

14 27336 Machine Screw Blk (Small) 4

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’ s Manual

STOP

1. 50K: Unplug heater from power source.

75KT, 125KT, 175KT & 210KT: Push “On/Off”

switch to “Off” position. For extended shutdown,

unplug heater from power source.

REST ART AFTER SAFETY SHUTDOWN (50K, 75KT,

125KT, 175KT & 210KT)

1. Wait 5 minutes.

2. Press reset button.

4

Page 5

MAINTENANCE AND STORAGE

WARNING. To prevent personal injury, unplug the

heater from the wall outlet before servicing.

For maximum efficiency and trouble-free service,

make the following periodic maintenance, cleaning

and inspections.

DAILY SCHEDULE

1. GENERAL. Make general visual inspection of heater for

loose or damaged parts. Check nuts and bolts to insure

against looseness caused by vibration or rough

handling. Damaged parts should be repaired or

replaced before using heater again. Check heater

operation to be sure it is operating normally (See

"Servicing" section for description of normal operation).

2. FILTERS. Dirty air or fuel filters will cause an imbalance

in the air-fuel mixture. The best indication that this

condition exists is an increase in odors or difficulty

getting your heater to ignite. This heater should never

be operated without the filters in place. If required,

clean filters as described under "500 Hours" and

"Annual Schedules".

500 HOUR SCHEDULE

1. AIR INTAKE FILTER. Remove and wash the filter

element with a mild detergent, dry thoroughly and

replace. Do not oil the filter element. If your heater is

used where there is considerable dust or dirt, clean as

often as necessary (approximately every 50 hrs.).

2. REMOVE DUST. Clean heater twice a season (more

often under dusty conditions). Remove accumulated

dust from the transformer, burner, motor and fan blades

with compressed air. Wipe area clean with a clean dry

cloth. Inspect area to insure all foreign materials are

removed, especially around the burner and combustion

area.

3. CAD CELL. Clean the glass portion of the cad cell with

a soft dry cloth.

4. NOZZLE. Accumulation of dirt from fuel and carbon

from the compressor vanes will eventually fill up the

passages in the nozzle, resulting in reduction of fuel

and air flow. Pressure will gradually increase giving

improper fuel-air mixture and excess odor and smoke.

If this occurs, replace the fuel nozzle.

5. FUEL TANK. Clean twice a season (during frequently

used periods, clean twice a month). Drain and flush the

fuel tank with clean fuel oil.

ANNUAL SCHEDULE

1. AIR OUTPUT FILTER. Remove the air output filter and

tap the contaminated side gently on a solid object to

remove contaminates. Compressed air or liquids

should not be used to clean this filter. Reinstall cleaned

filter in filter body in the same position as it was when

removed. If the filter appears extremely dirty, replace it

with a new filter of the same type. When replacing the

filter cover, be sure the gasket is firmly in place and the

screws in the filter cover are tight to prevent air leaks.

2. FUEL FILTER. Remove the fuel filter from fuel line and

direct compressed air through the filter in the opposite

direction of fuel flow. Safety glasses should be worn

when using compressed air.

3. AIR AND FUEL LINES. If the air or fuel lines are

removed during cleaning, be sure all connections are

tight before operating unit.

4. AIR PRESSURE SETTING. The air pressure has been

properly set at the factory. If the air pressure is out of

adjustment, it will most likely be caused by dirty air

filters, a partially plugged nozzle, an air leak in the

system or improperly set pressure. If adjustment

becomes necessary, first determine the proper

pressure setting for your heater which is printed on the

serial label located on the fuel tank. Remove the plug

from the air filter cover and attach an accurate pressure

gauge calibrated to a maximum reading of 15 PSI. Start

the heater and note the pressure reading. If the

pressure is low, slowly turn the pressure adjusting

screw in (Clockwise) until the correct pressure is

obtained. If the air pressure is high, turn the adjusting

screw out (counterclockwise) until the pressure is

correct. When correct pressure is reached, unplug the

heater, remove the gauge and replace the plug.

STORAGE

Store the heater in a dry location free from fumes or dust.

At the end of each heating season, clean the heater as

described in the MAINTENANCE section. Drain and flush the

fuel tank with clean fuel. The manufacturer recommends

completely filling the tank with fuel for extended storage to

minimize condensation inside the tank.

SERVICING

A hazardous condition may result if a heater is used that

has been modified or is not functioning properly. When

the heater is working properly:

* The flame is contained within the heater.

* The flame is essentially yellow.

* There is no strong disagreeable odor, eye burning or

other physical discomfort.

* There is no smoke or soot internal or external to the

heater.

* There are no unplanned or unexplained shut downs of

the heater.

DIAGNOSTIC FLAME CONTROL:

This heater is eqiupped with a diagnostic control board and

flashing LED error indicator. This flashing LED signals when

there is a Malfunction of a monitored component. See the

following diagnostic Guide for error signal and a brief

description of the error:

LED UNIT OPERA TION

Show Flash ........ System lockout-High temp limit or rollout

........................... switch open

2 Flashes .......... System lockout-flame exist before motor

.......................... starting

4 Flashes ........... System lockout-motor no normal operation

5 Flashes ........... System lockout-RESET KEY error

6 Flashes ........... System lockout-failled to detect flame

Steady Off .......... Waiting or normal operation

Steady On .......... Ignition control failure

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’ s Manual

5

04/05 70276 Rev. A

Page 6

The parts lists and wiring diagram show the heater as it was constructed. Do not use a heater which is different from that shown.

Heater performance is effected by air pressure setting. If there is any uncertainty about the air pressure setting, have it checked.

A heater which is not working right must be repaired, but only by a trained, experienced service person.

In-warranty products will be repaired with no charge for either parts or labor. Please include a brief statement indicating date, place

of purchase, the nature of the problem and proof of purchase.

Out-of-warranty products will be repaired with a charge for parts and labor.

WIRING DIAGRAM

PARTS LIST

Ref.# Item # Item # Item # Item # Item # Description

50K 75KT 125KT 175KT 210KT

1 21036 21036 21036 21036 21036 Power Cord

2 21676 22213 22214 22214 22214 Fuel Tank Assembly

3 21679 22215 22216 21783 22099 RadiationShield Ass’y

4 21688 22217 22218 22219 22218 Control Box Ass’y

5 21682 22258 22259 22259 22259 Power Pac Ass’y

6 21686 24343 24346 24346 24346 Fuel Tube

7 21685 28734 21771 21768 21771 Grille Assembly

8 —— 28779 28780 28780 28780 Fuel Filter Ass’y

9 24011 24011 24011 24011 24011 Oil Cad Cell Bracket

10 23449 23449 23449 23449 23449 Motor Cord Sleeve

11 21050 21075 21125 21175 22127 Bottom Shell

12 22050 22075 22125 22175 22102 Top Shell

13 23704 24332 24333 24334 24333 Motor Mounting Brkt

14 ——— 22103 22103 22103 22103 AC Receptacle

16 ——— 28788 28735 28735 28735 Start Capacitor

17 23725 23725 24345 24345 24345 Air Tube

18 26225 26225 26225 26225 26225 Snap Bushing

19 21796 21796 21797 21798 22105 High Limit Control

20 26831 26831 26831 26831 26831 Air Pump Rotor

21 ——— 22104 22104 22104 22104 AC Receptacle Cover

22 26833 26833 26833 26833 26833 Air Pump Cylinder

23 26834 26834 26834 26834 26834 Nylon Air Pump Insert

24 26835 26835 26835 26835 26835 Air Pump Vane(4 ea.)

25 22106 22106 22106 22106 22106 Outlet Housing

26 23255 23255 23255 23255 23255 Inlet Housing

27 —— ——— 22257 22257 22257 Burner Head Ass’y

28 23260 23260 23260 23260 23260 Gasket

29 23265 23265 23265 23265 23265 Adjusting Screw

30 23270 23270 23270 23270 23270 Outlet Filter

31 23275 23275 23275 23275 23275 Inlet Filter

32 —— —— —— —— ——

33 26849 26849 26849 26849 26849 Nylon Pipe Plug

34 26850 26850 26850 26850 26850 Ball,. Pressure adj.

35 26851 26851 26851 26851 26851 Spring, Pressure adj.

37 22141 22141 22141 22141 22141 Oil Flame Control Ass’y

38 26865 26865 26865 26865 26865 Cad Cell Flame Sensor

Ref.# Item # Item # Item # Item # Description

50K 75KT 125KT 175KT 210KT

39 ——— 22232 22233 22234 22107 Comb.Chamber Cyl.Ass’y

41 26993 28736 28736 28736 28736 Oil Fuel Cap

43 27339 28737 28738 28738 28738 Motor

44 27790 27790 28739 28739 28739 Nozzle Adapter

45 27421 28740 26885 26866 22108 Fan

46 ——— ——— 26227 26227 26227 Snap Bushing

47 22142 22142 22142 22142 22142 Igniter Assembly

48 27416 28741 28742 28743 22109 Fuel Air Aspir . Nozzle

49 26223 26223 26223 26223 26223 Strain Relief Bushing

50 22143 22143 22144 22144 22144 Electrode Assembly

51 27429 27429 27429 27429 27429 Extrnl. Retaining Ring

53 22145 22145 22145 22145 22145 Fuel Cap Gasket

54 26847 26847 28744 28744 28744 Hose Barb Adapter

* 27094 27094 ——— ——— ——— Clip Hanle Mtg.

* 27095 27095 ——— ——— ——— Handle

* 21683 21683 21683 21683 21683 Lead Wire Ass’y Green

* ——— 21040 21040 21040 21040 Lead Wire Ass’y Black

* ——— 28745 26862 26862 26862 Fuel Filter Bushing

* ——— 22146 22146 22146 22146 Bracket Thermostat Mtg.

* ——— 28790 28790 28790 Adapter,T-hose barb

* ——— 26070 26070 26070 26070 Clamp Loop

* 24171 24171 ——— ——— ——— Nozzle mtg. plate

64 26838 26838 26838 26838 26838 Screw, Tapping #9 x1-1/4"

65 26908 26908 26908 26908 26908 Screw,Machine#10x1-1/4"

66 26906 26906 26906 26906 26906 Screw, Machine#10 x 1/2"

67 ——— 21942 21942 21942 21942 Thermostat Knob

68 ——— 21734 21734 21734 21734 Thermostat Assembly

69 ——— 28785 28785 28785 28785 ON/OFF Switch

70 ——— 28782 28781 28781 28781 Pressure Gauge

71 ——— 28791 28778 28778 28778 Fuel Gauge

72 22147 22148 22149 22149 22149 Control Panel

73 ——— ——— 28783 28783 28783 Hose Barb Adaptor

* ——— 28682 28683 28683 28683 Logo, Mr. Heater

* Not shown in drawing

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’s Manual

6

Page 7

20

33

26

34

29

35

11

30

18

28

4 pcs

25

22

4 pcs

24

23

31

12

27

9

38

50

44

48

3

2 pcs

37

19

49

45

43

10

17

6

46

68

72

69

67

16

7

70

8

41

71

53

5

13

4

1

47

2

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’ s Manual

7

04/05 70276 Rev. A

Page 8

OPERATING INSTUCTIONS AND OWNER’S MANUAL

MR. HEATER HEATSTAR

READ INSTRUCTIONS CAREFULLY : Read and

follow all instructions. Place instructions in a safe

MODEL

MH50KT, MH75KT,

MH125KT, MH175KT,

MH210KT

place for future reference. Do not allow anyone

who has not read these instructions to assemble,

light, adjust or operate the heater.

MODEL

HS50KT, HS75KT,

HS125KT, HS175KT,

HS210KT

WARNING: USE ONLY MANUFACTURER’S REPLACEMENT PARTS.

USE OF ANY OTHER PARTS COULD CAUSE INJURY OR DEATH.

REPLACEMENT PARTS ARE ONLY A VAILABLE DIRECT FROM THE

FACT ORY AND MUST BE INSTALLED BY A QUALIFIED SER VICE

AGENCY.

P ARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Mr . Heater/HeatStar local

dealer or direct from the factory

FOR INFORMA TION REGARDING SERVICE

Please call Toll-Free 800-251-0001 • www .enerco-mrheater.com

Our office hours are 8:30 AM – 5:00 PM, EST, Monday through Friday.

Email to: techservice@enerco-mrheater.com

Please include the model number, date of purchase, and description of problem

in all communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or

workmanship, under normal and proper use in accordance with instructions of The

Company, for a period of one year from the date of delivery to the buyer. The Company,

at its option, will repair or replace products returned by the buyer to the factory,

transportation prepaid within said one year period and found by the Company to have

imperfections in material or workmanship.

If a part is damaged or missing, call our Technical Support Department at 800-251-

0001.

Address any Warranty Claims to the Service Department, Enerco Group, Inc., 4560 W.

160TH ST., Cleveland, Ohio 44135. Include your name, address and telephone number

and include details concerning the claim. Also, supply us with the purchase date and

the name and address of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no other

warranties, express or implied. Specifically there is no warranty of fitness for a particular

purpose and there is no warranty of merchantability. In no event shall the Company be

liable for delay caused by imperfections, for consequential damages, or for any charges

of the expense of any nature incurred without its written consent. The cost of repair or

replacement shall be the exclusive remedy for any breach of warranty. There is no

warranty against infringement of the like and no implied warranty arising from course of

dealing or usage of trade. This warranty will not apply to any product which has been

repaired or altered outside of the factory in any respect which in our judgment affects its

condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This Warranty

gives you specific legal rights, and you may have other rights which vary from state to

state.

Enerco Group, Inc.

or obligation, in colors, specifications, accessories, materials and models.

reserves the right to make changes at any time, without notice

UL-733, &CSA/CAN3-B140.9.3

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’ s Manual

ENERCO GROUP, INC. 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

Mr. Heater is a registered trademark of Enerco Group, Incs.

© 2003, Enerco Group Inc. All right s reserved

8

04/05 70276 Rev. A

Page 9

8

04/05 70276 Rev. A

Guide d'utilisation et instructions de fonctionnement

• (216) 881-5500 Indiquez vos nom, adresse et

Enerco, Group, Inc. | Appareil de chauf fage à air pulsé au kérosène

© Enerco Group Inc, 2003. Tous droits réservés.

Mr. Heater est une marque de commerce déposée de Enerco Group Inc.

ENERCO GROUP, INC. 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

obligation, aux couleurs, aux spécifications, aux accessoires, aux matériaux et aux modèles.

Enerco Group Inc. se réserve le droit d'effectuer des modifications en tout temps, sans préavis ni

vous pourriez avoir d'autres droits qui varient selon la province ou l'État.

concernent peut-être pas. La présente garantie vous accorde des droits juridiques précis, mais

subséquents. Par conséquent, les limitations ou exclusions ci-dessus mentionnées ne vous

Certains États ou provinces ne permettent pas d'exclure ou de limiter les dommages indirects ou

fonctionnement, selon notre jugement.

fabricant si cela influe de quelque façon que ce soit sur la condition de l'appareil ou son

présente garantie ne s'applique à aucun produit qui a été réparé ou modifié par d'autres que le

aucune garantie tacite découlant de la façon habituelle de traiter ou des usages du commerce. La

de violation de garantie. Il n'y a aucune garantie contre la transgression des semblables ni

soit leur nature. Le coût de la réparation ou du remplacement sera le seul recours possible en cas

ni des dommages indirects, ni des dépenses encourues sans son consentement écrit, quelle que

aucun cas l'entreprise ne saura être tenue responsable des retards causés par des défectuosités,

l'adéquation à une utilisation particulière ni aucune garantie concernant la qualité marchande. En

autre garantie, expresse ou tacite. Plus précisément, il n'y a aucune garantie concernant

Ce qui est énoncé ci-dessus constitue la responsabilité totale de l'entreprise. Il n'existe aucune

d'achat et le nom et l'adresse du détaillant de qui vous avez acheté le produit.

numéro de téléphone ainsi que les détails de la réclamation. Indiquez-nous également la date

W. 160TH ST., CLEVELAND, OHIO 44135

Adressez toute réclamation relative à la garantie à Service Department, Enerco Group, Inc., 4560

(800) 251-0001.

Si une pièce est endommagée ou manquante, téléphonez à notre service de soutien technique au

d'œuvre.

période de un an et jugés par l'entreprise comme présentant des défauts de matériel ou de mainremplacera, à sa discrétion, les produits retournés port payé par l'acheteur au fabricant dans la

une période de un an à compter de la date de livraison à l'acheteur. L'entreprise réparera ou

conditions d'utilisation normale et adéquate, conformément aux instructions de l'entreprise, pour

L'entreprise garantit ce produit contre tout défaut de matériel ou de main-d'œuvre, dans des

GARANTIE LIMITÉE

UL-733, &CSA/CAN3-B140.9.3

HS210KT

HS125KT, HS175KT,

HS50KT, HS75KT,

MODÈLE

HEATSTAR

problème dans toutes vos communications avec nous.

Veuillez indiquer le numéro du modèle, la date d'achat et la description du

Adressez vos courriels à : techservice@enerco-mrheater.com

Nos heures de bureau sont de 8 h 30 à 17 h HE, du lundi au vendredi

Appelez sans frais au (800) 251-0001 • www.enerco-mrheater.com

POUR OBTENIR DES INFORMA TIONS SUR LE SERVICE

régional des produits Mr . Heater/HeatStar ou directement du fabricant.

ACHA T : Il est possible de se procurer des accessoires chez le dét aillant

INSTRUCTIONS POUR COMMANDER DES PIÈCES :

ET DOIVENT ÊTRE INSTALLÉES PAR UNE ENTREPRISE SPÉCIALISÉE.

DE REMPLACEMENT NE SONT OFFERTES QUE PAR LE FABRICANT

RISQUE DE CAUSER DES BLESSURES, VOIRE LA MOR T. LES PIÈCES

REMPLACEMENT DU F ABRICANT. L'UTILISATION D'AUTRES PIÈCES

A VERTISSEMENT :N'UTILISEZ QUE LES PIÈCES DE

régler ou de faire fonctionner cette fournaise.

présentes instructions d'assembler, d'allumer, de

ultérieurement. Interdisez à quiconque n'a pas lu les

les instructions en sécurité pour vous y référer

lisez et observez toutes les instructions. Conservez

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS :

MH210KT

MH125KT, MH175KT,

MH50KT, MH75KT,

MODÈLE

MR. HEATER

GUIDE D'UTILISATION ET INSTRUCTIONS DE FONCTIONNEMENT

Page 10

7

04/05 70276 Rev. A

Guide d'utilisation et instructions de fonctionnement

Enerco, Group, Inc. | Appareil de chauffage à air pulsé au kérosène

2

16

7

5

6

37

2 pcs

44

13

47

48

17

27

10

50

43

67

69

68

1

4

8

71

53

41

70

72

46

11

49

18

4 pcs

45

19

3

38

9

34

35

33

12

29

31

4 pcs

22

24

23

20

25

28

26

30

Page 11

6

Guide d'utilisation et instructions de fonctionnement

* ——— 28682 28683 28683 28638 Logo, Mr. Heater

73 ——— ——— 28783 28783 27783 Adaptateur à barbelures

72 22147 22148 22149 22149 22149 Panneau d'accès

71 ——— 28791 28778 28778 28778 Jauge à combustible

70 ——— 28782 28781 28781 28781 Manomètre

69 ——— 28785 28785 28785 28785 Interrupteur

68 ——— 21734 21734 21734 21734 Ens. thermostat

67 ——— 21942 21942 21942 21942 Bouton thermostat

66 26906 26906 26906 26906 26906 Vis mécanique n° 10 x 1/2 po

65 26908 26908 26908 26908 26908 Vis mécanique n° 10 x 1-1/4 po

64 26838 26838 26838 26838 26838 Vis taraudeuse n° 9 x 1-1/4 po

* 24171 24171 ——— ——— ——— Plaque de montage gicleur

* ——— 28790 28790 28790 Adaptateur, barbelures T

* ——— 26070 26070 26070 26070 Boucle étrier

* ——— 22146 22146 22146 22146 Support montage thermostat

* ——— 28745 26862 26862 26862 Bague filtre combustible

* ——— 21040 21040 21040 21040 Fil conducteur noir

* 21683 21683 21683 21683 21683 Fil conducteur vert

* 27095 27095 ——— ——— ——— Poignée

* 27094 27094 ——— ——— ——— Serre-câble poignée

54 26847 26847 28744 28744 28744 Adaptateur à barbelures

53 22145 22145 22145 22145 22145 Joint bouchon réservoir

51 27429 27429 27429 27429 27429 Anneau de retenue ext.

50 22143 22143 22144 22144 22144 Ens. électrode

49 26223 26223 26223 26223 26223 Bague serre-câble

48 27416 28741 28742 28743 22109 Gicleur air-comb.

47 22142 22142 22142 22142 22142 Ens. allumeur

46 ——— ——— 26227 26227 26227 Bague pression

45 27421 28740 26885 26866 22108 Ventilateur

44 27790 27790 28739 28739 28739 Adaptateur du gicleur

43 27339 28737 28738 28738 28738 Moteur

41 26993 28736 28736 28736 28736 Bouchon du réservoir

39 ——— 22232 22233 22234 22107 Ens. cyl. ch. de comb.

50K 75KT 125KT 175KT 210KT

N° réf. N° art. N° art. N° art. N° art. Description

Enerco, Group, Inc. | Appareil de chauf fage à air pulsé au kérosène

38 26865 26865 26865 26865 26865 Capteur flamme cell. cad.

37 22141 22141 22141 22141 22141 Ens. commande de flamme

35 26851 26851 26851 26851 26851 Ressort, régl. pression

34 26850 26850 26850 26850 26850 Boule, régl. pression

33 26849 26849 26849 26849 26849 Bouchon nylon canal.

32 —— —— —— —— ——

31 23275 23275 23275 23275 23275 Filtre d'entrée

30 23270 23270 23270 23270 23270 Filtre de sortie

29 23265 23265 23265 23265 23265 Vis de réglage

28 23260 23260 23260 23260 23260 Joint d'étanchéité

27 —— ——— 22257 22257 22257 Brûleur

26 23255 23255 23255 23255 23255 Boîtier d'entrée

25 22106 22106 22106 22106 22106 Boîtier de sortie

24 26835 26835 26835 26835 26835 Ailette pompe à air (4)

23 26834 26834 26834 26834 26834 Raccord nylon pompe à air

22 26833 26833 26833 26833 26833 Cylindre pompe à air

21 ——— 22104 22104 22104 22104 Couvre-prise secteur

20 26831 26831 26831 26831 26831 Rotor pompe à air

19 21796 21796 21797 21798 22105 Dispositif commande max.

18 26225 26225 26225 26225 26225 Bague pression

17 23725 23725 24345 24345 24345 Canalisation d'air

16 ——— 28788 28735 28735 28735 Condensateur de démarrage

14 ——— 22103 22103 22103 22103 Prise secteur

13 23704 24332 24333 24334 24334 Support montage moteur

12 22050 22075 22125 22175 22102 Coque supérieure

11 21050 21075 21125 21175 22101 Coque inférieure

10 23449 23449 23449 23449 23449 Gaine du cordon moteur

9 24011 24011 24011 24011 24011 Support cellule au cadmium

8 —— 28779 28780 28780 28780 Filtre à combustible

7 21685 28734 21771 21768 21771 Grille

6 21686 24343 24346 24346 24346 Canal. combustible

5 21682 22258 22259 22259 22259 Boîtier d'alimentation

4 21688 22217 22218 22219 22218 Module de commande

3 21679 22215 22216 21783 22099 Écran contre rayon.

2 21676 22213 22214 22214 22214 Ensemble réservoir

1 21036 21036 21036 21036 21036 Cordon d'alimentation

50K 75KT 125KT 175KT 210KT

N° réf. N° art. N° art. N° art. N° art. Description

LISTE DES PIÈCES

SCHÉMA DE CÂBLAGE

Les produits non couverts par la garantie seront réparés moyennant facturation des pièces et de la main-d'œuvre.

nature du problème avec la date, le lieu et la preuve d'achat.

Les produits couverts par la garantie seront réparés sans frais, pièces et main-d'œuvre comprises. Veuillez joindre une courte description de la

Si un appareil de chauffage ne fonctionne pas correctement, il doit être réparé, mais seulement par un technicien formé et expérimenté.

pression d'air, faites-la vérifier.

diffère de ce qui est montré. Le rendement de l'appareil de chauffage dépend du réglage de la pression d'air. Si vous avez un doute au sujet de la

La liste des pièces et le schéma de câblage présentent l'appareil de chauffage tel qu'il a été construit. N'utilisez pas un appareil de chauffage qui

Page 12

04/05 70276 Rev. A

5

Toujours allumé .....Anomalie de commande d’allumage

Toujours éteint ....... Attente ou fonctionnement normal

6 clignotements .....Système bloqué, aucune flamme détectée

............................... RÉINITIALISATION

5 clignotements ..... Système bloqué, erreur de BOUTON DE

............................... moteur

4 clignotements .....Système bloqué, fonctionnement anormal du

............................... démarrage du moteur

2 clignotements .....Système bloqué, flamme allumée avant le

............................... limiteur de température élevée ouvert

Clignotement lent .. Système bloqué, commutateur de lancement ou

Témoin lumineux FONCTIONNEMENT DE L’APPAREIL

correspondante.

pouvant être affichés et une brève description de l’anomalie

tableau de diagnostic cidessous énumère les codes d’erreurs

erreurs de fonctionnement d’un composant sous surveillance. Le

d’un témoin lumineux d’anomalie. Le témoin lumineux signale les

Cet appareil de chauffage est équipé d’un panneau de diagnostic et

DIAGNOSTIC DES ANOMALIES :

l'appareil.

* Il ne se produit pas d'arrêts imprévus ou inexpliqués de

l'extérieur de l'appareil de chauffage.

* Il n'y a pas de production de fumée ou de suie à l'intérieur ou à

brûlure aux yeux, ni de malaise physique en général.

* Il n'y a pas de forte odeur désagréable, ni de sensation de

* La flamme est vraiment jaune.

* La flamme reste dans l'appareil de chauffage.

Lorsqu'il fonctionne correctement :

pas correctement risque d'être une cause de dangers.

Un appareil de chauffage qui a été modifié ou qui ne fonctionne

RÉPARATION

les risques de condensation.

de combustible avant un entreposage prolongé pour diminuer

fabricant recommande de remplir complètement le réservoir

et vidangez le réservoir à l'aide de combustible propre. Le

chauffage tel qu'indiqué dans la section ENTRETIEN. Rincez

À la fin de chaque saison de chauffage, nettoyez l'appareil de

exempt de vapeurs et de poussières.

Entreposez l'appareil de chauffage dans un endroit sec

ENTREPOSAGE

manomètre et replacez le bouchon.

obtenue, débranchez l'appareil de chauffage, enlevez le

correcte soit obtenue. Lorsque la pression adéquate est

pression en sens antihoraire, jusqu'à ce que la pression

elle est haute, tournez doucement la vis d'ajustement de

horaire jusqu'à ce que la pression correcte soit obtenue. Si

tournez doucement la vis d'ajustement de pression en sens

et notez la lecture de pression. Si le pression s'avère basse,

lecture maximale de 15 Psi. Démarrez l'appareil de chauffage

filtre à air et fixez un manomètre précis gradué pour une

située sur le réservoir. Enlevez le bouchon du couvercle du

votre appareil. Il est inscrit sur l'étiquette du numéro de série

nécessaire, commencez par déterminer le réglage approprié à

mauvais réglage de la pression. Si un réglage s'avère

partiellement obstrué, une fuite d'air dans le système ou un

probablement causé par un filtre à air encrassé, un gicleur

correctement réglée en usine. Si elle se dérègle, ce sera

4. RÉGLAGE DE LA PRESSION D'AIR. La pression d'air a été

l'appareil.

vous de bien serrer les raccords avant de faire fonctionner

canalisations sont enlevées au cours du nettoyage, assurez-

3. CANALISATIONS D'AIR ET DE COMBUSTIBLE. Si ces

Enerco, Group, Inc. | Appareil de chauf fage à air pulsé au kérosène Guide d'utilisation et instructions de fonctionnement

des lunettes protectrices en utilisant de l'air comprimé.

dans le sens contraire du débit du combustible. Veuillez porter

de combustible et dirigez de l'air comprimé à travers le filtre

2. FILTRE À COMBUSTIBLE. Enlevez le filtre de la canalisation

fuites d'air.

les vis du couvercle sont assez serrées pour empêcher des

vous que le joint d'étanchéité est solidement en place et que

type. En remettant le couvercle du filtre en place, assurezextrêmement sale, remplacez-le par un nouveau du même

réceptacle dans la position où il était. Si le filtre paraît

pour nettoyer le filtre. Replacez le filtre propre dans son

enlever les saletés. N'utilisez pas d'air comprimé ni de liquide

frappez-en doucement le côté sale sur un objet dur pour

1. FILTRE DE SORTIE D'AIR. Enlevez le filtre de sortie d'air et

PROGRAMME ANNUEL

de mazout propre.

le deux fois par mois). Rincez et vidangez le réservoir à l'aide

saison (au cours des périodes d'utilisation intensive, nettoyez-

5. RÉSERVOIR DE COMBUSTIBLE. Nettoyez-le deux fois par

un tel cas, remplacez le gicleur.

combustible et produira un surplus de fumée et d'odeur. Dans

graduellement, ce qui déséquilibrera le mélange aird'air et de combustible. La pression augmentera

les conduits du gicleur et entraînera une diminution du débit

carbone causée par l'aube d'entrée obstruera éventuellement

4. GICLEUR. L'accumulation de poussière de combustible et de

au cadmium à l'aide d'un chiffon doux et sec.

3. CELLULE AU CADMIUM. Nettoyez la partie vitrée de la cellule

brûleur et de la zone de combustion.

matière étrangère a été enlevée, particulièrement autour du

propre. Inspectez ces endroits pour vous assurer que toute

d'air comprimé. Essuyez les surfaces avec un chiffon sec et

brûleur, le moteur et les pales du ventilateur à l'aide d'un jet

Enlevez la poussière accumulée sur le transformateur, le

fois par saison (plus souvent dans les endroits poussiéreux).

2. ENLEVER LA SALETÉ. Nettoyez l'appareil de chauffage deux

heures environ).

saletés, nettoyez le filtre aussi souvent que requis (aux 50

dans un endroit contenant beaucoup de poussières et de

place. Ne huilez pas l'élément filtrant. Si vous utilisez l'appareil

l'aide d'un détergent doux. Séchez-le à fond et remettez-le en

1. FILTRE D'ADMISSION D'AIR. Enlevez le filtre et lavez-le à

PROGRAMME 500 HEURES

Programme annuel ».

décrit aux sections « Programme 500 heures « et »

sans les filtres. Si nécessaire, nettoyez les filtres tel qu'il est

démarrera difficilement. Ne faites pas fonctionner l'appareil

défaut de quoi, l'odeur augmentera et l'appareil de chauffage

propres pour assurer l'équilibre du mélange air-combustible. À

2. FILTRES. Les filtres à air et à combustible doivent être

Réparation » pour une description du fonctionnement normal).

vous assurer qu'il est normal (consultez la section «

de chauffage. Examinez le fonctionnement de l'appareil pour

réparées ou remplacées avant d'utiliser à nouveau l'appareil

les ont pas desserrés. Les pièces endommagées doivent être

assurer que les vibrations et les manipulations brusques ne

ou desserrées. Inspectez les boulons et les écrous pour vous

l'appareil de chauffage pour déceler les pièces endommagées

1. GÉNÉRAL. Faites une inspection visuelle générale de

PROGRAMME QUOTIDIEN

l'entretien suivants.

effectuez régulièrement les inspections, le nettoyage et

Pour optimiser le fonctionnement et éviter les problèmes,

l'entretien.

l'appareil de chauffage de la prise murale avant d'en effectuer

AVERTISSEMENT. Pour éviter toute blessure, débranchez

ENTRETIEN ET ENTREPOSAGE

Page 13

4

Guide d'utilisation et instructions de fonctionnement

kérosène

2. Enfoncez le bouton de réinitialisation.

1. Attendez cinq minutes.

(50K, 75KT, 125KT, 175KT et 210KT)

REDÉMARRAGE APRÈS UN ARRÊT D'URGENCE

source d'alimentation.

prolongé, débranchez l'appareil de chauffage de sa

à la position « OFF » (Arrêt). Pour un arrêt

75KT, 125KT, 175KT et 210KT : Réglez l'interrupteur

d'alimentation.

1. 50K : Débranchez l'appareil de chauffage de sa source

ARRÊT

réinitialisation est enfoncé.

S'il ne démarre pas, vérifiez si le bouton de

muni d'un disjoncteur situé près du cordon électrique.

que l'appareil de chauffage démarre. Cet appareil est

l'extrémité de la vis de réglage de pression, jusqu'à ce

démarrage sera facilité en tenant un doigt sur

Pour tous les modèles : à basse température, le

besoin.

L'appareil de chauffage s'arrêtera et redémarrera au

Réglez le thermostat à la température désirée.

(Marche) (la lumière s'allume à la position « ON »).

réglant l'interrupteur à bascule à la position « ON »

la plus élevée. Démarrez l'appareil de chauffage en

de 115 V, 60 Hz, 1 Ø. Réglez le thermostat à sa position

l'appareil de chauffage dans une prise mise à la terre

l'interrupteur est fermé. Branchez le cordon de

à sa plus basse position et assurez-vous que

75KT, 125KT, 175KT et 210KT : Réglez le thermostat

dans une prise mise à la terre de 115 V, 60 Hz, 1 Ø.

1. 50K : Branchez le cordon de l'appareil de chauffage

DÉMARRAGE

l'appareil d'au moins 90 cm (3 pi) de tous les côtés.

adéquat d'au moins 2,5 cm (1 po) d'épaisseur et dépassant

l'appareil de chauffage doit reposer sur un matériau isolant

d'autres matériaux combustibles. Lors de son fonctionnement,

pas conçus pour être utilisés sur des planchers de bois ou

matériaux combustibles. Les modèles 50K et 75KT ne sont

4. Placez l'appareil de chauffage à une distance sécuritaire des

condensation.

après des périodes d'entreposage prolongées, enlevez-en la

IMPORTANT : Avant de remplir le réservoir la première fois ou

entonnoir ou d'un contenant muni d'un long bec verseur.

niveau et que le réservoir ne déborde pas. Servez-vous d'un

du réservoir. Assurez-vous que l'appareil de chauffage est de

moins 2 gallons (8 litres) de combustible lors du remplissage

antigivrant par gallon (4 litres) de combustible. Utilisez au

recommandé d'ajouter une cuillère à table de liquide

condensation se forme dans le réservoir. Il est donc

conditions de froid intense, il est possible que de la

3. Remplissez le réservoir de kérosène propre. Dans des

2. Respectez toutes les « Précautions ».

avertissez immédiatement le fabricant.

dommages lors de l'expédition. Si vous en découvrez,

1. Vérifiez attentivement si l'appareil de chauffage a subi des

AVANT LE FONCTIONNEMENT

Enerco, Group, Inc. | Appareil de chauf fage à air pulsé au

14 27336 Boulons courts (paquet) 4

13 28754 Guides de cordon électrique 2

12 28750 Goupilles fendues 2

11 28749 Rondelle, grande 2

10 28747 Rondelle, petite 4

9 28748 Séparateurs 2

8 28751 Capuchons 2

7 22110 Roues (210KT) 2

7 28752 Roues 2

6 28746 Essieu 1

5 26037 Écrous à rondelle dentée (paquet)12

4 26977 Boulons longs (paquet) 8

3 24339 Cadre de support des roues 1

2 24338 Poignée, arrière 1

1 24338 Poignée, avant 1

ARTICLE N° PIÈCE DESCRIPTION QTÉ

210KT seulement.

Assemblage de la poignée pour les modèles 125KT, 175KT et

et écrous n° 14 et n° 5.

5. Fixez les guides de cordon aux poignées à l'aide des boulons

4. Serrez tous les écrous.

qu'ils ne soient tous vissés.

roues. Vissez les écrous à la main et ne les serrez pas avant

poignées, la bride du réservoir et le cadre de support des

dessus de la bride du réservoir. Les boulons traverseront les

3. À l'aide des huit écrous et boulons, fixez les poignées au

roues, le côté sortie par-dessus les roues.

2. Placez l'appareil de chauffage sur le cadre de support des

terminer l'assemblage des roues.

g. Installez les capuchons sur les grandes rondelles pour

fixez-les en place avec l'autre goupille fendue.

f. Insérez la roue sur l'essieu, puis la grande rondelle et

petite rondelle, un séparateur et une autre petite rondelle.

e. Insérez sur l'essieu, à côté du cadre de support, une

support des roues.

d. Insérez l'essieu partiellement assemblé dans le cadre de

un séparateur et une autre petite rondelle.

c. Insérez sur l'essieu, à côté de la roue, une petite rondelle,

goupille fendue, puis la roue.

b. Insérez la grande rondelle sur l'essieu, à côté de la

bout de l'essieu.

a. Insérez l'une des goupilles fendues dans le trou situé au

suivante :

1. Assemblez les roues sur leur cadre de support de la façon

Page 14

04/05 70276 Rev. A

3

Guide d'utilisation et instructions de fonctionnement

Enerco, Group, Inc. | Appareil de chauf fage à air pulsé au kérosène

chauffage et à 3 pi (1 m) du dessus et des côtés de l'appareil

le bois, à au moins 8 pi (2,4 m) de la sortie de l'appareil de

6. Gardez tous les matériaux combustibles, comme le papier et

additionnel.

ouvertures tel qu'indiqué pour chaque appareil de chauffage

ajustable de 3/8 po et une pince ordinaire.

à l'assemblage sont : une clé de 5/16 po, une clé ouverte ou

l'assemblage se trouvent dans un emballage. Les outils nécessaires

servant à l'assemblage. Les roues, l'essieu et les pièces servant à

Les roues et les poignées se trouvent dans la boîte avec les pièces

seulement)

ASSEMBLAGE (pour les modèles de 125 000 et de 175 000 Btu/h

vous l'avez acheté.

dommage, avertissez-en immédiatement le détaillant de qui

dommages lors de l'expédition. Si vous constatez quelque

3. Vérifiez attentivement si l'appareil de chauffage a subi des

2. Retirez l'appareil de chauffage de la boîte.

pour le transport.

1.

Enlevez tout le matériel de protection installé sur l'appareil

directement sur l'extérieur. Augmentez la dimension de ces

autre d'au moins 2 pi² (0,19 m²) près du plafond, qui donnent

une ouverture d'au moins 2 pi² (0,19 m²) près du plancher et une

5. Faites fonctionner l'appareil dans des endroits bien aérés. Laissez

intempéries.

4. N'utilisez qu'à l'intérieur. L'appareil ne doit pas être exposé aux

quelque nature que ce soit.

de diluant à peinture, d'alcool ni d'autres combustibles de

3. N'utilisez que du kérosène. N'utilisez jamais d'essence, de naphte,

fonctionner s'il n'est plus dans son état original.

2. NE MODIFIEZ PAS l'appareil de chauffage et ne le faites pas

endommagé.

dommages. NE FAITES PAS fonctionner un appareil

1. Vérifiez attentivement si l'appareil de chauffage a subi des

PRÉCAUTIONS LIÉES À LA SÉCURITÉ

DÉBALLAGE

INSTRUCTIONS DE FONCTIONNEMENT

municipalité concernés.

et les exigences du pays, de la province, de l'État ou de la

15. Ne l'utilisez qu'en conformité avec les codes, les ordonnances

pas d'en faire l'entretien lorsqu'il est chaud.

14. Ne déplacez pas l'appareil, ne lui touchez pas et n'essayez

munie de trois broches.

13. N'utilisez qu'avec une prise ou une rallonge mises à la terre

partie 1 (Canada).

(É.-U.) - et au Code canadien de l'électricité - CSA C22.1 -,

conformes au Code national de l'électricité - ANSI/NFPA 70

raccordement électrique et la mise à la terre doivent être

12. N'utilisez qu'avec l'alimentation électrique spécifiée. Le

la prise et la sortie d'air.

11. N'utilisez pas l'appareil avec des conduits d'air. N'obstruez pas

planchers de bois)

niveau. (MH50K et MH75KT : voir l'avertissement au sujet des

10. Ne faites fonctionnez que sur des surfaces stables et de

à l'habitation ni où sont présents des enfants.

9. Ne l'utilisez jamais dans des endroits qui servent normalement

exposé directement à l'eau.

8. Placez l'appareil de chauffage de façon à ce qu'il ne soit pas

de l'appareil.

enfants, les vêtements et les produits combustibles à distance

des vêtements. Ne touchez pas à l'appareil. Gardez les

distances de sécurité pour éviter des brûlures et l'inflammation

à la sortie, les adultes et les enfants doivent respecter les

7. Attention : En raison des températures élevées à la surface et

d'empêcher tout battement.

toiles et des revêtements plastiques, et fixez-les afin

ainsi que de la prise d'air. Placez l'appareil à 10 pi (3 m) des

dangers inhérents.

instructions et précautions liées à la sécurité et de les avertir des

personnes, l'utilisateur est responsable d'informer ces dernières des

Lorsque l'appareil de chauffage doit fonctionner en présence d'autres

contournés ni modifiés pour faire fonctionner l'appareil.

ordre d'idée, les systèmes de sécurité ne doivent pas être

modifié ni fonctionner avec des pièces manquantes. Dans le même

débit d'air. Par conséquent, l'appareil de chauffage ne doit pas être

chauffage par un ventilateur. La qualité de la combustion est liée au

Un appareil à air pulsé signifie que l'air est soufflé dans l'appareil de

tion mentionnés dans ces instructions.

Assurez-vous donc de respecter les conseils au sujet de la ventila-

• mal de gorge ou bouche sèche

• nausée

• sensation de brûlure au nez et aux yeux

• étourdissement

• mal de tête

ventilation inadéquate sont les suivants :

pourrait ainsi causer la mort. Les symptômes ressentis en cas de

CO s'accumule dans le local à chauffer. Une ventilation déficiente

ne peut en supporter que de faibles quantités. Il est possible que le

Le monoxyde de carbone (appelé CO) est toxique. Notre organisme

produit quand même de petites quantités de monoxyde de carbone.

combustion de l'appareil de chauffage est presque complète, il

combustion se retrouvent dans l'air ambiant. Même si l'efficacité de

Son fonctionnement à feu direct signifie que tous les produits de

en réparation.

temporairement des édifices en construction, en rénovation ou

kérosène. Il est destiné principalement à chauffer

Cet appareil de chauffage à air pulsé et à feu direct fonctionne au

FONCTIONNEMENT

PRÉCAUTIONS LIÉES AU

Certification:

Appareil de commande : Commande transistorisée Commande transistorisée Commande transistorisée Commande transistorisée Commande transistorisée

Générateur d'étincelle : Allumeur 13 kV, 10ma Allumeur 13 kV , 10ma Allumeur 13 kV, 10ma Allumeur 13 kV , 10ma Allumeur 13 kV , 10ma

Allumage : Par étincelle, en continu Par étincelle, en continu Par étincelle, en continu Par étincelle, en continu Par étincelle, en continu

Contenance du réservoir : 4 gallons (15,1 L) 6 gallons (22,7 L) 14 gallons (53 L) 14 gallons (53 L) 14 gallons (53 L)

F (704

F (704

F (704

F (704

F (704

C)

o

o

C) 1300

o

o

C) 1300

o

o

C) 1300

o

o

C) 1300

o

o

T empérature maximale de sortie : 1300

Réglage de la pression : 3.5 psig (24 kPa) 4.2 psig (29 kPa) 5.0 psig (34 kPa) 5.8 psig (40 kPa) 8.5 psig (58.6 kPa)

fonctionnement : 110V 110 V 110V 110V 1 10V

Intensité maximale : 10 amps 10 amps 20 amps 20 amps 20 amps

Consommation électrique : 115V , 60Hz, 3.5a 1 15V , 60Hz, 4a 1 15V , 60Hz, 5.5a 115V , 60Hz, 5.5a 1 15V, 60Hz, 5.5a

Consommation de combustible : 0.37 gal/hr (1,4 L/hr) 0.55 gal/hr (2,1 L/hr) 0.96 gal./hr (3,5 L/hr) 1.3 gal/hr (5,0 L/hr) 1.6 gal/hr (6,0 L/hr)

T aux de combustion : 50,000 Btu/hr (22 kW) 75,000 Btu/hr (22 kW) 125,000 Btu/hr (37 kW) 175,000 Btu/hr (51 kW) 210,000 Btu/hr (61.5 kW)

Modèle5 50K 75KT 125KT 175KT 210KT

Type de combustible : à utiliser avec du kérosène ou du mazout de première catégorie SEULEMENT pour TOUS les modèles.

SPÉCIFICATIONS

Page 15

2

Guide d'utilisation et instructions de fonctionnement

INSTRUCTIONS POUR COMMANDER DES PIÈCES ....... 8

GARANTIE............................................................................ 8

VUE ÉCLATÉE ..................................................................... 7

LISTE DES PIÈCES ............................................................. 6

SCHÉMA DE CABLÂGE....................................................... 6

ENTREPOSAGE, RÉPARATION ET ENTRETIEN .............. 5

INSTRUCTIONS DE FONCTIONNEMENT.......................... 3

PRÉCAUTIONS LIÉES À LA SÉCURITÉ ............................ 3

PRÉCAUTIONS LIÉES AU FONCTIONNEMENT ............... 3

SPÉCIFICATIONS................................................................ 3

AVERTISSEMENTS ............................................................. 2

TABLE DES MATIÈRES

Enerco, Group, Inc. | Appareil de chauf fage à air pulsé au kérosène

cm (3 pi) de tous les côtés.

po) d'épaisseur et dépassant l'appareil d'au moins 90

sur un matériau isolant adéquat d'au moins 2,5 cm (1

fonctionnement, l'appareil de chauffage doit reposer

bois ou d'autres matériaux combustibles. Lors de son

Non conçus pour être utilisés sur des planchers de

AVERTISSEMENT RELATIF AUX MODÈLES 50K ET 75KT :

ALVÉOLES.

PRISE ADÉQUATE MISE À LA TERRE AYANT TROIS

• BRANCHEZ LE CORDON ÉLECTRIQUE DANS UNE

SUR L'APPAREIL DE CHAUFFAGE.

• NE PLACEZ PAS D'INSTRUMENTS DE CUISSON

ACCUMULÉ DANS LA CHAMBRE DE COMBUSTION.

SI UN SURPLUS DE COMBUSTIBLE S'EST

• NE DÉMARREZ PAS L'APPAREIL DE CHAUFFAGE

SI LA CHAMBRE DE COMBUSTION EST CHAUDE.

• NE DÉMARREZ PAS L'APPAREIL DE CHAUFFAGE

INFLAMMABLES RISQUENT D'ÊTRE PRÉSENTS.

CHAUFFAGE SI DES VAPEURS OU DES LIQUIDES

• NE FAITES PAS FONCTIONNER L'APPAREIL DE

EXTERNE.

• N'UTILISEZ PAS DE SOURCE DE COMBUSTIBLE

L'EXTÉRIEUR, LOIN D'UNE FLAMME NUE.

• REMPLISSEZ TOUJOURS LE RÉSERVOIR À

BLE.

CHAUFFAGE AVANT D'Y AJOUTER DU COMBUSTI-

• CESSEZ LE FONCTIONNEMENT DE L'APPAREIL DE

PRODUITS COMBUSTIBLES VOLATILS.

• N'EMPLOYEZ PAS D'ESSENCE, DE NAPHTE OU DE

AVERTISSEMENT :

AUTRES RISQUES POUR LA REPRODUCTION).

CANCER ET D'ANOMALIES CONGÉNITALES (OU

L'ÉTAT DE LA CALIFORNIE COMME CAUSE DE

CARBONE, UN PRODUIT CHIMIQUE RECONNU PAR

BUSTION CONTENANT DU MONOXYDE DE

APP AREIL CRÉE DES SOUS-PRODUITS DE COM-

AVERTISSEMENT : L'UTILISATION DE CET

L'État de la Californie émet la mise en garde suivante :

DES PRODUITS CHIMIQUES INCONNUS.

À PEINTURE, DES PARTICULES DE POUSSIÈRE OU

QUE DE L'ESSENCE, DES SOLVANTS, DU DILUANT

SUSPENSION DANS L'AIR OU DES PRODUITS TELS

CONTENIR DES P ARTICULES COMBUSTIBLES EN

DANS UN LOCAL QUI CONTIENT OU RISQUE DE

N'UTILISEZ JAMAIS L'APPAREIL DE CHAUFFAGE

COMME LE RECOMMANDENT LES INSTRUCTIONS.

SÉCURITAIRE DE L'APPAREIL DE CHAUFFAGE

PAPIER ET LE CARTON À UNE DISTANCE

TELS QUE LES MA TÉRIAUX DE CONSTRUCTION, LE

CONSERVEZ LES MATÉRIAUX COMBUSTIBLES

D'EXPLOSION ET DE PROBLÈME DE RESPIRATION.

AVERTISSEMENT : DANGER D'INCENDIE,

VÉHICULE RÉCRÉATIF

UNE UTILISATION DANS LA MAISON OU UN

AVERTISSEMENT : NON CONÇU POUR

COMMUNIQUEZ AVEC LE FABRICANT.

D'INSTRUCTIONS, ÉTIQUETTES, ETC.),

AU SUJET DE L'APPAREIL DE CHAUFFAGE (MANUEL

SI VOUS AVEZ BESOIN D'AIDE OU D'INFORMA TION

APPAREIL DE CHAUFFAGE.

UTILISER OU EFFECTUER L'ENTRETIEN DE CET

ET À RESPECTER LES INSTRUCTIONS DEVRAIENT

SEULES LES PERSONNES APTES À COMPRENDRE

MONOXYDE DE CARBONE OU D'ÉLECTROCUTION.

BRÛLURE, D'ASPHYXIE, D'INTOXICA TION AU

RÉSULTANT D'INCENDIE, D'EXPLOSION, DE

DES DOMMAGES OU DES PERTES MATÉRIELLES

CAUSER LA MORT, DES BLESSURES GRAVES ET

AVEC CET APPAREIL DE CHAUFFAGE RISQUE DE

PRÉVENTION ET AUX INSTRUCTIONS FOURNIES

LE DÉFAUT DE SE CONFORMER AUX MESURES DE

DANGER :

AVERTISSEMENT GÉNÉRAL DE

CHAUFFAGE.

AVANT D'UTILISER CET APPAREIL DE

TOUS, VEUILLEZ LIRE LES INSTRUCTIONS

PERSONNELLE ÉT ANT IMPOR TANTE POUR

AVERTISSEMENT :VOTRE SÉCURITÉ

Page 16

04/05 70276 Rev. A

UL-733, et CSA/CAN3-B140.9.3

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

page 3.

circulation d'air adéquate doit être assurée pour la combustion et la ventilation. Consultez la

Cet appareil de chauffage portatif n'est pas ventilé. Il utilise l'oxygène de l'air ambiant. Une

—L'entretien doit être effectué par un fournisseur de services d'entretien qualifié.

proximité de ce type d'appareil.

—N'entreposez ni n'utilisez d'essence ou autres liquides ou vapeurs inflammables à

causant des dommages matériels, des blessures et des pertes de vie.

présent guide avec exactitude risque d'entraîner une explosion ou un incendie

AVERTISSEMENT :Le fait de ne pas respecter les instructions données dans le

KÉROSÈNE

CHAUFFAGE À AIR PULSÉ AU

APPAREIL DE

HS210KT

HS125KT, HS175KT,

HS50KT, HS75KT,

MODÈLE

HEATSTAR

chauffage.

régler ou de faire fonctionner cet appareil de

présentes instructions d'assembler, d'allumer, de

ultérieurement. Interdisez à quiconque n'a pas lu les

les instructions en sécurité pour vous y référer

lisez et observez toutes les instructions. Conservez

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS :

MH210KT

MH125KT, MH175KT,

MH50KT, MH75KT,

MODÈLE

MR. HEATER

GUIDE D'UTILISATION ET INSTRUCTIONS DE FONCTIONNEMENT

Loading...

Loading...