Page 1

TI00126R/09/EN/14.18

71404948

2018-05-31

Products

Solutions Services

Technical Information

T13, T14 and T15

Explosion proof RTD assemblies in thermowells

with spring loaded insert and enclosure for process

industry

Application

• Heavy duty applications

• The sensor assemblies can be used in process industries such as:

– Chemicals

– Petrochemical

– Refineries

– Offshore platforms

• Measuring range: –200 to 600 °C (–328 to 1 112 °F)

• Protection class: IP66/67

Head transmitter

All Endress+Hauser transmitters are available with enhanced accuracy and reliability

compared to directly wired sensors. Easy customizing by choosing one of the

following outputs and communication protocols:

• Analog output 4 to 20 mA

• HART

• PROFIBUS® PA

• FOUNDATION Fieldbus™

Field transmitter

Temperature field transmitters with HART® or FOUNDATION Fieldbus™ protocol for

highest reliability in harsh industrial environments. Backlit display with large

measured value, bargraph and fault condition indication for ease of reading.

Your benefits

• FM/CSA XP Class I, Div. 1 approved temperature assemblies for maximum safety

• One source shopping for temperature measurement solutions. World class

• Remove and install straight out of the box

• Improved galvanic isolation on most devices (2 kV)

• Simplified model structure: Competitively priced, offers great value. Easy to order

• All iTEMP transmitters provide long-term stability ≤ 0.05% per year

®

transmitter with integrated sensor offering for heavy process industry applications

and reorder. A single model number includes sensor, thermowell and transmitter

assembly for a complete point solution

Page 2

Function and system design

U

= 20-250V DC/AC

» 50/60Hz

4...20 mA

24V DC / 30 mA

2

3

1

Measuring principle Resistance thermometer (RTD)

These resistance thermometers use a Pt100 temperature sensor according to IEC 60751. The

temperature sensor is a temperature-sensitive platinum resistor with a resistance of 100 Ω at

0 °C (32 °F) and a temperature coefficient α = 0.003851 °C-1.

There are generally two different kinds of platinum resistance thermometers:

• Wire wound (WW): Here, a double coil of fine, high-purity platinum wire is located in a ceramic

support. This is then sealed top and bottom with a ceramic protective layer. Such resistance

thermometers not only facilitate very reproducible measurements but also offer good long-term

stability of the resistance/temperature characteristic within temperature ranges up to

600 °C (1 112 °F). This type of sensor is relatively large in size and it is comparatively sensitive to

vibrations.

• Thin film platinum resistance thermometers (TF): A very thin, ultrapure platinum layer,

approx. 1 μm thick, is vaporized in a vacuum on a ceramic substrate and then structured

photolithographically. The platinum conductor paths formed in this way create the measuring

resistance. Additional covering and passivation layers are applied and reliably protect the thin

platinum layer from contamination and oxidation, even at high temperatures.

The primary advantages of thin film temperature sensors over wire wound versions are their smaller

sizes and better vibration resistance. A relatively low principle-based deviation of the resistance/

temperature characteristic from the standard characteristic of IEC 60751 can frequently be observed

among TF sensors at high temperatures. As a result, the tight limit values of tolerance category A as

per IEC 60751 can only be observed with TF sensors at temperatures up to 200 °C (392 °F).

T13, T14 and T15

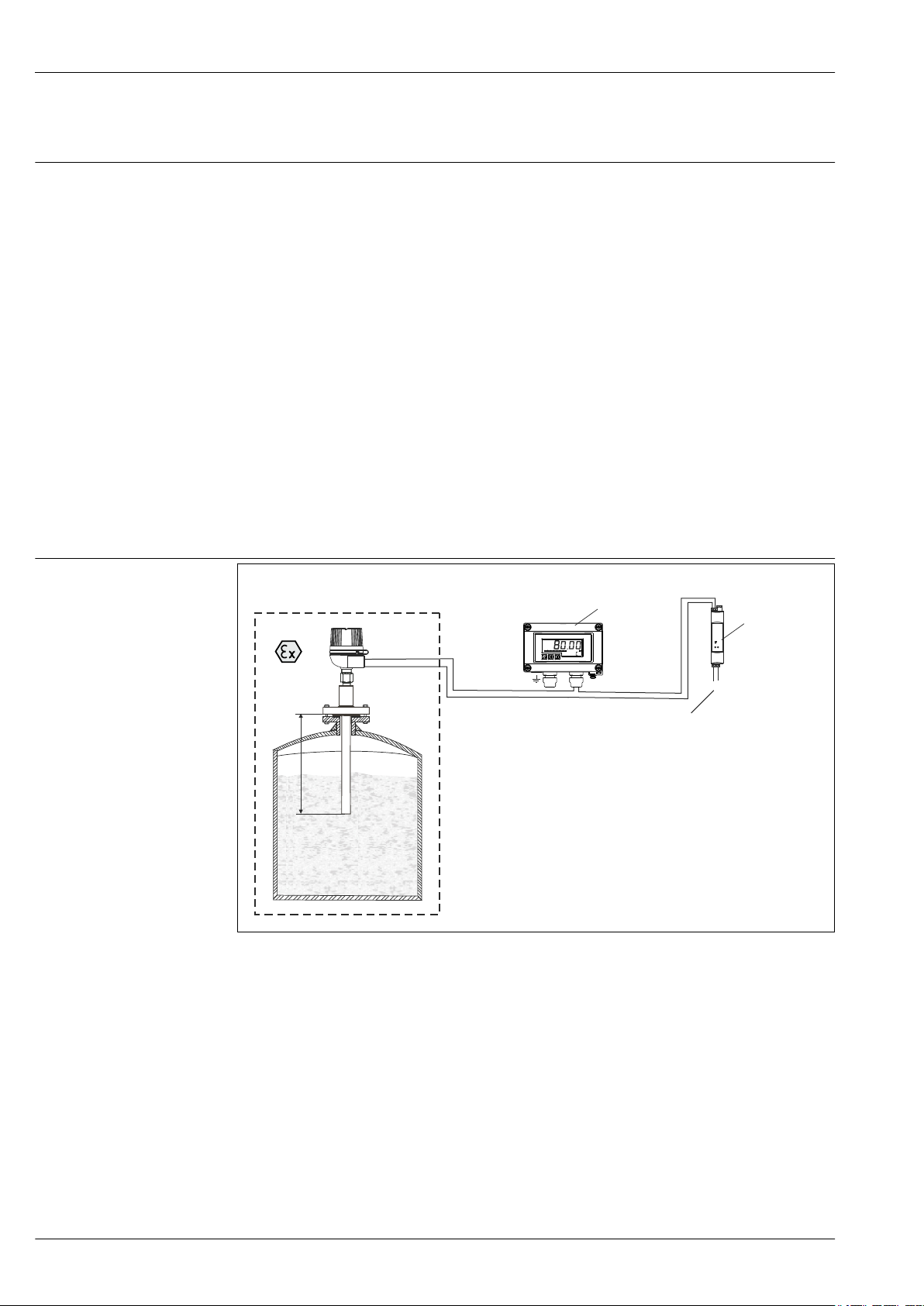

Measuring system

1 Application example

1 Mounted thermometer with head transmitter installed.

2 RIA15 process display - The display unit records the analog measuring signal from the head transmitter and

shows this on the display. The LC display shows the current measured value in digital form and as a bar graph

indicating a limit value violation. The process display unit is integrated in the 4 to 20 mA or HART® loop and

is powered directly from the current loop. Optionally up to four of a sensor's HART® process variables can be

displayed. More information on this can be found in the Technical Information, see "Documentation".

3 Active barrier RN221N - The RN221N (24 VDC, 30 mA) active barrier has a galvanically isolated output for

supplying voltage to loop-powered transmitters. The universal power supply works with an input supply

voltage of 20 to 250 V DC/AC, 50/60 Hz, which means that it can be used in all international power grids.

More information on this can be found in the Technical Information, see "Documentation".

A0024883

2 Endress+Hauser

Page 3

T13, T14 and T15

Input

Measurement range

Output signal

Construction Model code (class and type of sensor) Max. measurement range

T13-_ _ _ _ _ (A/C/E/G/J/L) _ _ _ _ _

Low temperature range

T15-_ _ _ (A/C/E/G/J/L) _ _ _ _ _

T13-_ _ _ _ _ (B/D/F/H/K/M) _ _ _ _ _

High temperature range

T15-_ _ _ (B/D/F/H/K/M) _ _ _ _ _ _

Options J, K, L, M are duplex platinum elements of two sensors inside the same sheath.

–50 to 200 °C (–58 to 392 °F)T14-_ _ _ _ _ (A/C/E/G/J/L) _ _ _ _ _

–200 to 600 °C (–328 to 1 112 °F)T14-_ _ _ _ _ (B/D/F/H/K/M) _ _ _ _ _

Output

Generally, the measured value can be transmitted in one of two ways:

• Directly-wired sensors - sensor measured values forwarded without a transmitter.

• Via all common protocols by selecting an appropriate Endress+Hauser iTEMP temperature

transmitter. All the transmitters listed below are mounted directly in the terminal head or as field

transmitter and wired with the sensory mechanism.

Family of temperature transmitters

Thermometers fitted with iTEMP transmitters are an installation-ready complete solution to

improve temperature measurement by significantly increasing accuracy and reliability, when

compared to direct wired sensors, as well as reducing both wiring and maintenance costs.

PC programmable head transmitters

They offer a high degree of flexibility, thereby supporting universal application with low inventory

storage. The iTEMP transmitters can be configured quickly and easily at a PC. Endress+Hauser offers

free configuration software which can be downloaded from the Endress+Hauser Website. More

information can be found in the Technical Information.

HART® programmable head transmitters

The transmitter is a 2-wire device with one or two measuring inputs and one analog output. The

device not only transfers converted signals from resistance thermometers and thermocouples, it also

transfers resistance and voltage signals using HART® communication. It can be installed as an

intrinsically safe apparatus in Zone 1 hazardous areas and is used for instrumentation in the

terminal head (flat face) as per DIN EN 50446. Swift and easy operation, visualization and

maintenance using universal device configuration tools like FieldCare, DeviceCare or

FieldCommunicator 375/475. For more information, see the Technical Information.

PROFIBUS® PA head transmitters

Universally programmable head transmitter with PROFIBUS® PA communication. Conversion of

various input signals into digital output signals. High accuracy over the complete ambient

temperature range. The configuration of PROFIBUS PA functions and of device-specific parameters is

performed via fieldbus communication. For more information, see the Technical Information.

FOUNDATION Fieldbus™ head transmitters

Universally programmable head transmitter with FOUNDATION Fieldbus™ communication.

Conversion of various input signals into digital output signals. High accuracy over the complete

ambient temperature range. All transmitters are released for use in all important process control

systems. The integration tests are performed in Endress+Hauser's "System World". For more

information, see the Technical Information.

Advantages of the iTEMP transmitters:

• Dual or single sensor input (optionally for certain transmitters)

• Pluggable display (optionally for certain transmitters)

• Unsurpassed reliability, accuracy and long-term stability in critical processes

Endress+Hauser 3

Page 4

T13, T14 and T15

3

5

6

RTD

3

4

5

6

RTD

1

2

3-wire

4-wire

Power supply

head transmitter and

analog output 4 to 20 mA,

or bus connection

(red) (red)

(red) (red)

(white) (white)

(white)

mA

• Mathematical functions

• Monitoring of the thermometer drift, sensor backup functionality, sensor diagnostic functions

• Sensor-transmitter matching for dual sensor input transmitters, based on Callendar/Van Dusen

coefficients

Field transmitter

Field transmitter with HART® or FOUNDATION Fieldbus™ communication and backlit display. Can

be read easily from a distance, in sunlight and at night. Large measurement value, bargraph and

fault indication displayed. Benefits are: dual sensor input, highest reliability in harsh industrial

environments, mathematic functions, thermometer drift monitoring and sensor back-up

functionality, corrosion detection.

Galvanic isolation

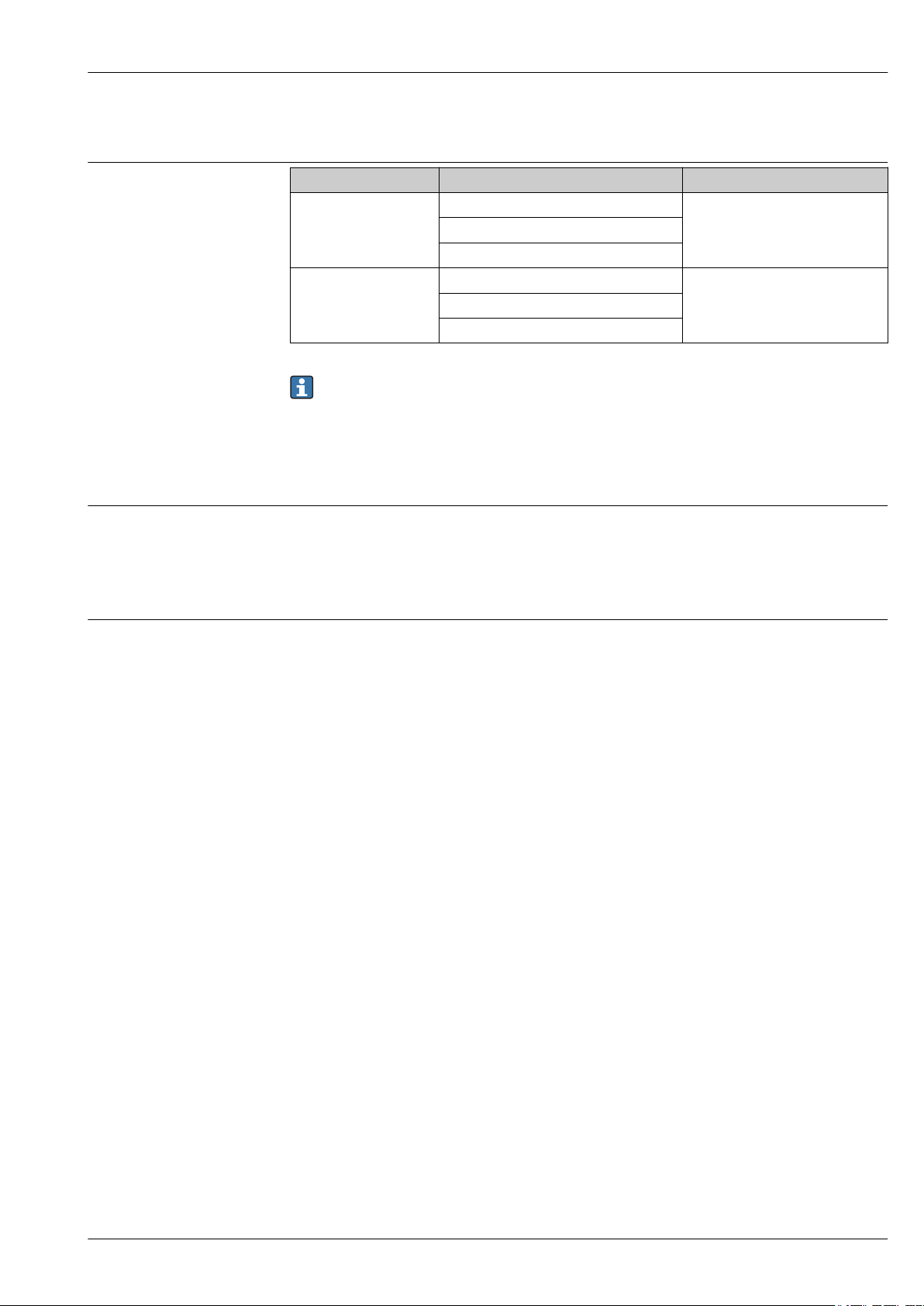

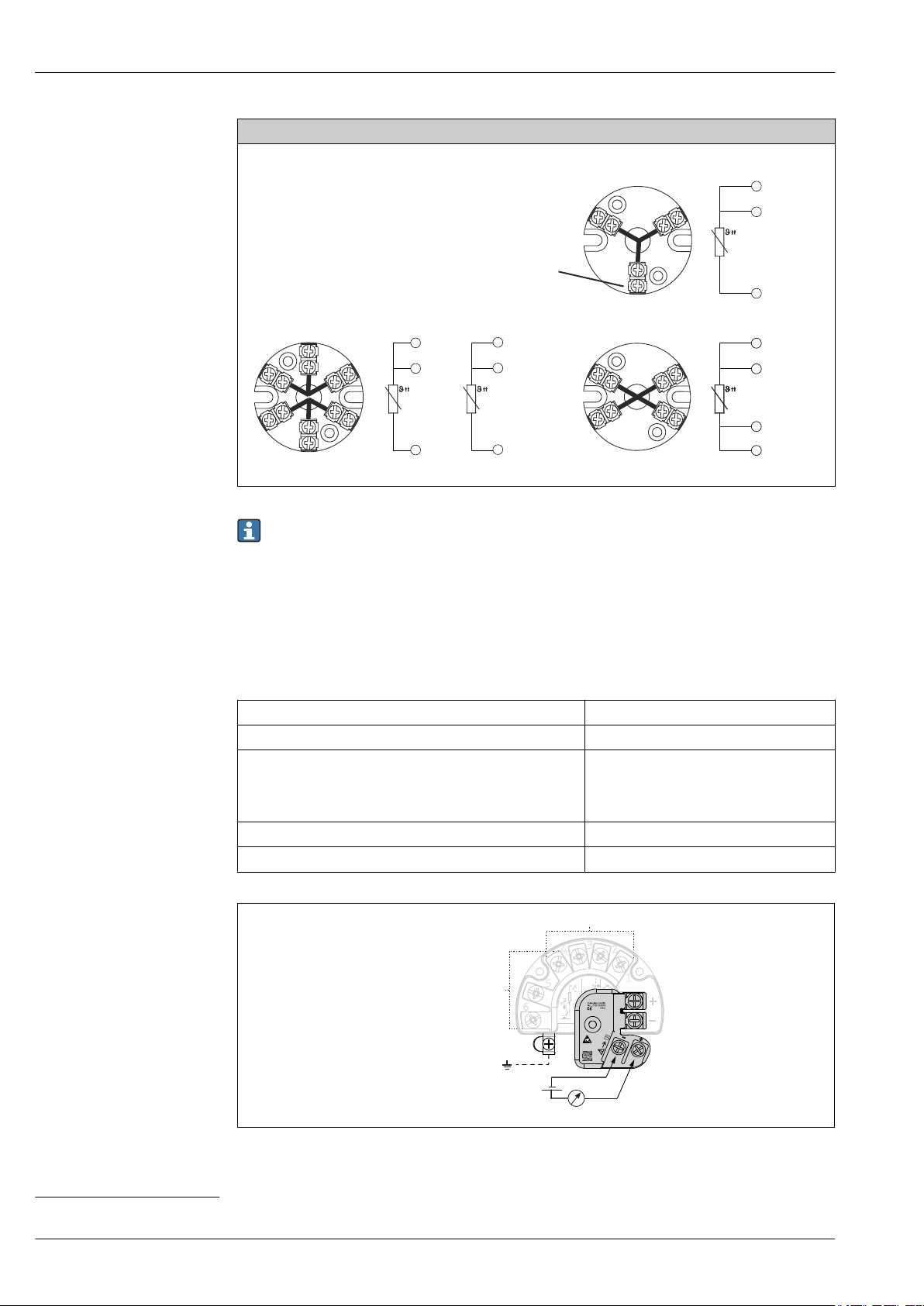

Terminal assignment

Galvanic isolation of Endress+Hauser iTEMP transmitters

Transmitter type Sensor

TMT181 PCP Û = 3.75 kV AC

TMT182 HART® U = 2 kV AC

TMT162 HART® Field transmitter U = 2 kV AC

Power supply

Type of sensor connection

Head mounted transmitter TMT18x (single input)

A0016433-EN

4 Endress+Hauser

Page 5

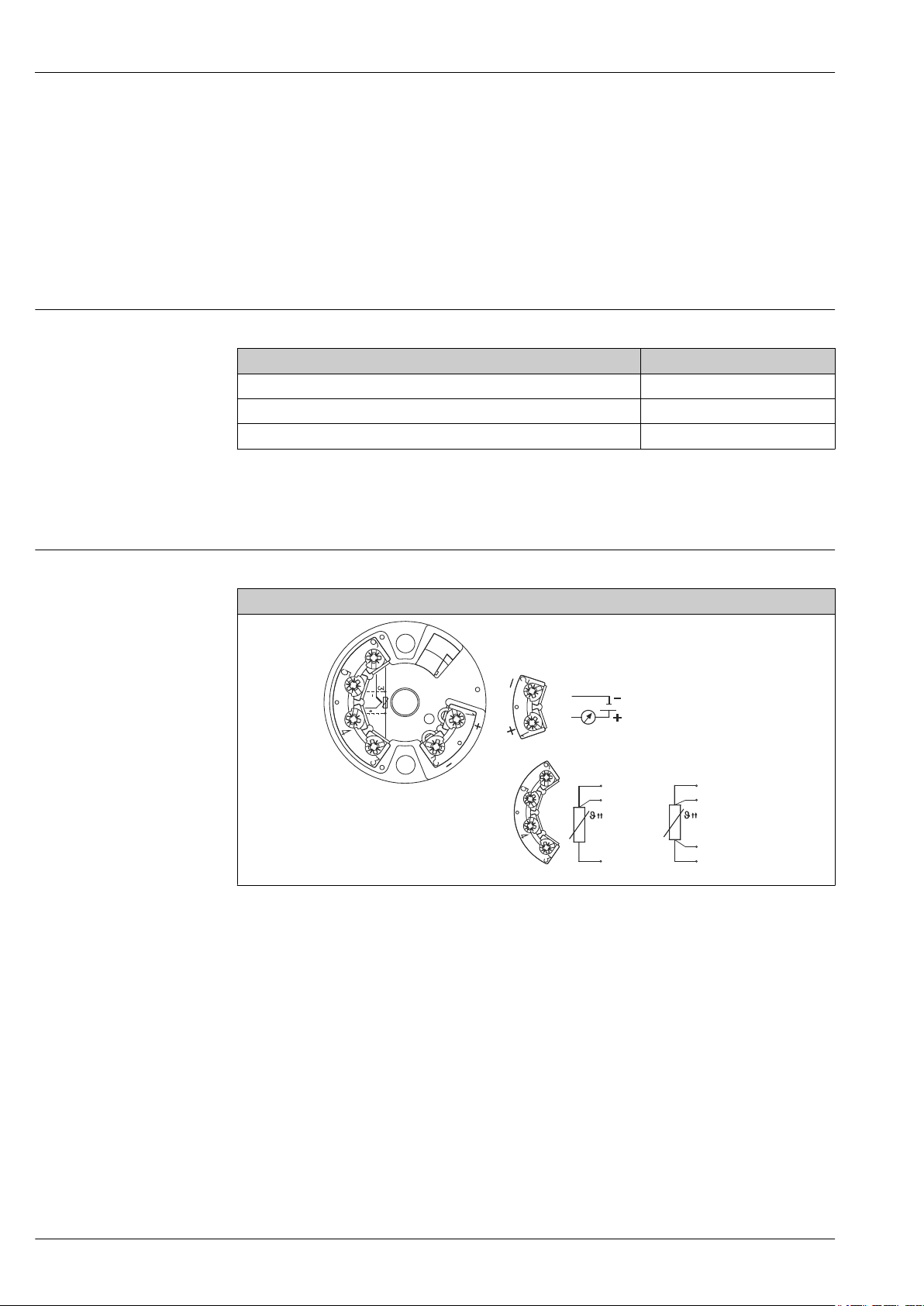

T13, T14 and T15

-

+

+

1

-

2

7

6

5

4

3

1

2

7

6

5

4

3

Sensor input 2

Sensor input 1

RTD 4- and 3-wire:

RTD 3-wire:

Bus connection

and supply voltage

Display connection

red

white

red

red

red

white

white

(black)

(black)

(green)

4

3

3

1

1

4

2

2

RTD

RTD

5

6

RTD

4

+

-

1

2

3

5

6

+

-

3

4

S1

3

S2

-

+

+

-

!

(black)

(black)

4-wire

3-wire

Power supply

field transmitter and

analog output 4 to 20 mA

or bus connection

Sensor 1

Sensor 2 (not TMT142)

Sensor 1

Sensor 2 (not TMT142)

(white) (red) (white) (red)

(green)

Head mounted transmitter TMT8x (dual input)

A0029556-EN

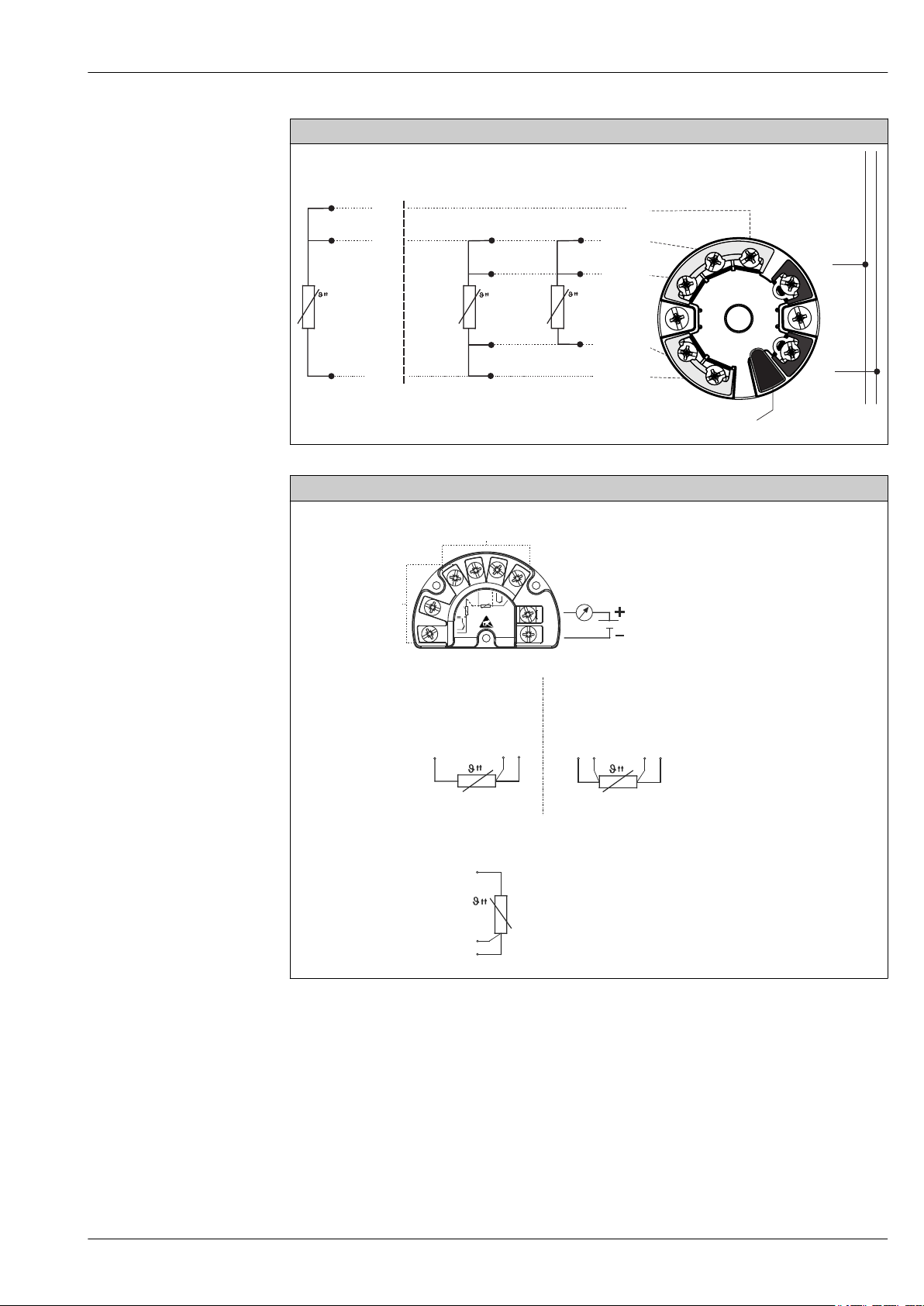

Field mounted transmitter

Endress+Hauser 5

A0024961-EN

Page 6

Terminal block mounted

R1

R1

B6

R1

R3

R2

B5

G4

R3

W5

W3

W6

W4

3-wire single

2 x 3-wire single

Outside screw

4-wire single

W5 = White5

W3 = White3

G4 = Green4

R3 = Red3

R2 = Red2

B6 = Black6

R1 = Red1

R1 = Red1

B5 = Black5

W6 = White6

W4 = White4

R3 = Red3

R1 = Red1

4

+

-

1

2

3

5

6

+

-

3

4

S1

3

S2

-

+

+

-

!

+

Sensor 2

Sensor 1

-

Bus connection and

supply voltage

T13, T14 and T15

A0025284-EN

The blocks and transmitters are shown as they sit inside the heads in reference to the conduit

opening.

Integrated overvoltage protection

The integrated overvoltage protection module can be ordered as an optional extra

1)

. The module

protects the electronics from damage from overvoltage. Overvoltage occurring in signal cables (e.g.

4 to 20 mA, communication lines (fieldbus systems) and power supply is diverted to ground. The

functionality of the transmitter is not affected as no problematic voltage drop occurs.

Connection data:

Maximum continuous voltage (rated voltage) UC = 42 V

Nominal current I = 0.5 A at T

Surge current resistance

• Lightning surge current D1 (10/350 µs)

• Nominal discharge current C1/C2 (8/20 µs)

• I

• In = 5 kA (per wire)

Temperature range –40 to +80 °C (–40 to +176 °F)

Series resistance per wire 1.8 Ω, tolerance ±5 %

DC

= 80 °C (176 °F)

amb.

= 1 kA (per wire)

imp

In = 10 kA (total)

2 Electrical connection of the overvoltage protection

1) Available for the field transmitter with HART® 7 specification

6 Endress+Hauser

A0033027-EN

Page 7

T13, T14 and T15

Grounding

The device must be connected to the potential equalization. The connection between the housing and the local

ground must have a minimum cross-section of 4 mm2 (13 AWG) . All ground connections must be secured

tightly.

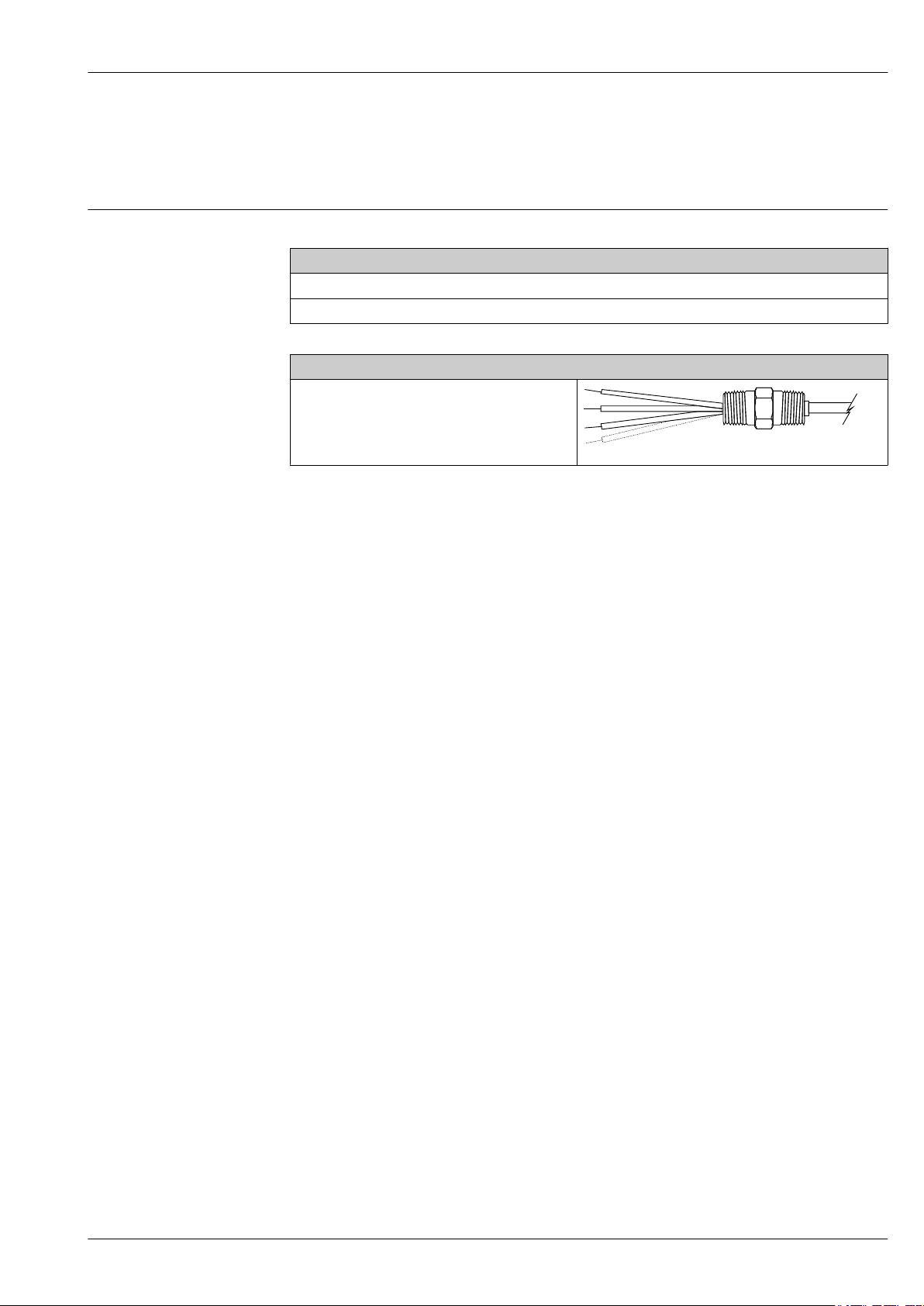

Wire specifications

24 AWG, 19 strand silver plated copper with 0.025 mm (0.010 in) PTFE extruded outer.

Electrical connection

Flying leads, standard 3" for wiring in terminal head, head mounted transmitter or terminal block mounted

Flying leads, 5½" for wiring with TMT162 or TMT142 assemblies

Design of leads

Flying leads 3" or 5½" with brass crimped sleeves

A0026119

Endress+Hauser 7

Page 8

Performance characteristics

T13, T14 and T15

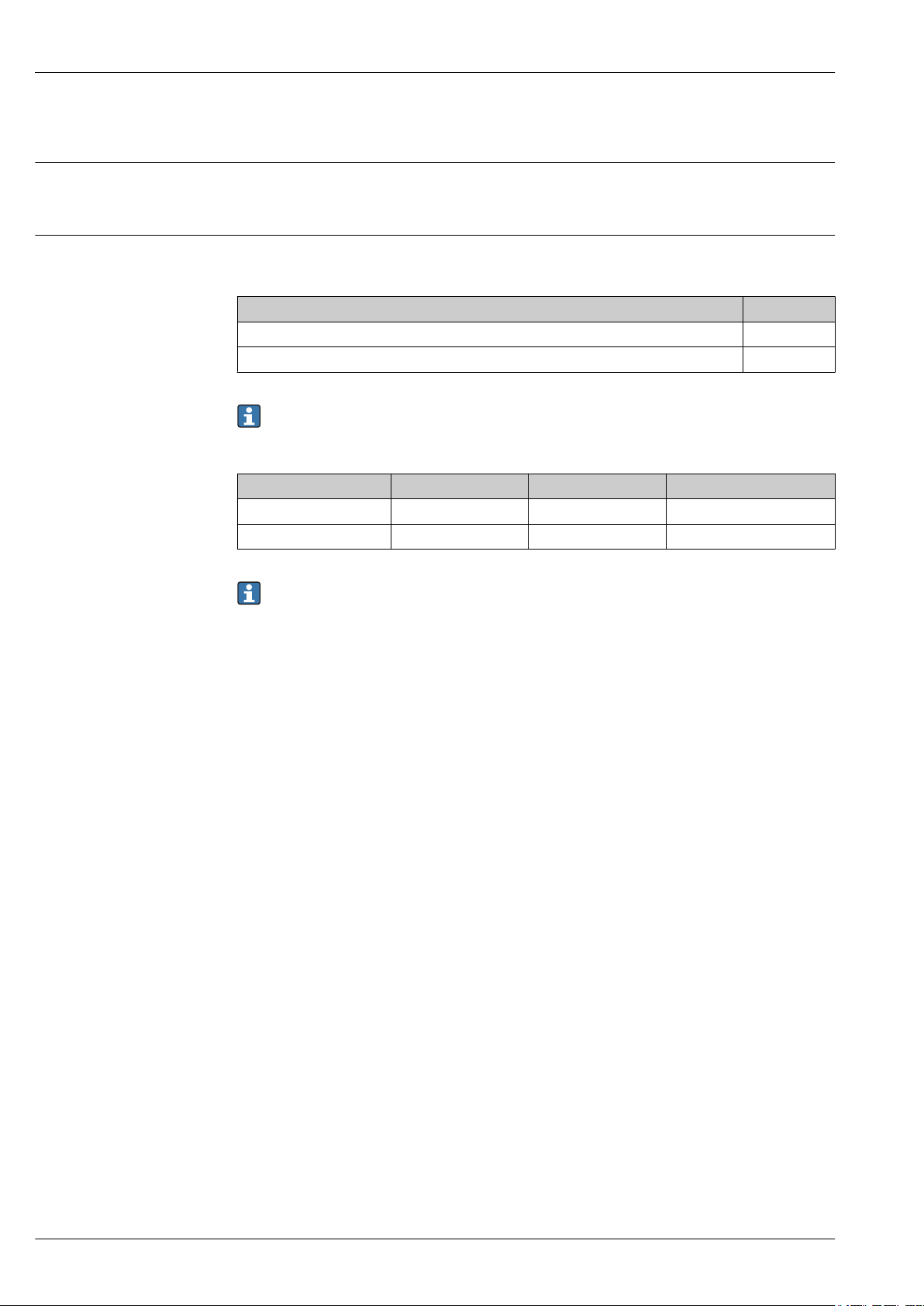

Reference conditions

Response time

These data are relevant for determining the accuracy of the temperature transmitters used. More

information on this can be found in the Technical Information of the iTEMP temperature

transmitters.

63% response time per ASTM E644

RTD assembly T15 without thermowell

Construction

High temperature range 3 s

Low temperature range 9 s

Response time for the sensor assembly without transmitter.

Response time examples for RTD assemblies with thermowell T13 and T14

Construction Stepped thermowell Tapered thermowell Straight thermowell (¾")

High temperature range 20 s 25 s 30 s

Low temperature range 25 s 30 s 35 s

Response times for RTD assemblies with thermowell are provided for general design guidance

without transmitter.

When the temperature of a process media changes, the output signal of a RTD assembly follows this

change after a certain time delay. The physical cause is the time related to heat transfer from the

process media through the thermowell and the insert to the sensor element (RTD). The manner in

which the reading follows the change in temperature of the assembly over time is referred to as the

response time. Variables that influence or impact the response time are:

• Wall thickness of thermowell

• Spacing between RTD insert and thermowell

• Sensor packaging

• Process parameters such as media, flow velocity, etc.

8 Endress+Hauser

Page 9

T13, T14 and T15

A

AA

-200 -100 0 100 200 300 400 500 600°C

0.5

1.0

1.5

2.0

B

2.5

3.0

- 0.5

- 1.0

- 1.5

- 2.0

- 2.5

- 3.0

B

A

AA

Max. deviation (°C)

Max. deviation (°C)

Reference operating conditions

Accuracy

RTD resistance thermometer as per IEC 60751

Class Max. tolerances (°C) Characteristics

Cl. AA, former 1/3

± (0.1 + 0.0017 · |t|

1)

)

Cl. B

Cl. A ± (0.15 + 0.002 · |t|

Cl. B ± (0.3 + 0.005 · |t|

1)

)

1)

)

Temperature ranges for compliance with the

tolerance classes

Wire wound

sensor (WW):

Cl. A Cl. AA

–

–50 to +250 °C

100 to +450 °C

Thin-film version

Cl. A Cl. AA

(TF):

Standard –30 to +300 °C 0 to +150 °C

1) |t| = absolute value °C

In order to obtain the maximum tolerances in °F, the results in °C must be multiplied by a factor

of 1.8.

Transmitter long-term stability

Dielectric strength

≤ 0.1 °C (0.18 °F) / year or ≤ 0.05 % / year

Data under reference conditions; % relates to the set span. The larger value applies.

The units are factory tested with 500 VAC for one minute between live parts (terminals) and exposed

non-current-carrying metal parts (e.g. probe sheath).

Self heating

Calibration specifications

RTD elements are passive resistances that are measured using an external current. This

measurement current causes a self-heating effect in the RTD element itself which in turn creates an

additional measurement error. In addition to the measurement current, the size of the measurement

error is also affected by the temperature conductivity and flow velocity of the process. This selfheating error is negligible when an Endress+Hauser iTEMP temperature transmitter (very small

measurement current) is connected.

The manufacturer provides comparison temperature calibrations from –20 to 300 °C (–4 to 572 °F)

on the International Temperature Scale of 1990. Calibrations are traceable to standards maintained

by the National Institute of Standards and Technology (NIST). Calibration services are in

conformance with ASTM E220, IEC 17025 and ANSI/NCSL Z540-1-1994. The report of calibration

is referenced to the serial number of the assembly.

Three point calibrations are provided, given that the specified temperatures are within the

recommended range and the minimum length requirements are met as specified. The minimum

length is based on the overall length "x" of the spring loaded insert.

A0008588-EN

Endress+Hauser 9

Page 10

Installation

U

U

B

A

U

C

T13, T14 and T15

Orientation

Installation instructions

No restrictions.

A0025312

3 Installation examples

A-C In pipes with a small cross section the thermowell tip should reach or extend slightly past the center line of

the pipe (= U)

B Threaded, angled installation of T13 assembly

C Flange installation of T14 assembly

The immersion length of the thermometer influences the accuracy. If the immersion length is too

small then errors in the measurement are caused by heat conduction via the process connection and

the container wall. If installing into a pipe then the immersion length should be at least half of the

pipe diameter. A further solution could be an angled (tilted) installation (see C). When determining

the immersion length all thermometer parameters and the process to be measured must be taken

into account (e.g. flow velocity, process pressure).

• Installation possibilities: Pipes, tanks or other plant components

• Minimum immersion length per ASTM E644, ΔT ≤ 0.05 °C (0.09 °F):

For temperature assemblies with themowell (T13 and T14) the minimum immersion is the depth to

which the thermowell is immersed in the medium, measured from the tip. To minimize errors from

ambient temperature the following minimum immersion lengths are recommended:

Construction Minimum immersion

Stepped thermowell 63.5 mm (2.5 in)

Tapered thermowell 114.3 mm (4.5 in)

¾" straight thermowell 101.6 mm (4 in)

Weld-in thermowell 114.3 mm (4.5 in)

T15 assemblies can only be used in existing thermowells.

Environment

Ambient temperature range

10 Endress+Hauser

Terminal head Temperature in °C (°F)

Without mounted head

transmitter

With mounted head

transmitter

Depends on the terminal head used and the cable gland or fieldbus connector,

see 'Terminal heads' section

–40 to 85 °C (–40 to 185 °F)

SIL mode (HART 7 transmitter): –40 to 70 °C (–40 to 158 °F)

Page 11

T13, T14 and T15

Terminal head Temperature in °C (°F)

With mounted head

transmitter and display

With mounted field

transmitter

–20 to 70 °C (–4 to 158 °F)

• Without display: –40 to 85 °C (–40 to 185 °F)

• With display and/or integrated overvoltage protection module:

–40 to +80 °C (–40 to +176 °F)

• SIL mode: –40 to +75 °C (–40 to +167 °F)

Shock and vibration resistance

4 g/2 to 150 Hz as per IEC 60068-2-6

Endress+Hauser 11

Page 12

Mechanical construction

A

XP certified

union

¾”

¼”

¼”

¼”

"¼”

½”

½”

½”

½”

NPT

½”

NPT

½”

"¼”

"5/8”"5/8”

"½”

T

1¾” + T

1¾” + T

U

Q

Q

Q

U

U

2½”

1”

A

A

P P

X

E

E

X

A

X

X

A

2 1/4” + T

U

Q

Full penetration

weld thermowell

Standard weld

thermowell

4

5

6

7

8

1

2

3

"0.26”

"0.26”

"0.26”

X

A

"0.26”

"5/8”

¼”

¼”

"¾”

T13, T14 and T15

Design, dimensions

All dimensions in inch. For values related to the graphics please refer to the tables and equations

below.

4 Dimensions of the sensor assemblies

1 T13 weld-in thermowell (tapered)

2 T13 threaded thermowell (stepped)

3 T13 socket weld thermowell (tapered)

4 T13/T14 extension, nipple-XP-union-nipple (NUN), without thermowell

5 T13/T14 extension hex nipple without thermowell

6 TU111 spring loaded insert

7 T14 flange thermowell (tapered)

8 Straight thermowell tip

E Extension length

P Pipe size

Q Thermowell root diameter

T Lag dimension

U Thermowell immersion length

XA Immersion length RTD sensor

A Drill depth of thermowell

X Overall insert length

For T13 thermowells with ½" NPT and 1" process thread length and ¾" hex length dimensions,

spring loaded sensor assemblies must be used with the thermowells.

A0025328-EN

12 Endress+Hauser

Page 13

T13, T14 and T15

Dimensions of T13

All thermowells are marked with a material ID, CRN (Canadian Registration Number) and heat

number.

U E (nominal dimension) T Process

connection

63.5 mm (2.5 in) Material: Steel or 316SS

Hex nipple = 25.4 mm (1 in)

Nipple Union Nipple (NUN) =

114.3 mm (4.5 in)

190.5 mm (7.5 in)

266.7 mm (10.5 in)

342.9 mm (13.5 in)

419.1 mm (16.5 in)

571.5 mm (22.5 in)

specified length

50.8 to 571.5 mm

(2 to 22.5 in) in ½"

increments

Immersion length RTD sensor = thermowell drilled length X A= A = U + 38.1 mm (1.5 in) + T

Overall insert length X = A + E

P = Pipe size

• ¾" Nominal utilizes 1.050"

• 1" Nominal utilizes 1.315"

101.6 mm (4 in)

177.8 mm (7 in)

76.2 mm (3 in) or

specified length

25.4 to 152.4 mm

(1 to 6 in) in ½"

increments

½" NPT Stepped (standard

¾" NPT Stepped (standard

1" NPT Stepped (standard

¾" socket weld Stepped (standard

1" socket weld Stepped (standard

¾" weld in Tapered (heavy

1" weld in Tapered (heavy

Shape of

thermowell

duty)

Tapered (heavy

duty)

duty)

Tapered (heavy

duty)

duty)

Tapered (heavy

duty)

duty)

Tapered (heavy

duty)

duty)

Tapered (heavy

duty)

duty)

duty)

⌀Q

16 mm (⁵⁄₈ in)

16 mm (⁵⁄₈ in)

19.05 mm

(³⁄₄ in)

22.3 mm

(⁷⁄₈ in)

22.3 mm

(⁷⁄₈ in)

26.9 mm (1¹⁄₁₆

in)

19.05 mm

(³⁄₄ in)

22.3 mm

(⁷⁄₈ in)

22.3 mm

(⁷⁄₈ in)

25.4 mm (1 in)

26.6 mm

(1.050 in)

33.4 mm

(1.315 in)

Dimensions of T14

U E (nominal dimension) T Flange size ⌀Q, tapered version

50.8 mm (2 in) Hex nipple = 25.4 mm (1 in) or specified length 25.4 mm (1 in) 22.3 mm (⁷⁄₈ in)

101.6 mm (4 in) Nipple Union Nipple (NUN) =

177.8 mm (7 in)

254 mm (10 in)

330.2 mm (13 in)

406.4 mm (16 in)

558.8 mm (22 in)

specified length

50.8 to 571.5 mm

(2 to 22.5 in) in ½" increments

101.6 mm (4 in)

177.8 mm (7 in)

25.4 to 254 mm (1 to 10 in) in ½"

increments

38.1 mm (1¹⁄₂ in) 26.9 mm (1¹⁄₁₆ in)

50.8 mm (2 in) 26.9 mm (1¹⁄₁₆ in)

Endress+Hauser 13

Page 14

T13, T14 and T15

T15

Extension

Lamination nipple,

Union, Nipple

T15

Extension

Lamination nipple

TU211

spring loaded

insert

!6.35

(¼)

38.1 (1½)

50.8 (2)

nom.

1/2”

NPT

LN

LN

LN

1/2”

NPT

12.7 ( nom.½)

E

X

A1

X

A1

X

A2

38.1 (1½)

38.1 (1½)

12.7 ( nom.½)

12.7

( nom.½)

12.7

( nom.½)

!6.35

(¼)

!6.35

(¼)

!9.5

(3/8)

U E (nominal dimension) T Flange size ⌀Q, tapered version

Immersion length RTD sensor = thermowell drilled length X = A = U + 50.8 mm (2 in) + T

Overall insert length X = A + E

Weight

Material

5 Design and dimensions of T15 (without thermowell), all dimensions in mm (in)

E Extension length (nominal dimension)

LN Lamination nipple (flamepath nipple)

XA1 Insert immersion length

XA2 Insert immersion length TU211

When ordering a sensor with a ³⁄₈" diameter, only the bottom 2" will have an outer diameter of

³⁄₈".

Dimensions of T15 (without thermowell) Extension E

Immersion length RTD sensor X

1) Order code for spring loaded insert TU211 (TU211-_ _ _5 _ _ _ _ _ )

1 to 30 lbs

Process connection and thermowell

A1

specified length 101.6 to 2 540 mm (4 to 100 in) in ½"

increments

RTD sensor XA2 for spring loaded insert TU211 as

spare part insert for Lamination Nipple Union Nipple

(LUN) version

Calculate XA2 as follows: XA1+E

1)

Lamination Nipple Union

Nipple (LUN) =

76.2 mm (3 in) or

152.4 mm (6 in)

A0025456-EN

14 Endress+Hauser

Page 15

T13, T14 and T15

The temperatures for continuous operation specified in the following table are only intended as

reference values for use of the various materials in air and without any significant compressive load.

The maximum operation temperatures are reduced considerably in some cases where abnormal

conditions such as high mechanical load occur or in aggressive media.

Material

name

Short form Recommended

max. temperature

Properties

for continuous use

in air

AISI 316/

1.4401

X5CrNiMo17-12-2 650 °C (1 202 °F)

1)

• Austenitic, stainless steel

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorinebased and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g.

phosphoric and sulfuric acids, acetic and tartaric

acids with a low concentration)

AISI 316L/

1.4404

1.4435

X2CrNiMo17-12-2

X2CrNiMo18-14-3

650 °C (1 202 °F)

1)

• Austenitic, stainless steel

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorinebased and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g.

phosphoric and sulfuric acids, acetic and tartaric

acids with a low concentration)

• Increased resistance to intergranular corrosion and

pitting

• Compared to 1.4404, 1.4435 has even higher

corrosion resistance and a lower delta ferrite

content

1) Can be used to a limited extent up to 800 °C (1472 °F) for low compressive loads and in non-corrosive

media. Please contact your Endress+Hauser sales team for further information.

Process connection

The process connection is the means of connecting the thermometer to the process. The following

process connections are available:

T13

Thread Version

NPT thread NPT 1/2"

A0026110

NPS for socket weld NPS 3/4"

A0026111

NPS for weld-in NPS 3/4"

A0026108

NPT 3/4"

NPT 1"

NPS 1"

NPS 1"

Endress+Hauser 15

Page 16

L

D

K

d

b

f

T15

N

N

ML

TL

ML

Type

N

Type

NUN

T14

Flange

For detailed information on the flange dimensions

refer to the following flange standard:

ANSI/ASME B16.5

T13, T14 and T15

A0010471

The flange material must be the same as of the stem

of the thermowell.

Type Thermowell

connection

Type N ½" NPT external

thread

Type NUN ½" NPT external

thread

A0026181

Housing Terminal heads

All terminal heads have an internal shape and size in accordance with DIN EN 50446, flat face and a

thermometer connection with a ½" NPT thread. All dimensions in mm (in). Specifications without

head transmitter installed. For ambient temperatures with head transmitter installed, see the

'Environment' section.

As a special feature, Endress+Hauser offers terminal heads with optimized terminal accessibility for

easy installation and maintenance.

Some of the specifications listed below may not be available on this product line.

Extension neck lengths in

mm (in)

25.4 mm (1 in)

101.6 mm (4 in)

177.8 mm (7 in)

16 Endress+Hauser

Page 17

T13, T14 and T15

125 (4.92)

89.5 (3.52)

28

(1.1)

78 (3.01)

20.5 (0.8)

125 (4.92)

115 (4.53)

28

(1.1)

78 (3.01)

20.5 (0.8)

TA30H Specification

• Flameproof (XP) version, explosion-protected, captive screw

cap, available with one or two cable entries

• Degree of protection: IP 66/68, NEMA Type 4x Encl.

Ex-version: IP 66/67

• Temperature: –50 to +150 °C (–58 to +302 °F) for rubber seal

without cable gland (observe max. permitted temperature of

cable gland!)

• Material:

– Aluminum with polyester powder coating

– Stainless steel 316L without coating

• Thread: ½" NPT, ¾" NPT, M20x1.5, G½"

• Extension neck/thermowell connection: ½" NPT

• Color of aluminum head: blue, RAL 5012

• Color of aluminum cap: gray, RAL 7035

A0009832

• Weight:

– Aluminum: approx. 640 g (22.6 oz)

– Stainless steel: approx. 2 400 g (84.7 oz)

TA30H with display window in cover Specification

• Flameproof (XP) version, explosion-protected, captive screw

cap, available with one or two cable entries

• Degree of protection: IP 66/68, NEMA Type 4x Encl.

Ex-version: IP 66/67

• Temperature: –50 to +150 °C (–58 to +302 °F) for rubber seal

without cable gland (observe max. permitted temperature of

cable gland!)

• Material:

– Aluminum with polyester powder coating

– Stainless steel 316L without coating

• Thread: ½" NPT, ¾" NPT, M20x1.5, G½"

• Extension neck/thermowell connection: ½" NPT

• Color of aluminum head: blue, RAL 5012

• Color of aluminum cap: gray, RAL 7035

• Weight:

– Aluminum: approx. 860 g (30.33 oz)

A0009831

– Stainless steel: approx. 2 900 g (102.3 oz)

• Head transmitter optionally available with TID10 display

Endress+Hauser 17

Page 18

T13, T14 and T15

K

E

E

P

T

I

G

H

T

W

H

E

N

C

I

R

C

U

I

T

A

L

I

V

E

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

°C

10

0

20

30

40

50

60

70

80

90

100

110 (4.33)

112 (4.41)

132.5 (5.22)*

132 (5.2)

135 (5.3)

112 (4.4)

106 (4.2)

121 (4.8)

121 (4.8)

!6.4

(0.25)

0

10

30

40

50

20

°F

Field transmitter

Temperature field transmitter iTEMP TMT162

A0024608

* Dimensions without display = 112 mm (4.41 in)

• Separate electronics compartment and connection compartment

• Protection class: IP67, NEMA type 4x

• Material: Die-cast aluminum housing AlSi10Mg with powder coating on polyester base, 316L

• Display rotatable in 90° increments

• Cable entry: 2x ½" NPT

• Brilliant backlit display with ease of visibility in bright sunshine or pitch darkness

• Gold plated terminals to avoid corrosion and additional measurement errors

• SIL certification as per IEC 61508:2010 (HART-protocol)

Temperature field transmitter iTEMP HART® TMT142

A0025824

• Protection class: IP67, NEMA type 4x

• Material: Die-cast aluminum housing AlSi10Mg with powder coating on polyester base

• Display rotatable in 90° increments

• Cable entry: 3x ½" NPT

• Brilliant blue backlit display with ease of visibility in bright sunshine or pitch darkness

• Gold plated terminals to avoid corrosion and additional measurement errors

CE Mark

18 Endress+Hauser

Certificates and approvals

The device meets the legal requirements of the EC directives if applicable. Endress+Hauser confirms

that the device has been successfully tested by applying the CE mark.

Page 19

T13, T14 and T15

Other standards and guidelines

UL

CSA/FM

• IEC 60529: Degree of protection of housing (IP code)

• IEC 61010-1: Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 1: General requirements

• IEC 60751: Industrial platinum resistance thermometers

• ASTM E644: American society for testing and materials, standard test methods for testing

industrial resistance thermometers

• NEMA - ANSI/NEMA 250: Enclosures for Electrical Equipment

• ASME PTC 19.3 TW2010: Performance test codes

• CSA Standard C22.2 (No. 25, no. 30, no. 157, no. 213, no. 1010.1):

Requirements for hazardous locations & safety requirements for electrical equipment for

measurement, control and laboratory use

• FM Standards (Class No. 3600, 3611, 3615, 3810):

Requirements for hazardous locations & electrical and electronic test, measuring and process

control equipment

Temperature transmitters UL recognized components under Category Code.file number

QUYX8.E225237 and QUYX2.E225237 except for TMT84 PROFIBUS® PA.

T13, T14 with blue connection head or field housing

FM XP DIP Class I, II, III Div. 1+2, Grp. A-G

FM XP NI DIP Class I, II, III Div. 1+2, Grp. A-G

CSA XP DIP Class I, II, III Div. 1+2, Grp. A-G

CSA XP NI DIP Class I, II, III Div. 1+2, Grp. A-G

FM/CSA XP DIP Class I, II, III Div. 1+2, Grp. A-G

FM/CSA XP NI DIP Class I, II, III Div. 1+2, Grp. A-G

CSA General Purpose

T15 with blue connection head or field housing

FM XP DIP Class I, II, III Div. 1+2, Grp. A-G

FM XP NI DIP Class I, II, III Div. 1+2, Grp. A-G

CSA XP DIP Class I, II, III Div. 1+2, Grp. A-G

CSA XP NI DIP Class I, II, III Div. 1+2, Grp. A-G

FM/CSA XP DIP Class I, II, III Div. 1+2, FM Grp. A-G, CSA Grp. A-G

FM/CSA XP NI DIP Class I, II, III Div. 1+2, FM Grp. A-G, CSA Grp. A-G

CSA General Purpose

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Endress+Hauser 19

Page 20

T13, T14 and T15

Accessories

Various accessories, which can be ordered with the device or subsequently from Endress+Hauser, are

available for the device. Detailed information on the order code in question is available from your

local Endress+Hauser sales center or on the product page of the Endress+Hauser website:

www.endress.com.

Device-specific accessories

Communication-specific accessories

Mounting bracket SS316L, for tube 1.5...3"

Order code: 51007995

Adapter M20x1.5 - ½" NPT cable entry

Order code: 51004387

Cable gland ½" NPT, D4.5-8.5, IP 68

Order code: 51006845

Integrated overvoltage

protection module

Configuration kit TXU10 Configuration kit for PC-programmable transmitter with setup software and

Commubox FXA195

HART

Commubox FXA291 Connects Endress+Hauser field devices with a CDI interface (= Endress+Hauser

Wireless HART adapter

SWA70

The module protects the electronics from overvoltage. Available for TMT162

housing.

interface cable for PC with USB port

Order code: TXU10-xx

For intrinsically safe HART communication with FieldCare via the USB interface.

For details, see "Technical Information" TI00404F

Common Data Interface) and the USB port of a computer or laptop.

For details, see "Technical Information" TI00405C

Is used for the wireless connection of field devices.

The WirelessHART adapter can be easily integrated into field devices and existing

infrastructures, offers data protection and transmission safety and can be operated

in parallel with other wireless networks with minimum cabling complexity.

For details, see Operating Instructions BA061S

Service-specific accessories

Field Xpert SFX350 Field Xpert SFX350 is a mobile computer for commissioning and maintenance. It

enables efficient device configuration and diagnostics for HART and FOUNDATION

Fieldbus devices in the non-Ex area.

For details, see Operating Instructions BA01202S

Field Xpert SFX370 Field Xpert SFX370 is a mobile computer for commissioning and maintenance. It

enables efficient device configuration and diagnostics for HART and FOUNDATION

Fieldbus devices in the non-Ex area and the Ex area.

For details, see Operating Instructions BA01202S

Accessories Description

Applicator Software for selecting and sizing Endress+Hauser measuring devices:

• Calculation of all the necessary data for identifying the optimum measuring

device: e.g. pressure loss, accuracy or process connections.

• Graphic illustration of the calculation results

Administration, documentation and access to all project-related data and

parameters over the entire life cycle of a project.

Applicator is available:

• Via the Internet: https://portal.endress.com/webapp/applicator

• On CD-ROM for local PC installation.

20 Endress+Hauser

Page 21

T13, T14 and T15

Configurator Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information

such as measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output

format

• Ability to order directly in the Endress+Hauser Online Shop

The Configurator is available on the Endress+Hauser website: www.endress.com ->

Click "Corporate" -> Select your country -> Click "Products" -> Select the product

using the filters and the search field -> Open the product page -> The "Configure"

button to the right of the product image opens the Product Configurator.

W@M Life cycle management for your plant

W@M supports you with a wide range of software applications over the entire

process: from planning and procurement, to the installation, commissioning and

operation of the measuring devices. All the relevant device information, such as

the device status, spare parts and device-specific documentation, is available for

every device over the entire life cycle.

The application already contains the data of your Endress+Hauser device. Endress

+Hauser also takes care of maintaining and updating the data records.

W@M is available:

• Via the Internet: www.endress.com/lifecyclemanagement

• On CD-ROM for local PC installation.

System components

FieldCare SFE500 FDT-based plant asset management tool from Endress+Hauser.

It can configure all smart field units in your system and helps you manage them. By

using the status information, it is also a simple but effective way of checking their

status and condition.

For details, see Operating Instructions BA00027S and BA00065S

DeviceCare SFE100 Configuration tool for devices via fieldbus protocols and Endress+Hauser service

protocols.

DeviceCare is the tool developed by Endress+Hauser for the configuration of

Endress+Hauser devices. All smart devices in a plant can be configured via a pointto-point or point-to-bus connection. The user-friendly menus enable transparent

and intuitive access to the field devices.

For details, see Operating Instructions BA00027S

Accessories Description

Field display unit RIA16 The display unit records the analog measuring signal from the head transmitter

and shows this on the display. The LC display shows the current measured value in

digital form and as a bar graph indicating a limit value violation. The display unit is

looped into the 4 to 20 mA circuit and gets the required energy from there.

For details, see the "Technical Information" document TI00144R/09/en

Process display RIA15 Process display, digital loop-powered display for 4 to 20 mA circuit, panel

mounting, with optional HART® communication. Displays 4 to 20 mA or up to 4

HART® process variables

For details, see "Technical Information", TI01043K/09/en

Endress+Hauser 21

Page 22

T13, T14 and T15

Active barrier RN221N Active barrier with power supply for safe separation of 4 to 20 mA standard signal

circuits. Has bidirectional HART® transmission and optional HART® diagnostics if

transmitters are connected with monitoring of 4 to 20 mA signal or HART® status

byte analysis and an E+H-specific diagnostic command.

For details, see "Technical Information", TI00073R/09/en

Documentation

Brief operating instructions - explosion proof RTD assemblies

• T13 with thermowell, KA00236R/24/EN

• T14 with flanged thermowell, KA00237R/24/AE

• T15 KA00238R/24/EN

Technical Information temperature transmitter iTEMP

• HART® TMT82, TI01010T/09/EN

• PROFIBUS PA TMT84, TI00138R/09/EN

• FOUNDATION Fieldbus™ TMT85 (TI00134R/09/)

• Field transmitter:

– TMT162 HART® 5, PROFIBUS PA and FOUNDATION Fieldbus™ (TI00086R/09/EN)

– TMT162 HART® 7 and SIL certification (TI01344T/09/EN)

– TMT142 HART® (TI00107R/09/EN)

• Pt TMT180, TI00088R/09/EN

• PCP TMT181, TI00070R/09/EN

• HART® TMT182, TI00078R/09/EN

22 Endress+Hauser

Page 23

Page 24

www.addresses.endress.com

Loading...

Loading...