Endress+Hauser Liquisys M CCM223, Liquisys M CCM253 Operating Instructions Manual

Products Solutions Services

BA00214C/07/EN/14.13

71212626

valid as of:

Software-version 2.40

Operating Instructions

Liquisys M CCM223/253

Transmitter for Free Chlorine, Chlorine Dioxide and Total

Chlorine

Endress+Hauser

About this document

Safety messages

The structure, signal words and safety colors of the signs comply with the specifications of

ANSI Z535.6 ("Product safety information in product manuals, instructions and other

collateral materials").

Symbols

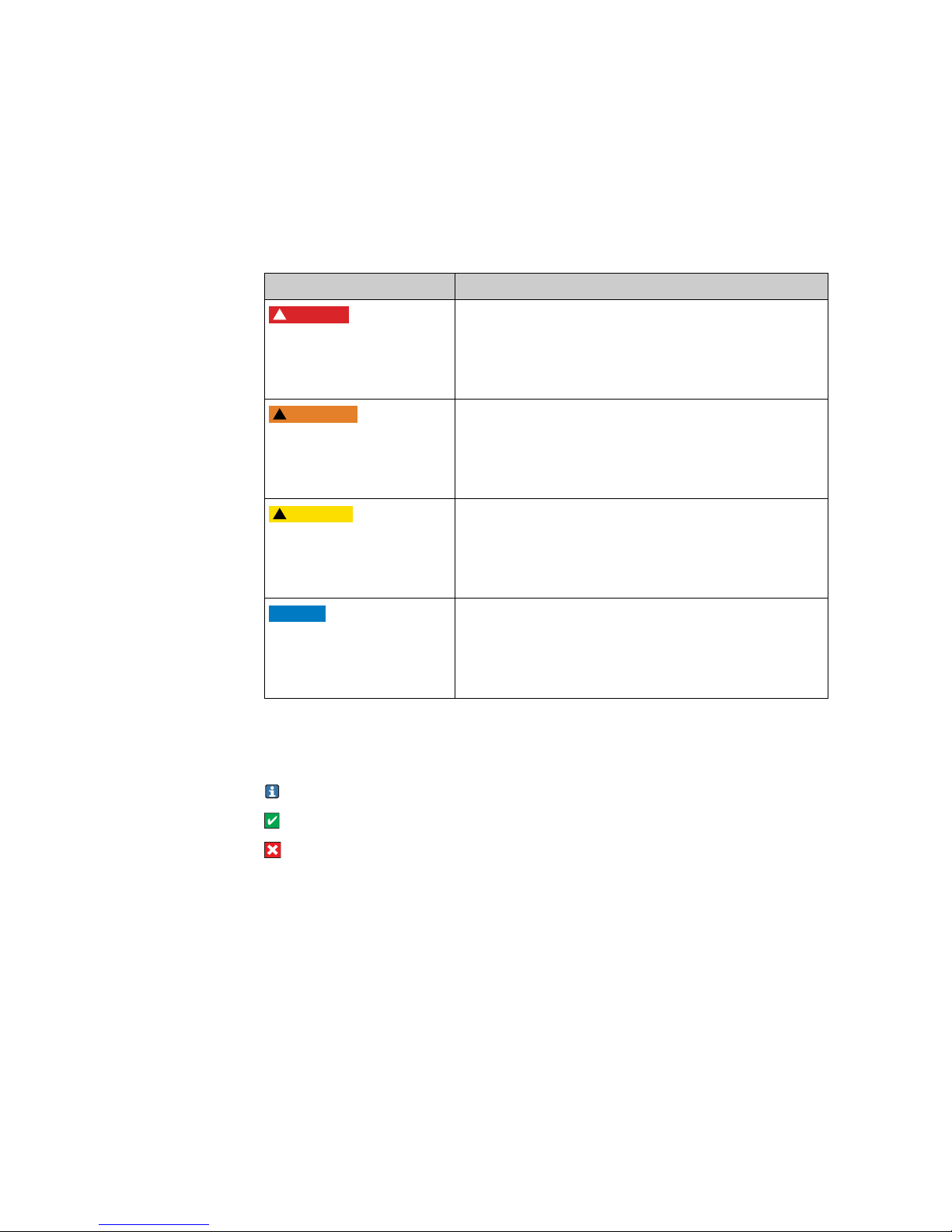

Safety message structure Meaning

DANGER

!

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the situation will result in a fatal or serious

injury.

WARNING

!

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the situation can result in a fatal or serious

injury.

CAUTION

!

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or

medium injury.

NOTICE

Cause/situation

Consequences if safety

message is not heeded

‣ Action/note

This symbol alerts you to situations that can result in

damage to property and equipment.

Additional information, tips

Permitted or recommended

Forbidden or not recommended

Liquisys M CCM223/253

Endress+Hauser 3

Table of contents

1 Basic safety instructions . . . . . . . . . . . . . 5

1.1 Requirements for the personnel . . . . . . . . . . . . . . . 5

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Electrical symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Identifying the product . . . . . . . . . . . . . . . . 8

2.4 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 8

2.4.1 CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4.2 CSA general purpose . . . . . . . . . . . . . . . . . . 8

3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Measuring system . . . . . . . . . . . . . . . . . . . . 9

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Field instrument . . . . . . . . . . . . . . . . . . . . 11

3.2.2 Panel-mounted instrument . . . . . . . . . . . 12

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . 13

3.3.1 Field instrument . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Panel-mounted instrument . . . . . . . . . . . 16

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 16

4 Electrical Connection . . . . . . . . . . . . . . . 17

4.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Connecting supply voltage . . . . . . . . . . . 17

4.1.2 Electrical connection version 1 . . . . . . . 18

4.1.3 Electrical connection version 2 . . . . . . . 19

4.1.4 Device connection . . . . . . . . . . . . . . . . . . . 20

4.1.5 Measuring cable and sensor connection 22

4.1.6 Three-point step controller for

Cl2 / ClO2 / total chlorine . . . . . . . . . . . . 26

4.1.7 Alarm contact . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Post-connection check . . . . . . . . . . . . . . . . . . . . . 26

5 Operability. . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . 27

5.2 Display and operating elements . . . . . . . . . . . . . 27

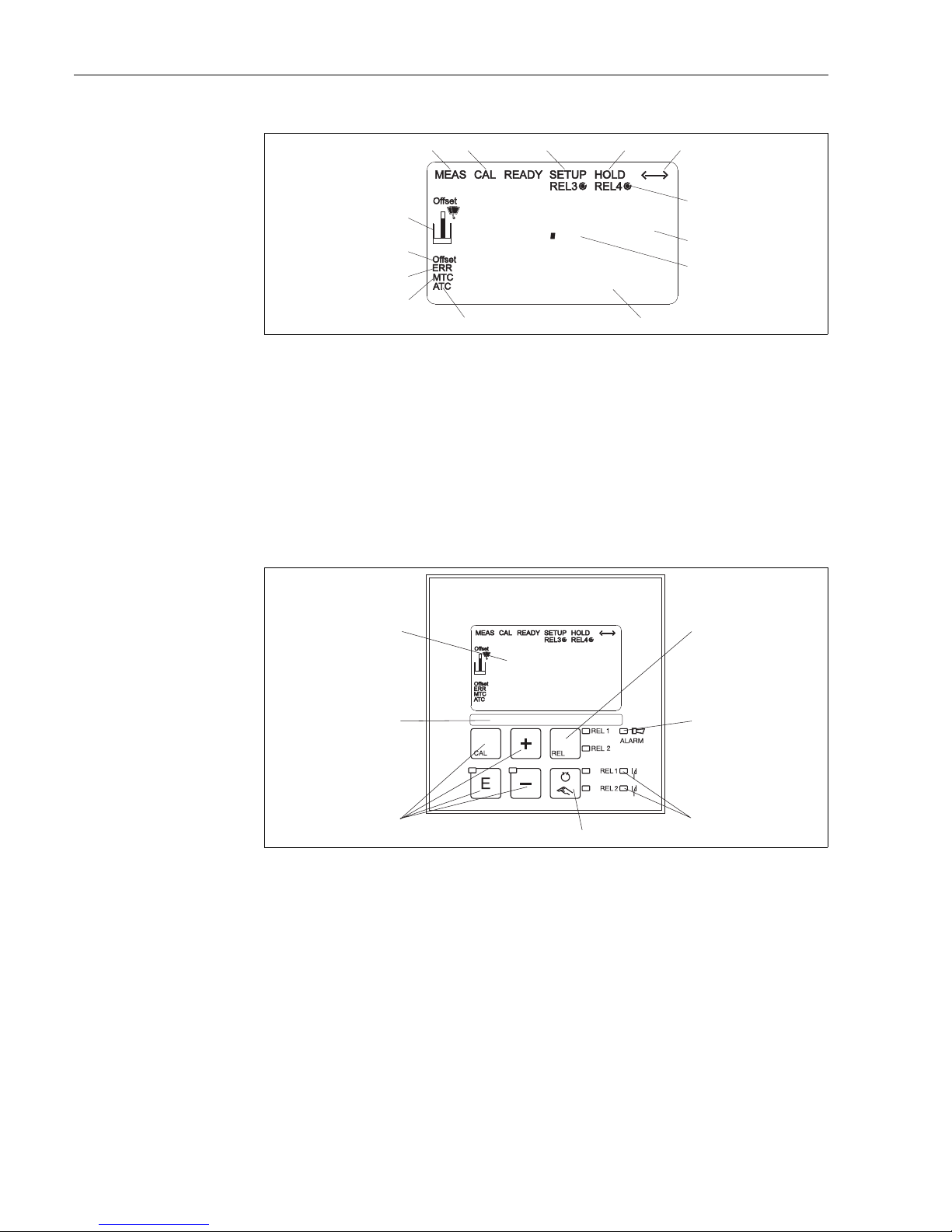

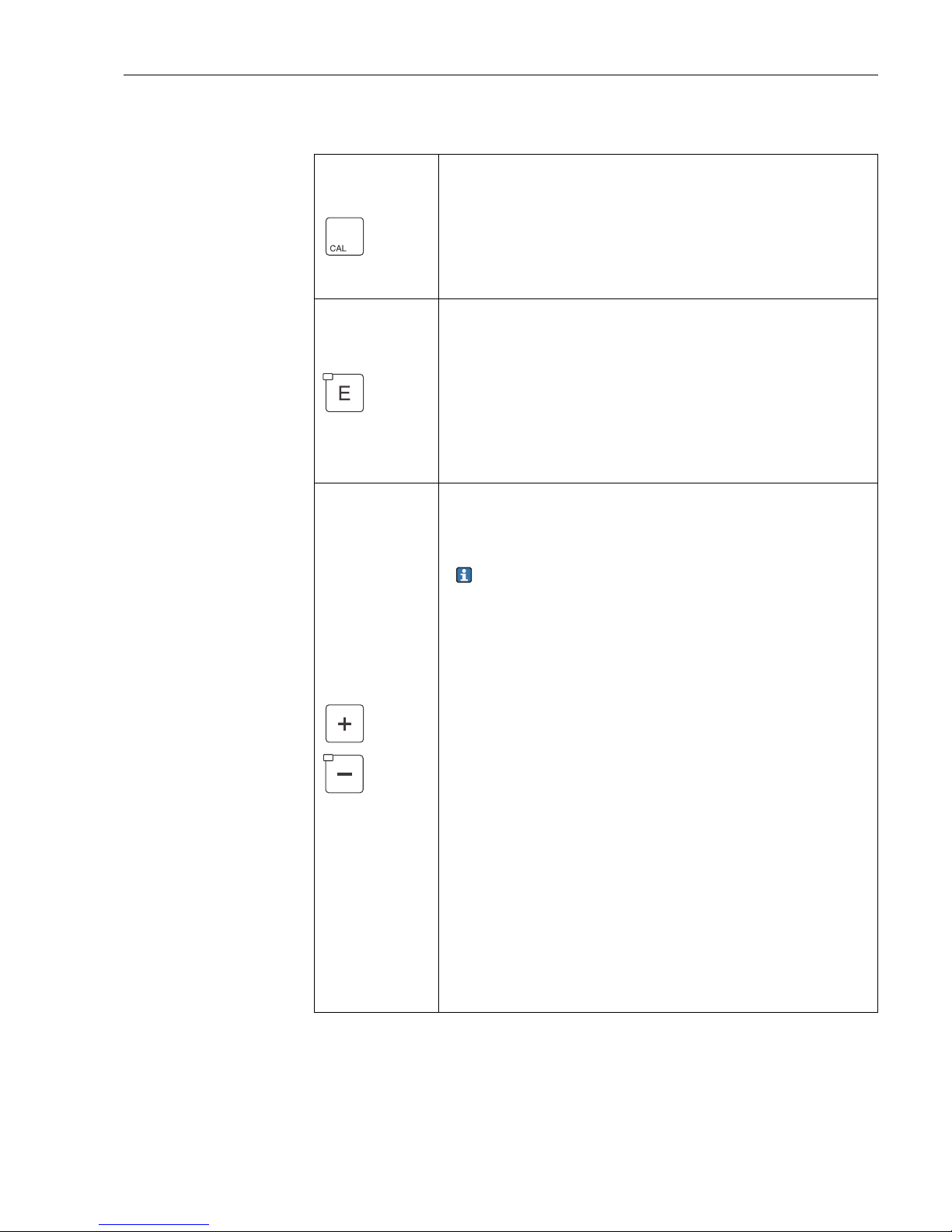

5.2.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.2 Operating elements . . . . . . . . . . . . . . . . . 28

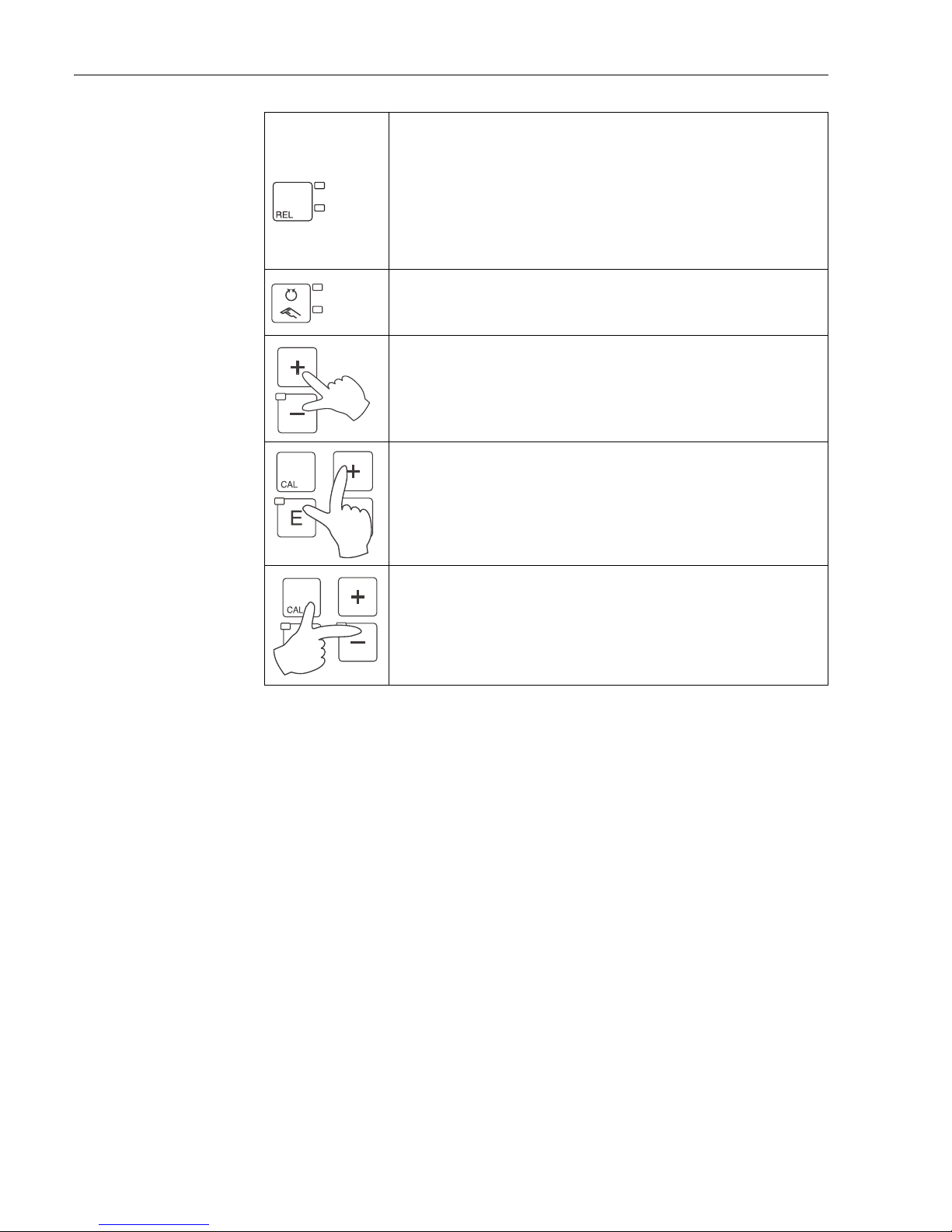

5.2.3 Key assignment . . . . . . . . . . . . . . . . . . . . 29

5.3 Local Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3.1 Automatic/manual mode . . . . . . . . . . . . 31

5.3.2 Operating concept . . . . . . . . . . . . . . . . . . 32

6 Commissioning . . . . . . . . . . . . . . . . . . . 34

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3 Quick start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4 System configuration . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.1 Setup 1 (chlorine/chlorine dioxide) . . . . . 38

6.4.2 Setup 2 (pH/ORP and temperature) . . . . 40

6.4.3 Current input . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.4 Current outputs . . . . . . . . . . . . . . . . . . . . . 46

6.4.5 Monitoring functions . . . . . . . . . . . . . . . . 50

6.4.6 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4.7 Relay contact configuration . . . . . . . . . . . 55

6.4.8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4.9 E+H Service . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.4.10 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.5 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.6 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7 Diagnostics and troubleshooting . . . . 76

7.1 Troubleshooting instructions . . . . . . . . . . . . . . . . 76

7.2 System error messages . . . . . . . . . . . . . . . . . . . . . 76

7.3 Process-specific errors . . . . . . . . . . . . . . . . . . . . . . 79

7.4 Instrument-specific errors . . . . . . . . . . . . . . . . . . . 83

8 Maintenance . . . . . . . . . . . . . . . . . . . . . 85

8.1 Maintenance of the entire measuring point . . . . 85

8.1.1 Cleaning the transmitter . . . . . . . . . . . . . . 85

8.1.2 Maintenance of chlorine sensors . . . . . . . 86

8.1.3 Maintenance of the assembly . . . . . . . . . 86

8.1.4 Maintenance of pH/ORP sensors

(version EP) . . . . . . . . . . . . . . . . . . . . . . . . 86

8.1.5 Maintenance pH connecting lines and

junction boxes (EP) . . . . . . . . . . . . . . . . . . 88

8.2 Test and simulation . . . . . . . . . . . . . . . . . . . . . . . . 89

8.2.1 Chlorine sensors . . . . . . . . . . . . . . . . . . . . . 89

8.2.2 Temperature measurement . . . . . . . . . . . 89

8.2.3 pH/ORP measurement . . . . . . . . . . . . . . . 90

8.2.4 Flow monitoring . . . . . . . . . . . . . . . . . . . . 90

9 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2 Dismantling the panel-mounted instrument . . . 91

9.3 Dismantling the field instrument . . . . . . . . . . . . . 94

9.4 Replacing the central module . . . . . . . . . . . . . . . . 97

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Liquisys M CCM223/253

4 Endress+Hauser

10 Accessories . . . . . . . . . . . . . . . . . . . . . . .99

10.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.2 Connection accessories . . . . . . . . . . . . . . . . . . . . . 99

10.3 Mounting accessories . . . . . . . . . . . . . . . . . . . . . 100

10.4 Measuring system . . . . . . . . . . . . . . . . . . . . . . . . 102

10.5 Software and hardware add-ons . . . . . . . . . . . . 102

10.6 Calibration accessories . . . . . . . . . . . . . . . . . . . . 102

11 Technical data. . . . . . . . . . . . . . . . . . . .103

11.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.4 Performance characteristics . . . . . . . . . . . . . . . . 107

11.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.6 Mechanical construction . . . . . . . . . . . . . . . . . . . 108

12 Appendix . . . . . . . . . . . . . . . . . . . . . . . .110

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Liquisys M CCM223/253 Basic safety instructions

Endress+Hauser 5

1 Basic safety instructions

1.1 Requirements for the personnel

‣

Installation, commissioning, operation and maintenance of the measuring system must

only be carried out by trained technical personnel.

‣ The technical personnel must be authorized by the plant operator to carry out the

specified activities.

‣ The electrical connection may only be performed by an electrical technician.

‣ The technical personnel must have read and understood these Operating Instructions

and must follow the instructions they contain.

‣ Measuring point faults may only be rectified by authorized and specially trained

personnel.

Repairs not described in the enclosed Operating Instructions may only be carried out

directly at the manufacturer's or by the service organization.

1.2 Designated use

Liquisys M is a field-tested and reliable transmitter which determines the amount of free

chlorine, chlorine dioxide or total chlorine dissolved in water.

The transmitter is particularly suited for use in the following areas:

• Drinking water

• Water treatment

• Cooling water

• Gas scrubbers

• Reverse osmosis

• Food processing

• Swimming pool and bathing pool water.

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is, therefore, not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Regulations for explosion protection

• Installation instructions

• Local standards and regulations

Electromagnetic compatibility

With regard to electromagnetic compatibility, this device has been tested in accordance with

the applicable European standards for industrial applications.

The electromagnetic compatibility indicated only applies to a device that has been connected

in accordance with the instructions in these Operating Instructions.

1.4 Operational safety

‣

Before commissioning the entire measuring point, make sure all the connections are

correct. Ensure that electrical cables and hose connections are not damaged.

‣ Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Mark the damaged product as defective.

‣ If faults cannot be rectified, the products must be taken out of service and secured against

unintentional commissioning.

Basic safety instructions Liquisys M CCM223/253

6 Endress+Hauser

1.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested and

left the factory in a condition in which it is safe to operate. Relevant regulations and

European standards have been observed.

1.6 Electrical symbols

%

Direct Current (DC)

A terminal at which DC is applied or through which DC flows.

&

Alternating Current (AC)

A terminal at which (sine-form) AC is applied or through which AC flows.

)

Ground connecting

A terminal which, from the user’s point of view, is already grounded using a grounding

system.

*

Protective ground terminal

A terminal which must be grounded before other connections may be set up.

Class II (isolated ) device

Double insulation

b

Alarm relay

Input

Output

DC voltage source

Temperature sensor

Liquisys M CCM223/253 Incoming acceptance and product identification

Endress+Hauser 7

2 Incoming acceptance and product

identification

2.1 Incoming acceptance

• Make sure the packaging is undamaged!

• Inform the supplier about any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

• Make sure the contents are undamaged!

• Inform the supplier about damage to the contents. Keep the damaged products until the

matter has been settled.

• Check that the order is complete and agrees with your shipping documents.

• The packaging material used to store or to transport the product must provide shock

protection and humidity protection. The original packaging offers the best protection.

Also, keep to the approved ambient conditions (see "Technical data").

• If you have any questions, please contact your supplier or your local sales center.

2.2 Scope of delivery

The delivery of the field instrument includes:

• 1 transmitter CCM253

• 1 plug-in screw terminal

•1 cable gland Pg 7

• 1 cable gland Pg 16 reduced

• 2 cable glands Pg 13.5

• 1 Operating Instructions BA00214C/07/EN

•1 Operating Instructions

• versions with HART communication:

1 Operating Instructions Field Communication with HART, BA00208C/07/EN

• versions with PROFIBUS communication:

1 Operating Instructions Field Communication with PROFIBUS PA/DP, BA00209C/07/EN

The delivery of the panel-mounted instrument includes:

• 1 transmitter CCM223

• 1 set of plug-in screw terminals

• 2 tensioning screws

•1 Operating Instructions

• 1 Operating Instructions BA00214C/07/EN

• versions with HART communication:

1 Operating Instructions Field Communication with HART, BA00208C/07/EN

• versions with PROFIBUS communication:

1 Operating Instructions Field Communication with PROFIBUS PA/DP, BA00209C/07/EN

If you have any questions, please contact your supplier or your local sales center.

Incoming acceptance and product identification Liquisys M CCM223/253

8 Endress+Hauser

2.3 Product identification

2.3.1 Nameplate

The nameplate contains the following information:

• Manufacturer data

•Order code

• Extended order code

• Serial number

• Operating conditions

•Safety icons

Compare the order code on the nameplate with your order.

2.3.2 Identifying the product

The order code and serial number of your device can be found in the following locations:

• On the nameplate

• In the delivery papers

To find out the version of your device, enter the order code indicated on the nameplate

in the search screen at the following address: www.products.endress.com/order-ident

2.4 Certificates and approvals

2.4.1 CE mark

Declaration of conformity

The product meets the requirements of the harmonized European standards. It thus

complies with the legal requirements of the EC directives.

The manufacturer confirms successful testing of the product by affixing the 4 symbol.

2.4.2 CSA general purpose

CSA General Purpose

The products listed below are eligible to bear the CSA Mark shown with adjacent indicators

"C" and "US":

Version Approval

CCM253-..2...

CCM253-..3...

CCM253-..7...

CSA Mark for Canada and USA

CCM223-..2...

CCM223-..3...

CCM223-..7...

CSA Mark for Canada and USA

Liquisys M CCM223/253 Mounting

Endress+Hauser 9

3Mounting

3.1 Quick installation guide

Proceed as follows to completely install the measuring point:

• Install the transmitter (see "Installation instructions" section).

• If the sensor is not yet installed in the measuring point, install it (see Technical

Information of the sensor).

• Connect the sensor to the transmitter as illustrated in the "Electrical connection" section.

• Connect the transmitter as illustrated in the "Electrical connection" section.

• Commission the transmitter as explained in the "Commissioning" section.

3.1.1 Measuring system

A complete measuring system comprises:

Version 1 (free chlorine and chlorine dioxide)

• The transmitter Liquisys M CCM223 or CCM253

• A membrane covered sensor CCS140/141 for Cl

2

or CCS240/241 for ClO2 or an open

sensor 963 for Cl

2

• A flow assembly CCA250 (not necessary for sensor 963)

and optional:

• A pH or ORP sensor

• An INS proximity switch for flow monitoring (omitted with 963 sensor)

• CMK extension cable for chlorine measurement if required

• CYK71 extension cable for pH/ORP measurement if required

• MK extension cable for INS proximity switch if required

• VBC junction box

Version 2 (total chlorine)

• The transmitter Liquisys M CCM223 or CCM253

• A sensor for total chlorine CCS120

• A flow assembly CCA250 or immersion assembly CYA611

• A special measuring cable CPK9, PM wire internally

and optional:

• A pH or ORP sensor

• An INS proximity switch for flow monitoring (omitted with immersion assembly)

• CMK extension cable (PM wire internally) for chlorine measurement if required

• CYK71 extension cable for pH/ORP measurement if required

• MK extension cable for INS proximity switch if required

• VBC junction box

Mounting Liquisys M CCM223/253

10 Endress+Hauser

a0001691

Fig. 1: Measuring system with flow assembly (example)

1 Flow assembly CCA250 6 Medium outlet

2 Medium inlet 7 Sampling tap

3 Proximity switch for flow monitoring 8 Measuring cable

4 Mounting place for pH/redox sensor 9 Transmitter

5Chlorine sensor

a0001791

Fig. 2: Measuring system with immersion assembly (example)

1 Junction box 4 Immersion assembly CYA611

2 Transmitter 5 Chlorine sensor CCS120

3 Measuring cable 6 Assembly adapter G1

CAL REL

REL1

REL1

ALARM

REL2

REL2

E

mg/l

25.0 ¡C

0.42

1

2

3

4

5

6

7

8

9

1

2

4

5

3

CAL REL

REL1

REL1

ALARM

REL2

REL2

E

mg/l

25.0 ¡C

0.42

6

Liquisys M CCM223/253 Mounting

Endress+Hauser 11

3.2 Installation conditions

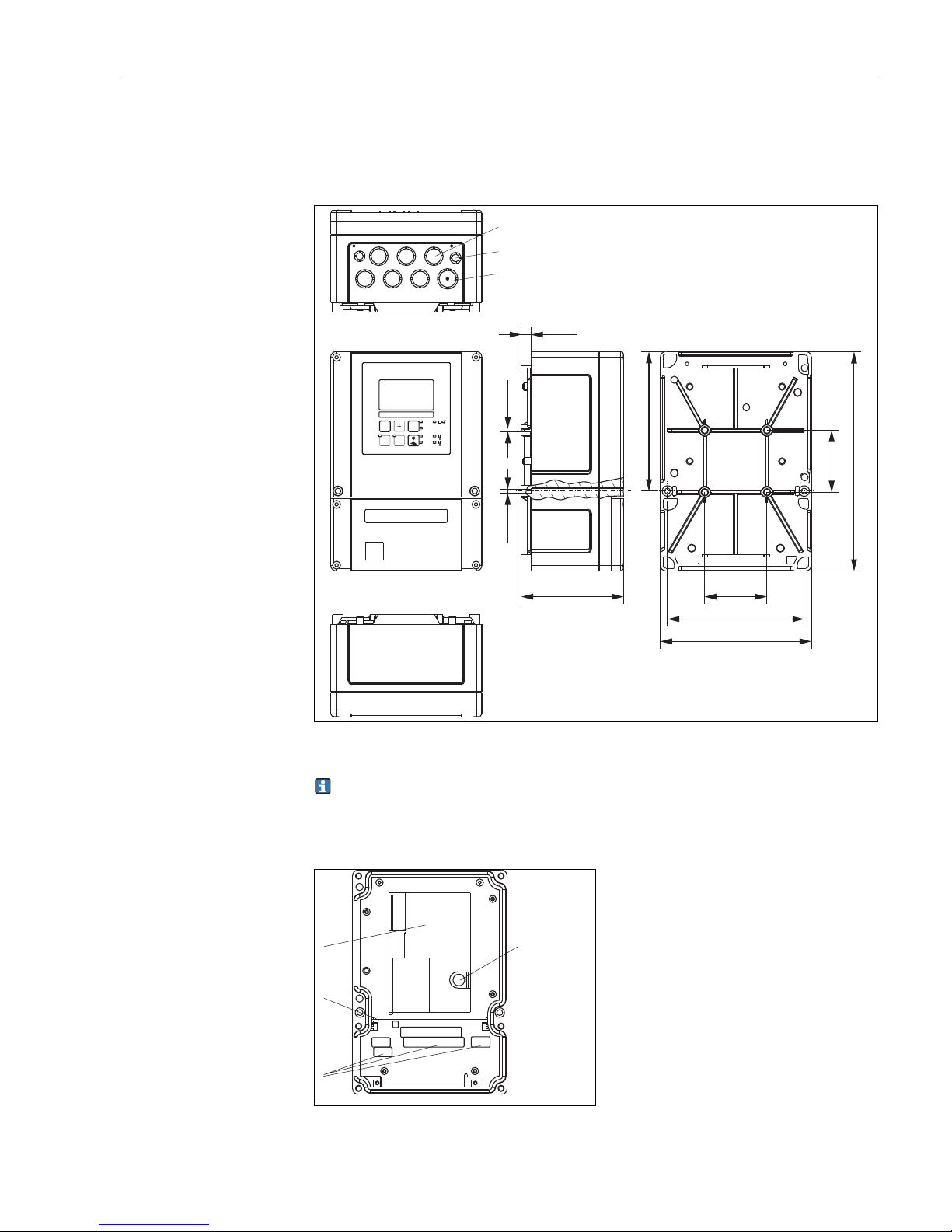

3.2.1 Field instrument

a0005733

Fig. 3: Field instrument

There is a hole in the punching for the cable entry (connection of supply voltage). It

serves as a pressure balance during air freight dispatching. Make sure no moisture

penetrates the inside of the housing before the cable installation. The housing is

completely air-tight after the cable installation.

CAL REL

REL1

REL1

ALARM

REL2

REL2

E

Pg 7

Pg 16

M5

11/

0.43

Ø6/

Ø 0.24

115 / 4.53

157 / 6.18

247 / 9.72

70 / 2.76

70 / 2.76

154 / 6.06

170 / 6.69

mm / inch

Pg 13.5

a0005734

Fig. 4: View into the field housing

1

2

3

4

Removable electronics box

Partition plate

Terminals

Fuse

1

2

3

4

Mounting Liquisys M CCM223/253

12 Endress+Hauser

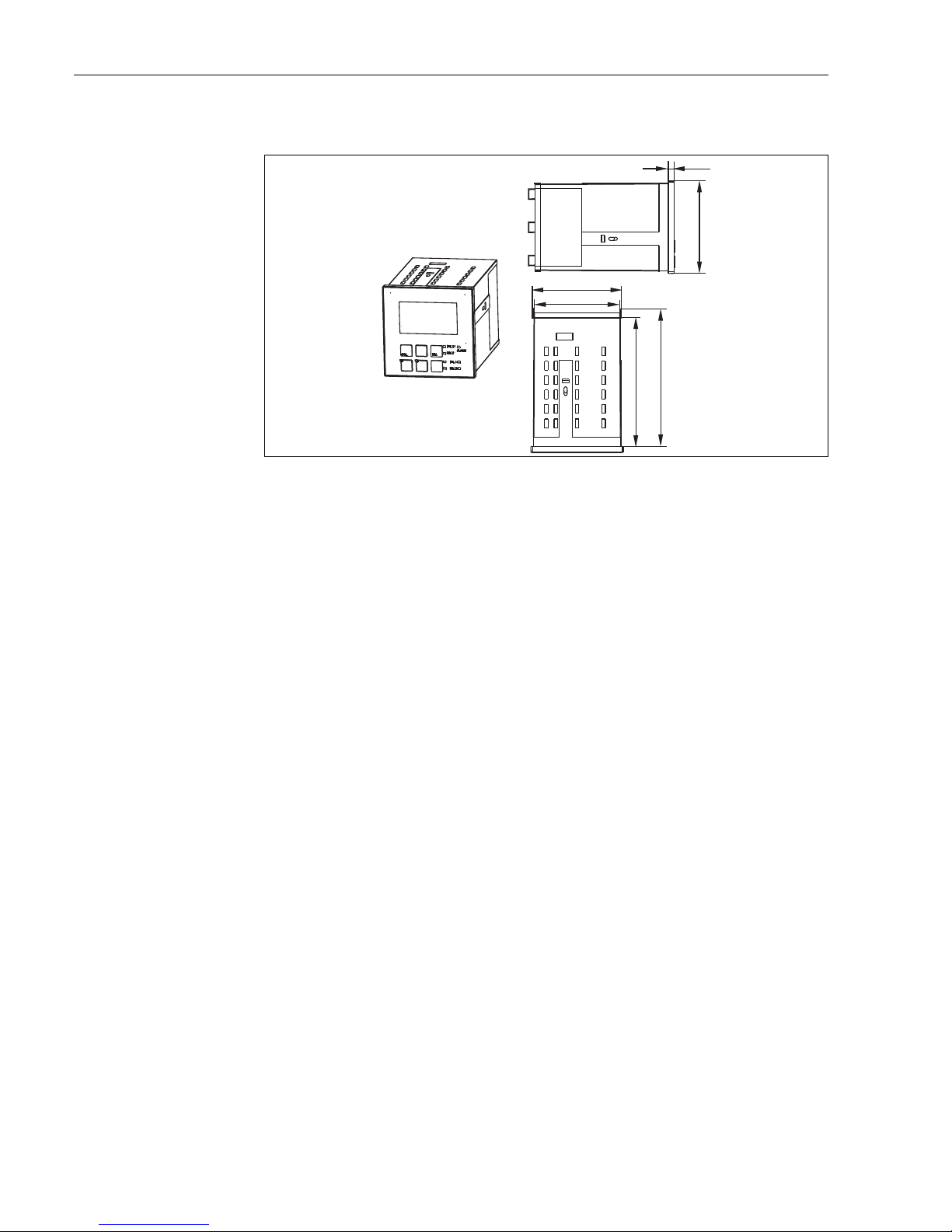

3.2.2 Panel-mounted instrument

a0005735

Fig. 5: Panel-mounted instrument

90 / 3.54

139 / 5.47

96 / 3.78

6/

0.24

mm / inch

92 / 3.62

149.5 / 5.89

Liquisys M CCM223/253 Mounting

Endress+Hauser 13

3.3 Installation instructions

3.3.1 Field instrument

There are several ways of securing the field housing:

• Wall mounting with fixing screws

• Post mounting to cylindrical pipes

• Post mounting to square securing masts

NOTICE

Effect of climate conditions (rain, snow, direct sun etc.)

Impaired operation to complete transmitter failure

‣ When installing outside, always use the weather protection cover (accessory).

Transmitter wall mounting

a0005736

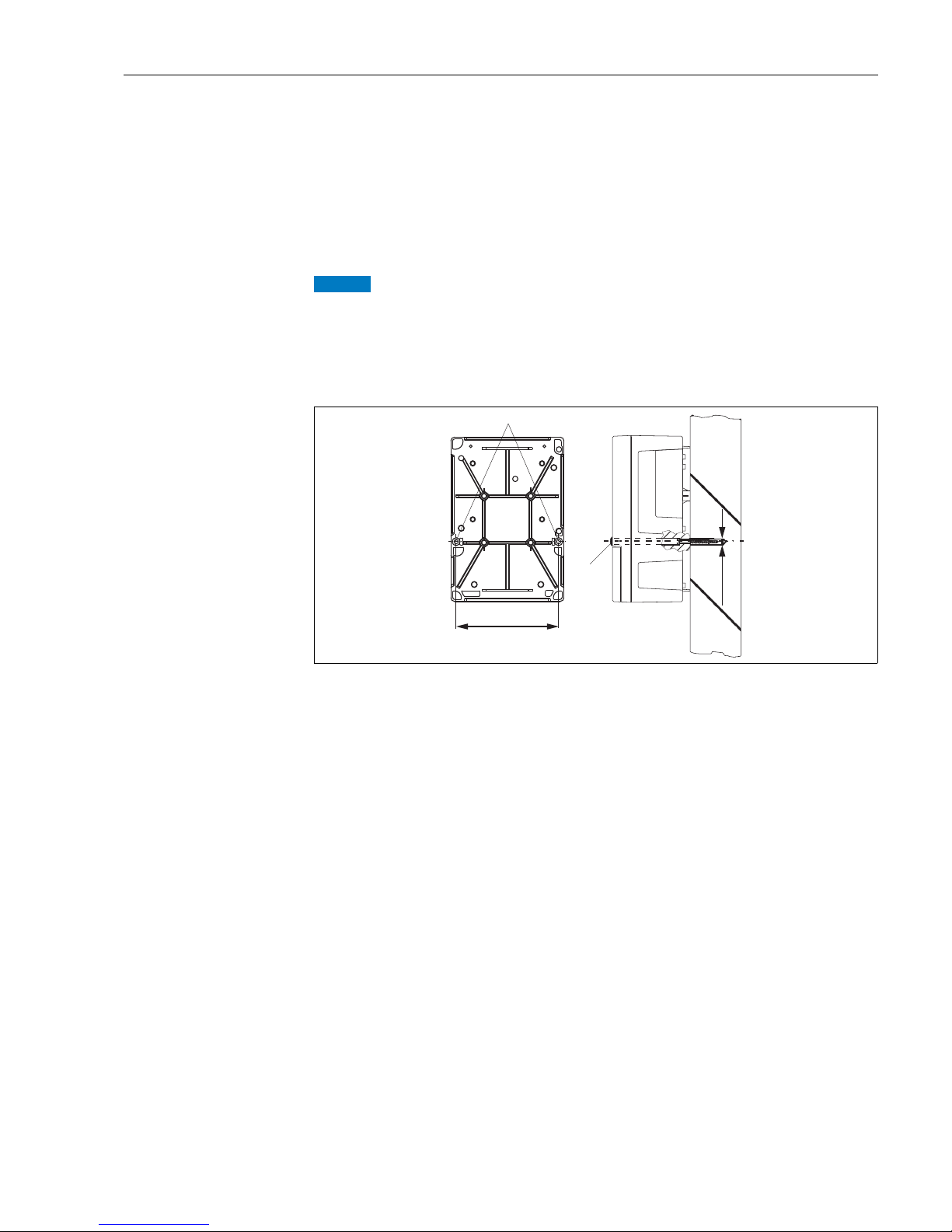

Fig. 6: Wall mounting field device

For wall mounting the transmitter, proceed as follows:

1. Drill the bores as shown in å 6.

2. Drive the two fixing screws through the securing bores (1) from the front.

3. Mount the transmitter on the wall as shown.

4. Cover the bores with plastic caps (2).

1

2

154 / 6.06

mm / inch

Ø6/

Ø 0.24

Mounting Liquisys M CCM223/253

14 Endress+Hauser

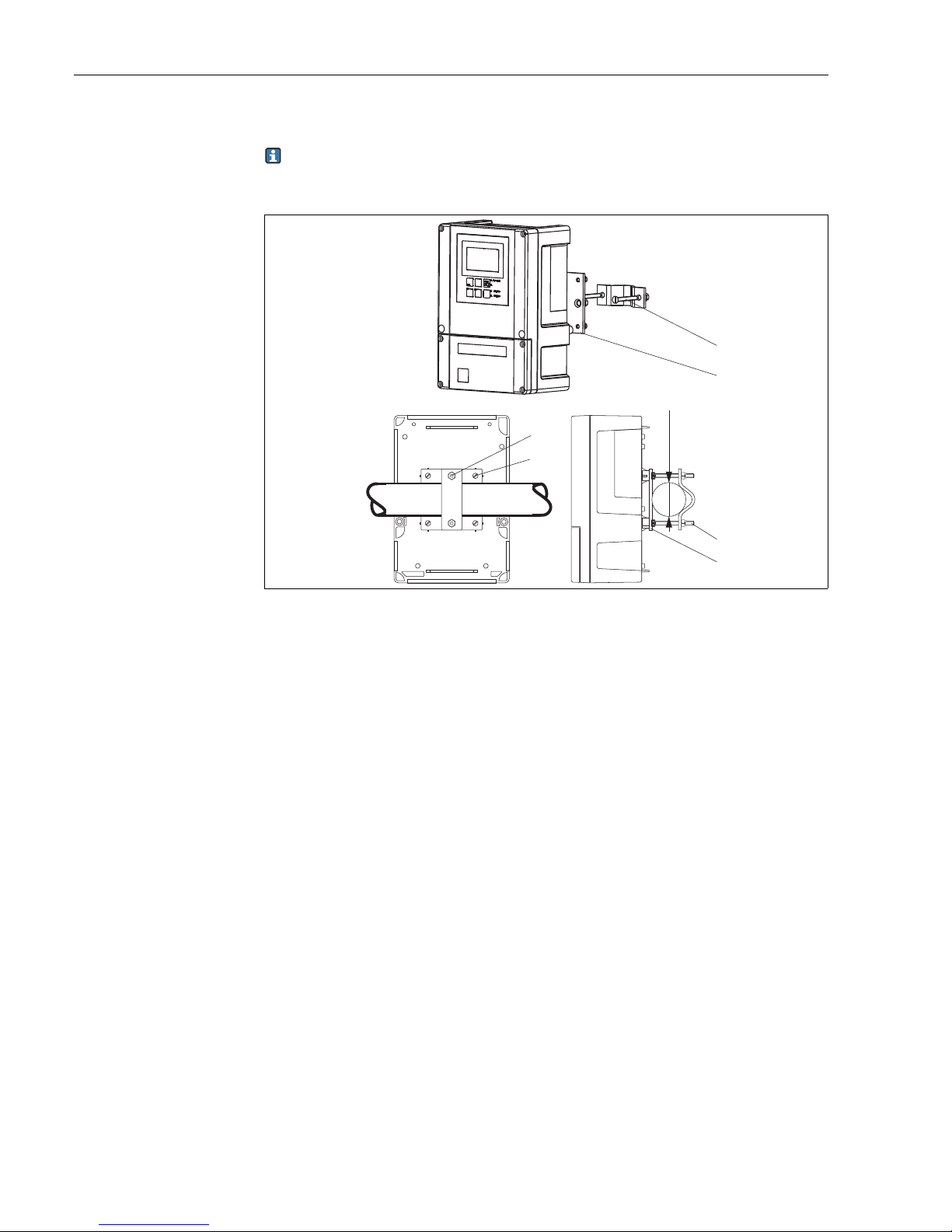

Transmitter post mounting

You require a post mounting kit to secure the field device to horizontal and vertical posts

or pipes (max. Ø 60 mm (2.36")). The kit can be acquired as an accessory (see

"Accessories" section).

a0005737

Fig. 7: Post mounting field device to cylindrical pipes

For post mounting the transmitter, proceed as follows:

1. Guide the two securing screws (1) of the mounting kit through the openings of the

securing plate (3).

2. Screw the securing plate onto the transmitter using the four fixing screws (2).

3. Secure the retainer with the field device on the post or pipe using the clip.

1

2

3

1

1

3

Ø max. 60 /

2.36

mm / inch

Liquisys M CCM223/253 Mounting

Endress+Hauser 15

You can also secure the field device to a square universal post in conjunction with the

weather protection cover. These can be acquired as accessories, see "Accessories" section.

a0005738

Fig. 8: Mounting field device with universal posts and weather protection cover

For mounting the weather protection cover, proceed as follows:

1. Screw the weather protection cover with 2 screws (bores 1) to the upright post

(bores 2).

2. Secure the field device to the weather protection cover. To do so, use the bores (3).

3

1

2

3

Mounting Liquisys M CCM223/253

16 Endress+Hauser

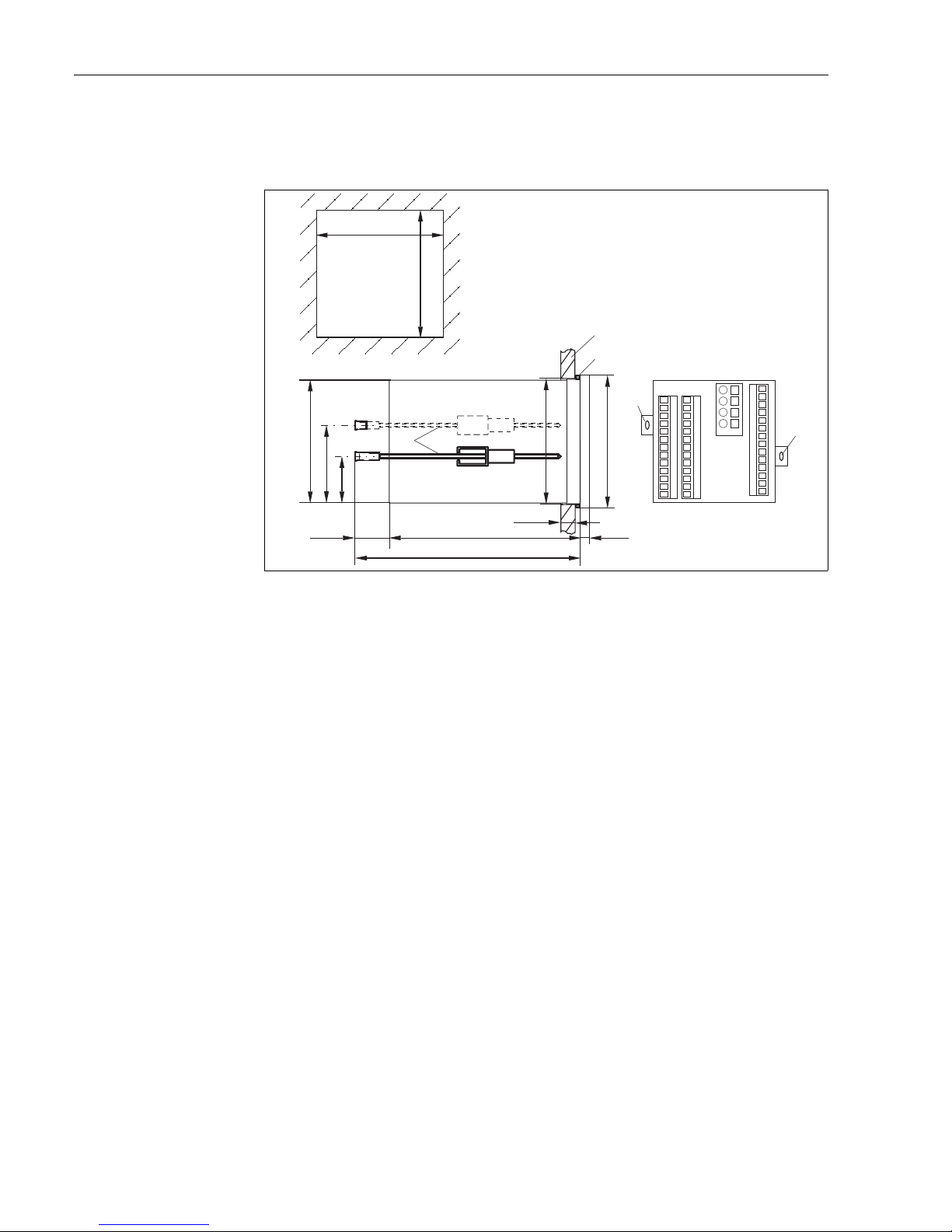

3.3.2 Panel-mounted instrument

The panel-mounted instrument is secured with the clamping screws supplied (see å 9).

The necessary installation depth is approx. 165 mm (6.50").

a0005739

Fig. 9: Securing the panel-mounted instrument

1 Wall of the cabinet

2Seal

3 Clamping screws

* Required installation depth

3.4 Post-installation check

• After installation, check the transmitter for damage.

• Check whether the transmitter is protected against moisture and direct sunlight (e.g. by

the weather protection cover).

1

2

3

3

3

92 / 3.62

+0.5 +0.02

92 / 3.62

+0.5 +0.02

90 / 3.54

57 / 2.24

33 /

1.30

approx. 25 /

0.98

139 / 5.47

max. 45 /

1.77

6 /

0.24

96 / 3.78

92 /

3.62

approx. 165 / 6.50*

mm / inch

Liquisys M CCM223/253 Electrical Connection

Endress+Hauser 17

4 Electrical Connection

WARNING

!

Device is energized

Improper connection can cause injury or death.

‣ The electrical connection must only be carried out by a certified electrician.

‣ Technical personnel must have read and understood the instructions in this manual and

must adhere to them.

‣ Prior to beginning any wir ing wor k, ma ke s ure vol tag e is n ot a ppl ied to a ny of the cab les .

The electrical connection of the transmitter differs depending on the sensor:

• If you are using the membrane-covered sensor CCS140 / 141 / 240 / 241 or the open

sensor 963, please read the instructions in the "Electrical connection version 1" section.

• If you are using the total chlorine sensor CCS120, please read the instructions in the

"Electrical connection version 2" section.

4.1 Wiring

4.1.1 Connecting supply voltage

NOTICE

The device does not have a power switch

‣ You must provide a protected circuit breaker in the vicinity of the device.

‣ This must be a switch or a power-circuit breaker and you must label it as the circuit

breaker for the device.

‣ At the supply point, the power supply for the 24 V versions must be isolated from

dangerous live cables by double or reinforced insulation.

Electrical Connection Liquisys M CCM223/253

18 Endress+Hauser

4.1.2 Electrical connection version 1

The wiring diagram shows the connections of the transmitter with all options

The device is approved for protection class II and is generally operated without

protective ground connection.

The circuits "E" and "I" are not galvanically separated from each other.

a0001903

Fig. 10: Electrical connection of the transmitter (version 1)

A

B

C

D

E

F

G

H

*

pH / ORP input (optional)

Sensor CCS140/141/240/241

Sensor 963 (alternative)

Signal output 1 chlorine / chlorine dioxide

Signal output 2 temperature, pH or ORP

Binary input 1 (hold / cleaning)

Proximity switch INS

Binary input 2

Aux. voltage output terminal 85/86 applicable

I

J

K

L

M

N

O

P

Aux. voltage output

Alarm (current-free contact position)

Relay 1 (current-free contact position)

Relay 2 (current-free contact position)

Relay 3 (current-free contact position)

Relay 4 (current-free contact position)

Current input 4 to 20 mA

Power supply

15 V

85

86

81

93

82

94

mA

31

32

mA

mA

33

34

54

55

56

23

24

90

12

11

91

92

S

ClO

2

ClO

2

Cl

2

Cl

2

K

A

A

K

K

A

NTC

pH

Red.

Ref.

PA/

PM

10–50 V

41

42

43

47

48

49

57

58

59

51

52

53

L+

L–N

L1

~=

pH/

Redox

GN

BN

RD

BU

RD

BK

BN

BU

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

*

Liquisys M CCM223/253 Electrical Connection

Endress+Hauser 19

4.1.3 Electrical connection version 2

The wiring diagram shows the connections of the transmitter with all options

The device is approved for protection class II and is generally operated without

protective ground connection.

The circuits "E" and "C" are not galvanically separated from each other.

a0001904

Fig. 11: Electrical connection of the transmitter (version 2)

A

B

C

D

E

F

G

H

*

pH / ORP input (optional)

Sensor CCS120

Aux. voltage output

Signal output 1 total chlorine

Signal output 2 temperature, pH or ORP

Binary input 1 (hold / cleaning)

Proximity switch INS

Binary input 2

Aux. voltage output terminal 85/86 applicable

J

K

L

M

N

O

P

Alarm (current-free contact position)

Relay 1 (current-free contact position)

Relay 2 (current-free contact position)

Relay 3 (current-free contact position)

Relay 4 (current-free contact position)

Current input 4 to 20 mA

Power supply

15 V

85

86

81

93

82

94

mA

31

32

mA

mA

33

34

54

55

56

23

24

90

12

11

S

ClO

2

ClO

2

Cl

2

Cl

2

pH

Red.

Ref.

PA/

PM

10–50 V

41

42

43

47

48

49

57

58

59

51

52

53

L+

L–N

L1

~=

pH/

Redox

YE

BK

BK

BN

BU

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

15 V

85

86

CCS

120

WH

GN

BN

C

*

Electrical Connection Liquisys M CCM223/253

20 Endress+Hauser

4.1.4 Device connection

Field instrument connection

Proceed as follows to connect the field instrument:

1. Open the housing cover to access the terminal block in the connection compartment.

2. Break the punching of a cable gland from the housing, mount a cable gland and guide

the cable through this cable gland.

3. Connect the cable in accordance with the terminal assignment ( å 12).

4. Tighten the cable gland.

NOTICE

Nonobservance could cause incorrect measurement

‣ Make sure to protect the connectors, cable ends and terminals against moisture.

‣ Terminals marked NC may not be wired.

‣ Unmarked terminals may not be wired.

a0002276

Fig. 12: Field instrument connection compartment sticker

Please label the sensor terminal block with the sticker provided.

pH / Redox

42

+

+

++++-

-

----

434154 55 56

NC

91

90

31

11

12

32

92

PA/ PM

3433

S

REF

NC 938685 94 812382

24

NC

51 52 53 57 58 59 47 48 49

Cl

ClO

2

(963:92/K)

2

Temp.

pH/Redox

(opt.)

+15V

10mA

BN

(RD)GN(BU)

BN

REL 4SENSOR REL 3 REL 2 REL 1

131194-4D

CCM 253

Digital 2

(INS)

Digital 1

4..20mA

1191/A

1290/K

NC

Mains

Hilfsenergie

L1+N

-

(AC)

(DC)

Contacts:

max. 2A

AC: 250V/500VA

DC: 30V/60W

Liquisys M CCM223/253 Electrical Connection

Endress+Hauser 21

Panel-mounted instrument connection

Connect the cable in accordance with the terminal assignment ( å 13)

a0002277

Fig. 13: Panel-mounted instrument connection sticker

NOTICE

Nonobservance could cause incorrect measurement

‣ Make sure to protect the connectors, cable ends and terminals against moisture.

‣ Terminals marked NC may not be wired.

‣ Unmarked terminals may not be wired.

Please label the sensor terminal block with the sticker provided.

REL1

REL2

REL3

REL4

4..20mA

24

23

49

COM

COM

COM

COM

-

+

59

54

55

56

52

51

53

58

57

48

47

131084-4C

31 +

32 -

33 +

PA/ PM

34 -

85 +

NC

91

90

NC

(REF)

Sensor

NC

86 -

93 + S

94 - 42

81 + 43

82 - 41

Cl

2

Tem p.

pH

Redox

(opt.)

+15V

10mA

Digital 2

(INS)

Digital 1

92

12

11

K

A

BN

BN

GN

131192-4C

K

ClO

2

963

CCS..

963

BNC: pH/Redox + REF

RD

BU

Mains

Contacts: max. 2A, AC:250V/500VA, DC:30V/60W

L1 +

AC DC

N-

Electrical Connection Liquisys M CCM223/253

22 Endress+Hauser

4.1.5 Measuring cable and sensor connection

Connection of the sensors CCS140 / 141 / 240 /241

The sensors are equipped with a 3 m (9.8 ft) fixed cable. Connect the sensor to the

transmitter as follows:

Connection of the total chlorine sensor CCS120

Connect the sensor with the measuring cable l CPK9-N*A1B (with internal PML) as follows:

* The white and the yellow wire are interconnected inside of the TOP68 plug.

a0001689

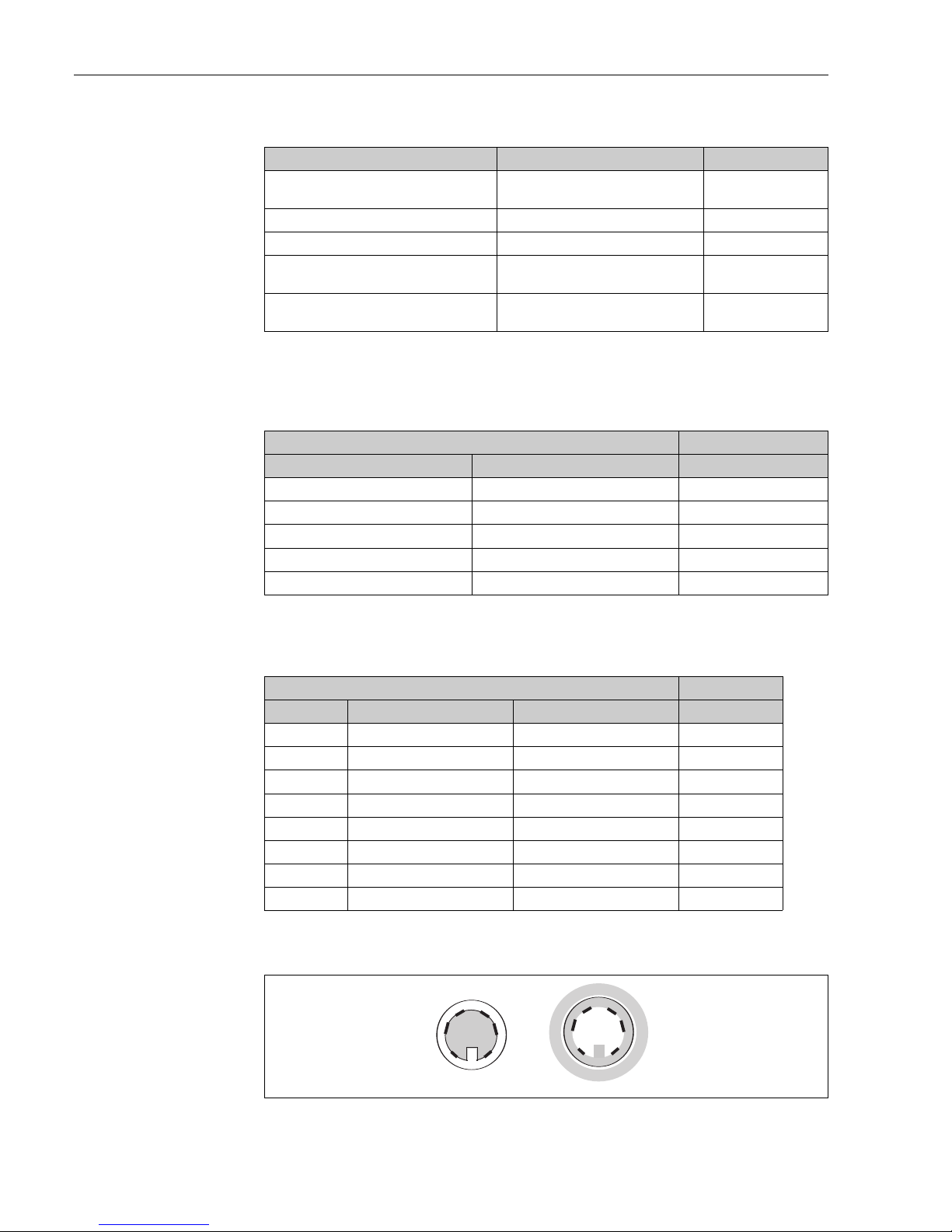

Fig. 14: TOP68 plug connection; pin assignment of plug, male and female (shown from contact side)

Type of sensor Cable Extension

Chlorine / chlorine dioxide sensors

CCS140 / 141 / 240 / 241

3 m (9.8 ft) CMK, fixed cable VBC junction box +

CMK

Chlorine sensor 963 – VBC junction box + MK

Temperature sensor for sensor 963 CPK1

Total chlorine sensor CCS120 CPK9-N*A1B VBC junction box +

CYK71

pH or ORP sensor without temperature

sensor

CPK1 for sensors with GSA plug-in head

CPK9 for sensors with ESA plug-in head

VBC junction box +

CYK71

Sensor with 3 m (9.8 ft) fixed cable Transmitter

Pin assignment Wire Terminal

Outer screen S

Anode [A] red 91

Cathode [K] 90

NTC temperature sensor green 11

NTC temperature sensor brown 12

Cable with TOP68 plug connection Transmitter

Pin Assignment Wire Terminal

1 TC signal coax inside (white) 90

2 AGND coax outside(black) 12

3

4 +UB (15 V) green 85

5NTC1 yellow* 11

NTC1 white* 11

6NTC2/AGND brown 86

S screen S S

1

2

3

5

6

4

1

2

3

5

6

4

Liquisys M CCM223/253 Electrical Connection

Endress+Hauser 23

Connection of the sensors 963

The sensor 963 is supplied without temperature sensor ex factory. Connect the sensor to the

transmitter as follows:

• Without temperature measurement:

Connect the supplied resistor10 k to the terminals 11 and 12. The measured value

display will constantly indicate 25 °C (77 °F).

• With temperature measurement:

Install the NTC temperature sensor10 k / 25 °C (77 °F) (120 mm installation version TSP

3692) into the sensor 963. Use the measuring cable CPK1 to connect the temperature

sensor to the terminals 11 and 12 of the transmitter.

• Chlorine sensor:

Connect the red wire to terminal 92 (cathode) and the blue wire to the terminal 91

(anode).

Connection of pH or ORP sensors

Connect the pH or ORP sensor always symmetrically to prevent a mutual interference of

several sensors mounted in the CCA250 assembly.

Symmetrical connection requires a potential matching pin. It is integrated as standard in the

CCA250 flow assembly and is connected to the PA/PM terminal by a potential matching

line.

a0002330-en

Fig. 15: Connection of the pH or ORP sensor to the field instrument with the cables CPK1 or CPK9

CPK1

CPK9

PM

pH / Redox

PM

pH + Pt 100 / Pt 1000

Coax Ref.

pH or Redox

BN PM

Coax BK Ref.

inner pH

GN Temp.

WH Temp.

YE Temp.

BN PM

Electrical Connection Liquisys M CCM223/253

24 Endress+Hauser

If you are using glass electrodes with the panel-mounted instrument, you have to terminate

the measuring cable with a BNC connector. A solder-free BNC connector is supplied with the

device.

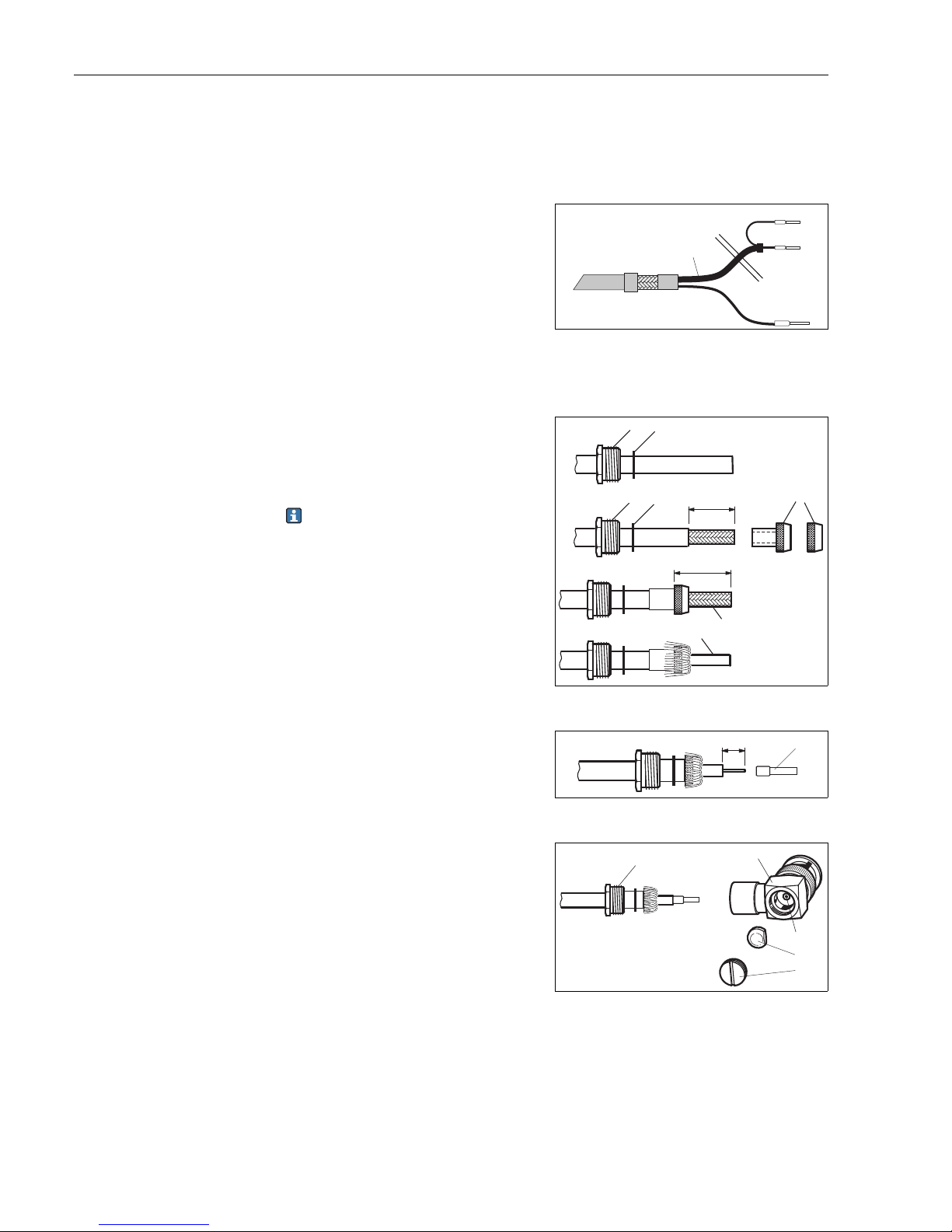

Proceed as follows:

1. Cut off end sleeves 2 and 3 of the coaxial

cable ( å 16).

a0005744

Fig. 16: Cable CPK1: device connection

1Coaxial cable

2 Inner screen BK (ref.)

3 Inner coax (pH/mV)

4Strand BN (PA)

2. Push the cable gland 5 and the washer 6

onto the coaxial cable.

3. Remove the insulation (13 mm(0.51"))

and screw the clamping ring 7 onto the

insulation.

Parts 5 to 7 are supplied with the BNC

connector for cable diameters 3.2 mm

(0.13") and 5 mm (0.20").

4. Fold the braided screen 8 over the

clamping ring and cut off the excess

material.

5. There is a semi-conductor layer 14

(conductive foil) between the inner

insulation and the braided screen 8. Strip

this semi-conductor layer to the braided

screen.

a0005745

Fig. 17: Terminating the pH connecting cable for mounting

the BNC elbow plug

6. Remove the inner insulation (4 mm

(0.16")).

7. Position the end sleeve 13 onto the

stripped inner conductor and secure the

end sleeve with crimping pliers.

a0005746

Fig. 18: Terminating the pH connecting cable for mounting

the BNC elbow plug

8. Push the BNC connector housing 9 over

the cable. The inner conductor must be

located on the clamping surface 10 of the

connector.

9. Tighten the cable gland 5.

10.Insert the clamp element 11 and screw in

the connector cover 12. This creates a safe

connection between the inner conductor

and the connector pin.

a0005747

Fig. 19: Mounting the pH connecting cable in the BNC elbow

plug

3

4

1

2

56

56

7

8

14

13 / 0.51

16 / 0.63

mm / inch

13

4/

0.16

mm / inch

5

9

10

11

12

Liquisys M CCM223/253 Electrical Connection

Endress+Hauser 25

Cable extension

To extend the measuring cable use the junction box VBC and the corresponding extension

cable.

a0005740

Fig. 20: VBC junction box with grounding point

A View in arrow direction

B 2 fixing holes Ø 4.5 mm / 0.18 "

NOTICE

Incorrect measurement due to short-circuit

‣ Make sure to remove the black semiconductor layer up to the inner screen when

performing termination work!

Maximum cable lengths

Sensors CCS140/141/240/241 max. 30 m (98.4 ft) with cable CMK

Chlorine sensor 963 max. 30 m (98.4 ft) with cable MK

Total chlorine sensor CCS120 max. 15 m (49.2 ft) with cable CYK71

pH or ORP measurement max. 50 m (164 ft) with cable CYK71

2xPg7

2xPg11

5xPg7

A

B

B

mm / inch

54 / 2.13

113 / 4.45

125 / 4.92

52 / 2.05

a0002331

Fig. 21: CMK cable

1 Outer screen

2 Inner screen, anode

3 Semiconductor layer

4 Inner insulation

5 Inner conductor, measuring signal

6 Temperature sensor connection

7 2nd insulation

8 Outer insulation

a0002332

Fig. 22: CYK71 cable

1 Outer screen

2 Inner screen, reference signal

3 Inner insulation

4 Inner conductor, measuring signal

5 Semiconductor layer

6 2nd insulation

7 Outer insulation

BN

GN

1

2

3

4

5

6

7

8

1

23

45

6

7

Electrical Connection Liquisys M CCM223/253

26 Endress+Hauser

4.1.6 Three-point step controller for Cl2 / ClO2 / total chlorine

Connect the continuously variable motor valves as follows:

• Connect the "closing" contact of the motor valve to relay 3.

• Connect the "opening" contact of the motor valve to relay 4.

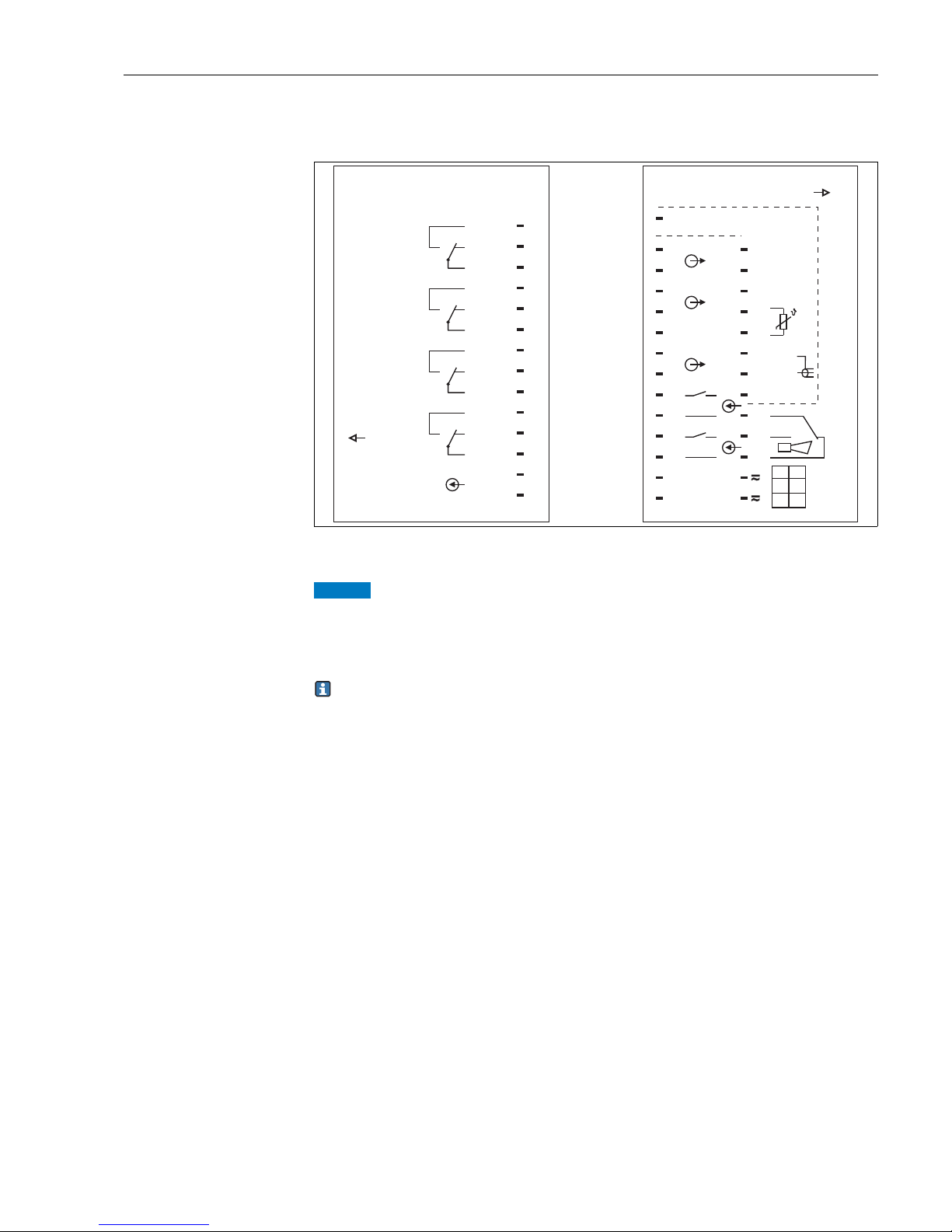

4.1.7 Alarm contact

4.2 Post-connection check

After the electrical connection, carry out the following checks:

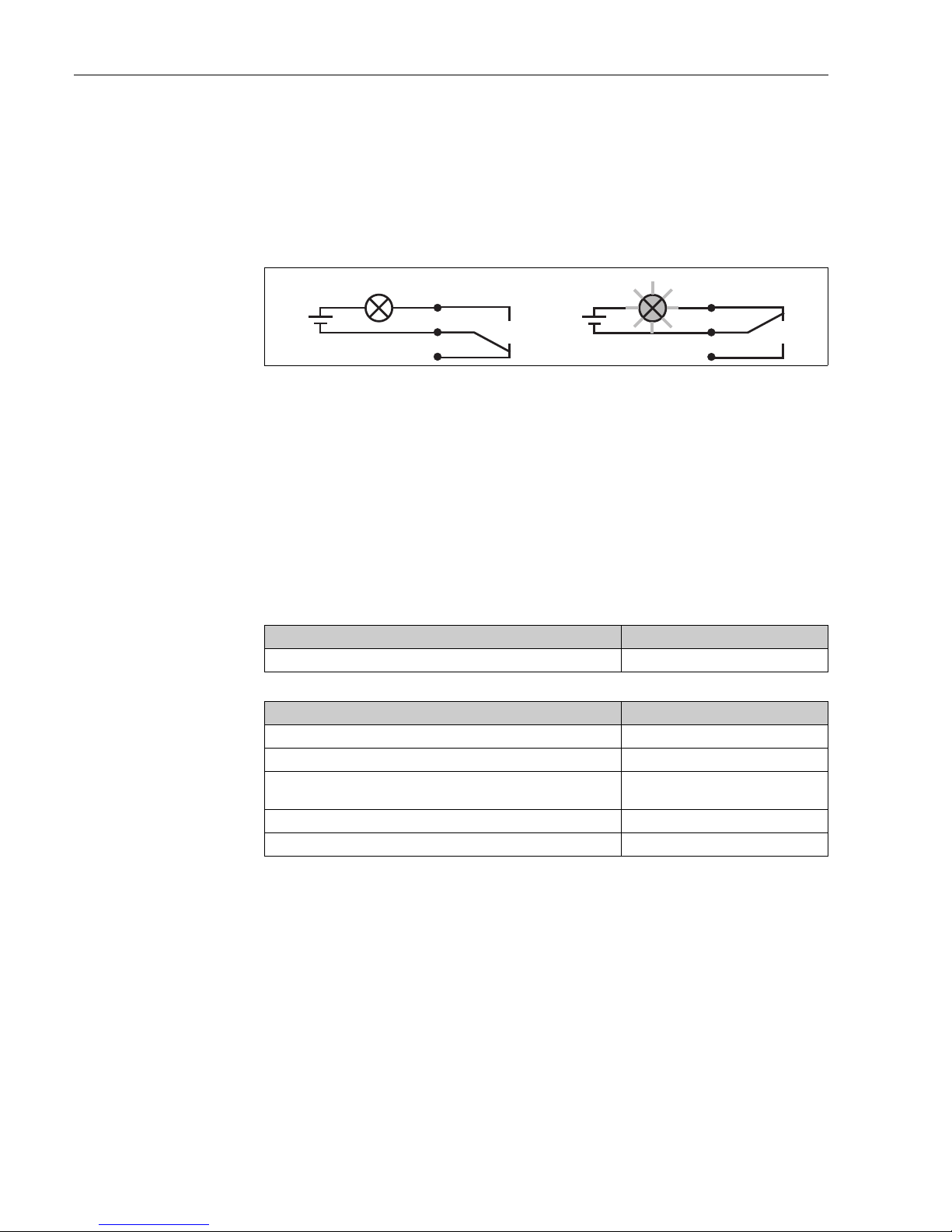

a0006415

Fig. 23: Recommended fail-safe switching for the alarm contact

A Normal operating status B Alarm condition

Normal operating status:

Device in operation and no error message

present (alarm LED off)

• Relay energized

• Contact 42/43 closed

Alarm condition

Error message present (alarm LED red) or

device defective or voltage-free (alarm LED off)

• Relay de-energized

• Contact 41/42 closed

Device condition and specifications Notes

Are the transmitter and cables damaged on the outside? Visual inspection

Electrical connection Notes

Are the mounted cables strain relieved?

Cable run without loops and cross-overs?

Are the signal lines correctly connected in accordance with the wiring

diagram?

Are all screw terminals tightened?

Are all cable entries installed, tightened and sealed?

41

42

43

41

42

43

A

B

Liquisys M CCM223/253 Operability

Endress+Hauser 27

5Operability

5.1 Quick operation guide

You have the following ways of operating the transmitter:

• On site via the key field

• Via the HART interface (optional, with corresponding order version) per:

– HART handheld terminal or

– PC with HART modem and the FieldCare software package

• Via PROFIBUS PA/DP (optional, with corresponding order version) with:

PC with corresponding interface and the FieldCare software package (see Accessories) or

via a programmable logic controller (PLC)

For operation via HART or PROFIBUS PA/DP, please read the relevant sections in the

additional Operating Instructions:

•PROFIBUS PA/DP, field communication for Liquisys M CXM223/253,

BA00209C/07/EN

•HART, field communication for Liquisys M CXM223/253, BA00208C/07/EN

The following section only explains operation via the keys.

5.2 Display and operating elements

5.2.1 Display

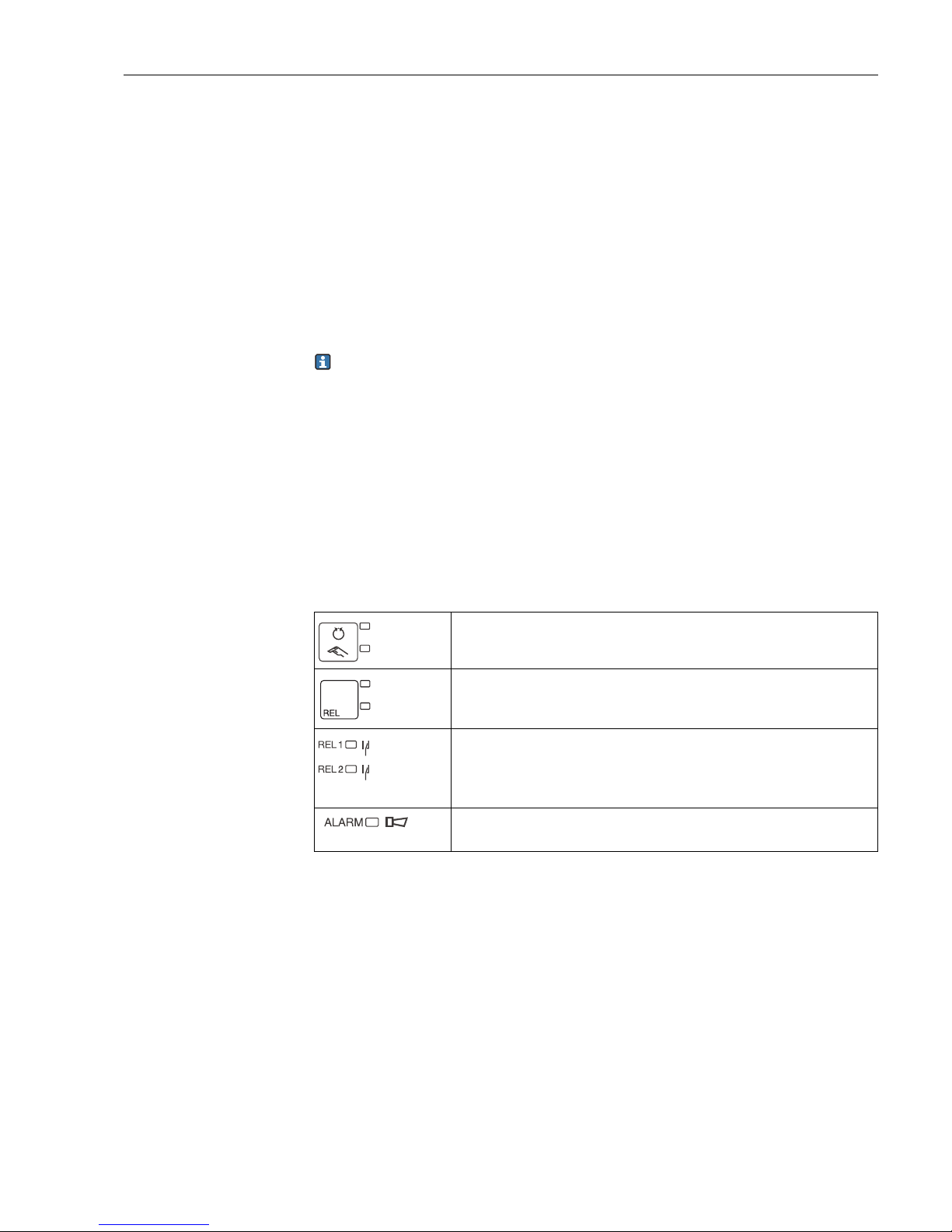

LED display

Indicates the current operating mode, "Auto" (green LED) or

"Manual" (yellow LED)

Indicates the activated relay in the "Manual" mode (red LED)

Indicates the working status of relay 1 and 2

LED green: measured value within the permitted limit, relay

inactive

LED red: measured value outside the permitted limit, relay active

Alarm display, e.g. for continuous limit value overshoot,

temperature sensor failure or system error (see error list)

REL 1

REL 2

Operability Liquisys M CCM223/253

28 Endress+Hauser

LC display

5.2.2 Operating elements

a0001925-en

Fig. 25: Operating elements

1 LC display for displaying the measured values and configuration data

2 Field for user labelling

3 4 main operating keys for calibration and device configuration

4 Changeover switch for automatic/manual mode of the relays

5 LEDs for limit contactor relay (switch status)

6 LED for alarm function

7 Display of the active contact and key for relay changeover in manual mode

a0001924-en

Fig. 24: Liquid crystal display

1

2

3

4

5

6

7

Indicator for measuring mode (normal operation)

Indicator for calibration mode

Indicator for setup mode (configuration)

Indicator for "Hold" mode (current outputs remain

at last current state)

Indicator for receipt of a message for devices with

communication

Indicator of working status of relays 3/4:

d

inactive, cactive

Function code display

8

9

10

11

12

13

14

In measuring mode: measured variable

In setup mode: configured variable

In measuring mode: secondary measured value

In setup/calibr. mode: e.g. setting value

Indicator for autom. temperature compensation

Indicator for man. temperature compensation

"Error": error display

Temperature offset

Sensor symbol

mg/l

R242

1

23

4

5

6

7

8

9

12

13

14

042

10

11

Setpoint

0.42

mg/l

R242

1

2

3

4

5

6

7

Setpoint

Liquisys M CCM223/253 Operability

Endress+Hauser 29

5.2.3 Key assignment

CAL key

When you press the CAL key, the device first prompts you for the

calibration access code:

• Code 22 for calibration

• Code 0 or any other code for reading the last calibration data

Use the CAL key to accept the calibration data or to switch from field

to field within the calibration menu.

ENTER key

When you press the ENTER key, the device first prompts you for the

setup access code:

• Code 22 for setup and configuration

• Code 0 or any other code for reading all configuration data.

The ENTER key has several functions:

• Calls up the Setup menu from the measuring mode.

• Saves (confirms) data entered in the setup mode.

• Moves on within function groups.

PLUS key and MINUS key

In setup mode, the PLUS and MINUS keys have the following

functions:

• Selection of function groups.

Press the MINUS key to select the function groups in the order

given in the "System configuration" section.

• Configuration of parameters and numerical values

• Operation of the relay in manual mode

In measuring mode, you get the following sequence of functions by

repeatedly pressing the PLUS key:

1. Temperature display in °F

2. Temperature display hidden

3. pH measuring value or ORP potential (only on EP version)

4. pH sensor signal in mV (only on EP version)

5. Measured value display of Cl

2

/ ClO2 in nA

6. Zero current of the sensor CCS120

7. Measured value display of current input in %

8. Measured value display of current input in mA

9. Return to basic settings

In measuring mode, the following is displayed in sequence by

repeatedly pressing the MINUS key:

1. Current errors are displayed in rotation (max. 10).

2. Once all errors have been displayed, the standard measurement

display appears. In the function group F, an alarm can be defined

separately for each error code.

Operability Liquisys M CCM223/253

30 Endress+Hauser

REL key

In manual mode, you can use the REL key to switch between the relay

and the manual start of cleaning.

In automatic mode, you can use the REL key to read out the switch-on

points (for limit contactor) or set points (for PID controller) assigned

to the relay in question.

Press the PLUS key to jump to the settings of the next relay. Use the

REL key to get back to the display mode (automatic return after 30 s).

AUTO key

You can use the AUTO key to switch between automatic mode and

manual mode.

Escape function

If you press the PLUS and MINUS key simultaneously, you return to

the main menu or are taken to the end of calibration if calibrating. If

you press the PLUS and MINUS key again, you return to the

measuring mode.

Locking the keyboard

Press the PLUS and ENTER key for at least 3 s to lock the keyboard

against any unauthorized data entry. All the settings can continue to

be read.

The code prompt displays the code 9999.

Unlocking the keyboard

Press the CAL and MINUS key for at least 3 s to unlock the keyboard.

The code prompt displays the code 0.

REL 1

REL 2

Loading...

Loading...