Endress+Hauser CUA250 Specifications

Technical

Nothing beats know-how

Endress

Hauser

SO

900

Information

TI 096C/07/en

Process and Flow Assemblies

for Turbidity Measurement

CUA 120 / FlowFit W CUA 250

Adapter for flow assembly and flange mounting,

optionally available with spray function

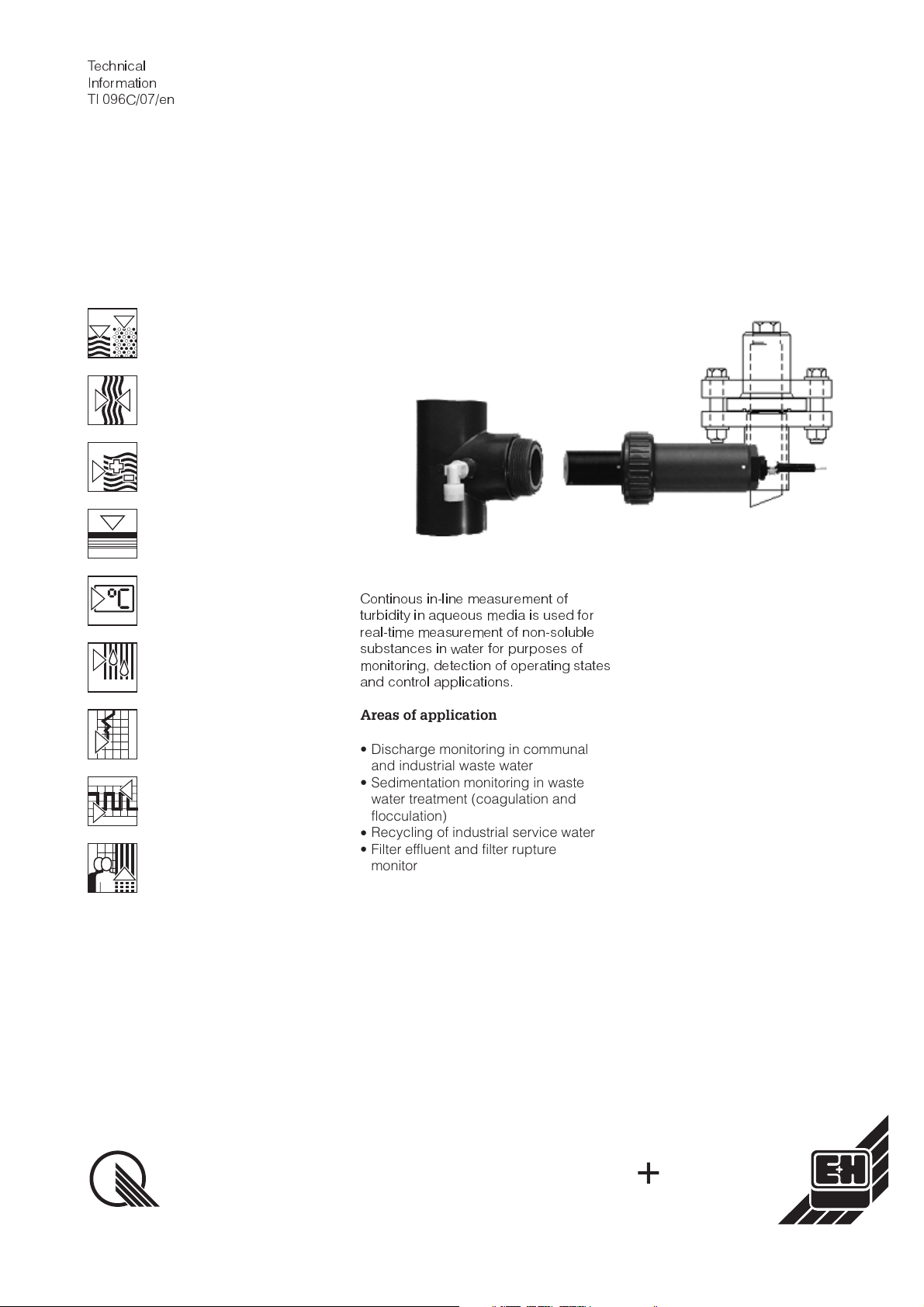

Continous in-line measurement of

turbidity in aqueous media is used for

real-time measurement of non-soluble

substances in water for purposes of

monitoring, detection of operating states

and control applications.

Areas of application

•

Discharge monitoring in communal

and industrial waste water

•

Sedimentation monitoring in waste

water treatment (coagulation and

flocculation)

•

Recycling of industrial service water

•

Filter effluent and filter rupture

monitoring

•

Clear rinse cycle monitoring

•

Flotation process monitoring

•

Monitoring of closed circuits, e.g.

cooling water, product pipelines

Benefits at a glance

•

Flow assemblies featuring simple

adaptation to standard piping

•

Excellent handling properties

•

Optimized fluidic design prevents

sedimentation

•

Sensor orientation can be adapted to

individual requirements of application

•

Self-cleaning effect due to medium

flow against sensor and rejection of

water bubbles

•

Additional cleaning device employs

spray cleaning to increase sensor

maintenance intervals

•

Robust, compact design

•

Flange adapter for standardized

DN 50 flange installation

Quality made by

Endress+Hauser

I

1

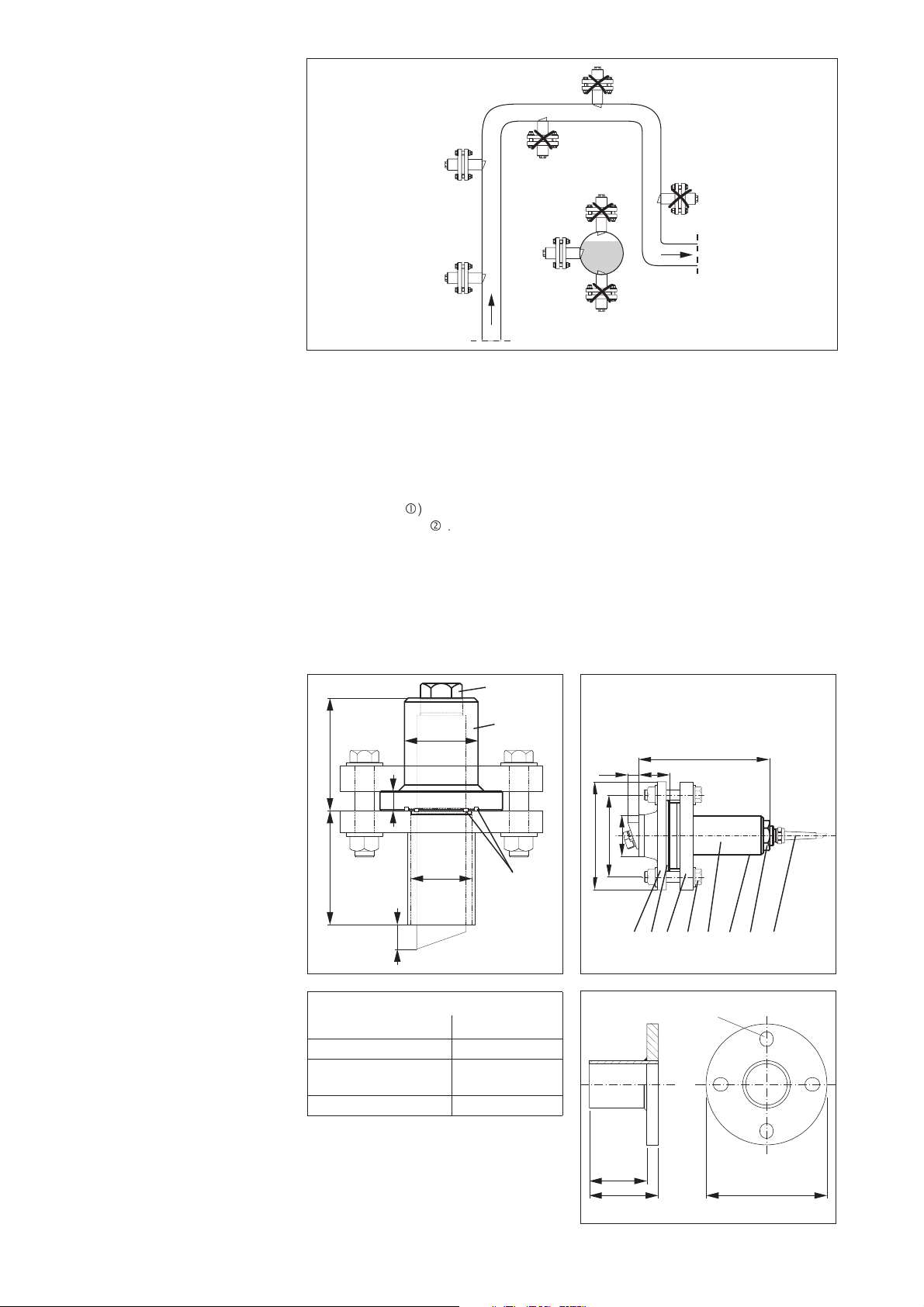

Pipeline

Recommended

mounting positions of

CUS with CUA 120-A/-B

adapter or CUA 461

retractable assembly

left:

CUA 120-B adapter

with welding socket

DN 50 / ANSI 2"

(s.b. / accessory) and

loose flange

DN 50 / ANSI 2" (to be

provided by customer)

right:

120-A adapter

1 Weld-on flange

2 Seal

3 Loose flange

4 Bolted flange joint

5Sleeve

6 Marking hole

7 Hexagon gland

8 Connecting cable

(1-4 to be provided by

customer)

Notes for installation

•

The pipe diameter must be at least DN

100 when bright materials (VA or the

like) are used.

•

Install the sensor in places with

constant flow conditions.

Do not install it in places where air

may collect, where foam bubbles are

likely to form () or where suspended

solids may settle ().

•

Orient the sensor surface against the

medium flow.

•

Suitable for CUS 1*, CUS 4*, CUS 5,

CUS 31, CUS 41

*

(version only without wiper)

Nut

46 AF (G 1")

Material

∅ 60

92

16

d

50

93

min

~20

PVC black

EPDM O-ring

TI176Y11.CDR

Welding socket DN 50 / ANSI 2"

Material

Order no.

Stainless steel 1.4571 50080249

Polyvinyl chloride

PVC

50080250

Polypropylene PP 50080251

TI176Y09.CDR

Mounting

•

Lead connection cable through sleeve

and hexagon coupling without

twisting it.

•

Insert sensor body into the sleeve so

that the O-ring adjoins under G 1"

screw thread in the sleeve.

Note marking pin and marking hole on

the sleeve.

•

Install CUS sensor into the adapter in

such a way that the acute-angled

edge of the sensor lies opposite the

marking hole and points away from it.

The marking hole renders the sensor

orientation clearly identifiable.

197

47

18

∅162

∅63

∅165

1234567 8

UA-250-2.CDR

Holes for

DN 50 and ANSI 2"

right:

Welding socket for pipe

diameter greater than

80 mm

75

93

∅ 165

TI176Y12.CDR

Loading...

Loading...