Endress+Hauser Cerabar T PMC131, Cerabar T PMP131, Cerabar T PMP135 Technical Information

TI415P/00/en

Technical Information

Cerabar T PMC131, PMP131, PMP135

Pressure Transducer

With ceramic and metal sensors

For absolute pressure and gauge pressure measurement up to 400 bar

Extremely stable, overload-resistant and reliable

Application

Cerabar T is a pressure transducer for measuring absolute

pressure and gauge pressure in gases, vapors, liquids and

dusts.

Hygienic and threaded connections are available as

process connections.

Your benefits

This compact pressure transducer impresses with its

well-engineered construction:

• High reproducibility and long-term stability.

• Finely graduated measuring ranges from vacuum up to

400 bar/6000 psi.

•Ceraphire

®

ceramic sensor: corrosion-proof, abrasion-

proof and extremely overload-resistant.

• Deployed for pressure monitoring up to SIL 2 as per

IEC 61508/IEC 61511-1

•Sensors

– Dry capacitance ceramic sensor (Ceraphire

®

) for

measuring ranges up to 40 bar:

overload-resistant, vacuum-proof, stable against

alternating load

– Piezoresistive sensor with metal diaphragm for

measuring ranges up to 400 bar

Cerabar T

2 Endress+Hauser

Table of contents

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Device selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Switch frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Input PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inductive loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PMC131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PMP131 and PMP135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PMP131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Residual ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance characteristics. . . . . . . . . . . . . . . . . . . . . 8

Reference operating

conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Long-term stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maximum measured error

of analog output

(under reference operating conditions) . . . . . . . . . . . . . . . . . . . . . 8

Switch point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rise time (T90) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Settling time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermal change of the lower range value and the span . . . . . . . . . 9

Temperature coefficient (TK) for lower range value and span . . . . . 9

Operating conditions (Installation instructions). . . . . . 9

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Location dependence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating conditions (environment) . . . . . . . . . . . . . 10

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operating conditions (process) . . . . . . . . . . . . . . . . . 11

Process temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overload resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Vacuum resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 12

PMC131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PMP131 and PMP135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PMP131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PMP135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 17

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ex approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pressure Equipment Directive (PED) . . . . . . . . . . . . . . . . . . . . . 17

Functional safety SIL 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Suitability for hygenic processes . . . . . . . . . . . . . . . . . . . . . . . . . 17

TSE Certificate of Suitability . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 18

PMC131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PMC131 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PMP131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PMP131 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PMP135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Welding neck with

sealing taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Welding neck with

sealing surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Plug-in jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Plug-on display

PHX20/PHX21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Field of Activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Functional Safety Manual (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . 24

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cerabar T

Endress+Hauser 3

Function and system design

Device selection

Measuring principle PMC131

The measuring pressure causes a slight deflection of the ceramic diaphragm of the sensor. The pressureproportional change in capacitance is measured at the electrodes of the ceramic sensor. The ceramic sensor is

a dry sensor, i.e. no fill fluid is required for the pressure transfer. This makes the sensor completely suitable for

vacuums. Extremely high stability, comparable with the material Alloy, is achieved by using ultrapure

Ceraphire® as the ceramic.

PMP131 and PMP135 with analog output

The process pressure acting upon the metallic separating diaphragm of the sensor is transmitted to a resistance

bridge via a fluid. The pressure-proportional change of the bridge output voltage is measured and processed

further.

PMP131 and PMP135 with switch output

The process pressure acting upon the metallic separating diaphragm of the sensor is transmitted to a resistance

bridge via a fluid. A differential amplifier creates a standard signal from the pressure-proportional change in

output voltage of the bridge. A comparator with an adjustable hysteresis compares this signal with the pre-set

switch point and then activates the transistor output.

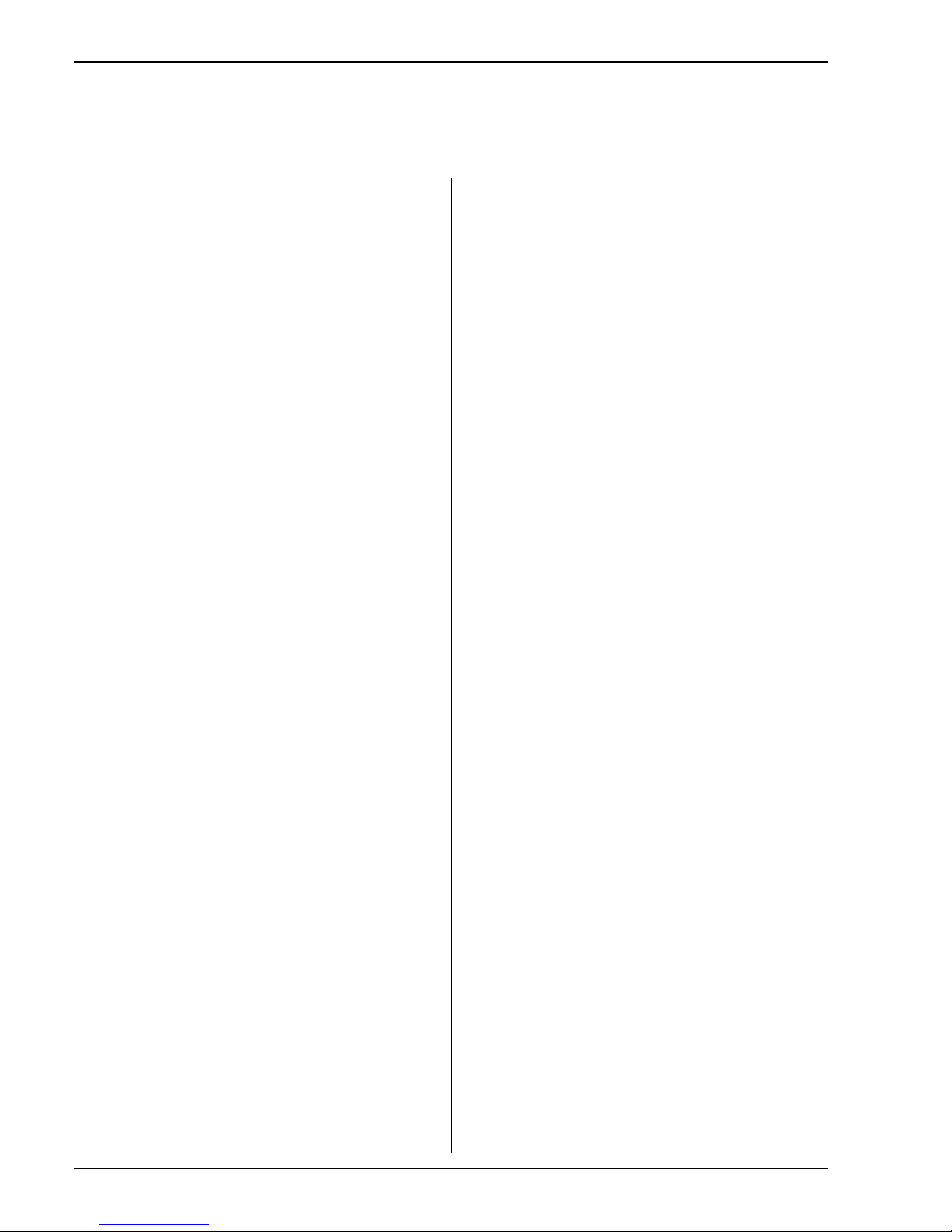

Cerabar T PMC131 PMP131 PMP135

P01-PMC131xx-14-xx-xx-xx-000 P01-PMP131xx-14-xx-xx-xx-000 P01-PMP135xx-14-xx-xx-xx-000

With capacitive measuring

cell and ceramic measuring

diaphragm (Ceraphire

®

)

With piezoresistive

measuring cell and metallic

measuring diaphragm

With piezoresistive measuring cell

and metallic measuring

diaphragm for hygienic

applications

Field of

application

Absolute pressure and gauge

pressure

Absolute pressure and gauge

pressure

Absolute pressure and gauge pressure

in hygienic processes

Output Current output 4 to 20 mA – Current output 4 to 20 mA

– Voltage output 0 to 10 V

– Switch output PNP

–4 to 20 mA

– Switch output PNP

Process

connection

Thread:

–G ½

– ½ MNPT and ¼ FNPT

– G ½, bore 11 mm

Thread:

–G ½

– ½ MNPT and ¼ FNPT

– ½ MNPT, bore 4 mm

–G ¼

– ¼ MNPT, bore 3.5 mm

– M 20 x 1.5

Hygiene:

– Clamp DN 22 (¾")

– Tri-Clamp DN 25 to 38 (1" to 1½")

– Tri-Clamp DN 40 to 51 (2")

–G 1

– SMS 1½"

Measuring

range

–1 to 0 bar/–100 to 0 kPa

up to

0 to 40 bar/0 to 4 MPa

0 to 1 bar/0 to 100 kPa

up to

0 to 400 bar/0 to 40 MPa

0 to 1 bar/0 to 100 kPa

up to

0 to 40 bar/0 to 4 MPa

Process

temperature

–20 to +100 °C –25 °C to +70 °C –25 to +100 °C

(+135 °C for max. 1 hour)

ENDRESS+HAUSER

CERABART

ENDRESS+HAUSER

CERABART

ENDRESS+HAUSER

CERABART

Cerabar T

4 Endress+Hauser

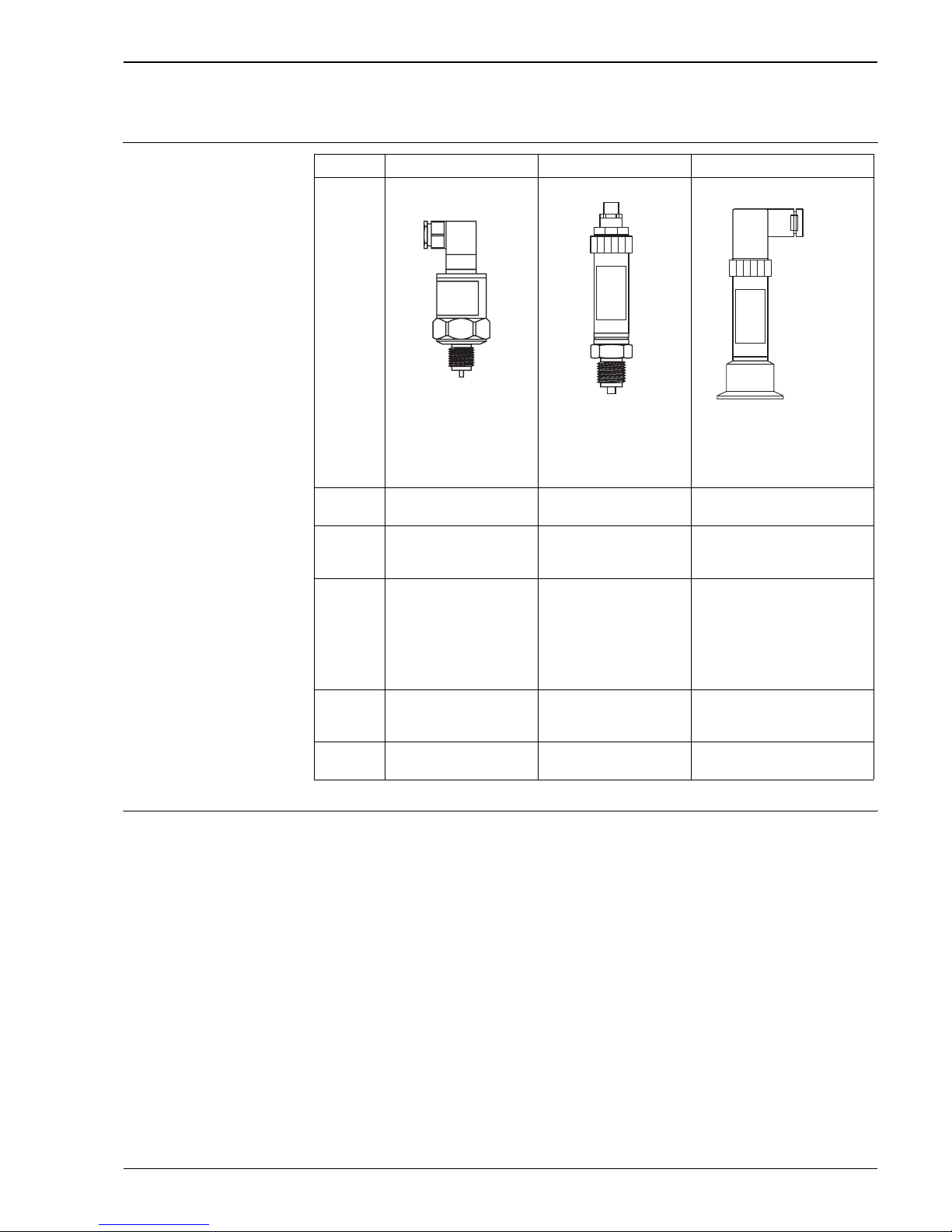

Measuring system

P01-PMx13xxx-14-xx-xx-xx-002

1 PMP131, PMP135: current output with transmitter power supply unit, e.g. RN 221N from Endress+Hauser

2 PMP131, PMP135: switch output with load, e.g. PLC, DCS, relay

3 PMC131: voltage output with transmitter power supply unit, e.g. RIA452 from Endress+Hauser

4 PMC131: current output with transmitter power supply unit, e.g. RN 221N from Endress+Hauser

Input

Measured variable Absolute pressure or gauge pressure

Measuring range up to 400 bar/6000 psi, see Page 18, "Ordering information" section

Output

Analog output (PMC131, PMP131, PMP135)

Output signal 4 to 20 mA

Load PMC131

R

Lmax

[Ω] ≤ (US – 1 V) / 0.02 A

PMP131 and PMP135 (current output)

R

Lmax

[Ω] ≤ (US – 12 V) / 0.02 A (R

Lmax

: Maximum load resistance, US: Supply voltage)

PMP131 (voltage output)

Load resistance R

Lmax

≥5 kΩ, current consumption ≤6 mA

Switch output (PMP131, PMP135)

Output signal PNP switch output (positive voltage signal), rate depends on power supply voltage

Output current • Switch status ON: I

a

≤ 500 mA

• Switch status OFF: Ia ≤ 1 mA

4...20 mA

0...10 V

4...20 mA

➩

➩

➩

➩

p

pp

p

–

–

–

+

+

+

+

1

2

3

4

R

Cerabar T

Endress+Hauser 5

Power max. 6 W

Switch frequency max. 10 Hz

Input PLC • Input resistance R

i

≤ 2 kΩ

• Input current Ii ≥ 10 mA

Inductive loads To prevent electrical interference, only operate an inductive load (relays, contactors, solenoid valves) when

directly connected to a protective circuit (free-wheeling diode or capacitor).

Power supply

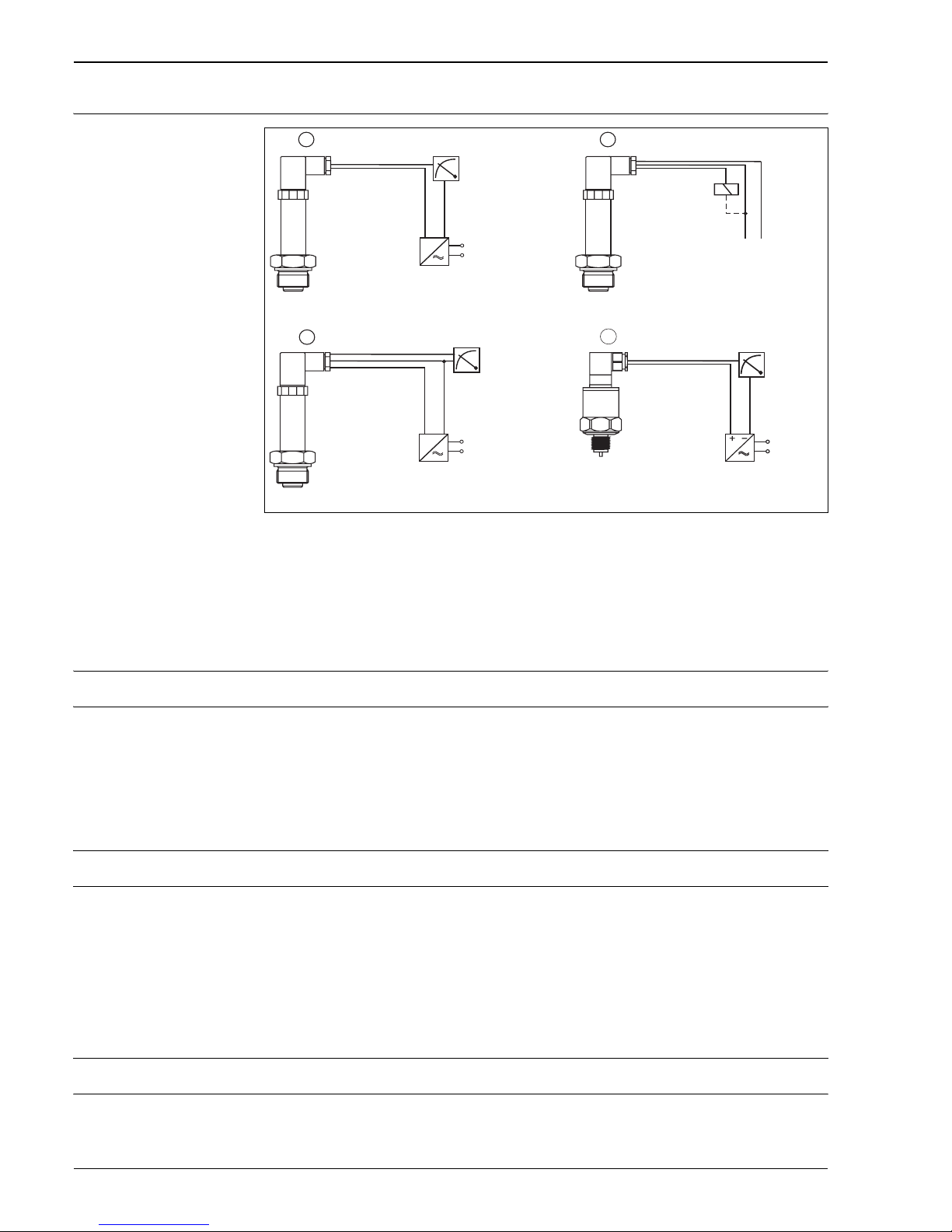

PMC131 Plug/cable connection

P01-PMC131xx-04-xx-xx-xx-001

Electrical connection: Analog/current output

P01-PMC131xx-04-xx-xx-xx-002

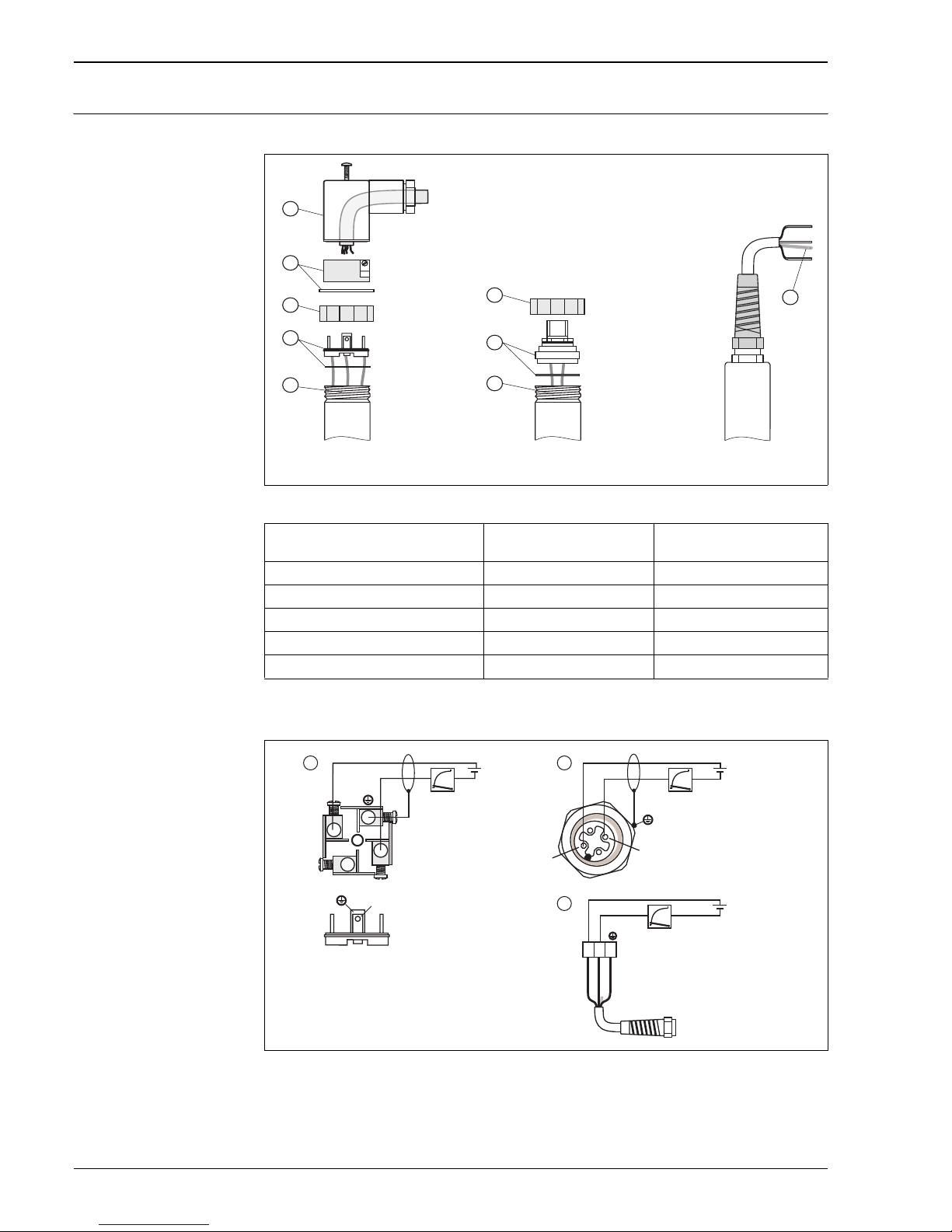

1 Plug M 16 x 1.5 (DIN 43650/A), ½ NPT

2 Plug M 12 x 1

3 Cable (rd = red, bk = black, gnye = green-yellow)

Plug M 16 x 1.5 (DIN 43650/A), ½ NPT Plug M 12x1 5 m/25 m cable

➀ Plug-in housing ➀ Reference pressure line

➁ Gasket

M16 / ½ NPT

M12x1

5 m/25 m

1

2

ENDRESS+HAUSER

CERABAR T

ENDRESS+HAUSER

CERABAR T

ENDRESS+HAUSER

CERABAR T

1

–

–

–

+

+

+

+

PE

–

rd

bk

gnye

2

1

1+

2–

12...30 V

12...30 V

12...30 V

4...20 mA

4...20 mA

4...20 mA

1

2

3

1+

2

3-

Cerabar T

6 Endress+Hauser

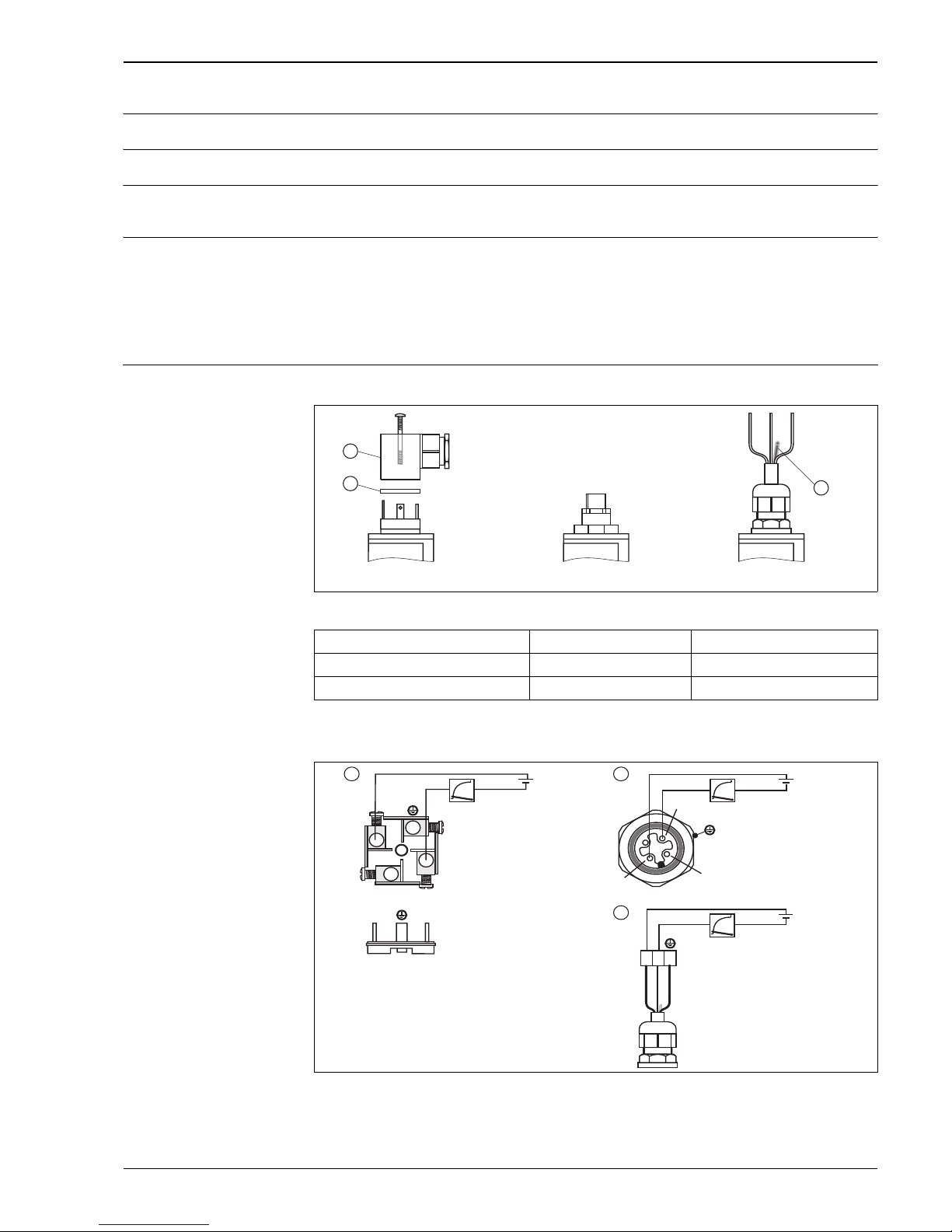

PMP131 and PMP135 Plug/cable connection

P01-PMP13xxx-04-xx-xx-xx-001

Electrical connection: Analog/current output

P01-PMP13xxx-04-xx-xx-xx-002

1 Plug M 16 x 1.5 (DIN 43650/A), ½ NPT and plug DIN 43650/C

2 Plug M 12 x 1

3 Cable (rd = red, wh = white, gn = green)

For electrical connection provided by customer use only shielded cable

Plug M 16 x 1.5 (DIN 43650/A), ½ NPT

Plug DIN 43650/C

Plug M 12x1 5 m cable, only analog output

➀ Plug-in housing ➀ Coupling nut ➀ Reference pressure line

➁ Plug-in jack with gasket ➁ Connector with gasket

➂ Coupling nut ➂ Operating potentiometer (inner)

➃ Plug with O-ring

➄ Operating potentiometer (inner)

DIN 43 650/A (M16 / ½ NPT)

DIN 43650/C

M12x1

5 m

1

1

1

2

2

3

3

4

5

–

–

–

+

+

+

+

PE

–

rd

wh

gn

3

3

2

1

1+

2–

12...30 V

12...30 V

12...30 V

4...20 mA

4...20 mA

4...20 mA

1

2

3

1+

3-

Cerabar T

Endress+Hauser 7

Electrical connection (switch output)

P01-PMP13xxx-04-xx-xx-xx-003

1 Plug M 16 x 1.5 (DIN 43650/A), ½ NPT

2 Plug M 12 x 1

R External load, e.g. relay, programmable logic controller, distributed control system

For electrical connection provided by customer use only shielded cable

PMP131 Electrical connection: Analog-/voltage output

P01-PMP131xx-04-xx-xx-xx-001

1 Plug M 16 x 1,5 (DIN 43650/A), ½ NPT and plug DIN 43 650/C

2 Plug M 12 x 1

3 Cable (rd = red, wh = white, gn = green)

For electrical connection provided by customer use only shielded cable

Supply voltage PMC131

11 to 30 V DC

PMP131 and PMP135 (current output, 2-wire version)

• For non-hazardous areas: 12 to 30 V DC

• Ex i: no-load voltage ≤ 26 V DC, short-circuit current ≤ 100 mA, power consumption ≤ 0.8 W

PMP131 (voltage output, 3-wire version)

• 15...30 V DC

PMP131 and PMP135 (switch output)

• 18 to 32 V DC, current consumption without load < 20 mA, with reverse polarity protection

Residual ripple • Analog output: max. 5 % of supply voltage

• Switch output: max. 10 % of supply voltage

Cable entry → See Page 18, "Ordering information" section.

––

++

2–1+

3+

R

R

18...32 V18...32 V

3

2

1

1

2

1+

2-

3

–

–

–

+

+

+

+

+

PE

–

rd

bk

wh

gn

3+

3-

2-

1+

1+

2+

15...30 V

15...30 V

15...30 V

0...10 V

0...10 V

0...10 V

1

2

3

Cerabar T

8 Endress+Hauser

Performance characteristics

Reference operating

conditions

as per DIN IEC 60770, TU = 25 °C

Long-term stability ≤ 0.15 % of URL per year

Maximum measured error

of analog output

(under reference operating

conditions)

The measured error comprises the non-linearity including hysteresis and non-reproducibility in accordance

with the limit point method as per IEC 60770.

PMC131

• ≤ 0.5 % of (URL - LRL) x TD

1)

PMP131 and PMP135

• ≤ 0.5 % of URL

Switch point PMP131 and PMP135

• Deviation: ≤ 1 % of URL

• Non-reproducibility: ≤ 0.5 % of URL

Rise time (T90) PMC131

20 ms

Settling time PMP131 and PMP135

2 to 5 ms

1) extended specifications apply to customer-specific measuring ranges

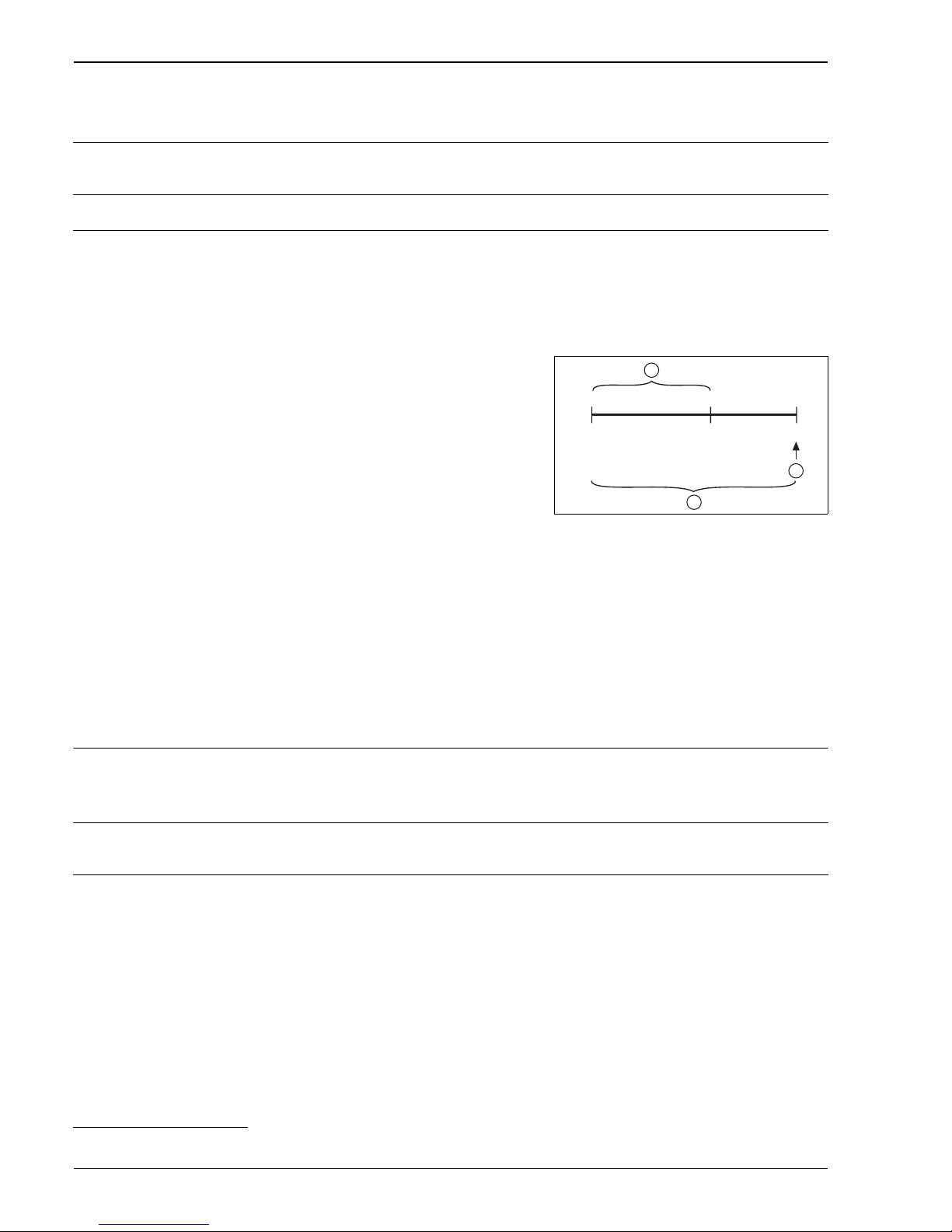

Example: PMC131 version "A1R"

• Nominal value = 10 bar

• Upper range value (URV) = 6 bar

• Lower range value (LRV) = 0 bar

Turn down (is set at factory):

• Nominal value / (URV – LRV)⏐= 10 bar/6 bar = 10:6

P01-PMx13xxx-05-xx-xx-xx-001

Example: PMC131 version "A1R"

set span: 0 to 6 bar; nominal value = 10 bar

1 Span set and calibrated at the factory (measuring

range)

2 Nominal value i Upper Range Limit (URL)

3 Sensor measuring range

LRL Lower Range Limit

URL Upper Range Limit

LRV Lower Range Value

URV Upper Range Value

0 bar +10 bar

URLURV

LRL = LRV

+6 bar

2

1

3

Loading...

Loading...