Endress+Hauser Cerabar T PMP 13 Technical Information

Technical Information

TI 372P/00/en

Pressure Transducer

cerabar T PMP 135

Pressure transducer for hygienic processes

For absolute and gauge pressures up to 40 bar

Flush-mounted process connections with

metal diaphragm

Application

The Cerabar T PMP 135 is a pressure

transducer for hygienic applications, e.g.

in the food processing and pharmaceutical industries. It is designed for measuring absolute and gauge pressures in

gases, vapours, liquids and dust.

• Finely graduated measuring ranges up

to 40 bar or 500 psi.

• Electronic versions:

– Analogue output 4...20 mA

– Switch output

– Approved for use in hazardous areas

Your benefits

This compact pressure transducer

impresses with its well-engineered

construction:

• Flush-mounted process connections

with metal diaphragm.

• Hygienic design as per 3A guidelines.

• Up to 4 times overload resistance and

extremely longterm stable.

• Optional with 3.1.B inspection certifi-

cate.

• Materials in contact with the process

only made of 316L stainless steel with a

surface quality R

≤ 0.8 µm.

a

Function and system design

Measuring principle PMP 135 with analogue output

The process pressure acting upon the metallic separating diaphragm of the sensor is transmitted

to a resistance bridge via a fluid. The change in the output voltage of the bridge is proportional to

the pressure and can be measured directly.

PMP 135 with switch output

The process pressure acting upon the metallic separating diaphragm of the sensor is transmitted

to a resistance bridge via a fluid. A differential amplifier creates a standard signal from the pressure-proportional change in output voltage of the bridge. A comparator with an adjustable hysteresis compares this signal with the pre-set switch point and then activates the transistor output

and the LED display.

Measuring system Cerabar T PMP 135 pressure transducer with

• 4…20 mA analogue output.

Power supply, e.g. with RN 221N transmitter power supply unit from Endress+Hauser

• Switch output.

Preferably in connection with programmable logic controllers (PLC). Positive signal at electronics switch output (PNP).

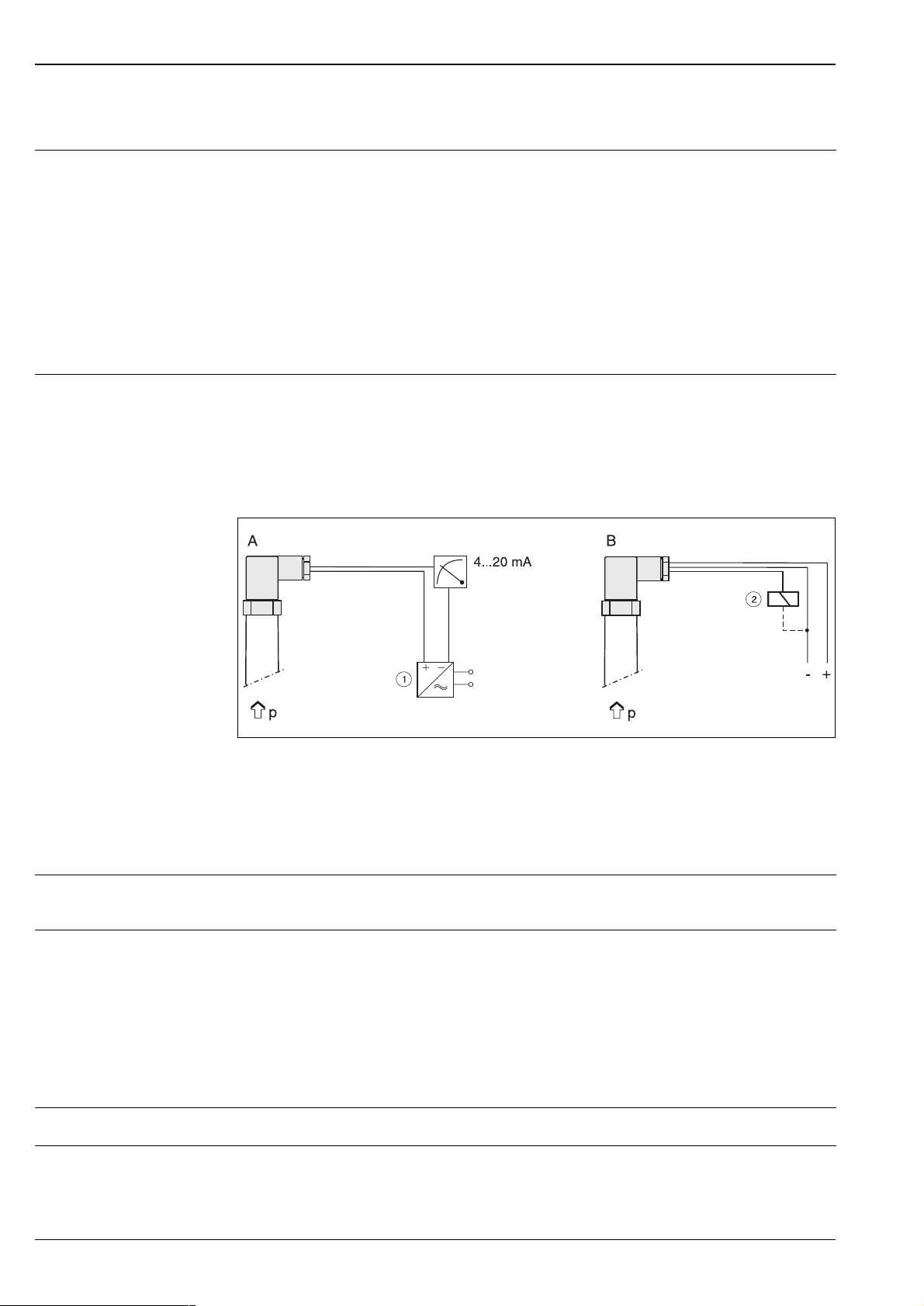

Cerabar T PMP 135

P01-PMx13x xx-14-xx-xx-xx- 001

A = analogue output with transmitter power supply unit ➀

B = switch output with load ➁, e.g. PLC, DCS, relay

Input

Measured variable The measured variable for the Cerabar T PMP 135 pressure transducer can be selected as either

gauge pressure or absolute pressure.

Measuring range Measuring ranges up to 40 bar or 500 psi, see "Ordering information" section.

Output

Analogue output

Output signal 4...20 mA

Load R

≤ (US -12 V) / 0.02 A (US = power supply)

B

2 Endress+Hauser

Cerabar T PMP 135

Switch output

Output signal Positive voltage signal (rate depends on power supply voltage) at electronics switch output

(PNP).

Output current Switch status ON: I

Switch status OFF: I

≤ 500 mA

a

≤ 1 mA

a

Power max. 6 W

Switch frequency max. 10 Hz

Input PLC Input resistance R

Input current I

≤ 2 kΩ

i

≥ 10 mA

i

Inductive loads To prevent electrical interference, only operate an inductive load (relays, contactors, solenoid val-

ves) when directly connected to a protective circuit (free-wheeling diode or capacitor).

Power supply

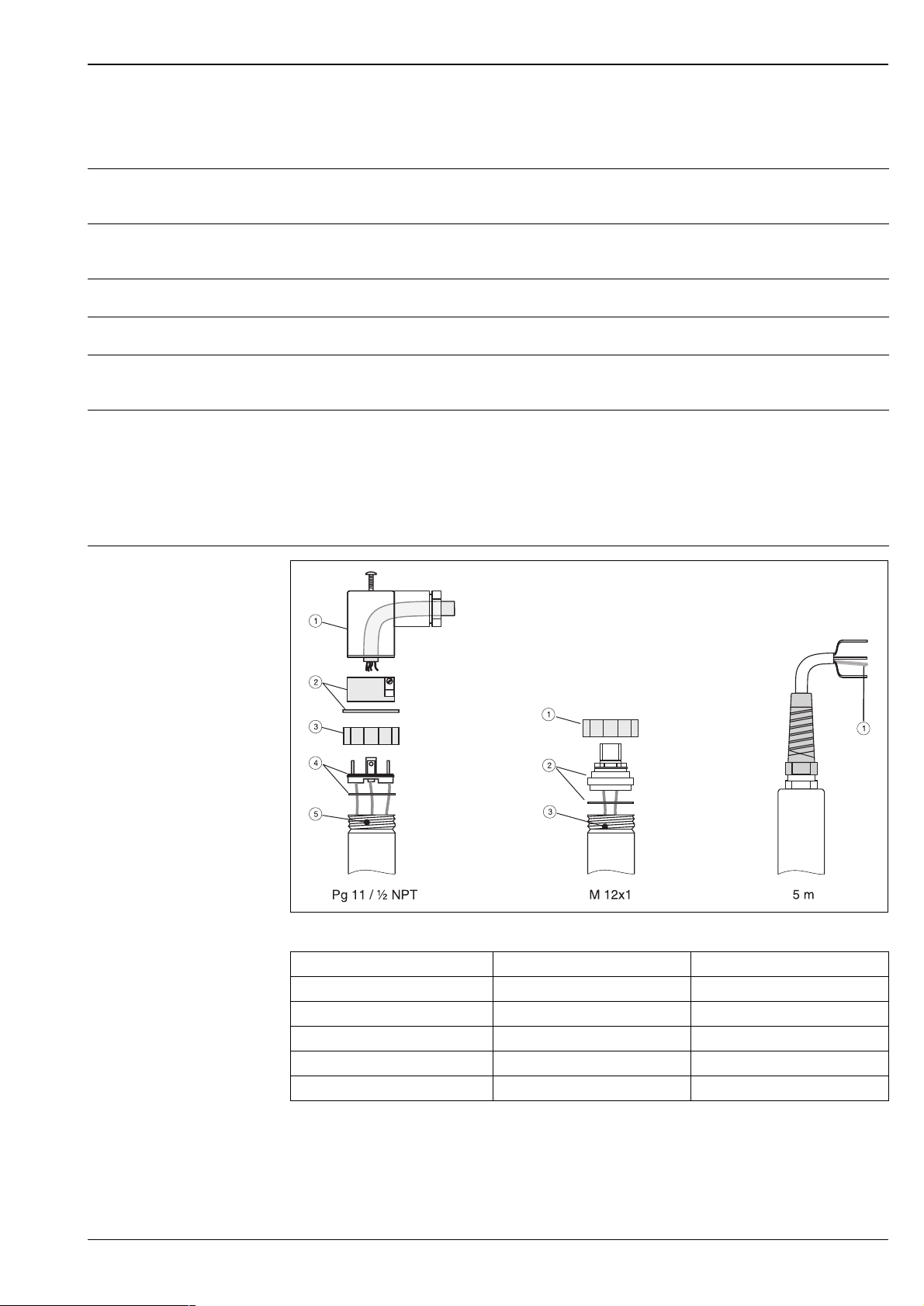

Cable entry

P01-PMx13xxx-04-xx-xx-xx-001

Plug with Pg 11 or ½ NPT gland M 12x1 plug 5 m cable, only analogue output

➀ Plug-in housing ➀ Coupling nut ➀ Reference pressure line

➁ Plug-in jack with gasket ➁ Connector with gasket

➂ Coupling nut ➂ Operating potentiometer (inner)

➃ Plug with O-ring

➄ Operating potentiometer (inner)

Endress+Hauser 3

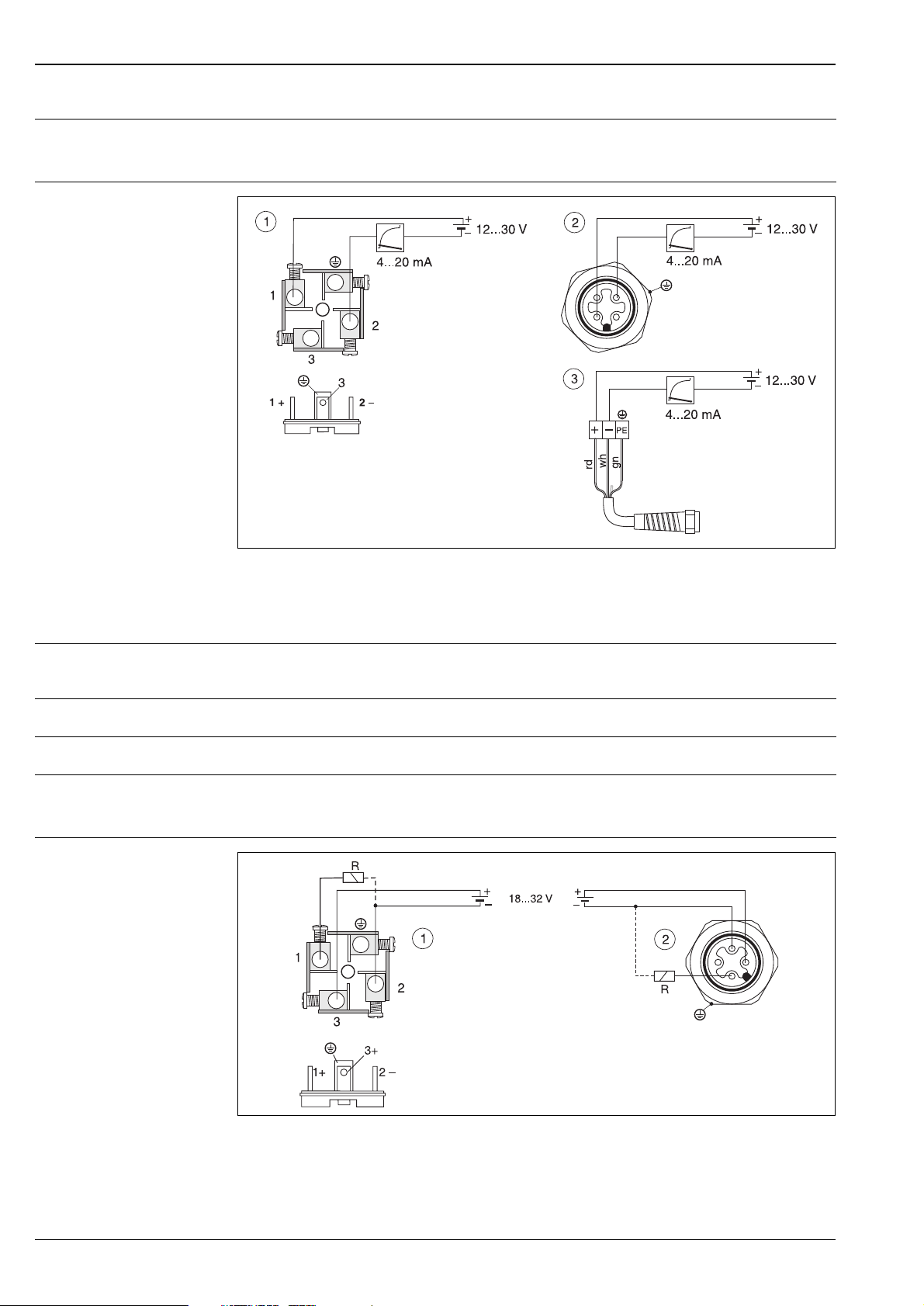

Electrical connection

Cerabar T PMP 135

Analogue output

➀ Plug with Pg 11 or ½ NPT gland

➁ M 12x1 plug

➂ Cable (rd = red, wh = white, gn = green)

Supply voltage 12...30 V DC

Ex i: no-load voltage ≤ 26 V DC, short-circuit current ≤ 100 mA, power consumption ≤ 0.8 W

Residual ripple max. 5 %

Cable entry Plug with Pg 11 or NPT ½ gland, M 12x1 plug or cable

Switch output

Electrical connection

P01-PMx13x xx-04-xx-xx-xx- 002

P01-PMx13x xx-04-xx-xx-xx- 003

➀ Plug with Pg 11 or ½ NPT gland

➁ M 12x1 plug

R: external load, e.g. relay, programmable logic controller, distributed control system

4 Endress+Hauser

Loading...

Loading...