Page 1

Operating Instructions – Description of device functions

Cerabar S/Deltabar S

Pressure and Differential pressure transmitters

9

BA303P/00/en/04.05

52027503

valid from

Software version 02.00

Hardware version 01.00

Page 2

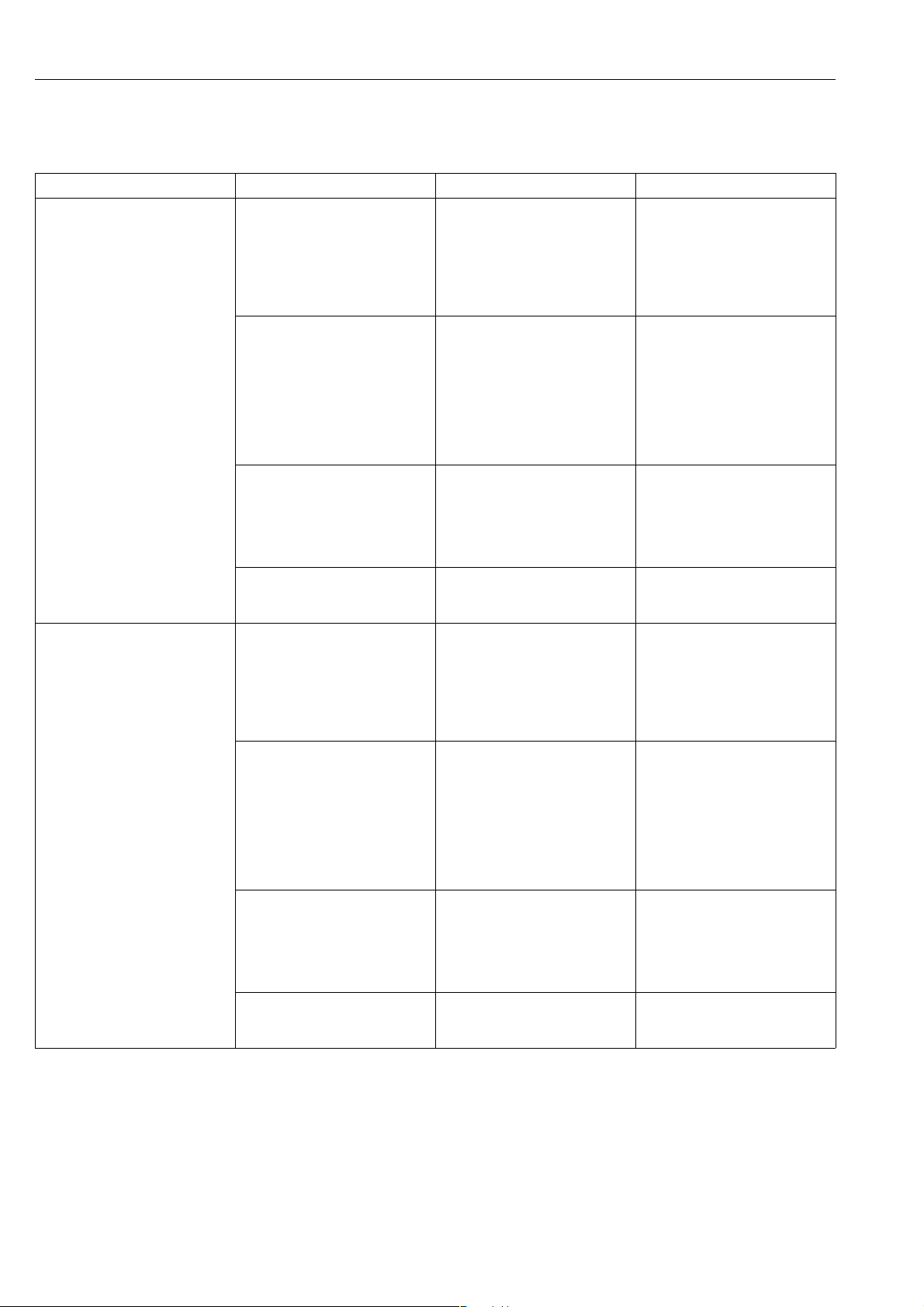

Overview documentation Cerabar S/Deltabar S

Overview documentation

Device Documentation Content Note

Cerabar S FOUNDATION Fieldbus Technical Information TI383P Technical data – The documentation is located on the

ToF Tool CD. The CD is enclosed

with every device ordered with the

"HistoROM/M-DAT" option.

– The documentation is also available

via the Internet. → See:

www.endress.com

Operating Instructions BA302P – Identification

– Installation

– Wiring

– Operation

– Commissioning, Description of

Quick Setup menus

– Maintenance

– Trouble-shooting and spare parts

– Appendix: Illustration of menu

Operating Instructions BA303P – Examples of configuration for

pressure, level and flow

measurement

– Description of parameters

– Trouble-shooting

– Appendix: Illustration of menu

Brief Operating Instructions KA252P – Wiring

– Description of operating elements

– Operation HistoROM

Deltabar S FOUNDATION Fieldbus Technical Information TI382P Technical data – The documentation is located on the

Operating Instructions BA301P – Identification

– Installation

– Wiring

– Operation

– Commissioning, Description of

Quick Setup menus

– Maintenance

– Trouble-shooting and spare parts

– Appendix: Illustration of menu

Operating Instructions BA303P – Examples of configuration for

pressure, level and flow

measurement

– Description of parameters

– ’Trouble-shooting

– Appendix: Illustration of menu

Brief Operating Instructions KA252P – Wiring

– Description of operating elements

– Operation HistoROM

®

/M-DAT

®

/M-DAT

– The documentation is supplied with

the device.

– The documentation is also available

via the Internet. → See:

www.endress.com

– The documentation is also available

via the Internet. → See:

www.endress.com

– The documentation is supplied with

the device. See cover of the terminal

compartment.

ToF Tool CD. The CD is enclosed

with every device ordered with the

"HistoROM/M-DAT" option.

– The documentation is also available

via the Internet. → See:

www.endress.com

– The documentation is supplied with

the device.

– The documentation is also available

via the Internet. → See:

www.endress.com

– The documentation is also available

via the Internet. → See:

www.endress.com

– The documentation is supplied with

the device. See cover of the terminal

compartment.

2 Endress+Hauser

Page 3

Cerabar S/Deltabar S Table of contents

Table of contents

1 Notes on use . . . . . . . . . . . . . . . . . . . . 4

1.1 Finding function group using graphic representation

(ToF Tool) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Finding parameter description using parameter names

(index) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Graphic representation of function

groups (ToF Tool). . . . . . . . . . . . . . . . . 5

3 Pressure measurement

(FF configuration program). . . . . . . . . . 6

4 Level measurement

(FF configuration program). . . . . . . . . . 7

4. 1 Overview of level measurement . . . . . . . . . . . . . . 7

4. 2 "Linear" level type . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. 3 "Pressure linearized" level type . . . . . . . . . . . . . . 10

4. 4 "Height linearized" level type . . . . . . . . . . . . . . . 14

5 Flow measurement

(FF configuration program). . . . . . . . . 17

10 Description of parameters

(ToF Tool) . . . . . . . . . . . . . . . . . . . . . . 92

11 Trouble-shooting . . . . . . . . . . . . . . . . 151

11.1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

11.2 Response of outputs to errors . . . . . . . . . . . . . . . . 159

11.3 Confirming messages . . . . . . . . . . . . . . . . . . . . . . 160

12 Appendix . . . . . . . . . . . . . . . . . . . . . . 161

12.1 Operating menu (ToF Tool) . . . . . . . . . . . . . . . . . 161

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

5. 1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. 2 Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Description of parameters

(FF configuration program). . . . . . . . . 21

6.1 Deltabar S and Cerabar S block model . . . . . . . . . . 21

6.2 Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Transducer Blocks . . . . . . . . . . . . . . . . . . . . . . . . . 31

6. 4 Analog Input Block (function block) . . . . . . . . . . . . 65

7 Pressure measurement (ToF Tool) . . . 74

8 Level measurement (ToF Tool) . . . . . 75

8.1 Overview of level measurement . . . . . . . . . . . . . . 75

8.2 "Linear" level type . . . . . . . . . . . . . . . . . . . . . . . . 76

8.3 "Pressure linearized" level type . . . . . . . . . . . . . . 80

8.4 "Height linearized" level type . . . . . . . . . . . . . . . . 84

9 Flow measurement (ToF Tool) . . . . . . 89

9.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.2 Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Endress+Hauser 3

Page 4

Notes on use Cerabar S/Deltabar S

1 Notes on use

Sections 3 to 6 describe operation by means of an FF configuration program.

In FOUNDATION Fieldbus, all the device parameters are categorised depending on their functional

properties and tasks and assigned to the Resource Block, the Transducer Blocks and the function

blocks. The parameters of the Resource Block, the Transducer Blocks and the Analog Input Block

are described in Section 6. For a parameter description of other function blocks, such as the PID or

Discrete Output Block, see Operating Instructions BA013S "FOUNDATION Fieldbus Overview" or

the FOUNDATION Fieldbus Specification.

Sections 3 to 5 describe typical configuration examples.

Sections 7 to 10 describe operation by means of the Endress+Hauser ToF Tool operating program.

Section 10 describes all the parameters in the order as they appear in the menu. Sections 7 to 9

describe typical configuration examples.

Sections 1.1 and 1.2 tell you how you can find a certain parameter description more easily.

1.1 Finding function group using graphic representation (ToF Tool)

All the function groups are shown in table form in Section 2. The page reference/link takes you to

the function group in question. In Section 10, all the parameters of a function group are compiled

in a table.

1.2 Finding parameter description using parameter names (index)

The index lists all the parameters in alphabetical order. The page reference/link takes you to the

parameter in question.

4 Endress+Hauser

Page 5

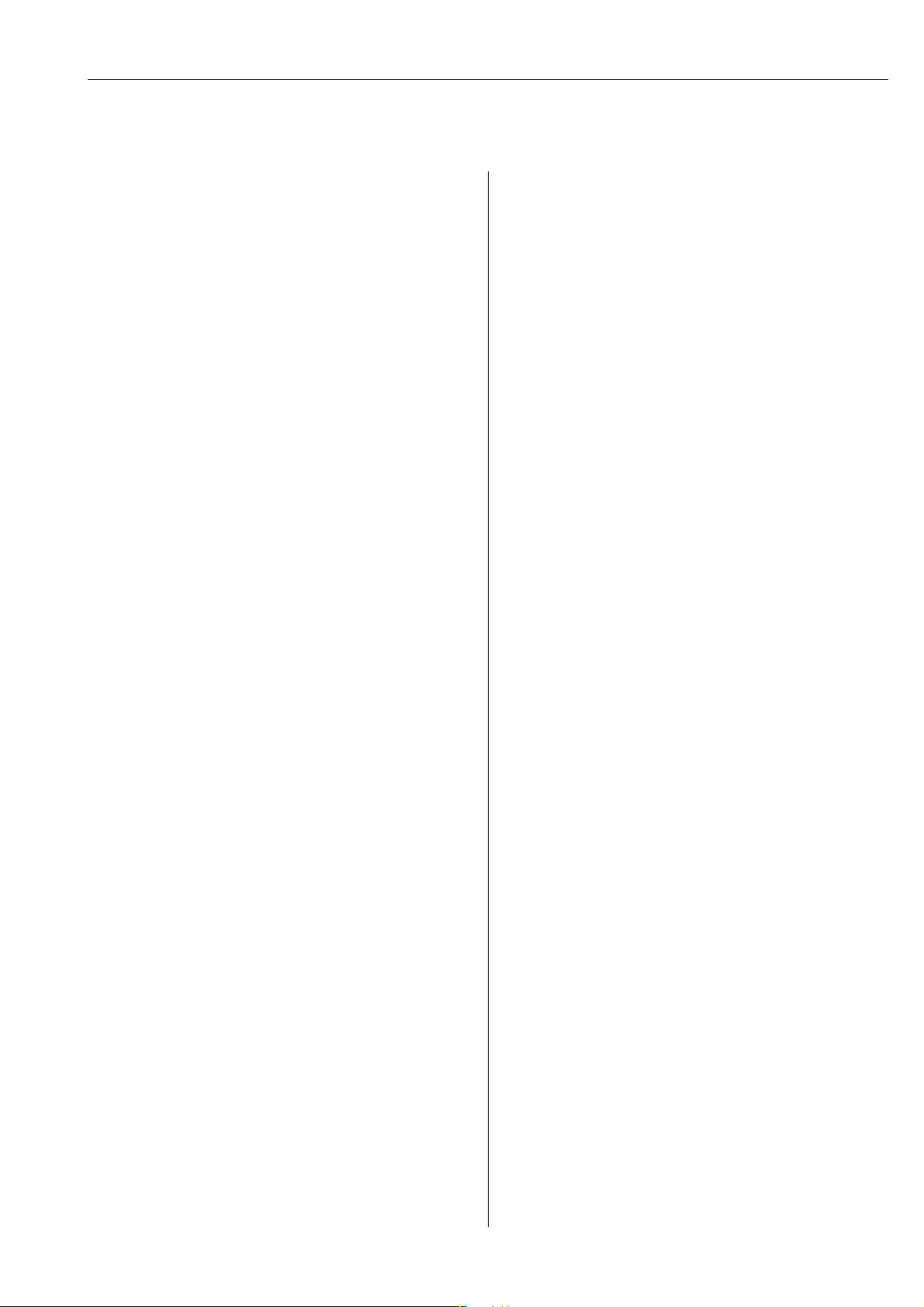

Cerabar S/Deltabar S Graphic representation of function groups (ToF Tool)

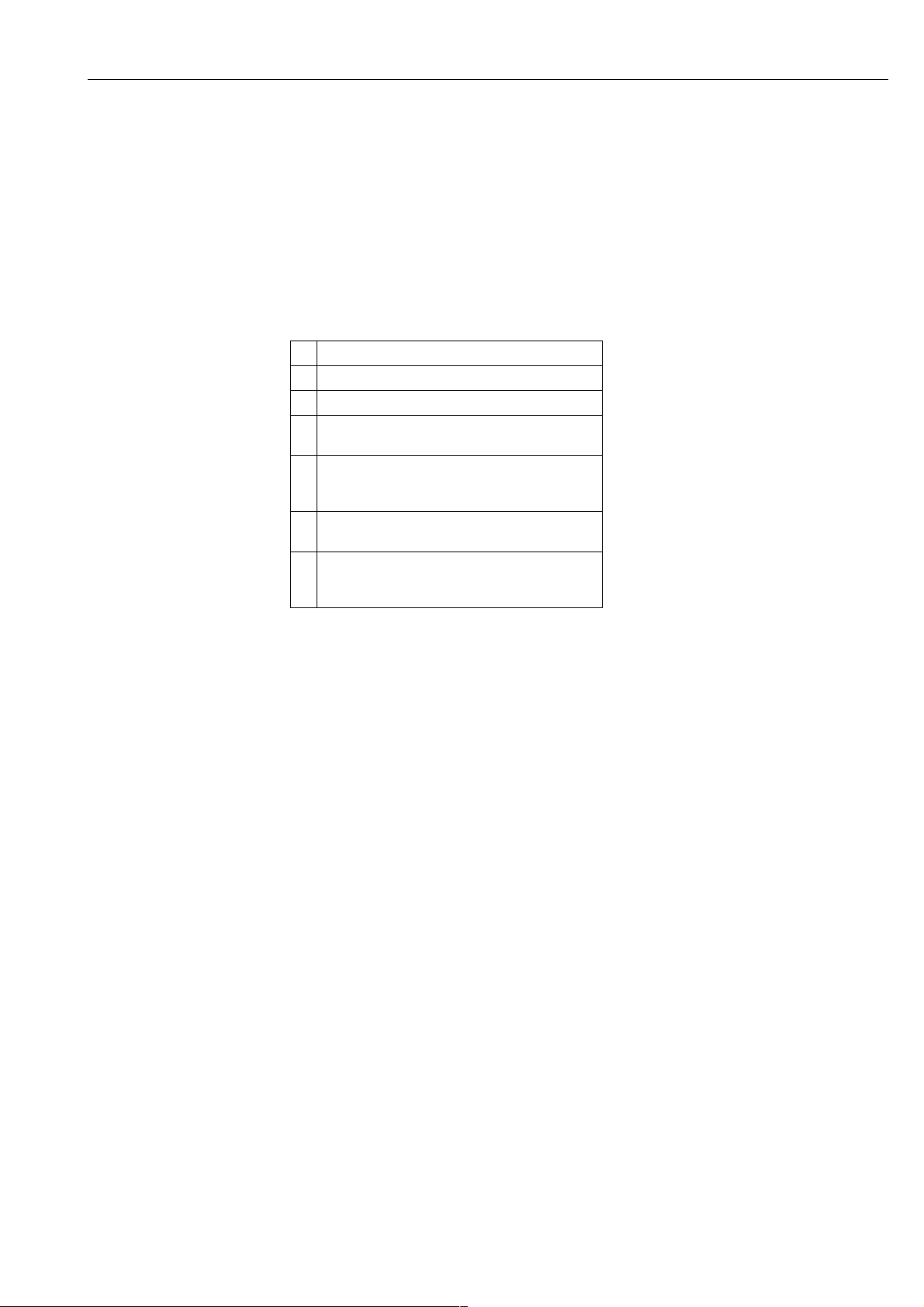

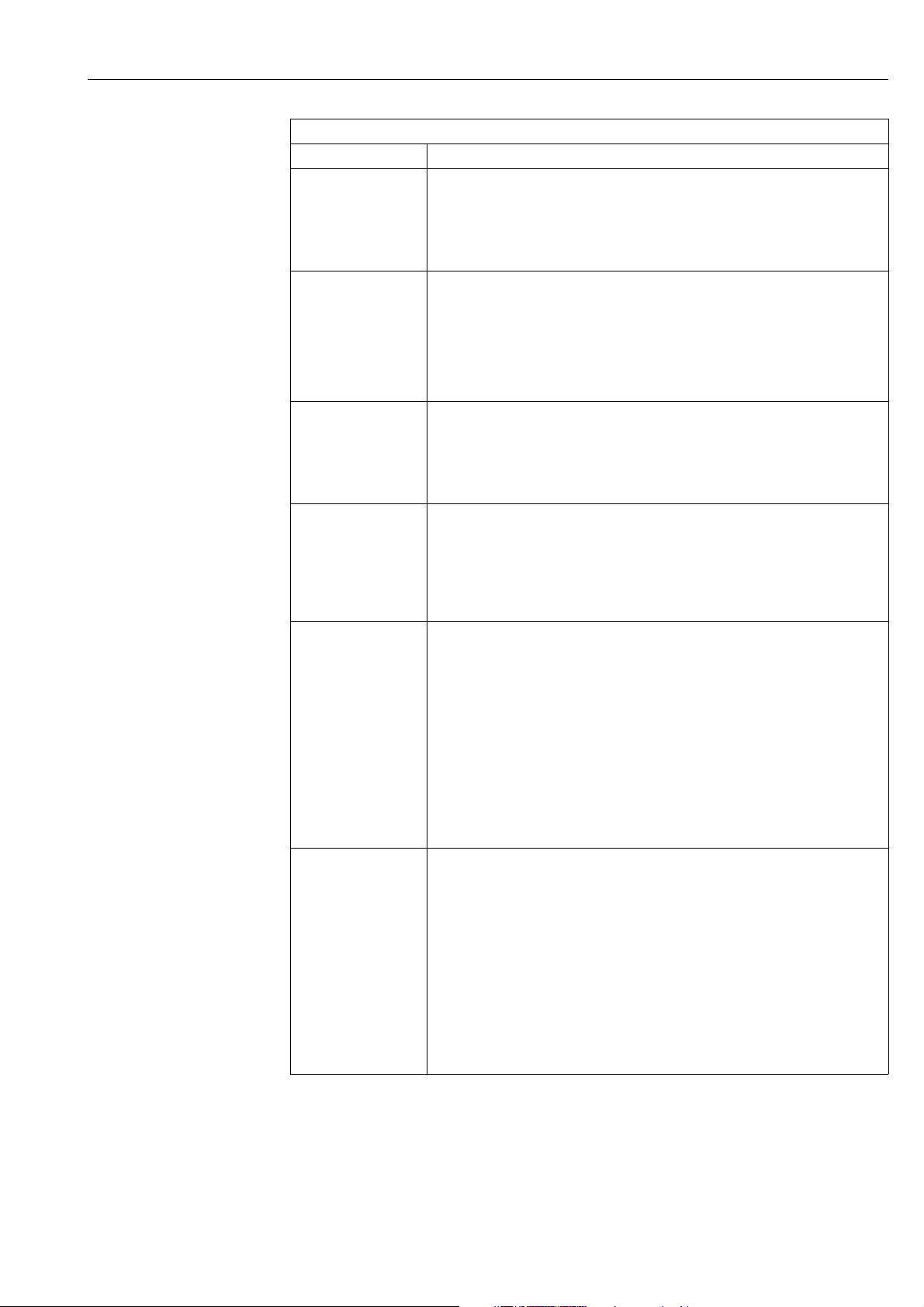

2 Graphic representation of function groups

(ToF Tool)

!

Note!

The "Flow" measuring mode is only available for the Deltabar S differential pressure transmitter. The

groups marked with "*" are only displayed for Deltabar S.

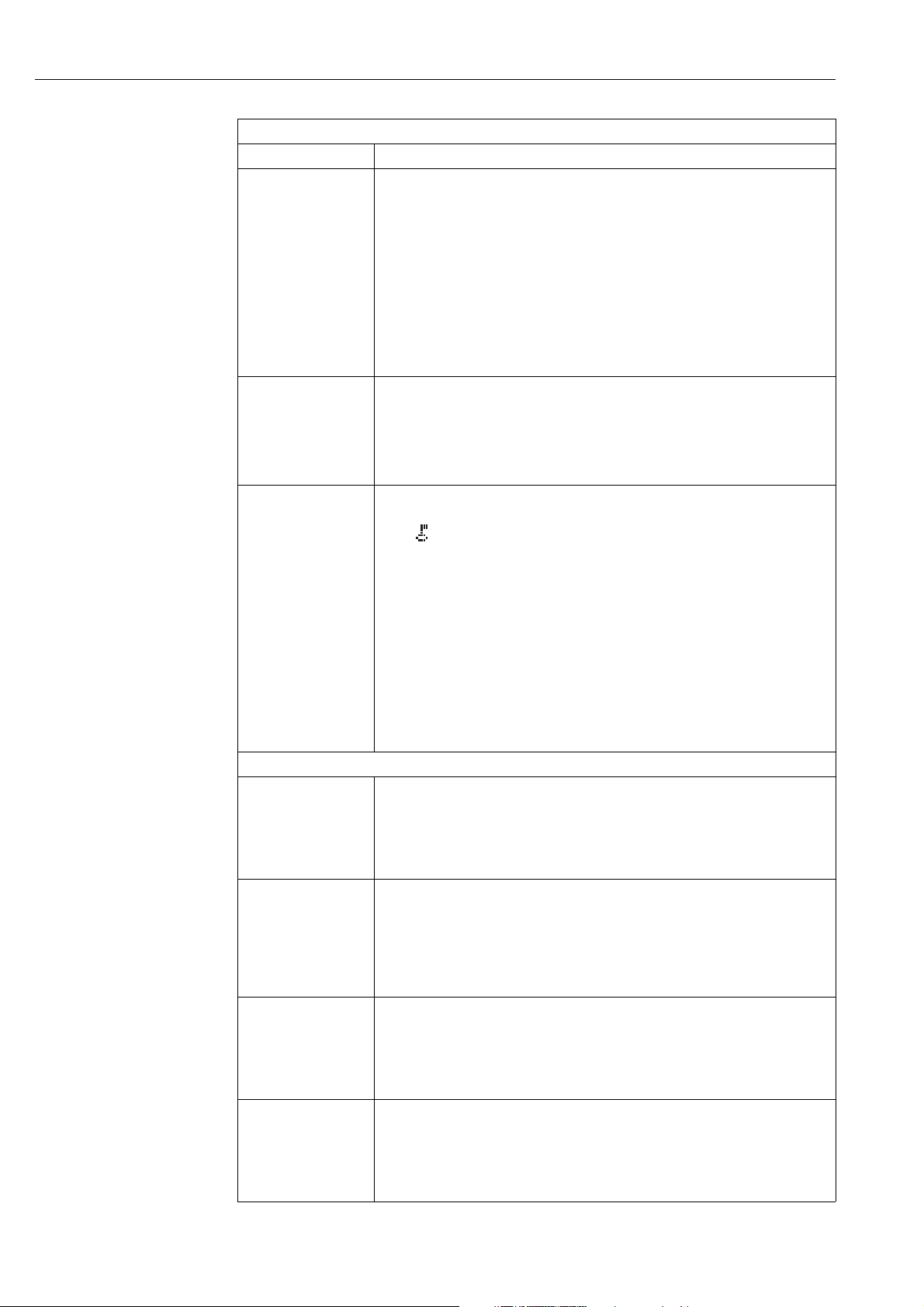

1st selection level 2nd selection level (groups) Function groups Description,

see Page

QUICK SETUP Pressure → → 92

QUICK SETUP Level → → 94

QUICK SETUP Flow * → → 96

OPERATING MENU → SETTINGS → POSITION ADJUSTMENT → 98

→ BASIC SETUP Pressure → 99

→ BASIC SETUP Level → 101

→ BASIC SETUP Flow * → 125

→ EXTENDED SETUP Pressure → 129

→ EXTENDED SETUP Level → 129

→ EEXTENDED SETUP Flow * → 130

→ LINEARISATION → 132

→ TOTALIZER SETUP * → 134

→ DISPLAY → 136

→ TRANSMITTER INFO → INFO → 138

→ TRANSMITTER DATA → 138

→ PROCESS CONNECTION → 139

→ SENSOR DATA → 140

→ PROCESSINFO → PROCESS VALUES pressure → 142

→ PROCESS VALUES level → 143

→ PROCESS VALUES flow * → 144

→ PEAK HOLD INDICATOR → 144

→ OPERATING → 146

→ DIAGNOSTICS → SIMULATION

→ MESSAGES → 149

→ USER LIMITS → 150

→ 148

Endress+Hauser 5

Page 6

Pressure measurement (FF configuration program) Cerabar S/Deltabar S

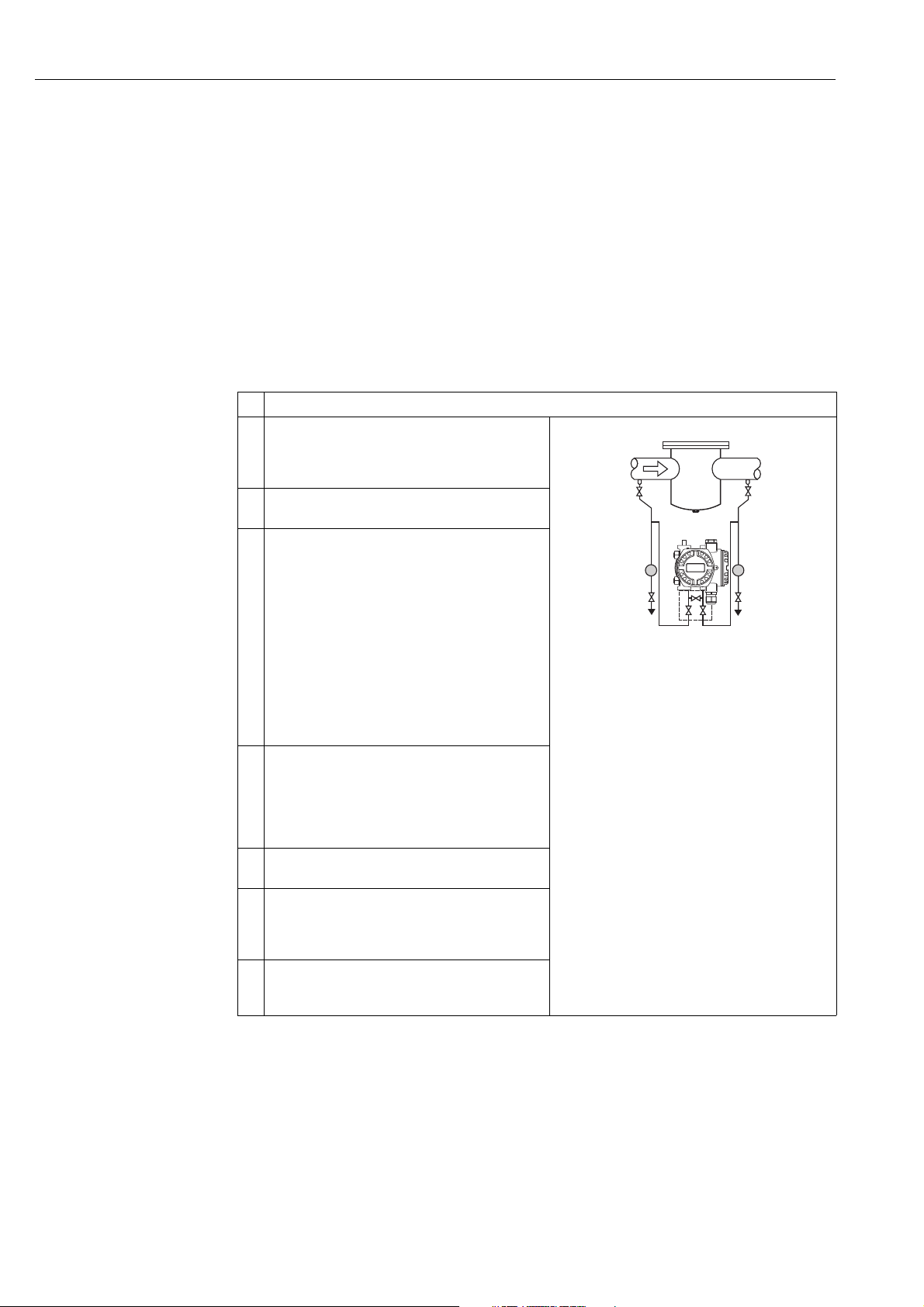

3 Pressure measurement

(FF configuration program)

!

Note!

• The device is configured for the Pressure measuring mode as standard. The measuring range and

the unit in which the measured value is transmitted, as well as the digital output value of the

Analog Input Block OUT, correspond to the data on the nameplate.

• See also Operating Instructions BA301P Deltabar S, Section 6.7 "Differential pressure

measurement" or Operating Instructions BA302P Cerabar S, Section 6.5 "Pressure

measurement".

• For a description of the parameters mentioned, see

– Page 33, Pressure Transducer Block

– Page 65, Analog Input Block.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and the

device filled with fluid. See Operating Instructions

BA301P, Section 6.7.

2 Open the Pressure Transducer Block and set the block

mode to OOS.

3 Carry out position adjustment if necessary.

You have the following ways of carrying out position

adjustment:

• By means of the "Pos. zero adjust" method, see

Operating Instructions BA301P or BA302P,

Section 6.4.

• By means of the parameters

– PRESSURE_1_ACCEPT_ZERO_INSTALL_

OFFSET/POS. ZERO ADJUST (→ Page 38) or

– PRESSURE_1_ACCEPT_INSTALL_OFFSET/

POS. INPUT VALUE (→ Page 38) or

– PRESSURE_1_INSTALL_OFFSET/CALIB. OFFSET

(→ Page 38).

4 Select the measuring mode if necessary:

• Select the "No linearization" option by means of the

LINEARIZATION parameter.

• Select the "Differential pressure", Gauge pressure" or

"Absolute pressure" option, depending on the sensor,

by means of the PRIMARY_VALUE_TYPE parameter.

5 Set the Pressure Transducer Block to the "Auto" block

mode.

6 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

7Result:

The measuring device is ready for pressure

measurement.

+

–

P01-PMD75xxx-19-xx-xx-xx-000

!

Note!

• You can select another pressure unit by means of the CAL_UNIT parameter (→ Page 34). This

parameter also allows you to specify a customer-specific unit.

6 Endress+Hauser

Page 7

Cerabar S/Deltabar S Level measurement (FF configuration program)

4 Level measurement

(FF configuration program)

4. 1 Overview of level measurement

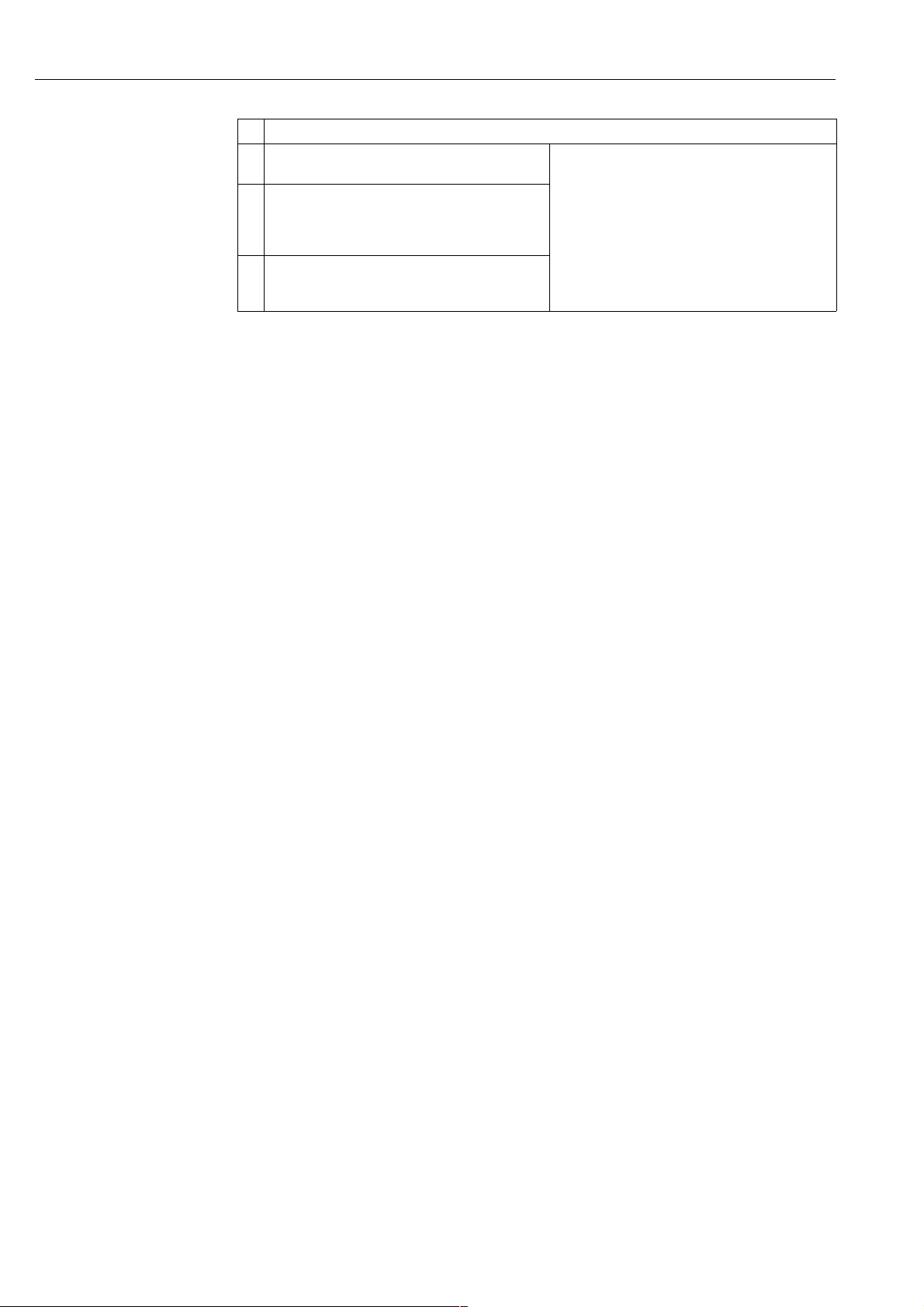

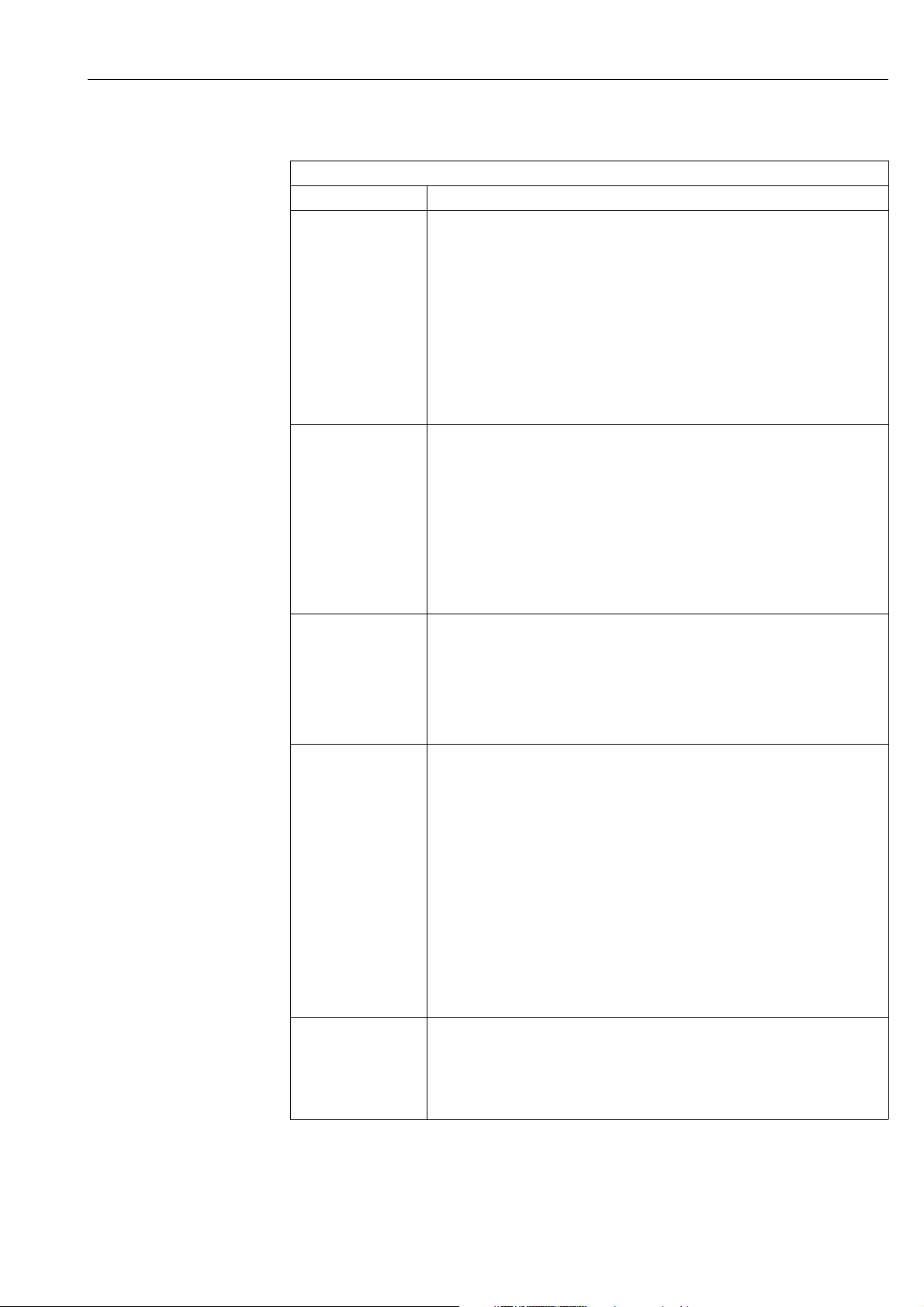

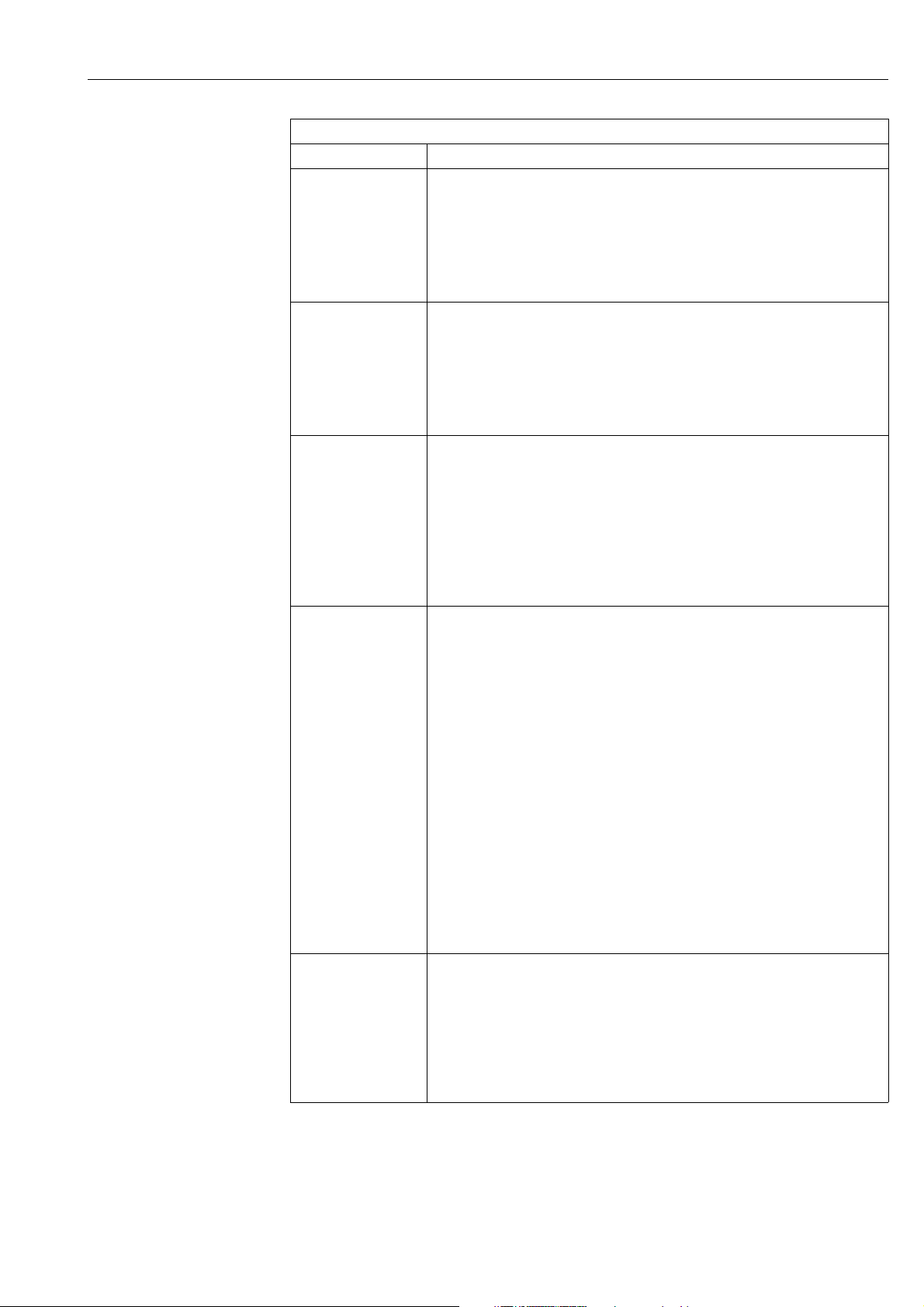

Measuring task Measured variable

selection

The measured variable is in direct

proportion to the measured

pressure.

The measured variable is not in

direct proportion to the measured

pressure as, for example, with

containers with a conical outlet.

A linearisation table must be

entered for the calibration.

– Two measured variables are

required or

– The container shape is given

by value pairs, such as height

and volume.

The 1st measured variable %height or height must be in direct

proportion to the measured

pressure. The 2nd measured

variable volume, mass or % must

not be in direct proportion to the

measured pressure. A

linearisation table must be

entered for the 2nd measured

variable. The 2nd measured

variable is assigned to the 1st

measured variable by means of

this table.

– % (level)

– Level

–Volume

–Mass

– Pressure and %

– Pressure and volume

– Pressure and mass

– Height and volume

– Height and mass

– Height and %

–%-height and volume

–%-height and mass

–%-height and %

LEVEL_TYPE/

LEVEL MODE

Linear Calibration without reference

Pressure linearized – Calibration with reference

Height linearized – Calibration without reference

Description Measured value display

pressure – dry calibration, see

Page 8, Section 4.2.1

pressure: semiautomatic entry

of linearisation table, see

Page 10, Section 4.3.1

– Calibration without reference

pressure: manual entry of

linearisation table, see Page 12,

Section 4.3.2

pressure: dry calibration and

manual entry of linearisation

table, see Page 14, Section

4.4.1

The measured value display and

the PRIMARY_VALUE and

MEASURED_LEVEL_AFTER_

SIMULATION/LEVEL BEFORE

LIN. parameters show the

measured value.

The measured value display and

the PRIMARY_VALUE parameter

display the measured value.

The measured value display and

the PRIMARY_VALUE parameter

display the 2nd measured value

(volume, mass or %).

The MEASURED_LEVEL_

AFTER_SIMULATION/LEVEL

BEFORE LIN parameter displays

the 1st measured value (% height

or height).

Endress+Hauser 7

Page 8

Level measurement (FF configuration program) Cerabar S/Deltabar S

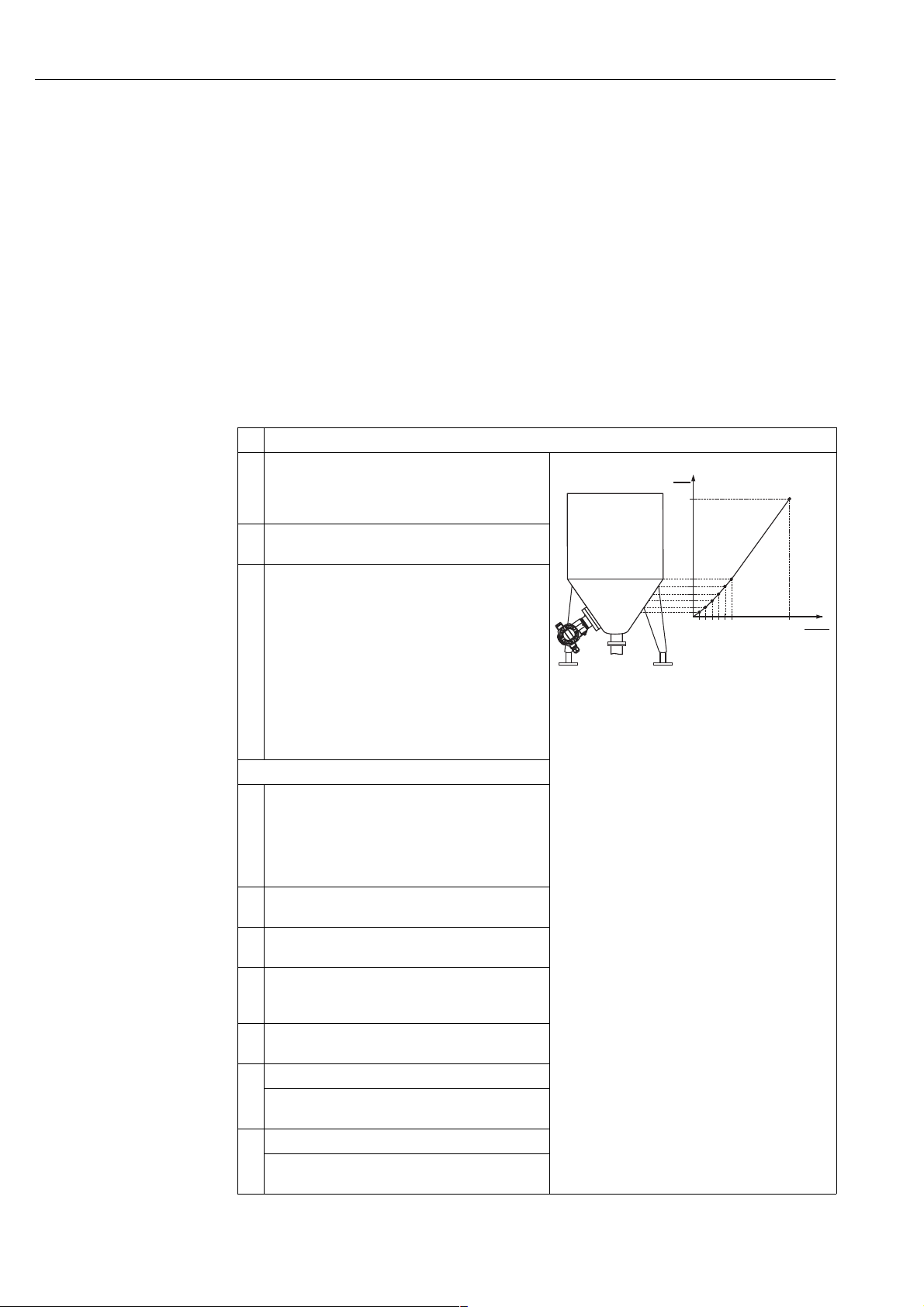

4. 2 "Linear" level type

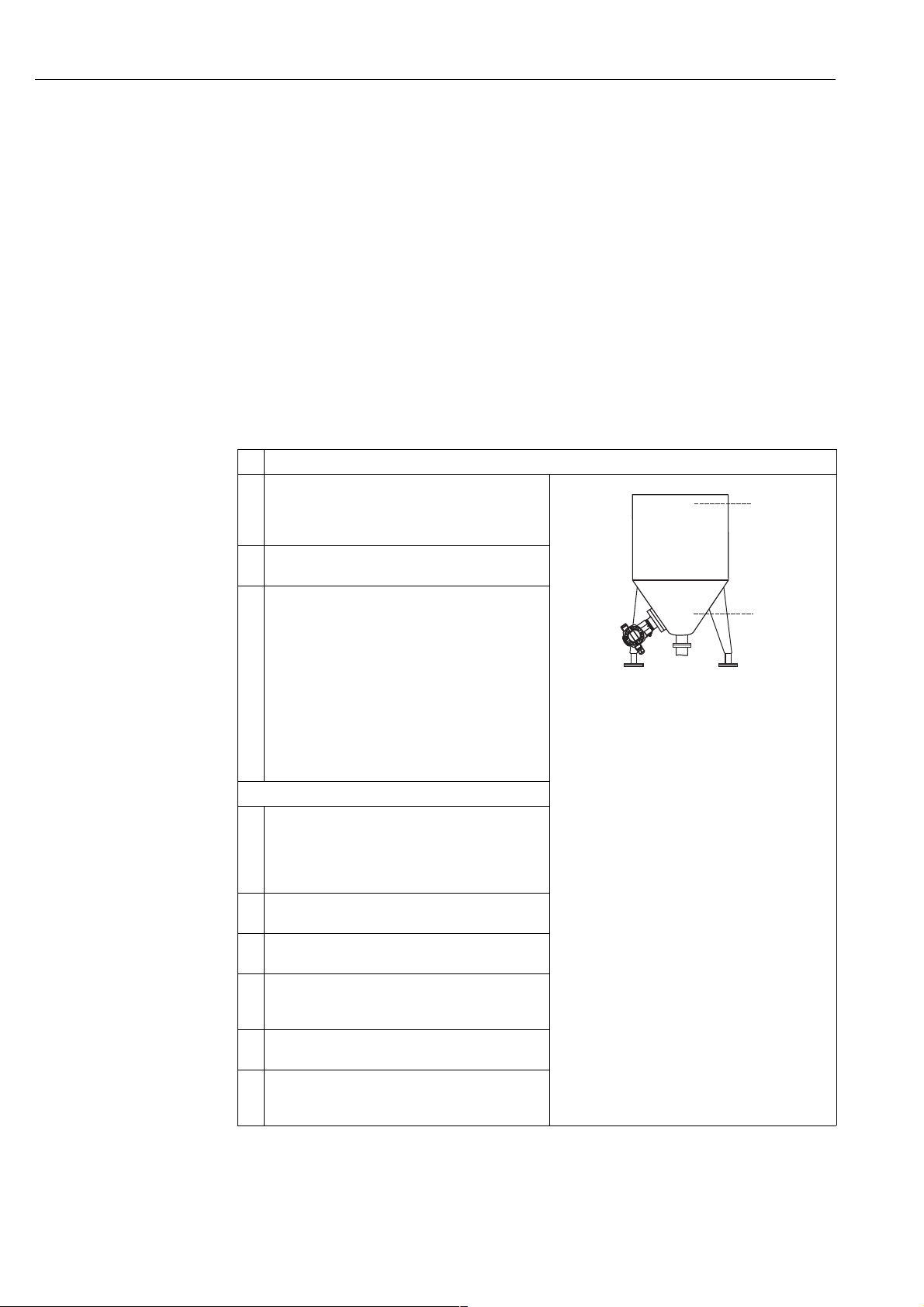

4.2.1 Calibration without reference pressure – dry calibration

!

Example:

In this example, the volume in a tank should be measured in m

and the maximum height is 4 m. The density of the fluid is 1 kg/dm

3

. The maximum volume is 5 m3

3

. The device is mounted below

the level lower range value.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration, i.e. the tank volume, tank height and density of the fluid are known.

Note!

• See also Operating Instructions BA301P Deltabar S or Operating Instructions BA302P Cerabar S,

Section 6.6 "Level measurement".

• For a description of the parameters mentioned, see

– Page 33, Pressure Transducer Block

– Page 65, Analog Input Block.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and the

device filled with fluid. See Operating Instructions

BA301P, Section 6.6.1.

2 Open the Pressure Transducer Block and set the block

mode to OOS.

3 You have the following ways of carrying out position

adjustment:

• By means of the "Pos. zero adjust" method, see

Operating Instructions BA301P or BA302P, Section

6.4.

• By means of the parameters

– PRESSURE_1_ACCEPT_ZERO_INSTALL_

OFFSET/POS. ZERO ADJUST (→ Page 38) or

– PRESSURE_1_ACCEPT_INSTALL_OFFSET/

POS. INPUT VALUE (→ Page 38) or

– PRESSURE_1_INSTALL_OFFSET/CALIB. OFFSET

(→ Page 38).

4 Select the measuring mode if necessary:

• Select the "No linearization" option by means of the

LINEARIZATION parameter.

• Select the "Volume" option by means of the

PRIMARY_VALUE_TYPE parameter.

5 Select a pressure unit via the CAL_UNIT parameter, here

mbar for example.

6 Select the "Linear" option by means of the

LEVEL_TYPE/LEVEL MODE parameter.

7 Select the "Volume" option by means of the

MEASURAND_LINEAR/LIN. MEASURAND parameter.

8 Select a volume unit via the VOLUME_UNIT/UNIT

VOLUME parameter, here m

9 Select the "Dry" option by means of the

LEVEL_ADJUST_MODE/CALIBRATION MODE

parameter. See also the following note, point 3.

10 Enter the value for density via the

LEVEL_ADJUST_DENSITY/ADJUST DENSITY and

DENSITY_UNIT parameters, here 1 kg/dm

example.

11 Enter the tank volume via the

LEVEL_TANK_VOLUME/TANK VOLUME parameter,

3

here 5 m

for example.

3

for example.

3

for

3

V = 5 m

➁

➀

kg

ρ = 1

3

dm

P01-PMP75xxx-19-xx-xx-xx-003

Fig. 1: Calibration without reference pressure –

dry calibration

1 See Table, Step 10.

2 See Table, Step 11.

3 See Table, Step 12.

4 See Table, Step 13.

➂

4 m

➃

–0.5 m

8 Endress+Hauser

Page 9

Cerabar S/Deltabar S Level measurement (FF configuration program)

Description

12 Enter the tank height via the LEVEL_TANK_HEIGHT/

TANK HEIGHT parameter, here 4 m for example.

13 Enter the level offset via the LEVEL_OFFSET/ZERO

POSITION parameter, here 0.5 m for example.

14 Set the Pressure Transducer Block to the "Auto" block

mode.

15 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

16 Result:

The measuring device is ready for level measurement.

!

Note!

1. For this level type, the measured variables %, level, volume and mass are available. → See

Page 40 ff.

2. You can also specify customer-specific units. See parameter descriptions for CAL_UNIT

(→ Page 34), HEIGHT_UNIT (→ Page 41), VOLUME_UNIT (→ Page 42) and MASS_UNIT

(→ Page 43).

3. The "Wet" calibration mode (LEVEL_ADJUST_MODE) is not available by means of the

FF operating programs. A kind of wet calibration can be carried out as follows:

– Select the "No linearization" option by means of the LINEARIZATION parameter.

– Select the "Level", "Volume" or "Mass" option, depending on the measured variable required,

by means of the PRIMARY_VALUE_TYPE parameter.

– Fill the tank up to the lower level point.

– The PRESSURE_1_AFTER_SENSOR/SENSOR PRESSURE parameter displays the pressure

present at the device. Enter the value displayed for the SCALE_IN parameter, EU_0

element.

– Enter the associated level value for the SCALE_OUT parameter, EU_0 element.

– Using the SCALE_OUT parameter, "Units Index" element, select a unit to suit the measured

variable.

– Fill the tank up to the upper level point.

– The PRESSURE_1_AFTER_SENSOR/SENSOR PRESSURE parameter displays the pressure

present at the device. Enter the value displayed for the SCALE_IN parameter, EU_100

element.

– Enter the associated level value for the SCALE_OUT parameter, EU_100 element.

Endress+Hauser 9

Page 10

Level measurement (FF configuration program) Cerabar S/Deltabar S

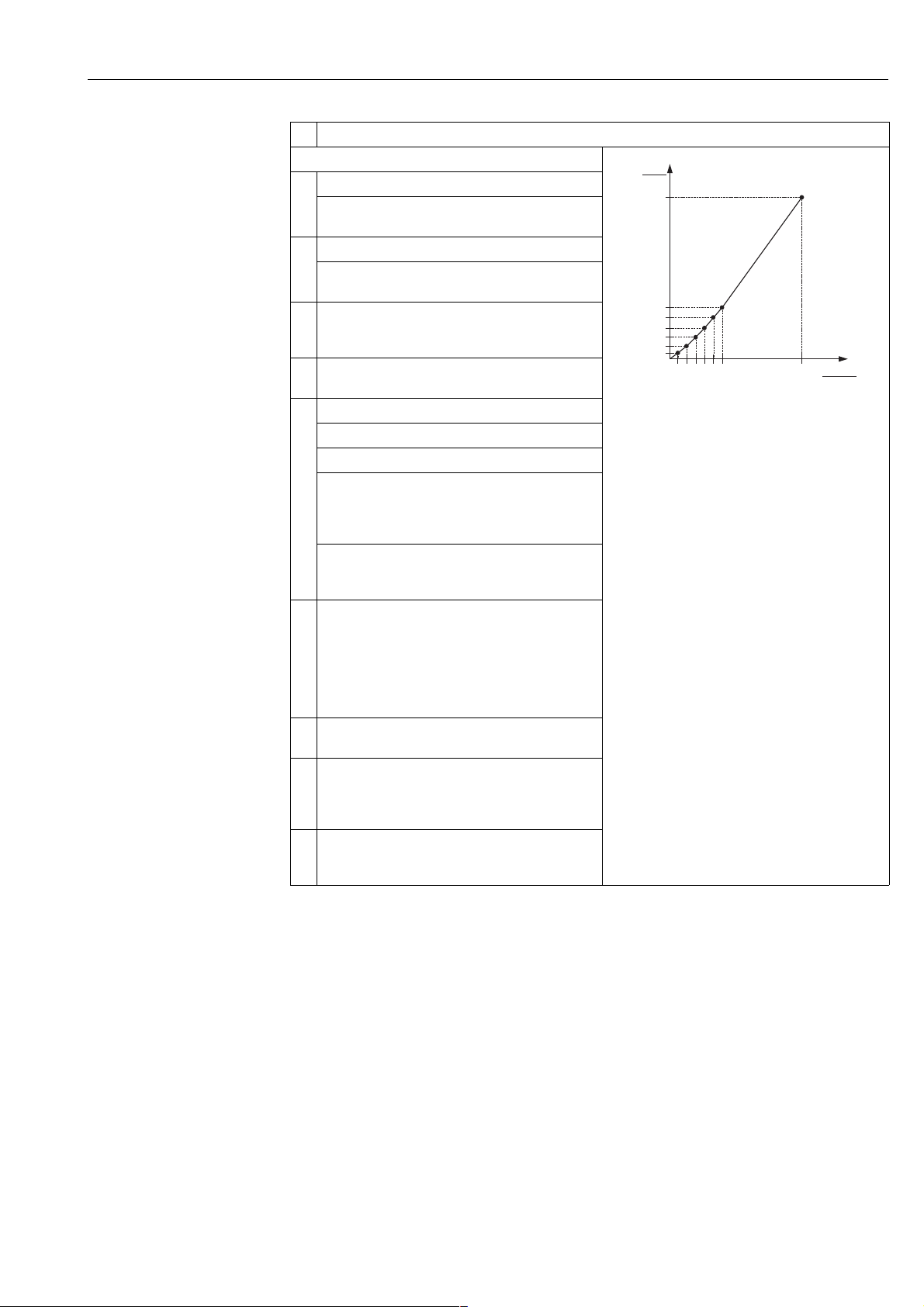

4. 3 "Pressure linearized" level type

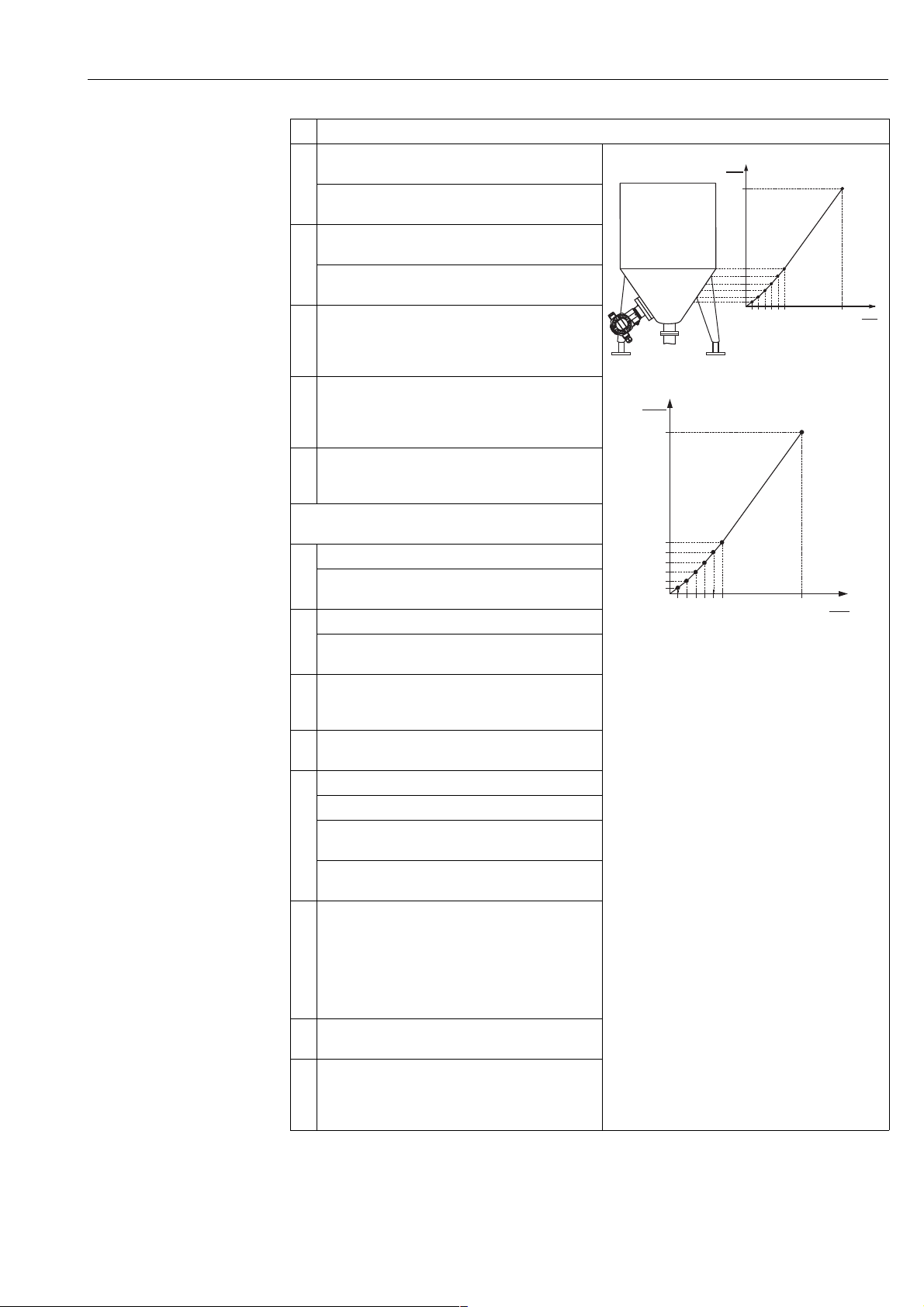

4.3.1 Semiautomatic entry of the linearisation table

!

Example:

In this example, the volume in a tank with a conical outlet should be measured in m

3

.

Prerequisite:

• The tank can be filled. The linearisation characteristic must rise continuously.

Note!

• See also Operating Instructions BA301P Deltabar S or Operating Instructions BA302P Cerabar S,

Section 6.6 "Level measurement".

• For a description of the parameters mentioned, see

– Page 33, Pressure Transducer Block.

– Page 65, Analog Input Block.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and the

device filled with fluid. See Operating Instructions

BA301P, Section 6.6.1.

2 Open the Pressure Transducer Block and set the block

mode to OOS.

3 You have the following ways of carrying out position

adjustment:

• By means of the "Pos. zero adjust" method, see

Operating Instructions BA301P or BA302P,

Section 6.4.

• By means of the parameters

– PRESSURE_1_ACCEPT_ZERO_INSTALL_

OFFSET/POS. ZERO ADJUST (→ Page 38) or

– PRESSURE_1_ACCEPT_INSTALL_OFFSET/

POS. INPUT VALUE (→ Page 38) or

– PRESSURE_1_INSTALL_OFFSET/CALIB. OFFSET

(→ Page 38).

Carry out basic setup:

4 Select the measuring mode if necessary:

• Select the "Level linearized" option by means of the

LINEARIZATION parameter.

• Select the "Volume" option by means of the

PRIMARY_VALUE_TYPE parameter. See also the

following note, point 3.

5 Select a pressure unit via the CAL_UNIT parameter, here

mbar for example.

6 Select the "Pressure linearized" option by means of the

LEVEL_TYPE/LEVEL MODE parameter.

7 Select the "Pressure and volume" option by means of the

MEASURAND_LINEAR/Lind. MEASURAND

parameter.

8 Select a volume unit via the VOLUME_UNIT/UNIT

VOLUME parameter, here m

9Select SCALE_IN parameter, EU_0 element.

Enter the minimum hydrostatic pressure to be expected,

here 0 mbar for example.

10 Select SCALE_IN parameter, EU_100

Enter the maximum hydrostatic pressure to be expected,

here 350 mbar for example.

3

for example.

element.

V

3

[m ]

3.5

0

0 350

P01-PMP75xxx-19-xx-xx-xx-002

p

[mbar]

10 Endress+Hauser

Page 11

Cerabar S/Deltabar S Level measurement (FF configuration program)

Description

Carry out linearisation:

11 Select SCALE_OUT parameter, EU_0 element.

Specify the minimum tank contents to be expected, here

3

0 m

for example.

12 Select SCALE_OUT parameter, EU_100 element.

Specify the maximum tank contents to be expected, here

3

3.5 m

for example. See also the following note, point 4.

13 Select the "Semiautomatic" option by means of the

LINEARIZATION_TABLE_MODE/LIN. EDIT MODE

parameter.

14 Select the "Edit table" option by means of the

TAB_OBCODE/TABLE SELECTION parameter.

15 Enter linearisation table (min. 2 points, max. 32 points).

Fill the tank to the height of the 1st point.

TAB_ENTRY: enter the value of the corresponding point.

The PRESSURE_1_AFTER_DAMPING/PRESSURE

parameter displays the measured hydrostatic pressure.

This hydrostatic pressure displayed is saved by

confirming the Y-value. See the following line.

TAB_XY_VALUE, 2nd element (Y-value): enter the

volume value, here 0 m

value.

16 You can enter further points for the linearisation table as

explained in Step 15. The previous point first has to be

saved in the linearisation table before the next point can

be entered. In other words, a complete linearisation table

cannot be saved to the device. Once all the points have

been entered, the table must be activated by means of

the TAB_OBCODE/TABLE SELECTION parameter.

17 Set the Pressure Transducer Block to the "Auto" block

mode.

18 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

19 Result:

The linearisation table is entered and the measuring

device is ready for level measurement.

3

for example, and confirm the

V

3

[m ]

3.5

➃

➄

0

➂

0 350

➀

Fig. 2: Semiautomatic entry of the linearisation

table

1 See Table, Step 9.

2 See Table, Step 10.

3 See Table, Step 11.

4 See Table, Step 12.

5 See Table, Steps 13 to 16.

p

[mbar]

➁

P01-xxxxxxxx-05-xx-xx-xx-015

!

Note!

1. For this level type, the measured variables %, volume and mass are available. → See Page 40 ff.

2. You can also specify customer-specific units. See parameter descriptions for CAL_UNIT

(→ Page 34), HEIGHT_UNIT (→ Page 41), VOLUME_UNIT (→ Page 42) and MASS_UNIT

(→ Page 43).

Endress+Hauser 11

Page 12

Level measurement (FF configuration program) Cerabar S/Deltabar S

3. Once you have selected the "Pressure linearized" level type (LEVEL_TYPE), the warning

message "W710 Set span too small. Not allowed." can appear. At this stage the linearisation

table already consists of two points as standard. It could be the case that the 2nd value, and

thus the highest X-value of the linearisation table, is smaller than the minimum span permitted

(→ CAL_MIN_SPAN, Page 34). The message goes out as soon as the highest X-value is larger

than the minimum span and the table entered is active.

4. Once you have entered the maximum tank contents to be expected for SCALE_OUT, EU_100

element, the alarm "A719 Y-Val of lin. table out of edit limits" can appear. At this stage the

linearisation table already consists of two points as standard. It could be the case that the 2nd

value, and thus the highest Y-value of the linearisation table, is larger than the value entered

for SCALE_OUT, EU_100 element. The message goes out as soon as no Y-value is larger than

the value for SCALE_OUT, EU_100 element and the table entered is active.

4.3.2 Manual entry of the linearisation table

!

Example:

In this example, the volume in a tank with a conical outlet should be measured in m

3

.

Prerequisite:

• This is a theoretical calibration, i.e. the points for the linearisation table are known.

Note!

• See also Operating Instructions BA301P Deltabar S or Operating Instructions BA302P Cerabar S,

Section 6.6 "Level measurement".

• For a description of the parameters mentioned, see

– Page 33, Pressure Transducer Block.

– Page 65, Analog Input Block.

Description

1 Perform calibration as per Section 4.3.1, Steps 1 to 10.

Carry out linearisation:

2 Select SCALE_OUT parameter, EU_0 element.

Specify the minimum tank contents to be expected, here

3

0 m

for example.

3Select SCALE_OUT parameter, EU_100 element.

Specify the maximum tank contents to be expected, here

3

3.5 m

for example. See also the following note, point 3.

4 Select the "Manual" option by means of the

LINEARIZATION_TABLE_MODE/LIN. EDIT MODE

parameter.

5 Select the "Edit table" option by means of the

TAB_OBCODE/TABLE SELECTION parameter.

V

3

[m ]

3.5

0

0 350

P01-PMP75xxx-19-xx-xx-xx-002

p

[mbar]

12 Endress+Hauser

Page 13

Cerabar S/Deltabar S Level measurement (FF configuration program)

Description

6 Enter linearisation table (min. 2 points, max. 32 points).

TAB_ENTRY: enter the value of the corresponding point.

TAB_XY_VALUE, 1st element (X-value): enter the

pressure value.

TAB_XY_VALUE, 2nd element (Y-value): enter the

volume value, here 0 m

7 You can enter further points for the linearisation table as

explained in Step 6. The previous point first has to be

saved in the linearisation table before the next point can

be entered. In other words, a complete linearisation table

cannot be saved to the device. Once all the points have

been entered, the table must be activated by means of

the TAB_OBCODE/TABLE SELECTION parameter.

8 Set the Pressure Transducer Block to the "Auto" block

mode.

9 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

10 Result:

The linearisation table is entered and the measuring

device is ready for level measurement.

3

for example, and confirm.

V

3

[m ]

3.5

➃

➄

0

➂

0 350

➀

Fig. 3: Manual entry of the linearisation table

1 See Section 4.3.1, Table, Step 9.

2 See Section 4.3.1, Table, Step 10.

3 See this Table, Step 2.

4 See this Table, Step 3.

5 See this Table, Steps 4 to 7.

p

[mbar]

➁

P01-xxxxxxxx-05-xx-xx-xx-015

!

Note!

1. For this level type, the measured variables %, volume and mass are available. → See Page 40 ff.

2. You can also specify customer-specific units. See parameter descriptions for CAL_UNIT

(→ Page 34), HEIGHT_UNIT (→ Page 41), VOLUME_UNIT (→ Page 42) and MASS_UNIT

(→ Page 43).

3. Once you have entered the maximum tank contents to be expect ed f or S CAL E_OUT, EU_100

element, the alarm "A719 Y-Val of lin. table out of edit limits" can appear. At this stage the

linearisation table already consists of two points as standard. It could be the case that the 2nd

value, and thus the highest Y-value of the linearisation table, is larger than the value entered

for SCALE_OUT, EU_100 element. The message goes out as soon as no Y-value is larger than

the value for SCALE_OUT, EU_100 element and the table entered is active.

Endress+Hauser 13

Page 14

Level measurement (FF configuration program) Cerabar S/Deltabar S

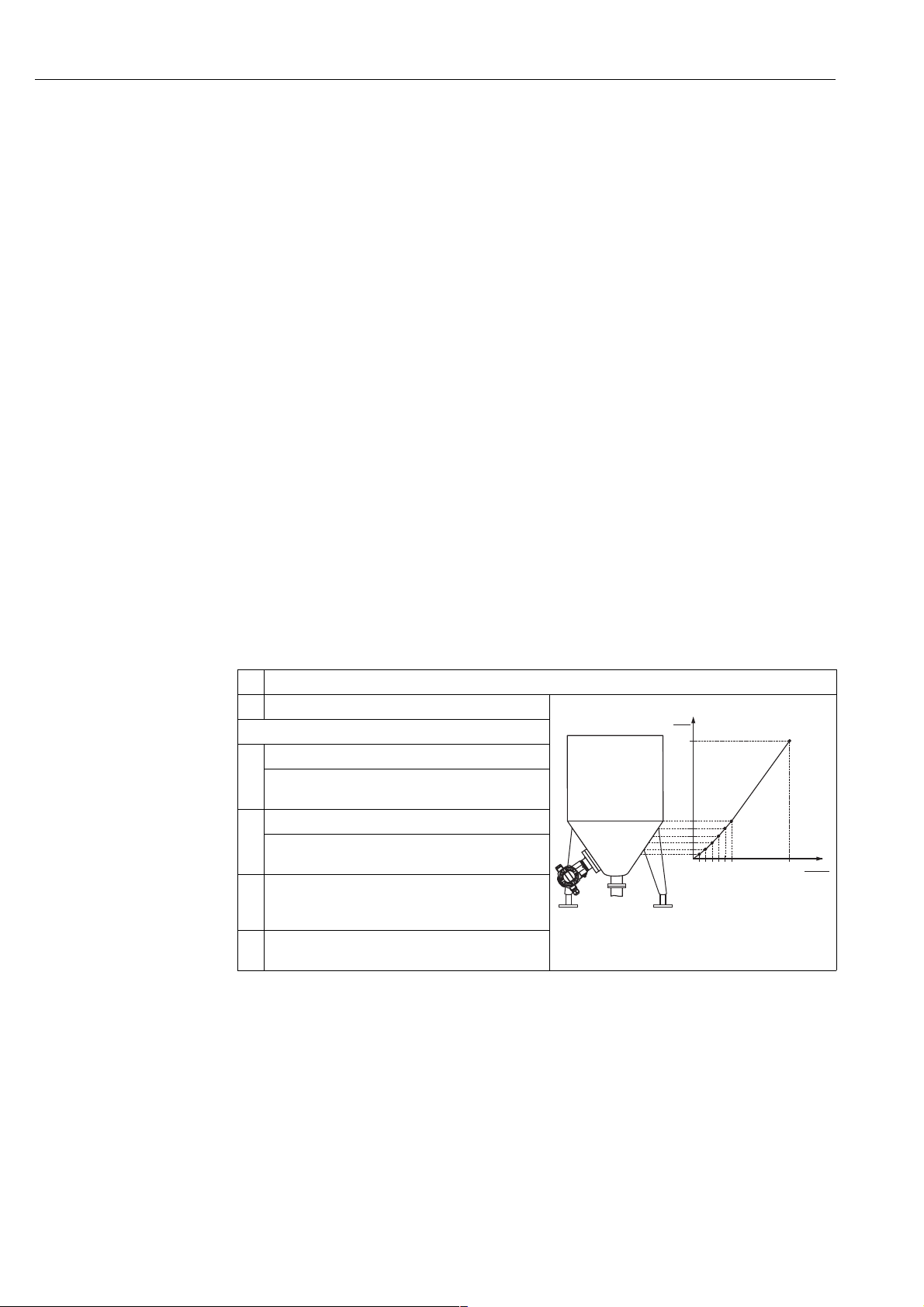

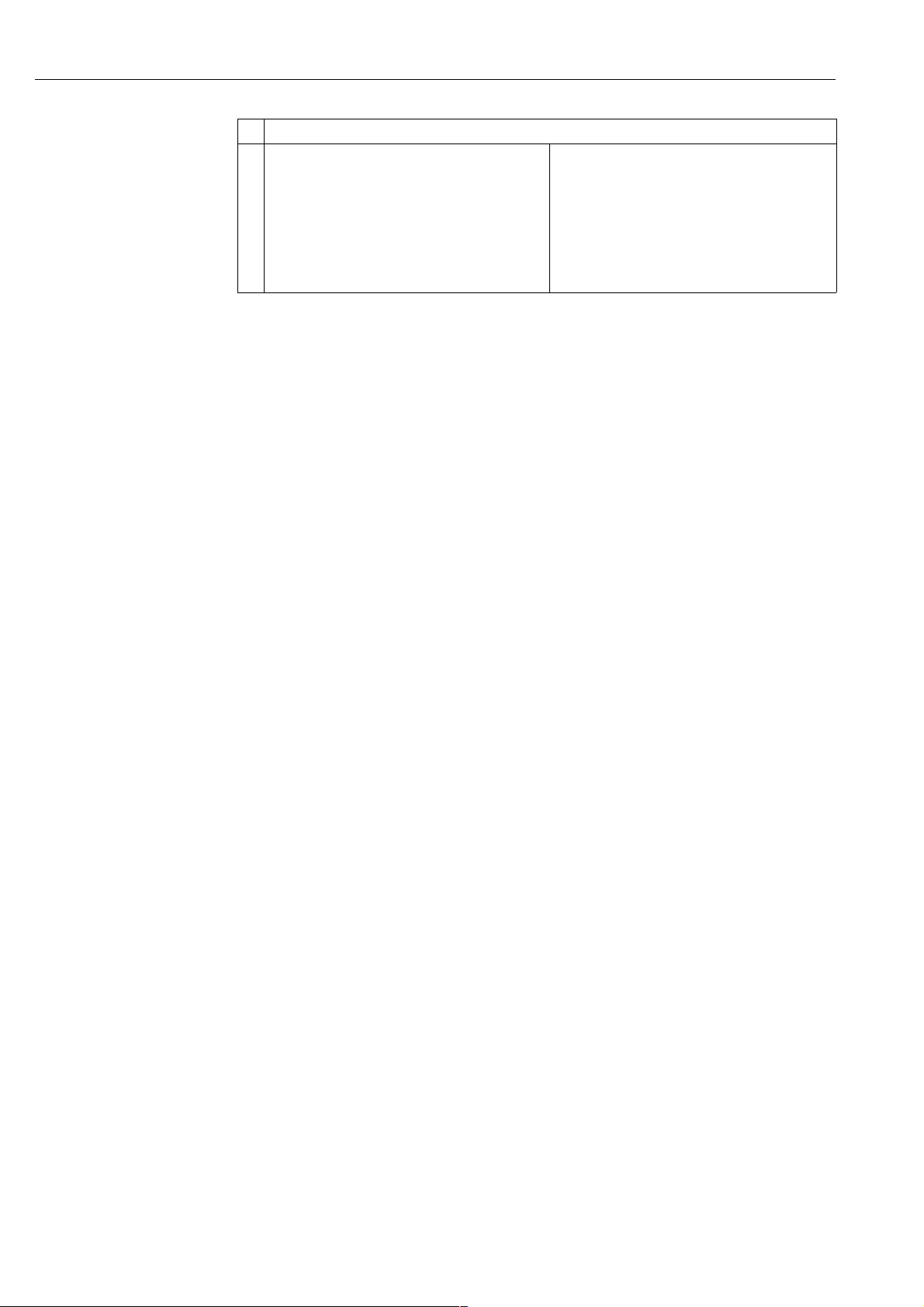

4. 4 "Height linearized" level type

4.4.1 Dry calibration and manual entry of the linearisation table

Example:

In this example, the height and the volume should be measured at the same time.

Prerequisite:

• This is a theoretical calibration, i.e. the points for the linearisation table are known.

!

Note!

• See also Operating Instructions BA301P Deltabar S or Operating Instructions BA302P Cerabar S,

Section 6.6 "Level measurement".

• For a description of the parameters mentioned, see

– Page 33, Pressure Transducer Block.

– Page 65, Analog Input Block.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and the

device filled with fluid. See Operating Instructions

BA301P, Section 6.6.1

2 Open the Pressure Transducer Block and set the block

mode to OOS.

3 You have the following ways of carrying out position

adjustment:

• By means of the "Pos. zero adjust" method, see

Operating Instructions BA301P or BA302P,

Section 6.4.

• By means of the parameters

– PRESSURE_1_ACCEPT_ZERO_INSTALL_

OFFSET/POS. ZERO ADJUST (→ Page 38) or

– PRESSURE_1_ACCEPT_INSTALL_OFFSET/

POS. INPUT VALUE (→ Page 38) or

– PRESSURE_1_INSTALL_OFFSET/CALIB. OFFSET

(→ Page 38).

Perform calibration for the 1st measured variable:

4 Select the measuring mode if necessary:

• Select the "Level combined" option by means of the

LINEARIZATION parameter.

• Select the "Volume" option by means of the

PRIMARY_VALUE_TYPE parameter.

5 Select a pressure unit via the CAL_UNIT parameter, here

mbar for example.

6 Select the "Height linearised" option by means of the

LEVEL_TYPE/LEVEL MODE parameter.

7 Select the "Height + volume" option by means of the

MEASURAND_COMBINED/COM. MEASURAND

parameter.

8 Select the unit for the 1st measured value via the

HEIGHT UNIT parameter, here m for example.

9 Select the unit for the 2nd measured variable via the

VOLUME_UNIT/UNIT VOLUME parameter, here m

for example.

3

Fig. 4: Calibrating the 1st measured variable

1 See Table, Step 10.

2 See Table, Step 11.

➁

➀

P01-PMP75xxx-19-xx-xx-xx-006

14 Endress+Hauser

Page 15

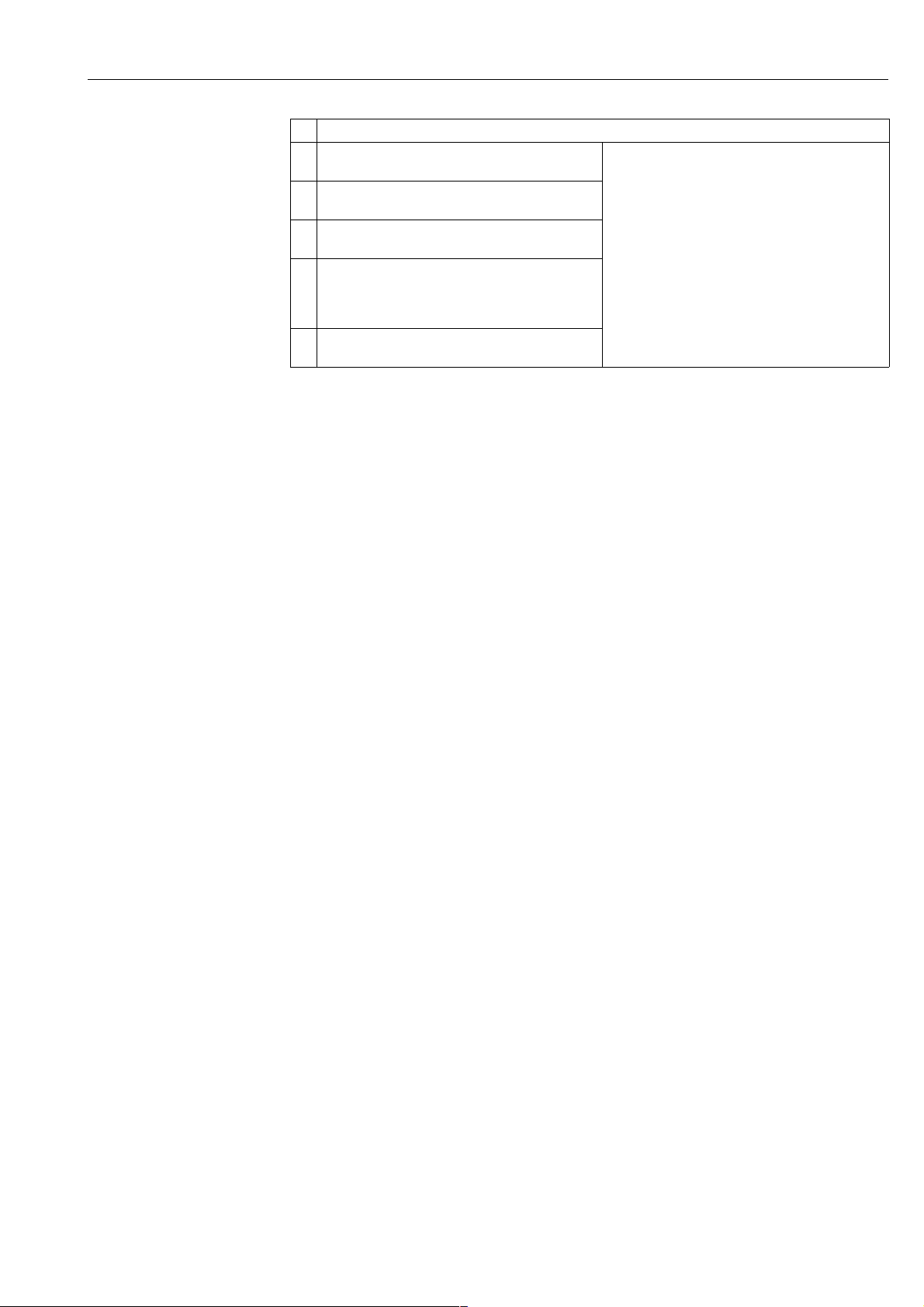

Cerabar S/Deltabar S Level measurement (FF configuration program)

Description

10 Select the LINEAR_LEVEL_MIN/LEVEL MIN.

parameter.

Enter the minimum level to be expected, here 0 m for

example.

11 Select the LINEAR_LEVEL_MAX/LEVEL MAX.

parameter.

Enter the maximum height to be expected, here 3 m for

example. See also the following note, point 3.

12 Select the "Dry" option by means of the

LEVEL_ADJUST_MODE/ CALIBRATION MODE

parameter (calibration mode for the 1st measured

variable). See also the following note, point 4.

13 Enter the value for density via the

LEVEL_ADJUST_DENSITY/ADJUST DENSITY and

DENSITY_UNIT parameters, here 1 kg/dm

3

for

example.

14 Result:

The calibration for the 1st measured variable is carried

out.

Perform linearisation (calibration for the 2nd

measured variable)

15 Select SCALE_OUT parameter, EU_0 element.

Specify the minimum tank contents to be expected, here

3

0 m

for example.

16 Select SCALE_OUT parameter, EU_100 element.

Specify the maximum tank contents to be expected, here

3

5 m

for example.

17 Select the "Manual" option by means of the

LINEARIZATION_TABLE_MODE/LIN. EDIT MODE

parameter.

18 Select the "Edit table" option by means of the

TAB_OBCODE/TABLE SELECTION parameter.

19 Enter linearisation table (min. 2 points, max. 32 points).

TAB_ENTRY: enter the value of the corresponding point.

TAB_XY_VALUE, 1st element (X-value): enter the level,

here 0 m for example.

TAB_XY_VALUE, 2nd element (Y-value): enter the

volume value, here 0 m

3

.

20 You can enter further points for the linearisation table as

explained in Step 19. The previous point first has to be

saved in the linearisation table before the next point can

be entered. In other words, a complete linearisation table

cannot be saved to the device. Once all the points have

been entered, the table must be activated by means of

the TAB_OBCODE/TABLE SELECTION parameter.

21 Set the Pressure Transducer Block to the "Auto" block

mode.

22 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

V

3

[m ]

5

➃

0

➂

03

Fig. 5: Calibrating the 2nd measured variable

3 See Table, Step 15

4 See Table, Step 16.

5 See Table, Steps 17 to 20.

V

3

[m ]

5

0

03

P01-PMP75xxx-19-xx-xx-xx-005

[m]

h

➄

h

[m]

P01-xxxxxxxx-05-xx-xx-xx-022

Endress+Hauser 15

Page 16

Level measurement (FF configuration program) Cerabar S/Deltabar S

Description

23 Result:

– The linearisation table has been entered.

– The measured value display and the

PRIMARY_VALUE parameter display the 2nd

measured value (here the volume).

– The MEASURED_LEVEL_AFTER_SIMULATION/

LEVEL BEFORE LIN parameter displays the 1st

measured value (here the height). See also the

following note, point 5.

!

Note!

1. For this level type, the measured variables "height + %", "height + volume", "height + mass",

"%-height + %", "%-height + volume" and "%-height + mass" are available.

→ See Page 41 ff.

2. You can also specify customer-specific units. See parameter descriptions for CAL_UNIT

(→ Page 34), HEIGHT_UNIT (→ Page 41), VOLUME_UNIT (→ Page 42) and MASS_UNIT

(→ Page 43).

3. Once you have entered the maximum height to be expected for LINEAR_LEVEL_MAX/

LEVEL MAX., the alarm "A707 X-Val of lin. table out of edit limits" can appear. At this stage

the linearisation table already consists of two points as standard. It could be the case that the

2nd value, and thus the highest X-value of the linearisation table, is greater than the maximum

level entered. The message goes out as soon as the highest X-value is larger than the maximum

level and the table entered is active.

4. The "Wet" calibration mode is not available by means of the FF operating programs.

5. You can use the DISPLAY_MAINLINE_CONTENT/ MENU DESCRIPTOR parameter

(→ Page 60) to specify which measured value should be displayed on the on-site display.

16 Endress+Hauser

Page 17

Cerabar S/Deltabar S Flow measurement (FF configuration program)

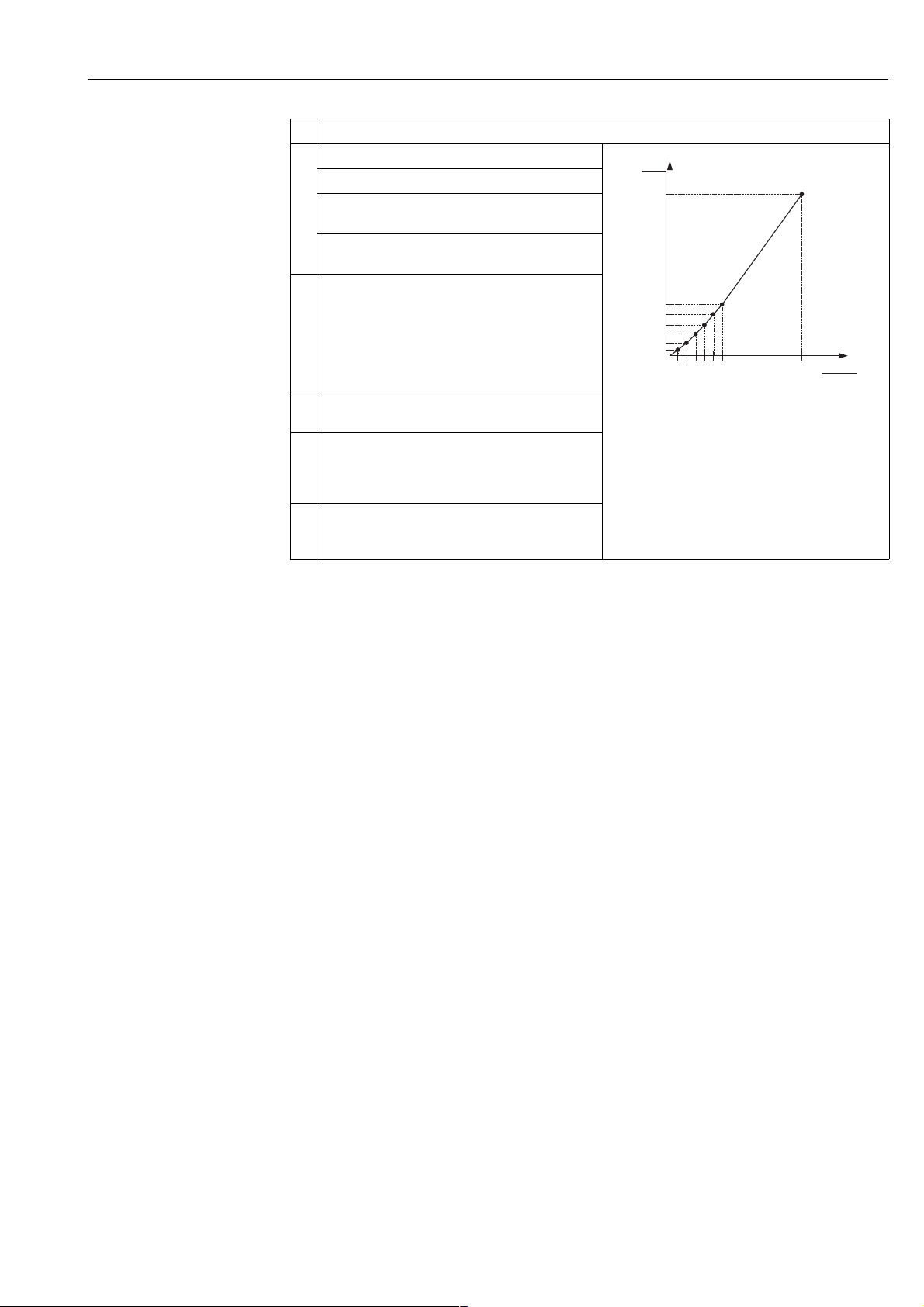

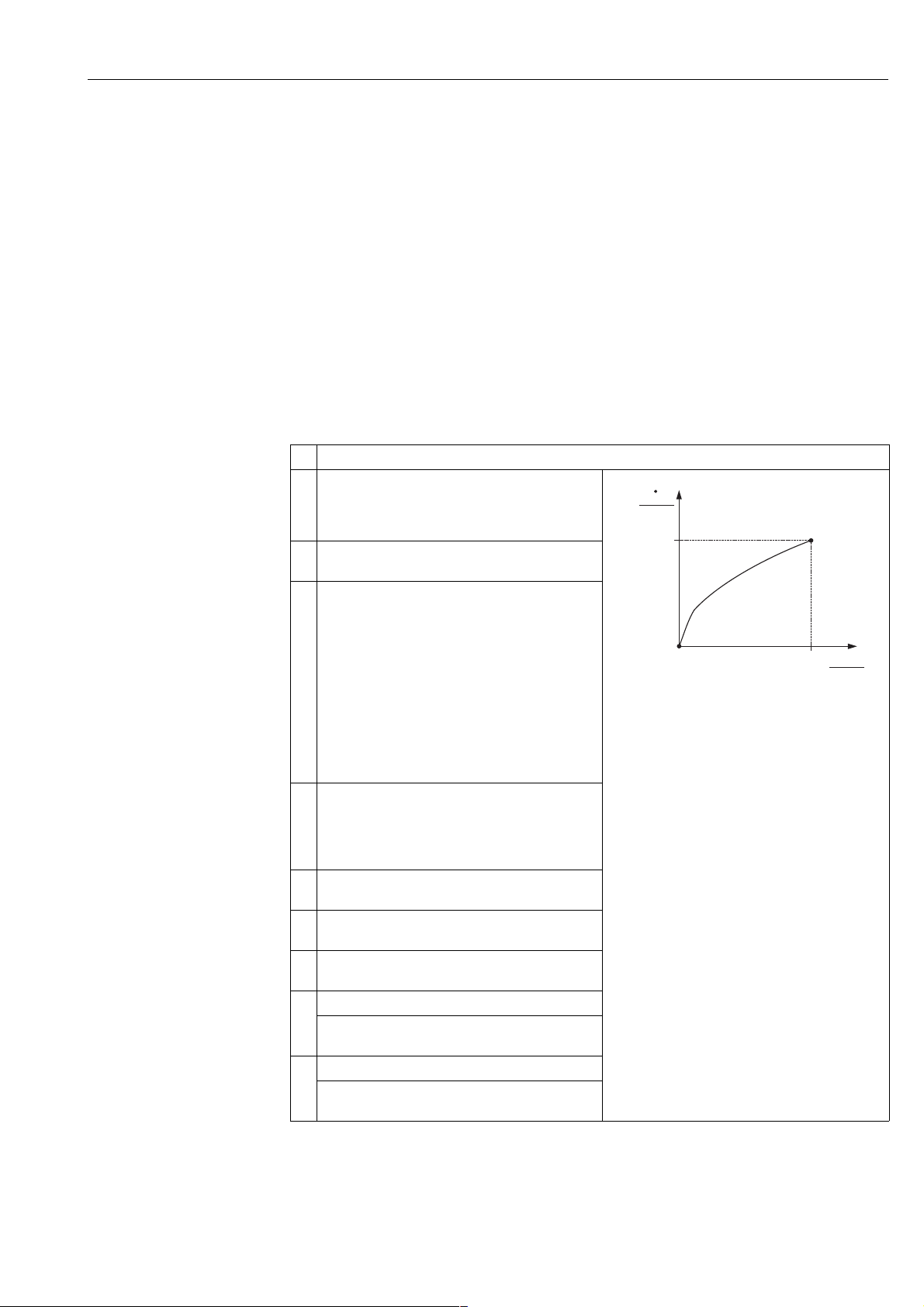

5Flow measurement

(FF configuration program)

5. 1 Calibration

!

Example:

In this example, a volume flow should be measured in m

3

/h.

Note!

• The "Flow measurement" measuring mode is only available for the Deltabar S differential pressure

transmitter.

• See also Operating Instructions BA301P Deltabar S, Section 6.5 "Flow measurement".

• For a description of the parameters mentioned, see

– Page 33, Pressure Transducer Block.

– Page 65, Analog Input Block.

Description

1 Before configuring the device for your application, the

pressure piping must be cleaned and the device filled

with fluid. See Operating Instructions BA301P, Section

6.5.1.

2 Open the Pressure Transducer Block and set the block

mode to OOS.

3 Carry out position adjustment if necessary.

You have the following ways of carrying out position

adjustment:

• By means of the "Pos. zero adjust" method, see

Operating Instructions BA301P, Section 6.4.

• By means of the parameters

– PRESSURE_1_ACCEPT_ZERO_INSTALL_

OFFSET/POS. ZERO ADJUST (→ Page 38) or

– PRESSURE_1_ACCEPT_INSTALL_OFFSET/

POS. INPUT VALUE (→ Page 38) or

– PRESSURE_1_INSTALL_OFFSET/CALIB. OFFSET

(→ Page 38).

4 Select the measuring mode if necessary:

• Select the "Flow Square root" option by means of the

LINEARIZATION parameter.

• Select the "Flow" option by means of the

PRIMARY_VALUE_TYPE parameter.

5 Select a pressure unit via the CAL_UNIT parameter, here

mbar for example.

6 Select the "Volume p. cond." option by means of the

FLOW_TYPE/FLOW-MEAS. TYPE parameter.

7 Select a flow unit via the FLOW_UNIT/UNIT FLOW

parameter, here m

8 Select SCALE_OUT parameter, EU_100 element.

Enter the maximum flow value of the primary device,

here 6000 m

9 Select SCALE_IN parameter, EU_100 element.

Enter the maximum pressure, here 400 mbar for

example. See also layout sheet of primary device.

3

/h for example.

3

/h. See also layout sheet of primary device.

V

3

[m /h]

6000

➀

0

0 400

Fig. 6: Flow measurement calibration

1 See Table, Step 8.

2 See Table, Step 9.

p

[mbar]

➁

P01-xMD7xxx-05-xx-xx-xx-010

Endress+Hauser 17

Page 18

Flow measurement (FF configuration program) Cerabar S/Deltabar S

Description

10 Set the Pressure Transducer Block to the "Auto" block

mode.

11 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

12 Result:

The measuring device is configured for flow

measurement.

!

Note!

1. Using the FLOW_TYPE/FLOW_MEAS. TYPE parameter, you can choose between the

following flow types:

– Volume p. cond. (volume under operating conditions)

– Gas norm. cond. (norm volume under norm conditions in Europe: 1013.25 mbar and

273.15 K (0 °C))

– Gas std. cond. (standard volume under standard conditions in USA: 1013.25 mbar (14.7 psi)

and 288. 15 K (15 °C/59 °F))

– Mass p. cond. (mass under operating conditions)

2. The unit selected by means of the FLOW_UNIT/UNIT FLOW (→ Page 47) parameter must

suit the flow type selected (FLOW_TYPE/FLOW_MEAS. TYPE).

3. In the lower measuring range, small flow quantities (creepages) can lead to large measured

value fluctuations. You can activate low flow cut-off via the CREEP_FLOW_SUPPRESSION_

ENABLE/LOW FLOW CUT-OFF parameter (→ Page 48).

18 Endress+Hauser

Page 19

Cerabar S/Deltabar S Flow measurement (FF configuration program)

5. 2 Totalizers

!

Example:

In this example, the volume flow should be totalised and displayed in the unit m

should be added to the flow rate.

Note!

• For a description of the parameters mentioned, see

– Page 58, Totalizer Transducer Block

– Page 65, Analog Input Block.

• Totalizer 1 can be reset. Totalizer 2 cannot be reset.

Description

1 Calibrate the device as per Section 5.1.

2 Open the Totalizer Transducer Block.

3 Select a flow unit via the TOTALIZER_1_UNIT/TOTAL.

1 ENG. UNIT parameter, here m

4 Use the TOTALIZER_1_MODE/ NEG. FLOW TOT. 1

parameter to specify the totalising mode for negative

flows, here the "Positive" option for example.

5 Reset totalizer 1 to zero via the TOTALIZER_1_RESET/

RESET TOTALIZER 1 parameter.

6Result:

The TOTALIZER_1_VALUE parameter displays the

totalised volume flow.

3 E3

for example.

3E3

. Negative flows

!

Note!

• You can also specify a customer-specific unit. → See parameter description for TOTALIZER_1_

UNIT (→ Page 58).

• You can use the DISPLAY_MAINLINE_CONTENT/ MENU DESCRIPTOR parameter

(→ Page 60) to specify which measured value should be displayed on the on-site display.

• The parameters for the 2nd totalizer such as TOTALIZER_2_UNIT/TOTAL. 2 ENG. UNIT,

TOTALIZER_2_MODE/NEG. FLOW TOT. 2 and TOTALIZER_2_FLOAT/TOTALIZER 2 are in

the Pressure Transducer Block.

Endress+Hauser 19

Page 20

Flow measurement (FF configuration program) Cerabar S/Deltabar S

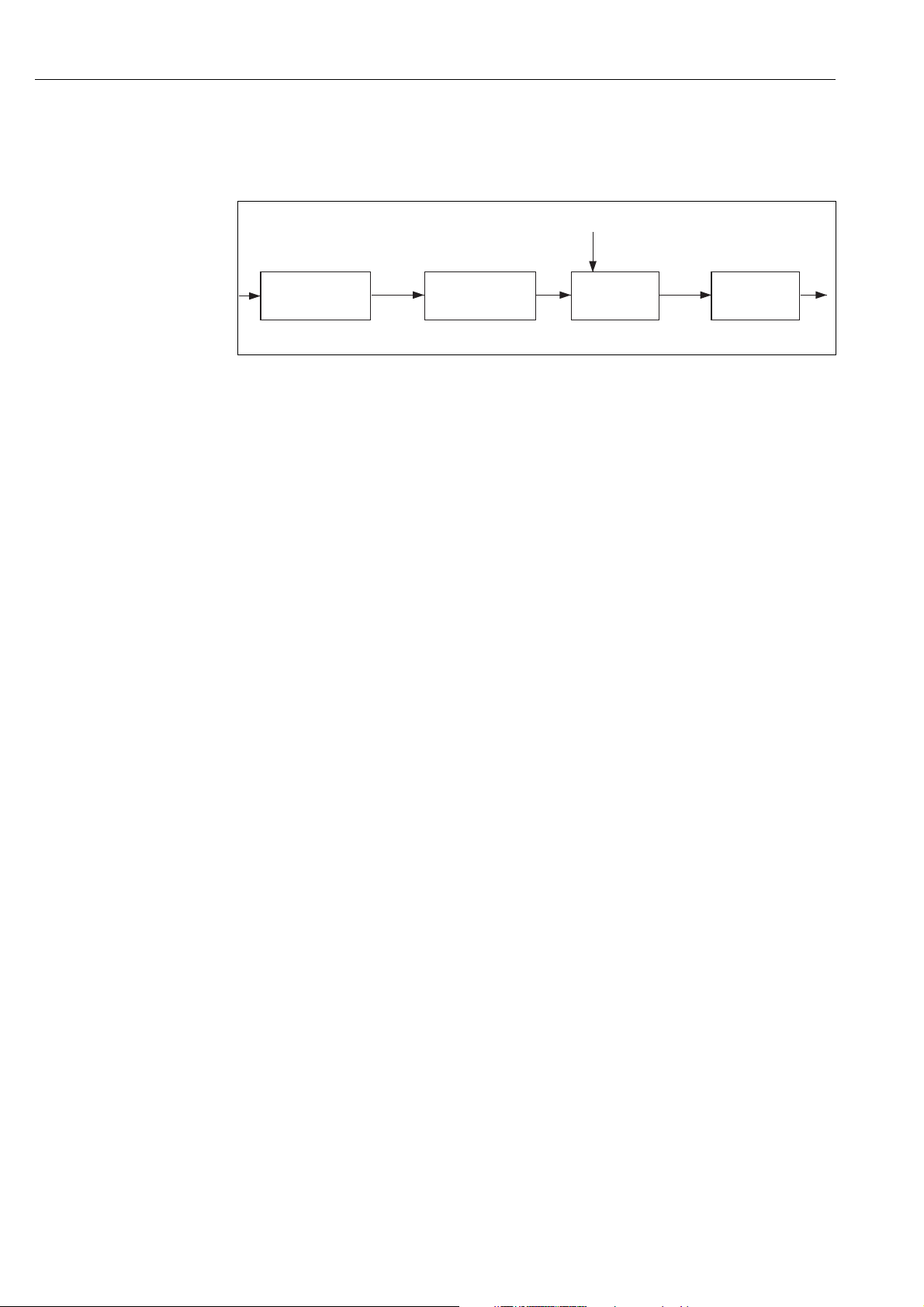

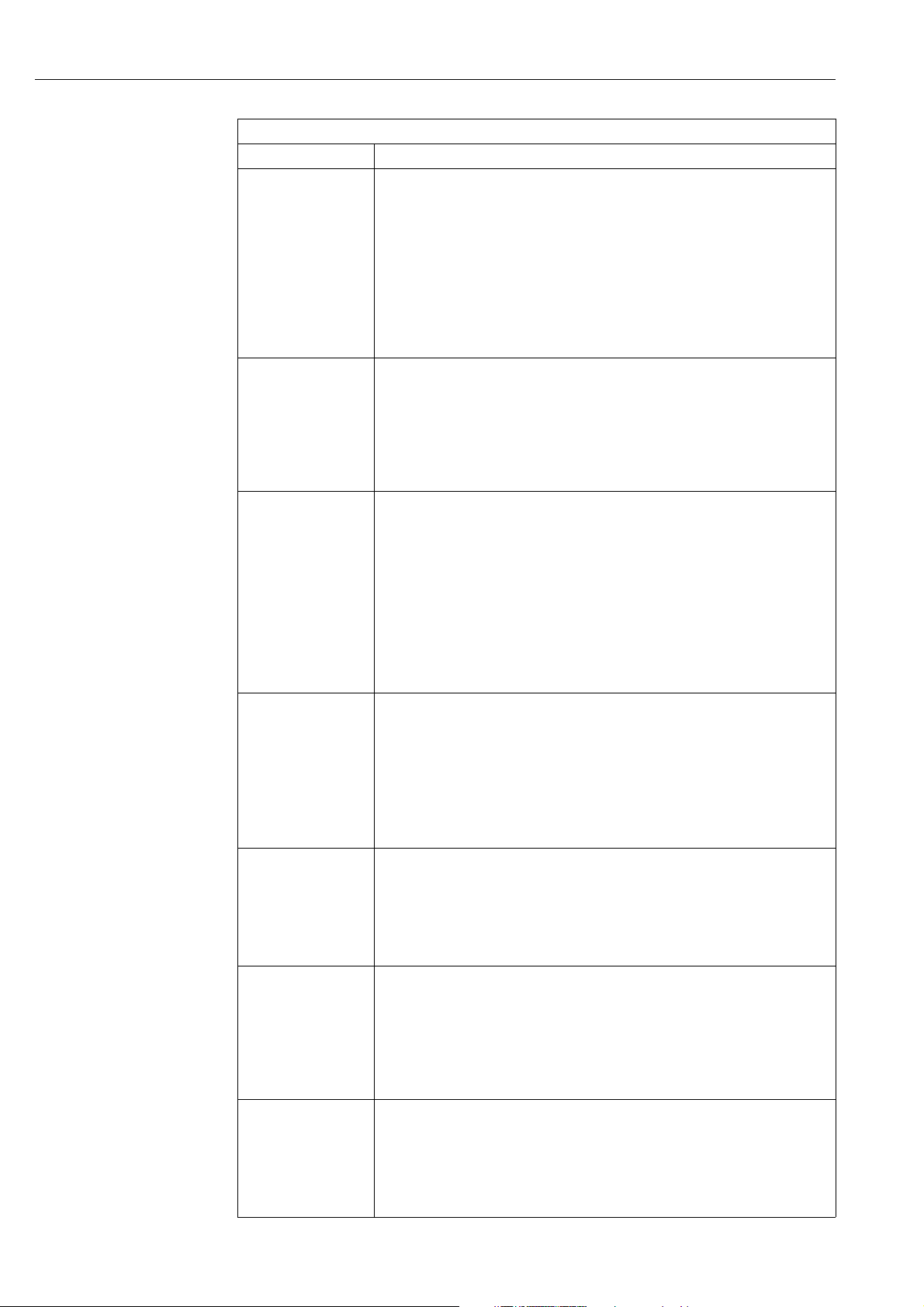

5.2.1 Resetting totalizer 1 automatically

Use the Analog Alarm and Discrete Output Block to automatically reset Totalizer 1 in the Totalizer

Transducer Block.

HI_HI_LIM

HI_HI_ALM

Totalizer

Transducer Block

Analog Input Block 3

TOTALIZER_1_

VALUE/

TOTALIZER 1

CHANNEL = 6

L_TYPE = Direct

Analog Alarm

OUT

IN

Block

CAS_IN_D

OUT_ALM

Discrete Output

Block

CHANNEL = 2

P01-xxxxxxxx-02-xx-xx-xx-002

OUT_D

The Totalizer Transducer Block is linked to an Analog Input Block by means of the CHANNEL

parameter (CHANNEL = 6). In the Analog Alarm Block, the HI_HI_LIM parameter is used to set a

limit value at which the totalizer should be reset to zero. As soon as this limit value is overshot, the

Analog Alarm Block sends an alarm value to the downstream Discrete Output Block. This changes

its output from 0 to 1, thereby resetting the totalizer in the Totalizer Transducer Block to 0. The

output of the Analog Alarm Block changes back to the value 0.

20 Endress+Hauser

Page 21

Cerabar S/Deltabar S Description of parameters (FF configuration program)

6 Description of parameters

(FF configuration program)

!

Note!

• In FOUNDATION Fieldbus, all the device parameters are categorised depending on their

functional properties and tasks and assigned to the Resource Block, the Transducer Blocks and the

function blocks. This Section describes the parameters of the Resource Block, the Transducer

Blocks and the Analog Input Block. For a parameter description of other function blocks, such as

the PID or Discrete Output Block, see Operating Instructions BA013S "FOUNDATION Fieldbus

Overview" or the FOUNDATION Fieldbus Specification.

• Some parameters are only displayed if other parameters are appropriately configured. For

example, the PRESSURE_1_UNIT_TEXT/CUSTOMER UNIT P parameter is not displayed unless

the "User Unit" option was selected for the CAL_UNIT parameter. There is a comment in the

parameter description here stating: Note: prerequisite: CAL_UNIT = User Unit.

• Parameter names are written in upper case in the text.

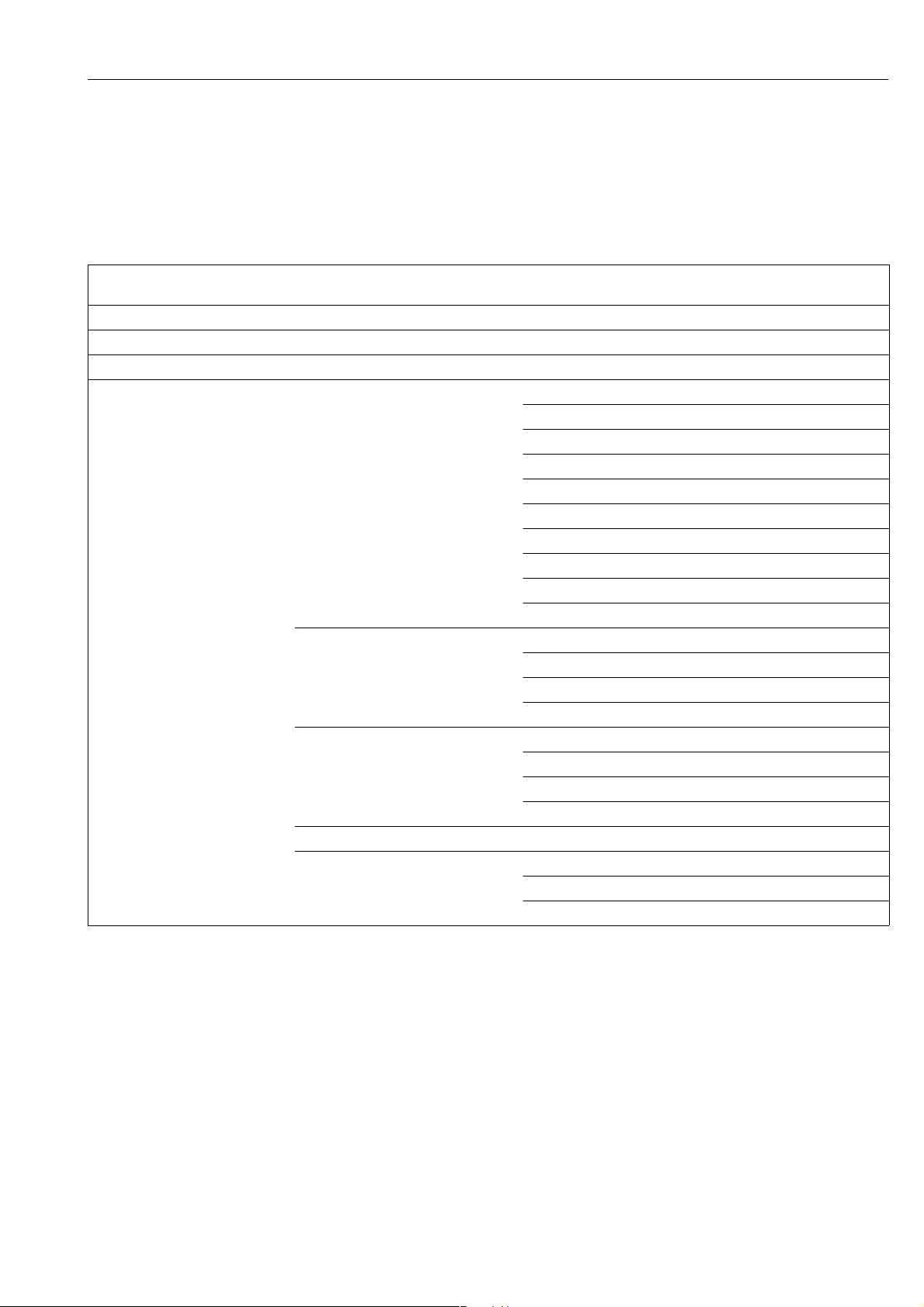

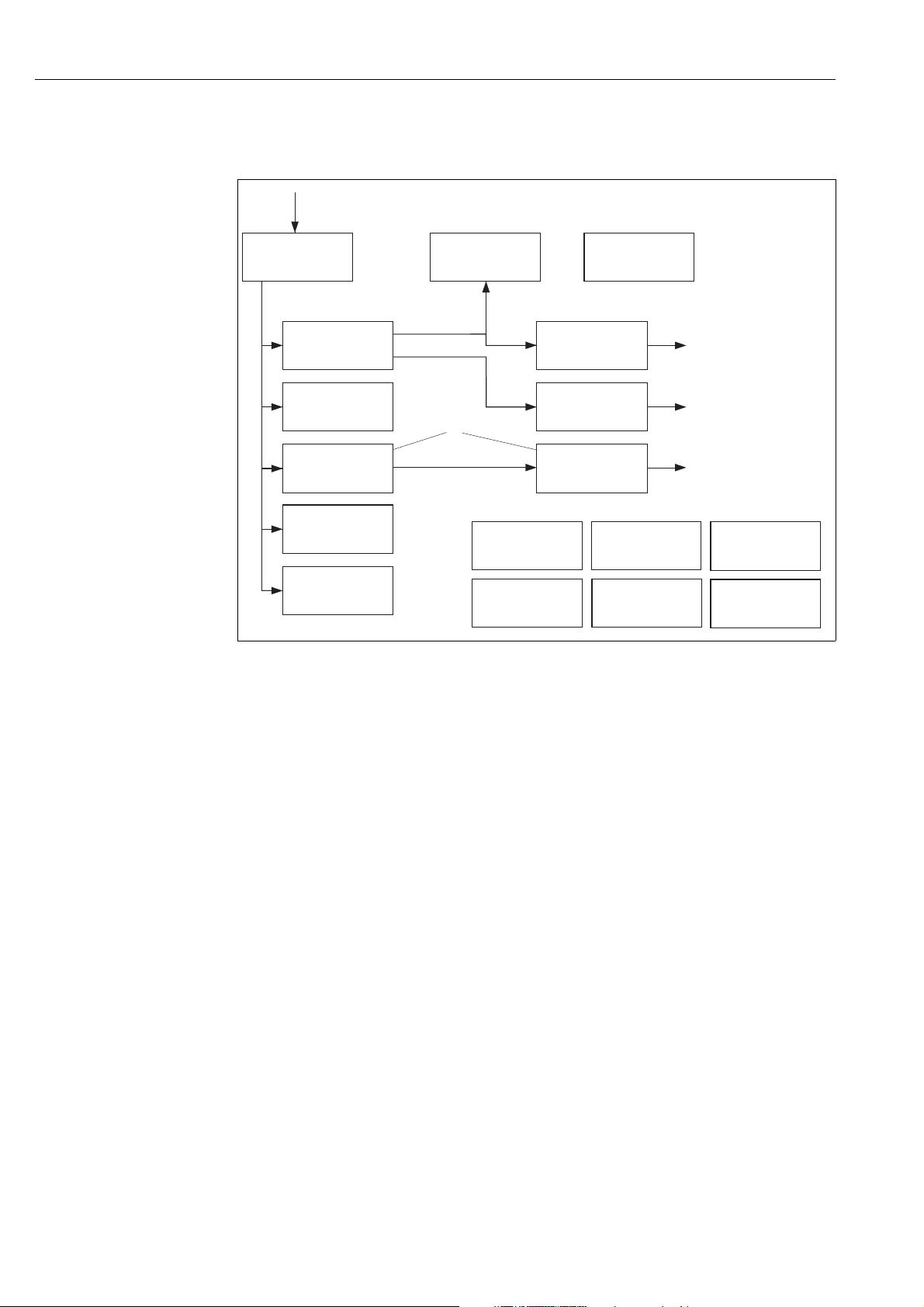

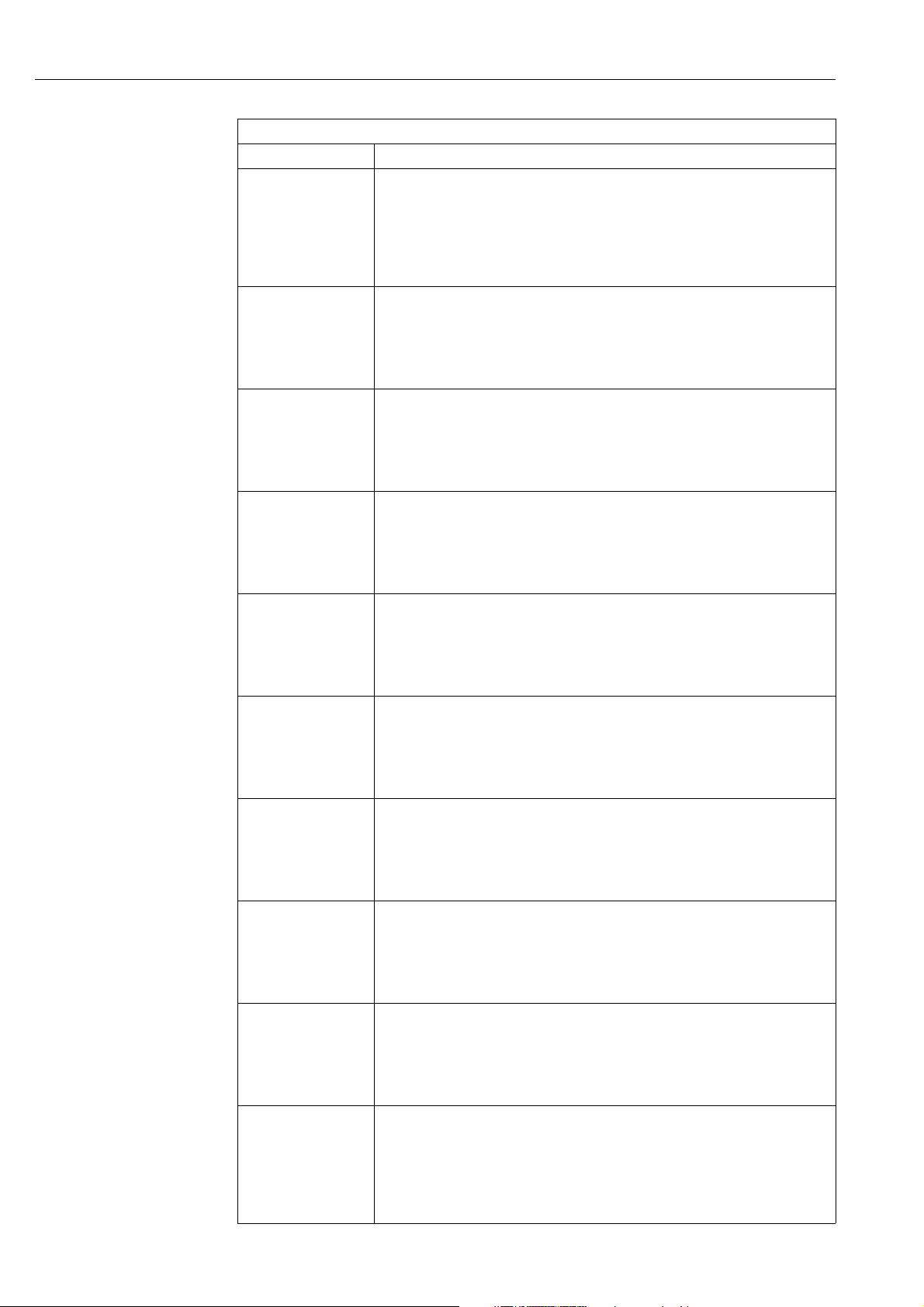

6.1 Deltabar S and Cerabar S block model

Deltabar S/Cerabar S has the following blocks:

• Resource Block (device block)

• Transducer Blocks

– Pressure Transducer Block

This Block supplies the output variables PRIMARY_VALUE and SECONDARY_VALUE. It

contains all the parameters to configure the measuring device for the measuring task such as

measuring mode selection, linearisation function and unit selection.

– Service Transducer Block

This Block supplies the output variables PRESSURE, MAX. MEAS. PRESS. and

COUNTER: P > Pmax. It also includes all the counters for measuring range overshoot/

undershoot for pressure and temperature, minimum and maximum measured values for

pressure and temperature and the HistoROM function.

– Totalizer Transducer Block (Deltabar S only)

This Block supplies the output variable TOTALIZER_1_VALUE/TOTALIZER 1. It contains all

the parameters that are needed to configure this totalizer.

– Display Transducer Block

This Block does not return any output variable. It contains all the parameters for configuring

the on-site display such as DISPLAY_LANGUAGE/LANGUAGE and DISPLAY_CONTRAST.

– Diagnostic Transducer Block

This Block does not return any output variable. It contains the simulation function for the

Pressure Transducer Block, parameters to configure the alarm response and the user limits for

pressure and temperature.

• Function blocks

– Deltabar S: 3 Analog Input Blocks (AI), Cerabar S: 2 Analog Input Blocks (AI)

– Discrete Output Block (DO)

– PID Block (PID)

– Arithmetic Block (ARB)

– Signal Characterizer Block (SCB)

– Input Selector Block (ISB)

– Analog Alarm Block (AALB)

Endress+Hauser 21

Page 22

Description of parameters (FF configuration program) Cerabar S/Deltabar S

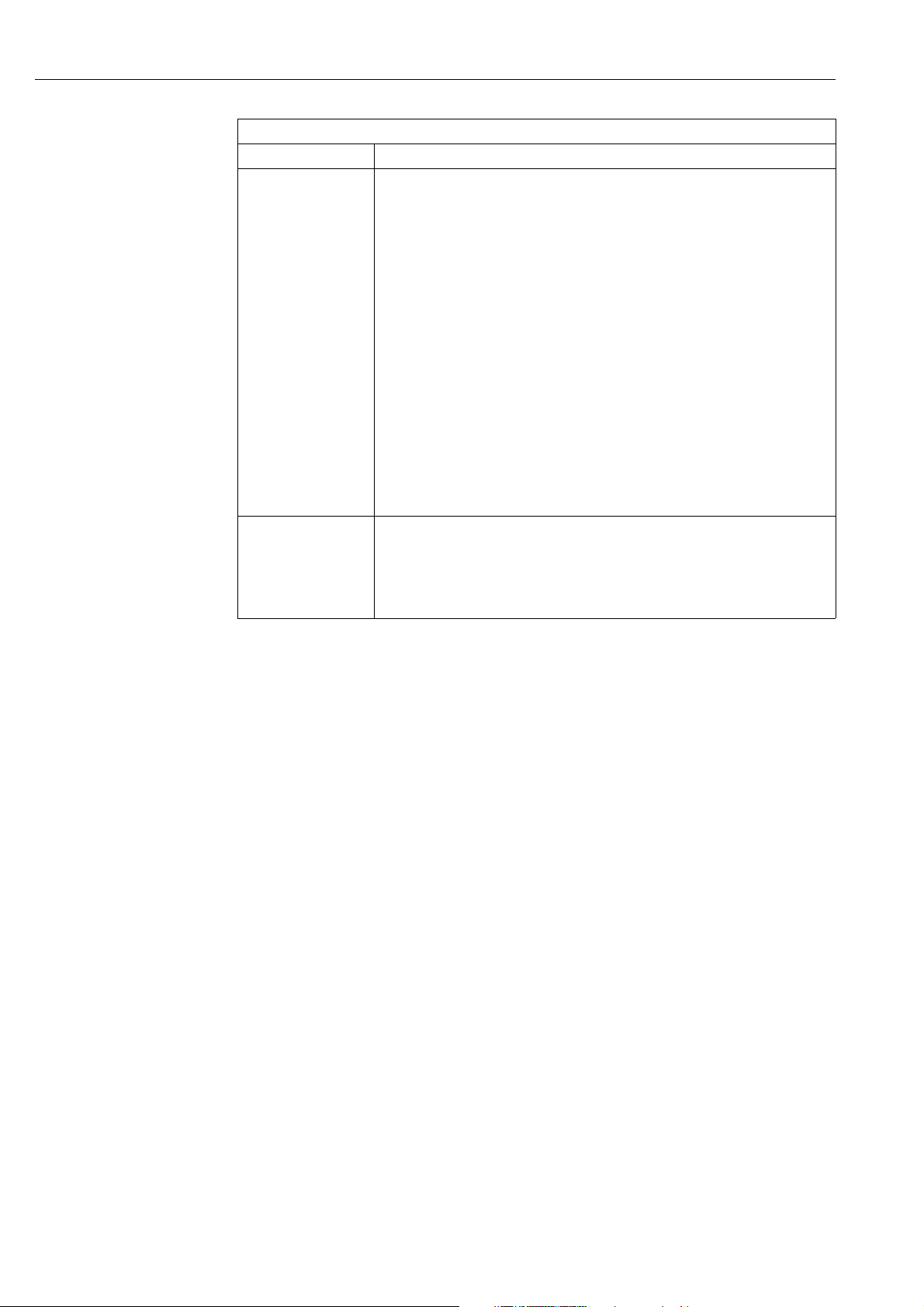

Block configuration when delivered

The block model shown below illustrates the block configuration when the device is delivered.

Measured variable

Sensor

Signal evaluation

Pressure

Transducer Block

Service

Transducer Block

Totalizer

Transducer Block

Display

Transducer Block

Diagnostic

Transducer Block

Fig. 7: Block configuration when delivered

Display

with scaling

Primary value

Secondary value

Deltabar only

TOTALIZER 1

Analog Input Block 1

CHANNEL = 1

L_TYPE = Direct

Analog Input Block 2

CHANNEL = 2

L_TYPE = Direct

Analog Input Block 3

CHANNEL = 6

L_TYPE = Direct

Arithmetic Block

Discrete Output

Block

Resource Block

PID Block

Signal Characterizer

Block

Input Selector Block

Analog Alarm Block

P01-xMx7xxxx-02-xx-xx-xx-000

!

Cerabar S

The Pressure Transducer Block returns the Primary Value (pressure measured value) and the

Secondary Value (sensor temperature). Primary Value and Secondary Value are each transferred to

one Analog Input Block by means of the CHANNEL parameter (→ see also Page 67, parameter

description CHANNEL).

The Discrete Output, PID, Arithmetic, Signal Characterizer, Input Selector and Analog Alarm Block

are not connected in the as-delivered state.

Deltabar S

The Pressure Transducer Block returns the Primary Value (pressure measured value) and the

Secondary Value (sensor temperature). In the Totalizer Transducer Block, the flow is totalized in

the "Flow" measuring mode and output by means of the TOTALIZER_1_VALUE/TOTALIZER 1

parameter. Primary Value, Secondary Value and TOTALIZER_1_VALUE are each transferred to one

Analog Input Block by means of the CHANNEL parameter (→ see also Page 67, parameter

description CHANNEL).

The Discrete Output, PID, Arithmetic, Signal Characterizer, Input Selector and Analog Alarm Block

are not connected in the as-delivered state.

Note!

Please note that the links between the blocks are deleted and the FF parameters are reset to the

default values following a reset by means of the RESTART parameter in the Resource Block,

"Default" option.

22 Endress+Hauser

Page 23

Cerabar S/Deltabar S Description of parameters (FF configuration program)

6.2 Resource Block

Resource Block

Parameter Description

ACK_OPTION

Selection

Index: 38

Data type: Bit String

Access: Auto, OOS

ALARM_SUM

Display, Selection

Index: 45

Data type: DS-74

Access: Auto, OOS

ALERT_KEY

Entry

Index: 4

Data type: Unsigned8

Access: Auto, OOS

BLOCK_ALM

Display, Selection

Index: 36

Data type: DS-72

Access: Auto, OOS

BLOCK_ERR

Display

Index: 6

Data type: Bit String

Access: Read only

Use this parameter to specify which process alarm is automatically acknowledged by the

fieldbus host system when it is detected. If the option is activated for a process alarm, this

process alarm is automatically acknowledged by the fieldbus host system.

Options:

• DiscAlm: write protection alarm

• BlockAlm: block alarm

Note!

!

For process alarms for which automatic confirmation is not active, the message must be

acknowledged by means of the BLOCK_ALM parameter, UNACKNOWLEDGE element.

Factory setting:

The option is not active for any process alarm, i.e. every process alarm message must be

acknowledged manually.

The ALARM_SUM parameter is a structured parameter consisting of four elements.

CURRENT

• Displays the current status of the process alarms in the Resource Block.

The following alarms are possible: DiscAlm and BlockAlm.

UNACKNOWLEDGED

• Displays the process alarms not confirmed.

UNREPORTED

• Displays the process alarms not reported.

DISABLED

• Possibility to deactivate process alarms.

Enter the identification number for the measuring device or for every individual block.

The host system uses this identification number to sort alarm and event messages and initiate

further processing.

Input range:

1...255

Factory setting:

0

The BLOCK_ALM parameter is a structured parameter consisting of five elements.

UNACKNOWLEDGED

• If the "Deactivated" option was selected for the alarm occurring via the ACK_OPTION

parameter, this alarm can only be acknowledged via this element.

ALARM_STATE

• Displays the current block status with information on the pending configuration, hardware

or system errors. The following block alarm messages are possible for the Resource Block:

–Simulate Active

–Out of Service

TIME_STAMP

• Displays the time the alarm occurred.

SUB_CODE

• Displays the reason why the alarm was reported.

VALUE

• Displays the value of the parameter at the time the alarm was reported.

Displays the active block errors.

Possibilities:

• Out Of Service: the Resource Block is in the OOS block mode.

• Simulation active: DIP switch 2 "Simulation" on the electronic insert is set to "On", i.e.

simulation is possible.

Endress+Hauser 23

Page 24

Description of parameters (FF configuration program) Cerabar S/Deltabar S

Resource Block

Parameter Description

CLR_FSTATE/

CLEAR FAULT STATE

Selection

Index: 30

Data type: Unsigned8

Access: Auto, OOS

CONFIRM_TIME

Entry

Index: 33

Data type: Unsigned32

Access: Auto, OOS

CYCLE_SEL

Display

Index: 20

Data type: Bit String

Access: Auto, OOS

CYCLE_TYPE

Display

Manually deactivate the fault state of the Discrete Output function block. → See also this

table, SET_FSTATE parameter description.

Possibilities:

• Uninititalized

•Off

• Clear (the fault state is deactivated.)

Enter the confirmation time for the event report. If the device does not receive any

confirmation within this period, the event report is sent again to the fieldbus host system.

Factory setting:

1

640000

/32 ms

Displays the block execution method used by the fieldbus host system. The fieldbus host

system selects the block execution method.

Possibilities:

• Scheduled: cyclical block execution method

• Block execution: sequential block execution method

Displays the block execution methods supported by the device. → See also this table,

CYCLE_SEL parameter description.

Index: 19

Data type: Bit String

Access: Read only

DD_REV

Display

Index: 13

Data type: Unsigned8

Access: Read only

DEV_REV

Display

Index: 12

Data type: Unsigned8

Access: Read only

DEV_TYPE

Display

Index: 11

Data type: Unsigned16

Access: Read only

FAULT_STATE

Display

Index: 28

Data type: Unsigned8

Access: Read only

FEATURES

Display

Displays the revision number of the device description (DD).

Displays the revision number of the device.

Displays the device identification number.

Deltabar S: hexadecimal: 1009, decimal: 4105.

Cerabar S: hexadecimal: 1007, decimal: 4103.

Current status display of the fault state of the Discrete Output function block.

Possibilities:

• Uninititalized

• Clear (fault state not active)

• Active (fault state active)

Displays the additional functions supported by the device. → See also this table,

FEATURE_SEL parameter description.

Index: 17

Data type: Bit String

Access: Read only

FEATURE_SEL/

FEATURE SELECTION

Selection

Index: 18

Data type: Bit String

Access: Auto, OOS

Select additional device functions. The additional functions the device supports is displayed in

the FEATURES parameter (→ Page 24).

24 Endress+Hauser

Page 25

Cerabar S/Deltabar S Description of parameters (FF configuration program)

Resource Block

Parameter Description

FREE_SPACE

Display

Index: 24

Data type: Float

Access: Read only

FREE_TIME

Display

Index: 25

Data type: Float

Access: Read only

GRANT_DENY

Selection

Index: 14

Data type: DS-70

Access: Auto, OOS

HARD_TYPES

Display

Displays in percent the system space available to execute further function blocks.

Input range:

0...100 %

Displays in percent the free system time available to execute further function blocks.

Input range:

0...100 %

Grant or restrict access rights for a fieldbus host system to the device. This parameter is not

evaluated by Deltabar S and Cerabar S.

Displays the input signal type for the Analog Input function blocks.

Index: 15

Data type: Bit String

Access: Read only

ITK_VER

Display

Index: 41

Data type: Unsigned16

Access: Read only

LIM_NOTIFY

Entry

Index: 32

Data type: Unsigned8

Access: Auto, OOS

MANUFAC_ID

Display

Index: 10

Data type: Unsigned16

Access: Read only

MAX_NOTIFY

Display

Index: 31

Data type: Unsigned8

Access: Read only

MEMORY_SIZE

Display

Displays the revision status of the ITKs (Interoperability Test Kit).

Enter the maximum possible number of event reports that can be simultaneously present as

unacknowledged. The parameter is not evaluated by Deltabar S and Cerabar S.

Displays the manufacturer identification number.

Endress+Hauser: 0 x 452B48 (decimal: 4533064)

Displays the number of event reports supported by the device that can be simultaneously

present as unacknowledged. → See also this table, LIM_NOTIFY parameter description.

Displays the configuration memory available in kilobyte. This parameter is not supported by

Deltabar S and Cerabar S.

Index: 22

Data type: DS-69

Access: Read only

MIN_CYCLE_T

Display

Index: 21

Data type: Unsigned32

Access: Read only

Displays the shortest execution time supported by the device.

Factory setting:

1

1600

/32 ms (≅ 50 ms)

Endress+Hauser 25

Page 26

Description of parameters (FF configuration program) Cerabar S/Deltabar S

Resource Block

Parameter Description

MODE_BLK

Selection, Display

Index: 5

Data type: DS-69

Access: Auto, OOS

NV_CYCLE_T/

NONVOLATILE CYCLE

TIME

Display

Index: 23

Data type: Unsigned32

Access: Read only

RESTART

Selection

Index: 16

Data type: Unsigned8

Access: Auto, OOS

RS_STATE

Display

Index: 7

Data type: Unsigned8

Access: Read only

SET_FSTATE/

SET FAULT STATE

Selection

Index: 29

Data type: Unsigned8

Access: Auto, OOS

SHED_RCAS/

SHED REMOTE

CASCADE

Entry

Index: 26

Data type: Unsigned32

Access: Auto, OOS

SHED_ROUT/

SHED REMOTE OUT

Entry

Index: 27

Data type: Unsigned32

Access: Auto, OOS

The MODE_BLK parameter is a structured parameter consisting of four elements.

The Resource Block supports the "Auto" (automatic mode) and OOS (out of service) modes.

TARGET

• Change the block mode.

ACTUAL

• Displays the current block mode.

PERMITTED

• Displays the modes supported by the block.

NORMAL

• Displays the block mode during standard operation.

Displays the time interval in which the dynamic device parameters are stored in the nonvolatile memory. As Cerabar S and Deltabar S do not store dynamic device parameters in the

non-volatile memory, the parameter constantly displays the value 0

1

/32 ms.

Select reset mode.

Options:

• Run: standard operating mode

• Resource: this mode is not supported by Endress+Hauser.

• Defaults: device data and the function block link are reset to the factory setting. The

manufacturer-specific parameters of the Transducer Block are not reset to the factory

setting.

→ See also Operating Instructions BA301P (Deltabar S) or BA302P (Cerabar S),

Section 5.7 "Factory setting" (reset).

• Processor: warm start, of device, new processor start.

• Factory: the function block links, all FF and resettable manufacturer-specific parameters

are reset to the factory setting.

Displays the current status of the Resource Block.

Possibilities:

• Standby: the Resource Block is in the OOS mode (out of service). It is not possible to

execute the remaining blocks.

• Online linking: the configured links between the function blocks have not yet been

established.

• Online: standard block mode, the Resource Block works in the Auto mode. All the

configured links between the function blocks have been established. If a link is missing,

this parameter displays the "online linking" status.

Manually activate the fault state of the Discrete Output function block. → See also this table,

CLR_FSTATE parameter description.

Possibilities:

• Uninititalized

•Off

• Set (the fault state is activated.)

Enter the monitoring time for checking the link between the fieldbus host system and the

PID function block in the RCAS block mode. Once this monitoring time elapses, the PID

function block changes from the RCAS block mode to the block mode selected by means of

the SHED_OPT parameter.

Factory setting:

1

640000

/32 ms

Enter the monitoring time for checking the link between the fieldbus host system and the

PID function block in the ROUT block mode. Once this monitoring time elapses, the PID

function block changes from the ROUT block mode to the block mode selected by means of

the SHED_OPT parameter.

Factory setting:

1

640000

/32 ms

26 Endress+Hauser

Page 27

Cerabar S/Deltabar S Description of parameters (FF configuration program)

Resource Block

Parameter Description

ST_REV

Display

Index: 1

Data type: Unsigned16

Access: Read only

STRATEGY

Entry

Index: 3

Data type: Unsigned16

Access: Auto, OOS

TAG_DESC

Entry

Index: 2

Data type: Octet String

Access: Auto, OOS

TEST_RW/

TEST READ WRITE

Display

Index: 8

Data type: DS-85

Access: Auto, OOS

UPDATE_EVT

Display

Index: 35

Data type: DS-73

Access: Read only

WRITE_ALM

Display

Index: 40

Data type: DS-72

Access: Read only

Displays the counter for static parameters of the Resource Block

This counter is incremented by one with each change of a static parameter of the Resource

Block. The counter counts up to 65535 and then starts again at zero.

Enter a user-specific value for grouping and thus faster evaluation of the blocks.

Grouping takes place by entering the same numerical value for the STRATEGY parameter of

the block in question. This value is neither checked nor processed by the Resource Block.

Input range:

0...65535

Factory setting:

0

Enter a description for the associated block or the measuring point e.g. TAG number (max.

32 alphanumeric characters).

This parameter is only needed for the FF conformance test and does not have any relevance

during measuring operation.

The UPDATE_EVT parameter is a structured parameter consisting of five elements.

UNACKNOWLEDGED

• This element is set to "Unacknowledged" as soon as a static parameter changes.

UPDATE_STATE

• Displays whether the change was reported.

TIME_STAMP

• Displays the date and time a static parameter was changed.

STATIC_REVISION

• The revision counter is increased when a static parameter changes.

RELATIVE_INDEX

• Displays the altered parameter in the form of the relative index. See also this table,

"Parameter, Index" column.

The WRITE_ALM parameter is a structured parameter consisting of five elements.

UNACKNOWLEDGED

• If the "Deactivated" option was selected for the alarm occurring via the ACK_OPTION

parameter, this alarm can only be acknowledged via this element.

ALARM_STATE

• Status display of the write protection alarm.

TIME_STATE

• Displays the time the alarm occurred.

SUB_CODE

• Displays the reason why the alarm was reported.

VALUE

• Displays the value of the parameter at the time the alarm was reported.

Endress+Hauser 27

Page 28

Description of parameters (FF configuration program) Cerabar S/Deltabar S

Resource Block

Parameter Description

WRITE_LOCK

Display

Index: 34

Data type: Unsigned8

Access: Read only

WRITE_PRI

Entry

Index: 39

Data type: Unsigned8

Access: Read only

SW_LOCK/

INSERT PIN No.

Entry

Index: 43

Data type: Unsigned16

Access: Auto, OOS

Endress+Hauser Resource Block parameters

DEVICE_DIALOG

Display

Index: 42

Data type: Unsigned8

Access: Read only

DEVICE_ORDER_CODE

/DEVICE DESIGN.

Display

Displays the status of DIP switch 1 on the electronic insert.

You can lock and unlock parameters relevant to the measured value with DIP switch 1. If

operation is locked by means of the SW_LOCK/INSERT PIN No. parameter (→ see Page 28),

you can only unlock operation again by means of this parameter. → See also Operating

Instructions BA301P (Deltabar S) or BA302P (Cerabar S), Section 5.6 "Locking/unlocking

operation".

Possibilities:

• Locked: locking switched on, i.e. the parameters cannot be written to.

• Not Locked: locking switched off. Depending on the block mode in question, the

parameters can be written to (→ see tables, "Parameter", Access column).

Factory setting:

Locked (locking switched off)

Disabling write protection generates an alarm. Use this parameter to specify which priority

should be assigned to this alarm.

Input range:

• 0...15

• 0: The alarm is suppressed.

• 15: Critical alarm with the highest priority.

For entering a code to lock or unlock operation.

Note!

!

• The symbol on the on-site display indicates that operation is locked. Parameters which

refer to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST can still be

altered.

• If operation is locked by means of the DIP-switch, you can only unlock operation again by

means of the DIP-switch. If operation is locked by means of remote operation, you can

only unlock operation again by means of remote operation.

→ See also Operating Instructions BA301P (Deltabar S) or BA302P (Cerabar S), Section 5.6

"Locking/unlocking operation".

Options:

• Lock: enter a number between 0...9999 which is ≠100.

• Unlock: enter number 100.

Factory setting:

100

If the configuration is not suitable, this parameter displays a message saying that a

configuration error is present. The message can indicate which parameter was incorrectly

configured.

Displays the device designation and the order code.

Index: 44

Data type: Visible String

Access: Read only

HARDWARE_REVISION

Display

Index: 45

Data type: Visible String

Access: Read only

SOFTWARE_VERSION

Display

Index: 46

Data type: Float

Access: Read only

Displays the revision number of the main electronics e.g. V01.00.

Displays the software version e.g. V02.00.

28 Endress+Hauser

Page 29

Cerabar S/Deltabar S Description of parameters (FF configuration program)

Resource Block

Parameter Description

ELECTRONIC _SERIAL

_NUMBER/

ELECTR. SERIAL No.

Display

Index: 47

Data type: Float

Access: Read only

DEVICE_SERIAL_

NUMBER/

DEVICE SERIAL No.

Display

Index: 48

Data type: Float

Access: Read only

PROCESS_CONNECTION_MODEL/

PROC. CONN. TYPE

Selection

Index: 49

Data type: Unsigned16

Access: Auto, OOS

PROCESS_CONNECTION_MATERIAL_

POSITIVE/

MAT. PROC. CONN. +

Selection

Index: 50

Data type: Float

Access: Auto, OOS

PROCESS_CONNECTION_MATERIAL_

NEGATIVE/

MAT.PROC. CONN.–

Selection

Displays the serial number of the main electronics (11 alphanumeric characters).

Displays the serial number of the device (11 alphanumeric characters).

For selecting and displaying the process connection type.

Options:

•Not used

•Unknown

•Special

•Oval flange

• Thread female

•Thread male

•Flange

•Remote seal

For selecting and displaying the material of the process connection (P+).

→ See also parameter description MAT. PROC. CONN. –

Options:

•Not used

•Unknown

•Special

• Steel

• 304 st. steel

• 316 st. steel

• Alloy C

•Monel

•Tantalum

• Titanium

•PTFE (Teflon)

• 316L st. steel

•PVC

•Inconel

•PVDF

•ECTFE

Factory setting:

As per order specifications

For selecting and displaying the material of the process connection (P–).

→ See also parameter description MAT. PROC. CONN. +

Index: 51

Data type: Float

Access: Auto, OOS

Endress+Hauser 29

Page 30

Description of parameters (FF configuration program) Cerabar S/Deltabar S

Resource Block

Parameter Description

PROCESS_FLANGE_

GASKET_MATERIAL/

SEAL TYPE

Selection

Index: 52

Data type: Visible String

Access: Auto, OOS

SCI_OCTET_STR

Display

For displaying and selecting the material of the process seal.

Options:

•Not used

•Unknown

•Special

• FKM Viton

•NBR

•EPDM

•Urethane

•IIR

•Kalrez

• FKM Viton oxyg

•CR

•MVQ

•PTFE glass

•PTFE graphite

• PTFE oxygen

• Copper

• Copper f. oxygen

Factory setting:

As per order specifications

Internal service parameter.

Index: 53

Data type: Visible String

Access: Read only

30 Endress+Hauser

Page 31

Cerabar S/Deltabar S Description of parameters (FF configuration program)

6.3 Transducer Blocks

6.3.1 FOUNDATION Fieldbus standard parameters Transducer Blocks

Transducer Block, FOUNDATION Fieldbus standard parameters (all Transducer Blocks)

Parameter Description

ST_REV

Display

Index: 1

Data type: Usigned16

Access: Read only

TAG_DESC

Entry

Index: 2

Data type: Octet String

Access: Auto, OOS

STRATEGY

Entry

Index: 3

Data type: Unsigned16

Access: Auto, OOS

ALERT_KEY

Entry

Index: 4

Data type: Unsigned8

Access: Auto, OOS

MODE_BLK

Display, Selection

Index: 5

Data type: DS-69

Access: Auto, OOS

BLOCK_ERR

Display

Index: 6

Data type: Bit String

Access: Read only

Displays the counter for the static parameters of the Transducer Block

This counter is increased by one with each change to a static parameter of the Transducer

Block in question. The counter counts to 65535 and then starts again at zero.

Enter a description for the associated block or the measuring point e.g. TAG number

(max. 32 alphanumeric characters).

Factory setting:

Empty field

Enter a user-specific value for grouping and thus faster evaluation of the blocks.

Grouping takes place by entering the same numeric value for the STRATEGY parameter of

the block in question. These data are neither checked nor processed by the Transducer

Blocks.

Input range:

0...65535

Factory setting:

0

Enter the identification number for the device or for each individual block.

The host system uses this identification number to sort alarm and event messages and initiate

further processing.

Input range:

1...255

Factory setting:

0

The MODE_BLK parameter is a structured parameter consisting of four elements.

The Transducer Blocks support the "Auto" (automatic mode) and OOS

(out of service) modes.

TARGET

• Change the block mode.

ACTUAL

• Displays the current block mode.

PERMITTED

• Displays the modes supported by the block.

NORMAL

• Displays the block mode during standard operation.

Note!

!

Measured values or information can be forwarded to an Analog Input Block by means of the

Pressure, Service and Totalizer Transducer Block. If the Pressure Transducer Block is set to

the OOS block mode, for example, the primary and secondary value continue to be updated

but the status of the downstream Analog Input Block changes to BAD.

Displays the warning and error messages of the software and hardware of the Transducer

Block in question. This parameter also triggers an alarm. If two or more messages occur at the

same time, the message with the highest priority is the one shown on the display.

For the Pressure, Service and Totalizer Block, see possible messages in these Operating

Instructions, Section 11.1 "Messages". The Display and Diagnostic Blocks do not display any

warning or error messages.

Endress+Hauser 31

Page 32

Description of parameters (FF configuration program) Cerabar S/Deltabar S

Transducer Block, FOUNDATION Fieldbus standard parameters (all Transducer Blocks)

Parameter Description

UPDATE_EVT

Display

Index: 7

Data type: DS-73

Access: Read only

BLOCK_ALM

Display, Selection

Index: 8

Data type: DS-72

Access: Auto, OOS

TRANSDUCER_

DIRECTORY

Display

Index: 9

Data type: Unsigned16

Access: Read only

TRANSDUCER_TYPE

Display

Index: 10

Data type: Unsigned16

Access: Read only

XD_ERROR

Display

Index: 11

Data type: Usigned8

Access: Read only

COLLECTION_

DIRECTORY

Display

Index: 12

Data type: Unsigned32

Access: Read only

The UPDATE_EVT parameter is a structured parameter consisting of five elements.

UNACKNOWLEDGED

• This element is set to "Unacknowledged" as soon as a static parameter changes.

UPDATE_STATE

•Displays whether the change was reported.

TIME_STAMP

• Displays the date and time a static parameter was changed.

STATIC_REVISION

• The revision counter is increased when a static parameter changes.

RELATIVE_INDEX

• Displays the altered parameter in the form of the relative index. See also this table,

"Parameter, Index" column.

The BLOCK_ALM parameter is a structured parameter consisting of five elements.

UNACKNOWLEDGED

• If the "Deactivated" option was selected for the alarm occurring via the ACK_OPTION

parameter, this alarm can only be acknowledged via this element.

ALARM_STATE

• Displays the current block status with information on the pending configuration, hardware

or system errors.

TIME_STAMP

• Displays the date and time the alarm occurred.

SUB_CODE

• Displays the reason why the alarm was reported.

VALUE

• Displays the value of the parameter at the time the alarm was reported.

A directory that specifies the number of transducers mapped in the Pressure Transducer

Block and their indices. This parameter is only displayed in the Pressure Transducer Block.

Display:

0: Only one transducer is mapped in the Pressure Transducer Block.

Displays the Transducer Block type.

Displays the active device status.

→ See also these Operating Instructions, Section 11.1 "Messages".

Prerequisite:

• Pressure Transducer Block

• Service Transducer Block

• Totalizer Transducer Block (only Deltabar S)

A directory that specifies the number of parameter groups (data collection) mapped in the

Pressure Transducer, their indices and DD item IDs. This parameter is only displayed in the

Pressure Transducer Block.

Display:

0: This parameter is not used.

32 Endress+Hauser

Page 33

Cerabar S/Deltabar S Description of parameters (FF configuration program)

6.3.2 Pressure Transducer Block

Pressure Transducer Block

Parameter Description

PRIMARY_VALUE_TYPE

Selection

Index: 13

Data type: Unsigned16

Access: OOS

PRIMARY_VALUE

Display

Index: 14

Data type: DS-65

Access: Read only

PRIMARY_VALUE_

RANGE

Display

Index: 15

Data type: DS-68

Access: Read only

CAL_POINT_HI/

HIGH SENSOR TRIM

Entry

Index: 16

Data type: Float

Access: OOS

Use this parameter and the LINEARIZATION parameter (→ Page 36) to select the measuring

mode and the measured variable.

→ See also Operating Instructions Deltabar S (BA301P) and Cerabar S (BA302P), select

Section 6.3 "Language and measuring mode".

Selection

• Differential pressure with Deltabar S

• Gauge pressure with Cerabar S with absolute pressure sensors.

• Absolute pressure with Cerabar S with overpressure sensors.

• Level

•Volume

•Mass

• Flow (only Deltabar S)

• Tank content (PV) in %

Note!

!

Make sure that the unit selected by means of the SCALE_OUT parameter, "Units Index"

element, matches the measured variable.

The PRIMARY_VALUE parameter is a structured parameter consisting of two elements.

VALUE

• Displays the primary value, which, depending on the measuring mode, is a pressure, level

or flow value.

STATUS

• Displays the status of the primary value.

Note!

!

You can transfer the value and status of the PRIMARY_VALUE parameter via the CHANNEL

parameter (→ Page 67) in the Analog Input Block. For this purpose, the CHANNEL must be

set to "1".

The PRIMARY_VALUE_RANGE parameter is a structured parameter consisting of four

elements.

EU_100

• Displays the upper limit for the primary value.

EU_0

• Displays the lower limit for the primary value.

UNITS_INDEX

• Displays the unit.

DECIMAL

• Displays the number of places after the decimal point.

Note!

!