Endress+Hauser Cerabar M PMP51, Cerabar M PMC51, Cerabar M PMP55 Technical Information

Technical Information

Cerabar M PMC51, PMP51, PMP55

Process pressure measurement

Pressure transmitter with ceramic and metal sensors;

Modular design and easy operation;

With analog or HART electronics

Application

The Cerabar M pressure transmitter is used for the

following measuring tasks:

• Absolute pressure and gauge pressure measurement in

gases, steams or liquids in all areas of process

engineering and process measurement technology

• Level, volume or mass measurements in liquids

• High process temperature

– without diaphragm seals up to 125°C (257°F)

– with diaphragm seals up to 400°C (752°F)

• High pressure up to 400 bar (6000 psi)

• International usage thanks to a wide range of approvals

Your benefits

• Very good reproducibility and long-term stability

• High reference accuracy: up to 0.15%,

as PLATINUM version: 0.075%

• Turn down up to 100:1

• End-to-end modularity for differential pressure,

hydrostatics and pressure (Deltabar M – Deltapilot M –

Cerabar M), e.g.

– replaceable display

– universal electronics

• Easy commissioning without the need for an operating

tool

• Menu-guided operation

• Output signals: 4 to 20 mA, 4 to 20 mA with HART

TI436P/00/EN/02.10

No. 71109889

Table of contents

Cerabar M PMC51, PMP51, PMP55

Function and system design. . . . . . . . . . . . . . . . . . . . . 4

Device selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Level measurement (level, volume and mass) . . . . . . . . . . . . . . . . 6

Electrical differential pressure measurement with gauge pressure

sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System integration (except analog electronics) . . . . . . . . . . . . . . . . 6

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Explanation of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Signal range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Load - 4 to 20 mA analog and 4 to 20 mA HART . . . . . . . . . . . . 10

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dead time, Time constant (T63) . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dynamic behavior: 4 to 20 mA (analog electronics) . . . . . . . . . . . 11

Dynamic behavior: current output (HART electronics) . . . . . . . . 11

Dynamic behavior: digital output (HART electronics) . . . . . . . . . 11

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating conditions (installation) . . . . . . . . . . . . . . 19

General installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . 19

Measuring arrangement for devices without diaphragm seal –

PMC51, PMP51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Measuring arrangement for devices with diaphragm seal

– PMP55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wall and pipe mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

"Separate housing" version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Oxygen applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Silicone-free applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ultrapure gas applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Applications with hydrogen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operating conditions (environment) . . . . . . . . . . . . . 22

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Storage temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overvoltage protection (optional) . . . . . . . . . . . . . . . . . . . . . . . . 23

Operating conditions (process) . . . . . . . . . . . . . . . . . 24

Process temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pressure specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Residual ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Influence of power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Performance characteristics – general . . . . . . . . . . . . 15

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Uncertainty of measurement for small absolute pressure ranges . . 15

Long-term stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Influence of orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Warm-up period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance characteristics – ceramic process isolating

diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reference accuracy – PMC51 . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Total performance – PMC51 . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Total error - PMC51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal change in the zero output and the output span – PMC51 .

16

Performance characteristics – metal process isolating

diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reference accuracy – PMP51, PMP55 . . . . . . . . . . . . . . . . . . . . 17

Total performance – PMP51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Total error - PMP51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Thermal change in the zero output and the output span – PMP51 and

PMP55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 26

F31 aluminum housing dimensions . . . . . . . . . . . . . . . . . . . . . . 26

F15 stainless steel housing dimensions (hygienic) . . . . . . . . . . . . 26

Process connections PMC51 (with ceramic process isolating

diaphragm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Process connections PMP51 (with metal process isolating diaphragm)

32

PMP55 basic device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Process connections PMP55 (with diaphragm seal) . . . . . . . . . . . 38

Wall and pipe mounting with mounting bracket . . . . . . . . . . . . 52

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Onsite operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Planning instructions for diaphragm seal systems . . . 58

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Function and design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Diaphragm seal filling oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operating temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 62

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Ex approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Suitability for hygienic processes . . . . . . . . . . . . . . . . . . . . . . . . . 62

Pressure Equipment Directive (PED) . . . . . . . . . . . . . . . . . . . . . 62

Standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2 Endress+Hauser

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . 63

PMC51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

PMC51 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PMC51 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PMC51 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

PMP51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

PMP51 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

PMP51 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

PMP51 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

PMP55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

PMP55 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

PMP55 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PMP55 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

PMP55 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

PMP55 (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Brief Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installation/Control Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Cerabar M PMC51, PMP51, PMP55

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Shutoff valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Welding necks and Weld-in tool flanges . . . . . . . . . . . . . . . . . . . 80

Mounting bracket for wall and pipe mounting . . . . . . . . . . . . . . 80

M12 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Configuration data sheet (HART electronics) . . . . . . 81

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Configuration data sheet (analog electronics) . . . . . . 83

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3 Endress+Hauser

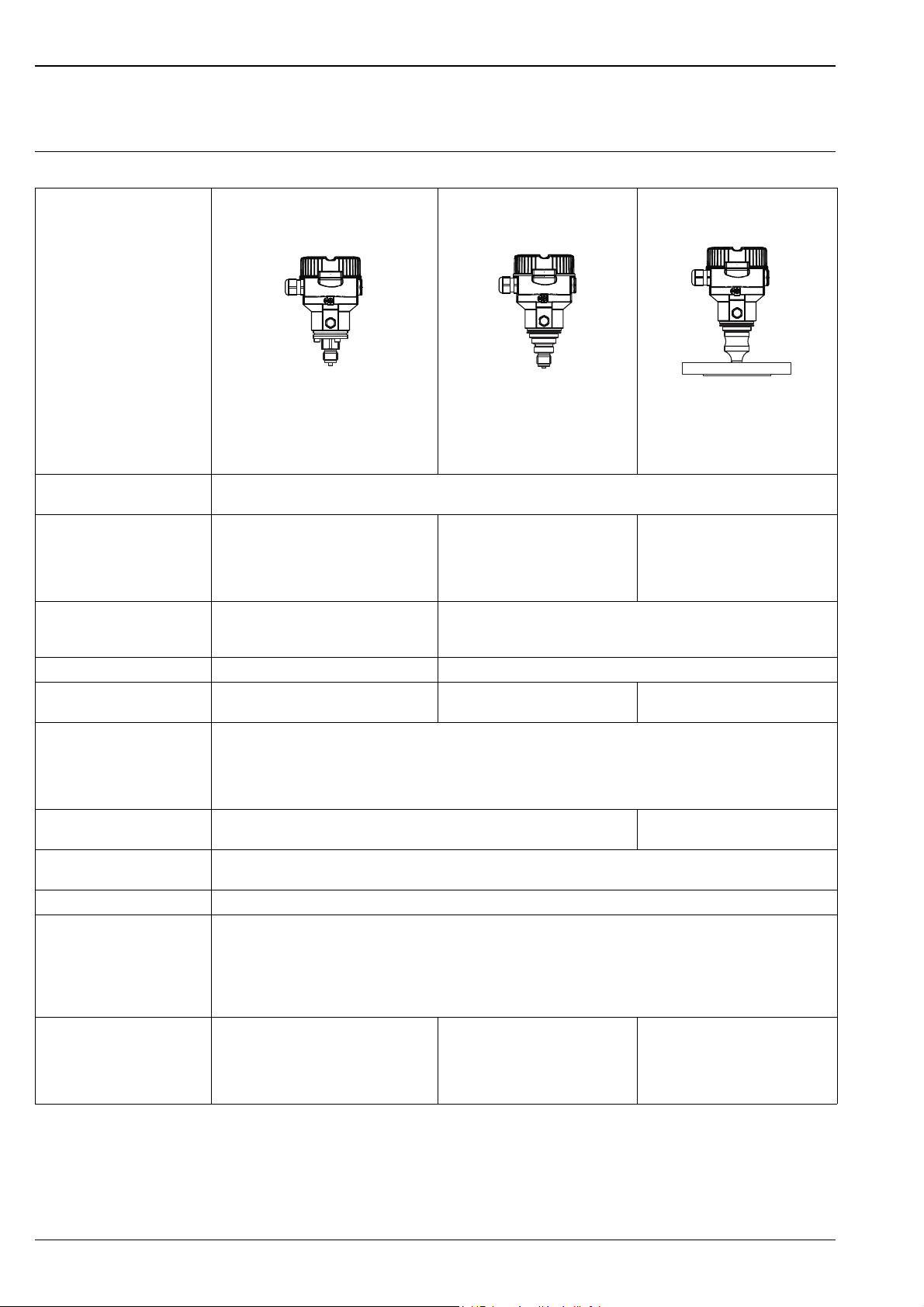

Device selection

Cerabar M PMC51, PMP51, PMP55

Function and system design

Cerabar M –

PMC51

PMP51

PMP55

Product family

P01-PMC51xxx-16-xx-xx-xx-000

With capacitive measuring cell and

ceramic process isolating diaphragm

(Ceraphire

®

)

With piezoresistive measuring cell

and metal welded process isolating

diaphragm

P01-PMP51xxx-16-xx-xx-xx-000

P01-PMP55xxx-16-xx-xx-xx-000

With diaphragm seal

Field of application – Gauge pressure and absolute pressure

– Level

Process connections – Thread

– EN flanges DN 25 – DN 80

– ANSI flanges 1" – 4"

– JIS flanges 50 A – 100 A

–Thread

– EN flanges DN 25 – DN 80

–ANSI flanges 1" – 4"

– JIS flanges 25 A – 100 A

– Wide range of diaphragm seals

– Prepared for diaphragm seal mount

Measuring ranges From –100/0 to 100 mbar (–1.5/0 to

1.5 psi)

From –400/0 to 400 mbar (–6/0 to 6 psi)

to –1/0 to 400 bar (–15/0 to 6000 psi)

to –1/0 to 40 bar (–15/0 to 600 psi)

1

OPL

Max. 60 bar (900 psi) Max. 600 bar (9000 psi)

Process temperature range –20 to +100 °C (–4 to +212°F) –40 to +125°C (–40 to +257°F) –70 to 400 °C (–94 to +752 °F)

depending on the filling oil

Ambient temperature range • Without LCD display: -40 to +85°C (–40 to +185 °F)

• With LCD display: –20 to +70°C (–4 to +158°F) (extended temperature application range (-40 to 85°C (-40 to 185°F)) with

restrictions in optical properties such as display speed and contrast)

• Separate housing: –20 to +60°C (–4 to +140°F)

• Diaphragm seal systems depending on the version

Reference accuracy – Up to 0.15% of the set span

Up to 0.15% of the set span

– PLATINUM version: up to 0.075% of the set span

Supply voltage – 11.5 to 45 V DC (versions with plug-in connection 35 V DC)

– For intrinsically safe device versions: 11.5 to 30 V DC

Output 4 to 20 mA, 4 to 20 mA with superimposed HART protocol

Options – PMP51, PMP55: NACE-compliant materials

– PMC51, PMP51, PMP55: inspection certificate 2.2 or 3.1 or other certificates

– Specific firmware versions

– Initial device settings

– Separate housing

– Broad range of accessories

Specialties – Metal-free measurement with PVDF

connection

– Special cleaning of the transmitter to

remove paint-wetting substances, for use

in paint shops

– Process connections with minimum

oil volume

– Gas-tight, elastomer-free

– Wide range of diaphragm seals

– For extreme medium temperatures

– Process connections with minimum

oil volume

– Completely welded versions

1) OPL = over pressure limit; depends on the lowest-rated element, with regard to pressure, of the selected components

4 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

p

➃

➂➀➁

➂

➀

➁

p

➃

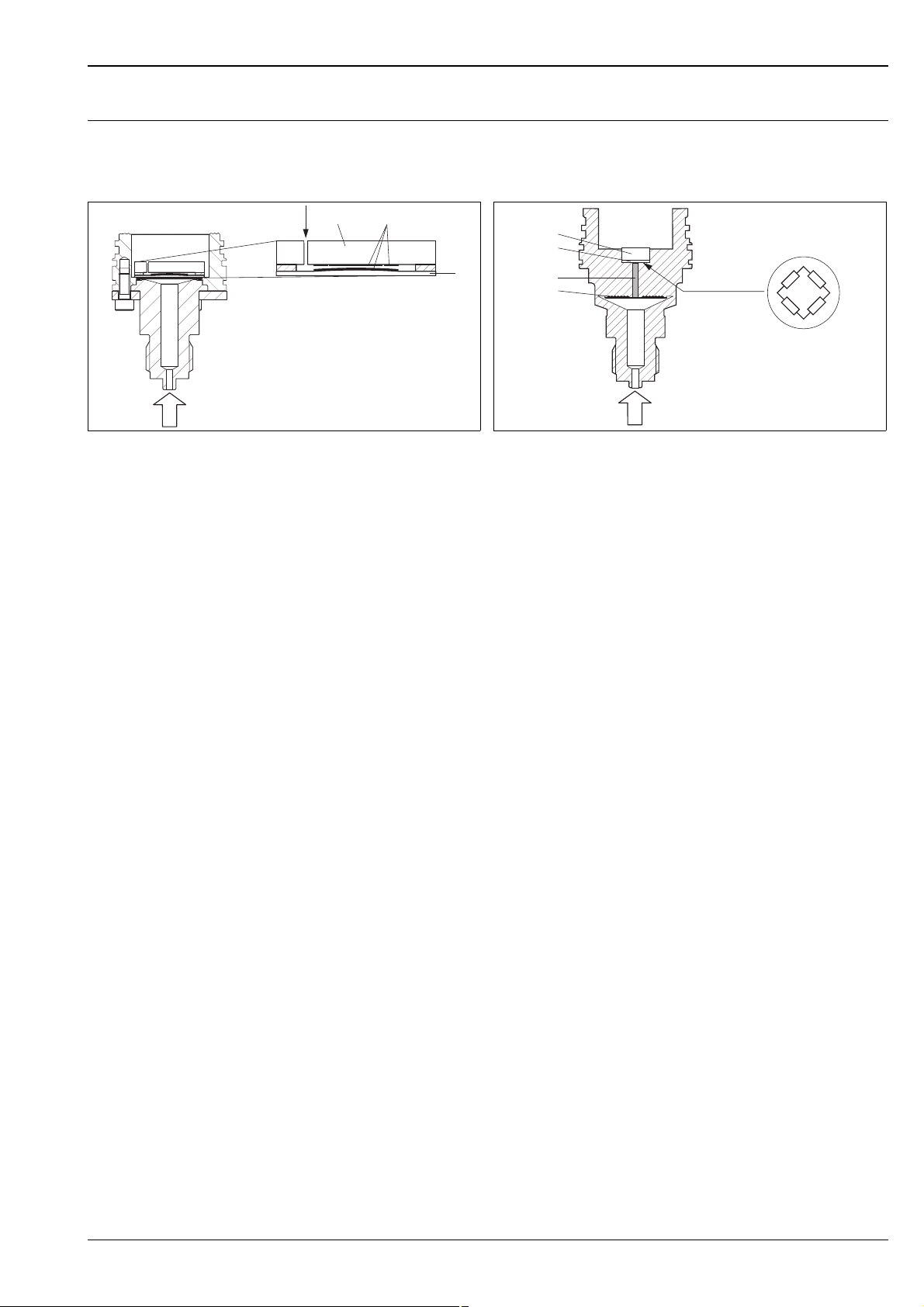

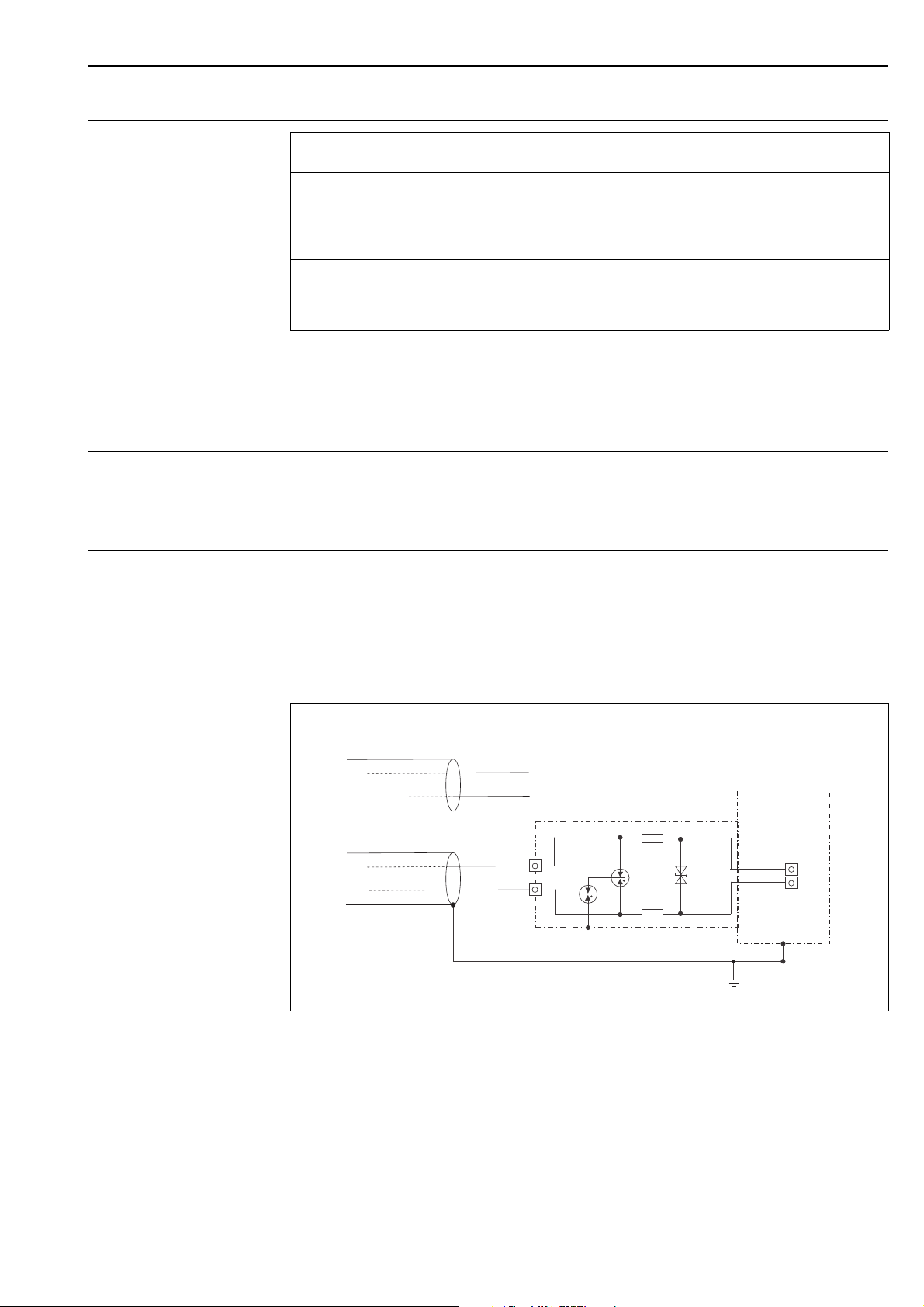

Measuring principle

Ceramic process isolating diaphragm used in PMC51 (Ceraphire®) Metal process isolating diaphragm used in PMP51 and PMP55

Ceramic sensor

1 Air pressure (gauge pressure sensors)

2 Ceramic substrate

3 Electrodes

4 Ceramic process isolating diaphragm

Ceramic process isolating diaphragm used in PMC51 (Ceraphire

The ceramic sensor is a dry sensor, i.e. the process pressure acts directly on the robust ceramic process isolating

diaphragm and deflects it. A pressure-dependent change in capacitance is measured at the electrodes of the

ceramic substrate and the process isolating diaphragm. The measuring range is determined by the thickness of

the ceramic process isolating diaphragm.

Advantages:

• Guaranteed overload resistance up to 40 times the nominal pressure

• Thanks to ultrapure 99.9% ceramic (Ceraphire

• Can be used in absolute vacuum

• Outstanding surface finish, R

Metal process isolating diaphragm used in PMP51 and PMP55

PMP51

The operating pressure deflects the process isolating diaphragm and a fill fluid transfers the pressure to a

resistance bridge (semiconductor technology). The pressure-dependent change in the bridge output voltage is

measured and evaluated.

Advantages:

• Can be used for process pressure up to 400 bar (6000 psi)

• High long-term stability

• Guaranteed overload resistance up to 4 times the nominal pressure

• Significantly less thermal effect compared to diaphragm seal systems

P01-PMC71xxx-03-xx-xx-xx-000

Metal sensor

1 Silicon measuring element, substrate

2 Wheatstone bridge

3 Channel with fill fluid

4 Metal process isolating diaphragm

®

, see also "www.endress.com/ceraphire")

– extremely high chemical stability, comparable with Alloy C

– less relaxation

– high mechanical stability

0.3 m (11.8 in)

a

P01-PMP7xxxx-03-xx-xx-xx-000

®

)

PMP55

The operating pressure acts on the process isolating diaphragm of the diaphragm seal and is transferred to the

process isolating diaphragm of the sensor by a diaphragm seal fill fluid. The process isolating diaphragm is

deflected and a fill fluid transfers the pressure to a resistance bridge. The pressure-dependent change in the

bridge output voltage is measured and evaluated.

Advantages:

• Depending on the version, can be used for process pressure up to 400 bar (6000 psi) and simultaneous

extreme process temperatures

• High long-term stability

• Guaranteed overload resistance up to 4 times the nominal pressure

Endress+Hauser 5

Cerabar M PMC51, PMP51, PMP55

h =

p

r g

h

Fieldgate

FXA520

FXN 520

FXN 520

Multidrop-Connector

FXN520

Cerabar M

➀

➁

➀

➁

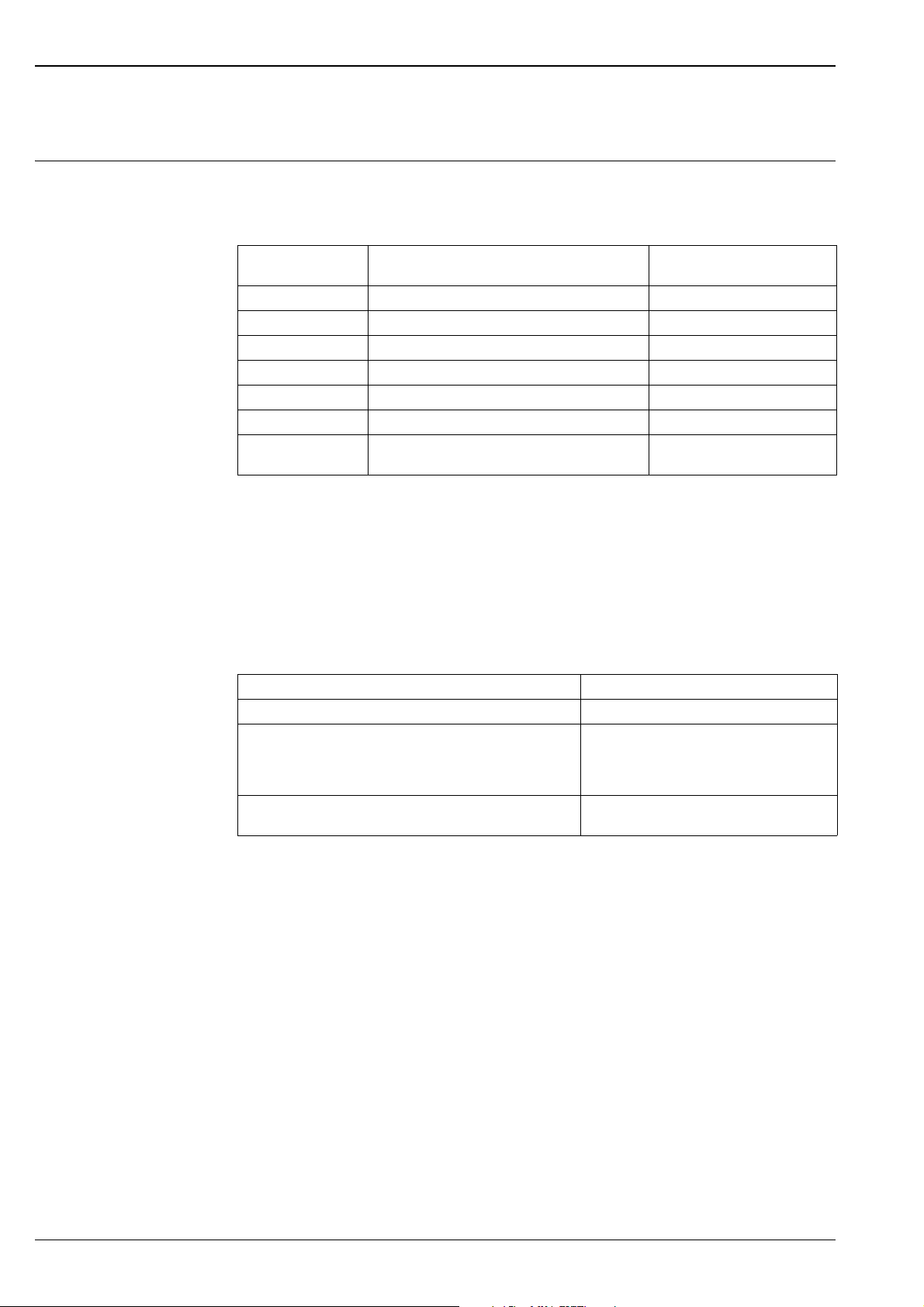

Level measurement (level, volume and mass)

Function and design

P01-PMx5xxxx-15-xx-xx-xx-000

Level measurement

h Height (level)

pPressure

Density of the medium

g Gravitation constant

Your benefits

• Choice of different level measuring modes in the device software

• Volume and mass measurements in any tank shapes by means of a freely programmable characteristic curve

• Choice of diverse level units

• Has a wide range of uses, even in the following cases:

– in the event of foam formation

– in tanks with agitators or screen fittings

– in the event of liquid gases

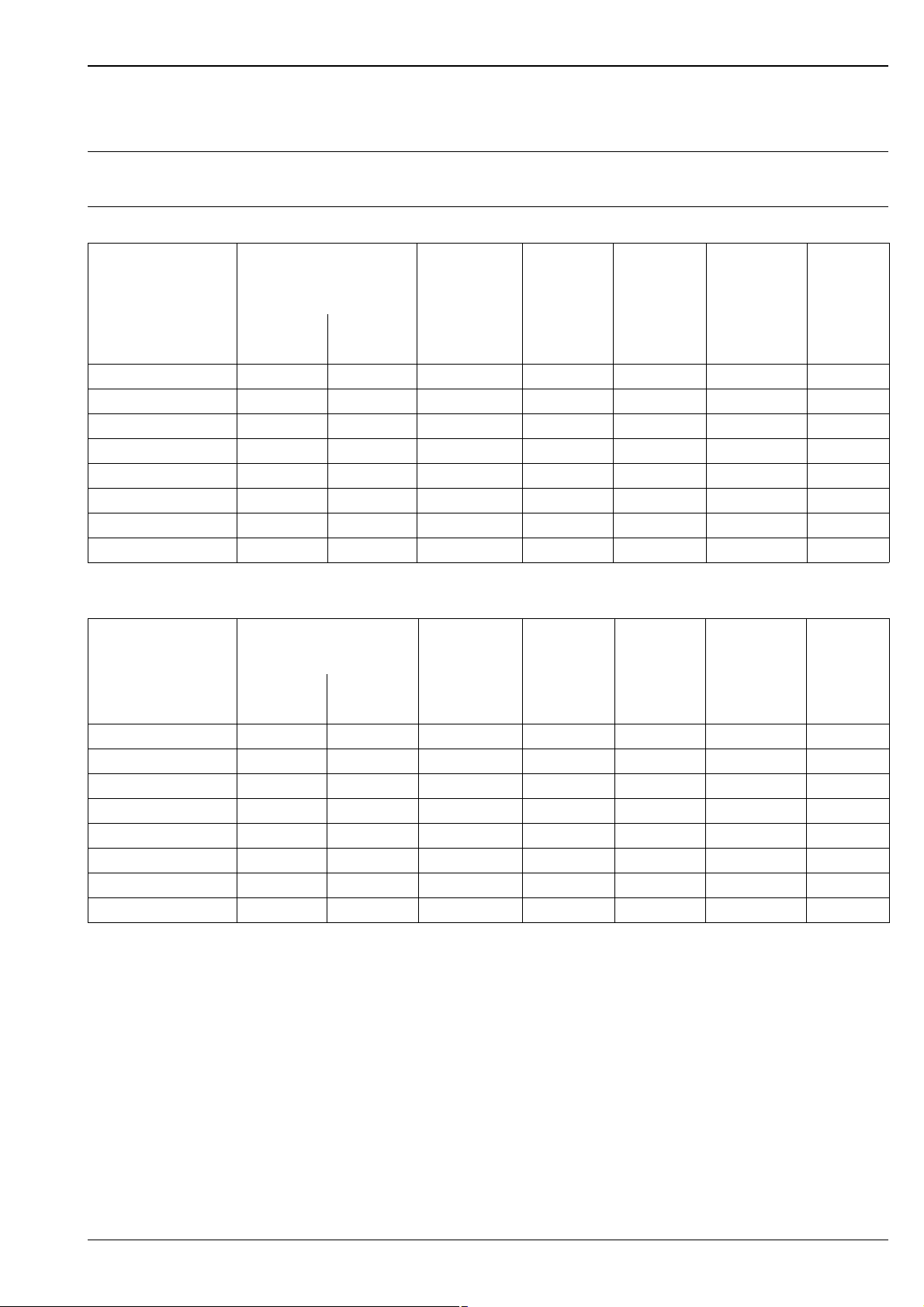

Electrical differential pressure measurement with gauge pressure sensors

1 Shut-off valves

2 e.g. filter

In the example given, two Cerabar M devices (each with a gauge pressure sensor) are interconnected. The

pressure difference can thus be measured using two independent Cerabar M devices.

Caution!

"

If using intrinsically safe devices, strict compliance with the rules for interconnecting intrinsically safe circuits

as stipulated in IEC60079-14 (proof of intrinsic safety) is mandatory.

Communication protocol • 4 to 20 mA without communication protocol (analog electronics)

• 4 to 20 mA with HART communication protocol

P01-PMX51xxx-14-xx-xx-xx-001

System integration (except analog electronics)

6 Endress+Hauser

The device can be fitted with a tag name and a preset bus address, see ä 63 ff "Ordering information"

feature 895 "Identification:" version "Z1" and "Z2".

Cerabar M PMC51, PMP51, PMP55

Input

Measured variable • Analog electronics: Absolute pressure and gauge pressure

• HART electronics: Absolute pressure and gauge pressure, from which level (level, volume or mass) is derived

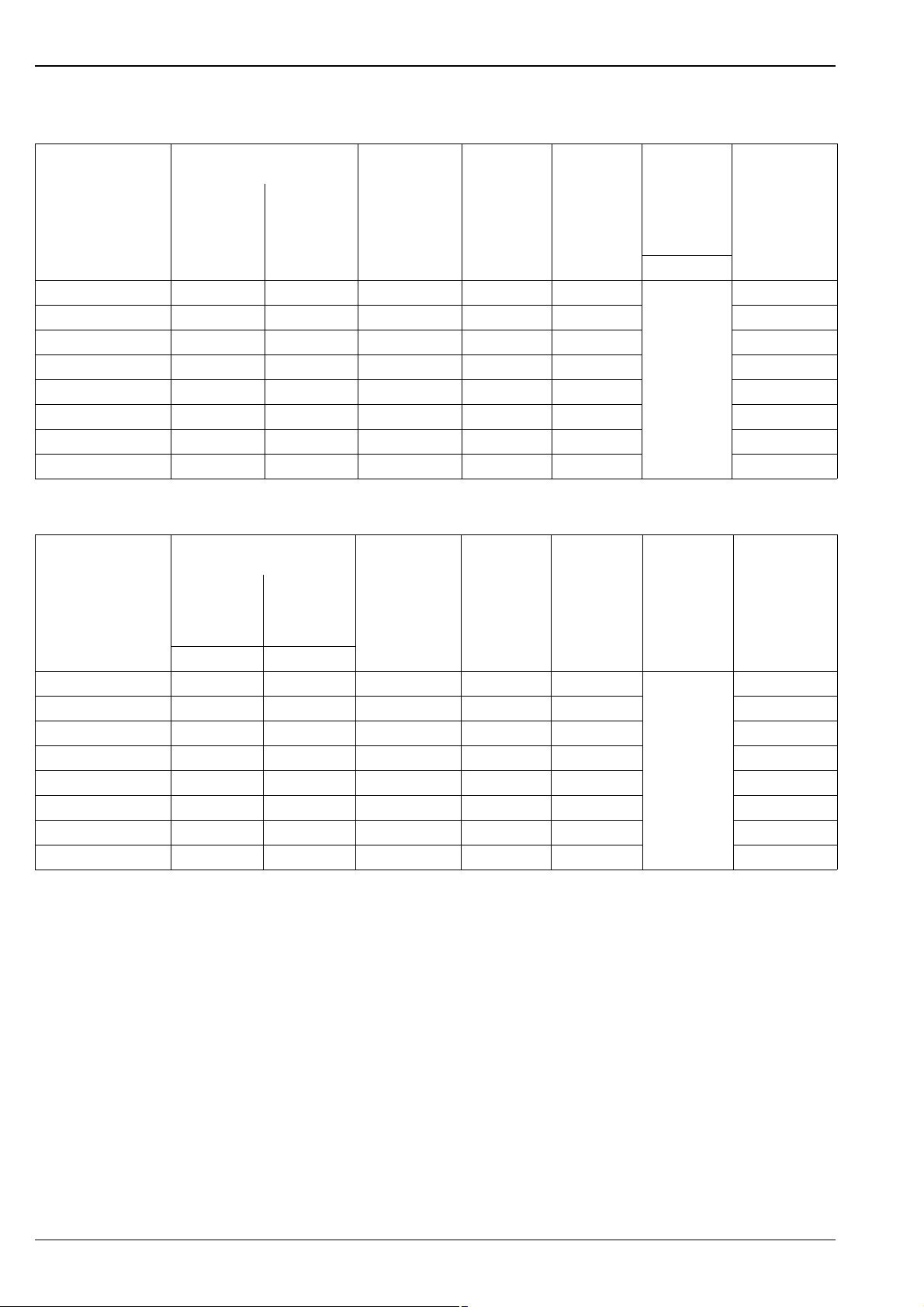

Measuring range PMC51 – with ceramic process isolating diaphragm (Ceraphire

®

) for gauge pressure

Nominal value Range limit Smallest

calibratable span

(preset at the

factory)

MWP

OPL

Vacuum

resistance

Version in

the order

code

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar

abs

(psi

abs

)]

100 mbar (1.5 psi) –0.1 (–1.5) +0.1 (+1.5) 0.01 (0.15) 2.7 (40.5) 4 (60) 0.7 (10.5) 1C

250 mbar (4 psi) –0.25 (–4) +0.25 (+4) 0.01 (0.15) 3.3 (49.5) 5 (75) 0.5 (7.5) 1E

400 mbar (6 psi) –0.4 (–6) +0.4 (+6) 0.02 (0.3) 5.3 (79.5) 8 (120) 0 1F

1 bar (15 psi) –1 (–15) +1 (+15) 0.05 (1) 6.7 (100.5) 10 (150) 0 1H

2 bar (30 psi) –1 (–15) +2 (+30) 0.1 (1.5) 12 (180) 18 (270) 0 1K

4 bar (60 psi) –1 (–15) +4 (+60) 0.2 (3) 16.7 (250.5) 25 (375) 0 1M

10 bar (150 psi) –1 (–15) +10 (+150) 0.5 (7.5) 26.7 (400.5) 40 (600) 0 1P

40 bar (600 psi) –1 (–15) +40 (+600) 2 (30) 40 (600) 60 (900) 0 1S

®

PMC51 – with ceramic process isolating diaphragm (Ceraphire

Nominal value Range limit Smallest span

(factory

calibration)

1

MWP

2

OPL

) for absolute pressure

3

Vacuum

resistance

Version in

the order

code

lower (LRL) upper (URL)

[bar

(psi

abs

)] [bar

abs

abs

(psi

)] [bar (psi)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

abs

)]

100 mbar (15 psi) 0 +0.1 (+1.5) 0.01 (0.15) 2.7 (40.5) 4 (60) 0 2C

250 mbar (4 psi) 0 +0.25 (+4) 0.01 (0.15) 3.3 (49.5) 5 (75) 0 2E

400 mbar (6 psi) 0 +0.4 (+6) 0.02 (0.3) 5.3 (79.5) 8 (120) 0 2F

1 bar (15 psi) 0 +1 (+15) 0.05 (1) 6.7 (100.5) 10 (150) 0 2H

2 bar (30 psi) 0 +2 (+30) 0.1 (1.5) 12 (180) 18 (270) 0 2K

4 bar (60 psi) 0 +4 (+60) 0.2 (3) 16.7 (250.5) 25 (375) 0 2M

10 bar (150 psi) 0 +10 (+150) 0.5 (7.5) 26.7 (400.5) 40 (600) 0 2P

40 bar (600 psi) 0 +40 (+600) 2 (30) 40 (600) 60 (900) 0 2S

4

1) Recommended turn down: Max 100:1.

Factory calibration turn down: Max 20:1, higher on request or configurable in the device.

2) The MWP (maximum working pressure) for the measuring device depends on the lowest-rated element, with regard to pressure, of the selected components,

i.e. the process connection ( ä 26 ff) has to be taken into consideration in addition to the measuring cell ( see Table above). Pay attention to the

pressure-temperature dependence also. For the appropriate standards and other information, see ä 25, "Pressure specifications" section.

3) OPL: over pressure limit depends on the lowest-rated element, with regard to pressure, of the selected components

4) Version in the order code see also ä 63 ff, feature 70 "Sensor range"

Endress+Hauser 7

Cerabar M PMC51, PMP51, PMP55

PMP51 and PMP55 – metal process isolating diaphragm for gauge pressure

Nominal value Range limit Smallest

calibratable span

(preset at the

factory)

MWP

OPL

Vacuum

resistance

Version in the

order code

Silicone oil/

Inert oil

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar

400 mbar (6 psi) –0.4 (–6) +0.4 (+6) 0.02 (0.3) 4 (60) 6 (90)

abs

(psi

abs

)]

1F

1 bar (15 psi) –1 (–15) +1 (+15) 0.05 (1) 6.7 (100) 10 (150) 1H

2 bar (30 psi) –1 (–15) +2 (+30) 0.1 (1.5) 13.3 (200) 20 (300) 1K

4 bar (60 psi) –1 (–15) +4 (+60) 0.2 (3) 18.7 (280.5) 28 (420) 1M

10 bar (150 psi) –1 (–15) +10 (+150) 0.5 (7.5) 26.7 (400.5) 40 (600) 1P

0.01/0.04

(0.15/0.6)

40 bar (600 psi) –1 (–15) +40 (+600) 2 (30) 100 (1500) 160 (2400) 1S

100 bar (1500 psi) –1 (–15) +100 (+1500) 5 (75) 100 (1500) 400 (6000) 1U

400 bar (6000 psi) –1 (–15) +400 (+6000) 20 (300) 400 (6000) 600 (9000) 1W

PMP51 and PMP55 – metal process isolating diaphragm for absolute pressure

Nominal value Range limit Smallest

calibratable span

(preset at the

factory)

1

MWP 2 OPL 3Vacuum

resistance

Silicone oil/

Inert oil

Version in the

4

order code

5

lower (LRL) upper (URL)

[bar

(psi

abs

)] [bar

abs

400 mbar (6 psi) 0 +0.4 (+6) 0.02 (0.3) 4 (60) 6 (90)

abs

(psi

)] [bar (psi)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

abs

)]

2F

1 bar (15 psi) 0 +1 (+15) 0.05 (1) 6.7 (100) 10 (150) 2H

2 bar (30 psi) 0 +2 (+30) 0.1 (1.5) 13.3 (200) 20 (300) 2K

4 bar (60 psi) 0 +4 (+60) 0.2 (3) 18.7 (280.5) 28 (420) 2M

10 bar (150 psi) 0 +10 (+150) 0.5 (7.5) 26.7 (400.5) 40 (600) 2P

0.01/0.04

(0.15/0.6)

40 bar (600 psi) 0 +40 (+600) 2 (30) 100 (1500) 160 (2400) 2S

100 bar (1500 psi) 0 +100 (+1500) 5 (75) 100 (1500) 400 (6000) 2U

400 bar (6000 psi) 0 +400 (+6000) 20 (300) 400 (6000) 600 (9000) 2W

1) Recommended turn down: Max 100:1.

Factory calibration turn down: Max 20:1, higher on request or configurable in the device.

2) The MWP (maximum working pressure) for the measuring device depends on the lowest-rated element, with regard to pressure, of the selected components,

i.e. the process connection ( ä 26 ff) has to be taken into consideration in addition to the measuring cell (see Table above). Pay attention to the

pressure-temperature dependence also. For the appropriate standards and other information, see ä 25, "Pressure specifications" section.

3) OPL: over pressure limit (= sensor overload limit)

4) The vacuum resistance applies to the measuring cell at reference conditions. The pressure and temperature application limits of the selected filling oil must

also be observed for the PMP55. ä 59, "Diaphragm seal filling oils" section.

5) Version in the order code ä 63 ff, feature 70 "Sensor range"

8 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

0 bar

+1 bar

URLURV

➂

LRL = LRV

0.5 bar

➃

➁➀

=

➄

=

–1 bar

+1 bar

LRV

URLURV

➂

0

LRL

0.5 bar

➁➀

=

➃

➄

–1 bar

+1 bar

LRV

URLURV

➂

0

LRL

–0.6 bar

➁➀

=

➃

➄

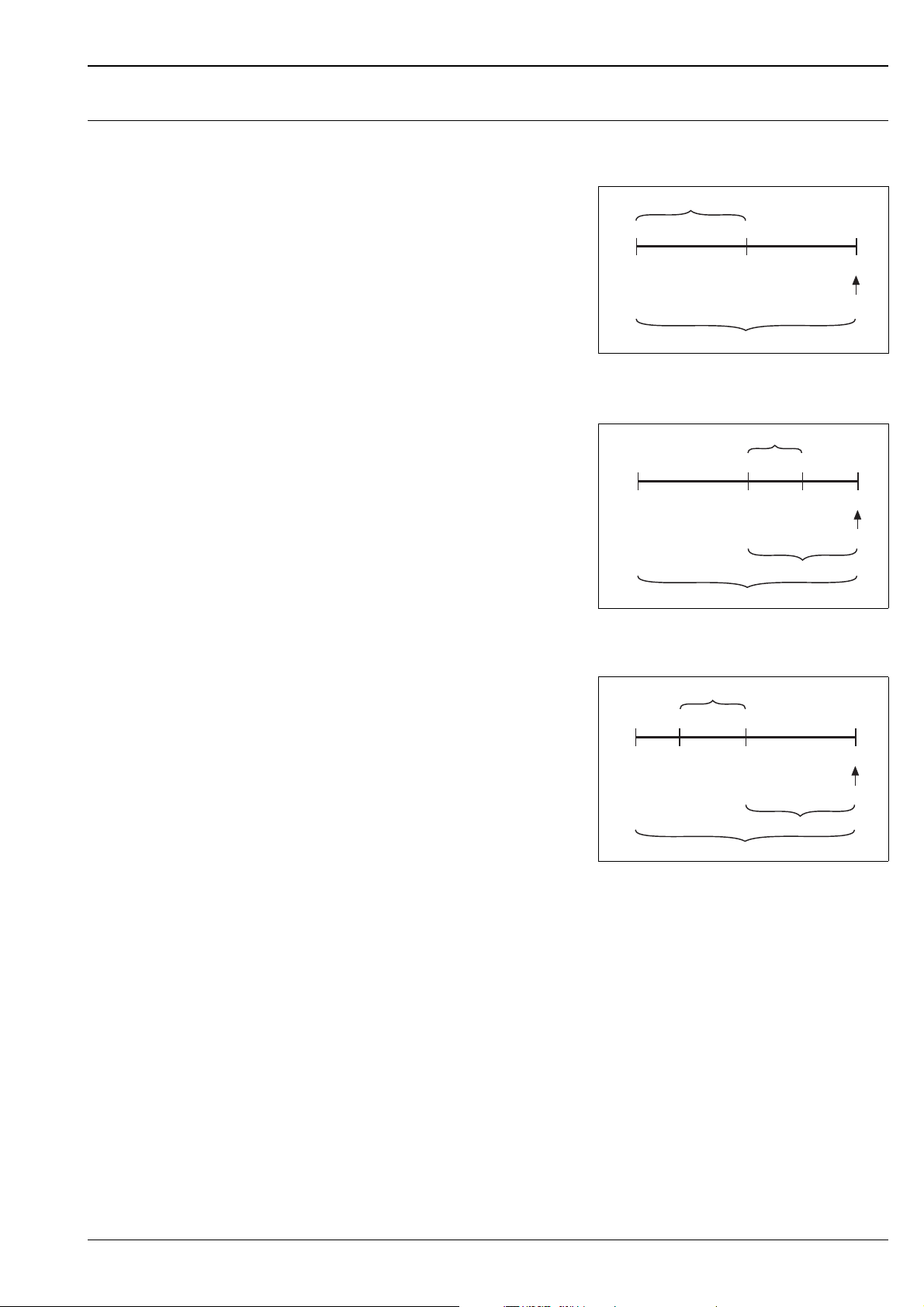

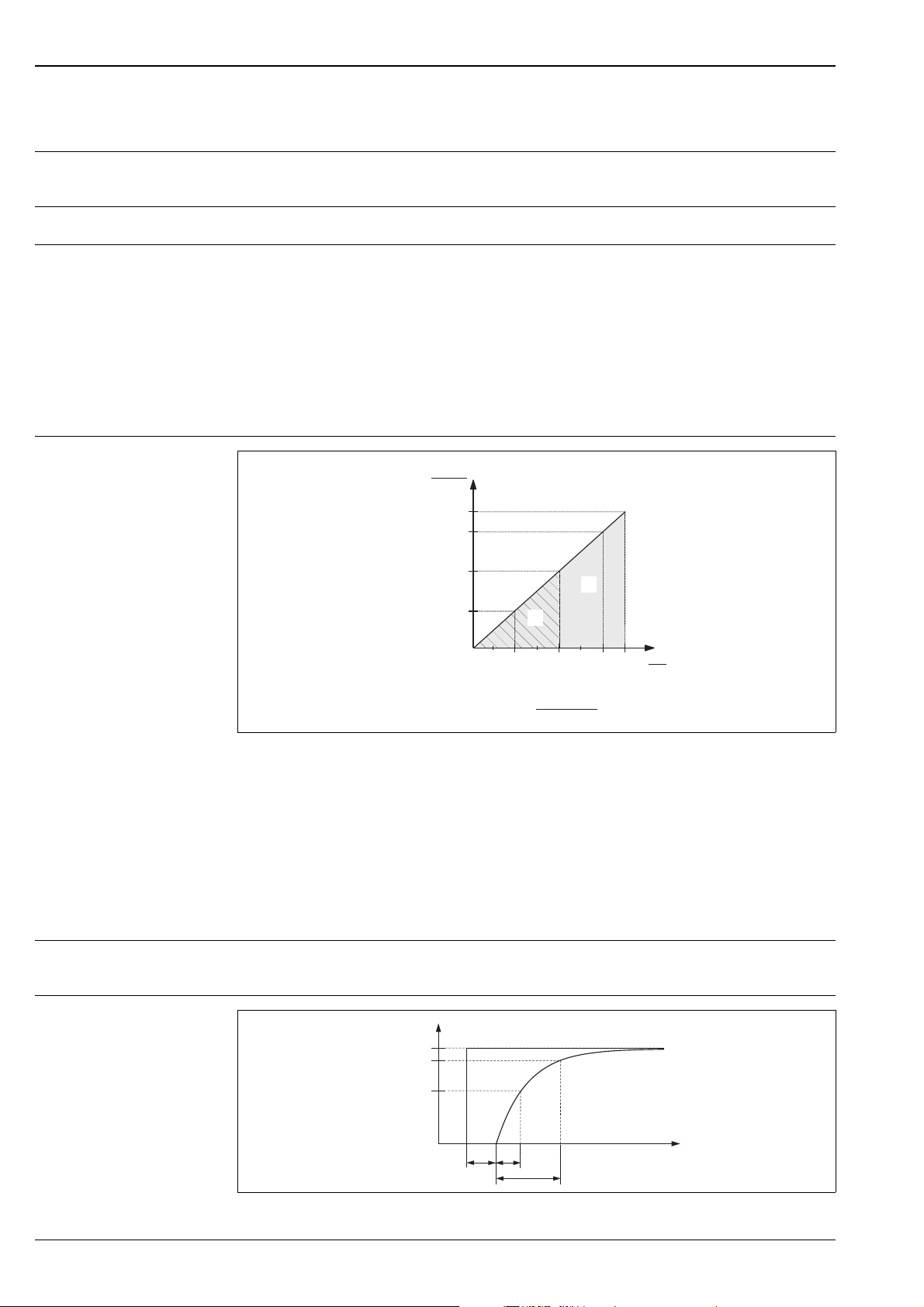

Explanation of terms

Explanation of terms: turn down (TD),

set span and span based on zero point

Case 1:

• Lower range value (LRV) Upper range value

(URV)

Example:

• Lower range value (LRV) = 0 bar

• Upper range value (URV) = 0.5 bar (7.5 psi)

• Nominal value (URL) = 1 bar (15 psi)

Turn down:

•TD = URL /URV2:1

Set span:

• URV – LRV = 0.5 bar (7.5 psi)

This span is based on the zero point.

Case 2:

• Lower range value (LRV) Upper range value

(URV)

Example:

• Lower range value (LRV) = 0 bar

• Upper range value (URV) = 0.5 bar (7.5 psi)

• Nominal value (URL) = 1 bar (15 psi)

Turn down:

•TD = URL /URV= 2:1

Set span:

• URV – LRV = 0.5 bar (7.5 psi)

This span is based on the zero point.

P01-PMx7xxxx-05-xx-xx-xx-012

Example: 1 bar (15 psi) measuring cell

P01-PMx7xxxx-05-xx-xx-xx-007.

Example: 1 bar (15 psi) measuring cell

Case 3:

• Lower range value (LRV) Upper range value

(URV)

Example:

• Lower range value (LRV) = –0.6 bar (–9 psi)

• Upper range value (URV) = 0 bar

• Nominal value (URL) = 1 bar (15 psi)

Turn down:

•TD = URL /LRV = 1.67:1

Set span:

• URV – LRV = 0.6 bar (–9 psi)

This span is based on the zero point.

P01-PMx7xxxx-05-xx-xx-xx-008

Example: 1 bar (15 psi) measuring cell

1 Set span

2 Span based on zero point

3 Nominal value i upper range limit (URL)

4 Nominal measuring range

5 Sensor measuring range

LRL Lower range limit

URL Upper range limit

LRV Lower range value

URV Upper range value

Endress+Hauser 9

Output

U – 11.5 V

R

L

max

0.023 A

£

30

20

11.5

U

[V]

40 45

1239

1456

804

369

[]W

R

L

max

➀

➁

I

63 %

100 %

t

t1t

2

90 %

t

3

Output signal • 4 to 20 mA analog, 2-wire

• 4 to 20 mA with superimposed digital communication protocol HART 6.0, 2-wire

Signal range 4 to 20 mA analog, 4 to 20 mA HART: 3.8 to 20.5 mA

Signal on alarm As per NAMUR NE 43

• 4 to 20 mA Analog:

– Signal overshoot: > 20.5 mA

– Signal undershoot: < 3.8 mA

– Min Alarm (3.6 mA)

• 4 to 20 mA HART

Options:

– Max. alarm: can be set from 21 to 23 mA (factory setting: 22 mA)

– Hold measured value: last measured value is held

– Min. alarm: 3.6 mA

Load - 4 to 20 mA analog and

4 to 20 mA HART

Cerabar M PMC51, PMP51, PMP55

P01-xxxxxxxx-05-xx-xx-xx-002

Load diagram

1 Power supply 11.5 to 30 V DC for intrinsically safe device versions

2 Power supply 11.5 to 45 V DC (versions with plug-in connector 35 V DC) for other types of protection and for

uncertified device versions

R

Maximum load resistance

Lmax

U Supply voltage

Note!

When operating via a handheld terminal or via a PC with an operating program, a minimum communication

resistance of 250 must be taken into account.

Resolution • Current output: 1 A

• Display HART: can be set (factory setting: presentation of the maximum accuracy of the transmitter)

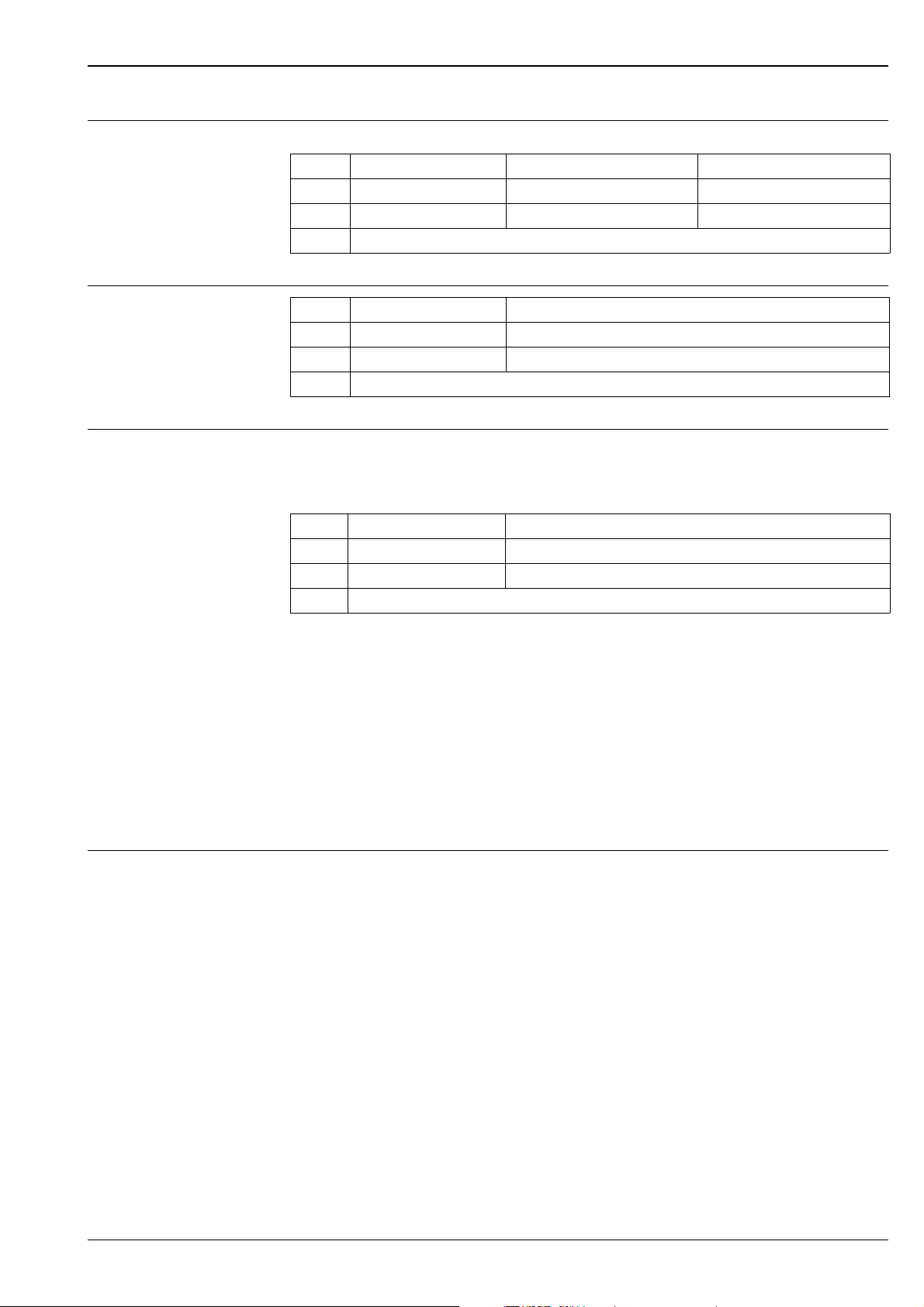

Dead time,

Time constant (T63)

10 Endress+Hauser

Presentation of the dead time and the time constant

P01-xxxxxxxx-05-xx-xx-xx-036

Cerabar M PMC51, PMP51, PMP55

Dynamic behavior: 4 to 20 mA (analog electronics)

Dynamic behavior:

current output (HART

electronics)

Dynamic behavior: digital output (HART electronics)

Dead time, time constant (T63)

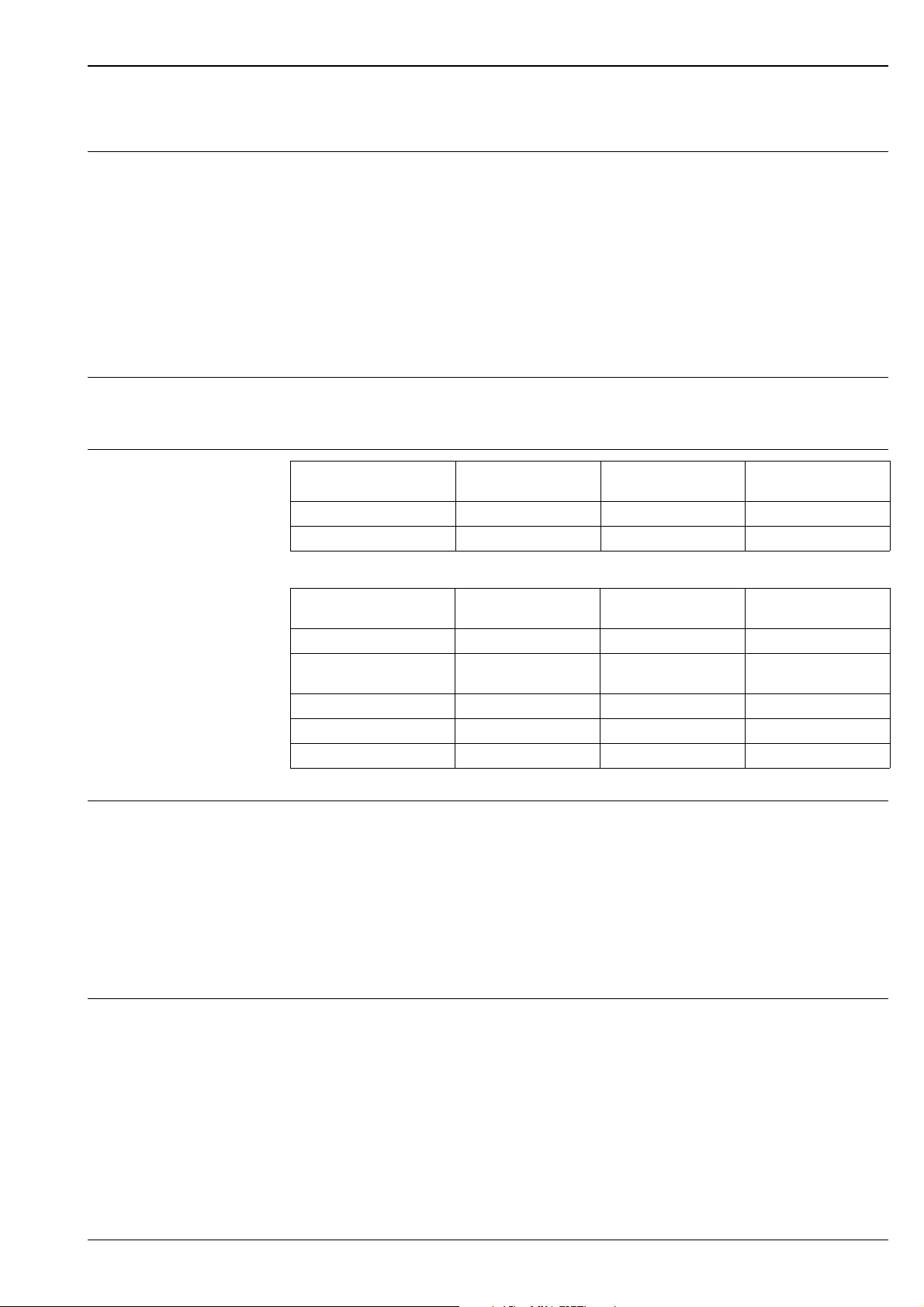

Type Dead time t

PMC51 60 ms 40 ms 50 ms

PMP51 40 ms 40 ms 50 ms

PMP55 PMP51 + influence of the diaphragm seal

Type Dead time t

PMC51 90 ms 120 ms

PMP51 60 ms 70 ms

PMP55 PMP51 + influence of the diaphragm seal

1

1

Time constant (T63), t

Time constant (T63), t

2

2

Time constant (T90), t

Dead time, time constant (T63)

A typical configuration for the PLC of 2 to 3 values per second results in the following

total dead time:

Type Dead time t

PMC51 340 ms 120 ms

PMP51 310 ms 70 ms

PMP55 PMP51 + influence of the diaphragm seal

1

Time constant (T63), t

2

3

Reading cycle

HART commands: 2 to 3 per second on average.

The Cerabar M commands the BURST MODE function for cyclic value transmission via the HART

communication protocol.

Response time

250 ms

Cycle time (update time)

On average 310 to 520 ms.

Damping A damping affects all outputs (output signal, display).

• Analog electronics: via DIP switch on the electronic insert,

switch position "on" = 2s; switch position "off" = 0s

• HART: via DIP switch on the electronic insert, switch position "on" = value set in the software (factory

setting: 2 s) and "off". Via local display, handheld terminal or PC with operating program, continuous from

0 to 999 s

Endress+Hauser 11

Power supply

4…20 mA

11.5 V DC

- +

6

1 2

3

4

5

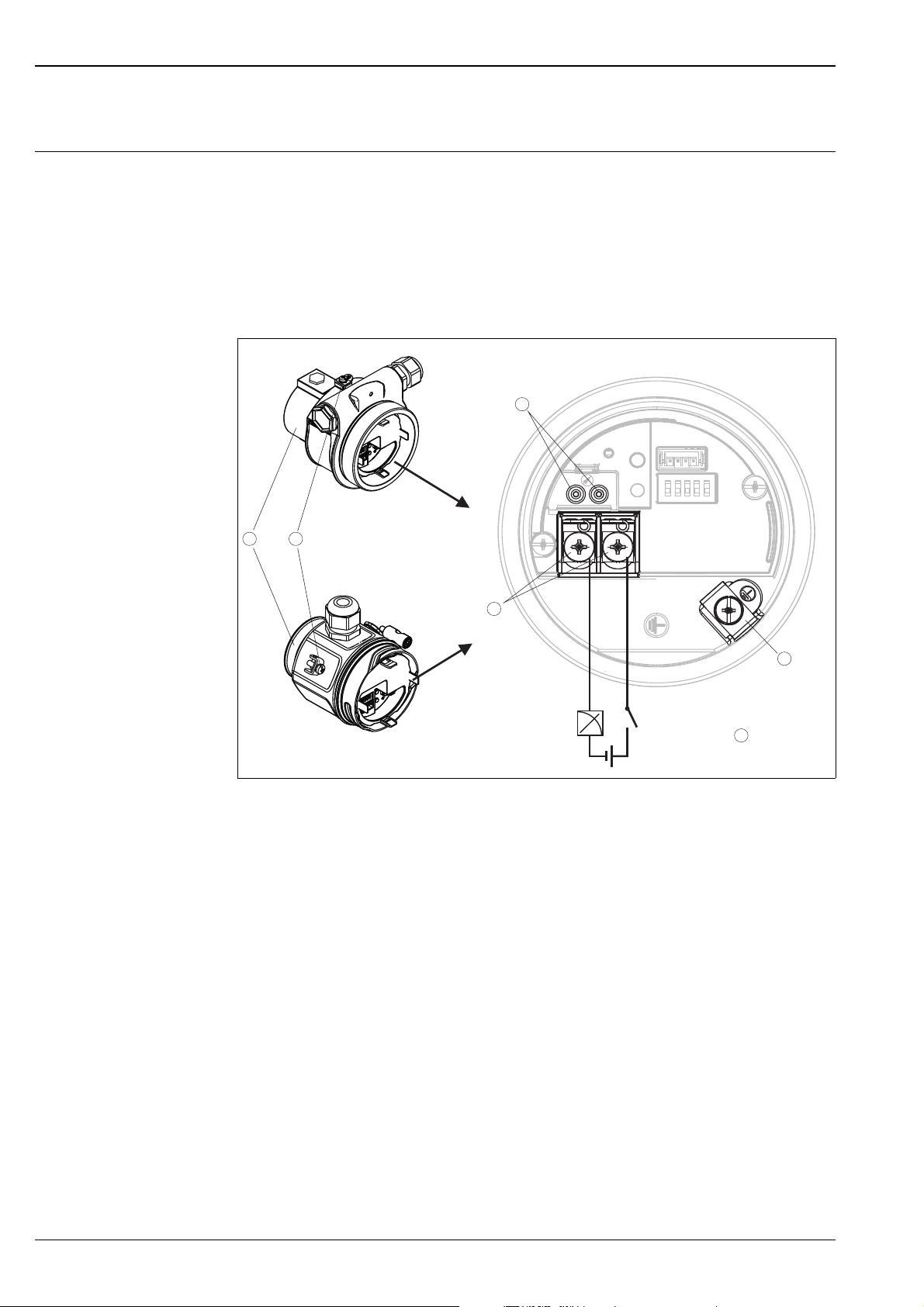

Electrical connection Note!

• When using the measuring device in hazardous areas, installation must comply with the corresponding

national standards and regulations and the Safety Instructions or Installation or Control Drawings.

ä 77 ff, "Safety Instructions" and "Installation/Control Drawings" sections.

• HART: Overvoltage protection HAW569Z for the non-hazardous area and for ATEX II 1/2 G Exi can be

ordered as an option (see "Ordering information" section).

• Protective circuits against reverse polarity, HF influences and overvoltage peaks are installed.

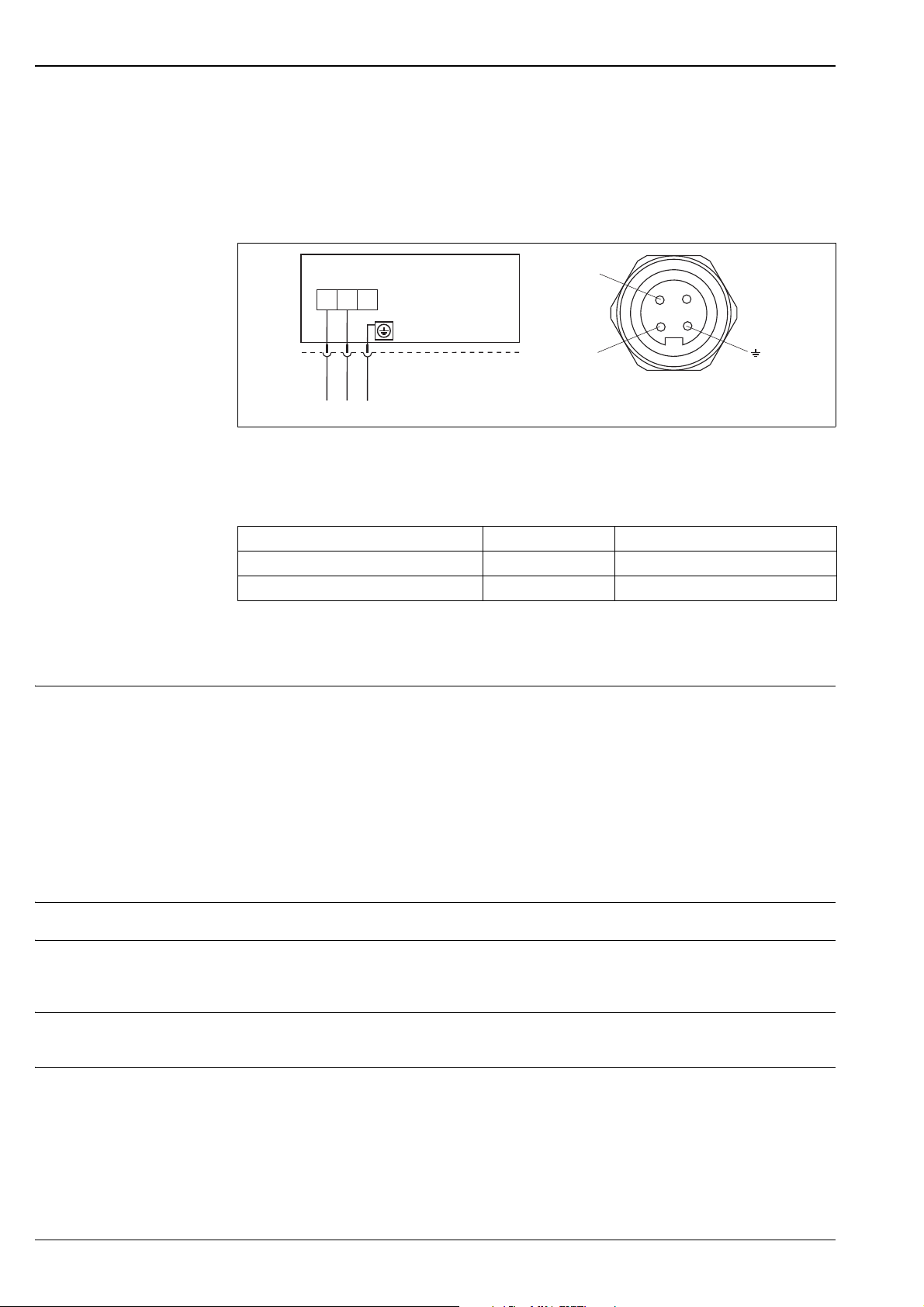

4 to 20 mA analog, 4 to 20 mA HART

Cerabar M PMC51, PMP51, PMP55

P01-xMx5xxxx-04-xx-xx-xx-004

Electrical connection

1 Housing

2 External ground terminal

3 Internal ground terminal

4 Power supply terminals

5 Test terminals, see "Taking 4 to 20 mA test signal" section

6 Minimum supply voltage = 11.5 V DC

Taking 4 to 20 mA test signal

A 4 to 20 mA test signal may be measured via the test terminals without interrupting the measurement.

12 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

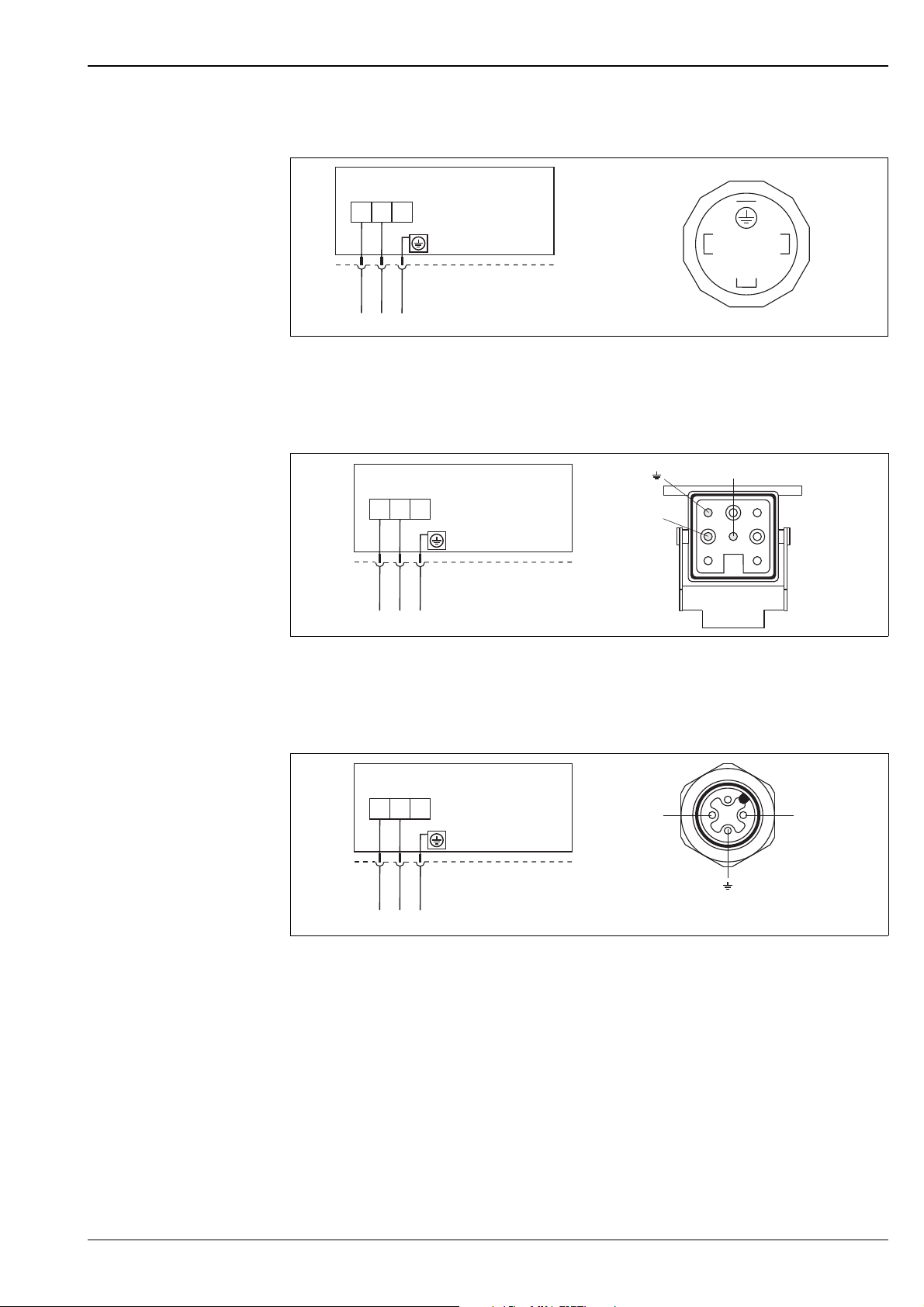

–

+

+–

+

–

Han7D

–

+

+–

–

+

1

5

4

6

7

8

2

3

M12

–

+

+–

–

+

Devices with valve connector

Left: electrical connection for devices with a valve connector

Right: view of the connector at the device

Devices with Harting connector Han7D

P01-xMx5xxxx-04-xx-xx-xx-005

P01-xxx7xxxx-04-xx-xx-xx-001

Left: electrical connection for devices with a Harting connector Han7D

Right: view of the connector at the device

Devices with M12 connector

P01-xxx7xxxx-04-xx-xx-xx-000

Left: electrical connection for devices with an M12 connector

Right: view of the connector at the device

Endress+Hauser offers the following accessories for devices with an M12 connector:

Plug-in jack M 12x1, straight

• Material: body PA; coupling nut CuZn, nickel-plated

• Degree of protection (fully locked): IP67

• Order number: 52006263 or through device order, see also ä 63 ff "Ordering information" section

Plug-in jack M 12x1, elbowed

• Material: body PBT; coupling nut GD-Zn, nickel-plated

• Degree of protection (in screwed situation): IP67

• Order number: 71091284 or through device order, see also ä 63 ff "Ordering information" section

Endress+Hauser 13

Cerabar M PMC51, PMP51, PMP55

–

+

7/8”

–

+

+–

Cable 4x0.34 mm2 (20 AWG) with M12 socket, elbowed, screw plug, 5 m (16 ft) length

• Material: body PUR; coupling nut CuSn/Ni; cable PVC

• Degree of protection (fully locked): IP67

• Order number: 52010285 or through device order, see also ä 63 ff "Ordering information" section

Devices with 7/8" connector

P01-xxx7xxxx-04-xx-xx-xx-003

Left: electrical connection for devices with a 7/8" connector

Right: view of the connector at the device

Cable gland

Approval Type Clamping area

Standard, II1/2G Exia, IS Plastic M20x1.5 5 to 10 mm (0.2 to 0.39 in)

ATEX II1/2D, II1/2GD Exia, II3G Ex nA Metal M20x1.5 (Ex e) 7 to 10.5 mm (0.28 to 0.41 in)

Terminals

For wire cross-sections of 0.5 to 2.5 mm² (20 to 14 AWG).

Supply voltage Note!

• When using the measuring device in hazardous areas, installation must comply with the corresponding

national standards and regulations and the Safety Instructions or Installation or Control Drawings.

• All explosion protection data are given in separate documentation which is available upon request. The

Ex documentation is supplied as standard with all devices approved for use in explosion hazardous areas.

ä 77 ff, "Safety Instructions" and "Installation/Control Drawings" sections.

4 to 20 mA, 4 to 20 mA HART

• 11.5 to 45 V DC

(Versions with plug-in connection 35 V DC)

• For intrinsically safe device versions: 11.5 to 30 V DC

Cable entry ä 63 ff, feature 50 "Electrical connection".

Cable specification • Endress+Hauser recommends using twisted, shielded two-wire cables.

• Terminals for wire cross-sections 0.5 to 2.5 mm

• Cable outer diameter: 5 to 9 mm (0.2 to 0.35 in)

2

(20 to 14 AWG)

Residual ripple No influence on 4 to 20 mA signal up to 5 % residual ripple within the permitted voltage range [according to

HART hardware specification HCF_SPEC-54 (DIN IEC 60381-1)]

Influence of power supply 0.001% of URL/1 V

14 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

Performance characteristics – general

Reference operating conditions

Uncertainty of measurement for small absolute pressure ranges

Long-term stability

• As per IEC 60770

• Ambient temperature T

= constant, in the range of: +21 to +33°C (+70 to +91°F)

A

• Humidity = constant, in the range of: 5 to 80 % RH

• Ambient pressure pA = constant, in the range of: 860 to 1060 mbar (12.47 to 15.37 psi)

• Position of the measuring cell: constant, in range: 1° horizontally

• Input of LOW SENSOR TRIM and HIGH SENSOR TRIM for lower range value and upper range value

• Span based on zero point

• Material of the process isolating diaphragm PMC51: Al

(aluminum-oxide ceramic, Ceraphire®)

2O3

• Material of the process isolating diaphragm PMP51 and PMP55: AISI 316L

• Filling oil PMP51 and PMP55: silicone oil

• Supply voltage: 24 V DC ± 3 V DC

• Load with HART: 250

The smallest expanded uncertainty of measurement that can be returned by our standards is:

• 0.4% of the measured value in the range of 1 to 30 mbar

• 1% of the measured value in the range < 1 mbar.

PMC51 Long-term stability of

< 1 bar (15 psi) ±0.2 % ±0.4 % ±0.5 %

> 1 bar (15 psi) ±0.1 % ±0.25 % ±0.4 %

PMP51 Long-term stability of

< 1 bar (15 psi) ±0.2 % ±0.4 % ±0.5 %

> 1 bar to 10 bar (15 to

150 psi)

40 bar (600 psi) ±0.1 % ±0.2 % ±0.4 %

100 bar (1500 psi) ±0.1 % ±0.25 % ±0.2 %

400 bar (6000 psi) ±0.1 % ±0.25 % ±1.0 %

URL / 1 year

URL / 1 year

±0.1 % ±0.175 % ±0.4 %

Long-term stability of

URL / 5 years

Long-term stability of

URL / 5 years

Long-term stability of

URL / 10 years

Long-term stability of

URL / 10 years

1

Influence of orientation • PMC51

• PMP51

: 0.2 mbar (3 psi)

1,2

– 4 mbar (0.06 psi) for process connections with 1/2" thread and silicone oil

– 10 mbar (0.15 psi) for process connections with > thread 1/2" and flanges

1) Device rotated 180°, process connection pointing upwards.

2) This value is doubled for inert oil.

Note!

Position-dependent zero point shift can be corrected at the device. ä 19, "General installation instructions"

section and ä 60 ff, "Installation instructions" section.

Warm-up period • 4 to 20 mA analog: <1.5 s

• 4 to 20 mA HART: <5 s

Endress+Hauser 15

Cerabar M PMC51, PMP51, PMP55

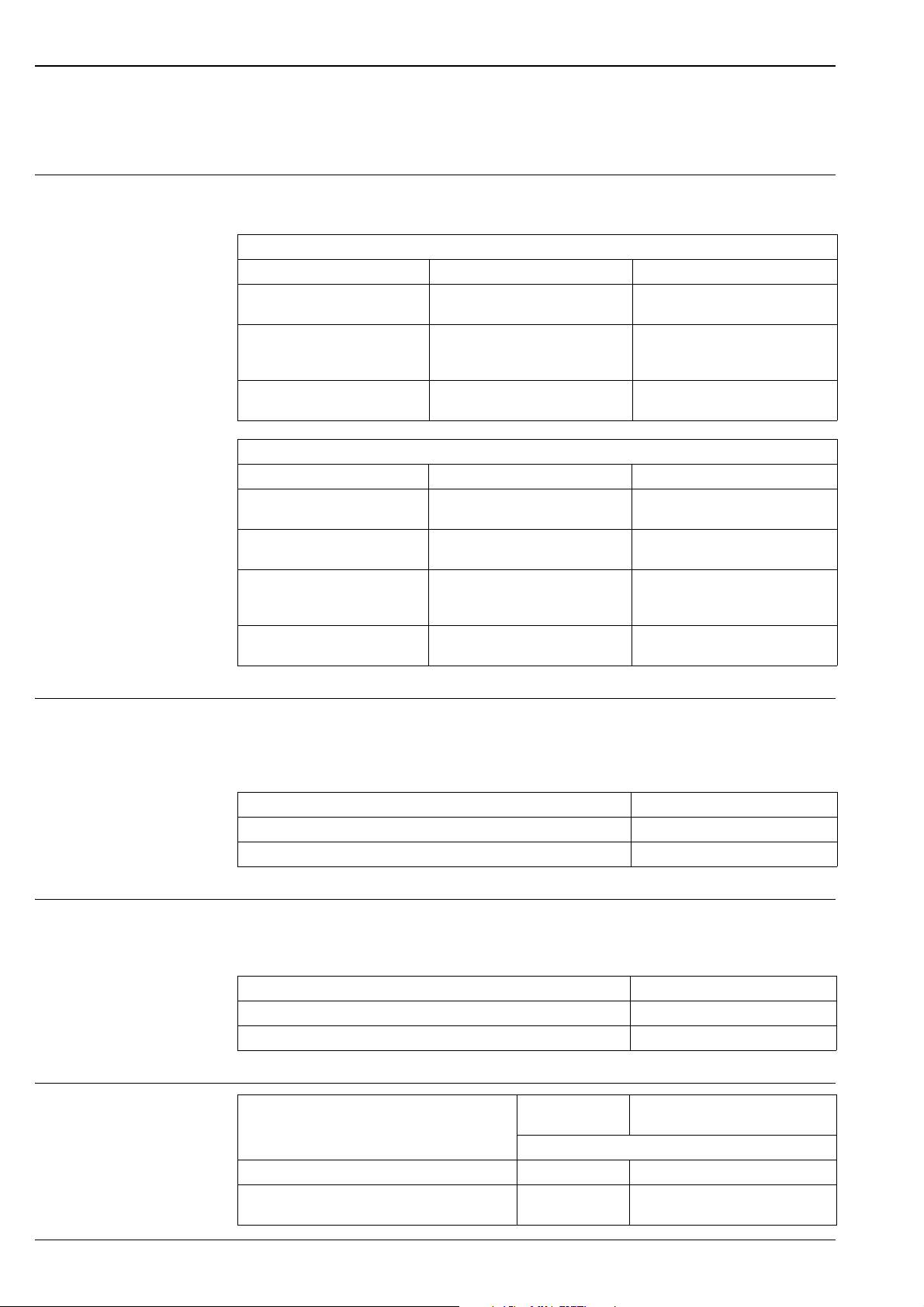

Performance characteristics – ceramic process isolating diaphragm

Reference accuracy – PMC51 The reference accuracy comprises the non-linearity according to limit point setting, hysteresisand

non-reproducibility as per IEC 60770. The data refer to the calibrated span.

Gauge pressure sensors

Measuring cell Standard reference accuracy Platinum reference accuracy

100 mbar (1.5 psi)

250 mbar (4 psi), 400 mbar (6 psi),

1 bar (15 psi), 2 bar (30 psi),

4 bar (60 psi), 10 bar (150 psi)

40 bar (600 psi)

Absolute pressure sensors

Measuring cell Standard reference accuracy Platinum reference accuracy

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi), 1 bar (15 psi),

2 bar (30 psi), 4 bar (60 psi),

10 bar (150 psi)

40 bar (600 psi)

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 20:1: 0.20 %

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 20:1: 0.20 %

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 20:1: 0.20 %

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 13:1: 0.20 %

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 20:1: 0.20 %

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 20:1: 0.20 %

• TD 1:1 to TD 10:1: 0.15 %

• TD > 10:1 to TD 20:1: 0.20 %

•TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 13:1: ±0.1 %

•TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 20:1: ±0.1 %

•TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 13:1: ±0.1 %

• TD 1:1 to TD 5:1: ±0.075 %

• ---

•TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 13:1: ±0.1 %

•TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 20:1: ±0.1 %

•TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 13:1: ±0.1 %

Total performance – PMC51 The "Total performance" specification comprises the non-linearity including hysteresis, non-reproducibility as

well as the thermal change in the zero point. All specifications apply to the temperature range –10 to +60°C

(+14 to +140°F) and Turndown 1:1.

For devices with NBR or HNBR seals, the values must be multiplied by a factor of 3.

Measuring cell % URL

100 mbar (1.5 psi), 250 mbar (4 psi), 400 mbar (6 psi) TD 1:1: ±0.5

1 bar (15 psi), 2 bar (30 psi), 4 bar (60 psi), 10 bar (150 psi), 40 bar (600 psi) TD 1:1: ±0.44

Total error - PMC51 The total error comprises the long-term stability and the total performance. All specifications apply to the

temperature range –10 to +60°C (+14 to +140°F) and Turndown 1:1.

For devices with NBR or HNBR seals, the values must be multiplied by a factor of 3.

Measuring cell % URL/year

100 mbar (1.5 psi), 250 mbar (4 psi), 400 mbar (6 psi) ±0.55

1 bar (15 psi), 2 bar (30 psi), 4 bar (60 psi), 10 bar (150 psi), 40 bar (600 psi) ±0.47

Thermal change in the zero output and the output span – PMC51

Measuring cell –10 to +60 °C

(+14 to +140°F)

% of the calibrated measuring span

100 mbar (1.5 psi), 250 mbar (4 psi), 400 mbar (6 psi) (0.34 + 0.15 x TD) (0.39 + 0.25 x TD)

1 bar (15 psi), 2 bar (30 psi), 4 bar (60 psi), 10 bar

(150 psi), 40 bar (600 psi)

(0.32 + 0.1 x TD) (0.36 + 0.2 x TD)

–20 to –10 °C, +60 to +100 °C

(–4 to +14°F, +140 to +212°F)

16 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

Performance characteristics – metal process isolating diaphragm

Reference accuracy –

PMP51, PMP55

The reference accuracy comprises the non-linearity according to limit point setting, hysteresisand

non-reproducibility as per IEC 60770. The data refer to the calibrated span.

Gauge pressure sensors/absolute pressure sensors

Measuring cell Standard reference accuracy Platinum reference accuracy

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi),

40 bar (600 psi)

100 bar (1500 psi)

400 bar (6000 psi)

1) Only PMP51, PMP55 with direct diaphragm seal mounting

• TD 1:1: ±0.15 %

• TD >1:1: ±0.15 % x TD

• TD 1:1 to TD 5:1: ±0.15 %

• TD >5:1: ±0.03 % x TD

• TD 1:1 to TD 10:1: ±0.15 %

• TD >10:1 to TD 13:1: ±0.20 %

• TD 1:1 to TD 10:1: ±0.15 %

• TD >10:1 to TD 20:1: ±0.20 %

• TD 1:1 to TD 10:1: ±0.15 %

• TD >10:1 to TD 20:1: ±0.20 %

• TD 1:1 to TD 10:1: ±0.15 %

• TD >10:1 to TD 20:1: ±0.20 %

• TD 1:1 to TD 5:1: ±0.15 %

• TD >5:1: ±0.03 % x TD

• TD 1:1: ±0.15 %

• TD >1:1: ±0.15 % x TD

• TD 1:1 to TD 2.5:1: ±0.075 %

• TD >2.5:1: ±0.03 % x TD

• TD 1:1 to TD 5:1: ±0.075 %

• TD >5:1: ±0.015 % x TD

• TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 13:1: ±0.1 %

• TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 20:1: ±0.1 %

• TD 1:1 to TD 10:1: ±0.075 %

• TD > 10:1 to TD 13:1: ±0.1 %

• TD 1:1 to TD 5:1: ±0.15 %

• TD >5:1: ±0.03 % x TD

1)

Total performance – PMP51 The "Total performance" specification comprises the non-linearity including hysteresis, non-reproducibility as

well as the thermal change in the zero point. All specifications apply to the temperature range –10 to +60°C

(+14 to +140°F) and Turndown 1:1.

Measuring cell PMP51 PMP51 with gold/rhodium-coated

process isolating diaphragm

% of URL

400 mbar (6 psi)

1 bar (15 psi) ±0.75

2 bar (30 psi) ±0.45

4 bar (60 psi) ±0.30 ±0.3

10 bar (150 psi), 40 bar (600 psi),

100 bar (1500 psi)

400 bar (6000 psi) ±0.4 ±0.4

±0.34

±0.25 ±0.25

±1.25

Total error - PMP51 The total error comprises the long-term stability and the total performance. All specifications apply to the

temperature range –10 to +60°C (+14 to +140°F) and Turndown 1:1.

Measuring cell % of URL/year

400 mbar (6 psi) ±0.44

1 bar to 100 bar (15 psi to 1500 psi) ±0.35

400 bar (6000 psi) ±0.5

Endress+Hauser 17

Cerabar M PMC51, PMP51, PMP55

Thermal change in the zero output and the output span – PMP51 and PMP55

Note!

When using a PMP55, the influence from the respective diaphragm seal must also be taken into account

( ä 58 ff "Planning instructions for diaphragm seal systems").

PMP51 and PMP55 (basic device)

The data refer to the calibrated span.

Measuring cell –10 to +60 °C

(+14 to +140°F)

400 mbar (6 psi), 1 bar (15 psi),

2 bar (30 psi), 4 bar (60 psi), 10 bar

(150 psi), 40 bar (600 psi), 100 bar

(1500 psi)

400 bar (6000 psi) ±(0.3 + 0.35 x TD) ±(0.3 + 0.7 x TD)

±(0.34 + 0.15 x TD) ±(0.4 + 0.25 x TD)

–40 to –10°C, +60 to +85°C

(–40 to +14°F, +140 to +185°F)

18 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

Operating conditions (installation)

General installation instructions

Measuring arrangement for

devices without diaphragm

seal – PMC51, PMP51

• The position-dependent zero point shift can be corrected:

– directly at the device via operating keys on the electronic insert

– directly at the device via operating keys on the display (except analog electronics)

– via digital communication if the cover is not open (except analog electronics)

Note!

In hazardous areas, comply strictly with the safety instructions when the housing cover is closed and open.

• Endress+Hauser offers a mounting bracket for installing the device on pipes or walls.

See also ä 19, "Wall and pipe mounting" section.

• Use flushing rings for flange and cell diaphragm seals if medium buildup or clogging can be expected at the

diaphragm seal connection. The flushing ring can be inserted between the process connection and the

diaphragm seal. Thanks to the two lateral flushing bore holes, material buildup in front of the process

isolating diaphragm can be rinsed away and the pressure chamber can be ventilated.

Cerabar M transmitters without diaphragm seals are mounted as per the norms for a manometer

(DIN EN 837-2). We recommend the use of shutoff devices and siphons. The orientation depends on the

measuring application.

Pressure measurement in gases

• Mount Cerabar M with shutoff device above the tapping point so that any condensate can flow into the

process.

Pressure measurement in steams

• Mount Cerabar M with siphon below the tapping point.

• Fill the siphon with liquid before commissioning.

The siphon reduces the temperature to almost the ambient temperature.

Pressure measurement in liquids

• Mount Cerabar M with shutoff device below or at the same level as the tapping point.

Level measurement

• Mount Cerabar M below the lowest measuring point (zero point of the measurement).

• Do not mount the device at the following positions: In the filling curtain, in the tank outlet or at a point in

the container which could be affected by pressure pulses from an agitator or a pump.

• The calibration and functional test can be carried out more easily if you mount the device downstream of a

shutoff device.

Measuring arrangement for

devices with diaphragm seal

–PMP55

Wall and pipe mounting Endress+Hauser offers a mounting bracket for installing the device on pipes or walls.

• ä 58, "Planning instructions for diaphragm seal systems" section.

ä 63 ff, feature 620, "Accessory enclosed", version "PA" or as a separate accessory

(part number: 71102216).

For the dimensions, see ä 52.

Endress+Hauser 19

Cerabar M PMC51, PMP51, PMP55

➀

➁

➂

➃

r ³ 120 mm

IP xx

(see chapter

“Ordering information”)

FEP cable:

IP 69K

IP 66/68 NEMA 4/6P

PE cable:

IP 66/68 NEMA 4/6P

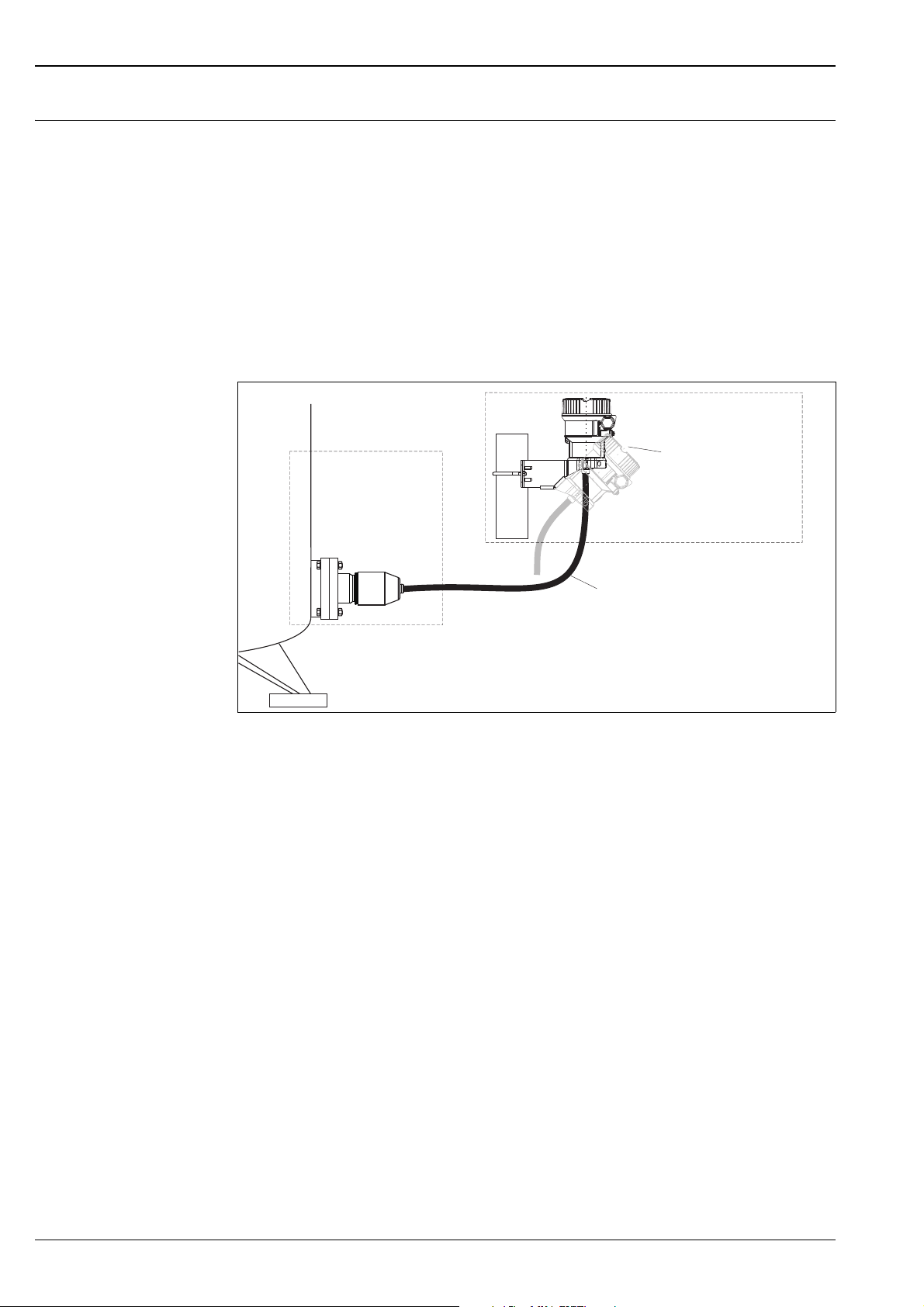

"Separate housing" version With the "separate housing" version, you are able to mount the housing with the electronics insert at a distance

from the measuring point. This version allows for trouble-free measurement:

• Under particularly difficult measuring conditions (at installation locations that are cramped or difficult to

access)

• If extreme cleaning of the measuring point is required

• If the measuring point is exposed to vibrations

• For space-saving installations

You can choose between different cable versions:

• PE (2 m (6.6 ft), 5 m (16 ft) and 10 m (33 ft))

• FEP (5 m (16 ft)).

ä 63 ff, feature 600, "Separate housing".

For the dimensions, ä 52.

P01-PMx5xxxx-11-xx-xx-en-002

In the case of the "separate housing" version, the sensor is delivered with the process connection and cable ready

mounted. The housing and a mounting bracket are enclosed as separate units. The cable is provided with a socket at both

ends. These sockets are simply connected to the housing and the sensor.

1 Process connection with sensor

2 Cable, both ends are fitted with a socket

3 Mounting bracket provided, suitable for pipe and wall mounting

4 Housing with electronic insert

Degree of protection for the process connection and sensor when using:

• FEP cable:

– IP 69K

– IP 66/68 NEMA 4/6P

• PE cable:

– IP 66/68 NEMA 4/6P

Technical data of the PE and FEP cable:

• Minimum bending radius: 120 mm (4.72 in)

• Cable extraction force: max. 450 N (101 lbf)

• Resistance to UV light

Use in hazardous area:

• Intrinsically safe installations (Ex ia/IS)

• FM/CSA IS: for Div.1 installation only

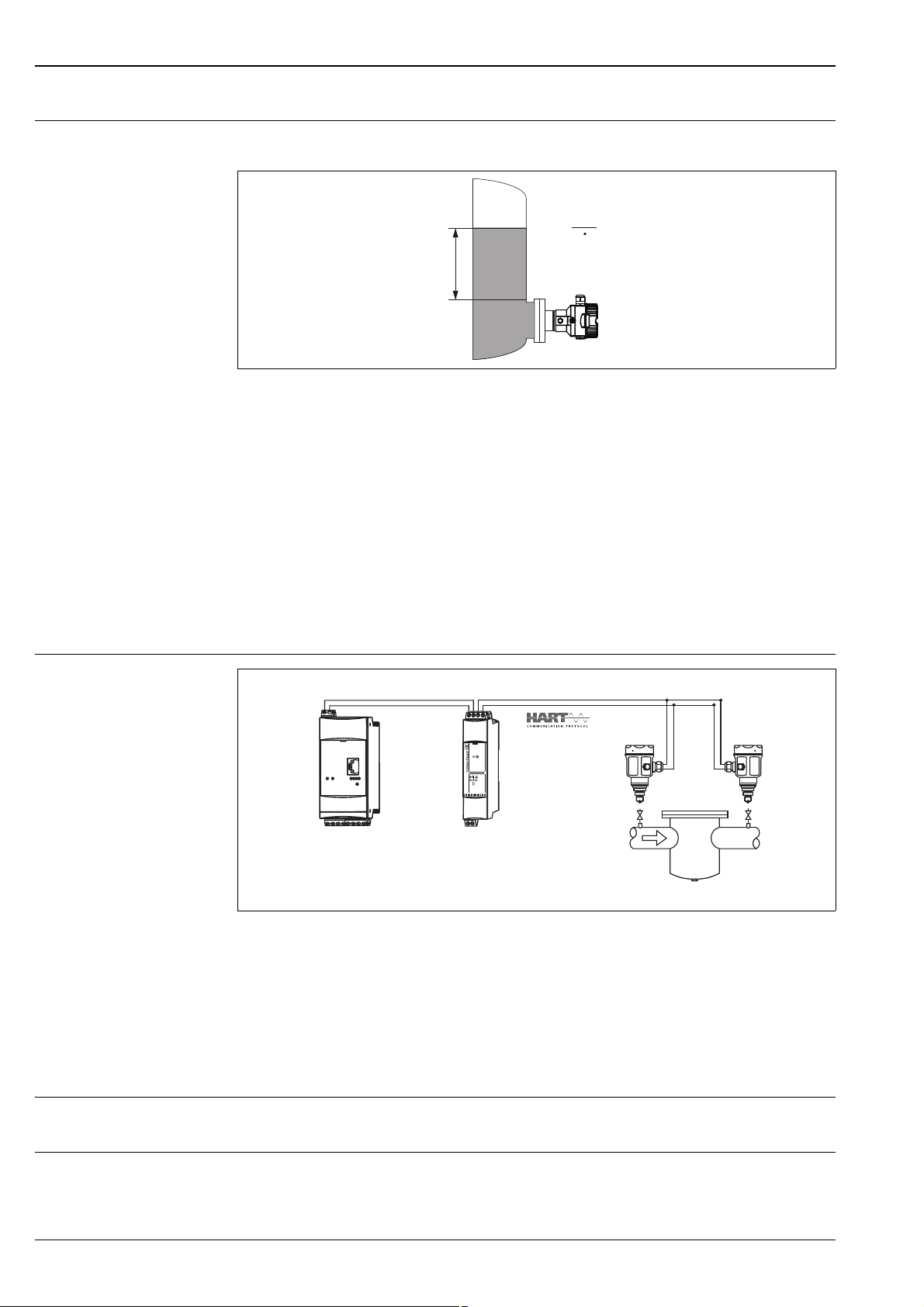

Reduction in installation height

If the separate housing is used, the mounting height of the process connection is reduced compared to the

dimensions of the standard version (see graphic).

20 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

ø54.1

29

81

F31

r ³ 120 mmr ³ 120 mm r ³ 120 mmr ³ 120 mm

➀ ➀

44

F15

r ³ 120 mmr ³ 120 mm

➀

17

36

P01-xMx5xxxx-06-xx-xx-xx-000

Oxygen applications Oxygen and other gases can react explosively to oils, grease and plastics. As a result, the following are some of

the precautions that must be taken:

– All components of the system, such as measuring devices, must be cleaned in accordance with the BAM

(DIN 19247) requirements.

– Depending on the materials used, a certain maximum temperature and maximum pressure must not be

exceeded for oxygen applications.

The devices suitable for gaseous oxygen applications are listed in the following table with the specification p

max

.

Ordering information for devices

cleaned for oxygen applications

1)

PMC51

nominal value < 10 bar (150 psi)

PMC51

nominal value 10 bar (150 psi)

PMP51 PMP55

1) Feature 570 "Service" version "HB"

2) ä 63 ff "Ordering information", feature 70 "Sensor range"

3) PMC51 with PVDF thread or PVDF flange p

– devices with sensors,

)

– devices with sensors,

)

p

for oxygen applications T

max

Over pressure limit (OPL) of sensor

40 bar (600 psi) 60°C (140°F)

Depends on the lowest-rated element, with regard to

pressure, of the selected components: over pressure limit

(OPL) of sensor

(160 bar (2320 psi))

, process connection (1.5 x PN) or fill fluid

= 15 bar (225 psi)

max

2, 3

Silicone-free applications Special cleaning of the transmitter to remove paint-wetting substances, for use in paint shops

ä 66 feature 570 "Service", version "HC".

Ultrapure gas applications Endress+Hauser also provides devices which have been cleaned of oil and grease for special applications, such

as for ultrapure gas. No special restrictions regarding the process conditions apply to these devices.

ä 63 ff, "Ordering information PMC51", feature 570 "Service" version "HA".

ä 68 ff, "Ordering information PMP51", feature 570 "Service" version "HA".

Applications with hydrogen With regard to materials in which hydrogen formation takes place, hydrogen atoms can diffuse through the

metal process isolating diaphragm. This can result in incorrect measurement results.

Endress+Hauser offers process isolating diaphragms with a gold/rhodium coating for such instances.

ä 67 ff "Ordering information PMP51" and ä 71 ff "Ordering information PMP55",

feature 170 "Membrane Material" version "M".

for

max

oxygen applications

60°C (140°F)

85°C (185°F)

Endress+Hauser 21

Operating conditions (environment)

Cerabar M PMC51, PMP51, PMP55

Ambient temperature range

Storage temperature range

Version PMC51 PMP51 PMP55

Without LCD display –40°C to +85°C (–40°F to +185°F)

With LCD display

With M12 plug , elbowed –25°C to +85°C (–13°F to +185°F)

With separate housing –20°C to +60°C (–4°F to +140°F)

Diaphragm seal systems ä 58

1) Extended temperature application range (–40°C to +85°C (–40°F to +185°F)) with restrictions in optical properties

such as display speed and contrast

1

(installation without insulation)

–20°C to +70°C (–4°F to +158°F)

Note!

For high-temperature applications, either a PMP55 with a temperature isolator or with a capillary can be used.

If vibrations also occur in the application, Endress+Hauser recommends you use a PMP55 with a capillary. If

a PMP55 with a temperature isolator or capillary is used, we recommend a suitable bracket for mounting (see

"Wall and pipe mounting" section on ä 19).

For devices for use in hazardous areas, see Safety Instructions, Installation or Control Drawing. ( ä 77 ff,

"Safety Instructions" and "Installation/Control Drawings" sections)

Version PMC51 PMP51 PMP55

Without LCD display –40°C to +90°C (–40°F to +194°F)

With LCD display –40°C to +85°C (–40°F to +185°F)

With M12 plug , elbowed –25°C to +85°C (–-13°F to +185°F)

With separate housing –40°C to +60°C (–40°F to +140°F)

Diaphragm seal systems ä 58

Degree of protection • ä 63 ff, feature 50 "Electrical connection".

• Separate housing ( ä 20)

Climate class Class 4K4H (air temperature: –20 to 55°C (–4 to +131°F), relative humidity: 4 to 100%) satisfied as per

DIN EN 60721-3-4 (condensation possible. In the case of the PMC51, condensate in the device must be

avoided.)

22 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

➀

➁

Unit to be

protected

Connection

cables

Incoming

connection cables

HAW569Z

+

-

+

-

Red

Black

+

-

Shield grounding

without

direct

➀

➁

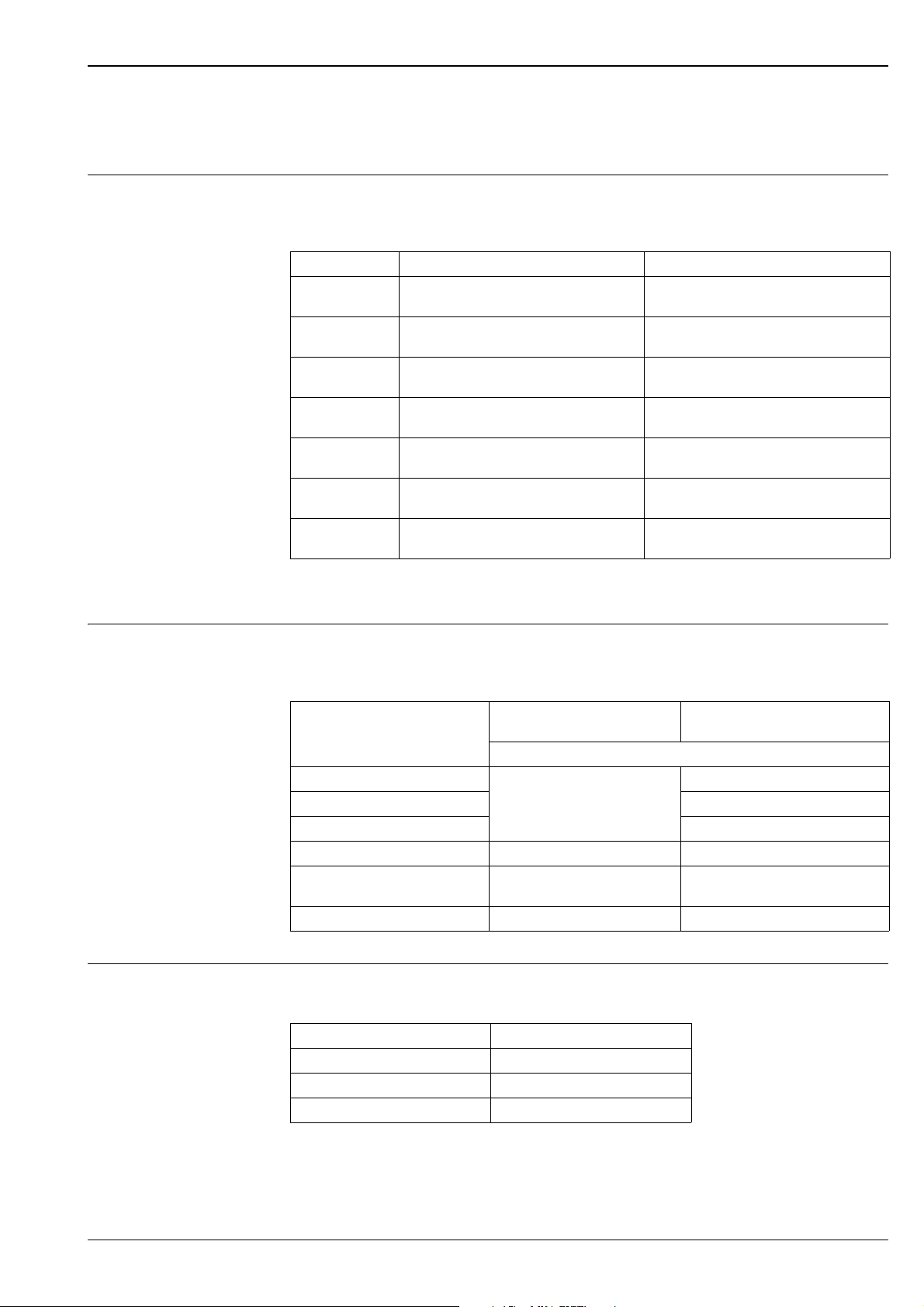

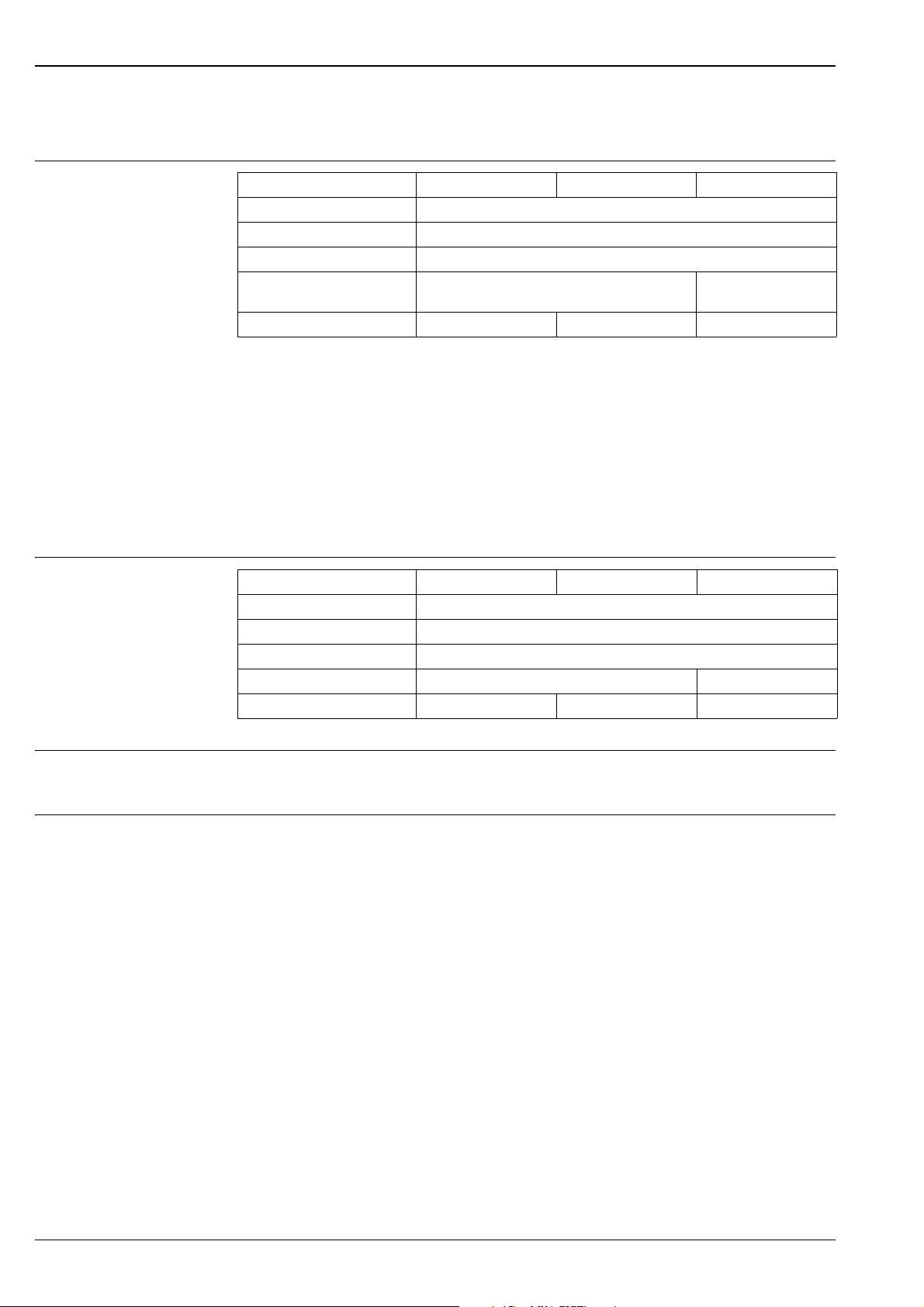

Vibration resistance

Device/Additional

option

PMC51, PMP51, PMP55 GL VI-7-2

with mounting bracket IEC 61298-3

Test standard Vibration resistance

• Part 7: Guidelines for the Performance of Type

Approvals

• Chapter 2: Test Requirements for Electrical /

Electronic Equipment and Systems

IEC 60068-2-6

guaranteed for

3 to 18 Hz: ±4 mm (0.16 in);

25 to 500 Hz: 5 g

in all 3 planes

guaranteed for

10 to 58 Hz: ±0.15 mm (0.01 in);

58 to 500 Hz: 2 g

in all 3 planes

Note!

For high-vibration applications, either a PMC51/PMP51 with a separate housing or a PMP55 with a capillary

can be used. We recommend a suitable bracket for mounting (see "Wall and pipe mounting" section on

ä 19).

Electromagnetic compatibility • Electromagnetic compatibility as per all the relevant requirements of the EN 61326 series and NAMUR

Recommendation EMC (NE21). Details can be found in the Declaration of Conformity (in the Download

area of "www.de.endress.com", "search area - Approvals and Certificates", "Manufact. Declaration").

• Maximum deviation: < 0.5 % of span

Overvoltage protection (optional)

NAThe device can be fitted with overvoltage protection, see ä 63 ff "Ordering information" feature 610

"Accessory mounted:" version "NA". The overvoltage protection is mounted at the factory on the housing

thread (M20x1.5) for the cable gland and is approx. 70 mm (2.76 in) in length (take additional length into

account when installing). The device is connected as illustrated in the following graphic.

For details refer to TI103R/09/EN, XA036R/09/A3 and KA161R/09/A6.

Wiring

P01-xMx5xxxx-04-xx-xx-en-006

Endress+Hauser 23

Operating conditions (process)

Process temperature limits PMC51 (with ceramic process isolating diaphragm)

• –20 to +100 °C (–4 to +212°F)

• Observe the process temperature range of the seal. See also the following table.

Cerabar M PMC51, PMP51, PMP55

Version for feature

190 in the order code

A FKM Viton -20 to +125°C (-4 to +257°F)

1)

A

B FKM Viton, FDA -20 to +125°C (-4 to +257°F)

F NBR -10 to +100°C (-14 to +212°F)

G HNBR, FDA, 3A Class II, KTW, AFNOR, BAM -25 to +125°C (-13 to +257°F)

J EPDM -20 to +125°C (-4 to +257°F)

K EPDM, FDA, 3A Class II, USP Class VI, DVGW, KTW,

1) With feature 570 "Service", version "HB - Cleaned for oxygen service"

Seal Process temperature range

FKM Viton, cleaned for O2 application -5 to +60°C (+23 to +140°F)

-20 to +125°C (-4 to +257°F)

W270, WRAS, ACS, NSF61

Physical limitations

Extreme jumps in temperature can result in temporary measuring errors. Temperature compensation takes

effect after several minutes. Internal temperature compensation is faster the smaller the jump in temperature

and the longer the time interval involved.

For further information please contact your local Endress+Hauser Sales Center.

PMP51 (with metal process isolating diaphragm)

Description Temperature operating range

Process connections with internal process isolating diaphragm -40 to +125°C (-40 to +257°F)

Process connections with flush-mounted process isolating

diaphragm,

G 1 A, G 1 1/2 A, G 2 A, 1 NPT, 1 1/2 NPT, 2 NPT,

M 44 x 1.25, EN/DIN, ANSI and JIS flanges

Process connections with flush-mounted process isolating

diaphragm, G 1/2 A, M 20x1.5

-40 to +100°C (-40 to +212°F)

-20 to +85°C (-4 to +185°F)

PMP55 (with diaphragm seal)

• Depending on the diaphragm seal and filling oil from -70°C (-94°F) up to +400°C (+752°F). Observe the

temperature application limits ä 58.

Note!

• Do not use diaphragm seals with 0.09 mm (0.0035 in) PTFE foil on AISI 316L for vacuum applications,

upper temperature limit +204°C (+399°F).

• For oxygen applications, observe ä 21, "Oxygen applications" section.

24 Endress+Hauser

Cerabar M PMC51, PMP51, PMP55

Pressure specifications • The maximum pressure for the measuring device depends on the lowest-rated element with regard to

pressure.

See the following sections:

– ä 7 ff, "Measuring range" section

– "Mechanical construction" section.

The MWP (maximum working pressure) is specified on the nameplate. This value refers to a reference

temperature of +20°C (68°F), or 100°F (38°C) for ANSI flanges, and may be applied to the device for an

unlimited time. Observe temperature dependency of the MWP.

• The pressure values permitted at higher temperatures can be found in the following standards:

– EN 1092-1: 2001 Tab. 18

– ASME B 16.5a – 1998 Tab. 2-2.2 F316

– ASME B 16.5a – 1998 Tab. 2.3.8 N10276

– JIS B 2220.

• The test pressure corresponds to the over pressure limit of the device (over pressure limit OPL =

1.5 x MWP

2

) and may be applied for only a limited time period in order to avoid permanent damage.

• The Pressure Equipment Directive (EC Directive 97/23/EC) uses the abbreviation "PS". The abbreviation

"PS" corresponds to the MWP (maximum working pressure) of the measuring device.

• In the case of sensor range and process connection combinations where the OPL (over pressure limit) of the

process connection is smaller than the nominal value of the sensor, the device is set at the factory, at the

very maximum, to the OPL value of the process connection. If you want to use the entire sensor range, select

a process connection with a higher OPL value (1.5 x PN; PN = MWP).

• In oxygen applications, the values for "p

applications" may not be exceeded.

1

max

and T

for oxygen applications" as per ä 21, "Oxygen

max

1) With regard to their stability-temperature property, the materials 1.4435 and 1.4404 are grouped together under 13EO

in EN 1092-1 Tab. 18. The chemical composition of the two materials can be identical.

2) The equation does not apply for PMP51 and PMP55 with a 40 bar (600 psi) - or a 100 bar (1500 psi) - measuring cell.

Endress+Hauser 25

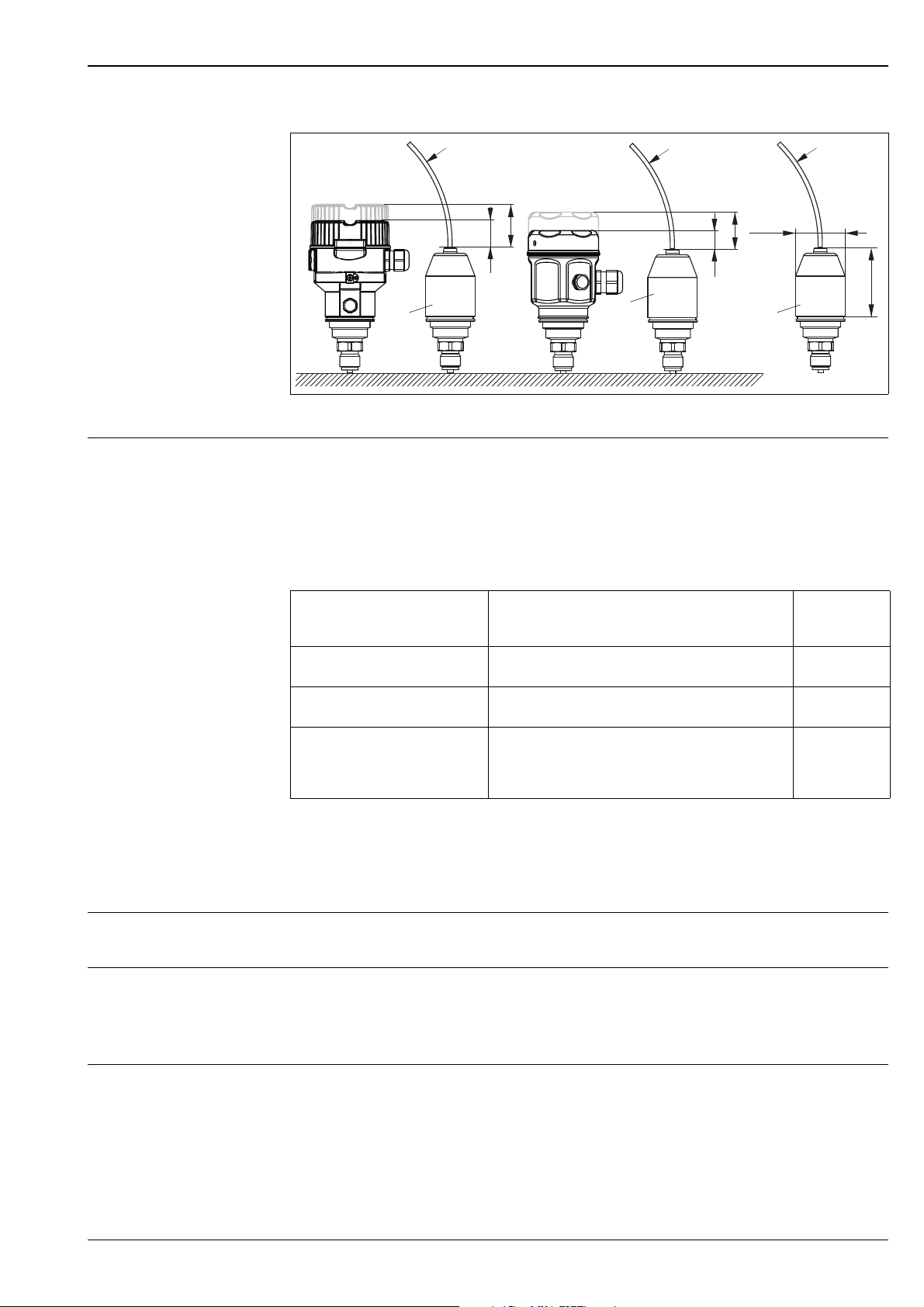

F31 aluminum housing

115

103

94

H

➀

15

76

100

H

➀

19

G 1/2

17

20

ø11.4

ø17.5

G 1/2A 11.4 mm

ø8

ø3

ø6

G 1/2

17

20

H

3

G 1/2A

13

17

20

G 1/4

ø17.5

G 1/2

G 1/2A G 1/4

➂➁➀

H

H

dimensions

F15 stainless steel housing dimensions (hygienic)

Cerabar M PMC51, PMP51, PMP55

Mechanical construction

P01-F31xxxx-06-00-xx-xx-000

Front view, left-hand side view, top view

➀ The cover with viewing window is 15 mm (0.59 in) higher than the cover without viewing window.

For installation height H for housing with viewing window, see the specific process connection. Housing weight ä 52

P01-F15xxxx-06-00-xx-xx-000

Front view, top view.

➀ The cover with viewing window is 19 mm (0.75 in) higher than the cover without viewing window.

For installation height H for housing with viewing window, see the specific process connection. Housing weight ä 52

Process connections PMC51

Thread, internal process isolating diaphragm

(with ceramic process

isolating diaphragm)

P01-PMC71xxx-06-09-xx-xx-001

Process connections PMC51, thread ISO 228

Installation height H ä 27.

26 Endress+Hauser

1 Thread ISO 228 G 1/2 A EN 837;

Material version GCJ: AISI 316L, version GCC: Alloy C276

Version GCF: PVDF (max.: 15 bar (217.5 psi), –10 to +60 °C (+14 to +140 °F)), mount version"GCF" with a

mounting bracket only ( ä 19); weight: 0.63 kg (1.39 lbs)

2 Thread ISO 228 G 1/2 A G 1/4 (female);

Material version GLJ: AISI 316L, version GLC: Alloy C276; weight: 0.63 kg(1.39 lbs)

3 Thread ISO 228 G 1/2 A hole 11.4 mm (0.45 in);

Material version GMJ: AISI 316L, version GMC: Alloy C276; weight: 0.63 kg(1.39 lbs)

Loading...

Loading...