Endress+Hauser cerabar M PMP 46, cerabar M PMP 48 Technical Information

Technical

Information

TI322P/00/en

Pressure Transmitter

cerabar M PMP 46

cerabar M PMP 48

Overload resistant pressure transmitter with

diaphragm seal and analogue, Smart or

PROFIBUS-PA electronics

PMP 46

Clamp

PMP 48

Flange

Applications

The Cerabar M transmitter measures the

gauge and absolute pressure of gases,

vapours and liquids and can be used in

all areas of industry.

Installation and process conditions often

make the use of diaphragm seals

necessary. Endress+Hauser offers you

the following:

•

PMP 46: diaphragm seals for hygienic

applications

•

PMP 48: diaphragm seals with

threaded boss, separator, flange or

flange with extension

Features and Benefits

•

Accuracy

− Linearity better than 0.2% of set span

− Adjustable measuring range with

TD 10:1

− Long-term stability better than 0.1%

•

Piezoresistive metal sensor with metal

diaphragm for measuring ranges up to

400 bar (6000 psi).

•

Electronics

− Analogue: cost effective version with

short response time especially for

fast processes

− Smart: intelligent with versatile

operating procedures via HART

protocol

− PROFIBUS-PA: tried and tested for

digital communications

•

Housing

With its stainless steel housing and no

dead volume, the Cerabar M fulfils all

the special hygienic requirements of

the food and pharmaceutical

industries. The polyester-epoxy

coated aluminium housing has proven

itself well in the process industry.

•

Process connections

All customary thread versions,

hygienic connections and flanges

available.

Endress

The Power of Know How

+

Hauser

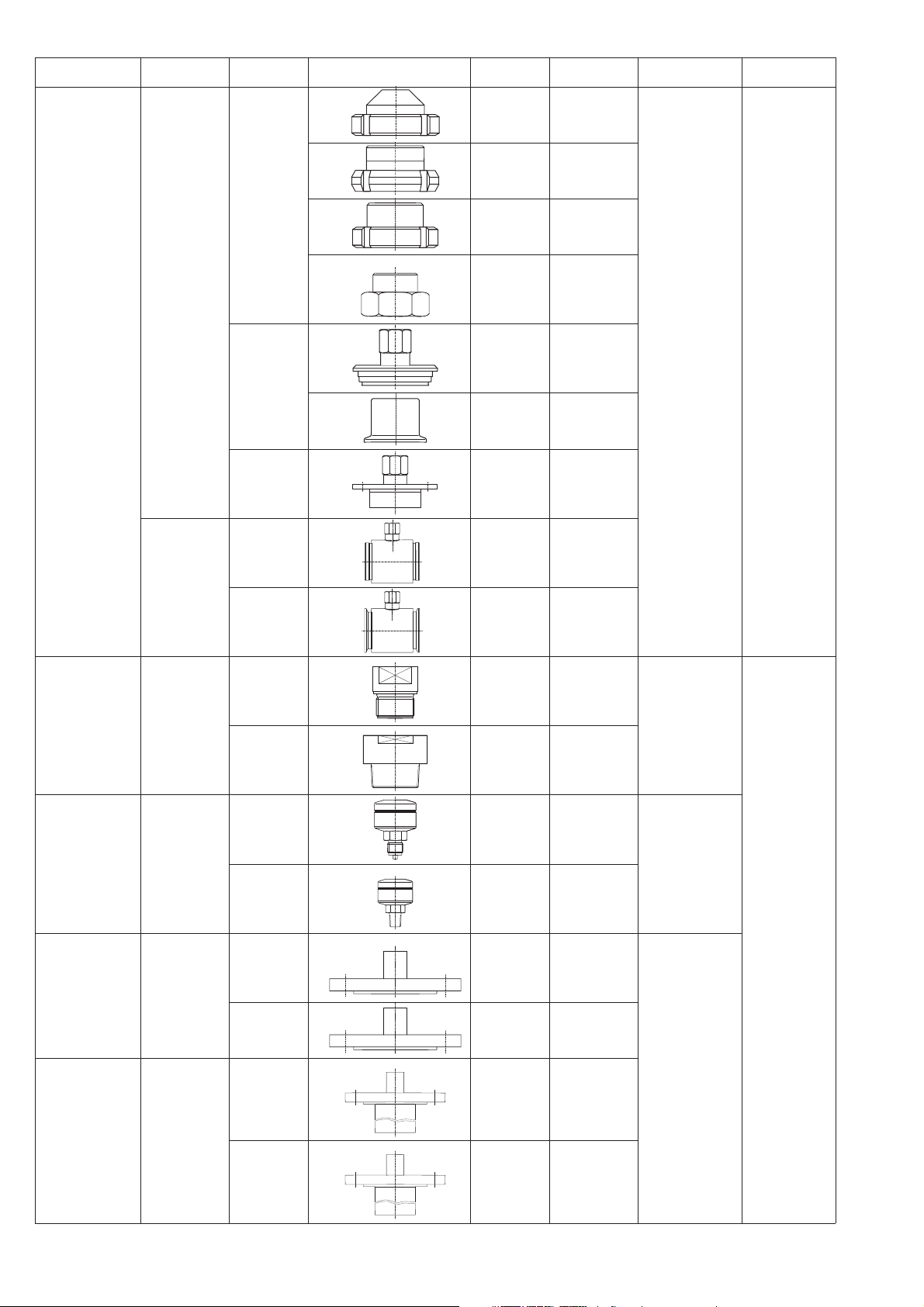

Construction Diaphragm

Hygienic

applications

seal

Diaphragm

seal

Connection Page/Version Standard Nominal width Pressure

Groove nut Page 21 DIN 11851 DN 32,

DN 40,

DN 50

Page 23 SMS 1½", 2"

Page 23 RJT 1½", 2"

Page 23 ISS 1½", 2"

range

max. 40 bar

(600 psi)

Instrument type

PMP 46

Threaded boss

Pipe

diaphragm

seal

Diaphragm

seal

Clamping

bracket

Flange Page 24 DRD D = 65 mm

Thread

adapter

Clamping

bracket

G Page 27 DIN ISO

NPT Page 27 ANSI

Page 24 Varivent Type N

Page 22 Clamp 1½", 2", 3"

Page 21 DIN 11851 DN 25,

Page 22 Clamp ¾", 1", 1½", 2"

228/1

B1.20.1

DN 40,

DN 50

G 1

G 1½

G 2

1 NPT

1½ NPT

2 NPT

max. 400 bar

(6000 psi)

PMP 48

Threaded boss

with separator

Flange

Flange with

extension

Diaphragm

seal

Diaphragm

seal

Diaphragm

seal

G Page 28 EN 837 G ½ max. 160 bar

NPT Page 28 ANSI

DIN

flange

ANSI

flange

DIN

flange

ANSI

flange

Page 29 DIN 2501 DN 25

Page 30 ANSI B.16.5 1", 2", 3", 4"

Page 29 DIN 2501 DN 50

Page 30 ANSI B.16.5 2", 3", 4"

B1.20.1

½ NPT

DN 50

DN 80

DN 80

(2300 psi)

max. 400 bar

(6000 psi)

2

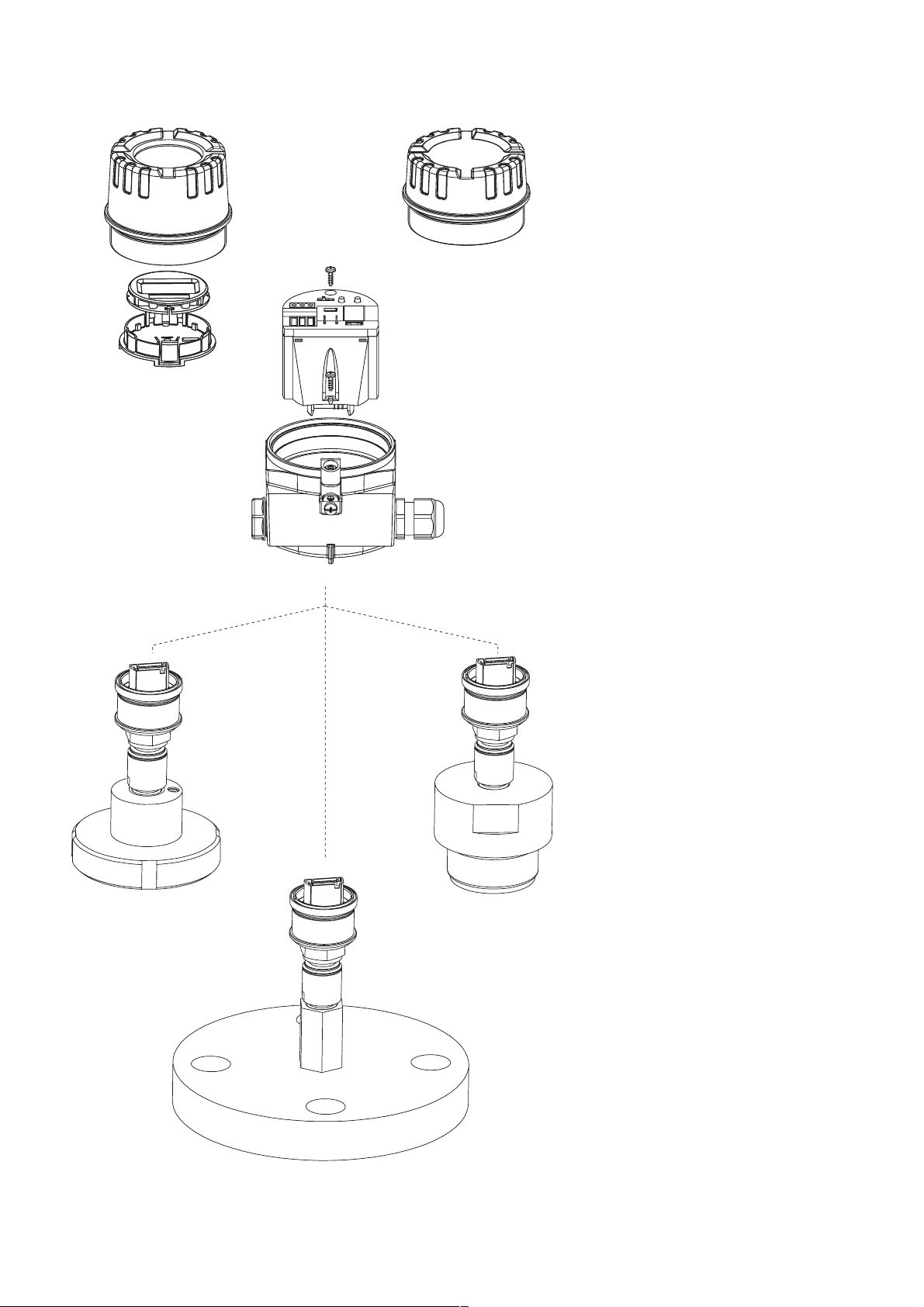

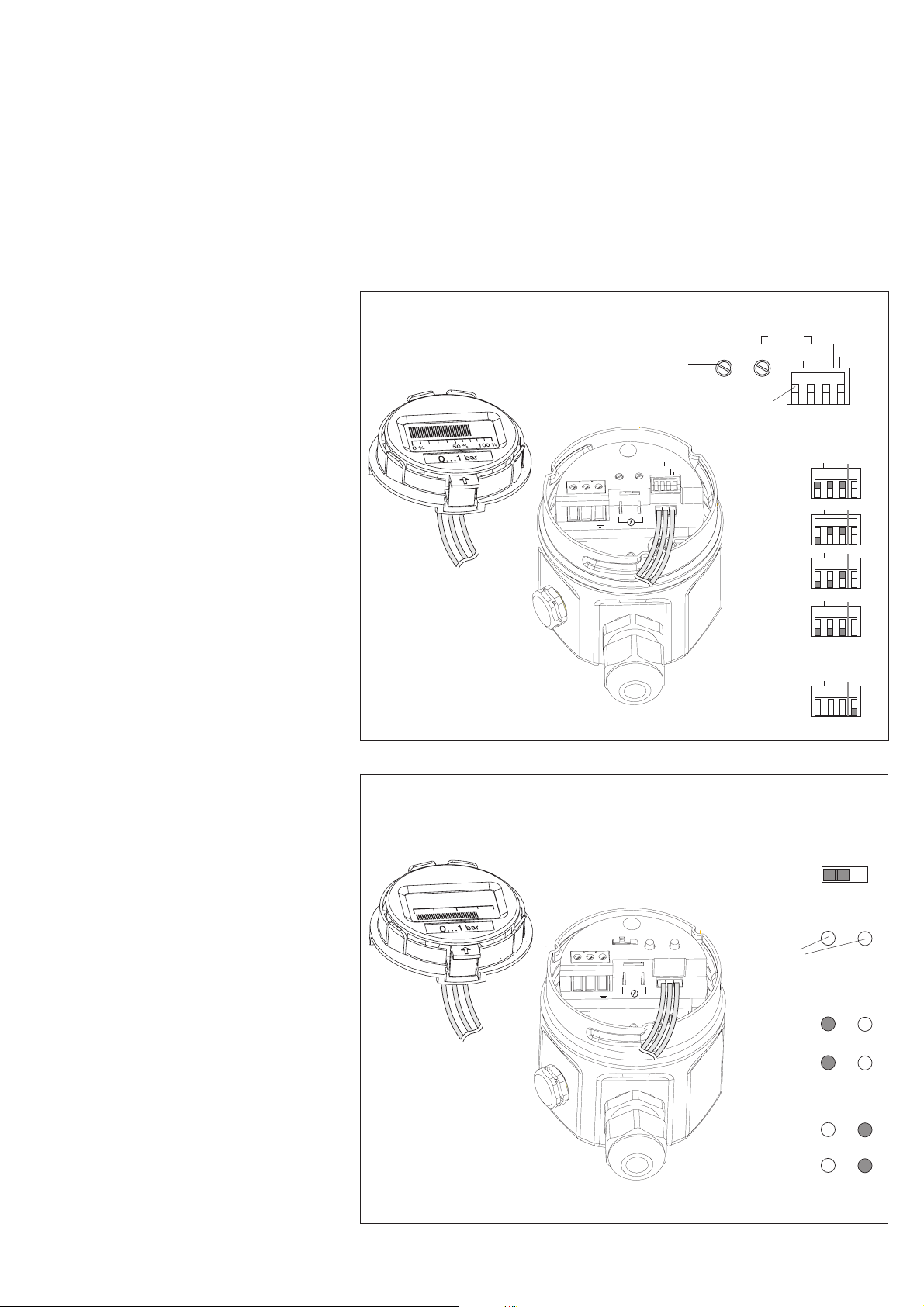

Instrument Configuration of Cerabar M with Stainless Steel Housing

Housings

The stainless steel housing of Cerabar M

is especially remarkable due to its

chemical resistance and hygienic

properties. Having no dead volume and

being condensation-tight with a surface

roughness of Ra ≤ 0,8 µm, it is easy to

clean and thereby ideal for the food and

pharmaceutical industry.

The aluminium housing has proven its

ruggedness and has become a

standard in many industries such as

chemicals, papermaking, power

generation, water and wastewater

treatment.

•

Ingress protection

− IP 65 with Harting plug (Han7D),

− IP 66/Nema 4X as standard or

− IP 68/Nema 6P with 5 m (16.4 ft)

assembled cable with pressure

compensation or plug M 12x1.

This version is recommended for

very moist applications (e.g. wet

vessel walls or pipes).

•

Optional connection with

− cable gland M 20x1.5 or

− cable entry ½ NPT or G ½,

− Harting plug (Han7D) or

plug M 12x1 or

− with assembled cable

•

A raised cover with sight glass is

provided when using a display. A low

cover is available for versions without

a local display.

display

holder for

display

process connection

PMP 46

e.g. with dairy

thread connection

with sight glass

low coverraised cover

for display

electronic insert

housing

process connection

PMP 48

e.g. with G 2 A thread

process connection

PMP 48

e.g. flange

Electronic Inserts

Cerabar M has three electronics versions

•

Analogue: 4…20 mA

Operation directly at the measuring

point with one potentiometer each for

lower range-value and upper

range-value and a three-step range

switch as well as an on/off switch for

damping.

•

Smart: 4…20 mA with HART protocol

Operation:

− at the measuring point via two push

buttons for lower range-value and

upper range-value as well as an

on/off switch for damping, or

− via the Universal HART Communicator

DXR 275 handheld terminal at any

point along the 4…20 mA line, or

− via PC e.g. with the Endress+Hauser

Commuwin II operating program.

•

PROFIBUS-PA:

Operation:

– Using a PC with an operating

program, e.g. Commuwin II from

Endress+Hauser, or

– using two keys for lower range-value

and upper range-value.

3

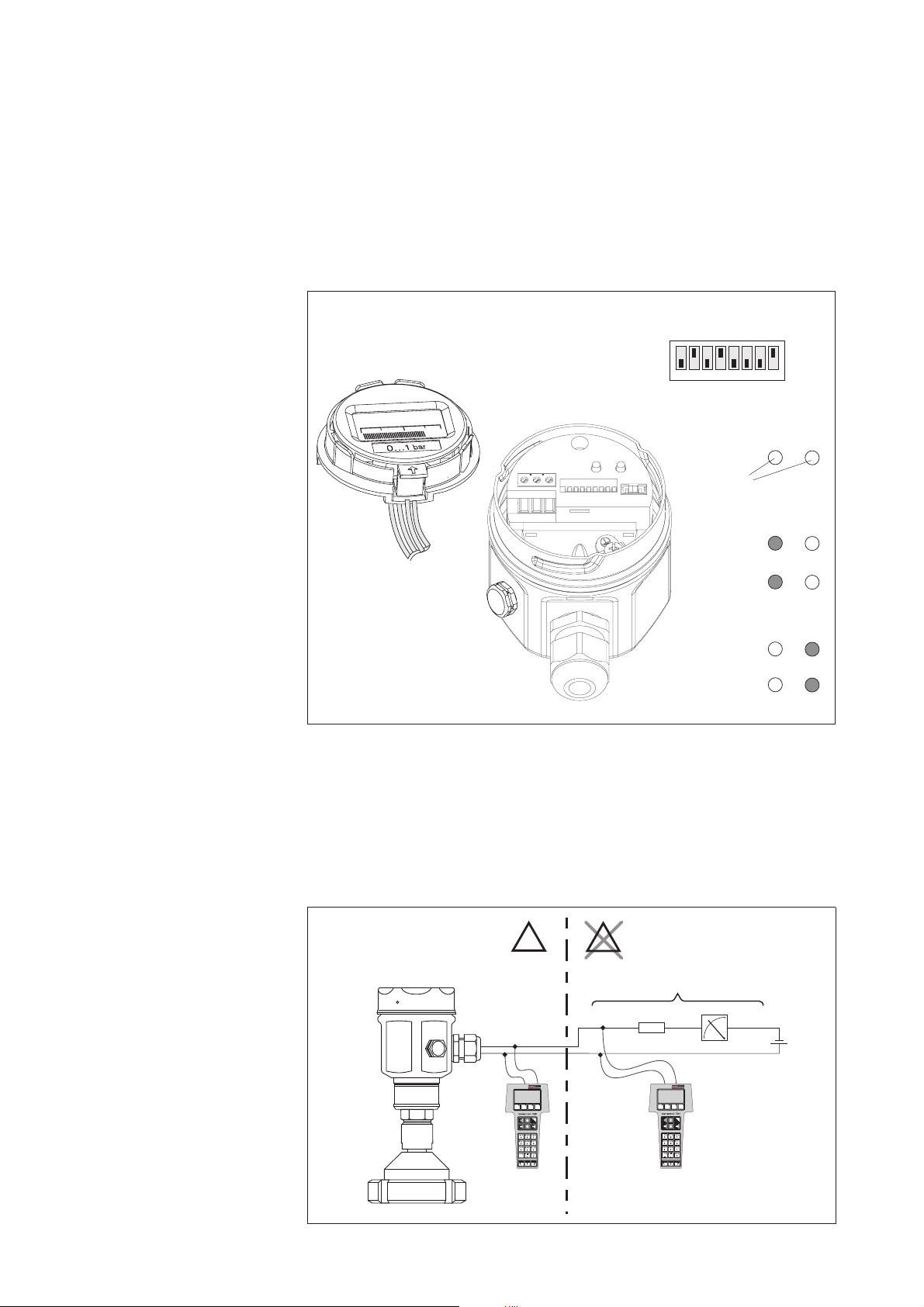

Instrument Configuration of Cerabar M with Aluminium Housing

Displays

A display module can be used for

showing measured values and for

simplifying local operation. The display

is plugged onto the electronic insert

using a holder.

•

Analogue display for Cerabar M with

analogue electronics: The analogue

display gives the current pressure

value related to the measuring range

in the form of a bar graph.

•

Digital display for Cerabar M with

Smart electronics: The digital display

gives the pressure in the form of a

four-digit number. The appropriate

current value from 4…20 mA is shown

as a bar graph underneath.

•

Digital display for Cerabar M with

PROFIBUS-PA electronics:

The digital display gives the pressure

in the form of a four-digit number. The

bar graph depicts the current pressure

value related to the measuring range.

Process Connections

•

Process connections are available

with all common threads,

flush-mounted hygienic connections

and flanges (see summary, page 2).

•

Chemical resistance can be

guaranteed by selecting suitable

materials for the process connection.

This applies especially to the metal

separating diaphragm of the

diaphragm seal in contact with the

medium.

•

The diaphragm is welded to every

diaphragm seal with no dead volume.

display

holder for

display

process connection

PMP 46

e.g. with dairy

thread connection

raised cover

with sight glass

for display

low cover

electronic insert

housing

process connection

PMP 48

e.g. with G 2 A thread

process connection

PMP 48

e.g. flange

4

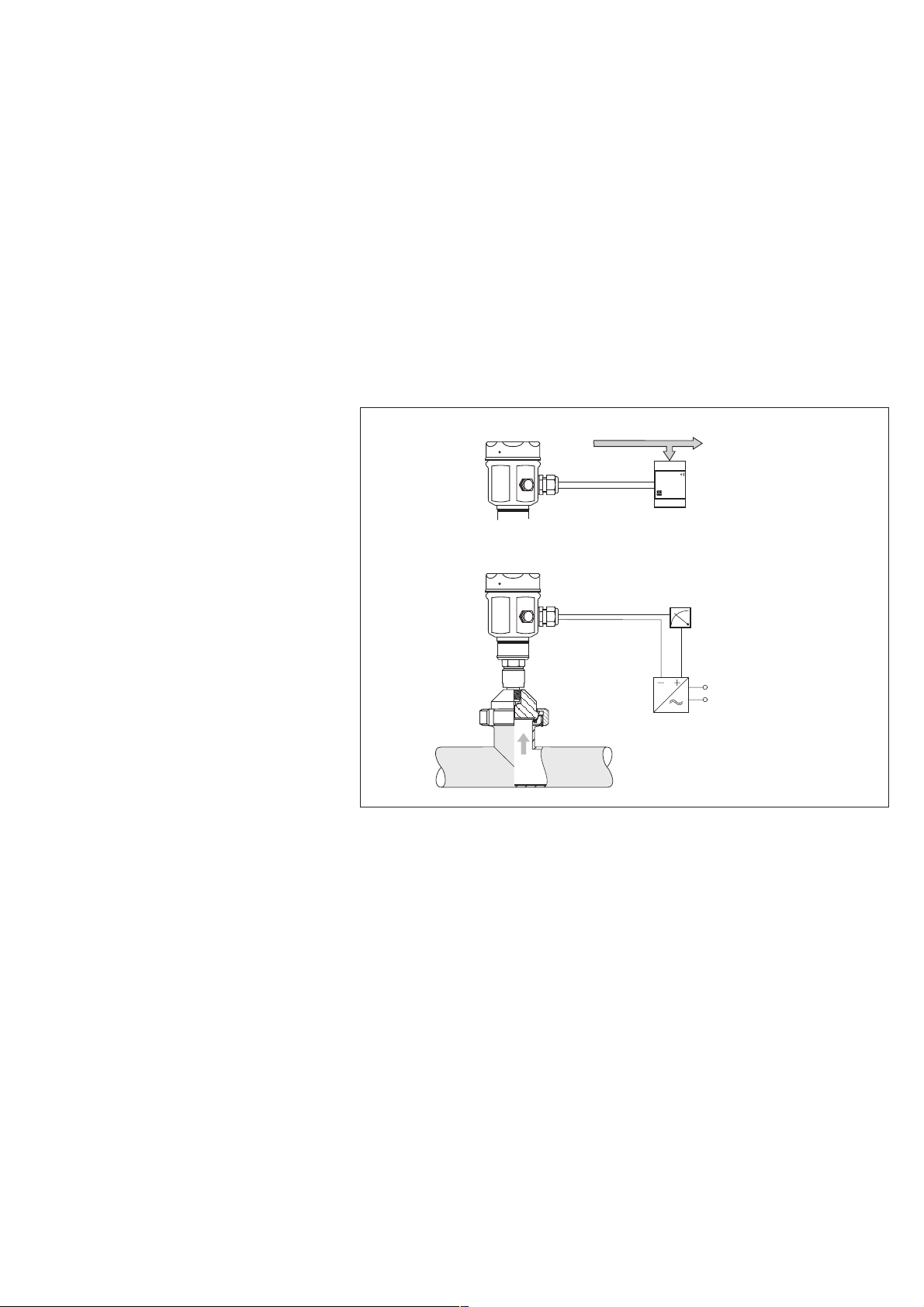

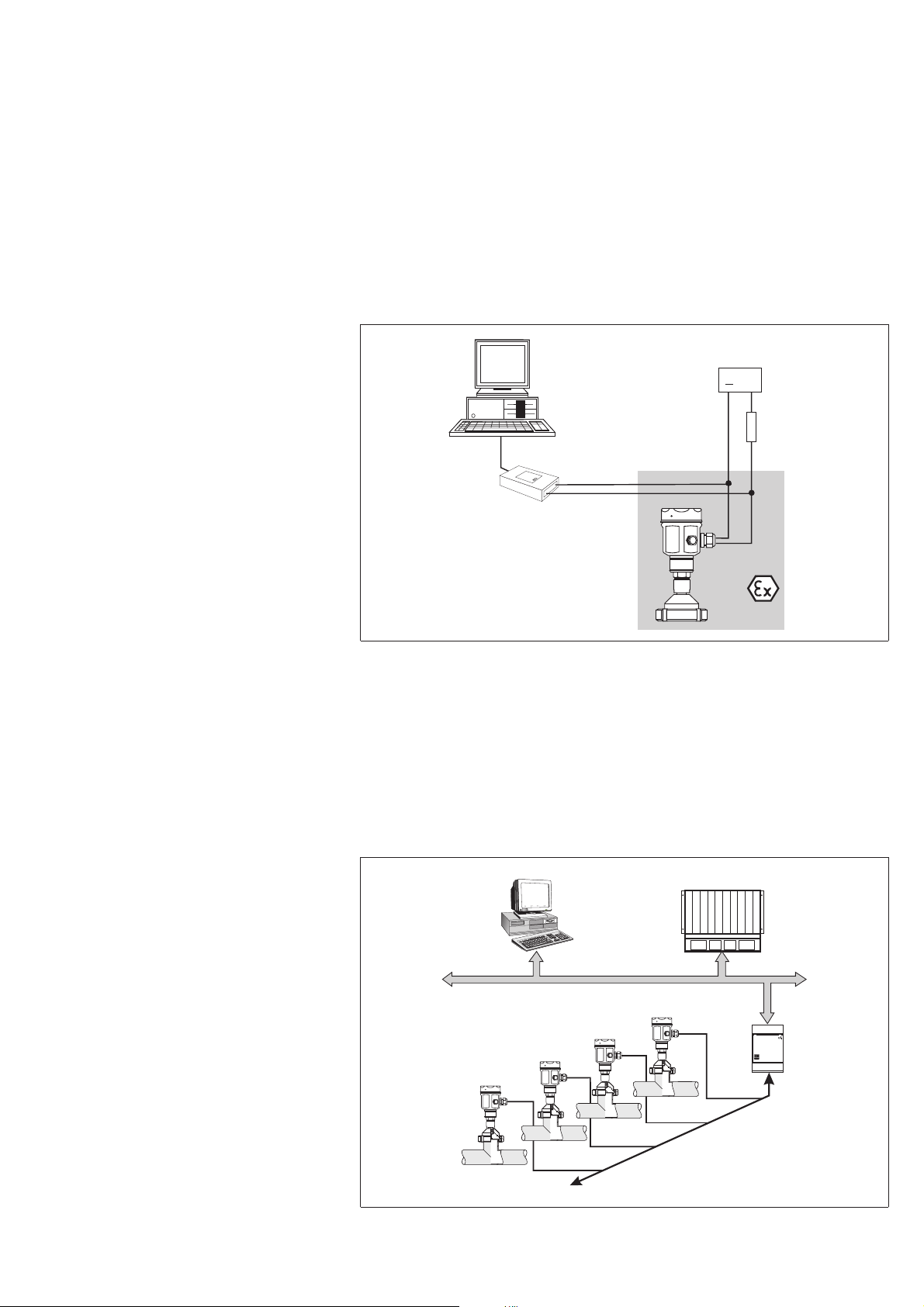

Measuring System

System Components

The complete measuring system

consists of:

•

Cerabar M pressure transmitter with

− analogue output 4…20 mA and

− supply voltage, e.g. with the

RN 221N transmitter power supply

unit from Endress+Hauser

Supply voltage: 11.5…45 V DC

Cerabar M

PROFIBUS-DP

PROFIBUS-PA

or

•

Cerabar M pressure transmitter with

− 4…20 mA signal output and HART

communication signal and

− supply voltage, e.g. RN 221N

transmitter power supply unit from

Endress+Hauser

Supply voltage: 11.5…45 V DC

or Ex ia: 11.5…30 V DC

or

•

Cerabar M pressure transmitter with

− PROFIBUS-PA digital communication

signal and

− connection via segment coupler to a

PLC or PC using e.g. the

Endress+Hauser Commuwin II

operating program

Supply voltage: 9…32 V DC

or Ex ia: 9…24 V DC

via segment coupler

connection to

ENDRESS+ HAUSER

PLC or PC

Complete measuring

system Cerabar M

above:

with PROFIBUS-PA

electronics

below:

with Smart electronics or

with analogue electronics

Cerabar M

4…20 mA

Supply voltage

(e.g. with RN 221N):

11.5…45 V DC

for Ex ia (Smart electronics only):

11.5…30 V DC

5

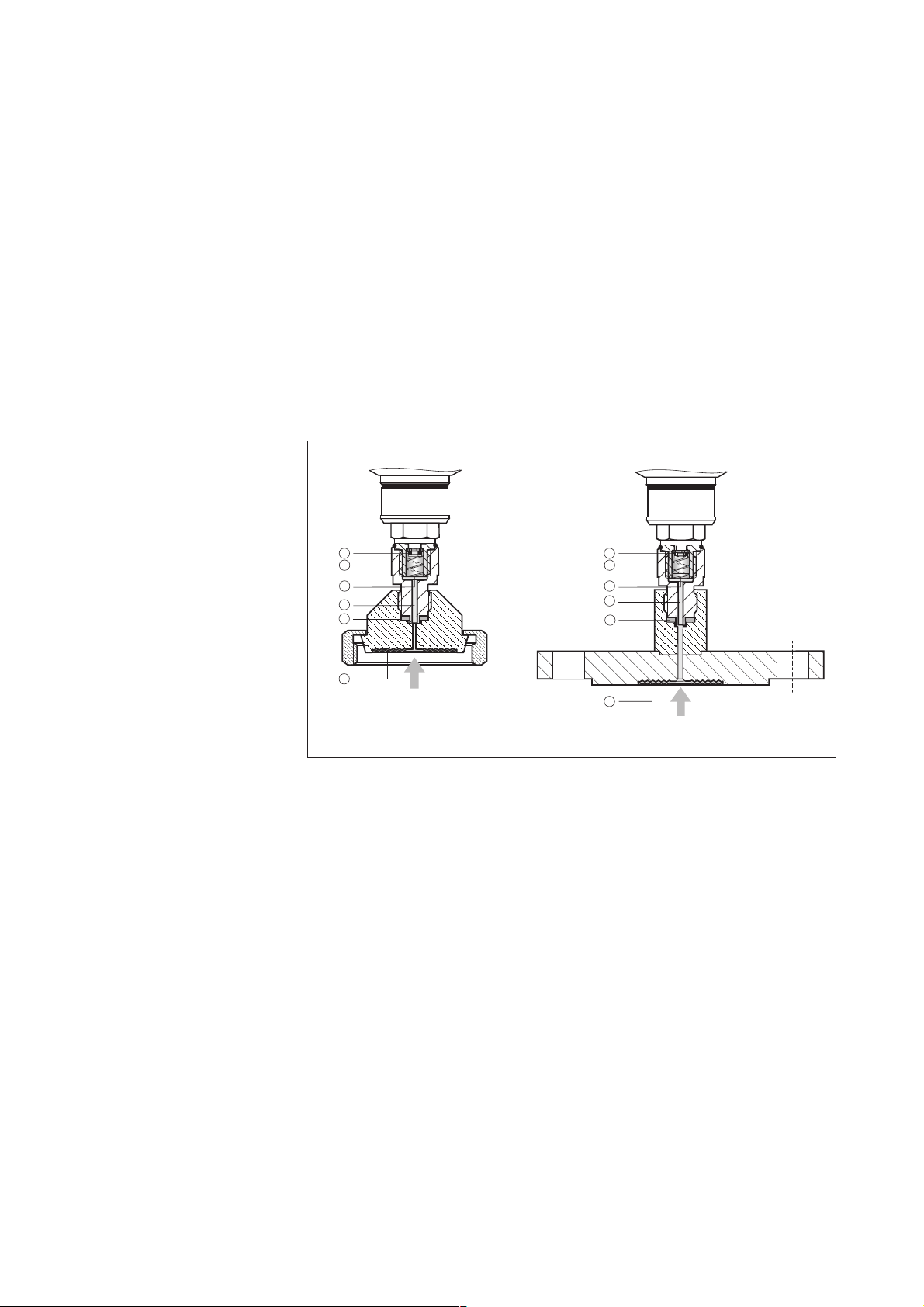

Operating Principle

Piezoresistive Sensor with

Diaphragm Seal

The process pressure acting on the

diaphragm of the diaphragm seal is

transmitted to the metallic separating

diaphragm of the sensor by the filling

fluid of the diaphragm seal. The

separating diaphragm is deflected and

the fluid transmits the pressure to a

resistance bridge. The bridge output

voltage, which is proportional to

pressure, is then measured and

evaluated.

Advantages:

•

For process pressures up to 400 bar

(6000 psi)

•

Excellent long-term stability

•

Guaranteed resistance to overload up

to 4-times nominal pressure

(max. 600 bar/9000 psi)

➀ Diaphragm of

diaphragm seal

➁ Copper ring

➂ Diaphragm seal filling

fluid

➃ Metallic

separation diaphragm

➄ Channel with

filling fluid

➅ Polysilicone

measuring element

6

5

4

3

2

1

process pressure

6

5

4

3

2

1

process pressure

6

Operation

Three electronics versions are available

for operating the Cerabar M.

•

The analogue electronics is the

simplest and most cost-effective

method to operate the Cerabar M.

•

Smart electronics opens up a wide

range of operating and calibration

routines. It can then be operated

either by means of a handheld

terminal or an operating program (e.g.

Endress+Hauser Commuwin II).

•

The PROFIBUS-PA electronics provide

direct connection to the PROFIBUS-PA

field bus. The PROFIBUS-PA can be

easily set up and many values are

retrievable from the control room.

Analogue Electronics

For the Cerabar M with analogue

electronics lower range-value (Zero)

and upper range-value (Span) are

directly calibrated at the measuring

point via two potentiometers. The

required lower and upper range-values

must be applied as reference pressure.

•

For coarse calibration of the

measuring span, a spread between

TD 1:1 and TD 10:1 can be selected

using DIP switches.

•

A 2 s damping of the measured value

can be activated using a DIP switch.

•

The analogue display shows the

pressure on a bar graph as a ratio to

the measuring range.

•

Over- or under-run of the signal can

be indicated by a flashing of the bar

graph.

Analogue display

(optional)

Potentiometer for

calibrating the

lower range-value

Zero

3

2

1

–

+

Operating elements

Zero

Potentiometer and switches

for calibrating the upper range-value

Span

coarse

τ

fine

123

Display

Switch position “on”

Damping = 2 s activated

Span

fine coarse τ

Coarse adjustment

for upper range-value

TD 1:1

TD 3:1

TD 6:1

TD 10:1

TD: turn down

1

23

1

23

1

23

1

23

1

23

Damping switch

1

23

off

on

τ

off

on

τ

off

on

τ

off

on

τ

off

on

τ

off

on

Smart Electronics

A Cerabar M with Smart electronics can

be calibrated with or without reference

pressure.

– When calibrating with reference

pressure, the pressure for lower

range-value and upper range-value

must be entered and confirmed by

pressing the Zero or Span key twice.

Press these keys once to display saved

values for lower range-value and upper

range-value.

– If you calibrate without reference

pressure, enter the measuring points

using a handheld terminal or using an

operating program.

•

A damping of 2 s can be set directly

on the instrument. A damping value of

0...40 s can be selected using

communication.

•

The digital display shows the pressure

as a four-character number. The

appropriate 4…20 mA current is

shown as a bar graph underneath.

•

Error codes on the digital display and

in Commuwin II simplify error

diagnosis.

Digital display

(optional)

0,753

12+–3

Damping

on off

Zero

Span

Display

Operating elements

Switch position "on"

Damping = 2 s activated

Zero

Keys for

calibrating the

lower rangevalue

and upper

range-value

1x

2x

1x

2x

Damping

off

on

Span

Lower rangevalue:

Display

Registration

Upper rangevalue:

Display

Registration

7

PROFIBUS-PA Electronics

A Cerabar M with PROFIBUS-PA

electronics has the following operating

options.

•

You can set a damping of between 0

and 40 s using communication.

•

You can set instrument bus address

direct in the instrument using the

address switch.

Digital display

(optional)

0,753

123

•

The digital display gives the pressure

as a four-digit number. The bar graph

depicts the current pressure value

related to the measuring range. The

measuring range can be set either on

site using the Zero and Span keys or

remotely using an operating program,

such as Commuwin II.

•

Error codes on the digital display and

in Commuwin II simplify error

diagnosis.

Operating elements

16 32 64

28

5678

1x

2x

1x

2x

on

off

Zero

address

Span

Display

14

1234

DIP switches to set

bus address

Keys for

calibrating the

lower rangevalue

and upper

range-value

SW

HW

Value

ON

OFF

Switch No.

Zero

Span

Lower rangevalue:

Display

Registration

Upper rangevalue:

Display

Registration

Cerabar M

operation with Smart

electronics using a

handheld terminal

Smart Electronics Operation Using a

Handheld Terminal

Using the Universal HART

Communicator DXR 275 handheld

terminal, you can set the Cerabar M,

make checks and use additional

functions such as "Damping" and

"Calibration without reference pressure"

all along the 4...20 mA line.

EX

Cerabar M

I

O

EX

minimum line resistance

250 Ω

R

4...20 mA

I

O

Universal HART Comunicator

DXR 275

*

* Use an

intrinsically

safe supply

voltage for Ex i

(e.g. RN 221 N)

8

Smart Electronics Operation Using

PC

The Commubox FXA 191 connects

4…20 mA Smart transmitters that have a

HART protocol to the RS 232 C serial

interface of a personal computer. This

enables the transmitter to be remotely

operated with the Endress+Hauser

Commuwin II operating program.

You can connect the Commubox

FXA 191 at any point along the

4…20 mA line. It is also suited for

connection to intrinsically-safe signal

circuits.

Cerabar M

operation with Smart

electronics using PC

PC with

operating program

e.g. Commuwin II

Commubox

FXA 191

Cerabar M

Connecting to PROFIBUS-PA

PROFIBUS-PA is an open fieldbus

standard to enable serveral sensors and

actuators, including those in

explosion-hazardous areas, to be

connected to bus line. With

PROFIBUS-PA, two-wire looped

instruments can be supplied by the

sensor with power and digital process

information.

supply voltage

+

minimum line

resistance

250 Ω

4…20 mA

The number of instruments operated by

one bus segment is:

•

up to 10 for Ex ia applications

•

up to 32 for all further applications

(e.g. non-Ex, EEx nA)

Cerabar M

operation with

PROFIBUS-PA

electronics

Cerabar M

pressure transmitters

9

PC with

operating program

e.g. Commuwin II

PROFIBUS-DP

Fieldbus with

PROFIBUS-PA

PLC

segment coupler

ENDRESS+ HAUSER

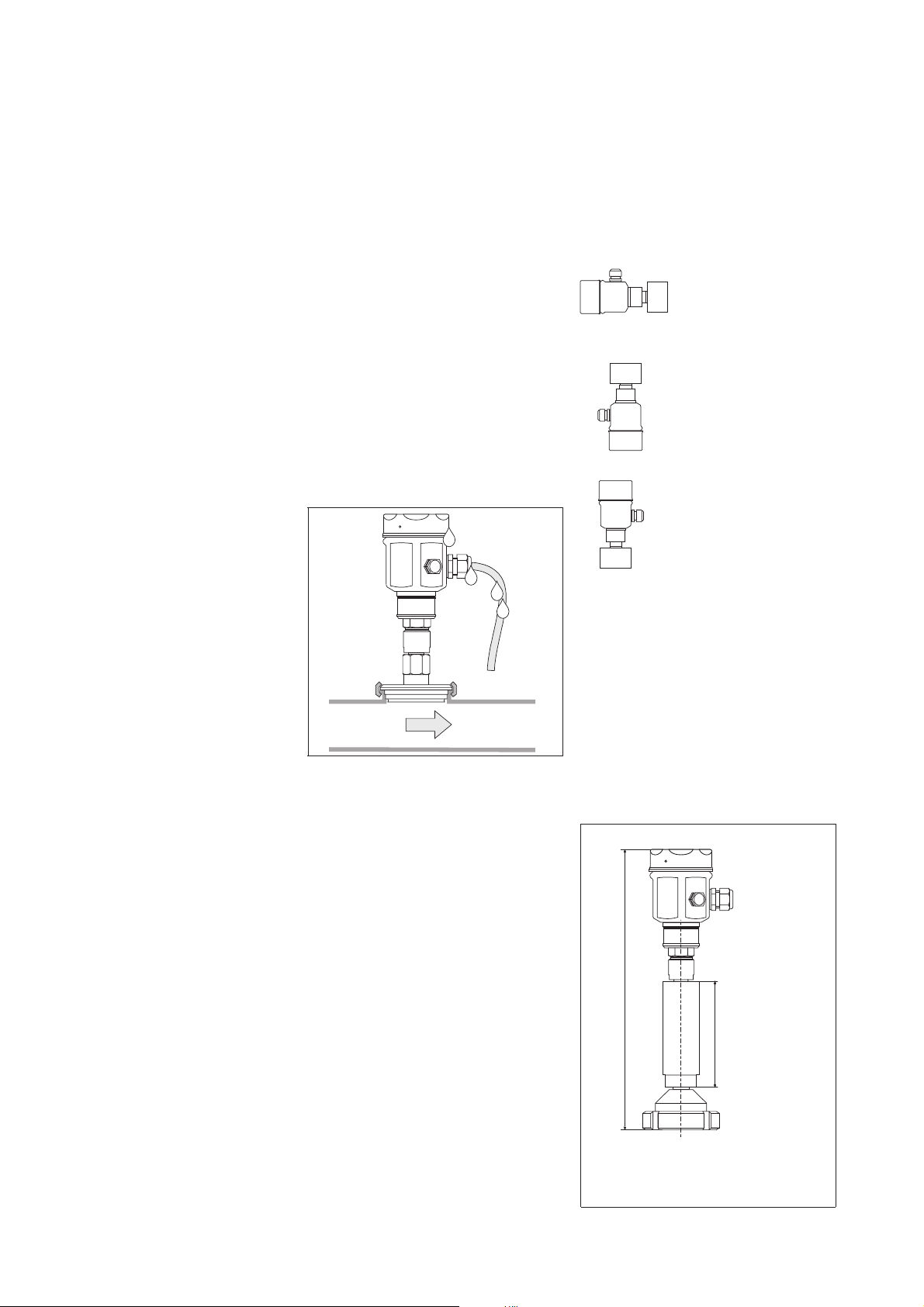

Installation

Mounting Instructions

•

The protective cap of the diaphragm

seal should only be removed just

before mounting.

•

The diaphragm seal and the pressure

sensor together form a closed,

oil-filled, calibrated system. The

following rules should be observed:

− The filling hole is sealed and not to

be opened.

− When mounting the Cerabar M, it

should only be turned by the nut of

the diaphragm seal and not by the

hex nut of the Cerabar M.

Cleaning

The diaphragm of the diaphragm seal

must not be pressed in or cleaned with

pointed or hard objects.

Mounting

To prevent moisture from entering, the

cable entry should preferably hang

downwards or to the side.

Shifting of the Zero Point due to

Position

The Cerabar M is calibrated based on

the limit point method according to

DIN 16086.

Depending on the orientation of the

instrument, there may be a slight shift in

the measured value. Diaphragm seals

also shift the zero point depending on

the orientation of the instrument.

•

neutral calibration position

•

max. positive zero point shift

•

max. negative zero point shift

vertical

mounting

cable points

downwards

Mounting with Temperature Spacer

Endress+Hauser recommends the use

of a temperature spacer when extreme

media temperatures (from approx.

150°C/302°F) continually cause the

ambient temperature to exceed the

permissible limit of +85°C (+185°F).

This zero point shift due to position can

be corrected (refer to zero point

increase and decrease, page 16).

The max. effect of position for all

diaphragm seals is given in the tables

on page 21 onwards. These values are

for silicone oil. For other oils available,

the shift in zero point due to position

varies according to the density of the oil

(see page 12).

Cerabar M with

temperature spacer

10

*

m

(3.94 in)

100 m

Information on the maximum installation

height is given on page 21 onwards

* Additional zero point shift

caused by the hydrostatic

pressure of the water column

in the temperature spacer:

10 mbar (0.15 psi)

Loading...

Loading...