Page 1

BA01906C/07/EN/02.18

71461453

2018-12-03

Products Solutions Services

Operating Instructions

CCS51D

Digital sensor with Memosens technology for

determining free chlorine

Page 2

Page 3

CCS51D Table of contents

Table of contents

1 About this document ........... 4

1.1 Warnings ........................... 4

1.2 Symbols used ........................ 4

11 Accessories .................... 41

11.1 Maintenance kit CCV05 .............. 41

11.2 Device-specific accessories ............ 41

2 Basic safety instructions ....... 6

2.1 Requirements for personnel ........... 6

2.2 Designated use ...................... 6

2.3 Workplace safety .................... 6

2.4 Operational safety ................... 7

2.5 Product safety ....................... 7

3 Product description ............. 8

3.1 Product design ....................... 8

4 Incoming acceptance and

product identification ......... 13

4.1 Incoming acceptance ................ 13

4.2 Product identification ................ 13

5 Installation .................... 15

5.1 Installation conditions ............... 15

5.2 Mounting the sensor ................ 17

5.3 Post-installation check ............... 25

6 Electrical connection .......... 25

6.1 Connecting the sensor ............... 26

6.2 Ensuring the degree of protection ..... 26

6.3 Post-connection check ............... 26

7 Commissioning ................ 28

7.1 Function check ..................... 28

7.2 Sensor polarization .................. 28

7.3 Sensor calibration ................... 28

12 Technical data ................. 42

12.1 Input .............................. 42

12.2 Performance characteristics .......... 43

12.3 Environment ....................... 44

12.4 Process ............................ 44

12.5 Mechanical construction ............. 45

13 Installation and operation in

hazardous environment Class

I Div. 2 .......................... 46

Index ................................. 48

8 Diagnostics and

troubleshooting ............... 30

9 Maintenance .................. 32

9.1 Maintenance schedule ............... 32

9.2 Maintenance tasks .................. 33

10 Repair .......................... 40

10.1 Spare parts ........................ 40

10.2 Return ............................ 40

10.3 Disposal ........................... 40

Endress+Hauser 3

Page 4

About this document CCS51D

1 About this document

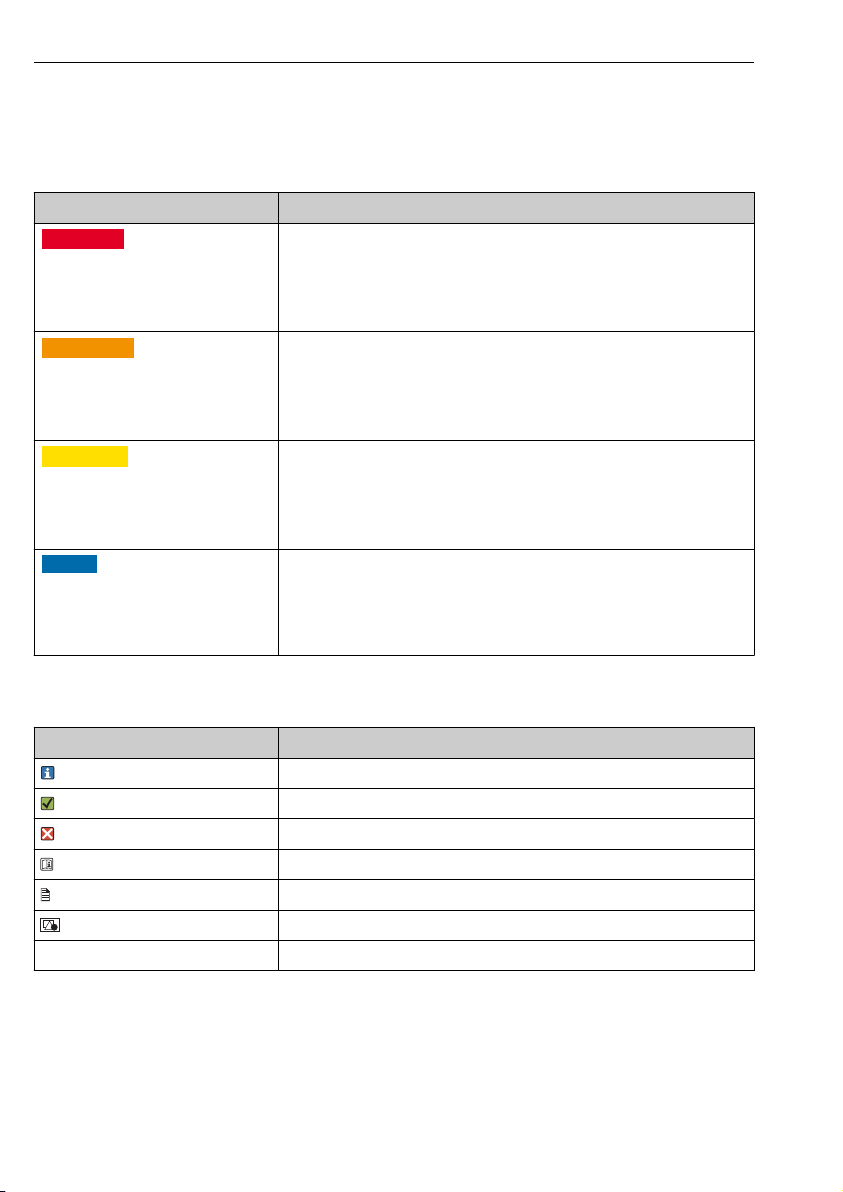

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

4 Endress+Hauser

Page 5

CCS51D About this document

1.2.1 Symbols on the device

Symbol Meaning

Reference to device documentation

Minimum immersion depth

Endress+Hauser 5

Page 6

Basic safety instructions CCS51D

2 Basic safety instructions

2.1 Requirements for personnel

Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

The technical personnel must be authorized by the plant operator to carry out the specified

‣

activities.

The electrical connection may be performed only by an electrical technician.

‣

The technical personnel must have read and understood these Operating Instructions and

‣

must follow the instructions contained therein.

Measuring point faults may be repaired only by authorized and specially trained personnel.

‣

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

Drinking water, process water and bathing water must be disinfected through the addition of

appropriate disinfectants such as inorganic chlorine compounds. The dosing quantity must be

adapted to continuously fluctuating operating conditions. Too low concentrations in the water

could jeopardize the effectiveness of the disinfection. Too high concentrations can lead to

signs of corrosion and have an adverse effect on the taste and smell, while also generating

unnecessary costs.

The sensor was specifically developed for this application and is designed for continuous

measurement of free chlorine in water. In conjunction with measuring and control equipment,

it allows optimal control of disinfection.

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.2.1

‣

Hazardous environment in accordance with cCSAus NI Cl. I, Div. 2

Pay attention to the control drawing and the specified application conditions in the

appendix of these Operating Instructions, and follow the instructions.

1)

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

1) Only if connected to CM44x(R)-CD*

6 Endress+Hauser

Page 7

CCS51D Basic safety instructions

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable international standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.4.1 Special instructions

Do not operate the sensors under process conditions where it is expected that osmotic

‣

conditions will cause electrolyte components to pass through the membrane and into the

process.

Use of the sensor for its intended purpose in liquids with a conductivity of at least 10 nS/cm

can be classified as safe in terms of the application.

2.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

Endress+Hauser 7

Page 8

Product description CCS51D

4

1

2

5

6

8

7

9

3

3 Product description

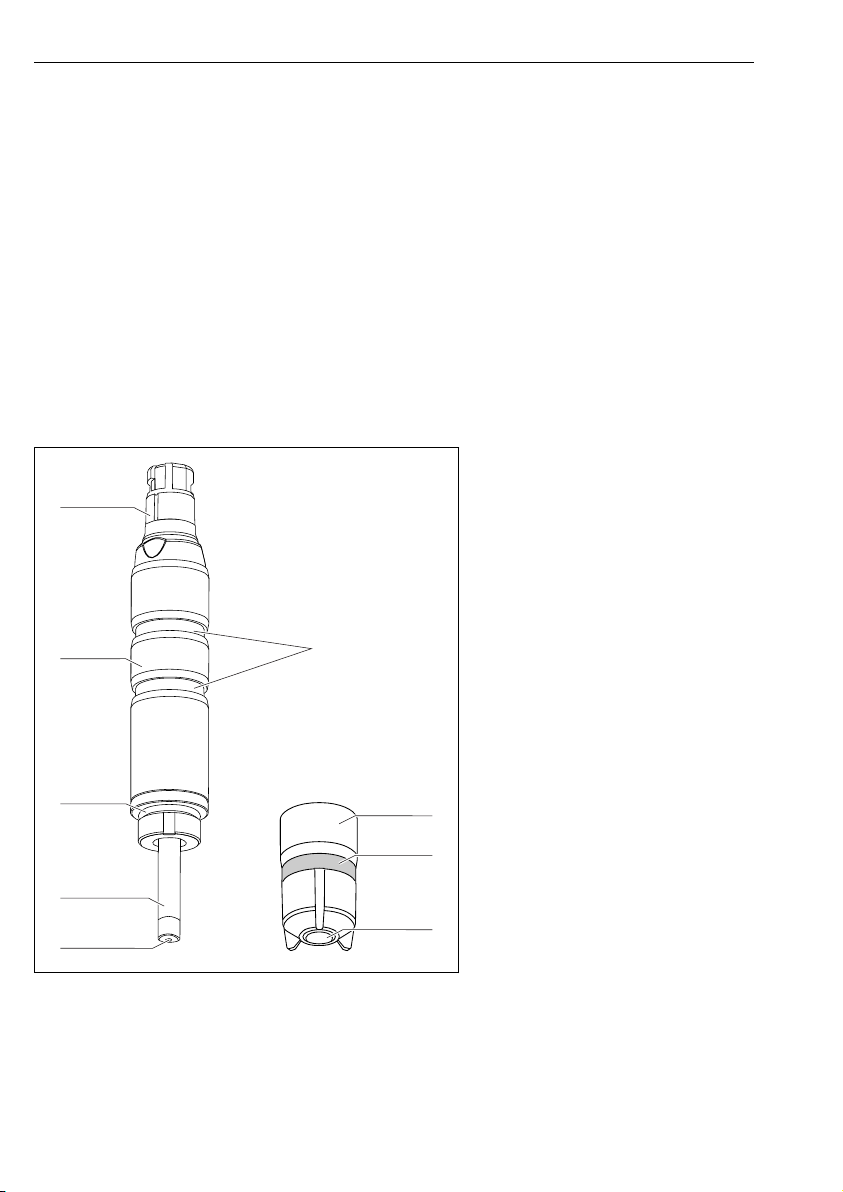

3.1 Product design

The sensor consists of the following functional units:

• Membrane cap (measuring chamber with membrane)

• Separates the inner amperometric system from the medium

• With robust PET membrane and pressure relief valve

• With special support grid between working electrode and membrane for a defined and

consistent electrolyte film and thus a relatively constant indication even at varying

pressures and flows

• Sensor shaft with

• Large counter electrode

• Working electrode embedded in plastic

• Embedded temperature sensor

1 Memosens plug-in head

2 Sensor shaft

3 O-ring

4 Large counter electrode, silver/silver

chloride

5 Gold working electrode

6 Grooves for installation adapter

7 Membrane cap with membrane

8 Pressure relief valve (elastic)

9 Sensor membrane

1 Sensor structure

3.1.1 Measuring principle

A0034227

Free chlorine is determined via hypochlorous acid (HOCl) according to the amperometric

measuring principle.

8 Endress+Hauser

Page 9

CCS51D Product description

The hypochlorous acid (HOCl) contained in the medium diffuses through the

sensor membrane and is reduced to chloride ions (Cl-) at the gold working electrode. At the

silver counter electrode, silver is oxidized to silver chloride. Electron donation at the gold

working electrode and electron acceptance at the silver counter electrode causes a current to

flow which is proportional to the concentration of free chlorine in the medium at constant

conditions.

The concentration of hypochlorous acid (HOCl) depends on the pH value. An additional pH

measurement should be used to compensate for this dependency.

The transmitter uses the current signal in nA to calculate the measured variable for

concentration in mg/l (ppm).

3.1.2 Effects on the measured signal

pH value

pH dependency

Molecular chlorine (Cl2) is present at pH values < 4. Consequently, hypochlorous acid (HOCl)

and hypochlorite (OCl–) remain as components of free chlorine within the range of pH 4 to

11. As hypochlorous acid splits up (dissociates) with an increasing pH value to form

hypochlorite ions (OCl–) and hydrogen ions (H+), the amounts of the individual components of

free effective chlorine change with the pH value. For example, if the proportion of

hypochlorous acid is 97 % at pH 6, it drops to approx. 3 % at pH 9.

With amperometric measurement using the chlorine sensor, only the amount of hypochlorous

acid (HOCl) is selectively measured. This works as a powerful disinfectant in an aqueous

solution. Hypochlorite (OCl–), however, is an extremely weak disinfectant. Therefore, when

used as a disinfectant at higher pH values, the effectiveness of chlorine is limited. Since

hypochlorite ions cannot diffuse through the sensor membrane, the sensor does not record

this part.

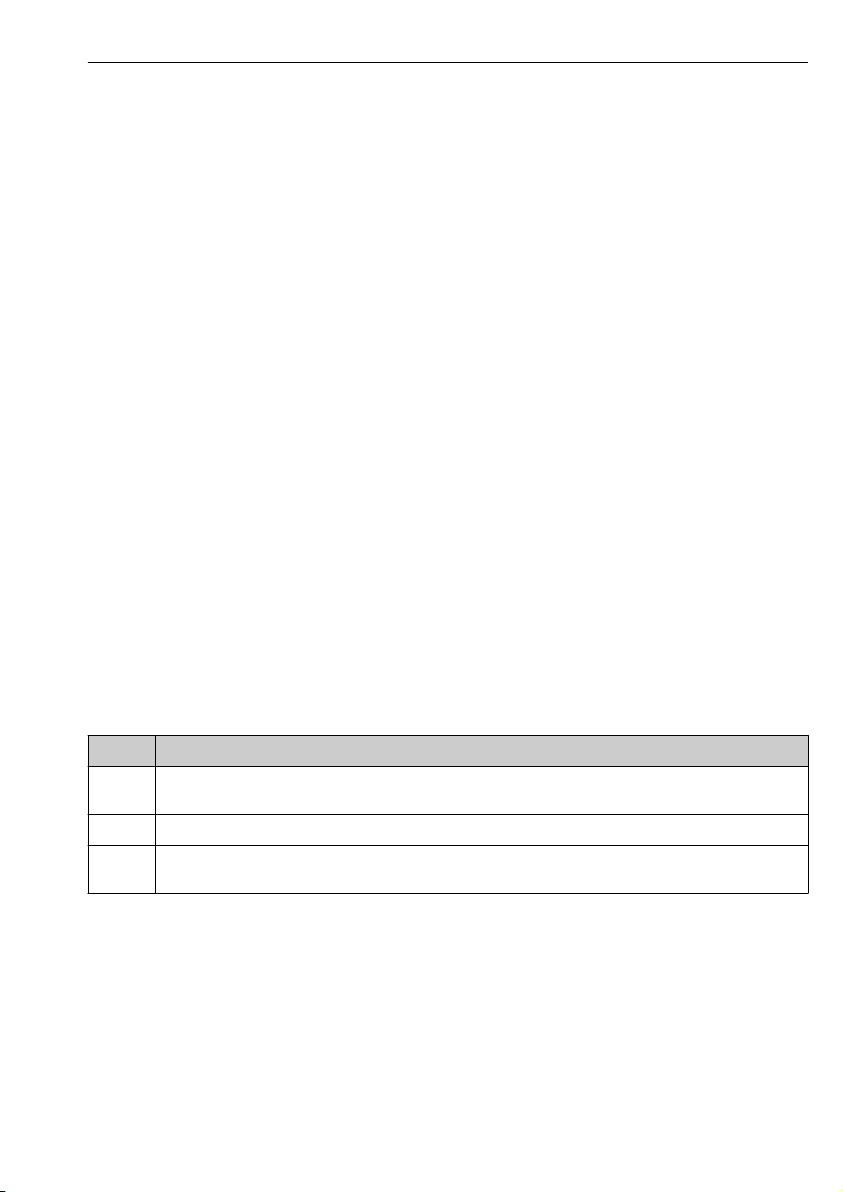

pH value Result

< 4 Chlorine is produced if chloride (Cl-) is present in the medium at the same time causing an increase in the

4 to 9 pH compensation works perfectly in this range. A pH-compensated concentration value can be specified.

> 9 The measured signal is very weak in this range as the level of hypochlorous acid present is very low. The

measured value.

determined concentration value depends mainly on other conditions of the measuring point.

pH compensation of chlorine sensor signal

To calibrate and verify the chlorine measuring system, a colorimetric reference measurement

must be carried out using the DPD method. Free chlorine reacts with diethyl-pphenylendiamine to form a red dye. The intensity of the red color increases proportionally to

the chlorine content. For the DPD test, the sample is buffered to a specified pH value.

Therefore, the pH value of the sample is not taken into account in the DPD measurement. Due

to the buffer function in the DPD method, all components of free effective chlorine (HOCl and

OCl-) are detected and thus the total free chlorine is measured.

Endress+Hauser 9

Page 10

Product description CCS51D

%

100

80

60

40

20

0

4

5 6 7 8 9 10 11

100

%

80

60

40

20

0

A

pH

OCl

-

HOCl

C

B

The chlorine sensor only measures the hypochlorous acid. If you select pH compensation in

the transmitter, the sum of hypochlorous acid and hypochlorite is calculated from the

measured signal and the pH value. This value corresponds to the DPD measurement.

When free chlorine is measured with pH compensation switched on, always perform

calibration in pH-compensated mode.

When you use pH compensation, the measured chlorine value displayed and output by the

device corresponds to the DPD value even if the pH value changes. If no pH compensation is

used, the chlorine value of the DPD measurement corresponds only to the chlorine value of

the sensor at the same pH value with respect to the calibration. Without pH compensation,

the chlorine measuring system must be recalibrated when the pH value changes.

2 Principle of pH compensation

A Measured value with pH compensation

B Measured value without pH compensation

C pH compensation

Accuracy of pH compensation

The accuracy of the pH-compensated measured chlorine value is derived from the sum of

A0002017

several individual deviations (free chlorine, pH, temperature, DPD measurement etc.).

High levels of hypochlorous acid (HOCl) during chlorine calibration have a positive effect on

accuracy, whereas low levels of hypochlorous acid have a negative effect. The inaccuracy of

the pH-compensated measured chlorine value increases the greater the pH difference

10 Endress+Hauser

Page 11

CCS51D Product description

80

90

100

relative slope / maximum slope in %

CCA151 flow gal/hr

CCA250 flow gal/hr

flow velocity at the membrane "/s

0 0.5 1 1.5 2 3

0 5 10 25 40

0

1

2 3 4 5 6

2.5

15

20

30 35

between measuring mode and chlorine calibration or the more inaccurate the underlying

individual measured values are.

Calibration taking into account the pH value

For the DPD test, the sample is buffered to a specified pH value. In contrast to this,

amperometric measurement determines only the HOCl component.

During operation, pH compensation is effective up to a pH value of 9. However, there is

virtually no hypochlorous acid (HOCl) left at this pH value, and the measured current is very

low. pH compensation has the effect of increasing the measured HOCl value to the actual

value of the free chlorine. Calibration of the entire measuring system is practicable only if the

medium has a pH value of up to pH 8.

Above these pH values, the total error of the measuring system is unacceptably high.

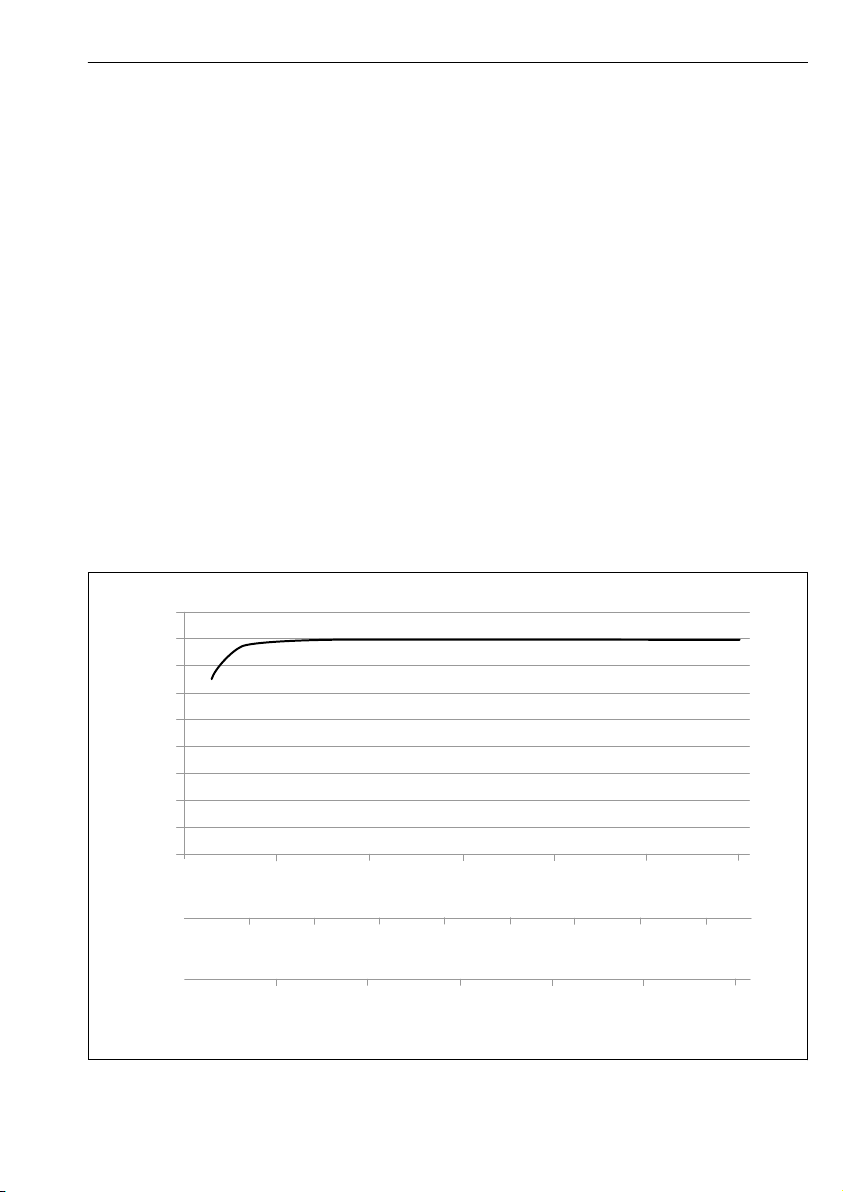

Flow

The minimum flow velocity at the membrane-covered measuring cell is 15 cm/s (0.5 ft/s).

• When using the Flowfit CCA151 flow assembly, the minimum flow velocity corresponds to

a volume flow of 5 l/h (1.3 gal/h). The pH value for compensation must be provided in

another way.

• When using the CCA250 flow assembly, the minimum flow velocity corresponds to a

volume flow of 30 l/h (7.9 gal/h) (upper edge of float at the height of the red bar mark).

3 Correlation between slope of electrode and flow velocity at the membrane/volume flow in

assembly

Endress+Hauser 11

A0041365-EN

Page 12

Product description CCS51D

At higher flow rates, the measured signal is virtually flow-independent. However, if the flow

rate falls below the specified value, the measured signal depends on the flow.

The installation of an INS proximity switch in the assembly enables reliable detection of this

invalid operating status, thus triggering an alarm or causing the dosing process to be switched

off if necessary.

Below the minimum flow rate, the sensor current is more sensitive to flow fluctuations. For

abrasive media, it is recommended not to exceed the minimum flow. If suspended solids are

present, which may form deposits, the maximum flow rate is recommended.

Temperature

Changes in the temperature of the medium affect the measured value:

• Increases in temperature result in a higher measured value (approx. 4 % per K)

• Decreases in temperature result in a lower measured value.

Use of the sensor in combination with the Liquiline enables automatic temperature

compensation (ATC). Recalibration in the case of temperature changes is not necessary.

1. If automatic temperature compensation is disabled at the transmitter, the temperature

must be maintained at a constant level following calibration.

2. Otherwise, recalibrate the sensor.

In the event of normal and slow changes in temperature (0.3 K / minute), the internal

temperature sensor is sufficient. In the event of very rapid temperature fluctuations with high

amplitude (2 K / minute), an external temperature sensor is necessary to ensure maximum

accuracy.

For detailed information on the use of external temperature sensors, see the Operating

Instructions for the transmitter.

Cross-sensitivities

2)

There are cross-sensitivities for: chlorine dioxide, ozone, free bromine.

There are no cross-sensitivities for: H2O2, peracetic acid.

2) The listed substances have been tested with different concentrations. An additive effect has not been

investigated.

12 Endress+Hauser

Page 13

CCS51D Incoming acceptance and product identification

4 Incoming acceptance and product identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Extended order code

• Serial number

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.2.2 Product page

www.endress.com/ccs51d

4.2.3 Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

Endress+Hauser 13

Page 14

Incoming acceptance and product identification CCS51D

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

4.2.4 Manufacturer address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

4.2.5 Scope of delivery

The delivery comprises:

• Disinfection sensor (membrane-covered, ⌀25 mm) with protection cap (ready for use)

• Bottle with electrolyte (50 ml (1.69 fl.oz))

• Replacement membrane cap in protection cap

• Operating Instructions

• Manufacturer inspection certificate

4.2.6 Certificates and approvals

mark

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

EAC

The product has been certified according to guidelines TP TC 004/2011 and TP TC 020/2011

which apply in the European Economic Area (EEA). The EAC conformity mark is affixed to the

product.

Ex approvals

3)

cCSAus NI Cl. I, Div. 2

This product complies with the requirements defined in:

• UL 61010-1

• ANSI/ISA 12.12.01

• FM 3600

• FM 3611

• CSA C22.2 NO. 61010-1-12

• CSA C22.2 NO. 213-16

• Control drawing: 401204

3) Only if connected to CM44x(R)-CD*

14 Endress+Hauser

Page 15

CCS51D Installation

15°

15°

B

A

5 Installation

5.1 Installation conditions

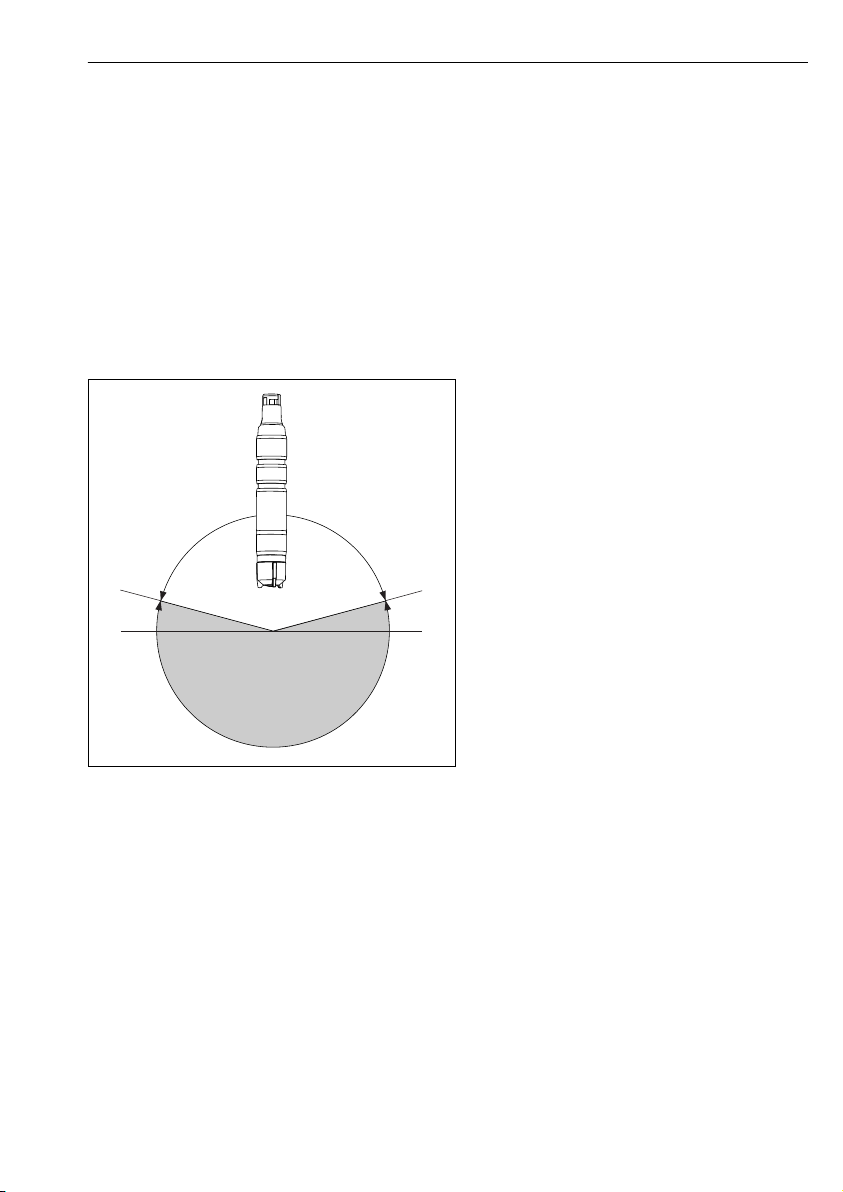

5.1.1 Installation position

Do not install upside-down!

Install the sensor in an assembly, support or appropriate process connection at an angle of

‣

at least 15 ˚ to the horizontal.

Other angles of inclination are not permitted.

‣

Follow the instructions for installing the sensor in the Operating Instructions of the

‣

assembly used.

A Permitted orientation

B Incorrect orientation

A0034236

5.1.2 Immersion depth

50 mm (1.97 in)

Endress+Hauser 15

Page 16

Installation CCS51D

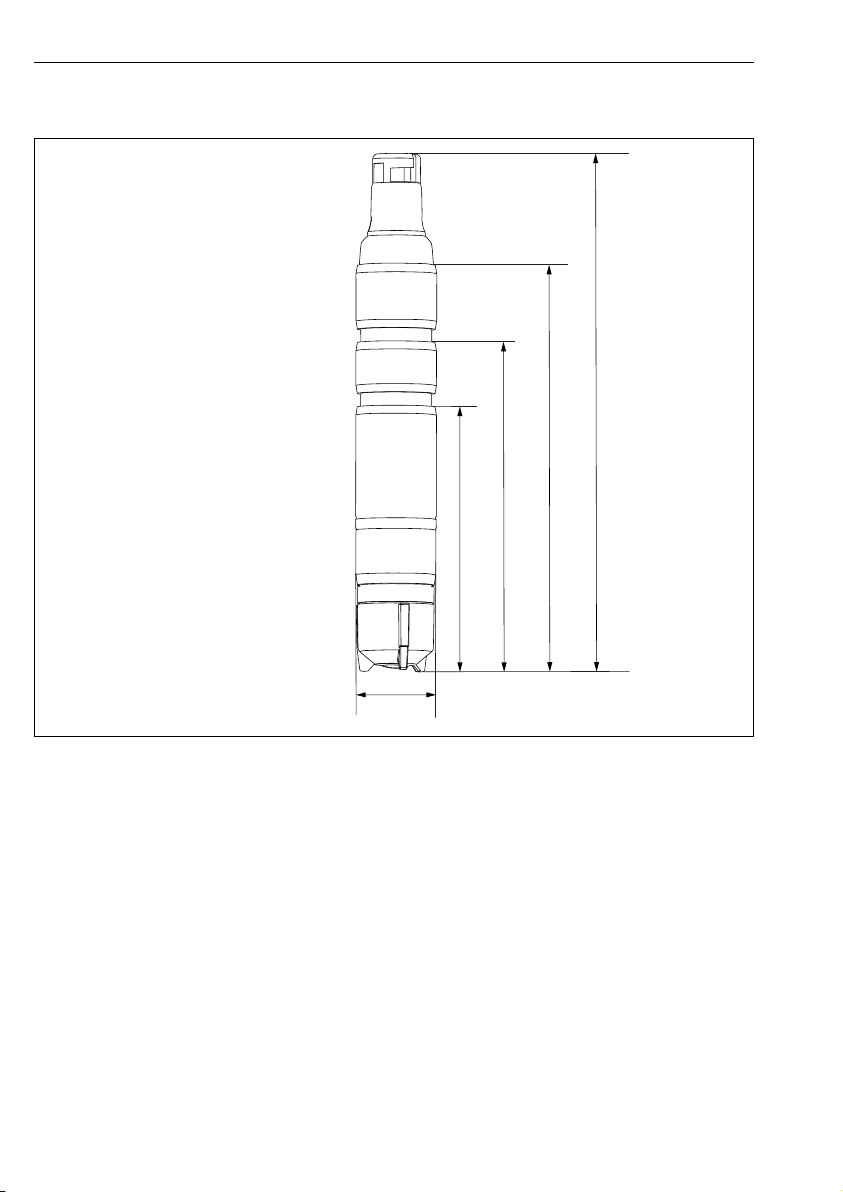

161 (6.34)

82 (3.23)

102 (4.02)

126 (4.96)

!25

(0.98)

5.1.3 Dimensions

A0034238

4 Dimensions in mm (in)

16 Endress+Hauser

Page 17

CCS51D Installation

5.2 Mounting the sensor

5.2.1 Measuring system

A complete measuring system comprises:

• Disinfection sensor CCS51D (membrane-covered, ⌀25 mm) with corresponding

installation adapter

• Flowfit CCA250 flow assembly

• Measuring cable CYK10, CYK20

• Transmitter, e. g. Liquiline CM44x with firmware version 01.06.08 or higher or CM44xR

with firmware version 01.06.08 or higher

• Optional: pH sensor CPS31D

• Optional: extension cable CYK11

• Optional: proximity switch

• Optional: CPS31

• Optional: Flowfit CCA151 flow assembly (if the pH value is provided in another way)

• Optional: Flexdip CYA112

Endress+Hauser 17

Page 18

Installation CCS51D

3

8

2

4

1

5

7

6

5 Example of a measuring system

1 Liquiline CM44x transmitter

2 Power cable for transmitter

3 Disinfection sensor CCS51D (membrane-covered, ⌀25 mm)

4 Flowfit CCA250 flow assembly

5 Inlet to Flowfit CCA250 flow assembly

6 Proximity switch (optional)

7 CPS31D pH sensor

8 Measuring cable CYK10

18 Endress+Hauser

A0007341

Page 19

CCS51D Installation

5.2.2 Preparing the sensor

Removing protection cap from sensor

NOTICE

Negative pressure causes damage to the sensor's membrane cap

If the protection cap is attached, carefully remove it from sensor.

‣

1. When supplied to the customer and when in storage, the sensor is fitted with a

protection cap: First release just the top part of the protection cap by turning it.

A0034263

6 Releasing top part of protection cap by turning

2. Carefully remove protection cap from sensor.

A0034350

7 Carefully remove protection cap

Endress+Hauser 19

Page 20

Installation CCS51D

1

5.2.3 Installing sensor in CCA151 assembly

The disinfection sensor (membrane-covered, ⌀25 mm) is designed for installation in the

Flowfit CCA151 flow assembly if the pH value for compensation is provided in another

way.

Please note the following during installation:

The volume flow must be at least 5 l/h (1.3 gal/h).

‣

If the medium is fed back into an overflow basin, pipe or similar, the resulting

‣

counterpressure on the sensor may not exceed 1 bar (14.5 psi)(2 bar abs. (29 psi abs.)) and

must remain constant.

Avoid negative pressure at the sensor, e.g. due to medium being returned to the suction

‣

side of a pump.

To avoid buildup, heavily contaminated water should also be filtered.

‣

Preparing the assembly

1. The assembly is supplied to the customer with a union nut screwed onto the assembly:

unscrew union nut from assembly.

A0034262

8 Flowfit CCA151 flow assembly

1 Union nut

2. The assembly is supplied to the customer with a dummy plug inserted in the assembly:

remove dummy plug from assembly.

20 Endress+Hauser

Page 21

CCS51D Installation

1

2

3

Equipping sensor with adapter

The required adapter (clamping ring, thrust collar and O-ring) can be ordered as a mounted

sensor accessory or as a separate accessory → 42.

1. First slide the clamping ring, then the thrust collar, and then the O-ring from the

membrane cap towards the sensor head and into the lower groove.

A0034247

9 Slide clamping ring (1), thrust collar (2) and O-ring (3) upwards from the membrane

cap to the sensor shaft and into the lower groove.

Installing sensor in assembly

2. Slide sensor with adapter for Flowfit CCA151 into the opening in the assembly.

Endress+Hauser 21

Page 22

Installation CCS51D

1

2

3

3. Screw union nut onto assembly on block.

A0034261

10 Flowfit CCA151 flow assembly

1 Disinfection sensor

2 Flowfit CCA151 flow assembly

3 Union nut for securing a disinfection sensor

5.2.4 Installing sensor in CCA250 assembly

The sensor can be installed in the Flowfit CCA250 flow assembly. In addition to allowing the

installation of a chlorine or chlorine dioxide sensor, this also allows the simultaneous

operation of a pH and an ORP sensor for example. A needle valve controls the volume flow in

the range of 30 to 120 l/h (7.9 to 31.7 gal/h).

Please note the following during installation:

The volume flow must be at least 30 to 120 l/h (7.9 to 31.7 gal/h). If the flow drops below

‣

this value or stops completely, this can be detected by an inductive proximity switch and

used to trigger an alarm with locking of the dosage pumps.

If the medium is fed back into an overflow basin, pipe or similar, the resulting

‣

counterpressure on the sensor may not exceed 1 bar (14.5 psi)(2 bar abs. (29 psi abs.)) and

must remain constant.

Negative pressure at the sensor, e.g. due to medium being returned to the suction side of a

‣

pump, must be avoided.

22 Endress+Hauser

Page 23

CCS51D Installation

Equipping sensor with adapter

The required adapter can be ordered as a mounted sensor accessory or as a separate

accessory.→ 42

1. Slide adapter for Flowfit CCA250 from the sensor head up to the stop on the sensor.

A0034245

11 Slide on adapter for Flowfit CCA250.

2. Fix the adapter with the 2 stud screws supplied and an Allen screw (2 mm).

A0041320

3. Screw the sensor into the assembly.

For detailed information on "Installing sensor in Flowfit CCA250 assembly", see

Operating Instructions for assembly

5.2.5 Installing sensor in other flow assemblies

When using other flow assemblies, please ensure the following:

A flow velocity of at least 15 cm/s (0.49 ft/s) must always be ensured at the membrane.

‣

Endress+Hauser 23

Page 24

Installation CCS51D

The flow direction is upwards. Transported air bubbles must be removed so that they do

‣

not collect in front of the membrane.

The flow must be directed to the membrane.

‣

Pay attention to the additional installation instructions in the Operating Instructions for

the assembly.

5.2.6 Installing sensor in immersion assembly CYA112

Alternatively, the sensor can be installed in an immersion assembly with a G1 threaded

connection.

Ensure sufficient flow towards the sensor when using the immersion assembly → 11.

Equipping sensor with adapter

The required adapter can be ordered as a mounted sensor accessory or as a separate

accessory.→ 42

1. Slide adapter for Flexdip CYA112 from the sensor head up to the stop on the sensor.

A0034246

12 Slide on adapter for Flexdip CYA112.

24 Endress+Hauser

Page 25

CCS51D Electrical connection

2. Fix the adapter with the 2 stud screws supplied and an Allen screw (2 mm).

A0041320

3. Screw the sensor into the assembly. The use of a quick release fastener is recommended.

For detailed information on "Installing sensor in Flexdip CYA112 assembly", see

Operating Instructions for assembly

5.3 Post-installation check

1. Is the adapter locked in place and unable to move freely?

2. Is the sensor installed in an assembly and not freely suspended from the cable?

Install the sensor in an assembly or directly via the process connection.

3. Is the membrane cap leak-tight?

Screw tight or replace.

4. Is the membrane intact and lying flat: Is the membrane bulging slightly (not flat)?

5. Is there electrolyte in the membrane cap?

If necessary, refill the membrane cap with electrolyte.

6 Electrical connection

CAUTION

L

Device is live

Incorrect connection may result in injury!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions and

‣

must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

Endress+Hauser 25

Page 26

Electrical connection CCS51D

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

6.1 Connecting the sensor

The electrical connection to the transmitter is established using measuring cable CYK10 or

CYK20.

A0024019

13 Measuring cable CYK10/CYK20

To extend the cable, use measuring cable CYK11. The maximum cable length is 100 m

‣

(328 ft).

A0018861

14 Electrical connection, M12 plug

6.2 Ensuring the degree of protection

Only the mechanical and electrical connections which are described in these instructions and

which are necessary for the required, designated use, may be carried out on the device

delivered.

Exercise care when carrying out the work.

‣

Otherwise, the individual types of protection (Ingress Protection (IP), electrical safety, EMC

interference immunity) agreed for this product can no longer be guaranteed due, for example

to covers being left off or cable (ends) that are loose or insufficiently secured.

6.3 Post-connection check

Device condition and specifications Notes

Are the sensor, assembly, or cables free from damage on the outside? Visual inspection

Electrical connection Notes

Are the mounted cables strain-relieved and not twisted?

Is a sufficient length of the cable cores stripped, and are the cores

positioned in the terminal correctly?

Are all the screw terminals properly tightened? Tighten

26 Endress+Hauser

Check the fit (by pulling gently)

Page 27

CCS51D Electrical connection

Device condition and specifications Notes

Are all the cable entries installed, tightened and sealed? For lateral cable entries, make sure the cables

Are all cable entries installed downwards or mounted laterally?

loop downwards to allow water to drip off

Endress+Hauser 27

Page 28

Commissioning CCS51D

7 Commissioning

7.1 Function check

Prior to initial commissioning, ensure that:

• The sensor is correctly installed.

• The electrical connection is correct.

• There is sufficient electrolyte in the membrane cap and the transmitter is not displaying a

warning about electrolyte depletion.

Please note the information on the safety data sheet to ensure safe use of the electrolyte.

Always keep the sensor moist after commissioning.

WARNING

L

Escaping process medium

Risk of injury from high pressure, high temperatures or chemical hazards

Before applying pressure to an assembly with cleaning system, ensure that the system has

‣

been connected correctly.

Do not install the assembly in the process if you cannot reliably establish the correct

‣

connection.

7.2 Sensor polarization

The voltage applied by the transmitter between the working electrode and counter electrode

polarizes the surface of the working electrode. Therefore, after switching on the transmitter

with the sensor connected, you must wait until the polarization period has elapsed before

starting calibration.

To achieve a stable display value, the sensor requires the following polarization periods:

Initial commissioning 60 min.

Recommissioning 30 min.

7.3 Sensor calibration

Reference measurement according to the DPD method

To calibrate the measuring system, carry out a colorimetric comparison measurement in

accordance with the DPD method. Chlorine reacts with diethyl-p-phenylendiamine (DPD)

producing a red dye, the intensity of the red color being proportional to the chlorine content.

Measure the intensity of the red color using a photometer (e. g. PF-3→ 41) . The

photometer indicates the chlorine content.

28 Endress+Hauser

Page 29

CCS51D Commissioning

Requirements

The sensor reading is stable (no drifts or unsteady values for at least 5 minutes). This is

normally guaranteed once the following preconditions have been met:

• The polarization period has elapsed.

• The flow is constant and within the correct range.

• The sensor and the medium are at the same temperature.

• The pH value is within the permitted range.

Zero point adjustment

A zero point adjustment is not required due to the zero point stability of the membranecovered sensor.

However, a zero point adjustment can be performed if desired.

1. To perform a zero point adjustment, operate the sensor for at least 15 min. in chlorinefree water, using the assembly or protection cap as a vessel.

2. Alternatively, perform the zero point adjustment using the zero point gel

COY8→ 41.

Slope calibration

Always perform a slope calibration in the following cases:

• After replacing the membrane cap

• After replacing electrolyte

1. Ensure that the pH value and temperature of the medium are constant.

2. Take a representative sample for the DPD measurement. This must be done in close

proximity to the sensor. Use the sampling tap if available.

3. Determine the chlorine content using the DPD method.

4. Enter the measured value into the transmitter (see Operating Instructions for

transmitter).

5. To ensure greater accuracy, check the calibration several hours or 24 hours later using

the DPD method.

Endress+Hauser 29

Page 30

Diagnostics and troubleshooting CCS51D

8 Diagnostics and troubleshooting

When troubleshooting, the entire measuring point must be taken into account. This

comprises:

• Transmitter

• Electrical connections and lines

• Assembly

• Sensor

The possible causes of error in the following table refer primarily to the sensor. Before

commencing troubleshooting, ensure that the following operating conditions have been met:

• Measurement in "temperature-compensated" mode (can be configured on transmitter

CM44x) or constant temperature following calibration

• Flow rate of at least 15 cm/s (0.5 ft/s) (when using the Flowfit CCA151 flow assembly)

• No organic chlorination agents are used

If the value measured by the sensor differs significantly from that of the DPD method,

first consider all possible malfunctions of the photometric DPD method (see Operating

Instructions for photometer). If necessary, repeat the DPD measurement several times.

Error Possible cause Remedy

No display, no sensor current No supply voltage at the transmitter

Connection cable between sensor and

transmitter interrupted

There is no electrolyte in the

membrane cap

No input flow of medium

Display value too high Polarization of the sensor not yet

completed

Membrane defective

Shunt resistance (e.g. moisture

contact) in the sensor shaft

Foreign oxidants interfering with

sensor

Establish mains connection

‣

Establish cable connection

‣

Fill membrane cap

‣

Establish flow, clean filter

‣

Wait for polarization to be completed

‣

Replace membrane cap

‣

Remove membrane cap, rub working

‣

electrode dry.

If the transmitter display does not return

‣

to zero, there is a shunt present: replace

sensor.

Examine medium, check chemicals

‣

30 Endress+Hauser

Page 31

CCS51D Diagnostics and troubleshooting

Error Possible cause Remedy

Display value too low Membrane cap not screwed on fully

Membrane soiled

Air bubble in front of membrane

Air bubble between working

electrode and membrane

Input flow of medium too low

Foreign oxidants interfering with

DPD reference measurement

Use of organic disinfectants

Display fluctuates

considerably

Hole in membrane

Fill membrane cap with fresh electrolyte

‣

→ 34

Screw membrane cap on fully

‣

Clean membrane → 33

‣

Release air bubble

‣

Remove membrane cap, top up electrolyte

‣

Remove air bubble by tapping on the

‣

outside of the membrane cap

Screw on membrane cap

‣

Establish correct flow

‣

Examine medium, check chemicals

‣

Use suitable agent (e.g. as per DIN 19643)

‣

(water may need to be replaced first)

Use suitable reference system.

‣

Replace membrane cap

‣

Endress+Hauser 31

Page 32

Maintenance CCS51D

9 Maintenance

Please note the information on the safety data sheet to ensure safe use of the electrolyte.

Take all the necessary precautions in time to ensure the operational safety and reliability of

the entire measuring system.

NOTICE

Effects on process and process control!

When carrying out any work on the system, bear in mind any potential impact this could

‣

have on the process control system and the process itself.

For your own safety, only use genuine accessories. With genuine parts, the function,

‣

accuracy and reliability are also ensured after maintenance work.

9.1 Maintenance schedule

Interval Maintenance work

If deposits are visible on the membrane (biofilm, limescale) Clean sensor membrane

If dirt is visible on the surface of the electrode body Clean electrode body of

The operating life of the electrolyte depends greatly on the salt content of the medium. We

recommend you change the electrolyte every 6-9 months. The electrolyte should be changed

every 6 months at least in the case of media with a low conductivity. The membrane cap

should be replaced annually.

• Slope depending on application:

• Every 6-9 months (at maximum) under constant conditions in the permitted range of

0 to 55 °C (32 to 131 °F)

• In the case of severe temperature fluctuations, e.g. from 10 °C (50 °F) to 25°C (77 °F)

and back 100 times

• Zero point calibration:

• If operated in concentration range below 0.5 mg/l (ppm)

• If negative measured value is displayed with factory calibration

• If electrolyte counter warning is active

• If cap is replaced

• For determining the zero point

• If the slope is too low or too high relative to the nominal slope and the membrane cap is

not visibly damaged or dirty

• If there are grease/oil deposits (dark or transparent spots on the membrane)

• If slope is too high or too low or sensor current is very noisy

• If it is obvious that the sensor current is significantly dependent on the temperature

(temperature compensation not working).

If changes are visible on the working electrode or counter electrode (brown coating no

longer present)

→ 34

sensor → 34

Change electrolyte

Replace membrane cap

→ 35

Sensor calibration

Fill membrane cap with

fresh electrolyte

→ 34

Replace membrane cap

→ 35

Regenerate sensor

→ 38

32 Endress+Hauser

Page 33

CCS51D Maintenance

1

2

3

9.2 Maintenance tasks

9.2.1 Cleaning the sensor

CAUTION

L

Diluted hydrochloric acid

Hydrochloric acid causes irritation if it comes into contact with the skin or eyes.

When using diluted hydrochloric acid, wear protective clothing such as gloves and goggles.

‣

Avoid splashes.

‣

NOTICE

Chemicals that reduce surface tension (e.g. surfactants in cleaning agents or organic

solvents such as alcohol that can be mixed with water)

Due to chemicals that reduce surface tension, the sensor membrane loses its water-repellent

characteristics and becomes permeable to water. The sensor membrane loses its protective

effect, resulting in measured errors.

Do not use any chemicals that reduce surface tension.

‣

Removing the sensor from assembly CCA151

1. Remove the cable.

2. Unscrew the union nut from the assembly.

A0034261

1 Disinfection sensor CCS51D

2 Flowfit CCA151 flow assembly

3 Union nut for securing a disinfection sensor CCS51D

3. Pull sensor out through opening in assembly.

Removing the sensor from assembly CCA250

1. Remove the cable.

Endress+Hauser 33

Page 34

Maintenance CCS51D

2. Unscrew the sensor, along with the adapter, from the assembly.

The adapter does not need to be disassembled.

For detailed information on "Removing sensor from assembly CCA250", see Operating

Instructions for assembly.

Removing the sensor from assembly CYA112

1. Remove the cable.

2. Unscrew the sensor, along with the adapter, from the assembly.

The adapter does not need to be disassembled.

For detailed information on "Removing sensor from assembly CYA112", see Operating

Instructions for assembly.

Cleaning sensor membrane

If the membrane is visibly dirty, e.g. biofilm, proceed as follows:

1. Remove sensor from flow assembly .

2. Remove membrane cap → 35.

3. Clean the membrane cap mechanically only using a gentle water jet. Alternatively, clean

for several minutes in diluted acids or in specified cleaning agents without any further

chemical additives.

4. Then rinse thoroughly with water.

5. Screw membrane cap back onto sensor → 35.

Cleaning electrode body

1. Remove sensor from flow assembly .

2. Remove membrane cap → 35.

3. Wipe gold electrode carefully using a soft sponge.

4. Rinse electrode body with demineralized water, alcohol or acid.

5. Screw membrane cap back onto sensor → 35.

9.2.2 Filling membrane cap with fresh electrolyte

Please note the information on the safety data sheet to ensure safe use of the electrolyte.

34 Endress+Hauser

Page 35

CCS51D Maintenance

NOTICE

Damage to membrane and electrodes, air bubbles

Possibility of measured errors to complete failure of the measuring point

Avoid damage to membrane and electrodes.

‣

The electrolyte is chemically neutral and is not hazardous to health. Nonetheless, do not

‣

swallow it and avoid contact with eyes.

Keep the electrolyte bottle closed after use. Do not transfer electrolyte to other vessels.

‣

Do not store electrolyte for longer than 2 years. The electrolyte must not be yellow in color.

‣

Observe the use-by date on the label.

Avoid air bubbles when pouring electrolyte into membrane cap.

‣

Filling the membrane cap with electrolyte

1. Remove membrane cap → 36.

2. Approx. 7 ml (0.24 fl.oz) Fill the membrane cap with electrolyte until it is level with the

start of the internal thread.

3. Slowly screw on membrane cap up to the stop . This will cause excess electrolyte to be

displaced at the valve and thread.

4. If necessary, pat the sensor and membrane cap dry using a cloth.

5. Reset operating hours counter for electrolyte on transmitter. For detailed information,

see Operating Instructions for transmitter.

9.2.3 Replacing membrane cap

1. Remove sensor from flow assembly .

2. Remove membrane cap → 36.

3. Pour fresh electrolyte into the new membrane cap until it is level with the start of the

internal thread.

4. Check if the sealing ring is mounted in the membrane cap.

5. Screw new membrane cap onto sensor shaft → 37.

6. Screw on membrane cap until the membrane at the working electrode is slightly

overstretched (1 mm (0.04 in)).

7. Reset operating hours counter for membrane cap on transmitter. For detailed

information, see Operating Instructions for transmitter.

Endress+Hauser 35

Page 36

Maintenance CCS51D

1

Removing the membrane cap

Carefully rotate membrane cap and remove.

‣

A0034406

15 Carefully rotate membrane cap.

A0034408

16 Carefully remove membrane cap.

1 Electrode body

36 Endress+Hauser

Page 37

CCS51D Maintenance

1

Screwing the membrane cap onto the sensor

Screw membrane cap onto sensor shaft: hold sensor by the shaft. Keep valve clear.

‣

A0034480

17 Screw on membrane cap: keep pressure relief valve clear.

1 Pressure relief valve

9.2.4 Storing the sensor

If measurement is suspended for a short period of time and it can be guaranteed that the

sensor will be kept moist while in storage:

1. If the assembly is guaranteed not to empty out,

you may leave the sensor in the flow assembly.

2. If there is a possibility that the assembly may empty out,

remove the sensor from assembly .

3. To keep the membrane moist after the sensor has been removed, refill the protection

cap with electrolyte or clean water.

4. Fit protection cap on sensor → 38.

During longterm interruptions to measurement, particularly if dehydration is possible:

1. Remove sensor from assembly.

2. Clean sensor shaft and membrane cap with cold water and leave to dry.

3. Loosely screw on membrane cap up to the stop. This ensures that the membrane

remains slack.

4. Pour electrolyte or clean water into protection cap and attach → 37.

5. For recommissioning, follow the same procedure as for commissioning → 28.

Ensure that no biofouling occurs during longer interruptions to measurement. Remove

continuous organic deposits, such as films of bacteria.

Endress+Hauser 37

Page 38

Maintenance CCS51D

Fitting the protection cap on the sensor

1. To keep the membrane moist after the sensor has been removed, fill the protection cap

with some electrolyte or clean water.

A0034264

18 Carefully slide protection cap onto the membrane cap.

2. Top part of protection cap is in the open position.

Carefully slide protection cap onto the membrane cap.

3. Secure protection cap by rotating the top part of the protection cap.

A0034494

19 Securing protection cap by rotating the top part

9.2.5 Regenerating the sensor

During measurement, the electrolyte in the sensor is gradually exhausted due to chemical

reactions. The gray-brown silver chloride layer that is applied to the counter electrode at the

factory continues to grow during sensor operation. However, this has no effect on the reaction

taking place at the working electrode.

38 Endress+Hauser

Page 39

CCS51D Maintenance

A change in the color of the silver chloride layer indicates an effect of the reaction that is

taking place. Carry out a visual inspection to ensure that the gray-brown color of the counter

electrode has not changed. If the color of the counter electrode has changed, e.g. if it is

spotted, white or silvery, the sensor must be regenerated.

Send the sensor to the manufacturer for regeneration.

‣

Endress+Hauser 39

Page 40

Repair CCS51D

10 Repair

10.1 Spare parts

For more detailed information on spare parts kits, please refer to the "Spare Part Finding Tool"

on the Internet:

www.endress.com/spareparts_consumables

10.2 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

10.3 Disposal

The device contains electronic components. The product must be disposed of as electronic

waste.

Observe the local regulations.

‣

40 Endress+Hauser

Page 41

CCS51D Accessories

11 Accessories

The following are the most important accessories available at the time this documentation

was issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

11.1 Maintenance kit CCV05

Order according to product structure

• 2 x membrane caps and 1 x electrolyte 50 ml (1.69 fl.oz)

• 1 x electrolyte50 ml (1.69 fl.oz)

• 2 x sealing set

11.2 Device-specific accessories

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Memosens laboratory cable CYK20

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk20

Flowfit CCA250

• Flow assembly for disinfection and pH/ORP sensors

• Product Configurator on the product page: www.endress.com/cca250

Technical Information TI00062C

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Photometer PF-3

• Compact hand-held photometer for determining the reference measured value

• Color-coded reagent bottles with clear dosing instructions

• Order No.: 71257946

Endress+Hauser 41

Page 42

Technical data CCS51D

Kit adapter CCS5xD for CCA151

• Clamping ring

• Thrust collar

• O-ring

• Order No. 71372027

Adapter kit CCS5x(D) for CCA250

• Adapter incl. O-rings

• 2 studs for locking in place

• Order No. 71372025

Adapter kit CCS5x(D) for CYA112

• Adapter incl. O-rings

• 2 studs for locking in place

• Order No. 71372026

COY8

Zero-point gel for oxygen and disinfection sensors

• Oxygen-free and chlorine-free gel for the verification, zero point calibration and adjustment

of oxygen and disinfection measuring points

• Product Configurator on the product page: www.endress.com/coy8

Technical Information TI01244C

12 Technical data

12.1 Input

12.1.1 Measured variables

Free chlorine (HOCl)

Temperature [°C, °F]

12.1.2 Measuring ranges

CCS51D-**11AD

CCS51D-**11BF 0 to 20 mg/l (ppm) HOCl

CCS51D-**11CJ 0 to 200 mg/l (ppm) HOCl

12.1.3 Signal current

CCS51D-**11AD

CCS51D-**11BF 9 to 18 nA per 1 mg/l (ppm) HOCl

CCS51D-**11CJ 9 to 18 nA per 1 mg/l (ppm) HOCl

42 Endress+Hauser

Hypochlorous acid (HOCl)

[mg/l, μg/l, ppm, ppb]

0 to 5 mg/l (ppm) HOCl

33 to 63 nA per 1 mg/l (ppm) HOCl

Page 43

CCS51D Technical data

12.2 Performance characteristics

12.2.1 Reference operating conditions

Temperature 20 °C (68 °F)

pH value pH 5.5 ±0.2

Flow 40 to 60 cm/s

HOCl-free base medium Mains water

12.2.2 Response time

T90 < 25 s (after completing polarization)

The T90 time can be longer under certain conditions. If the sensor is operated or stored in a

chlorine-free medium for a longer period, the sensor response starts immediately if chlorine is

present but only reaches the exact concentration value after a delay.

12.2.3 Measured value resolution of sensor

CCS51D-**11AD

0.03 µg/l (ppb) HOCl

CCS51D-**11BF 0.13 µg/l (ppb) HOCl

CCS51D-**11CJ 1.1 µg/l (ppb) HOCl

12.2.4 Maximum measured error

±2 % or ±5 µg/l (ppb) of value measured (depending on which value is higher)

LOD (limit of detection)

1)

LOQ (limit of quantification)

1)

CCS51D-**11AD 0.002 mg/l (ppm) 0.005 mg/l (ppm)

CCS51D-**11BF 0.002 mg/l (ppm) 0.007 mg/l (ppm)

CCS51D-**11CJ 0.008 mg/l (ppm) 0.027 mg/l (ppm)

1) Based on ISO 15839. The measured error includes all the uncertainties of the sensor and transmitter (electrode

system). It does not contain all the uncertainties caused by the reference material and adjustments that may have

been performed.

12.2.5 Repeatability

CCS51D-**11AD

0.0031 mg/l (ppm)

CCS51D-AA11BF 0.0035 mg/l (ppm)

CCS51D-AA11CJ 0.062 mg/l (ppm)

12.2.6 Nominal slope

CCS51D-**11AD

48 nA per 1 mg/l (ppm) HOCl

CCS51D-**11BF 14 nA per 1 mg/l (ppm) HOCl

CCS51D-**11CJ 14 nA per 1 mg/l (ppm) HOCl

Endress+Hauser 43

Page 44

Technical data CCS51D

12.2.7 Long-term drift

< 1 % per month (mean value, determined while operating at varying concentrations and

under reference conditions)

12.2.8 Polarization time

Initial commissioning 60 min

Recommissioning 30 min

12.2.9 Operating time of the electrolyte

at 10 % of measuring range and 20 °C 2 years

at 50 % of measuring range and 20 °C 1 year

at maximum concentration and 55 °C 60 days

12.3 Environment

12.3.1 Ambient temperature range

-20 to 60 °C (-4 to 140 °F)

12.3.2 Storage temperature

Long-term storage up to 2 years (maximum) Storage up to 48 h (maximum)

With electrolyte 0 to 35 °C (32 to 95 °F) (non-freezing) 35 to 50 °C (95 to 122 °F)

Without electrolyte –20 to 60 °C (–4 to 140 °F)

12.3.3 Degree of protection

IP68 (1.8 m (5.91 ft)) water column over 7 days at 20 °C (68 °F)

12.4 Process

12.4.1 Process temperature

0 to 55 °C (32 to 130 °F), non-freezing

12.4.2 Process pressure

The inlet pressure depends on the specific fitting and installation.

The measurement can take place with a free outlet.

The sensor can be operated at process pressures up to 1 bar (14.5 psi) (2 bar abs. (29 psi

abs.)).

In terms of sensor condition and performance, it is essential that the flow velocity limits

‣

specified in the following table be observed.

44 Endress+Hauser

Page 45

CCS51D Technical data

Flow

velocity

[cm/s]

Minimum 15 30 5 The sensor is suspended freely in the medium; pay

Maximum 80 120 20

Flowfit

CCA250

Flowfit

CCA151

Volume flow [l/h]

Flexdip CYA112

attention to the minimum flow velocity of 15 cm/s

during installation.

12.4.3 pH range

Range of effectiveness of free chlorine pH 4 to 9

1)

Calibration pH 4 to 8

Measurement pH 4 to 9

1)

Up to pH 4 and in the presence of chloride ions (Cl-), free chlorine is produced and included in the measurement

12.4.4 Flow

At least 5 l/h (1.3 gal/h), in the Flowfit CCA151 flow assembly

At least 30 l/h (7.9 gal/h), in the Flowfit CCA250 flow assembly

12.4.5 Flow

At least 15 cm/s (0.5 ft/s) , e.g. with Flexdip CYA112 immersion assembly

12.5 Mechanical construction

12.5.1 Dimensions

→ 16

12.5.2 Weight

Sensor with membrane cap and electrolyte (without protection cap and without adapter)

Approx. 95 g (3.35 oz)

12.5.3 Materials

Sensor shaft

PVC

Membrane PVDF

Membrane cap PVDF

Protection cap • Vessel: PC Makrolon (polycarbonate)

• Seal: Kraiburg TPE TM5MED

• Cover: PC Makrolon (polycarbonate)

Sealing ring FKM

Sensor shaft coupling PPS

12.5.4 Cable specification

max. 100 m (330 ft), incl. Cable extension

Endress+Hauser 45

Page 46

Installation and operation in hazardous environment Class I Div. 2 CCS51D

13 Installation and operation in hazardous environment

Class I Div. 2

Non-sparking device for use in specified hazardous environment in accordance with:

• cCSAus Class I Div. 2

• Gas group A, B, C, D

• Temperature class T6, -5 °C (23 °F) < Ta < 55 °C (131 °F)

• Control drawing: 401204

46 Endress+Hauser

Page 47

CCS51D Installation and operation in hazardous environment Class I Div. 2

Endress+Hauser 47

Page 48

Index CCS51D

Index

A

Accessories ..................... 41

Ambient temperature range ........... 44

C

Cable specification ................. 45

Check

Connection .................. 26

Function ....................28

Installation .................. 25

Cleaning .......................33

Connection

Check ..................... 26

Ensuring the degree of protection ..... 26

D

Declaration of Conformity .............14

Degree of protection

Ensuring ....................26

Technical data ................ 44

Designated use ....................6

Device description .................. 8

Diagnostics ..................... 30

Disposal ....................... 40

E

Effect on the measured signal

Flow ...................... 11

pH value .....................9

Temperature ................. 12

Electrical connection ................25

Environment .................... 44

Ex approvals .................... 14

F

Flow .......................11, 45

Flow assembly ................. 22, 23

Function check ................... 28

I

Immersion assembly ................24

Incoming acceptance ............... 13

Installation

Check ..................... 25

Flow assembly ................ 22

Immersion assembly .............24

Installation position ............. 15

Sensor ..................... 17

Installation position ................ 15

L

Long-term drift ...................44

M

Maintenance schedule ...............32

Maintenance tasks .................33

Materials ...................... 45

Maximum measured error ............ 43

Measured signal ................... 9

Measured value resolution ............ 43

Measured variables ................ 42

Measuring principle .................8

Measuring ranges ................. 42

Measuring system ................. 17

Mounting instructions ...............15

N

Nameplate ..................... 13

Nominal slope ................... 43

O

Operating principle ................. 8

Operating time of the electrolyte .........44

P

Performance characteristics ........... 43

pH range .......................45

pH value ........................9

Polarization time ..................44

Post-installation check .............. 28

Process ........................44

Process pressure .................. 44

Process temperature ................44

R

Reference operating conditions ......... 43

Regeneration .................... 38

Repair ........................ 40

Repeatability .................... 43

Response time ................... 43

Return ........................ 40

48 Endress+Hauser

Page 49

CCS51D Index

S

Safety instructions ..................6

Scope of delivery .................. 14

Sensor

Calibration .................. 28

Cleaning ....................33

Connecting .................. 26

Mounting ................... 17

Polarization ..................28

Regenerating ................. 38

Storage .................... 37

Spare parts ..................... 40

Storage ....................... 37

Storage temperature ................44

Symbols ........................ 4

T

Technical data

Environment ................. 44

Input ......................42

Mechanical construction .......... 45

Performance characteristics ........ 43

Process .....................44

Temperature .................... 12

Troubleshooting .................. 30

U

Use ...........................6

W

Warnings ....................... 4

Weight ........................45

Endress+Hauser 49

Page 50

Page 51

Page 52

*71461453*

71461453

www.addresses.endress.com

Loading...

Loading...