Page 1

TI01423C/07/EN/01.18

71426484

2018-09-20

Products

Solutions Services

Technical Information

Memosens CCS51D

Digital sensor with Memosens technology for

determining free chlorine

Memosens CCS51D offers high-precision

measurement with long-term stability to

guarantee optimum process monitoring

Application

Memosens CCS51D is a free chlorine sensor for skid builders and end customers. It

measures reliably in:

• Drinking water - to ensure reliable disinfection

• Food - to guarantee food safety and provide hygienic packaging and bottling

• Utilities - to detect the absence or presence of free chlorine

• Pool water - to dose disinfectant efficiently

Your benefits

• The right sensor version for every application: From trace measurement up to free

chlorine concentrations of 200 mg/l.

• Fast response time (t90 < 25 s) provides an accurate process view and enables

prompt reaction to process changes as well as efficient process control.

• Increased process safety: precise and long-term stable measurement ensures

consistent process monitoring and allows for individually adapted disinfectant

dosing.

• The low-maintenance, amperometric sensor reduces the cost of ownership of the

measuring point, particularly compared to colorimetric measuring systems.

• More process up-time thanks to fast sensor exchange: pre-calibrate the sensor in

your lab and then swap it into your process with plug & play.

• Connection to the Liquiline multiparameter transmitter allows for easy

combination with other relevant parameters of liquid analysis such as pH and ORP.

Other advantages of Memosens technology

• Maximum process safety

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Recording of sensor load data in the sensor enables predictive maintenance

Page 2

Function and system design

Memosens CCS51D

Measuring principle

Function

Measuring system

Free chlorine levels are determined using hypochlorous acid in accordance with the amperometric

measuring principle.

The hypochlorous acid (HOCl) contained in the medium diffuses through the sensor membrane and

is reduced to chloride ions (Cl-) at the gold cathode. At the silver anode, silver is oxidized to silver

chloride. Electron donation at the gold cathode and electron acceptance at the silver anode causes a

current to flow which is proportional to the concentration of free chlorine in the medium at constant

conditions.

The concentration of hypochlorous acid depends on the pH value. An additional pH measurement is

used to compensate for this dependency.

The transmitter uses the current signal to calculate the measured variable for concentration in mg/l

(ppm).

The sensor consists of:

• Membrane cap (measuring chamber with membrane)

• Sensor shaft with anode with large surface area (counter-electrode) and a cathode embedded in

plastic (working electrode)

The electrodes are in an electrolyte which is separated from the medium by a membrane. The

membrane prevents the electrolyte from leaking and protects against contaminant penetration.

The measuring system is calibrated by means of a colorimetric comparison measurement in

accordance with the DPD method for free chlorine. The calibration value determined is entered in the

transmitter.

A complete measuring system comprises:

• Disinfection sensor CCS51D (membrane-covered, ⌀25 mm) with corresponding

installation adapter

• Flowfit CCA250 flow assembly

• Measuring cable CYK10, CYK20

• Transmitter , e. g. Liquiline CM44x or CM44xR

• Optional: extension cable CYK11

• Optional: Immersion assembly Flexdip CYA112

• Optional: proximity switch

2 Endress+Hauser

Page 3

Memosens CCS51D

3

8

2

4

1

5

7

6

MEMO SENS

A0007341

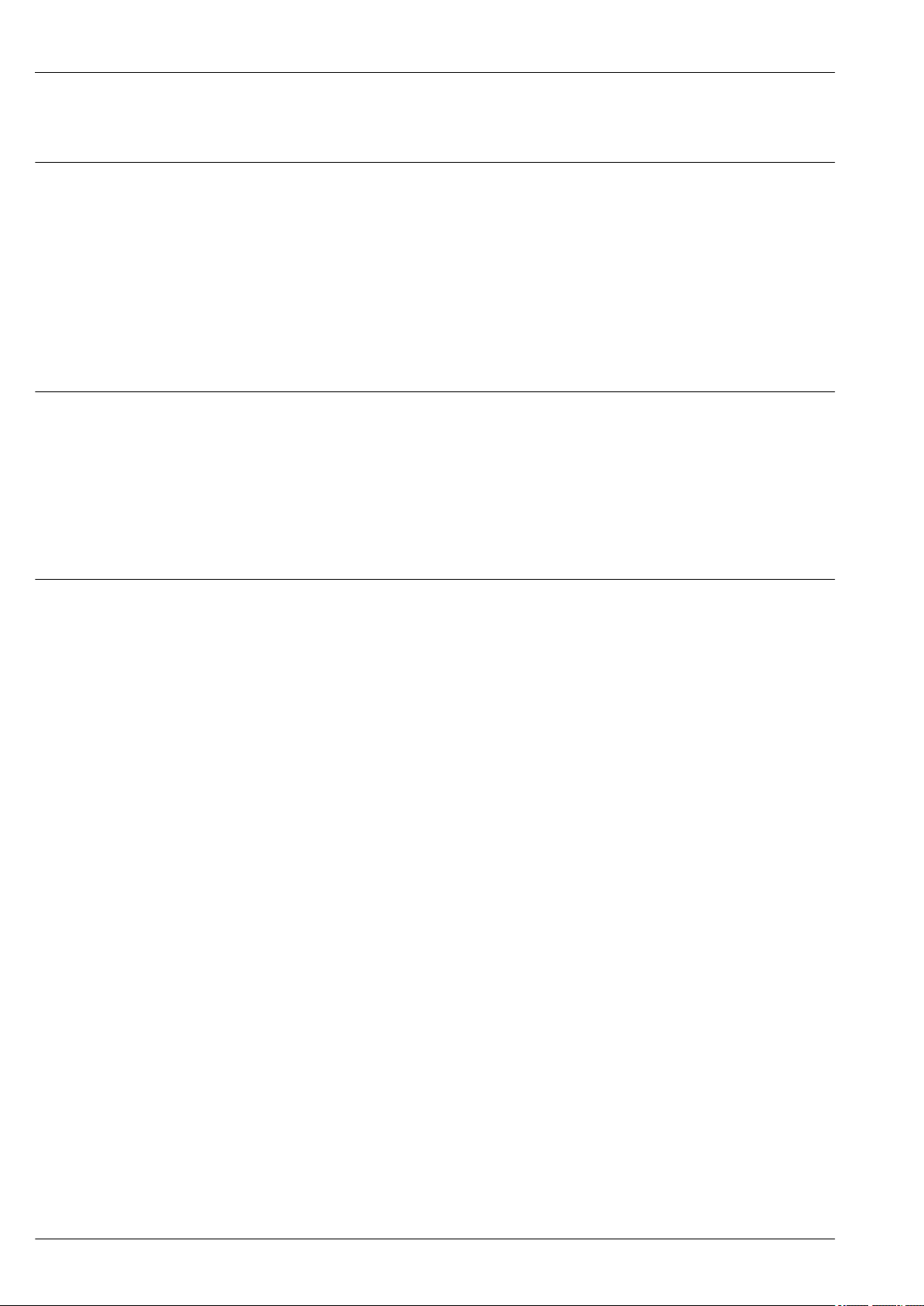

1 Example of a measuring system

1 Liquiline CM44x transmitter

2 Power cable for transmitter

3 Disinfection sensor CCS51D (membrane-covered, ⌀25 mm)

4 Flowfit CCA250 flow assembly

5 Inlet to Flowfit CCA250 flow assembly

6 Proximity switch (optional)

7 CPS31D pH sensor

8 Measuring cable CYK10

Dependability Reliability

Memosens

Memosens makes your measuring point safer and more reliable:

• Non-contact, digital signal transmission enables optimum galvanic isolation

• Dust- and waterproof (IP 68)

• Sensor can be calibrated in a lab, thus increasing the availability of the measuring point in the

process

• Predictive maintenance thanks to recording of sensor data, e.g.:

– Total hours of operation

– Hours of operation with very high or very low measured values

– Hours of operation at high temperatures

– Calibration history

Maintainability

Easy handling

Sensors with Memosens technology have integrated electronics that store calibration data and other

information (e. g. total hours of operation or operating hours under extreme measuring conditions).

Once the sensor has been connected, the sensor data are transferred automatically to the transmitter

Endress+Hauser 3

Page 4

Memosens CCS51D

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

and used to calculate the current measured value. As the calibration data are stored in the sensor,

the sensor can be calibrated and adjusted independently of the measuring point. The result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point.

• Thanks to the availability of the sensor data, maintenance intervals can be accurately defined and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs,.

• Thus, the current application of the sensors can be made to depend on their previous history.

Safety

Data security thanks to digital data transmission

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter via a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Input

Measured variables

Measuring ranges

Signal current

Electrical connection

Free chlorine (HOCl)

[mg/l, μg/l, ppm, ppb]

Temperature [°C, °F]

CCS51D-**11AD

0 to 5 mg/l (ppm) HOCl

CCS51D-**11BF 0 to 20 mg/l (ppm) HOCl

CCS51D-**11CJ 0 to 200 mg/l (ppm) HOCl

CCS51D-**11AD

33 to 63 nA per 1 mg/l (ppm) HOCl

CCS51D-**11BF 9 to 18 nA per 1 mg/l (ppm) HOCl

CCS51D-**11CJ 9 to 18 nA per 1 mg/l (ppm) HOCl

Power supply

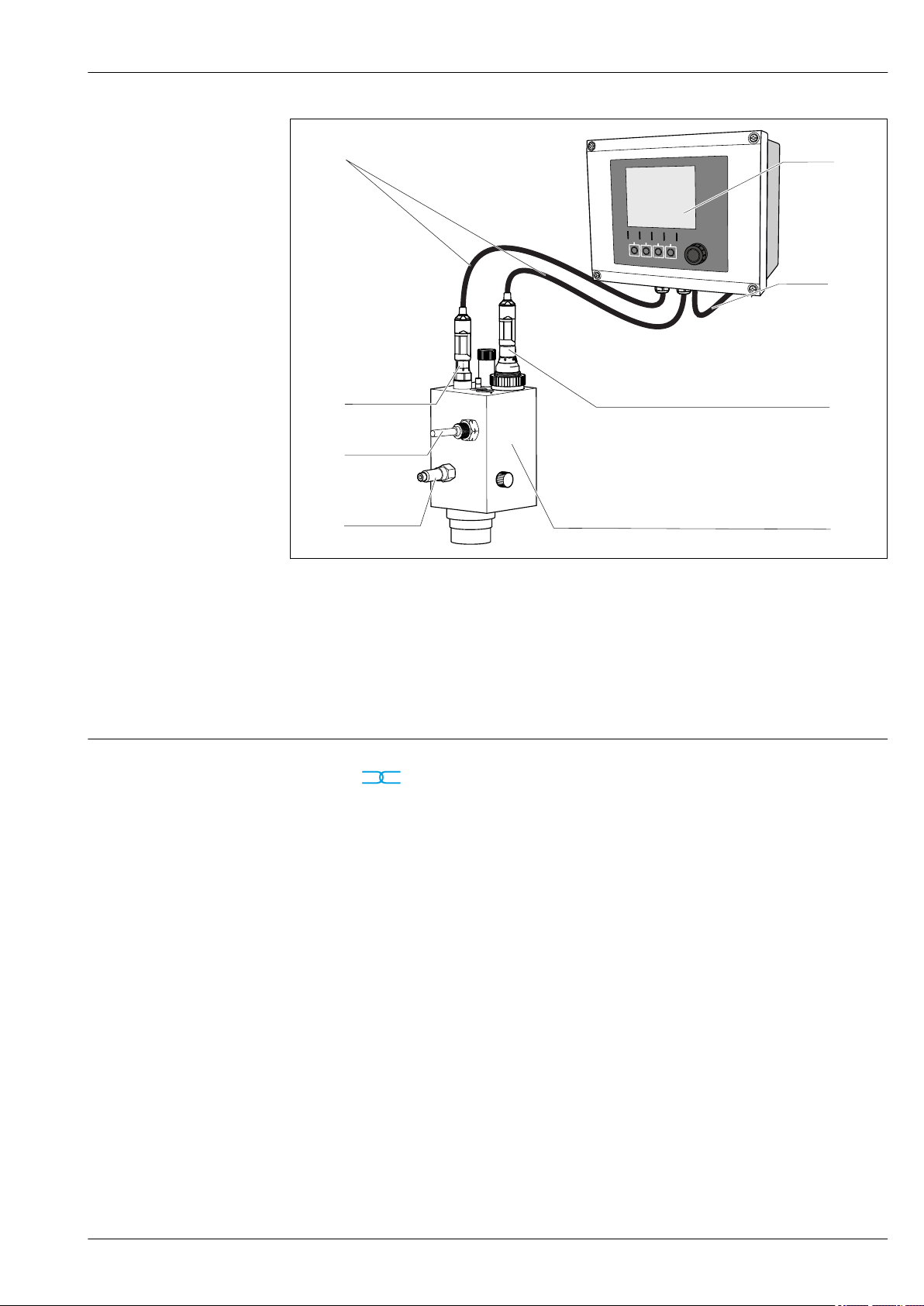

The electrical connection to the transmitter is established using measuring cable CYK10 or CYK20.

A0024019

2 Measuring cable CYK10/CYK20

To extend the cable, use measuring cable CYK11. The maximum cable length is 100 m (328 ft).

‣

3 Electrical connection, M12 plug

4 Endress+Hauser

A0018861

Page 5

Memosens CCS51D

Performance characteristics

Reference operating conditions

Response time

Measured value resolution of sensor

Measured error

1)

Repeatability

Temperature 20 °C (68 °F)

pH value pH 5.5 ±0.2

Flow 40 to 60 cm/s

HOCl-free base medium Mains water

T90 < 25 s (after completing polarization)

The T90 time can be longer under certain conditions. If the sensor is operated or stored in a

chlorine-free medium for a longer period, the sensor response starts immediately if chlorine is

present but only reaches the exact concentration value after a delay.

CCS51D-**11AD

0.03 µg/l (ppb) HOCl

CCS51D-**11BF 0.13 µg/l (ppb) HOCl

CCS51D-**11CJ 1.1 µg/l (ppb) HOCl

±2 % or ±5 µg/l (ppb) of value measured (depending on which value is higher)

LOD (limit of detection)

LOQ (limit of quantification)

CCS51D-**11AD 0.002 mg/l (ppm) 0.005 mg/l (ppm)

CCS51D-**11BF 0.002 mg/l (ppm) 0.007 mg/l (ppm)

CCS51D-**11CJ 0.008 mg/l (ppm) 0.027 mg/l (ppm)

CCS51D-**11AD

0.0031 mg/l (ppm)

CCS51D-AA11BF 0.0035 mg/l (ppm)

CCS51D-AA11CJ 0.062 mg/l (ppm)

Nominal slope

Long-term drift

Polarization time

Operating time of the electrolyte

CCS51D-**11AD

CCS51D-**11BF 14 nA per 1 mg/l (ppm) ClO

CCS51D-**11CJ 14 nA per 1 mg/l (ppm) ClO

48 nA per 1 mg/l (ppm) ClO

2

2

2

< 1 % per month (mean value, determined while operating at varying concentrations and under

reference conditions)

Initial commissioning

60 min

Recommissioning 30 min

at maximum concentration and 55 °C

60 days

at 50 % of measuring range and 20 °C 1 year

at 10 % of measuring range and 20 °C 2 years

1) Based on ISO 15839. The measured error includes all the uncertainties of the sensor and transmitter (measuring chain). It does not contain all

the uncertainties caused by the reference material and adjustments that may have been performed.

Endress+Hauser 5

Page 6

Installation

15°

15°

B

A

Memosens CCS51D

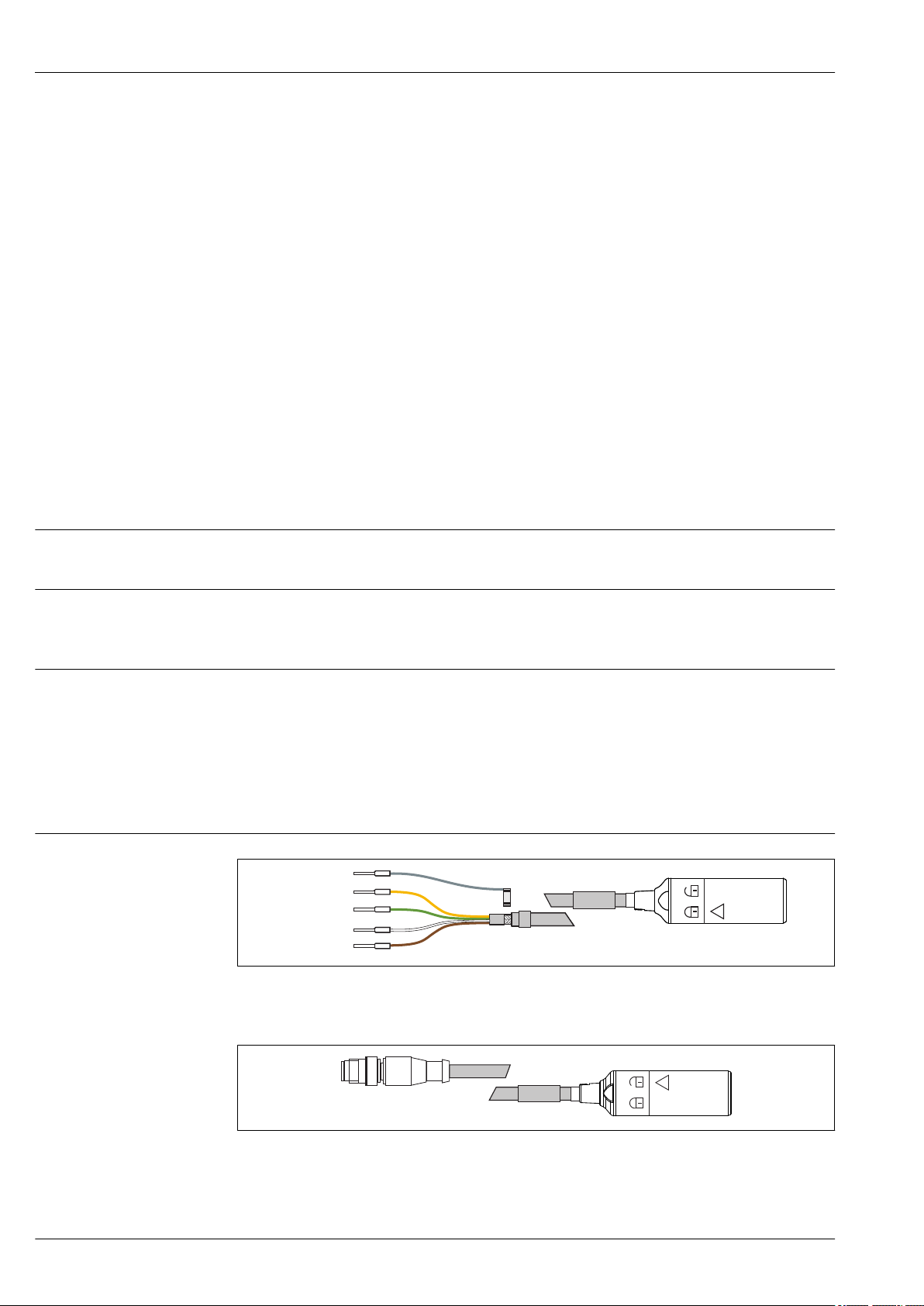

Orientation

Do not install upside-down!

Install the sensor in an assembly, support or appropriate process connection at an angle of at

‣

least 15 ˚ to the horizontal.

Other angles of inclination are not permitted.

‣

Follow the instructions for installing the sensor in the Operating Instructions of the assembly

‣

used.

A Permitted orientation

B Incorrect orientation

A0034236

Immersion depth

Installation instructions Installation in Flowfit CCA151 flow assembly

77 mm (3.03 in)

The disinfection sensor (membrane-covered, ⌀25 mm) is designed for installation in the

Flowfit CCA151 flow assembly if the pH value for compensation is provided in another way.

Please note the following during installation:

The flow rate must be at least 5 l/h (1.32 gal/h).

‣

If the medium is returned to an overflow basin, pipe or similar, the resulting counterpressure on

‣

the sensor must not exceed 1 bar (14.5 psi) and must remain constant.

Avoid negative pressure at the sensor, e.g. due to medium being returned to the suction side of a

‣

pump.

To avoid buildup, heavily contaminated water should also be filtered.

‣

6 Endress+Hauser

Page 7

Memosens CCS51D

1

1

2

3

Preparing assembly

1. The assembly is supplied to the customer with a union nut screwed onto the assembly: unscrew

union nut from assembly.

A0034262

4 Flowfit CCA151 flow assembly

1 Union nut

2. The assembly is supplied to the customer with a dummy plug inserted in the assembly: remove

dummy plug from assembly.

Equip sensor with adapter

The required adapter (clamping ring, thrust collar and O-ring) can be ordered as a mounted sensor

accessory or as a separate accessory .

1. First slide the clamping ring, then the thrust collar, and then the O-ring from the membrane

cap towards the sensor head and into the lower groove.

A0034247

5 Slide clamping ring (1), thrust collar (2) and O-ring (3) upwards from the membrane cap to

the sensor shaft and into the lower groove.

Installing sensor in assembly

2. Slide sensor with adapter for Flowfit CCA151 into the opening in the assembly.

Endress+Hauser 7

Page 8

3. Screw union nut onto assembly on block.

1

2

3

6 Flowfit CCA151 flow assembly

1 Disinfection sensor

2 Flowfit CCA151 flow assembly

3 Union nut for securing a disinfection sensor

Memosens CCS51D

A0034261

Installation in Flowfit CCA250 flow assembly

The sensor can be installed in the Flowfit CCA250 flow assembly. It allows a pH and ORP sensor to

be installed, in addition to the chlorine or chlorine dioxide sensor. A needle valve regulates the flow

in the range of 30 to 120 l/h (7.9 to 30 gal/h).

Please note the following during installation:

The flow rate must be at least 30 l/h (7.92 gal/h). If the flow drops below this value or stops

‣

completely, this can be detected by an inductive proximity switch and used to trigger an alarm

with locking of the dosage pumps.

If the medium is returned to an overflow basin, pipe or similar, the resulting counterpressure on

‣

the sensor must not exceed 1 bar (14.5 psi) and must remain constant.

Negative pressure at the sensor e.g. due to medium being returned to the suction side of a pump,

‣

must be avoided.

Equip sensor with adapter

The required adapter can be ordered as a mounted sensor accessory or as a separate accessory.

1. Slide adapter for Flowfit CCA250 from the sensor head up to the stop on the sensor.

7 Slide on adapter for Flowfit CCA250.

2. Lock the adapter in place using the two studs provided.

For detailed information on "Installing sensor in Flowfit CCA250 assembly", see Operating

Instructions for assembly

8 Endress+Hauser

A0034245

Page 9

Memosens CCS51D

Installation in other flow assemblies

When using other flow assemblies, please ensure the following:

The flow velocity at the membrane must always be at least 15 cm/s (0.49 ft/s).

‣

The flow direction is upwards. Transported air bubbles must be removed so that they do not

‣

collect in front of the membrane.

The flow must be directed to the membrane.

‣

Installation in Flexdip CYA112 immersion assembly

Alternatively, the sensor can be installed in an immersion assembly with G1 threaded connection,

e. g.

Ensure sufficient flow towards the sensor when using the immersion assembly .

Equip sensor with adapter

The required adapter can be ordered as a mounted sensor accessory or as a separate accessory.

1. Slide adapter for Flexdip CYA112 from the sensor head up to the stop on the sensor.

Ambient temperature range

Storage temperature

Degree of protection

A0034246

8 Slide on adapter for Flexdip CYA112.

2. Lock the adapter in place using the two studs provided.

For detailed information on "Installing sensor in Flexdip CYA112 assembly", see Operating

Instructions for assembly

Environment

-20 to +60 °C (-4 to 140 °F)

Longterm storage Storage up to max 48 h

With electrolyte +0 to 35 °C (32 to 95 °F) (non-freezing) 35 to 50 °C (95 to 122 °F) (non-freezing)

Without electrolyte –20 to 60 °C (–4 to 140 °F)

IP 68 (1.8 m (5.91 ft)) water column over 7 days at 20 °C (68 °F)

Process

Process temperature

Process pressure

+0 to 55 °C (32 to 130 °F), non-freezing

The inlet pressure depends on the specific fitting and installation.

The measurement can take place with a free outlet.

Endress+Hauser 9

Page 10

Memosens CCS51D

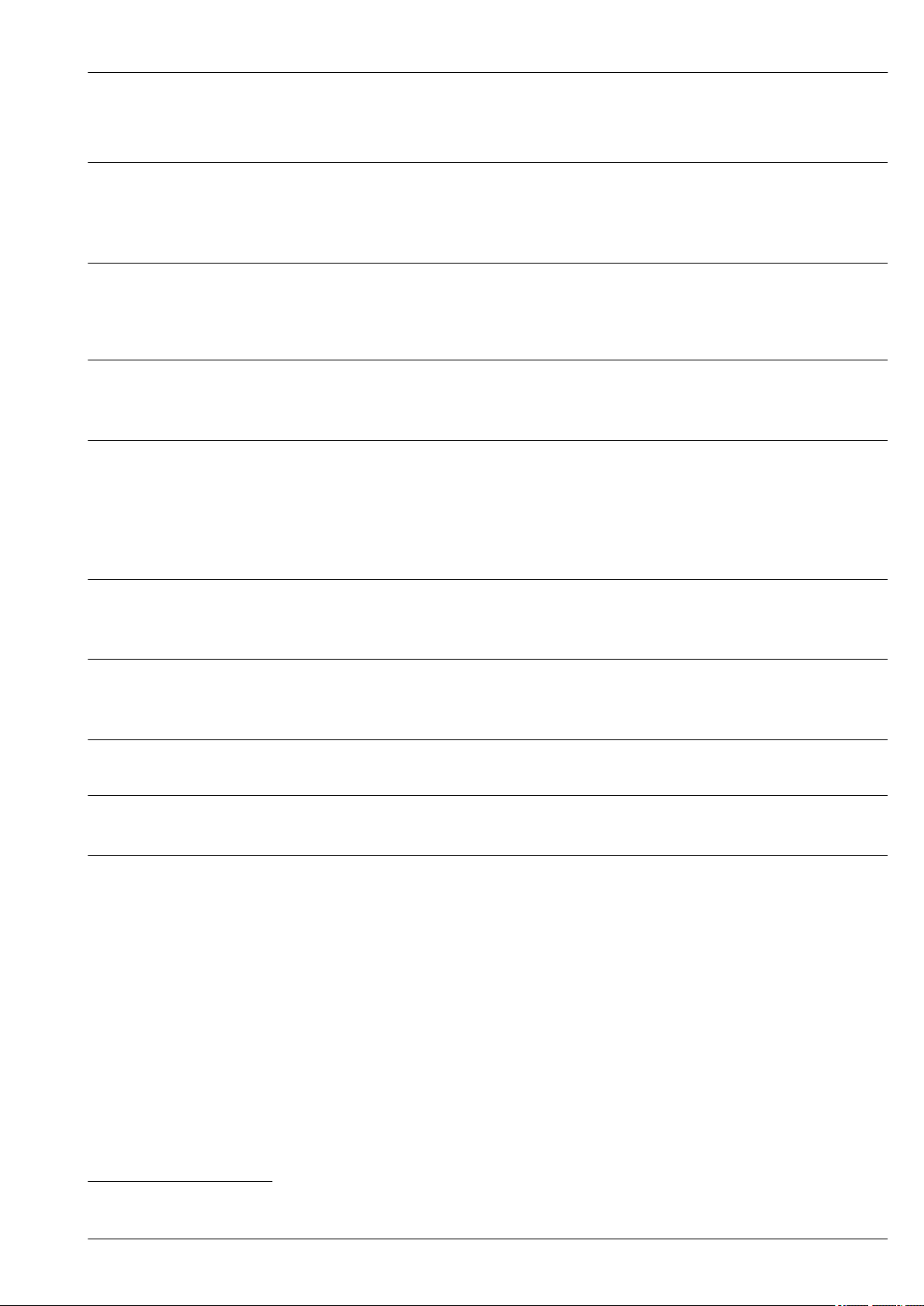

161 (6.34)

82 (3.23)

102 (4.02)

126 (4.96)

!25

(0.98)

The medium pressure directly upstream from the sensor membrane must not exceed 1 bar (14.5 psi)

abs.

In terms of sensor condition and performance, it is essential that the flow velocity limits specified

‣

in the following table be observed.

pH range

Flow

Minimum flow

Dimensions

Flow

velocity

[cm/s]

Minimum 15 30 5 The sensor is suspended freely in the medium;

Maximum 80 145 20

Calibration

Flowfit

CCA250

Flowfit

CCA151

pH 4 to 8

Volume flow [l/h]

FlexdipCYA112

pay attention to the minimum flow velocity of

15 cm/s during installation.

Measurement pH 4 to 9

remains stable for a minimum of 5 l/h (1.32 gal/hr), in the Flowfit CCA151 flow assembly

remains stable for a minimum of 30 l/h (8 gal/hr), in the Flowfit CCA250 flow assembly

remains stable for a minimum of 15 cm/s (0.5 ft/s), e.g. with Flexdip CYA112 immersion assembly

Mechanical construction

A0034238

Approx. 95 g (3.35 oz)

Weight

9 Dimensions in mm (in)

Sensor with membrane cap and electrolyte (without protection cap and without

adapter)

10 Endress+Hauser

Page 11

Memosens CCS51D

Materials

Cable specification

mark

Ex approvals

2)

Sensor shaft PVC

Membrane PVDF

Membrane cap PVDF

Protection cap • Vessel: PC Makrolon (polycarbonate)

• Seal: Kraiburg TPE TM5MED

• Cover: PC Makrolon (polycarbonate)

Sealing ring FKM

max. 100 m (330 ft), incl. Cable extension

Certificates and approvals

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

cCSAus NI Cl. I, Div. 2

This product complies with the requirements defined in:

• UL 61010-1

• ANSI/ISA 12.12.01

• FM 3600

• FM 3611

• CSA C22.2 NO. 61010-1-12

• CSA C22.2 NO. 213-16

• Control drawing: 401204

Product page

Product Configurator

Scope of delivery

Ordering information

www.endress.com/ccs51d

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

The delivery comprises:

• Disinfection sensor (membrane-covered, ⌀25 mm) with protection cap (ready for use)

• Bottle of electrolyte (50 ml (1.69 fl.oz))

• Replacement membrane cap in protection cap

• Operating Instructions

2) Only if connected to CM44x(R)-CD*

Endress+Hauser 11

Page 12

Memosens CCS51D

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Maintenance kit CCV05

Device-specific accessories

Order according to product structure

• 2 x membrane caps and 1 x electrolyte 50 ml (1.69 fl.oz)

• 1 x electrolyte50 ml (1.69 fl.oz)

• 2 x sealing set

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Memosens laboratory cable CYK20

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk20

Flowfit CCA151

• Flow assembly for chlorine dioxide sensors

• Product Configurator on the product page: www.endress.com/cca151

Technical Information TI01357C

Flowfit CCA250

• Flow assembly for chlorine and pH/ORP sensors

• Product Configurator on the product page: www.endress.com/cca250

Technical Information TI00062C

FlexdipCYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Photometer PF-3

• Compact hand-held photometer for determining free available chlorine

• Color-coded reagent bottles with clear dosing instructions

• Order No.: 71257946

Adapter kit CCS5x(D) for CCA250

• Adapter incl. O-rings

• 2 studs for locking in place

• Order No. 71372025

Adapter kit CCS5x(D) for CYA112

• Adapter incl. O-rings

• 2 studs for locking in place

• Order No. 71372026

COY8

Zero-point gel for oxygen and chlorine sensors

• Oxygen-free gel for the validation, calibration and adjustment of oxygen measuring cells

• Product Configurator on the product page: www.endress.com/coy8

Technical Information TI01244C

12 Endress+Hauser

Page 13

Page 14

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...