Page 1

Operating Instructions

CCS120

Sensor for total chlorine

BA388C/07/en/07.06

51517372

Page 2

Brief overview

Here is how to use these Operating Instructions to commission your sensor quickly and safely:

Safety instructions

→ Page 4 ff.

→ Page 5

→ Page 7

→ Page 8 ff.

→ Page 11 ff. Refer to these pages for sensor wiring.

→ Page 14 ff. This chapter describes how to fill in the electrolyte.

General safety instructions

Explanation of the warning symbols

Æ

Installation

Here you can find installation conditions such as sensor dimensions.

Installation examples can be found here.

Æ

Wiring

Æ

Operating

Æ

Commissioning

→ Page 16 ff. Here you find how to calibrate the sensor.

Æ

Maintenance

→ Page 18

→ Page 19 ff.

→ Page 20 ff. If faults occur during operation, use the checklist to locate the cause.

→ Page 25 ff. You can find important terms and keywords on the individual sections

It is absolutely essential to carry out maintenance tasks on a regular basis.

An overview of the available spare parts and accessories.

Æ

Trouble shooting

Æ

Index

here. Use the keyword index to find the information you need quickly and

efficiently.

Page 3

CCS120

Table of contents

1 Safety instructions . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Notes on safety icons and symbols . . . . . . . 5

2 Identification . . . . . . . . . . . . . . 6

2.1 Product structure . . . . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . 6

3.1 Incoming acceptance, transport, storage . . . 6

3.2 Installation conditions . . . . . . . . . . . . . . . . 7

3.3 Installation instructions . . . . . . . . . . . . . . . 8

3.4 Post-installation check . . . . . . . . . . . . . . . 10

4 Wiring . . . . . . . . . . . . . . . . . . 11

4.1 Direct connection to the transmitter . . . . . 11

4.2 Connection via junction box . . . . . . . . . . 12

4.3 Post-connection check . . . . . . . . . . . . . . . 12

9 Troubleshooting . . . . . . . . . . . 20

9.1 Troubleshooting instructions . . . . . . . . . . . 20

9.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Technical data . . . . . . . . . . . . 23

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.3 Performance characteristics . . . . . . . . . . . . 23

10.4 Power supply . . . . . . . . . . . . . . . . . . . . . . 24

10.5 Environment . . . . . . . . . . . . . . . . . . . . . . 24

10.6 Mechanical construction . . . . . . . . . . . . . . 24

Index. . . . . . . . . . . . . . . . . . . . 25

5 Operation . . . . . . . . . . . . . . . . 13

5.1 Sensor design . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Measuring principle . . . . . . . . . . . . . . . . . 13

5.3 Electrolyte fill in . . . . . . . . . . . . . . . . . . . . 14

6 Commissioning. . . . . . . . . . . . 16

6.1 Function check . . . . . . . . . . . . . . . . . . . . 16

6.2 Polarisation . . . . . . . . . . . . . . . . . . . . . . . 16

6.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Maintenance. . . . . . . . . . . . . . 18

8 Accessories. . . . . . . . . . . . . . . 19

8.1 Connection accessories . . . . . . . . . . . . . . 19

8.2 Installation accessories . . . . . . . . . . . . . . . 19

8.3 Transmitter . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Maintenance/calibration . . . . . . . . . . . . . 20

Endress+Hauser

Page 4

Safety instructions CCS120

1 Safety instructions

1.1 Designated use

The sensor is used for continuous measurement of total chlorine in water. Within this context

the following compounds are included in the term total chlorine:

• free chlorine (Cl2 (dissolved), HOCl, OCL-)

• bound chlorine (chloramines)

• organic-bound chlorine (e.g. cyanuric acid derivates)

Typical applications are:

• Controlling total chlorine content of drinking, industrial, process, cooling water and pool

sector

• Measuring total chlorine content in fresh water and sea water for process, swimming pool and

whirl pool treatment

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is, therefore, not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Installation, commissioning and operation

Please note the following items:

• Installation, commissioning, operation and maintenance of the measuring system must only

be carried out by trained technical personnel.

The technical personnel must be authorized for the specified activities by the system operator.

• Electrical connection must only be carried out by a certified electrician.

• Technical personnel must have read and understood these Operating Instructions and must

adhere to them.

• Before commissioning the entire measuring point, check all the connections for

correctness. Ensure that electrical cables and hose connections are not damaged.

• Do not operate damaged products and secure them against unintentional

commissioning. Mark the damaged product as being defective.

• Measuring point faults may only be rectified by authorized and specially trained

personnel.

• If faults can not be rectified, the products must be taken out of service and secured against

unintentional commissioning.

• Repairs not described in these Operating Instructions may only be carried out at the

manufacturer’s or by the service organisation.

4 Endress+Hauser

Page 5

CCS120 Safety instructions

1.3 Operational safety

The sensor has been designed and tested according to the state of the art and left the factory in

perfect functioning order.

Relevant regulations and European standards have been met.

As the user, you are responsible for complying with the following safety conditions:

• Installation instructions

• Local prevailing standards and regulations.

1.4 Return

If the sensor has to be repaired, please return it cleaned to the sales centre responsible.

Please use the original packaging, if possible.

Please enclose the completed "Declaration of Hazardous Material and De-Contamination" (copy

the second last page of these Operating Instructions) with the packaging and the transportation

documents.

No repair without completed declaration!

#

"

!

1.5 Notes on safety icons and symbols

Warning!

This symbol alerts you to hazards. They can cause serious damage to the instrument or to

persons if ignored.

Caution!

This symbol alerts you to possible faults which could arise from incorrect operation. They could

cause damage to the instrument if ignored.

Note!

This symbol indicates important items of information.

Endress+Hauser 5

Page 6

Identification CCS120

2 Identification

2.1 Product structure

Mesuring range

A 0.1 ... 10 mg/l

Head type

S Thread NPT 3/4"; plug TOP 68

Options

0none

CCS120- complete order code

2.2 Scope of delivery

The following items are included in the delivery:

• 1 sensor CCS120

• 1 bottle containing electrolyte (50 ml) and nozzle

• 1 membrane cap for replacement

• 1 operating instructions BA 388C/07/en

3 Installation

3.1 Incoming acceptance, transport, storage

• Make sure the packaging is undamaged!

Inform the supplier about damage to the packaging. Keep the damaged packaging until the

matter has been settled.

• Make sure the contents are undamaged!

Inform the supplier about damage to the delivery contents. Keep the damaged products until

the matter has been settled.

• Check that the scope of delivery is complete and agrees with your order and the shipping

documents.

• The packaging material used to store or to transport the product must provide shock

protection and humidity protection. The original packaging offers the best protection. Also,

keep to the approved ambient conditions (see "Technical data").

• If you have any questions, please contact your supplier or your sales center responsible.

6 Endress+Hauser

Page 7

CCS120 Installation

3.2 Installation conditions

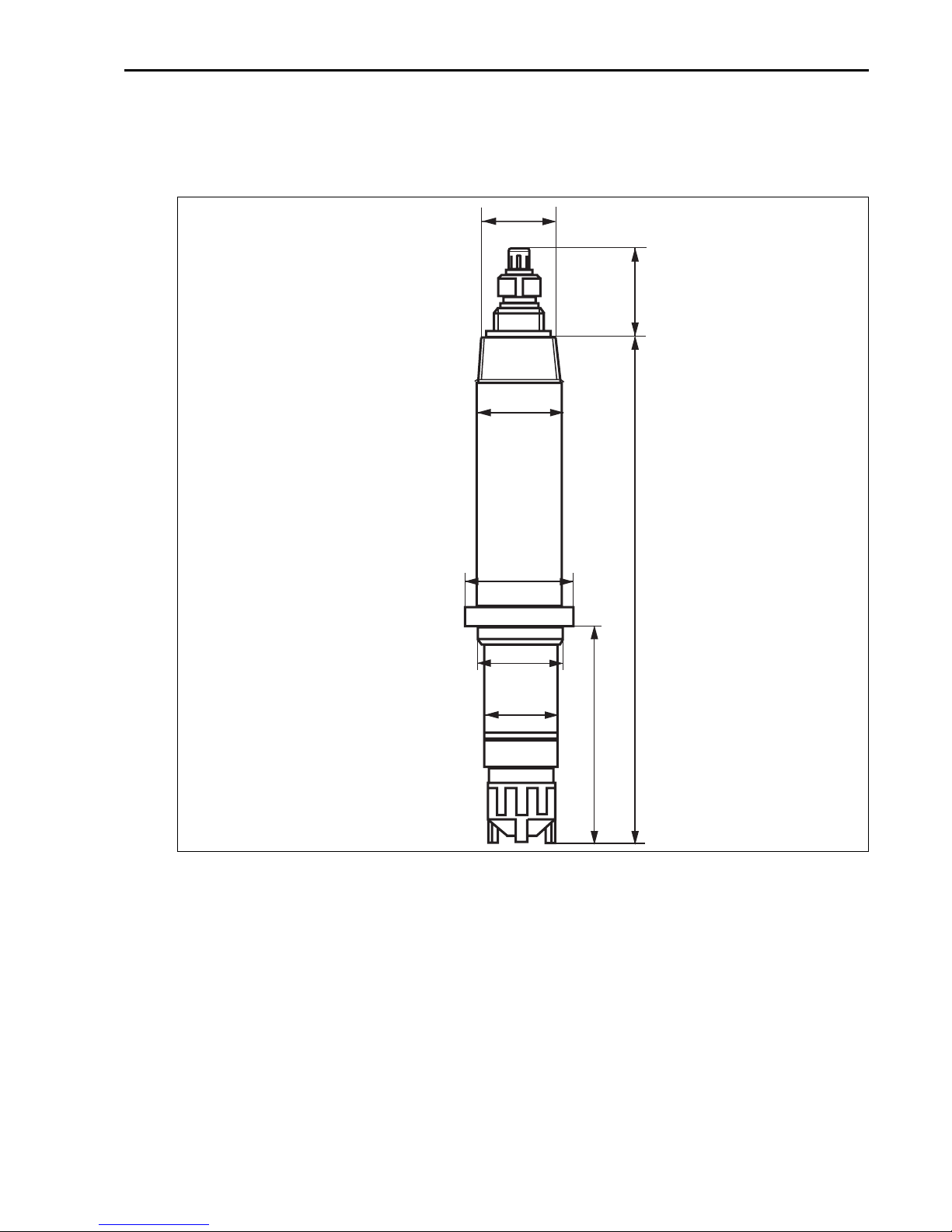

3.2.1 Dimensions

NPT 3/4

27/1.06

Ø 29/

1.14

Fig. 1: Dimensions

Ø 36/

1.42

183/7.20

Ø 28.8/

1.13

Ø 25/

0.98

74/2.91

mm/inch

a0003082

Endress+Hauser 7

Page 8

Installation CCS120

3.3 Installation instructions

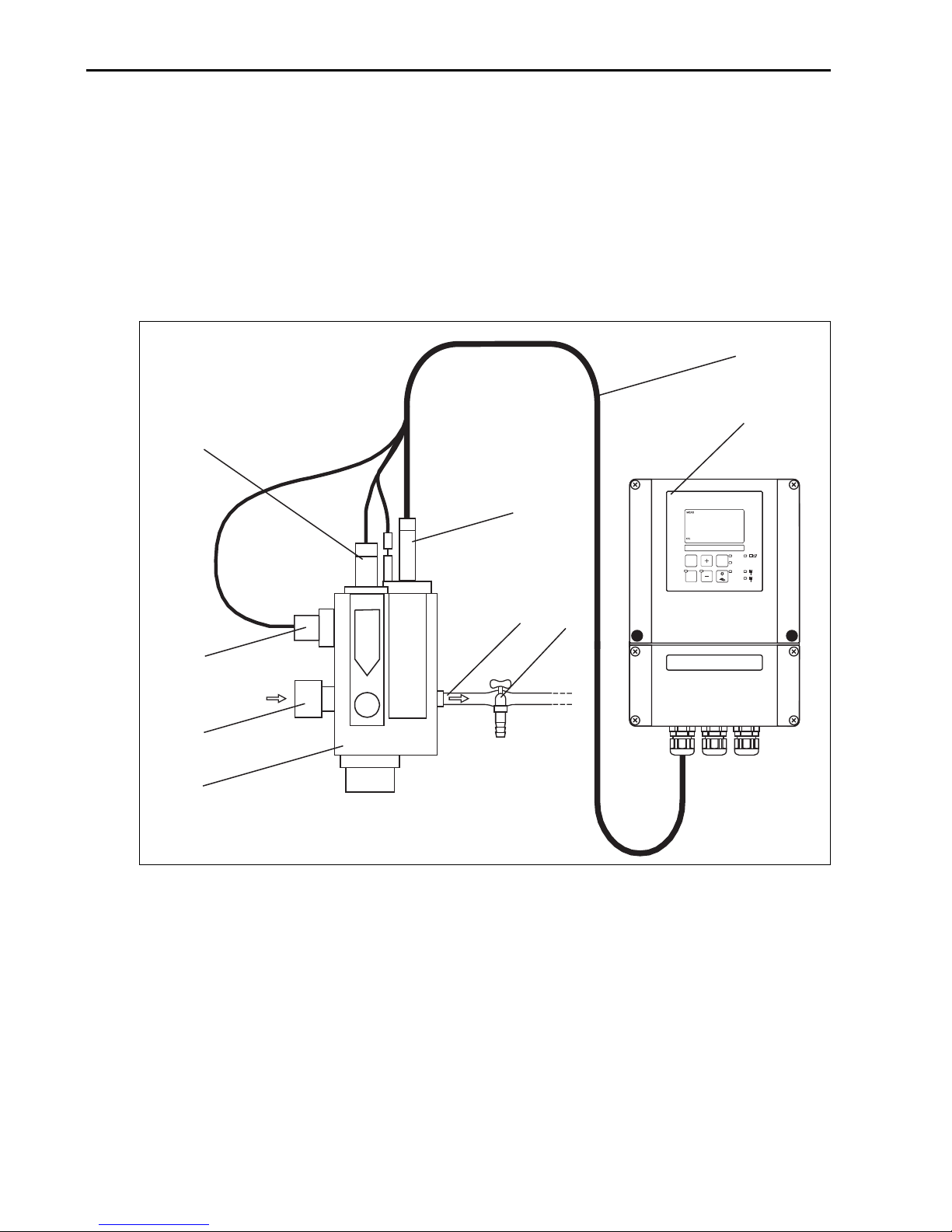

3.3.1 Measuring system

A complete measuring system in the flow mode comprises at least:

• Chlorine sensor

• Transmitter Liquisys M CCM223/253

• Special measuring cable

• Flow assembly

8

9

4

5

25.0 ¡C

CAL REL

E

6

7

3

2

1

Fig. 2: Measuring system in the flow mode (example)

1 Flow assembly CCA250 6 Medium outlet

2 Medium inlet 7 Sampling tap

3 Inductive proximity switch for flow monitoring 8 Measuring cable CPK9-N*A1B

4 Mounting place for pH/redox sensor 9 Transmitter

5 Chlorine sensor CCS120

0.42

mg/l

REL1

ALARM

REL2

REL1

REL2

a0001691

The measuring system described above is available as CCE-system (fully mounted on a board).

8 Endress+Hauser

Page 9

CCS120 Installation

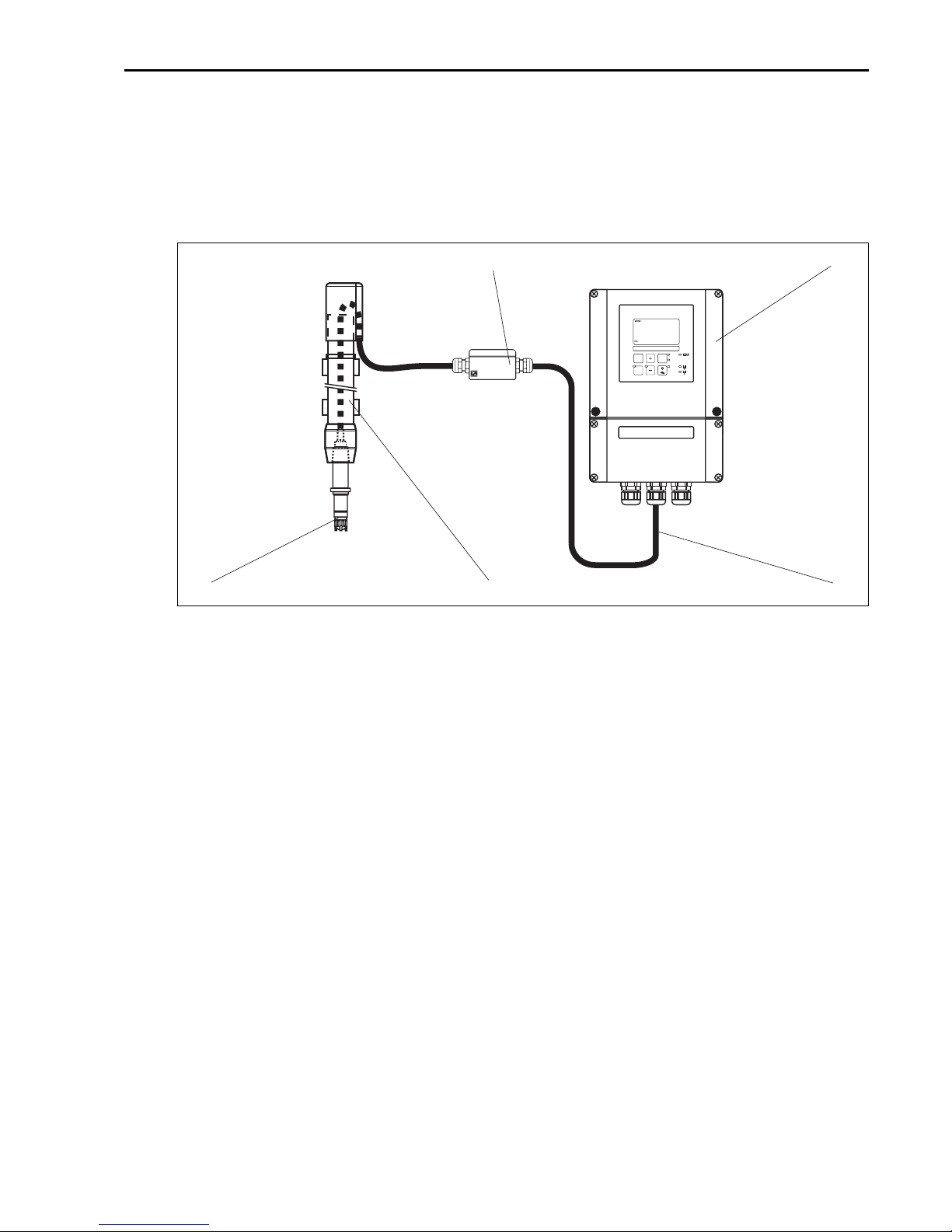

A complete measuring system in the immersion mode comprises at least:

• Chlorine sensor

• Transmitter Liquisys M CCM223/253

• Special measuring cable

• Immersion assembly

1

mg/l

0.42

25.0 ¡C

REL1

ALARM

REL2

CAL REL

REL1

E

REL2

5

4

Fig. 3: Measuring system in the immersion mode (example)

1 Junction box VBM 4 Immersion assembly CYA611-0B

2 Transmitter 5 Chlorine sensor CCS120

3 Measuring cable CYK71

2

3

a0003087

3.3.2 Installing the sensor in flow assembly CCA250

The flow assembly CCA250 is designed for on-site installation of the sensor. In addition to the

chlorine sensor, a pH and redox sensor can be installed. A needle valve regulates the flow within

the range of 30 ... 100 l/h (7.92 ... 26.40 US.gal/h). If the value drops below 30 l/h (7.92

US.gal/h) or flow stops completely, this can be detected by an inductive proximity switch and

an alarm signal plus locking of the dosage pumps can be triggered.

Note the instructions and safety guidelines in the operating instructions of the flow assembly.

If the medium is fed back into a surge tank, pipeline or the like, ensure that the thus generated

back pressure on the sensor does not exceed 1 bar (14.5 psi) and remains constant.

Negative pressure at the sensor, e.g. by feedback of medium to the suction side of a pump, must

be avoided.

Endress+Hauser 9

Page 10

Installation CCS120

3.3.3 Installing the sensor in immersion assembly CYA611

The immersion assembly CYA611-0B is designed for on-site installation of the sensor. Cover the

thread NPT 3/4" with a layer of Teflon tape. Screw the sensor into the assembly.

Note the instructions and safety guidelines in the operating instructions of the immersion

assembly.

3.4 Post-installation check

• Check the membrane for leak tightness und replace it if necessary.

• Is the sensor installed in an assembly and is not suspended from the cable?

10 Endress+Hauser

Page 11

CCS120 Wiring

4 Wiring

Warning!

#

• The electrical connection must only be carried out by a certified electrician.

• Technical personnel must have read and understood the instructions in this manual and must

adhere to them.

• Ensure that there is no voltage at the power cable before beginning the connection work.

4.1 Direct connection to the transmitter

Use the measuring cable CPK9-N*A1B (internal PM wire) to connect the sensor according to

the following connection table. See also the notes in the operating instructions of the transmitter.

Cable with TOP68 coupling Liquisys

Pin Assignment Core Terminal

1 TC-signal coax-inner (white) 90

2 AGND coax-outer (black) 12

3

4 +UB (15 V) green 85

5 NTC1 yellow* 11

NTC1 white* 11

6 NTC2/AGND brown 86

S screen S S

* The white and the yellow cores are connected inside of the TOP68 coupling.

5

4

3

2

Fig. 4: TOP68 plug pin arrangement (view from contact side)

5

6

6

1

1

4

3

2

a0001689

Endress+Hauser 11

Page 12

Wiring CCS120

4.2 Connection via junction box

To lengthen the sensor connection you require the junction box VBM (Fig. 5, Fig. 6) . The

connection is lengthened to the transmitter using the special measuring cable CYK71.

Pg 13,5

62.5/2.46

113/4.45

54/2.13

136/5.35

125/4.92

Fig. 5: Junction box VBM, side view

C07-COS41xxx- 04-05-00-en-00 3.eps

mm/inch

Fig. 6: Junction box VBM, top view

10/0.09

52/2.05

80/3.15

mm/inch

C07-COS41xxx- 04-05-00-en-00 4.eps

4.3 Post-connection check

Instrument status and specifications Remarks

Are the sensor, assembly, junction box or cable damaged? Visual inspection

Electrical connection Remarks

Does the supply voltage of the transmitter match the specifications on the

nameplate?

Are the installed cables strain-relieved and not twisted?

Is the cable type route completely isolated? Power cable/weak current cable

Are the power supply and signal cable correctly connected to the

transmitter?

110/230 V AC

24 V AC/DC

Use the connection diagram of

CCM2x3.

Are all the screws terminals properly tightened?

Are all the cable entries installed, tightened and sealed? For lateral cable entries : cable loops

Are all the cable entries installed downwards or lateral?

12 Endress+Hauser

downwards for water to be able to drip off.

Page 13

CCS120 Operation

5 Operation

5.1 Sensor design

2

1

4

3

Fig. 7: Sensor design

1 Membrane cap 3 Thread NPT 3/4"

2 Sensor shaft 4 TOP68 plug

a0006354

5.2 Measuring principle

The amperometric sensor is based on the conversion of the measuring variable chlorine in

electrical current. Two electrodes covered by an electrolyte are in contact to the medium via a

membrane. It has a platinum working electrode and a silver halogenide coated counter or

reference electrode. The chlorine compounds contained in the medium diffuse through the

membrane. The constant polarisation voltage between the two electrodes instigates the

electrochemical reaction of the chlorine compounds on the working electrode. The resulting

current is measured as a primary signal (amperometric measurement principle). It is proportional

to the chlorine concentration within the sensor’s operating range and only slightly pH dependant

for this type of sensor. The primary signal is converted by the amplifier electronics of the sensor

into a 0 ... 5 µA output signal which is displayed by the transmitter.

Endress+Hauser 13

Page 14

Operation CCS120

5.3 Electrolyte fill in

Warning!

#

Do not swallow the electrolyte. Avoid contact of the electrolyte with skin and eyes. Otherwise

wash with a lot of water. In case of eye inflamation, contact a doctor.

Caution!

"

• Do not touch or damage the membrane or electrodes.

• The electrolyte is sensitive to oxidation: always keep the electrolyte bottle closed after use. Do

not transfer the electrolyte into other containers.

• The electrolyte should not be stored for more than 1 year and should not yellow (use by date,

see label).

• Avoid forming air bubbles as far as possible when pouring the electrolyte into the membrane

cap.

• The membrane cap must be used once only.

!

Note!

• Store the electrolyte bottle upside down in order that the viscous electrolyte can be poured

easily and bubble free into the membrane cap.

• Smaller bubbles will not interfere, larger bubbles leave the electrolyte by rising to the surface.

3

4

2

1

Fig. 8: Membrane cap with electrolyte bottle

1 Nozzle 4 Membrane cap

2Vent hole 5Rubber seal

3 Electrolyte bottle A Electrolyte filling level

5

A

a0001688

14 Endress+Hauser

Page 15

CCS120 Operation

Perform the following steps to fill the membrane cap with electrolyte:

1. Open the electrolyte bottle and screw on the nozzle.

2. Squeeze out excess air.

3. Place the electrolyte bottle completely onto the membrane cap (Fig. 8).

4. Slowly squeeze the electrolyte out of the bottle in one steady stream, while continously

retracting the bottle. The cap is completely full when the electrolyte reaches the lower

edge of the thread.

Now you have to install the membrane cap:

1. Place the sensor shaft vertically onto the filled membrane cap.

2. Do not cover the vent hole below the rubber seal with your fingers.

3. Tighten on the membrane cap by hand as far as possible. There should not be a visible gap

between the sensor shaft and membrane cap. When you screw on the cap, excess

electrolyte will leak out through the hole below the rubber seal.

4. Wipe away any electrolyte with a soft paper tissue or similar.

5. Rinse the nozzle thoroughly with a clean, warm water jet so that no electrolyte remains

on the inside and outside of the nozzle.

Endress+Hauser 15

Page 16

Commissioning CCS120

6 Commissioning

!

Note!

• Read also the instructions for operation and commissioning in the operating instructions of the

transmitter.

• The power supply to the transmitter and to the sensor must not be interrupted. If the power

supply is interrupted (> 2 hours) the sensor must be re-commissioned (polarisation time).

• Do not switch off the measuring device during intermittent operation. Dosing devices may be

controlled by timer switches.

However, if no disinfectant is metered over a longer period of time (weeks), the sensor must

be disconnected from the system and stored dry.

• Once the sensor has been commissioned it must be kept permanently wet.

6.1 Function check

Before first commissioning, check if:

• the sensor ist correctly installed

• the electrical connection is correct.

6.2 Polarisation

The voltage applied between cathode and anode by the transmitter polarises the surface of the

working electrode. Therefore, after switching on the transmitter with connected sensor, you

have to wait until the polarisation period has elapsed before you can start a calibration.

In order to achieve a stable display value the sensor needs the following polarisation period:

First commissioning: 24 h

After changing membrane: 1 - 6 h

Re-commissioning: approx. 4 - 24 h

6.3 Calibration

Reference measurement according to the DPD method

The calibration of the measuring system requires a colormetric reference measurement

according to the DPD method. Chlorine reacts with diethyl-p-phenylenadiamine (DPD) by

producing a red dye, the intensity of the red colour being proportional to the chlorine

concentration.

The intensity of the red dye is measured by a photometer (e.g. CCM182, see accessories) and

displayed as chlorine concentration.

16 Endress+Hauser

Page 17

CCS120 Commissioning

Requirements

The sensor reading is stable (no drifts or unsteady values for at least 5 minutes). This is normally

fulfilled, when:

• The polarisation period is finished.

• The flow is constant and within the correct range.

• The sample medium and the sensor are at the same temperature.

• The pH value is within the admissible range.

Zero point calibration

Zero point calibration is only necessary when the sensor is used at the lower limit of the

measuring range.

For zero point calibration, perform the following steps:

1. Remove the sensor from the assembly (see operating instructions of the assembly).

2. Clean the sensor thoroughly. The sensor must be totally free of chlorine for the next

working step.

3. Stir the sensor in a container filled with clean water (free of chlorine and bromine) until

the measured value remains stable.

4. Adjust the transmitter to zero according to it operating instructions.

5. Reinstall the sensor into the assembly (see operating instructions of the assembly).

Slope calibration

For slope calibration, perform the following steps:

1. Insert the sensor into the assembly, if not already done (see operating instructions of the

assembly).

2. Take a sample for DPD measurement. Sampling location has to be close to the installed

sensor. Use the sampling tap in the case of the compact chlorine system CCE1.

3. Determine the total chlorine content with a photometer (e.g. CCM182, see accessories)

according to the DPD 1 / DPD 3 method. See the operating instructions of the

photometer. Alternatively you can use the DPD 4 methode.

4. Enter the measured value into the transmitter (see operating instructions of the

transmitter).

5. After initial installation of the sensor, check the calibration by DPD measurement 24 hours

later.

The following calibration intervals are recommended:

• Drinking, industrial, process and cooling water: depending on the specific conditions

(1 - 4 weeks)

• Swimming pools: weekly

• Whirlpools: daily

!

Note!

Carry out a slope calibration every time the membrane or electrolyte is changed.

Endress+Hauser 17

Page 18

Maintenance CCS120

7 Maintenance

!

Note!

• Service the sensor regularly to avoid incorrect dosing within a control system, due to incorrect

measured value.

• Do not touch the electrodes or allow them to come into contact with greasy substances.

• Never attempt to clean the membrane with acid/alkaline solutions, cleaning reagents or

mechanical aids (brushes or similar).

Maintenance intervals based on experience are:

• Drinking, industrial, process and cooling water: depending on the specific conditions

(1-4 weeks)

• Swimming pools: weekly

• Whirlpools: daily

Perform the following maintenance work:

• Check the sensor for dirt, algae and air bubbles. If neccessary clean the sensor with clear water

and a soft tissue. Eliminate air bubbles by increasing the flow rate.

• Check the displayed sensor value on the transmitter according to the DPD 1 / DPD 3 method.

Use a photometer (e.g. CCM182 , see accessories).

• If necessary, recalibrate the sensor.

• If calibration cannot be carried out properly, replace the membrane cap and repeat the

calibration.

18 Endress+Hauser

Page 19

CCS120 Accessories

8 Accessories

8.1 Connection accessories

Junction box VBM

• For cable extension, with 10 terminals

• IP 65 / NEMA 4X

• Material: aluminum

• Order numbers:

– cable entry Pg 13.5: 50003987

– cable entry NPT ½": 51500177

• Measuring cable CCS120-1M, cable length: 1 m (3.28 ft), for compact chlorine system CCE1

order no. 51517204

• Special measuring cable CPK9-N*A1B internal PM wire

For sensors with TOP68 plug-in head, for high-temperature and high-pressure applications,

IP 68

Ordering acc. to product structure, see Technical Information (TI118C/07/en)

8.2 Installation accessories

• Flow assembly CCA250

for chlorine, chlorine dioxide, pH and redox;

Ordering acc. to product structure, see Technical Information (TI062C/07/en)

• Immersion assembly Dipfit W CYA611-0B

for sensor immersion in basins, open channels and tanks, PVC;

Ordering acc. to product structure (Technical Information TI166C/07/en)

• Compact chlorine system CCE1

Factory-assembled and wired panel for transmitter with flow assembly CCA250-A1; see also

Technical Information TI014C/07/en

8.3 Transmitter

• Liquisys M CCM223/253

Transmitter for chlorine, field or panel-mounted housing,

Hart® or PROFIBUS available,

Ordering acc. to product structure, see Technical Information (TI214C/07/en)

Endress+Hauser 19

Page 20

Troubleshooting CCS120

8.4 Maintenance/calibration

• Photometer CCM182; microprocessor-controlled photometer for chlorine, pH value,

cyanuric acid;

Chlorine measuring range: 0.05 to 6 mg/l

pH measuring range: 6.5 to 8.4

• Electrolyte for CCS120, 50 ml

order no. 51516343

• Service kit for CCS120, consists of 2 membrane caps and 1 bottle of electrolyte (50 ml)

order no. 51517284

9 Troubleshooting

9.1 Troubleshooting instructions

Troubleshooting must take account of the whole measuring system. The measuring system

consists of:

•Transmitter

• Electrical leads and connectors

•Assembly

•Sensor

The possible causes of failure listed in the following table primarily refer to the total chlorine

sensor. Before commencing troubleshooting, please ensure that the following operating

conditions in "Technical data" are met:

• Chlorine content lies within the corresponding measurement range of the sensor

(0.1 ... 10 mg/l)

• Constant pH in the range 5.5 - 9.5

• Constant temperature in the range 4 ... 45 °C (39 ... 113 °F)

• Conductivity: 0.03 ... 40 mS/cm

• Flow: 30 ... 100 l/h (7.92 ... 26.40 US.gal./h)

If the value measured by the sensor differs significantly from that of the DPD method you need

to first consider all possible malfunctions of the DPD photometric method (see operating

instructions of the photometer). If necessary, repeat the DPD measurement several times.

20 Endress+Hauser

Page 21

CCS120 Troubleshooting

Fault Possible cause Action

Sensor cannot be calibrated.

Measured value higher than

DPD measurement

Sensor cannot be calibrated.

Measured value lower than DPD

measurement

Polarisation time not finished Wait until polarisation time is finished

Membrane cap is damaged Replace membrane cap; wait until

polarisation time is finished, calibrate

Interfering substances in medium Examine medium for interfering substances

and remedy

Short circuit in signal cable Locate and eliminate short circuit

Distance between electrode and

Screw the membrane until the limit

membrane is too large

DPD chemicals are outdated Use new DPD chemicals, repeat calibration

pH value < pH 5.5 Raise pH value (pH 5.5 ... 9.5)

Polarisation time not finished Wait until polarisation time is finished

Deposits on membrane cap Replace membrane cap; wait until

polarisation time is finished, calibrate

Flow rate too low Correct flow rate

Air bubbles on the outside of the

membrane

Interfering substances in medium

Increase the flow rate within the permitted

range

Contact sales center

(surfactants, oil, alcohols, corrosion

inhibitors)

Measured value of sensor is

0mg/l

Value substantially exceeds measuring

range

Deposits (carbonate, manganese, iron

oxide) have blocked membrane

Replace membrane cap; wait until

polarisation time is finished, calibrate

Replace membrane cap; wait until

polarisation time is finished, calibrate

pH value > pH 9.5 Lower pH value (pH 5.5 ... 9.5)

No electrolyte in membrane cap Refill membrane cap with electrolyte

Polarisation time not finished Wait until polarisation time is finished

Interfering substances which consume

chlorine

Examine medium for interfering substances

and remedy

Zero point has shifted Perform zero point calibration

Reference electrode defective Return sensor to sales center for

regeneration

Endress+Hauser 21

Page 22

Troubleshooting CCS120

Fault Possible cause Action

Measured value of sensor is

arbitrary and sensor current

>5µA

Measured value of sensor is not

stable

Chlorine concentration exceeds the

upper limit of measuring range

Distance between electrode and

membrane is too large

Sensor defective Return sensor to the sales center

Pressure fluctuation in sampling line

Reference electrode defective Return sensor to the sales center

Check the whole system, remedy fault and

calibrate sensor

Screw the membrane until the limit

Check installation position and change the

process if necessary

9.2 Return

If the sensor has to be repaired, please return it cleaned to the sales centre responsible.

Please use the original packaging, if possible.

Please enclose the completed "Declaration of Hazardous Material and De-Contamination" (copy

the second last page of these Operating Instructions) with the packaging and the transportation

documents.

No repair without completed declaration!

9.3 Disposal

The device contains electronic components and must therefore be disposed of in accordance

with regulations on the disposal of electronic waste.

Please observe local regulations.

22 Endress+Hauser

Page 23

CCS120 Technical data

10 Technical data

10.1 Input

Measured variable Total chlorine Free chlorine (Cl2 (dissolved), HOCl, OCl-)

Bound chlorine (chloramines)

Organic-bound chlorine (e.g. cyanuric acid derivates)

Applications Drinking, industrial, process, cooling water, fresh water and sea water for swimming

pool and whirlpool treatment

Measuring range 0.1 ... 10 mg/l

Slope 110 ... 120 nA/(mg/l)

10.2 Output

Output signal 0 ... 5 µA for the connection to the transmitter Liquisys M CCM223/253

10.3 Performance characteristics

Response time T

Resolution 0.01 mg/l

pH range 5.5 ... 9.5

Conductivity range 0.03 ... 40 mS/cm

Temperature range 5 ... 45 °C (41 ... 113 °F), no quick changes in temperature allowed

Pressure Medium in the CCA250 assembly: max. 1 bar (14.5 psi)

Flow optimum: 40 ... 60 l/h (10.56 ... 15.84 US.gal/h)

Medium velocity optimum: 20 ... 30 cm/s (0.7 ... 1.0 ft/s)

Cross sensitivity Oxidising reagents e.g. bromine, iodine, ozone, chlorine dioxide, permanganates

approx. 60 s (as concentration rises and falls)

90

pH dependency: jump from pH 7 to pH 8: approx. -10 % for free chlorine

minimum: 30 l/h (7.92 US.gal/h)

maximum: 100 l/h (26.40 US.gal/h)

minimum: 15 cm/s (0.5 ft/s)

maximum: 50 cm/s (1.6 ft/s)

result in false positive results.

Reducing reagents like sulphides, sulphites, tiosulphates, and hydrazine result in false

negative results.

Service life of membrane cap Typically 3 - 6 months, depending on water quality

Endress+Hauser 23

Page 24

Technical data CCS120

10.4 Power supply

Power supply 15 V DC, 10 mA

10.5 Environment

Storage temperature Filled with electrolyte: 5 ... 50 °C (41 ... 122 °F)

Without electrolyte: -20 ... +60 °C (-4 ... +140 °F)

Ingress protection IP 65

10.6 Mechanical construction

Design, dimensions see chapter "Installation"

Weight approx. 0.14 kg (0.3 lb)

Materials

(in contact with medium)

Cable length max. 15 m (49.22 ft)

Temperature compensation NTC temperature sensor 10 k

Sensor shaft

Membrane cap

PVC

PPE

Ω at 25 °C (77 °F)

24 Endress+Hauser

Page 25

CCS120

Index

A

Accessories

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Compact chlorine system . . . . . . . . . . . . . . . . 19

Connection accessories. . . . . . . . . . . . . . . . . . 19

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . 20

Photometer . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . 19

C

Cable length. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Checking

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . 4, 16

Connection

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Direct connection. . . . . . . . . . . . . . . . . . . . . . 11

Via junction box . . . . . . . . . . . . . . . . . . . . . . . 12

D

Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

E

Electrical connection . . . . . . . . . . . . . . . . . . . . . 11

Electrolyte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

F

Flow mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

I

Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 4, 6–7

Measuring system. . . . . . . . . . . . . . . . . . . . . . . 9

Installation instructions. . . . . . . . . . . . . . . . . . . . . 8

M

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Measured value. . . . . . . . . . . . . . . . . . . . . . . . . . 23

Measuring principle. . . . . . . . . . . . . . . . . . . . . . . 13

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . 23

Measuring system . . . . . . . . . . . . . . . . . . . . . . . 8–9

O

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4, 13

Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . 5

P

Polarisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Polarisation time . . . . . . . . . . . . . . . . . . . . . . . . . 23

Product structure . . . . . . . . . . . . . . . . . . . . . . . . . 6

R

Response time . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 22

S

Safety icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sensor

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Slope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

T

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Temperature compensation . . . . . . . . . . . . . . . . . 24

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting instructions . . . . . . . . . . . . . . . . 20

U

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

W

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Endress+Hauser

Page 26

CCS120

26

Page 27

Declaration of contamination

Dear customer,

Because of legal determinations and for the safety of our employees and operating equipment, we need this

"Declaration of contamination" with your signature before your order can be handled. Please, include the

completely filled in declaration with the device and the shipping documents in any case. Add also safety

sheets and / or specific handling instructions if necessary.

Type of device /sensor: Serial no.:

Medium / concentration: Temperature: Pressure:

Cleaned with: Conductivity: Viscosity:

Warning hints for medium used (mark up the appropriate hints)

SAFE

radioactive explosive caustic poisonous harmful to

health

Reason for return:

Company data

Company: Contact person:

Department:

Address: Phone:

Fax / e-mail:

Your order no.:

biologically

hazardous

inflammable safe

I hereby certify that the returned equipment has been cleaned and decontaminated acc. to good industrial

practices and is in compliance with all regulations. This equipment poses no health or safety risks due to

contamination.

(Place, date) (Company stamp and legally binding signature)

More information about services and repairs:

www.services.endress.com

Page 28

BA388C/07/en/07.06

Printed in Germany / FM+SGML 6.0 /

DT

www.endress.com/worldwide

51517372

Loading...

Loading...