Page 1

Operating Instructions

Flowfit W CCA250

Flow assembly for chlorine sensors

BA062C/07/en/07.09

71099066

Page 2

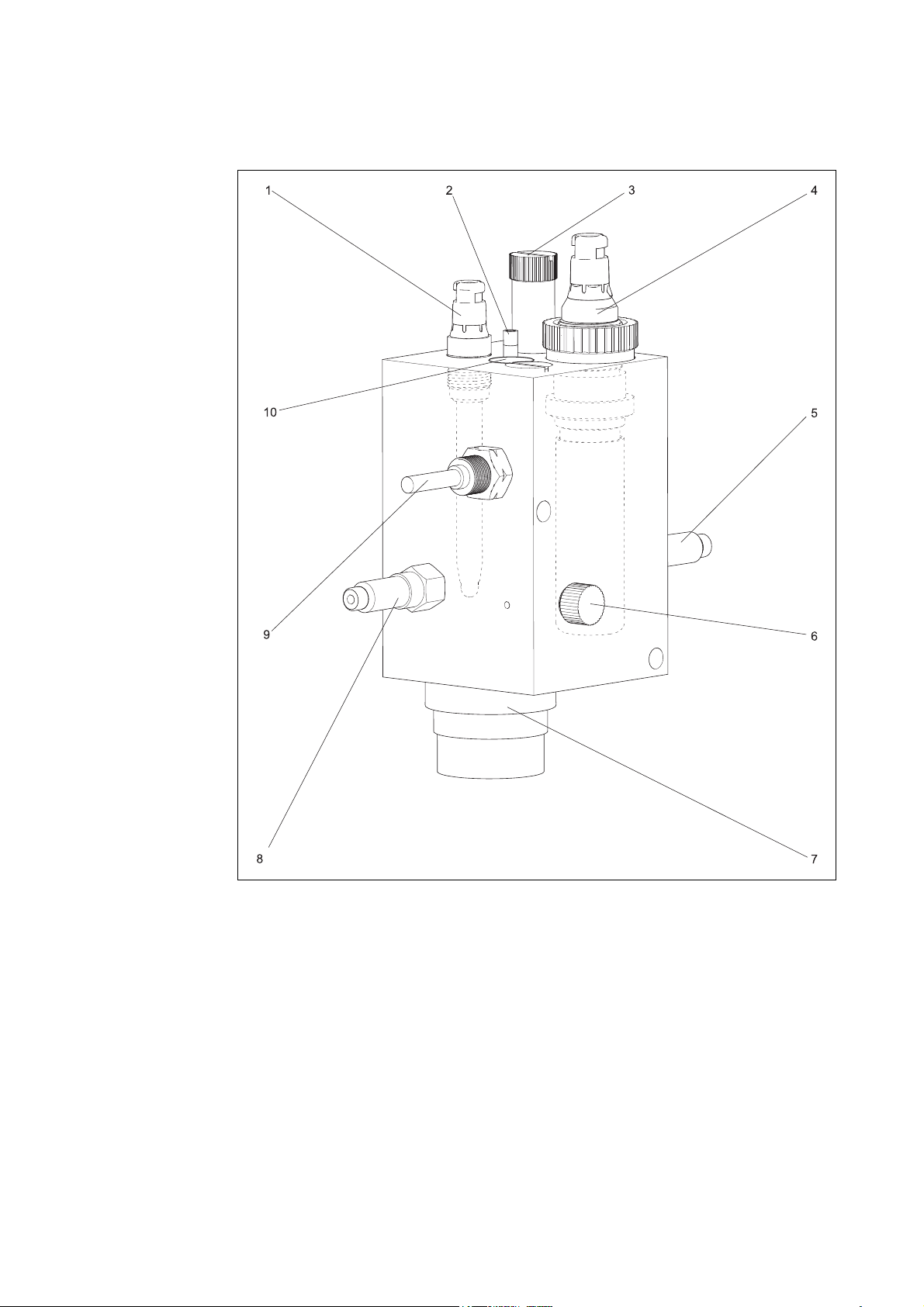

Brief overview

Fig. 1: CCA250 with sensors

1 pH sensor (accessories, not in scope of delivery)

2PML connection

3Vent screw

4 Chlorine sensor (accessories, not in scope of delivery)

5 Outlet (adapter depending on version)

6 Needle valve for flow <120 l/h (32 gal/h)

7 Locking cap with calibration vessel

8 Inlet (adapter depending on version)

9 Inductive limit switch for flow measurement (optional)

10 Installation position for a second pH/ORP sensor

a0007322

Page 3

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . . . . . . . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Notes on safety icons and symbols . . . . . . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . 6

2.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product structure . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Incoming acceptance, transport, storage . . . . . . . . . . 7

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 10

4 Commissioning. . . . . . . . . . . . . . . . . . 10

5 Maintenance. . . . . . . . . . . . . . . . . . . . 11

5.1 Cleaning the assembly . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Cleaning the sensor . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 Cleaning agents . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Accessories. . . . . . . . . . . . . . . . . . . . . 13

6.1 Accessories kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Trouble-shooting . . . . . . . . . . . . . . . . 15

7.1 Replacing damaged parts . . . . . . . . . . . . . . . . . . . . 15

7.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Technical data . . . . . . . . . . . . . . . . . . 16

8.1 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.2 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.3 Mechanical construction . . . . . . . . . . . . . . . . . . . . 17

Index . . . . . . . . . . . . . . . . . . . . . . . . . 18

3

Page 4

Safety instructions

1 Safety instructions

1.1 Designated use

The flow assembly has been designed for the installation of the membrane covered chlorine sensors

CCS120, CCS140, CCS141, CCS240, CCS241 and CCS142D. Additionally, there are two more

installation positions for the installation of sensors with Pg 13.5 and installation length 120 mm

(4.72 inch), e.g. pH resp. ORP sensors.

Its mechanical design permits its use in pressurised systems (see "Technical data").

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Installation, commissioning and operation

Please note the following items:

• Installation, commissioning, operation and maintenance of the measuring system must only be

carried out by trained technical personnel.

Trained personnel must be authorized for the specified activities by the system operator.

• Electrical connection must only be carried out by a certified electrician.

• Technical personnel must have read and understood these Operating Instructions and must

adhere to them.

• Before commissioning the entire measuring point, check all the connections. Ensure that

electrical cables and hose connections are not damaged.

• Do not operate damaged products and secure them against unintentional commissioning.

Mark the damaged product as being defective.

• Measuring point faults may only be rectified by authorized and specially trained personnel.

• If faults can not be rectified, the products must be taken out of service and secured against

unintentional commissioning.

• Repairs not described in these Operating Instructions may only be carried out at the

manufacturer’s or by the service organization.

1.3 Operational safety

The assembly has been designed and tested in accordance with the latest industry standards and left

the factory in perfect functioning order.

Relevant regulations and standards have been met.

As the user, you are responsible for complying with the following safety conditions:

• Installation instructions

• Local prevailing standards and regulations.

1.4 Return

If the assembly has to be repaired, please return it cleaned to the appropriate sales center.

Please use the original packaging, if possible.

Please enclose the completed "Declaration of contamination" (copy the second to last page of these

Operating Instructions) with the packaging and the transportation documents.

No repair without completed "Declaration of contamination"!

4

Page 5

#

"

!

Safety instructions

1.5 Notes on safety icons and symbols

Warning!

This symbol alerts you to hazards that can cause serious damage to the instrument or to persons if

ignored.

Caution!

This symbol alerts you to possible faults which could arise from incorrect operation. They could

cause damage to the instrument if ignored.

Note!

This symbol indicates important items of information.

5

Page 6

Identification

2 Identification

2.1 Nameplate

You can read the following information from the nameplate on the assembly:

•Product name

•Order code

• Serial number or week code

• Permissible process pressure and maximum process temperature

You can find possible assembly versions and the resulting order codes in the product structure.

2.2 Product structure

Process connection, adapter

A G1/2, none

B G1/2, 2x NV 1/2"

C G1/2, 2x D 6/12

D G1/2, D 6/12 + D 16

M NPT 1/2", none

Q NPT 1/4", none

Proximity switch

0none

1 with inductive proximity switch

CCA250- complete order code

2.3 Scope of delivery

The scope of delivery comprises:

• Flowfit assembly (ordered version)

• a PML adapter

• Operating Instructions (English)

If you have any questions, please contact your supplier or your local sales center.

6

Page 7

Installation

3 Installation

3.1 Incoming acceptance, transport, storage

• Make sure the packaging is undamaged!

Inform the supplier about any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

• Make sure the contents are undamaged!

Inform the supplier about damage to the contents. Keep the damaged products until the matter

has been settled.

• Check that the order is complete and agrees with your shipping documents.

• The packaging material used to store or to transport the product must provide shock protection

and humidity protection. The original packaging offers the best protection. Also, keep to the

approved ambient conditions (see "Technical data").

• If you have any questions, please contact your supplier or your local sales center.

3.2 Installation conditions

3.2.1 Dimensions

Fig. 2: Dimensions

a depending on version: G1/2, NPT 1/2" or NPT 1/4"

a0007328

7

Page 8

Installation

3.2.2 Notes on installation

Parts description used at ...

two shut-off valves bypass version

one shut-off valve version with open outlet

aperture in the main conduit bypass version

particle filter (500 μm or finer) if the process water contains large dirt particles

pressure-relief valve if the process water pressure is above the maximum

value (see chapter " technical data")

3.3 Installation instructions

3.3.1 Measuring system

A complete measuring system comprises:

• Flowfit CCA250

• Chlorine sensor, e.g. CCS142D

• Measuring cable, e.g. CYK10

• Transmitter, e.g. Liquiline M

Optional:

• up to two pH sensors, e.g. Orbisint CPS11D

• Junction box for cable extension, e.g. RM junction box

a0007341

Fig. 3: Measuring system

1 Transmitter Liquiline M CM44 with weather protection cover

2 Supply line of the transmitter

3 Chlorine sensor CCS142D

4 Flowfit CCA250

5 Assembly inlet (outlet at backside, not to be seen in figure)

6pH-Sensor

7 Measuring cable CYK10

8

Page 9

Installation

12

3

4

3.3.2 Installing the assembly into the process

To get a flow through the bypass, pressure p1 has to be higher than pressure p2. Therefore, you

have to install an aperture in the main conduit (→ å 4, pos. 5).

a0007337

Fig. 4: Installation example with bypass and aperture in the main conduit

1 Stop valve (to be provided by customer)

2 Dirt trap (filter), d = 500 μm (to be provided by customer). Installation of dirt trap is mandatory!

3 Pressure reducer (with p > 4 bar (58 psi))

4 Stop valve (to be provided by customer)

5 Aperture in the main conduit

!

In case of an open outlet installation, no pressure increasing procedure is needed (→ å 5).

a0007338

Fig. 5: Installation example with open outlet

Legend → å 4

Note!

• The flow assembly must be installed upright.

• Connect the process water with commercial fittings. You can use the normal sealing (e.g. teflon

tape) or an O-ring (e.g. EPDM).

• Installation in the by-pass is preferable to installation in the process pipe as the by-pass pipe can

be blocked off without process interruption (you have to install shut-off valves upstream and

downstream from the flow assembly). This permits maintenance of the sensors without

interrupting the process.

• A stop valve and a dirt trap (e.g.,a strainer) with a mesh size of 500 μm must be located upstream

from the flow assembly. Pressure reducers usually contain a dirt trap, i.e. an additional dirt trap

is not required when a pressure reducer is installed.

9

Page 10

Commissioning

"

!

• For the version with an open outlet, you have to install a shut-off valve upstream.

• Install a DN 5-8 sampling cock downstream from the flow assembly to permit reference

measurements according to the DPD method.

Caution!

• The medium pressure must not exceed the maximum permissible pressure of the flow assembly

or of the sensors.

• If the medium pressure exceeds 4 bar (58 psi), you have to install a pressure-relief valve.

3.3.3 Sensor installation

1. Installation of proximity switch: Screw in all the way and lock with hex nut.

2. Loosen and remove the clamping screw.

3. Insert the chlorine sensor in the mounting position and firmly tighten with the clamping screw.

4. Remove the two dummy plugs, place the pH/ORP sensors in the openings with the Pg13.5

threads and screw in.

5. Connect the sensors via the corresponding measuring cable to the transmitter.

Note!

Vent the assembly by unscrewing and screwing the vent screw at the time of the first

commissioning.

#

3.4 Post-installation check

• After installation, check that all connections are firmly in position and leak-tight.

• Check all hoses for damage.

4 Commissioning

Before the first commissioning, make sure of the following items:

• all seals are correctly seated (on the assembly and process connection)

• the sensor is correctly installed and connected

Warning!

Danger of squirting medium.

Before applying the process pressure to the assembly, make sure the connections are correctly fitted.

10

Page 11

5 Maintenance

Maintenance

#

!

!

Warning!

Risk of injury!

Before starting maintenance work on the assembly, make sure that the process line is depressurised,

empty and rinsed.

5.1 Cleaning the assembly

To ensure a reliable measurement, the assembly and the sensor must be cleaned at regular intervals.

The frequency and intensity of the cleaning operation depend on the process medium.

All parts in contact with the medium, e.g. the sensor and the sensor holder, must be cleaned at

regular intervals. Remove the sensor

• Remove light dirt using suitable cleaning agents (see chapter "Cleaning agents").

• Remove severe fouling with a soft brush and a suitable cleaning agent.

• Remove persistant fouling by soaking in a liquid cleaner and if neccessary by cleaning with a soft

brush.

Note!

A typical cleaning interval for e.g. drinking water is at least half a year.

1)

.

5.2 Cleaning the sensor

You have to clean the sensor:

• before every calibration

• regularly during operation

• before being returned for repair

• depending on the local conditions, at least twice a year

Note!

• Clean the sensor outside only. Do not open it!

• Do not use any abrasive cleaning agents. This can lead to irreparable damage of the sensor.

• After cleaning the sensor, rinse the rinse chamber of the assembly with copious amounts of water.

Otherwise, remaining residues of cleaning agent can corrupt measurement.

• If required, re-calibrate after cleaning.

5.3 Cleaning agents

The selection of the cleaning agent is dependent on the degree and type of contamination. The most

common contaminations and the suitable cleaning agents are listed in the following table.

Type of contamination Cleaning agent

Greases and oils Substances containing tensides (alkaline) or water-soluble organic

Calciferous deposits, metal hydroxide deposits,

lyophobic biological deposits

Sulphide deposits Mixture of 3% hydrochloric acid and thiocarbamide (commercially

Protein deposits Mixture of 3% hydrochloric acid and pepsin (commercially

Fibres, suspended substances Water under pressure, poss. with surface-active agents

Light biological deposits Water under pressure

1) in reverse sequence of operations to the installation procedure

solvents (e.g. Ethanol)

approx. 3% hydrochloric acid

available)

available)

11

Page 12

Maintenance

Caution!

"

Do not use organic solvents containing halogen or acetone. These solvents could destroy plastic

components on the assembly or the sensor and it is also partly suspected that they cause cancer (e. g.

Chloroform).

12

Page 13

6 Accessories

Accessories

!

Note!

In the following sections, you find the accessories available at the time of issue of this

documentation.

For information on accessories that are not listed here, please contact your local service.

6.1 Accessories kits

For G1/2 process connection versions only!

NV 1/2

• 2 PVC nipples for connection to PVC pipework

• for pipes with OD 16 mm (0.63 inch)

• order no. 50003228

SV 1/2

• 2 PVC nipples

• different adaptersfor hose connection

– with Ø 6/12 mm (0.24/0.47 inch) inlet and Ø 16 mm (0.63 inch) outlet

– order no. 50003232

• identical adapters

– for hose connection with Ø 6/12 mm (0.24/0.47 inch) inlet and outlet

– order no. 50003230

6.2 Sensors

CCS120

• Membrane covered amperometric sensor for total chlorine

• Measuring range 0.1 to 10 mg/l

• Ordering acc. to product structure, see Technical Information (TI388C/07/en)

CCS140

• Membrane covered amperometric sensor for free chlorine

• Measuring range 0.05 to 20 mg/l

• Ordering acc. to product structure, see Technical Information (TI058C/07/en)

CCS141

• Membrane covered amperometric trace sensor for free chlorine

• Measuring range 0.01 to 5 mg/l

• Ordering acc. to product structure, see Technical Information (TI058C/07/en)

CCS142D

• Membrane covered amperometric sensor for free chlorine

• Memosens technology

• Measuring range 0.01 to 20 mg/l

• Ordering acc. to product structure, see Technical Information (TI419C/07/en)

CCS240

• Membrane covered amperometric sensor for chlorine dioxide

• Measuring range 0.05 to 20 mg/l

• Ordering acc. to product structure, see Technical Information (TI114C/07/en)

CCS241

• Membrane covered amperometric trace sensor for chlorine dioxide

• Measuring range 0.01 to 5 mg/l

• Ordering acc. to product structure, see Technical Information (TI114C/07/en)

Orbisint CPS11/11D

• pH electrode for process applications with dirt-repellent PTFE diaphragm

• Optional Memosens technology (CPS11D)

• Ordering acc. to product structure, see Technical Information (TI028C/07/en)

13

Page 14

Accessories

Ceragel CPS71/CPS71D

• pH electrode with double junction reference system and integrated bridge electrolyte

• Optional with Memosens technology (CPS71D)

• Ordering acc. to product structure, see Technical Information (TI245C/07/en)

Ceragel CPS72/CPS72D

• Redox sensor with double junction reference system and integrated bridge electrolyte

• Optional with Memosens technology (CPS72D)

• Ordering acc. to product structure, see Technical Information (TI374C/07/de)

14

Page 15

7 Trouble-shooting

7.1 Replacing damaged parts

Trouble-shooting

#

Warning!

Damage to the assembly which affects the pressure safety must only be repaired by authorized

technical personnel.

After every repair and maintenance activity, suitable measures must be taken to test whether the

assembly shows any signs of leaking. The assembly must then correspond to the specifications stated

in the technical data.

Replace all other damaged components immediately. To order accessories and spare parts, please

use the "Accessories" and "Spare parts" chapters or contact your local sales center.

7.2 Return

If the assembly has to be repaired, please return it cleaned to the appropriate sales center.

Please use the original packaging, if possible.

Please enclose the completed "Declaration of contamination" (copy the second to last page of these

Operating Instructions) with the packaging and the transportation documents.

No repair without completed "Declaration of contamination"!

7.3 Disposal

Please dispose of the device in accordance with the local regulations.

15

Page 16

Technical data

8 Technical data

8.1 Environment

Ambient temperature

range

Storage temperature 0 to 50 °C (32 to 120 °F)

0 to 50 °C (32 to 120 °F)

8.2 Process

Process temperature 0 to 45 °C (32 to 110 °F), non-freezing

Process pressure max. medium pressure: 4 bar (58 psi) at 40 °C (104 °F)

Temperature-pressurediagram

Fig. 6: Temperature-Pressure diagram

Flow optimum 30 l/h (7.9 gal/h)

30 to 120 l/h (7.9 to 31.7 gal/h), adjustable

16

a0007413

Page 17

8.3 Mechanical construction

Design, dimensions see chapter "Installation"

Weight 0.5 to 0.8 kg (1.1 to 1.8 lbs), depending on process connection

Material In contact with medium:

• Assembly body: PMMA

• Mounting parts: PVC, stainless steel 1.4571 (AISI 316 Ti), EPDM

Process connection G1/2, NPT 1/2" or NPT 1/4"

Technical data

17

Page 18

Index

A

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assembly

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

C

Checking

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning

Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

D

Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

E

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

I

Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4, 7–8

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sensor

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

T

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

U

Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

M

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Measuring system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mechanical construction. . . . . . . . . . . . . . . . . . . . . . . . . . 17

N

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

O

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operational safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

P

Parts

Replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Product structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

R

Replacing

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4, 15

S

Safety icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

18

Page 19

P/SF/Konta XIV

Because of legal regulations and for the safety of our employees and operating equipment, we need the "Declaration of Hazardous Material

and De-Contamination", with your signature, before your order can be handled. Please make absolutely sure to attach it to the outside of the

packaging.

Aufgrund der gesetzlichen Vorschriften und zum Schutz unserer Mitarbeiter und Betriebseinrichtungen, benötigen wir die unterschriebene

"Erklärung zur Kontamination und Reinigung", bevor Ihr Auftrag bearbeitet werden kann. Bringen Sie diese unbedingt außen an der

Verpackung an.

Serial number

Seriennummer ________________________

Type of instrument / sensor

Geräte-/Sensortyp ____________________________________________

Process data/Prozessdaten

Temperature _____ [°F] [°C]

Conductivity / ________

_____

Leitfähigkeit

/

[µS/cm]

Temperatur

Pressure _____ [psi] [ Pa ]

Viscosity _____ [cp] [mm /s]

_____

_____

//Druck

Viskosität

2

corrosive

ätzend

harmless

unbedenklich

other *

sonstiges*

toxic

giftig

Process

medium

Identification

CAS No.

flammable

entzündlich

harmful/

irritant

gesundheits-

schädlich/

reizend

Medium /concentration

Medium /Konzentration

Returned part

cleaned with

Medium for

process cleaning

Medium and warnings

Warnhinweise zum Medium

* explosive; oxidising; dangerous for the environment; biological risk; radioactive

* explosiv; brandfördernd; umweltgefährlich; biogefährlich; radioaktiv

Please tick should one of the above be applicable, include safety data sheet and, if necessary, special handling instructions.

Zutreffendes ankreuzen; trifft einer der Warnhinweise zu, Sicherheitsdatenblatt und ggf. spezielle Handhabungsvorschriften beilegen.

Description of failure / Fehlerbeschreibung __________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

“We hereby certify that this declaration is filled out truthfully and completely to the best of our knowledge.We further certify that the returned

parts have been carefully cleaned. To the best of our knowledge they are free of any residues in dangerous quantities.”

“Wir bestätigen

w

bestätigen, die vorliegende Erklärung nach unserem besten Wissen wahrheitsgetreu und vollständig ausgefüllt zu haben. Wir

eiter, dass die zurückgesandten Teile sorgfältig gereinigt wurden und nach unserem besten Wissen frei von Rückständen in gefahrbringen-

der Menge sind.”

(

place, date / Ort, Datum)

Company data /Angaben zum Absender

Company / ________________________________

_________________________________________________

Address /

_________________________________________________

_________________________________________________

Firma ___

Adresse

Phone number of contact person /

____________________________________________

Fax / E-Mail ____________________________________________

Your order No. / ____________________________

Telefon-Nr. Ansprechpartner:

Ihre Auftragsnr.

Medium zur

Endreinigung

Medium zur

Prozessreinigung

Medium im

Prozess

Used as SIL device in a Safety Instrumented System / Einsatz als SIL Gerät in Schutzeinrichtungen

RA No.

Erklärung zur Kontamination und Reinigung

Declaration of Hazardous Material and De-Contamination

Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA#

clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

Bitte geben Sie die von E+H mitgeteilte Rücklieferungsnummer (RA#) auf allen Lieferpapieren an und vermerken Sie diese

auch außen auf der Verpackung. Nichtbeachtung dieser Anweisung führt zur Ablehnung ihrer Lieferung.

Name, dept./Abt.

(please print / )bitte Druckschrift

Signature / Unterschrift

Page 20

www.endress.com/worldwide

BA062C/07/en/07.09

71099066

FM+SGML 6.0

Loading...

Loading...