Page 1

BA01785C/07/EN/01.17

71371624

Products Solutions Services

Operating Instructions

Flowfit CCA151

Flow assembly for disinfections sensors CCS5xD

Page 2

Page 3

Flowfit CCA151 Table of contents

Table of contents

1 Document information ......... 4

1.1 Warnings ........................... 4

1.2 Symbols used ........................ 4

2 Basic safety instructions ....... 6

2.1 Requirements for the personnel ........ 6

2.2 Designated use ...................... 6

2.3 Occupational safety .................. 6

2.4 Operational safety ................... 7

2.5 Product safety ....................... 7

3 Product description ............. 8

3.1 Product design ....................... 8

4 Incoming acceptance and

product identification .......... 9

4.1 Incoming acceptance ................. 9

4.2 Product identification ................ 10

5 Installation .................... 11

5.1 Installation conditions ............... 11

5.2 Mounting the assembly .............. 14

5.3 Installing sensor in assembly ......... 19

5.4 Post-installation check ............... 22

6 Commissioning ................ 22

7 Maintenance .................. 23

7.1 Maintenance schedule ............... 23

7.2 Maintenance tasks .................. 24

8 Repairs ......................... 27

8.1 Spare parts ........................ 27

8.2 Return ............................ 27

8.3 Disposal ........................... 27

9 Accessories .................... 28

9.1 Device-specific accessories ............28

10 Technical data ................. 28

Index ................................. 31

Endress+Hauser 3

Page 4

Document information Flowfit CCA151

1 Document information

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

4 Endress+Hauser

Page 5

Flowfit CCA151 Document information

1.2.1 Symbols on the device

Symbol Meaning

Reference to device documentation

Endress+Hauser 5

Page 6

Basic safety instructions Flowfit CCA151

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the specified

activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions and

must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The flow assembly has been specially developed to hold the membrane-covered disinfection

sensors CCS5xD.

Thanks to its design, it can be used in pressurized systems → 28.

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

6 Endress+Hauser

Page 7

Flowfit CCA151 Basic safety instructions

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

Endress+Hauser 7

Page 8

Product description Flowfit CCA151

4

1

2

5

3

6

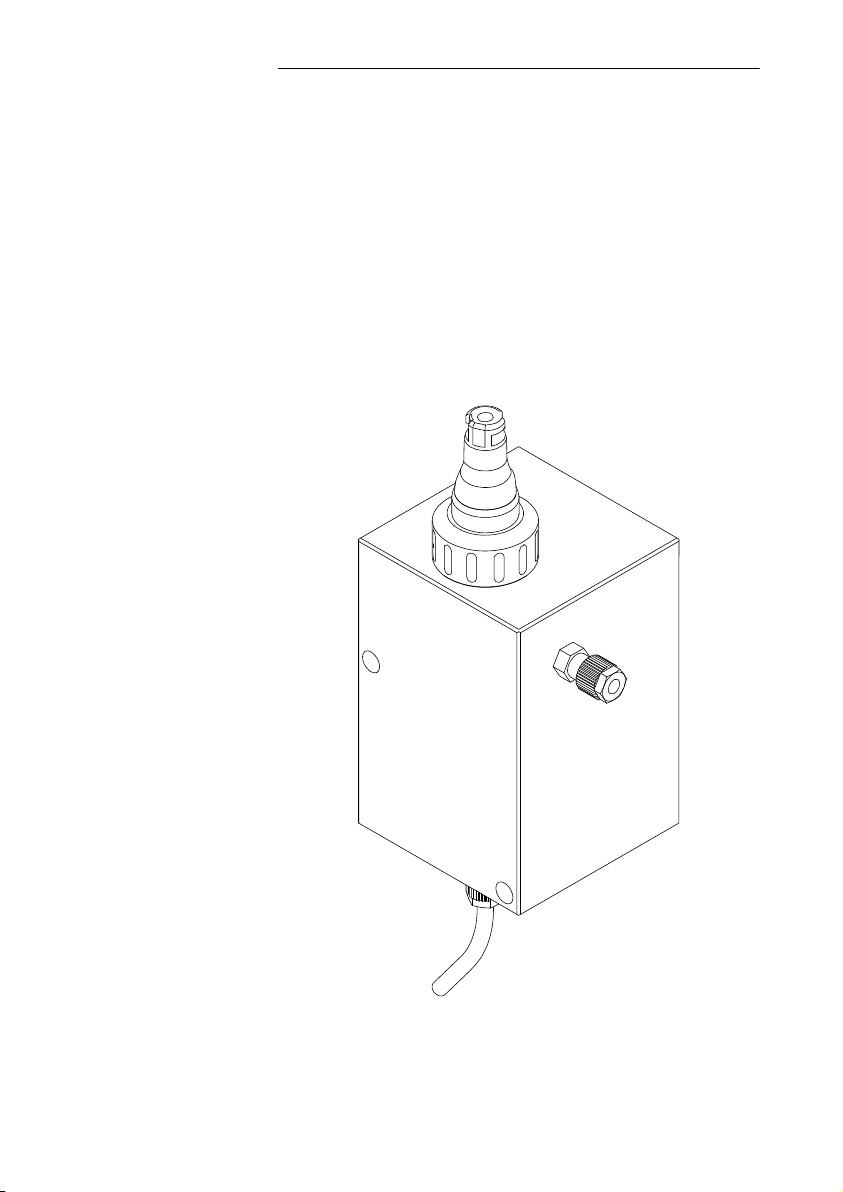

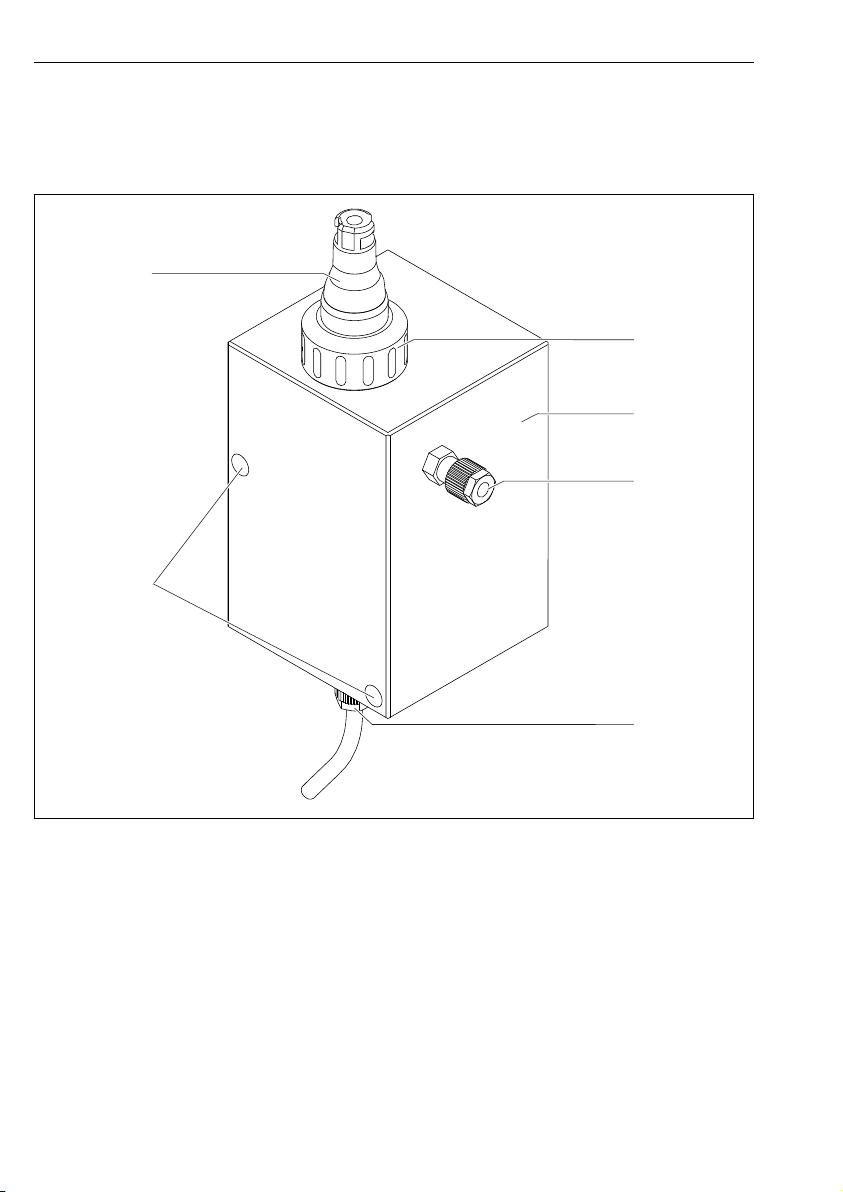

3 Product description

3.1 Product design

1 Disinfection sensor CCS5xD (membrane-covered, ⌀25 mm), e.g. CCS50D

2 Coupling nut (for securing a disinfection sensor)

3 Flowfit CCA151 flow assembly

4 Outlet from Flowfit CCA151 flow assembly (internal thread G 1/8") and hose connection

5 Inlet to Flowfit CCA151 flow assembly (internal thread G 1/8")

6 Openings (M5 Allen screw x 60) for securing Flowfit CCA151 flow assembly

8 Endress+Hauser

A0034257

Page 9

Flowfit CCA151 Incoming acceptance and product identification

4 Incoming acceptance and product identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions (→ Technical data).

If you have any questions, please contact your supplier or your local Sales Center.

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Flowfit CCA151

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.2.2 Product identification

Product page

www.endress.com/cca151

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Open the product website.

2. At the bottom of the page, select the link Online Tools and then select Access device

specific information .

An additional window opens.

3. Enter the order code from the nameplate into the search field. Then select Show

details .

Details of each feature (selected option) of the order code are displayed.

Manufacturer address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

Scope of delivery

The scope of delivery comprises:

• Assembly in the version ordered

• Operating Instructions

10 Endress+Hauser

Page 11

Flowfit CCA151 Installation

Certificates and approvals

RL 2014/34/EU (ATEX)

The assembly does not fall within the scope of the directive. However, if conditions for safe

use are adhered to, it may be deployed in the hazardous area.

RL 2014/68/EU PED

The assembly was manufactured in accordance with Article 3, paragraph 3, Pressure

Equipment Directive 97/23/EC in accordance with good engineering practice.

5 Installation

5.1 Installation conditions

5.1.1 Installation position

The assembly is designed for installation on panels, walls or level surfaces. G 1/8" connections

and a hose connection with an external diameter of 6 mm and an internal diameter of 4 mm

are provided for this purpose.

The assembly is designed in such a way that it must be installed vertically.

The sensor that is used can restrict the orientation.

Endress+Hauser 11

Page 12

Installation Flowfit CCA151

110 (4.33)

85 (3.35)

!14.5

(0.57)

7.5 (0.3)

70 (2.76)

70 (2.76)

105 (4.13)

130 (5.12)

150 (5.91)

194.5 (7.66)

M5 60·

M5 60·

150 (5.91)

219.5 (8.64)

! 25

(0.98)

! 14.5

(0.57)

! 39.5

(1.56)

5.1.2 Dimensions

1 Front view

To allow the sensor to be removed and for operation with Memosens data cables, the spacing

required for mounting is 150 mm (5.91 in).

12 Endress+Hauser

A0034258

Page 13

Flowfit CCA151 Installation

150 (5.91)

85 (3.35)

60 (2.36)

2 Side view

To allow the sensor to be removed and for operation with Memosens data cables, the spacing

required for mounting is 150 mm (5.91 in).

Endress+Hauser 13

A0034398

Page 14

Installation Flowfit CCA151

5.2 Mounting the assembly

5.2.1 Measuring system

A complete measuring system comprises:

• Disinfection sensor CCS50D (membrane-covered, ⌀25 mm) with corresponding installation

adapter

• Flowfit CCA151 flow assembly

• Measuring cable CYK10

• Transmitter, e.g. Liquiline CM44x or CM44xR

• Optional: Extension cable CYK11

14 Endress+Hauser

Page 15

Flowfit CCA151 Installation

1

3

6

8

2

7

4

5

A0034241

3 Example of a measuring system

1 Transmitter Liquiline CM44x

2 Power cable for transmitter

3 Disinfection sensor CCS5xD (membrane-covered, ⌀25 mm), e.g. CCS50D

4 Outlet from Flowfit CCA151 flow assembly

5 Inlet to Flowfit CCA151 flow assembly

6 Flowfit CCA151 flow assembly

7 Coupling nut for installing sensor CCS50D in Flowfit CCA151 flow assembly

8 Measuring cable CYK10

5.2.2 Mounting assembly on a vertical surface

To secure the assembly to a wall, use the wall mounting kit which can be ordered as an

‣

accessory→ 28.

For detailed information on mounting the assembly on a wall using the wall mounting

kit, see kit instructions for wall mounting kit

Endress+Hauser 15

Page 16

Installation Flowfit CCA151

5.2.3 Mounting assembly in the process

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process

medium escapes.

Wear protective gloves, protective goggles and protective clothing.

‣

Mount the assembly only if vessels or pipes are empty and unpressurized.

‣

Prior to installation, check the flange seal between the flanges.

1. Mount assembly on vertical surface→ 15.

2. Connect to the vessel or pipe via the process connection.

Bypass operation

To achieve flow through the assembly with a bypass, pressure p1 must be higher than

pressure p2.

This requires the installation of an orifice plate or throttle valve in the main pipe.

p1 must not exceed the permitted operating pressure for the assembly of 4 bar (58 psi).

If the sensor is installed, the sensor's pressure specifications must also be observed.

1. Mount the assembly vertically.

2. Connect the medium using the usual commercial connection fittings. Depending on

requirements, use the usual sealing materials, e.g. PMMA-compatible thread adhesive,

Teflon tape or O-ring made of FKM.

3. Installing the assembly in the bypass is preferable to installing it directly in the process

line. The bypass line can be blocked off without interrupting the process (a shut-off

valve is required upstream and downstream). This allows, for example, the sensor to be

cleaned without restricting the process.

4. Install a dirt trap (filter) with a mesh size of 500 μm upstream from the assembly. If a

pressure-reducing valve is used, it usually includes a dirt trap.

5. Set flow value upstream from the assembly, e. g. by installation of a flow setting.

6. Install a DN5-8 tap downstream from the assembly outlet to allow samples to be taken

for reference measurements in accordance with the DPD method.

16 Endress+Hauser

Page 17

Flowfit CCA151 Installation

1 2 3

4

p1

p2

p1 > p2

A0034259

4 Connection example with bypass and orifice plate in the main pipe

1 Shut-off valve (provided by customer)

2 Pressure-reducing valve (at p1 > 4 bar (58 psi)) (provided by customer)

3 Shut-off valve (provided by customer)

4 Orifice plate in process line (provided by customer)

Open outlet operation

p must not exceed the permitted operating pressure for the assembly of 4 bar (58 psi).

If the sensor is installed, the sensor's pressure specifications must also be observed.

If the medium pressure is above 4 bar (58 psi), a pressure-reducing valve is required.

1. Mount the assembly vertically.

2. Connect the medium using the usual commercial connection fittings. Depending on

requirements, use the usual sealing materials, e.g. PMMA-compatible thread adhesive,

Teflon tape or O-ring made of FKM.

3. Installing the assembly in the bypass is preferable to installing it directly in the process

line. The bypass line can be blocked off without interrupting the process (a shut-off

valve is required upstream and downstream). This allows, for example, the sensor to be

cleaned without restricting the process.

4. Install a dirt trap (filter) with a mesh size of 500 μm upstream from the assembly. If a

pressure-reducing valve is used, it usually includes a dirt trap.

5. Set flow value upstream from the assembly, e. g. by installation of a flow setting.

6. Install a DN5-8 tap downstream from the assembly outlet to allow samples to be taken

for reference measurements in accordance with the DPD method.

Endress+Hauser 17

Page 18

Installation Flowfit CCA151

1

2

3

p

A0034260

5 Connection example with open outlet

1 Shut-off valve (provided by customer)

2 Pressure-reducing valve (at p > 4 bar (58 psi)) (provided by customer)

3 Shut-off valve (provided by customer)

18 Endress+Hauser

Page 19

Flowfit CCA151 Installation

1

5.3 Installing sensor in assembly

The CCS50D disinfection sensor (membrane-covered, ⌀25 mm) is designed for installation in

the Flowfit CCA151 flow assembly.

Please note the following during installation:

The flow rate must be at least 5 l/h (1.32 gal/h).

‣

If the medium is fed back into an overflow basin, pipe or similar, the resulting

‣

counterpressure on the sensor may not exceed 1 bar (14.5 psi) and must remain constant.

Negative pressure at the sensor, e.g. due to medium being returned to the suction side of a

‣

pump, must be avoided.

Preparing assembly

1. The assembly is supplied to the customer with a coupling nut screwed onto the

assembly: unscrew coupling nut from assembly.

A0034262

6 Flowfit CCA151 flow assembly

1 Thread adapter nut

2. The assembly is supplied to the customer with a dummy plug inserted in the assembly:

remove dummy plug from assembly.

Endress+Hauser 19

Page 20

Installation Flowfit CCA151

Removing protection cap from sensor

NOTICE

Negative pressure causes damage to the sensor's membrane cap.

If the protection cap is attached, carefully remove protection cap from sensor.

‣

1. When supplied to the customer and when in storage, the sensor is fitted with a

protection cap: First release just the top part of the protection cap by turning it.

A0034263

7 Releasing top part of protection cap by turning

2. Carefully remove protection cap from sensor.

A0034350

8 Carefully remove protection cap.

20 Endress+Hauser

Page 21

Flowfit CCA151 Installation

Fit the adapter to the sensor.

The required adapter (clamping ring) can be ordered as a sensor accessory or as a separate

accessory.

1. Slide the adapter for CCA151 (clamping ring) from the membrane cap towards the

sensor head and into the lower groove.

A0034247

9 Slide the adapter (clamping ring) upwards from the membrane camp to the senor

shaft and into the lower groove.

Installing sensor in assembly

2. Slide the sensor with adapter for CCA151 (clamping ring) into the opening in the

assembly.

Endress+Hauser 21

Page 22

Commissioning Flowfit CCA151

1

2

3

3. Screw coupling nut onto assembly on block.

A0034261

1 Disinfection sensor CCS50D

2 Flowfit CCA151 flow assembly

3 Coupling nut for securing a CCS50D disinfection sensor

5.4 Post-installation check

1. After mounting, check all connections to ensure they are fully secured and leak-tight.

2. Check all hoses for damage.

6 Commissioning

Prior to commissioning, ensure that:

• all seals are correctly seated (on the assembly and on the process connection)

• the sensor is correctly installed and connected

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process

medium escapes.

Before subjecting the assembly to the process pressure, verify that all connections are

‣

sealed.

22 Endress+Hauser

Page 23

Flowfit CCA151 Maintenance

7 Maintenance

WARNING

L

Risk of injury if medium escapes

Before each maintenance task, ensure that the process pipe is empty and rinsed.

‣

7.1 Maintenance schedule

The specified intervals serve as a guide. For harsh process or ambient conditions, it is

recommended that the interval be shortened accordingly. Cleaning intervals for the

sensor and assembly are dependent on the medium.

Interval Maintenance work

Monthly

Biannually

Verify that process connections are leak-tight.

‣

1. Remove sensor and check for deposits.

2. If deposits are present, check cleaning cycle (cleaning agents,

temperature, duration, flow volume).

Replace seals in contact with medium.

‣

Endress+Hauser 23

Page 24

Maintenance Flowfit CCA151

7.2 Maintenance tasks

To ensure stable and reliable measurements, the assembly and the sensor must be cleaned

regularly. The frequency and intensity of the cleaning process depend on the medium.

7.2.1 Cleaning the assembly

A typical example of a cleaning interval would be 6 months in the case of drinking water.

1. All parts in contact with the medium, such as the sensor and the sensor guide, must be

cleaned regularly. To do so, remove the sensor → 26.

2. Remove light dirt and fouling using a cloth moistened with suitable cleaning solutions.

3. Remove heavy soiling using a soft brush and a suitable cleaning agent.

4. For very persistent dirt, soak the parts in a cleaning solution. Then clean the parts with

a brush.

24 Endress+Hauser

Page 25

Flowfit CCA151 Maintenance

Cleaning agent

The choice of cleaning agent depends on the degree and type of contamination. The most

common types of contamination and the appropriate cleaning agents can be found in the

following table.

Type of soiling Cleaning agent

Greases and oils Hot water or water-soluble organic solvents (e.g.

ethanol)

Limescale deposits, metal

Approx. 3% hydrochloric acid

hydroxide buildup, lyophobic

biological buildup

Sulfide deposits Mixture of 3% hydrochloric acid and thiocarbamide

(commercially available)

Protein buildup Mixture of 3% hydrochloric acid and pepsin

(commercially available)

Fibers, suspended substances Pressurized water, possibly surface-active agents

Light biological buildup Pressurized water

NOTICE

Health hazard due to solvents

Do not use any halogen-containing, organic solvents or acetone. These solvents may

‣

destroy plastic components of the sensor and are also suspected carcinogens (e.g.

chloroform).

NOTICE

Damage to sensor membrane

The sensor membrane must not come into contact with surfactant-containing agents.

‣

7.2.2 Cleaning the sensor

Cleaning the sensor

1. Prior to calibration if dirt is visible on the surface

2. Regularly during operation

3. Before returning it for repairs

For detailed information on "Cleaning the sensor", see Operating Instructions for sensor.

Endress+Hauser 25

Page 26

Maintenance Flowfit CCA151

1

2

3

7.2.3 Removing sensor from assembly

Remove sensor from assembly CCA151

1. Unscrew coupling nut from assembly.

A0034261

1 Disinfection sensor CCS50D

2 Flowfit CCA151 flow assembly

3 Coupling nut for securing a CCS50D disinfection sensor

2. Pull sensor out through opening in assembly.

26 Endress+Hauser

Page 27

Flowfit CCA151 Repairs

8 Repairs

WARNING

L

Danger resulting from improper repair

Damage to the assembly, which compromises pressure safety, must be repaired only by

‣

authorized and qualified personnel.

Following each repair and maintenance task, the assembly must be checked for leaks using

‣

appropriate procedures. Following this, the assembly must again comply with the

specifications in the technical data.

Replace all other damaged components immediately.

8.1 Spare parts

For more detailed information on spare parts kits, please refer to the "Spare Part Finding Tool"

on the Internet:

www.endress.com/spareparts_consumables

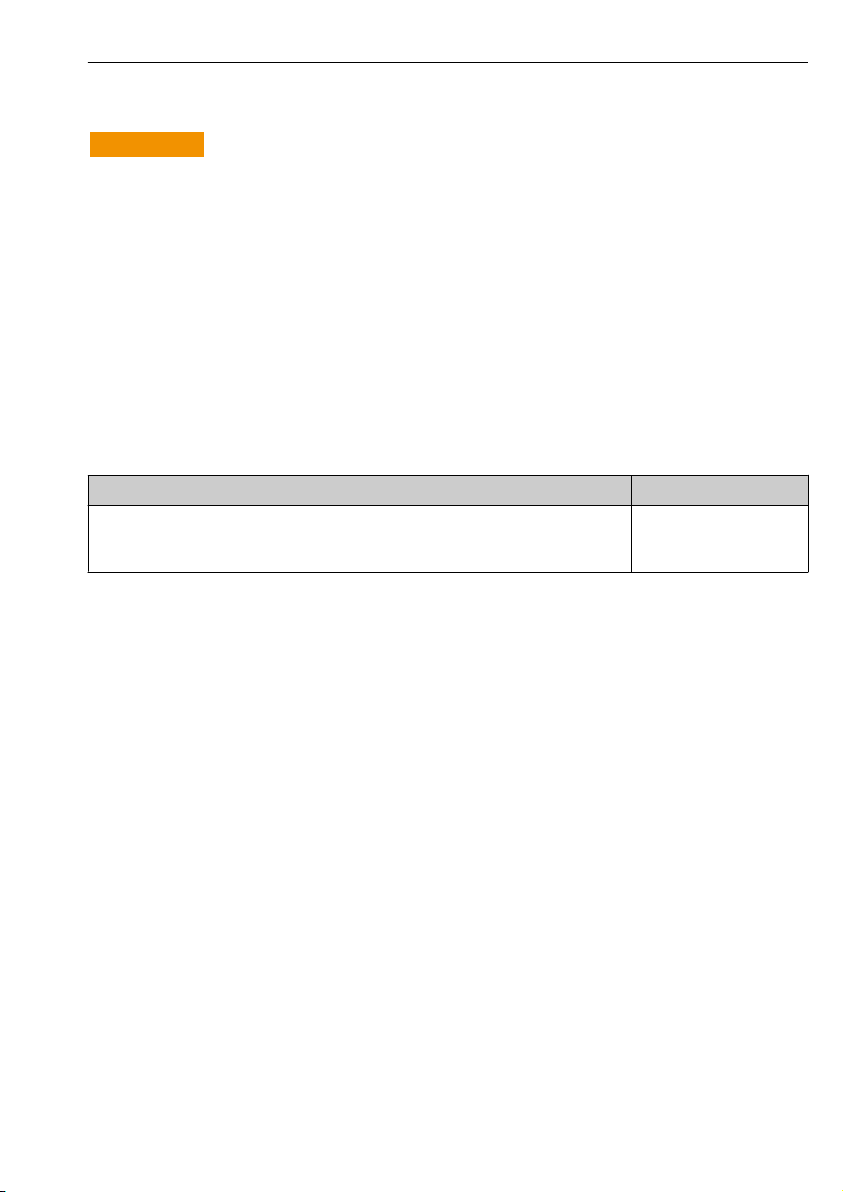

Description and contents Order No.

Kit CCA151, complete with blind plug

• Blind plug with O-ring

• Screw plug

8.2 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

71372020

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

8.3 Disposal

The device contains electronic components. and must therefore be disposed of in accordance

with regulations on the disposal of electronic waste.

Observe the local regulations.

‣

Endress+Hauser 27

Page 28

Accessories Flowfit CCA151

9 Accessories

The following are the most important accessories available at the time this documentation

was issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

9.1 Device-specific accessories

9.1.1 Disinfection sensor CCS50D

• Membrane-covered amperometric sensor for chlorine dioxide

• With Memosens technology

• Product Configurator on the product page: www.endress.com/ccs50d

Technical Information TI01353C

9.1.2 Wall mounting kit

Wall mounting kit for CCA151

Order No. 71372109

10 Technical data

10.1 Environment

10.1.1 Ambient temperature range

-20 to +60 °C (-4 to 140 °F)

10.1.2 Storage temperature

-20 to +60 °C (-4 to 140 °F)

10.2 Process

10.2.1 Process temperature

0 to 60 °C (32 to 140 °F), non-freezing

10.2.2 Process pressure

0 to 4 bar (0 to 58 psi) relative

28 Endress+Hauser

Page 29

Flowfit CCA151 Technical data

p [bar]

T[°C]

20 60

40

T[°F]

p [psi]

0

32

0

0

68 104 140

4

58

10.2.3 Pressure-temperature ratings

A0034376-EN

10 Pressure-temperature ratings

10.2.4 Process connections

G1/8"

Hose specification: External diameter 6 mm, internal diameter 4 mm

10.2.5 Flow

remains stable for a minimum of 5 l/h (1.32 gal/hr) when using 25 mm (0.98 in) disinfection

sensors with approx. 77 mm (3.03 in) immersion depth

Endress+Hauser 29

Page 30

Technical data Flowfit CCA151

10.3 Mechanical construction

→ 12

10.3.1 Weight

1.077 kg (2.37 lbs)

10.3.2 Materials

In contact with medium

Assembly: PMMA

Seals: PVDF

Dummy plug: PVC, FKM

30 Endress+Hauser

Page 31

Flowfit CCA151 Index

Index

A

Accessories ..................... 28

Approvals ...................... 11

C

Certificates ..................... 11

Cleaning agent ................... 25

Commissioning ...................22

D

Designated use ....................6

Dimensions ..................... 12

Disposal ....................... 27

I

Incoming acceptance ................ 9

Installation ................... 11, 14

Installation conditions ...............11

Installing the sensor ................19

M

Maintenance .................... 23

Maintenance schedule ...............23

Maintenance tasks .................24

Measuring system ................. 14

N

Nameplate ..................... 10

U

Use ...........................6

W

Warnings ....................... 4

P

Post-installation check .............. 22

Product identification ................ 9

R

Repairs ........................27

Return ........................ 27

S

Safety instructions ..................6

Scope of delivery .................. 10

Spare parts ..................... 27

Symbols ........................ 4

T

Technical data ................... 28

Endress+Hauser 31

Page 32

*71371624*

71371624

Loading...

Loading...