Page 1

TI01357C/07/EN/01.17

71371626

Products Solutions Services

Technical Information

Flowfit CCA151

Flow assembly for disinfection sensors CCS5xD

Simple assembly for measuring disinfection in

drinking and process water

Application

• Drinking water

• Utilities in all sectors

• Applications with low sample volumes

Your benefits

• Suitable for all disinfection processes without pH compensation - chlorine dioxide

and others

• Requires only low sample flow: At least 5 l/h (1.32 gal/h)

• A new addition to the flow assembly range: Same form as and can be exchanged

for CCA250

Page 2

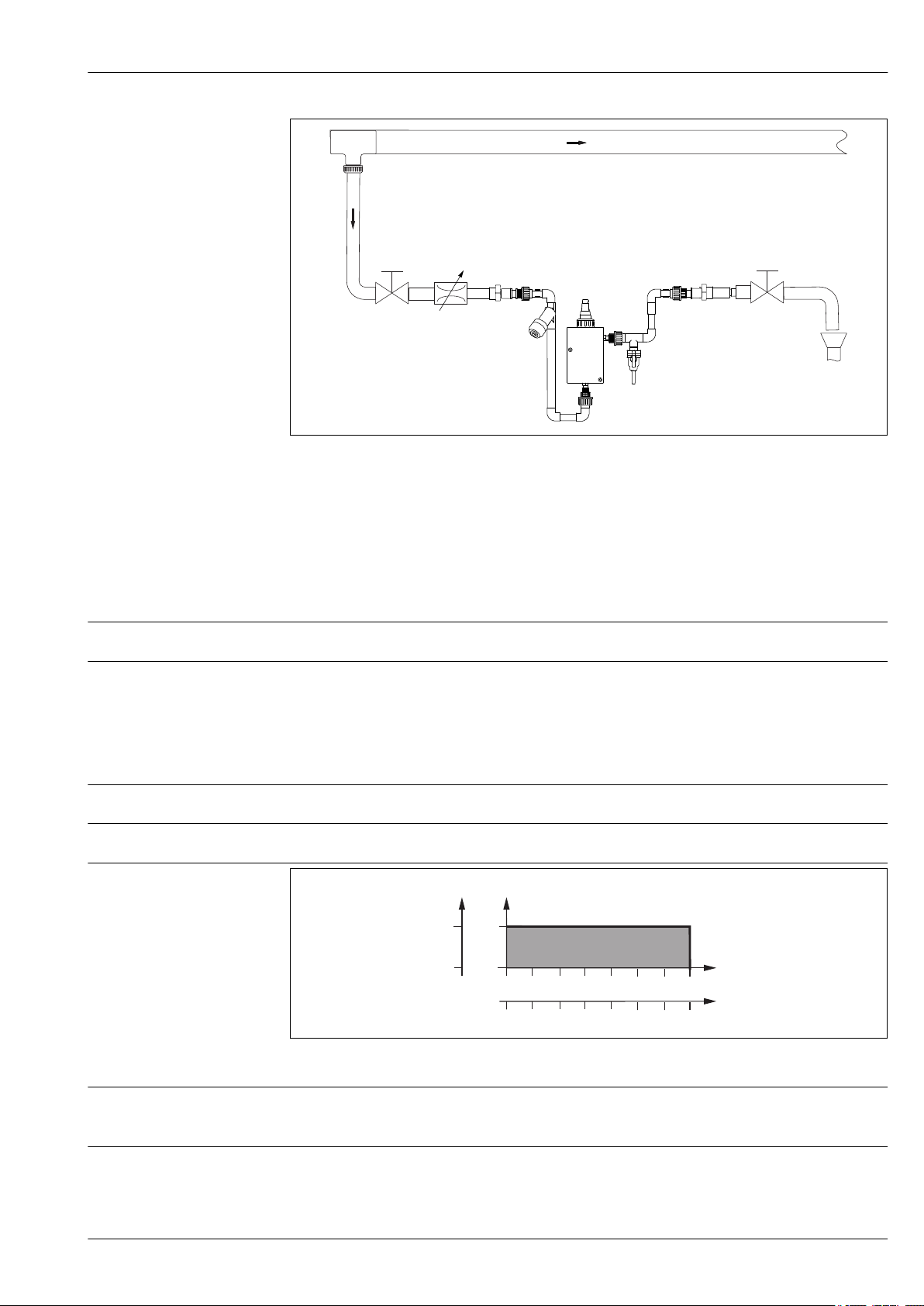

Function and system design

1

3

6

8

2

7

4

5

Flowfit CCA151

Mode of operation

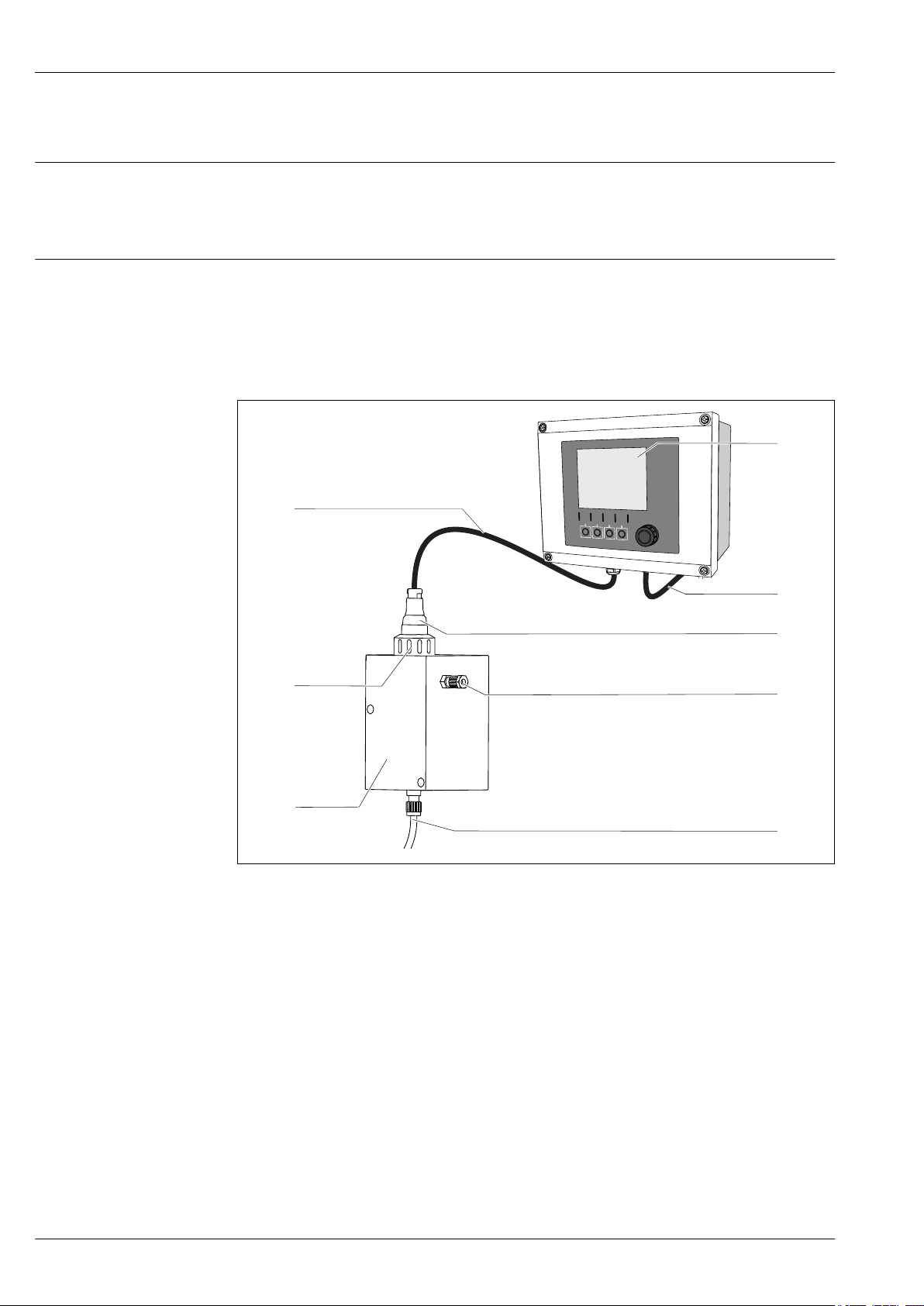

Measuring system

You can carry out reliable chlorine dioxide measurements using suitable sensors with flow assembly

CCA151 . You can remove, clean, sterilize or calibrate/adjust the sensors without interrupting the

process.

The assembly can be installed in both vessels and pipes.

A complete measuring system comprises:

• Disinfection sensor CCS50D (membrane-covered, ⌀25 mm) with corresponding installation

adapter

• Flowfit CCA151 flow assembly

• Measuring cable CYK10

• Transmitter, e.g. Liquiline CM44x or CM44xR

• Optional: Extension cable CYK11

1 Example of a measuring system

1 Transmitter Liquiline CM44x

2 Power cable for transmitter

3 Disinfection sensor CCS5xD (membrane-covered, ⌀25 mm), e.g. CCS50D

4 Outlet from Flowfit CCA151 flow assembly

5 Inlet to Flowfit CCA151 flow assembly

6 Flowfit CCA151 flow assembly

7 Coupling nut for installing sensor CCS50D in Flowfit CCA151 flow assembly

8 Measuring cable CYK10

2 Endress+Hauser

A0034241

Page 3

Flowfit CCA151

Installation

Orientation

Installation instructions

The assembly is designed for installation on panels, walls or level surfaces. G 1/8" connections and a

hose connection with an external diameter of 6 mm and an internal diameter of 4 mm are provided

for this purpose.

The assembly is designed in such a way that it must be installed vertically.

The sensor that is used can restrict the orientation.

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process medium

escapes.

Wear protective gloves, protective goggles and protective clothing.

‣

Mount the assembly only if vessels or pipes are empty and unpressurized.

‣

Prior to installation, check the flange seal between the flanges.

1. Mount assembly on vertical surface.

2. Connect to the vessel or pipe via the process connection.

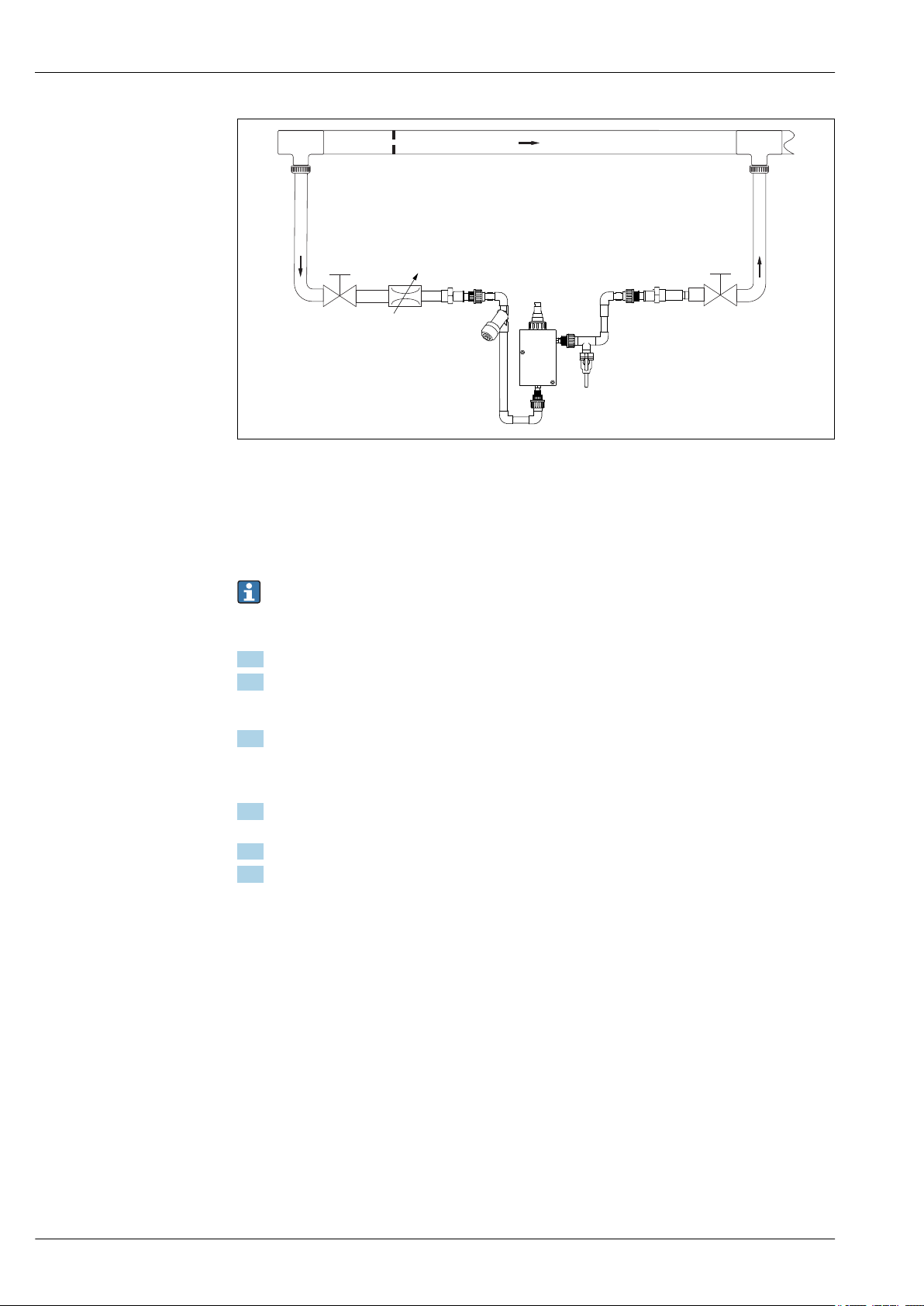

Bypass operation

To achieve flow through the assembly with a bypass, pressure p1 must be higher than pressure p2.

This requires the installation of an orifice plate or throttle valve in the main pipe.

p1 must not exceed the permitted operating pressure for the assembly of 4 bar (58 psi).

If the sensor is installed, the sensor's pressure specifications must also be observed.

1. Mount the assembly vertically.

2. Connect the medium using the usual commercial connection fittings. Depending on

requirements, use the usual sealing materials, e.g. PMMA-compatible thread adhesive, Teflon

tape or O-ring made of FKM.

3. Installing the assembly in the bypass is preferable to installing it directly in the process line.

The bypass line can be blocked off without interrupting the process (a shut-off valve is required

upstream and downstream). This allows, for example, the sensor to be cleaned without

restricting the process.

4. Install a dirt trap (filter) with a mesh size of 500 μm upstream from the assembly. If a

pressure-reducing valve is used, it usually includes a dirt trap.

5. Set flow value upstream from the assembly, e. g. by installation of a flow setting.

6. Install a DN5-8 tap downstream from the assembly outlet to allow samples to be taken for

reference measurements in accordance with the DPD method.

Endress+Hauser 3

Page 4

1 2 3

4

p1

p2

p1 > p2

2 Connection example with bypass and orifice plate in the main pipe

1 Shut-off valve (provided by customer)

2 Pressure-reducing valve (at p1 > 4 bar (58 psi)) (provided by customer)

3 Shut-off valve (provided by customer)

4 Orifice plate in process line (provided by customer)

Flowfit CCA151

A0034259

Open outlet operation

p must not exceed the permitted operating pressure for the assembly of 4 bar (58 psi).

If the sensor is installed, the sensor's pressure specifications must also be observed.

If the medium pressure is above 4 bar (58 psi), a pressure-reducing valve is required.

1. Mount the assembly vertically.

2. Connect the medium using the usual commercial connection fittings. Depending on

requirements, use the usual sealing materials, e.g. PMMA-compatible thread adhesive, Teflon

tape or O-ring made of FKM.

3. Installing the assembly in the bypass is preferable to installing it directly in the process line.

The bypass line can be blocked off without interrupting the process (a shut-off valve is required

upstream and downstream). This allows, for example, the sensor to be cleaned without

restricting the process.

4. Install a dirt trap (filter) with a mesh size of 500 μm upstream from the assembly. If a

pressure-reducing valve is used, it usually includes a dirt trap.

5. Set flow value upstream from the assembly, e. g. by installation of a flow setting.

6. Install a DN5-8 tap downstream from the assembly outlet to allow samples to be taken for

reference measurements in accordance with the DPD method.

4 Endress+Hauser

Page 5

Flowfit CCA151

1

2

3

p

p [bar]

T[°C]

20 60

40

T[°F]

p [psi]

0

32

0

0

68 104 140

4

58

A0034260

3 Connection example with open outlet

1 Shut-off valve (provided by customer)

2 Pressure-reducing valve (at p > 4 bar (58 psi)) (provided by customer)

3 Shut-off valve (provided by customer)

Environment

Ambient temperature

Storage temperature

-20 to +60 °C (-4 to 140 °F)

-20 to +60 °C (-4 to 140 °F)

Process

Process temperature range

Process pressure range

Pressure temperature load curve

0 to 60 °C (32 to 140 °F), non-freezing

0 to 4 bar (0 to 58 psi) relative

A0034376-EN

4 Pressure-temperature ratings

Process connections

G1/8"

Hose specification: External diameter 6 mm, internal diameter 4 mm

Flow

Endress+Hauser 5

remains stable for a minimum of 5 l/h (1.32 gal/hr) when using 25 mm (0.98 in) disinfection

sensors with approx. 77 mm (3.03 in) immersion depth

Page 6

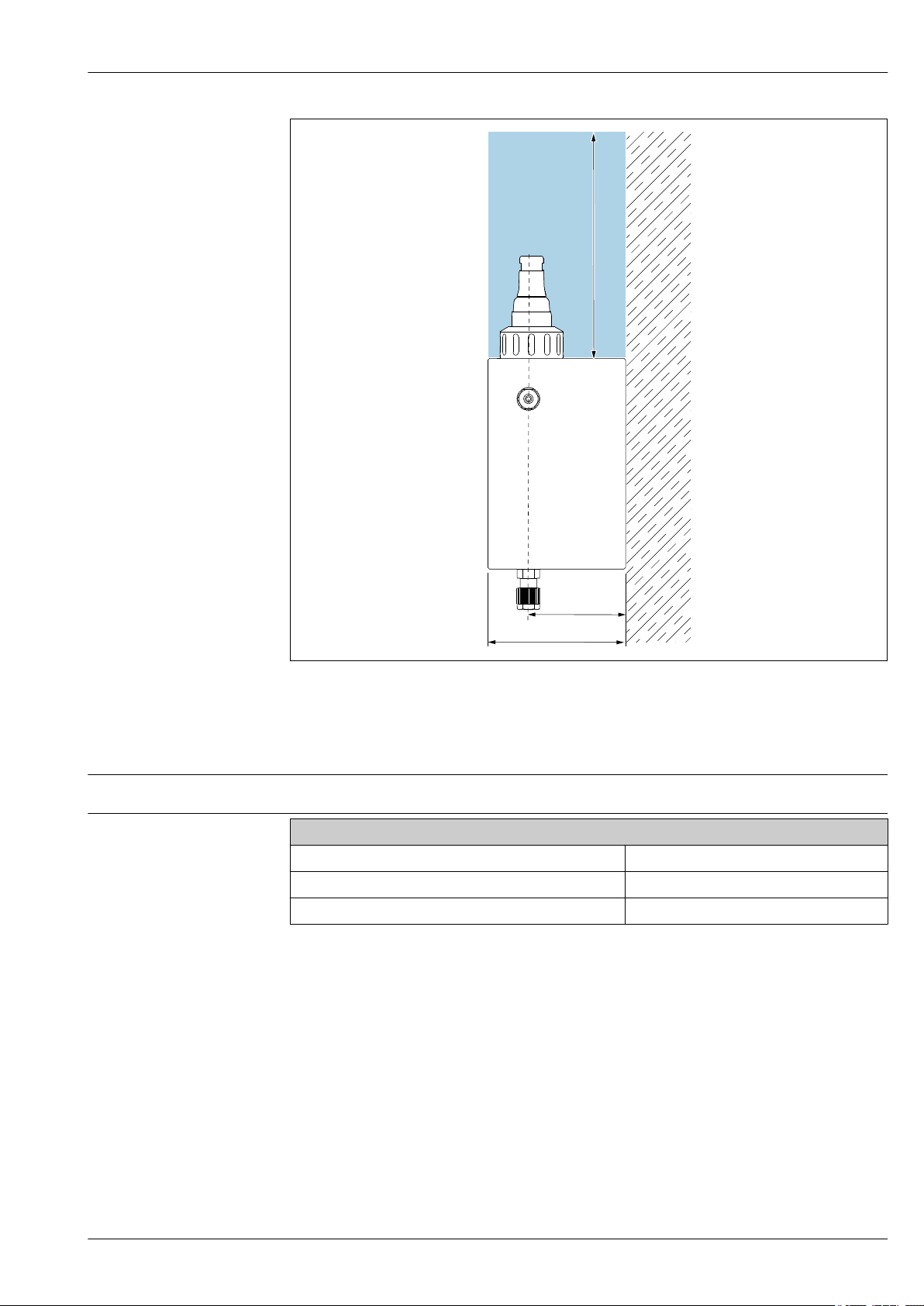

Dimensions

110 (4.33)

85 (3.35)

!14.5

(0.57)

7.5 (0.3)

70 (2.76)

70 (2.76)

105 (4.13)

130 (5.12)

150 (5.91)

194.5 (7.66)

M5 60·

M5 60·

150 (5.91)

219.5 (8.64)

! 25

(0.98)

! 14.5

(0.57)

! 39.5

(1.56)

Flowfit CCA151

Mechanical construction

A0034258

5 Front view

To allow the sensor to be removed and for operation with Memosens data cables, the spacing

required for mounting is 150 mm (5.91 in).

6 Endress+Hauser

Page 7

Flowfit CCA151

150 (5.91)

85 (3.35)

60 (2.36)

Weight

Materials

A0034398

6 Side view

To allow the sensor to be removed and for operation with Memosens data cables, the spacing

required for mounting is 150 mm (5.91 in).

1.077 kg (2.37 lbs)

In contact with medium

Assembly: PMMA

Seals: PVDF

Dummy plug: PVC, FKM

Certificates and approvals

RL 2014/34/EU (ATEX)

The assembly does not fall within the scope of the directive. However, if conditions for safe use are

adhered to, it may be deployed in the hazardous area.

RL 2014/68/EU PED

The assembly was manufactured in accordance with Article 3, paragraph 3, Pressure Equipment

Directive 97/23/EC in accordance with good engineering practice.

Endress+Hauser 7

Page 8

Ordering information

Flowfit CCA151

Product page

Product Configurator

Scope of delivery

www.endress.com/cca151

On the product page there is a "Configure" button to the right of the product image Configure.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the tab for this CAD and select the desired file type using

picklists.

The scope of delivery comprises:

• Assembly in the version ordered

• Operating Instructions

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Device-specific accessories Disinfection sensor

CCS50D

• Membrane-covered amperometric sensor for chlorine dioxide

• With Memosens technology

• Product Configurator on the product page: www.endress.com/ccs50d

Technical Information TI01353C

Wall mounting kit

Wall mounting kit for CCA151

Order No. 71372109

8 Endress+Hauser

Page 9

Page 10

Page 11

Page 12

www.addresses.endress.com

Loading...

Loading...