Page 1

BA00459C/07/EN/15.19

71447513

2019-01-31

Products Solutions Services

Operating Instructions

Viomax CAS51D

Photometric sensor for SAC or nitrate measurement

Page 2

Table of contents Viomax CAS51D

Table of contents

1 About this document ................ 3

1.1 Warnings ............................ 3

1.2 Symbols used .......................... 3

1.3 Symbols on the device ................... 3

2 Basic safety instructions ............ 4

2.1 Requirements for the personnel ............ 4

2.2 Designated use ........................ 4

2.3 Workplace safety ....................... 4

2.4 Operational safety ...................... 5

2.5 Product safety ......................... 5

3 Device description .................. 6

3.1 Sensor design ......................... 6

3.2 Dimensions ........................... 6

3.3 Operating principle ..................... 8

4 Incoming acceptance and product

identification ..................... 11

4.1 Incoming acceptance ................... 11

4.2 Product identification ................... 11

4.3 Scope of delivery ...................... 12

4.4 Certificates and approvals ............... 12

10 Repairs ........................... 37

10.1 Return .............................. 37

10.2 Disposal ............................ 37

11 Accessories ....................... 38

11.1 Assemblies .......................... 38

11.2 Holder .............................. 38

11.3 Compressed air cleaning ................ 38

11.4 Standard solutions ..................... 39

12 Technical data .................... 40

12.1 Input ............................... 40

12.2 Performance characteristics .............. 41

12.3 Environment ......................... 42

12.4 Process ............................. 42

12.5 Mechanical construction ................ 42

Index .................................. 43

5 Mounting ......................... 13

5.1 Installation conditions .................. 13

5.2 Mounting the sensor ................... 14

5.3 Immersion operation ................... 15

5.4 Flow operation ....................... 17

5.5 Mounting the cleaning unit .............. 22

5.6 Post-installation check .................. 23

6 Electrical connection .............. 24

6.1 Connecting to the transmitter ............ 24

6.2 Ensuring the degree of protection .......... 25

6.3 Post-connection check .................. 25

7 Operation ......................... 26

7.1 Calibration .......................... 26

7.2 Cyclic cleaning ........................ 35

8 Diagnostics and troubleshooting ... 35

9 Maintenance ...................... 36

9.1 Maintenance intervals .................. 36

9.2 Cleaning the sensor .................... 36

9.3 Maintenance of optical filters and strobe

lamp ............................... 37

2 Endress+Hauser

Page 3

Viomax CAS51D About this document

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

Endress+Hauser 3

Page 4

Basic safety instructions Viomax CAS51D

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

CAS51D is a photometric sensor for SAC or nitrate measurement in liquid media.

The sensor is particularly suited for use in the following applications:

• Monitoring and regulating water treatment plants

• Monitoring surface waters

SAC measurement

• Organic load in WWTP inlet

• Organic load WWTP outlet

• Discharger monitoring

• Organic load in drinking water

Nitrate measurement

• Nitrate measurement in natural bodies of water

• Monitoring nitrate content in WWTP outlet

• Monitoring nitrate content in aeration basins

• Monitoring and optimizing denitrification phases

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

CAUTION

L

UV light

UV light can damage the eyes!

Never look into the cuvette gap while the sensor is in operation.

‣

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable international standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

4 Endress+Hauser

Page 5

Viomax CAS51D Basic safety instructions

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

Endress+Hauser 5

Page 6

Device description Viomax CAS51D

50

(1.97)

40 (1.57)

388 (15.28)

78 (3.07)

NPT “¾

G1

2 (0.08)

8 (0.31)

12 (0.47)

20 (0.79)

14.5 (0.57)

NPT “¾

G1

78 (3.07)

394 (15.51)

8 (0.31)

40 (1.57)

14 (0.55)

20 (0.79)

12 (0.47)

14.5 (0.57)

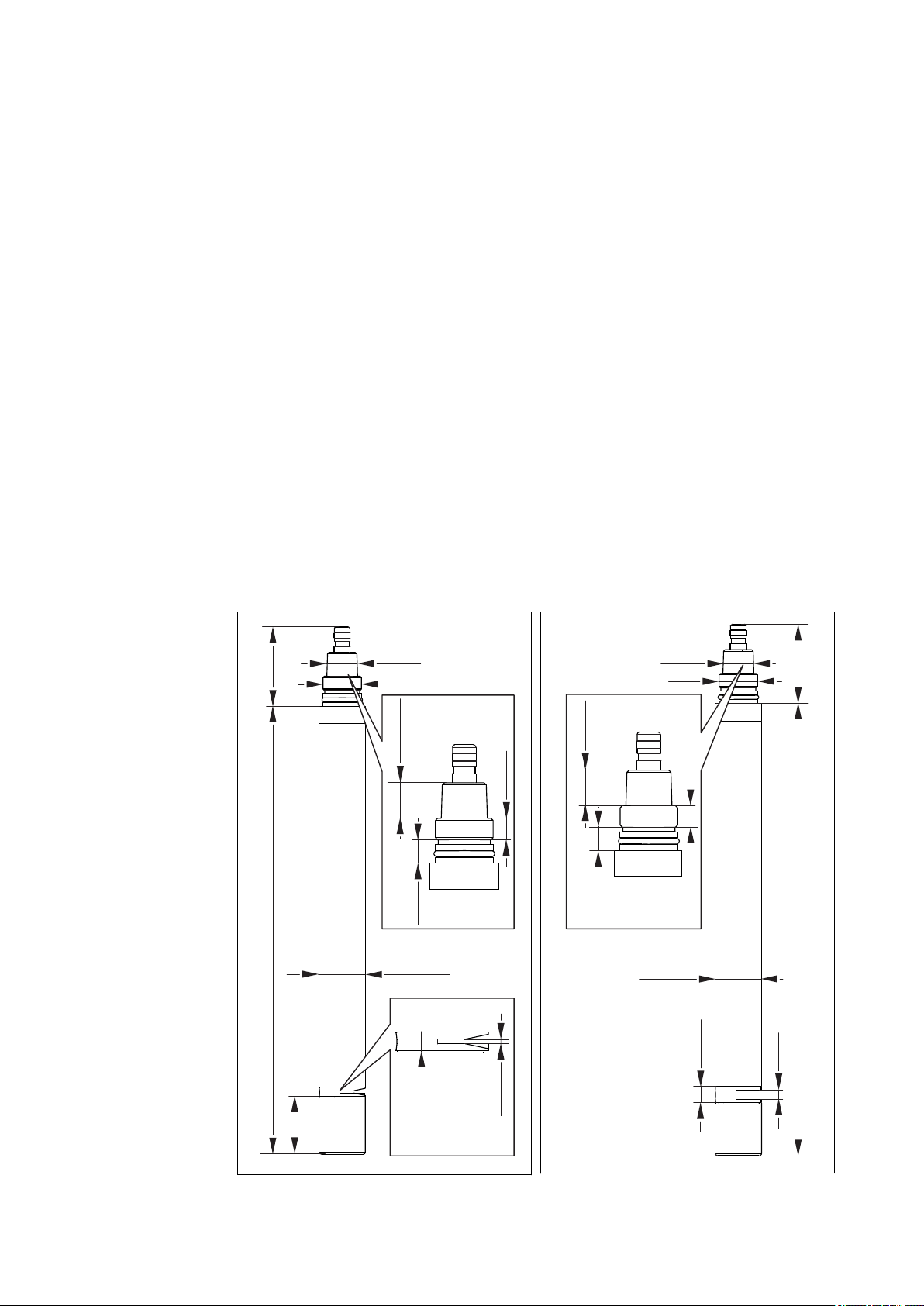

3 Device description

3.1 Sensor design

The sensor has a diameter of 40 mm and can be operated directly and completely in the

process without the need for further sampling (in situ). One version of the sensor

measures the amount of nitrate in the medium while another version measures the SAC

value of the medium.

The sensor comprises the following assemblies:

• Power supply

• High-voltage generation for the strobe lamp,

• Cuvette

Central component in which the measuring light interacts with the medium.

• Receiver assembly

Detect the measuring signals, digitize them and process them to form a measured value.

• Controller

Responsible for controlling internal sensor processes and transmitting data.

All data - including the calibration data - are stored in the sensor. The sensor can be

precalibrated and used at a measuring point, calibrated externally, or used for several

measuring points with different calibrations.

3.2 Dimensions

6 Endress+Hauser

1 Sensor with 2 mm gap width, dimensions in

mm (inch)

A0013193

2 Sensor with 8 mm gap width, dimensions in

mm (inch)

A0013208

Page 7

Viomax CAS51D Device description

20 (0.79)

12 (0.47)

14.5 (0.57)

40 (1.57)

NPT “¾

G1

69 (2.72)

40 (1.57)

46 (1.81)

426 (16.77)

A0031311

3 Sensor with 40 mm gap width, dimensions in

mm (inch)

Endress+Hauser 7

Page 8

Device description Viomax CAS51D

1

2

3

4

56

3.3 Operating principle

3.3.1 Measuring principle

The light from a pulsed, high-stability strobe lamp (item 3) passes through the measuring

1)

path

1 and 5). A filter upstream from the receivers only lets through light in the measuring

wavelength or reference wavelength.

(item 2). A beam splitter (item 6) directs the light beam to the two receivers (items

A0013213

4 Measuring principle of nitrate sensor

1 Measuring receiver with filter

2 Cuvette gap

3 Strobe lamp

4 Lens

5 Reference receiver with filter

6 Beam splitter

Within the measuring path, the medium in the cuvette (water, dissolved substances and

particles) absorbs light across the entire spectrum. In the measuring wavelength range, the

measured component

2)

takes an additional amount of energy from the light.

For the calculation of the measured value, the ratio of the light signal of the measuring

wavelength to the light signal of the reference wavelength is calculated in order to

minimize the effect of turbidity and lamp aging.

This change in the ratio can be converted to determine the nitrate concentration or the

SAC value. This dependency is non-linear.

Conclusion:

• Long measuring paths are required for low concentrations of the measured component.

For clear water measurements, this is achieved with the 8 mm cuvette for nitrate

measurement and the 40 mm cuvette for SAC measurement.

• For high turbidity values, longer measuring paths result in the total absorption of light the measured values are no longer valid.

The nitrate sensor with the 2 mm cuvette is recommended for media with high turbidity

values (activated sludge application).

The SAC sensor with the 2 mm cuvette is ideal for measuring the organic load in the

inlet of municipal wastewater treatment plants.

1) Measuring path = open path through cuvette

2) Nitrate or substances that contribute to the spectral absorption coefficient (SAC)

8 Endress+Hauser

Page 9

Viomax CAS51D Device description

3.3.2 Nitrate measurement

The sensor is designed for measuring nitrate. As nitrite is also measured, it could also be

regarded as an NOx sensor.

Nitrate ions absorb UV light in the range of approx. 190 to 230 nm. Nitrite ions have a

similar absorption rate in the same range.

The sensor measures the light intensity of the 214 nm wavelength (measuring channel).

At this wavelength, nitrate and nitrite ions absorb light in proportion to their

concentration, while the light intensity in the reference channel remains virtually

unchanged at 254 nm.

Interference factors, such as turbidity, fouling or organic hydrocarbons, are minimized.

The signal ratio between the reference wavelength and measurement wavelength

constitutes the measurement result. This ratio is converted to the concentration of nitrate

using the calibration curve programmed into the sensor.

3.3.3 Cross-interference when measuring with the nitrate version

The following have a direct impact on the measuring range:

• Total solids (TS) and turbidity

• Sludge properties

• Nitrite

Trends:

• A higher proportion of TS or greater turbidity reduces the upper end of the measuring

range, resulting in a smaller measuring range.

• High COD

measuring range.

• Nitrite is measured as nitrate, thus resulting in a higher measured value.

The following can be deduced from the interdependencies cited above:

• Sludge floc causes scattering in the medium, resulting in the attenuation of both the

measuring and reference signal to varying degrees. This in turn can bring about a

change in the nitrate value due to turbidity.

• High concentrations of oxidizable substances

in the measured value.

• Nitrite absorbs light in a similar wavelength range to nitrate and is measured along with

nitrate. The dependency is constant: 1.0 mg/l nitrite is displayed as 0.8 mg/l nitrate.

• An adjustment to the customer process is always worthwhile.

3)

levels reduce the upper end of the measuring range, resulting in a smaller

4)

in the medium may result in an increase

3.3.4 SAC measurement

Many organic substances absorb light in the range of 254 nm. In the SAC sensor,

absorption on the measuring wavelength (254 nm) is compared with the largely

unaffected reference measurement at 550 nm.

KHP (potassium hydrogen phthalate C8H5KO4) is the established organic reference in SAC

measurement operations. That is why the sensor is calibrated in the factory using KHP.

The SAC value can be regarded as a trend indicator of the organic load in a medium. For

this purpose, it is converted to COD, TOC, BOD and DOC

factors:

c (TOC) = 0.4705 * c (KHP)

c (COD) = 1.176 * c (KHP)

c (BOD) = 1.176 * c (KHP)

c (DOC) = 0.4705 * c (KHP)

3) COD = Chemical Oxygen Demand

4) Specified as COD. Corresponds to the quantity of oxygen that would be required to oxidize the substances if oxygen were the oxidizing agent.

5) Chemical Oxygen Demand (COD), Total Organic Carbon (TOC), Biochemical Oxygen Demand (BOD), Dissolved Organic Carbon (DOC)

Endress+Hauser 9

5)

using predefined, adjustable

Page 10

Device description Viomax CAS51D

The ratio to SAC (based on KHP) is calculated as follows:

1/m = 1.487 mg/l COD = 1.487 mg/l BOD = 0.595 mg/l TOC = 0.595 mg/l DOC

Many components that absorb light at 254 nm deviate significantly from KHP in terms of

their absorption behavior. For this reason, an adjustment to the customer process is

worthwhile.

3.3.5 Cross-interference when measuring with the SAC version

The following have a direct impact on the measuring range:

• Turbidity

• Color

Trends:

• Oxidizable substances, absorbing at 550 nm, corrupt the measurement result. In

instances of this nature, a comparison or calibration is necessary.

• Coloration that absorbs in the green spectral range increases the measured value.

• Oxidizable substances with spectral properties that differ to those of KHP (potassium

hydrogen phthalate) provide measurement results that can deviate from the factory

calibration. In instances of this nature, a comparison or adjustment is necessary.

• A higher proportion of TS or greater turbidity reduces the upper end of the measuring

range, resulting in a smaller measuring range.

• Sludge floc causes scattering in the medium, resulting in the attenuation of both the

measuring and reference signal to varying degrees. This in turn can bring about a

change in the measured value due to turbidity.

10 Endress+Hauser

Page 11

Viomax CAS51D Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Extended order code

• Serial number

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.2.2 Product identification

Product page

www.endress.com/cas51d

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

Endress+Hauser 11

Page 12

Incoming acceptance and product identification Viomax CAS51D

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

Manufacturer's address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

4.3 Scope of delivery

The delivery comprises:

• Sensor in the version ordered

• Operating Instructions

4.4 Certificates and approvals

4.4.1

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

4.4.2 EAC version

The product has been certified according to guidelines TP TC 004/2011 and TP TC

020/2011 which apply in the European Economic Area (EEA). The EAC conformity mark

is affixed to the product.

12 Endress+Hauser

Page 13

Viomax CAS51D Mounting

5 Mounting

5.1 Installation conditions

5.1.1 Mounting location

Choose a mounting location that can be easily accessed at a later stage.

‣

Ensure that upright posts and fittings are fully secured and vibration-free.

‣

Select an installation location that produces a typical nitrate concentration / a typical

‣

SAC value for the application in question.

Do not install the sensor above aeration discs. Oxygen bubbles may accumulate at the

‣

cuvette gap and distort the measured value.

5.1.2 Orientation

Align the sensor in such a way that the cuvette gap is

‣

rinsed with the flow of medium and air bubbles are

removed.

A0013268

5 Sensor orientation, arrow =

direction of flow

Flexdip CYA112 wastewater assembly and Flexdip CYH112 holder

A0013267

6 Horizontal, fixed installation

The installation angle is 90°.

Align the sensor in such a way that the

‣

cuvette gap is rinsed with the flow of

medium and air bubbles are removed.

7 Suspended vertically from a chain

The installation angle is 0°. Tried and tested

arrangement for operation in aerated zones.

Ensure that the sensor is adequately

‣

cleaned. There must be no buildup on the

optical windows.

A0013270

Endress+Hauser 13

Page 14

Mounting Viomax CAS51D

1

2

3

4

5

1 2

3

4

5

6

Flow assembly CAS51D 2-40 mm for small sample volumes

A0013266

8 Horizontally, in flow assembly, arrow points in the direction of flow

1 Sensor

2 Flow assembly

3 Medium outlet

4 Medium inflow

5 Window, required for aligning the sensor

Flowfit CYA251 flow assembly

9 Horizontally, in flow assembly CYA251, arrow points in the direction of flow

1 Sensor

2 Medium outlet

3 Cap

4 Flow assembly

5 Medium inflow

6 Rinse connection

A0032901

5.2 Mounting the sensor

5.2.1 Installation instructions

14 Endress+Hauser

To ensure correct measurement, the windows in the cuvette must be free from any

sedimentation. The best way to ensure this is through the use of a cleaning unit

(accessory) operated by compressed air.

For horizontal orientations:

‣

Mount the sensor in such a way that air bubbles can escape from the cuvette slot (do

not point it downwards).

Page 15

Viomax CAS51D Mounting

1

2

3

4

1

2

3

4

5

5.3 Immersion operation

5.3.1 Fixed installation with wastewater assembly

10 Installation secured on railing

1 Wastewater assembly Flexdip CYA112

2 Flexdip CYH112 holder

3 Rail

4 Viomax CAS51D

A0013347

11 Installation with upright post

1 Protective cover

2 Liquiline CM44x multi-channel transmitter

3 Wastewater assembly Flexdip CYA112

4 Viomax CAS51D

5 Flexdip CYH112 holder

A0013215

This type of installation is particularly suitable for strong or turbulent medium flow

(>0.5 m/s (1.6 ft/s)) in basins or channels. A cleaning unit (accessory) operated by

compressed air significantly extends the maintenance intervals for the sensor.

Endress+Hauser 15

Page 16

Mounting Viomax CAS51D

2

3

2

3

4

5.3.2 Installation with chain retainer

12 Chain retainer on railing

1 Wastewater assembly Flexdip CYA112

2 Flexdip CYH112 holder

3 Rail

4 Viomax CAS51D

A0013348

13 Chain retainer on upright post

1 Protective cover

2 Liquiline CM44x multi-channel transmitter

3 Wastewater assembly Flexdip CYA112

4 Viomax CAS51D

5 Flexdip CYH112 holder

A0013351

The chain retainer is particularly suitable for applications that require a sufficient distance

between the mounting location and the edge of the aeration basin. As the assembly is

freely suspended, any vibration of the upright post is practically ruled out.

The swinging movement of the chain retainer enhances the self-cleaning effect of the

optics. A cleaning unit (accessory) operated by compressed air significantly extends the

maintenance intervals for the sensor.

16 Endress+Hauser

Page 17

Viomax CAS51D Mounting

2

3

4

Ø 6.5 (0.26)

86

(3.39)

30 (1.18)

100 (3.94)

70 (2.76)

**

70 (2.76)

60 (2.36)

5.4 Flow operation

5.4.1 Flow assembly for clear water and small sample volumes

A0013352

14 Sensor with flow assembly

1 Transmitter

2 Viomax CAS51D

3 Flow assembly

4 Sensor holder

Securing the holder

15 Dimensions in mm (inch)

** Variable length

1. For the necessary installation dimensions, refer to the drawing. Mount the sensor in

a horizontal position (as shown in the drawing).

Drill holes for the mounting clamps into a wall or panel.

2. Secure the mounting clamps. The required fastening fixtures (screws, wall plugs) are

not included in the scope of delivery of the kit and must be provided by the customer.

3.

A0013290

Endress+Hauser 17

Release the hexagonal nuts of the mounting clamps and remove the top half.

Page 18

Mounting Viomax CAS51D

M5

4.

Position the sensor in the mounting clamps and screw on the top parts, tightening by

hand (it should still be possible to move the sensor).

Mount the flow assembly

A0033056

16 Sensor installed in flow assembly

1.

Release the threaded rings of the flow assembly and remove the two O-rings.

2. Check if the silicone grease provided with the kit is permitted for use in your

application. If not, use a grease that is suitable for your application

Grease the O-rings.

3.

First slide a threaded ring (thread in the direction of the assembly) onto the sensor,

followed by an O-ring.

4.

Now slide the assembly onto the sensor, followed by the second O-ring and the

second threaded ring.

18 Endress+Hauser

Page 19

Viomax CAS51D Mounting

5.

Open the cap on the viewing window.

6.

Position the assembly on the sensor in such a way that the cuvette gap is visible in

the center of the window.

7.

Tighten the two threaded rings. Ensure that you do not change the position of the

assembly.

8.

The cuvette gap must still be visible in the center of the viewing window:

Close the viewing window again with the cap.

To guard against loss:

Secure the viewing window to one of the hose connections (no diagram) using

the transparent cord.

Endress+Hauser 19

Page 20

Mounting Viomax CAS51D

1

3

56

2

7

2

2 4

2

Connection diagram

A0013361

1 Main pipe 5 Flow assembly

2 Manually actuated or solenoid valves 6 Medium inflow

3 Medium outlet 7 Medium sampling

4 Medium return

Connect the medium inflow and outlet to the assembly's hose connections as shown in

‣

the diagram.

This fills the assembly from below and ensures that the assembly is self-venting.

There must be a minimum flow rate of 100 ml/h (0.026 gal/h). Increased response times

must be taken into account.

As an alternative to bypass operation, you can also direct the sample flow from a filter unit

with an open outlet through the assembly:

A0013434

17 Flow assembly with open outlet

1 Pump

2 Open outlet

3 Filter unit

20 Endress+Hauser

Page 21

Viomax CAS51D Mounting

3

4

6

5

2

1

3

56

2

7

2

2 4

5.4.2 Flow assembly Flowfit CYA251

A0032917

18 Measuring system with CYA251

1 Transmitter

2 Flow assembly

3 Medium outlet

4 Cap

5 Medium inflow

6 Viomax CAS51D

A0032920

19 Connection diagram

1 Main pipe 5 Medium inflow

2 Manually actuated or solenoid valves 6 Flow assembly

3 Medium outlet 7 Medium removal

4 Medium return

Mount the sensor in the assembly in accordance with its Operating Instructions

(BA00495C).

There must be a minimum flow rate of 100 ml/h (0.026 gal/h). Increased response

times must be taken into account.

Endress+Hauser 21

Page 22

Mounting Viomax CAS51D

2

As an alternative to bypass operation, you can also direct the sample flow from a filter unit

with an open outlet through the assembly:

20 Flow assembly with open outlet

1 Pump

2 Open outlet

3 Filter unit

5.5 Mounting the cleaning unit

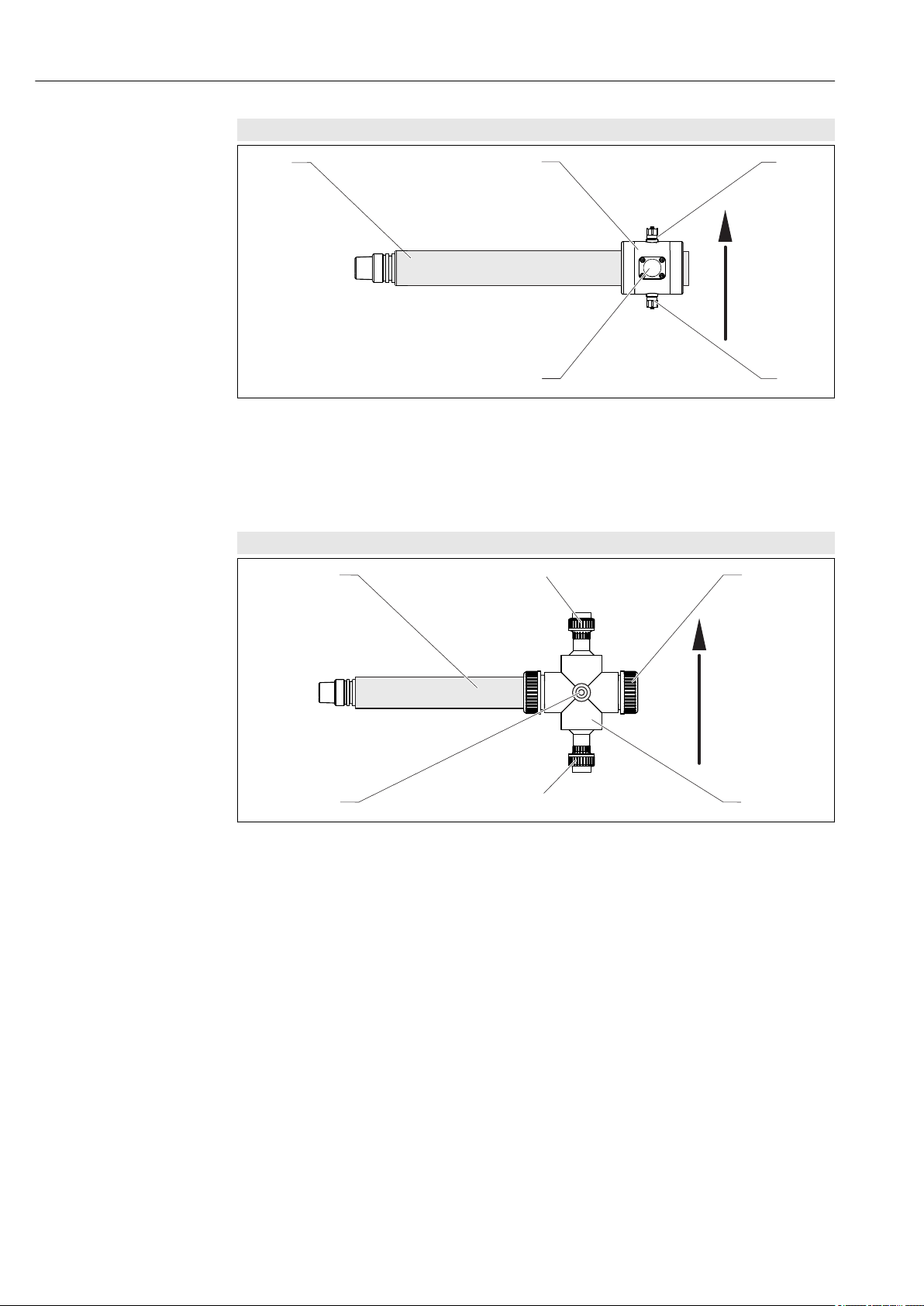

Sensors with gap width of 2 mm or 8 mm

Mount the compressed air cleaning unit prior to installing the sensor in the measuring

point, or remove the sensor from the medium. Clean the sensor if necessary.

1.

Screw the elbow plug from the accessory kit into the mounting hole behind the

sensor gap, and tighten by hand as far as it will go.

2.

A0032921

Connect the compressed air supply at the installation location. Use the hose piece

with hose coupling provided with the sensor if desired.

22 Endress+Hauser

Page 23

Viomax CAS51D Mounting

SAC sensors with a gap width of 40 mm

Mount the compressed air cleaning unit prior to installing the sensor in the measuring

point, or remove the sensor from the medium. Clean the sensor if necessary.

1.

Screw the air diffuser from the accessory kit into the mounting holes behind the

sensor gap, and tighten by hand as far as it will go.

2.

Connect the compressed air supply at the installation location. Use the hose piece

with hose coupling provided with the sensor if desired.

5.6 Post-installation check

Put the sensor into operation only if you can answer "yes" to the following questions:

• Are the sensor and cable undamaged?

• Is the orientation correct?

• Is the sensor installed in an assembly and not freely suspended from the cable?

• Is the cable routed so that it is completely dry (routed inside an assembly if necessary)?

Endress+Hauser 23

Page 24

Electrical connection Viomax CAS51D

1

2

3

4

6 Electrical connection

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

‣

and must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

6.1 Connecting to the transmitter

6.1.1 Connecting the cable shield to the grounding rail of the transmitter

WARNING

L

Sensor not grounded

If maintenance work (lamp replacement) is not performed correctly, moisture or dirt may

penetrate the housing and cause an electric shock to anyone who touches it.

To guarantee safety in the workplace, always connect the sensor's cable shield to the

‣

grounding rail of the transmitter or control cabinet.

If possible, only use terminated original cables. The sensor cables must be shielded.

Cable sample (does not necessarily correspond to the original cable supplied)

21 Terminated cable

1 Outer shield (exposed)

2 Cable cores with ferrules

3 Cable sheath (insulation)

1) Please note the instructions in the "Ensuring the degree of protection" section.

22 Inserting the cable

4 Grounding clip

23 Tighten screw (2 Nm)

The cable shield is grounded using

the grounding clamp.

1)

1. Release a suitable cable gland on the bottom of the housing and remove the dummy

plug.

2. Making sure the gland is facing the right direction, thread the gland onto the cable

end and pull the cable through the entry and into the housing.

3. Route the cable in the housing in such a way that the exposed cable shield fits into

one of the cable clamps and the cable cores can be easily routed as far as the

connection plug on the electronics module.

4. Open the cable clamp and clamp the cable in place. Then tighten the screw of the

cable clamp again.

5. Connect cable cores as per the wiring diagram.

24 Endress+Hauser

Page 25

Viomax CAS51D Electrical connection

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

Sensor

85 86

85

1

2

86

97 88 8798

Sensor 1

PK

GY

GN

YE

BN

WH

Sensor

6. Tighten the cable gland from outside.

6.1.2 Connecting the sensor

The following connection options are available:

• via M12 connector (version: fixed cable, M12 connector)

• via sensor cable to the plug-in terminals of a sensor input on the transmitter (version:

fixed cable, end sleeves)

A0033092

24 Sensor connection to sensor input (left) or via M12 connector (right)

The maximum cable length is 100 m (328.1 ft).

6.2 Ensuring the degree of protection

Only the mechanical and electrical connections which are described in these instructions

and which are necessary for the required, designated use, may be carried out on the device

delivered.

Exercise care when carrying out the work.

‣

Otherwise, the individual types of protection (Ingress Protection (IP), electrical safety, EMC

interference immunity) agreed for this product can no longer be guaranteed due,

for example to covers being left off or cable (ends) that are loose or insufficiently secured.

6.3 Post-connection check

Put the sensor into operation only if you can answer yes to all of the following

‣

questions.

Device condition and specifications Notes

Is the outside of the sensor, assembly and cable undamaged? Visual inspection

Electrical connection Notes

Has cable shield been applied to grounding rail of transmitter? Cable shield is absolutely

Are the installed cables strain-relieved and not twisted?

essential

Endress+Hauser 25

Page 26

Operation Viomax CAS51D

Device condition and specifications Notes

Is a sufficient length of the cable cores stripped, and is it positioned in the

terminal correctly?

Are all the screws terminals properly tightened? Tighten

Check the fit (by pulling

gently)

7 Operation

Verify that a representative measured value is displayed on the transmitter.

‣

For solids that have a tendency to form deposits, ensure that the medium is mixed

‣

sufficiently.

7.1 Calibration

Calibration is performed in the process by comparing the values to an external standard

method, by calibrating with standard solutions or by using a combination of both (addition

of standard).

7.1.1 Factory calibration

Nitrate sensor

The sensor is precalibrated on leaving the factory.

As such, it can be used in a wide range of clear water measurements without the need for

additional calibration.

SAC sensor

The sensor is precalibrated on leaving the factory (calibrated with KHP).

Calibration to the customer process is nevertheless advantageous in the majority of cases.

Reason: Organic compounds other than KHP react differently in the spectrum.

The factory calibration is based on 20 calibration points and is adjusted at three points

during production. The factory calibration cannot be deleted and can be retrieved at any

time. Single-point and two-point calibrations - performed as customer calibrations - are

referenced to this factory calibration.

7.1.2 Types of calibration

In addition to the factory calibrations, which cannot be changed, the sensor contains six

additional data records for storing process calibrations or for adaptation to the relevant

measuring point (application). Each calibration data record can have up to five calibration

points.

The sensor offers a wide range of options for adapting the measurement to the application

in question:

• Calibration or adjustment (1 to 5 points)

• Entry of a factor (multiplication of measured values by a constant factor)

• Entry of an offset (addition/subtraction of a constant factor to/from the measured

values)

• Duplication of factory calibration data records

One-point or multiple point calibration

You do not have to remove the sensor from the medium for calibration. You can calibrate it

directly in the application.

1. For the calibration, ensure that the measuring gap is not soiled with deposit buildup:

Clean the measuring gap of the sensor (remove soiling and deposits).

26 Endress+Hauser

Page 27

Viomax CAS51D Operation

1 2 3 4 5 6 7 8 9

1

2

3

4

5

6

7

8

9

x

y

2. To perform the calibration, immerse the sensor in the medium in such a way that the

measuring gap is completely filled with the medium.

All air bubbles and air pockets must be cleaned out of the measuring gap during

immersion.

• In the calibration table, the actual values can be edited as well as the set points

(right and left columns).

• Additional pairs of calibration values (actual values and set points) can be added, if

required, even without measurement in a medium.

Lines interpolate between the calibration points.

Give your calibration data records meaningful and useful names.

‣

For example, the name could contain the name of the application on which your data

record was originally based. This makes it easier for you to distinguish between different

data records.

Principle of a 1-point calibration

The measured error between the measured value of the sensor and the laboratory

measured value is too large. This is corrected by a 1-point calibration.

25 Principle of a 1-point calibration

x Measured value

y Target sample value

Blue Factory calibration

Red Application calibration

A0039320

1. Select data record.

2. Set the calibration point in the medium and enter the target sample value (laboratory

value).

Endress+Hauser 27

Page 28

Operation Viomax CAS51D

1 2 3 4 5 6 7 8 9

1

2

3

4

5

6

7

8

9

x

y

Principle of a 2-point calibration

Measured value deviations are to be compensated for at 2 different points in an

application (e.g. the maximum and minimum value of the application). This aims to ensure

a maximum level of accuracy between these two extreme values.

A0039325

26 Principle of a 2-point calibration

x Measured value

y Target sample value

Blue Factory calibration

Red Application calibration

1. Select a data record.

2. Set 2 different calibration points in the medium and enter the corresponding set

points.

A linear extrapolation is performed outside the calibrated operational range (gray

line).

The calibration curve must be monotonically increasing.

28 Endress+Hauser

Page 29

Viomax CAS51D Operation

1 2 3 4 5 6 7 8 9

1

2

3

4

5

6

7

8

9

x

y

Principle of multiple point calibration

A0039322

27 Principle of multipoint calibration (3 points)

x Measured value

y Target sample value

Blue Factory calibration

Red Application calibration

1. Select data record.

2. Set 3 different calibration points in the medium and specify the corresponding set

points.

A linear extrapolation is performed outside the calibrated operational range (gray

line).

The calibration curve must be monotonically increasing.

Endress+Hauser 29

Page 30

Operation Viomax CAS51D

1 2 3 4 5 6 7 8 9

1

2

3

4

5

6

7

8

9

x

y

f = 1.1

Principle of entering a factor

With the "Factor" function, the measured values are multiplied by a constant factor. The

functionality corresponds to that of a 1-point calibration.

Example:

This type of adjustment can be selected if the measured values are compared to the

laboratory values over a longer period of time and all values are too low by a constant

factor, e.g. 10%, in relation to the laboratory value (target sample value).

In the example, the adjustment is made by entering the factor 1.1.

A0039329

28 Principle of factor calibration

x Measured value

y Target sample value

Blue Factory calibration

Red Factor calibration

30 Endress+Hauser

Page 31

Viomax CAS51D Operation

1 2 3 4 5 6 7 8 9

1

2

3

4

5

6

7

8

9

x

y

Principle of entering an offset

With the "Offset" function, the measured values are offset by a constant amount (added or

subtracted).

A0039330

29 Principle of an offset

x Measured value

y Target sample value

Blue Factory calibration

Red Offset calibration

7.1.3 Stability criterion

During the calibration process, the measured values are checked to ensure that they

remain constant.

You use the stability criterion to define maximum deviations during a calibration. Only a

measured value within the specified deviation is accepted.

The stability criterion includes:

• The maximum permitted deviation in temperature measurement

• The maximum permitted deviation in measured value as a %

• the minimum time frame in which these values must be maintained

If the measured value or temperature deviate more than is permitted in the specified time

frame, this calibration point becomes invalid and a warning is issued.

Endress+Hauser 31

Page 32

Operation Viomax CAS51D

The stability criteria are used to monitor the quality of the individual calibration points in

the course of the calibration process. The aim is to achieve the best possible calibration

quality in the shortest possible time frame while taking external conditions into account.

• For high-precision calibrations in the laboratory, the maximum deviation permitted in

the measured value can be kept as small as possible and the time frame selected can be

as long as possible..

• For calibrations in the field in adverse weather and environmental conditions, the

maximum deviation permitted in the measured value can be kept suitably large and the

time frame selected can be kept suitably short.

Operating Instructions Memosens inputs BA01245C

7.1.4 Determining the reference values in the laboratory

Nitrate sensor

1. Take a representative sample of the medium.

2. Take suitable measures to ensure that the process of nitrate reduction in the sample

does not progress any further, such as immediate filtration (0.45 µm) of the sample

as per DIN 38402.

3. Determine the concentration of nitrate in the sample using the laboratory method

(for example, by colorimetric means using a cuvette test ‐ the standard method as per

DIN 38405 Part 9).

SAC sensor

1. Take a representative sample of the medium.

2. Take suitable measures to ensure that the process of biological and chemical

reduction in the sample does not progress any further.

3. Determine the measured values of your sample array using the laboratory method

(for example, by colorimetric means using a cuvette test).

7.1.5 Nitrate sensor

Processes with nitrate values > 0.1 mg/l

1. Take sample and determine nitrate concentration in the laboratory.

2. Calibrate and adjust the sensor using the laboratory value.

Processes with very different nitrate values

1. At time A, take a sample with a high concentration, and measure and calibrate the

sample.

2. At time B - which can be a few days later - take a sample with a low concentration,

and measure and calibrate the second value.

Calibration with the addition of standard

If the sludge parameters tend to be constant, you can perform the calibration with a

sample with a low concentration of nitrate and then add standard to the sample.

1. Take a larger sample (bucket) and analyze some of it by colorimetric means.

2. Calibrate the value of the calorimetric measurement in the sensor.

3. Add standard to the sample and determine the laboratory value.

4. Calibrate the laboratory value of the sample with added standard in the sensor.

32 Endress+Hauser

Page 33

Viomax CAS51D Operation

Avoid incorrect measurements.

Drinking water may contain higher concentrations of nitrate and is not suitable as a

‣

blank value. Use fully deionized water as a blank value.

During calibration, make sure the sample is homogeneous.

‣

When calibrating, start with a low concentration and increase the concentrations

‣

gradually to prevent nitrate carryover.

Clean and dry the sensor after a calibration. Ensure that there is no medium residue in

‣

the cuvette gap. In this way, you avoid mixing the different samples and changing the

nitrate concentrations.

7.1.6 SAC sensor

The required data record is activated by selecting the application in question and can be

adapted to that application using the following options:

• Calibration (1 to 10 points)

• Entry of a factor (multiplication of measured values by a constant factor)

• Entry of an offset (addition/subtraction of a constant factor to/from the measured

values)

• Duplication of factory calibration data records

• Adjustment of the conversion factors

Further data records can be created in the sensor and adapted to the application by

means of calibration or by entering a factor or offset. Two free, unused data records

are available for this. The number of free data records can be increased if necessary by

deleting (sample) data records that are not required. The sample data records are

restored to factory status when the sensor is reset.

General calibration steps

1. Take a sample.

2. Determine the SAC value of the sample in the laboratory.

3. Calibrate and adjust the sensor using the laboratory value.

In the SAC sensor version, the calculated variables COD, TOC, BOD and DOC can also be

output if desired, in addition to the actual measured variable. These variables are based on

the following ratios:

1 mg/l KHP = ~1.176 mg/l COD

1 mg/l KHP = ~0.4705 mg/l TOC

1 mg/l KHP = ~1.176 mg/l BOD

1 mg/l KHP = ~0.4705 mg/l DOC

Using other conversion factors

Sometimes the conversion factors for COD, TOC, BOD or DOC are predetermined by control

bodies. In such instances, these factors can be adjusted as follows:

1. Copy the factory data record to a free data record of your choice in the SAC basic

setting.

A copy is necessary because the factory data record cannot be modified. If you already have

another data record, you can change its factors directly.

2. Activate the new data record. (In the Setupmenu)

3. Set the desired factor. (In the CALmenu)

4. Set the device to the desired measured variable. (In the Setupmenu)

Operating Instructions Memosens inputs BA01245C.

The SAC sensor can be calibrated for the measured variables SAC, COD, TOC, BOD and

DOC.

Endress+Hauser 33

Page 34

Operation Viomax CAS51D

If the sensor has been calibrated for the measured variable SAC, the conversion factors for

COD, TOC, BOD or DOC can be adjusted at a later stage. If calibrated for TOC, COD, BOD or

DOC, only the factor for the measured variable in use can be changed subsequently.

Avoid incorrect measurements.

Drinking water contains many organic elements. The use of fully deionized water as a

‣

blank is also recommended here.

During calibration, make sure the medium is homogeneous.

‣

Avoid any carryover of organic elements during calibration.

‣

Processes with widely varying SAC values

Record calibration points for different operating statuses. Example of a WWTP inlet:

• After a rainy spell

• In "normal conditions"

• After a dry spell

1. Save the points in a data record of your choice and add the associated laboratory

results.

2. Activate the calibration once you have set a sufficient number of points.

While this type of calibration can be more time-consuming, it allows the precise

adjustment of the measurement technology to the operating conditions of the plant.

7.1.7 Calibrating and adjusting the sensor

To calibrate the sensor, use the same medium sample or sample array that you used to

determine the laboratory measured values. The sample array can also be pure standard

solutions.

The general sequence of a calibration is as follows:

1. Select data record.

2. Place sensor in medium.

3. During calibration, ensure that the medium is well homogenized.

4. Start the calibration for the measuring point.

5. If you wish to calibrate just one point:

End the calibration by accepting the calibration data.

Otherwise continue with the next step.

6. Add parent solution to the sample for the second measuring point and determine its

measured value. The reference value is calculated from the laboratory measured

value plus the added concentration.

7. Repeat the previous step as often as needed until you have reached the desired

number of calibration points (max. 5).

To avoid incorrect calibration from carryover:

• Always go from a low concentration to a high concentration.

• Clean and dry the sensor after each measurement.

• Make sure to remove medium residue in the sensor gap and in the connection opening

for the compressed air (e.g. by rinsing with the next calibration solution).

34 Endress+Hauser

Page 35

Viomax CAS51D Diagnostics and troubleshooting

7.2 Cyclic cleaning

Compressed air is most suitable for automatic cyclic cleaning. There is a connection for

compressed air on every sensor. The cleaning unit, which is supplied with the device or can

be retrofitted, operates effectively at a rate of 20 l/min (5.4 US gal/min).

Type of soiling Cleaning interval Cleaning duration

Severe fouling with rapid buildup 5 min 10 s

Low risk of soiling 10 min 10 s

8 Diagnostics and troubleshooting

When troubleshooting, the entire measuring point must be taken into account:

• Transmitter

• Electrical connections and cables

• Assembly

• Sensor

The possible causes of error in the following table relate primarily to the sensor.

Problem Testing Solution

No display, no sensor

reaction

Display value too high

or too low

Display value

fluctuating greatly

• Power supplied to transmitter?

• Sensor connected correctly?

• Medium flow present?

• Buildup on optical windows?

• Buildup on optical windows?

• Gas bubbles present?

• Sensor calibrated?

Gas bubbles present? 1. Eliminate gas bubbles

1. Connect mains voltage

2. Connect sensor correctly

3. Ensure medium is flowing

4. Clean sensor

1. Cleaning

2. Eliminate gas bubbles

3. Calibration

4. Check data record and modify if necessary

5. Examine in workshop with test unit

2. Check mounting location and select a

different mounting location if necessary.

Please observe the troubleshooting instructions provided in the Operating Instructions

of the transmitter. Check the transmitter if necessary.

Endress+Hauser 35

Page 36

Maintenance Viomax CAS51D

9 Maintenance

You must perform maintenance tasks at regular intervals.

‣

We recommend setting the maintenance times in advance in an operations journal or log.

The maintenance cycle primarily depends on the following:

• The system

• The installation conditions

• The medium in which measurement takes place

CAUTION

L

Acid or medium

Risk of injury, damage to clothing and the system!

Wear protective goggles and safety gloves.

‣

Clean away splashes on clothes and other objects.

‣

9.1 Maintenance intervals

The sensor requires very little maintenance, particularly if a cleaning unit is connected.

Nevertheless, maintenance must be performed at regular intervals. Schedule maintenance

times in advance in an operations journal or log.

Monthly: Visual check, clean sensor if necessary.

Cleaning intervals depend on the medium.

Every 125 million flashes (= two years at 2 Hz) or at least

every four years:

Every 250 million flashes (= four years at 2 Hz) or at least

every eight years:

Replace optical filters (manufacturer service team)

Replace strobe lamp (manufacturer service team)

9.2 Cleaning the sensor

Sensor fouling can affect the measurement results and even cause a malfunction.

The sensor must be cleaned regularly to ensure reliable measurement results. The

frequency and intensity of the cleaning process depend on the medium.

Clean the sensor:

• As specified in the maintenance schedule

• Before every calibration

• Before returning it for repairs

Type of fouling Cleaning measure

Lime deposits

Dirt particles on the optics

Deposit buildup on the optics There may be deposit buildup in the non-visible range (UV). Therefore, always

After cleaning:

Rinse the sensor thoroughly with water.

‣

Immerse the sensor in 1 to 5% hydrochloric acid (for several minutes).

‣

Clean the optics with a cleaning cloth.

‣

clean the optics.

Wet a cotton bud with 5-10% phosphoric acid or 5-10% hydrochloric acid

‣

and use it to clean the optics.

36 Endress+Hauser

Page 37

Viomax CAS51D Repairs

9.3 Maintenance of optical filters and strobe lamp

This work must be performed only by the manufacturer service team. Contact your Sales

Center.→ 37

Replacing the optical filter and strobe lamp also entails recalibrating and readjusting

the sensor in the factory.

10 Repairs

10.1 Return

The product must be returned if repairs or a factory calibration are required, or if the

wrong product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

10.2 Disposal

The device contains electronic components. The product must be disposed of as electronic

waste.

Observe the local regulations.

‣

Endress+Hauser 37

Page 38

Accessories Viomax CAS51D

11 Accessories

11.1 Assemblies

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Flowfit CYA251

• Connection: See product structure

• Material: PVC-U

• Product Configurator on the product page: www.endress.com/cya251

Technical Information TI00495C

Flow assembly for CAS51D

• For small flow volumes

• Connection: hose, OD 6 mm

• Material: PVC-U

• Two brackets for CAS51D

• Order number: 71110000

11.2 Holder

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the capstone, on the wall or directly onto

railings.

• Plastic or stainless steel version

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

11.3 Compressed air cleaning

Compressed air cleaning for CAS51D

• Connection: 6 or 8 mm (metric) or 6.35 mm (¼")

• Order numbers for sensor with 2 mm gap or 8 mm gap:

• 6 mm (with 300 mm hose and 8 mm adapter)

Order No.: 71110787

• 6.35 mm (¼")

Order No.: 71110788

• Order numbers for sensor with 40 mm gap:

• 6 mm (with 300 mm hose and 8 mm adapter)

Order No.: 71126757

• 6.35 mm (¼")

Order No.: 71126758

38 Endress+Hauser

Page 39

Viomax CAS51D Accessories

1

2

4

A

B

A0013263

30 Compressed air cleaning for CAS51D

A Cleaning for sensors with 2 mm and 8 mm gap

B Cleaning for sensors with 40 mm gap

1 Adapter, 8 mm

2 300 mm hose (Ø = 6 mm)

3 Coupling, 6 mm or 6.35 mm (¼") for 2 mm and 8 mm gap

4 Coupling, 6 mm or 6.35 mm (¼") for 40 mm gap

Compressor

• For compressed air cleaning

• 230 V AC order no. 71072583

• 115 V AC order no. 71194623

11.4 Standard solutions

Nitrate standard solutions, 1 liter

• 5 mg/l NO3-N, order number: CAY342-V10C05AAE

• 10 mg/l NO3-N, order number: CAY342-V10C10AAE

• 15 mg/l NO3-N, order number: CAY342-V10C15AAE

• 20 mg/l NO3-N, order number: CAY342-V20C10AAE

• 30 mg/l NO3-N, order number: CAY342-V20C30AAE

• 40 mg/l NO3-N, order number: CAY342-V20C40AAE

• 50 mg/l NO3-N, order number: CAY342-V20C50AAE

KHP standard solution

CAY451‐V10C01AAE, 1000 ml parent solution 5 000 mg/l TOC

Endress+Hauser 39

Page 40

Technical data Viomax CAS51D

12 Technical data

12.1 Input

Measured variables Nitrate

NO3-N [mg/l], NO3 [mg/l]

SAC

SAC [1/m], COD [mg/l], TOC [mg/l], BOD [mg/l], DOC [mg/l], transmission [%]

Measuring ranges

CAS51D-**A2 (2 mm gap) 0.1 to 50 mg/l NO3-N

0.4 to 200 mg/l NO

Clear water and sludge activation

CAS51D-**A1 (8 mm gap) 0.01 to 20 mg/l NO3-N

0.04 to 80 mg/l NO

Clear water (with a COD (KHP) content of up to 125 mg/l and up

to 50 FNU turbidity based on mineral kaolin)

CAS51D-**C1 (40 mm gap) SAC 0 to 50 1/m

CSB/BSB 0 to 75 mg/l

TOC/DOC 0 to 30 mg/l

Clear water, low measuring range, drinking water

CAS51D-**C2 (8 mm gap) SAC 0 to 250 1/m

COD/BOD 0 to 375 mg/l

TOC/DOC 0 to 150 mg/l

Clear water, medium measuring range, drinking water,

wastewater treatment plant outlet, monitoring of bodies of

water

CAS51D-**C3 (2 mm gap) SAC 0 to 1000 1/m

COD/BOD 0 to 1500 mg/l

TOC/DOC 0 to 600 mg/l

Organic load in the inlet, influent control, industrial processes

1) equivalent KHP

3

3

1)

1)

1)

1)

1)

1)

The possible measuring range depends greatly on the properties of the medium.

Empirical values for typical COD measuring ranges

Inlet of municipal wastewater treatment

plant

Influent from milk-processing industry 0 to 10 000 mg/l COD

Influent from chemical industry 0 to 10 000 mg/l COD

0 to 4000 mg/l COD

40 Endress+Hauser

Page 41

Viomax CAS51D Technical data

12.2 Performance characteristics

Reference operating

20 °C (68 °F), 1013 hPa (15 psi)

conditions

Measured error

Repeatability

6)

6)

Nitrate With 0.1 to 50 mg/l NO3-N (2 mm cuvette gap):

SAC 2 % of full scale value for standard measurement with potassium

Nitrate

At least ±0.2 mg/l NO3-N

SAC

0.5 % of end of measuring range (for homogeneous media)

Detection limits Nitrate

• CAS51D-AAA1

0.003 mg/l NO3-N

• CAS51D-AAA2

0.013 mg/l NO3-N

SAC

In relation to the standard potassium hydrogen phthalate (KHP):

• CAS51D-AAC1

0.045 mg/l COD

• CAS51D-AAC2

0.3 mg/l COD

• CAS51D-AAC3

1.5 mg/l COD

2 % of full scale value above 10 mg/l

0.4 % of full scale value below 10 mg/l

With 0.01 to 20 mg/l NO3-N (8 mm cuvette gap):

2 % of full scale value above 2 mg/l

0.2 % below 2 mg/l

hydrogen phthalate (KHP)

Determination limits Nitrate

• CAS51D-AAA1

0.01 mg/l NO3-N

• CAS51D-AAA2

0.043 mg/l NO3-N

SAC

In relation to the standard potassium hydrogen phthalate (KHP):

• CAS51D-AAC1

0.15 mg/l COD

• CAS51D-AAC2

1.0 mg/l COD

• CAS51D-AAC3

5.0 mg/l COD

Long-term drift Nitrate

Better than 0.1 mg/l NO3-N over one week

6) The measured error contains all the uncertainties of the sensor and transmitter (electrode system). It does not contain all the uncertainties

caused by the reference material and adjustments that may have been performed.

Endress+Hauser 41

Page 42

Technical data Viomax CAS51D

SAC

Better than 0.2 % of end of measuring range over one week

12.3 Environment

Ambient temperature range

Storage temperature –20 to 70 °C (–4 to 158 °F)

Degree of protection IP 68 (1 m (3.3 ft) water column, 60 days, 1 mol/l KCl)

–20 to 60 °C (–4 to 140 °F)

12.4 Process

Process temperature 5 to 50 °C (41 to 122 °F)

Process pressure (absolute) 0.5 to 10 bar (7.3 to 145 psi) (abs.)

Minimum flow No minimum flow required.

For solids which have a tendency to form deposits, ensure that sufficient mixing is

performed.

12.5 Mechanical construction

Dimensions → 6

Weight Approx. 1.6 kg (3.53 lbs) (without cable)

Materials Sensor Stainless steel 1.4404 (AISI 316 L)

Optical windows Sapphire

O-rings EPDM

Process connections G1 and NPT ¾''

42 Endress+Hauser

Page 43

Viomax CAS51D Index

Index

A

Accessories ................................ 38

Ambient temperature range ................... 42

Approvals ................................. 12

C

Cable shield ............................... 24

Calibration

Factory calibration ........................ 26

Certificates ................................ 12

Check

Connection ..............................25

Mounting ...............................23

Cleaning ............................... 35, 36

Cleaning unit .............................. 22

Cross-interference

Nitrate ..................................9

SAC ................................... 10

Cyclic cleaning ..............................35

D

Degree of protection ......................... 42

Designated use .............................. 4

Detection limits .............................41

Determination limits ......................... 41

Device description ............................ 6

Diagnostics ................................ 35

Dimensions .................................6

Disposal .................................. 37

E

Electrical connection ......................... 24

Ensuring the degree of protection ............... 25

F

Factor ....................................30

Factory calibration ...........................26

Flow operation ............................. 17

I

Immersion operation ......................... 15

Incoming acceptance ......................... 11

Input .....................................40

Installation instructions .......................14

Interpreting the order code .................... 11

L

Long-term drift ............................. 41

Measuring ranges ........................... 40

Mechanical construction ...................... 42

Minimum flow ............................. 42

Mounting ................................. 13

Mounting location ...........................13

Multiple point calibration ..................... 29

N

Nameplate ................................ 11

Nitrate .................................... 9

O

Offset .................................... 31

One-point calibration ........................ 27

Operating principle ........................... 8

Operation ................................. 26

Optical filters .............................. 37

Orientation ................................ 13

P

Performance characteristics ....................41

Post-connection check ........................25

Post-installation check ....................... 23

Process connections ..........................42

Process pressure (absolute) .................... 42

Process temperature ......................... 42

Product identification ........................ 11

Product page ...............................11

R

Reference operating conditions ................. 41

Repairs ................................... 37

Repeatability ...............................41

Return ................................... 37

S

SAC ...................................... 9

Safety instructions ............................4

Scope of delivery ............................ 12

Sensor ................................... 14

Cleaning ............................... 36

Connecting ..............................25

Design .................................. 6

Dimensions .............................. 6

Stability criterion ............................31

Storage temperature ......................... 42

Strobe lamp ............................... 37

Symbols ................................... 3

M

Maintenance ...............................36

Maintenance intervals ........................36

Manufacturer's address ....................... 12

Materials ................................. 42

Maximum measured error ..................... 41

Measured variables .......................... 40

Measuring principle ...........................8

Endress+Hauser 43

T

Technical data ..............................40

Troubleshooting ............................ 35

Two-point calibration ........................ 28

U

Use .......................................4

Page 44

Index Viomax CAS51D

W

Warnings .................................. 3

Weight ................................... 42

Wiring ................................... 24

44 Endress+Hauser

Page 45

Page 46

Page 47

Page 48

*71447513*

71447513

www.addresses.endress.com

Loading...

Loading...